Page 1

Operating and installation instructions

Cooker hood

DA 3560

DA 3590

DA 3560 EXT

DA 3590 EXT

To avoid the risk of accidents

or damage to this appliance,

it is essential to read these

instructions before it is installed

and used for the first time.

en-GB

M.-Nr. 09 466 100

Page 2

Contents

Caring for the environment..........................................3

Warning and Safety instructions .....................................4

Guide to the appliance ............................................10

Description of the functions ........................................12

Miele|home .....................................................13

Con|ctivity ......................................................13

Operation .......................................................14

To switch the fan on................................................14

To select a power level .............................................14

Intensive setting ................................................14

Run-on option 5 ¢15...............................................15

To switch the fan off................................................15

Hob lighting I....................................................15

Filter operating hours counter [ ....................................16

Cleaning and care ................................................18

Housing .........................................................18

Grease filters .....................................................19

Resetting the grease filter operating hours counter ....................20

Fitting and replacing the charcoal filters ................................21

Resetting the charcoal filter operating hours counter ...................21

Changing a halogen lamp ...........................................22

After Sales Service ...............................................23

Appliance dimensions.............................................24

Installation ......................................................26

Installation accessories .............................................26

Adjusting the deflector plate.......................................34

Connection for air extraction .......................................38

Condensate trap ..................................................39

Silencer .........................................................40

Electrical connection .............................................41

Operation with Control module DSM 400 .............................42

Potential free connection .........................................42

Connection to a push button switch .................................42

Technical data ...................................................43

2

Page 3

Caring for the environment

Disposal of the packing material

The transport and protective packing

has been selected from materials which

are environmentally friendly for

disposal, and should be recycled.

Packaging e.g. cling film, polystyrene

and plastic wrappings must be kept out

of the reach of babies and young

children. Danger of suffocation!

Disposal of your old appliance

Electrical and electronic appliances

often contain materials which, if

handled or disposed of incorrectly,

could be potentially hazardous to

human health and to the environment.

They are, however, essential for the

correct functioning of your appliance.

Please do not therefore dispose of it

with your household waste.

Please dispose of it at your local

community waste collection / recycling

centre or contact your dealer for

advice. Ensure that it presents no

danger to children while being stored

for disposal.

3

Page 4

Warning and Safety instructions

Any other usage is not supported by

This appliance complies with all

relevant local and national safety

requirements. Inappropriate use

can, however, lead to personal injury

and damage to property.

To avoid the risk of accidents and

damage to the appliance, please

read these instructions carefully

before using it for the first time.

They contain important information

on the safety, installation, use and

maintenance of the appliance.

the manufacturer and could be

dangerous. Miele cannot be held liable

for damage resulting from incorrect or

improper use or operation of the

appliance.

This appliance is not intended for

~

use by people with reduced physical,

sensory or mental capabilities, or lack

of experience or knowledge, unless

they are supervised whilst using it or

have been shown how to use it

correctly by a person responsible for

their safety.

Keep these instructions in a safe

place and ensure that all users are

familiar with the contents. Pass them

on to any future owner of the

appliance.

Correct application

This appliance is not designed for

~

commercial use. It is intended for use in

domestic households and in similar

working and residential environments

such as:

–

Shops

–

Offices and showrooms

and by residents in establishments

such as

–

Hostels and guesthouses

It must only be used as a domestic

~

appliance to extract vapours and

remove odours from cooking.

The cooker hood is not intended for

~

outdoor use.

Safety with children

This appliance is only intended for

~

use by adults who have read these

instructions.

This appliance is not a toy! To

~

prevent the risk of injury do not let

children play with the appliance or its

controls.

Children under 8 years of age must

~

be kept away from the cooker hood

unless they are constantly supervised.

Children 8 years and older may use

~

the cooker hood only if they have been

shown how to use it in a safe way and

understand the hazards involved.

Please be aware that on cooker

~

hoods with halogen lighting, the lamps

will get very hot during use and remain

hot for some time after switching off. To

safeguard against burning, keep

children well away from the lamps at all

times.

4

Page 5

Warning and Safety instructions

Technical safety

Before installation, check the cooker

~

hood for visible signs of damage.

Under no circumstances should you

use a damaged appliance. It could be

dangerous.

Before connecting the appliance to

~

the mains supply, make sure that the

voltage and frequency details given on

the data plate correspond with the

on-site electricity supply, otherwise the

appliance could be damaged. Consult

a qualified electrician if in any doubt.

The electrical safety of this

~

appliance can only be guaranteed if it

is correctly earthed. It is most important

that this basic safety requirement is

present and tested regularly, and

where there is any doubt, the

household wiring system should be

inspected by a qualified electrician.

The manufacturer cannot be held liable

for the consequences of an inadequate

earthing system (e.g. electric shock).

Installation, maintenance and

~

repairs may only be carried out by a

Miele authorised person in accordance

with current national and local safety

regulations.

Repairs and other work by unqualified

persons could be dangerous. The

manufacturer cannot be held liable for

unauthorised work.

Faulty components must only be

~

replaced by genuine Miele original

parts. The manufacturer can only

guarantee the safety of the appliance

when Miele replacement parts are

used.

During installation, maintenance and

~

repair work, the appliance must be

disconnected from the mains electricity

supply.

For safety reasons, this appliance

~

may only be used when it has been

fully installed.

Only open the housing as described

~

in the instructions given in the

installation sheet and in the Cleaning

and care section of this booklet. Under

no circumstances should any other

parts of the housing be opened.

Tampering with electrical connections

or components and mechanical parts is

highly dangerous to the user, and can

cause operational faults.

5

Page 6

Warning and Safety instructions

Do not connect the appliance to the

~

mains electricity supply by a

multi-socket unit or an extension lead.

These do not guarantee the required

safety of the appliance (e.g. danger of

overheating).

For appliances with an external fan

~

motor fitted (...EXT models) the

connection of the two units must be

made using the connection cable and

the plug connectors.

These models may only be combined

with a Miele external motor.

This appliance must not be used in

~

a non-stationary location (e.g. on a

ship).

In areas which may be subject to

~

infestation by cockroaches or other

vermin, pay particular attention to

keeping the appliance and its

surroundings in a clean condition at all

times. Any damage which may be

caused by cockroaches or other vermin

will not be covered by the guarantee.

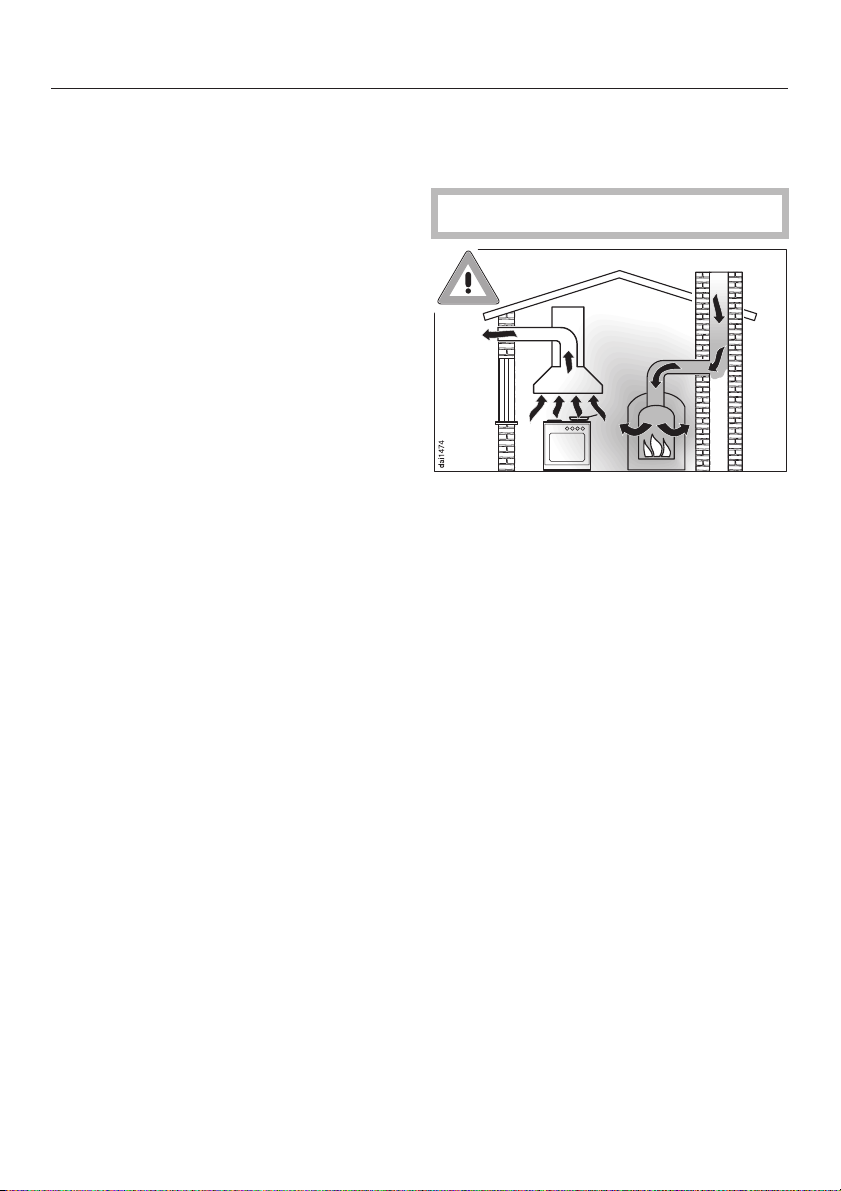

Using at the same time as other

heating appliances that depend on

the air from the room

Warning - danger of toxic fumes

Great care should be taken when

~

using the cooker hood at the same time

and in the same room or area of the

house as another heating appliance

which depends on the air in the room.

Such appliances include gas, oil, wood

or coal-fired boilers and heaters,

continuous flow or other water heaters,

gas hobs, cookers or ovens which draw

air in from the room and duct exhaust

gases out through a chimney or

extraction ducting.

When used in extraction mode, with or

without an external motor fitted, the

appliance draws air in from the room in

which it is installed and from

neighbouring rooms.

If there is insufficient air, an

underpressure will occur. The heating

appliance may be starved of oxygen,

impairing combustion.

Harmful gases could be drawn out of

the chimney or extraction ducting back

into the room, with potentially fatal

consequences.

6

Page 7

Warning and Safety instructions

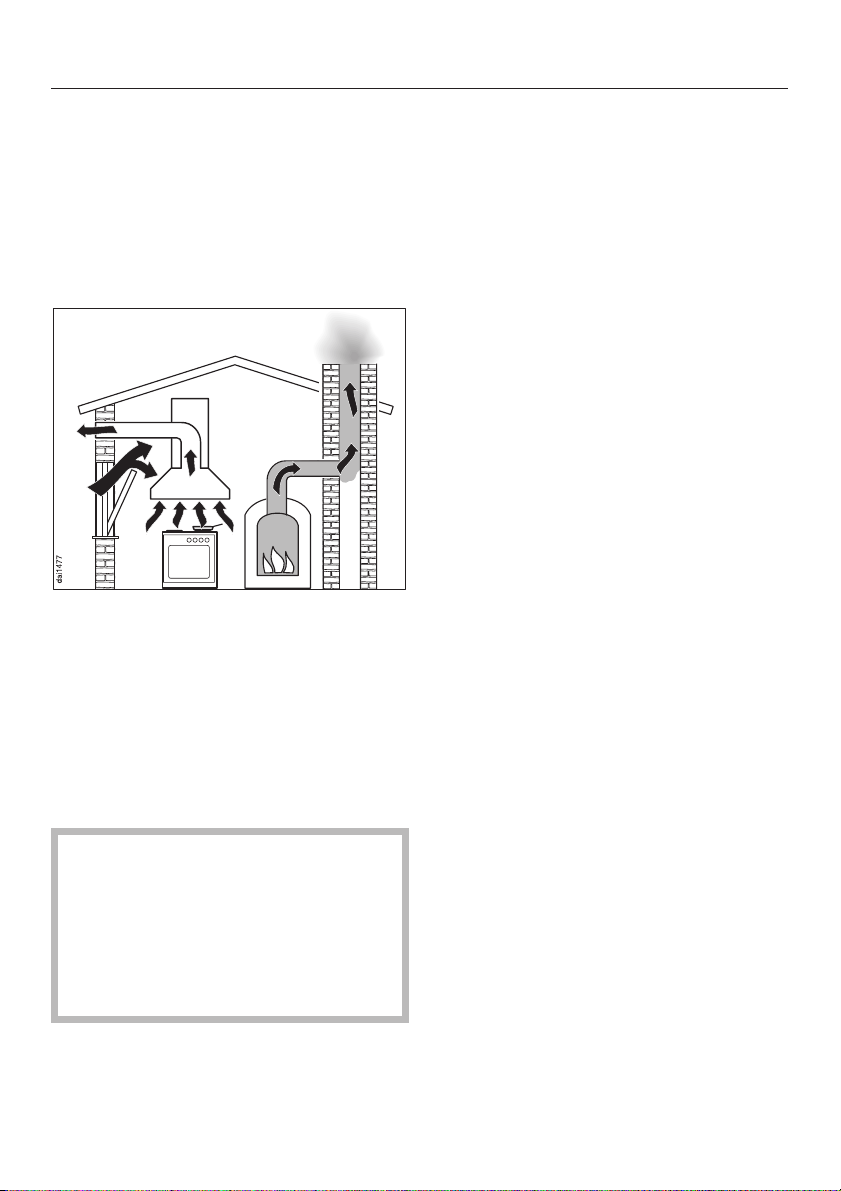

In order to ensure safe operation, and

to prevent gases given off by the

heating appliances from being drawn

back into the room when the cooker

hood and the heater are in operation

simultaneously, an underpressure of

0.04 mbar (4 pa) is the maximum

permissible in the room.

Ventilation can be maintained by air

inlets which must not be blocked, in

windows, doors and outside wall vents,

or by other technical measures, such

as ensuring that the cooker hood can

only be switched on when the heating

appliance is switched off or vice versa.

A ventilation brick alone is not generally

sufficient to ensure safe ventilation.

,

The overall ventilation condition

of the dwelling must be taken into

account. If in any doubt, the advice

of a competent builder or, for gas, a

qualified gas fitter (GasSafe

registered in the UK) must be

sought.

If the hood is being operated in

recirculation mode, the above

restrictions do not apply.

7

Page 8

Warning and Safety instructions

Correct use

Never use an open flame beneath

~

the cooker hood. To avoid the danger

of fire, do not flambé or grill over an

open flame.

When switched on, the cooker hood

could draw flames into the filter. Fat

particles drawn into the cooker hood

present a fire hazard.

When using the cooker hood over a

~

gas hob, ensure that any burners in use

are always covered by a pan. Switch

the cooking zone off when a pan is

removed, even for a short time.

Regulate the flame so that it does not

burn up the sides of the pan.

Do not allow the pans to overheat

excessively (e.g. when using a wok).

The cooker hood can become

damaged when exposed to excessive

heat.

Always switch the cooker hood on

~

when a cooking zone is in use,

otherwise condensation may collect in

the hood, which could cause corrosion.

When cooking with oil or fat, chip

~

pans and deep fat fryers etc, do not

leave the pans unattended. Never leave

an open grill unattended when grilling.

Overheated oil and fat can ignite and

could set the cooker hood on fire.

Do not use the cooker hood without

~

the filters in place. This way you will

avoid the risk of grease and dirt getting

into the appliance and hindering its

smooth operation.

The cooker hood can get very hot

~

during cooking due to heat rising from

the hob.

Do not touch the housing or the grease

filters until the cooker hood has cooled

down.

Do not use a steam-cleaner to clean

~

this appliance. Steam could reach

electrical components and cause a

short circuit.

Correct installation

Refer to the cooker or hob

~

manufacturer's instructions as to

whether a cooker hood may be

operated above the cooker/hob.

The minimum safety distances

~

between the top of the cooker or hob

and the bottom of the cooker hood

given in the "Appliance dimensions"

section of this booklet must be

maintained, unless the hob

manufacturer states that a greater

safety distance is required.

If more than one cooking appliance is

fitted beneath the cooker hood, and

they have different minimum safety

distances to the cooker hood, select

the greater distance.

Safety regulations prohibit the fitting

~

of a cooker hood over solid fuel stoves.

The filters should be regularly

~

cleaned or changed as appropriate.

Saturated filters are a fire hazard. See

"Cleaning and care".

8

Page 9

Warning and Safety instructions

All ducting, pipework and fittings

~

must be of non-flammable material.

These can be obtained from the Miele

Spare Parts department or from

builders' merchants.

The appliance must not be

~

connected to a chimney or vent flue

which is in use. Neither should it be

connected to ducting which ventilates

rooms with fireplaces.

If exhaust air is to be extracted into

~

a chimney or ventilation duct no longer

used for other purposes, seek

professional advice.

Accessories

Only use genuine Miele spare parts

~

and accessories with this appliance. If

spare parts or accessories from other

manufacturers are used, this will

invalidate the guarantee, and Miele

cannot accept liability.

The manufacturer cannot be held

liable for damage caused by

non-compliance with these Warning

and Safety instructions.

9

Page 10

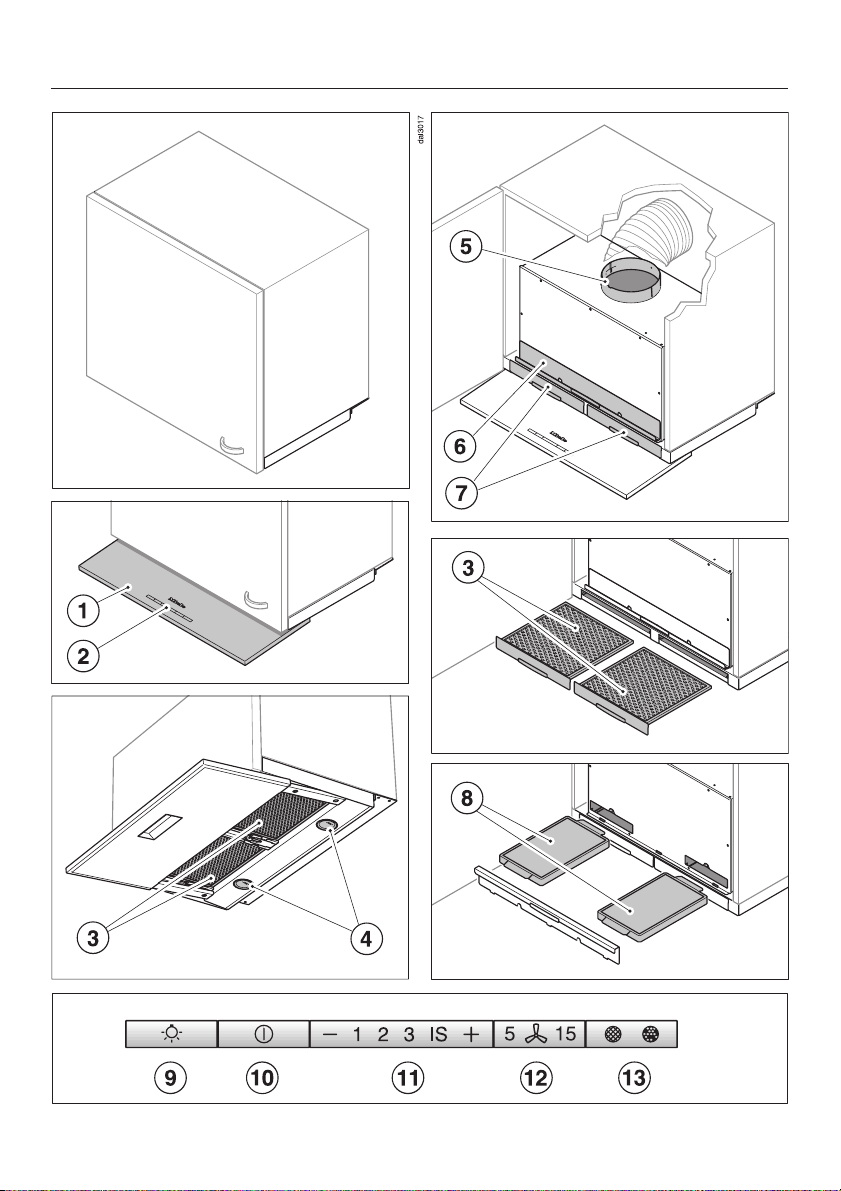

Guide to the appliance

10

Page 11

Guide to the appliance

a Pull-out deflector plate

b Controls

c Grease filters

d Hob lighting

e Exhaust socket C 150 mm

The exhaust socket can also be fitted at

the back.

f Slots for the charcoal filters

g Slots for the grease filters

h Charcoal filters

(extra accessory available to order for

recirculation mode)

i Hob lighting button

This button can be used to switch the

hob lighting on and off and is also a

dimmer switch.

j On/Off button for the fan

k Buttons for selecting the fan

power level

l Button for the run-on option

The fan can be set to switch off

automatically after either 5 or

15 minutes.

m Operating hours button

The grease filter symbol [ for the

operating hours button lights up when

the grease filters need to be cleaned.

The charcoal filter symbol lights up

when the charcoal filters used in

recirculation mode need to be

replaced. For this to happen, the

operating hours counter needs to be

activated before the appliance is used

for the first time.

The button is used to reset the

appropriate operating hours counter

each time the grease filters are cleaned

or the charcoal filters have been

replaced (see "Cleaning and care").

It can also be used to check and alter

the operating hours counter.

For information about using the

appliance, see "Operation".

11

Page 12

Description of the functions

The cooker hood works with

. . . air extraction:

The air is drawn in, cleaned by the

grease filters and directed outside.

If the on-site ventilation system does

not have a non-return flap, then the

non-return flap supplied with the

appliance must be fitted in the exhaust

socket of the motor unit.

Having a non-return flap fitted in the

ducting ensures that air, once ducted

to the outside, cannot get back into the

room again.

The flap is closed when the cooker

hood is switched off.

When the cooker hood is switched on,

the non-return flap opens for the

cooking vapours to be blown directly

outside.

. . . air recirculation:

(air recirculation conversion kit

required)

The air is drawn in and cleaned first by

the grease filters and then by two

charcoal filters. The cleaned air is then

recirculated back into the kitchen.

The charcoal filters are available to

order through your Dealer or Miele (see

back page for contact details and

Technical data for part number).

Before using the cooker hood in

recirculation mode, ensure that the

charcoal filters are in place. See

"Cleaning and care".

...anexternal motor:

(...EXT models only)

EXT models are designed to be

connected to an external motor located

outside the room.

12

The external motor is connected to the

cooker hood by means of a control

cable, and is operated by the controls

on the cooker hood.

Page 13

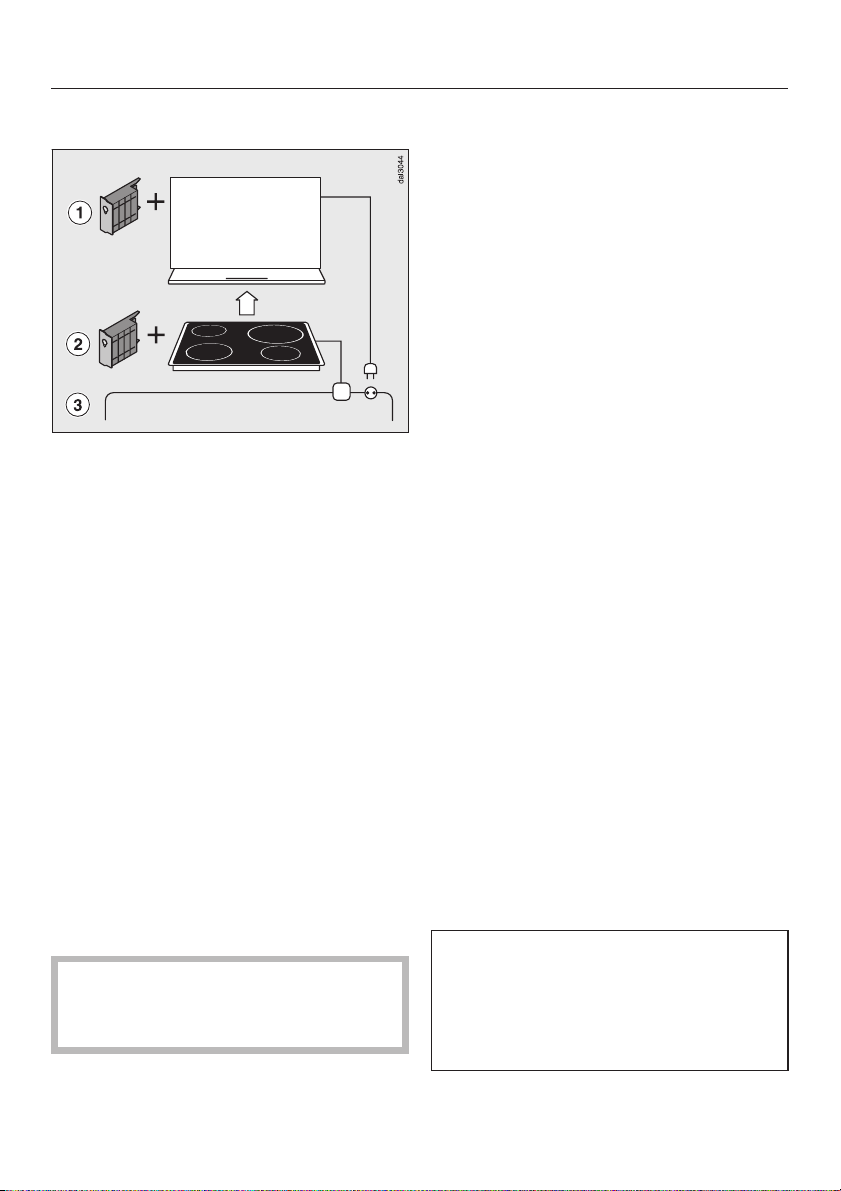

Miele|home

Con|ctivity

This cooker hood is communication

enabled.

Communication module XKM 2000 DA

a, available as an optional extra,

enables the operation of the cooker

hood to be automatically controlled by

the operating status of a Miele electric

hob with onset controls.

For communication to take place, the

hob must be fitted with communication

module XKM 2000 KM b.

The hob transmits information about its

operating status to the cooker hood via

the household power supply

(Powerline) c.

The communication module is fitted to

the housing of the cooker hood and is

connected to the controls of the cooker

hood.

The module must be installed by a

Miele service technician or suitably

qualified electrician.

Automatic operation

With the deflector plate pushed in on

^

the cooker hood, switch on the hob.

The hob lighting will switch on

automatically.

Then pull the deflector plate out. The

^

cooker hood fan will switch on.

During cooking, the cooker hood

automatically sets its power level

according to the number of cooking

zones in operation and their power

levels. You can still operate the cooker

hood manually at any time.

After the hob has been switched off, the

cooker hood fan and hob lighting will

switch off automatically after a period of

time.

If the deflector plate remains pulled out,

the cooker hood will switch on

automatically the next time the hob is

switched on.

Manual operation

^

If you want to operate the cooker

hood manually, pull the cooker hood

deflector plate out before switching

on the hob.

Proceed as described in "Operation".

For detailed information about this

function, please read the separate

instruction booklet supplied with the

XKM 2000 DA communication

module.

13

Page 14

Operation

To switch the fan on

Pull the deflector plate downwards

^

slightly and then towards you.

The fan will come on at power level 2.

The On/Off symbol K and Fan setting 2

will light up.

To select a power level

^ Press the – symbol to select a lower

power level or the + symbol to select

a higher power level.

Depending on the intensity of the

cooking vapours, levels 1 to 3 are

usually sufficient for normal cooking.

Intensive setting

^

For short periods of strong vapours

and cooking odours, e.g. whilst

searing meat, select the IS or

Intensive setting.

Pull the deflector plate out to its full

extent to gain maximum extraction

whilst avoiding excessive noise

levels.

Automatic switch-off of the Intensive

setting

You can set the Intensive setting so that

it always only runs for 10 minutes

before reverting automatically to level 3.

Pull the deflector plate out and switch

^

off the fan K and the lighting I.

Press the Run-on option button

^

5 ¢15 for approx. 10 seconds, until

the 1 lights up.

Then press in turn –

^

– the lighting button I,

– the – button, and

– the lighting button I again.

If Automatic switch-off is not activated,

1 and IS will flash.

^ Press the + button to activate Auto-

matic switch-off.

Fan power levels 1 and IS will now

light up constantly.

Press the – button to deactivate the

Automatic switch-off function.

^

Confirm your selection by pressing

the Run-on option button 5 ¢15.

If you do not confirm within 4 minutes,

the cooker hood will automatically

revert to the original setting.

14

Page 15

Operation

Run-on option 5 ¢15

It is advisable to run the fan for a few

minutes after cooking has finished to

neutralise any lingering odours in the

air, whether you are using air extraction

or recirculation mode.

The fan can be set to switch off

automatically after 5 or 15 minutes.

After cooking has finished, press the

^

Run-on option button 5 ¢15 whilst

the fan is still running

Press once = The fan will switch off

–

after 5 minutes (5 ¢ will light up).

– Press twice = The fan will switch off

after 15 minutes (¢15 will light up).

If you press the Run-on option button

5 ¢15 again, the fan remains on (5 ¢15

will go out).

To switch the fan off

^

Push the deflector plate back in. The

next time the deflector plate is pulled

out, the cooker hood will operate at

power level 2 again.

or

Hob lighting I

To switch the hob lighting on

Pull the deflector plate out.

^

or

Press the hob lighting button briefly

^

I.

The I symbol lights up.

The hob lighting will switch on at

maximum brightness.

To dim the hob lighting

The brightness of the hob lighting can

be adjusted.

^ With the hob lighting switched on,

press and hold the hob lighting

button I.

The brightness will dim gradually until

you release the button.

^ To increase the brightness, press

and hold the hob lighting button I in

again until the level required is

reached, then release it.

If you keep the hob lighting button

pressed in I, the lighting will continue

to change between bright and dim.

^

Press the On/Off button K for the fan.

All the indicator lights will go out.

To switch the hob lighting off

^

Push the deflector plate back in.

or

^

Press the hob lighting button I.

The I symbol will go out.

15

Page 16

Operation

Safety switch-off

Should the cooker hood be left on, the

fan will switch off automatically after 10

hours. The lighting will remain on.

Pressing the On/Off button K will

^

switch the fan back on again.

Filter operating hours

counter [

The number of hours the cooker hood

has been in operation is stored in

memory.

The Grease filter symbol [ or the

Charcoal filter symbol will light up to

tell you that the filters need to cleaned

or changed.

See "Cleaning and care" for further

information about cleaning and

changing the filters and resetting the

operating hours counters.

Altering the grease filter operating

hours counter [

You can set the operating hours

counter to suit the type of cooking you

do.

The operating hours counter is set at

the factory for 30 hours.

If you use very little fat for cooking,

select a longer time of 40 or 50 hours.

To alter the operating time:

Switch the fan off by pressing the

^

On/Off button K.

Press the Run-on option button

^

5 ¢15 and the operating hours

button [ at the same time.

The Grease filter symbol [ of the

operating hours button and one of the

fan power levels will flash.

Fan power level indicator lights 1 to IS

show the time set:

1........................20hours

2........................30hours

3........................40hours

IS .......................50hours

^ Press the – symbol to select a shorter

operating time or the + symbol to

select a longer operating time.

^ Confirm your selection by pressing

the operating hours button [.

All the indicator lights will go out.

If you do not confirm within 4 minutes,

the cooker hood will automatically

revert to the original setting.

Select a shorter time of 20 hours if you

fry a lot.

If you only cook occasionally, we still

recommend 20 hours because grease

which has built up gradually over a long

period of time will harden on the grease

filters and make cleaning more difficult.

16

Page 17

Operation

Activating and altering the charcoal

filter operating hours counter

(with recirculation mode)

The charcoal filters must be fitted for

the cooker hood to be used in

recirculation mode.

On delivery, the operating hours counter

for the charcoal filter is deactivated.

For recirculation mode, the operating

hours counter needs to be set to suit

the type of cooking you do.

Switch the fan off by pressing the

^

On/Off button K.

^ Press the + symbol and the

operating hours button [ on the

control panel at the same time.

The Charcoal filter symbol of the

operating hours button and one of the

fan power levels will flash.

Fan power level indicator lights 1 to IS

show the time set:

1.......................120hours

2.......................180hours

3.......................240hours

IS ....................Deactivated

^

Press the – symbol to select a shorter

operating time or the + symbol to

select a longer operating time.

Checking the filter operating hours

counter

To check the percentage of time set

already used:

Switch the fan on with the On/Off

^

button K.

Press and hold the operating hours

^

button [:

Once, to read the grease filter

–

operating hours. The Grease filter

symbol [ will light up.

Twice, to read the charcoal filter

–

operating hours. The Charcoal filter

symbol will light up.

One or more of the power level

indicators will flash at the same time.

The number of flashing indicator lights

shows the percentage of the operating

time which has already been used up:

1...........................25%

1 and 2 .....................50%

1 to 3 .......................75%

1 to

IS .....................100%

The number of operating hours used

remains in the memory, even when the

cooker hood is switched off or there is a

power cut.

^

Confirm your selection by pressing

the operating hours button [.

All the indicator lights will go out.

If you do not confirm within 4 minutes,

the cooker hood will automatically

revert to the original setting.

17

Page 18

Cleaning and care

Before any cleaning or

,

maintenance work is carried out,

disconnect the cooker hood from the

mains supply.

Exercise caution when changing

,

halogen lamps. They get very hot

during use and remain hot for some

time after being switched off. The

hot lamps are also susceptible to

damage from damp cleaning. Wait a

few minutes after switching off

before commencing cleaning.

Housing

General

The surfaces and controls are

susceptible to scratches and

abrasion. Please observe the

following cleaning instructions.

^

All external surfaces and controls can

be cleaned using warm water with a

little washing up liquid applied with a

soft sponge.

Avoid:

cleaning agents containing soda,

–

acids, chlorides or solvents,

abrasive cleaning agents, e.g.

–

powder cleaners or cream cleaners

and abrasive sponges, as well as pot

scourers or sponges which have

been used previously with abrasive

cleaning agents. These will damage

the surface material.

Important for appliances with

stainless steel housing

(This infomation does not apply to the

controls).

Stainless steel surfaces can be cleaned

using Miele's non-abrasive cleaning

agent for stainless steel, following the

manufacturer's instructions on the

packaging.

To help prevent re-soiling, Miele

conditioning agent for stainless steel

can also be used. Follow the

instructions on the packaging.

^

Wipe the surfaces dry using a soft

cloth.

Do not use too much water when

cleaning the controls. Water could

penetrate into the electronics and

cause damage.

18

Page 19

Cleaning and care

Controls

The controls may suffer

discolouration or damage if soiling is

left on them for too long. Remove

soiling straight away.

Please observe the General notes on

cleaning earlier in this section.

Do not use stainless steel cleaning

agents on the controls.

Grease filters

The re-usable metal grease filters in the

appliance remove solid particles

(grease, dust, etc.) from the kitchen

vapours, preventing soiling of the

cooker hood.

Clean the grease filters regularly but

always clean them immediately if the

Grease filter symbol [ of the operating

hours button lights up.

We recommend cleaning them at least

every 3-4 weeks. Otherwise grease

which builds up on the grease filters

over a long period of time can harden,

making cleaning more difficult.

An oversaturated filter is a fire

,

hazard.

^ Push in the deflector plate.

To avoid damaging the filter or the

hob below, make sure you hold the

filter securely at all times when

handling it.

^

Pull the filters out of the slots in the

front of the cooker hood housing.

19

Page 20

Cleaning and care

Cleaning the grease filters by hand

Clean the filters with a soft nylon

^

brush in a mild solution of hot water

and a little washing-up liquid.

Do not use "neat" washing-up liquid.

Avoid:

cleaning agents containing

–

descaling agents,

powder cleaners, cream cleaners or

–

abrasive all-purpose cleaners.

oven sprays.

–

Cleaning the grease filters in the

dishwasher

^ Place the filters as upright as

possible in the lower basket, with the

short sides upright. Make sure that

the spray arm can move freely.

^ Select a programme with a maximum

temperature of 65° C. If a Miele

dishwasher is being used, select the

Sensor wash programme.

When removing the filters for

^

cleaning, also clean off any residues

of oil or fat from the now accessible

housing to prevent the risk of these

catching fire.

Push the grease filters back into

^

position.

Resetting the grease filter operating

hours counter

After cleaning, the operating hours

counter needs to be reset.

Whilst the fan is switched on, press

^

the operating hours button [ for

approx. 3 seconds until only the 1 is

flashing.

The Grease filter symbol [ goes out.

If you want to clean the grease filters

before the operating hours counter has

reached its maximum:

^ Press the operating hours button [

for approx. 6 seconds until only the 1

is flashing.

^

Use a mild dishwasher detergent.

Depending on the dishwasher

detergent used, cleaning the filters

in a dishwasher can cause

permanent discolouration to the

surface.

However, this will not affect the

functioning of the filters in any way.

^

After cleaning, leave the filters to dry

on an absorbent surface before

replacing them.

20

Page 21

Cleaning and care

Fitting and replacing the

charcoal filters

If the cooker hood is connected for

recirculation, two active charcoal filters

(optional accessory) must be inserted

in addition to the grease filters. The

charcoal filters absorb normal kitchen

odours

Charcoal filters can be obtained from

your Dealer or Miele.

See back cover for contact details,

and "Technical data" for type and

reference number.

The slots for the charcoal filters are

located above the grease filters.

When fitting the charcoal filters for

^

the first time:

Activate the operating hours counter

(see "Operation").

Always replace the charcoal filters im

mediately if

the Charcoal filter symbol of the

–

operating hours button lights up,

or

they are no longer effective at

–

absorbing kitchen odours.

They should, however, be replaced at

least every 6 months.

^ Used charcoal filters can be

disposed of with normal household

waste.

Resetting the charcoal filter

operating hours counter

After replacing the charcoal filters, the

operating hours counter needs to be

reset.

-

^

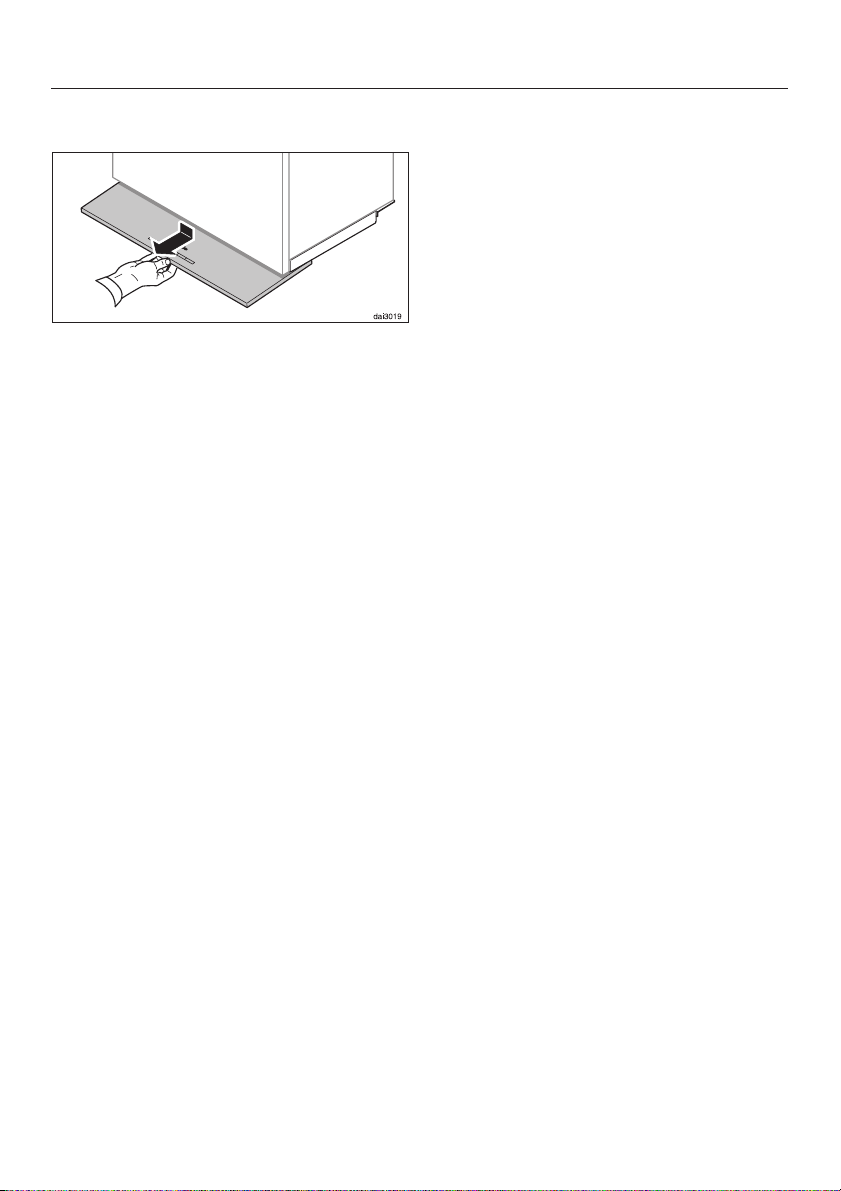

Remove the cover. It is held in place

by magnets.

^

Push the charcoal filters into the

slots.

^

Replace the lid.

^

To do this, with the fan switched on,

press the operating hours button [

twice. Hold the second press for

approx. 3 seconds until only the 1 is

flashing.

The Charcoal filter symbol will go

out.

If you want to replace the charcoal

filters before the operating hours

counter has reached its maximum:

^

Press the operating hours control

[ twice. Hold the second press for

approx. 6 seconds until only the 1 is

flashing.

21

Page 22

Cleaning and care

Changing a halogen lamp

Before any cleaning or maintenance

^

work, disconnect the cooker hood

from the mains supply.

Exercise caution when changing

,

halogen lamps. They get very hot

during use and remain hot for some

time after being switched off. Let

them cool down before you change

them.

^ To access the halogen lamp press

and release the lamp cover.

22

^ Pull the old halogen lamp out of the

connection socket.

^

Using a cloth or glove, push the new

lamp (12 V, 20 W, G4 cap) carefully

into the connection socket. Please

follow the manufacturer's instructions.

^

Push the cover back up and make

sure it clicks into place.

Page 23

After Sales Service

In the event of a fault which you cannot

correct yourself, or if the appliance is

under guarantee, please contact:

Your Miele Dealer / Chartered Agent

–

or

The Miele Service Department (see

–

back cover for address).

When contacting your Dealer or Miele,

please quote the model and serial

number of your appliance. These are

shown on the data plate which is visible

when the grease filter is removed.

For the U.K.: Please note that

telephone calls may be monitored

and recorded for training purposes.

N.B. A call-out charge will be applied

for service visits where the problem

could have been resolved as described

in these instructions.

Guarantee

For information on the appliance

guarantee specific to your country

please contact Miele. See back cover

for contact details.

In the U.K. your appliance is

guaranteed for 2 years from the date of

purchase. However, you must activate

your cover by calling 0845 365 6640 or

registering online at www.miele.co.uk

23

Page 24

Appliance dimensions

24

Page 25

Appliance dimensions

1) Air extraction and recirculation mode

with conversion kit DUU 150 if the air is

to be directed upwards out of the wall

unit.

2) Trim the wall unit carcase so that it is

38 mm shorter than the wall unit door.

3) Installation is also possible in a 600

mm wide unit.

4) The exhaust socket can also be fitted

at the back.

5) After installation the wall unit can be

fitted with an interim panel. If this is

done make sure that the slots for the

grease filters and the charcoal filters

remain easily accessible.

6) If the wall unit has a base, openings

must be provided to enable adjustment

of the retaining force of the deflector

plate. For example:

– The wall unit has side sections, as

shown.

– The cooker hood is installed in a

600 mm wide wall unit with units at

either side.

Safety distance between hob and

cooker hood (S)

The following distance must be

maintained between the top of the

cooker/hob and the bottom of the

cooker hood unless a greater

distance is specified by the

manufacturer of the cooker or hob:

450 mm: above electric hobs and

cookers

650 mm: above gas hobs and

cookers

650 mm: above an open grill or a

deep fat fryer

See “Warning and Safety

instructions” for further information.

When measuring for the height of the

wall housing unit and the cut-out,

account must be taken of any

accessories fitted, e.g. silencer, XKM

module.

25

Page 26

Installation

Installation accessories

26

Page 27

a 1 exhaust socket

for exhaust ducting C 150 mm.

Installation

b 1 reducing collar

for exhaust ducting C125 mm.

c 1 non-return valve

for fitting into the exhaust socket (not

for recirculation mode).

d 2 covers

for the brackets

e 2 brackets

to support the appliance in the wall

unit.

f 2 retaining brackets

for additional aligning and securing

of the cooker hood in a 900 mm wide

unit (DA 3590 only) .

g 1 cover

for the charcoal filter slots.

h 1 spacer strip

to conceal the gap between the rear

of the appliance and the wall.

i Conversion kit for recirculation

mode

(this is not supplied, but is available

as an optional accessory - see

"Technical data").

The kit contains an exhaust grille and

flexible aluminium hose with clips.

4 screws M4 x 16 mm

for securing the cooker hood to the

brackets and for securing the spacer

strip.

4 screws M4x8mm

for securing the spacer strip.

2 screws4x40mm,

2 plugs6x36mm

for additional securing of the cooker

hood to the wall (only when fitting the

DA 3590 into a 900 mm wide unit).

4 screws4x25mm

for additionally securing the DA 3590

into a 600 mm wide unit.

4 adhesive covers

to conceal the fixing holes which are

not required (DA 3590 only).

12 screws4x15mm

for securing the cooker hood into the

wall unit.

1xT20angled key

27

Page 28

Installation

Before installation, it is important

,

to read the information given on the

following pages as well as the

Warning and Safety instructions at

the beginning of this booklet.

This is particularly crucial when

using the cooker hood at the same

time as a heating appliance that

relies on oxygen from the same

room, which could result in the

build-up of toxic fumes.

Repositioning the venting

connection

The motor unit can be rotated to allow

the vent ducting to be fitted at the back

of the cooker hood.

This may be necessary if the cooker

hood is being fitted in a reduced height

wall unit, for example.

Repositioning is carried out before

installing the cooker hood.

Turn the motor unit towards the rear

^

and position the exhaust socket in

the exhaust vent on the back panel of

the cooker hood housing. Ensure

when turning the motor unit that the

connection cable does not become

detached.

Secure the motor unit in its new

^

position.

Now secure the cover taken from the

^

back panel to the top of the housing.

Refit the front panel and secure it

^

using the screws.

EXT models

On appliances with an external motor

(EXT models), the exhaust socket (not

the motor unit) needs to be

repositioned.

^ Unscrew the fixing screws and pull

the top and bottom sections of the

socket apart.

,

The cooker hood must be

disconnected from the mains

electricity supply.

^

Undo the fixing screws on the front

panel of the cooker hood housing

and remove the panel.

^

Undo the screws on the cover on the

back of the cooker hood housing and

remove the cover.

^

Unscrew the fixing screws on the

motor unit.

28

^

Position the top section of the socket

over the exhaust vent on the back

panel of the cooker hood housing

and attach the bottom section to it

from inside. Secure the exhaust

socket with the fixing screws.

Page 29

Installation

29

Page 30

Installation

^

Pull the grease filters out of the slots

in the front of the cooker hood

housing.

The spacer strip needs to be attached

to the back of the cooker hood housing

before the cooker hood is installed in

the wall unit. The spacer strip can be

attached to the upper a or lower edge

b of the deflector plate.

^

Calculate measurement T for the

spacer strip.

^

Cut the spacer strip to

measurement T. Score along the

groove for the smaller measurement

as shown, and remove the surplus.

30

^

Screw the spacer strip to the back of

the cooker hood at the required

position.

Use the screws supplied. To attach

the spacer strip to the lower edge b

use the screws in the housing unit.

Page 31

Installation

Screw the brackets onto the right and

^

left inside walls of the housing unit so

that they are flush with the bottom

edge of the wall unit.

The brackets are designed for

16 and 19 mm thick carcase sides.

Orientate the bracket so that the

vertical depth matches the thickness

of the carcase side, as shown.

^

Fit the screws for attaching the

cooker hood so that they protrude by

about 5 mm, as shown.

Only use the front screws when fitting a

900 mm wide cooker hood in a 600 mm

wide wall unit.

31

Page 32

Installation

^ Fit the cooker hood into the wall unit

from below, guiding it over the safety

notch, as shown. Push it back until

the spacer strip is flush with the wall.

Tighten the four securing screws

^

from below.

^

Pull the deflector plate downwards

slightly and then towards you.

32

^

When fitting a 900 mm wide cooker

hood in a 600 mm wide wall unit,

insert the two rear screws at this

stage. In this instance you will also

need to secure it to the base on

either side.

^

Push the deflector plate back in.

Page 33

Installation

When fitting the DA 3590 in a 900 mm

wide housing unit, the retaining

brackets supplied are used to align the

cooker hood and provide additional

support.

The retaining brackets are secured

either to the top or the back panel of

the wall unit.

If the wall unit does not have a solid

back panel, the cooker hood can be

secured directly to the wall using the

screws and plugs supplied.

The top housing screws are used to

secure the retaining brackets to the

cooker hood.

If the screws are difficult to access use

the angled key supplied to tighten

them.

^ Unscrew the appropriate housing

screws.

^

Attach the retaining brackets loosely

to the housing with the screws.

^

Align the cooker hood and mark the

position of the fixing holes in the wall

unit.

^

Now secure the brackets to the wall

unit.

^

Realign the cooker hood and tighten

up the screws on the housing unit.

^

Use the adhesive covers supplied to

conceal the fixing holes which are not

required.

33

Page 34

Installation

Adjusting the deflector plate

(DA 3560, DA 3590)

When retracted, the deflector plate is

held in place by magnets.

The retaining force of the magnets can

be adjusted.

The magnets should be adjusted so

that the deflector plate is held in place

securely on the left and right hand side

and can be lowered slightly.

An angled key is supplied for adjusting

the magnets.

^

Adjust both sides equally.

Turn in stages by half a turn each

time and check the adjustment by

lowering and raising the deflector

plate.

–

Turning the adjusting screws

clockwise increases the magnetic

retaining force.

–

Turning the adjusting screws

anti-clockwise reduces the magnetic

retaining force.

34

^

The covers for the brackets are

designed for 16 mm and 19 mm thick

carcase sides. Turn the covers so

that they are in the appropriate

position and fit them onto the

brackets.

Page 35

Secure the spacer strip to the bottom

^

of the wall unit as well.

Installation

Take the grease filters out and

^

remove any protective foil. Replace

the grease filters.

Exhaust connection

^

Insert the cover for the charcoal filter

slots as shown and close it. It is held

in place by magnets.

^

Insert the non-return flap, if required.

Make sure that it opens easily and

closes again by itself.

35

Page 36

Installation

^ Attach the vent ducting to the

exhaust socket, using e.g. a flexible

hose and clips (available as an

optional accessory).

When using C 125 mm ducting, fit

the reducing collar supplied into the

exhaust socket. (See "Connection for

air extraction").

Setting up for recirculation

mode

If site conditions are not suitable for the

cooker hood to be used with air

extraction, the appliance must be set

up for recirculation.

A conversion kit, available through your

dealer or from Miele is required for

operating the cooker hood in

recirculation mode.

You will also need two charcoal filters

(see "Technical data").

dai2699

^

Place the vent ducting onto the

exhaust socket on the cooker hood.

^

See "Connection for air extraction" for

further instructions on fitting the

ducting.

36

Conversion kit DUU 150 with a plastic

grille is suitable for fitting in a

non-visible area of the top of the wall

unit.

Conversion kit DUU 151 with a stainless

steel grille is recommended if the grille

is to be fitted in an area which is visible.

Page 37

Fit the conversion kit as described in

^

the installation instructions supplied

with the kit.

Make sure that the slats in the

^

exhaust grille point towards the

centre of the room and not towards a

wall or the ceiling.

A non-return flap is not used in

recirculation mode.

Fit the charcoal filters (see "Cleaning

^

and care").

Electrical connection

Refer to the notes in "Electrical

connection" and "Warning and

Safety instructions" before

connecting to the electricity supply.

^ For appliances connected to an

external motor (EXT models):

Connect the cooker hood to the

external motor using the connecting

cable and the 6-pole plug connector.

Installation

^

Connect the appliance to the

electricity supply.

37

Page 38

Connection for air extraction

Important: To avoid the danger of

toxic fumes, please observe the

Warning and Safety instructions.

This is especially crucial when using

the cooker hood at the same time as

another heating appliance which

relies on air from the same room.

The cooker hood should be installed

according to local and national

building regulations. Seek approval

from the building inspector where

necessary.

Only use smooth pipes or flexible

–

hoses made from non-flammable

materials for the extraction ducting.

When using an external motor, make

–

sure that the exhaust ducting is

sufficiently rigid. The external motor

can cause an underpressure which

can result in the exhaust ducting

distorting.

To achieve the greatest possible air

extraction with the lowest noise level,

please note the following:

To ensure efficient air extraction, the

–

diameter of the exhaust ducting

should not be less than 150 mm.

– If flat ducting is being used, the

cross-section must not be smaller

than the cross-section of the exhaust

connection.

– All ducting, pipework and fittings

must be of non-flammable materials.

38

– The exhaust ducting should be as

short and straight as possible.

–

Only use wide radius bends.

–

The exhaust ducting should not be

kinked or compressed.

–

Ensure that all connections are

strong and airtight.

–

Where ducting is horizontal, it must

be laid to slope away at at least 1 cm

per metre. This is to ensure that

condensate cannot drain back into

the cooker hood.

Page 39

Connection for air extraction

If the exhaust air is to be ducted into

–

the open air, the installation of a

telescopic wall vent or roof vent

(available as an optional accessory)

is recommended.

If the exhaust air is to be ducted into

–

a vent flue, the ducting must be

directed in the flow direction of the

flue.

Important:

If the exhaust ducting is to run through

rooms, ceiling space etc. where there

may be great variations in temperature

between the different areas, the

problem of condensation will need to

be addressed. The exhaust ducting will

need to be suitably insulated.

Condensate trap

(optional accessory)

In addition to insulating the exhaust

ducting, we recommend that a suitable

condensate trap is also installed to

collect and evaporate any condensate

which may occur. Condensate traps

are available for C 125 mm or

C 150 mm ducting.

When installing a condensate trap,

ensure that it is positioned vertically

and if possible directly above the

exhaust connection. The arrow on the

housing indicates the direction of

air-flow.

Cooker hoods designed for use with an

external motor (...EXT models) have an

integrated condensate trap.

39

Page 40

Connection for air extraction

Silencer

(optional accessory)

To achieve even further reductions in

noise levels, a special silencer can be

fitted in the ducting system.

...with air extraction:

The silencer not only reduces noise

from the fan, but also sounds from

outside (e.g. traffic noise).

For this reason the silencer must be

positioned as close as possible to the

ducting exit a.

...in recirculation mode:

The silencer needs to be positioned

between the fan and the exhaust grille

b. The space needs to be checked in

some cases.

...air extraction with external motor:

To minimise noise from the motor in the

kitchen, the silencer should be

positioned in front of the external motor

c if possible, or if the ducting is long,

then in the ducting inside the cooker

hood itself d.

In the case of an external motor placed

inside the house, fitting a silencer

behind the external motor e reduces

the noise of the motor outside the

house.

40

In all modes of operation, the most

effective noise reductions are

achieved if two silencers are fitted

one behind the other in the system.

Page 41

All electrical work should be

undertaken by a suitably qualified

and competent person in strict

accordance with current national

and local safety regulations

(BS 7671 in the UK).

Installation, repairs and other work

by unqualified persons could be

dangerous, for which the

manufacturer cannot be held liable.

Ensure power is not supplied to the

appliance until after installation or

repair work has been carried out.

Do not connect the appliance to the

mains electricity supply by an

extension lead. These do not

guarantee the required safety of the

appliance.

The connection data is given on the

data plate. This is visible when the

grease filters have been removed.

Ensure that this data matches the

household mains supply.

Electrical connection

If the switch is not accessible after

installation (depending on country), an

additional means of disconnection must

be provided for all poles.

For extra safety it is advisable to protect

the appliance with a suitable residual

current device (RCD). Contact a

qualified electrician for advice.

Important

This appliance is supplied for

connection to an a.c. 230 V single

phase 50 Hz supply.

The wires in the mains lead are

coloured in accordance with the

following code:

Green/yellow = earth

Blue = neutral

Brown = live

WARNING:

THIS APPLIANCE MUST BE

EARTHED

Connection of this appliance should be

made via a suitable isolator or a double

pole fused spur connection unit which

complies with national and local safety

regulations and the On-Off switch

should be easily accessible after the

appliance has been built in.

When switched off there must be an

all-pole contact gap of 3 mm in the

switch (including switch, fuses and

relays according to EN 60335).

41

Page 42

Operation with Control module DSM 400

The Miele DSM 400 control module

(optional accessory) can be used to

combine the cooker hood with other

components.

It enables the following:

Potential free connection

This can be used to operate another

appliance by pulling out the deflector

plate and using the On/Off button s of

the cooker hood.

Components used in the central

ducting system are not supplied by

Miele.

If in any doubt, the advice of a

competent builder or, for gas, a Gas

Safe installer must be sought.

Connection to a push button switch

The control module can be used to

switch on the cooker hood lighting

when the deflector plate is pulled out

via a push button switch in the house.

Installation

The control module must be installed at

the back of the the cooker hood

housing.

The electrical connection of

components to the control module

must be carried out by a suitably

qualified and competent person.

The potential free contact on the

DSM 400 a can, for example, be used

in a cooker hood with an external motor

...EXT, which is connected to a central

ducting system.

The contact can then be used to

operate an electrically driven non-return

flap b which is connected to the

central extraction unit c.

42

Page 43

Technical data

Connected load*

DA 3560..................170W

DA 3590..................190W

Fan motor* .................130W

Hob lighting

DA 3560................2x20W

DA 3590................3x20W

Voltage ................. AC230V

Frequency ..................50Hz

Fuse rating ....................5A

Electrical cable

length ......................1.5m

Weight

DA 3560 ....................15kg

DA 3560 EXT ................13kg

DA 3590 ....................18kg

DA 3590 EXT ................16kg

Fan performance*

Extraction power according to

EN 61591

Air extraction system C 150 mm:

Level I ...................200m

Level 2...................300m

Level 3...................400m

Intensive setting ...........640m

Recirculation power with charcoal

filters:

Level I ...................150m

Level 2...................230m

Level 3...................320m

Intensive setting ...........550m

Special accessories for recirculation

mode:

– Conversion kit DUU 150 or

DUU 151

– Miele charcoal filter set DKF 19-1.

Contains two charcoal filters.

3

/h

3

/h

3

/h

3

/h

3

/h

3

/h

3

/h

3

/h

* For EXT models the connected load

and extraction power will depend on

the type of external motor fitted.

EXT models:

Length of connection cable to external

motor.......................1.9m

43

Page 44

Alteration rights reserved / 4212

M.-Nr. 09 466 100 / 03

Loading...

Loading...