Page 1

Operating instructions

for the Ventilation System

DA 326 i

DA 329 i

To prevent accidents

and machine damage,ö]

read these Operating Instructions

before installation or use.

UV

M.-Nr.

05 473 640

Page 2

Contents

Help protect our environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Guide to the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Description of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning and care

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Grease filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

External filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Internal filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Inserting / replacing the active charcoal filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Defective lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

After Sales Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Appliance dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation

Installation accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1. Non-return flap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2. Reducing collar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3. Runners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4. Hang the cabinet door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5. Position the appliance in the cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6. Align the height of the appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 a. Installation of a DFB lightshield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7 b. Installation of a custom lightshield to match cabinetry . . . . . . . . . . . . . . . . . 27

8. Align the depth of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9 a. Install side spacers at the sides of the appliance . . . . . . . . . . . . . . . . . . . . . 28

9 b. Spacer strip for the rear of the appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9 c. Light cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10 a. Vented extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10 b. Set up for recirculation mode connection. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

11. Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Special installation instructions

Installation into a cabinet with 19 mm thick walls. . . . . . . . . . . . . . . . . . . . . . . 32

Installing in a 35

Air extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7

/16 " (90 cm) wide cabinet: . . . . . . . . . . . . . . . . . . . . . . . . . 32

2

Page 3

Help protect our environment

Disposal of packing materials

The cardboard box and packing materi

als protect the appliance during ship

ping. They have been designed to be

biodegradable and recyclable. Please

recycle.

-

Disposal of your old appliance

Old appliances contain materials that

can be recycled. Please contact your

local recycling center about the possi

bility of recycling these materials.

Before discarding an old appliance,

unplug it from the outlet and cut off

its power cord and remove any

doors to prevent it from becoming a

hazard.

-

3

Page 4

Warning and Safety Instructions

Read these Operating Instructions carefully before installing or using the

Ventilation System.

Do not connect the appliance to

This appliance is intended for resi

dential use only. Use the appliance

only for its intended purpose. The

manufacturer cannot be held re

sponsible for damages caused by

improper use of the hood.

-

-

the main electrical supply using an

extension cord. Extension cords do not

meet the safety requirements of this ap

pliance.

Do not turn on the hood until it has

been properly installed.

-

Read all the instructions before in

stalling or using for the first time.

SAVE THESE INSTRUCTIONS AND

REVIEW THEM PERIODICALLY

CAUTION

For General Ventilating Use Only. Do

Not Use To Exhaust Hazardous Or

Explosive Materials And Vapors.

This appliance is designed to vent

cooking smoke \ odors only.

Be certain your appliance is prop

erly installed and grounded by a

qualified technician.

To guarantee the electrical safety

of this appliance, continuity must

exist between the appliance and an ef

fective grounding system. It is impera

tive that this basic safety requirement

be met. If there is any doubt, have the

electrical system of the house checked

by a qualified electrician. The manufac

turer cannot be held responsible for

damages caused by the lack, or inade

quacy of, an effective grounding sys

tem.

-

-

Repairs on electric appliances

should only be performed by quali

fied technician. Do not repair or replace

any part of the appliance unless specifically recommended in this manual.

Before servicing, disconnect the

power supply by either removing

the fuse or unplugging the unit or manually "tripping" the circuit breaker.

When installing the hood, make

sure that the minimum safety distances between cooktops and the hood

are maintained.

– For electric cooktops: 18" (45 cm)

– For gas cooktops: 26" (65 cm)

– For a Miele open grill: 26" (65 cm)

Do not install this exhaust hood

over cooktops burning solid fuel.

-

-

-

-

-

4

Page 5

Warning and Safety Instructions

WARNING

To reduce the risk of fire, use only

metal ductwork.

Any fittings, sealant, or materials used

to install the ductwork must be made of

approved non-flammable materials.

Never connect an exhaust hood to

an active chimney, dryer vent, vent

flue, or room ventilating ductwork. Seek

professional advice before connecting

an exhaust hood vent to an existing, in

active chimney or vent flue.

Never operate gas burners without

pots. Heat generated by prolonged

operation of gas burners without pots

could damage the hood.

Do not flambé beneath the exhaust

hood. Flames could be drawn up

into the hood by the suction or the

grease filters may ignite.

Do not allow children to play with

the hood or its controls.

WARNING

TO REDUCE THE RISK OF A RANGE

TOP GREASE FIRE:

Keep the fan, filters and grease

laden surfaces clean.

Always turn hood "ON" when cook

ing at high heat.

Use high range settings on range

only when necessary. Heat oil

slowly on low to medium setting.

Don't leave range unattended

when cooking.

Always use cookware and utensils

appropriate for the type and

amount of food being prepared.

-

Do not leave cooking surfaces un

attended while in use. Overheated

food can ignite.

Do not use the exhaust hood with

out the grease filters in place.

Clean the grease filters regularly.

Dirty filters are a fire hazard.

Do not use a steam cleaner to

clean the hood. The steam could

penetrate to electrical components and

cause a short circuit.

-

-

5

Page 6

Warning and Safety Instructions

WARNING

TO REDUCE THE RISK OF INJURY

TO PERSONS IN THE EVENT OF A

RANGE TOP GREASE FIRE,

OBSERVE THE FOLLLOWING:

Smother flames with a close fitting

lid, cookie sheet, or metal tray, then

turn off the burner.

Be careful to prevent burns.

If the flames do not go out immediately,

evacuate and call the fire depart

ment.

Never pick up a flaming pan - You

may be burned.

Do not use water, including wet

dishcloths or towels - a violent

steam explosion will occur.

Use an extinguisher

only if:

– You know you have a Class ABC ex-

tinguisher, and you already know

how to operate it.

–

The fire is small and contained in the

area where it started.

–

The fire department is being called.

–

You can fight the fire with your back

to an exit.

-

WARNING

TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO

PERSONS,

OBSERVE THE FOLLOWING:

Use this unit only in the manner in

tended by the manufacturer. If you

have questions, contact the manufacturer.

Before servicing or cleaning the

unit, turn power off at circuit

breaker and lock the service discon

necting means to prevent power from

being turned on accidentally. When the

service disconnecting means cannot

be locked, securely fasten a prominent

warning device, such as a tag, to the

service panel.

Installation and electrical work

must be performed by qualified

technicians in accordance with all applicable codes and standards.

Make sure that the airflow in the

room is sufficient for combustion

and exhausting of all non-electric heat

ing appliances (water heaters, gas

cooktops, gas ovens, etc.), otherwise

back drafts may occur. Follow the heat

ing maunfacturer's guidelines and

safety standards or those published by

the National Fire Protection Association

(NFPA), or the American Society for

Heating, Refrigeration and Air Condi

tioning Engineers (ASHRAE).

If in doubt, consult an experienced pro

fessional.

-

-

-

-

-

-

Be careful not to damage hidden

electrical wiring or plumbing when

cutting or drilling into the wall or ceiling.

Ducted fans must always be

vented outdoors.

6

Page 7

Warning and Safety Instructions

When connecting the hood to an ex

ternal vent, make sure that there is

adequate ventilation in the room

where the exhaust hood is to be

used.

When using the hood in the same area

as other appliances requiring room air

(e.g. non-electric water heaters, gas

cooktops, gas ovens, etc.) make cer

tain that the air extracted by the hood

does not hinder their operation. These

appliances need air for combustion.

Adequate ventilation can be maintained

by installing air vents in windows or

walls or by ensuring that the hood can

only be turned on when the other appliances are off, or vice versa.

To prevent combustion gases being

drawn back into the room by the exhaust hood, the underpressure in the

room must be no greater than 0.0006

psi (0.04 mbar) when the hood and

these appliances are running simulta

neously.

-

-

-

Disposal of old appliances

Before discarding an old appliance, re

move its power cord and any doors to

prevent it from becoming a hazard.

SAVE THESE INSTRUCTIONS AND

REVIEW THEM PERIODICALLY

Throughout the manual, important

safety items will be highlighted in

boxes and should be read in con

junction with these "Warning and

Safety instructions".

-

-

If there are any doubts as to whether

there is adequate ventilation, consult an

experienced professional.

7

Page 8

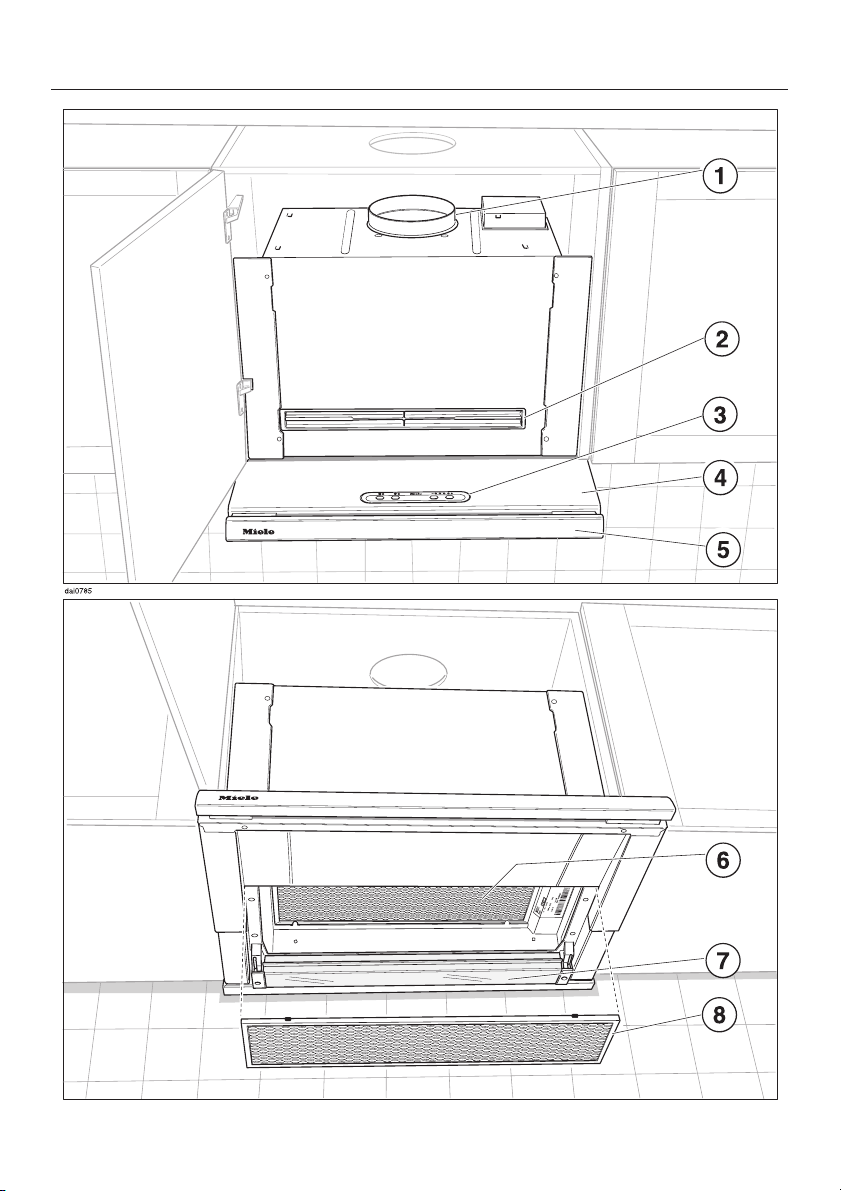

Guide to the appliance

8

Page 9

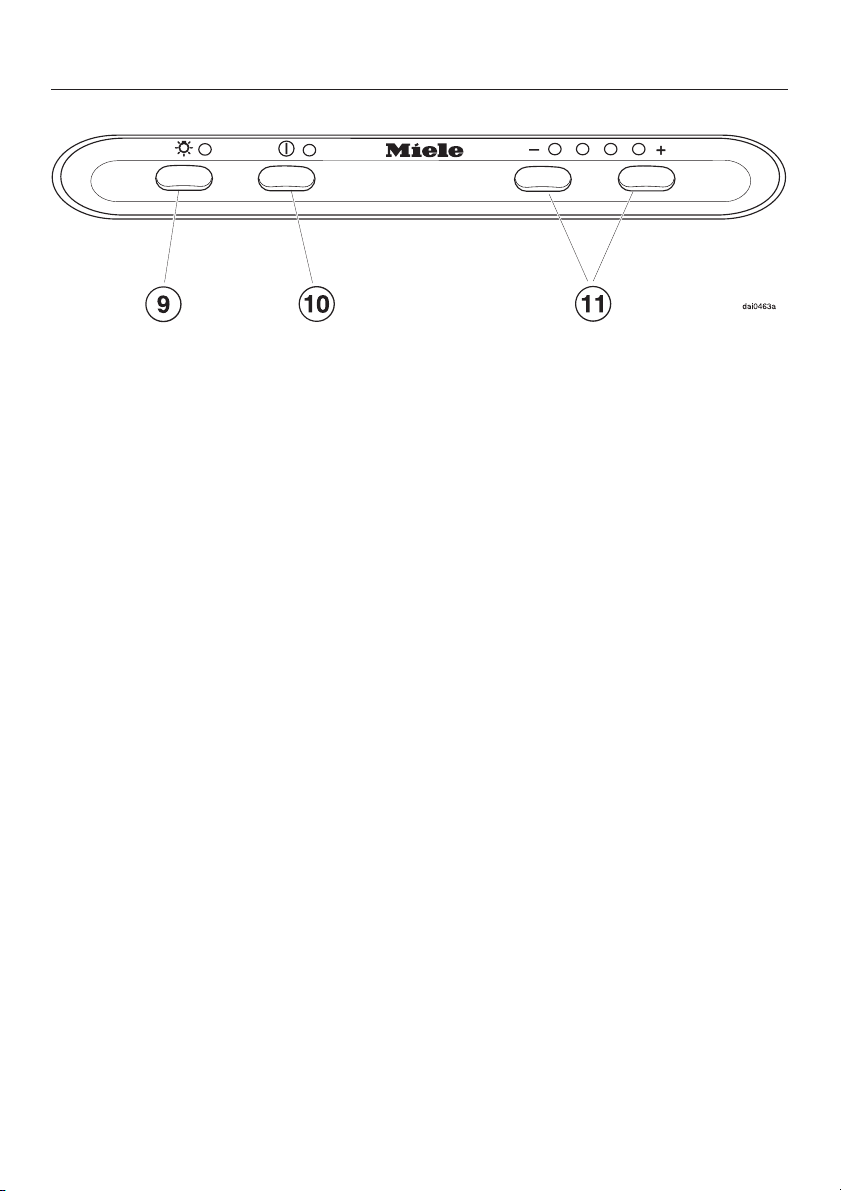

Guide to the appliance

a Vent connection

b Active charcoal filter slot

c Control panel

d Pull-out

deflector plate

e DFB Facia Panel

(must be ordered separately)

f Internal grease filter

g Overhead cooktop light

h External grease filter

i Light button

j On/Off button

k Power level buttons

Four fan speed selection

9

Page 10

Description of the functions

The hood works

...by air extraction:

The air is drawn in, cleaned by an ex

ternal filter and then passed through an

internal filter before being directed out

side.

The hood has a non-return flap , (see

"Installation").

This flap is closed when the hood is off.

No exchange of room air and outside

air can take place. When the hood is

turned on the non-return flap opens for

the cooking odors to be blown outside.

...by air recirculaton:

The air is drawn in and cleaned first by

the external filter, then by the internal filter before passing through an active

charcoal filter. The cleaned air is then

recirculated back into the kitchen

through a vent in the top of the hood.

Before using the hood for the first

time in recirculation mode, make

sure that the active charcoal filter is

in place. See Section on "Cleaning

and care".

-

-

10

Page 11

Operation

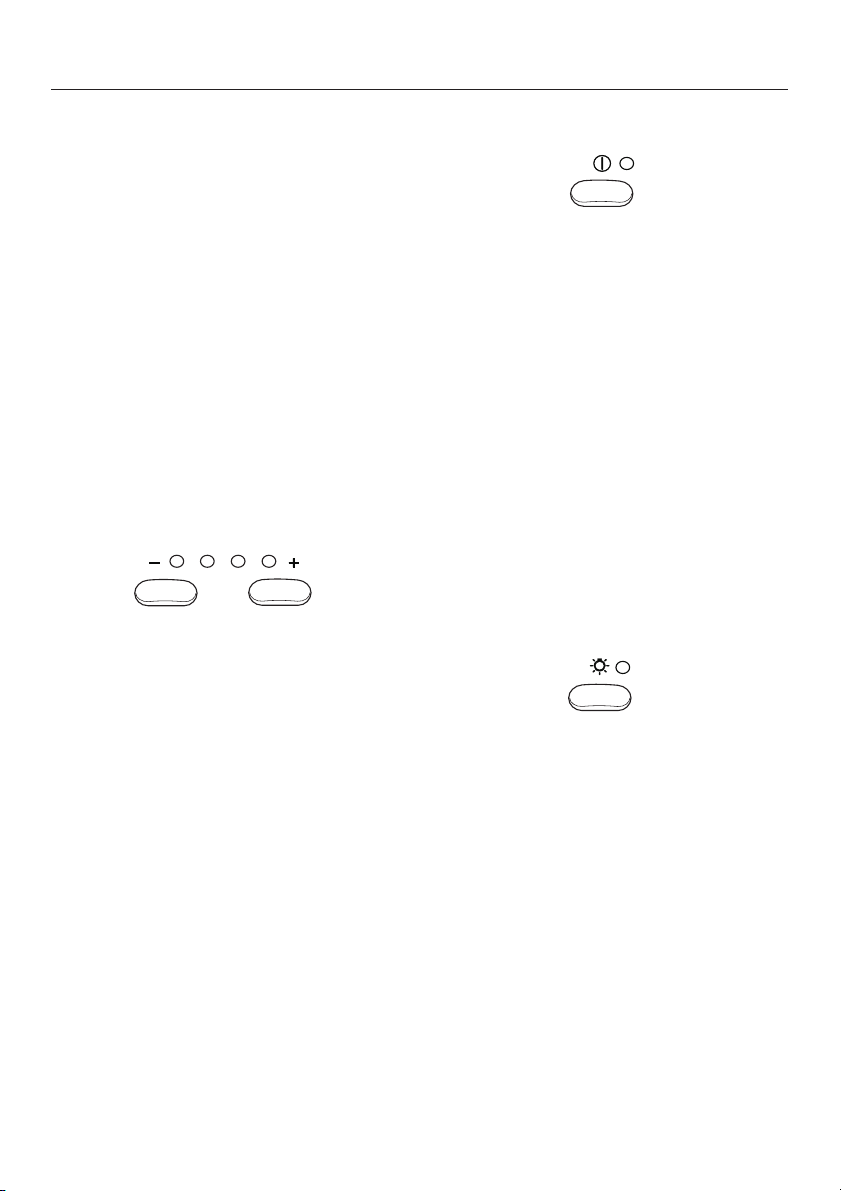

Turning the fan on

Pull the deflector plate out approxi

^

mately 2" (5 cm).

The hood will then begin to operate at

power level "II".

Selecting the power level

Depending on how much the air needs

to be filtered, there are four power lev

els available.

For normal cooking a low to medium

level is usually sufficient.

For frying or cooking food with a strong

aroma the highest level is recommended.

Lower level Higher level

^ Use the power level buttons to select

the power level required.

-

Turning the fan off

Press the On/Off button to turn the

^

fan off

or

Push the deflector plate back in.

^

The next time the deflector plate is

pulled out the hood will operate at

power level "II".

Turning the light on

The light for illuminating the cooktop

can be turned on or off independently

of the fan.

^ Pull the deflector plate out approxi-

mately 1.5" (3 cm).

The indicators show which power level

has been chosen.

11

^

Press the light button.

^

When the light is turned on the indi

cator next to the button illuminates

To turn the light off:

^

Press the light button again.

or

^

Push the deflector plate back in.

The next time the deflector plate is

pulled out the light will come back on.

-

Page 12

Cleaning and care

Before servicing or cleaning the

hood, disconnect it from the power

supply by "tripping" the circuit

breaker, removing the fuse or un

plugging it.

Make sure power is not restored to

the appliance while maintenance or

repair work is performed.

Housing

Lacquered surfaces can be cleaned

using a solution of hot water and liquid

soap. Dry with a soft cloth.

For stainless steel surfaces use a mild

non-abrasive stainless steel cleaner.

Never use cleaners which scour or

contain chlorine, acids or soda.

These will damage the surface of the

hood.

-

Grease filters

The hood has 2 re-usable metal filters

which remove solid particles (oil, dust,

etc.) from the vented kitchen air.

The hood has an external filter which is

visible on the underside of the appli

ance. An internal filter is situated above

it in the appliance.

The filters should be cleaned every

3 – 4 weeks to avoid a build-up of fat.

Clean the filters immediately if they are

obviously dirty.

Important! Always clean both filters.

A dirty filter is a fire hazard.

-

12

Page 13

Cleaning and care

External filter

To remove the external filter pull the

^

deflector plate out slightly.

Turn the fan off.

^

^ Holding the external filter at the front

tilt it approximately 1" (3 cm) downwards and then pull it towards you to

remove it.

Internal filter

^ Pull the deflector plate out to its full

extension.

The internal filter will now be visible.

Clean the filters –

^

– by hand: with a nylon brush in a

mild solution of warm water and liq

uid soap.

– in a dishwasher: place the filters

with the short side upright in the

lower basket, checking that the spray

arm is not blocked.

DA 329: The external grease filter can

be folded and cleaned in the dishwasher by twisting the latches as

shown.

Cleaning filters in the dishwasher

may cause permanent discoloration.

However, the performance of the fil

ters will not be affected.

-

-

^

Holding it by the handle pull it down

wards to remove it.

^

After cleaning, place the filters on a

towel to dry before putting them back

in place.

^

When removing the filters for clean

ing also clean off any residues of oil

or fat from the now accessible hous

ing to prevent fires.

-

-

-

13

Page 14

Cleaning and care

Replace the filters

Internal filter:

Fit the filter into the appliance so that

^

it hooks into position at the back,

then push it up at the front and make

sure it engages in position on the left

and right hand sides.

External filter:

Make sure that the red plastic

^

guides are at the front and facing up.

^ Insert the external filter into the

extended deflector plate and hold it

in position.

^

DA 329:

–

Twist the grease filter catch as

shown.

–

Unfold the grease filter and lock the

catch.

14

^

Tilt the rear of the filter up and gently

push it in until it snaps into place.

Page 15

Inserting / replacing the active

charcoal filter

Cleaning and care

For recirculation mode an active char

coal filter must be used in addition to

the grease filters. It is designed to absorb cooking odors.

The active charcoal filter is inserted into

the slot on the front of the appliance.

Replacement active charcoal filters

can be ordered from the Miele Technical Service Department at

1-800-999-1360.

Please quote

part number 05 182 190

Follow the instructions supplied with the

active charcoal filter when inserting it.

Always replace the filter immediately, if

it is no longer absorbing cooking odors.

However, it should be replaced at least

every 6 months.

-

15

Page 16

Cleaning and care

Defective lighting

If the light does not work the bulb may

need replacing or the starter could be

defective.

Before servicing or cleaning the

hood, disconnect it from the power

supply by "tripping" the circuit

breaker, removing the fuse, or un

plugging it.

Make sure power is not restored to

the appliance while maintenance or

repair work is performed.

-

Take out the external filter as already

^

described.

^ Unscrew the fixing screws on the

right and left hand sides of the light

cover. While undoing the screws hold

the cover securely so that it does not

drop on to the cooktop below!

^ Lower the cover to remove it.

^ Replace the fluorescent bulb or the

starter.

^ Replace the cover and secure in po-

sition with the fixing screws.

16

^

Replace the external filter.

Page 17

In the event of a problem which you

can not fix yourself, please contact:

Your Miele dealer

–

or

The Miele Technical Service Depart

–

ment,

(see address on back cover).

When contacting the Technical Service

Department, please quote the model

and serial number of your appliance,

both of which are shown on the data

plate, visible when the grease filters are

removed.

-

After Sales Service

17

Page 18

Appliance dimensions

18

Page 19

Appliance dimensions

* The DFB light shield must be pur

chased separately.

** For these dimensions to be applica

ble the rear panel of the upper cabi

net may have to be removed.

To ensure that the exhaust ducting can

be installed on the exhaust connection

easily, the upper cabinet must be at

least 460 mm high.

The slot for the active charcoal filter

–

a must be accessible if the appli

ance is being used in recirculation

mode.

The DA 327i can also be built into a 60

cm cabinet. In this case, the lower portion of the hood will overlap the bottom

cabinets on either side.

-

-

-

-

19

Page 20

Appliance dimensions

Installation in cabinetry

The depth of the installation depends

on what type of light shield is used and

the dimensions of surrounding

cabinetry.

Hood installed with a DFB light

shield

To install the hood so that the light

shield is flush with the adjacent

cabinetry, the following dimensions

must be used. (Please refer to the met

ric conversion table)

A = minimum of 273 mm when using a

16 mm thick door panel

A = minimum of 270 mm when using a

19 mm thick door panel

Hood installed with a cabinet match

ing light shield (custom made)

If wall cabinets have a decorative mold

ing along their lower edge, a matching

light shield can be made and mounted

on the hood. To do this the minimum

distance necessary (B) behind the light

shield will be 275 mm.

-

-

20

Page 21

Appliance dimensions

The adjustable filler strip C can be

used to conceal gaps of 10 to 70 mm

between the rear of the appliance and

the wall or cabinet back.

If the cabinet does not have a back

panel and there are no units to the

side of it then a traverse must be

used to provide the unit with extra

stability.

A traverse is available from the Miele

Spare Parts Department in the ap

propriate width (Miele DT 60 and DT

90).

-

Metric conversion table

Millimeters. . . . . . . . . . . . . . . . . . Inches

10 . . . . . . . . . . . . . . . . . . . . . . . . . . .3/8

15 . . . . . . . . . . . . . . . . . . . . . . . . . . .5/8

19 . . . . . . . . . . . . . . . . . . . . . . . . . . .3/4

30. . . . . . . . . . . . . . . . . . . . . . . . . 13/16

40. . . . . . . . . . . . . . . . . . . . . . . . . 19/16

70 . . . . . . . . . . . . . . . . . . . . . . . . . 23/4

75. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

85. . . . . . . . . . . . . . . . . . . . . . . . . . 33/8

88 . . . . . . . . . . . . . . . . . . . . . . . . . 31/2

100. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

115. . . . . . . . . . . . . . . . . . . . . . . . 49/16

125. . . . . . . . . . . . . . . . . . . . . . . 415/16

150. . . . . . . . . . . . . . . . . . . . . . . 515/16

165. . . . . . . . . . . . . . . . . . . . . . . . . 61/2

170. . . . . . . . . . . . . . . . . . . . . . . 611/16

175. . . . . . . . . . . . . . . . . . . . . . . . . 67/8

255. . . . . . . . . . . . . . . . . . . . . . . 101/16

258. . . . . . . . . . . . . . . . . . . . . . . 103/16

270. . . . . . . . . . . . . . . . . . . . . . . . 105/8

273. . . . . . . . . . . . . . . . . . . . . . . . 103/4

275. . . . . . . . . . . . . . . . . . . . . . 1013/16

285 . . . . . . . . . . . . . . . . . . . . . . . 111/4

345. . . . . . . . . . . . . . . . . . . . . . . 139/16

359. . . . . . . . . . . . . . . . . . . . . . . . 141/8

460. . . . . . . . . . . . . . . . . . . . . . . . 181/8

470 . . . . . . . . . . . . . . . . . . . . . . . 181/2

562. . . . . . . . . . . . . . . . . . . . . . . . 221/8

568. . . . . . . . . . . . . . . . . . . . . . . . 223/8

595. . . . . . . . . . . . . . . . . . . . . . . 237/16

600. . . . . . . . . . . . . . . . . . . . . . . . 235/8

862. . . . . . . . . . . . . . . . . . . . . . 3315/16

868. . . . . . . . . . . . . . . . . . . . . . . 343/16

895. . . . . . . . . . . . . . . . . . . . . . . . 351/4

900. . . . . . . . . . . . . . . . . . . . . . . 357/16

21

Page 22

Installation

Installation accessories

22

Page 23

Installation

a 1 hose clip for securing the vent

ducting to the vent connection.

b 1 reducing collar

for exhaust ducting of 5" (125 mm)

diameter.

c 1 non-return flap

for fitting into the vent connection.

d 2 runners

(1 x right, 1x left) to support the ap

pliance in the cabinet.

e 2 spacer blocks (DA 329 only)

for installing the appliance in a

7

35

/16" (90 cm) wide cabinet.

f 2 cover caps (DA 329 only)

(1 x right, 1x left) and two inserts g

for covering the support rails when

installing in a 35

7

/16" (90 cm) wide

cabinet.

h 2 side spacers

to conceal spaces at the side when

installing in a 60 cm wide cabinet.

i Active Charcoal Filter slot

for inserting the Active Charcoal Fil

ter.

j deflector plate handle

for the front panel.

8 screws 4.0x16 mm

For securing the runners d

in a 60 cm wide cabinet or for securing

the spacer blocks e in a 35

(90 cm) wide cabinet.

6 screws

3.5x9.5 mm

2 screws for securing the light cover l,m.

4 screws for securing the side spacers h.

DA 329 only : 8 additional screws for

securing the runners d to the spacer

blocks e when installing in a 35

(90 cm) wide cabinet.

1 adhesive strip with 3

sections for attaching a

decorative piece to the deflector plate

handle j.

7 screws

3.0x15 mm

2 for attaching the deflector plate han

dle j to the deflector plate;

5 for attaching a decorative piece to the

deflector plate handle j.

7

/16"

7

/16"

-

k 1 spacer strip

to conceal the gap between the rear

of the appliance and the wall.

l 1 light cover

with right and left holders m.

Screwdriver for aligning the cabinet

door after the appliance has been in

stalled.

-

23

Page 24

Installation

Safety regulations prohibit the instal

lation of this venting hood over a

solid fuel stove.

The minimum safety distance be

tween the top of the cooktop and the

bottom of the venting hood should

be at least:

– 18" (45 cm) above electric

cooktops

– 26" (65 cm) above gas cooktops

– 26" (65 cm) above a Miele

open grill.

See "Warning and Safety instructions" for further notes on safe installation.

Installation procedure

1. Non-return flap (if needed)

Prepare the vent connection/ vent

-

socket for air extraction or recirculation

mode before installation.

1. Non-return flap

-

Air extraction with integrated fan

^ Fit the non-return flap into the vent

socket so that the flaps can open upwards.

(This is not necessary if the ducting

system is already fitted with a non return flap, e.g. wall vent).

2. Reducing collar (if needed)

3. Fit the runners in the cabinet

4. Hang and align the cabinet door

5. Position the appliance in the cabinet

6. Align the height of the appliance

7. Attach the lightshield

8. Align the depth of the appliance

9. Fit the side spacers, the spacer strip,

and the light cover

10. Set up for air extraction or

recirculation mode

11. Connect to the electrical supply

24

Recirculation mode

When used in recirculation mode a

non-return flap it is not necessary.

Page 25

Installation

2. Reducing collar

Air extraction

The appliance is designed for vent

ducting 6" (150 mm) diameter ducting.

If a 5" (125 mm) diameter is required:

^ Place the reducing collar supplied on

the vent socket and turn it to secure it

in position (see "Connection for air

extraction").

Recirculation

^ Place the reducing collar for a 5" (125

mm) diameter on the vent socket as

described previously.

3. Runners

Now fit the two runners into the cabinet.

If the appliance is being installed in a

7

35

/16" (90 cm) wide cabinet the run-

ners are fitted with the spacer blocks.

Position the runners

The positioning will depend on the type

of lightshield used.

Appliance with a DFB lightshield:

^

Draw a vertical line approximately

7

7

/8 " (20 cm) long on both the left

and right sides of the cabinet 4"

(100 mm) in from the front edge (see

illustration).

25

Page 26

Installation

Appliance with a lightshield to match

cabinetry:

^ To calculate the position of the

lightshield:

Measure the distance "B" from the

front of edge of the cabinet (without

door) and the rear edge of the

lightshield.

^

Then draw a vertical line 7

7

/ 8 "

(20 cm) long 3" (75 mm) in from the

front edge of the cabinet on both the

left and right side panels of the cabi

net for dimension "C".

If dimension "B" is less than

3

/ 4 "

(20 mm), dimension "C" will be

4 " (100 mm).

If dimension "B" is between

9

1

/16 " (20 and 40 mm), dimension

"C" will be 4

7

/ 8 " (124 mm).

3

/ 4 " and

Installing the runners

5

(Standard cabinet: 23

/ 8 " (60 cm)

wide, 16 mm thick cabinet walls)

Hold the runner against the cabinet

^

so that the lower edge of the runner

is flush

with the cabinet. The first row

of screws must be aligned with the

pencil marks.

The "16 mm" marking should face upwards.

Secure each runner with four

4 x 16 mm screws.

Note: Please refer to the "Special installation instructions" at the end of the "Installation" section for instructions on installing the appliance into a cabinet

with 19 mm thick walls or into a 35

(90 cm) wide cabinet.

4. Hang the cabinet door

Before installing the appliance, hang

and align the cabinet

door.

Use the special tool

supplied, if you need

to re-align the cabinet

door after the appli

ance has been in

stalled and the hinges

are no longer acces

sible.

-

-

-

7

/16"

26

Page 27

Installation

5. Position the appliance in

the cabinet

Lift the venting hood into the cabinet,

^

making sure that the supports on the

venting hood are sitting on the run

ners in the cabinet. Push it into the

cabinet as far as it will go.

The supports will slide under the

anti-tip device b.

Insert the adjusting screws b on the

runners through the holes in the sup

ports.

^ Use a small screwdriver to push re-

tainer c down over adjusting screw

b.

6. Align the height of the

appliance

^ Use screw d to align the height.

-

-

Now align the appliance so that it is

horizontal.

Turning screw d clockwise, raises

the appliance upwards, turning it

counterclockwise lowers it.

^

Close the unit door and check that

the deflector plate goes in and out

smoothly. If necessary make more

adjustments as above.

Attach the lightshield before aligning

the depth.

27

Page 28

Installation

7 a. Installation of a DFB

lightshield

Follow the installation instructions sup

plied with the lightshield.

7 b. Installation of a custom

lightshield to match cabinetry

^

Fit the deflector plate handle into the

openings on the deflector plate.

^

Secure the grip in position with

screws (3.0 x 15 mm) fitted into the

underside of the deflector plate.

-

Stick the custom lightshield to the de

^

flector plate handle in the position re

quired.

^

Dismantle the deflector plate handle

again and secure the lightshield to

the deflector plate handle using five

3.0 x15 mm, two at either side and

one in the middle.

^

Reattach the lightshield on to the ap

pliance.

-

-

-

^

Stick the three lengths of double

sided adhesive tape to the deflector

plate handle.

^

Remove the protective backing.

28

Page 29

Installation

8. Align the depth of the

appliance

^ To move the appliance further out of

the cabinet:

Loosen screws b and tighten

screws e.

Tighten screws b again to secure it

into position.

9 a. Install side spacers at the

sides of the appliance

(Standard cabinet 60 cm wide)

The side spacers cover the gaps between the sides of the appliance and

the cabinet.

^ Before installing the side spacers,

use a knife to make a cut-out in the

side spacer for the appropriate side

of the cabinet to accommodate the

cabinet hinging.

^

Screw the side spacers to the hous

ing and press them in at the sides.

Use 3.5 x 9.5 mm screws.

-

^

To move the appliance further into the

cabinet:

Loosen screws e and tighten

screws b.

Tighten screws e again to secure it

in position.

^

Check the alignment again by pulling

the deflector plate out and pushing it

back in again.

Note: Please refer to the "Special instal

lation instructions" at the end of the "In

stallation" section for instructions on in

stalling the appliance into a cabinet

7

with 19 mm thick walls or into a 35

(90 cm) wide cabinet.

/16"

-

-

-

29

Page 30

Installation

9 b. Spacer strip for the rear

of the appliance

Measure the gap "T" to be covered

^

between the rear of the appliance

and the wall.

^ Use a knife to trim the spacer strip

supplied to measurement "T".

9 c. Light cover

Pull the deflector plate out slightly.

^

Tilt the external filter at the front down

^

slightly and pull it out towards the

front.

^ Insert the two holders on to the sides

of the light cover.

^

Stick the spacer strip to the under

side of the appliance.

^

Turn the side cover caps upwards

and press into position.

30

-

^

Secure the light cover using self-tap

ping screws 3.5 x 9.5 mm.

-

Page 31

Installation

Replace the external filter:

Make sure that the red plastic

^

guides are at the front and facing upwards.

^ Insert the external filter into the ex-

tended deflector plate from below

and hold it in position.

10 a. Vented extraction

Insert the panel supplied into the Ac

^

tive Charcoal Filter slot.

Secure the ventilation ducting over

^

the vent socket on the venting hood

using a hose clip.

^ Complete venting installation. (See

"Connection for air extraction").

-

^

Push the filter gently upwards and

push the deflector plate in. The filter

will slide into the holders.

31

Page 32

Installation

10 b. Set up for recirculation

mode connection

If the hood can not be installed for air

extraction the appliance must be con

nected for recirculation mode.

The following parts, available through

your Miele Dealer or from the Miele

Technical Service Department are nec

essary for using the appliance in

recirculation mode:

If the front of the unit is ceiling height

then an appropriate cut-out must be

made in the front panel d .

When installing the ventilation grill make

sure that the slats in the grill point to

wards the center of the room and not

towards a wall or the ceiling.The slot for

the Active Charcoal Filter is located on

-

the front of the appliance.

^ Install the Active Charcoal Filter (see

"Cleaning and care").

-

–

Air Recirculation Conversion kit 5"

(125 mm) diameter. Includes an ex

haust grill, flexible ducting, and a

hose clip

–

Active Charcoal Filter (see "Technical

data")

Connection

When installing the venting hood in a

cabinet the exhaust grill b must be fit

ted in the top of the unit. The vent con

nection (vent socket) a and the ex

haust grill b are joined together with a

pipe or flexible duct cut to size c.

32

-

11. Electrical connection

-

Refer to the notes in "Electrical con

nection" and "Warning and Safety in

structions" before connecting to

electricity.

-

-

-

-

Page 33

Installation

Special installation

instructions

Installation into a cabinet with

19 mm thick walls

^ The runners have to be adapted as

shown above.

7

Installing in a 35

cabinet:

The runners are fitted to spacer blocks.

357/16" (90 cm) wide cabinet

^ Screw the spacer block to the cabi-

net using 4.0 x 16 mm screws with

the lower edge flush

The first row of screws must be

aligned with the pencil marks.

/16 " (90 cm) wide

with the cabinet.

^

Screw the runners to the cabinet with

the "19 mm" marking facing upwards

as shown above.

^ Screw the runners to the spacer

block using the 3.5 x 9.5 mm self tap

ping screws.

-

33

Page 34

Installation

When installed in 357/16" (90 cm) wide

cabinet the runners are fitted with the

cover caps supplied.

^ Cut the inserts to the required depth

and fit into the sides of the cover

caps.

^ Fit the cover caps to the runners on

both sides of the unit.

^ On units with 19 mm thick sides the

cover caps for the runners must be

trimmed using a knife along the

groove.

34

^

Line up the pre-drilled holes of the

cover and housing and secure with

3.9 x 9.5 mm screws.

Page 35

Danger of toxic fumes.

Gas cooking appliances release car

bon monoxide that can be harmful

or fatal if inhaled. The exhaust

gases extracted by the hood

should be vented outside of the

building only

Do not terminate the exhaust

ducts in attics, garages,

crawlspaces, etc.

Please read and follow the "Warning

and Safety Instructions" to reduce the

risk of personal injury, and follow all lo

cal building codes when installing the

hood.

Exhaust ducting and connections

– The ducting should be as short and

straight as possible, and the number

of sharp bends should be minimized.

.

-

Air extraction

into attics, crawl spaces, or garages.

Use smooth or flexible pipes made

–

from approved non-flammable mate

rials for exhaust ducting.

Where the ductwork is horizontal, it

–

must slope away from the hood at

least 1/8" per foot (1cm per meter) to

prevent condensation dripping into

the appliance.

If the exhaust is ducted through an

–

outside wall, a Miele Telescopic Wall

Vent can be used.

-

– For most efficient air extraction, the

diameter of the ductwork should not

be less than 6" (150 mm). Use of flat

ducts also reduces the air extraction

efficiency.

–

Noise levels of the hood will increase

if flat ducts or round ducts of less

than 6" (150 mm) in diameter are

used.

WARNING

To reduce the risk of fire, Use only

metal ductwork.

CAUTION

To reduce risk of fire and to properly

exhaust air, be sure to duct air out

side - Do not vent exhaust air into

spaces within walls or ceilings or

-

–

If the exhaust is ducted into an inac

tive flue, the air must be expelled

parallel to the flow direction of the

flue.

-

35

Page 36

Air extraction

Never connect an exhaust hood to

an active chimney, dryer vent, vent

flue, or room venting ductwork. Seek

professional advice before connect

ing an exhaust hood vent to an exist

ing, inactive chimney or vent flue.

Ductwork with a diameter of less

than 6" (150 mm) should only be

used when absolutely necessary. As

duct diameter decreases, the hood

performance and sound levels will

be affected.

Note:

If the ductwork runs through rooms,

ceilings, garages, etc. where temperature variations exist, it may be necessary to use insulation to reduce condensation. In some cases, a condensate trap may also be required.

-

-

36

Page 37

Electrical connection

Electrical connection

All electrical work should only be per

formed by a qualified electrician in ac

cordance with national and local safety

regulations.

The hood comes equipped with a

5 ft (1,5 m) power cord for connection

to a 120 VAC, 15 A, 60 Hz power outlet.

-

Verify that the information on the data

plate matches the household electrical

supply before installing the hood. The

data plate is visible once the grease fil

ter has been removed.

Important

CAUTION:

Ensure that power supply is OFF

during installation.

-

-

If you have any questions as to how

to connect this hood to your building

power supply, please call Miele or

consult a licensed electrician.

WARNING

THIS APPLIANCE MUST BE

GROUNDED

37

Page 38

Technical data

Maximum load

– DA 326 i. . . . . . . . . . . . . . . . . . 365 W

– DA 329 i. . . . . . . . . . . . . . . . . . 366 W

Lighting

– DA 326 i, DA 326 i EXT . . . . 1 x 15 W

– DA 329 i, DA 329 i EXT . . . . 1 x 16 W

Voltage . . . . . . . . . . . . . . . . . . 120 VAC

Frequency . . . . . . . . . . . . . . . . ~ 60 Hz

Circuit breaker. . . . . . . . . . . . . . . . 15 A

Fan

Values derived using 6" (150 mm)

ducting and EN 61591 test procedures

Level I . . . . . . . . . . . 190 cfm (320 m

Level II . . . . . . . . . . 295 cfm (500 m

Level III . . . . . . . . . . 420 cfm (710 m

Intensive level . . . . . 495 cfm (840 m

Unrestricted . . . . . . 540 cfm (920 m

3

/h)

3

/h)

3

/h)

3

/h)

3

/h)

Recirculation mode with active charcoal

filter:

Level I . . . . . . . . . . . 165 cfm (280 m

Level II . . . . . . . . . . 250 cfm (430 m

Level III . . . . . . . . . . 350 cfm (600 m

Intensive level . . . . . 400 cfm (680 m

3

/h)

3

/h)

3

/h)

3

/h)

Miele Active Charcoal Filter DKF 8,

Part.No. 05 182 190

38

Page 39

39

Page 40

Alteration rights reserved / 44 / 2702

This paper consists of cellulose bleached without the use of chlorine

M.-Nr. 05 473 640 / V

01

Loading...

Loading...