Page 1

Operating and installation

instructions

SmartLine gas hob

To avoid the risk of accidents or damage to the appliance it is

essential to read these instructions before it is installed and used for

the first time.

en-AE, SA M.-Nr. 11 507 780

Page 2

This hob can be used in countries other than those specified on the appliance

and in these operating and installation instructions. It is, however, set up for

connection to the gas and electricity supplies in the countries specified. For

trouble-free operation of the appliance, it is best to use it in the countries

specified for use.

For use in other countries, please contact Miele in your country.

2

Page 3

Gas-heated appliances

Safety precautions to take if you smell gas

Turn off the gas emergency control valve immediately.

This is usually located near the gas meter.

Eliminate all sources of ignition in a safe manner.

Do not smoke, light cigarette lighters or matches.

Do not operate electrical lights or switches, i.e. do not switch them “On” or

“Off”.

Open all doors and windows to ventilate the area.

If the smell of gas persists, evacuate the building.

3

Page 4

Contents

Warning and Safety instructions...................................................................... 6

Caring for the environment .............................................................................. 17

Guide to the appliance...................................................................................... 18

Hob...................................................................................................................... 18

Control knobs...................................................................................................... 19

Burner.................................................................................................................. 20

Accessories supplied .......................................................................................... 21

Before using for the first time .......................................................................... 22

Cleaning the SmartLine element for the first time............................................... 22

Switching on the SmartLine element for the first time ........................................ 22

Pans .................................................................................................................... 23

Tips on saving energy ...................................................................................... 24

Operation............................................................................................................ 25

Switching on........................................................................................................ 25

FlameGuard......................................................................................................... 25

Adjusting the flame.............................................................................................. 26

Switching off........................................................................................................ 26

Safety features................................................................................................... 27

Thermo-electric flame failure monitor ................................................................. 27

Cleaning and care ............................................................................................. 28

Ceramic surface .................................................................................................. 29

Rotary controls.................................................................................................... 30

Pan supports ....................................................................................................... 30

Burner.................................................................................................................. 31

Problem solving guide ...................................................................................... 33

Optional accessories ........................................................................................ 35

After sales service............................................................................................. 36

Contact in case of malfunction ........................................................................... 36

Data plate ............................................................................................................ 36

Guarantee............................................................................................................ 36

Installation.......................................................................................................... 37

Safety instructions for installation ....................................................................... 37

Safety distances.................................................................................................. 38

Surface-mounted ................................................................................................ 41

4

Page 5

Contents

Installation notes – surface-mounted.................................................................. 41

Worktop cutout – surface-mounted .................................................................... 43

Spacer bars – surface-mounted.......................................................................... 46

Installation dimensions–Surface-mounted........................................................ 47

Installation – surface-mounted............................................................................ 48

Flush-fit ............................................................................................................... 50

Installation notes – flush-fit ................................................................................. 50

Worktop cutout – flush-fit.................................................................................... 52

Spacer bars – flush-fit ......................................................................................... 55

Installation dimensions–Flush ........................................................................... 56

Installation – flush-fit ........................................................................................... 57

Gas connection ................................................................................................... 59

Electrical connection ........................................................................................... 61

Burner ratings.................................................................................................... 63

Converting to another gas type ....................................................................... 64

Jet table............................................................................................................... 64

Changing the jets ................................................................................................ 64

Changing the main jets................................................................................... 64

Changing the small jets.................................................................................. 65

Functional check ................................................................................................. 65

5

Page 6

Warning and Safety instructions

This hob complies with all relevant local and national safety

requirements. Inappropriate use can, however, lead to personal

injury and material damage.

Read the operating and installation instructions carefully before

using the hob. They contain important information on safety,

installation, use and maintenance. This prevents both personal

injury and damage to the hob.

In accordance with standard IEC60335-1, Miele expressly and

strongly advises that you read and follow the instructions in the

chapter on installing the hob as well as the safety instructions and

warnings.

Miele cannot be held liable for injury or damage caused by noncompliance with these instructions.

Keep these instructions in a safe place and pass them on to any

future owner.

6

Page 7

Warning and Safety instructions

Correct application

This hob is intended for domestic use and use in other similar

environments.

This hob is not intended for outdoor use.

It is intended for domestic use only to cook food and keep it

warm. Any other use is not supported by the manufacturer and could

be dangerous.

This hob is not intended for use by people with reduced physical,

sensory or mental capabilities or lack of experience and knowledge,

unless they have been given supervision and instruction concerning

its use by a person responsible for their safety. They may only use

the hob unsupervised if they have been shown how to use it in a

safe way. They must be able to recognise and understand the

dangers of misuse.

7

Page 8

Warning and Safety instructions

Safety with children

Children under 8 years of age must be kept away from the hob

unless they are constantly supervised.

Children over 8years of age may use the hob without supervision

if its operation has been clearly explained to them and they are able

to use it safely. Children must be able to understand and recognise

the possible dangers caused by incorrect operation.

Children must not be allowed to clean the hob unsupervised.

Please supervise children in the vicinity of the hob and do not let

them play with it.

The hob gets hot when in use and remains hot for a while after

being switched off. Keep children well away from the hob until it has

cooled down and there is no danger of burning.

Danger of burning! Do not store anything which might arouse a

child's interest in storage areas above or behind the hob. Otherwise

they could be tempted into climbing onto the appliance with the risk

of burning themselves.

Risk of burning and scalding. Place pots and pans on the cooking

zone in such a way that children cannot pull them down and burn

themselves.

Danger of suffocation. Packaging, e.g. plastic wrappings, must be

kept out of the reach of babies and children. Whilst playing, children

could become entangled in packaging or pull it over their head and

suffocate.

8

Page 9

Warning and Safety instructions

Technical safety

Unauthorised installation, maintenance and repairs can cause

considerable danger for the user. Installation, maintenance and

repairs must only be carried out by a Miele authorised technician.

Damage to the hob can compromise your safety. Check the hob

for visible signs of damage. Do not use the hob if it is damaged.

Reliable and safe operation of this hob can only be assured if it

has been connected to the mains electricity supply.

The electrical safety of this hob can only be guaranteed when

correctly earthed. It is essential that this standard safety requirement

is met. If in any doubt please have the electrical installation tested by

a qualified electrician.

To avoid the risk of damage to the hob, make sure that the

connection data on the data plate (voltage and frequency) match the

mains electricity supply before connecting it to the mains.

Consult a qualified electrician if in doubt.

Do not connect the hob to the mains electrical supply by a multi-

socket adapter or extension lead. These are a fire hazard and do not

guarantee the required safety of the appliance.

For safety reasons, this hob may only be used after it has been

built in.

This hob must not be used in a non-stationary location (e.g. on a

ship).

Never open the casing of the hob.

Touching or tampering with electrical connections or components

and mechanical parts is highly dangerous to the user and can cause

operational faults.

While the hob is under warranty, repairs should only be

undertaken by a Miele authorised technician. Otherwise the warranty

is invalidated.

9

Page 10

Warning and Safety instructions

Miele can only guarantee the safety of the appliance when

genuine original Miele replacement parts are used. Faulty

components must only be replaced by Miele spare parts.

The hob is not intended for use with an external timer switch or a

remote control system.

The connection to the gas supply must be carried out by a

suitably qualified gas fitter, e.g. a Gas Safe registered technician in

the UK (see “Gas connection”).

If the plug has been removed from the connection cable or the

connection cable is not supplied with a plug, the hob must be

connected to the electricity supply by a suitably qualified electrician

(see “Installation – Electrical connection”).

If the mains connection cable is damaged, it must be replaced

with a special mains connection cable by a qualified electrician (see

“Electrical connection” in the “Installation” chapter).

During installation, maintenance and repair work, the hob must be

disconnected from the mains electricity supply. The gas supply must

also be shut off. Depending on country this is done in one of several

different ways:

- the mains fuse has been disconnected, or

- the screw-out fuse is removed (in countries where this is

applicable), or

- switch off at the wall socket and withdraw the plug from the

socket. Pull by the plug and not by the mains connection cable to

disconnect from the mains electricity supply.

- the gas inlet valve is closed.

10

Page 11

Warning and Safety instructions

Risk of electric shock. Do not use the hob if it is faulty, or if the

ceramic surface is cracked, chipped or damaged in any way. Switch

it off immediately, do not touch the appliance surface and

disconnect the hob from the mains electricity supply and the gas

supply. Contact your Miele dealer.

If the hob is installed behind a cabinet door, do not close the door

while the hob is in use. Heat and moisture can build up behind the

closed door. This can result in damage to the hob, the housing unit

and the floor. Leave the furniture door open until the hob has cooled

down completely.

11

Page 12

Warning and Safety instructions

Correct use

The hob gets hot when in use and remains hot for some time after

being switched off. Do not touch the hob if there is a possibility that

it could still be hot.

Due to the high temperatures radiated, objects left near the hob

when it is in use could catch fire.

Do not use the hob to heat up the room.

Oil and fat can overheat and catch fire. Do not leave the hob

unattended when cooking with oil and fat. If it does ignite do not

attempt to put the flames out with water.

Disconnect the hob from the mains and use a suitable fire blanket,

saucepan lid, damp towel or similar to smother the flames.

Do not leave the SmartLine element unattended whilst it is being

used. It should be continually monitored whilst boiling and flash

frying.

Flames could set the grease filters of a cooker hood on fire. Do

not flambé under a cooker hood.

Spray canisters, aerosols and other inflammable substances can

ignite when heated. Therefore do not store such items or substances

in a drawer under the hob. Cutlery inserts must be heat-resistant.

Do not use or store flammable materials near this appliance.

Do not use the wok to heat up the room.

Due to the high temperatures radiated, objects left near the wok

could catch fire.

Do not heat an empty pan.

Do not heat up food in closed containers e.g. tins or sealed jars

on the hob, as pressure can build up in the container, causing it to

explode.

12

Page 13

Warning and Safety instructions

Do not cover the hob, e.g. with a hob cover, a cloth or protective

foil. The material could catch fire, shatter or melt if the hob is

switched on by mistake or if residual heat is still present.

If the appliance is switched on by mistake, or if there is residual

heat present, there is the risk of any metal items placed on the hob

heating up. Other materials can melt or catch fire. Do not use the

appliance as a resting place for anything.

You could burn yourself on the hot hob. Protect your hands with

heat-resistant pot holders or gloves when handling hot pots and

pans. Do not let them get wet or damp, as this causes heat to

transfer through the material more quickly with the risk of scalding or

burning yourself on steam. Be sure to keep all textiles away from the

gas flames. Do not use oversized cloths, tea towels or other similar

materials.

When using an electrical appliance, e.g. a hand-held food blender,

near the hob, ensure that the cable of the electrical appliance cannot

come into contact with the hot hob. The insulation on the cable

could become damaged.

Even a light object can cause damage in certain circumstances.

Do not drop anything on the ceramic surface.

Plastic and aluminium foil containers melt at high temperatures.

Do not use plastic or aluminium foil containers on the hob.

When a control knob is pressed down, a spark is generated on the

ignitor. Do not press down the control knob while you are cleaning or

touching the hob or a burner in the vicinity of an ignitor.

If a cooker hood is installed above the hob, ensure that the

burners are always covered with a pan when in use. Otherwise

flames could reach the cooker hood, parts of which could then be

damaged or even set on fire.

Only light the gas burners after all burner parts have been properly

assembled.

13

Page 14

Warning and Safety instructions

Pans must be the correct size for the burner they are used on (see

“Suitable Pans”). A pan which is too small will be unstable on the

pan support. If the pan diameter is too large, flames can spread out

to the sides and damage or burn the worktop, wall claddings or

surrounding units and also parts of the hob. Miele cannot be held

liable for this type of damage.

Ensure that the flames from the burner do not spread out beyond

the base and up the sides of the pan.

Do not use pans with very thin bases on this hob, and never heat

up empty pans as they could get damaged. This could also damage

the appliance.

The pan support supplied with the appliance must always be

used. Never place a pan on the burner itself.

Replace the pan supports carefully to avoid scratching the surface

of the hob.

Do not use or store flammable materials near this hob.

Remove splashes of fat and other food debris from the surface of

the hob as soon as possible. These are a fire hazard.

Using the hob will cause a build-up of heat and moisture in the

room in which it is installed. Ensure that the room has sufficient

natural or mechanical means of ventilation, e.g.a cooker hood.

If the hob is used for very long periods of time, additional

ventilation of the room may be necessary, e.g. by opening windows

or doors, or running the cooker hood on the highest setting.

Do not use roasting dishes, pans or grilling stones that are large

enough to cover more than one burner. The resulting build-up of

heat could damage the hob.

If the hob has not been used for a long period of time it should be

thoroughly cleaned before it is used again. It is also advisable to

have the appliance tested by a qualified person for safety.

14

Page 15

Warning and Safety instructions

If you are operating a gas cooking element directly next to the

downdraft extractor, the FlameGuard must be placed between the

downdraft extractor and the element.

15

Page 16

Warning and Safety instructions

Cleaning and care

Do not use a steam cleaning appliance to clean this hob.

The steam could reach electrical components and cause a short

circuit.

16

Page 17

Caring for the environment

Disposal of the packing material

The packaging is designed to protect

the appliance from damage during

transportation. The packaging materials

used are selected from materials which

are environmentally friendly for disposal

and should be recycled.

Recycling the packaging reduces the

use of raw materials in the

manufacturing process and also

reduces the amount of waste in landfill

sites.

Disposal of your old appliance

Electrical and electronic appliances

often contain valuable materials. They

also contain materials which, if handled

or disposed of incorrectly, could be

potentially hazardous to human health

and to the environment. They are,

however, essential for the correct

functioning of your appliance. Please

do not therefore dispose of it with your

household waste.

Please dispose of it at your local

community waste collection / recycling

centre or contact your Miele dealer for

advice.

Ensure that it presents no danger to

children while being stored for disposal.

17

Page 18

Guide to the appliance

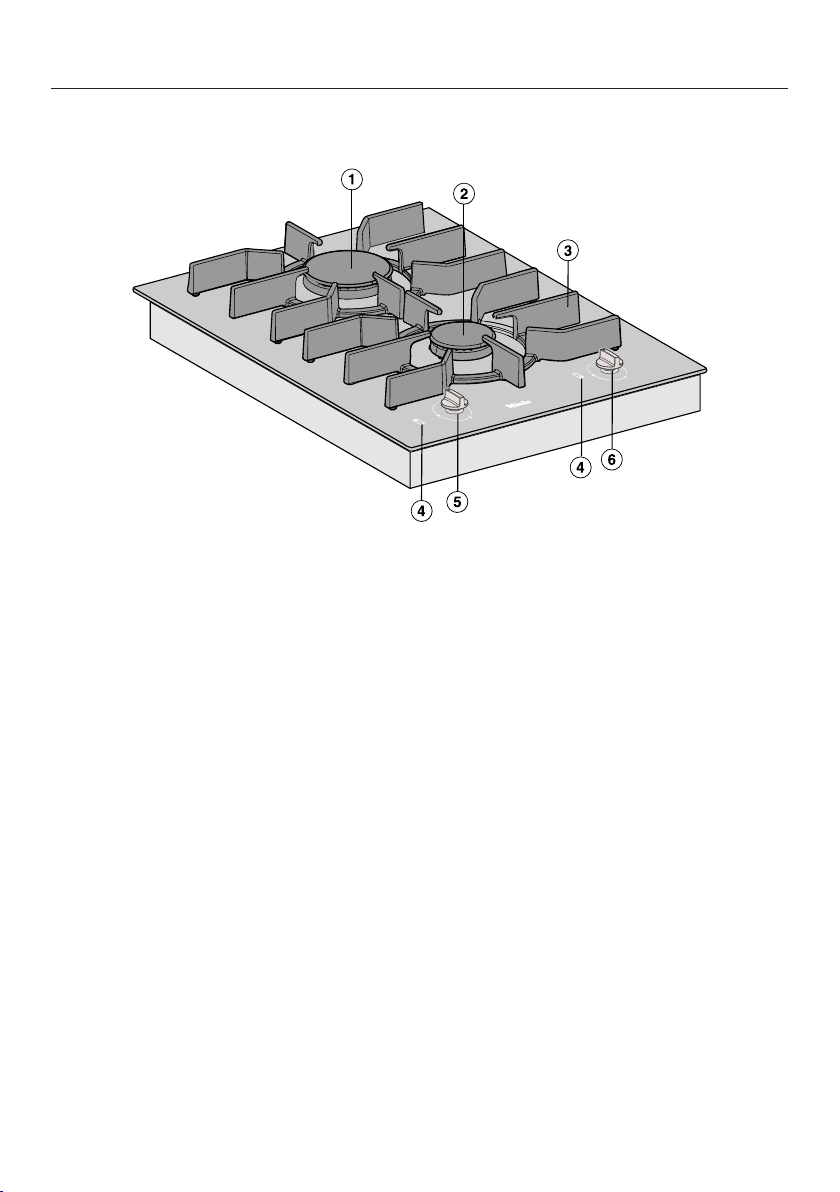

Hob

a

Burner

b

Burner

c

Pot rests

d

Symbols for allocation of operating controls

e

Control for rear burner

f

Control for front burner

18

Page 19

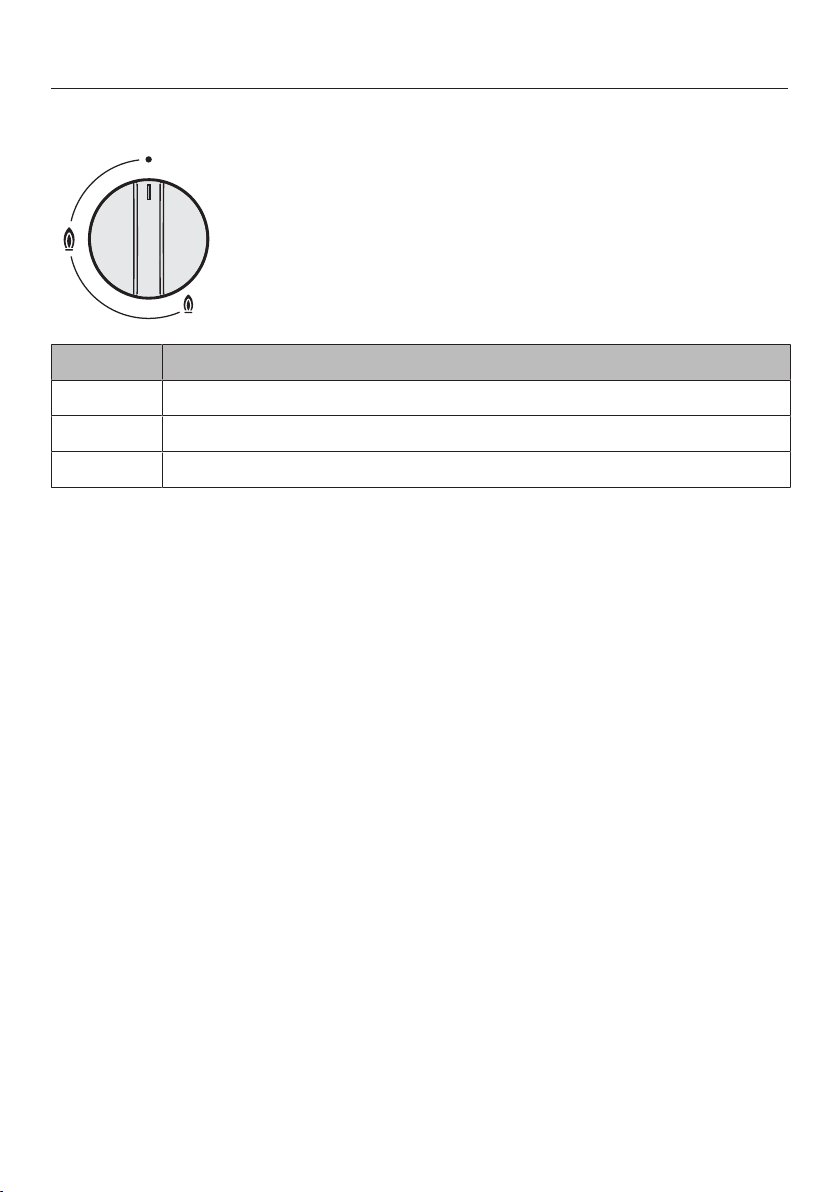

Control knobs

Symbol Description

Burner off, the gas supply is turned off

Largest flame

Smallest flame

Guide to the appliance

19

Page 20

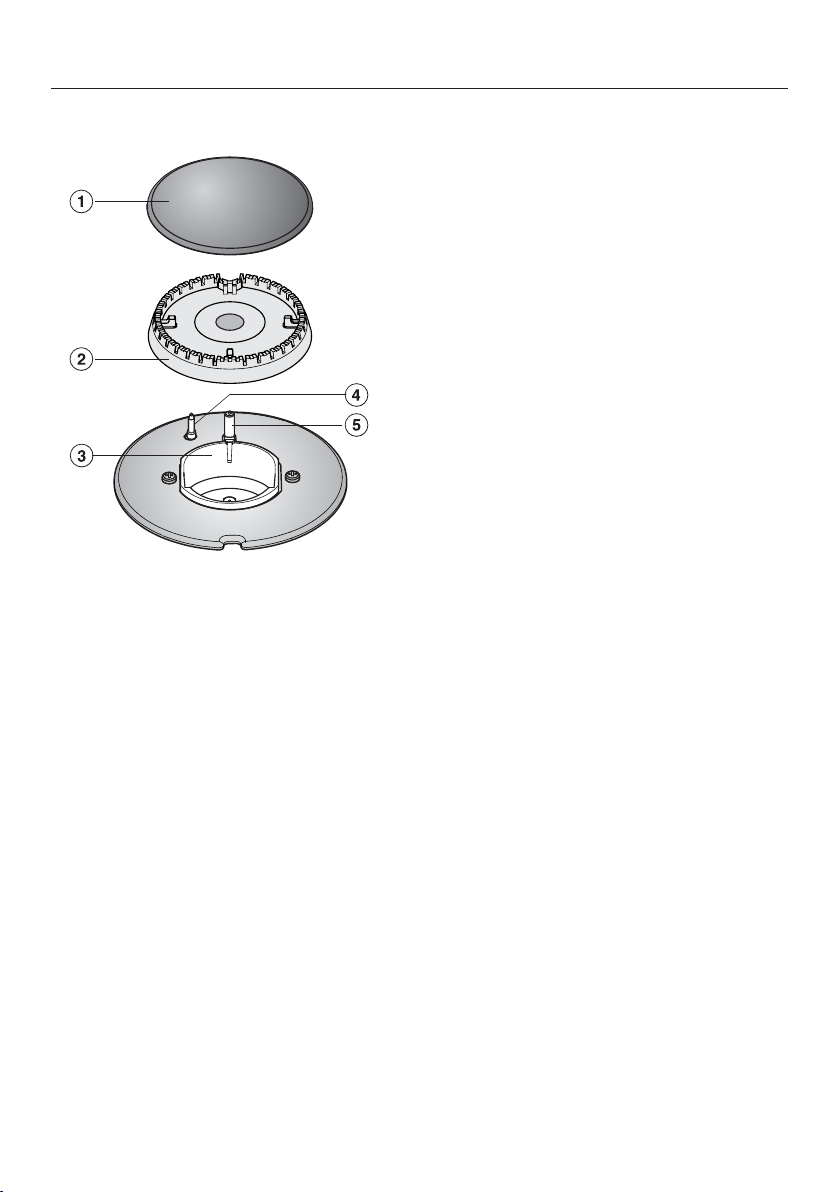

Guide to the appliance

Burner

a

Burner cap

b

Burner head

c

Burner base

d

Thermocouple

e

Ignition electrode

20

Page 21

Accessories supplied

The accessories supplied with your

appliance as well as a range of optional

ones are available to order from your

Miele dealer (see „Optional

accessories“).

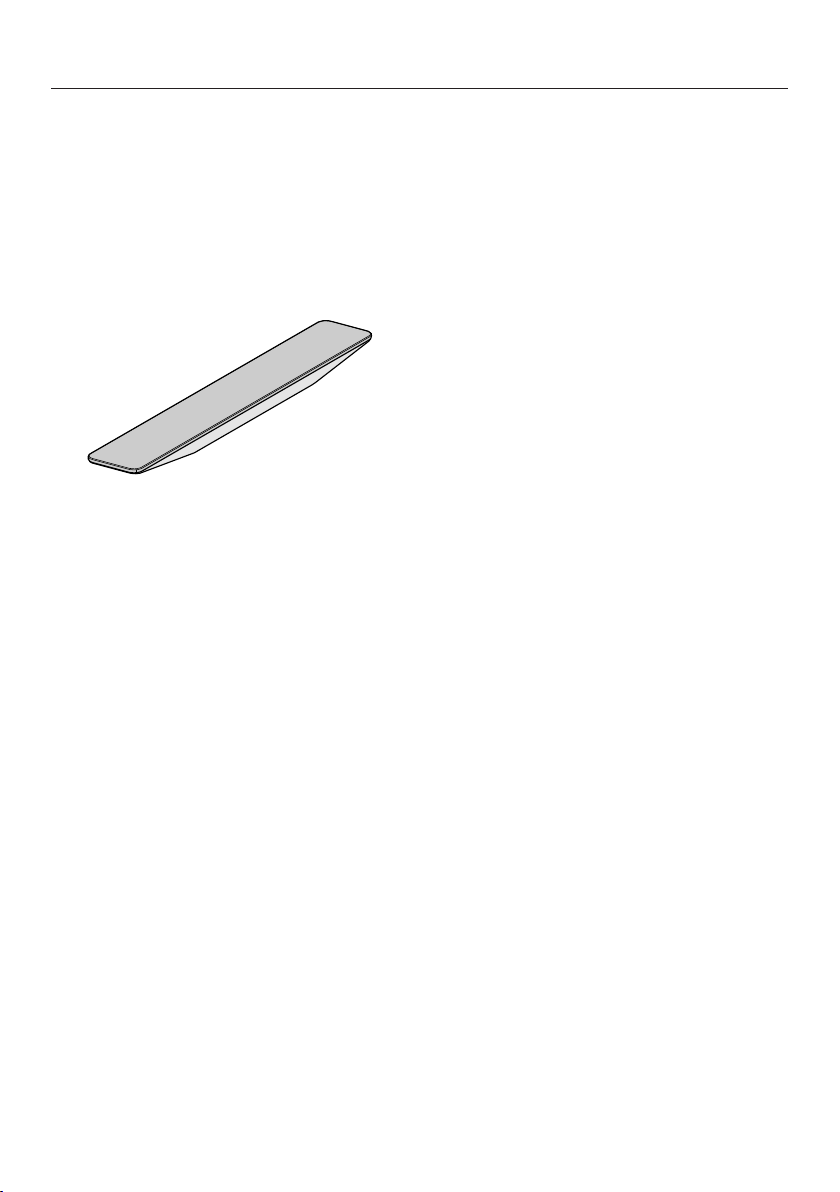

FlameGuard

For installing between the downdraft

extractor and a gas cooking element

Guide to the appliance

21

Page 22

Before using for the first time

Please stick the extra data plate for

the appliance supplied with this

documentation in the space provided

in the “After sales service” section of

this booklet.

Remove any protective wrapping and

stickers.

Cleaning the SmartLine element for the first time

Clean all removable parts of the

burners with a solution of warm water

and a small amount of washing-up

liquid applied with a soft sponge. Dry

all parts thoroughly after cleaning and

then reassemble the burners (see

“Cleaning and care”).

Clean the ceramic surface with a

damp cloth, and then wipe dry.

Switching on the SmartLine element for the first time

The metal components have a

protective coating. Smells and possibly

some vapours may occur when the

SmartLine element is used for the first

time.

The smell and any vapours given off do

not indicate a faulty connection or

appliance and they are not hazardous

to health.

22

Page 23

Pans

Ø Pan [cm]

Burner Minimum base

diameter

Normal burner 12

Large burner 14

Burner Maximum rim

diameter

Normal burner 22

Large burner 24

- Select the pan to suit the size of the

burner:

large diameter = large burner

small diameter = small burner.

- Observe the dimensions given in the

chart. Using pans that are too large

can cause the flames to spread out

and damage the surrounding worktop

or other appliances. Using pans of

the correct size improves efficiency.

Pans that are smaller than the pot

rests and pans that do not stand

safely (without wobbling) on the pot

rests are dangerous and should not

be used.

- Cookware with a thick base is

preferable as the heat is distributed

evenly. With thinner based cookware,

there is the risk that food will

overheat in places. Therefore it

should be stirred more frequently.

- Always place the cookware on the

pot rests supplied. Do not place

cookware directly on the burners.

- Place the cookware on the pot rests

in such a way that it cannot tip over.

A minor wobble can never be

completely excluded.

- Do not use pots or pans with an

edge-supported base.

- In contrast to pans for use on electric

hobs, the bases of pans for use on

gas hobs do not need to be flat to

achieve good results.

- Remember when purchasing new

pans that manufacturers usually refer

to the diameter at the top of the pan

in their documentation, and not to the

base diameter.

- You can use any cookware that is

heat-resistant.

23

Page 24

Tips on saving energy

- Use a pan lid whenever possible to

minimize heat loss.

- Wide, shallow pans are preferable to

tall, narrow ones. They will heat up

faster.

- Cook with as little water as possible.

- Reduce the size of the flame once the

water has come to the boil or the oil

is hot enough to fry in.

- Use a pressure cooker to reduce

cooking times.

24

Page 25

Operation

Switching on

If you are operating a gas cooking

element next to a downdraft

extractor, this will affect the gas

cooking element's function.

Place the FlameGuard between the

gas cooking element and the

downdraft extractor.

Risk of fire with overheated food.

Unattended food can overheat and

catch alight.

Do not leave the hob unattended

whilst it is being used.

Press in the relevant rotary control

and turn it anticlockwise to the large

flame symbol. The ignition electrode

will “click” and ignite the gas.

When the rotary control is operated, a

spark is automatically produced on all

burners. This is normal and does not

indicate a fault.

When a flame is visible, keep the

rotary control pressed down for 5–

10seconds, and then let it go.

Switching on during a power outage

If there is an interruption to the

electricity supply, the gas can be

ignited manually, e.g. with a match.

Press in the relevant control and turn

it anti-clockwise to the large flame

symbol.

Hold the control pressed in and light

the gas at the burner with a match.

Keep the control pressed in for a

further 5-10seconds and then

release it.

FlameGuard

Install the FlameGuard directly next to

the downdraft extractor when you are

operating a gas cooking element.

If the burner does not ignite, turn the

rotary control to the position.

Ventilate the room or wait for at least

1minute before trying again. When

making another ignition attempt, it

may be necessary to hold the rotary

control for longer.

If the burner does not ignite the

second time, turn the rotary control

back to the position and see

“Problem solving guide”.

25

Page 26

Operation

Adjusting the flame

The burners can be regulated at any

level between the strongest and

weakest flame.

As the outer part of the flame is much

hotter than the centre, the tips of the

flames should stay beneath the pan

base. Flame tips which extend beyond

the sides of the pan merely warm up

the air in the room and can also

damage pan handles and increase the

danger of injury.

Adjust the flame so that it does not

spread out beyond the sides of the

pan.

Switching off

Turn the rotary control clockwise to

the position.

The gas supply is cut off and the flame

goes out.

26

Page 27

Thermo-electric flame failure monitor

Your hob is equipped with a thermoelectric flame failure monitor. If a gas

flame is extinguished, e.g. by food

boiling over or by a draught, the gas

supply is switched off. This prevents the

release of gas. If you turn the rotary

control to the position, the burner is

ready for use again.

The thermo-electric flame failure

monitor operates independently from

the electricity supply. This means that

it will still work if the hob is used

during a power cut.

Safety features

27

Page 28

Cleaning and care

Danger of burning due to hot

surfaces.

The hob surface, pan supports and

burners will be hot after use.

Allow the hob to cool down before

cleaning it.

Risk of damage due to moisture

ingress.

The steam from a steam cleaning

appliance could reach live electrical

components and cause a short

circuit.

Do not use a steam cleaner to clean

the hob.

All surfaces could be discoloured or

damaged if unsuitable cleaning

agents are used. All surfaces are

susceptible to scratching.

Remove all cleaning agent residues

immediately.

Never use abrasive sponges or

cleaning agents.

Clean the SmartLine element and

accessories after each use.

Dry the SmartLine element thoroughly

after every cleaning to avoid

limescale residue.

Unsuitable cleaning agents

To avoid damaging the surfaces of the

appliance, do not use:

- cleaning agents containing soda,

alkalines, ammonia, acids or

chlorides

- cleaning agents containing descaling

agents

- stain and rust removers

- abrasive cleaning agents, e.g.

powder cleaners and cream cleaners

- solvent-based cleaning agents

- dishwasher cleaner

- oven sprays

- glass cleaning agents

Food boiling over can cause

discoloration of the burner

components.

Remove any soiling and salt and

sugar splashes immediately.

When a control knob is pressed

down, a spark is generated on the

ignitor. Do not press down the

control knob while you are cleaning

or touching the hob or a burner in the

vicinity of an ignitor.

Allow the SmartLine element to cool

down before cleaning.

28

- hard, abrasive brushes or sponges

(e.g. pot scourers), or sponges which

have been previously used and still

contain abrasive cleaning agents

- melamine eraser blocks

Page 29

Cleaning and care

Ceramic surface

Risk of damage by pointed

objects.

The seal between the SmartLine

element and the worktop could

suffer damage.

Do not use pointed objects for

cleaning.

Not all soiling and residues can be

removed using a solution of

washing-up liquid.

An invisible film can develop that can

lead to discolouration of the glass

ceramic surface. This discolouration

cannot be removed.

Clean the ceramic surface regularly

with a proprietary ceramic glass

cleaning agent.

Remove any coarse soiling with a

damp cloth and more stubborn

soiling with a shielded scraper blade

suitable for use on glass.

Then clean the ceramic glass surface

with the Miele ceramic and stainless

steel hob cleaner (see “optional

accessories”) or with a proprietary

ceramic glass cleaner applied with

kitchen paper or a clean cloth. Do not

apply the cleaner while the hob is still

hot, as this can result in marking.

Please follow the cleaning agent

manufacturer's instructions.

Residues can burn onto the hob the

next time it is used and cause damage

to the glass ceramic surface. Ensure

that all cleaning agent residues are

removed.

Spots caused by limescale, water

and aluminium residues (spots with a

metallic appearance) can be removed

using Miele's ceramic and stainless

steel hob cleaner.

Danger of burning due to hot

surfaces.

The surfaces get hot during cooking.

Wear oven gloves when removing

residues of sugar, plastic or

aluminium foil from a hot ceramic

surface with a shielded scraper

blade.

Should any sugar, plastic or

aluminium foil spill or fall onto the

hot ceramic surface while it is in use,

switch off the cooking zone.

Then carefully scrape off these

residues immediately whilst they are

still hot, using a scraper blade

suitable for use on glass.

Afterwards, clean the ceramic surface

in its cooled state, as described

above.

Finally wipe the glass ceramic surface

with a damp cloth and polish with a

soft, dry cloth.

29

Page 30

Cleaning and care

Rotary controls

Clean the rotary control(s) using a

solution of warm water and a little

washing-up liquid applied with a soft

sponge. Soften any stubborn soiling

beforehand.

Dry the control(s) with a clean cloth.

Pan supports

Remove the pan supports.

Clean the pan supports in the

dishwasher or with a solution of warm

water and a little washing-up liquid

applied with a soft sponge. Stubborn

soiling should be soaked first.

After cleaning, dry the pan supports

thoroughly with a clean cloth.

30

Page 31

Burner

Do not clean any parts of the burners

in a dishwasher.

The surface of the burner cap will

become duller with time. This is

completely normal and does not

indicate material deterioration.

The burner should be dismantled and

then cleaned by hand using a

solution of warm water and a little

washing-up liquid applied with a soft

sponge.

Clean any soiling from the flame

openings.

Cleaning and care

Danger of explosion.

Blocked flame openings can cause a

dangerous build-up of gas in the

base of the hob which could ignite

and cause an explosion. This can

lead to damage to the appliance and

injury.

Ensure the flame openings are kept

clean at all times.

Parts of the burner that cannot be

removed should be wiped clean with

a damp cloth only.

The ignitor and thermocouple should

be very carefully wiped clean using a

well wrung-out cloth.

The ignitor must not get wet,

otherwise it will not spark.

Finally dry everything thoroughly with

a clean cloth. Make sure that the

flame openings are completely dry.

Place the burner head onto the

burner base so that the

thermocouple and the ignition

electrode extend through their

respective holes in the burner head.

The burner head must click into place

correctly.

Place the burner cap flat over the

burner head. When correctly

positioned, the burner cap will not

slide about.

Ensure that all parts of the burner are

reassembled in the correct order.

31

Page 32

32

Page 33

Problem solving guide

Many malfunctions and faults that can occur in daily operation can be easily

remedied. Time and money will be saved because a service call will not be

needed.

The following guide may help you to find the reason for a malfunction or a fault,

and to correct it.

Issue Cause and remedy

The burners do not

ignite when the hob is

being used for the first

time or after it has been

out of use for a longer

period.

The burner does not

light after several

attempts.

The gas flame goes out

after ignition.

The flame suddenly

looks different.

There could be an air lock in the gas pipe.

You may need to make several attempts before the

burner ignites successfully.

There is a technical fault.

Turn all of the controls clockwise to the position

and interrupt the power supply to the hob for a few

seconds.

The burner is not correctly assembled.

Assemble the burner correctly.

The gas shut-off device has not been opened.

Open the gas shut-off device.

The burner is wet and/or dirty.

Clean and dry the burner.

The flame openings are blocked and/or wet.

Clean and dry the flame openings.

The flames do not touch the thermocouple and the

burner does not get hot enough:

The burner parts are not positioned correctly.

Assemble the burner components correctly.

The thermocouple is dirty.

Remove any soiling.

The burner parts are not positioned correctly.

Position the burner parts correctly.

The burner head or the holes in the burner cap are

dirty.

Remove any soiling.

33

Page 34

Problem solving guide

Issue Cause and remedy

The gas flame goes out

during use.

The electronic ignition

device on the burner is

not working.

The burner parts are not positioned correctly.

Position the burner parts correctly.

The mains fuse has tripped.

If necessary, contact a qualified electrician or your

Miele dealer for assistance.

There is food residue stuck between the ignitor and

the burner cap.

The thermocouple is dirty.

Remove any soiling (See “Cleaning and care”).

34

Page 35

Optional accessories

Miele offer a comprehensive range of

useful accessories as well as cleaning

and conditioning products for your

Miele appliances.

These can be ordered from your Miele

dealer (see end of this booklet for

contact details).

FlameGuard

For installing between the downdraft

extractor and a gas cooking element

Ceramic and stainless steel

hob cleaner 250ml

Removes heavy soiling, limescale

deposits and aluminium residues

Microfibre cloth

Removes finger marks and light soiling

35

Page 36

After sales service

Contact in case of malfunction

In the event of any faults which you cannot remedy yourself, please contact your

Miele dealer.

Contact details for your Miele dealer are given at the end of this document.

Please note that telephone calls may be monitored and recorded for training

purposes and that a call-out charge will be applied to service visits where the

problem could have been resolved as described in this booklet.

Please quote the model and serial number of your appliance when contacting your

Miele dealer. This information can be found on the data plate.

Data plate

Stick the extra data plate supplied with the appliance here. Make sure that the

model number matches the one specified on the back cover of this document.

Guarantee

For information on the appliance guarantee specific to your country please contact

your Miele dealer. See end of this booklet for contact details.

36

Page 37

*INSTALLATION*

Installation

Safety instructions for installation

Damage from falling objects.

Take care not to damage the SmartLine element when fitting wall units or a

cooker hood above it.

Fit the wall units and the cooker hood before the SmartLine element.

The room in which the SmartLine element is installed must

conform to all relevant local and national building regulations and

safety regulations.

In the UK: GasSafe regulations

The veneer or laminate coatings of worktops (or adjacent kitchen

units) must be treated with 100°C heat-resistant adhesive which will

not dissolve or distort. Any backmoulds must be of heat-resistant

material.

A deep fat fryer must not be installed directly next to a gas hob or

a wok burner as the gas flames could ignite the fat in the fryer. It is

essential to maintain a distance of at least 288mm between these

two appliances.

The SmartLine element must not be installed over a fridge, fridge-

freezer, freezer, dishwasher, washing machine, washer-dryer or

tumble dryer.

When installing the SmartLine element, make sure that the gas

pipe and mains connection cable cannot come into contact with hot

appliance parts.

The mains connection cable and any flexible gas connection pipes

must be installed in such a way so that they do not come into

contact with any moving kitchen parts (e.g. a drawer) after the

SmartLine element has been installed, and that they cannot be

subjected to any mechanical action which could cause damage.

Observe carefully the safety clearances listed on the following

pages.

37

Page 38

*INSTALLATION*

Installation

Safety distances

Safety distance above the SmartLine element

The safety distance specified by the

manufacturer of the cooker hood must

be maintained between the SmartLine

element and the cooker hood above it.

If combustible objects are installed

above the SmartLine element (e.g.

cabinets, utensil rail, etc.), a minimum

safety distance of 760mm must be

maintained.

When two or more SmartLine

elements which have different safety

distances are installed together

below a cooker hood, you should

observe the greatest specified safety

distance.

38

Page 39

*INSTALLATION*

Safety distances to the sides and back of the hob

The SmartLine element should

preferably be installed with plenty of

space on the right and left.

The minimum distance specified

below must be observed between the

rear of the SmartLine element and a tall

unit or room wall.

The minimum distance, specified

below must be adhered to between one

side of the SmartLine element (right or

left) and a tall unit or room wall. A

minimum distance of 300mm must be

observed on the opposite side.

Minimum distance between the back

of the worktop cut-out and the rear

edge of the worktop:

50mm

Installation

Not allowed

Highly recommended

Minimum distance on the right side

between the worktop cut-out and the

closest adjacent piece of furniture (e.g.

tall unit) or a room wall:

100mm.

Minimum distance on the left side

between the worktop cut-out and the

closest adjacent piece of furniture (e.g.

tall unit) or a room wall:

100mm.

Not recommended

Not recommended

39

Page 40

*INSTALLATION*

Installation

Safety distance when installing the appliance near a wall with additional niche cladding

If a niche cladding is installed, a minimum safety distance must be maintained

between the worktop cut-out and the cladding, since high temperatures can

damage these materials.

If the niche cladding is made from a combustible material (e.g. wood) a minimum

safety distance of 50mm must be maintained between the worktop cut-out and

the cladding.

If the niche cladding is made from a non-combustible material (e.g. metal, natural

stone, ceramic tiles) the minimum safety distance between the worktop cut-out

and the cladding will be 50mm less the thickness of the cladding.

Example: 15mm niche cladding

50mm - 15mm = minimum safety distance of 35mm

Flush-fit installation Onset installation

a

Masonry

b

Niche cladding dimension x = thickness of the niche cladding material

c

Worktop

d

Worktop cut-out

e

Minimum distance to

combustible materials 50mm

non-combustible materials 50mm - dimension x

40

Page 41

*INSTALLATION*

Installation

Surface-mounted

Installation notes – surface-mounted

Sealing between the SmartLine Element and the worktop

The SmartLine element and worktop

may be damaged if the element

needs to be removed after it has

been sealed with a sealant.

Do not use any sealant between the

SmartLine element and the worktop.

The seal under the edge of the top

part of the appliance provides a

sufficient seal for the worktop.

Tiled worktop

Grout lines and the hatched area

underneath the SmartLine element

frame must be smooth and even. If they

are not, the SmartLine element will not

sit flush with the worktop and the

sealing strip underneath the top part of

the appliance will not provide a good

seal between the appliance and the

worktop.

Sealing strip

Dismantling the SmartLine element

for service purposes may damage

the sealing strip underneath the edge

of the SmartLine element.

Always replace the sealing strip

before reinstalling the SmartLine

element.

41

Page 42

*INSTALLATION*

Installation

Installing several SmartLine elements

The gaps between the individual

SmartLine elements are sealed with a

silicone sealant that is heat-resistant to

at least 160°C. With flush-fit

installation, the gap between the

SmartLine element(s) and the worktop

must also be sealed with a silicone

sealant that is heat-resistant to at least

160°C.

After installation, the SmartLine

elements must be easily accessible

from below, so that the bottom half of

the casing can be removed for

maintenance. If the SmartLine elements

are not accessible from below, the

sealant must be removed so that they

can be removed.

Combination with a downdraft extractor

If the SmartLine element is installed in

combination with a downdraft extractor,

the latter must be installed first.

42

Page 43

*INSTALLATION*

Worktop cutout – surface-mounted

Installation

Information for calculating the cutout

The elements overlap the worktop by 10mm.

When installing several elements, a distance of 2mm must be observed between

the individual elements.

Calculating cutout dimensionB

1 element = Width of the element minus 10mm on the right, minus 10mm on the

left

Several elements = Total width of the elements plus 2mm distance between the

elements, minus 10mm on the right, minus 10mm on the left.

Some examples are illustrated below.

43

Page 44

*INSTALLATION*

Installation

Installation with a downdraft extractor

Combination examples Numberxwidth [mm] Dimension

Cooking

elements

Downdraft

extractor

1x378 1x120

B

[mm]

480

+1

2x378 1x120

1x378

2x120

1x620

3x378 2x120

2x378

2x120

1x620

4x378 2x120

1x620 2x120

860

1224

1362

1604

1742

844

+1

+1

+1

+1

+1

+1

44

Page 45

*INSTALLATION*

Installation without a downdraft extractor

Combination examples Numberxwidth [mm] DimensionB

Cooking elements

1x378

Installation

[mm]

+1

358

2x378

1x378

1x620

3x378

2x378

1x620

4x378

738

980

1118

1360

1498

+1

+1

+1

+1

+1

45

Page 46

*INSTALLATION*

Installation

Spacer bars – surface-mounted

When installing several SmartLine elements, an additional spacer bar must be

fitted in between the individual elements.

The clips supplied with the spacer bars are only required for installing a

CSDA700xFL.

Installing 3elements and 2spacer bars

46

Page 47

*INSTALLATION*

Installation dimensions–Surface-mounted

All dimensions are given in mm.

Installation

a

Front

b

Mains connection box with mains connection cable, L=2000mm

c

Gas connection R½ ISO7-1 (DINEN10226)

47

Page 48

*INSTALLATION*

Installation

Installation – surface-mounted

Preparing the worktop

Create the worktop cutout.

Remember to maintain the minimum

safety distances (see “Installation –

Safety distances”).

Seal any cut surfaces on wooden

worktops with a special varnish,

silicone sealant or resin to prevent the

wood from swelling as a result of

moisture ingress. The sealant must

be heat-resistant.

Make sure that the sealant does not

come into contact with the top of the

worktop.

Fitting the spacer bars

Use the middle screw holes if one of the

following SmartLine elements is

installed to the right or left of the spacer

bar: CS7611, CS 7641, CS7101(-1),

CS7102(-1)

Wooden worktops

Position the spacer bars flush onto

the upper edge of the cutout.

Secure the spacer bars with the

3.5x25mm wood screws supplied.

Natural stone worktops

You will need heavy-duty doublesided tape (not supplied) to secure the

spacer bars.

48

Stick the tape along the top edge of

the worktop cutout.

Position the spacer bars flush onto

the upper edge of the cutout.

Press the spacer bars firmly into

place.

Page 49

*INSTALLATION*

Installation

Installing the SmartLine element

Stick the supplied sealing strip under

the edge of the SmartLine element.

Do not apply the sealing strip under

tension.

Feed the mains connection cable

down through the worktop cutout.

Position the SmartLine element in the

worktop cutout. When doing this,

make sure that the seal of the

appliance sits flush with the worktop

on all sides. This is important to

ensure an effective seal all round.

If the seal does not meet the worktop

correctly on the corners, carefully

scribe the corner radii (≤R4) with a

jigsaw.

Do not use any additional sealant

(e.g. silicone) on the SmartLine

element.

Connect the SmartLine element to

the mains electricity supply.

Checking operation

After installation, ignite all burners to

check that they are operating

correctly:

- The flame must not go out on the

lowest setting, or when the control is

turned quickly from the highest to the

lowest setting.

- On the highest setting, the flame

must have a distinctive and visible

core.

If required, connect the SmartLine

element to the gas supply (see

“Installation – Gas connection”).

Check that the SmartLine element

works.

Seal the gaps between the individual

elements with a silicone sealant that

is heat-resistant to at least 160°C.

Unsuitable sealant can damage

natural stone.

For natural stone worktops and

natural stone tiles, only use silicone

sealant that is specially formulated

for natural stone. Follow the

manufacturer’s instructions.

49

Page 50

*INSTALLATION*

Installation

Flush-fit

Installation notes – flush-fit

Flush-fit installation is only possible in

natural stone (granite, marble), solid

wood and tiled worktops. For

installation in worktops made of other

materials, please consult the relevant

manufacturer as to whether their

worktops are suitable for flush-fit

installation.

The internal width of the base unit

underneath the appliance must be at

least as wide as the inner worktop

cutout (see “Installation – Building-in

dimensions – flush-fit”), so that the

SmartLine element is easily accessible

from underneath after installation and

the bottom half of the casing can be

removed for maintenance. If the

element is not freely accessible from

below after installation, the sealant

must be removed so that the element

can be removed.

Natural stone worktops

The SmartLine element is set directly in

the cutout.

Solid wood worktops, tiled worktops,

glass worktops

The SmartLine element is set on a

wooden frame inside the cutout. The

frame must be provided on site, and is

not supplied with the appliance.

Sealing strip

Dismantling the SmartLine element

for service purposes may damage

the sealing strip underneath the edge

of the SmartLine element.

Always replace the sealing strip

before reinstalling the SmartLine

element.

50

Page 51

*INSTALLATION*

Installing several SmartLine elements

The gaps between the individual

SmartLine elements are sealed with a

silicone sealant that is heat-resistant to

at least 160°C. With flush-fit

installation, the gap between the

SmartLine element(s) and the worktop

must also be sealed with a silicone

sealant that is heat-resistant to at least

160°C.

After installation, the SmartLine

elements must be easily accessible

from below, so that the bottom half of

the casing can be removed for

maintenance. If the SmartLine elements

are not accessible from below, the

sealant must be removed so that they

can be removed.

Installation

Combination with a downdraft extractor

If the SmartLine element is installed in

combination with a downdraft extractor,

the latter must be installed first.

51

Page 52

*INSTALLATION*

Installation

Worktop cutout – flush-fit

Natural stone worktop Wooden worktop

0.5

+

* 7

mm with CS7611FL

Information for calculating the cutout

The elements overlap the worktop by 10mm.

When installing several elements, a distance of 2mm must be observed between

the individual elements.

Calculating cutout dimensionA

1 element = Width of the element plus 2mm on the right, plus 2mm on the left.

Several elements = Total width of the elements plus 2mm distance between the

elements, plus 2mm on the right, plus 2mm on the left

Calculating cutout dimensionB = Cutout dimension A minus 12mm on the right,

minus 12mm on the left.

Some examples are illustrated below.

52

Page 53

*INSTALLATION*

Installation with a downdraft extractor

Installation

Combination examples Numberxwidth [mm] Dimensi

Cooking

elements

Downdraft

extractor

1x378 1x120

2x378 1x120

1x378

2x120

onA

[mm]

504

884

1248

+1

+1

+1

1x620

3x378 2x120

2x378

2x120

1386

1628

+1

+1

1x620

4x378 2x120

1x620 2x120

1766

868

+1

+1

Dimensi

onB

[mm]

+1

480

+1

860

+1

1224

+1

1362

+1

1604

+1

1742

+1

844

53

Page 54

*INSTALLATION*

Installation

Installation without a downdraft extractor

Combination

examples

Numberxwidth

[mm]

Cooking elements

1x378

2x378

1x378

1x620

3x378

2x378

1x620

4x378

DimensionA

[mm]

+1

382

+1

762

+1

1004

+1

1142

+1

1384

+1

1522

DimensionB

[mm]

+1

358

+1

738

+1

980

+1

1118

+1

1360

+1

1498

54

Page 55

*INSTALLATION*

Spacer bars – flush-fit

When installing several SmartLine elements, an additional spacer bar must be

fitted in between the individual elements.

The clips supplied with the spacer bars are only required for installing a

CSDA700xFL.

Installing 3elements and 2spacer bars

Installation

55

Page 56

*INSTALLATION*

Installation

Installation dimensions–Flush

All dimensions are given in mm.

a

Front

b

Mains connection box with mains connection cable, L=2000mm

c

Stepped cutout (for detailed illustrations, see “Installation – Worktop cutout –

flush-fit”)

d

12mm wooden frame (not supplied, for detailed illustrations, see “Installation –

Worktop cutout – flush-fit”)

e

Gas connection R½ ISO7-1 (DINEN10226)

56

Page 57

*INSTALLATION*

Installation

Installation – flush-fit

Preparing the worktop

Create the worktop cutout.

Remember to maintain the minimum

safety distances (see “Installation –

Safety distances”).

Seal any cut surfaces on wooden

worktops with a special varnish,

silicone sealant or resin to prevent the

wood from swelling as a result of

moisture ingress. The sealant must

be heat-resistant.

Make sure that the sealant does not

come into contact with the top of the

worktop.

For wooden worktops, secure the

wooden frame 5.5mm below the

upper edge of the worktop.

For CS7611FL, the wooden frame

must be secured 7mm under the

upper edge of the worktop.

Wooden worktops

Position the spacer bars flush onto

the lower step of the stepped cutout.

Secure the spacer bars with the

3.5x25mm wood screws supplied.

Natural stone worktops

You will need heavy-duty doublesided tape (not supplied) to secure the

spacer bars.

Fitting the spacer bars

Use the middle screw holes if one of the

following SmartLine elements is

installed to the right or left of the spacer

bar: CS7611, CS 7641, CS7101(-1),

CS7102(-1)

Stick the tape onto the lower step of

the stepped cutout.

Position the spacer bars flush onto

the lower step of the stepped cutout.

Press the spacer bars firmly into

place.

57

Page 58

*INSTALLATION*

Installation

Installing the SmartLine element

Stick the supplied sealing strip under

the edge of the SmartLine element.

Do not apply the sealing strip under

tension.

Feed the mains connection cable

down through the worktop cutout.

Position the SmartLine element in the

worktop cutout. When doing this,

make sure that the seal of the

appliance sits flush with the worktop

on all sides. This is important to

ensure an effective seal all round.

Connect the SmartLine element to

the mains electricity supply.

If required, connect the SmartLine

element to the gas supply (see

“Installation – Gas connection”).

Check that the SmartLine element

works.

Seal the gaps between the individual

elements and between the elements

and the worktop with a silicone

sealant that is heat-resistant to at

least 160°C.

Checking operation

After installation, ignite all burners to

check that they are operating

correctly:

- The flame must not go out on the

lowest setting, or when the control is

turned quickly from the highest to the

lowest setting.

- On the highest setting, the flame

must have a distinctive and visible

core.

Unsuitable sealant can damage

natural stone.

For natural stone worktops and

natural stone tiles, only use silicone

sealant that is specially formulated

for natural stone. Follow the

manufacturer’s instructions.

58

Page 59

*INSTALLATION*

Installation

Gas connection

Risk of explosion due to an

incorrect gas connection.

If the gas connection is carried out

incorrectly, it may result in gas

leakage.

Connection to the gas supply must

only be undertaken by an approved

and registered gas installer in strict

accordance with current local and

national safety and building

regulations. The installer is

responsible for ensuring that the

appliance functions correctly when

installed.

Risk of explosion due to an

incorrect conversion.

If the conversion to another type of

gas is carried out incorrectly, it may

result in gas leakage.

Conversion from one type of gas to

another must only be undertaken by

an approved and registered gas

installer in strict accordance with

current local and national safety and

building regulations. The installer is

responsible for ensuring that the

appliance functions correctly when

installed.

The gas connection must be

installed so that connection can be

made either from inside or outside

the kitchen furniture unit. The

isolating valve must be easily

accessible and visible (by opening

the cabinet door if necessary).

Check with your local gas supplier

about the type of gas supplied and

compare this information with the

type of gas quoted on the

appliance's data plate.

The hob is not connected to an

exhaust flue.

When installing and connecting the

appliance please observe all relevant

installation instructions and ensure it

has adequate ventilation once

installed.

The gas connection must be made in

accordance with national and local

regulations.

Any special local conditions relating

to gas installations as well as

building regulations must also be

observed.

Risk of heat damage.

Gas connections, pipes and

connection cables can suffer

damage if exposed to heat from the

hob.

After installation make sure that

neither the gas pipe nor the mains

cable can come into contact with hot

parts of the appliance and that the

gas pipe and connections on the hob

cannot come into contact with hot

gas exhaust.

59

Page 60

*INSTALLATION*

Installation

Risk of explosion due to

damaged gas pipes.

Gas can leak from damaged flexible

gas pipes.

Attach flexible gas pipes in such a

way so that they do not come into

contact with any moving kitchen

parts (e.g. a drawer) and are not

exposed to mechanical stress.

Connect the hob to the gas supply in

accordance with national and local

regulations. Check the gas

connection for any leaks.

Depending on country of destination

this appliance is set up for connection

to natural or liquid gas. See adhesive

label on the appliance.

Depending on country of destination,

jets are supplied for conversion to a

different type of gas. If the appropriate

jets have not been supplied with the

appliance, you will need to contact your

Miele dealer. Conversion to another

type of gas is described in the section

“Converting to another type of gas”.

Connecting the hob

The hob is supplied with a conical ¹/₂"

gas connection point. There are two

connection options:

Risk of explosion due to gas

leakage.

Unsuitable sealant will not ensure the

required leak protection for

connections.

Ensure that a suitable sealant is

used.

Using a 90° angle

c

Connection R¹/₂"

d

90° elbow

The installation height in the area of

the gas connection is increased by

approx. 60mm.

- Fixed connection

- Flexible connection in accordance

with DIN 3383 Part 1, maximum

length 2000 mm.

60

Page 61

*INSTALLATION*

Installation

Electrical connection

We recommend that you connect the

SmartLine element to the mains via a

suitable switched electrical socket. This

makes it easier to perform servicing

work. The socket must be easily

accessible after the SmartLine element

has been installed.

Danger of injury!

Installation, repairs and other work

by unqualified persons could be

dangerous. Miele cannot be held

liable for unauthorised work.

Miele cannot be held liable for

damage or injury caused by the lack

of or inadequacy of an on-site

earthing system (e.g. electric shock).

If the plug is removed from the

connection cable or if the cable is

supplied without a plug, the

SmartLine element must be

connected to the electrical supply by

a suitably qualified electrician.

If the socket is no longer accessible,

or if a hard-wired connection is

planned, an additional means of

disconnection must be provided for

all poles. Suitable means of

disconnection include switches with

an all-pole contact gap of at least

3mm. These include miniature circuit

breakers, fuses and contactors. The

required connection data is given on

the data plate. Please ensure this

information matches the mains

supply.

After installation, ensure that all

electrical components are shielded

and cannot be accessed by users.

Total power rating

See data plate

Connection data

The connection data is quoted on the

data plate. Please ensure these match

the household mains supply.

Residual current device

For extra safety, it is advisable to

protect the SmartLine element with a

suitable residual current device (RCD)

with a trip range of 30mA.

61

Page 62

*INSTALLATION*

Installation

Disconnecting from the mains

Risk of electric shock.

There is a risk of electric shock if the

appliance is connected to the mains

supply during repair or service work.

After disconnection, ensure the

appliance cannot be switched back

on by mistake.

To disconnect the appliance from the

mains power supply, do one of the

following depending on installation:

Safety fuses

Completely remove fuses.

Automatic circuit breakers

Press the (red) test button until the

middle (black) button springs out.

Built-in circuit breakers

Circuit breakers at least type B or C:

Switch the lever from 1 (on) to 0 (off).

Connecting the mains cable

Danger of electrical shock.

The mains connection cable must

only be fitted by a suitably qualified

and competent person.

If the mains cable needs to be replaced

it must be replaced with a special

connection cable, type H05VV-F (PVCinsulated), available from your Miele

dealer.

Residual current device (RCD)

Switch the main switch from 1 (on) to

0 (off) or press the test button.

62

Page 63

Burner ratings

Nominal ratings

Burner Gas type Highest setting Lowest

setting

kW g/h kW

Medium burner Natural gas H 1.7 – 0.3

Liquid gas 1.7 124 0.25

Large burner Natural gas H 2.7 – 0.5

Liquid gas 2.6 189 0.6

Total Natural gas H 4.4 – –

Liquid gas 4.3 313 –

63

Page 64

*INSTALLATION*

Converting to another gas type

Risk of explosion due to an

incorrect conversion.

If the conversion to another type of

gas is carried out incorrectly, it may

result in gas leakage.

Conversion from one type of gas to

another must only be undertaken by

an approved and registered gas

installer in strict accordance with

current local and national safety and

building regulations. The installer is

responsible for ensuring that the

appliance functions correctly when

installed.

Jet table

The jet markings refer to a ¹/₁₀₀mm

bore diameter.

Main jet Small jet

Natural gas H

Medium burner 0.94 0.42

Large burner 1.18 0.54

Liquid gas

Medium burner 0.66 0.23

Large burner 0.81 0.39

Changing the main jets

Remove the pot rest, burner cap

and burner head.

Using an M7 socket spanner,

unscrew the main jet.

Fit the correct jets securely (see jet

table).

Secure the jets against inadvertent

loosening with sealing wax.

Changing the jets

Disconnect the hob from the

electricity supply and turn off the gas

supply.

When converting to another type of

gas, both the main and small jets

need to be changed.

64

Page 65

*INSTALLATION*

a

b

Converting to another gas type

Changing the small jets

Remove the burner components.

Loosen the fixing screws on the

burners.

Pull the control knobs off.

Loosen the fixing nuts on the

underside of the appliance.

Carefully remove the underside of the

appliance.

Functional check

Check all gas fittings for leaks.

Reassemble the hob.

Ignite all burners to check that they

are operating correctly.

- The flame must not go out on the

lowest setting, or when the control is

turned quickly from the highest to the

lowest setting.

- On the highest setting, the flame

must have a distinctive and visible

core.

Adhere the label supplied with the

jets, stating the type of gas being

used.

Remove the ignition switch.

Using a small screwdriver, unscrew

the small jet in the gas fitting.

Pull out the jet with a pair of pliers.

Fit the correct jets securely (see jet

table).

Secure the jets against inadvertent

loosening with sealing wax.

65

Page 66

Page 67

Manufacturer:

Miele & Cie. KG, Carl-Miele-Straße 29, 33332 Gütersloh, Germany

Miele Saudi Arabia

AWAD BADI NAHAS TRADING CO. LTD

Head Office:

Jeddah

Miele United Arab Emirates

Miele Appliances Ltd.

Showroom 1

Eiffel 1 Building

Sheikh Zayed Road, Umm Al Sheif

P.O. Box 114782 - Dubai

United Arab Emirates

Tel. +971 4 3044 999

Fax. +971 4 3418 852

800-MIELE (64353)

E-Mail: info@miele.ae

Website: www.miele.ae

Webshop: shop.miele.ae

Taif

Riyadh

Branches:

Khobar

Jeddah

Jeddah

Jeddah

P.O. Box 11529 Jeddah 21463

Tel. +966 12 2560888, Fax. +966 12 2560555

Hotline for customer care: 920003240

Website: www.awadnahas.com

Madina Road

Tel. +966 12 6970060, Fax. +966 12 6970012

Sitteen Street

Tel. +966 12 6611675, Fax. +966 12 6606852

Miele Gallery

Al Thanyyan Group Building, Al-Madina Road,

Near, Al Rowdah District, Jeddah

Tel. +966 12 6989339 Ext. 100

Fax. +966 12 6989339 Ext. 200

Olaya Street

Tel. +966 11 2013501, Fax. +966 11 2013502

Hadiya Street

Tel. +966 12 7327001, Fax. +966 12 7369596

Al Zahran Road

Tel. +966 13 8646150, Fax. +966 13 8646190

Page 68

CS7102-1

M.-Nr. 11 507 780 / 01en-AE, SA

Loading...

Loading...