Page 1

Installation instructions

External motor

Roof installation

To prevent the risk of accidents or damage to the appliance, it is

essential to read these instructions before it is installed and used for

the first time.

en - AU, NZ M.-Nr. 10 695 670

Page 2

Contents

Warning and Safety instructions.......................................................................... 3

Caring for the environment ..................................................................................9

Installation............................................................................................................ 10

Before installation.................................................................................................. 10

Installation recommendations ............................................................................... 10

AWG 102 ............................................................................................................... 11

DDG 102................................................................................................................ 14

ABLG 202 .............................................................................................................. 17

DDF 125/150 ......................................................................................................... 19

Connection for air extraction ............................................................................. 20

Silencer.................................................................................................................. 21

After sales service and warranty .......................................................................22

Position of the data plate ...................................................................................... 22

Warranty: Other countries ..................................................................................... 22

Electrical connection ..........................................................................................23

Technical data...................................................................................................... 24

AWG 102 ............................................................................................................... 24

ABLG 202 .............................................................................................................. 25

DDG 102................................................................................................................ 26

2

Page 3

Warning and Safety instructions

This external motor complies with all relevant local and national

safety requirements. Inappropriate use can, however, lead to

personal injury and damage to property.

Please read these operating and installation instructions carefully

before using the appliance for the first time. They contain

important information on the safety, installation, use and

maintenance of the appliance. This prevents both personal injury

and damage to the external motor. Miele cannot be held liable for

damage caused by non-compliance with these instructions.

Keep these instructions in a safe place and pass them on to any

future owner.

Correct application

This external motor is intended for use in domestic households

and similar working and residential environments.

This external motor must only be used in conjunction with a Miele

"... EXT" model rangehood.

It must only be used to extract vapours and remove odours from

cooking.

All other types of use are not permitted.

3

Page 4

Warning and Safety instructions

Technical safety

Repairs and other work by unqualified persons could be

dangerous. Installation, maintenance work and repairs to electrical

appliances must only be carried out by a Miele approved service

technician.

A damaged external motor could be dangerous. Check the

appliance for visible signs of damage. Do not use the external motor

if it is damaged.

The electrical safety of this appliance can only be guaranteed

when continuity is complete between it and an effective earthing

system. It is essential that this basic safety requirement is present

and tested regularly. If in doubt, consult a suitably qualified

electrician.

Reliable and safe operation of this external motor can only be

assured if it has been connected to the mains electricity supply.

The connection data (voltage and frequency) on the data plate

must match the mains electricity supply in order to avoid the risk of

damage to the motor.

Compare this data before connecting the appliance to the mains. If

in doubt, consult a suitably qualified electrician.

Do not connect the downdraft extractor to the mains electrical

supply by a multi-socket adapter or extension lead. These are a fire

hazard and do not guarantee the required safety of the appliance.

4

Page 5

Warning and Safety instructions

For safety reasons, the external motor may only be used when it

has been fully installed.

This appliance must not be installed and operated in mobile

installations (e.g. on a ship).

Any contact with live connections or tampering with the electrical

or mechanical components of the external motor will endanger your

safety and may lead to appliance malfunctions.

Only open the housing as described in the installation instructions

and in the "Cleaning and care" section of this booklet. Under no

circumstances should any other parts of the housing be opened.

The manufacturer's warranty will be invalidated if the appliance is

not repaired by a Miele approved service technician.

Faulty components must only be replaced by genuine Miele spare

parts. The manufacturer can only guarantee the safety of the

appliance when Miele replacement parts are used.

If the mains connection cable is damaged, it must only be

replaced by a Miele authorised service technician or suitably

qualified electrician in order to avoid a hazard.

During installation, maintenance and repair work, the appliance

must be disconnected from the mains electricity supply. It is only

completely isolated from the electricity supply when:

– the mains circuit breaker is switched off, or

– the screw-out fuse is removed (in countries where this is

applicable), or

– the plug is withdrawn from the socket. Do not pull on the cable,

but pull the plug to do this.

5

Page 6

Warning and Safety instructions

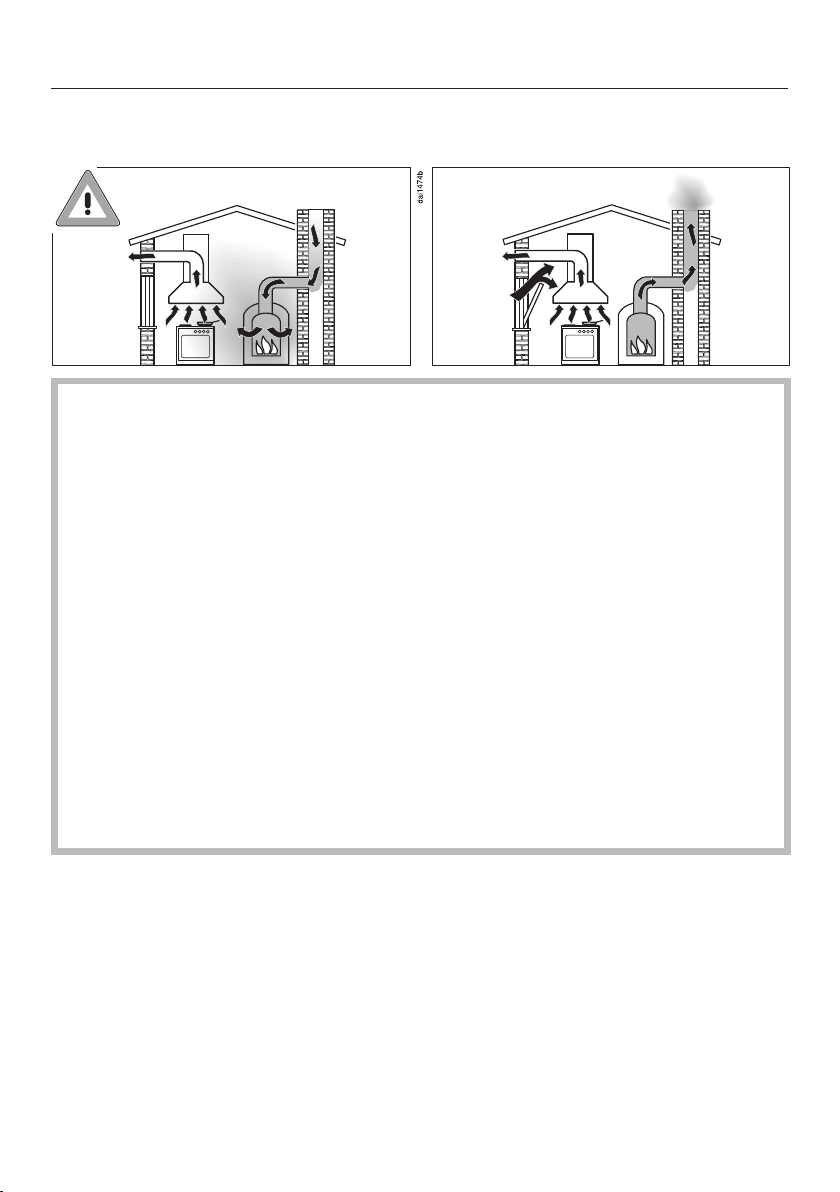

Using at the same time as another heating appliance that depends on the air from the room

Danger of toxic fumes!

Great care should be taken when using the external motor in the

same room or the same area of the house as another heating

appliance that depends on the air from the room.

Such heating appliances draw in air from the room and duct

exhaust gases out through a chimney or extraction ducting. They

include gas, oil, wood and coal-fired boilers and heaters,

continuous flow or other water heaters, gas cooktops and ovens.

The external motor draws in air from the kitchen and from

neighbouring rooms.

If there is insufficient air, an underpressure will occur. The heating

appliance may be starved of oxygen. This impairs combustion.

Harmful gases could be drawn from the chimney or extraction

ducting back into the room, with potentially fatal consequences.

Risk of death!

6

Page 7

Warning and Safety instructions

In order to ensure safe operation and to prevent gases given off by

the heating appliance from being drawn back into the room, when

the external motor and the heater are both operated

simultaneously, an underpressure in the room of 0.04mbar (4Pa)

is the maximum permissible.

Sufficient ventilation can be maintained by air inlets which cannot

be blocked, e.g. in windows, doors and outside wall vents. The

diameter of the inlet openings must enable sufficient ventilation. A

ventilation brick alone is not generally sufficient to ensure safe

ventilation.

The overall ventilation condition of the dwelling must be taken into

account. If in any doubt, the advice of a competent builder, or for

gas, a qualified gas fitter should be sought.

7

Page 8

Warning and Safety instructions

Correct installation

All ducting, pipework and fittings must be of non-flammable

material. These can be obtained from builders' merchants.

The appliance must not be connected to a chimney or vent flue

which is in current use for exhausting fumes from appliances burning

gas or other fuels. Neither should it be connected to ducting which

ventilates rooms with fireplaces.

8

Page 9

Caring for the environment

Disposal of the packing material

The transport and protective packaging

has been selected from materials which

are environmentally friendly for

disposal, and can normally be recycled.

Recycling the packaging reduces the

use of raw materials in the

manufacturing process and also

reduces the amount of waste in landfill

sites. Ensure that any plastic

wrappings, bags etc. are disposed of

safely and kept out of the reach of

babies and young children. Danger of

suffocation.

Disposing of your old appliance

Electrical and electronic appliances

often contain valuable materials. They

also contain specific materials,

compounds and components, which

were essential for their correct function

and safety. These could be hazardous

to human health and to the environment

if disposed of with your domestic waste

or if handled incorrectly. Please do not,

therefore, dispose of your old appliance

with your household waste.

Please dispose of it at your local

community waste collection / recycling

centre for electrical and electronic

appliances. You are also responsible for

deleting any personal data that may be

stored on the appliance prior to

disposal. Please ensure that your old

appliance poses no risk to children

while being stored prior to disposal.

9

Page 10

Installation

Before installation

Before installation, it is important

to read the information given on the

following pages as well as the

"Warning and Safety instructions" at

the beginning of this booklet.

Installation recommendations

– Make sure that the installation

location is easily accessible.

Installation work must be able to be

carried out without danger. This is

also important if the appliance needs

to be serviced.

10

Page 11

AWG 102

The AWG 102 external motor is

designed to be installed on an outside

wall.

The external motor must be installed

vertically on the outside wall. The

extraction outlet must face

downwards.

The external motor is connected to the

rangehood by means of a control cable

and is operated by the controls on the

rangehood.

Installation

Unscrew the two fixing screws on the

underside of the external motor and

take the motor unit off its fixing

bracket.

The ducting collar on the motor unit has

a diameter of 125 mm when the

appliance is supplied.

If exhaust ducting with a diameter of

150mm is required, the front ring

of the collar must be cut at the join

with a sharp knife.

Please refer to the operating and

installation instructions for the

rangehood before installing the

external motor and ducting.

11

Page 12

Installation

Make a 185 mm hole in the wall.

Push the telescopic wall pipe into the

hole so that it is sitting flush.

The telescopic wall pipe will make it

easier to feed the control cable and

the flexible ducting through later on.

Connect the three mountings through

the fixing holes in the bracket as

illustrated.

Position the motor unit fixing bracket

on the outside wall. The control cable

connection must be at the bottom.

Mark the position of the three holes

to be drilled.

Drill three 8 mm holes and insert

S8 wall anchors in the holes.

12

Position the bracket onto the outside

wall again and feed the control cable

with the six-pole connectors through

the telescopic wall pipe into the

house.

If equipotential bonding is required,

pull the earth cable through the hole

provided.

Equipotential bonding is required if

the control cable is to be extended

by more than the length of the

extension cable supplied (see

"Electrical connection").

Page 13

Feed the flexible ducting through the

telescopic wall pipe and secure it to

the collar on the motor unit fixing

bracket with a hose clip.

Secure the bracket to the external

wall with three screws.

Extend the flexible ducting from the

inside of the wall along the wall pipe

and seal the gap between the ducting

and the wall pipe with jointing

compound.

Installation

Connect the control cable plug

connectors.

Use the extension cable supplied to

lengthen the control cable if

necessary.

Refit the motor unit and secure it on

the underside of the external motor

with the two fixing screws.

13

Page 14

Installation

DDG 102

The DDG102 is designed for

installation on an angled tile, slate or

shingle roof. The slope of the roof must

be at least 22° to prevent the ingress of

the elements, such as rain or snow.

Please refer to the operating and

installation instructions for the

rangehood before installing the

external motor and ducting.

The ducting collar on the external motor

has a diameter of 125 mm when the

appliance is supplied.

If exhaust ducting with a diameter of

150mm is required, the front ring

of the collar must be cut at the join

with a sharp knife.

Consult a roof tiler or roof plumber for

advice regarding other types of roofing.

Installation on a flat roof is not

possible.

Installation must only be carried out

by a qualified and competent person.

The external motor is connected to the

rangehood by means of a control cable

and is operated by the controls on the

rangehood.

14

Page 15

Installation

Unscrew the two fixing screws and

remove the motor unit from the base

plate.

Fit the three distance bushes to the

base plate.

Secure the base plate to the

mounting frame with the screws and

nuts supplied.

Refit the motor unit.

15

Page 16

Installation

Remove the roofing around the

installation area.

Bend the flashing upwards.

Position the motor unit on the roof

with the air outlet directed down the

roof.

Secure the motor unit to the roof

substructure with the fixing plate .

Replace the roofing. Press down on

the flashing to ensure that it creates a

proper seal.

The flashing should be fitted under

the roofing at the top of the motor

unit and above the roofing at the

sides and bottom of the motor unit.

If equipotential bonding is required,

connect the earth lead to the earthed

connection point in the housing.

Equipotential bonding is required if

the control cable is to be extended

by more than the length of the

extension cable supplied (see

"Electrical connection").

Push the flexible ducting onto the

connection on the motor unit and

secure it with a hose clip.

Connect the control cable plug

connectors.

Use the extension cable supplied to

lengthen the control cable if

necessary.

When feeding the cable and the

exhaust ducting through the

substructure of the roof, be careful to

ensure that any gaps are sealed

properly afterwards.

16

Page 17

Installation

ABLG 202

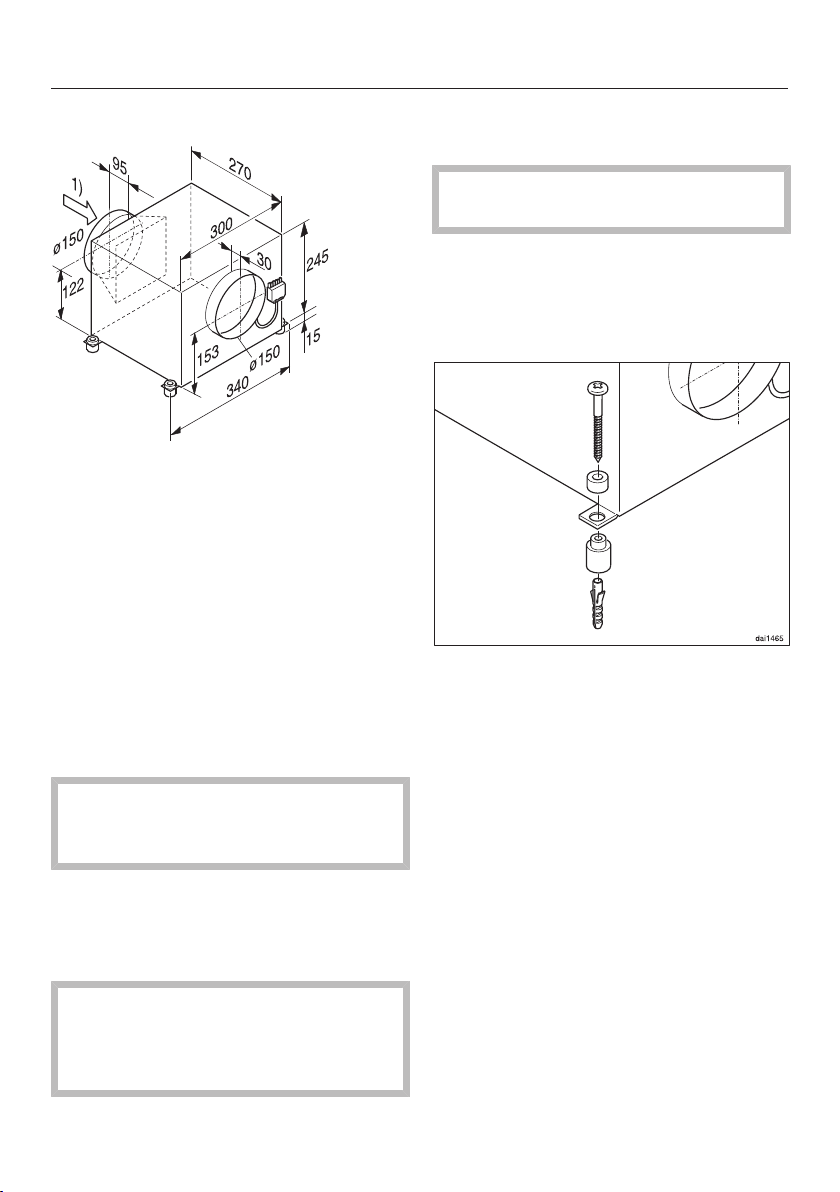

1) Suction side

The ABLG 202 external motor is

designed for installation inside the

house. Possible locations:

– In the attic or ceiling space

– In an adjoining room, e.g. a pantry or

garage

– In the kitchen, if sufficient insulation

is used

It can be installed in a vertical or

horizontal position.

If installing vertically please refer to

the installation instructions on the

next page.

The external motor is connected to the

rangehood by means of a control cable

and is operated by the controls on the

rangehood.

Position the external motor in a

suitable location.

Pay particular attention to the

direction of the ducting.

Mark the positions for the four motor

base plate holes on the installation

surface.

Place the motor to one side.

Drill four 8mm holes in the

positions marked to a depth of

40mm for securing the external

motor.

Press S8 anchors into the drill holes

so that they are flush.

Connect the installation mountings

through the fixing holes in the motor

unit base plate.

Secure the motor with the screws

supplied.

Please refer to the operating and

installation instructions for the

rangehood before installing the

external motor and ducting.

17

Page 18

Installation

The ducting collar on the motor unit has

a diameter of 150mm as standard.

If a diameter of 125mm is required a

reducing collar must be used.

This is available to order from Miele.

Push the flexible ducting onto the

collar and secure it with a hose clip.

Ducting with a diameter of 150mm is

then connected to the exhaust side.

If the exhaust air is to be ducted into

the open air, a telescopic wall vent kit

can be used. This is available to order

from Miele.

If the motor is installed vertically with

the exhaust ducting venting over a

roof, a roof vent kit DDF 125/150 or

similar must be used to prevent

rainwater from penetrating the

exhaust opening.

Connect the control cable plug

connectors.

Use the extension cable supplied to

lengthen the control cable if

necessary.

If equipotential bonding is required,

connect the earth lead to the earthed

connection point in the housing.

Equipotential bonding is required if

the control cable is to be extended

by more than the length of the

extension cable supplied (see

"Electrical connection").

18

Page 19

Installation

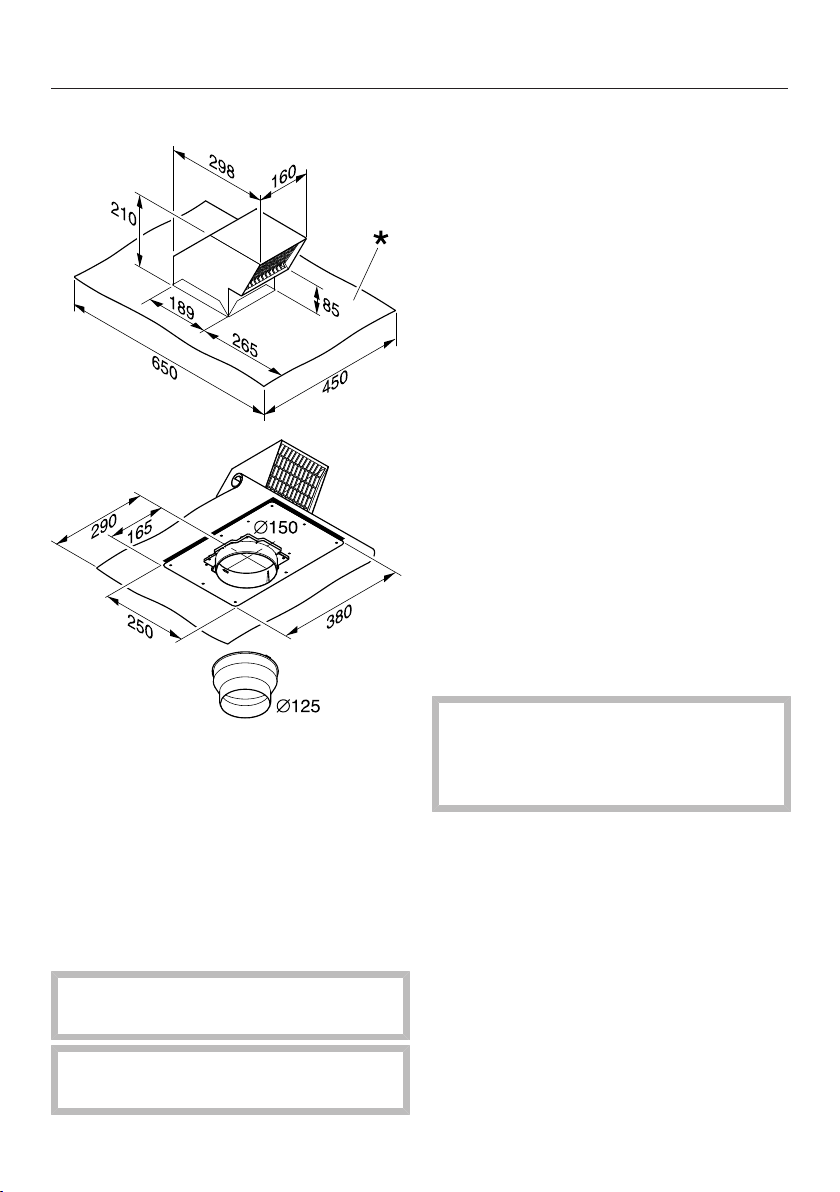

DDF 125/150

Remove the roofing around the

installation area.

Bend the flashing* upwards.

Position the roof vent on the roof with

the air outlet directed down the roof.

Secure the roof vent to the roof

substructure with the fixing plate.

Replace the roofing. Press down on

the flashing to ensure that it creates a

proper seal.

The flashing should be fitted under

the roofing at the top of the roof vent

and above the roofing at the sides

and the bottom of the roof vent.

The roof vent collar has a diameter of

150mm as standard.

If a diameter of 125mm is required a

reducing collar must be used.

Push the flexible ducting onto the

collar and secure it with a hose clip.

It has an integrated non-return flap.

*Flashing

The DDF 125/150 roof vent is designed

for installing ducting through an angled

tile, slate or shingle roof. The slope of

the roof must be at least 22° to prevent

the ingress of the elements, such as

rain or snow.

Consult a roof tiler or roof plumber for

advice regarding other types of roofing.

Installation on a flat roof is not

possible.

Installation must only be carried out

by a qualified and competent person.

When feeding the exhaust ducting

through the substructure of the roof,

be careful to ensure that any gaps

are sealed up properly afterwards.

19

Page 20

Connection for air extraction

Only use smooth pipes or flexible

hoses made from non-flammable

materials for the extraction ducting.

To achieve the greatest possible air

extraction with the lowest noise level,

please note the following:

– The cross-section of the exhaust

ducting must not be smaller than the

cross-section of the exhaust

connection (see "Appliance

dimensions").

– The exhaust ducting should be as

short and straight as possible.

– Only use wide radius bends.

– The exhaust ducting should not be

kinked or compressed.

– Ensure that all connections are

strong and airtight.

Remember that any constriction of

the airflow will reduce extraction

performance and increase operating

noise.

When ducting is horizontal it must be

laid to slope away at at least 1 cm per

metre. This is to ensure that

condensate cannot drain back into

the downdraft extractor.

If the exhaust ducting is to run

through rooms, ceiling space etc.

where there may be great variations

in temperature between the different

areas, the problem of condensation

will need to be addressed. The

exhaust ducting will need to be

suitably insulated.

If the exhaust air is to be ducted into

a vent flue, the ducting must be

directed in the flow direction of the

flue.

20

Page 21

Connection for air extraction

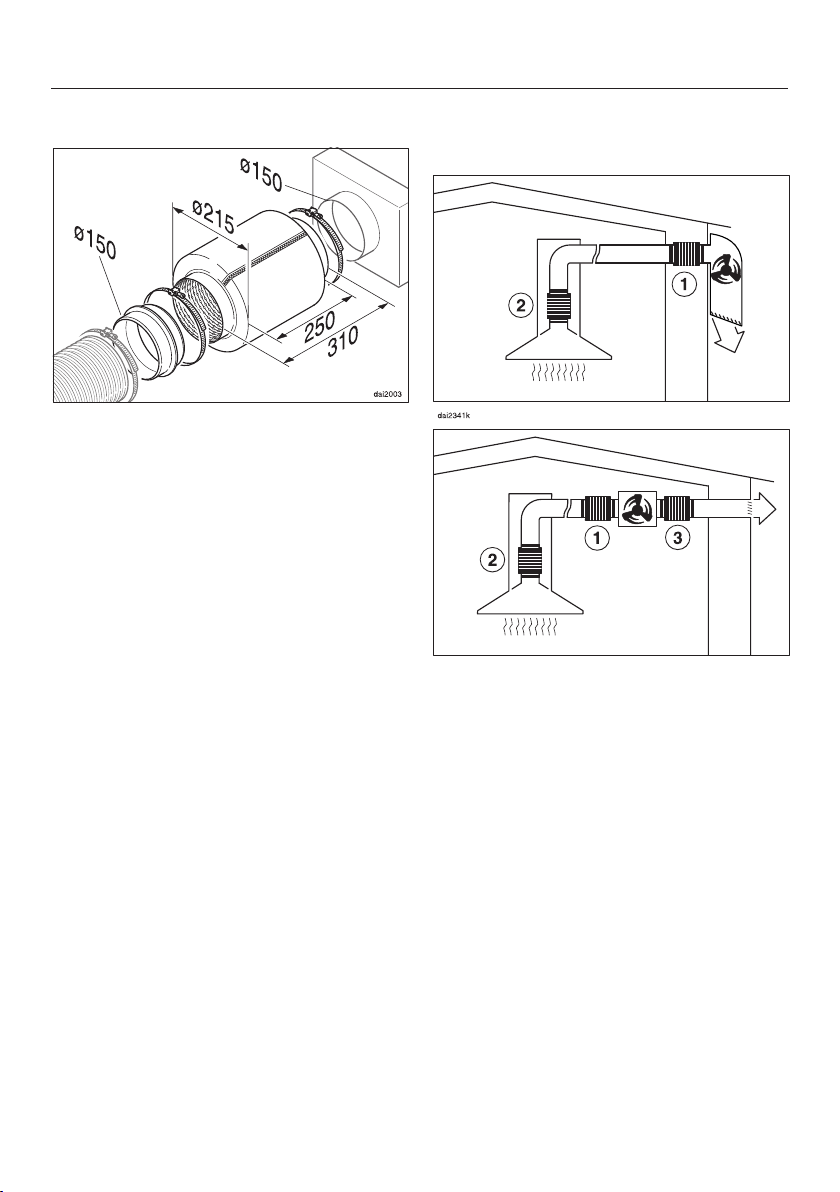

Silencer

To achieve even further reductions in

noise levels, a special silencer (optional

accessory) can be fitted in the ducting

system.

Air extraction with external motor

To minimise noise from the motor in the

kitchen, the silencer should be

positioned in front of the external motor

if possible, or if the ducting is long,

then in the ducting above the

rangehood itself . In the case of an

external motor that is placed inside the

house (ABLG 202), fitting a silencer

behind the external motor reduces

the noise of the motor outside the

house.

21

Page 22

After sales service and warranty

In the event of a fault which you cannot

remedy yourself, please contact Miele.

The contact details for Miele are given

at the back of these instructions.

When contacting Miele, please quote

the model and serial number of your

appliance.

These can be found on the data plate.

Position of the data plate

The data plate is located on the

housing.

Warranty: AU, NZ

The manufacturer's warranty for this

appliance is 2 years.

For further information, please refer to

your warranty booklet.

Warranty: Other countries

For information on the appliance

warranty specific to your country please

contact Miele. See end of this booklet

for contact details.

22

Page 23

The external motor is connected to the

rangehood by means of a special

control cable and is operated by the

touch controls on the rangehood.

The electrical system and connection of

this appliance must comply with

national and local safety regulations.

For extra safety, it is advisable to

protect the appliance with a suitable

residual current device (RCD) with a trip

current of 30mA.

The relevant connection data can be

found on the data plate (see "After sales

service and warranty"). Ensure that this

data matches the voltage and

frequency of your household mains

supply.

The external motor is supplied with a

5m extension cable. If the control

cable needs to be extended further

by means of an additional extension

cable or a hardwired connection

cable (at least 6x1.5mm²), the

installation must be carried out in

strict accordance with local and

national safety regulations.

Equipotential bonding is required in

this case.

The external motor is supplied with

an earthed connection point.

Electrical connection

This external motor has been

designed to be connected to a Miele

rangehood only and must not be

connected to a rangehood made by

another manufacturer.

23

Page 24

Technical data

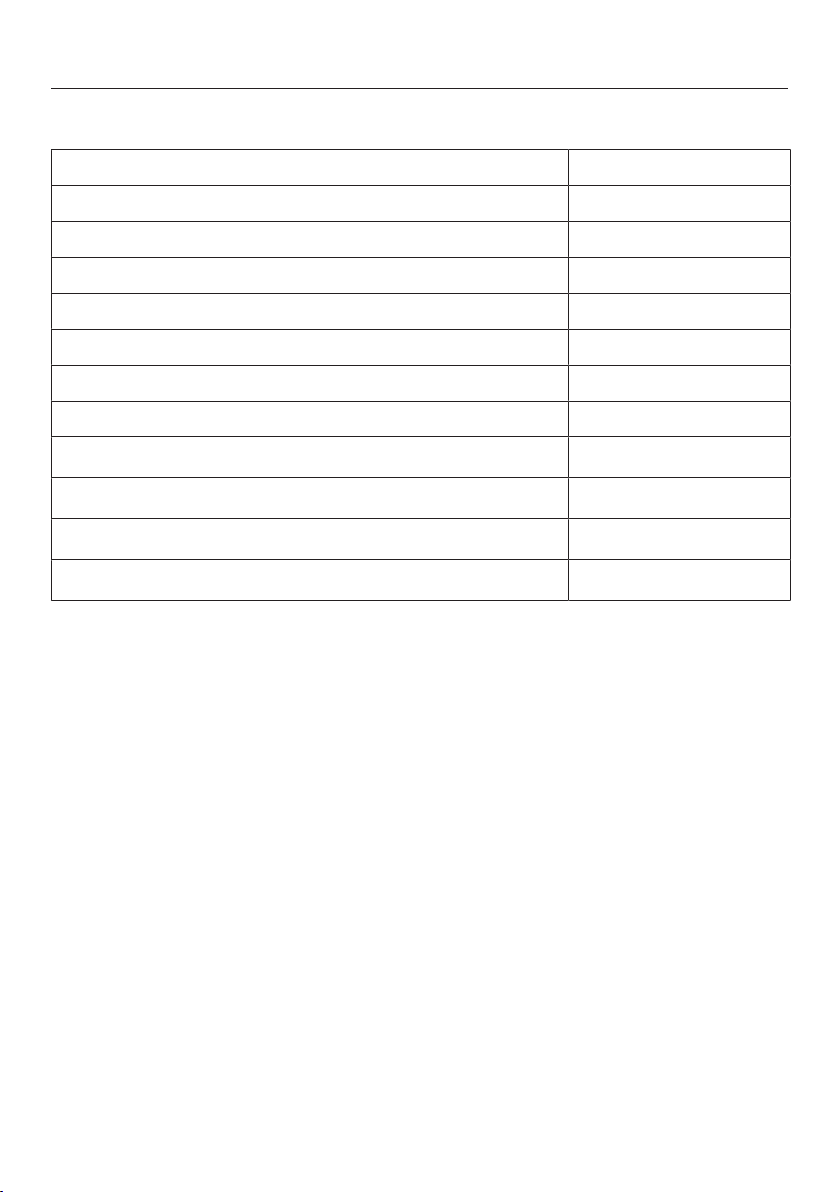

AWG 102

Total rated load 200 W

Voltage, frequency AC 230 V, 50 Hz

Fuse rating 10 A

Control cable length 0.75 m

Connection cable length 5 m

Weight 14.1 kg

Operating temperature up to - 20°C

Fan power according to EN61591*

Level 1

Level 2

Level 3

Booster setting (intensive setting)

*For example in combination with a DA 429-6 EXT rangehood

320 m3/h

460 m3/h

580 m3/h

760 m3/h

24

Page 25

Technical data

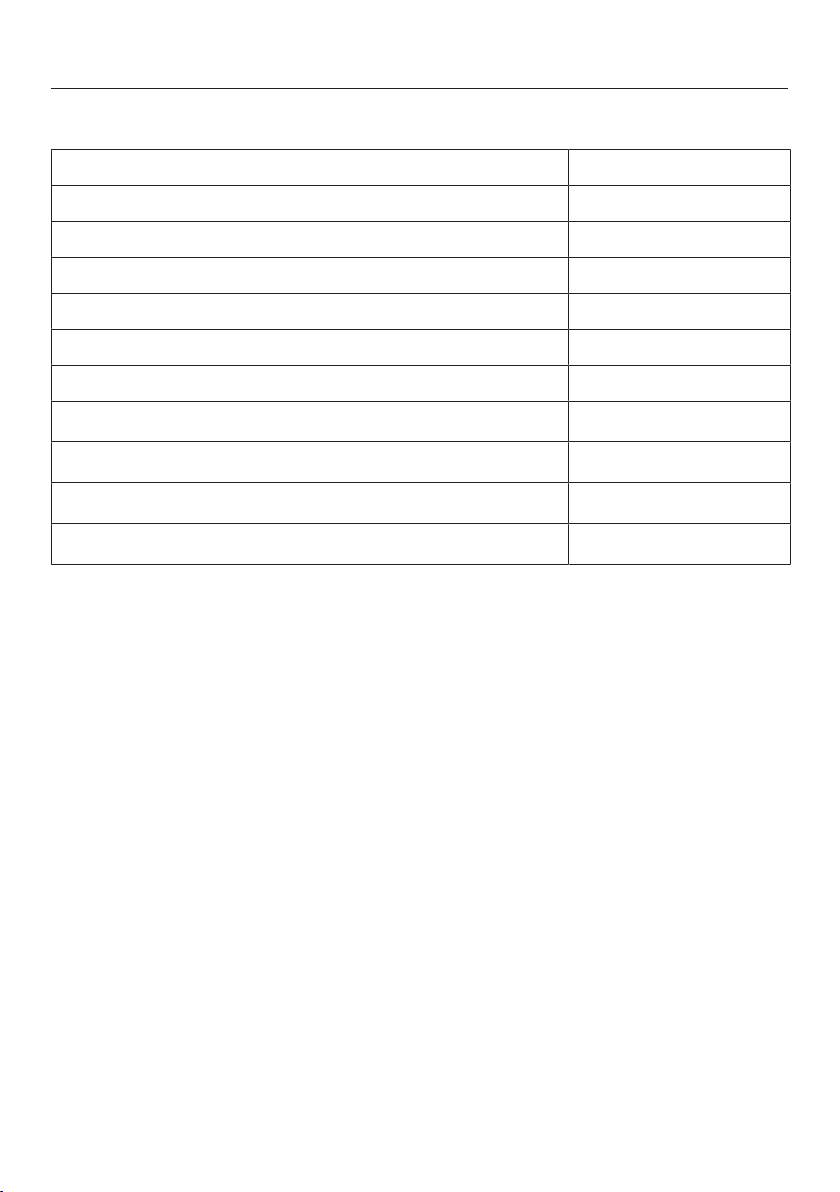

ABLG 202

Total rated load 290 W

Voltage, frequency AC 230 V, 50 Hz

Fuse rating 10 A

Connection cable length 5 m

Weight 8 kg

Operating temperature up to - 20°C

Fan power according to EN61591*

Level 1

Level 2

Level 3

Booster setting (intensive setting)

*For example in combination with a DA 429-6 EXT rangehood

300 m3/h

460 m3/h

600 m3/h

820 m3/h

25

Page 26

Technical data

DDG 102

Total rated load 200 W

Voltage, frequency AC 230 V, 50 Hz

Fuse rating 10 A

Control cable length 0.75 m

Connection cable length 5 m

Weight 15.2 kg

Operating temperature up to - 20°C

Fan power according to EN61591*

Level 1

Level 2

Level 3

Booster setting (intensive setting)

*For example in combination with a DA 429-6 EXT rangehood

320 m3/h

460 m3/h

580 m3/h

760 m3/h

26

Page 27

www.miele.com.au

Miele Experience Centre and

Head Office Melbourne:

1 Gilbert Park Drive

Knoxfield, VIC 3180

Miele Experience Centre South Melbourne:

206-210 Coventry Street

South Melbourne, VIC 3205

Miele Experience Centre and Office Sydney:

3 Skyline Place

Frenchs Forest, NSW 2086

Miele Experience Centre and Office Brisbane:

39 Harvey Street North

Eagle Farm, QLD 4009

Miele Experience Centre and Office Perth:

83-85 Sir Donald Bradman Drive

Hilton, SA 5033

205-207 Stirling Highway

Claremont, WA 6010

Miele Experience Centre and Office Adelaide:

Miele Australia Pty. Ltd.

Miele New Zealand Limited

Level 2, 10 College Hill

Freemans Bay, Auckland 1011

Miele Experience Centre

Auckland:

8 College Hill

Freemans Bay, Auckland 1011

Telephone:

0800 464 353 (0800 4 MIELE)

www.miele.co.nz

Miele Global Headquarters

Germany

Miele & Cie. KG

Carl-Miele-Straße 29

33332 Gütersloh

Federal Republic of Germany

Head Office:

IRD 98 463 631

ACN 005 635 398

ABN 96 005 635 398

Miele Experience Centre Gold Coast:

131 Ferry Road

Southport, QLD 4215

Page 28

AWG 102

DDG 102

ABLG 202

DDF 125/150

M.-Nr. 10 695 670 / 01en - AU, NZ

Loading...

Loading...