Contents i

R410A ON/OFF SERIES

Service Manual 2013

LEUS-B-1306

Content

Contents i

Part 1 General Information ................................................................... 1

Part 2 Indoor Units ................................................................................ 6

Part 3 Outdoor Units ........................................................................... 63

Part 4 Installation ................................................................................ 78

Part 5 Electrical Control System .....................................................104

※The specifications, designs, and information in this book are subject to change without notice for

product improvement.

General Information

General Information 1

Part 1

General Information

1. Model Lists ................................................................................................................ ....... 2

2. External Appearance ....................................................................................................... 3

2.1 Indoor Units ............................................................................................................... 3

2.2 Outdoor Units ............................................................................................................ 3

3. Nomenclature ................................................................................................................... 4

4. Features ............................................................................................................................ 5

Model Lists

2 General Information

1. Model Lists

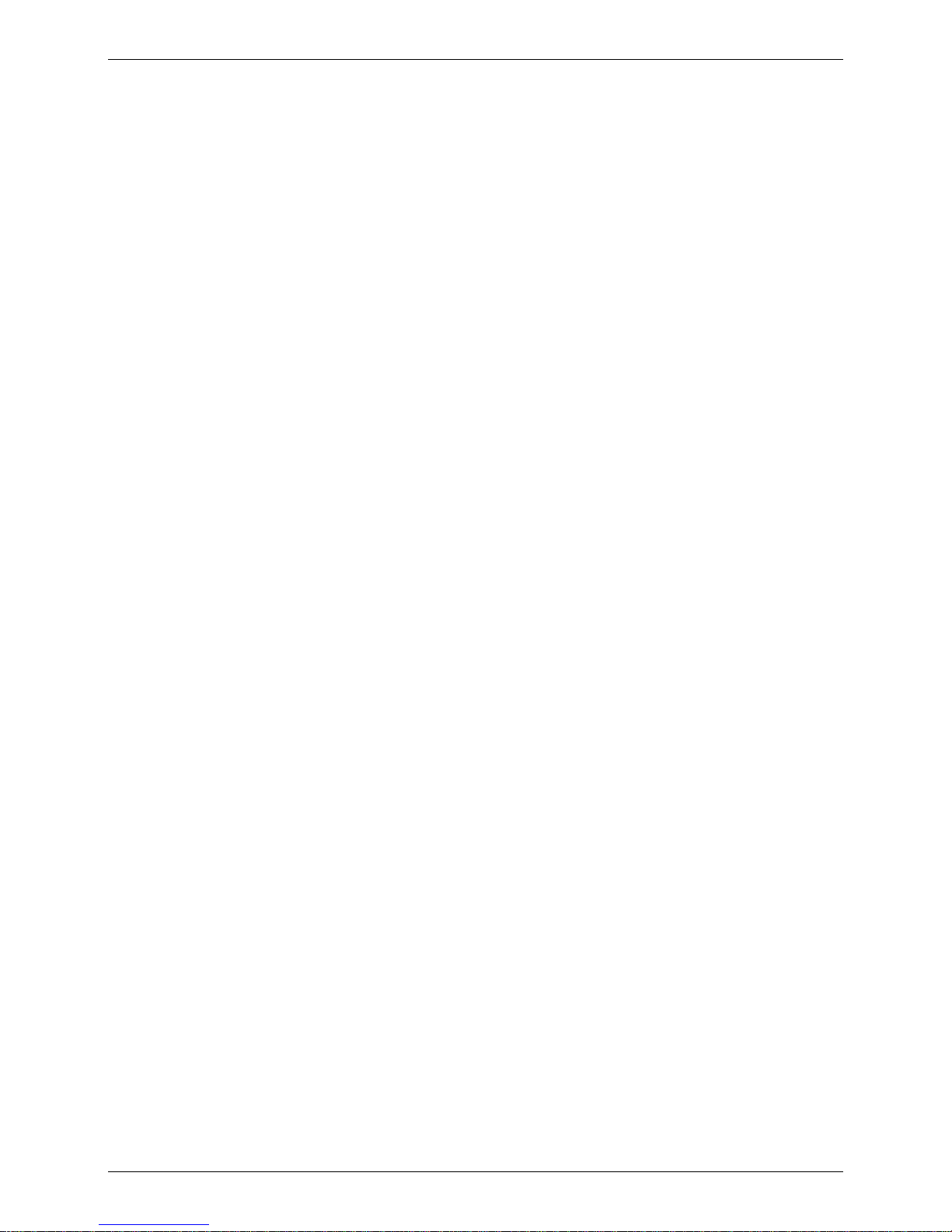

1.1 Indoor Units

R410A Capacity multiplied by 1000Btu/h

Type Function 18 24 30 36 48 60

A5 High static pressure duct Cooling and heating

● ● ● ● ● ●

Ceiling & Floor Cooling and heating

● ● ●

Super-slim 4-way cassette Cooling and heating

● ● ● ● ●

High static pressure duct Cooling and heating

●

1.2 Outdoor Units

Universal Outdoor unit Model Compressor type Compressor Brand Matched indoor units

Heat Pump

MOU-18HN1-Q ROTARY CMCC

MHF-18HWN1-Q

MCD-18HRN1-Q

MOU-24HN1-Q ROTARY CMCC

MHF-24HWN1-Q

MCD-24HRN1-Q

MHG-24HWN1-Q

MOU-30HN1-Q ROTARY CMCC MHF-30HWN1-Q

MOU-30HN1-R ROTARY CMCC MHF-30HWN1-R

MOU-36HN1-Q SCROLL SANYO

MHF-36HWN1-Q

MUE-36HRN1-Q

MOU-36HN1-R SCROLL SANYO

MHF-36HWN1-R

MUE-36HRN1-R

MCD-36HRN1-R

MOU-48HN1-R SCROLL SANYO

MHF-48HWN1-R

MUE-48HRN1-R

MCD-48HRN1-R

MOUA-60HN1-R SCROLL SANYO

MHF-60HWN1-R

MUE-60HRN1-R

MCD-60HRN1-R

External Appearance

General Information 3

2. External Appearance

2.1 Indoor Units

A5 High static pressure duct

Ceiling & floor type

Super-slim 4-way Cassette High static pressure duct

2.2 Outdoor Units

Single fan outdoor unit

Double fan outdoor unit

Nomenclature

4 General Information

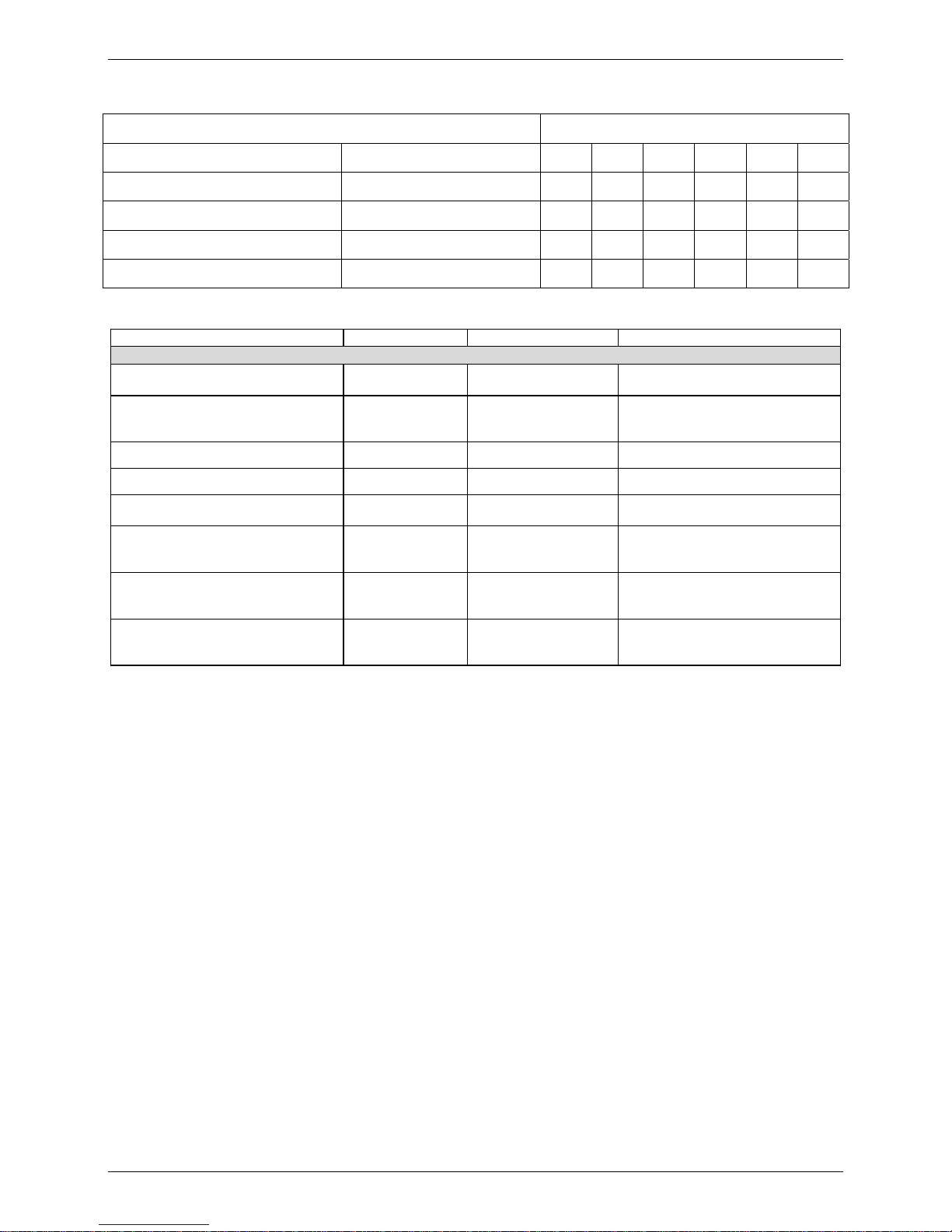

3. Nomenclature

3.1 Indoor Unit

M U B T- 36 H R D N1- Q RC4

Energy Efficiency Code

Power Supply

Q 220~240V,1N, 50Hz

R 380~420V, 3N, 50Hz

N 220~230V, 1N, 60Hz

D 220V~, 3N, 60Hz

C 380~420V,3N,60Hz

Refrigerant

N1 R410A -- R22

D DC Inverter -- On-Off

F Full DC

Control Mode

W Wired Control E Electric Control

M Mechanical Control R Remote Control

Function Code

C Cooling Only H Cooling & Heating

A Cooling & Heating+PTC

Capacity (×1000Btu/h)

T Tropical Condition

-- T1 Condition

Designed Time

A Time A Designed B Time B Designed

C Time C Designed D Time D Designed

Product Category

C Cassette Type V AHU Type

T Duct Type F Console Type

U Ceiling & Floor Type

H High Static Pressure Duct Type

Midea

3.2 Outdoor Unit

M O U T- 36 H D N1- R RC4

Energy Efficiency Code

Power Supply

Q 220~240V,1N, 50HZ

R 380~420V, 3N, 50Hz

N 220~230V, 1N, 60Hz

D 220V~, 3N, 60Hz

C 380~420v,3N,60HZ

Refrigerant

N1 R410A -- R22

D DC Inverter -- On-Off

F Full DC

Function Code

C Cooling Only H Cooling & Heating

A Cooling & Heating+PTC

Capacity (×1000Btu/h)

T Tropical Condition

-- T1 Condition

U Side Discharge Outdoor Unit

V Top Discharge Outdoor Unit

S Centrifugal Fan Outdoor Unit

O Outdoor unit

Midea

Features

General Information 5

4. Features

4.1 High quality coils:

The coil is constructed of advanced inner grooved copper tube and aluminum fins.

4.2 Anti-rust, 500 hours salt spray test.

4.3 Low operation sound level: Well-known stable and quiet running fan motor.

4.4 Well-known compressor.

4.5 Compact design: Smaller dimension and larger stuffing capacity.

4.6 Universal outdoor unit design.

4.7 Optional air outlet grille: plastic type and wire type.

Wire type Plastic type Plastic type

4.8 Optional low temperature cooling module.

4.9 R410A environment friendly refrigerant.

Indoor Units

6 Indoor Units

Part 2

Indoor Units

A5 High Static Pressure Duct Type ..................................... 7

Ceiling & Floor Type ........................................................... 25

Super-slim Cassette Type .................................................. 35

High Static Pressure Duct Type ......................................... 52

A5 High Static Pressure Duct Type

Duct Type 7

A5 High Static Pressure Duct Type

1. Features ...................................................................................................... 8

2. Dimensions ............................................................................................... 11

3. Service Space ........................................................................................... 12

4. Wiring Diagrams ....................................................................................... 13

5. Static Pressure ......................................................................................... 18

6. Electric Characteristics ........................................................................... 19

7. Sound Levels ............................................................................................ 20

8. Accessories .............................................................................................. 21

9. The Specification of Power ..................................................................... 22

10. Field Wiring ............................................................................................. 23

Features

8 Duct Type

1. Features

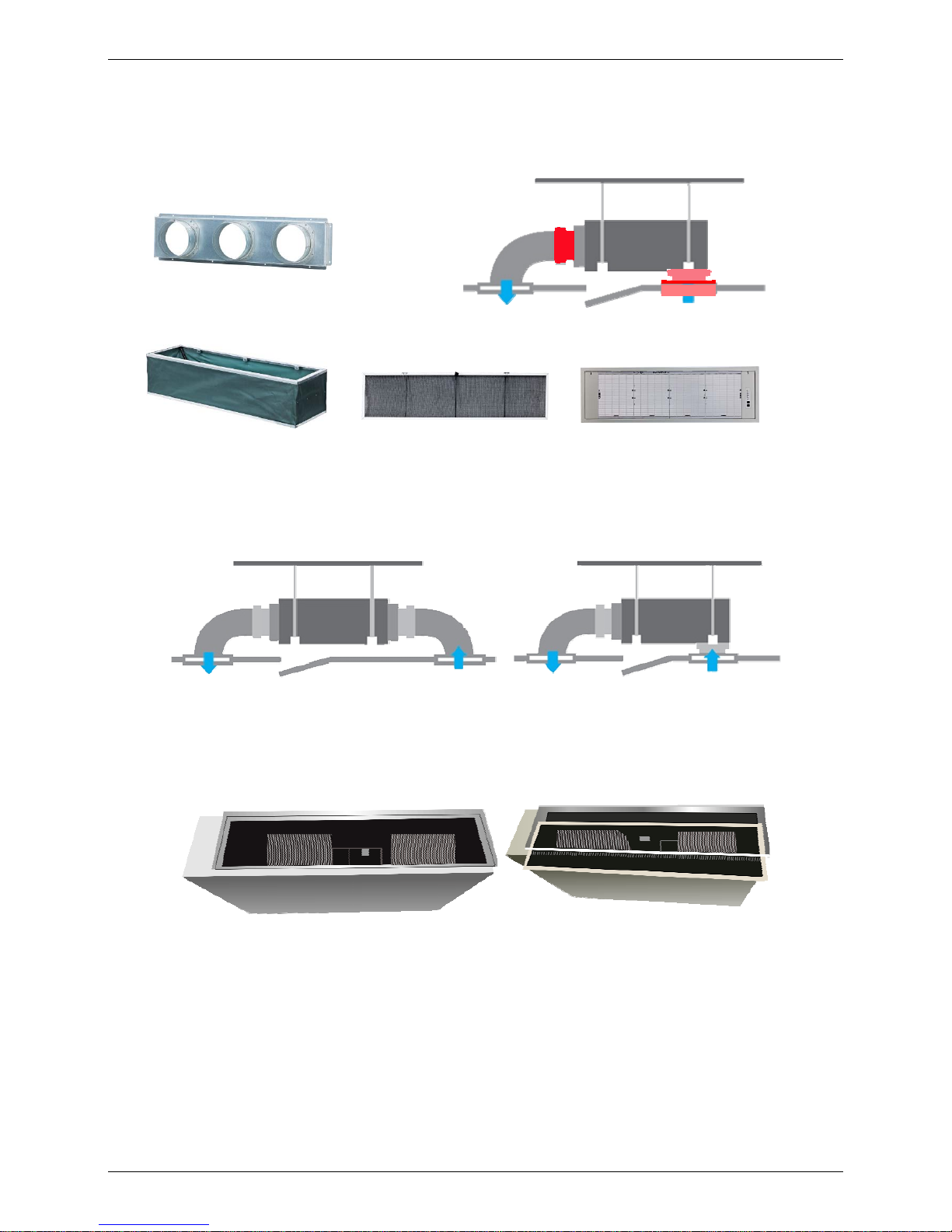

1.1 Installation accessories: (Optional)

Front Board, Canvas Air Passage, Filter, Panel, for easy installation

1.2 Easy Installation: Two air inlet styles (Bottom side or Rear side)

Air inlet from rear is standard for all capacity; air inlet from bottom is optional.

The size of air inlet frame from rear and bottom is same, it’s very easy to move the cover from bottom to

rear side, or from rear to the bottom, in order to matching the installation condition.

1.3 Easy maintenance

Clean the filter (Optional, standard product without filter)

It is easy to draw out the filter from the indoor unit for cleaning, even the filter is installed in rear side or

bottom side.

Replace the motor or centrifugal fan

Remove the ventilated panel firstly. Remove a half of blower housing and take out the motor with

centrifugal fan. Directly remove two bolts, and then replace the motor or centrifugal fan easily.

Front Board

Canvas Air Passage Filter Panel

Air intake from rear (Standard)

Air intake from bottom (Optional)

Features

Duct Type 9

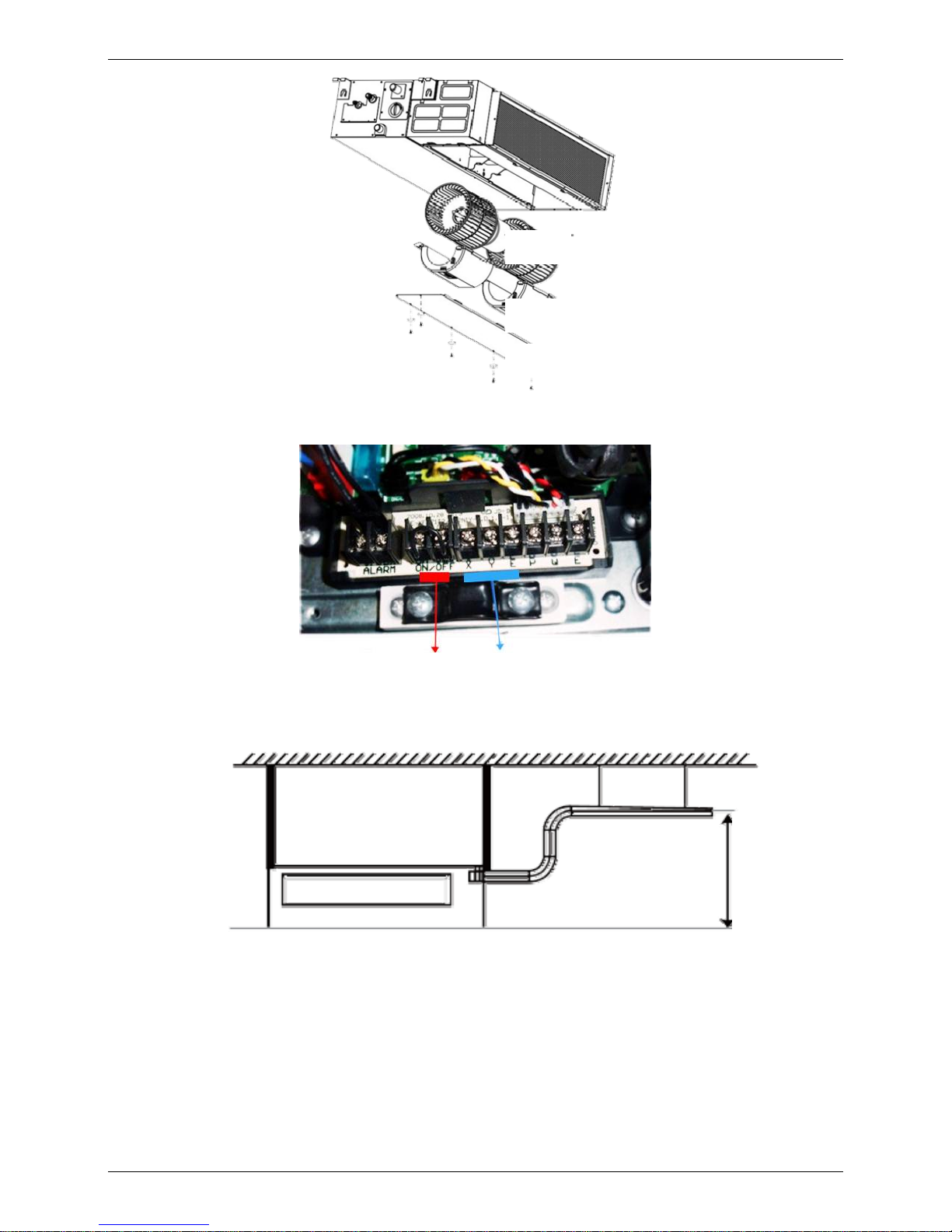

1.4 Reserved remote on-off and central control ports

Reserved remote on-off ports and central control ports, can connect the cable of an on-off controller or a

central controller to realize remote on-off control function or group control function.

1.5 Built-in drain pump (Optional):

Built-in drain pump can lift the water to 750mm upmost. It’s convenient to install drainage piping under

most space condition.

Motor

Blower Housing

Ventilated Panel

Remote on-off ports

Central control ports

750mm upmost

Features

10 Duct Type

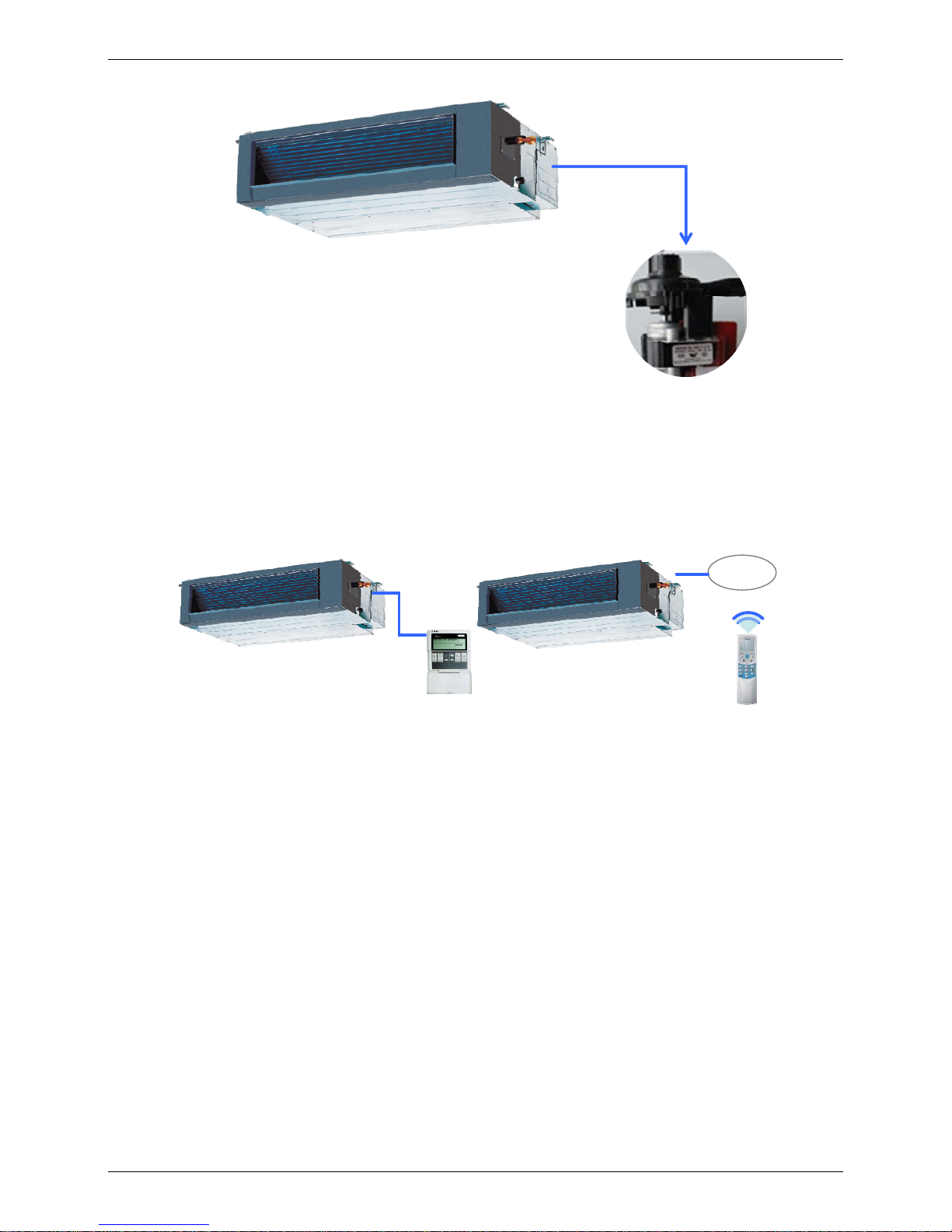

1.6 Built-in display board

The standard indoor unit can be controlled by wired controller.

There is a display board with a receiver in the E-box. Move out the display, and fix it in other place, even

in the distance of 10m. The unit will realized remoter control.

The wired controller and the display board can display the error code or production code when the chips

detect some failure.

Display

Wired Controller (Standard)

Remote Controller (Optional)

Dimensions

Duct Type 11

2. Dimensions

H

G

E

F

A

B

D

C

L

M

Capacity

(KBtu)

Outline

dimension(mm)

Air outlet

opening size

Air return

opening size

Size of outline dimension

mounted plug

A B C D E F G H I J K L M

18 920 210 635 570 65 713 35 119 815 200 80 960 350

24 920 270 635 570 65 713 35 179 815 260 20 960 350

30/36 1140 270 775 710 65 933 35 179 1035 260 20 1180 490

48/60 1200 300 865 800 80 968 40 204 1094 288 45 1240 500

Service Space

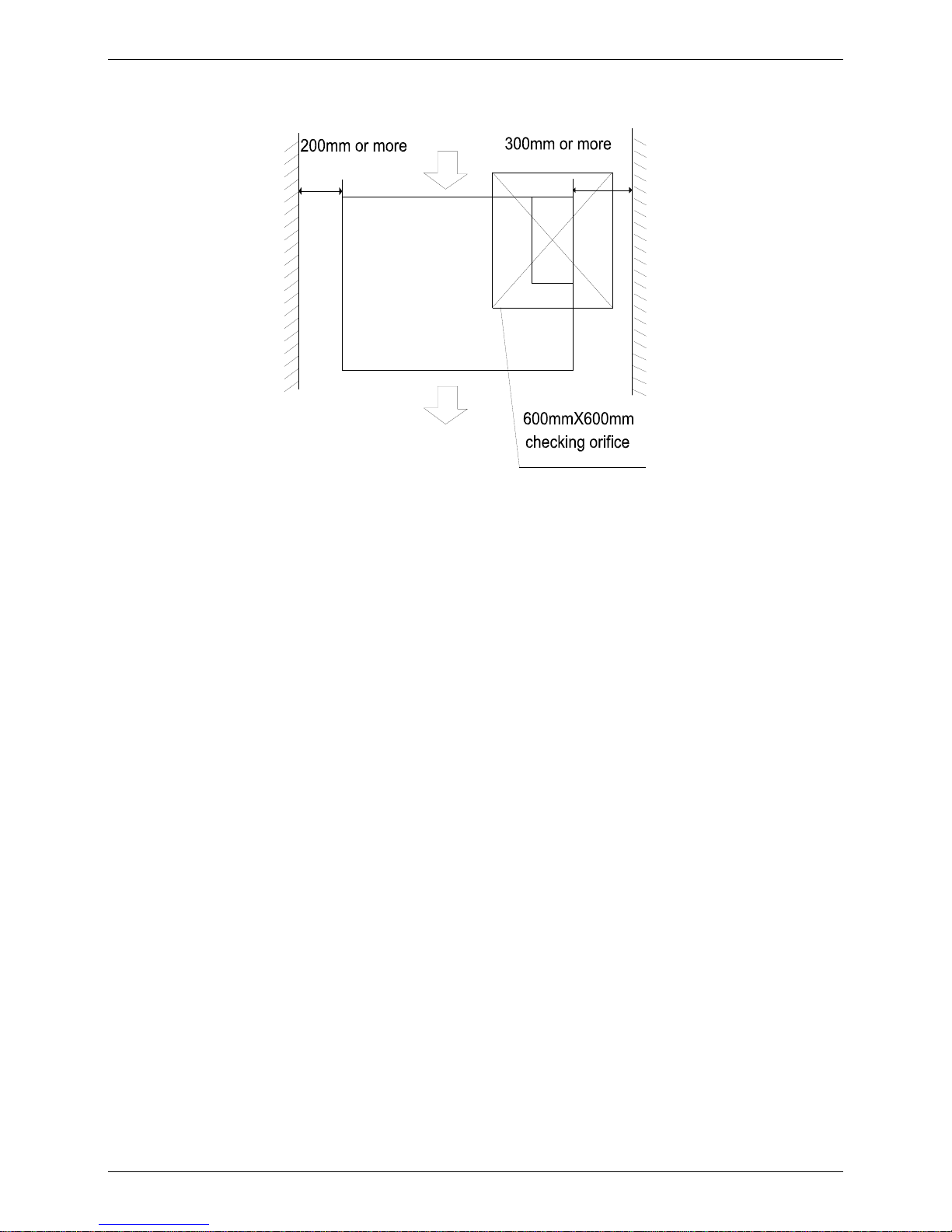

12 Duct Type

3. Service Space

Ensure enough space required for installation and maintenance.

Wiring Diagrams

Duct Type 13

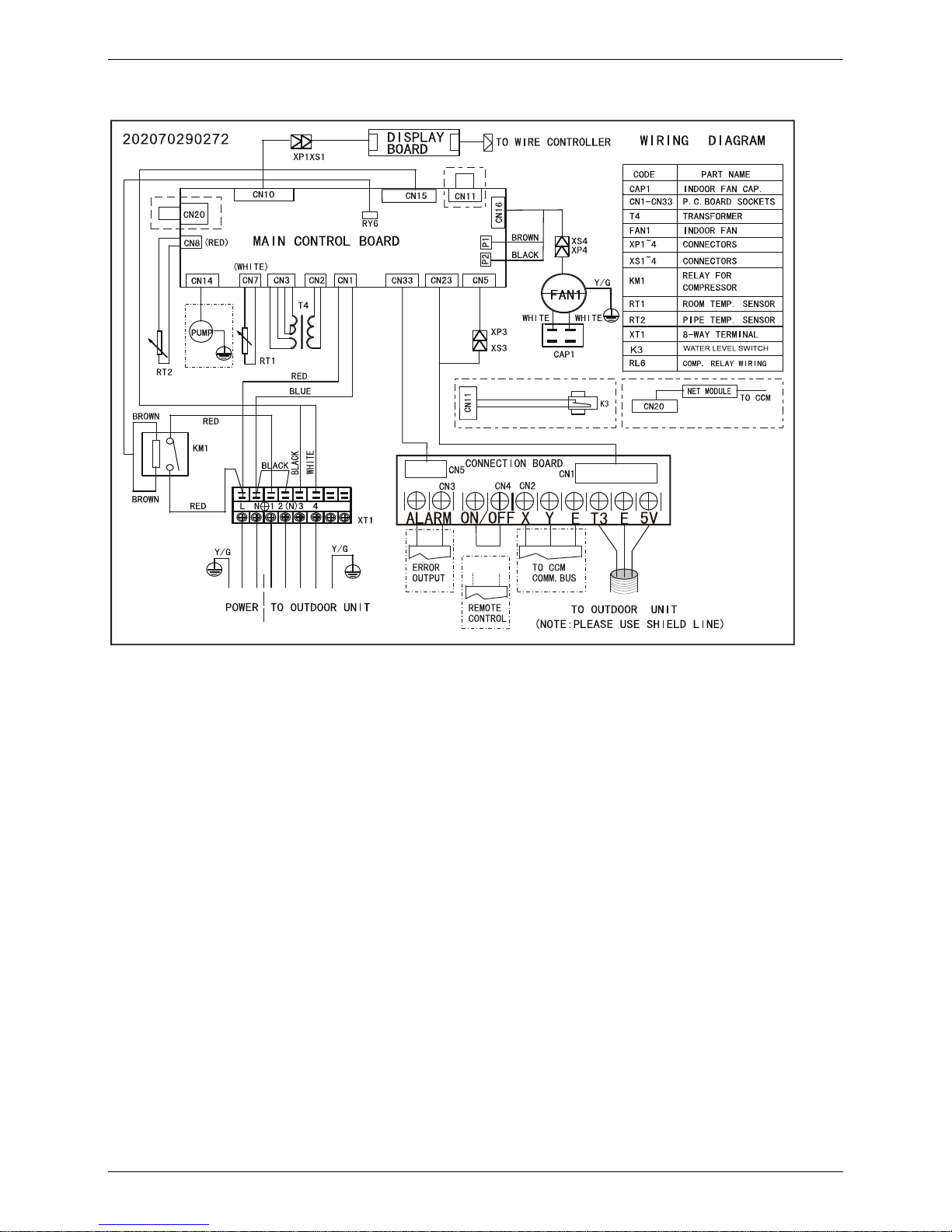

4. Wiring Diagrams

MHF-18HWN1-Q

Wiring Diagrams

14 Duct Type

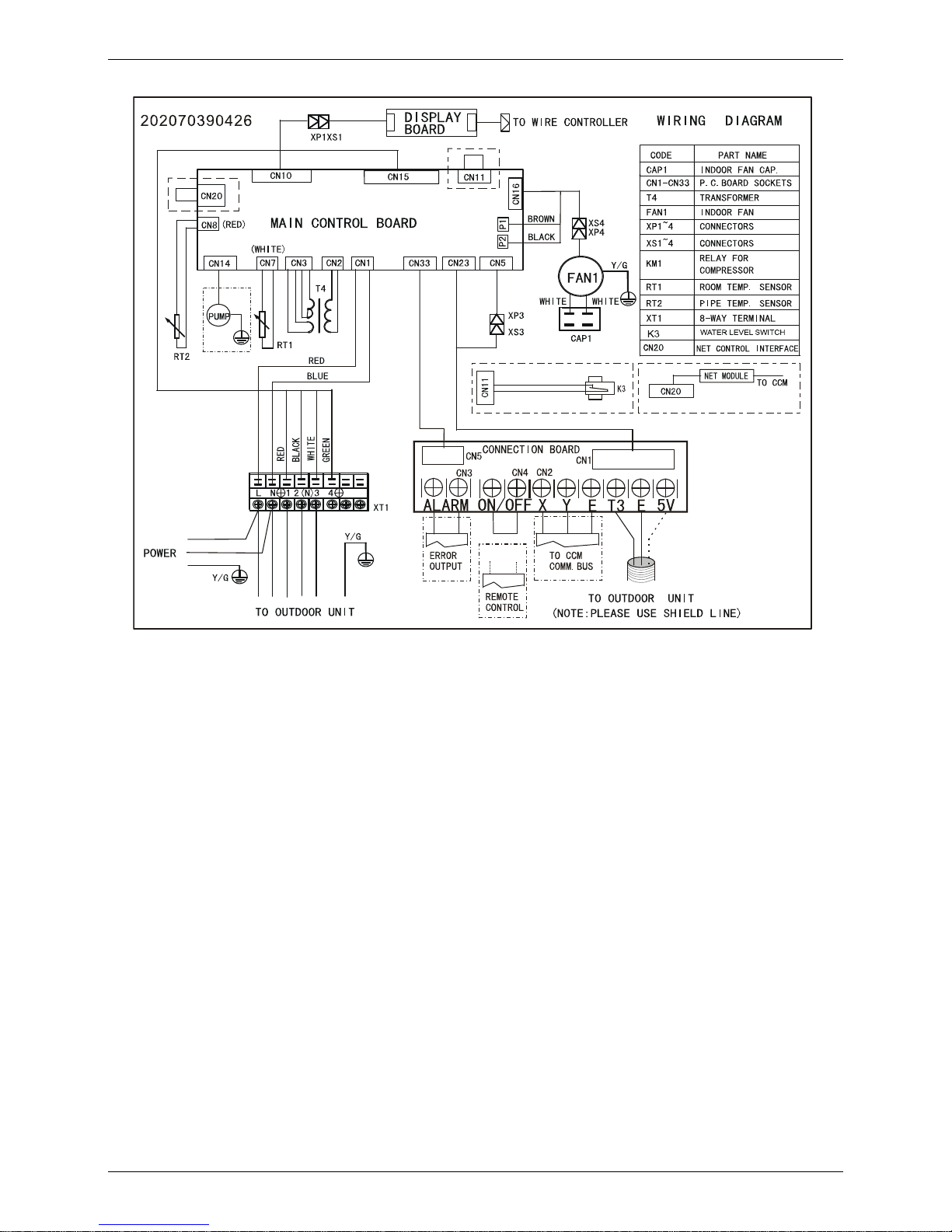

MHF-24HWN1-Q

Wiring Diagrams

Duct Type 15

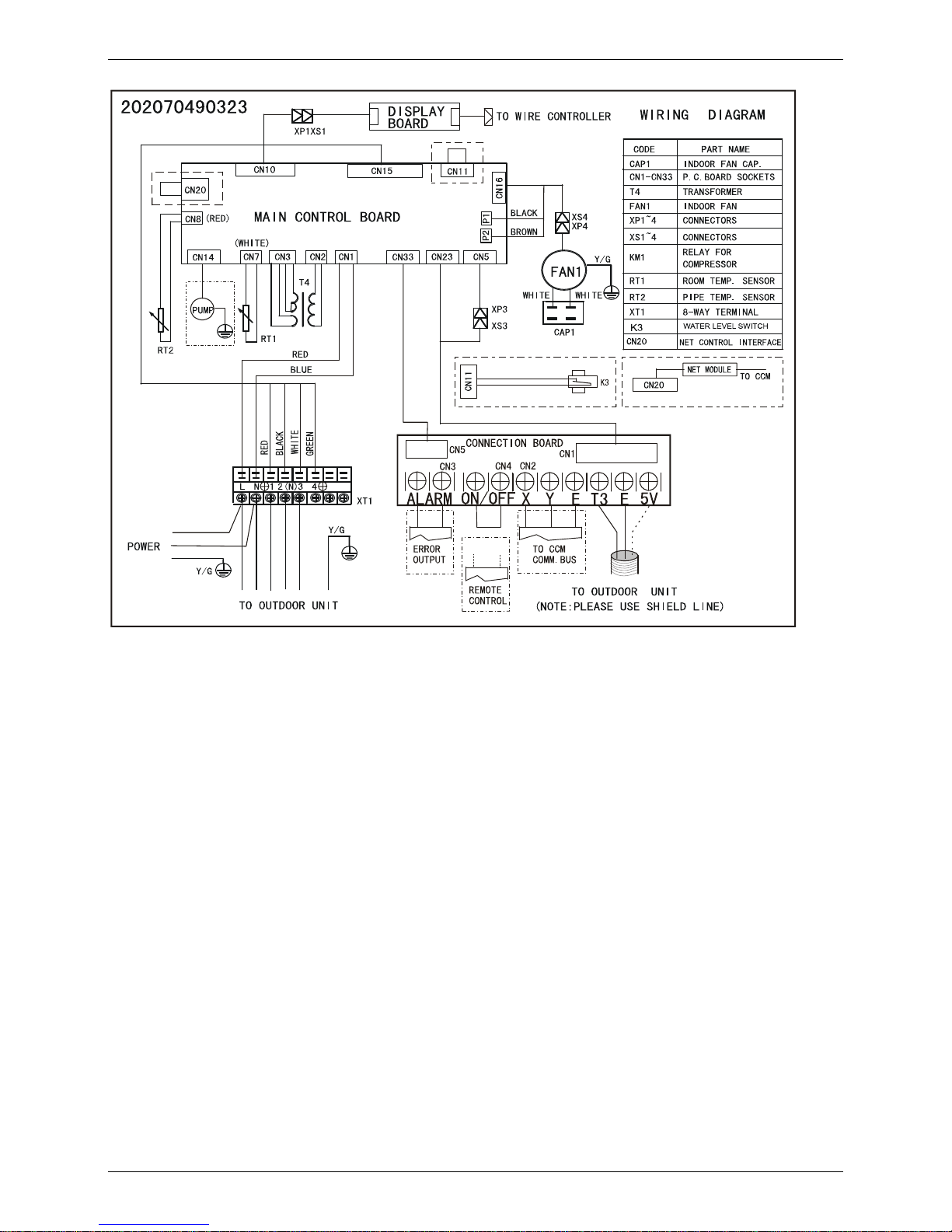

MHF-30HWN1-Q、MHF-36HWN1-Q

Wiring Diagrams

16 Duct Type

MHF-30HWN1-R、MHF-36HWN1-R、MHF-48HWN1-R、MHF-60HWN1-R

Wiring Diagrams

Duct Type 17

Static Pressure

18 Duct Type

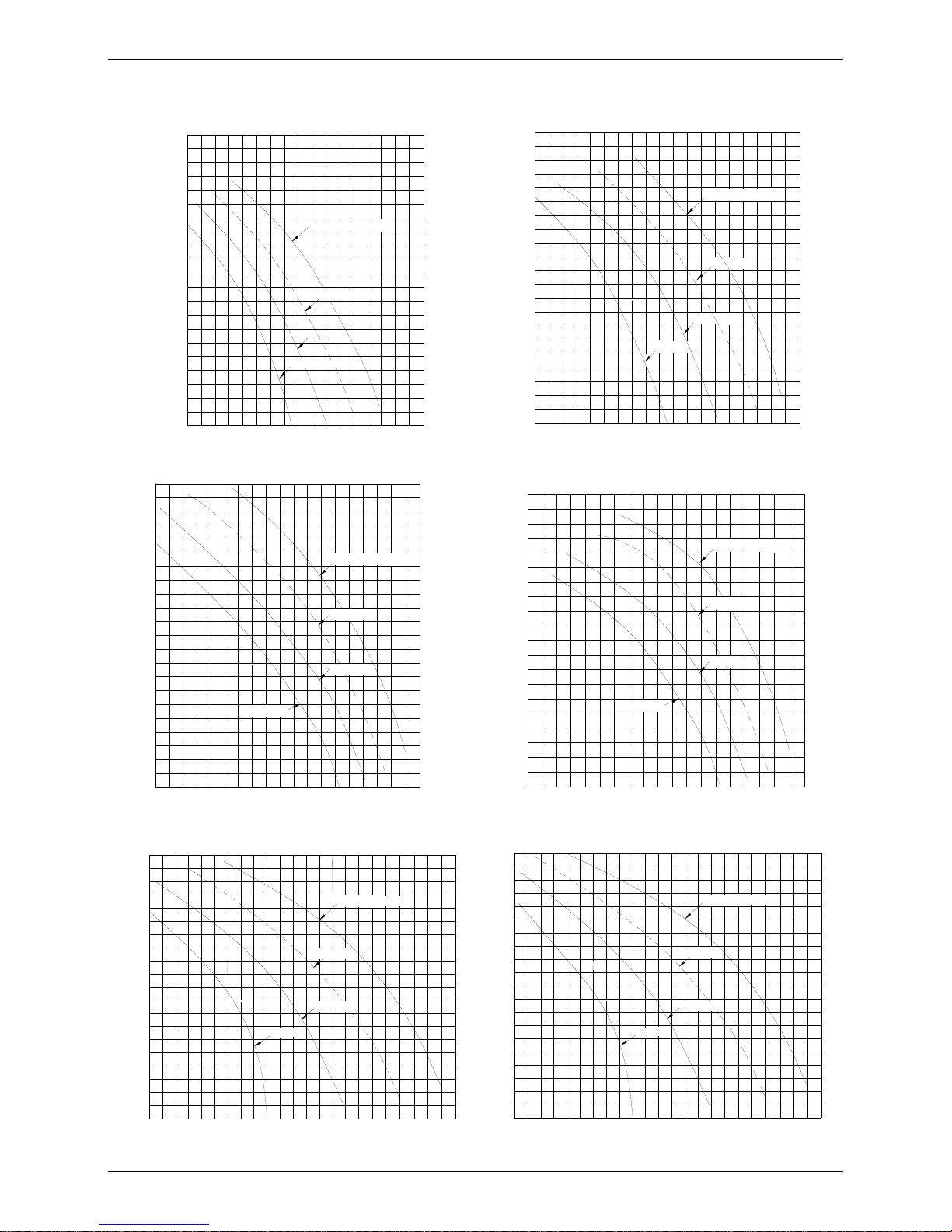

5. Static Pressure

18,000 Btu/h 24,000 Btu/h

Mid speed

High speed

External static pressure (Pa)

14001300

1200

1100

1000

Pa

90

80

70

60

50

40

30

20

10

Low speed

700

Super high speed

800

900

1500

3

Air volume(m /h)

Mid speed

High speed

External static pressure (Pa)

14001300

1200

1100

1000

Pa

90

80

70

60

50

40

30

20

10

Low speed

700

Super high speed

800

900

1500

1600

3

Air volume(m /h)

30,000 Btu/h 36,000 Btu/h

Mid speed

High speed

External static pressure (Pa)

2000

1800

1600

1400

1200

Pa

90

80

70

60

50

40

30

20

10

Low speed

600

Super high speed

800

1000

2200

2400

3

Air volume(m /h)

100

Mid speed

High speed

External static pressure (Pa)

2000

1800

1600

1400

1200

Pa

180

160

140

120

100

80

60

40

20

Low speed

600

Super high speed

800

1000

2200

2400

3

Air volume(m /h)

48,000 Btu/h 60,000 Btu/h

Mid speed

High speed

External static pressure (Pa)

3200

3000

2800

2600

2400

Pa

180

160

140

120

100

80

60

40

20

Low speed

800

Super high speed

1000

2200

3400

3600

3

Air volume(m /h)

2000

1600

Mid speed

High speed

External static pressure (Pa)

3200

3000

28002600

2400

Pa

180

160

140

120

100

80

60

40

20

Low speed

800

Super high speed

1000

2200

3400

3600

3

Air volume(m /h)

2000

1600

Electric Characteristics

Duct Type 19

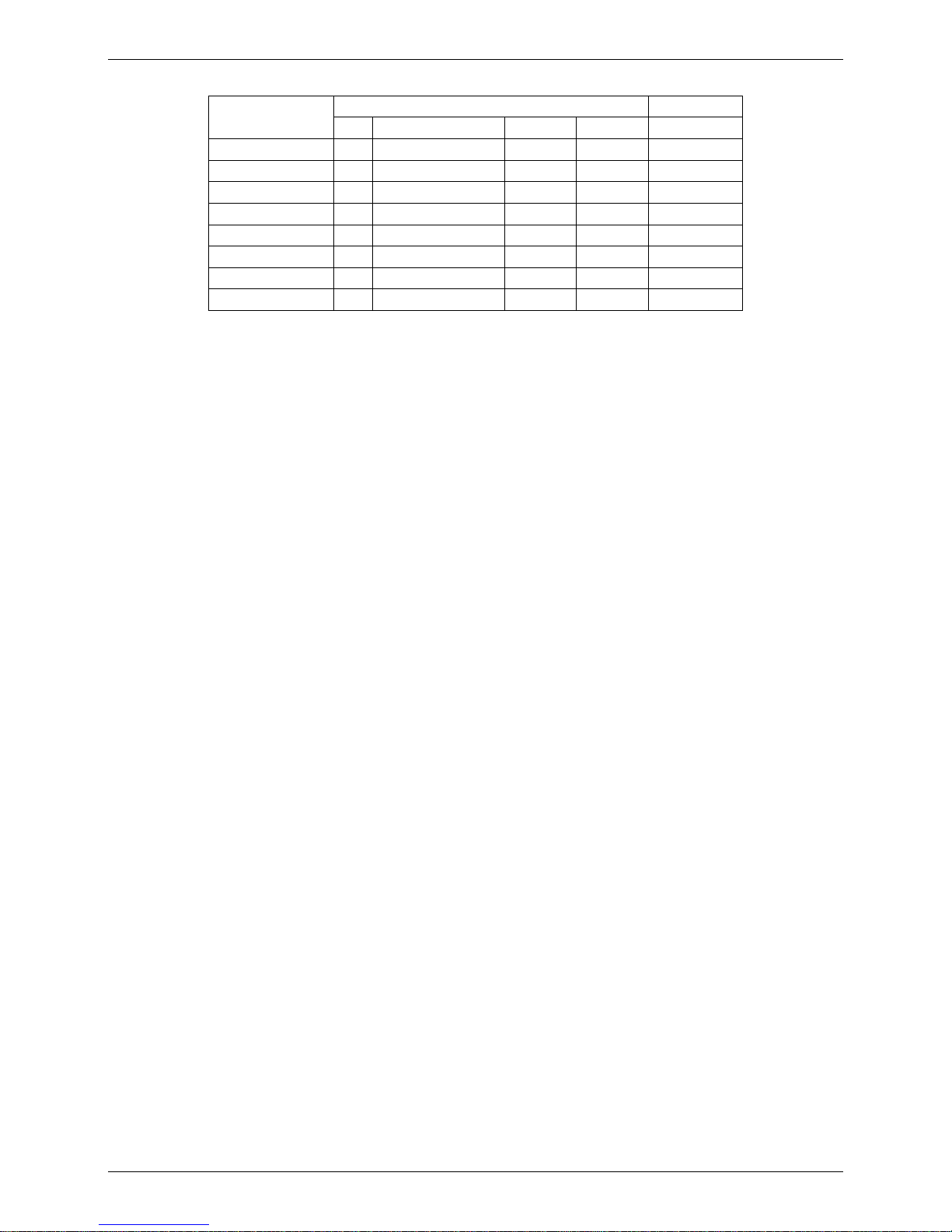

6. Electric Characteristics

Model

Indoor Units Power Supply

Hz Voltage Min. Max. MFA

MHF-18HWN1-Q 50 220-240V 198V 254V 16

MHF-24HWN1-Q 50 220-240V 198V 254V 25

MHF-30HWN1-Q 50 220-240V 198V 254V 30

MHF-30HWN1-R 50 380-420V 342V 440V 20

MHF-36HWN1-Q 50 220-240V 198V 254V 30

MHF-36HWN1-R 50 380-420V 342V 440V 20

MHF-48HWN1-R 50 380-420V 342V 440V 20

MHF-60HWN1-R 50 380-420V 342V 440V 20

Notes:

MFA: Max. Fuse Amps. (A)

Sound Levels

20 Duct Type

7. Sound Levels

Suction

Discharge

Microphone

1.4m

Concealed Duct Type

DuctDuct

Model

Noise level dB(A)

H M L

MHF-18HWN1-Q 42 38 36

MHF-24HWN1-Q 46 40 38

MHF-30HWN1-Q 50 48 45

MHF-30HWN1-R 50 48 45

MHF-36HWN1-Q 52 48 45

MHF-36HWN1-R 49 47 44

MHF-48HWN1-R 51 49 46

MHF-60HWN1-R 50 48 44

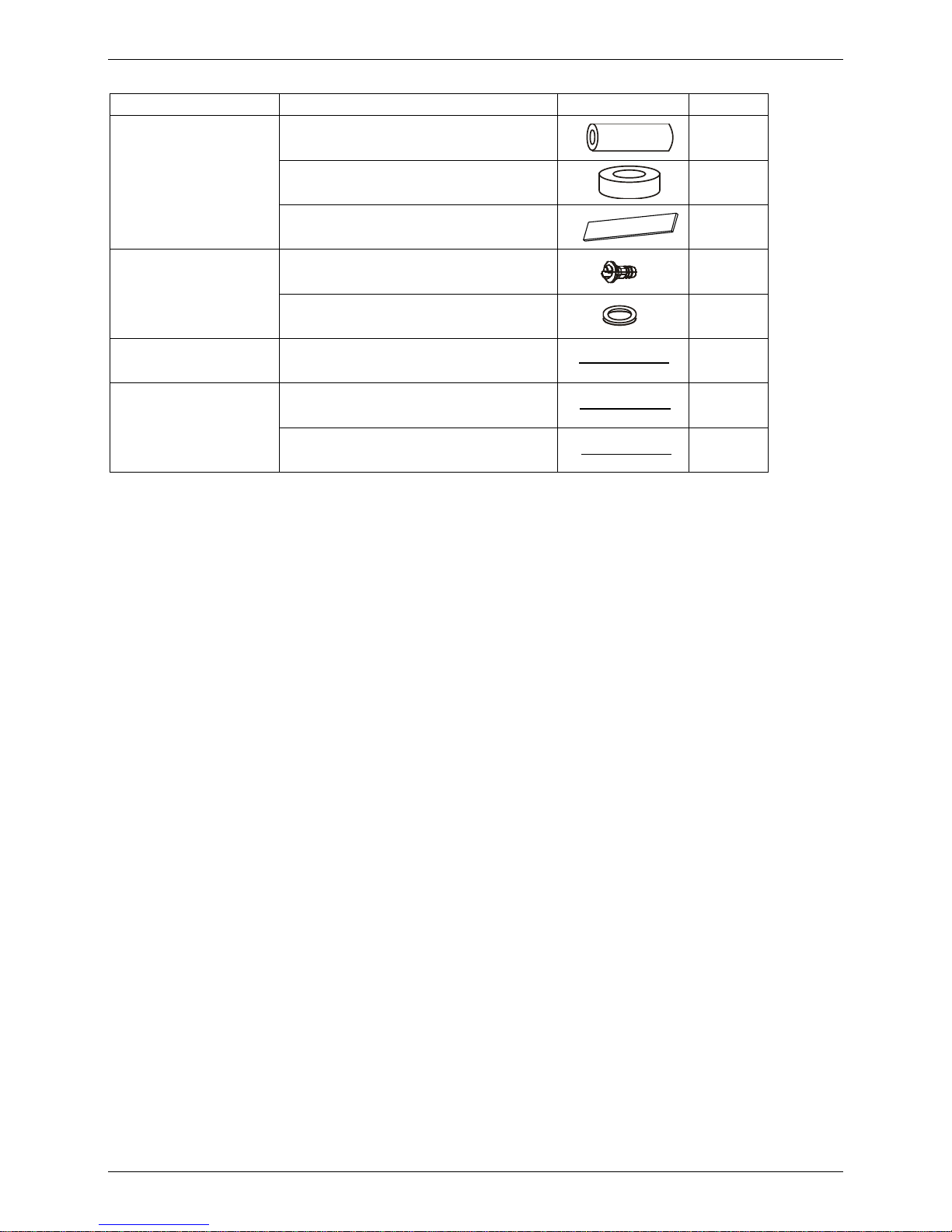

Accessories

Duct Type 21

8. Accessories

Name Shape Quantity

Tubing & Fittings

Soundproof/insulation sheath

2

Binding tape

1

Seal sponge

1

Drainpipe Fittings

Drain joint

1

Seal ring

1

Wire controller Wire controller

1

others

Owner's manual

1

Installation manual

1

The Specification of Power

22 Duct Type

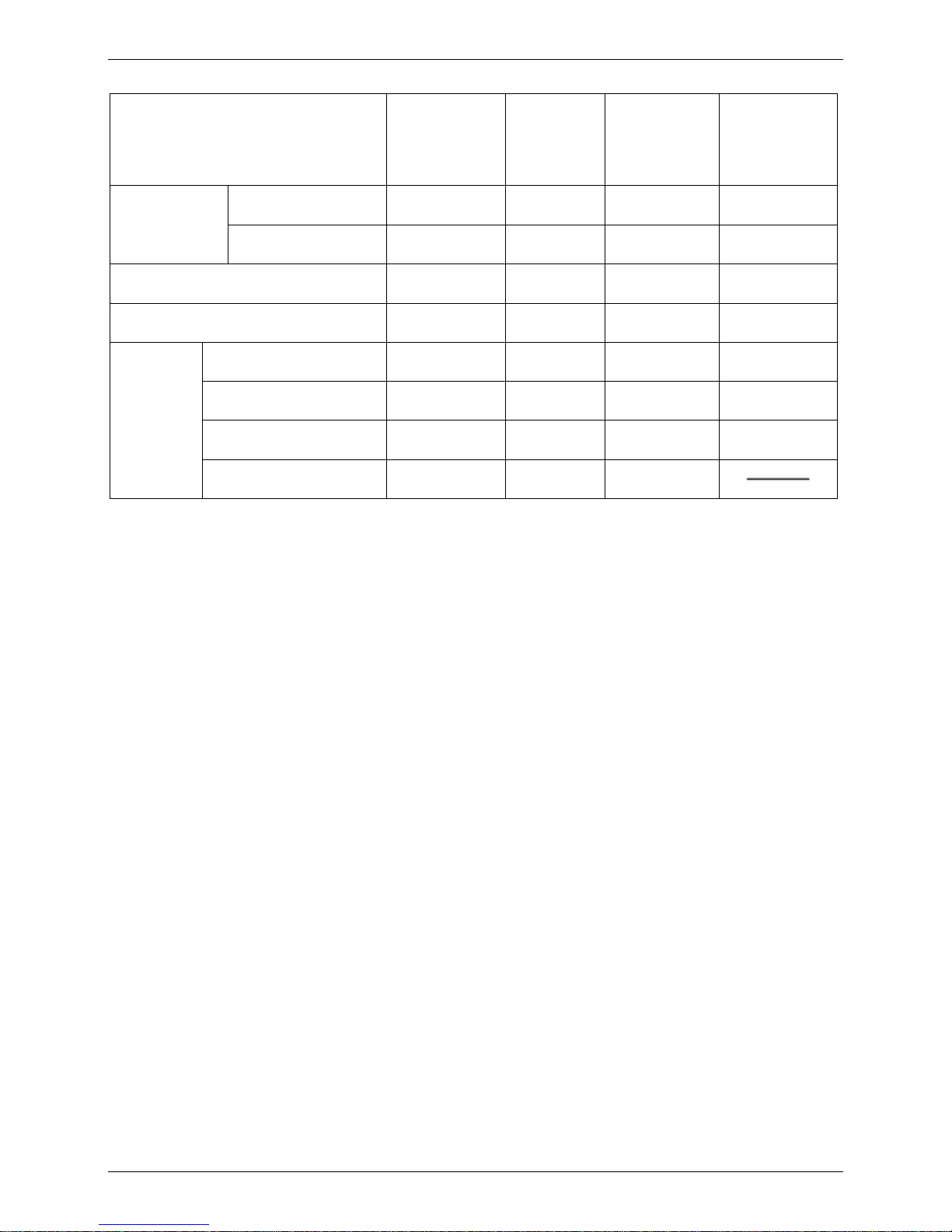

9. The Specification of Power

Model

18000 Btu/h 24000 Btu/h

30000-36000

Btu/h

30000-60000

Btu/h

Power

Phase 1-Phase 1-Phase 1-Phase 3-Phase

Frequency and Volt

220-240V,50Hz 220-240V,50Hz 220-240V,50Hz 380-415V, 50Hz

Circuit Breaker/Fuse(A) 20/16 40/25 50/30 25/20

Indoor unit power wiring(mm²) 3×2.5 3×2.5 3×4.0 5×2.5

Indoor/outdoor

connecting

wiring(mm²

)

Ground wiring 2.5 2.5 4.0 2.5

Outdoor unit power wiring 3×2.5 3×2.5 3×4.0 5×2.5

Strong electric signal 2×1.0 3×1.0 3×1.0 3×1.0

Weak electric signal 2×0.75/2×0.5 2×0.2 2×0.2

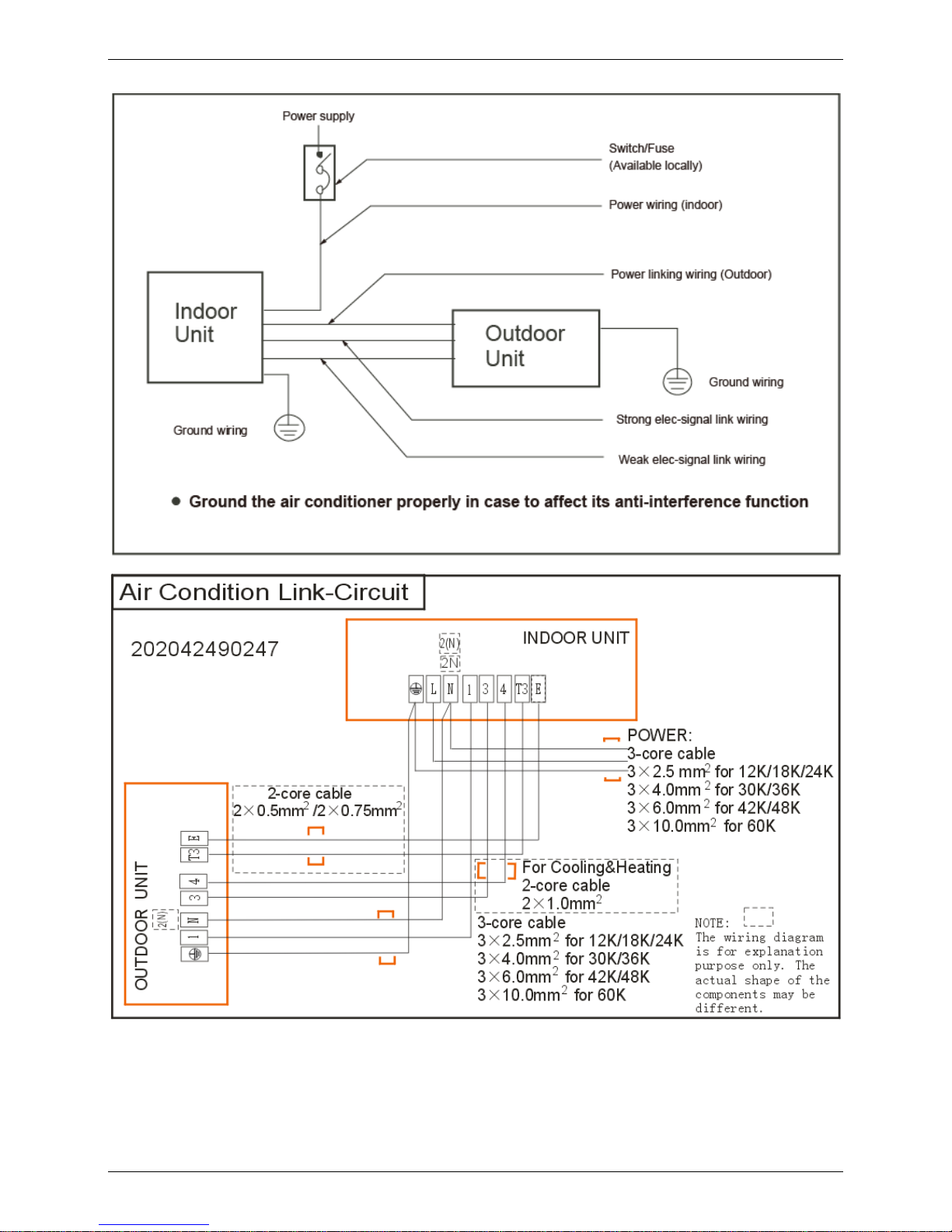

Field Wiring

Duct Type 23

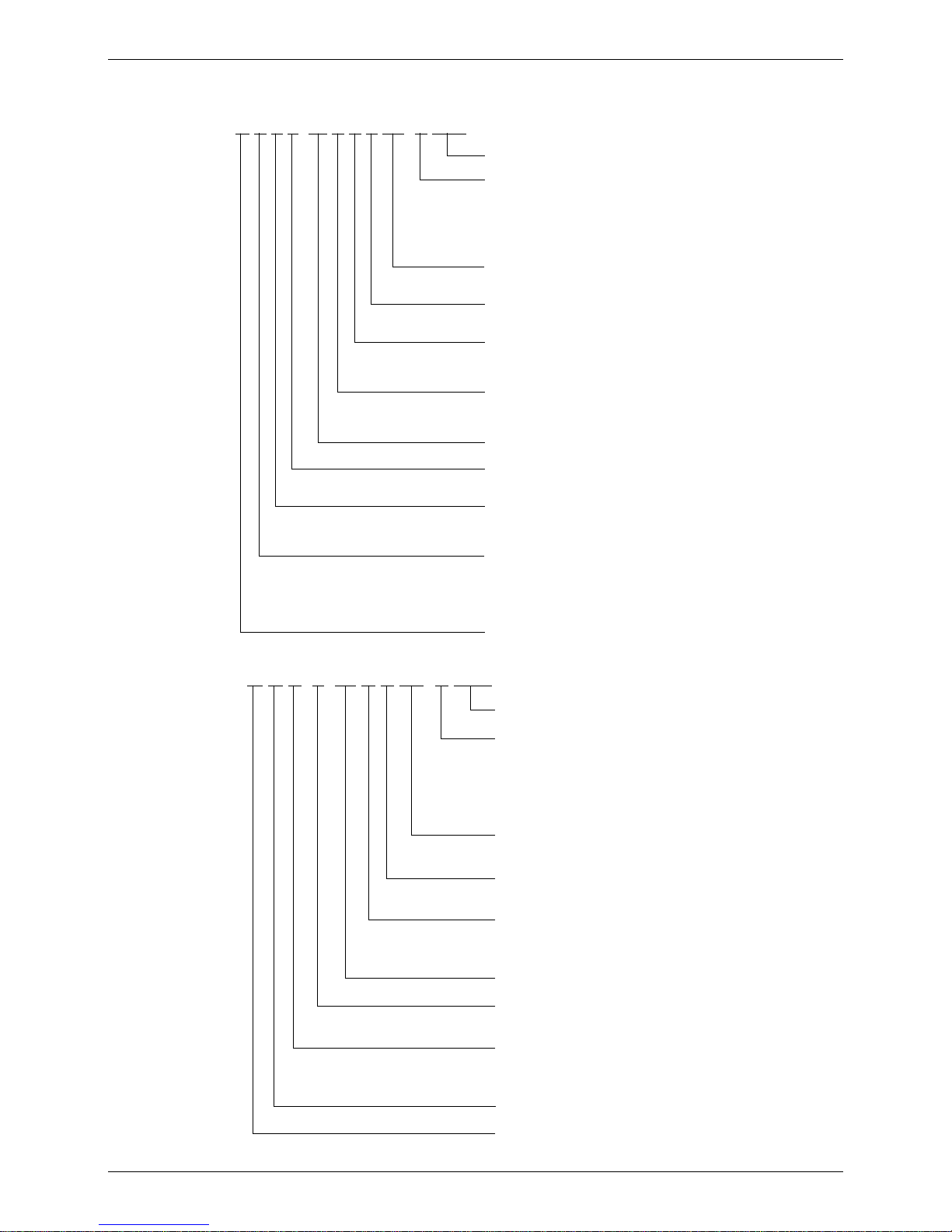

10. Field Wiring

MHF-18HWN1-Q

Field Wiring

24 Duct Type

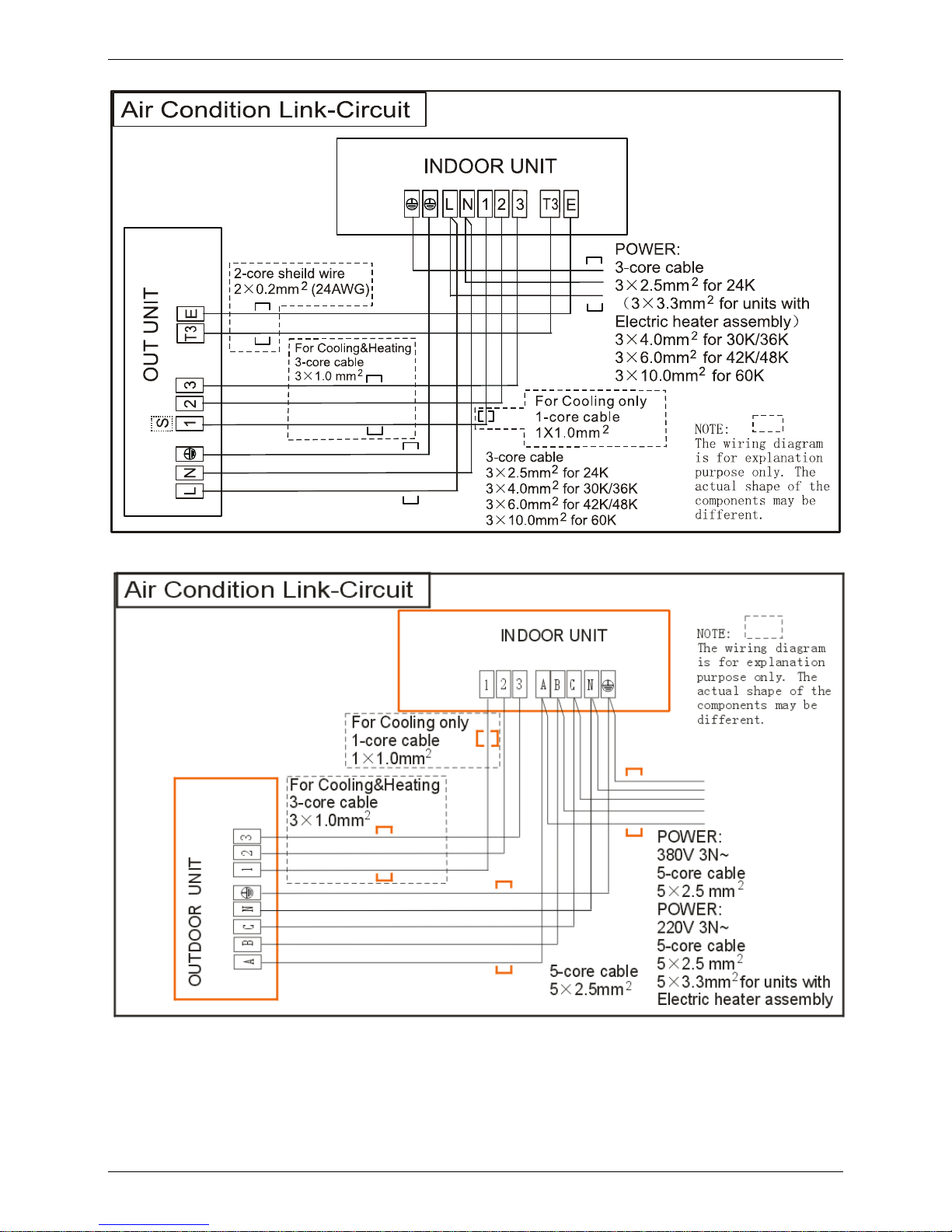

MHF-24HWN1-Q、MHF-30HWN1-Q、MHF-36HWN1-Q

MHF-30HWN1-R、MHF-36HWN1-R、MHF-48HWN1-R、MHF-60HWN1-R

Ceiling & Floor Type

Ceiling & Floor Type 25

Ceiling & Floor Type

1. Features ........................................................................... 26

2. Dimensions ...................................................................... 27

3. Service Space .................................................................. 28

4. Wiring Diagrams ............................................................. 29

5. Electric Characteristics .................................................. 31

6. Sound Levels ................................................................... 31

7. Accessories ..................................................................... 32

8. The Specification of Power ............................................ 32

9. Field Wiring ..................................................................... 33

Features

26 Ceiling & Floor Type

1. Features

1.1. New design, more modern and elegant appearance.

1.2. Convenient installation

--The ceiling type can be easily installed into a corner of the ceiling even if the ceiling is very narrow

--It is especially useful when installation of an air conditioner in the center of the ceiling is impossible

due to a structure such as one lighting.

1.3. Two direction auto swing (vertical & horizontal) and wide angle air flow,

--Air flow directional control minimizes the air resistance and produces wilder air flow to vertical

direction.

--The range of horizontal air discharge is widened which secures wider air flow distribution to provide

more comfortable air circulation no matter where the unit is set up

1.4. Three level fan speed, more humanism design, meets different air-supply requirement.

1.5. New foam drain pan with plastic-spraying inner surface

1.6. Easy operation.

1.7. Remote control and optional wired control method.

Dimensions

Ceiling & Floor Type 27

2. Dimensions

Capacity (Btu/h)

A B C D E

36K 1285 675 235 1200 220

48K, 60K 1650 675 235 1565 220

Service Space

28 Ceiling & Floor Type

3. Service Space

Wiring Diagrams

Ceiling & Floor Type 29

4. Wiring Diagrams

MUE-36HRN1-Q

Wiring Diagrams

30 Ceiling & Floor Type

MUE-36HRN1-R、MUE-48HRN1-R、MUE-60HRN1-R

Electric Characteristics

Ceiling & Floor Type 31

5. Electric Characteristics

Model

Indoor Units Power Supply

Hz Voltage Min. Max. MFA

MUE-36HRN1-Q 50 220-240V 198V 242V 30

MUE-36HRN1-R 50 380-420V 342V 440V 20

MUE-48HRN1-R 50 380-420V 342V 440V 20

MUE-60HRN1-R 50 380-420V 342V 440V 20

Remark:

MFA: Max. Fuse Amps. (A)

6. Sound Levels

Microphone

1m

1m

Air outlet side

1.5m

1m

Microphone

Ceiling Floor

Model

Noise level dB(A)

H M L

MUE-36HRN1-Q 53 48 44

MUE-36HRN1-R 53 48 44

MUE-48HRN1-R 53 48 44

MUE-60HRN1-R 54 49 46

Accessories

32 Ceiling & Floor Type

7. Accessories

Remote controller & Its

holder

1. Remote controller

1

2. Remote controller holder 1

3. Mounting screw (ST2.9×10-C-H) 2

4. Alkaline dry batteries (AM4) 2

Others

5. Owner's manual

1

6. Installation manual

1

7. Remote controller manual

1

8. The Specification of Power

Model

36000 Btu/h 30000-60000 Btu/h

Power

Phase 1-Phase 3-Phase

Frequency and Volt

220-240V,50Hz 380-415V, 50Hz

Circuit Breaker/Fuse(A) 50/30 25/20

Indoor unit power wiring(mm²) 3×4.0 5×2.5

Indoor/out-door connecting wiring(mm²)

Ground wiring 4.0 2.5

Outdoor unit power wiring 3×4.0 5×2.5

Strong electric signal 3×1.0 3×1.0

Weak electric signal 2×0.2

Field Wiring

Ceiling & Floor Type 33

9. Field Wiring

MUE-36HRN1-Q

Field Wiring

34 Ceiling & Floor Type

MUE-36HRN1-R、MUE-48HRN1-R、MUE-60HRN1-R

Super-slim Cassette Type

Super-slim Cassette Type 35

Super-slim Cassette Type

1. Features ...................................................................... 36

2. Dimensions ................................................................. 40

3. Service Space ............................................................. 41

4. Wiring Diagrams ......................................................... 42

5. Electric Characteristics ............................................. 46

6. Sound Levels .............................................................. 47

7. Accessories ................................................................ 48

8. The Specification of Power ....................................... 49

9. Field Wiring ................................................................. 50

Features

36 Super-slim Cassette Type

1. Features

1.1 Overview

Compact design, super slim body size, less space requiring in installation

Each louver can be separately controlled, more comfort air blowing is possible.

Auto-lifting panel design, more convenient to clean and maintain the filter. (optional)

Old Cassette New slim cassette Volume change

Dimension

18K-24K: 840*230*840 18K-24K: 840*205*840

11%↓

30K: 840*300*840 30K: 840*205*840

32%↓

36K-48K: 840*300*840 36K-48K: 840*245*840

18%↓

1.2

Fresh air intake function

Fresh air fulfills air quality more healthy and comfortable.

Ventilation motor is optional to increase the effect of fresh air.

Features

Super-slim Cassette Type 37

1.3 Optional ionizer generator

Ionizer generator is optional to get refreshing air to your room.

Ionizer can be switched on or off by remote controller.

When pressing the Clean Air button on the remote controller, Ionizer will work and the indicator light on

display board will shine.

New air-intake

IIoonniizzeerr ggeenneerraattoorr

ccoonnnneeccttoorr

VVeennttiillaattiioonn mmoottoorr

ccoonnnneeccttoorr

Features

38 Super-slim Cassette Type

1.4 External air duct design

Reserve external air duct, more flexible for the air supply.

1.5

Built-in draining pump

Due to the improvement of structure, more convenient to repair or replace the draining pump.

Built-in draining pump to make sure condensed water drain out reliably.

Draining Pump

Features

Super-slim Cassette Type 39

1.6 Terminals for alarm lamp and long-distance on-off controller connection are

standard

Reserve terminals for the connection of alarm lamp and long-distance on-off controller, more human

control.

1.7 Optional touch screen wired controller

Touch screen wired controller is optional, with error code indication function. Better

man-machine conversation interface.

Undated structure design, 4-way wire layout design, no raised part at backside, more convenient to

place the wires and install the device.

1.8 Twins Combination (inverter 18k-30k units only)

The units can be installed as Twin systems: one outdoor unit can connect with two indoor units. The

indoor units can be combined in any of the different available ratings.

Alarm lamp

Long-distance on-off controller

Dimensions

40 Super-slim Cassette Type

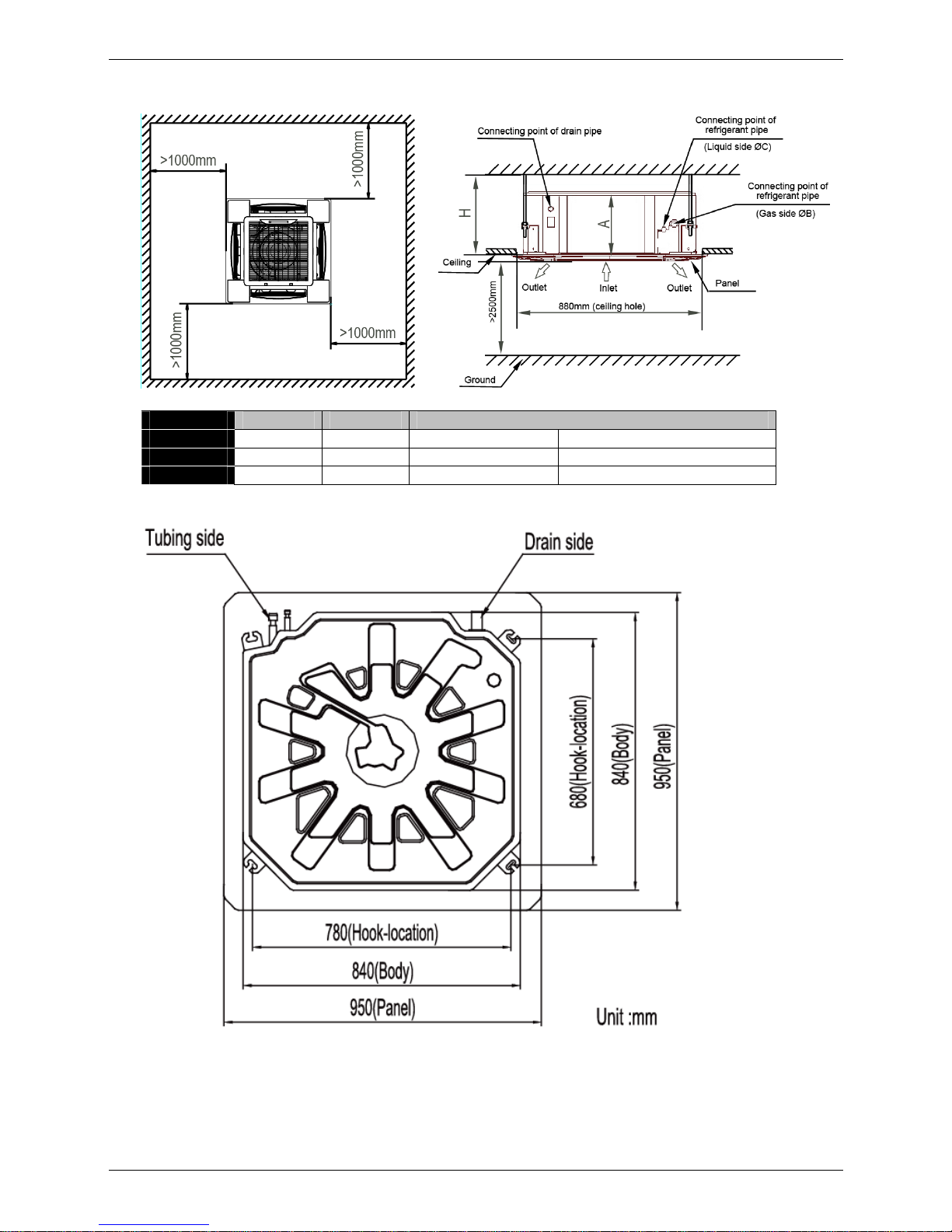

2. Dimensions

Model A H

18-30 205 >235

36-48 245 >275

60 287 >317

Service Space

Super-slim Cassette Type 41

3. Service Space

>1000 mm

>1000mm

>1000mm

>1000mm

Wiring Diagrams

42 Super-slim Cassette Type

4. Wiring Diagrams

MCD-18HRN1-Q

Wiring Diagrams

Super-slim Cassette Type 43

MCD-24HDN1-Q

Wiring Diagrams

44 Super-slim Cassette Type

MCD-36HDN1-R

Wiring Diagrams

Super-slim Cassette Type 45

MCD-48HDN1-R MCD-60HDN1-R

Electric Characteristics

46 Super-slim Cassette Type

5. Electric Characteristics

Model

Indoor Unit

Power

Supply

Hz Voltage Min Max MFA

MCD-18HRN1-Q

50 220-240V 198V 254V 16

MCD-24HRN1-Q

50 220-240V 198V 254V 25

MCD-36HRN1-R

50 380-420V 342V 440V 20

MCD-48HRN1-R

50 380-420V 342V 440V 20

MCD-60HRN1-R

50 380-420V 342V 440V 20

Notes:

MFA: Max. Fuse Amps. (A)

Sound Levels

Super-slim Cassette Type 47

6. Sound Levels

1.4m

Microphone

Model

Noise level dB(A)

H M L

MCD-18HRDN1-Q

37 34 32

MCD-24HRDN1-Q

43 41 38

MCD-36HRDN1-R

46 45 43

MCD-48HRDN1-R

48 46 45

MCD-60HRDN1-R

48 46 45

Accessories

48 Super-slim Cassette Type

7. Accessories

INSTALLATION FITTINGS

Name Shape Quantity

Installation paper board

1

Bolt M5 4

Tubing & Fittings Soundproof / insulation sheath

2

Drainpipe Fittings

Out-let pipe

1

Out-let pipe sheath

1

Out-let pipe clasp 1

Remote controller & Its

Frame

Remote controller & Its Frame

1

Remote controller holder 1

Mounting screw(ST2.9×10-C-H) 2

Remote controller manual 1

Alkaline dry batteries (AM4)

2

Others

Owner's manual

1

Installation manual 1

Network wires

1

Installation accessory

(The product you have

might not be provided the

following accessories

Expansible hook

4

Installation hook

4

Orifice

1

The Specification of Power

Super-slim Cassette Type 49

8. The Specification of Power

Model 18000 Btu/h 24000 Btu/h 36000-60000 Btu/h

Power

Phase 1-Phase 1-Phase 3-Phase

Frequency and Volt 220-240V,50Hz 220-240V,50Hz 380-415V, 50Hz

Circuit Breaker/Fuse(A) 20/16 40/25 25/20

Indoor unit power wiring(mm²) 3×2.5 3×2.5 5×2.5

Indoor/out-door

connecting

wiring(mm²)

Ground wiring 2.5 2.5 2.5

Outdoor unit power wiring 3×2.5 3×2.5 5×2.5

Strong electric signal 2×1.0 3×1.0 3×1.0

Weak electric signal 2×0.75/2×0.5 2×0.2

Field Wiring

50 Super-slim Cassette Type

9. Field Wiring

MCD-18HRN1-Q

Field Wiring

Super-slim Cassette Type 51

MCD-24HRN1-Q

MCD-36HRN1-R MCD-48HRN1-R MCD-60HRN1-R

High Static Pressure Duct Type

52 Indoor Units

High Static Pressure Duct Type

1. Features ............................................................................ 53

2. Dimensions ...................................................................... 54

3. Service Space .................................................................. 55

4. Wiring Diagrams ............................................................. 56

5. Static Pressure ................................................................ 57

1. Electric Characteristics .................................................. 58

6. Sound Levels ................................................................... 59

7. Accessories ..................................................................... 60

8. The Specification of Power ............................................ 61

9. Field Wiring ..................................................................... 62

Features

High Static Pressure Duct Type 53

1. Features

1.1 High static pressure design

Max static pressure of indoor unit is 200Pa.

The longest distance of air supply is 14m, the max height of air supply is 6.5m.

Specially recommended for spacious and large rooms like large stores and factories.

1.2 Easy maintenance

The unit can be opened from top or bottom.

The air outlet flange is isolated from either top panel or base panel, which makes the maintenance

much easier when connecting duct.

1.3 Flexible Installation

Different solutions for any shape room by using kinds of air distribution ducts.

L-shaped

Areas far

Y-sha

p

ed

High static pressure design enables long duct.

Outle

t

The height of air

supply is 6.5m

Max. 14m long distance

Indoor Unit

Fresh

Air Intake

Intak

e

Dimensions

54 High Static Pressure Duct Type

2. Dimensions

24K-48K

Capacity

(KBtu)

Outline dimension

Size of

mounted lug

Air outlet opening size Air inlet opening size

A B C D E F G H I J K L M N O

24 450 1110 270 397 1146 1054 185 220 960 120 1075 875 315 110 242

(Unit: mm)

Service Space

High Static Pressure Duct Type 55

3. Service Space

Ensure enough space required for installation and maintenance.

500mm or more

600mm or more

Indoor unit

600mmx600mm

Maintenance and repair space

Wiring Diagrams

56 High Static Pressure Duct Type

4. Wiring Diagrams

MHG-24HWN1-Q

Static Pressure

High Static Pressure Duct Type 57

5. Static Pressure

24,000Btu/h

Electric Characteristics

58 High Static Pressure Duct Type

6. Electric Characteristics

Model

Indoor Unit Power Supply

Hz Voltage Min. Max. MFA

MHG-24HWN1-Q

50 220-240 198 254 25

Notes:

MFA: Max. Fuse Amps. (A)

Sound Levels

High Static Pressure Duct Type 59

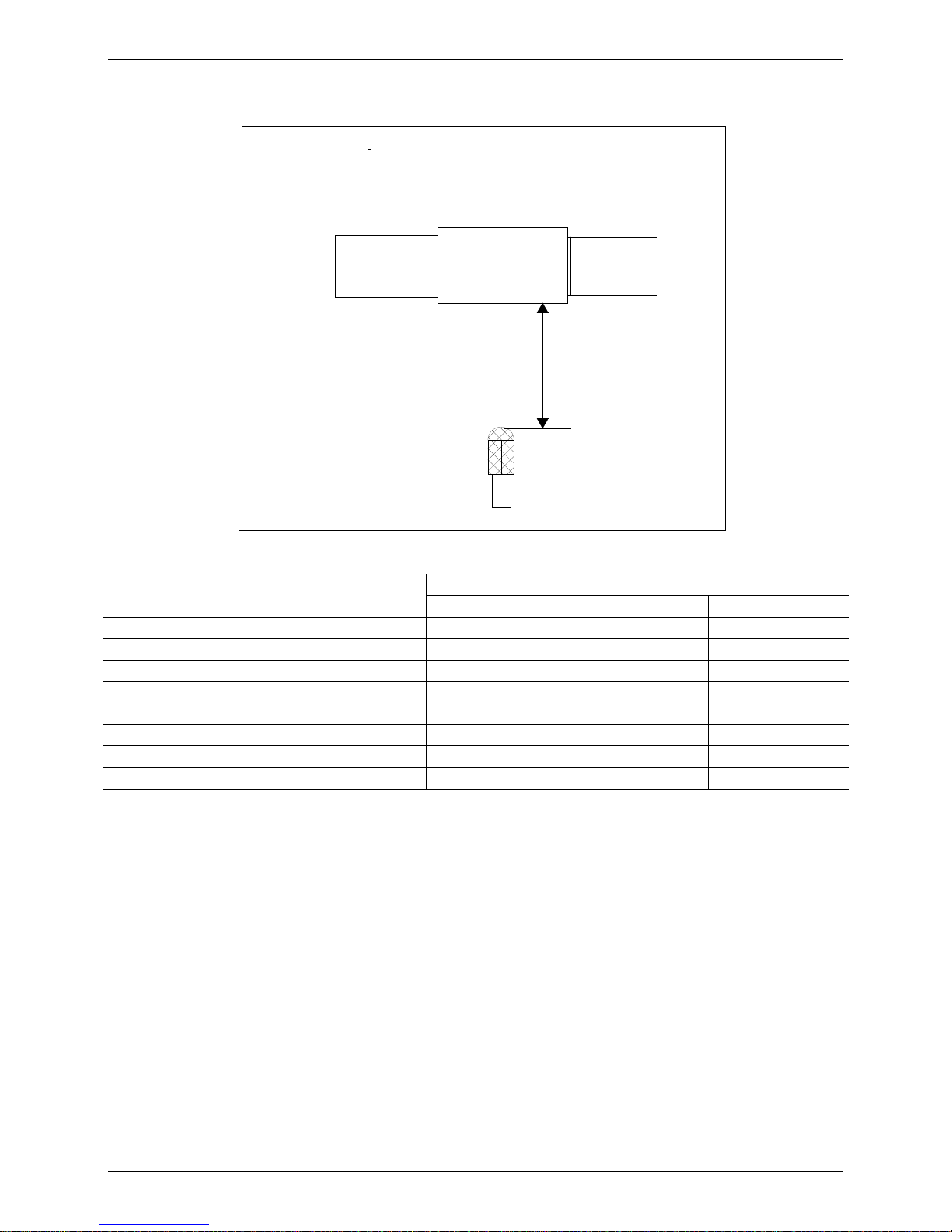

7. Sound Levels

Suction

Discharge

Microphone

1.5m

Concealed Duct Type

DuctDuct

Model

Noise level dB(A)

H M L

MHG-24HWN1-Q

48 44 39

Accessories

60 High Static Pressure Duct Type

8. Accessories

Tubing & Fittings

Name Shape Quantity

Soundproof / insulation sheath

2

Drainpipe Fittings

(for cooling & heating)

Drain joint

1

Seal ring

1

Wired controller & Its Frame

Wired controller

1

Owner,s manual of wired controller

1

Wired controller installation manual

1

Others

Owner,s manual

1

Installation manual

1

The Specification of Power

High Static Pressure Duct Type 61

9. The Specification of Power

Model 24000 Btu/h

Power

Phase 1-Phase

Frequency and Volt 220-240V,50Hz

Circuit Breaker/Fuse(A) 40/25

Indoor unit power wiring(mm²) 3×2.5

Indoor/out-door connecting wiring(mm²)

Ground wiring 2.5

Outdoor unit power wiring 3×2.5

Strong electric signal 3×1.0

Weak electric signal 2×0.2

Field Wiring

62 High Static Pressure Duct Type

10. Field Wiring

MHG-24HWN1-Q

Outdoor Units

Outdoor Units 63

Part 3

Outdoor Units

1. Dimensions ...................................................................... 64

2. Service Space .................................................................. 66

3. Piping Diagrams .............................................................. 67

4. Wiring Diagrams .............................................................. 69

5. Electric Characteristics ................................................... 75

6. Operation Limits .............................................................. 76

7. Sound Levels ................................................................... 77

Dimensions

64 Outdoor Units

1. Dimensions

Model

Unit:mm

A B C D E F H

MOU-18HN1-Q 760 530 290 315 270 285 590

MOU-24HN1-Q 845 560 335 360 312 320 700

MOU-30HN1-Q 990 624 366 396 340 345 965

MOU-30HN1-R 990 624 366 396 340 345 965

MOU-36HN1-Q 990 624 366 396 340 345 965

MOU-36HN1-R 990 624 366 396 340 345 965

Dimensions

Outdoor Units 65

Model

Unit:mm

A B C D E F H

MOU-48HN1-R 900 590 378 400 330 350 1170

MOUA-60HN1-R 900 590 378 400 330 350 1170

Service Space

66 Outdoor Units

2. Service Space

More than 60cm

More than 30cm

More than 60cm

More than 200cm

Air inlet

Air inlet

More than 30cm

Air outlet

(Wall or obstacle)

Maintain channel

Piping Diagrams

Outdoor Units 67

3. Piping Diagrams

MOU-18HN1-Q、MOU-24HN1-Q、MOU-30HN1-Q、MOU-30HN1-R

LIQUID SIDE

GAS SIDE

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

2-WAY VALVE

3-WAY VALVE

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

T1 Room temp.

sensor

T3 Condenser

temp. sensor

INDOOR OUTDOOR

T4 Ambient

temp. sensor

CHECK VALVE

(Heating Model only)

CAPILIARY TUBE

MOU-36HN1-Q、MOU-36HN1-R

LIQUID SIDE

GAS SIDE

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

2-WAY VALVE

3-WAY VALVE

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

T1 Room temp.

sensor

T3 Condenser

temp. sensor

ACCUMULATOR

INDOOR OUTDOOR

T4 Ambient

temp. sensor

CHECK VALVE

(Heating Model only)

CAPILIARY TUBE

T5 Discharge temp. sensor

Piping Diagrams

68 Outdoor Units

MOU-48HN1-R、MOUA-60HN1-R

LIQUID SIDE

GAS SIDE

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

Compressor

2-WAY VALVE

3-WAY VALVE

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

T1 Room temp.

sensor

T3 Condenser

temp. sensor

Accumulator

T5 Discharge temp. sensor

High pressure switch

T4 Ambient

temp. sensor

Low pressure

switch

INDOOR OUTDOOR

Oil return Capillary

Oil separator

CHECK VALVE

(Heating Model only)

CAPILIARY TUBE

Wiring Diagrams

Outdoor Units 69

4. Wiring Diagrams

MOU-18HN1-Q

Wiring Diagrams

70 Outdoor Units

MOU-24HN1-Q

MOU-30HN1-Q

Wiring Diagrams

Outdoor Units 71

MOU-30HN1-R

MOU-36HN1-Q

Wiring Diagrams

72 Outdoor Units

MOU-36HN1-R

Wiring Diagrams

Outdoor Units 73

MOU-48HN1-R

Wiring Diagrams

74 Outdoor Units

MOUA-60HN1-R

Electric Characteristics

Outdoor Units 75

5. Electric Characteristics

Model

Outdoor Unit

Hz Voltage Min. Max.

MOU-18HN1-Q 50 220~240V 198V 254V

MOU-24HN1-Q 50 220~240V 198V 254V

MOU-30HN1-Q 50 220~240V 198V 254V

MOU-30HN1-R 50 380~420V 342V 440V

MOU-36HN1-Q 50 220~240V 198V 254V

MOU-36HN1-R 50 380~420V 342V 440V

MOU-48HN1-R 50 380~420V 342V 440V

MOUA-60HN1-R 50 380~420V 342V 440V

Operation Limits

76 Outdoor Units

6. Operation Limits

Temperature

Mode

Cooling operation Heating operation

Room temperature 17℃~32℃ 0℃~30℃

Outdoor temperature

18℃~43℃

-7℃~24℃

(-7℃~43℃:For the

models with low

temperature cooling

system)

10 15 25 30 3520

15

20

25

30

35

40

45

Indoor temperature(℃ WB)

Outdoor temperature(℃ DB)

STD

Cooling

43

17 32

10

5

0

-5

-10

18

-7

With Low

Ambient

Cooling

System

10 15 25 3020

15

20

25

Indoor temperature(℃ WB)

Outdoor temperature(℃ DB)

Heating

10

5

0

-5

-10

24

-7

05

STD

Sound Levels

Outdoor Units 77

7. Sound Levels

Microphone

Outdoor Unit

H

1.0m

Note: H= 0.5 × height of outdoor unit

Model Noise level dB(A)

MOU-18HN1-Q 58

MOU-24HN1-Q 59

MOU-30HN1-Q 64

MOU-30HN1-R 63

MOU-36HN1-Q 57

MOU-36HN1-R 57

MOU-48HN1-R 59

MOUA-60HN1-R 59.3

Installation

78 Installation

Part 4

Installation

1. Installation Procedure ..................................................... 79

2. Location selection ........................................................... 80

3. Indoor unit installation .................................................... 81

4. Outdoor unit installation (Side Discharge Unit) ............ 93

5. Refrigerant pipe installation ........................................... 95

6. Drainage pipe installation ............................................... 96

7. Vacuum Drying and Leakage Checking ...................... 100

8. Additional refrigerant charge ....................................... 101

9. Engineering of insulation ............................................. 101

10. Engineering of electrical wiring ................................... 102

11. Test operation ................................................................ 103

Insulation Work

Installation 79

1. Installation Procedure

Vacuum drying and leakage checking

Additional refrigerant charge

Insulation the joint part of refrigerant pipe

Wiring connection and electric safety checking

Test operation

Refrigerant pipe

installation and insulation

Drainage pipe installation

and insulation

Indoor unit installation

location selection

Outdoor unit installation

location selection

Indoor unit installation Outdoor unit installation

Refrigerant pipe

installation and insulation

Drainage pipe installation

and insulation

Location selection

80 Installation

2. Location selection

2.1 Indoor unit location selection

The place shall easily support the indoor unit’s weight.

The place can ensure the indoor unit installation and inspection.

The place can ensure the indoor unit horizontally installed.

The place shall allow easy water drainage.

The place shall easily connect with the outdoor unit.

The place where air circulation in the room should be good.

There should not be any heat source or steam near the unit.

There should not be any oil gas near the unit

There should not be any corrosive gas near the unit

There should not be any salty air neat the unit

There should not be strong electromagnetic wave near the unit

There should not be inflammable materials or gas near the unit

There should not be strong voltage vibration.

2.2 Outdoor unit location selection

The place shall easily support the outdoor unit’s weight.

Locate the outdoor unit as close to indoor unit as possible

The piping length and height drop can not exceed the allowable value.

The place where the noise, vibration and outlet air do not disturb the neighbors.

There is enough room for installation and maintenance.

The air outlet and the air inlet are not impeded, and not face the strong wind.

It is easy to install the connecting pipes and cables.

There is no danger of fire due to leakage of inflammable gas.

It should be a dry and well ventilation place

The support should be flat and horizontal

Do not install the outdoor unit in a dirty or severely polluted place, so as to avoid blockage of the heat

exchanger in the outdoor unit.

If is built over the unit to prevent direct sunlight, rain exposure, direct strong wend, snow and other scraps

accumulation, make sure that heat radiation from the condenser is not restricted.

More than 30cm

More than 60cm

More than 70cm

More than 30cm

More than 60cm

(Service space

︶

F

e

n

c

e

o

r

o

b

s

t

a

c

l

e

s

Insulation Work

Installation 81

3. Indoor unit installation

3.1 A5 high static pressure duct indoor unit installation

3.1.1 Service space for indoor unit

3.1.2 Bolt pitch

Capacity (KBtu)

Size of outline dimension mounted plug

L M

18/24 960 350

30/36 1180 490

48/60 1240 500

3.1.3 Install the pendant bolt

Select the position of installation hooks according to the hook holes positions showed in upper picture.

Indoor unit installation

82 Installation

Drill four holes of Ø12mm, 45~50mm deep at the selected positions on the ceiling. Then embed the

expansible hooks (fittings).

3.1.4 Install the main body

Make the 4 suspender through the 4 hanger of the main body to suspend it. Adjust the hexangular nuts on

the four installation hooks evenly, to ensure the balance of the body. Use a leveling instrument to make sure

the levelness of the main body is within ±1°.

3.1.5 Install the air filter

Insert the air filter through the filter slot and fix it with 2 screws.

3.1.6 Install the air duct

Please design the air duct as below recommended picture

Insulation Work

Installation 83

3.1.7 Change the air inlet direction

① Take off ventilation panel and flange, cut off the staples at side rail.

② Stick the attached seal sponge as per the indicating place in the following fig, and then change the

mounting positions of air return panel and air return flange .

③ When install the filter mesh, please plug it into flange inclined from air return opening, and then push up.

④ The installation has finish, upon filter mesh which fixing blocks have been insert to the flange positional

holes.

Indoor unit installation

84 Installation

3.2 Ceiling & floor indoor unit installation

3.2.1 Service space for indoor unit

3.2.2 Bolt pitch

① Ceiling installation

Capacity (Btu/h)

D E

36K 1200 220

48K, 60K 1565 220

② Wall-mounted installation

Insulation Work

Installation 85

3.2.3 Install the pendant bolt

① Ceiling installation

Select the position of installation hooks according to the hook holes positions showed in upper picture.

Drill four holes of Ø12mm, 45~50mm deep at the selected positions on the ceiling. Then embed the

expansible hooks (fittings).

② Wall-mounted installation

Install the tapping screws onto the wall.(Refer to picture below)

3.2.4 Install the main body

① Ceiling installation (The only installation method for the unit with drain pump)

Remove the side board and the grille.

Indoor unit installation

86 Installation

Locate the hanging arm on the hanging screw bolt. Prepare the mounting bolts on the unit.

Put the side panels and grilles back.

② Wall-mounted installation

Hang the indoor unit by insert the tapping screws into the hanging arms on the main unit. (The bottom of

body can touch with floor or suspended, but the body must install vertically.)

Insulation Work

Installation 87

3.3 Super-slim cassette indoor unit installation

3.3.1 Service space for indoor unit

Model A H Remark

18-30 205 >235 R410A and R22 Cooling / Cooling & Heating

36-48 245 >275 R410A and R22 Cooling / Cooling & Heating

48-60 287 >317 R410A and R22 Cooling / Cooling & Heating

3.3.2 Bolt pitch

3.3.3 Install the pendant bolt

Select the position of installation hooks according to the hook holes positions showed in upper picture.

Drill four holes of Ø12mm, 45~50mm deep at the selected positions on the ceiling. Then embed the

expansible hooks (fittings).

Indoor unit installation

88 Installation

3.3.4 Install the main body

Make the 4 suspender through the 4 hanger of the main body to suspend it. Adjust the hexangular nuts on

the four installation hooks evenly, to ensure the balance of the body. Use a leveling instrument to make sure

the levelness of the main body is within ±1°.

Adjust the position to ensure the gaps between the body and the four sides of ceiling are even. The body's

lower part should sink into the ceiling for 10~12 mm. In general, L is half of the screw length of the

installation hook.

Locate the air conditioner firmly by wrenching the nuts after having adjusted the body's position well.

3.3.5 Install the panel

Remove the grille

Insulation Work

Installation 89

Remove the 4 corner covers.

Hang the panel to the hooks on the mainbody. If the panel is with auto-lift grille, please watch the ropes lifing

the grille, DO NOT make the ropes enwinded or blocked.

Tighten the screws under the panel hooks till the panel closely stick on the ceiling to avoid condensate

water.

Indoor unit installation

90 Installation

Hang the air-in grill to the panel, then connect the lead terminator of the swing motor and that of the control

box with corresponding terminators on the body respectively.

Install the 4 corner covers back.

Note: The panel shall be installed after the wiring connected.

Insulation Work

Installation 91

3.4 HESP duct indoor unit installation

3.4.1 Service space for indoor unit

500mm or more

600mm or more

Indoor unit

600mmx600mm

Maintenance and repair space

3.4.2 Bolt pitch

Capacity

(KBtu)

Size of mounted lug

D E

24 397 1146

Indoor unit installation

92 Installation

3.4.3 Install the pendant bolt

Select the position of installation hooks according to the hook holes positions showed in upper picture.

Drill four holes of Ø12mm, 45~50mm deep at the selected positions on the ceiling. Then embed the

expansible hooks (fittings).

3.4.4 Install the main body

Make the 4 suspender through the 4 hanger of the main body to suspend it. Adjust the hexangular nuts on

the four installation hooks evenly, to ensure the balance of the body. Use a leveling instrument to make sure

the levelness of the main body is within ±1°.

3.4.5 Install the air duct

Please design the air duct as below recommended picture

Insulation Work

Installation 93

4. Outdoor unit installation (Side Discharge Unit)

4.1 Service space for outdoor unit

4.2 Bolt pitch

Model B C D

MOU-18HN1-Q 530 290 315

MOU-24HN1-Q

560 335 360

MOU-30HN1-Q 624 366 396

MOU-30HN1-R 624 366 396

MOU-36HN1-Q

624 366 396

Outdoor unit installation (Side Discharge Unit)

94 Installation

MOU-36HN1-R 624 366 396

MOU-48HN1-R

590 378 400

MOUA-60HN1-R 590 378 400

4.3 Install the Unit

Since the gravity center of the unit is not at its physical center, so please be careful when lifting it with a sling.

Never hold the inlet of the outdoor unit to prevent it from deforming.

Do not touch the fan with hands or other objects.

Do not lean it more than 45, and do not lay it sidelong.

Make concrete foundation according to the specifications of the outdoor units.

Fasten the feet of this unit with bolts firmly to prevent it from collapsing in case of earthquake or strong wind.

Insulation Work

Installation 95

5. Refrigerant pipe installation

5.1 Maximum pipe length and height drop

Considering the allowable pipe length and height drop to decide the installation position. Make sure the

distance and height drop between indoor and outdoor unit not exceeded the date in the following table.

Model Max. Length Max. Elevation

18,000Btu/h ~24,000Btu/h 25m 12m

30,000Btu/h 25m 15m

36,000Btu/h 30m 20m

48,000Btu/h~60,000Btu/h 50m 25m

5.2 The procedure of connecting pipes

5.2.1 Choose the pipe size according to the specification table.

5.2.2 Confirm the cross way of the pipes.

5.2.3 Measure the necessary pipe length.

5.2.4 Cut the selected pipe with pipe cutter

Make the section flat and smooth.

90

Lean

Crude

Burr

o

5.2.5 Insulate the copper pipe

Before test operation, the joint parts should not be heat insulated.

5.2.6 Flare the pipe

Insert a flare nut into the pipe before flaring the pipe

According to the following table to flare the pipe

Pipe diameter

Flare dimension A (mm)

Flare shape

Min Max

1/4" (6.35) 8.3 8.7

R0.4~0.8

A

4

5

°

90°

4

-

+

3/8" (9.52) 12.0 12.4

1/2" (12.7) 15.4 15.8

5/8" (15.9) 18.6 19.1

3/4" (19) 22.9 23.3

After flared the pipe, the opening part must be seal by end cover or adhesive tape to avoid duct or

exogenous impurity come into the pipe.

5.2.7 Drill holes if the pipes need to pass the wall.

5.2.8 According to the field condition to bend the pipes so that it can pass the wall smoothly.

5.2.9 Bind and wrap the wire together with the insulated pipe if necessary.

Drainage pipe installation

96 Installation

5.2.10 Set the wall conduit

5.2.11 Set the supporter for the pipe.

5.2.12 Locate the pipe and fix it by supporter

For horizontal refrigerant pipe, the distance between supporters should not be exceed 1m.

For vertical refrigerant pipe, the distance between supporters should not be exceed 1.5m.

5.2.13 Connect the pipe to indoor unit and outdoor unit by using two spanners.

Be sure to use two spanners and proper torque to fasten the nut, too large torque will damage the

bellmouthing, and too small torque may cause leakage. Refer the following table for different pipe

connection.

Pipe Diameter

Torque Sketch map

(kgf.cm) (N.cm)

1/4" (6.35) 144~176 1420~1720

3/8" (9.52) 333~407 3270~3990

1/2" (12.7) 504~616 4950~6030

5/8" (15.9) 630~770 6180~7540

3/4" (19) 990~1210 9270~11860

6. Drainage pipe installation

Install the drainage pipe as shown below and take measures against condensation. Improperly installation

could lead to leakage and eventually wet furniture and belongings.

6.1 Installation principle

Ensure at least 1/100 slope of the drainage pipe

Adopt suitable pipe diameter

Adopt nearby condensate water discharge

6.2 Key points of drainage water pipe installation

6.2.1 Considering the pipeline route and elevation

Before installing condensate water pipeline, determine its route and elevation to avoid intersection with

other pipelines and ensure slope is straight.

6.2.2 Drainage pipe selection

The drainage pipe diameter shall not small than the drain hose of indoor unit

According to the water flowrate and drainage pipe slope to choose the suitable pipe, the water flowrate

is decided by the capacity of indoor unit.

Relationship between water flowrate and capacity of indoor unit

Capacity (x1000Btu) Water flowrate (l/h)

12 2.4

18 4

24 6

30 7

36 8

42 10

48 12

60 14

Loading...

Loading...