Page 1

Midea

Cooker Hood

Instructions

MODEL: MHC60GSS

MHC90GSS

Read the instructions carefully before using your cooker hood, and keep them carefully.

If you follow the instructions, your cooker hood will serve you many years well.

SAVE THESE INSTRUCTIONS CAREFULLY

Page 2

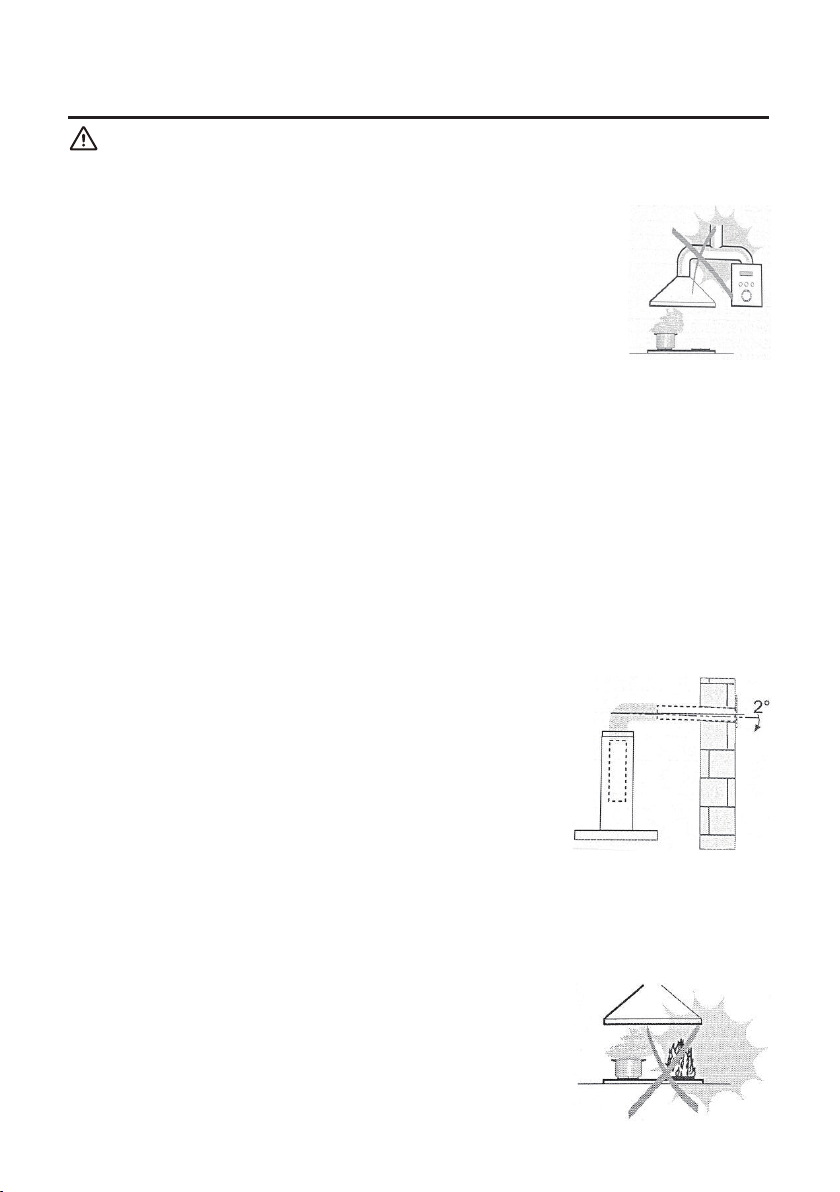

RECOMMENDATIONS AND SUGGESTIONS

The instructions apply to several versions of this appliance. Accordingly, you may nd

descriptions of individual features that do not apply to your appliance.

INSTALLATION

● The manufacturer will not be held liable for any damages resulting from incorrect or

improper installation.

● The minimum distance between the supporting surface for the cooking vessels on the

hob and the lowest part of the cooker hood. (When the cooker hood is located above

a gas appliance, the distance shall be at least 65 cm. If the installation instructions for

the gas hob specify a greater distance, it has to be taken into account. The distance

of 65 cm can be reduced for non-combustible parts of the cooker hood and parts

operating at safety extra low voltage, provided these parts do not give access to live

parts if deformed.)

● Check that the mains voltage corresponds to that indicated on the rating plate xed to

the inside of the hood.

● For Class I appliances, check that the domestic power supply guarantees adequate earthing.

● Connect the extractor to the exhaust ue through a pipe with the minimum diameter of 120 mm.

● The route of the ue must be as short as possible.

● The air must not be discharged into a ue that is used for exhausting fumes from appliances, burning gas or

other fuels.

● If the extractor is used in conjunction with non-electrical appliances (e.g. gas burning appliances), a sufcient

degree of aeration must be guaranteed in the room in order to prevent backow of the exhaust gas. The

kitchen must have an opening communicating directly with the open air in order to guarantee the entry of

clean air.

● When the cooker hood is used in conjunction with appliances supplied with energy other than electric, the

negative pressure in the room must not exceed 0.04 mbar to prevent fumes being drawn back into the room

by the cooker hood.

● If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualied

persons in order to avoid a hazard.

● Regulations concerning the discharge of air have to be fullled.

USE

● The cooker hood is only for home use, not suitable for barbecue, roast shop

and other commercial purposes.

● Never use the hood for purposes other than those intended.

● Never leave high naked ames under the hood when it is in operation.

● Adjust the ame intensity to direct the the ame upto the bottom of a pan only,

making sure that it does not engulf the sides.

● Deep fat fryers must be continuously monitored during use: overheated oil

can burst into ames.

● Do not ame under the cooker hood, with a risk of re.

● This appliance can be used by children aged 8 and above and persons with

reduced physical, sensory or mental capabilities or lacking experience and

knowledge if they have been given supervision or instruction concerning use of the appliance in a safe way

and understood the hazards involved.

● Children should be supervised to ensure that they do not play with the appliance.

● Cleaning and maintenance shall not be made by children without supervision.

● “CAUTION: Accessible parts may become hot when used with cooking appliances”.

MAINTENANCE

● The cooker hood and its lter should be cleaned regularly according to the

instructions.

● Switch off or unplug the appliance from the mains supply before carrying out

any maintenance work.

● Clean and/or replace the lters after the specied period (re hazard).

● Clean the hood using a damp cloth and a neutral liquid detergent.

● The appliance uses 4 hob elements at most.

2

Page 3

COMPONENTS

Ref. Qty. Product Components

1 1

2.1 1 Lower Decorative Chimney

2.2 1 Upper Decorative Chimney

4 1 Exhaust Pipe

5 2 Activated Charcoal Filter (optional)

Ref. Qty. Installation Components

10 7 Screws 5x50

11 7 Wall Plug

12 6 Screw 4,2x9,5/2 Spare

13 4 Screw M4 x 20

14 4 Decorative Washer

15 4 Spare

20 1 Hood Fixing Bracket (optional )

21 2 Chimney Fixing Bracket (0 / 1 optional)

Hood Body, complete with Control,

Light, Blower, Filter.

2.2

2.1

1

20

21

12

13

4

3

5

10

11

Qty. Documentation

1 Instruction Manual

15

14

3

Page 4

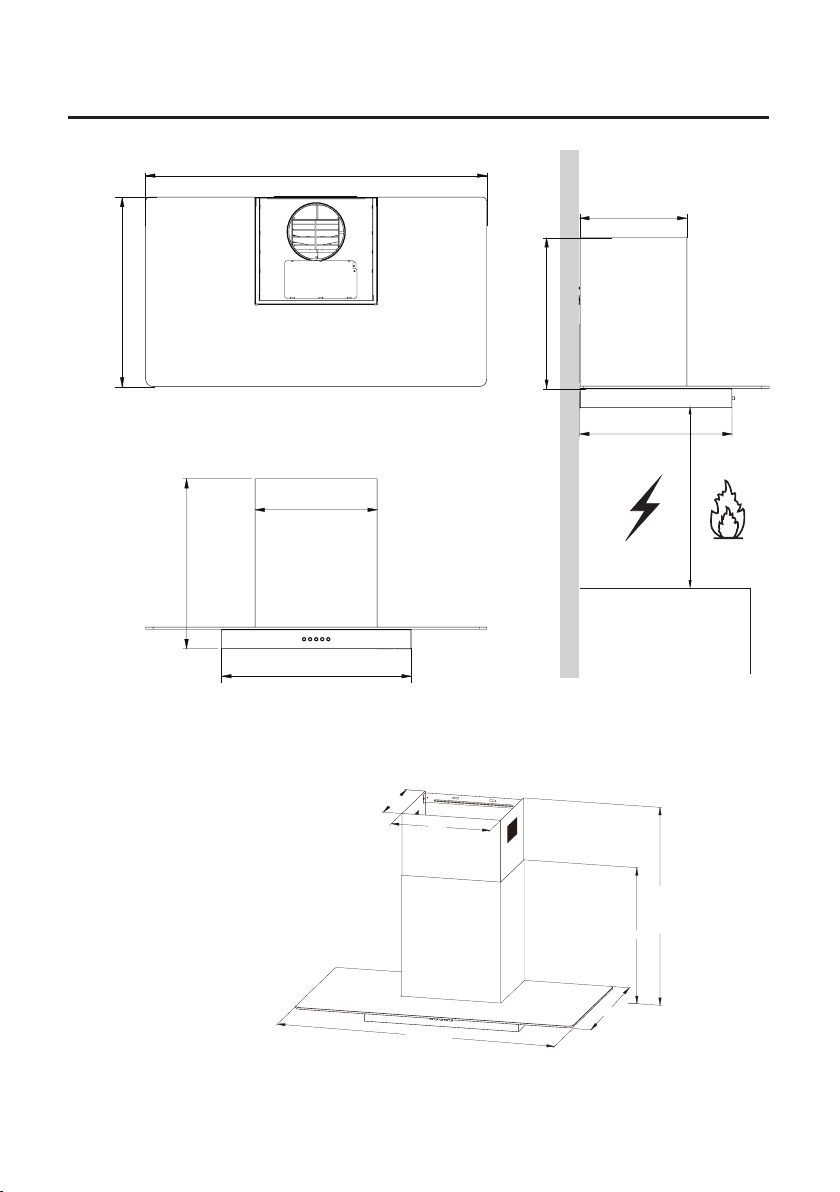

COMPONENTS

500

600/900

282

391

401

322

448

500

282

322

600/900

500

Min.

650mm

min.

448

max.

828

448

Min.

650mm

4

Page 5

INSTALLATION

WALL DRILLING AND BRACKET FIXING

As the rst step, proceed with the following drawings:

● A vertical line up to the ceiling or up to the upper limit, at the center of the area in which the

hood is to be tted.

● A horizontal line A at 1083-1183 mm above the cooker top.

● A horizontal line B at 30-377 mm above the horizontal line A.

● A horizontal line C at 118 mm below the horizontal line A.

Mark points:

● Mark a point (1) on the horizontal line A, 60 mm to the vertical reference line.

● Repeat this operation on the other side and on the vertical reference line, checking that the

three marks are on one horizontal line.

● Mark a point (2) on the horizontal line B, 60 mm to the vertical reference line.

● Repeat this operation on the other side, checking that the two marks are on one horizontal line.

5

Page 6

● Mark a point (3) on the horizontal line C, 80 mm to the vertical reference line.

● Repeat this operation on the other side, checking that the two marks are on one horizontal line.

Fix the brackets (optional):

● Drill holes at the marked points with a ɸ10 mm drill bit.

● Insert the wall plugs 11 into the holes.

● Fix the hood xing bracket 20 with 3 screws 10 (5 x 50) at the horizontal line A,

● Fix the chimney xing bracket 21 with 2 screws 10 (5 x 50) at the horizontal line B.

Hook the hood body

Hook the hood body to the bracket 20.

Level the hood body itself.

Lock screws (M5*12) into the hood xing bracket to prevent the hood body from accidentally sliding off.

Remove the lter from the inside of the hood body, and x the screw 10 to wall plug 11 at the point

(3) (optional).

Right Wrong

CONNECTIONS

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to the

chimney using either a exible or a rigid pipe of ɸ 150 or ɸ 120 mm,

the choice of which is left to the installer.

● Insert the reducer ange 3 onto the hood body outlet to install a

ɸ 120 mm air exhaust connection.

● Fix the pipe 4 in place using sufcient pipe clamps (not

supplied).

● Remove possible charcoal lters.

6

Page 7

CHIMNEY ASSEMBLY

The chimney can only be installed with an exhausting hood.

Lower decorative chimney

● Fix the chimney xing bracket 21 onto the lower decorative chimney with 2 screws

12 (4.2 x 9.5) supplied with the hood.

21

2.1

12

Upper Decorative Chimney

● Slightly widen the two sides of the upper chimney and hook them between the wall and the

bracket 21 which is xed on the lower decorative chimney.

● Fix the upper chimney onto the bracket 21 with 2 screws 12 (4.2 x 9.5) supplied with the hood.

7

Page 8

USE

MOTOR OFF SWITCH: Press this switch to stop the motor.

SPEED SWITCH: Press this switch, and the motor runs at LOW speed.

SPEED SWITCH: Press this switch, and the motor runs at MEDIUM speed.

SPEED SWITCH: Press this switch, and the motor runs at HIGH speed.

LIGHT ON/OFF SWITCH: Press this switch to turn on the light, and press again

to turn it off.

8

Page 9

MAINTENANC

GREASE FILTER

METAL SELF-SUPPORTING GREASE FILTER CLEANING

● The lters must be cleaned every 2 months of operation or more

frequently for particularly heavy usage, and can be washed in a

dishwasher.

● Pull the comfort panel to open them.

● Remove the lters one by one by pushing them towards the back side

of the hood unit and simultaneously pulling downwards.

● Any kind of bending of the lters has to be avoided when washing

them. Before tting them again into the hood, make sure that they are

completely dry. (The color of the lter surface may change over time,

but this has no inuence to the lter efciency).

● When tting the lters into the hood, pay attention that they should be

mounted in correct position with the handle facing outwards.

● Close the comfort panel.

ACTIVATED CHARCOAL FILTER (RECIRCULATION VERSION)

These lters are not washable and cannot be regenerated, and must be replaced approximately

every 4 months of operation or more frequently for heavy usage.

ACTIVATED CHARCOAL FILTER REPLACEMENT

● Open the comfort panel by pulling them downwards.

● Remove the metal grease lters.

● Remove the saturated activated charcoal lter.

● Fit the new lters.

● Replace the metal grease lters.

● Close the comfort panel.

9

Page 10

LED LIGHT REPLACEMENT

LED LIGHT MODULE DISMANTLEMENT

Replacing the light module

● You should not replace the light bulb but the entire light module.

● When changing the light module, the contacts are live.

● Before changing the light module, unplug the appliance from the mains or switch off the circuit

breaker in the fuse box.

1. Remove the grease lter, and carefully remove 2 screws from each side on the opening (a

cross headed screwdriver will be needed to remove the screws).

2. Lower the control panel at the front by carefully pulling it downwards. You can now access the

light module and terminals. Replace the light (commercially available LED light (max.1.5 w)).

、

Max Power Voltage Picture Light Cap ILCOS D Code

Round/ Diameter:

70 mm

1.5 W DC 12 V

OLD ELECTRICAL APPLIANCE DISPOSAL

The European Directive 2012/19/EU on Waste Electrical and Electronic Equipment

(WEEE), requires that old household electrical appliances must not be disposed of

in the normal unsorted municipal waste stream. Old appliances must be collected

separately in order to optimize the recovery and recycling of the materials they

contain and reduce the impact on human health and the environment.

The crossed out “Wheeled Bin” symbol on the product reminds you of your

obligation, that when disposing the appliance, you need separately collect them.

Consumers should contact their local authority or retailer for information concerning

the correct disposal of their old appliance.

10

— — DSR-1.5-S-70

Page 11

TROUBLE SHOOTING

Fault Cause Solution

The blade is blocked.

Light is on, but

motor does not

work

Both light and

motor do not work

Oil leakage

Vibration

Insufcient suction

Machine incline

The capacitor is damaged. Replace the capacitor.

The motor is damaged. Replace the motor.

The internal wiring of motor is cut off/

disconnected. An unpleasant smell may

be produced.

Apart from the above mentioned, check the following:

Light is damaged. Replace the light.

Power cord is loose.

Outlet and the air ventilation entrance

are not tightly sealed.

Leakage from the connection of

U-shaped section and cover.

The blade, if damaged, can cause

vibration.

The motor is not tightly fastened. Fasten the motor tightly.

The cooker hood is not tightly xed. Fix the cooker hood tightly.

The distance between the cooker hood

and the cooker top is too large.

Too much ventilation from open doors

or windows.

The xing screw is not tight enough.

The hanging screw is not tight enough

Replace the motor.

Connect the cord as per the electric diagram.

Take down the outlet and seal with

glue.

Take down U-shaped section and

seal with soap or paint.

Replace the blade.

Readjust the distance.

Choose a new place to install the

appliance or close some doors /

windows.

Tighten the xing screw and make

it horizontal.

Tighten the hanging screw and

make it horizontal.

11

Page 12

To ensure the appliance continues to operate at peak performance, we recommend a routine

service call every 3 years for the life of the appliance.

Maintenance schedule:

FOR SPARE PARTS OR TO FIND THE ADDRESS OF

YOUR NEAREST STATE SPARE PARTS CENTRE IN AUSTRALIA

MIDEA HOME APPLIANCES AUSTRALIA PTY LTD

11/75 Lorimer Street, Docklands, Melbourne, 3008

After-sales service No.: 1800 88 60 10

Loading...

Loading...