Middleby PS310, PS360 Service Manual

©1998 Middleby Marshall Co., Inc.

Part No. 88210

-

0019

TTEECCHHNNIICCAALL

MAANNUUAALL

M

MODELS PS 310/360,

PS360

MODEL PS200

PACESETTER OVENS

PS200

Price $30.00

R. 5/98, Rev.B,Ver. 2

WWAARRNNIINNGG

POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE

FOLLOWED IN THE EVENT YOU SMELL GAS.

Instructions to be followed in the event the user smells gas

shall be obtained by consulting the local gas supplier. If the

smell of gas is detected, immediately call the emergency

phone number of your local Gas Company. They will have

personnel and provisions available to correct the problem.

FFOORR YYOOUURR SSAAFFEETTYY

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS AND LIQUIDS

OVEN MUST BE KEPT FREE AND CLEAR

OF COMBUSTIBLES AT ALL TIMES

NNOOTTIICCEE

Using any parts other than genuine

Middleby Marshall factory

manufactured parts relieves the

manufacturer of all liability.

WWAARRNNIINNGG

There must be adequate clearance

construction. Clearance must also be

provided for servicing and operation.

NNOOTTIICCEE

between oven and combustible

NNOOTTIICCEE

Middleby Marshall (Manufacturer)

reserves the right to

change specifications

at any time.

WWAARRNNIINNGG

Do Not Obstruct The Flow Of Combustion

And Ventilation Air To And From Your Oven.

Section

1 PS310/360 Functional Operation

1 I.

Gas Oven Sequence of Operation

1

A. Door Switch

1

B. Closing the Door Switch

1

C. Closing the Conveyor Switch

1

D. Closing the Blower Switch

1

E. Closing

the Heat Switch

1

F. Heat Switch Light

2 II.

Electric Oven Sequence of Operation

2

A. Door Switch

2

B. Closing the Power Relay

2

C. Closing Conveyor Switch

2

D. Closing Blower Switch

3

E. Closing the Heat Switch

3

PS200 F

unctional Operation

4 I.

Gas Oven Sequence of Operation

4

A. Door Switch

4

B. Closing the Door Switch

4

C. Closing the Convey or Switch

4

D. Closing the Blower Switch

4

E. Closing the Heat Switch

4

F. Heat Switch Light

5 II.

Electric Oven Sequence of Operation

5

A. Door Switch

5

B. Closing the Door Switch

5

C. Closing Conveyor Switch

5

D. Closing Blower Switch

6

E. Closing the Heat Switch

6

Section

2 – Servicing Components

7 I.

Digital Loop C

onveyor Control

7

A. Controller and Microcomputer Parts

8

B. Identifying Microcomputer Chip

9

C. Pre

-

troubleshooting Checkout Procedure For

Pacesetter Oven Digital Loop Conveyor Control

10

D. Controller/Motor Failure

12

E. Troubleshooting Convey or System

13

F. Troubleshooting Controller

15

G. Conveyor Control Check Using a

Frequency Counter

16

H. Conveyor Controller Pickup Test

17

I.

Conveyor Motor Test

18

J. Magnetic Pickup Replac

ement

19

PS360/570 Conveyor Sensor Wiring Changes

.

19A Dip Switch Conveyor Control Assembly

19B

II.

Temperature Controller

23

A. Honeywell (DialaPak) Controller

23

PS570S Thermocouple Wiring

26A B. Thermoc

ouple (Type J)

27

C. High Limit/Cooldown Switch

30

D. Troubleshooting Limit Switches

31

E. Testing Procedure for Temperature Controller

31

Part

1 - High Limit Switch and Thermocouple

Using the Altek Testing Device

31

Digital Temperature Controller P/N

28071

-

0028 31 B Part

2 - Oven Temperature Adjustment

32

Part 3

- Temperature Controller Main

Board Replacement

33 III. Motor Centrifugal Safety Switch

37 IV.

Air Pressure Sw

itch

PS200

ONLY

37 V. Gas Burner and Tram

38

A. Sequence of Operation

38

B. Intermittent Ignition Device

38

C. Gas Burner Components

39

Burner Pilot/lgnitor Assembly Changes,

7/22/91

42A Pilot Line Tee Kit

42C D.

Burner Troubleshooting

45

E. Burner Ignition System

- Start-up and Checkout

46

Honeywell Ignition Module

48A

VI.

High Flame Solenoid Valve

55 VII.

Main Gas Valve

55 VIII.

Low Flame Orifice

56

Gas Control Kit Changes,

11/27/91

56A

IX.

LP Conversion Kit

59

Gas Conversion Kit Changes,

12/19/94

60A

NOTE:

The PS

310

and

PS360 ovens are very

similar. For

simplification and

clarification purposes,

all references in this

manual to the

PS310 also include

the PS360 except

where noted.

TABLE OF CONTENTS

Page

TABLE OF CONTENTS (continued) Page

X.

Pipe Sizing

61

XI.

Electrically Heated Oven

- PS310/360 ONLY

64

A. Ratings of Heating Elements

64

B. Operation

64

C. Checking the Heating Elements

65

D. Changing Heating Elements

67

XII.

Electric

ally Heated Oven

- PS200 ONLY

69

A. Rating of Heating Elements

69

B. Operation

69

C. Checking the Heating Elements

70

D. Changing Heating Elements

72

XIII.

Electrically Heated Oven

-

ALL MODELS

-

Mercury Contactor Replacement

74

A. Replacing the Coil And/Or Contact Tube

-

PS360 Electric Oven

75

B. Replacing the Coil And/Or Contact Tube

-

PS200

Electric Oven

76

XIV.

Blowers

- PS3

10/360

ONLY

80

A. Blower Balancing

80

B. Direction of Blow

er Rotation

- PS31

0/360

ONLY

81

XV.

Blowers

- PS200

ONLY

82

A. Blower Balancing

82

B. Blower Rotation

83

C. Main Blower Fan Shaft Bearings Lubrication

84

D. Checking Main Blower Fan Belt

84 E. PS200

Fan Shaft Bearing Replacement

and Alignment

85

PS200

Indirect Fan Drive Assembly Changes,

7/1/90

86A

XVI.

Air Distribution

88

A. Test Bake

88

B. Dough Test

88 XVII.

Finger Usage

&

Identification

90

A. Basic Finger Components Explanation

91

B. Chart o

f Fingers Used in Oven Models

93

C. Finger List with Photos and Explanations

94

D. Model

360

Standard (Shutter) Finger Adjustment

103 Section

3 - Troubleshooting

107

PS310/360

107

I. Blowers

107

II.

Conveyor

107

III. Heat (Gas Oven)

107

IV.

Trial for Flame

108

V. Heat (Electric Oven)

109 PS200

110

I. Blower Fan

110

II.

Conveyor

110

III. Heat (Gas Oven)

110

IV.

Trial for Flame

111

V. Heal (Electric Oven)

111

Section

4 113

Electrical Schematics

PS310/360

114 Gas Oven Schematic, 208

-

240V, 50/60Hz, 1Ph, 3W

114

Gas Oven Schematic, 208

-

240V, 50/60Hz,

1

Ph, 4W

114A

Gas Oven Scnematic, 208

-

240V,50/60Hz, 1Ph,2W, ExportOnly

115

Gas Oven Schematic, 190

-

380V, 50/60Hz,

1

Ph, 2W, Export Only

116

Electric Oven S

chematic, 200

-

220V, 50/60Hz, 3Ph, 3W, Export

117

Electric Oven Schematic, 208

-

240V, 50/60Hz, 3Ph, 4W

with Single Phase Blower Motor

118

Electric Oven Schematic, 208

-

240V, 50/60Hz, 3Ph, 4W

with 3 Phase Blower Motor

119

Electric O

ven Schematic, 240V, 50/60Hz, 3Ph, 3W

120

Electric Oven Schematic, 380V, 50/60Hz, 3Ph, 3W, Export Only

121

Electric Oven Schematie, 480V, 50/60Hz, 3Ph , 3W

122

Electric Oven Schematic, 400

-

440V, 50/60Hz, 3Ph, 3W, Export

123 PS

200

Schematics

124

Gas Oven

Schematic, 208

-

240V, 50/60Hz

, 1

Ph , 3W 124

Gas Oven Schematic,

208-240V, 50/60Hz,

1Ph,

4W 124A

Gas Oven Schematic, 200V, 50/60Hz, 1 Ph, 2W

125

Gas Oven Schematic, 208V, 50/60Hz, 1 Ph, 2W

126

Gas Oven Schematic, 220

-

240V, 50/60

Hz, 1Ph, 2W

127

Electric Oven

Schematic, 208

-

240V, 50/60Hz , 3Ph , 4W

128

Electric Oven

Schematic , 380V ,50/60Hz , 3Ph , 4W

129

Electric Oven Schematic , 400

-

416V, 50/60Hz ,3Ph, 4W

130

Appendix 131

SECTION 1

PS31

0/360

FUNCTIONAL OPERATION

SECTION 1

FUNCTIONAL OPERATION

NOTE: This section to be used in conjunction with the electrical wiring diagrams in Section 4.

Complete description and troubleshooting of individual components are explained in Section 2.

D. Closing the Blower Switch

FUNCTIONAL OPERATION

I. GAS OVEN SEQUENCE OF OPERATION

AIl gas heated ovens operate on 208/230 V, single

phase.

Incoming power wiring for the (208/230 V) ovens

require 2-single phase 208/230 V supply (hot) lines, 1

neutral and 1 safety ground. From either hot line to

neutral the voltage should never exceed 130V.

A. Door Switch

Closing the control cabinet door will close the Door

Switch. The Door Switch has a "cheater" position.

When the control cabinet door is open, grasp the

switch actuator and pull it out as far as possible. This

will close the Door Safety Switch and permit

troubleshooting. Closing the control cabinet door will

reset the switch.

B. Closing the Door Switch

1. Closing the Door Switch permits a circuit to go

through the motor fuse, (two 9 Amp fuses per motor for

a 208/240 V oven).

Closing the Blower Switch energizes:

1. Two Cooling (axial fan) Motors.

2. Blower Motor Contactor (C1).

Closing this contactor starts both Blower Motors. When

both Blower Motors are up to speed a Centrifugal

Switch located inside the rear end of both Motors will

close, setting up the heat circuit.

3. Temperature Controller.

E. Closing the Heat Switch

Closing the Heat Switch completes a circuit:

1. Through the Heat Switch.

2. Through the Blower Motor Centrifugal Switches.

3. Through the Temperature High Limit Switch.

4. One circuit then goes to the:

a. Burner (L1).

b. Transformer (110 V to 24 V).

2. Also, closing the Door Switch permits a circuit to go

through a 9 amp fuse to one side of the Conveyor

Switch, Blower Motor Switch, Cooldown Relay and to

the Heat (Burner) Switch.

C. Closing the Conveyor Switch

Closing Conveyor Switch permits a circuit to go to the

Variable Speed Conveyor Motor Control. This serves

two functions:

1. One is to convert AC to DC.

2. The second is to achieve infinite speed control of the

Conveyor Motor by adjusting the Thumbwheel to the

desired conveyor belt speed.

c. Motor Relay Coil. On a cold start the heater on

this relay takes about 30 seconds to warm up before

the relay will energize. This gives an additional

prepurge.

d. Burner Blower Motor. As the Burner Motor

reaches full operating RPM the Centrifugal Switch

(Rear End Motor Switch) closes and applies voltage to

the Burner Control. This energizes the Ignitor Control

Spark Transformer and the Pilot Valve. The spark then

lights the Pilot. The Flame Sensor proves the presence

of the pilot flame and the Ignitor Control then shuts off

the spark. At the same time, the Main Burner Valve is

opened. The Main Burner is then ignited.

1

SECTION 1

II.

ELECTRIC OVEN SEQUENCE OF OPERATION.

FUNCTIONAL OPERATION

If the Pilot does not light within approximately 90

seconds, the oven will shut down. All 310/314/360's

have 100% lockout modules for oven shut down.

The Pilot and Main Gas Valve will stay on (open) as

long as the Heat Switch is ON and the flame is

proven. If the flame goes out for any reason the Pilot

will try to light for 90 seconds, and then go into

automatic lockout. To relight the Pilot after it has gone

into automatic lockout the Burner must be turned OFF

for 60 seconds and then turned ON again.

e. Temperature Controller (Terminal 5) Power for

the Primary relay contacts for the high flame valve.

As long as the temperature inside the oven is below

the setting of the Temperature Controller the

Thermocouple will energize the Temperature

Controller.

When the Temperature Controller is energized, one

set of the contacts of the controller energize the High

Flame Solenoid, another set of contacts close and

energize the green primary output light located in the

upper left -hand corner of the Temperature Controller

dial.

F. Heat Switch Light

The Heat Switch light is an extremely useful

troubleshooting tool. If after turning the Blower Switch

and Heat Switch ON the Heat Switch does not light

this indicates a problem with one of the safety

switches (Blower Centrifugal Switch).

If the Heat Switch does light it indicates a problem in

the Burner Unit (Relay, burner blower motor, control

board) or High Limit Switch.

When the oven reaches the desired setting of the

Temperature Controller, the Temperature Controller

will be de-energized. This will de-energize the High

Flame Valve and the green primary output light. The

Burner will remain ON in the low flame mode. When

the temperature drops a few degrees the

Temperature Controller will energize and re-energize

the High Flame Solenoid.

During cooldown the Temperature Controller dial will

continue to read oven temperature.

NOTE: The red light on the Temperature Controller will

stay ON at fire-up each day until the oven temperature

goes above 180° F(82°C).

NOTE: This section to be used in conjunction with the

electrical wiring diagrams, in Section 4. Complete

description and troubleshooting of individual

components are explained in Section 2.

All electrically heated ovens operate on a

208/230/380/440V, 3 phase, 4 wire system. The fourth

wire is for a 120 V neutral ground. This 120 V neutral

ground eliminates the need for a control transformer.

Where a neutral is not available a 240/110V transformer

is supplied.

A. Door Switch

1. Closing the control cabinet door will close the Door

Switch. The Door Switch has a "cheater" position. When

the control cabinet door is open, grasp the switch

actuator and pull it out as far as it will go. This will close

the Door Safety Switch and permit troubleshooting.

Closing the control cabinet door will reset the switch.

NOTE: On all electrically heated ovens high voltage is

present at fuses and contactors in machinery

compartment.

B. Closing the Door Switch

Closing the Door Switch permits a circuit to go to one

side of the Conveyor Switch, Blower Motor Switch and

to the Heat Switch (208/240 V ovens use one 5 amp

fuse in this circuit).

C. Closing Conveyor Switch

The Temperature Controller also incorporates both

the High Limit Safety and the cooldown features The

High Limit relay will shut the oven burner OFF if the

oven goes above 650° F. If this occurs the red light

located in the upper right corner of the Temperature

Controller will be lit.

When the Heat and Blower Switches are turned OFF

the Cooldown Relay will allow the blowers to remain

ON until the oven temperature falls to 180° F (82°C).

Closing Conveyor Switch permits a circuit to go to the

Variable Speed Conveyor Motor control. This serves

two functions:

1. One is to convert AC to DC.

2. The second is to achieve infinite speed control of the

Conveyor Motor by adjusting the thumbwheel to the

desired belt speed.

2

D. Closing Blower Switch

Closing Blower Switch energizes:

1. Two Cooling (axial fan) motors.

2. Blower Motor Contactors (C4 and C5).

Closing this contactor starts both blower motors. When

both Blower Motors are up to speed a Centrifugal

Switch located inside the rear end of both Motors will

close setting up the heating circuit.

E. Closing the Heat Switch

Closing the Heat Switch completes a circuit:

1. Through the Heat Switch.

2. Through the Blower Motor Centrifugal Switch.

3. Through the Temperature Override Switch.

4. To the primary relay contacts of the Temperature

Controller.

When the Thermocouple located inside the oven

indicates that the temperature inside the oven has

fallen below the set point indicated on the Temperature

Controller the Relay Switch inside the Temperature

Controller will energize Contactors C1, C2 and C3.

This will in turn energize the three banks of 8 KW

heaters.

SECTION 1

FUNCTIONAL OPERATION

5. When the Temperature Controller is calling for

heat, another set of contacts from the Temperature

Controller close and energize the green primary

output light located in the upper left -hand comer of the

Temperature Controller dial face.

The High Limit Safety and the Cooldown features are

located separately from the temperature controller.

The High Limit Relay will shut the heat circuit OFF if

the oven goes above 650° F (343°C). If this occurs

the red light located in the upper right comer of the

Temperature Controller will be lit.

When the Heat and Blower Switches are turned OFF

the Cooldown Relay will allow the blowers to remain

ON until the oven temperature falls to 180° F (82°C).

During cooldown the Temperature Controller dial will

continue to read oven temperature.

6. When the oven reaches the desired setting of the

Temperature Controller, the Temperature Controller

will be de-energized. This will de-energize the coils

C1, C2 and C3. This will also de-energize the green

primary output light. When the temperature drops a

few degrees the Temperature Controller will energize

again, re-energizing contactors C1, C2 and C3.

3

SECTION 1

PS200

the relay will energize

. This gives an additional

d. Burner Blower Motor. As the Burner Motor

FUNCTIONAL OPERATION

D. Closing the Blower Switch

FUNCTIONAL OPERATION

I. GAS OVEN SEQUENCE OF OPERATION

All gas heated ovens operate on 208/230 V, single

phase.

Incoming power wiring for the (208/230 V) ovens

require 2-single phase 208/230 V supply (hot) lines, 1

neutral and 1 safety ground. From either hot line to

neutral the voltage should never exceed 130V.

A. Door Switch

Closing the control cabinet door will close the Door

Switch. The Door Switch has a "cheater" position.

When the control cabinet door is open, grasp the switch

actuator and pull it out as far as possible. This will close

the Door Safety Switch and permit troubleshooting.

Closing the control cabinet door will reset the switch.

B. Closing the Door Switch

1. Closing the Door Switch permits a circuit through a 9

amp fuse to one side of the Blower Motor Switch,

Cooldown Relay and to the Heat (Burner) Switch.

C. Closing the Conveyor Switch

Closing Conveyor Switch completes a circuit to go to

the Variable Speed Conveyor Motor Control. This

serves two functions:

1. Supplies power to one side of the Conveyor Switch.

2. Energizes Blower Motor Contactor (C1).

Energizing this contactor starts the Blower Motor.

When the Blower Motor is up to speed an air pressure

switch located in the control compartment senses the

air pressure in the air plenum and closes a switch.

This completes the heat circuit.

3. Energizes the Temperature Controller.

E. Closing the Heat Switch

Closing the Heat Switch completes a circuit:

1. Through the Heat Switch.

2. Through the Air Pressure Switch.

3. Through the Temperature High Limit Switch.

4. One circuit then goes to the:

a. Burner (L1).

b. Transformer (110 V to 24 V).

c. Motor Relay Coil. On a cold start the heater on

this relay takes about 15 seconds to warm up before

prepurge.

1. One is to convert AC to DC.

2. The second is to achieve infinite speed control of the

Conveyor Motor by adjusting the Thumbwheel to the

desired conveyor belt speed.

reaches full operating RPM the Centrifugal Switch

(Rear End Motor Switch) closes and applies voltage to

the Burner Control. This energizes the Ignitor Control

Spark Tr ansformer and the Pilot Valve. The spark then

lights the Pilot. The Flame Sensor proves the.

presence of the pilot flame and the Ignitor Control then

shuts off the spark. At the same time, the Main Burner

Valve is opened. The Main Burner is then ignited.

4

If the Pilot does not light within approximately 90

seconds, the oven will shut down. All PS200's have

100% lockout modules for oven shut down.

The Pilot and Main Gas Valve will stay on (open) as long

as the Heat Switch is ON and the flame is proven. If the

flame goes out for any reason the Pilot will try to light for

90 seconds, and then go into automatic lockout. To

relight the Pilot after it has gone into automatic lockout

the Burner must be turned OFF for 60 seconds and

then turned ON again.

e. Temperature Controller (Terminal 5) Power for

the Primary relay contacts for the high flame valve.

As long as the temperature inside the oven is below

the setting of the Temperature Controller the

Thermocouple will energize the Temperature

Controller.

When the Temperature Controller is energized, one

set of the contacts of the controller energize the High

Flame Solenoid, another set of contacts close and

energize the green primary output light located in the

upper left -hand comer of the Temperature Controller

dial.

F. Heat Switch Light

The Heat Switch light is an extremely useful

troubleshooting tool. If after turning the Blower Switch

and Heat Switch ON the Heat Switch does not light this

indicates a problem with the Air Pressure Switch.

If the Heat Switch does light it indicates a problem in

the Burner Unit (Relay, burner blower motor, control

board).

When the oven reaches the desired setting of the

Temperature Controller, the Temperature Controller

will be de-energized. This will de-energize the High

Flame Valve and the green primary output light. The

Burner will remain ON in the low flame mode. When the

temperature drops a few degrees the Temperature

Controller will energize and re-energize the High Flame

Solenoid.

The Temperature Controller also incorporates both the

High Limit Safety and the cooldown features The High

Limit relay will shut the oven burner OFF if the oven

goes above 650° F. If this occurs the red light located in

the upper right comer of the Temperature Controller

will be lit.

When the Heat and Blower Switches are turned OFF

the Cooldown Relay will allow the blowers to remain ON

SECTION 1 FUNCTIONAL

OPERATION

until the oven temperature falls to 180° F (82°C).

During cooldown the Temperature Controller dial will

continue to read oven temperature.

NOTE: The red light on the Temperature Controller

will stay ON at fire-up each day until the oven

temperature goes above 180° F (82°C).

II. ELECTRIC OVEN SEQUENCE OF

OPERATION.

NOTE: This section to be used in conjunction with

the electrical wiring diagrams, in Section 4.

Complete description and troubleshooting of

individual components are explained in Section 2.

All electrically heated ovens operate on a 208/230 V,

3 phase, 4 wire system. The fourth wire is for a 120 V

neutral ground. This 120 V neutral ground eliminates

the need for a control transformer.

A. Door Switch

1. Closing the control cabinet door will close the Door

Switch. The Door Switch has a "cheater" position.

When the control cabinet door is open, grasp the

switch actuator and pull it out as far as it will go. This will

close the Door Safety Switch and permit trouble

shooting. Closing the control cabinet door will reset

the switch.

NOTE: On all electrically heated ovens high voltage

is present at fuses and contactors in machinery

compartment.

B. Closing the Door Switch

Closing the Door Switch permits a circuit to go to one

side of the Conveyor Switch, Blower Motor Switch and

to the Heat Switch (208/240 V ovens use one 9 amp

fuse in this circuit).

C. Closing Conveyor Sw itch

Closing Conveyor Switch permits a circuit to go to the

Variable Speed Conveyor Motor control.

This serves two functions:

1. One is to convert AC to DC.

2. The second is to achieve infinite speed control of

the Conveyor Motor by adjusting the thumbwheel to

the desired belt speed.

5

Controller will be lit.

read oven temperature.

SECTION 1

FUNCTIONAL OPERATION

D. Closing Blower Switch

Closing Blower Switch energizes:

1. Supplies power to one side of Conveyor Switch.

2. Blower Motor Contactor.

Closing this contactor starts the blower motor. When the

Blower Motor is up to speed an Air Pressure Switch

located inside the control compartment senses the air

pressure in the air plenum and closes contacts. This

completes the heat circuit.

E. Closing the Heat Switch

Closing the Heat Switch completes a circuit:

1. Through the Heat Switch.

2. Through the Air Pressure Switch.

3. Through the Temperature High Limit Switch.

4. To the primary relay contacts of the Temperature

Controller.

5. When the Temperature Controller is calling for heat,

another set of contacts from the Temperature Controller

close and energize the green primary output light located

in the upper left -hand comer of the Temperature

Controller dial face.

The High Limit Safety and the Cooldown features are

located separately from the Temperature Controller. The

High Limit Relay will shut the heat circuit OFF if the oven

goes above 650° F (343°C). If this occurs the red light

located in the upper right comer of the Temperature

When the Heat and Blower Switches are turned OFF the

Cooldown Relay will allow the blowers to remain ON until

the oven temperature falls to 180° F (82°C). During

cooldown the Temperature Controller dial will continue to

6. When the oven reaches the desired setting of the

Temperature Controller, the Temperature Controller will

be de-energized. This will de-energize the coils C1, C2

and C3. This will also de-energize the green primary

output light. When the temperature drops a few degrees

the Temperature Controller will energize again, reenergizing contactors C1, C2 and C3.

When the Thermocouple located inside the oven

indicates that the temperature inside the oven has fallen

below the set point indicated on the Temperature

Controller the Relay Switch inside the Temperature

Controller will energize Contactors C1, C2 and C3. This

will in turn energize the three banks of 8 KW heaters.

6

SECTION 2 SERVICING

I. DIGITAL LOOP CONVEYOR CONTROL

SECTION 2

SERVICING COMPONENTS

COMPONENTS

The Digital Loop Conveyor Control is used to set and

monitor the speed of the conveyor. Included in the control

is a Microcomputer connected to a thumbwheel switch

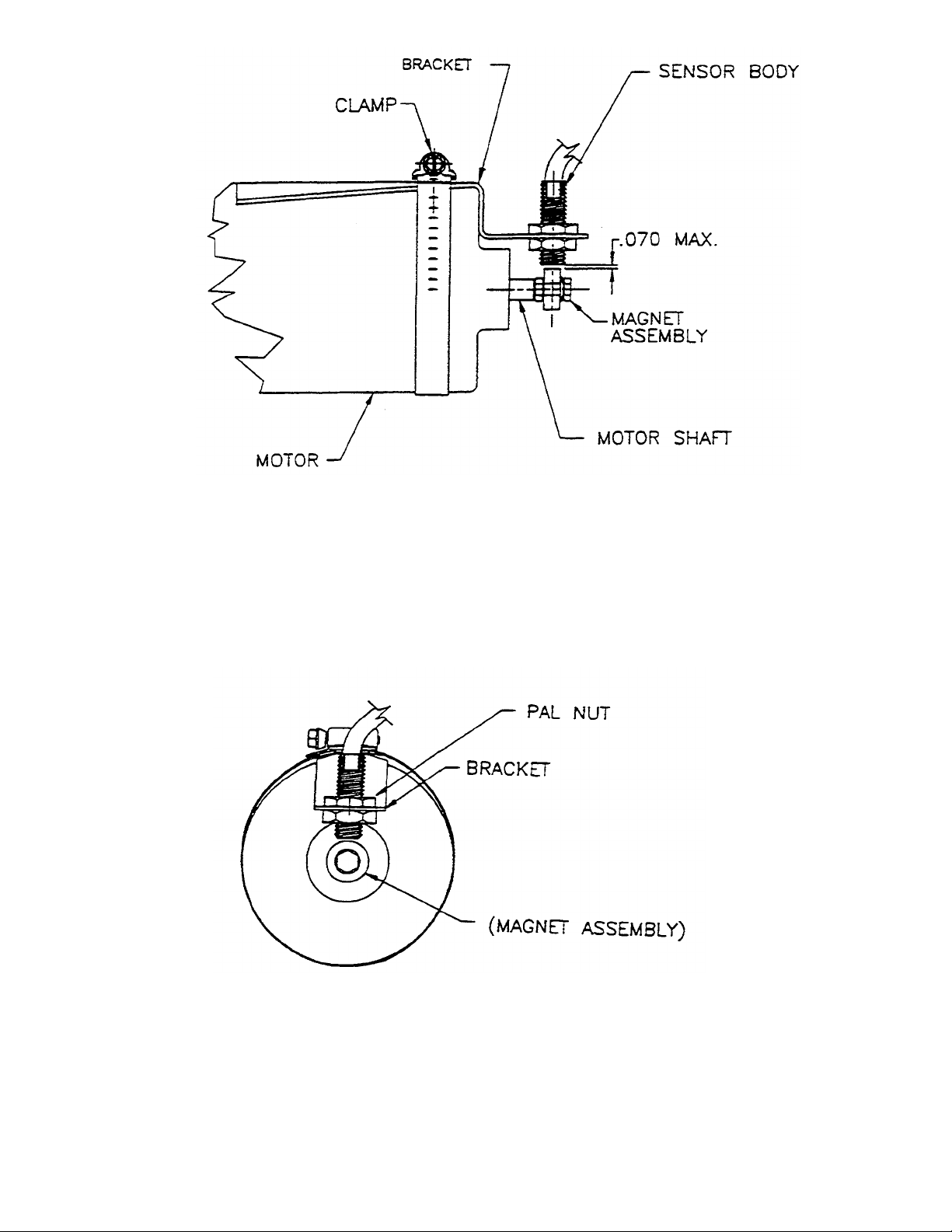

and a Magnetic Pickup Wheel on the motor shaft. As the

magnetic wheel attached to the motor shaft turns, the

revolutions of the magnet are monitored by the Hall

Device. The Hall Device is located next to, but not

touching, the magnetic wheel. The signals are sent to the

Microcomputer and the computer compares the motor

speed with the speed set by the thumbwheel. The

Microcomputer increases or decreases the voltage to the

gearmotor depending on the signal.

Power Must Be Off Before Replacing The

Microcomputer And A Middleby Marshall

Qualified Service Technician Must Be Present.

NOTE: To property service this equipment you must

use a good quality Digital Meter, preferably with a

frequency counter feature. An Analog Meter will not

NOTE: The basic controller is the same for all

Pacesetter Ovens (Models 314, 310, 360, 200). The

only parts that must be changed per the oven model

is the Microcomputer on the board. This is an

advantage for the service representative because

only one basic controller, one pickup and two styles of

motors and Microcomputers must be stocked. See

Figure 1 for description of parts.

WARNING

CAUTION

The Microcomputer Must Be Removed With The

Proper Equipment Such As A Microcomputer

Removal Tool (MMPN 27170-0190).

SECTION 2

Terminal

SERVICING COMPONENTS

C. Pre -troubleshooting Checkout Procedure For Pacesetter Oven Digital Loop Conveyor

Control

1. Before troubleshooting the digital loop conveyor control check the following:

a. Conveyor belt tight.

b. Drive chain tight and aligned.

c. Drive sprockets tight (set screws).

d. Axial fan running and clean (cooling).

e. Motor and pickup wires on Conveyor Terminal Block are secure (see Figure 2), also wires on controller

are secure.

2. Check the Pickup for the following (see Figures 3 & 4):

a. Pickup is secure.

b. Magnet is not cracked or chipped.

c. Magnet is not rubbing on plastic housing.

d. Mounting bolt is not worn or bent.

e. Pickup bearing in good condition.

f. On old style pickup (see Figure 4) gap between magnet and Hall Device is spaced approximately 1/16"

or a business card thickness.

Block

Figure 2. Terminal Block in Motor Compartment on PS360.

10

FIGURE 1

10A

SECTION 2

SERVICING COMPONENTS

NOTE: Maximum Ambient Temperature 160° F.

Figure 3. Pickup

NOTE: 1. Maximum Ambient Temperature 160° F

Figure 4. Old Style Pickup

Originally Used on PS350 and Early 360 Ovens

11

SECTION 2

SERVICING COMPONENTS

D. Controller/Motor Failure

When the conveyor controller fails, it is very possible

that a snorted conveyor motor caused the problem.

Unless the motor is changed, the installation of

another conveyor controller will simply result in

burning up the new controller.

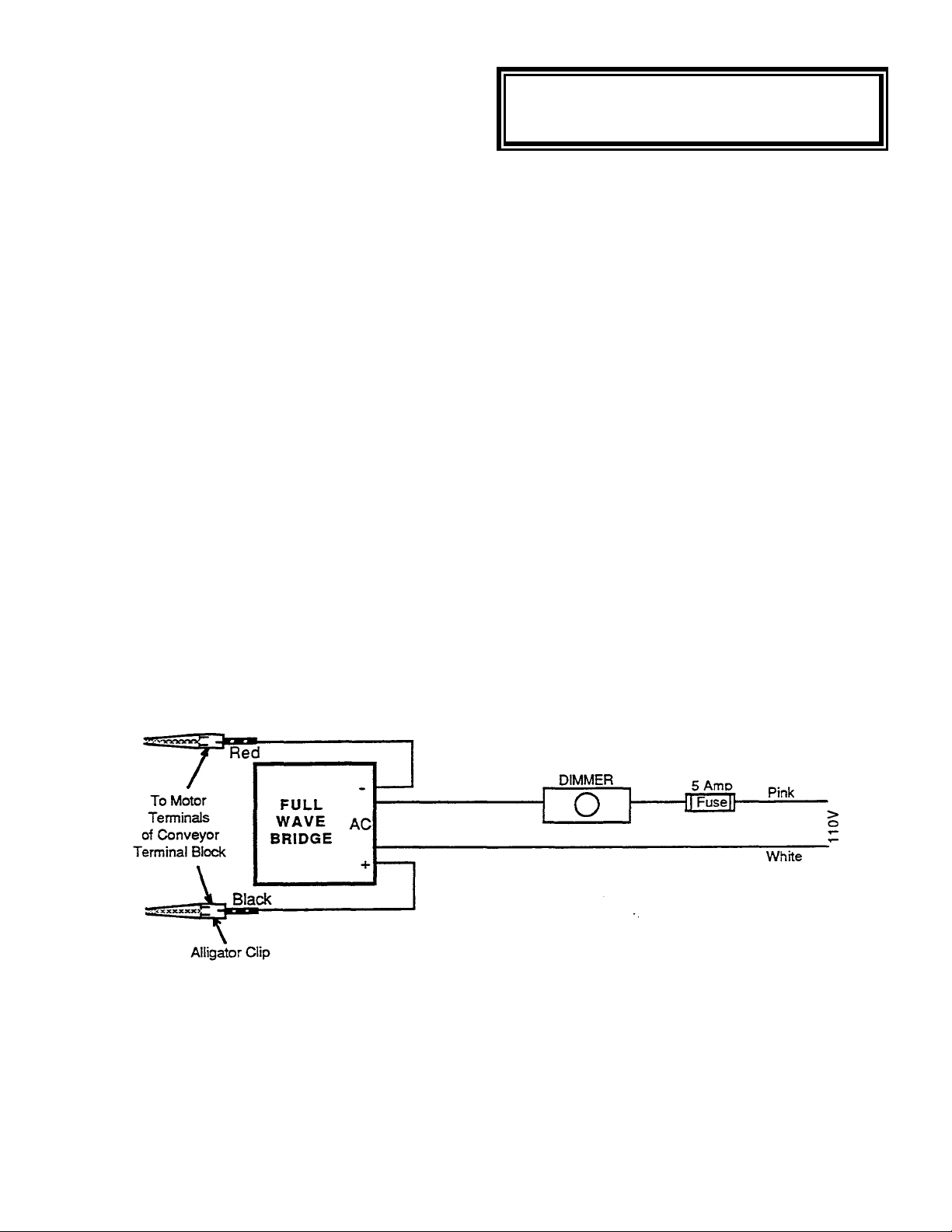

You are strongly advised to bypass the conveyor

controller and install the tester unit (see Figure 5) in

any oven that has burned up the conveyor controller

before installing a new conveyor controller to be sure

the problem is in the controller and not the motor. It is

much less expensive to bum out the tester than

another conveyor controller.

The components for this tester can be purchased at

any Radio Shack store or any good electronic supply

house. This tester is not nearly as accurate or

sensitive as the conveyor controller. If it is left on the

oven it will give inconsistent baking results. Therefore,

CAUTION!

DO NOT turn conveyor switch on while Field

On a PS310/360 remove the Red and Black motor

lead wires from the terminal block (Figure 2) and

attach motor leads to field tester.

On a PS200 disconnect the Red and Black motor

lead wires from the speed controller and then attach

motor leads to field tester.

NOTE: To reverse conveyor motor direction,

interchange Red and Black DC leads. The dimmer

switch must be turned over half way to start the

motor. It then can be turned down to the desired

motor speed.

Components Needed:

1 - Full wave AC-DC Bridge, 400 volt, 4 ampere

(Radio Shack P/N 276-11743).

1 - Light Dimmer Switch (5 amp rating).

1 - In line 5 amp AC fuse enclosed in plastic case.

2 - Alligator clips.

Figure 5. Field Tester For Conveyor Drive

Motor Controllers

12

Ye

All wiring between Controller, Magnetic

Check for 120 Vac

Repair wire

Comple

te the pickup/Controller Test

Replace

Replace

Conveyor still

Complete the Motor Test

Replace

Conveyor still

Replace Speed

E. Troubleshooting Conveyor System

SECTION 2

SERVICING COMPONENTS

MOTOR ALWAYS RUNS FULL SPEED

Pickup and Motor in good condition

s

to Speed Controller

Yes

(See Pages 16 & 17)

Passed Failed

Microprocessor

runs to fast

Magnetic Pickup

No

connection

Motor OK

runs too fast

Control Board

as explained on Page 18

Motor Failed

Motor

13

Yes

No

SECTION 2

Is thumbwheel speed selector

Set speed to customer

All wiring between Motor and Speed

Check for 120 Vac

Is there DC volta

ge present

Trace wiring

and

Replace

Still no DC

Complete the Motor Test

Replace

Motor still

Repair wire

Motor still

SERVICING COMPONENTS

MOTOR WILL NOT RUN

set to 0 minutes 0 seconds?

requirements

Yes

across terminals ARM+ and

ARM- on Speed Controller?

Yes

Yes

to Speed Controller

Microprocessor

No

Control in good condition

No

connection

No

determine why there is

no voltage to controller

Motor checks out OK

not running

output

Explained on Page 18

Motor Failed

Motor

not running

14

SECTION

2

F. Troubleshooting Controller

AC AC

AC AC

Thumbwheel Setting

4 50 63 5 40 51 6 34 43 7 28 37 8 25 32 9 22 29 10 20 27 11 18 24 12 17 22

13

14

19

AC AC

15 110-120

Vac

NOTE: When changing conveyor speeds it is

advisable to first turn the Conveyor Switch OFF

before adjusting the thumbwheel switch.

Step 1 - Check all connections at terminal board to

ensure connections are correct and tight.

Connections are as follows:

-ARM

+ARM

AC

AC

NO CONNECT

COM

RED

BLK

PINK

WHITE

BROWN OR BLACK

SERVICING COMPONENTS

with the voltages shown on the chart below. If the

voltage reading is more than ±5Vdc of that shown on

chart, complete motor test shown on Page 18.

-ARM

+ARM

NO CONNECT

COM

COUNT

+5V

Figure 8

COUNT

+5V

YELLOW OR WHITE

ORANGE OR RED

Figure 6

If wiring is not correct, make corrections are tight,

including connections on plugs and receptacles,

proceed to Step 2.

Step 2 - Ensure there is power to controller. Use a

Digital Multimeter to read voltage between the

terminal connections marked "AC" on controller.

Meter should read between 110-120 VAC.

-ARM

+ARM

NO CONNECT

COM

(Minutes)

3

15

DC Motor Voltage

PS310/360 PS200

67 84

13

18

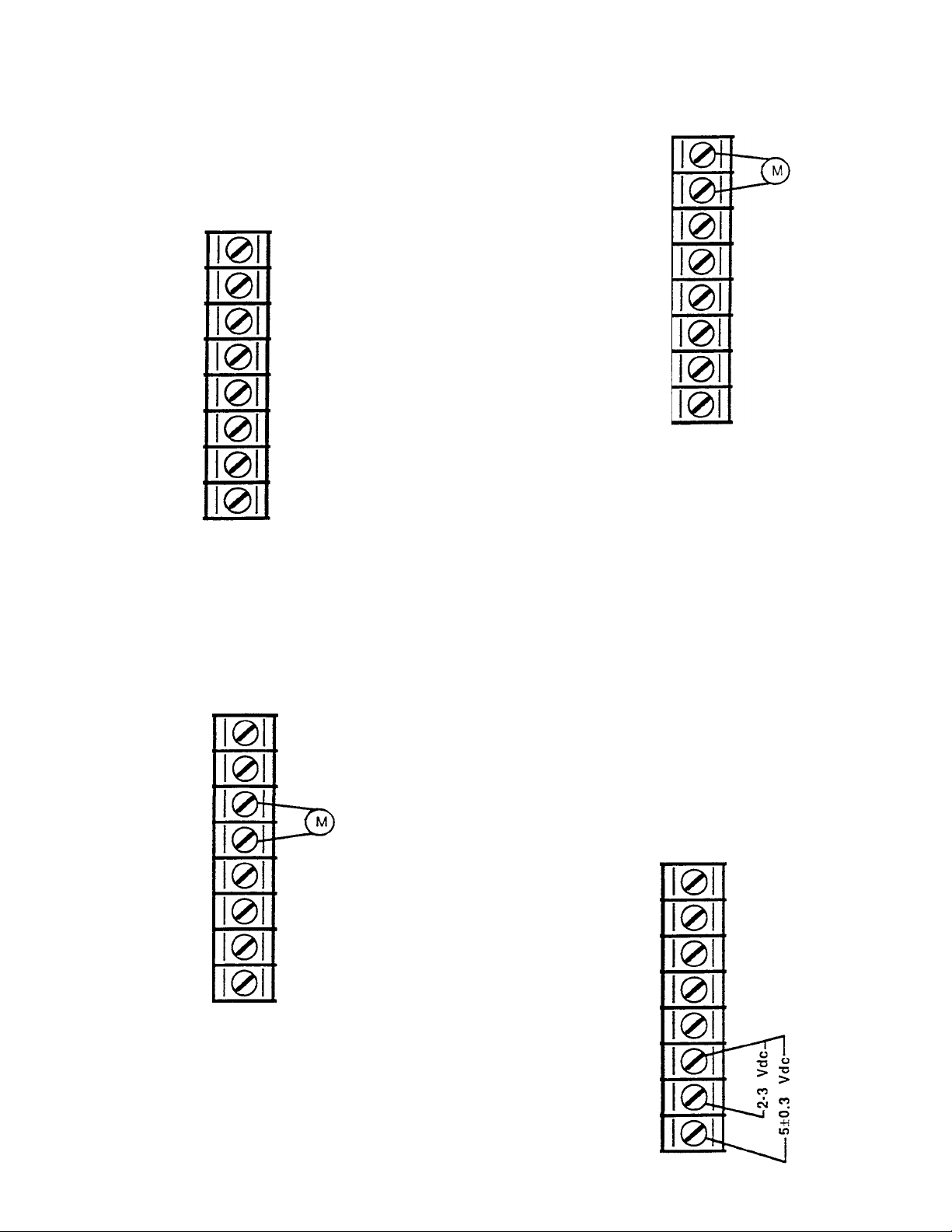

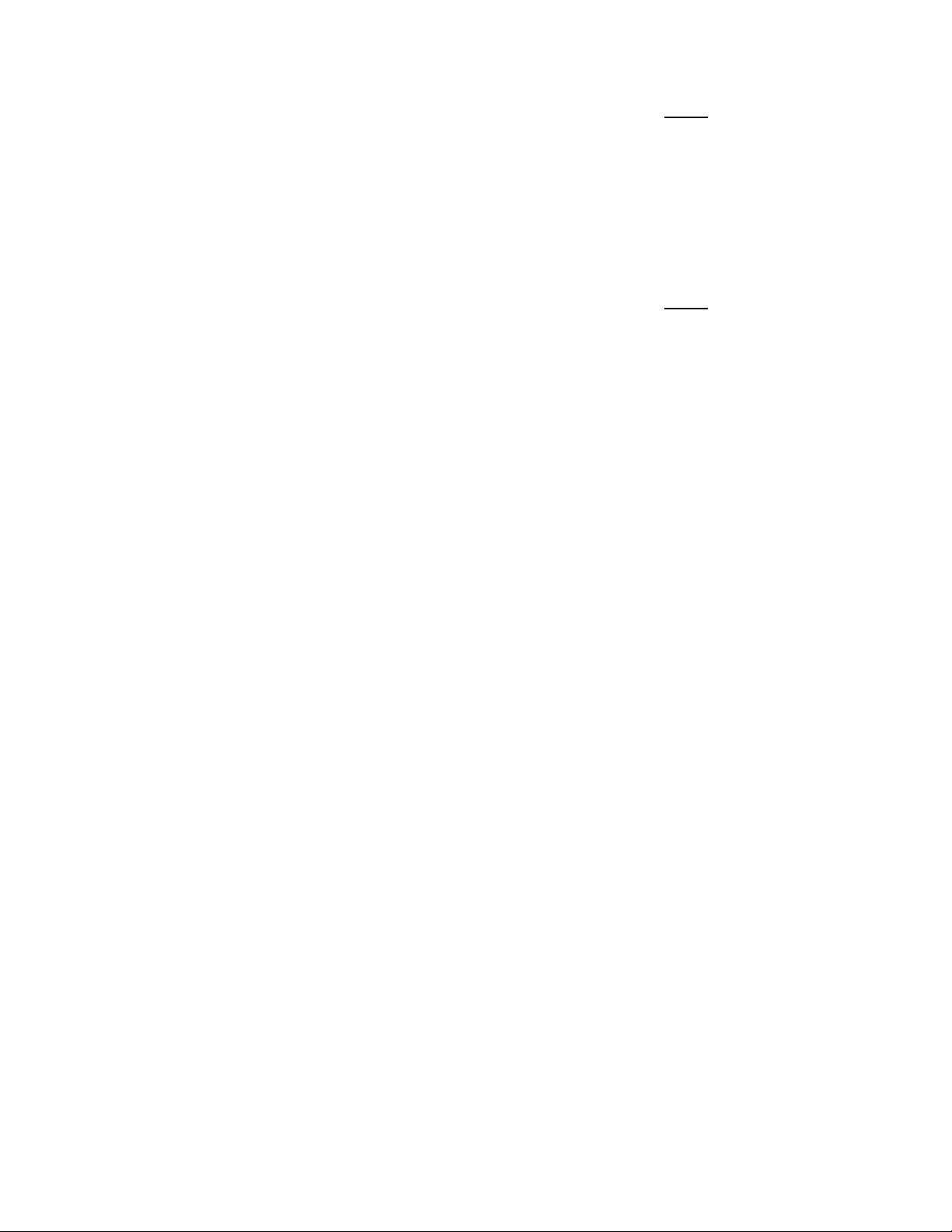

Step 4 - Check Magnetic Pickup at back of motor. If the

pickup is in good condition as per Step 3, check the

voltages. Make sure conveyor is running. Using your

meter set at DC, check between COM and ±5 V. Voltage

should read +5 Vdc, ±0.3V. Next check between COM

and Signal (count). Reading should stay between 2 to 3

Vdc. If either of these two readings are incorrect, see

Conveyor Control Pickup Test on Page 17.

-ARM

+ARM

Figure 7

If power is not available, check power source.

If power is available, proceed to Step 3.

Step 3 - With the AC power on, check the DC voltage

to the conveyor motor and match the motor vottage

COUNT

+5V

NO CONNECT

COM

COUNT

+5V

Figure 9

SECTION 2 SERVICING

27 23

COMPONENTS

G. Conveyor Control Check Using A

Frequency Counter

The following procedures are to be used ONLY if you

have a Frequency Counter feature on your Digital

Multimeter. If no Frequency Counter is available,

disregard this test procedure and go to Conveyor

Controller Pickup Test on the following page.

Using a Frequency Counter is the easiest and fastest

way to diagnose a problem with the speed control or

pickup.

We recommend you do your test at the 3, 6, and 10

minute thumbwheel settings before using the

following Troubleshooting Chart.

PS200

Thumbwheel Setting Vdc Frequency

(Minutes) to Motor

3.0 84 75

6.0 43 37

10.0

The charts to the right show the Thumbwheel setting

(belt speed) along with the corresponding DC voltage

and frequency reading. All readings should be plus or

minus 3 Vdc or 3 Hz of that stated in charts.

To measure the DC voltage output to gear motor,

place your meter leads across the speed controller

terminals ARM + and ARM -.

To measure the Pickup Feedback Frequency place

your Red (+) lead on the +5 Vdc terminal and the

Black (common) lead on the COUNT terminal.

TROUBLESHOOTING CHART

ARM (DC) voltage reading high but frequency is

correct.

ARM (DC) voltage reading is high and frequency is

zero. Also check for +5 Vdc and COM terminal on

speed control board. +5Vdc is present.

+5Vdc is not present ARM (DC) voltage reading is

high and frequency is high.

PS360

Thumbwheel Setting Vdc Frequency

(Minutes) to Motor

3.0 67 91

6.0 34 46

10.0 20 27

Replace Pickup

Replace Pickup

Replace Microchip. If still no change replace

speed control board.

Replace Microchip. If no change replace

speed control board.

Replace Microchip. If no change replace

ARM (DC) voltage reading is low but not zero and

speed control board.

frequency is low but not zero.

Replace Gear Motor.

ARM (DC) voltage reading is good and pulse is good

but motor not turning.

16

SECTION 2

Figure

10

SERVICING COMPONENTS

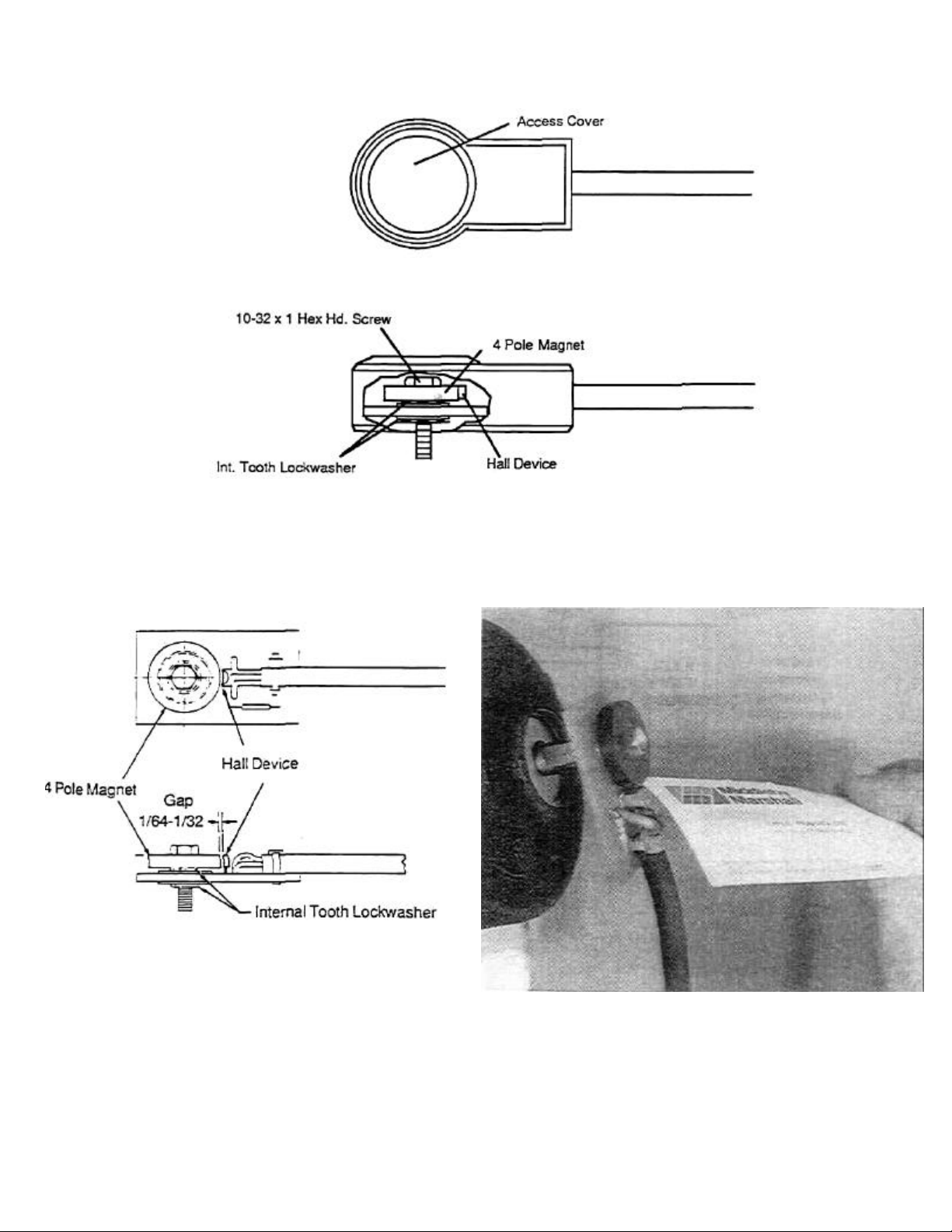

1. Visually check pickup for the

following:

• Magnet clean and bearing in

good condition.

• Chips or cracks on the

magnet.

• Old style pickup (not encased

in blue plastic housing) has a

1/64 to 1/32 gap between

magnet and hall device.

2. Set voltmeter on Volts DC

scale then connect meter

probes as shown. Black (- corn.)

probe to COM terminal on

speed control board and Red

(+VQ) probe to +5V terminal of

speed control. +5Vdc should be

present at all times when

conveyor is operating. If 5 Vdc is

present go to Step 3. If 5 Vdc is

not present, disconnect the

three pickup wires (connect-ed

to COM. SIGNAL and +5V

terminals) and again check for

+5Vdc. If 5Vdc is present with

pickup disconnected, change

pickup. If 5Vdc is not present

change speed controller.

3. If ±5Vdc is present with

pickup connected to speed

control, connect volt meter red

(+) lead to signal terminal and

disconnect motor wires from the

- ARM and + ARM terminals.

Using a 5/16" open end wrench

on the motor pickup shaft very

slowly rotate motor shaft while

observing volt meter. Two (2)

changes from +5V to 0V should

occur for every one motor

revolution. If signal is always at

0V, go to Step 4. If signal is

always at 5V or changes more

than 2 times per revolution,

change the pickup.

4. If signal is always at 0 Vdc,

disconnect pickup signal wire

from speed control and check

for +5Vdc at signal terminal of

control. If +5Vdc is present,

change pickup. If 0 Vdc is

present, replace speed control.

Figure 11

17

SECTION 2 SERVICING

COMPONENTS

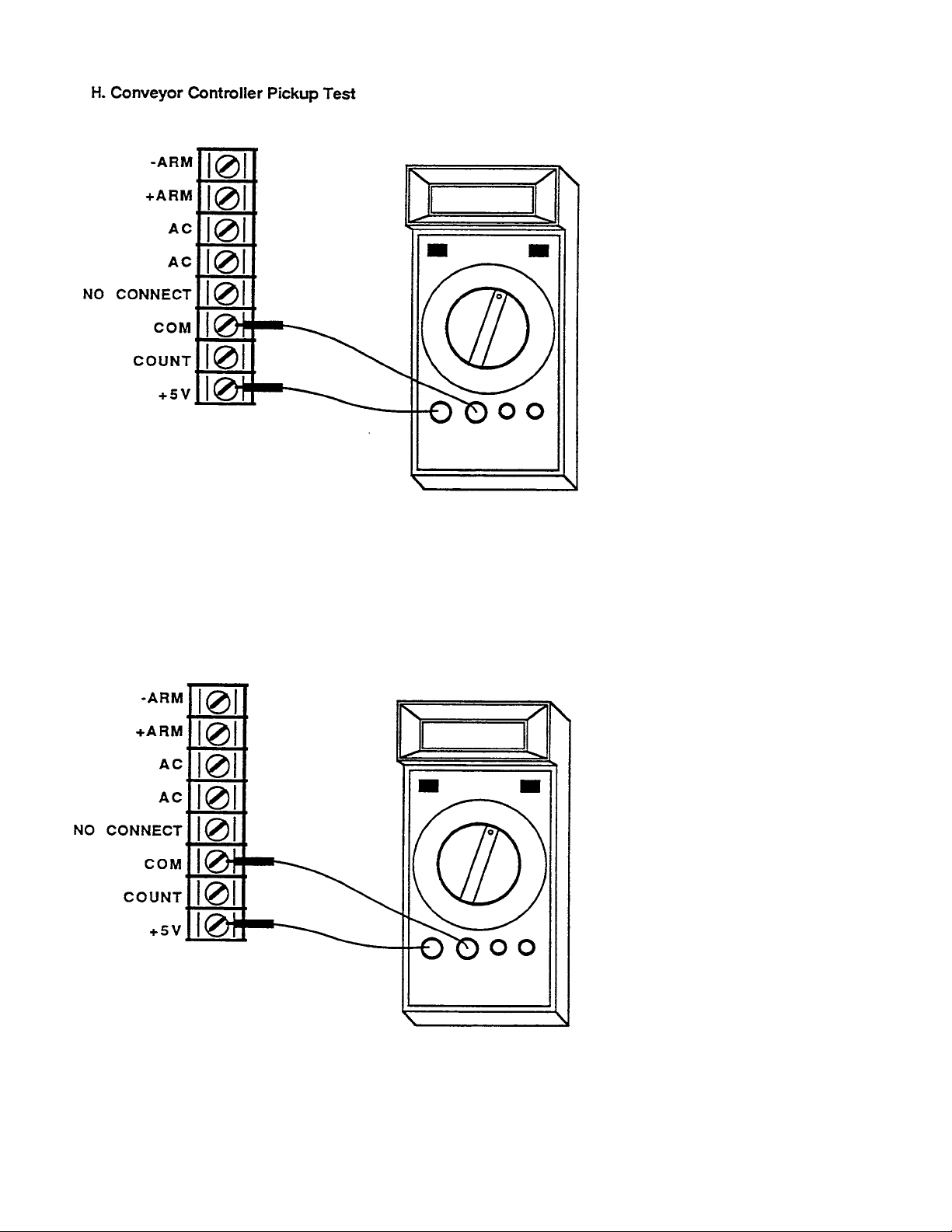

I. Conveyor Motor Test

1. Disconnect motor wires from Speed Controller terminals - ARM and + ARM.

2. Remove brush retainer caps. DO NOT remove the brushes.

3. Using an Ohm Meter (set to lowest scale) place one meter lead on each brush retaining plate Make sure

neither meter probe touches motor case.

4. Using a 5/16" open end wrench on the motor pickup shaft, very slowly rotate the shaft while observing the

Ohm Meter. There should never be a complete short 0 Ohm reading or a high Ohm reading during a 1/2

rotation. If either condition occurs, replace motor. The Ohm reading should stay between 3-5 Ohms.

Figure 12

18

SECTION

2

SERVICING

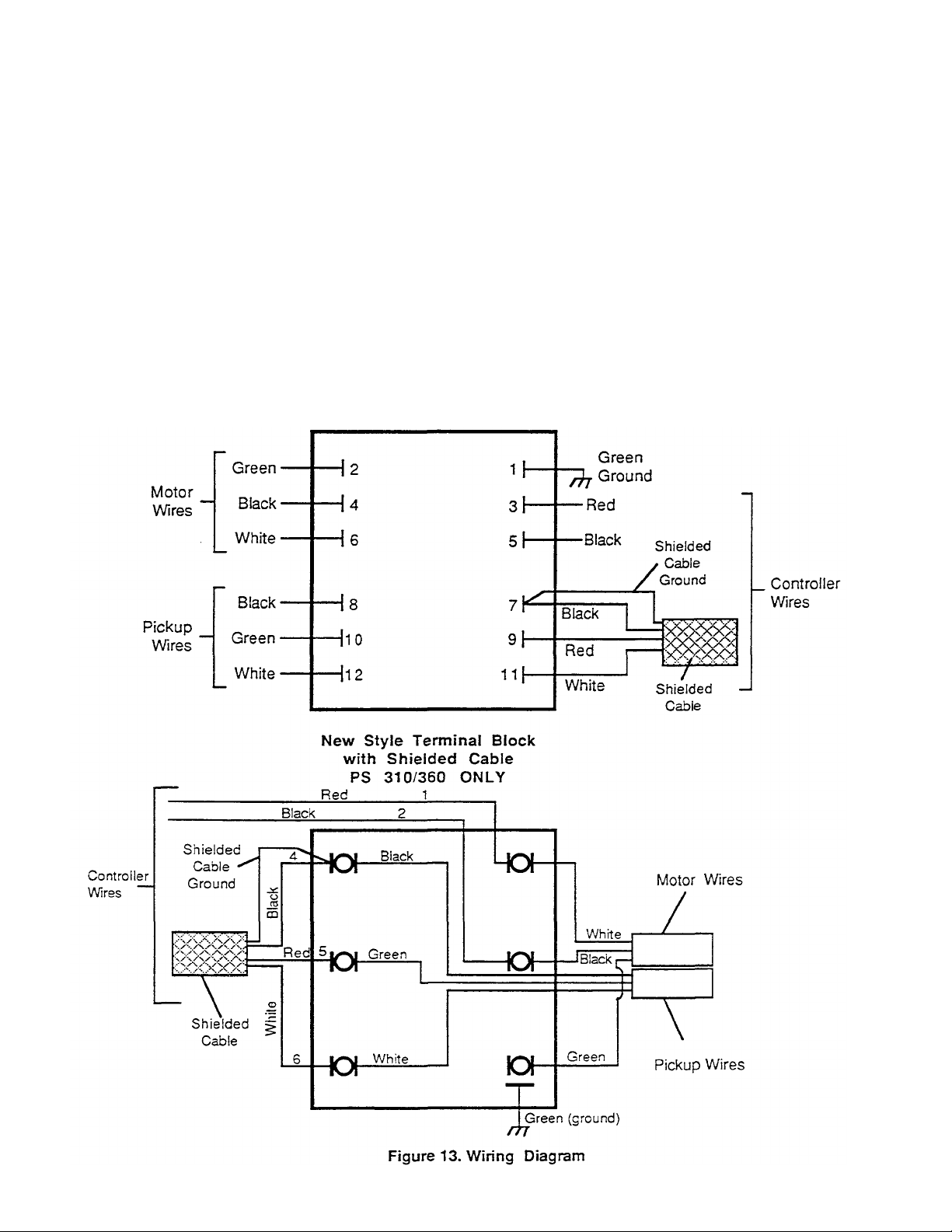

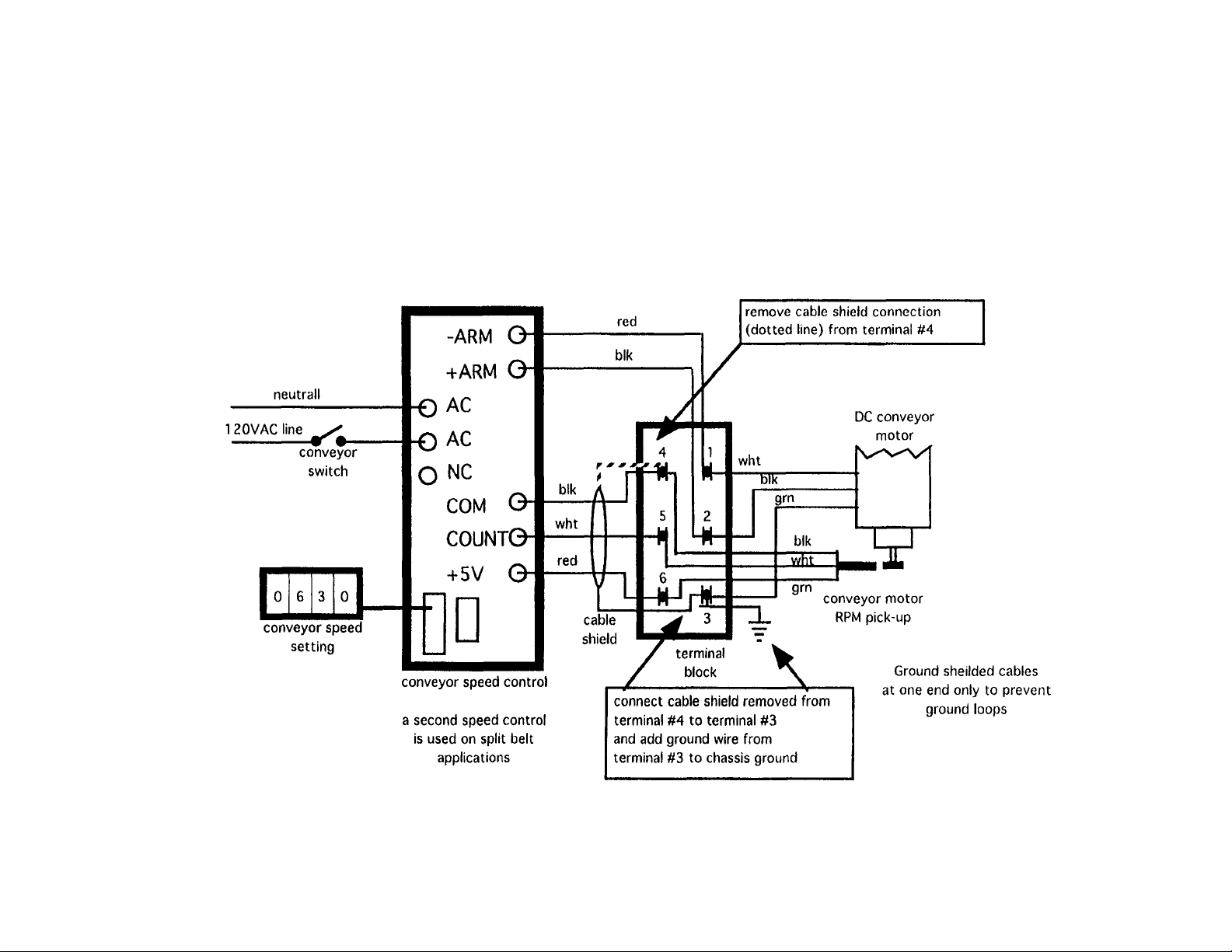

J. Magnetic Pickup Replacement

When replacing magnetic pickup apply LOCTITE

REMOVABLE #242 sparingly on threads, turn

mounting screw until finger tight, then 1/4 turn more

with a wrench.

On rare occasions the speed control board on early

Model 360's may be affected by electrical noise

transmitted by other electrical components or

wiring. This noise is picked up by the speed

control's pickup wires and transmitted to the control

board. In most cases the conveyor will fail when

burner spark ignition is present. After ignition is

complete, turn the conveyor switch OFF and ON

and the controller should reset.

Old Style Conveyor Terminal Block-Located In Left

Blower Motor Compartment PS 310/360 ONLY

COMPONENTS

The permanent fix is to replace the pickup wiring

between the controller and terminal block (located in

left end motor compartment) with a shielded cable

MM/PN 42400-0334. When installing the shielded

cable follow the color code change shown below:

Old Wiring Shielded Cable

Brown Black

Orange Red

Yellow White

There will be a fourth lead on one end of the shielded

cable. This end always attaches to the terminal block

in the motor compartment. The extra wire lead is a

ground lead which is attached to the Black wire of the

shielded cable. Newer Model 360's have shielded

cable from factory. See diagrams in Fiaure 13.

19

PS360 and PS570

conveyor sensor wiring changes

10/3/95 TRM

Application

Subject

Bulletin No. MM-133B

Date 04/07/95

Middleby Cooking Systems Group

1400 Toastmaster Drive • Elgin, Illinois 60120 (708)741-3300 •

Service & Parts (708) 741-4406

Service Bulletin

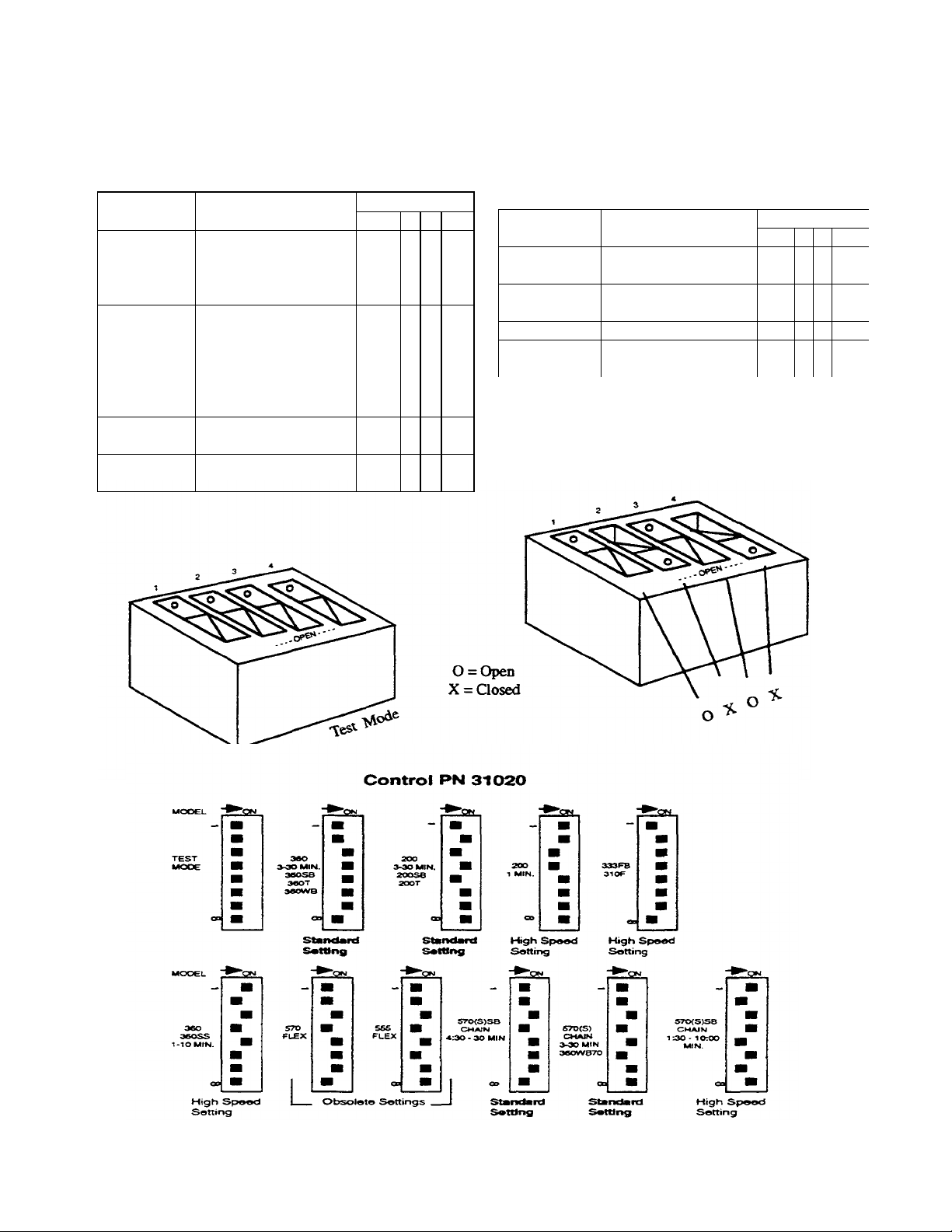

Installation and Diagnostic Instructions DIP

Switch Conveyor Control Assembly Part

Number 42810-0133

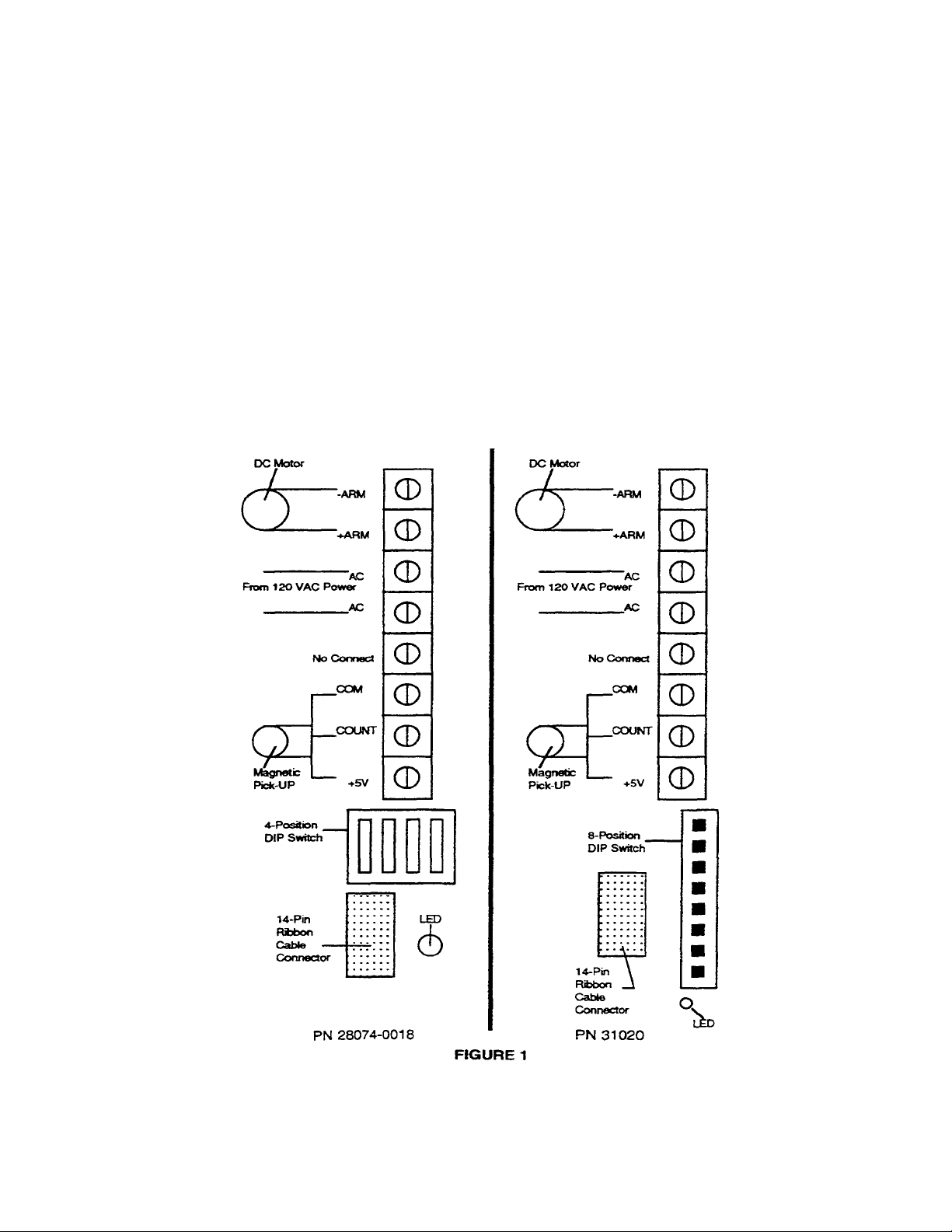

This service bulletin describes the original DIP switch conveyor control. Part Number 28074-0018, the new

DIP switch conveyor speed control, Part Number 31020 and introduces the latest instructions for installation

and set up- Either control can be contained in Kit Part Number 42810-0133. Both controls use advanced

digital electronics to improve reliability and provide diagnostic features. The installation and operation of

these controls are identical to each other and both replace prior non-DIP switch model controls.

Both control's printed circuit boards are housed in metal covers and both have

detachable/replaceable and interchangeable thumbwheel switches.

The distinguishing features between the original and the current control are the DIP switch

blocks and the markings on their metal covers.

Control PN 28074-0018 has a 4 position DIP switch and the control PN 31020 has an 8 position DIP

switch. Control PN 31020 has its individual DIP switch program settings silk screened on the metal

cover for easy reference.

Features

1. Control Part Number 31020 has enhanced tolerance to electrical systems that have

unstable frequency control (50 or 60 cycles). This control also continuously monitors the cycles

and adjusts itself accordingly. If an unstable frequency utility is common to the area, it is

recommended to use the PN 31020 control.

2. All DIP switch Conveyor Speed Controls provide a variable DC voltage output determined by the

thumbwheel setting and the frequency input from the speed control pick-up assembly.

3. DIP switch control PN 28074-0018 (REV. B)* and DIP switch control PN 31020

contain the program settings for all Middleby Marshall Ovens that use digital conveyor controls.

4. Both controls have built-in diagnostics to assist the service technician.

19B

Features Continued

5. Both controls are protected against gear motor shorts.

6. Both controls have metal housing covers that guard against handling damage and

minimizes radio frequency interference (RFI).

•Note: Control PN 28074-0018 REVISION B contains all current DIP switch settings currently used in the

field. Prior to REV B. this control was not compatible with the 570 Series conveyor chain driven ovens. The

revision letter is printed on the controls label should you be concerned if your inventory is not updated.

Compatibility

Both the above referenced controls are compatible with all current and previous Middleby

Marshall digital conveyor controls, gear motors and pick -ups. Consult the gear motor/sprocket

combinations chart - contained in the attached instructions - for optional conveyor speed set ups.

The replacement thumb wheels used on both DIP switch controls can be interchanged.

Availability

All orders for replacement controls will be filled with control PN 31020. All newly manufactured

ovens are fitted with control PN 31020. Continue to order replacement controls under kit PN

42810-0133 which will contain the attached updated instructions along with control PN 31020.

19C

DIP Switch Conveyor Control Installation and Diagnostic Instructions

Part Number 88210-0077 General

The following provides instructions for the Installation and Diagnostics of the DIP Switch Conveyor Control Part

Number 28074-0018 or Part Number 31020 contained in kit Part Number 42810-0133. Either of these controls

can be installed into the PS200, 300, and the 500 Series Ovens. Note: If installing PN 28074-0018 control into a

PS570(S) chain driven conveyor oven, be sure the control is marked "Revision B" on the label.

A. DIP Switch Conveyor Control Installation

The DIP Switch Conveyor Control Module is installed and secured with Phillips Head Screws and External Tooth

Lockwashers (not supplied) in the oven control compartment. The Thumb Wheel is installed in a rectangular

opening on the oven front panel. The ribbon cable from the Thumbwheel is connected to the 14-pin connector on

the control module.

Terminals on the specific control are arranged and marked to show electrical connections (See Figure 1). Consult

the specific oven model wire schematic for further wiring details especially for magnetic pick - up wire color

codes. The oven application must be selected by setting the "DIP" switches on the specific control to the proper

positions. The LED is used for diagnostics.

19D

DIP SWITCH SETTINGS

Standard Conveyor Speed Settings

FOR BOTH CONTROLS

Control PN 28074-0018 (REV. B)

SWITCH SETTING

MODEL(S) OVEN TlMES(MlN/MAX) 1 2 3 4

PS200

PS200SB

PS200-20 PS224 2:40 M1N TO 29:50 MIN x 0 x x

PS200T

PS360

PS310

PS350 2:40 MIN TO 29:50 M1N 0 x x x

PS360SB

PS360T

PS360WB

PS570 PS570S 2:40 MIN TO 29:50 MIN 0 x x 0

PS360WB70

PS570-SB 4:30 M1N TO 30 MIN

PS570S-SB EXTENDED BAKE x x x 0

High Speed Option Conveyor Settings

SWTCH SETTING

MODEL(S) OVEN TlME(MtN/MAX) 1 2 3 4

PS200

(1 MIN) 40 SEC TO 10 MIN 0 0 x X

PS333FB 1:30 MIN TO 10 MIN x x 0 X

PS310F

PS360SS 1 MIN T010 MIN 0 x 0 X

PS570-SB HIGH SPEED OPT.

PS570S-SB 1:30 TO 10 M1N x 0 X 0

FIGURE 2

19E

B. Replacement Thumb Wheel Switch Installation

1. Disconnect the power to the conveyor control by turning the conveyor switch to the "off' (0) position and

additionally by turning off the main power disconnect to the oven.

2. Remove the two screws that secure the failed switch body to the control door. Remove the switch body from the

door.

3. Locate the ribbon cable connector that links the thumb wheel switch to the controller. Note the orienta tion of the

cable for replacement. Grasp the connector frimly and pull it away from the control.

4. The thumb wheel connector is a polarized interlocking type connector that can only be installed in the correct

orientation. Locate the connector to the terminal strip so that the polarized interlocking lug on the connector is

aligned with the mating slot on the terminal and use your thumb to press the connector firmly into the terminal.

5. Locate the switch body to the control panel and assemble the switch body to the panel using the screws from

step 2.

6. Set the switches on the control to "diagnostic mode" in Figure 2.

7. Run diagnostic tests to determine performance to the control, (see diagnostic instructions below)

8. Set the mode switches back to the correct settings for the oven type and control version (see switch setting

instructions in Figure 2.

C. Diagnostics (Test Mode)

To assist the service technician, both controls feature built -in diagnositic software. Most of these diagnostic routines

are accessed by setting the dip switches to the test mode setting and then by powering up the conveyor control.

Also, certain conditions can be diagnosed by observing the red LED during normal operating conditions. Refer to

figure 2 to identify the control and test mode.

These test features are in addition to the diagnostic pr ocedures depicted in the applicable oven technical manual.

Note: Control PN 28074-0018 Test Mode setting is applicable to diagnosing 300 Series ovens and single belt 570

Series ovens only.

1. Diagnostics With Control In Normal Running Mode

If the red LED is lit and the control is not working (0 volts DC output at ARM then the gear motor short circuit

protection feature has been enabled.

Service the gear motor to correct the cause of the short circuit, then cycle the A.C. power switch to the conveyor to

restart the control.

19F

3

Diagnostics With Control in Test Mode

4

The control in this mode provides a fast and convenient method of troubleshooting the control. When running the

diagnostic procedure the entire procedure must run or the control must be powered down and reset. There is no

option to perform individual tests.

1. Turn the conveyor power switch off.

2. Set the thumbwheel switch to 00:00.

3. Open the control panel door.

4. Set the control DIP switch to test mode.

5. Pull out the control box door safety switch so that the power will be on at the controls.

6. Turn the conveyor power on; CAUTION: The control will automatically start and operate the conveyor, make

sure that the conveyor drive mechanism and the conveyor path is not obstructed.

Gear Motor and Sensor Test

The controller automatically operates the gear motor at three speeds: slow (for 10 seconds), medium (for 10

seconds), and high (for 10 seconds).

a) If the gear motor reverts to medium speed after 30 seconds and the LED on the controller is lit, the test passed

and gear motor operation is normal.

b) If the gear motor stops after 30 seconds and the LED on the controller is lit, this indicates a Pick-up failure.

c) If the motor stops in less than 30 seconds (does not complete the test cycle of 10 seconds each speed) and the

LED is lit, this indicates a gear motor failure.

Thumbwheel Test* Once the pick-up passes the sensor test, the gear motor will be automatically set to

mid speed.

Set the thumbwheel to 00:10, observe the LED for 5 flashes. Then set the thumbwheel to 00:20, observe the LED

again for 5 flashes. Repeat this procedure in: 10 increments up to :^0 waiting until the LED stops flashing between

each setting change.

Roll the switch setting back to 00:00 then repeat the procedure using the minutes switch up to 09:00 minutes. Roll

back the thumbwheel to 00:00 and repeat the procedure for the 10's segment up to 20:00.

Upon successful completion of this test the test sequence will automatically repeat itself starting with the 30 second

motor test. The service routin e can now be repeated or the control can be returned to the normal operating mode. Be

sure to change the DIP switch back to the correct oven position before operating the oven.

*The LED located at the bottom right comer of the control will indicate the thumbwheel test results (pass/fail). Pass is indicated by five flashes of the LED at 1

second intervals followed by the LED remaining lit. failure is indicated by the LED remaining lit with no flashing. The LED must be observed after each

setting change.

19G

D. Gear Motor/Sprocket Combinations

5

The chart reference below lists the different motor sprocket combinations used with the DIP switch conveyor control

system.

CONVEYOR MOTOR/SPROCKET COMBINATIONS

MODEL & CHAMBER GEAR MOTOR CONVEYOR BAKE TIME

LENGTH MOTOR SPROCKET SPROCKET PARAMETERS

PS200 40.5" 1350:1 Ratio 15T 10T 2:40 Min to 29:50 Min

PS220FS 27384-0011 22151-0003 22151-0002

PS224

(Standard)

PS200T 81" 1350:1 Ratio 30T 10T 2:40 Min to 29:50 Min

(Tandem) 27384-0011 22159-0004 22151-0002

PS200 1 Min 40.5" 311:1 Ratio 15T 10T 40 Sec to 10 Mm

(High Speed) 27384-0014 22151-0003 22151-0002

PS200SB 40.5" 1350:1 Ratio 30T 20T 2:40 Min to 29:50 Min

(Split Belt) 27384-0011 22159-0004 22159-0003

PS360 54.5"

PS310

PS314 1400:1 Ratio 15T 9T

PS360SB 27384-0008 22152-0018 22152-0017 2:40 Min to 29:50 Min

PS360WB

PS350

(Standard)

PS360WB70 70" 1400:1 Ratio 15T 9T 2:40 Min to 29:50 Min

(Wide Body Stretch) 27384-0008 22152-0018 22152-0017

PS360SS 54.5" 1400:1 Ratio 45T 9T 1 Min to 10 Min

(High Speed) 27384-0008 22152-0027 22152-0017

PS360T 109" 1400:1 Ratio 30T 9T 2:40 Min to 29:50 Min

(Tandem) 27384-0008 22152-0022 22152-0017

PS570 70" 1400:1 Ratio 15T 9T 2:40 Min to 29:50 Min

PS570S 27384-0008 22152-0018 22152-0017

(Standard)

PS570SB 70" 1350:1 Ratio 15T 9T 4:30 Min to 29:50 Min

(Standard) 27384-0011 22152-0024 22152-0017

PS570SB 70" 311:1 Ratio 15T 9T 1:30 Min to 10 Min

(High Speed) 27384-0014 22152-0024 22152-0017

19H