Micro Motion CDM100 Operating Manual

Configuration and Use Manual

MMI-20020944, Rev AC

April 2016

Micro Motion® Compact Density Meters (CDM)

Configuration and Use Manual

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully before proceeding to the next step.

Emerson Flow customer service

Email:

•Worldwide: flow.support@emerson.com

•Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America |

Europe and Middle East |

Asia Pacific |

|

|

|||

|

|

|

|

|

|

|

|

United States |

800-522-6277 |

U.K. |

0870 240 1978 |

Australia |

800 |

158 727 |

|

|

|

|

|

|

|

|

|

Canada |

+1 303-527-5200 |

The Netherlands |

+31 (0) 704 136 666 |

New Zealand |

099 |

128 804 |

|

|

|

|

|

|

|

|

|

Mexico |

+41 |

(0) 41 7686 111 |

France |

0800 917 901 |

India |

800 |

440 1468 |

|

|

|

|

|

|

|

|

Argentina |

+54 |

11 4837 7000 |

Germany |

0800 182 5347 |

Pakistan |

888 |

550 2682 |

|

|

|

|

|

|

|

|

Brazil |

+55 |

15 3413 8000 |

Italy |

8008 77334 |

China |

+86 |

21 2892 9000 |

|

|

|

|

|

|

|

|

Venezuela |

+58 |

26 1731 3446 |

Central & Eastern |

+41 (0) 41 7686 111 |

Japan |

+81 |

3 5769 6803 |

|

|

|

|

|

|

|

|

|

|

|

Russia/CIS |

+7 495 981 9811 |

South Korea |

+82 |

2 3438 4600 |

|

|

|

|

|

|

|

|

|

|

|

Egypt |

0800 000 0015 |

Singapore |

+65 |

6 777 8211 |

|

|

|

|

|

|

|

|

|

|

|

Oman |

800 70101 |

Thailand |

001 |

800 441 6426 |

|

|

|

|

|

|

|

|

|

|

|

Qatar |

431 0044 |

Malaysia |

800 |

814 008 |

|

|

|

|

|

|

|

|

|

|

|

Kuwait |

663 299 01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

South Africa |

800 991 390 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Saudi Arabia |

800 844 9564 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UAE |

800 0444 0684 |

|

|

|

|

|

|

|

|

|

|

|

Contents

Contents

Part I |

Getting Started |

|

||

Chapter 1 |

Before you begin ............................................................................................................ |

3 |

||

|

1.1 |

About this manual ....................................................................................................................... |

3 |

|

|

1.2 |

Model codes and device types ..................................................................................................... |

3 |

|

|

1.3 |

Communications tools and protocols .......................................................................................... |

4 |

|

|

1.4 |

Additional documentation and resources .................................................................................... |

5 |

|

Chapter 2 |

Quick start |

..................................................................................................................... |

7 |

|

|

2.1 |

Power up the transmitter ............................................................................................................. |

7 |

|

|

2.2 |

Check meter status ...................................................................................................................... |

7 |

|

|

2.3 |

Make ..............................................................................a startup connection to the transmitter |

8 |

|

|

2.4 |

Zero the ............................................................................................................................meter |

9 |

|

|

|

2.4.1 ................................................................................... |

Zero the meter using the display |

9 |

|

|

2.4.2 .................................................................................. |

Zero the meter using ProLink III |

10 |

|

|

2.4.3 ............................................................ |

Zero the meter using the Field Communicator |

11 |

Part II |

Configuration and commissioning |

|

||

Chapter 3 |

Introduction to configuration and commissioning ....................................................... |

15 |

||

|

3.1 |

Default values ............................................................................................................................ |

15 |

|

|

|

3.1.1 |

CDM default values ..................................................................................................... |

15 |

|

3.2 |

Enable access to the off-line menu of the display ....................................................................... |

16 |

|

|

3.3 |

Disable HART security ................................................................................................................ |

17 |

|

|

3.4 |

Set the HART lock ...................................................................................................................... |

19 |

|

|

3.5 |

Restore the factory configuration .............................................................................................. |

19 |

|

Chapter 4 |

Configure process measurement .................................................................................. |

21 |

||

|

4.1 |

Verify the calibration factors ...................................................................................................... |

21 |

|

|

|

4.1.1 |

Calibration factors ...................................................................................................... |

22 |

|

4.2 |

Configure line density measurement ........................................................................................ |

23 |

|

|

|

4.2.1 |

Configure Density Measurement Unit ................................................................................ |

23 |

|

|

4.2.2 |

Configure Density Damping ........................................................................................... |

25 |

|

|

4.2.3 |

Configure Density Cutoff ................................................................................................ |

26 |

|

|

4.2.4 |

Configure two-phase flow parameters ........................................................................ |

26 |

|

4.3 |

Configure temperature measurement ....................................................................................... |

28 |

|

|

|

4.3.1 |

Configure Temperature Measurement Unit ........................................................................ |

28 |

|

|

4.3.2 |

Configure Temperature Damping ..................................................................................... |

29 |

|

|

4.3.3 |

Configure Temperature Input .......................................................................................... |

30 |

|

4.4 |

Configure the pressure input ..................................................................................................... |

33 |

|

|

|

4.4.1 |

Configure the pressure input using ProLink III ............................................................. |

33 |

|

|

4.4.2 |

Configure the pressure input using the Field Communicator ....................................... |

35 |

|

|

4.4.3 |

Options for Pressure Measurement Unit ........................................................................... |

36 |

|

4.5 |

Set up the API referral application .............................................................................................. |

37 |

|

Configuration and Use Manual |

i |

Contents

|

|

4.5.1 |

Set up the API referral application using ProLink III ...................................................... |

37 |

|

|

4.5.2 |

Set up the API referral application using the Field Communicator ............................... |

42 |

|

4.6 |

Set up concentration measurement .......................................................................................... |

50 |

|

|

|

4.6.1 |

Preparing to set up concentration measurement ........................................................ |

50 |

|

|

4.6.2 |

Set up concentration measurement using ProLink III ................................................... |

51 |

|

|

4.6.3 |

Set up concentration measurement using the Field Communicator ............................ |

58 |

|

|

4.6.4 |

Using equations to calculate specific gravity, °Baumé, °Brix, °Plato, and °Twaddell ...... |

63 |

|

|

4.6.5 |

Matrix switching ......................................................................................................... |

64 |

|

4.7 |

Set up flow monitoring .............................................................................................................. |

66 |

|

|

|

4.7.1 |

Configure velocity measurement ................................................................................ |

66 |

|

|

4.7.2 |

Configure volume flow rate measurement .................................................................. |

68 |

|

|

4.7.3 |

Configure Flow Direction ................................................................................................ |

70 |

|

|

4.7.4 |

Configure Flow Damping ................................................................................................ |

74 |

Chapter 5 |

Configure device options and preferences .................................................................... |

75 |

||

|

5.1 |

Configure the transmitter display .............................................................................................. |

75 |

|

|

|

5.1.1 |

Configure the language used for the display ............................................................... |

75 |

|

|

5.1.2 |

Configure the process variables and diagnostic variables shown on the display ........... |

76 |

|

|

5.1.3 |

Configure the number of decimal places (precision) shown on the display .................. |

76 |

|

|

5.1.4 |

Configure the refresh rate of data shown on the display .............................................. |

77 |

|

|

5.1.5 |

Enable or disable automatic scrolling through the display variables ............................ |

77 |

|

5.2 |

Enable or disable the Acknowledge All Alerts display command ...................................................... |

78 |

|

|

5.3 |

Configure security for the display menus .................................................................................. |

79 |

|

|

5.4 |

Configure alert handling ............................................................................................................ |

80 |

|

|

|

5.4.1 |

Configure Fault Timeout ................................................................................................. |

80 |

|

|

5.4.2 |

Configure Alert Severity ................................................................................................. |

81 |

|

5.5 |

Configure informational parameters ......................................................................................... |

83 |

|

Chapter 6 |

Integrate the meter with the control system ................................................................ |

85 |

||

|

6.1 |

Configure Channel B .................................................................................................................. |

85 |

|

|

6.2 |

Configure the mA output .......................................................................................................... |

86 |

|

|

|

6.2.1 |

Configure mA Output Process Variable ............................................................................. |

86 |

|

|

6.2.2 |

Configure Lower Range Value (LRV) and Upper Range Value (URV) .................................... |

88 |

|

|

6.2.3 |

Configure Added Damping ............................................................................................. |

89 |

|

|

6.2.4 |

Configure mA Output Fault Action and mA Output Fault Level ............................................... |

91 |

|

6.3 |

Configure the discrete output ................................................................................................... |

92 |

|

|

|

6.3.1 |

Configure Discrete Output Source .................................................................................... |

92 |

|

|

6.3.2 |

Configure Discrete Output Polarity ................................................................................... |

93 |

|

|

6.3.3 |

Configure Discrete Output Fault Action ............................................................................. |

94 |

|

6.4 |

Configure an enhanced event .................................................................................................... |

95 |

|

|

6.5 |

Configure HART/Bell 202 communications ............................................................................... |

96 |

|

|

|

6.5.1 |

Configure basic HART parameters ............................................................................... |

96 |

|

|

6.5.2 |

Configure HART variables (PV, SV, TV, QV) .................................................................. |

97 |

|

|

6.5.3 |

Configure burst communications ............................................................................... |

99 |

|

6.6 |

Configure Modbus communications ........................................................................................ |

103 |

|

|

6.7 |

Configure Digital Communications Fault Action ............................................................................... |

105 |

|

|

|

6.7.1 |

Options for Digital Communications Fault Action ............................................................... |

105 |

Chapter 7 |

Complete the configuration ....................................................................................... |

107 |

||

|

7.1 |

Test or tune the system using sensor simulation ...................................................................... |

107 |

|

|

7.2 |

Back up transmitter configuration ........................................................................................... |

107 |

|

|

7.3 |

Enable HART security ............................................................................................................... |

108 |

|

ii |

Micro Motion® Compact Density Meters (CDM) |

Contents

Part III |

Operations, maintenance, and troubleshooting |

|

||

Chapter 8 |

Transmitter operation ................................................................................................ |

113 |

||

|

8.1 |

Record the process variables ................................................................................................... |

113 |

|

|

8.2 |

View process variables and diagnostic variables ...................................................................... |

113 |

|

|

|

8.2.1 |

View process variables using the display ................................................................... |

114 |

|

|

8.2.2 |

View process variables and other data using ProLink III ............................................. |

114 |

|

|

8.2.3 |

View process variables using the Field Communicator .............................................. |

115 |

|

8.3 |

View and acknowledge status alerts ........................................................................................ |

115 |

|

|

|

8.3.1 |

View and acknowledge alerts using the display ........................................................ |

115 |

|

|

8.3.2 |

View and acknowledge alerts using ProLink III ........................................................... |

117 |

|

|

8.3.3 |

View alerts using the Field Communicator ................................................................ |

118 |

|

|

8.3.4 |

Alert data in transmitter memory ............................................................................. |

118 |

Chapter 9 |

Measurement support ............................................................................................... |

121 |

||

|

9.1 |

Perform the inline calibration check procedure ....................................................................... |

121 |

|

|

|

9.1.1 |

Perform the inline calibration check using ProLink III ................................................. |

122 |

|

|

9.1.2 |

Perform the inline calibration check using the Field Communicator .......................... |

123 |

|

9.2 |

Perform the Known Density Verification procedure ................................................................. |

123 |

|

|

|

9.2.1 |

Perform the Known Density Verification procedure using the display ....................... |

124 |

|

|

9.2.2 |

Perform the Known Density Verification procedure using ProLink III ......................... |

125 |

|

|

9.2.3 |

Perform the Known Density Verification procedure using the |

|

|

|

|

Field Communicator ................................................................................................. |

125 |

|

9.3 |

Adjust density measurement with Density Offset or Density Meter Factor ....................................... |

126 |

|

|

9.4 |

Perform density offset calibration ............................................................................................ |

127 |

|

|

|

9.4.1 |

Perform density offset calibration using the display .................................................. |

128 |

|

|

9.4.2 |

Perform density offset calibration using ProLink III .................................................... |

129 |

|

|

9.4.3 |

Perform density offset calibration using the Field Communicator ............................. |

129 |

|

9.5 |

Adjust temperature measurement with Temperature Offset ........................................................ |

130 |

|

|

9.6 |

Adjust concentration measurement with Trim Offset ................................................................. |

131 |

|

|

9.7 |

Adjust concentration measurement with Trim Slope and Trim Offset ........................................... |

132 |

|

|

9.8 |

Set up user-defined calculations .............................................................................................. |

134 |

|

|

|

9.8.1 |

Equations used in user-defined calculations .............................................................. |

136 |

|

|

9.8.2 |

Measurement units used in user-defined calculations ............................................... |

136 |

|

9.9 |

Diagnostic density ................................................................................................................... |

137 |

|

|

|

9.9.1 |

Enable diagnostic input density ................................................................................ |

138 |

|

|

9.9.2 |

Enable calculated diagnostic density ......................................................................... |

138 |

Chapter 10 |

Troubleshooting ........................................................................................................ |

139 |

||

|

10.1 |

Quick guide to troubleshooting ............................................................................................... |

139 |

|

|

10.2 |

Check power supply wiring ...................................................................................................... |

140 |

|

|

10.3 |

Check grounding ..................................................................................................................... |

141 |

|

|

10.4 |

Perform loop tests ................................................................................................................... |

142 |

|

|

|

10.4.1 |

Perform loop tests using the display ......................................................................... |

142 |

|

|

10.4.2 |

Perform loop tests using ProLink III ........................................................................... |

143 |

|

|

10.4.3 |

Perform loop tests using the Field Communicator .................................................... |

144 |

|

10.5 |

Status LED states ..................................................................................................................... |

146 |

|

|

10.6 |

Status alerts, causes, and recommendations ........................................................................... |

147 |

|

|

10.7 |

Density measurement problems ............................................................................................. |

153 |

|

|

10.8 |

Temperature measurement problems ..................................................................................... |

154 |

|

|

|

10.8.1 |

Thermal insulation .................................................................................................... |

155 |

Configuration and Use Manual |

iii |

Contents

|

10.9 |

API referral problems ............................................................................................................... |

155 |

|

|

10.10 |

Concentration measurement problems ................................................................................... |

156 |

|

|

10.11 |

Velocity measurement problems ............................................................................................ |

156 |

|

|

10.12 |

Milliamp output problems ....................................................................................................... |

158 |

|

|

10.13 |

Discrete output problems ........................................................................................................ |

160 |

|

|

10.14 |

Time Period Signal (TPS) output problems ............................................................................... |

160 |

|

|

10.15 |

Using sensor simulation for troubleshooting ........................................................................... |

161 |

|

|

10.16 |

Trim mA outputs ..................................................................................................................... |

161 |

|

|

|

10.16.1 Trim mA outputs using ProLink III .............................................................................. |

161 |

|

|

|

10.16.2 Trim mA outputs using the Field Communicator ....................................................... |

162 |

|

|

10.17 |

Check HART communications ................................................................................................. |

162 |

|

|

10.18 |

Check Lower Range Value and Upper Range Value ......................................................................... |

164 |

|

|

10.19 |

Check mA Output Fault Action ...................................................................................................... |

164 |

|

|

10.20 |

Check for radio frequency interference (RFI) ............................................................................ |

165 |

|

|

10.21 |

Check Flow Direction .................................................................................................................. |

165 |

|

|

10.22 |

Check the cutoffs .................................................................................................................... |

165 |

|

|

10.23 |

Check for two-phase flow (slug flow) ....................................................................................... |

166 |

|

|

10.24 |

Check the drive gain ................................................................................................................ |

166 |

|

|

|

10.24.1 Excessive or erratic drive gain .................................................................................... |

167 |

|

|

|

10.24.2 Collect drive gain data .............................................................................................. |

168 |

|

|

10.25 |

Check the pickoff voltage ........................................................................................................ |

168 |

|

|

|

10.25.1 Collect pickoff voltage data ...................................................................................... |

169 |

|

|

10.26 |

Check for internal electrical problems ..................................................................................... |

169 |

|

|

10.27 |

Locate a device using the HART 7 Squawk feature ................................................................... |

170 |

|

Appendices and reference |

|

|||

Appendix A |

Calibration certificate ................................................................................................ |

171 |

||

|

A.1 |

Sample calibration certificates ................................................................................................ |

171 |

|

Appendix B |

Using the transmitter display ..................................................................................... |

175 |

||

|

B.1 |

Components of the transmitter interface ................................................................................ |

175 |

|

|

B.2 |

Use the optical switches .......................................................................................................... |

175 |

|

|

B.3 |

Access and use the display menu system ................................................................................. |

176 |

|

|

|

B.3.1 |

Enter a floating-point value using the display ............................................................ |

177 |

|

B.4 |

Display codes for process variables .......................................................................................... |

180 |

|

|

B.5 |

Codes and abbreviations used in display menus ...................................................................... |

180 |

|

Appendix C |

Using ProLink III with the transmitter ......................................................................... |

193 |

||

|

C.1 |

Basic information about ProLink III ........................................................................................... |

193 |

|

|

C.2 |

Connect with ProLink III ........................................................................................................... |

194 |

|

|

|

C.2.1 |

Connection types supported by ProLink III ................................................................ |

194 |

|

|

C.2.2 |

Connect with ProLink III over Modbus/RS-485 ........................................................... |

195 |

|

|

C.2.3 |

Connect with ProLink III over HART/Bell 202 ............................................................. |

198 |

Appendix D |

Using the Field Communicator with the transmitter ................................................... |

207 |

||

|

D.1 |

Basic information about the Field Communicator .................................................................... |

207 |

|

|

D.2 |

Connect with the Field Communicator .................................................................................... |

208 |

|

Appendix E |

Concentration measurement matrices, derived variables, and process variables ........ |

211 |

||

|

E.1 |

Standard matrices for the concentration measurement application ........................................ |

211 |

|

|

E.2 |

Concentration measurement matrices available by order ........................................................ |

212 |

|

|

E.3 |

Derived variables and calculated process variables .................................................................. |

214 |

|

iv |

Micro Motion® Compact Density Meters (CDM) |

Contents

Appendix F MID applications ........................................................................................................ |

217 |

|

F.1 |

Certification ............................................................................................................................ |

217 |

F.2 |

MID flow computer and power supply requirements ............................................................... |

218 |

F.3 |

Flow computer density calculations ........................................................................................ |

218 |

F.4 |

TPS and external input connections to the flow computer ....................................................... |

220 |

F.5 |

MID support ............................................................................................................................ |

220 |

F.6 |

Read revision and checksum data ............................................................................................ |

221 |

F.7 |

Secure the meter ..................................................................................................................... |

221 |

F.8 |

Switch to unsecured mode ...................................................................................................... |

224 |

Configuration and Use Manual |

v |

Contents

vi |

Micro Motion® Compact Density Meters (CDM) |

Getting Started

Part I

Getting Started

Chapters covered in this part:

•Before you begin

•Quick start

Configuration and Use Manual |

1 |

Getting Started

2 |

Micro Motion® Compact Density Meters (CDM) |

Before you begin

1 Before you begin

Topics covered in this chapter:

•About this manual

•Model codes and device types

•Communications tools and protocols

•Additional documentation and resources

1.1About this manual

This manual provides information to help you configure, commission, use, maintain, and troubleshoot the Micro Motion Compact Density Meter (CDM).

The following versions of the CDM are documented in this manual:

•Compact Density Meter with Analog Outputs

•Compact Density Meter with Analog Output and Discrete Output

•Compact Density Meter with Time Period Signal Output

For the Compact Density Meter with FOUNDATION™ Fieldbus, see Micro Motion® Compact Density Meters with FOUNDATION™ Fieldbus: Configuration and Use Manual.

Important

This manual assumes that the following conditions apply:

•The meter has been installed correctly and completely, according to the instructions in the installation manual.

•The installation complies with all applicable safety requirements.

•The user is trained in all government and corporate safety standards.

1.2Model codes and device types

Your device can be identified by the model code on the device tag.

Table 1-1: Model codes and device types

|

|

|

|

Electronics mount- |

Model code |

Device nickname |

I/O |

|

ing |

|

|

|

|

|

CDM100M****C |

CDM mA |

• |

Two mA outputs |

Integral |

|

|

• |

RS-485 terminals |

|

|

|

|

|

|

CDM100M****D |

CDM DO |

• |

One mA output |

Integral |

|

|

• |

One discrete output |

|

|

|

• |

RS-485 terminals |

|

|

|

|

|

|

Configuration and Use Manual |

3 |

Before you begin

Table 1-1: Model codes and device types (continued)

|

|

|

|

Electronics mount- |

Model code |

Device nickname |

I/O |

|

ing |

|

|

|

|

|

CDM100M****B |

CDM TPS |

• |

One mA output |

Integral |

|

|

• One Time Period Sig- |

|

|

|

|

|

nal output |

|

|

|

• |

RS-485 terminals |

|

|

|

|

|

|

CDM100M****A |

CDM FF |

• |

FOUNDATION™ field- |

4-wire remote |

|

|

|

bus |

transmitter |

|

|

|

|

|

Restriction

The CDM mA, CDM DO, and CDM FF support a complete set of application and configuration options. The CDM TPS supports a subset of configuration options. Refer to the product data sheet for details.

1.3Communications tools and protocols

You can use several different communications tools and protocols to interface with the device. You may use different tools in different locations or for different tasks.

Table 1-2: Communications tools, protocols, and related information

Communica- |

|

|

|

|

|

|

tions tool |

Supported protocols |

Scope |

In this manual |

For more information |

||

|

|

|

|

|

||

Display |

Not applicable |

Basic configuration and |

Complete user informa- |

Not applicable |

||

|

|

|

commissioning |

tion. See Appendix B. |

|

|

|

|

|

|

|

|

|

ProLink III |

• |

Modbus/RS-485 |

Complete configuration |

Basic user information. |

User manual |

|

|

• |

HART/Bell 202 |

and commissioning |

See Appendix C. |

• |

Installed with soft- |

|

• |

Service port |

|

|

|

ware |

|

|

|

|

|

• |

On Micro Motion |

|

|

|

|

|

|

user documentation |

|

|

|

|

|

|

CD |

|

|

|

|

|

• |

On Micro Motion |

|

|

|

|

|

|

web site |

|

|

|

|

|

|

(www.micromo |

|

|

|

|

|

|

tion.com) |

|

|

|

|

|

|

|

Field Commu- |

• |

HART/Bell 202 |

Complete configuration |

Basic user information. |

User manual on |

|

nicator |

|

|

and commissioning |

See Appendix D. |

Micro Motion web site |

|

|

|

|

|

|

(www.micromo |

|

|

|

|

|

|

tion.com ) |

|

|

|

|

|

|

|

|

4 |

Micro Motion® Compact Density Meters (CDM) |

Before you begin

Tip

You may be able to use other communications tools from Emerson Process Management, such as AMS Suite: Intelligent Device Manager, or the Smart Wireless THUM™ Adapter. Use of AMS or the Smart Wireless THUM Adapter is not discussed in this manual. For more information on the Smart Wireless THUM Adapter, refer to the documentation available at www.micromotion.com.

1.4Additional documentation and resources

Micro Motion provides additional documentation to support the installation and operation of the device.

Table 1-3: Additional documentation and resources

Topic |

Document |

|

|

Device installation |

Micro Motion Compact Density Meters (CDM): Installation Manual |

|

|

Product data sheet |

Micro Motion Compact Density Meters: Product Data Sheet |

|

|

All documentation resources are available on the Micro Motion web site at

www.micromotion.com or on the Micro Motion user documentation DVD.

Configuration and Use Manual |

5 |

Before you begin

6 |

Micro Motion® Compact Density Meters (CDM) |

Quick start

2 Quick start

Topics covered in this chapter:

•Power up the transmitter

•Check meter status

•Make a startup connection to the transmitter

•Zero the meter

2.1Power up the transmitter

The transmitter must be powered up for all configuration and commissioning tasks, or for process measurement.

1.Ensure that all transmitter and sensor covers and seals are closed.

WARNING!

WARNING!

To prevent ignition of flammable or combustible atmospheres, ensure that all covers and seals are tightly closed. For hazardous area installations, applying power while housing covers are removed or loose can cause an explosion.

2.Turn on the electrical power at the power supply.

The transmitter will automatically perform diagnostic routines. During this period, Alert 009 is active. The diagnostic routines should complete in approximately

30 seconds.

Postrequisites

Although the sensor is ready to receive process fluid shortly after power-up, the electronics can take up to 10 minutes to reach thermal equilibrium. Therefore, if this is the initial startup, or if power has been off long enough to allow components to reach ambient temperature, allow the electronics to warm up for approximately 10 minutes before relying on process measurements. During this warm-up period, you may observe minor measurement instability or inaccuracy.

2.2Check meter status

Check the meter for any error conditions that require user action or that affect measurement accuracy.

1.Wait approximately 10 seconds for the power-up sequence to complete.

Immediately after power-up, the transmitter runs through diagnostic routines and checks for error conditions. During the power-up sequence, Alert A009 is active. This alert should clear automatically when the power-up sequence is complete.

Configuration and Use Manual |

7 |

Quick start

2.Check the status LED on the transmitter.

Table 2-1: Transmitter status reported by status LED

LED state |

Description |

Recommendation |

|

|

|

Green |

No alerts are active. |

Continue with configuration or process meas- |

|

|

urement. |

|

|

|

Yellow |

One or more low-severity alerts are active. |

A low-severity alert condition does not affect |

|

|

measurement accuracy or output behavior. |

|

|

You can continue with configuration or proc- |

|

|

ess measurement. If you choose, you can iden- |

|

|

tify and resolve the alert condition. |

|

|

|

Flashing yellow |

Calibration in progress, or Known Density Veri- |

The measurement can fluctuate during the |

|

fication in progress. |

calibration process or change as a result of the |

|

|

calibration process. The alert will clear when |

|

|

the calibration is complete. Check the calibra- |

|

|

tion results before continuing. |

|

|

|

Red |

One or more high-severity alerts are active. |

A high-severity alert condition affects meas- |

|

|

urement accuracy and output behavior. Re- |

|

|

solve the alert condition before continuing. |

|

|

|

• |

View and acknowledge status alerts (Section 8.3) |

|

• |

Status alerts, causes, and recommendations (Section 10.6) |

|

2.3Make a startup connection to the transmitter

For all configuration tools except the display, you must have an active connection to the transmitter to configure the transmitter.

Identify the connection type to use, and follow the instructions for that connection type in the appropriate appendix. Use the default communications parameters shown in the appendix.

Communications tool |

Connection type to use |

Instructions |

|

|

|

ProLink III |

Modbus/RS-485 |

Appendix C |

|

HART/Bell 202 |

|

|

|

|

Field Communicator |

HART/Bell 202 |

Appendix D |

|

|

|

Postrequisites

(Optional) Change the communications parameters to site-specific values.

•To change the communications parameters using ProLink III, choose Device Tools >

Configuration > Communications.

8 |

Micro Motion® Compact Density Meters (CDM) |

Quick start

•To change the communications parameters using the Field Communicator, choose

Configure > Manual Setup > HART > Communications.

Important

If you are changing communications parameters for the connection type that you are using, you will lose the connection when you write the parameters to the transmitter. Reconnect using the new parameters.

2.4Zero the meter

Zeroing the meter establishes a baseline for the velocity indicator by analyzing the sensor's output when there is no flow through the sensor tubes.

Note

Do not zero the meter if a high-severity alert is active. Correct the problem, then zero the meter. You may zero the meter if a low-severity alert is active.

In most cases, the default value (0) is adequate for flow indication. Do not zero the meter unless the velocity switch is being triggered incorrectly and you need to apply an offset to the velocity measurement.

• |

Zero the meter using the display |

(Section 2.4.1) |

• |

Zero the meter using ProLink III |

(Section 2.4.2) |

• |

Zero the meter using the Field Communicator (Section 2.4.3) |

|

2.4.1Zero the meter using the display

Restriction

You cannot change the Zero Time setting from the display. The current setting of Zero Time will be applied to the zero procedure. The default value is 20 seconds. If you need to change Zero Time, you must make a connection to the transmitter from a communications tool such as ProLink III.

Procedure

1.Prepare the meter:

a.Stop flow through the sensor by shutting the downstream valve, and then the upstream valve if available.

b.Verify that the sensor is blocked in, that flow has stopped, and that the sensor is completely full of process fluid.

c.Verify that the process fluid is not flashing or condensing, and that it does not contain particles that can settle out.

d.Remove or reduce sources of electromechanical noise if appropriate.

2.Start the zero process.

a.Navigate to the Zero menu: OFFLINE MAINT > OFFLINE CALIB > VEL ZERO.

Configuration and Use Manual |

9 |

Quick start

b.Scroll to CAL VEL/ZERO and activate Select, then select CAL/YES?.

The status LED changes to flashing yellow while the zero is in progress.

3.Read the zero result on the display.

The display reports CAL PASS if the zero was successful, or CAL FAIL if it was not.

Postrequisites

Restore normal flow through the sensor by opening the valves.

Need help? If the zero fails:

•Ensure that there is no flow through the sensor, then retry.

•Remove or reduce sources of electromechanical noise, then retry.

•Set Zero Time to a lower value, then retry.

•If the zero continues to fail, contact Micro Motion.

•If you want to return the meter to operation using a previous zero value, choose OFFLINE MAINT > CAL > RESTORE VEL/ZERO.

2.4.2Zero the meter using ProLink III

1.Prepare the meter:

a.Stop flow through the sensor by shutting the downstream valve, and then the upstream valve if available.

b.Verify that the sensor is blocked in, that flow has stopped, and that the sensor is completely full of process fluid.

c.Verify that the process fluid is not flashing or condensing, and that it does not contain particles that can settle out.

d.Remove or reduce sources of electromechanical noise if appropriate.

2.Choose Device Tools > Calibration > Zero Velocity.

3.Modify Zero Time, if desired.

Zero Time controls the amount of time the transmitter takes to determine its zeroflow reference point. The default Zero Time is 20 seconds. For most applications, the default Zero Time is appropriate.

4.Click Calibrate Zero.

The Calibration in Progress message is displayed. When the calibration is complete:

•If the zero procedure was successful, a Calibration Success message and a new zero value are displayed.

•If the zero procedure failed, a Calibration Failed message is displayed.

Postrequisites

Restore normal flow through the sensor by opening the valves.

10 |

Micro Motion® Compact Density Meters (CDM) |

Quick start

Need help? If the zero fails:

•Remove or reduce sources of electromechanical noise, then retry.

•If the zero continues to fail, contact Micro Motion.

•If you want to return the meter to operation using a previous zero value, choose Device Tools >

Calibration > Zero Velocity > Restore Prior Zero. Restore Prior Zero is available only while the Zero Velocity window is open. If you close the Zero Velocity window, you will no longer be able to restore the prior zero.

2.4.3Zero the meter using the Field Communicator

1.Prepare the meter:

a.Stop flow through the sensor by shutting the downstream valve, and then the upstream valve if available.

b.Verify that the sensor is blocked in, that flow has stopped, and that the sensor is completely full of process fluid.

c.Verify that the process fluid is not flashing or condensing, and that it does not contain particles that can settle out.

d.Remove or reduce sources of electromechanical noise if appropriate.

2.Choose Service Tools > Maintenance > Calibration > Zero Calibration.

3.Modify Zero Time, if desired.

Zero Time controls the amount of time the transmitter takes to determine its zeroflow reference point. The default Zero Time is 20 seconds. For most applications, the default Zero Time is appropriate.

4.Press Perform Auto Zero to start the zero, and wait while the zero calibration is performed.

5.When the zero is complete, data from the zero calibration is displayed.

•Press OK to accept the data and store the values.

•Press ABORT to discard the data and return to the previous zero values.

Postrequisites

Restore normal flow through the sensor by opening the valves.

Need help? If the zero fails:

•Ensure that there is no flow through the sensor, then retry.

•Remove or reduce sources of electromechanical noise, then retry.

•Set Zero Time to a lower value, then retry.

•If the zero continues to fail, contact Micro Motion.

Configuration and Use Manual |

11 |

Quick start

12 |

Micro Motion® Compact Density Meters (CDM) |

Configuration and commissioning

Part II

Configuration and commissioning

Chapters covered in this part:

•Introduction to configuration and commissioning

•Configure process measurement

•Configure device options and preferences

•Integrate the meter with the control system

•Complete the configuration

Configuration and Use Manual |

13 |

Configuration and commissioning

14 |

Micro Motion® Compact Density Meters (CDM) |

Introduction to configuration and commissioning

3 Introduction to configuration and commissioning

Topics covered in this chapter:

•Default values

•Enable access to the off line menu of the display

•Disable HART security

•Set the HART lock

•Restore the factory configuration

3.1Default values

Default values for your meter are configured at the factory.

Important

Default values are based on your purchase order options. Therefore, the default values described in the following tables may not be the factory default values configured for your system. For absolute accuracy, refer to the configuration sheet that was shipped with your meter.

3.1.1CDM default values

Table 3-1: CDM default mA scaling values

Variable |

Default 4 mA |

Default 20 mA |

|

|

|

Line density |

0.500 g/cm3 |

1.500 g/cm3 |

|

|

|

Line temperature |

-50°C |

200.000°C |

|

-58°F |

392°F |

|

|

|

Tube-case temperature differ- |

0°C |

10°C |

ential |

32°F |

50°F |

|

|

|

Drive gain |

0.000 % |

100.000 % |

|

|

|

External temperature |

-50.000°C |

200.000°C |

|

-58.00000°F |

392.0000°F |

|

|

|

External pressure |

0.000 PSIg |

1450.377 PSIg |

|

|

|

Case temperature |

-50°C |

200°C |

|

|

|

Sensor time period |

5000 us |

10000 us |

|

0 us |

5000 us |

|

|

|

Velocity |

-10 m/s |

10 m/s |

|

|

|

Configuration and Use Manual |

15 |

Introduction to configuration and commissioning

Table 3-1: CDM default mA scaling values (continued)

Variable |

Default 4 mA |

Default 20 mA |

|

|

|

User-defined calculation out- |

0 |

100 |

put |

|

|

|

|

|

Volume flow rate |

-0.2 l/s |

0.2 l/s |

|

|

|

API Referral option enabled |

|

|

|

|

|

Referred density (API) |

500 kg/m3 |

1500 kg/m3c |

|

|

|

Concentration Measurement option enabled |

|

|

|

|

|

Concentration |

0 % |

100 % |

|

|

|

Referred density (concentra- |

0.5 g/cm3 |

1.5 g/cm3 |

tion) |

|

|

|

|

|

Specific gravity |

0.5 SGU |

1.5 SGU |

|

|

|

Table 3-2: CDM default variables

Default variable |

Output option A |

Output options B and C |

|

|

|

Primary Variable (PV), mA1 |

Sample Temperature |

Density |

|

|

|

Secondary Variable (SV), |

Sensor Time Period |

Sample Temperature |

mA2 |

|

|

|

|

|

Tertiary Variable (TV) |

Velocity |

Velocity |

|

|

|

Quaternary Variable (QV) |

Case Temp |

Case Temp |

|

|

|

3.2Enable access to the off-line menu of the display

Display |

Not available |

|

|

ProLink III |

Device Tools > Configuration > Transmitter Display > Display Security |

|

|

Field Communicator |

Configure > Manual Setup > Display > Display Menus > Offline Menu |

|

|

Overview

By default, access to the off-line menu of the display is enabled. If it is disabled, you must enable it if you want to use the display to configure the transmitter.

Restriction

You cannot use the display to enable access to the off-line menu. You must make a connection from another tool.

16 |

Micro Motion® Compact Density Meters (CDM) |

Introduction to configuration and commissioning

3.3Disable HART security

If you plan to use HART protocol to configure the device, HART security must be disabled. HART security is disabled by default, so you may not need to do this.

Prerequisites

•Strap wrench

•3 mm hex key

Procedure

1.Power down the meter.

2.Using the strap wrench, loosen the grub screws and remove the transmitter endcap.

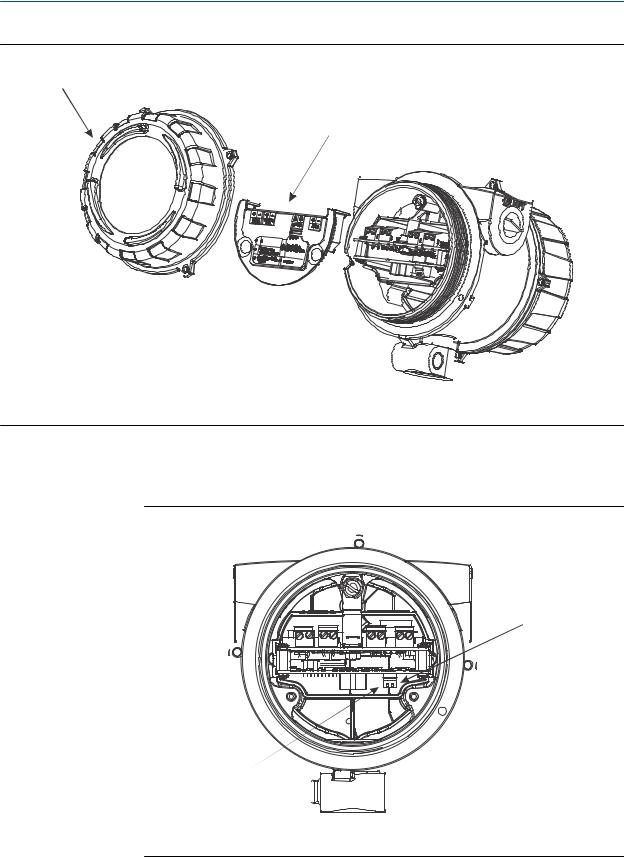

Figure 3-1: Transmitter with end-cap removed

A

A. Transmitter end cap

3.Using the hex key, remove the safety spacer.

Configuration and Use Manual |

17 |

Introduction to configuration and commissioning

Figure 3-2: Transmitter with end-cap and safety spacer removed

A

B

A.Transmitter end cap

B.Safety spacer

4.Move the HART security switch to the OFF position (up). The HART security switch is the switch on the left.

Figure 3-3: HART security switch

B

A

A.HART security switch

B.Unused

18 |

Micro Motion® Compact Density Meters (CDM) |

Introduction to configuration and commissioning

5.Replace the safety spacer and end-cap.

6.Power up the meter.

3.4Set the HART lock

If you plan to use a HART connection to configure the device, you can lock out all other HART masters. If you do this, other HART masters will be able to read data from the device but will not be able to write data to the device.

Restrictions

•This feature is available only when you are using the Field Communicator or AMS.

•This feature is available only with a HART 7 host.

Procedure

1.Choose Configure > Manual Setup > Security > Lock/Unlock Device.

2.If you are locking the meter, set Lock Option as desired.

Option Description

Permanent Only the current HART master can make changes to the device. The device will remain locked until manually unlocked by a HART master. The HART master can also change Lock Option to Temporary.

Temporary Only the current HART master can make changes to the device. The device will remain locked until manually unlocked by a HART master, or a power-cycle or device reset is performed. The HART master can also change Lock Option to Permanent.

Lock All No HART masters are allowed to make changes to the configuration. Before changing Lock Option to Permanent or Temporary, the device must be unlocked. Any HART master can be used to unlock the device.

Postrequisites

To avoid future confusion or difficulties, ensure that the device is unlocked after you have completed your tasks.

3.5Restore the factory configuration

Display |

Not available |

|

|

ProLink III |

Device Tools > Configuration Transfer > Restore Factory Configuration |

|

|

Field Communicator |

Service Tools > Maintenance > Reset/Restore > Restore Factory Configuration |

|

|

Configuration and Use Manual |

19 |

Introduction to configuration and commissioning

Overview

Restoring the factory configuration returns the transmitter to a known operational configuration. This may be useful if you experience problems during configuration.

Tip

Restoring the factory configuration is not a common action. You may want to contact Micro Motion to see if there is a preferred method to resolve any issues.

20 |

Micro Motion® Compact Density Meters (CDM) |

Configure process measurement

4 Configure process measurement

Topics covered in this chapter:

•Verify the calibration factors

•Configure line density measurement

•Configure temperature measurement

•Configure the pressure input

•Set up the API referral application

•Set up concentration measurement

•Set up flow monitoring

4.1Verify the calibration factors

Display |

Not available |

|

|

ProLink III |

Device Tools > Calibration Data |

|

|

Field Communicator |

Configure > Manual Setup > Calibration Factors |

|

|

Overview

The calibration factors are used to adjust measurement for the unique traits of the sensor. Your device was calibrated at the factory. However, you should verify that the calibration factors that are configured in your device match the factory values.

Prerequisites

You will need the factory values for the calibration factors. These are provided in two locations:

•The calibration certificate shipped with your meter

•The label inside the transmitter's end-cap

Important

If the transmitter is not the original component, do not use the values from the transmitter label.

Procedure

1.View the calibration factors that are stored in the device.

2.Compare them to the factory values.

•If the values match, no action is required.

•If the values do not match, contact Micro Motion customer service.

Configuration and Use Manual |

21 |

Configure process measurement

Related information

Sample calibration certificates

4.1.1Calibration factors

The original calibration factors are obtained from factory calibration, and are unique to each device. They are used to adjust measurements for the specific physical properties of the device.

Contents of the calibration certificate

The calibration certificate contains several sets of factors:

Density calibration |

Define the relationship between density and the response |

coefficients |

of your sensor |

Temperature |

Adjust density measurement for the effect of temperature |

compensation coefficients |

on sensor response |

Pressure compensation |

Adjust density measurement for the effect of pressure on |

coefficients |

sensor response |

Flow compensation |

Adjusts density measurement for the effect of flow on |

coefficient |

sensor response |

The calibration certificate also provides the results of the Known Density Verification procedure that was performed at the factory.

For each calibration performed at the factory, the calibration certificate contains the data used to calculate the calibration coefficients.

CDM format and legacy format (A factors and K factors)

The calibration factors are provided on three calibration certificates:

•The first certificate provides the calibration factors in the CDM format, An, in SI units. These are obtained from factory calibration of your device.

•The second certificate provides the calibration factors in the legacy format, Kn, in SI units. These factors represent the current calibration factors converted to the format used by the 7835 and 7845 meters.

•The third certificate provides the calibration factors in the legacy format, Kn, in imperial units. These factors represent the current calibration factors converted to the format used by the 7835 and 7845 meters, and then converted to imperial units.

If you have existing programs that use the K factors, update your programs with the new K values in the appropriate units. In all other situations, use the A-format calibration factors.

Related information

Sample calibration certificates

22 |

Micro Motion® Compact Density Meters (CDM) |

Loading...

Loading...