Micro Motion 3700, 3500 Operating Manual

Installation Manual

P/N 3300991, Rev. C

November 2003

Micro Motion®

Series 3000

Installation Manual

Micro MotionTM

Micro Motion®

Series 3000

Installation Manual

For online technical support, refer to the EXPERT2™ tool at www.expert2.com. To speak to a customer service representative, call the support center nearest you:

•In U.S.A., phone 1-800-522-MASS (1-800-522-6277)

•In Canada and Latin America, phone (303) 530-8400

•In Asia, phone (65) 6770-8155

•In the U.K., phone 0800 - 966 180 (toll-free)

•Outside the U.K., phone +31 (0) 318 495 670

©2003, Micro Motion, Inc. All rights reserved. Micro Motion is a registered trademark of Micro Motion, Inc. The Micro Motion and Emerson logos are trademarks of Emerson Electric Co. All other trademarks are property of their respective owners.

Contents

1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . 1

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1.2 European installations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1.2 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Installing the Model 3300 or 3500 in a Panel . . . 3

2.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2.2 Hazardous area installations . . . . . . . . . . . . . . . . . . . . . . 3 2.3 Procedure for mounting in a panel . . . . . . . . . . . . . . . . . . 3

3 Installing the Model 3300 or 3500

in a Subrack. . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 3.2 Hazardous area installations . . . . . . . . . . . . . . . . . . . . . 15 3.3 Procedure for mounting in subrack . . . . . . . . . . . . . . . . 15

4 Installing the Model 3350 or 3700 . . . . . . . . . . 23

4.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 4.2 Hazardous area classifications . . . . . . . . . . . . . . . . . . . 23 4.3 Procedure for field mounting . . . . . . . . . . . . . . . . . . . . . 23

5 Connecting the Transmitter to a Sensor . . . . . . 33

5.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 5.2 Cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 5.3 Cable and conduit preparation . . . . . . . . . . . . . . . . . . . . 34 5.4 Wiring connections to sensor. . . . . . . . . . . . . . . . . . . . . 37 5.5 Wiring connections to transmitter. . . . . . . . . . . . . . . . . . 37

6 Installing Relays. . . . . . . . . . . . . . . . . . . . . . 43

6.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 6.2 Specifications for user-supplied relays. . . . . . . . . . . . . . 43 6.3 Hazardous area installations . . . . . . . . . . . . . . . . . . . . . 43 6.4 Replacing relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 6.5 Software configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 44 6.6 Installing factory-supplied relays . . . . . . . . . . . . . . . . . . 45 6.7 Installing user-supplied relays . . . . . . . . . . . . . . . . . . . . 50 6.8 Discrete output configuration . . . . . . . . . . . . . . . . . . . . . 53

Series 3000 Installation Manual |

i |

Contents continued

7 Printer Setup . . . . . . . . . . . . . . . . . . . . . . . . 55

7.1 About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.1 Startup and display test . . . . . . . . . . . . . . . . . . . . . . . . . 61 8.2 Configuration mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 8.3 Sensor zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 8.4 Fault outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 8.5 Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 8.6 Repair and substitution of components . . . . . . . . . . . . . 66 8.7 Customer service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Appendix A Specifications . . . . . . . . . . . . . . . . . . 67

Model 3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Model 3350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Model 3500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Model 3700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Model 3100 accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Appendix B Optional Housing Dimensions . . . . . . . 85

Appendix C Labels . . . . . . . . . . . . . . . . . . . . . . . 91

Appendix D Return Policy . . . . . . . . . . . . . . . . . . 93

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

ii |

Series 3000 Installation Manual |

1 |

|

Before You Begin |

||||

1.1 |

About this manual |

This instruction manual explains how to install the Micro Motion® Series |

||||

|

|

3000 Applications Platform. |

||||

|

Chapters |

• Chapter 2 explains how to mount the Model 3300 application |

||||

|

|

peripheral or Model 3500 transmitter in a panel. |

||||

|

|

• Chapter 3 explains how to mount the Model 3300 application |

||||

|

|

peripheral or Model 3500 transmitter in a 19-inch (486,2 mm) |

||||

|

|

subrack. |

||||

|

|

• Chapter 4 explains how to mount the Model 3350 application |

||||

|

|

peripheral or Model 3700 transmitter. |

||||

|

|

• Chapter 5 explains how to connect the Model 3500 or 3700 |

||||

|

|

transmitter to a Micro Motion® flow and density sensor. |

||||

|

|

• Chapter 6 explains how to connect internally or externally powered |

||||

|

|

relays to the discrete outputs. |

||||

|

|

• Chapter 7 explains how to set up the applications platform to send a |

||||

|

|

ticket to a printer. |

||||

|

|

• Chapter 8 explains startup procedures. |

||||

|

Appendixes |

• Appendix A lists specifications. |

||||

|

|

• Appendix B provides dimensions for NEMA housing options. |

||||

|

|

• Appendix C shows labels on the applications platform. |

||||

|

|

• Appendix D is the return goods policy. |

||||

1.1 |

Safety |

Safety messages are provided throughout this manual to protect |

||||

|

|

personnel and equipment. Read each safety message carefully before |

||||

|

|

proceeding to the next step. |

||||

|

|

|

|

|

|

|

|

|

|

|

WARNING |

|

|

|

|

|

Improper installation in a hazardous area can cause |

|

||

|

|

|

an explosion. |

|

||

|

|

|

For information about hazardous applications, refer to |

|

||

|

|

|

Micro Motion ATEX, UL, or CSA installation instructions, |

|

||

|

|

|

shipped with the applications platform or available from |

|

||

|

|

|

the Micro Motion web site. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION |

|

|

|

|

|

Improper installation could cause measurement error |

|

||

|

|

|

or flowmeter failure. |

|

||

|

|

|

Follow all instructions to ensure applications platform will |

|

||

|

|

|

operate correctly. |

|

||

|

|

|

|

|

|

|

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

1 |

|

|

|

|

Before You Begin continued

1.2European installations This Micro Motion product complies with all applicable European

directives when properly installed in accordance with the instructions in this manual. Refer to the EC declaration of conformity for directives that apply to this product.

The EC declaration of conformity, with all applicable European directives, and the complete ATEX Installation Drawings and Instructions are available on the internet at www.micromotion.com/atex or through your local Micro Motion support center.

1.2 Symbols |

Below is a list of symbols pertaining to the manual and the product: |

Earth (ground) terminal

Protective conductor terminal

Frame or chassis terminal

Direct current

Alternating current

Input

Output

Alert

Warning, risk of electric shock

Pulse wave

Explosion hazard

2 |

Series 3000 Installation Manual |

2 |

|

Installing the Model 3300 |

|

|

or 3500 in a Panel |

2.1 |

About this chapter |

This chapter explains how to mount the Model 3300 application |

|

|

peripheral or Model 3500 transmitter through a panel cutout. |

2.2 |

Hazardous area |

If you are installing the applications platform or the core processor in a |

|

installations |

hazardous area, ensure that your equipment and installation meet the |

|

|

hazardous area requirements. For more information about hazardous |

|

|

area classifications, see Appendix A. See Figure 2-4 or Figure 2-5 for |

|

|

location of the approvals tag on your applications platform. |

If you are installing the Model 3300 application peripheral, see the following section.

Model 3300 installation

The Model 3300 may be installed outdoors, if it is installed in a panel providing a degree of ingress protection IP 65 according to EN 50529 (IEC 529). The Model 3300 is suitable for installation in Zone 2, complying with ATEX Directive (94/9/EC) for group II category 3G, according to CENELEC standard prEN 50021:1998 and marked as EEx nVL IIC T4.

2.3Procedure for mounting in The procedure for mounting the applications platform in a panel includes

a panel |

the following steps: |

|

|

1. |

Choosing an appropriate location |

|

2. |

Installing the applications platform in the panel |

|

3. |

Installing power-supply wiring |

|

4. |

Installing input and output wiring using the I/O cable or the |

|

|

screw-type wiring connector |

|

5. |

If the applications platform is a Model 3500, connecting the Model |

|

|

3500 to a sensor. To perform Step 5, see Chapter 5. |

Installation kit for panel For mounting in a panel, the installation kit includes a bezel, frame, two mounting mounting brackets with screws, a power-supply wiring connector, and a

retaining clip assembly for power-supply wiring. See Figure 2-1.

•The applications platform fits through a 5 7/16-inch (138 mm) square cutout in a panel that is 5/64 inch (2 mm) to 1/2 inch (13 mm) thick.

•The panel cutout is the same size as the cutout for a Micro Motion DRT, FMS-3, DMS, NFC, or NOC peripheral device.

•The bezel provides a NEMA 4X (IP65) watertight seal between the panel cutout and the applications platform housing.

•The bezel is larger than the bezel on a Micro Motion DRT, FMS-3, DMS, NFC, or NOC peripheral device.

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

3 |

|

|

|

|

Installing the Model 3300 or 3500 in a Panel continued

Figure 2-1. Panel-mount installation kit

Bezel

Power-supply wiring connector

Retaining-clip assembly for power-supply wiring

Frame

Panel thickness:

• 5/64 inch (2 mm) minimum

• 1/2 inch (13 mm) maximum

2 x Mounting bracket with screw

Step 1 Choose an appropriate location

WARNING

WARNING

Improper installation in a hazardous area could cause an explosion.

Install the applications platform in an area that is compatible with the rating on the approvals tag. See

Figure 2-4 and Figure 2-5.

•Install the applications platform where ambient temperature remains between –4 and 140°F (–20 and 60°C).

•Maximum length of cable from a Micro Motion® sensor to the Model 3500 is 1000 feet (300 meters).

•Maximum length of wiring from the frequency input for a Micro Motion IFT9701 or RFT9739 transmitter is 500 feet (150 meters).

•If the applications platform has I/O cables, illustrated in Figure 2-2, see Figure 2-4 for dimensions.

•If the applications platform has screw-type wiring connectors, illustrated in Figure 2-3, see Figure 2-5 for dimensions.

4 |

Series 3000 Installation Manual |

Installing the Model 3300 or 3500 in a Panel continued

Figure 2-2. I/O cables

Model 3300 |

Model 3500 |

Figure 2-3. Screw-type wiring connectors

Model 3300 |

Model 3500 |

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

5 |

|

|

|

|

Installing the Model 3300 or 3500 in a Panel continued

Figure 2-4. Panel-mount dimensions with I/O cables

6 1/2

(165)

Panel

Bezel

6

(152)

6

(152)

8 3/4

(222)

Frame

5 5/16

(135)

6 11/16

(170)

Approvals tag

Minimum 4 1/4" (108 mm) bend radius

1/2

(12)

6 |

Series 3000 Installation Manual |

Installing the Model 3300 or 3500 in a Panel continued

Figure 2-5. Panel-mount dimensions with screw-type connectors

6 1/2

(165)

Panel |

8 7/16 |

|

|

|

(214) |

|

7 7/8 |

|

(200) |

|

Frame |

Bezel

4 1/2

6 (114)

(152)

6 11/16

(170)

|

Approvals tag |

|

6 |

Intrinsic safety barrier |

|

(152) |

||

Model 3500 only |

||

|

||

|

1/2 |

|

|

(12) |

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

7 |

|

|

|

|

Installing the Model 3300 or 3500 in a Panel continued

Step 2 Install the applications platform in the panel

Refer to Figure 2-6 and follow these steps:

a.Insert the applications platform through the cutout.

b.Slide the frame over the housing.

c.Insert the posts on the brackets into the rails on the housing.

d.Tighten the screws evenly to 10 to 14 inch-pounds (1,13 to 1,38 Nm) to ensure a watertight seal between the gasket and the panel.

Figure 2-6. Steps for installation in panel

1. Insert applications platform through cutout in panel

2.Slide frame over housing

3. Insert brackets into |

4. Tighten screws to 10 to 14 |

upper and lower rails |

in-lb (1,13 to 1,38 Nm) |

8 |

Series 3000 Installation Manual |

Installing the Model 3300 or 3500 in a Panel continued

Step 3 Install power-supply wiring

CAUTION

CAUTION

Improper wiring installation can cause device failure or measurement error.

•To avoid device failure or measurement error, do not install power-supply wiring in the same cable tray or conduit as input/output wiring.

•Shut off power supply before installing the applications platform.

•Make sure power-supply voltage matches voltage that is indicated on power-supply wiring terminals. See

Figure 2-8.

To install power-supply wiring, follow these steps:

a.Plug in the power-supply wiring connector. See Figure 2-7.

b.Connect 18 to 14 AWG (0,75 to 2,5 mm2) wiring to the power-supply wiring connector. See Figure 2-8.

•Connect the ground wire to the ground lug for the power supply. Connect the power-supply ground directly to earth ground.

•Keep all ground leads as short as possible.

•Ground wiring must have less than 1 ohm impedance.

c.Connect wires to the power-supply wiring terminals.

•If the applications platform has a DC power supply, the upper terminal is negative (–), the lower terminal is positive (+).

•If the applications platform has an AC power supply, the upper terminal is neutral (N or L1), the lower terminal is line (L or L2).

d.Slide the retaining clip over the wiring, then tighten the screw to hold the clip in place. See Figure 2-7.

e.A switch may be installed in the power-supply line. For compliance with low-voltage directive 73/23/EEC, a switch in close proximity to the applications platform is required.

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

9 |

|

|

|

|

Installing the Model 3300 or 3500 in a Panel continued

Figure 2-7. Wiring connectors and terminals on panel-mount platform

Sensor wiring terminal strip

Model 3500 only

Input/output wiring terminal strip

Intrinsic safety barrier

Model 3500 only

Retaining clip and screw

Power-supply wiring connector

Figure 2-8. Power-supply wiring terminals on panel-mount platform

• Connect power-supply ground directly to earth ground

• Keep all ground leads as short as possible

• Ground wiring must have less than 1 ohm impedance

Ground lug for power supply

Power-supply wiring terminals

DC power-supply terminal designations

AC power-supply terminal designations

10 |

Series 3000 Installation Manual |

Installing the Model 3300 or 3500 in a Panel continued

Step 4 Install input and output wiring

If the platform has screw-type connectors

Installation of input and output wiring depends on the type of wiring connector that is installed.

a.Plug the bracketed wiring connectors onto the terminal strips on the back panel of the applications platform.

b.Tighten the captive screws to secure the bracket to the back panel.

c.Connect input and output wiring to the appropriate terminals in the input/output wiring connector, which is the far right connector.

•Install twisted-pair shielded wiring.

•Wire size is 24 to 16 AWG (0,25 to 1,5 mm2).

•Ground the shields at the field device.

•Clip the shields at the end that connects to the applications platform.

A card that is inserted into the sleeve on the top panel lists input/output wiring terminal designations.

•See Table 2-1 and the accompanying figure.

•Input and output assignments depend on the application. For more information, see the Series 3000 Detailed Setup Manual.

Table 2-1. Input/output wiring terminals on screw-type connector

Terminal number |

|

|

Designation |

|

c 2+ |

a 2 – |

Primary 4-20 mA output |

||

c 4 + |

a 4 – |

Secondary 4-20 mA output |

||

|

|

|

||

c 6 + |

a 6 – |

Frequency input |

||

|

|

|

||

c 8 + |

a 8 – |

Discrete input 1 |

||

c 10 + |

a 10 – |

Discrete input 2 |

||

|

|

|

||

c 12 + |

a 12 – |

Frequency output |

||

|

|

|

|

|

c 14 |

+ |

a 14 |

– |

Discrete output 1 |

c 16 |

+ |

a 16 |

– |

Discrete output 2 |

c 18 |

+ |

a 18 |

– |

Discrete output 3 |

|

|

|

|

|

c 32 |

(B line) |

a 32 |

(A line) |

RS-485 output |

|

|

|

|

|

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

11 |

|

|

|

|

Installing the Model 3300 or 3500 in a Panel continued

If the platform has I/O cables

a.Plug the bracketed wiring connectors onto the terminal strips on the back panel of the applications platform. Tighten the captive screws to secure the bracket to the back panel.

b.Attach the supplied I/O terminal block to a DIN rail. The terminal block accommodates various rail types. See Figure 2-9.

c.Plug the I/O cable connector onto the terminal block. Tighten the captive screws to secure the connector to the terminal block.

d.Connect input and output wiring to the appropriate terminals on the terminal block.

•Install twisted-pair shielded wiring.

•Wire size is 24 to 16 AWG (0,25 to 1,5 mm2).

•A label that is attached to the terminal block shows terminal designations for input/output wiring. See Table 2-2.

•Input and output assignments depend on the application. For more information, see the Series 3000 Detailed Setup Manual.

e.The terminal block ground is available for continuation of user cable shielding to I/O cable shielding.

•The cable connector does not connect the I/O cable shielding to the chassis ground.

•See Figure 2-10.

Figure 2-9. Installing input/output terminal block on DIN rail

|

|

|

|

3 3/64 |

|

|

|

|

|

|

(77) |

|

|

|

|

|

|

|

I/O cable |

|

|

|

|

|

Label is |

Connector |

|

|

|

|

|

mounted |

|

|

|

|

|

|

here |

|

|

|

|

|

|

|

9 |

Terminal |

|

|

|

|

|

block |

|

|

|

|

|

|

(229) |

|

|

2 31/64 |

|

|

|||

|

2 1/4 |

2 15/64 |

|

|||

|

|

(63) |

|

|

||

|

|

|

(57) |

|

||

|

|

|

|

(57) |

|

|

|

|

|

2 19/64 |

|

||

2 37/64 |

|

|

|

|||

|

|

(59) |

|

|

||

(66) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIN rail type TS 15 |

Din rail type TS 32 |

3 17/32 |

|

|

|

|

(90) |

||

|

|

|

|

|

|

|

|

|

DIN rail type TS 35 x 7.5 |

DIN rail type TS 35 x 15 |

|

||

12 |

Series 3000 Installation Manual |

Installing the Model 3300 or 3500 in a Panel continued

Begin You Before

Table 2-2. Input/output wiring terminals on terminal block

Terminal number |

|

|

Designation |

|

1 + |

2 – |

|

Secondary 4-20 mA output |

|

14 |

+ |

15 |

– |

Primary 4-20 mA output |

|

|

|

|

|

3 + |

4 – |

|

Frequency input |

|

|

|

|

|

|

5 + |

6 – |

|

Discrete input 1 |

|

7 + |

8 – |

|

Discrete input 2 |

|

|

|

|

|

|

16 |

+ |

17 |

– |

Frequency output |

|

|

|

|

|

18 |

+ |

19 |

– |

Discrete output 1 |

20 |

+ |

21 |

– |

Discrete output 2 |

22 |

+ |

23 |

– |

Discrete output 3 |

|

|

|

|

|

24 |

(B line) |

25 |

(A line) |

RS-485 output |

|

|

|

|

|

Figure 2-10.Shield wiring for I/O cable to field device

Terminal block |

Applications platform |

|

|

|

I/O cable |

Ground shields at field device only

Chassis Terminal marked ground

Do not ground at this point

Mount-Panel Installation:

Mount-Rack Installation:

Step 5 Connect the Model 3500 to the sensor

To connect the Model 3500 transmitter to a Micro Motion® sensor, see

Chapter 5.

Mount-Field Installation:

Series 3000 Installation Manual |

13 |

|

|

|

|

14 |

Series 3000 Installation Manual |

3 |

|

Installing the Model 3300 |

|

|

or 3500 in a Subrack |

3.1 |

About this chapter |

This chapter explains how to mount the Model 3300 application |

|

|

peripheral or Model 3500 transmitter in a 19-inch (486,2 mm) subrack. |

3.2 |

Hazardous area |

If you are installing the applications platform or the core processor in a |

|

installations |

hazardous area, ensure that your equipment and installation meet the |

|

|

hazardous area requirements. For more information about hazardous |

|

|

area classifications, see Appendix A. See Figure 3-1 for location of the |

approvals tag on your applications platform. If you are installing the Model 3300 application peripheral, see below.

Model 3300 installation

The Model 3300 should be installed in a rack providing a degree of ingress protection IP 4X according to EN 50529 (IEC 529). The Model 3300 is suitable for installation in Zone 2, complying with ATEX Directive (94/9/EC) for group II category 3G, according to CENELEC standard prEN 50021:1998 and marked as EEx nVL IIC T4.

3.3Procedure for mounting in The procedure for mounting the applications platform in a subrack

subrack |

includes the following steps: |

|

|

1. |

Choosing an appropriate location for the installation |

|

2. |

Installing guide rails and wiring connectors |

|

3. |

Installing the applications platform in the subrack |

|

4. |

Connecting power-supply wiring |

|

5. |

Connecting input/output wiring |

|

6. |

If the applications platform is a Model 3500, connecting the Model |

|

|

3500 to a sensor. To perform Step 6, see Chapter 5. |

Installation kit for rack |

Model 3300 installation kit |

|

mounting |

For mounting in a subrack, the Model 3300 installation kit includes the |

|

|

following parts (see Figure 3-3): |

|

|

• |

One DIN standard 41612, Type D connector for input/output wiring, |

|

|

with solder tails or screw terminals |

|

• |

One plug-in connector for power-supply wiring |

|

• |

Four slotted cheese-head machine screws, size M2.5x8, for securing |

|

|

wiring connectors to the subrack |

|

Model 3500 installation kit |

|

|

For mounting in a subrack, the Model 3500 installation kit includes the |

|

|

following parts (see Figure 3-3): |

|

|

• |

One DIN standard 41612, Type D connector for input/output wiring, |

|

|

with solder tails or screw terminals |

|

• |

One DIN standard 41612, keyed Type D connector for sensor wiring, |

|

|

with solder tails or screw terminals |

|

• |

One plug-in connector for power-supply wiring |

|

• |

Six slotted cheese-head machine screws, size M2.5x8, for securing |

|

|

wiring connectors to the subrack |

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

15 |

|

|

|

|

Installing the Model 3300 or 3500 in a Subrack continued

Figure 3-1. Dimensions for mounting in subrack

1 U = 1 HE = 1.750 inches (44,45 mm) 1 HP = 1 TE = 0.200 inch (5,08 mm)

25 HP (25 TE)

4 x M2.5x11

3 U

(3 HE)

5 1/16

4 13/16 (128,52)

(122,5)

5.6

(142,2)

28 HP (28 TE)

19-inch (486,2 mm) subrack conforms to DIN 41494, Part 5, and IEC 297-3

Not included with applications platform

Optional screw terminal

Rear rail for mounting connectors that conform to DIN 41612 and IEC 603-2

Not included with applications platform

Intrinsic safety barrier

Model 3500 only

Approvals tag

1 |

6 11/16 |

(25,4) |

(169,93) |

7 11/32

(186,7)

7 29/32

(200,6)

8 33/64

(216,23)

16 |

Series 3000 Installation Manual |

Installing the Model 3300 or 3500 in a Subrack continued

Step 1 Locate and orient the applications platform

|

|

|

WARNING |

|

|

|

Improper installation in a hazardous area could cause |

|

|

|

|

an explosion. |

|

|

|

|

Install the applications platform in an area that is |

|

|

|

|

compatible with the rating on the approvals tag. See |

|

|

|

|

Figure 3-1. |

|

|

|

|

|

|

|

Dimensions |

The applications platform conforms to DIN standard 41494, Part 5 |

|||

|

|

(IEC 297-3) for 19-inch (486,2 mm) racks. |

||

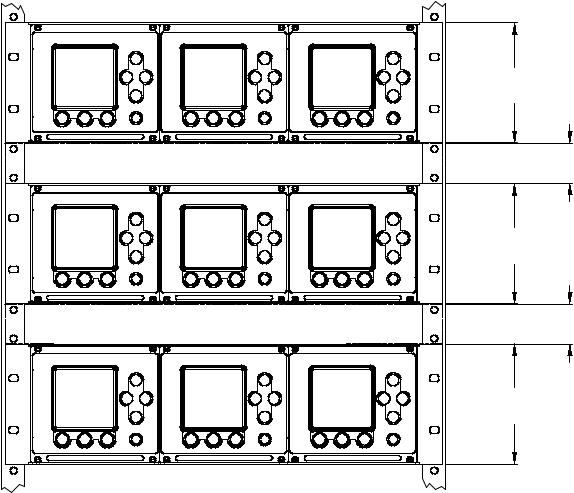

•Up to three applications platform enclosures fit into one subrack. See

Figure 3-2.

•Height is 128 mm (3 U or 3 HE).

•Width is 142 mm (28 HP or 28 TE).

•Depth is 160 mm.

Location guidelines |

• Locate the applications platform where ambient temperature remains |

|

between –4 and 140°F (–20 and 60°C). |

|

• Maximum length of cable from a Micro Motion® sensor to the Model |

|

3500 is 1000 feet (300 meters). |

|

• Maximum length of wiring from the frequency input for a Micro |

|

Motion IFT9701 or RFT9739 transmitter is 500 feet (150 meters). |

|

• To ensure proper ventilation if multiple application platforms are |

|

installed, provide at least 1 U (1 HE) of vertical space between |

|

subracks, as shown in Figure 3-2. |

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

17 |

|

|

|

|

Installing the Model 3300 or 3500 in a Subrack continued

Figure 3-2. Space requirements for proper ventilation

1 U = 1 HE = 1.750 inches (44,45 mm)

3 U (3 HE)

1 U (1 HE)

3 U (3 HE)

1 U (1 HE)

3 U (3 HE)

18 |

Series 3000 Installation Manual |

Installing the Model 3300 or 3500 in a Subrack continued

|

Step 2 Install guide rails and wiring connectors |

Guide rails |

Positions of guide rails and wiring connectors are indicated in |

|

Figure 3-3. Centers of guide rails should be 27 HP (27 TE) apart, for |

|

example, at 1 HP (TE) and 28 HP (TE). |

Wiring connectors |

• Use the supplied M2.5x8 screws to install the wiring connectors onto |

|

the back of the subrack. |

|

• Install screws and connectors from the front of the subrack. |

|

Model 3300 wiring connectors |

|

The Model 3300 comes with a solder tail or screw-type connector for |

|

input/output wiring and a plug-in connector for power-supply wiring. |

|

Model 3500 wiring connectors |

|

The Model 3500 comes with a solder tail or screw-type connector for |

|

input/output wiring, a keyed solder tail or screw-type connector for |

|

sensor wiring, and a plug-in connector for power-supply wiring. |

Using the centers of the guide rails as reference points and referring to Figure 3-3, install the wiring connectors in the following positions on the back of the subrack:

•Install the input/output wiring connector at 4 HP (4 TE) from the neighboring unit or from the edge of the subrack.

•If the applications platform is a Model 3500, install the keyed sensor wiring connector at 16 HP (16 TE) from the neighboring unit or from the edge of the subrack.

•Install the power-supply wiring connector at 25 HP (25 TE) from the neighboring unit or from the edge of the subrack.

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

19 |

|

|

|

|

Installing the Model 3300 or 3500 in a Subrack continued

Step 3 Install the applications platform in the subrack

After installing guide rails and wiring connectors as instructed in Step 2, follow these steps to install the applications platform in the subrack:

a.Align the applications platform with the guide rails.

b.Slide the applications platform into the subrack. Make sure the pins on the back panel make contact with the wiring connectors.

c.Tighten the supplied captive screws to secure the front panel of the applications platform to the guide rails.

Figure 3-3. Positions of guide rails and wiring connectors

|

|

Guide rail centers should be 27 HP (27 TE) apart; |

|

|

for example, 1 HP (1 TE) and 28 HP (28 TE) |

|

Back |

Keys on sensor |

|

|

|

Install screws and connectors from front of subrack |

|

wiring connector |

• Model 3300 has four M2.5x8 screws and two connectors |

|

Model 3500 only |

• Model 3500 has six M2.5x8 screws and three connectors |

|

|

Front |

|

|

M2.5x8

Power-supply wiring connector is 25 HP (25 TE) from neighboring unit or from edge of subrack

Model 3500 only

Keyed sensor wiring connector is 16 HP (16 TE) from neighboring unit or from edge of subrack

Input/output wiring connector is 4 HP (4 TE) from neighboring unit or from edge of subrack

20 |

Series 3000 Installation Manual |

Installing the Model 3300 or 3500 in a Subrack continued

Step 4 Connect power-supply wiring

CAUTION

CAUTION

Improper wiring installation can cause device failure or measurement error.

•To avoid device failure or measurement error, do not install power-supply wiring in the same cable tray or conduit as input/output wiring.

•Shut off power supply before installing the applications platform.

•Make sure power-supply voltage matches voltage that is indicated on power-supply wiring terminals. See

Figure 3-4.

Referring to Figure 3-4, follow these steps to connect 18 to 14 AWG (0,75 to 2,5 mm2) wiring to the power-supply wiring connector.

a.Connect the ground wire to the middle terminal.

b.Connect the power-supply ground directly to earth ground.

•Keep all ground leads as short as possible.

•Ground wiring must have less than 1 ohm impedance.

c.Connect wires to the upper and lower terminals.

•If the applications platform has a DC power supply, the upper terminal is negative (–), the lower terminal is positive (+).

•If the applications platform has an AC power supply, the upper terminal is neutral (N or L1), the lower terminal is line (L or L2).

d.A switch may be installed in the power-supply line. For compliance with low-voltage directive 73/23/EEC, a switch in close proximity to the subrack is required.

Figure 3-4. Power-supply wiring terminals on rack-mount platform

Power-supply wiring terminals

Terminal designations for DC power

Terminal designations for AC power

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

21 |

|

|

|

|

Installing the Model 3300 or 3500 in a Subrack continued

Step 5 Connect input and output wiring

Connect input and output wiring to the appropriate terminals on the input/output wiring connector, which is the far right connector.

•Install twisted-pair shielded wiring, 24 to 16 AWG (0,25 to 1,5 mm2).

•Ground the shields at the field device.

•Clip the shields at the end that connects to the applications platform.

A card that is inserted into the sleeve on the top panel lists input/output wiring terminal designations.

•See Table 3-1 and the accompanying figure.

•Input and output assignments depend on the application. For more information, see the Series 3000 Detailed Setup Manual.

Table 3-1. Input/output wiring terminals on rack-mount platform

Terminal number |

|

|

Designation |

|

c 2+ |

a 2 – |

Primary 4-20 mA output |

||

c 4 + |

a 4 – |

Secondary 4-20 mA output |

||

|

|

|

||

c 6 + |

a 6 – |

Frequency input |

||

|

|

|

||

c 8 + |

a 8 – |

Discrete input 1 |

||

c 10 + |

a 10 – |

Discrete input 2 |

||

|

|

|

||

c 12 + |

a 12 – |

Frequency output |

||

|

|

|

|

|

c 14 |

+ |

a 14 |

– |

Discrete output 1 |

c 16 |

+ |

a 16 |

– |

Discrete output 2 |

c 18 |

+ |

a 18 |

– |

Discrete output 3 |

|

|

|

|

|

c 32 |

(B line) |

a 32 |

(A line) |

RS-485 output |

|

|

|

|

|

Step 6 Connect the Model 3500 to the sensor

To connect the Model 3500 transmitter to a Micro Motion® sensor, see

Chapter 5.

22 |

Series 3000 Installation Manual |

4

4.1About this chapter

4.2Hazardous area classifications

Installing the

Model 3350 or 3700

This chapter explains how to install the Model 3350 application peripheral or Model 3700 transmitter. The Model 3350 or 3700 can be installed on an instrument pole or a flat surface.

If you are installing the applications platform or the core processor in a hazardous area, ensure that your equipment and installation meet the hazardous area requirements. For more information about hazardous area classifications, see Appendix A. See Figure 4-2 for location of the approvals tag on your applications platform.

WARNING |

Explosion Hazard.

Do not open wiring compartments when an explosive gas atmosphere is present.

Figure 4-4 identifies the compartments.

|

|

|

|

WARNING |

|

|

|

|

Using a dry cloth to clean the display cover can cause |

|

|

|

|

|

static discharge, which could result in an explosion in |

|

|

|

|

|

an explosive atmosphere. |

|

|

|

|

|

To prevent an explosion, use a clean, damp cloth to clean |

|

|

|

|

|

the display cover in an explosive atmosphere. |

|

|

|

|

|

|

||

4.3 Procedure for field |

The procedure for field mounting includes the following steps: |

||||

mounting |

1. |

Choosing an appropriate location for the installation |

|||

|

|

2. |

Orienting the display cover for optimal viewing |

||

|

|

3. |

Mounting the applications platform on an instrument pole or flat |

||

|

|

|

surface |

||

|

|

4. |

Connecting power-supply wiring |

||

|

|

5. |

Connecting input/output wiring |

||

|

|

6. |

If the applications platform is a Model 3700, connecting the Model |

||

|

|

|

3700 to a sensor. To perform Step 6, see Chapter 5. |

||

Installation kit for field |

The field-mount installation kit includes the parts shown in Figure 4-1. |

||||

mounting |

|

|

|

|

|

Begin You Before

Mount-Panel Installation:

Mount-Rack Installation:

Mount-Field Installation:

Series 3000 Installation Manual |

23 |

|

|

|

|

Installing the Model 3350 or 3700 continued

Figure 4-1. Parts in field-mount installation kit

Mounting bracket

Mounting bracket

4 x Flat washer

4 x Lock washer

4 x M8x16

Using a 13 mm hex wrench, install to 12 ft-lb (16 Nm)

|

|

Step 1 Locate and orient the applications platform |

||

|

|

|

|

|

|

|

|

WARNING |

|

|

|

Improper installation in a hazardous area could cause |

|

|

|

|

an explosion. |

|

|

|

|

Install the applications platform in an area that is |

|

|

|

|

compatible with the rating on the approvals tag. See |

|

|

|

|

Figure 4-2. |

|

|

|

|

|

|

|

Proximity to other devices |

• Maximum length of cable from a Micro Motion® sensor to the Model |

|||

|

|

3700 is 1000 feet (300 meters). |

||

|

|

• Maximum length of wiring from the frequency input for a Micro |

||

|

|

Motion IFT9701 or RFT9739 transmitter is 500 feet (150 meters). |

||

Visibility of tags |

To ensure personal and system safety, all tags attached to the housing |

|||

|

|

must remain visible. Clean them as often as necessary. Replace tags |

||

|

|

that are damaged, missing, or worn. |

||

Temperature, humidity, |

Install the applications platform according to specified limits: |

|||

and vibration |

• Ambient temperature: –4 to 140°F (–20 to 60°C) |

|||

|

|

• Humidity: SAMA PMC 31.3, Section 5.2, Environmental |

||

|

|

NEMA 4X (IP65) |

||

|

|

• Vibration: Per IEC 68-2-6 at 1.0 g, 15 to 2000 Hz, 50 sweep cycles |

||

Orientation |

Orient the applications platform so wiring compartments and conduit |

|||

|

|

openings are easily accessible. Conduit openings can be on the right, |

||

|

|

left, bottom, or top of the housing, regardless of the positions of the |

||

|

|

display cover or wiring compartments. See Figure 4-2 and Figure 4-3. |

||

|

|

• To orient the applications platform on the mounting bracket, use the |

||

|

|

four supplied mounting bolt assemblies. |

||

|

|

• Install the bolt assemblies to 12 ft-lb (16 Nm) of torque. |

||

24 |

Series 3000 Installation Manual |

Loading...

Loading...