Page 1

Configuration and Use Manual

Micro Motion™ 5700 with Ethernet

Transmitters

Configuration and Use Manual

MMI-20029769, Rev AF

January 2021

Page 2

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Safety and approval information

This Micro Motion product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EU declaration of conformity for directives that apply to this product. The EU declaration

of conformity, with all applicable European directives, and the complete ATEX Installation Drawings and Instructions are available

on the internet at www.emerson.com or through your local Micro Motion support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found on the internet at

www.emerson.com.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the configuration

manual. Product data sheets and manuals are available from the Micro Motion web site at www.emerson.com.

Return policy

Follow Micro Motion procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Micro Motion employees. Micro Motion will not accept

your returned equipment if you fail to follow Micro Motion procedures.

Return procedures and forms are available on our web support site at www.emerson.com, or by phoning the Micro Motion

Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: flow.support@emerson.com

• Asia-Pacific: APflow.support@emerson.com

Telephone:

North and South America

United States 800-522-6277 U.K. and Ireland 0870 240 1978 Australia 800 158 727

Canada +1 303-527-5200 The Netherlands +31 (0) 70 413

Mexico +52 55 5809 5010 France +33 (0) 800 917

Argentina +54 11 4809 2700 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy +39 8008 77334 China +86 21 2892 9000

Chile +56 2 2928 4800 Central & Eastern +41 (0) 41 7686

Peru +51 15190130 Russia/CIS +7 495 995 9559 South Korea +82 2 3438 4600

Europe and Middle East Asia Pacific

New Zealand 099 128 804

6666

India 800 440 1468

901

Japan +81 3 5769 6803

111

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

2

Page 3

Configuration and Use Manual Contents

MMI-20029769 January 2021

Contents

Chapter 1 Before you begin........................................................................................................7

1.1 About this manual....................................................................................................................... 7

1.2 Hazard messages.........................................................................................................................7

1.3 Related documents......................................................................................................................8

1.4 Communication methods............................................................................................................8

Chapter 2 Quick start................................................................................................................. 9

2.1 Power up the transmitter.............................................................................................................9

2.2 Check meter status......................................................................................................................9

2.3 Commissioning wizards............................................................................................................. 10

2.4 Make a startup connection to the transmitter............................................................................10

2.5 Set the transmitter clock............................................................................................................11

2.6 View the licensed features......................................................................................................... 11

2.7 Set informational parameters.................................................................................................... 12

2.8 Characterize the meter (if required)...........................................................................................12

2.9 Verify mass flow measurement..................................................................................................15

2.10 Verify the zero......................................................................................................................... 15

Chapter 3 Introduction to configuration and commissioning....................................................17

3.1 Security and write protection.....................................................................................................17

3.2 Work with configuration files.....................................................................................................22

Chapter 4 Configure process measurement..............................................................................29

4.1 Configure Sensor Flow Direction Arrow .....................................................................................29

4.2 Configure mass flow measurement........................................................................................... 30

4.3 Configure volume flow measurement for liquid applications..................................................... 35

4.4 Configure Gas Standard Volume (GSV) flow measurement........................................................39

4.5 Configure density measurement................................................................................................44

4.6 Configure temperature measurement....................................................................................... 46

4.7 Configure Pressure Measurement Unit ......................................................................................48

4.8 Configure Velocity Measurement Unit ...................................................................................... 49

Chapter 5 Configure process measurement applications.......................................................... 51

5.1 Set up the API Referral application ............................................................................................ 51

5.2 Set up concentration measurement...........................................................................................61

5.3 Configure the batching application............................................................................................77

Chapter 6 Configure advanced options for process measurement............................................ 83

6.1 Configure Response Time ......................................................................................................... 83

6.2 Detect and report two-phase flow............................................................................................. 83

6.3 Configure Flow Rate Switch .......................................................................................................85

Configuration and Use Manual 3

Page 4

Contents Configuration and Use Manual

January 2021 MMI-20029769

6.4 Configure events....................................................................................................................... 86

6.5 Configure totalizers and inventories.......................................................................................... 88

6.6 Configure logging for totalizers and inventories.........................................................................91

6.7 Configure Process Variable Fault Action .................................................................................... 92

Chapter 7 Configure device options and preferences................................................................ 97

7.1 Configure the transmitter display.............................................................................................. 97

7.2 Configure the transmitter's response to alerts......................................................................... 103

Chapter 8 Integrate the meter with the control system.......................................................... 113

8.1 Channel configuration............................................................................................................. 113

8.2 Configure Ethernet Channel A and Channel B...........................................................................113

8.3 Configure I/O Channel C.......................................................................................................... 113

8.4 Configure an mA Output..........................................................................................................114

8.5 Configure a Frequency Output.................................................................................................123

8.6 Configure a Discrete Output.................................................................................................... 127

8.7 Configure a Discrete Input....................................................................................................... 131

Chapter 9 Set the Ethernet protocol....................................................................................... 135

Chapter 10 Configure, setup, and use a printer for tickets.........................................................137

10.1 TM-T88VI printer limitations..................................................................................................137

10.2 Set up the printer...................................................................................................................137

10.3 Reset the interface settings................................................................................................... 140

10.4 Configure the printer and print tickets...................................................................................141

10.5 Configure a Discrete Input or discrete event.......................................................................... 142

10.6 Ticket types........................................................................................................................... 142

Chapter 11 Complete the configuration................................................................................... 147

11.1 Test or tune the system using sensor simulation....................................................................147

11.2 Enable or disable software write-protection...........................................................................148

Chapter 12 Transmitter operation............................................................................................ 151

12.1 View process and diagnostic variables................................................................................... 151

12.2 View and acknowledge status alerts...................................................................................... 152

12.3 Read totalizer and inventory values........................................................................................153

12.4 Start, stop, and reset totalizers and inventories..................................................................... 154

Chapter 13 Operation using the batcher...................................................................................157

13.1 Run a batch............................................................................................................................157

13.2 Perform AOC calibration........................................................................................................ 160

Chapter 14 Measurement support............................................................................................163

14.1 Use Smart Meter Verification................................................................................................. 163

14.2 Advanced Phase Measurement..............................................................................................170

14.3 Piecewise linearization (PWL) for calibrating gas meters........................................................ 171

14.4 Zero the meter...................................................................................................................... 171

4 Micro Motion 5700 with Ethernet Transmitters

Page 5

Configuration and Use Manual Contents

MMI-20029769 January 2021

14.5 Set up pressure compensation...............................................................................................174

14.6 Validate the meter.................................................................................................................177

14.7 Perform a (standard) D1 and D2 density calibration...............................................................179

14.8 Adjust concentration measurement with Trim Offset ............................................................182

14.9 Adjust concentration measurement with Trim Slope and Trim Offset ................................... 182

Chapter 15 Maintenance.......................................................................................................... 185

15.1 Install a new transmitter license.............................................................................................185

15.2 Upgrade the transmitter firmware......................................................................................... 186

15.3 Reboot the transmitter.......................................................................................................... 187

15.4 Battery replacement..............................................................................................................188

Chapter 16 Log files, history files, and service files....................................................................189

16.1 Generate history files.............................................................................................................189

16.2 Generate service files.............................................................................................................195

Chapter 17 Troubleshooting.................................................................................................... 201

17.1 Status LED and device status..................................................................................................201

17.2 Network status LED................................................................................................................201

17.3 API Referral troubleshooting..................................................................................................202

17.4 Batch troubleshooting...........................................................................................................202

17.5 Concentration measurement troubleshooting...................................................................... 204

17.6 Alert when connecting a core processor to a remote 5700 transmitter..................................205

17.7 Density measurement troubleshooting................................................................................. 206

17.8 Discrete Input troubleshooting..............................................................................................208

17.9 Discrete Output troubleshooting...........................................................................................208

17.10 Flow measurement troubleshooting....................................................................................209

17.11 Frequency Output troubleshooting..................................................................................... 212

17.12 mA Output troubleshooting................................................................................................ 214

17.13 Status alerts, causes, and recommendations....................................................................... 217

17.14 Perform a core processor resistance test..............................................................................235

17.15 Check the cutoffs.................................................................................................................237

17.16 Check the direction parameters...........................................................................................237

17.17 Check the drive gain............................................................................................................ 237

17.18 Check for internal electrical problems..................................................................................238

17.19 Check Frequency Output Fault Action .................................................................................239

17.20 Check the scaling of the Frequency Output..........................................................................239

17.21 Check grounding................................................................................................................. 239

17.22 Perform loop tests............................................................................................................... 240

17.23 Check Lower Range Value and Upper Range Value ..............................................................246

17.24 Check mA Output Fault Action ............................................................................................246

17.25 Trim mA Output.................................................................................................................. 246

17.26 Check the pickoff voltage.................................................................................................... 247

Configuration and Use Manual 5

Page 6

Contents Configuration and Use Manual

January 2021 MMI-20029769

17.27 Check power supply wiring.................................................................................................. 248

17.28 Check for radio frequency interference (RFI)........................................................................ 249

17.29 Check sensor-to-transmitter wiring..................................................................................... 249

17.30 Using sensor simulation for troubleshooting....................................................................... 250

17.31 Check the printing............................................................................................................... 250

17.32 Check for two-phase flow (slug flow)................................................................................... 250

17.33 Check the sensor coils..........................................................................................................251

Appendix A Using the transmitter display................................................................................. 253

A.1 Components of the transmitter display................................................................................... 253

A.2 Access and use the display menus........................................................................................... 255

Appendix B Using ProLink III with the transmitter..................................................................... 259

B.1 Basic information about ProLink III .......................................................................................... 259

B.2 Connect with ProLink III ...........................................................................................................260

Appendix C Using a web browser to configure the transmitter..................................................263

C.1 Recommended web browsers................................................................................................. 263

C.2 Configuring transmitter and PC Ethernet settings....................................................................263

C.3 Log in with a web browser using a secure connection.............................................................. 264

C.4 Log in with a web browser using an unsecure connection........................................................ 266

C.5 Change Ethernet login passwords............................................................................................267

C.6 Import the SSL Certificate into Microsoft® Windows®.............................................................. 268

C.7 Private key file......................................................................................................................... 269

C.8 Import from a Certificate Authority......................................................................................... 269

Appendix D Concentration measurement matrices, derived variables, and process variables.... 271

D.1 Standard matrices for the concentration measurement application........................................ 271

D.2 Derived variables and calculated process variables.................................................................. 272

Appendix E Environmental compliance.....................................................................................275

E.1 RoHS and WEEE........................................................................................................................275

Appendix F Example tickets......................................................................................................276

F.1 Print examples......................................................................................................................... 276

6 Micro Motion 5700 with Ethernet Transmitters

Page 7

Configuration and Use Manual Before you begin

MMI-20029769 January 2021

1 Before you begin

1.1 About this manual

This manual helps you configure, commission, use, maintain, and troubleshoot Micro Motion 5700

transmitters with Ethernet.

Important

This manual assumes that:

• The transmitter has been installed correctly and completely according to the instructions in the

transmitter installation manual

• Users understand basic transmitter and sensor installation, configuration, and maintenance concepts and

procedures

1.2 Hazard messages

This document uses the following criteria for hazard messages based on ANSI standards Z535.6-2011

(R2017).

DANGER

Serious injury or death will occur if a hazardous situation is not avoided.

WARNING

Serious injury or death could occur if a hazardous situation is not avoided.

CAUTION

Minor or moderate injury will or could occur if a hazardous situation is not avoided.

NOTICE

Data loss, property damage, hardware damage, or software damage can occur if a situation is not avoided.

There is no credible risk of physical injury.

Physical access

NOTICE

Unauthorized personnel can potentially cause significant damage and/or misconfiguration of end users'

equipment. Protect against all intentional or unintentional unauthorized use.

Physical security is an important part of any security program and fundamental to protecting your system.

Restrict physical access to protect users' assets. This is true for all systems used within the facility.

Configuration and Use Manual 7

Page 8

Before you begin Configuration and Use Manual

January 2021 MMI-20029769

1.3 Related documents

You can find all product documentation on the product documentation DVD shipped with the product or at

www.emerson.com.

See any of the following documents for more information:

• Micro Motion 5700 Product Data Sheet

• Micro Motion 5700 with Ethernet Transmitters: Installation Manual

• Micro Motion Ethernet PROFINET Siemens Integration Guide

• Micro Motion 5700 Transmitters Ethernet Rockwell RSLogix Integration Guide

• Replacing the Junction Box for the 4200 Transmitter and the 5700 Transmitter

• Replacing the Sensor Cable for the 4200 Transmitter and the 5700 Transmitter

• Sensor installation manual

1.4 Communication methods

You can use several different communications methods to interface with the transmitter. You may use

different methods in different locations or for different tasks.

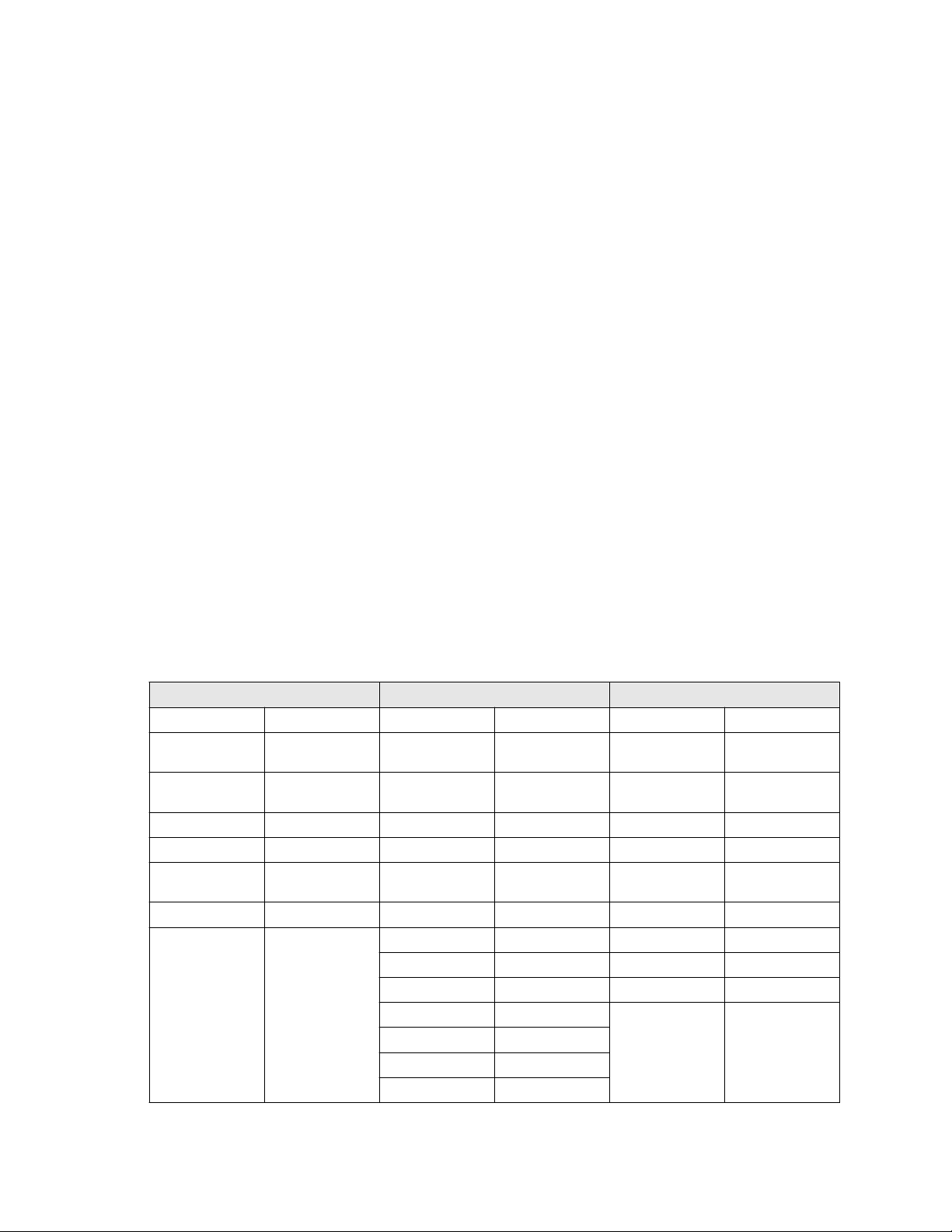

Interface Tool

Display Infrared-sensitive buttons

Universal Service Port ProLink™ III

Ethernet ports Web browser (http)

• EtherNet/IP

• Modbus® TCP

• PROFINET

For information about how to use the communication tools, see the appendices in this manual.

8 Micro Motion 5700 with Ethernet Transmitters

Page 9

Configuration and Use Manual Quick start

MMI-20029769 January 2021

2 Quick start

2.1 Power up the transmitter

The transmitter must be powered up for all configuration and commissioning tasks, or for process

measurement.

Procedure

1. Follow appropriate procedures to ensure that a new device on the network does not interfere with

existing measurement and control loops.

2. Verify that the cables are connected to the transmitter as described in the installation manual.

3. Verify that all transmitter and sensor covers and seals are closed.

WARNING

To prevent ignition of flammable or combustible atmospheres, ensure that all covers and seals are

tightly closed. For hazardous area installations, applying power while housing covers are removed or

loose can cause an explosion resulting in injury or death.

4. Turn on the electrical power at the power supply.

Postrequisites

Although the sensor is ready to receive process fluid shortly after power-up, the electronics can take up to

10 minutes to reach thermal equilibrium. Therefore, if this is the initial startup, or if power has been off long

enough to allow components to reach ambient temperature, allow the electronics to warm up for

approximately 10 minutes before relying on process measurements. During this warm-up period, you may

observe minor measurement instability or inaccuracy.

2.2 Check meter status

Check the meter for any error conditions that require user action or that affect measurement accuracy.

Procedure

1. Wait approximately 10 seconds for the power-up sequence to complete.

Immediately after power-up, the transmitter runs through diagnostic routines and checks for error

conditions. During the power-up sequence, the Transmitter Initializing alert is active. This

alert should clear automatically when the power-up sequence is complete.

2. Check the status LED on the transmitter.

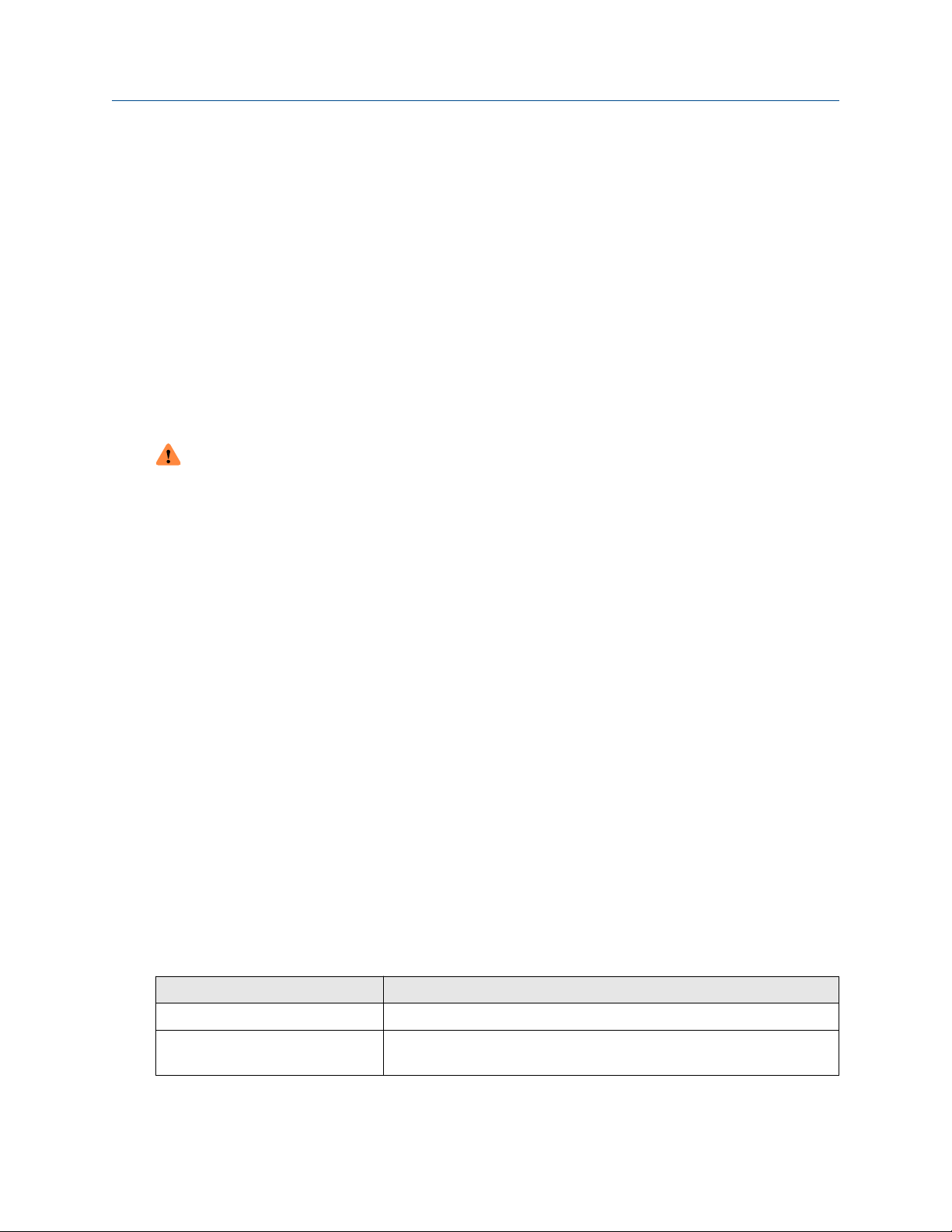

Table 2-1: Status LED and device status

Status LED condition Device status

Solid green No alerts are active.

Solid yellow One or more alerts are active with Alert Severity = Out of Specification,

Maintenance Required, or Function Check.

Configuration and Use Manual 9

Page 10

Quick start Configuration and Use Manual

January 2021 MMI-20029769

Table 2-1: Status LED and device status (continued)

Status LED condition Device status

Solid red One or more alerts are active with Alert Severity = Failure.

Flashing yellow (1 Hz) The Function Check in Progress alert is active.

Table 2-2: Network status LED and Ethernet network connection status

Network status LED condition Network status

Flashing green No connections made with primary protocol host.

Solid green Connection made with primary protocol host.

Flashing red Connection from primary protocol host has timed out.

Solid red Address Conflict Detection (ACD) algorithm has detected a duplicate IP

address.

2.3 Commissioning wizards

The transmitter menu includes a Guided Setup to help you move quickly through the most common

configuration parameters. ProLink III also provides a commissioning wizard.

By default, when the transmitter starts up, the Guided Setup menu is offered. You can choose to use it or not.

You can also choose whether or not Guided Setup is displayed automatically.

• To enter Guided Setup upon transmitter startup, choose Yes at the prompt.

• To enter Guided Setup after transmitter startup, choose Menu → Startup Tasks.

• To control the automatic display of Guided Setup, choose Menu → Configuration → Guided Setup.

For information on the ProLink III commissioning wizard, see the Micro Motion ProLink III with ProcessViz

Software User Manual.

As the commissioning wizards are self guided, they are not documented in detail.

2.4 Make a startup connection to the transmitter

For all configuration tools except the display, you must have an active connection to the transmitter to

configure the transmitter.

Procedure

Identify the connection type to use, and follow the instructions for that connection type in the appropriate

appendix.

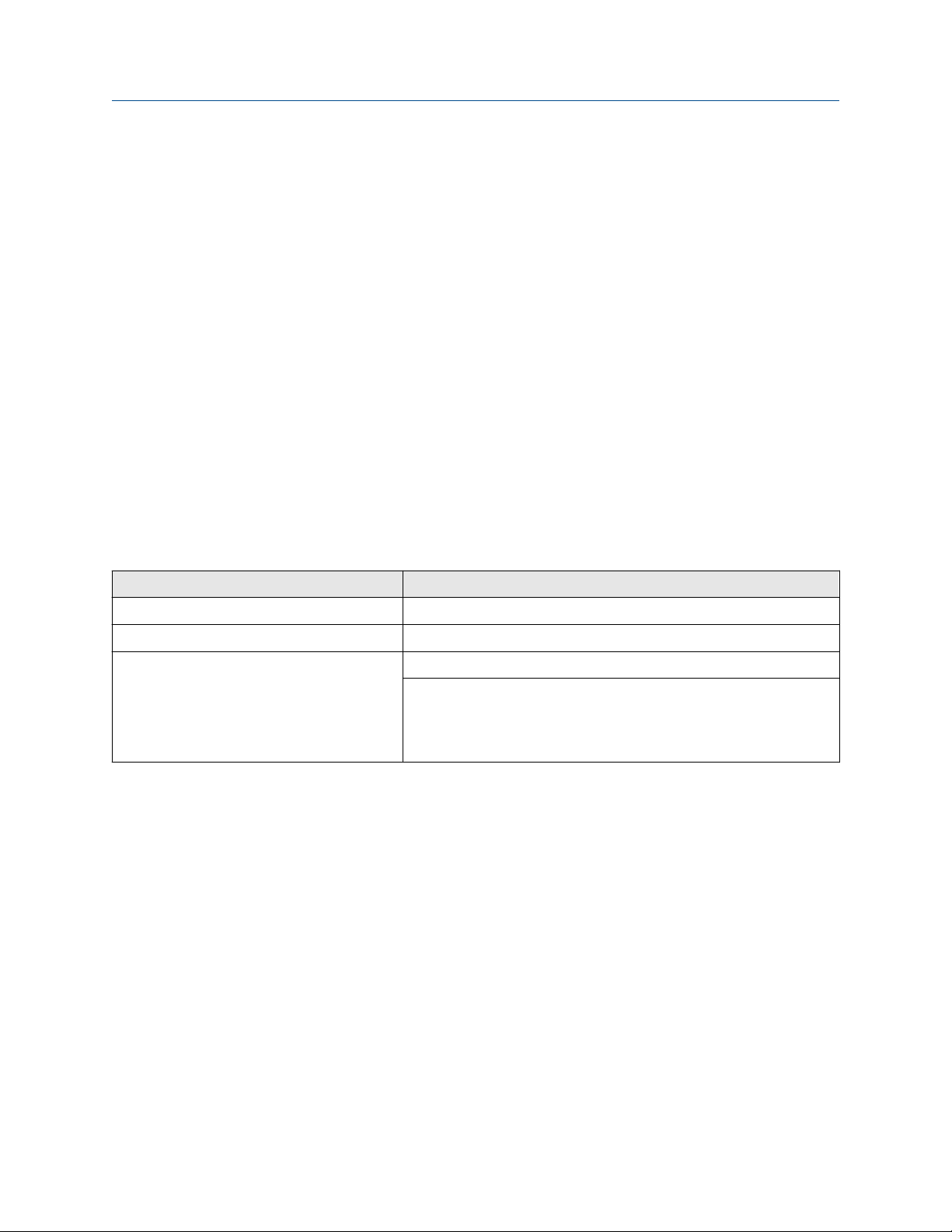

Communications tool

ProLink III Service port Using ProLink III with the transmitter

Web browser Ethernet Using a web browser to configure the

10 Micro Motion 5700 with Ethernet Transmitters

Connection type to use Instructions

transmitter

Page 11

Configuration and Use Manual Quick start

MMI-20029769 January 2021

2.5 Set the transmitter clock

Display Menu → Configuration → Time/Date/Tag

ProLink III Device Tools → Configuration → Transmitter Clock

Web browser Configuration → Time/Date/Tag

The transmitter clock provides timestamp data for alerts, service logs, history logs, and all other timers and

dates in the system. You can set the clock for your local time or for any standard time you want to use.

Tip

You may find it convenient to set all of your transmitter clocks to the same time, even if the transmitters are

in different time zones.

Procedure

1. Select the time zone that you want to use.

2. If you need a custom time zone, select Special Time Zone and enter your time zone as a difference

from UTC (Coordinated Universal Time).

3. Set the time appropriately for the selected time zone.

Tip

The transmitter does not adjust for Daylight Savings Time. If you observe Daylight Savings Time, you

must reset the transmitter clock manually.

4. Set the month, day, and year.

The transmitter tracks the year and automatically adds a day for leap years.

2.6 View the licensed features

Display

ProLink III Device Tools → Device Information → Licensed Features

Web browser Configuration → Device Information → Licensed Features

The transmitter license controls the features (applications) that are enabled on the transmitter. You can view

the licensed features to ensure that the transmitter was ordered with the required features.

Licensed features are purchased and available for permanent use. The options model code represents the

licensed features.

A trial license allows you to explore features before purchasing. The trial license enables the specified features

for a limited number of days. This number is displayed for reference. At the end of this period, the feature will

no longer be available.

Menu → About → Licenses → Licensed Features

To purchase additional features or request a trial license, document the Unique ID Number and current

license key from your transmitter and contact customer service. To enable the additional features or trial

license, you will need to install the new license on the transmitter.

Configuration and Use Manual 11

Page 12

Quick start Configuration and Use Manual

January 2021 MMI-20029769

2.7 Set informational parameters

Display Menu → Configuration → Device Information

ProLink III Device Tools → Configuration → Informational Parameters

Web browser Configuration → Time/Date/Tag

You can set several parameters that identify or describe the transmitter and sensor. These parameters are not

used in processing and are not required.

Procedure

1. Set informational parameters for the transmitter.

a) Set Transmitter Serial Number to the serial number of your transmitter.

The transmitter serial number is provided on the metal tag that is attached to the transmitter

housing.

b) Set Descriptor to any desired description of this transmitter or measurement point.

c) Set Message to any desired message.

d) Verify that Model Code (Base) is set to the base model code of the transmitter.

The base model code completely describes your transmitter, except for the features that can be

licensed independently. The base model code is set at the factory.

e) Set Model Code (Options) to the options model code of the transmitter.

The options model code describes the independent features that have been licensed for this

transmitter. The original options model code is set at the factory. If you license additional

options for this transmitter, Micro Motion will supply an updated options model code.

2. Set informational parameters for the sensor.

a) Set Sensor Serial Number to the serial number of the sensor connected to this transmitter.

The sensor serial number is provided on the metal tag that is attached to the sensor case.

b) Set Sensor Material to the material used for the sensor.

c) Set Sensor Liner to the material used for the sensor liner, if any.

d) Set Flange Type to the type of flange that was used to install the sensor.

Do not set Sensor Type. Sensor Type is set or derived during characterization.

2.8 Characterize the meter (if required)

Display

ProLink III Device Tools → Calibration Data

Web browser Configuration → Sensor Parameters

12 Micro Motion 5700 with Ethernet Transmitters

Menu → Configuration → Sensor Parameters

Page 13

Configuration and Use Manual Quick start

MMI-20029769 January 2021

Characterizing the meter adjusts your transmitter to match the unique traits of the sensor it is paired with.

The characterization parameters (also called calibration parameters) describe the sensor’s sensitivity to flow,

density, and temperature. Depending on your sensor type, different parameters are required.

Values for your sensor are provided on the sensor tag or the calibration certificate.

• If your transmitter was ordered with a sensor, it was characterized at the factory. However, you should still

verify the characterization parameters.

• Perform a characterization whenever you replace a core processor.

Procedure

1. Optional: Specify Sensor Type.

• Straight Tube (T-Series sensors)

• Curved Tube (all sensors except T-Series)

Note

Unlike earlier transmitters, the 5700 derives Sensor Type from the user-specified values for FCF and K1

in combination with an internal ID.

2. Set the flow calibration factor: FCF (also called Flow Cal or Flow Calibration Factor). Be sure to include

all decimal points.

3. Set the density characterization parameters: D1, D2, TC, K1, K2, and FD. (TC is sometimes shown as

DT.)

4. Apply the changes as required by the tool you are using.

The transmitter identifies your sensor type, and characterization parameters are adjusted as required:

• If Sensor Type changed from Curved Tube to Straight Tube, five characterization parameters are

added to the list.

• If Sensor Type changed from Straight Tube to Curved Tube, five characterization parameters are

removed from the list.

• If Sensor Type did not change, the list of characterization parameters does not change.

5. T-Series sensors only: Set the additional characterization parameters listed below.

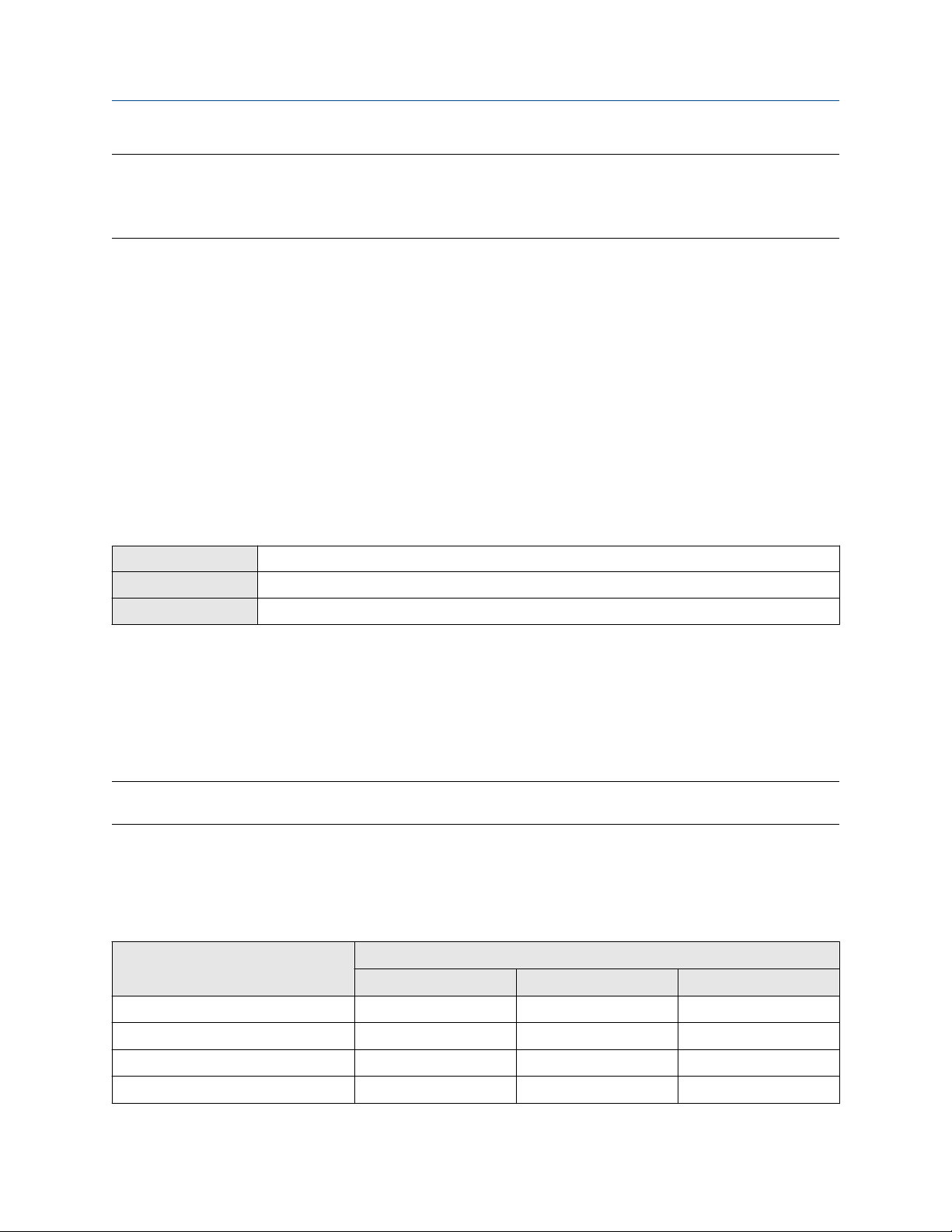

Characterization parameter type

Flow FTG, FFQ

Density DTG, DFQ1, DFQ2

Parameters

Configuration and Use Manual 13

Page 14

Quick start Configuration and Use Manual

January 2021 MMI-20029769

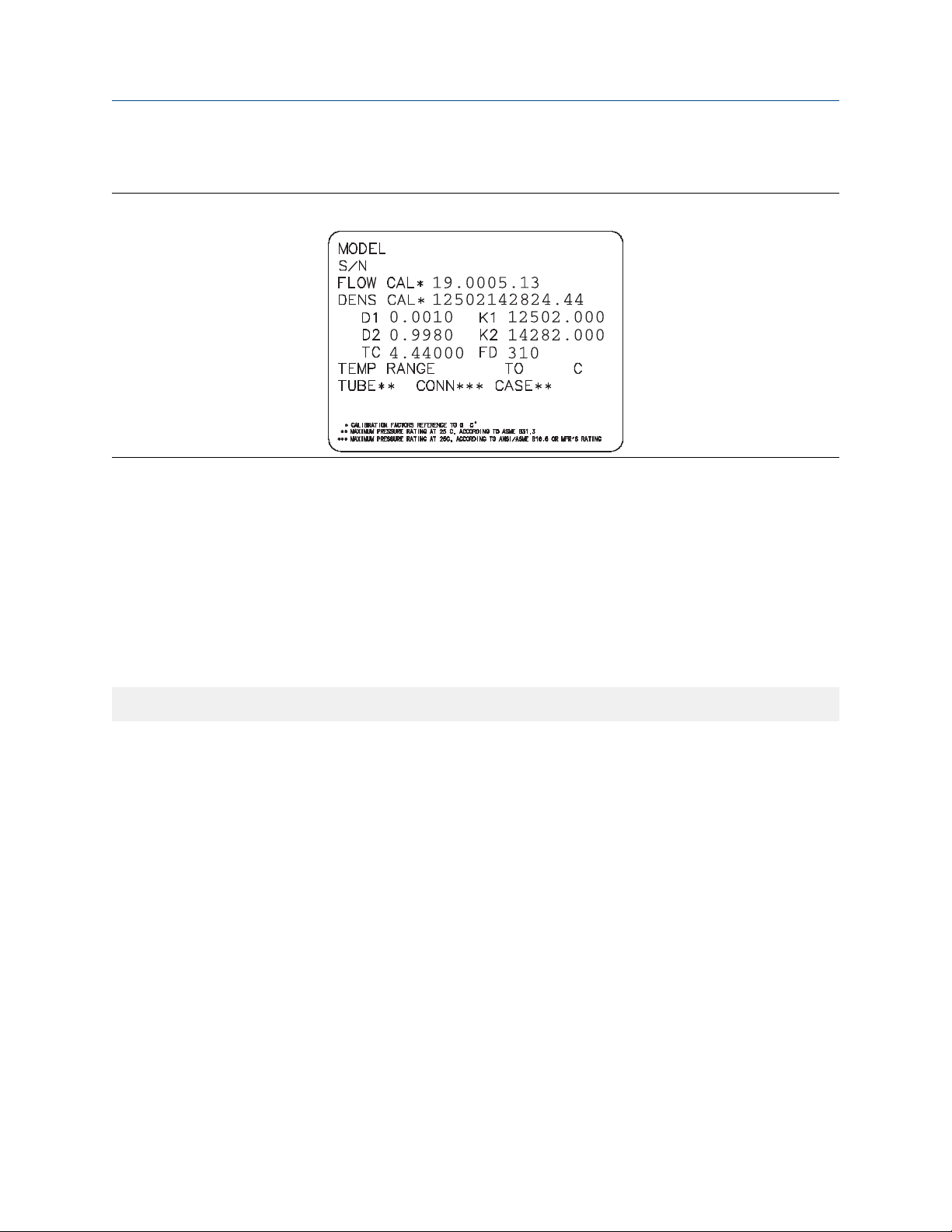

2.8.1 Sample sensor tags

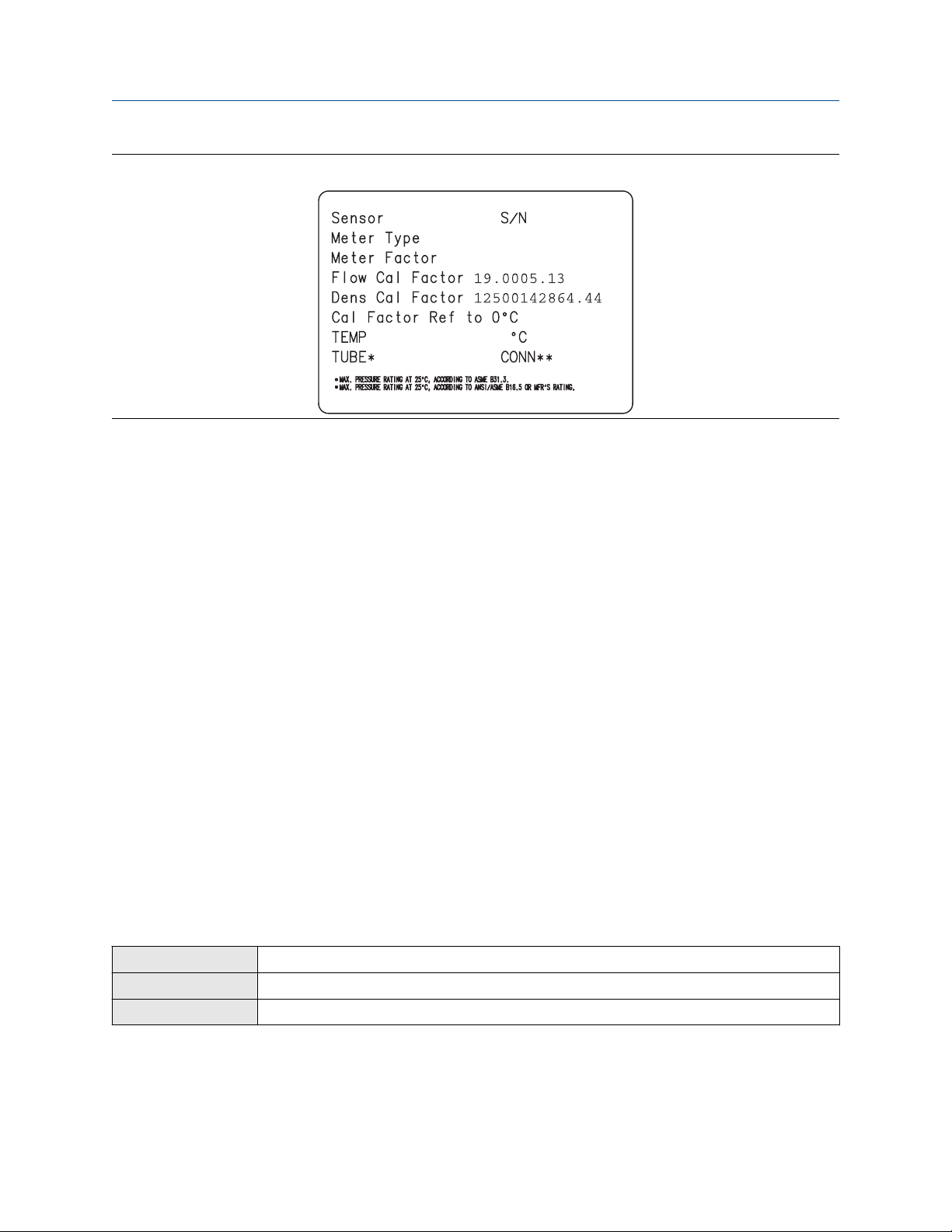

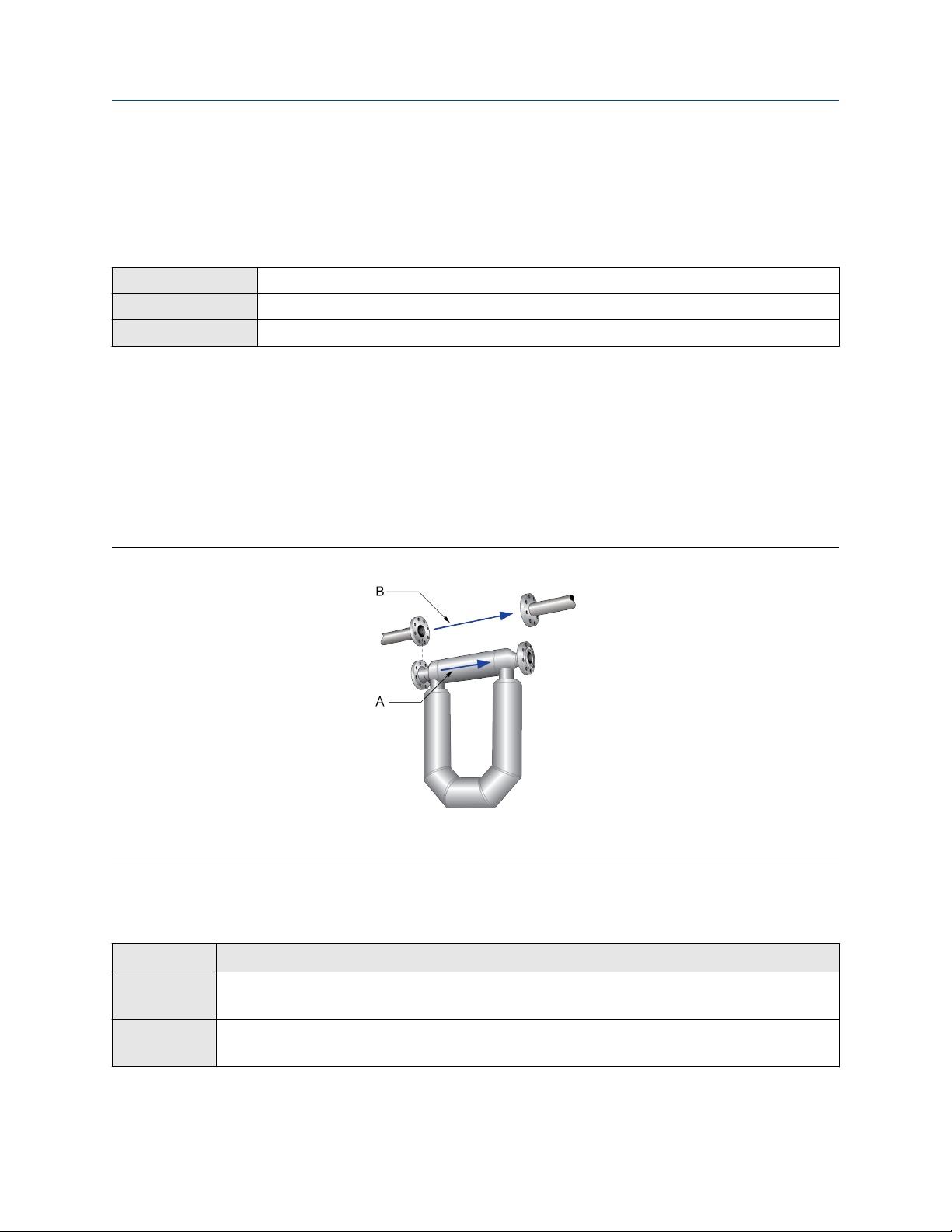

Figure 2-1: Tag on newer curved-tube sensors (all sensors except T-Series)

2.8.2 Flow calibration parameters (FCF, FT)

Two separate values are used to describe flow calibration: a 6-character FCF value and a 4-character FT value.

They are provided on the sensor tag.

Both values contain decimal points. During characterization, these are entered as a single 10-character string.

The 10-character string is called either Flowcal or FCF.

If your sensor tag shows the FCF and the FT values separately and you need to enter a single value,

concatenate the two values to form the single parameter value, retaining both decimal points.

Concatenating FCF and FT

FCF = x.xxxx FT = y.yy Flow calibration parameter: x.xxxxy.yy

2.8.3 Density calibration parameters (D1, D2, K1, K2, FD, DT, TC)

Density calibration parameters are typically on the sensor tag and the calibration certificate.

If your sensor tag does not show a D1 or D2 value:

• For D1, enter the Dens A or D1 value from the calibration certificate. This value is the line-condition

density of the low-density calibration fluid. Micro Motion uses air. If you cannot find a Dens A or D1 value,

enter 0.001 g/cm3.

• For D2, enter the Dens B or D2 value from the calibration certificate. This value is the line-condition density

of the high-density calibration fluid. Micro Motion uses water. If you cannot find a Dens B or D2 value,

enter 0.998 g/cm3 .

If your sensor tag does not show a K1 or K2 value:

• For K1, enter the first five digits of the density calibration factor. In this sample tag, this value is shown as

12500.

• For K2, enter the second five digits of the density calibration factor. In this sample tag, this value is shown

as 14286.

14 Micro Motion 5700 with Ethernet Transmitters

Page 15

Configuration and Use Manual Quick start

MMI-20029769 January 2021

Figure 2-2: K1, K2, and TC values in the density calibration factor

If your sensor does not show an FD value, contact customer service.

If your sensor tag does not show a DT or TC value, enter the last four characters of the density calibration

factor. In the sample tag shown above, the value is shown as 4.44.

Do not confuse the Meter Factor line on the pictured sensor tag with any meter factor settings discussed in

this manual.

2.9 Verify mass flow measurement

Check to see that the mass flow rate reported by the transmitter is accurate. You can use any available

method.

Procedure

• Read the value for Mass Flow Rate on the transmitter display.

• Connect to the transmitter with ProLink III and read the value for Mass Flow Rate in the Process Variables

panel.

Postrequisites

If the reported mass flow rate is not accurate:

• Check the characterization parameters.

• Review the troubleshooting suggestions for flow measurement issues.

2.10 Verify the zero

Display

ProLink III Device Tools → Calibration → Smart Zero Verification and Calibration → Verify Zero

Web browser Service Tools → Verification and Calibration → Meter Zero → Zero Verification

Menu → Service Tools → Verification & Calibration → Meter Zero → Zero Verification

Configuration and Use Manual 15

Page 16

Quick start Configuration and Use Manual

January 2021 MMI-20029769

Verifying the zero helps you determine if the stored zero value is appropriate to your installation, or if a field

zero can improve measurement accuracy.

Important

In most cases, the factory zero is more accurate than the field zero. Do not zero the meter unless one of the

following is true:

• The zero is required by site procedures.

• The stored zero value fails the zero verification procedure.

Do not verify the zero or zero the meter if a high-severity alert is active. Correct the problem, then verify the

zero or zero the meter. You may verify the zero or zero the meter if a low-severity alert is active.

Procedure

1. Prepare the meter:

a) Allow the meter to warm up for at least 20 minutes after applying power.

b) Run the process fluid through the sensor until the sensor temperature reaches the normal

process operating temperature.

c) Stop flow through the sensor by shutting the downstream valve, and then the upstream valve if

available.

d) Verify that the sensor is blocked in, that flow has stopped, and that the sensor is completely full

of process fluid.

2. Start the zero verification procedure, and wait until it completes.

3. If the zero verification procedure fails:

a) Confirm that the sensor is completely blocked in, that flow has stopped, and that the sensor is

completely full of process fluid.

b) Verify that the process fluid is not flashing or condensing, and that it does not contain particles

that can settle out.

c) Repeat the zero verification procedure.

d) If it fails again, zero the meter.

Postrequisites

Restore normal flow through the sensor by opening the valves.

Related information

Zero the meter

16 Micro Motion 5700 with Ethernet Transmitters

Page 17

Configuration and Use Manual Introduction to configuration and commissioning

MMI-20029769 January 2021

3 Introduction to configuration and commissioning

3.1 Security and write protection

The transmitter has several features that can help to protect it against intentional or unintentional access and

configuration changes.

• When locked, the mechanical lock switch on the front of the display prevents any configuration changes

to the transmitter from any local or remote configuration tool. A transmitter without a display does not

have a lock switch.

• When enabled, the software setting Write Protection prevents any configuration changes. The setting

can only be enabled if the transmitter does not have a display.

• If the Universal Service Port (USP) is disabled, the port cannot be used by any service tool to communicate

with or make changes to the transmitter.

• When enabled, Security prevents any configuration changes being made from the display unless the

appropriate password is entered.

3.1.1 Web server security

You can configure this transmitter using web services. There are multiple levels of security built into the

transmitter that you can configure according to your needs and security standards, including:

• Disabling the web servers

• Disallowing firmware upgrades through the Ethernet interface

• Allowing downloads of configuration and historian files, but disallowing file uploads to the transmitter

through the Ethernet interface

• Configuring Transport Layer Security (TLS) on the web server to encrypt all data transmitted between the

web server and the transmitter

• Requiring user authentication and strong passwords to access the web server and the transmitter

• Notifying users through alerts if the default password has not been changed

• Disallowing configuration changes from all interfaces including the Ethernet port using transmitter

security switches, such as the lock switch or write protection

This transmitter:

• Was designed to be implemented in an industrial automation control system (Level 1 and Level 2 of the

Purdue Reference Architecture Model), with defense in depth security controls

(1)

(1)

(1)

• Is not intended to be directly connected to an enterprise or to an internet-facing network without a

compensating control in place

Version 2.0 and higher

(1)

Configuration and Use Manual 17

Page 18

Introduction to configuration and commissioning Configuration and Use Manual

January 2021 MMI-20029769

3.1.2 Universal Service Port security

This transmitter is equipped with a Universal Service Port that works with USB type A connections, including

compatible flash drives. There are multiple levels of security built into the transmitter's service port that you

can configure according to your needs and security standards.

The service port offers the following features that enhance interface security:

• The service port is inaccessible without physical access to the transmitter and requires removal of the

terminal cover

• The service port can be disabled from the transmitter through software

• The transmitter has a non-traditional operating system that is not designed to execute programs or run

scripts

• The display can be password protected to limit access to the USB file menu

• Overall transmitter security switches such as the lock switch or write-protection disallows configuration

changes from all interfaces including the Universal Service Port

This transmitter:

• Was designed to be implemented in an industrial automation control system (Level 1 and Level 2 of the

Purdue Reference Architecture Model), with defense in depth security controls

• Is not intended to be directly connected to an enterprise or to an internet-facing network without a

compensating control in place

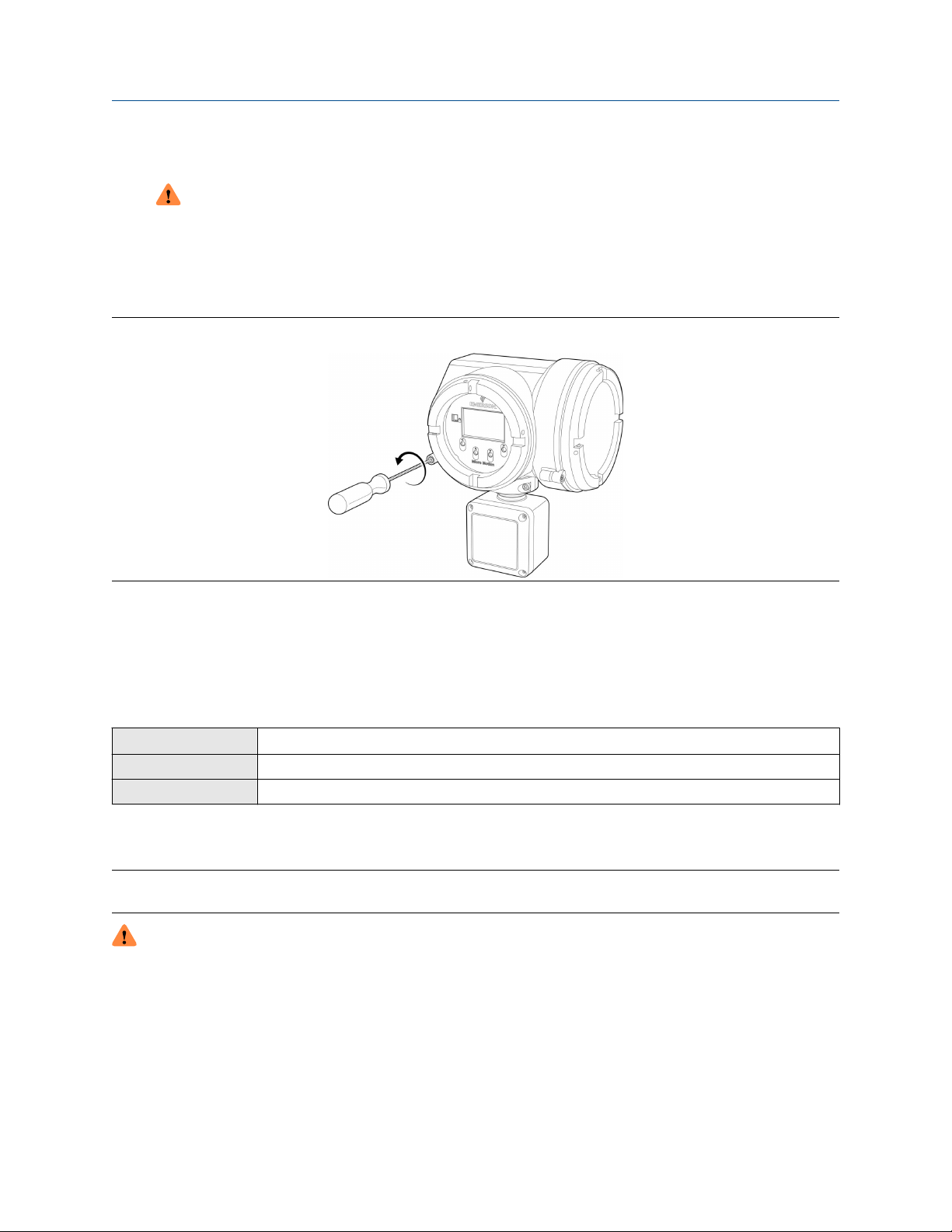

3.1.3 Lock or unlock the transmitter

If the transmitter has a display, a mechanical switch on the display can be used to lock or unlock the

transmitter. When locked, no configuration changes can be made using any configuration tool.

Figure 3-1: Lock switch on transmitter display

You can determine whether you need to lock or unlock the transmitter by looking at the switch.

• If the switch is in the right position, the transmitter is locked.

• If the switch is in the left position, the transmitter is unlocked.

Note

The top switch is reserved for future use.

18 Micro Motion 5700 with Ethernet Transmitters

Page 19

Configuration and Use Manual Introduction to configuration and commissioning

MMI-20029769 January 2021

Procedure

1.

WARNING

If the transmitter is in a hazardous area, do not remove the housing cover while the transmitter is

powered up. Failure to follow these instructions can cause an explosion resulting in injury or death.

If you are in a hazardous area, power down the transmitter.

2. Remove the transmitter housing cover.

Figure 3-2: Removing the transmitter housing cover

3. Using a fine-pointed tool, move the switch to the desired position.

4. Replace the transmitter housing cover.

5. If necessary, power up the transmitter.

3.1.4 Enable or disable the service port

Display

ProLink III Not available

Web browser Not available

The service port is enabled by default, so you can use it for transferring files or connect to it with ProLink III. If

you want to completely prevent it from being used, you can disable it.

Note

Enabling or disabling the service port will not take effect until power has been cycled to the transmitter.

WARNING

Do not use the service port if the transmitter is in a hazardous area because using the service port means

that you must open the transmitter wiring compartment. Opening the wiring compartment in a hazardous

area while the transmitter is powered up can cause an explosion resulting in injury or death.

Menu → Configuration → Security → Service Port

Configuration and Use Manual 19

Page 20

Introduction to configuration and commissioning Configuration and Use Manual

January 2021 MMI-20029769

3.1.5 Enable or disable software write-protection

Display Use the mechanical switch on the display.

ProLink III Device Tools → Configuration → Write-Protection

Web browser Configuration → Security → Write Protection

When enabled, Write-Protection prevents changes to the transmitter configuration. You can perform all

other functions, and you can view the transmitter configuration parameters.

Note

The write protection setting via software methods (such as ProLink III) is available only on transmitters

without a display.

For transmitters with a display, write protection is available only using the lock switch on the display. See Lock

or unlock the transmitter.

Write-protecting the transmitter primarily prevents accidental changes to configuration, not intentional

changes. Any user who can make changes to the configuration can disable write protection.

3.1.6 Configure security for the display

Display Menu → Configuration → Security → Display Security

ProLink III Device Tools → Configuration → Transmitter Display → Display Security

Web browser Not available

When using the display, you can require users to enter a password to do any of the following tasks:

• Enter the main menu

• Change a parameter

• Access alert data through the display

• Start, stop, or reset totalizers or inventories via the context menu

The display password can be the same or different from the totalizer/inventory context menu control

password. If different, the display password is used to reset, start, and stop totalizers or inventories using

Menu → Operations → Totalizers.

20 Micro Motion 5700 with Ethernet Transmitters

Page 21

Configuration and Use Manual Introduction to configuration and commissioning

MMI-20029769 January 2021

Procedure

1. Configure Password Required as desired.

Option Description

At Write When an user chooses an action that leads to a configuration change, they are

prompted to enter the display password.

Enter Menu When the menu is selected from the process variable screen, the display password

will be immediately required if Password Required is set.

Never (default) When a user chooses an action that leads to a configuration change, they are

prompted to activate ⇦⇧⇩⇨. This is designed to protect against accidental changes

to configuration. It is not a security measure.

2. If the At Write or Enter Menu option was selected, enable or disable alert security as desired.

Option Description

Enabled If an alert is active, the alert symbol ⓘ is shown in the upper right corner of the display but

the alert banner is not displayed. If the operator attempts to enter the alert menu, they are

prompted to enter the display password.

Disabled If an alert is active, the alert symbol ⓘ is shown in the upper right corner of the display and

the alert banner is displayed automatically. No password or confirmation is required to

enter the alert menu.

Restriction

You cannot set Password Required to Never and enable alert security.

• If you did not enable Password Required, alert security is disabled and cannot be enabled.

• Alert security is disabled automatically if you set Password Required to Never after:

— Password Required is initially set to either At Write or Enter Menu

— Alert security is enabled

3. If Password Required has been set to At Write or Enter Menu, you will be prompted to enter the

desired password.

• Default: AAAA

• Range: Any four alphanumeric characters

• Password Required must be set to At Write or Enter Menu to enable the totalizer/inventory control

context menu password option.

Important

If you enable Password Required but you do not change the display password, the transmitter will post

a configuration alert.

Configuration and Use Manual 21

Page 22

Introduction to configuration and commissioning Configuration and Use Manual

January 2021 MMI-20029769

4. Configure Main Menu Available as desired.

Option Description

Enabled The local display Menu option from the process variable screen will be accessible.

Disabled The local display Menu option from the process variable screen will not be accessible.

Important

Once Main Menu Available has been disabled, you cannot enable it from the local display. Use another

configuration tool, such as ProLink III, to re-enable main menu access from the local display.

3.2 Work with configuration files

You can save the current transmitter configuration in two forms: a backup file and a replication file. You can

save the configuration to the SD card on your transmitter or to a USB drive.

Tip

You can use a saved configuration file to change the nature of the transmitter quickly. This might be

convenient if the transmitter is used for different applications or different process fluids.

You can load a configuration file to the transmitter's working memory or to the transmitter's SD card. You can

load either a backup file or a replication file.

Backup files

Replication files

Contain all parameters. They are used to restore the current device if required.

The .spare extension is used to identify backup files.

Contain all parameters except the device-specific parameters, e.g., calibration factors or

meter factors. They are used to replicate the transmitter configuration to other devices.

The .xfer extension is used to identify replication files.

3.2.1 Save a configuration file using the display

Prerequisites

If you are planning to use the USB drive, the service port must be enabled. It is enabled by default. However, if

you need to enable it, choose Menu → Configuration → Security and set Service Port to On.

Procedure

• To save the current configuration to the transmitter's SD card as a backup file:

a) Choose Menu → Configuration → Save/Restore Config → Save Config to Memory.

b) Enter the name for this configuration file.

The configuration file is saved to the transmitter's SD card as yourname.spare.

• To save the current configuration to a USB drive, as either a backup file or a replication file:

a)

22 Micro Motion 5700 with Ethernet Transmitters

WARNING

If the transmitter is in a hazardous area, do not remove the housing cover while the transmitter is

powered up. Failure to follow these instructions can cause an explosion resulting in injury or

death.

Page 23

Configuration and Use Manual Introduction to configuration and commissioning

MMI-20029769 January 2021

Open the wiring compartment on the transmitter and insert a USB drive into the service port.

b) Choose Menu → USB Options → Transmitter --> USB Drive → Save Active Config to USB Drive.

c) Choose Backup or Replicate.

d) Enter the name for this configuration file.

The configuration file is saved to the USB drive as yourname.spare or yourname.xfer.

• To copy a configuration file from the transmitter's SD card to the USB drive:

a)

b) Choose Menu → USB Options → Transmitter --> USB Drive → Transfer Config File to USB Drive.

c) Choose Backup or Replicate.

d) Select the file that you want to transfer.

The configuration file is copied to the USB drive, using its existing name.

WARNING

If the transmitter is in a hazardous area, do not remove the housing cover while the transmitter is

powered up. Failure to follow these instructions can cause an explosion resulting in injury or

death.

Open the wiring compartment on the transmitter and insert a USB drive into the service port.

3.2.2 Save a configuration file using ProLink III

Note

When you use ProLink III format for configuration files, you can specify configuration parameters individually

or by groups. Therefore, you can use this format for both backup and replication.

Procedure

• To save the current configuration to the transmitter's SD card:

a) Choose Device Tools → Configuration Transfer → Save Configuration.

b) Select On my 5700 Device Internal Memory and select Next.

c) Select Save.

d) Enter the name for this configuration file.

e) Set the file type.

— To save a backup file, set the file type to Backup.

— To save a replication file, set the file type to Transfer.

f) Select Save.

The configuration file is saved to the transmitter's SD card as yourname.spare or yourname.xfer.

• To save the current configuration to your PC, in 5700 format:

a) Choose Device Tools → Configuration Transfer → Save Configuration.

b) Select On my computer in 5700 device file format and select Next.

Configuration and Use Manual 23

Page 24

Introduction to configuration and commissioning Configuration and Use Manual

January 2021 MMI-20029769

c) Select Save.

d) Browse to the desired location, then enter the name for this configuration file.

e) Set the file type.

— To save a backup file, set the file type to Backup.

— To save a replication file, set the file type to Transfer.

f) Select Save.

The configuration file is saved to the specified location as yourname.spare or yourname.xfer.

• To save the current configuration to your PC, in ProLink III format:

a) Choose Device Tools → Configuration Transfer → Save Configuration.

b) Select On my computer in ProLink III file format and click Next.

c) Select Save.

d) Select the configuration parameters to be included in this file.

— To save a backup file, select all parameters.

— To save a replication file, select all parameters except device-specific parameters.

e) Select Save.

f) Browse to the desired location, then enter the name for this configuration file.

g) Set the file type to ProLink configuration file.

h) Select Start Save.

The configuration file is saved to the specified location as yourname.pcfg.

3.2.3 Load a configuration file using the display

Prerequisites

You must have a backup file or a replication file available for use.

If you are planning to use the USB drive, the service port must be enabled. It is enabled by default. However, if

you need to enable it, choose Menu → Configuration → Security and set Service Port to On.

Procedure

• To load either a backup file or a replication file from the transmitter's SD card:

a) Choose Menu → Configuration → Save/Restore Config → Restore Config from Memory.

b) Select Backup or Replicate.

c) Select the file that you want to load.

The file is loaded to working memory and becomes active immediately.

• To load a either a backup file or a replication file from a USB drive:

24 Micro Motion 5700 with Ethernet Transmitters

Page 25

Configuration and Use Manual Introduction to configuration and commissioning

MMI-20029769 January 2021

a) WARNING

If the transmitter is in a hazardous area, do not remove the housing cover while the transmitter is

powered up. Failure to follow these instructions can cause an explosion resulting in injury or

death.

Open the wiring compartment on the transmitter and insert the USB drive containing the backup

file or replication file into the service port.

b) Choose Menu → USB Options → USB Drive --> Transmitter → Upload Configuration File.

c) Select Backup or Replicate.

d) Select the file that you want to load.

e) Choose Yes or No when prompted to apply the settings.

— Yes: The file is loaded to working memory and becomes active immediately.

— No: The file is loaded to the transmitter's SD card but not to working memory. You can load it

from the SD card to working memory at a later time.

3.2.4 Load a configuration file using ProLink III

You can load a configuration file to the transmitter's working memory. You can load a backup file or a

replication file. Two PC file formats are supported: the 5700 format and the ProLink III format.

Note

When you use ProLink III format for configuration files, you can specify configuration parameters individually

or by groups. Therefore, you can use this format for both backup and replication.

Procedure

• To load a backup file or replication file from the transmitter's SD card:

a) Choose Device Tools → Configuration Transfer → Load Configuration.

b) Select On my 5700 Device Internal Memory and select Next.

c) Select Restore.

d) Set the file type.

— To load a backup file, set the file type to Backup.

— To load a replication file, set the file type to Transfer.

e) Select the file that you want to load and select Load.

The parameters are written to working memory, and the new settings become effectively immediately.

• To load a backup file or replication file in 5700 format from the PC:

a) Choose Device Tools → Configuration Transfer → Load Configuration.

b) Select On my computer in 5700 device file format and select Next.

c) Select Restore.

Configuration and Use Manual 25

Page 26

Introduction to configuration and commissioning Configuration and Use Manual

January 2021 MMI-20029769

d) Set the file type.

— To load a backup file, set the file type to Backup.

— To load a replication file, set the file type to Transfer.

e) Navigate to the file you want to load, and select it.

The parameters are written to working memory, and the new settings become effectively immediately.

• To load a file in ProLink III format from the PC:

a) Choose Device Tools → Configuration Transfer → Load Configuration.

b) Select On my computer in ProLink III file format and select Next.

c) Select the parameters that you want to load.

d) Select Load.

e) Set the file type to Configuration file.

f) Navigate to the file you want to load, and select it.

g) Select Start Load.

The parameters are written to working memory, and the new settings become effectively immediately.

3.2.5 Restore the factory configuration

Display

ProLink III Device Tools → Configuration Transfer → Restore Factory Configuration

Web browser Service Tool → Download Device Files → Factory Config File (download only, no restoration)

A file containing the factory configuration is always saved in the transmitter's internal memory, and is

available for use.

This action is typically used for error recovery or for repurposing a transmitter.

If you restore the factory configuration, the real-time clock, the audit trail, the historian, and other logs are

not reset.

Note

Using a web browser, you can download the factory (.cfg) configuration file and view it with a text editor, but

you must use ProLink III or the display to restore the factory configuration.

Menu → Configuration → Save/Restore Configuration → Restore Config from Memory

3.2.6 Replicate a transmitter configuration

Replicating a transmitter configuration is a fast method to set up similar or identical measurement points.

Procedure

1. Configure a transmitter and verify its operation and performance.

2. Use any available method to save a replication file from that transmitter.

3. Use any available method to load the replication file to another transmitter.

26 Micro Motion 5700 with Ethernet Transmitters

Page 27

Configuration and Use Manual Introduction to configuration and commissioning

MMI-20029769 January 2021

4. At the replicated transmitter, set device-specific parameters and perform device-specific procedures:

a) Set the clock.

b) Set the tag, long tag, Modbus address, and related parameters.

c) Characterize the transmitter.

d) Perform zero validation and take any recommended actions.

e) Perform loop tests and take any recommended actions, including mA Output trim.

f) Use sensor simulation to verify transmitter response.

5. At the replicated transmitter, make any other configuration changes.

6. Follow your standard procedures to ensure that the replicated transmitter is performing as desired.

Configuration and Use Manual 27

Page 28

Introduction to configuration and commissioning Configuration and Use Manual

January 2021 MMI-20029769

28 Micro Motion 5700 with Ethernet Transmitters

Page 29

Configuration and Use Manual Configure process measurement

MMI-20029769 January 2021

4 Configure process measurement

4.1 Configure Sensor Flow Direction Arrow

Display Menu → Configuration → Process Measurement → Flow Variables → Flow Direction

ProLink III Device Tools → Configuration → Process Measurement → Flow → Sensor Direction

Web browser Configuration → Process Measurement → Flow Variables → Sensor Direction

Sensor Flow Direction Arrow is used to accommodate installations in which the Flow arrow on the sensor

does not match the majority of the process flow. This typically happens when the sensor is accidentally

installed backwards.

Sensor Flow Direction Arrow interacts with mA Output Direction, Frequency Output Direction, and

Totalizer Direction to control how flow is reported by the outputs and accumulated by the totalizers and

inventories.

The Sensor Flow Direction Arrow also affects how flow is reported on the transmitter display and via digital

communications. This includes ProLink III, the web browser, and all other user interfaces.

Figure 4-1: Flow arrow on sensor

A. Flow arrow

B. Actual flow direction

Procedure

Set Sensor Flow Direction Arrow as appropriate.

Option

With Arrow The majority of flow through the sensor matches the Flow arrow on the sensor. Actual

Description

forward flow is processed as forward flow.

Against Arrow The majority of flow through the sensor is opposite to the Flow arrow on the sensor. Actual

forward flow is processed as reverse flow.

Configuration and Use Manual 29

Page 30

Configure process measurement Configuration and Use Manual

January 2021 MMI-20029769

Tip

Micro Motion sensors are bidirectional. Measurement accuracy is not affected by actual flow direction or the

setting of Sensor Flow Direction Arrow. Sensor Flow Direction Arrow controls only whether actual flow is

processed as forward flow or reverse flow.

Related information

Configure mA Output Direction

Configure Frequency Output Direction

Configure Discrete Output Source

Configure totalizers and inventories

Effect of Sensor Flow Direction Arrow on digital communications

4.2 Configure mass flow measurement

The mass flow measurement parameters control how mass flow is measured and reported. The mass total

and mass inventory are derived from the mass flow data.

4.2.1 Configure Mass Flow Measurement Unit

Display Menu → Configuration → Process Measurement → Flow Variables → Mass Flow Settings → Units

ProLink III Device Tools → Configuration → Process Measurement → Flow → Mass Flow Rate Unit

Web browser Configuration → Process Measurement → Flow Variables → Mass Flow Rate Unit

Mass Flow Measurement Unit specifies the unit of measure that will be used for the mass flow rate. The

default unit used for mass total and mass inventory is derived from this unit.

Procedure

Set Mass Flow Measurement Unit to the unit you want to use.

Default: g/sec (grams per second)

Tip

If the measurement unit you want to use is not available, you can define a special measurement unit.

Options for Mass Flow Measurement Unit

The transmitter provides a standard set of measurement units for Mass Flow Measurement Unit, plus one

user-defined special measurement unit. Different communications tools may use different labels for the

units.

Label

Unit description

Grams per second gram/s g/sec g/sec

Grams per minute gram/min g/min g/min

Grams per hour gram/h g/hr g/hr

Kilograms per second kg/s kg/sec kg/sec

30 Micro Motion 5700 with Ethernet Transmitters

Display ProLink III Web browser

Page 31

Configuration and Use Manual Configure process measurement

MMI-20029769 January 2021

Label

Unit description

Kilograms per minute kg/min kg/min kg/min

Kilograms per hour kg/h kg/hr kg/hr

Kilograms per day kg/d kg/day kg/day

Metric tons per minute MetTon/min mTon/min mTon/min

Metric tons per hour MetTon/h mTon/hr mTon/hr

Metric tons per day MetTon/d mTon/day mTon/day

Pounds per second lb/s lbs/sec lbs/sec

Pounds per minute lb/min lbs/min lbs/min

Pounds per hour lb/h lbs/hr lbs/hr

Pounds per day lb/d lbs/day lbs/day

Short tons (2000 pounds) per minute STon/min sTon/min sTon/min

Short tons (2000 pounds) per hour STon/h sTon/hr sTon/hr

Short tons (2000 pounds) per day STon/d sTon/day sTon/day

Long tons (2240 pounds) per hour LTon/h lTon/hr lTon/hr

Long tons (2240 pounds) per day LTon/d lTon/day lTon/day

Special unit SPECIAL Special Special

Display ProLink III Web browser

Define a special measurement unit for mass flow

Display

ProLink III Device Tools → Configuration → Process Measurement → Flow → Mass Flow Rate Unit → Special

Web browser Configuration → Process Measurement → Flow Variables → Mass Flow Rate Unit → Special

Procedure

1. Specify Base Mass Unit.

Base Mass Unit is the existing mass unit that the special unit will be based on.

2. Specify Base Time Unit.

Base Time Unit is the existing time unit that the special unit will be based on.

3. Calculate Mass Flow Conversion Factor as follows:

a) x base units = y special units

b) Mass Flow Conversion Factor = x ÷ y

4. Enter Mass Flow Conversion Factor.

The original mass flow rate value is divided by this value.

Menu → Configuration → Process Measurement → Flow Variables → Mass Flow Settings → Units →

SPECIAL

Configuration and Use Manual 31

Page 32

Configure process measurement Configuration and Use Manual

January 2021 MMI-20029769

5. Set Mass Flow Label to the name you want to use for the mass flow unit.

6. Set Mass Total Label to the name you want to use for the mass total and mass inventory unit.

The special measurement unit is stored in the transmitter. You can configure the transmitter to use the

special measurement unit at any time.

Example: Defining a special measurement unit for mass flow

If you want to measure mass flow in ounces per second (oz/sec):

1. Set Base Mass Unit to Pounds (lb).

2. Set Base Time Unit to Seconds (sec).

3. Calculate Mass Flow Conversion Factor:

a. 1 lb/sec = 16 oz/sec

b. Mass Flow Conversion Factor = 1 ÷ 16 = 0.0625

4. Set Mass Flow Conversion Factor to 0.0625.

5. Set Mass Flow Label to oz/sec.

6. Set Mass Total Label to oz.

4.2.2 Configure Flow Damping

Display

ProLink III Device Tools → Configuration → Process Measurement → Flow → Flow Rate Damping

Web browser Configuration → Process Measurement → Flow Variables → Flow Rate Damping

Flow Damping controls the amount of damping that will be applied to the measured mass flow rate. It affects

flow rate process variables that are based on the measured mass flow rate. This includes volume flow rate and

gas standard volume flow rate.

Flow Damping also affects specialized flow rate variables such as temperature-corrected volume flow rate

(API Referral) and net mass flow rate (concentration measurement).

Damping is used to smooth out small, rapid fluctuations in process measurement. The damping value

specifies the time period, in seconds, over which the transmitter will spread changes in the process variable.

At the end of the interval, the internal value of the process variable (the damped value) will reflect 63% of the

change in the actual measured value.

Procedure

Set Flow Damping to the value you want to use.

• Default: 0.64 seconds

Menu → Configuration → Process Measurement → Flow Variables → Flow Damping

• Range: 0 seconds to 60 seconds

Note

If a number greater than 60 is entered, it is automatically changed to 60.

32 Micro Motion 5700 with Ethernet Transmitters

Page 33

Configuration and Use Manual Configure process measurement

MMI-20029769 January 2021

Tip

• A high damping value makes the process variable appear smoother because the reported value changes

slowly.

• A low damping value makes the process variable appear more erratic because the reported value changes

more quickly.

• The combination of a high damping value and rapid, large changes in flow rate can result in increased

measurement error.

• Whenever the damping value is non-zero, the reported measurement will lag the actual measurement

because the reported value is being averaged over time.

• In general, lower damping values are preferable because there is less chance of data loss, and less lag time

between the actual measurement and the reported value.

• The transmitter automatically rounds off any entered damping value to the nearest valid value. Therefore,

the recommended damping value for gas applications should be 3.2 seconds. If you enter 2.56, the

transmitter will round it off to 3.2.

• For filling applications, Micro Motion recommends using the default value of 0.04 seconds.

Effect of flow damping on volume measurement

Flow damping affects volume measurement for liquid volume data. Flow damping also affects volume

measurement for gas standard volume data. The transmitter calculates volume data from the damped mass

flow data.

Interaction between Flow Damping and mA Output Damping

In some circumstances, both Flow Damping and mA Output Damping are applied to the reported mass flow

value.

Flow Damping controls the rate of change in flow process variables. mA Output Damping controls the rate

of change reported via the mA Output. If mA Output Process Variable is set to Mass Flow Rate, and both

Flow Damping and mA Output Damping are set to non-zero values, flow damping is applied first, and the

added damping calculation is applied to the result of the first calculation.

4.2.3 Configure Mass Flow Cutoff

Display

ProLink III Device Tools → Configuration → Process Measurement → Flow → Mass Flow Cutoff

Web browser Configuration → Process Measurement → Flow Variables → Mass Flow Cutoff

Mass Flow Cutoff specifies the lowest mass flow rate that will be reported as measured. All mass flow rates

below this cutoff will be reported as 0.

Menu → Configuration → Process Measurement → Flow Variables → Mass Flow Settings → Low Flow

Cutoff

Procedure

Set Mass Flow Cutoff to the value you want to use.

• Default: A sensor-specific value set at the factory. If your transmitter was ordered without a sensor, the

default may be 0.0.

Configuration and Use Manual 33

Page 34

Configure process measurement Configuration and Use Manual

January 2021 MMI-20029769

• Recommendation: 0.5% of maximum flow rate of the attached sensor. See the sensor specifications.

Important

Do not use your meter for measurement with Mass Flow Cutoff set to 0.0 g/sec. Ensure that Mass Flow

Cutoff is set to the value that is appropriate for your sensor.

Effect of Mass Flow Cutoff on volume measurement

Mass Flow Cutoff does not affect volume measurement. Volume data is calculated from the actual mass data

rather than the reported value.

Volume flow has a separate Volume Flow Cutoff that is not affected by the Mass Flow Cutoff value.

Interaction between Mass Flow Cutoff and mA Output Cutoff

Mass Flow Cutoff defines the lowest mass flow value that the transmitter will report as measured. mA

Output Cutoff defines the lowest flow rate that will be reported via the mA Output. If mA Output Process

Variable is set to Mass Flow Rate, the mass flow rate reported via the mA Output is controlled by the higher of

the two cutoff values.

Mass Flow Cutoff affects all reported values and values used in other transmitter behavior (e.g., events

defined on mass flow).

mA Output Cutoff affects only mass flow values reported via the mA Output.

Example: Cutoff interaction with mA Output Cutoff lower than Mass Flow Cutoff

Configuration:

• mA Output Process Variable: Mass Flow Rate

• Frequency Output Process Variable: Mass Flow Rate

• mA Output Cutoff: 10 g/sec

• Mass Flow Cutoff: 15 g/sec

Result: If the mass flow rate drops below 15 g/sec, mass flow will be reported as 0, and 0 will be used in all

internal processing.

Example: Cutoff interaction with mA Output Cutoff higher than Mass Flow Cutoff

Configuration: