Page 1

MTE

™

Series Encoders

Sensor Installation

Manual and Reference

Guide

MicroE Systems • 125 Middlesex Turnpike • Bedford, MA 01730 • USA

www.microesys.com info@microesys.com T. 781-266-5700

MTE-IM Series Rev C1 ©2015 MicroE Systems

Page 2

Table of Contents

MTE™Sensor Installation

Introduction

Introduction (Precautions, Patents, Manual Revisions) ...............................................................3

Recommendations for Power, Installation Consideration .........................................................4

Items Required for Sensor Installation .........................................................................................5

MTE, Top Mount Configuration

System Overview Diagram ...........................................................................................................6

Sensor Head Installation .............................................................................................................7

Sensor Head Aignment ................................................................................................................8

MTE, Side Mount Configuration

System Overview Diagram ............................................................................................................9

Sensor Head Installation ............................................................................................................10

Sensor Head Alignment ..............................................................................................................12

Appendix

A. Specifications ......................................................................................................................13

B. Wiring Diagrams ..................................................................................................................14

C. Interface Cable Requirements ......................................................................................15,16

D. RS-422 Compliance ............................................................................................................17

E. Troubleshooting ..................................................................................................................18

F. Order Guide ........................................................................................................................19

Contacting MicroE Systems

Contact MicroE............................................................................................................................20

Page 3

LASER SAFETY INFORMATION: MTE Series

This product is sold solely for use as a component (or replacement) in an electronic product; therefore it is not

required to, and does not comply with, 21 CFR 1040.10 and 1040.11 which pertain to complete laser products. The

manufacturer of the complete system-level electronic product is responsible for complying with 21 CFR 1040.10

and 1040.11 and for providing the user with all necessary safety warnings and information.

MicroE encoders contain an infrared laser diode or diodes. Emitted invisible laser radiation levels have been

measured to be within the CDRH Class 1 range, which is not considered hazardous; however, to minimize

exposure to the diverging beam, the encoder sensor should be installed in its operational configuration in close

proximity to the encoder scale before power is applied.

• Invisible laser radiation; wavelength: 850 nm

• Max power 2.4 mW CW

• CAUTION – The use of optical instruments with this product will increase eye hazard. DO NOT VIEW

DIRECTLY WITH OPTICAL INSTRUMENTS (MICROSCOPES, EYE LOUPES OR MAGNIFIERS).

• All maintenance procedures such as cleaning must be performed with the MicroE encoder turned off.

• Do not insert any reflective surface into the beam path when the encoder is powered.

• Do not attempt to service the MicroE encoder.

Precautions

Follow standard ESD precautions. Turn power off before connecting the sensor. Do

not touch the electrical pins without static protection such as a grounded wrist strap.

Do not touch the tape/glass scale unless you are wearing talc-free gloves or finger

cots. Please read this installation manual for full instructions.

1

2

MTE models are CE and RoHS compliant.

Manual Version Numbers

MTE-IM Sensor Installation Rev C, issued May 2014

Changes: Page 5, changed Items Required to Items Recommended. For Model ZG-CET,

changed ‘ships with each sensor’ to ‘sold separately.’

MTE-IM Sensor Installation Rev B, issued February 2014

Changes: Added Side Mount Configuration.

MTE-IM Sensor Installation Rev A, issued November 2013

Changes: N/A

Related Documents

-MTE Data Sheet

-MTE Interface Drawing

-Compact Encoder Tape (CET™) Scale Installation for MTE Series Encoders

INVISIBLE LASER RADIATION

DO NOT VIEW DIRECTLY WITH OPTICAL

INSTRUMENTS

(MICROSCOPES, EYE LOUPES OR

MAGNIFIERS)

RoHS

Page 4

Recommendations for Power; Installation Considerations

MTE™Series Encoders

1.

Recommendations for Power

MTE™encoders require a minimum of 4.75VDC continuously. When designing circuits and extension

cables, be sure to account for voltage loss over distance and tolerances from the nominal supply

voltage so that at least 4.75VDC is available to the MTE encoder under all operating conditions. The

input voltage should not exceed 5.25VDC.

2.

Installation Considerations

The MTE encoder is a precision electronic instrument. It has been designed to function in a wide

range of applications and environments. To take full advantage of the modular system design,

considerations should be made to allow easy access to the sensor for service and/or replacement.

For optimal performance and reliability:

DO follow standard ESD precautions while handling the sensor and interpolator.

DO allow proper alignment clearance for sensor head alignment.

DO follow setup instructions for the encoder system.

DO, where possible, install the scales in an

“upside down” or vertical position to minimize accumulation of dust.

DO consider redundant encoders or additional feedback devices as part of an overall risk

management program for medical applications.

DO NOT store sensors in an uncontrolled environment.

DO NOT electrically overstress the sensor (Power supply ripple/noise).

DO NOT intentionally “hot swap” the sensor if the device is energized.

DO NOT use in high contamination applications (dust, oil, excessive humidity, or other airborne

contaminants.).

Page 5

System Overview

MTE™Series Encoders

Items Recommended for MTE Encoder Installation Using Compact Encoder Tape (CET)

Scales

• Hex wrench (M2.5 for Top Mount, 5/64”, M3.5 and M2.5 for Side Mount).

• For MTE, Top Mount configuration

- Z height spacer Model Number: ZG-CET (sold separately).

• For MTE Side Mount

Side Mount Bracket Kit, Model Number: BK-SM-MTE.

- Z height spacer shim, ships with each bracket kit - 1.00mm (red) for use with CET scales.

• Optional: MK-FFA bracket kit for installation into industry-standard mounting hole patterns.

Refer to encoder model data sheets for detailed ordering guide and more information

about MicroE Part Numbers.

Page 6

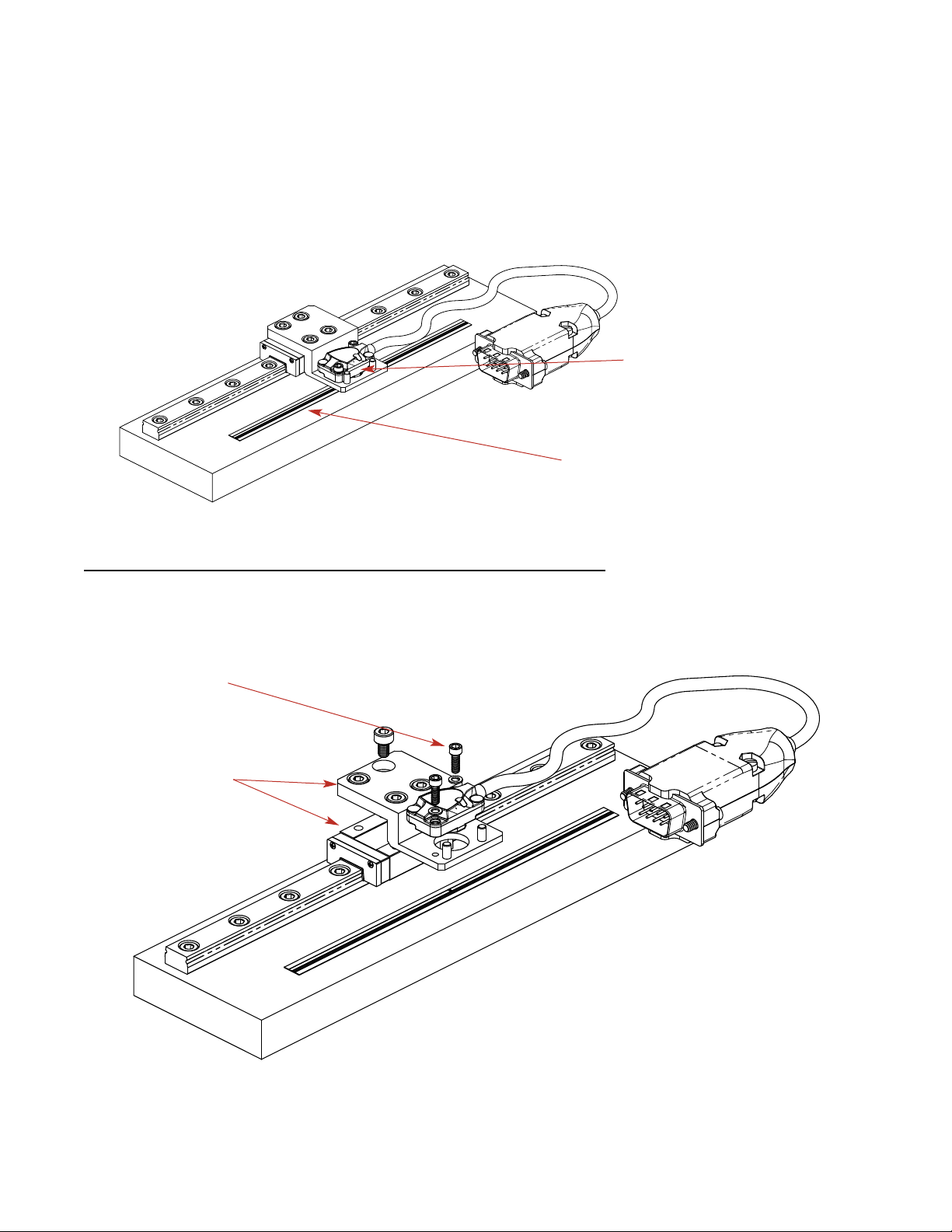

System Overview, (Top Mount Configuration)

MTE™Series Encoders

MTE

TM

Series

System View

Expanded View

Sensor

(shown attached on a linear slide base

with mounting bracket)

Typical user-supplied

sensor mounting bracket

Sensor mounting screws (2)

and flat washers (2)

Compact Encoder Tape scale

(shown mounted on a stationary

surface)

Page 7

Sensor Head Installation (Top Mount Configuration)

MTE™Series Encoders

1.

Verify Sensor Mounting Surface Height

Verify that the distance between the mounting

surface of the sensor and the top of the scale is as

follows:

Tape scale after blue protective film is removed:

3.84 mm ± 0.15 mm.

MicroE's Z-axis height gauge can be used to easily

verify this distance. (P/N: ZG-CET)

Use the gauge to check that there are no

gaps between:

1. The mounting surface of the gauge and the

mounting bracket, or

2. The bottom surface of the gauge and the scale.

Place the gauge in position and use the mounting

screws as guides. If the bottom of the gauge hits the

tape, you will see the gap between the gauge

bottom mounting surface and your mounting bracket

surface.

If you hand tighten the sensor mounting screws,

there should be no gap between the tape scale and

the bottom of the plastic gauge tool.

2.

Install Sensor

Install the sensor on the mounting surface

referencing the appropriate datum surface as

shown on the Interface Drawing. Use two M2 or

2-56 screws to loosely affix the sensor.

A benching edge is recommended to locate the

sensor to meet the mechanical mounting

tolerances. Refer to the Interface Drawing for

recommended location and height of edge.

Note: Tolerance for each axis is specified

independently, assuming nominal alignment in all

other axes.

Gauge P/N: ZG-CET

MTE

Sensor Alignment Tolerances

Axis Alignment Tolerance

X Direction of Motion

Y ± 0.15mm

Z ± 0.15mm

θ

X

± 1.0°

θ

Y

± 2.0°

θ

Z

± 2.0°

Page 8

Sensor Head Alignment (Top Mount Configuration)

MTE™Series Encoders

1.

Proper sensor alignment may require minor

adjustments to the sensor position with respect to

the scale. This can be performed easily using the

sensor’s LED indicator.

The red, yellow, or green Signal LEDs will light

depending on sensor alignment. Slowly move the

sensor by allowing it to slide on the mounting

surface until the green Signal LED, is illuminated.

Optimal alignment will be displayed as a “bright

green” Signal LED.

Confirm that the green Signal LED blinks when

passing over the index. If not, readjust the sensor

in the Y direction and repeat the above procedure.

When alignment is completed, tighten the sensor

mounting screws (0.37Nm [3.3 inch-lbs.] maximum

torque).

2.

Confirm that the Signal LED remains green over

the full range of motion by sliding the scale past

the sensor. The green Signal LED must remain on

over the entire range. If not aligned over the entire

range of motion, loosen the sensor mounting

screws and repeat steps 1 and 2.

The LED will, and should, blink when passing

the index mark.

Z

Y

X

θ

z

Green:

Optimal

Performance

Yellow:

Marginal

Performance

Red:

Improper

Performance

Page 9

System Overview, (Side Mount Configuration)

MTE™Series Encoders

MTE

TM

Series

System View

Expanded View

MTE Sensor

Typical user-supplied

sensor mounting fixture

Sensor mounting screws

(2) and flat washers (2)

Compact Encoder Tape scale

(shown mounted on a stationary

surface)

Typical user-supplied

sensor mounting fixture

MTE Side Mount Bracket Kit,

Model Number: BK-SM-MTE

D

“D” tape scale datum edge

(see MTE Interface Drawing)

Index track

Page 10

MTE

Sensor Alignment Tolerances

Axis Alignment Tolerance

X Direction of Motion

Y ± 0.15mm

Z ± 0.15mm

θ

X

± 1.0°

θ

Y

± 2.0°

θ

Z

± 2.0°

Z

Y

X

θ

z

Sensor Head Installation (Side Mount Configuration)

MTE™Series Encoders

Sensor Mounting Orientation and

Tolerances

Axis diagram (Side mount bracket not shown.)

1.

Install the Sensor

Use a wrench and M2, M3 screws to install the sensor and Side Mount Bracket Kit. Refer to the interface

drawing to make sure sensor is oriented properly with reference to the scale.

1.2 Install the sensor into the

Side Mount Bracket Kit.

Customer mounting

fixture

1.1 Install the Side Mount

Bracket Kit on to the customer

mounting fixture.

Customer mounting

fixture

Side Mount Bracket Kit,

Model Number: BK-SM-MTE

Side Mount Bracket Kit

Page 11

Sensor Head Installation (Side Mount Configuration)

MTE™Series Encoders

2.1 Loosen the Mounting

Fixture in the Y-axis.

2.3 Press down gently in

the Z-axis and tighten

the mounting fixture

screws.

2.2 Place shim between the bottom of the

Bracket Kit Adaptor and the top of the scale.

Mounting

fixture loose in

the Y-axis.

2.4 Carefully remove the shim by rotating it

off the scale with the shim’s handle.

Gently push

the mounting

fixture/Bracket

Kit and sensor

against the top

of the tape

scale in the

z-axis.

Z-Height (red)

spacer

Mounting fixture

screws

2.

Verify Sensor Mounting Surface Height

Refer to the MTE interface drawing for detailed dimensions.

Use the Z-Height red spacer shim (1.00mm) to set the proper Z-height distance between the bottom

surface of the Side Mount Bracket Kit/MTE Sensor and the top of the scale.

Page 12

Sensor Head Alignment (Side Mount Configuration)

MTE™Series Encoders

1.

Proper sensor alignment may require minor

adjustments to the sensor position with respect to the

scale. This can be performed easily using the sensor’s

LED indicator.

The red, yellow, or green Signal LEDs will light

depending on sensor alignment. Optimal alignment will

be displayed as a “bright green” Signal LED.

Confirm that the green Signal LED blinks when

passing over the index. If not, readjust the sensor in

the Y-direction and repeat the above procedure.

When alignment is completed, tighten the sensor

mounting screws (0.37Nm [3.3 inch-lbs.] maximum

torque).

2.

Confirm that the Signal LED remains green over the full range of motion by sliding the scale past the

sensor. The green Signal LED must remain on over the entire range. If not aligned over the entire

range of motion, loosen the sensor mounting screws and repeat step 1.

The LED should blink when passing the index mark.

Z

Y

X

θ

z

Green:

Optimal

Performance

Yellow:

Marginal

Performance

Red:

Improper

Performance

Loosen the

sensor mounting

screws/washers

to reposition the

sensor in the

Y-axis if needed.

Page 13

Appendix A

Specifications

Agency Standards Conformance: In accordance with

Electromagnetic Compatibility Directive 2004/108/EC:

EN 55011:2007

EN 61000-4-2, -3, -4, -6

Shock 300G 0.5 ms half sine

Vibration 30G at 17Hz

Sensor Cable Double Shield

Diameter 3.6mm (0.142")

Flex Life 20x10

6

cycles @ 20mm bending radius

Standard 9 pin D-sub connector

Outputs

Digital A-quad-B, Index Window; A, B and IW outputs are

differential. Alarm is single ended open drain.

Signal Level

A/B/I (differential): RS-422 compatible

A/B/I (single ended): High>4.2VDC, Low <0.2VDC

Alarm: 0.2VDC-Vcc

Operating and Electrical Specifications

Power Supply 5VDC +

5% @ 135mA max. when used

with recommended termination, 80mA

max. unterminated

Temperature

Operating 0 to 70

o

C

Storage -20 to 85oC

Humidity 10 to 90% RH non-condensing

Linearity

Compact Encoder Tape Scale Linearity ≤ +10µ

m/m*

*After two point correction in the customer’s controller.

Sensor Size & Weight

Height Width Length

0.33 [8.4mm] 0.50 [12.7mm] 0.81 [20.6mm]

Weight 5g (without cable)

Reliability Information

5 Year Expected Reliability >99.8% under normal operating

conditions

Digital Output Signals

System

MTE sensors are compatible with PurePrecision

TM

Compact

Encoder Tape (CET

TM

) Scale.

Scale Pitch 20µm

System Resolution 5

µ

m, 2.5µm, or 1µm

(specify at time of ordering)

A

B

Quadrature

Open drain, requires external pull-up.

Pins 8 & 4

Pins 7 & 3

Pins 6 & 2

20µm Typical

4.5VDC

Pin 1

Duration of alarm event

Vcc

Alarm

Index

Inverse signals are not shown for clarity.

Page 14

Appendix B

Wiring Diagrams

Connector Pin Configuration

Electrically conductive mechanical

connection (as supplied by MicroE

Systems).

INNER SHIELD:

Insulated from outer shield, sensor case, and

connector housing. Connected to circuit common

internally as supplied by MicroE Systems

OUTER SHIELD: Connected to

sensor and connector housing

Grounding Considerations

Sensor mounted with good electrical contact to well grounded surface (preferred):

Sensor mounted to poorly grounded or non-conducting surface:

NOTE: GND and INNER SHIELD ARE INTERNALLY CONNECTED.

Max cable length: 5m. Contact MicroE Applications Engineering if longer length required.

Recommended Signal Termination

Cable Zo=

120 Ω

MTE Series

Encoder

Customer

Electronics

120

Ω

+

−

Digital Outputs:

A, B, I

A, B, I

Standard RS-422 Line Receiver Circuitry

5 Volts

0 Volts

POWER

SUPPLY

5 Volts

0 Volts

POWER

SUPPLY

Alarm output is an open drain,

N-channel MOSFET. Drain circuit is normally closed (current

flows) and opens when the

encoder signal is too low. Alarm

requires the use of an external

pull-up resistor. See customer

supplied circuit example on right.

Alarm circuit

Alarm:

PIN 5

PIN 1

PIN 9

PIN 6

$#"!

#

#

"

Power

Supply

5 Volts

0 Volts

Power

Supply

5 Volts

0 Volts

Page 15

Appendix C

Interface Cable Requirements

1. Customer Interface Cable Requirements

Customer cables that interface to MTE™series encoders must have the following characteristics:

• Twisted pair signal wiring.

• Characteristic impedance of 100-120 ohms.

• Sufficient wire gauge to meet the minimum voltage requirement at the encoder, for example 24AWG

gauge wire for a 2m length cable. Examples of acceptable cables with 24AWG gauge wire and 4

twisted pairs are Belden 9831, 8104, and 9844 or other manufacturer’s equivalents.

• Single shield cable with a minimum of 90% coverage. Note that a double shielded cable may be

required in high-noise applications.

MTE

Signal Twisted Pair

A+ Pair 1

A-

B+ Pair 2

B-

Index+ Pair 3

Index-

+5V Pair 4

GND

Fold braided shield back over jacket. Example shows double-shielded cable.

Dimensions shown are for illustration only.

Jacket

Aluminum

Polyester

Shied

Braided

Shield

3. Shield Termination:

The customer's cable shield should be in 360° contact with the connector shroud and the connector shell to

provide complete shielding. The connector shell should be metal with conductive surfaces. Suggested metal

connector shells for use with MTE™ encoders: AMP 748676-1 or equivalent. The shield should be terminated

as illustrated in the following diagram.

2. Signal Wiring

Each differential signal should be connected to a corresponding twisted pair as follows:

Page 16

Appendix C

Interface Cable Requirements

4. Grounding:

The diagrams below show how to make the connections when the encoder's connector is plugged into the

customer's controller chassis. If a customer-supplied extension cable is used, it should be a double shielded

cable with conductive connector shells and must provide complete shielding over the conductors contained within

it over its entire length. Furthermore, the shields should be grounded at the connection to the controller chassis

the same way as the encoder connectors in the diagrams below.

5 Volts

0 Volts

Electrically conductive

mechanical connection

(as supplied by MicroE Systems).

POWER

SUPPLY

INNER SHIELD:

Insulated from outer shield, sensor case, and

connector housing. Connected to circuit common

inter

nally as supplied by MicroE Systems

OUTER SHIELD: Connected to

sensor and connector housings

4.1 Sensor mounted with good electrical contact to a well-grounded surface (preferred)

9 - pin D-sub connector grounding: The encoder's connector shell must be in contact with the customer-supplied

mating connector, which must be isolated from the controller's ground. If a customer-supplied shielded cable

connects the encoder to the controller, then the outer shield on the customer-supplied cable must be isolated

from the controller's ground.

The sensor mounting surface must have a low impedance (DC/AC) connection to ground. The encoder sensor

mounting surface may have to be masked during painting or anodizing to insure good electrical contact with the

sensor.

NOTE:

For best performance, isolate the encoder outer shield from motor cable shields and separate the encoder cable

as far possible from motor cables.

4.2 Sensor mounted to a surface that is grounded through bearings or a poorly-grounded surface, or

mounted to a non-conducting surface

9 - pin D-sub connector grounding: The encoder's connector shell must be in contact with the customer-supplied

mating connector, which must be connected to the controller's ground. If a customer-supplied shielded cable

connects the encoder to the controller, then the outer shield on the customer-supplied cable must be connected

to the controller's ground. The controller must be grounded to earth at the point of installation.

The encoder sensor must be mounted so that it is electrically isolated from ground.

5 Volts

0 Volts

POWER

SUPPLY

Power

Supply

5 Volts

0 Volts

Power

Supply

5 Volts

0 Volts

Page 17

The MTE is RS-422 compatible. Encoder signals are “sending end terminated.” Therefore customer

receiving terminations are not required. If you elect to use them, the supply current will increase.

Optional RS-422 compliant circuitry for long cable runs in harsh electrical environments is illustrated below.

Appendix D

RS-422 Compliance

Page 18

Appendix E

Troubleshooting

Problem

The Sensor LED indicator won’t turn on.

Solution

• Make sure that the MTE Series electronics’ 9-pin D-sub connector is fully seated and connected.

• Confirm that +5 Volts DC is being applied to the MTE Sensor. Refer to the MTE interface drawing for

proper pinouts.

Problem

Can't get the MTE Series electronics’ "Signal" LED better than red or yellow; or the green, “ Proper

Alignment” indicator doesn't stay illuminated over the full length of the scale.

Solution

• Verify that the sensor is mounted in the correct orientation with reference to the scale and scale

mounting reference edge. Refer to the Interface Drawing.

• Verify that the sensor has been aligned to the scale and that the mounting screws are tight. Check the

dimensions for the mechanical mounting holes (and clamps if any) to make sure that the sensor is

correctly located over the scale in the Y and Z dimensions. Refer to the Interface Drawing.

• Check that the scale is firmly mounted and can't jiggle or move in any direction.

• Make sure that the scale is clean over its entire length or circumference.

Page 19

Appendix F

Order Guide

How to Order

MK-FFA

FlexFit Adaptor Mounting Kit.

Reference design is available upon

request.

End Cap Kit, PurePrecision Tape Scales

EC Optional Tape Scale End Caps

Scales

Sensor Installation Tools

ZG-CET Z-Height Gauge, Compact Encoder

Tape, top mount configuration

FlexFit™ Adaptor

TSAT-CET

Tape Applicator Tool for MTE, top

mount configuration

CET™ Tape Scale Applicator Tools

(use for lengths >1m)

TSAT-SM-PPT

Tape Applicator Tool for MTE,

side mount configuration

CET20 – N – A – I

– xxxx –C

I = Individual Lengths

C = Continuous reel with index and

cut marks (unless otherwise

specified)

Length in mm (10mm-30,000mm)

For length >5000mm, contact

MicroE for custom P/N.

Sensor

MTE – 20 –2

Cable Length*

1 = 1.0m

2 = 2.0m

5 = 5.0m

Interpolation (Resolution)

4 = x4 (5

µ

m)

8 = x8 (2.5

µ

m)

20 = x20 (1

µ

m)

Index

I = Center Index

C = Custom Index

Example 1: CET20-N-A-I-4550-C

= 4550mm long, single center index (2775mm from

cut marks), continuous

Example 2: CET20-N-A-C-5xxx-I

= Multiple indexes, individually cut, with index

dimensions per factory issued part # 5xxx (e.g.,

index at 50mm and 350mm, segment length

400mm)

Example 3: CET20-N-A-C-5xxx-C

= Single index which is offset from center of segment,

continuous, with index dimensions per factory

issued part # 5xxx (e.g., index at 50mm from left cut

mark, segment length 400mm)

Compact Encoder Tape (CETTM)

* Custom cable lengths and connectors are available.

Contact MicroE Applications Engineering.

BK-SM-MTE

Side Mount Bracket Kit. Reference

design is available upon request.

MTE Side Mount Bracket Kit

Page 20

Contacting MicroE

MicroE Systems is a world leader in optical encoder technology with

offices in major industrial centers around the globe.

To learn more about MicroE Systems products, visit:

www.microesystems.com.

Our products have been used by thousands of companies worldwide to

solve a wide range of motion control applications. Our advanced

encoder technology and application expertise has driven innovations in

the design of machinery, equipment and instrumentation in many

industries, including medical, industrial, robotics, automation, metrology,

semiconductor manufacturing, packaging equipment, entertainment,

energy, military, and scientific research.

MicroE Systems

125 Middlesex Turnpike

Bedford, MA 01730 USA

T 781-266-5700

F 781-266-5112

info@microesys.com

www.microesystems.com

© 2015 MicroE Systems

Loading...

Loading...