Mercury II™ 5000

Series Encoders

MicroE Systems • 125 Middlesex Turnpike • Bedford, MA 01730 • USA

www.microesystems.com

info@microesystems.com

T. 781-266-5700

F. 781-266-5112

Installation Manual

and Reference Guide

Installation Manual

and Reference Guide

IM-Mercury-II-5000-Series Rev. 1

©2014 MicroE Systems

Introduction

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Table of Contents

1.0 Introduction ...................................................................................................................................... 2

1.1 Overview ............................................................................................................................. 2

1.2 Precautions ......................................................................................................................... 2

1.3 Laser Safety Information ..................................................................................................... 2

1.4 Patents ................................................................................................................................ 3

1.5 Standards Compliance ........................................................................................................ 3

1.6 Related Documentation ...................................................................................................... 3

1.7 Manual Revisions ................................................................................................................ 3

1.8 Trademarks ......................................................................................................................... 3

2.0 Before Installation ............................................................................................................................ 4

2.1 Power Recommendations ................................................................................................... 4

2.2 Installation Considerations .................................................................................................. 4

2.3 Items Required for Installation ............................................................................................ 4

3.0 System Overview ............................................................................................................................. 5

3.1 System View ....................................................................................................................... 5

3.2 Expanded View ................................................................................................................... 5

3.3 SmartPrecision Alignment Tool ........................................................................................... 6

4.0 Sensor Installation ............................................................................................................................ 7

4.1 Sensor Mounting Orientation and Tolerances .................................................................... 7

4.2 Verify Sensor Mounting Surface Height .............................................................................. 7

4.3 Install Sensor ...................................................................................................................... 7

5.0 Sensor Alignment and Calibration ................................................................................................... 8

5.1 Using the Cal. Pushbutton .................................................................................................. 9

5.1.1 Sensor Alignment ................................................................................................... 9

5.1.2 Sensor Calibration ............................................................................................... 11

5.2 Using the Software ............................................................................................................ 14

5.2.1 Connect the Alignment Tool and Encoder ........................................................... 14

5.2.2 Use the FindMII Program to locate the Encoder .................................................. 15

5.2.3 Sensor Alignment and Calibration ....................................................................... 16

6.0 Appendix ........................................................................................................................................ 19

6.1 Specifications .................................................................................................................... 19

6.2 Resolution and Maximum Speed Tables .......................................................................... 20

6.3 Wiring Diagrams ................................................................................................................ 23

6.4 Customer Interface............................................................................................................ 25

6.5 Serial Interface Specifications ........................................................................................... 27

6.6 Index Speed Considerations ............................................................................................. 32

6.7 RS-422 Compliance .......................................................................................................... 33

6.8 Troubleshooting ................................................................................................................ 34

7.0 Order Guide ................................................................................................................................... 35

8.0 Contacting MicroE .......................................................................................................................... 39

IM-Mercury_II_5000_Series Rev. 1 Page 1 ©2014 MicroE Systems

Introduction

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

MII5500

MII5700

MII5800

MII5800Si

MII5800Pa

1.0 Introduction

1.1 Overview

The instructions in this manual apply to the following Mercury II 5000 Series Encoders:

Refer to the Mercury II 5000 Series Encoder data sheet for additional details on ordering parts.

1.2 Precautions

1. Follow standard ESD precautions. Turn power to off before connecting

the sensor.

2. Do not touch electrical pins without static protection such as a

grounded wrist strap.

1.3 Laser Safety Information

This product is sold solely for use as a component (or replacement) in an electronic product;

therefore, it is not required to, and does not comply with U.S. FDA 21 CFR 1040.10 and 1040.11

which pertain to complete laser products. The manufacturer of the complete system-level

electronic product is responsible for complying with 21 CFR.

MicroE Systems encoders contain an infrared laser diode or diodes. Emitted invisible laser

radiation levels have been measured to be within the CDRH Class 1 range, which is not

considered hazardous; however, to minimize exposure to the diverging beam, install the encoder

sensor in its operational configuration in close proximity to the encoder scale before

applying power.

Invisible laser radiation; wavelength: 850 nm.

Maximum power of 4.8 mW CW for Mercury II.

Caution: The use of optical instruments with this product will increase eye hazard. Do

not view directly with optical instruments (microscopes, eye loupes, or magnifiers).

All maintenance procedures such as cleaning must be performed with the MicroE

Do not insert any reflective surface into the beam path when the encoder is powered.

Do not attempt to service the MicroE encoder.

IM-Mercury_II_5000_Series Rev. 1 Page 2 ©2014 MicroE Systems

encoder turned off.

Introduction

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

US 5,991,249

EP 895,239

JP 3,025,237

US 6,897,435

EP 1,451,933

Version

Date

Notes

IM-MII5000 Series Rev. 1

11/21/2014

Initial Release. Combines coverage for entire series of

Mercury II 5000 Series Encoders.

RoHS

1.4 Patents

Mercury II 5000 Encoders design is covered by the following patents:

Additional patents and patents pending may apply.

1.5 Standards Compliance

Mercury II models are CE and RoHS compliant.

1.6 Related Documentation

Mercury II 5000 Series Encoders Data Sheet

Mercury II 5000 Series Encoders Interface Drawings

Mercury II PurePrecision Tape and Glass Scales Installation Manual and Reference

Guide

1.7 Manual Revisions

1.8 Trademarks

Mercury II™, PurePrecision™, and SmartPrecision™ are trademarks of MicroE Systems®.

IM-Mercury_II_5000_Series Rev. 1 Page 3 ©2014 MicroE Systems

Before Installation

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Items Required for Installation

Item

Tape Scale

Glass Scale

Index and Limit Marker sheets

Hex Wrench for Sensor Mounting Screws

Finger Cots or talc-free gloves

Acetone or isopropyl alcohol

Lint-free cotton cloths or wipes

Two-part epoxy (Tra-Bond 2116 or equivalent)

Stick and disposable surface for stirring epoxy

Shears

Tape Applicator Tool*

Silicone adhesive

2.0 Before Installation

Review the items in this section prior to installing the encoder.

2.1 Power Recommendations

Mercury II encoders require a minimum of 4.75VDC continuously.

When designing circuits and extension cables to use Mercury II encoders, be sure to

account for voltage loss over distance and tolerances from the nominal supply voltage so

that at least 4.75VDC is available to the Mercury II encoder under all operating

conditions.

The input voltage should not exceed 5.25VDC.

2.2 Installation Considerations

The Mercury II encoder is a precision electronic instrument. It has been designed to function in a

wide range of applications and environments. To take full advantage of the Mercury II modular

system design, considerations should be made to allow easy access to the sensor (and

interpolator modules where applicable) for service and/or replacement. For optimal performance

and reliability:

DO follow standard ESD precautions while handling the sensor and interpolator.

DO allow proper clearance for sensor head alignment.

DO follow setup and calibration instructions for the encoder system.

DO, where possible, install the scales in an inverted or vertical position to minimize

accumulation of dust.

DO NOT store sensors in an uncontrolled environment.

DO NOT electrically overstress the sensor (power supply ripple/noise).

DO NOT intentionally “hot swap” the sensor if the device is energized.

DO NOT use in high contamination applications (dust, oil, excessive humidity, or other

airborne contaminants).

2.3 Items Required for Installation

In addition to the items identified in the Section 3.0 System Overview, you will need the

following items available for installation:

Note*: Not required for some installations.

IM-Mercury_II_5000_Series Rev. 1 Page 4 ©2014 MicroE Systems

System Overview

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Index Marker

15-Pin Male

D-Sub Connector

Double-Shielded

Cable

Left Limit Marker

Scale Mounting Surface Reference Edge (Benching Surface)

Tape Scale: shown mounted on

a fixed (non-moving) substrate.

Sensor: shown mounted on

a linear bearing using a

mounting bracket.

Sensor Connector

Mounting Screws

Typical User-Supplied

Sensor Mounting Bracket

Sensor Mounting Holes

Sensor Benching Pins

Bracket Mounting Holes

Right Limit Marker

3.0 System Overview

This section identifies parts for the sensor installation.

3.1 System View

3.2 Expanded View

IM-Mercury_II_5000_Series Rev. 1 Page 5 ©2014 MicroE Systems

System Overview

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

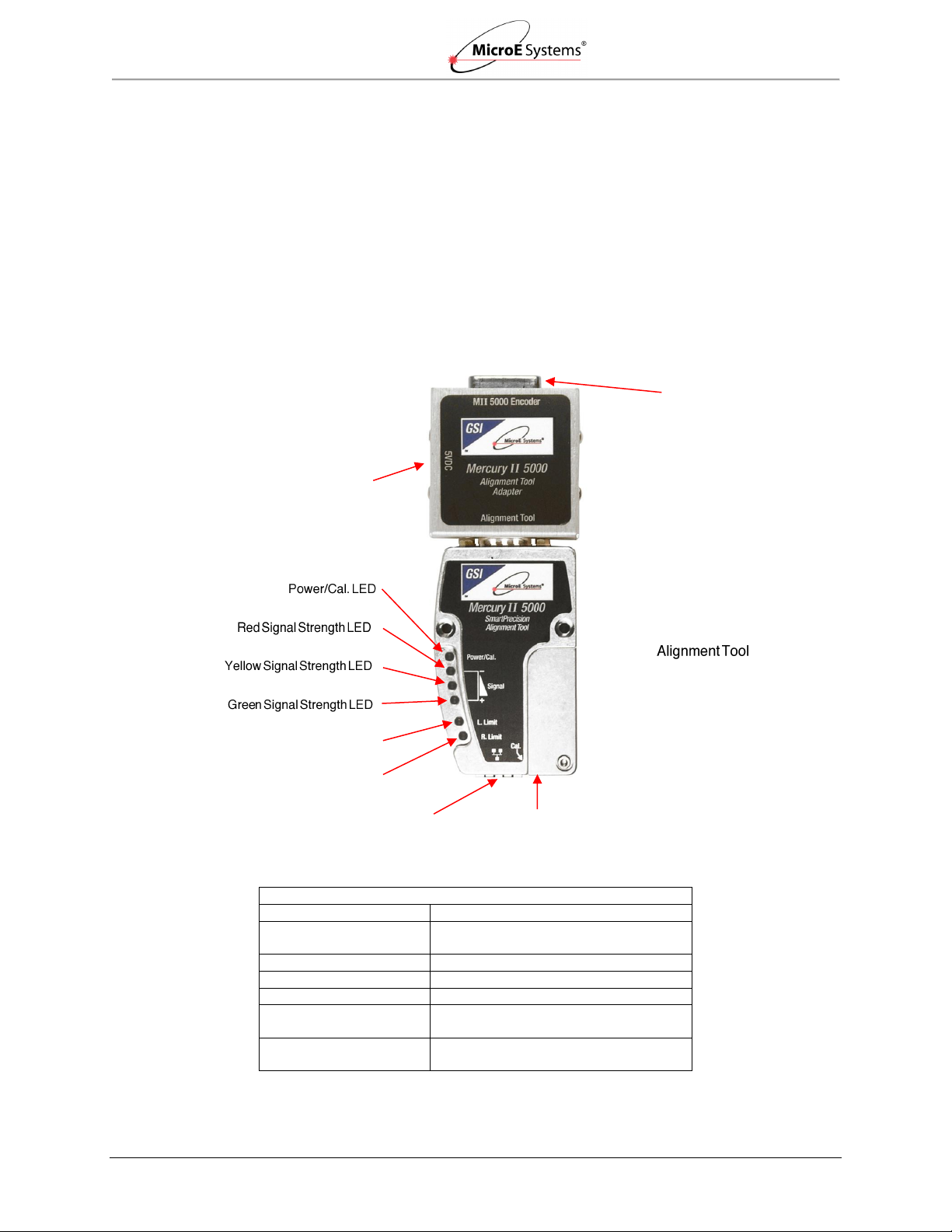

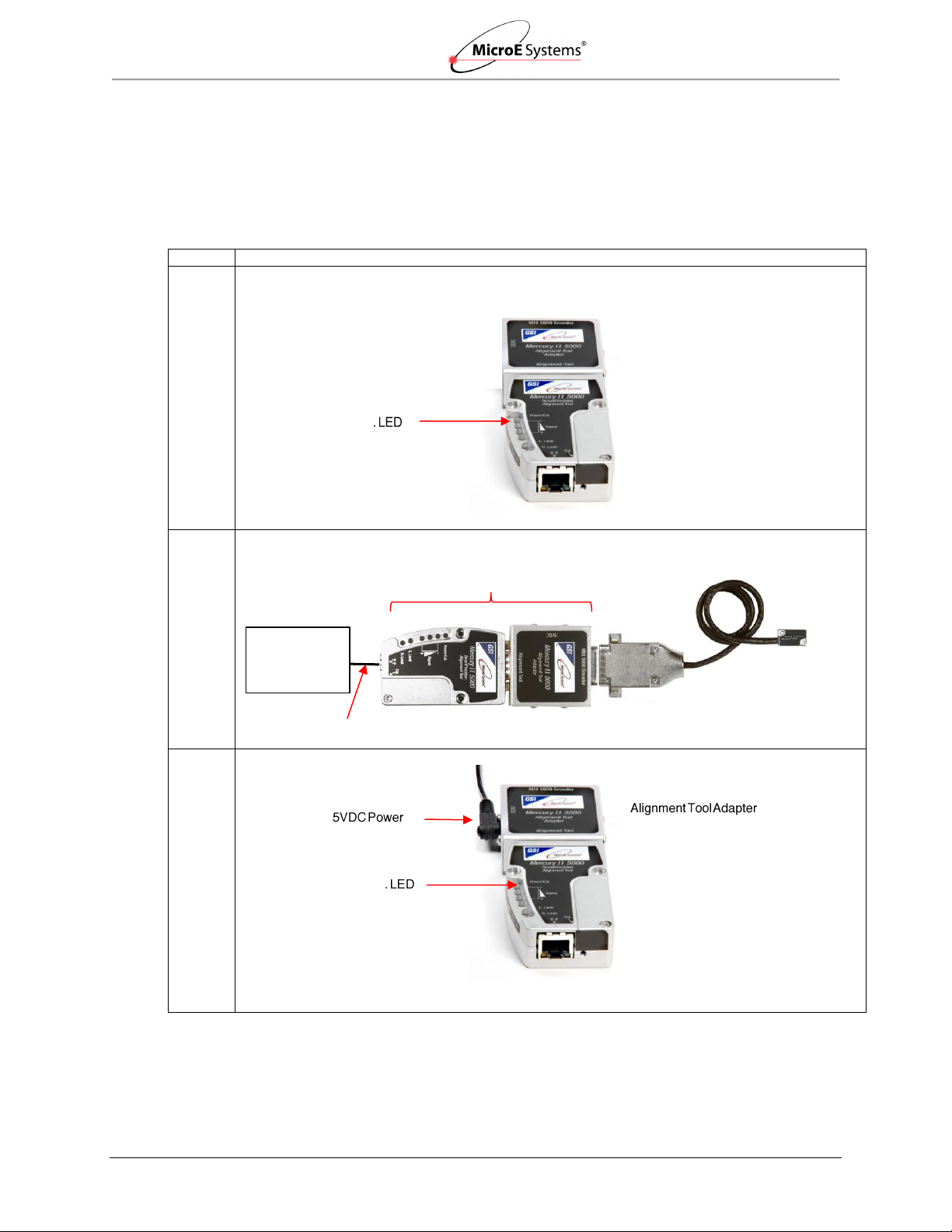

Mercury II 5000 Alignment Tool LEDs

LED

Function

Power/Cal.

Indicates power is on and when

encoder is in Alignment Mode

Red Signal Strength

Indicates improper alignment

Yellow Signal Strength

Indicates improved alignment

Green Signal Strength

Indicates proper alignment

Left Limit

Blinks in Alignment Mode and when

sensor is located over left limit

Right Limit

Blinks in Alignment Mode and when

sensor is located over right limit

15 Pin D-Sub

Sensor Connector

Left Limit LED

Cal. Pushbutton

(Recessed)

Ethernet Connector

Alignment Tool

Adapter

Right Limit LED

Power Supply

Connect

3.3 SmartPrecision Alignment Tool

The Mercury II ATMII5000 SmartPrecision Alignment Tool is required for aligning the Mercury II

5000 Series Encoders. The Alignment Tool includes the following:

Alignment Tool

SmartPrecision II Software

USB Cable

Power Supply

For more details, see Sensor Installation Tools in Appendix 7.0 Order Guide.

IM-Mercury_II_5000_Series Rev. 1 Page 6 ©2014 MicroE Systems

Sensor Installation

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

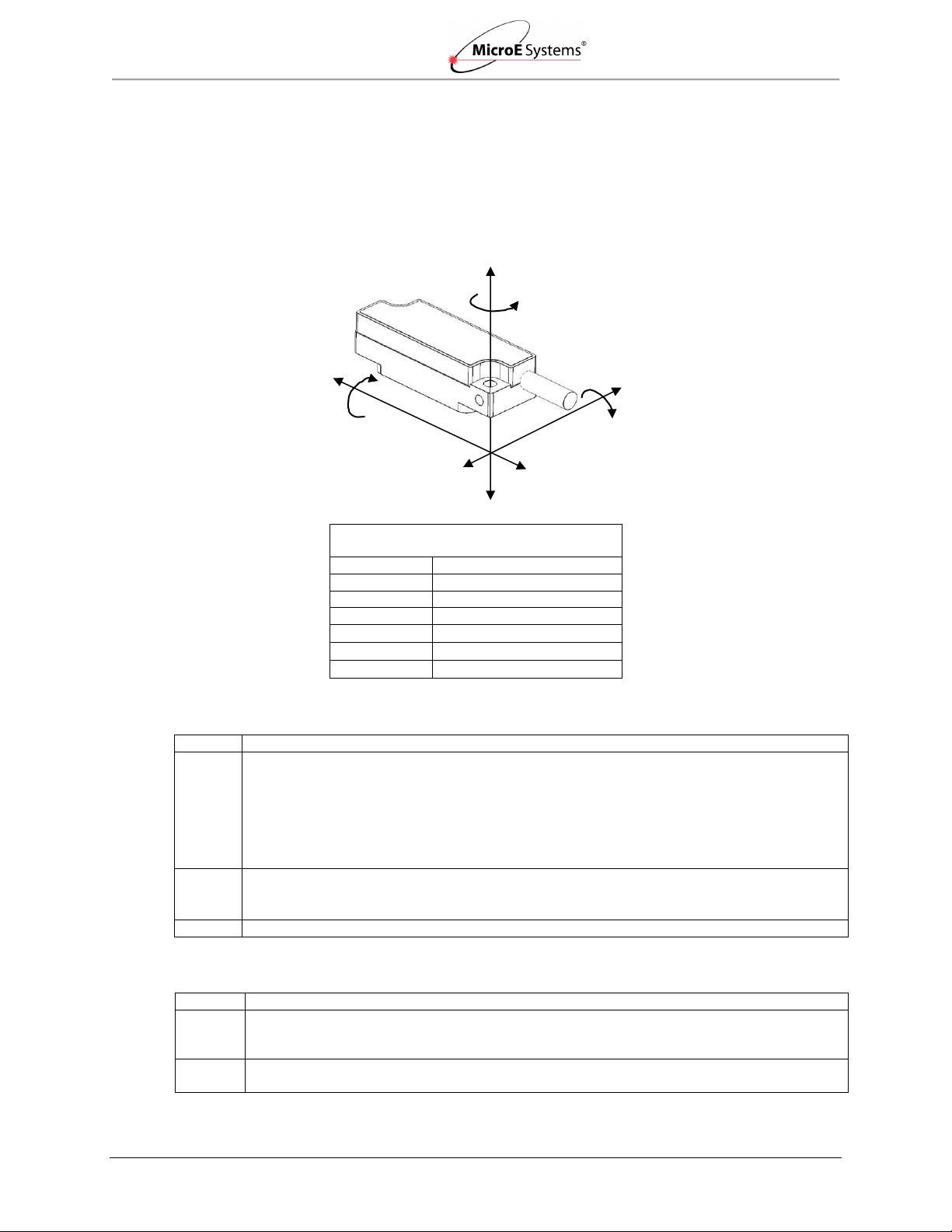

Mercury II

Sensor Alignment Tolerances

Axis

Alignment Tolerance

X

Direction of Motion

Y

± 0.20mm

Z

± 0.15mm

X

± 1.0°

Y

± 1.0°

Z

± 2.0°

Step

Action

1.

Verify that the vertical distance between the reference surface of the sensor and the top of the

scale is as follows:

Tape scale/marker tape after blue protective film is removed: 3.09 mm +/-0.13

Linear or rotary glass scales: 2.93 mm +/-0.13

Note: Use MicroE’s Z-axis Height Gauges to easily verify this distance:

Blue Gauge - for use with tape scales (Part Number 409-00196)

White Gauge - for use with linear and rotary glass scales (Part Number 409-00197)

2.

Use the correct gauge to check that there are no gaps between:

The mounting surface of the gauge and the mounting bracket, or

The bottom surface of the gauge and the scale

3.

Check the height at a location on the scale where there are no index or limit markers.

Step

Action

1.

Install the sensor on the mounting surface referencing the appropriate datum surface as

shown in the MII5000 Interface Drawings. Use two M-2 screws to loosely attach the sensor.

Note: Do not tighten the two M2 screws at this time.

2.

Use benching pins to locate the sensor if the system's mechanical tolerances are adequate.

Refer to MII5000 Interface Drawings for recommended locations and heights of pins.

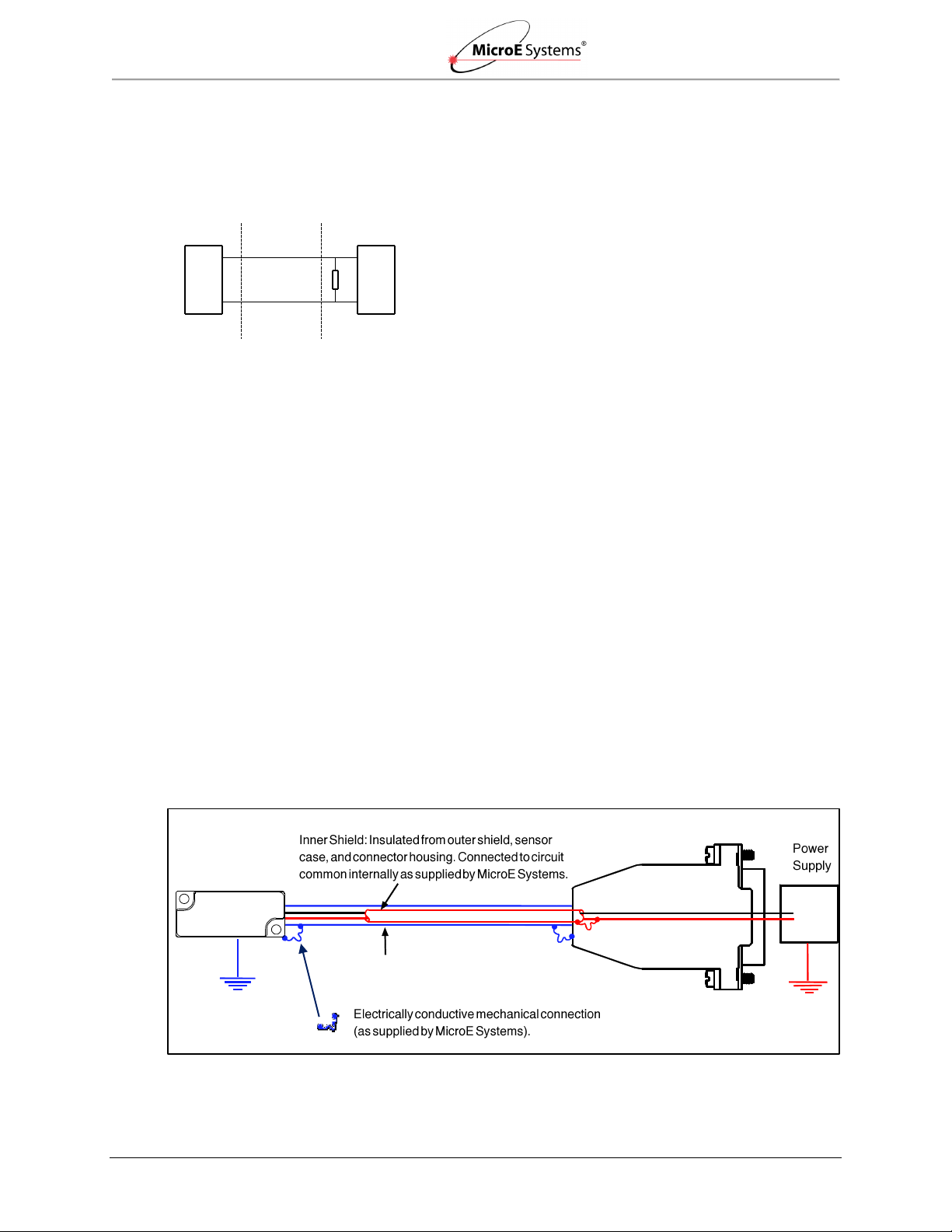

Sensor Axes

Orientation

Tolerances

XY Z

Ө

X

Ө

Ө

To align the sensor,

move it in the Y or ӨZ

directions

4.0 Sensor Installation

This section contains instructions for installing the sensor.

4.1 Sensor Mounting Orientation and Tolerances

Refer to the following specifications when installing and aligning the Mercury II 5000 encoder.

Z

4.2 Verify Sensor Mounting Surface Height

4.3 Install Sensor

IM-Mercury_II_5000_Series Rev. 1 Page 7 ©2014 MicroE Systems

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

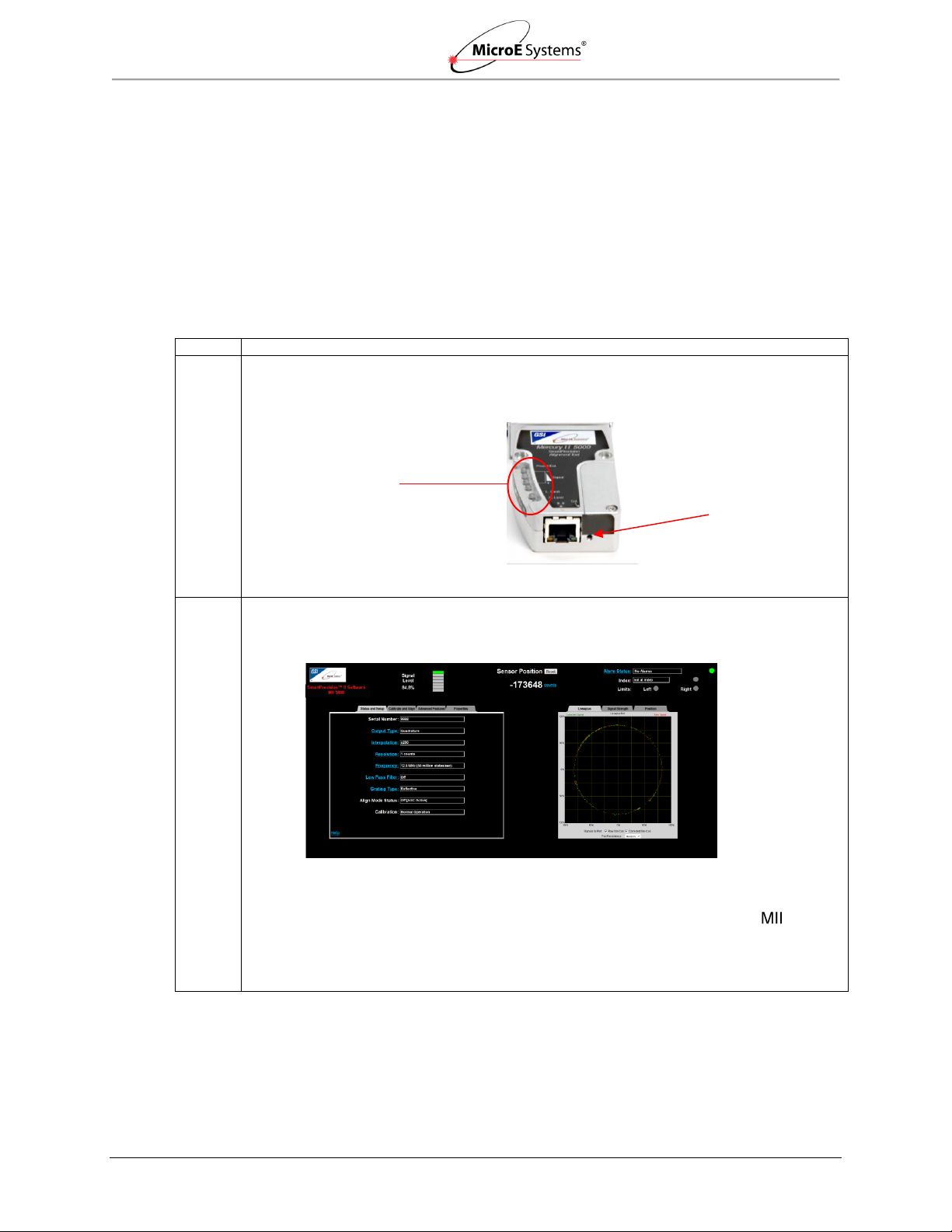

Method

Description

1.

Use the Calibration (Cal) Pushbutton:

Align and calibrate the sensor head using the Calibration (Cal) pushbutton and the LED

indicators on the Alignment Tool.

Continue to Section 5.1 Using the Cal. Pushbutton.

2.

Use the SmartPrecision II Software*:

Align and calibrate the sensor head using the Alignment Tool and the SmartPrecision II

Software.

Continue to Section 5.2 Using the Software.

Note*: The SmartPrecision II Software is built in to the Alignment Tool AT 5000

for setup and diagnostics; only a web browser is needed (use of software is

optional). See the Sensor Installation Tools in Appendix 7.0 Order Guide for

details.

Access to Cal.

Pushbutton

(Recessed)

Alignment Tool

LED Indicators

SmartPrecision II

Main Screen

5.0 Sensor Alignment and Calibration

After installing the MII5000 encoder, use the SmartPrecision Alignment Tool ATMII5000 to align

and calibrate the sensor using one of the following methods:

Calibration (Cal) Pushbutton: if you don’t have access to a computer or are very

experienced at performing encoder alignment and calibration.

SmartPrecision II Software: if you have access to a computer and either are new at

performing encoder alignment and calibration or want to take advantage of the graphic

interface.

Select a method:

IM-Mercury_II_5000_Series Rev. 1 Page 8 ©2014 MicroE Systems

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

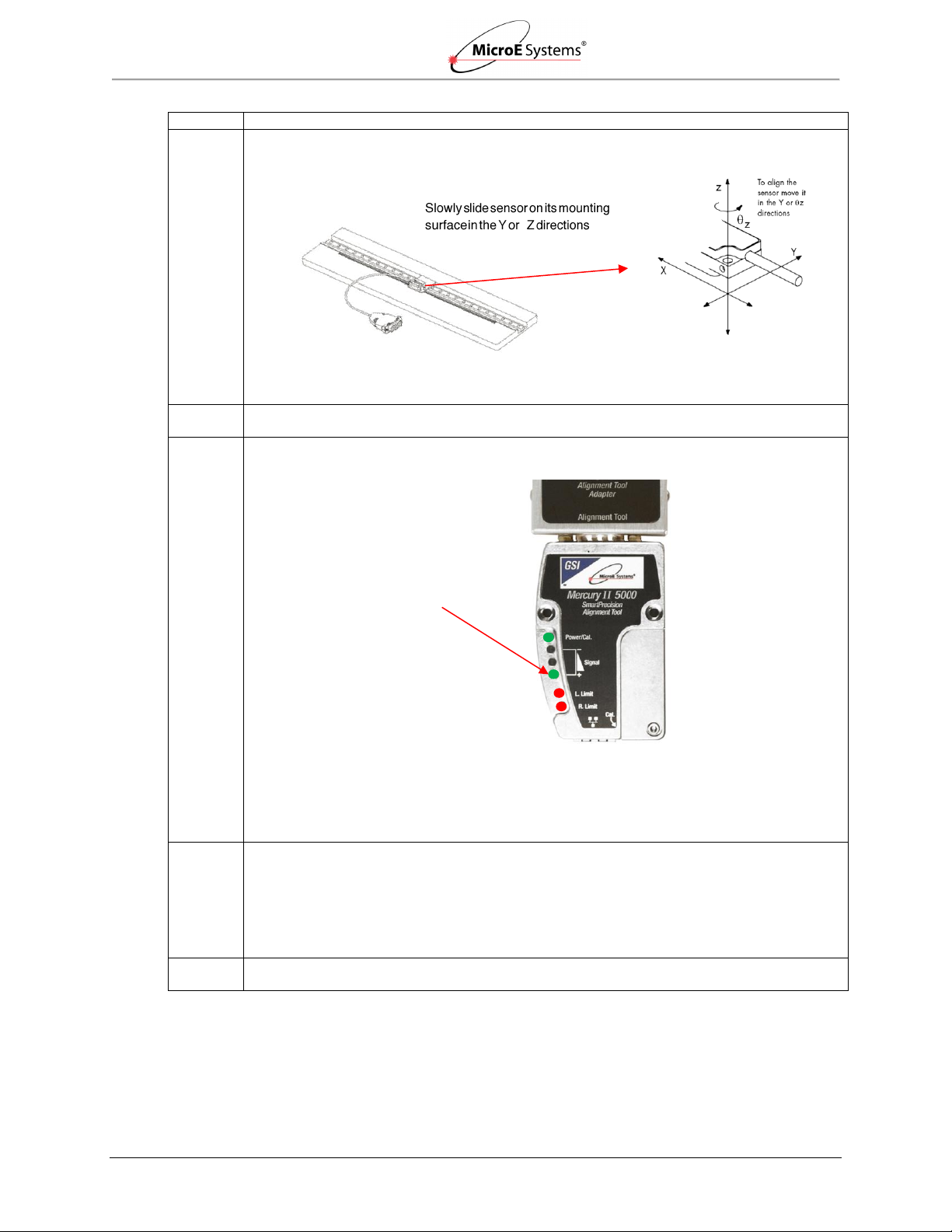

Step

Action

1.

Connect the MII5000 encoder to the SmartPrecision Alignment Tool.

2.

Insert the 5VDC power connector to the Alignment Tool Adapter and apply power.

Result: The Power/Cal. LED illuminates a steady green. The sensor is initialized after an

approximate 10 second delay.

3.

Enter the Alignment Mode by gently pressing and releasing the Cal. pushbutton quickly (within

a second) using a small screwdriver or similar tool.

Result: The two Limit LEDs will begin to blink in unison (slowly). Automatic Gain Control

(AGC) is now inactive. The AGC adjusts gain to maintain a steady signal level.

Alignment Tool

5VDC Power

Alignment Tool Adapter

Encoder

Sensor Connector

Alignment Tool

Power/Cal. LED

Access to Cal. Pushbutton

(Recessed)

Limit LEDs (two)

Screwdriver

5.1 Using the Cal. Pushbutton

Use the following instructions to perform sensor alignment and calibration by using the Cal.

Pushbutton located on the ATMII5000 Alignment Tool.

5.1.1 Sensor Alignment

Note: Make sure that the 5VDC power input is disconnected. Encoder should never be

connected to an already energized alignment tool since equipment can be damaged.

IM-Mercury_II_5000_Series Rev. 1 Page 9 ©2014 MicroE Systems

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

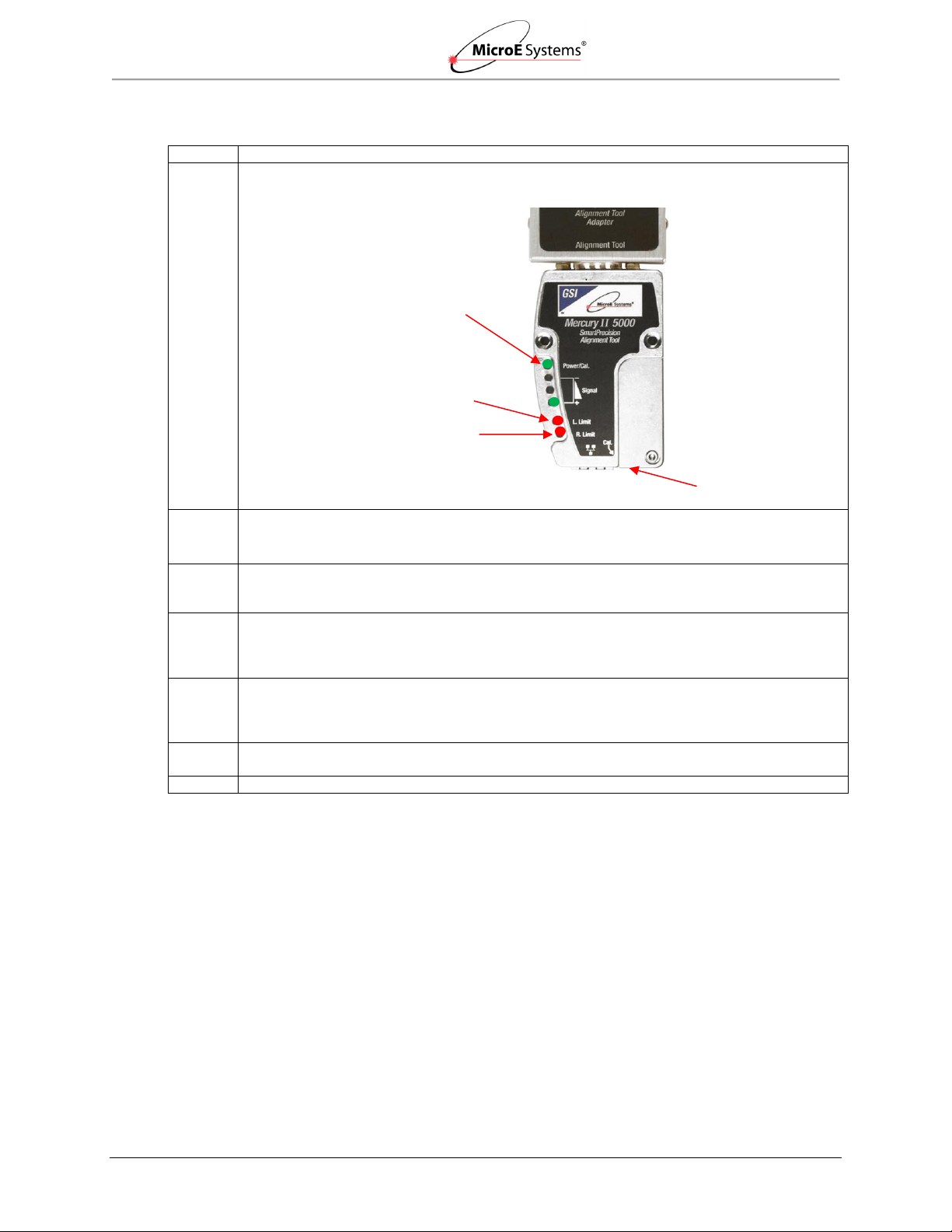

Step

Action

4.

Align the sensor by slowly sliding the sensor on its mounting surface in the Y or Z directions

until the green Signal Strength LED is illuminated*:

Note*: Optimal alignment is indicated by Bright Green.

5.

Once the sensor is aligned, tighten the two sensor mounting screws (0.37Nm [3.3 inch-lbs.]

maximum torque).

6.

Move the sensor over the index mark and confirm that the green Signal Strength LED blinks.

Result:

If the green Signal Strength LED blinks when the sensor passes over the index, then

proceed to the next step.

If the green Signal Strength LED does not blink when the sensor passes over the index,

then loosen the mounting screws and repeat the alignment procedure (go back to Step 3).

Note*: Optimal alignment is indicated by Bright Green and a blink over the index.

7.

Move the sensor over the entire length of the scale.

Result:

If the green Signal Strength LED remains illuminated over the entire length of travel (the

yellow and red LED’s do not illuminate), then proceed to the next step.

Otherwise, clean the scale and try Step 3 again. If cleaning the scale is not successful,

loosen the sensor mounting screws and repeat the alignment procedure (go back to

Step 3).

8.

Press and release the Cal button quickly to exit Alignment Mode.

Result: The limit LED’s will stop blinking and AGC will reactivate.

Green Signal Strength LED

(Proper Alignment)*

IM-Mercury_II_5000_Series Rev. 1 Page 10 ©2014 MicroE Systems

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Grating Type

Limit Polarity

5.1.2 Sensor Calibration

Perform calibration when installing the sensor for first time, or if the sensor is subsequently

remounted, or the scale is replaced. This section contains instructions for calibrating the

following:

Linear Scales or Rotary Scales used in applications less than <360°

Rotary Scales used in applications less than >360° without Limit Markers

Confirm Settings

Confirm the following before calibration:

Always perform calibration of the left and right limits while Limit Polarity is set to Limits

Normal mode. See the Left and Right Limits Settings in the Calibration and Align tab of

the SmartPrecision II Software in Section 5.2.3 Sensor Alignment and Calibration.

Select correct Reflective or Non-Reflective Grating Type on Status and Setup tab.

Note: Perform all procedures below at ≤1 meter/second relative motion between the sensor and

the scale.

IM-Mercury_II_5000_Series Rev. 1 Page 11 ©2014 MicroE Systems

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Step

Action

1.

To start calibration, press and hold the Cal. button for about two seconds until the Power/Cal.

LED starts blinking slowly.

2.

Move the sensor 50mm to perform Gain/Offset/Phase calibration. Move the sensor back and

forth if scale has <50mm of measuring length.

Result: After calibration both limit LEDs come on steady.

3.

Move the sensor to an area of the scale away from the index and limit markers. Press the Cal.

button once quickly.

Result: The Power/Cal LED will start blinking quickly.

4.

Move the sensor over the index up to 20 passes (one pass is a single cycle back and forth).

Result: The Left Limit LED will start blinking quickly.

Note: If the sensor is positioned over the left limit marker, the Left Limit LED will come on

steady.

5.

Move the sensor over the left limit marker and press the Cal. button once quickly.

Result: The Right Limit LED will start blinking.

Note: if the sensor is positioned over the right limit marker, the Right Limit LED will come on

steady.

6.

Move the sensor over the right limit marker and press the Cal. button once quickly.

Result: All LEDs will flash together twice to indicate that setup is completed.

7.

The encoder is now ready for connection to the controller for use in servo control.

Power/Cal LED

Cal. Pushbutton

(Recessed)

Right Limit LED

Left Limit LED

Linear Scales or Rotary Scales used in applications less than <360°

Note: To skip any portion of this calibration and move to the next procedure, press and hold the

Cal. button for two seconds.

IM-Mercury_II_5000_Series Rev. 1 Page 12 ©2014 MicroE Systems

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Step

Action

1.

To start calibration, press and hold the Cal. button for about 10 seconds: until the three Signal

LEDs blink twice to indicate that rotary calibration has been activated.

2.

Move the sensor 50mm to perform Gain/Offset /Phase calibration. After calibration both limit

LED’s come on steady. Move the sensor back and forth if your scale has a circumference of

<50mm.

Result: After calibration both limit LEDs come on steady.

3.

Move the sensor to an area of the scale away from the index marker. Press the Cal. button

once quickly.

Result: The Power/Cal. LED will start blinking quickly.

4.

Move the sensor over the index up to 20 passes (one pass is a single cycle back and forth).

Result: The Power/Cal. LED and both limit LEDs will start to blink in sets of three.

5.

Move the sensor away from the index and press the Cal. button once quickly.

Result: The Power/Cal. LED and both limit LED’s will start to blink in sets of two.

6.

Move the sensor over the index once.

Result: The LEDs will change to Power/Cal. LED and both limit LEDs blinking just once.

7.

Make a full revolution of the rotary scale in order to go over the index again in the same

direction. The two passes over the index must be at least 1000 20µm fringes apart (equivalent

of 20mm linear travel), if they are not, the Alignment Tool will wait for another pass that is 1000

fringes from the first.

8.

The encoder is now ready for connection to the controller for use in servo control.

Signal LEDs (3)

Cal. Pushbutton

(Recessed)

Rotary Scales used in applications less than >360° without Limit Markers

Note: To skip any portion of` this calibration and move on to the next procedure, press and hold

IM-Mercury_II_5000_Series Rev. 1 Page 13 ©2014 MicroE Systems

the Cal. button for two seconds.

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

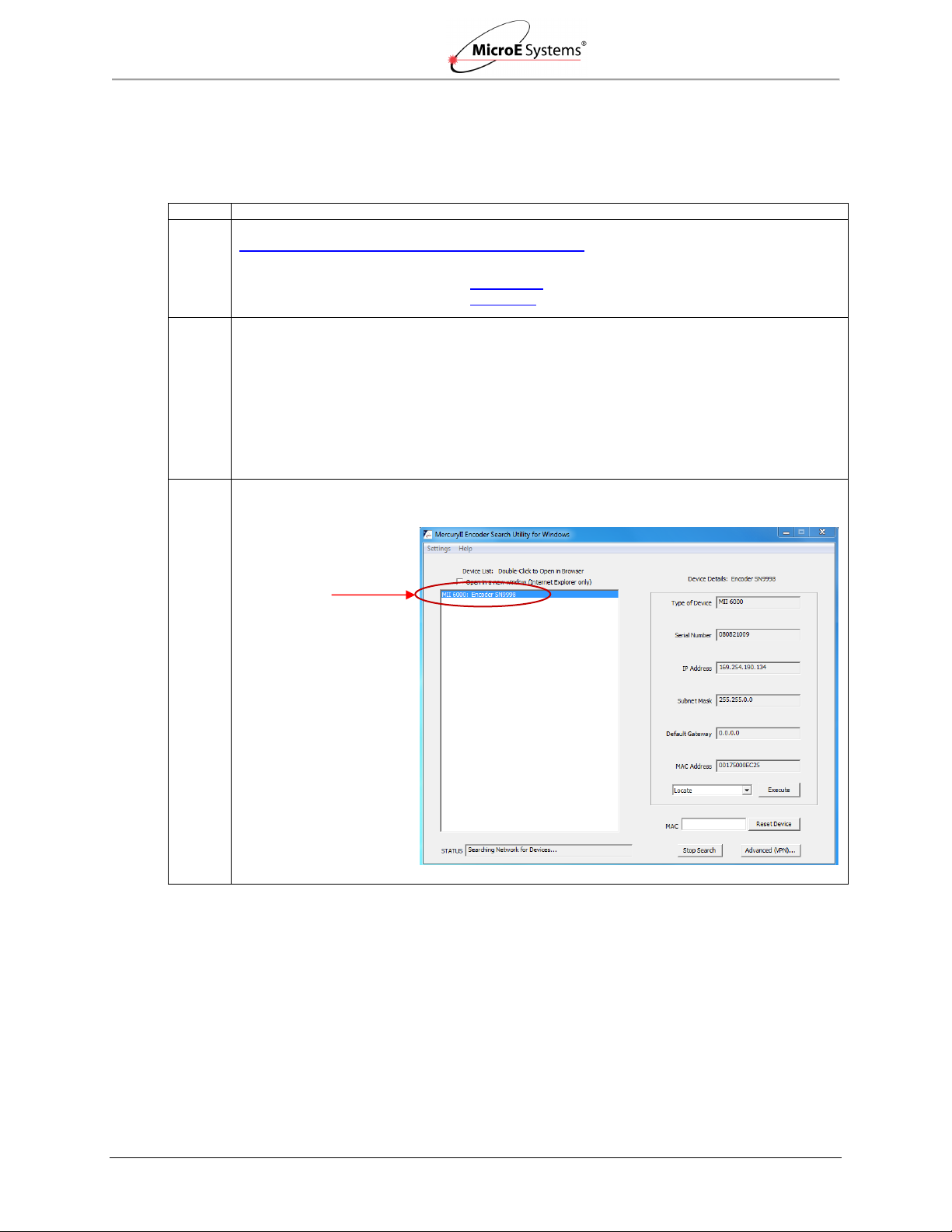

Step

Action

1.

Verify that the Alignment Tool Adapter/SmartPrecision II Alignment Tool is not powered on. The

Power/Cal. LED should be off.

2.

Connect the MII5000 encoder, Ethernet cable, and computer as shown below.

3.

Power up the Alignment Tool by plugging in 5VDC to the Alignment Tool Adapter.

Result: The Power/Cal. LED illuminates a steady green. The sensor is initialized after an

approximate 10 second delay.

Power/Cal

Power/Cal

Alignment Tool

Encoder

Ethernet Cable

Sensor Connector

Computer

(Windows or

other OS)

5.2 Using the Software

Use the following instructions to perform sensor alignment and calibration using the Alignment

Tool and the SmartPrecision II Software.

5.2.1 Connect the Alignment Tool and Encoder

IM-Mercury_II_5000_Series Rev. 1 Page 14 ©2014 MicroE Systems

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Step

Action

1.

To locate the correct version for your operating system, go to Software Downloads at

http://www.microesys.com/products/documentation or click on one of the following links:

For Windows operating systems:

FindMII.exe

For all other operating systems:

FindMII.jar

2.

Double-click on the appropriate link to launch the FindMII program.

Result: The FindMII program locates the encoder and allows you to use the embedded

SmartPrecision II Software on your web browser.

Note: You may receive an Application Blocked by Security Settings message when

attempting to load the plotApplet. Go to the Java applet in your Control Panel and try reducing

the Security Level in the Security Tab (covers up to Java 7, versions beyond 7 may require

additional steps).

Warning: Reducing the Security Level in the Security Tab may decrease protection of your

computer against malicious software.

3.

Once located, the FindMII program displays the MercuryII Encoder Search Utility screen. The

screen will list all the encoders connected to the network as seen in the following example.

Encoder

found by the

program

5.2.2 Use the FindMII Program to locate the Encoder

Once the encoder is connected to the computer using an ethernet cable, run the software

program FindMII (Mercury II Encoder Search Utility) version 1.2.2.1 or higher.

IM-Mercury_II_5000_Series Rev. 1 Page 15 ©2014 MicroE Systems

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

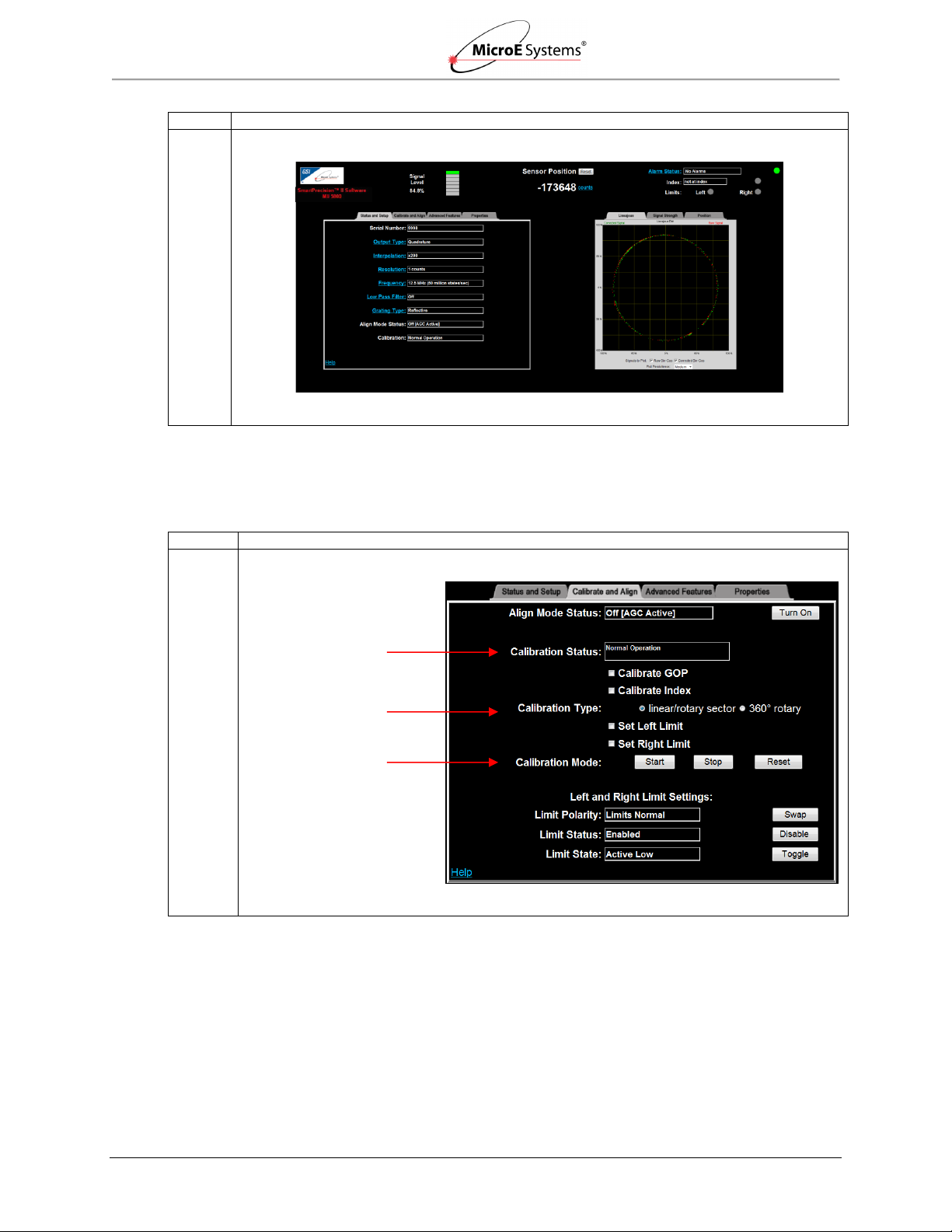

Step

Action

4.

Double-click the name of the encoder to open the SmartPrecision II Software.

Results: The SmartPrecision II Software Screen displays.

Step

Action

1.

Click on the Calibrate and Align tab.

Results: The Calibrate and Align screen opens.

Calibrate and Align Tab

Calibration Status

Calibration Type

Calibration Mode

5.2.3 Sensor Alignment and Calibration

Once the SmartPrecision II Software is open, perform sensor alignment and calibration by using

the Calibrate and Align tab.

IM-Mercury_II_5000_Series Rev. 1 Page 16 ©2014 MicroE Systems

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Step

Action

2.

Turn on Align Mode by clicking on the Align Mode Turn On button.

Results: The Turn On button will change to Turn Off. Align Mode Status will change to On

(AGC Inactive). On the Alignment Tool, both Left and Right Limit LEDS will begin blinking.

3.

Adjust the sensor position until the maximum signal strength is achieved. See the Signal Level

Indicator at the top of the SmartPrecision screen.

4.

Tighten the sensor mounting screws. Check for index indication (using the status display at the

top right of the screen).

Results: The Index indication is “not at index” when the sensor is not located at the Index

marker, and “index crossed” when the sensor has passed over the Index marker.

5.

Turn off Align Mode by clicking on the Align Mode Turn Off button.

Result: The Turn Off button will change to Turn On. Align Mode Status will change to Off

(AGC Active). On the Alignment Tool, both Left and Right Limit LEDS will stop blinking.

Signal Level Indicator

Align Mode Turn On/Off Button

Index Indication

Align Mode Turn On/Off Button

Limits Indication

IM-Mercury_II_5000_Series Rev. 1 Page 17 ©2014 MicroE Systems

Sensor Alignment and Calibration

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

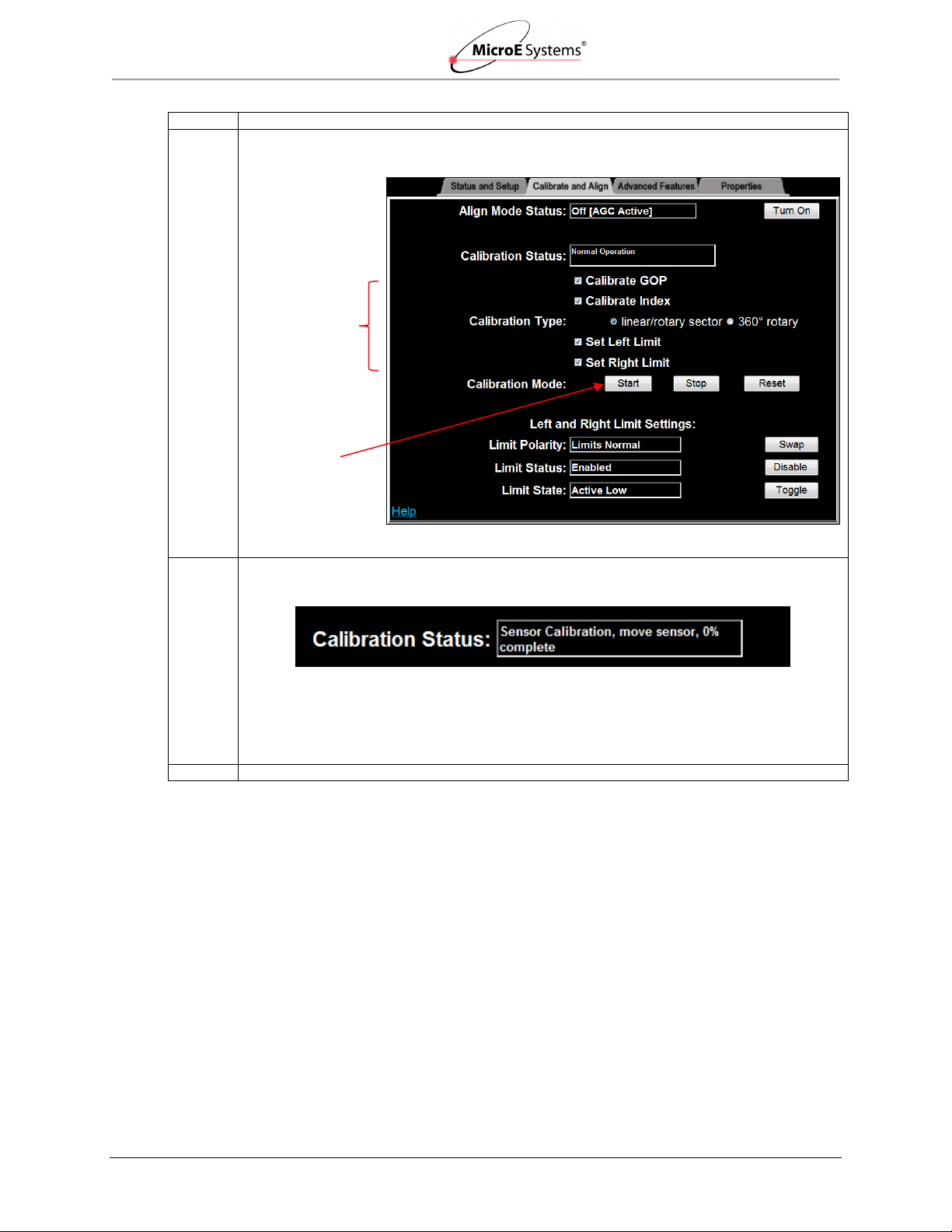

Step

Action

6.

Perform setup by checking the Calibrate GOP, Calibrate Index, Set Left Limit, and Set Right

Limit boxes.

Note: Not all applications require all steps.

7.

Ensure that the Calibration Type is correctly selected for your encoder (linear/rotary sector is

selected above). Press the Start button in Calibration Mode to begin calibration/setup.

Results: Sensor Calibration will begin. Follow the steps in the Calibration Status box to

complete setup of the MII5000 encoder. For example, in the status box above, the instructions

are to move the sensor until reaching 100% complete and then the next calibration step will

start.

8.

If there is a failure, turn off the sensor and clean the scale. After cleaning, return to this section.

Start Button

Check Boxes

IM-Mercury_II_5000_Series Rev. 1 Page 18 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

System

Sensor Size

Scales:

PurePrecision Laser Tape scale - available in

continuous lengths up to 30m.

Linear glass scales for high accuracy.

Rotary glass scales for rotary applications.

H: 11.03mm

W: 13.50mm

L: 38.50mm

Operating and Electrical Specifications

Grating Period

20µm

Agency Standards Conformance: In accordance with

Electromagnetic Compatibility Directive 2004/108/EC:

EN 55011:2007, EN 61000-4-2, -3, -6

Signal Period

20µm

SPI Interface Clock Speed: 25MHz - 50MHz

Max Sample Rate: 227,272 position reads/s - 50MHz clock

System

Resolution

5µm - 0.00122µm* in integer

interpolation steps (factory set or

user programmed using included

SmartPrecision II Software.

Power Supply: 5VDC ±5%

*Value rounded for readability. Use the formula

20µm/interpolation multiplier to calculate the

exact resolution in units of µm/count.

Note: MII5800Pa resolution is fixed at 1.2nm.

@

@

@

140mA (no outputs terminated)

180mA (A, B, I, and both limits

terminated)

172mA (all serial I/O connections

terminated)

Accuracy/Linearity

Cyclical Error

Tape

Scales:

Glass

Scales:

± 30nm typical over any 20µm

movement

± 20nm typical over any 20µm

movement

Temperature

Operating:

Storage:

0°C to 70°C

-20°C to 85°C

Tape Scale

Linearity:

± 5µm/m

Humidity:

10 - 90% RH non-condensing

Glass Scale Accuracy

EMI

CE Compliant

High Accuracy

Grade:

±1µm for scales up to 130mm

±2µm for scales from130mm to 1m

Shock:

300G 0.5 ms half sine (Sensor)

Vibration:

30G @ 17Hz

Sensor

Weight:

3g (Sensor without cable)

Standard

Accuracy

Grade:

±1.5µm for scales up to 130mm

±5µm for scales from 130mm to

1m

Cable:

Double Shield

Maximum length: 10m (contact MicroE

Systems for applications >5m)

Diameter: 4.2mm

Flex Life: 20 x 106 cycles @ 20mm

bending radius

Note: Accuracy is the maximum error over the

specified movement when compared to a

NIST-traceable laser interferometer standard

used at room temperature.

Rotary

Accuracy*

Scale O.D.

Micro

radians

Arc-

Seconds

Reliability Information

5 Year Expected Reliability: >99.8% under normal

operating conditions.

44.45mm

± 38

± 7.8

63.50mm

± 19

± 3.9

120.65mm

± 10

± 2.1

Note: *Based on ideal scale mounting concentricity.

Index: Built-in or stick-on; bi-directional, full speed.

Note: After power up, the index mark must be passed once at 1 m/s for proper operation.

Limits: Separate built-in or stick-on left and right limits.

Laser-written embedded index and limits available. Contact MicroE.

6.0 Appendix

6.1 Specifications

Note: Refer to the MII5000 Interface Drawings for additional dimensional details and important notes.

IM-Mercury_II_5000_Series Rev. 1 Page 19 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Maximum

Interpolation

Resolution

Maximum

Speed*

Applicable

Mercury II 5000 Models

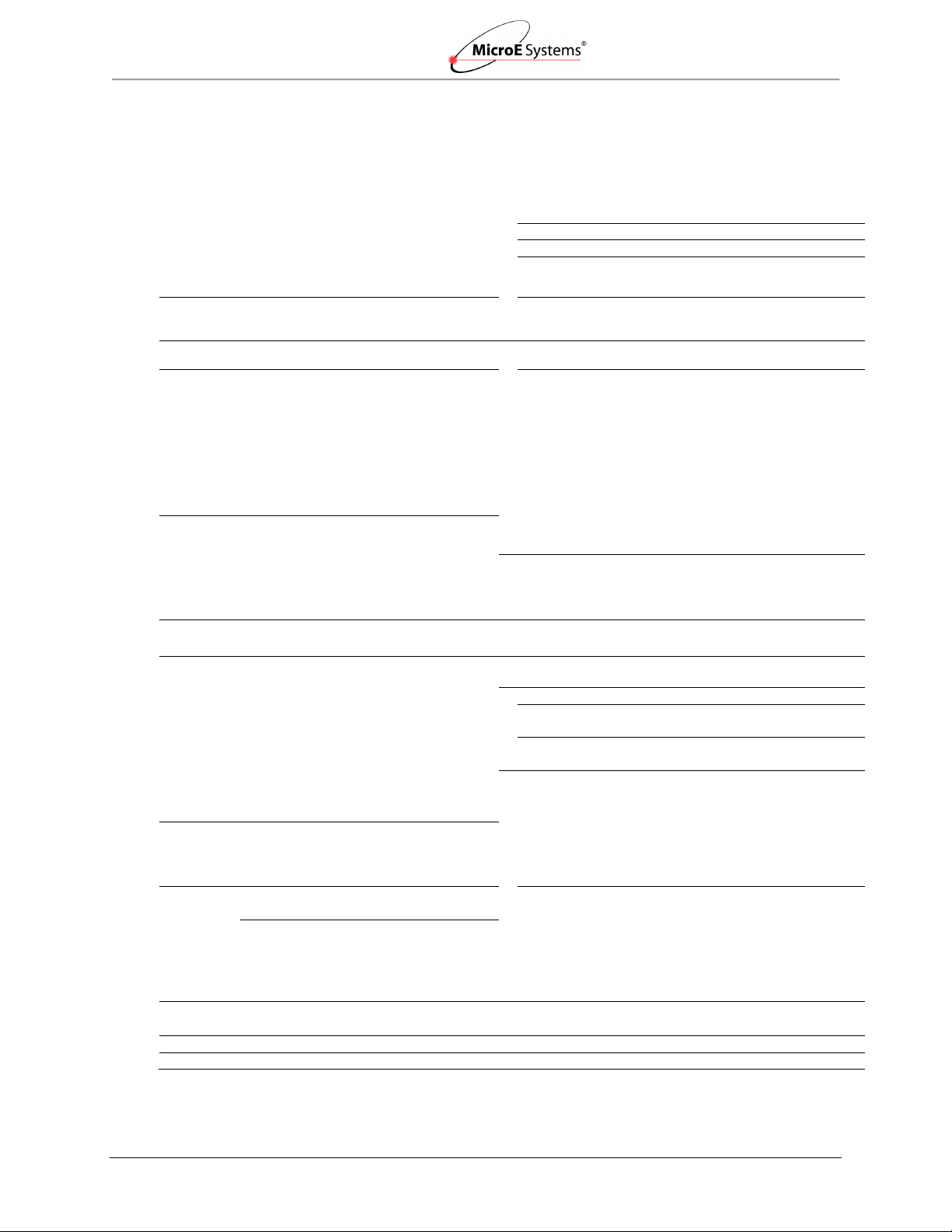

MII5000 Output Signals

6.2 Resolution and Maximum Speed Tables

Resolution and Maximum Speed Tables - Quadrature Output

Mercury II 5000 systems (MII5500/MII5700/MII5800) have programmable interpolation from x4 to

x16384 in integer steps. Below are tables of sample values. For applications requiring up to

10m/s at full resolution, use the MII5800Si/Pa with high speed serial interface.

Linear – 20µ Grating Pitch

Note: †Value rounded for readability; use the following formula to calculate the exact resolution

in units of µm/count:

𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 =

IM-Mercury_II_5000_Series Rev. 1 Page 20 ©2014 MicroE Systems

20µ

𝐼𝑛𝑡𝑒𝑟𝑝𝑜𝑙𝑎𝑡𝑖𝑜𝑛 𝑀𝑢𝑙𝑡𝑖𝑝𝑙𝑖𝑒𝑟

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Rotary

Glass

Scale

Diameter

Fundamental

Resolution

Interpolation

44.45mm

5000 Lines

x4

x20

x40

x400

x1000

x4000

x16384

interpolated resolution (CPR)

20000

100000

200000

2000000

5000000

20000000

81920000

interpolated resolution (arcsec/count)**

64.8

12.96

6.48

0.648

0.259

0.0648

0.01582

interpolated resolution

(µrad/count)**

314

62.8

31.4

3.14

1.257

0.314

0.0767

maximum speed* (RPM)

6000

6000

6000

1500

600

150

36.6

63.50mm

8192 Lines

interpolated resolution (CPR)

32768

163840

327680

3276800

8192000

32768000

134217728

interpolated resolution (arcsec/count)**

39.6

7.91

3.96

0.396

0.1582

0.0396

0.00966

interpolated resolution

(µrad/count)**

191.7

38.3

19.17

1.917

0.767

0.1917

0.0468

maximum speed* (RPM)

3660

3660

3660

915

366

91.5

22.3

120.65mm

16384 Lines

interpolated resolution (CPR)

65536

327680

655360

6553600

16384000

65536000

268435456

interpolated resolution (arcsec/count)**

19.78

3.96

1.978

0.1978

0.0791

0.01978

0.00483

interpolated resolution

(µrad/count)**

95.9

19.17

9.59

0.959

0.383

0.0959

0.0234

maximum speed* (RPM)

1830

1830

1830

457

183.1

45.7

11.17

Applicable Mercury II 5000 Models

5500,

5700,

5800

5500,

5700,

5800

5500,

5700,

5800

5700,

5800

5700,

5800

5800

5800

Rotary – 20µ Grating Pitch

Note: Interpolation - the range of available values is x4 to x16384 in integer steps; sample values

below.

Note: *Maximum speed produces an encoder quadrature output of 50 million states per second

(12.5MHz). See Page 24 for additional output frequencies. Maximum speeds shown above will be

reduced if a lower quadrature output frequency is selected.

Note: **Resolution values shown are approximate. To calculate exact resolution values, convert from

CPR (Counts per Revolution) to the desired units.

Note: To calculate desired rotary interpolation multiplier, use the following equation:

𝐼𝑛𝑡𝑒𝑟𝑝𝑜𝑙𝑎𝑡𝑖𝑜𝑛 𝑀𝑢𝑙𝑡𝑖𝑝𝑙𝑖𝑒𝑟 =

𝐷𝑒𝑠𝑖𝑟𝑒𝑑 𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 (𝐶𝑃𝑅)

𝐹𝑢𝑛𝑑𝑎𝑚𝑒𝑛𝑡𝑎𝑙 𝑆𝑐𝑎𝑙𝑒 𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 (𝐿𝑖𝑛𝑒𝑠)

Note: Specifications assume XOR function which is available in all standard controllers.

IM-Mercury_II_5000_Series Rev. 1 Page 21 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Interpolation

Multiplier

Interpolation

Bits

Resolution

Maximum Speed

x 4

2

5.000µm/count

10000mm/sec

x 8

3

2.500µm/count

10000mm/sec

x 16

4

1.250µm/count

10000mm/sec

x 32

5

0.6250µm/count

10000mm/sec

x 64

6

0.3125µm/count

10000mm/sec

x 128

7

0.15625µm/count

10000mm/sec

x 256

8

0.078125µm/count

10000mm/sec

x 512

9

0.0390625µm/count

10000mm/sec

x 1024

10

19.53125nm/count

10000mm/sec

x 2048

11

9.765625nm/count

10000mm/sec

x 4096

12

4.8828125nm/count

10000mm/sec

x 8192

13

2.44140625nm/count

10000mm/sec

x 16384

14

1.220703125nm/count

10000mm/sec

Rotary Glass

Scale Diameter

Fundamental Resolution

Interpolation

44.45mm

5000 Lines

x4

x1024

x4096

x16384

interpolated resolution (CPR)

20000

5120000

20480000

81920000

interpolated resolution (arcsec/count)*

64.8

0.253

0.0630

0.01582

interpolated resolution (µrad/count)*

314

1.23

0.306

0.0767

maximum speed (RPM)

6000

6000

6000

6000

63.50mm

8192 Lines

x4

x1024

x4096

x16384

interpolated resolution (CPR)

32768

8388608

33554432

134217728

interpolated resolution (arcsec/count)*

39.6

0.154

0.038

0.00966

interpolated resolution (µrad/count)*

191.7

0.749

0.187

0.0468

maximum speed (RPM)

3660

3660

3660

3660

120.65mm

16384 Lines

x4

x1024

x4096

x16384

interpolated resolution (CPR)

65536

16777216

67108864

268435456

interpolated resolution (arcsec/count)*

19.78

0.0772

0.01978

0.00481

interpolated resolution (µrad/count)*

95.9

0.375

0.0937

0.0234

maximum speed (RPM)

1830

1830

1830

1830

Resolution and Maximum Speed Tables - Serial Output

Mercury II 5800Si/Pa systems have programmable interpolation from x4 to x16384 in binary

steps. Below is a table of examples. Unlike A-quad-B encoders, the MII5800Si/Pa resolution does

not drop off with speed.

Linear – 20µ Grating Pitch

Rotary – 20µ Grating Pitch

Note: The range of available values is x4 to x16384 in binary steps; sample values below.

Note*: Resolution values shown are approximate. To calculate exact resolution values, convert from

CPR (Counts per Revolution) to the desired units.

Note: To calculate desired rotary interpolation multiplier, use the following equation:

𝐼𝑛𝑡𝑒𝑟𝑝𝑜𝑙𝑎𝑡𝑖𝑜𝑛 𝑀𝑢𝑙𝑡𝑖𝑝𝑙𝑖𝑒𝑟 =

𝐷𝑒𝑠𝑖𝑟𝑒𝑑 𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 (𝐶𝑃𝑅)

𝐹𝑢𝑛𝑑𝑎𝑚𝑒𝑛𝑡𝑎𝑙 𝑆𝑐𝑎𝑙𝑒 𝑅𝑒𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 (𝐿𝑖𝑛𝑒𝑠)

IM-Mercury_II_5000_Series Rev. 1 Page 22 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Output Frequency (MHz)

A-Quad-B Output Rate

(millions of states/sec)

Dwell Time

(or edge separation) (µsec)

12.50

50.00

0.02

6.25

25.00

0.04

3.125

12.50

0.08

1.563

6.25

0.16

0.781

3.125

0.32

0.391

1.5625

0.64

0.195

0.78125

1.28

0.098

0.390625

2.56

0.049

0.1953125

5.12

0.024

0.09765625

10.24

𝑂𝑢𝑡𝑝𝑢𝑡 𝐹𝑟𝑒𝑞𝑢𝑒𝑛𝑐𝑦 = 12.5𝑀𝐻𝑧/2^𝑛

where n = number of steps below 12.5MHz

𝑂𝑢𝑡𝑝𝑢𝑡 𝑅𝑎𝑡𝑒 = 50/2^𝑛

where n = number of steps below 50 million states per second

Mercury II 15P D-Sub Pin Outs

Quad Output

Pin

Function

1

Right Limit+

2

GND

3

Right Limit-

4

Index-

5

B- 6 A- 7 +5V

8

+5V

9

GND

10

Left Limit+

11

Left Limit-

12

Index+

13

B+

14

A+

15

No Connect

Maximum Quadrature Output Frequency

Note: Values shown are approximate. Exact values may be calculated using either of the

following equations:

6.3 Wiring Diagrams

15-Pin Standard Male D-sub Connector Configuration

Note: Alarm: A and B are tri-stated if the encoder signal becomes too low for reliable operation.

Note: GND and Inner Shield are internally connected.

IM-Mercury_II_5000_Series Rev. 1 Page 23 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

5 Volts

O Volts

Outer Shield: Connector to sensor and

connector housing.

Mercury II

Cable Z0 = 120Ω

120Ω

Consumer

Electronics

Recommended Interface Termination

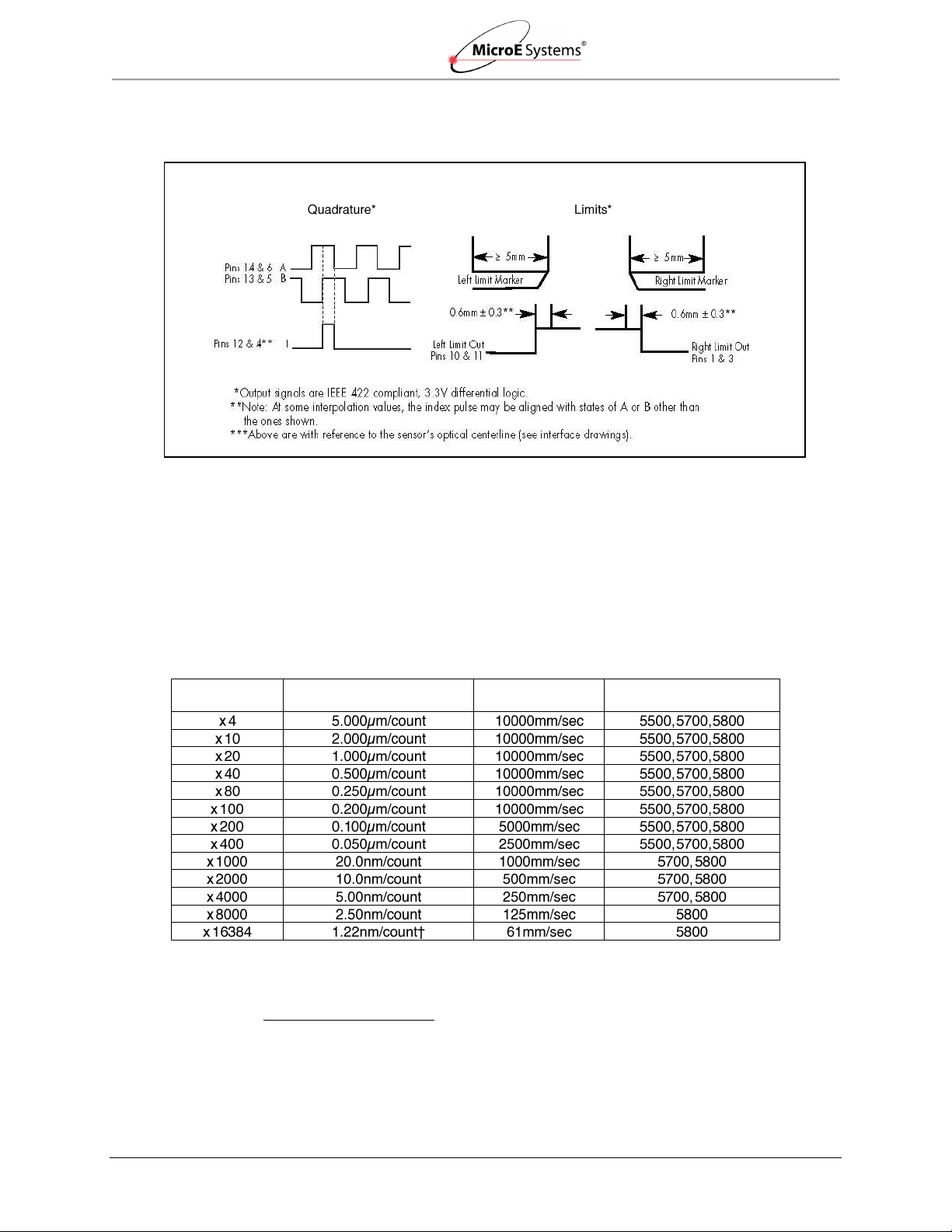

Customer Differential Line Receiver – RS 422: The following diagram shows the recommended

signal termination for a-quad-b, serial, index, and limits signals for the Mercury II 5000 Series

Encoders. Standard RS-422 Line Receiver Circuitry:

5800Si/Pa

Grounding Considerations

The diagrams below show how to make the connections when the encoder's connector is

plugged into the customer's controller chassis. If a customer-supplied extension cable is used, it

should be a double-shielded cable with conductive connector shells and must provide complete

shielding over the conductors contained within it over its entire length. Furthermore, the shields

should be grounded at the connection to the controller chassis the same way as the encoder

connectors in the diagrams below.

Note: For best performance, isolate the encoder outer shield from motor cable shields and

separate the encoder cable as far possible from motor cables.

Sensor mounted with good electrical contact to a well-grounded surface (preferred)

The encoder's connector shell must be in close, electrically-conductive contact with the customersupplied mating connector, which must be isolated from the controller's ground. If a customersupplied shielded cable connects the encoder to the controller, then the outer shield on the

customer-supplied cable must be isolated from the controller's ground.

The sensor mounting surface must have a low-impedance (DC/AC) connection to ground. The

encoder sensor mounting surface may have to be masked during painting or anodizing to ensure

good electrical contact with the sensor.

IM-Mercury_II_5000_Series Rev. 1 Page 24 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Mercury II 5000

Signal

Twisted Pair

Pin

A+

Pair 1

14

A-

6

B+

Pair 2

13

B-

5

Index+

Pair 3

12

Index-

4

Left Limit+

Pair 4

10

Left Limit-

11

Right Limit+

Pair 5

1

Right Limit-

3

+5V

Pair 6

7, 8

GND

2, 9

5 Volts

O Volts

Sensor mounted to poorly-grounded or non-conducting surface

6.4 Customer Interface

Cable Requirements

Customer cables that interface to Mercury II series encoders must have the following

characteristics:

Twisted pair signals wiring.

Characteristic impedance of 100-120 ohms.

Sufficient wire gauge to meet the minimum voltage requirement at the encoder. For

example: 24AWG gauge wire for a 2m length cable. Recommended cables are 24AWG

gauge wire with 6 twisted pairs.

Single shield cable with a minimum of 90% coverage. Note that a double shielded cable

may be required in high-noise applications.

Signal Wiring for A-quad-B

Each differential signal should be connected to a corresponding twisted pair as follows for the 15pin standard male D-sub connector:

Note: The Alarm signal on pin 15 is not differential and is not part of a pair.

IM-Mercury_II_5000_Series Rev. 1 Page 25 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Mercury II 5800Si/Pa Signals

Twisted Pair

DB15 Pins

5800Si Signals

5800Pa Signals

Pair 1

14

SDATA_OUT+

NC*

6

SDATA_OUT-

NC

Pair 2

13

SCLOCK_OUT+

NC

5

SCLOCK_OUT-

NC

Pair 3

10

SCLOCK_IN+

REQ_SD+

11

SCLOCK_IN-

REQ_SD-

Pair 4

1

nCS+

NC

3

nCS-

NC

Pair 5

7

+5V

NC 8 +5V

NC

Pair 6

2

GND

NC 9 GND

NC

7.6 (.30)

Braided

Aluminum

Jacket

28.7 (1.13)

Aluminum Polyester Shield not to

be exposed in this area.

Do not twist.

Signal Wiring for Serial Interface

Each differential signal should be connected to a corresponding twisted pair as follows:

Note: NC - No Connect

Shield Termination

The customer's cable shield must be in 360° contact with the connector shroud and the

connector shell to provide complete shielding.

The connector shell should be metal with conductive surfaces. Suggested metal

connector shells for use with Mercury II encoders: AMP 748676-1 or equivalent; where

the dash number is dependent on the customer's outside cable diameter.

Terminate the shield as illustrated in the following diagram.

Polyester

Shield

Note: Fold braided shield back over jacket. Example shows double-shielded cable. Dimensions

shown are for purpose of illustration only.

IM-Mercury_II_5000_Series Rev. 1 Page 26 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Pin

Name

Direction

Description

Pin

Name

Direction

Description

6.5 Serial Interface Specifications

Introduction

The serial interface to the Mercury II 5800Si/Pa allows a serial host (controller) to receive position

and status information serially from the sensor. Serial communications between the encoder and

controller permit high speed motion system operation with high encoder resolution: up to 10m/s

with the 1.2nm. The serial data word consists of the following sequence:

Position word of four start bits

Four to thirty-five position bits

Nine bits of status

Six-bit Cyclic Redundancy Check (CRC) to provide error detection

Four stop bits

The encoder’s position is sampled by the MII5800Si at the moment the host commands a sample

(falling edge of nCS); the only latency in the system is the time required for the host to receive the

position word. This architecture minimizes latency and eliminates jitter due to sampling

uncertainty.

Serial Interface Input/Output

MII5800Si (Serial Interface)

MII5800Pa (Panasonic)

The following are the pins used by the MII5800Pa Panasonic serial interface.

Pins 2, 7, 8, 9 are the same for both MII5800Si and Panasonic

Pins 10 and 11 are different for Panasonic

All other pins for Pa are not connected (NC)

IM-Mercury_II_5000_Series Rev. 1 Page 27 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Parameter

Minimum

Typical

Maximum

Differential Output Voltage

500 mv

2v

Common Mode Output Voltage

500 mv

2v

Termination

Parameter

Minimum

Typical

Maximum

Differential Output Voltage

Common Mode Output Voltage

1.1v

1.6v

Absolute Maximum Single-Ended Voltage

-0.3V

2v

Recommended Common Mode Voltage

1.2v

2v

Recommended Differential Input Voltage

250 mv

2v

Impedance

Signal

Definition

Note

Clock frequency requirements: 30MHz to 50MHz

Maximum position sample frequency (falling edge to falling edge): 220 clock cycles

Minimum Pulse Width (high or low): 2 clock cycles

Output Signal Specifications

SDATA_OUT

SCLOCK_OUT

Input Signal Specifications

SLOCK_IN

nCS

Signal Definitions

Power-Up Sequence

Power is supplied from the host to the sensor. After power is supplied, the following sequence is

performed:

The sensor waits for the serial clock to be provided by the host on the signal SCLOCK_IN

for 100ms.

If a clock is not provided, the sensor switches to operate in the final mode (quadrature or

serial).

Upon detecting a serial clock on SCLOCK_IN, the sensor returns the clock to the host on

SCLOCK_OUT.

Within the first 500ms after the serial clock is provided by the host, SCLOCK_OUT may

be unstable.

IM-Mercury_II_5000_Series Rev. 1 Page 28 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

First Bit ------------------------------------------------------------------------------------------------------------------------ Last Bit

Start Bits

Position Word

Status Bits

CRC Word

Stop Bits

Status Bit

ID

Definition

IW

Index Window

Active when the sensor is over the optical index mark

RL

Right Limit

Active when the sensor is over the right limit marker

LL

Left Limit

Active when the sensor is over the left limit marker

Y

Yellow Alarm

Active during marginal alignment to the main track

R

Red Alarm

Active during poor or bad alignment to the main track

S

Saturation Alarm

Active if the main track signal is too large

C

Communication

Error

Active if there is a communication error internal to the

encoder

Sp

Over-Speed Alarm

Active if the encoder exceeds 10m/s (the speed alarm

threshold)*

Ø

Reserved bit is always zero

Once it remains on continuously for at least 500ms, the sensor is ready for data transfers

and SCLOCK_OUT will remain stable.

Data Word Format

Start Bits

The data word will always start with bits one, zero, one, one.

Position Word

The 2’s complement position word has two sections and is user adjustable. The Inter-Fringe bits

which determine encoder resolution are adjustable between 14 bits (1.22nrm resolution) and 2

bits (5µm resolution). The Fringe-Counter bits are increments of 20µm which determine the total

travel and are adjustable between 21 bits (±21 meters) and 0 bits (±10 microns). The total

number of bits (inter-fringe + fringe-counter) must be at least 4 and no more than 35. Position

word length is edited via the SmartPrecision II software in the Status and Setup tab. The position

word is always transmitted most significant bit (MSB) first.

Status Bits

The encoder status bits are all active high with the exception of the Right and Left Limits. Limit

status is user programmable (active high or active low) by using the SmartPrecision II software in

the Calibrate and Align tab.

The nine status bits are defined as follows:

Example: ØØØØ_ØØØØ_Ø = normal operation, not at the index mark.

Note*: The encoder maximum operational speed is 10 meters/second, regardless of the speed

alarm setting. The alarm is a user configured feature, to be set for specific application

requirements, or the bit may be ignored if desired. The speed alarm is dependent on the

clock frequency, the sample rate, and the desired speed where the user would like the bit

to assert high. The speed alarm register is defaulted to 3604, and may be changed using

IM-Mercury_II_5000_Series Rev. 1 Page 29 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

the alignment tool and Smart Precision software. The register must be set using the

following formula:

Register value = (8.19E108 x ST x NC)/CF

ST = the desired speed alarm threshold in m/s

NC = number of clocks between samples

CF = clock frequency in Hz

Register value should be rounded to the nearest integer and entered into the settings

screen in the SmartPrecision software.

The speed alarm may also be disabled in the SmartPrecision software.

CRC bits

The cyclic redundancy check or CRC includes only the position and status bits. The CRC format

is 6-bit polynomial:

X6 + X + 1, MSB first after preloading the CRC register with all 1’s

Stop Bits

The data word will always end with bits one, zero, one, one (1011).

Timing Diagram

IM-Mercury_II_5000_Series Rev. 1 Page 30 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Configurable Settings

There are a number of settings that may be configured for serial output operation:

Index Mode: The encoder can be set to reset the position to 0 every time the index is

crossed (“Index Mode 1”) or to use the position at power up as the 0 position (“Index

Mode 0”).

Number of Fringe Count Bits: Each fringe is 20µm long on the encoder’s scale. The

number of fringe count bits can be set from 0 bits (no fringes) to 21 bits (2,097,152

fringes). Use enough fringe count bits to ensure that the position word is large enough for

the expected range of motions. For example, 18 fringe count bits will make the range of

position values from -2.62144m to +2.62144m (total travel of 5.24288m). The total travel

in meters is calculated as follows: travel = 0.00002m * 2n, where n = the number of

interpolation bits.

Number of Interpolated Bits: The number of bits to calculate the position within a fringe,

and thus the encoder’s resolution. The number of interpolated bits can be set from 2 bits

(x4 interpolation; 5µm resolution) to 14 bits (x16, 384 interpolation; approximately 1.22

nm resolution). Using fewer fringe count and interpolation bits than the maximums can

increase the sample rate to the controller. The encoder’s resolution, in µm, is calculated

as follows: Resolution = 20µm/2n, where n = the number of interpolation bits.

Low Pass Filter: The digital low pass filter is used to limit the bandwidth of the encoder

system if desired. It is set in terms of % of sample rates and can be set from 0.01% to

40% in 0.01% increments.

Note: Fringe count bits + interpolated bits must be ≥ 4 bits total.

IM-Mercury_II_5000_Series Rev. 1 Page 31 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Limit Settings

Left and Right Limit Settings can be changed by clicking on the associated controls

(Swap, Enable/Disable, and Toggle):

o Limit Polarity: Normal - left limit marker triggers left limit signal; right limit marker

triggers right limit signal. Reversed - left limit marker triggers right limit signal;

right limit marker triggers left limit signal.

o Limit Status: The limits may also be enabled or disabled.

o Limit State: Active High - status bit = 1 when limits is active; Active Low - status

bit = 0 when limit is active.

See examples in Calibrate and Align screen below.

Performance Specifications

Resolution: 5µm to approximately 1.22nm

Maximum travel before position counter rollover, with fringe count bits set to 21: 41.94304

meters

Maximum speed: 10m/s

Maximum cable length: 10m

6.6 Index Speed Considerations

MII5000

Maximum Speed for MII5000 Index after Power-up (MII5800, MII5700 and MII5500 Models):

Each time an MII5800, MII5700, or MII5500 encoder is powered up, the first pass over the index

mark must occur at a speed ≤1m/s. Once the index is initially detected, the index will function at

all speeds (up to 10m/s) until the next power cycle.

IM-Mercury_II_5000_Series Rev. 1 Page 32 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

MII5800Si/Pa

Controller Sample Rate and Maximum Encoder Speed for MII5800Si/Pa Index:

The Index Window is part of the MII5800Si’s serial word and does not latch. To detect the index

mark, the controller must issue a sample command while the sensor is over the index mark on

the scale. When this happens, the Index Window bit will be high. If the sensor is not over the

index mark, the IW bit will be low. Consequently, the sample rate must be at least as fast as the

output from the following equation to ensure that a sample command occurs when the sensor is

over the index mark:

Index Window duration (µs) = Index Window width (µm) / encoder speed (m/s)

The Index Window’s width can be in the range from 5µm to 30µm. It is typically 20µm

after calibration. To ensure reliable index sampling, a value of 5µm can be used in the

above equation for all systems.

The maximum position sample rate is 4.4µs; there is no minimum sample rate.

For example:

Index Window width = 5µm.

Speed = up to 1.1m/s.

Index Window duration = 4.55µs.

Therefore, the controller’s position sample rate must be 4.55µs or faster to read the Index

Window (at least one position word with the IW bit high).

6.7 RS-422 Compliance

The Mercury II 5000 Series Encoders are RS-422 compatible. Encoder signals are “sending end

terminated.” Therefore, customer receiving terminations are not required. For more details, see

the Proper Signal Termination of 422 Data Transmission Signals Tech Note located at

http://www.microesys.com/products/technical-notes-and-white-papers.

Optional RS-422 compliant circuitry for long cable runs in harsh electronic environments is

illustrated below:

IM-Mercury_II_5000_Series Rev. 1 Page 33 ©2014 MicroE Systems

Appendix

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Problem

Solution

The Power/Calibration indicator will not

come on.

Make sure that the SmartPrecision II Electronics 15-pin D-

sub connector is fully seated and connected.

Confirm that +5 Volts DC is being applied to pin 7 and 8 on

the SmartPrecision II electronics 15-pin connector and that

pins 2 and 9 are connected to ground.

Can't get the SmartPrecision II

Electronics "Signal" LEDs better than

red or yellow; or the green “Proper

Alignment” indicator doesn't stay

illuminated over the full length of the

scale.

Verify that the sensor is mounted in the correct orientation

with reference to the scale and scale mounting reference

edge. Refer to the Interface Drawing.

Verify that the sensor has been aligned to the scale and

that the mounting screws are tight. Check the dimensions

for the mechanical mounting holes (and clamps if any) to

make sure that the sensor is correctly located over the

scale in the Y and Z dimensions. Refer to the Interface

Drawing.

Check that the scale is firmly mounted and can't jiggle or

move in any direction other than the axis of motion.

Make sure that the scale is clean over its entire length or

circumference.

The green Power/Calibration indicator

LED or limit LEDs are flashing

unexpectedly.

Part of the normal setup procedure is to activate the

SmartPrecision II Electronics Calibration/Setup process by

pressing the recessed button in the electronics module.

The Power/Cal. LED or limit LEDs will begin to flash until

the relevant setup process is complete. See the

instructions beginning at Section 5.1.1 Sensor Alignment.

Can't complete the Calibration/Setup

process - the green Power/Calibration

indicator doesn't stop flashing.

Verify that the sensor is mounted in the correct orientation

to the scale for the desired index mark. Refer to the

Interface Drawing.

Refer to Section 4.2 Verify Sensor Mounting Surface

Height to ensure proper sensor alignment and index

marker operation.

Signal Plots in Smart Precision II

Software not displaying in browser

window.

Reduce the Security Level setting for Java to “Medium” by

going to the Windows Start Menu/Control Panel/Java and

selecting the Security tab (covers up to Java 7, versions

beyond 7 may require different steps).

You may receive an Application Blocked by Security

Settings message when attempting to load the plotApplet.

Warning: Reducing the Security Level in the Security Tab may

decrease protection of your computer against malicious

software.

6.8 Troubleshooting

IM-Mercury_II_5000_Series Rev. 1 Page 34 ©2014 MicroE Systems

Order Guide

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Sensors

MII5800, A-quad-B Output, with Resolution from

5µm to 1.22nm

MII5700, A-quad-B Output, with Resolution

from 5µm to 5nm

MII5810-AB-16384-1-1-0

MII5710-AB-4000-1-1-0

Low Pass Filter Roll

Off Frequency (kHz)

0=Off (full bandwidth)

1=1khz

2=2khz

100=100kHz

Low Pass Filter Roll

Off Frequency (kHz)

0=Off (full bandwidth)

1=1khz

2=2khz

100=100kHz

Limit Logic

1=Active Low (fail

safe) 2=Active High

Limit Logic

1=Active Low (fail safe)

2=Active High

Maximum Output

Frequency

1=12.50 MHz

2=6.25 MHz

3=3.125 MHz

4=1.563 MHz

5=0.781 MHz

6=0.391 MHz

7=0.195 MHz

8=0.098 MHz

9=0.049 MHz

10=0.024 MHz

Maximum Output

Frequency

1=12.50 MHz

2=6.25 MHz

3=3.125 MHz

4=1.563 MHz

5=0.781 MHz

6=0.391 MHz

7=0.195 MHz

8=0.098 MHz

9=0.049 MHz

10=0.024 MHz

Interpolation

(Integer Steps)

4=x4

5=x5

16384=x16384

Interpolation

(Integer Steps)

4=x4

5=x5

4000=x4000

AB

AB=A-quad-B output

AB

AB=A-quad-B output

MII58XX (Cable

Length)

MII5810=1m cable

MII5830=3m cable

MII5850=5m cable

MII57XX (Cable

Length)

MII5710=1m cable

MII5730=3m cable

MII5750=5m cable

Note: All specificationsare subject to change.

7.0 Order Guide

How to Order

IM-Mercury_II_5000_Series Rev. 1 Page 35 ©2014 MicroE Systems

Order Guide

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Sensors

MII5500, A-quad-B Output, with

Resolution from 5µm to 50nm

MII5800Si, Serial Output, with Output

Resolution up to 1.22nm

MII5510-AB-4000-1-1-0

MII5810-Si-14-21-1-0

Low Pass Filter Roll

Off Frequency (kHz)

0=Off (full bandwidth)

1=1khz

2=2khz

100=100kHz

Low Pass Filter Roll Off

Frequency

(% of Sample Rate)

0=Off (full bandwidth)

1=1% of sample rate

2=2% of sample rate

40=40% of sample rate

Limit Logic

1=Active Low (fail safe)

2=Active high

Index Mode

0=No change to position

of index

1=Position reset at

every index

Maximum Output

Frequency

1=12.50 MHz

2=6.25 MHz

3=3.125 MHz

4=1.563 MHz

5=0.781 MHz

6=0.391 MHz

7=0.195 MHz

8=0.098 MHz

9=0.049 MHz

10=0.024 MHz

Number of Fringe

Count Bits*

2=2

3=3

21=21

Interpolation Bits*

2=2

3=3

14=14

Interpolation

(Integer Steps)

4=x4

5=x5

4000=x4000

Si

Si=Serial Interface

AB

AB=A-quad-B output

MII58XX (Cable Length)

MII5810=1m cable

MII5830=3m cable

MII5850=5m cable

MII55XX (Cable

Length)

MII5510=1m cable

MII5530=3m cable

MII5550=5m cable

Note*: Interpolation bits plus fringe bits must be

≤35 bits.

Note: All specifications are subject to change.

How to Order

IM-Mercury_II_5000_Series Rev. 1 Page 36 ©2014 MicroE Systems

Order Guide

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Sensors

Sensor Installation Tools

MII5800Pa, Serial Output, with Output

Resolution up to 1.22nm

ATMII5000

*Alignment Tool Kit for MII5000

encoders includes:

- Alignment Tool

- SmartPrecision II Software

- USB Cable

- Power Supply

(100V- 240VAC/50-60Hz)

US=Power supply with US

standard 2-prong plug

EU=Power supply with European

standard 2-prong plug

MII5810-Pa-14-10-1-0

-US

-EU

Low Pass Filter Roll

Off

Frequency (kHz)

0=Off (full bandwidth)

1=1% of sample rate

2=2% of sample rate

ZG-PP2

Z-Height Gauge, PurePrecision

Tape Scales

40=40% of sample

rate

ZG-GS2

Z-Height Gauge, Glass Scales

Index Mode

0=Default (no option)

Note*: Required for MII5000/MII6000 setup.

Number of Fringe

Count Bits

2=2

3=3

21=21

Interpolation Bits

2=2

3=3

14=14

Adapter for Open Collector Limit Outputs

MIIA-OCL

Small DB15 adaptor to convert

3.3V left and right limit output

signals to open collector type

(7407)

End Cap Kit, PurePrecision Tape Scales

EC

Optional Tape Scale End Caps

Pa

Pa=Panasonic

MII58XX (Cable

Length)

MII5810=1m cable

MII5830=3m cable

MII5850=5m cable

Tape Scale Applicator Tools

(use for lengths > 300mm)

TSAT-PPT

Tape Applicator Tool for applying

tape scale

Note: Interpolation bits plus fringe bits must be ≤24 bits.

Note: All specifications are subject to change.

How to Order

IM-Mercury_II_5000_Series Rev. 1 Page 37 ©2014 MicroE Systems

Order Guide

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

Scales

PurePrecision Marker Tape II

MT-N-A-L-9999-I

I = Individual Lengths

C = Continuous reel with index and cut marks (unless otherwise

specified)

Length in mm (40mm – 9,999mm)

For lengths >10,000mm, contact MicroE for custom part number

L=Center Index and Limits

I=Center Index Only

C=Custom

A=Adhesive

PurePrecision Laser Tape II

TS-3000

Length in mm (40mm – 30,000 mm)

PurePrecision Linear Glass Scales

(Standard accuracy grade)

MIIL-100

Length in mm (10mm – 1,000 mm)

For high accuracy grade scales, contact MicroE.

Note: Index and limit markers must be ordered separately.

Stick-On Index and Limit Markers

(for Laser Tape II and Performance and Value Linear Glass Scales)

RIMS

Qty of 8 Stick-On Index Markers

RLMS

Qty of 4 Stick-On Left Limit Markers and

Qty of 4 Stick-On Right Limit Markers

Note: To use RIMS/RLMS, MII5000 must be configured for Reflective Grating Type.

PurePrecision Rotary Glass Scales

(For example: 44.45mm OD Rotary Glass Scale with Hub: MIIR4513-HI)

MIIRxxxx* - Hub

NH=Without Hub

HI=for R4513

HJ=for R6425

HK= for R12151

MIIR4513

MIIR6425

MIIR12151

Note*: Custom Versions are available.

Note: Rotary glass scales are shipped not mounted to hub. Hub mounting is available, contact

MicroE Systems for information.

Note: All specifications are subject to change.

How to Order

IM-Mercury_II_5000_Series Rev. 1 Page 38 ©2014 MicroE Systems

Contacting MicroE

Mercury II 5000 Series Encoders

Installation Manual and Reference Guide

8.0 Contacting MicroE

To learn more about Mercury™ encoders, or other MicroE Systems products, visit:

www.microesystems.com.

To learn more about GSI Group, visit our corporate web site: www.gsig.com.

MicroE Systems is a world leader in optical encoder technology with offices in major industrial

centers around the globe. As one of fourteen product brands that comprise GSI Group, we deliver

enabling technology that brings advanced applications to life in the motion control, medical,

semiconductor, electronics, and industrial markets.

Headquarters

MicroE Systems

125 Middlesex Turnpike

Bedford, MA 01730 USA

Tel: 781-266-5700

Fax: 781-266-5112

www.microesystems.com

Email: info@microesystems.com

IM-Mercury_II_5000_Series Rev. 1 Page 39 ©2014 MicroE Systems

IM-MII_PurePrecision_Scales Rev. 1

™

Tape and Glass Scale Installation

for Mercury II™ Series Encoders

MicroE Systems • 125 Middlesex Turnpike • Bedford, MA 01730 • USA

www.microesystems.com

info@microesystems.com

T. 781-266-5700

F. 781-266-5112

Installation Manual

and Reference Guide

Introduction

Mercury II PurePrecision Tape and Glass Scales

Installation Manual and Reference Guide

Table of Contents

1.0 Introduction ...................................................................................................................................... 2

1.1 Overview ............................................................................................................................. 2

1.2 Applicable Encoders ........................................................................................................... 2

1.3 Related Documents............................................................................................................. 2

1.4 Manual Revisions ................................................................................................................ 2

1.5 Patents ................................................................................................................................ 2

1.6 Trademarks ......................................................................................................................... 2

1.7 Standards Compliance ........................................................................................................ 3

1.8 Special Conventions Used .................................................................................................. 3

2.0 PurePrecision Rotary Scales ........................................................................................................... 3

3.0 PurePrecision Laser Tape II Scale Installation ................................................................................ 4

3.1 Before Installation ............................................................................................................... 4

3.1.1 Items Required for Tape Scale Installation ............................................................ 4

3.1.2 Pre-Installation Information and Precautions ......................................................... 4

3.1.3 Flowchart for PurePrecision Tape Scale Installation ............................................. 5

3.1.4 Design Guide ......................................................................................................... 6

3.1.5 Mounting Surface Preparation ............................................................................... 7

3.2 Cut the Tape Scale ............................................................................................................. 8

3.3 Install Tape Scale ................................................................................................................ 9

3.3.1 Install Tape Scale Manually ................................................................................... 9

3.3.2 Install Tape Scale Using the Applicator Tool ....................................................... 14

4.0 PurePrecision Linear Glass Scales Installation ............................................................................. 22

4.1 Before Installation ............................................................................................................. 22

4.1.1 Items Required for Glass Scale Installation ......................................................... 22

4.1.2 Mounting Surface Preparation ............................................................................. 22

4.2 Mount Linear Glass Scales ............................................................................................... 22

4.3 Install Linear Glass Scales ................................................................................................ 23

5.0 Stick-On Index and Limit Markers Installation................................................................................ 24

5.1 Stick-On Marker Strips ...................................................................................................... 24

5.2 Remove Markers from Strip .............................................................................................. 24

5.3 Attach Markers to Scale .................................................................................................... 26

6.0 End Caps Installation ..................................................................................................................... 27

7.0 Final Cleaning, Inspection, and Cure Time .................................................................................... 28

7.1 Reworking to Correct Mistakes ......................................................................................... 28

7.2 Cleaning Scales ................................................................................................................ 28

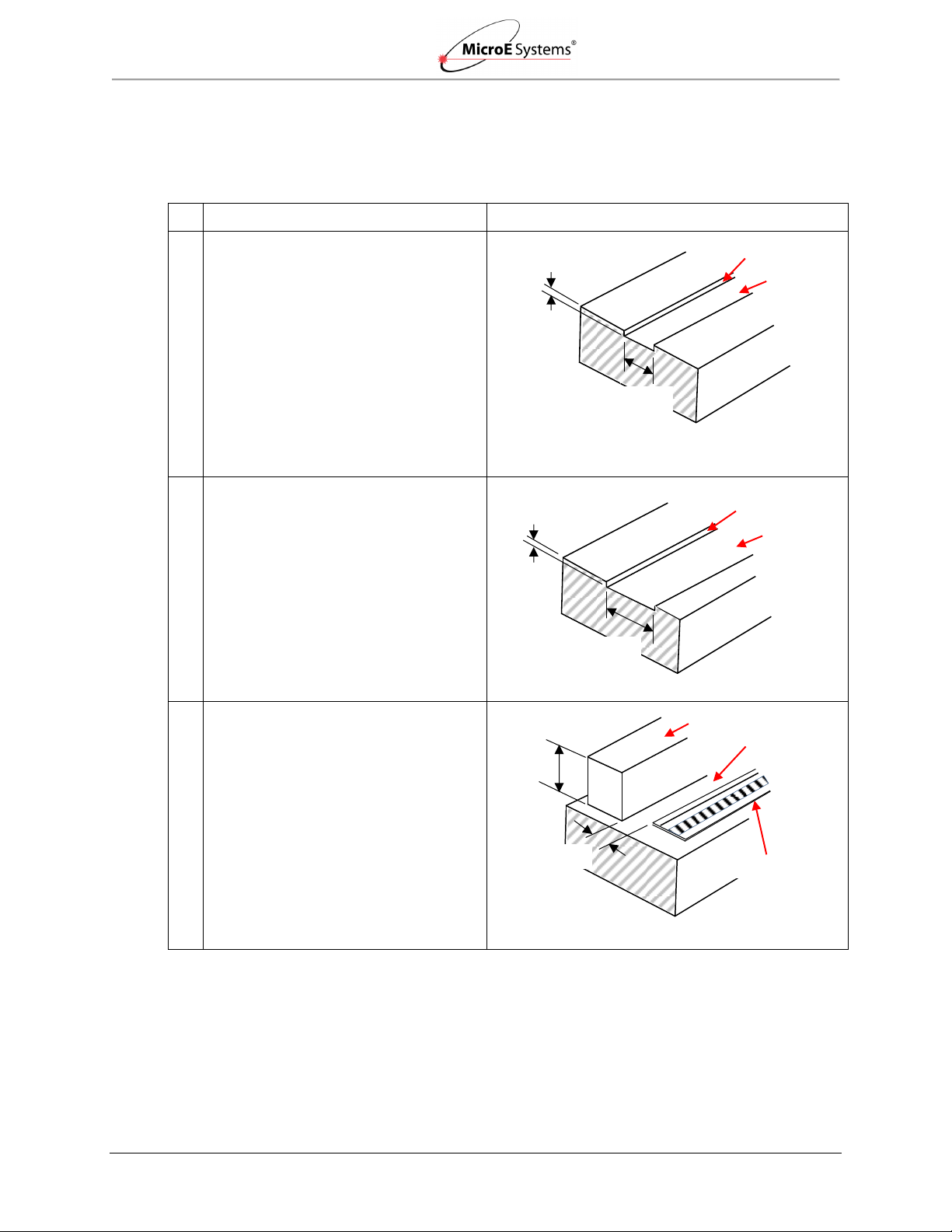

8.0 Contacting MicroE .......................................................................................................................... 29