Page 1

Compact Encoder Tape

for MTE Series Encoders

Installation Manual

and Reference Guide

MicroE Systems • 125 Middlesex Turnpike • Bedford, MA 01730 • USA

www.microesys.com info@microesys.com T. 781-266-5700

(CET™) Scale Installation

MTE-IM CET Scale Installation Rev A1

© 2015 MicroE Systems

Page 2

Table of Contents

Compact Encoder Tape (CET™) Scale Installation

Introduction

Introduction (Precautions, Patents, Manual Revisions) ............................................................................3

Overview ....................................................................................................................................................4

Items Required for Scale Installation ........................................................................................................4

Pre-Installation Information and Precautions ............................................................................................5

Design Guidelines for Top Mount and Side Mount Configurations............................................................6

Mounting Surface Preparation for Top Mount and Side Mount Sensors ..................................................7

Cutting CET Scales ..................................................................................................................................8

Tape Scale, Lengths <1000mm

By Hand, for MTE Top Mount and MTE Side Mount ................................................................................9

Tape Scale, Lengths >1000mm

By Applicator Tool, for MTE Top Mount ..................................................................................................13

By Applicator Tool, for MTE Side Mount..................................................................................................19

End Cap Installation

End Cap Installation ................................................................................................................................25

Final Clean, Inspection, Cure Time, and Rework ..............................................................26

Contacting MicroE Systems ..............................................................................................................27

Page 3

Precautions

Follow standard ESD precautions. Turn power off before connecting the sensor. Do

not touch the electrical pins without static protection such as a grounded wrist strap.

Do not touch the scale unless you are wearing talc-free gloves or finger cots. Please

read this installation manual for full instructions.

1

2

MTE models are CE and RoHS compliant.

Manual Version Numbers

MTE-IM CET Scale Installation Rev A, issued February 2014

Changes: N/A

Related Documents

-MTE Data Sheet

-MTE Sensor Installation Manual

-MTE Interface Drawing

RoHS

Page 4

Overview

This manual applies to the installation of the following scale types.

• PurePrecision Compact Encoder Tape (CET™) for MTE Series, Model CET20-

Items Required for CET Scale Installation

You will need the following items available:

• Shears (recommend, Clauss, Item# 18003)

• Tape Applicator Tool, for applications >1000mm (not required for installations <1000mm)

MTE Top Mount Configuration tool Model Number: TSAT-CET

MTE Side Mount Configuration tool Model Number: TSAT-SM-PPT

• Finger Cots or talc-free gloves

• Acetone or isopropyl alcohol

• Lint-free cotton cloths or wipes

• End caps (optional)

• Two-part epoxy (Tra-Con Tra-Bond 2116)

• Stick and disposable surface for stirring epoxy

Refer to encoder model data sheets for detailed ordering guide and more information

about MicroE Part Numbers.

Page 5

Pre-Installation Information and Precautions

Read all instructions completely before beginning the

installation process.

The CET™ Scale is a precision metrological device. Handle it with the

utmost care at all times.

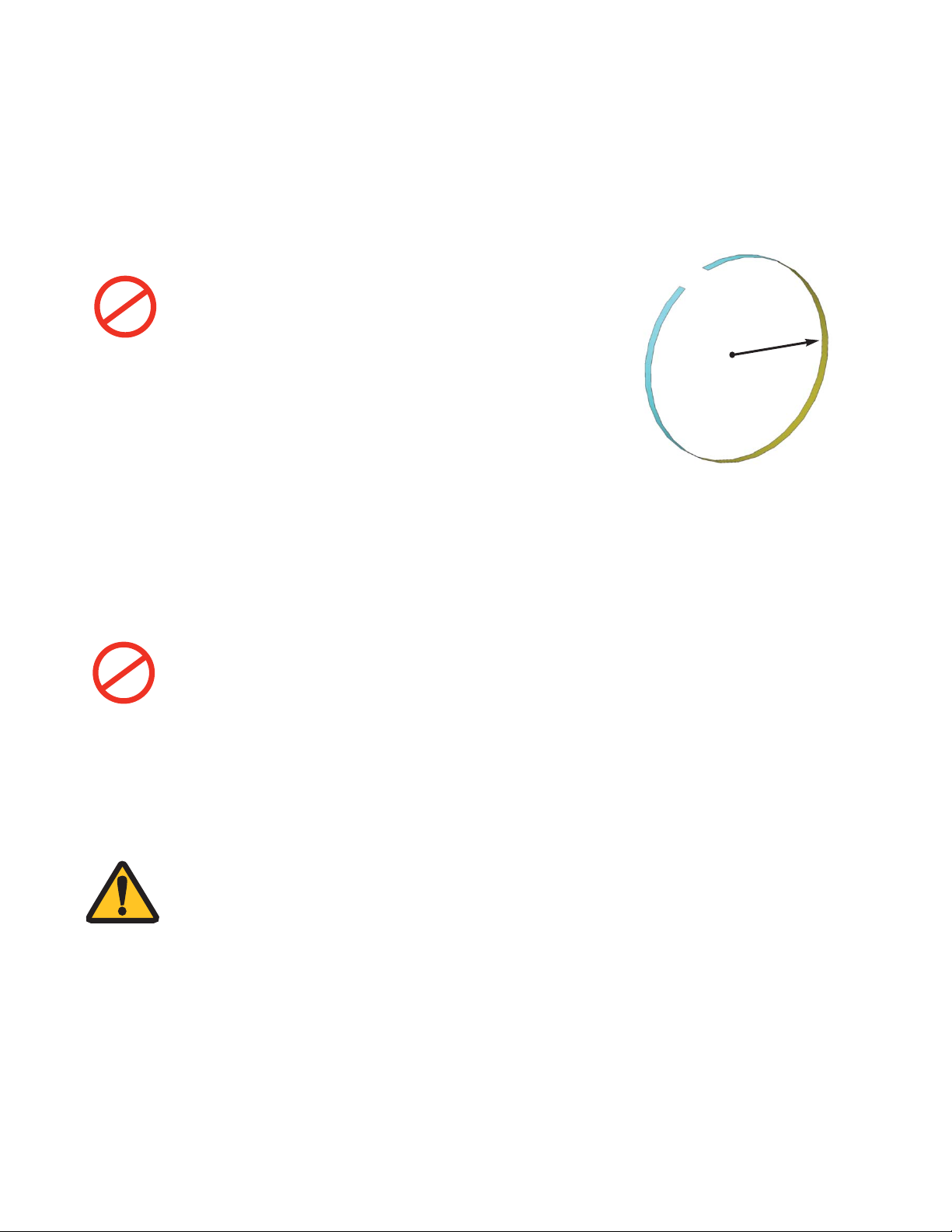

Avoid bending the tape scale to a radius less than 90mm (3.5

inches)

Avoid twisting the CET Scale.

Do not let any sharp object touch the tape scale after the blue

protective film is removed.

The CET Scale is protected by a blue film on the top that

prevents contamination and damage to the grating pattern

during installation.

Once the adhesive on the tape scale is exposed (by removing

the adhesive liner), do not touch the adhesive or allow any

contamination to come into contact with it.

CET Scale is designed for one time installation only.

If removed from the mounting surface for any reason, it should

not be used for any kind of reapplication. This will affect the

performance and reliability of the encoder system.

Minimum

storage radius

90mm (3.5 inches)

The adhesive on the CET Scale is permanent.

Do not touch the adhesive once the adhesive liner is removed.

Do not remove the tape scale from the mounting surface once it has been installed.

Do not reinstall the tape scale if it has already been installed once.

Avoid any contamination to the adhesive. Any particulate matter or other contamination that

is trapped between the scale and the mounting surface will affect encoder performance.

NOTE:

MicroE does not recommend installing CET Scale on a curved

(cylindrical) surface.

Page 6

Design Guidelines

1.

Verify the tolerances of the scale's mounting

surface given in the Interface Drawing.

2.

Verify the dimensions of the scale benching

edge (groove or straight edge) given in the

Interface Drawing.

3.

Calculate the length of CET™ Scale required for

your application. Refer to the Interface Drawing.

4.

Tape scales less than 1000mm can be installed by

hand against a straight edge. For lengths greater

than 1000mm, tape scale applicator tools are

needed:

Top Mount Configuration:

Applicator tool Model Number: TSAT-CET

Side Mount Configuration:

Applicator tool Model Number: TSAT-SM-PPT

5.

If the tape scale is being installed into a 6mm

grove, it must be installed by hand (regardless of

scale length). Refer to the Interface Drawing.

6.

If machining the mounting surface is undesirable,

or not possible, a temporary straight edge can be

used that meets the dimensions and tolerances

specified in the Interface Drawing.

Two kinds of temporary straight edge can be

used -

• Type I (thin)-

Temporary Straight Edge of thickness

0.76 ± 0.05 mm (0.030 ± 0.002 inches).

Refer to the Interface Drawing for additional

dimensional requirements. A steel rule may be

one of the options for this type of temporary

straight edge.

• Type II (thick)-

Temporary straight edge with minimum

thickness 9.53mm (0.375 inches). Refer to the

Interface Drawing for additional dimensional

requirements.

NOTE:

See the appropriate section on Tape Applicator Tool

installations.

Page 7

Mounting Surface Preparation

1.

Inspect the mounting surface for any machining irregularities. MicroE Systems recommends a surface finish

of better than 1.6 micrometers Ra.

2.

The straight edge (either permanent or temporary) must be sharp on the benching side in order to use it as a

guide in hand mounted applications. In order for the tape scale to be mounted close to the straight edge, the

maximum radius of 0.127 mm (0.005 inches) should be used where the edge meets the bottom of the

mounting surface.

3.

Thoroughly clean the scale mounting surface and reference edge using a cotton swab or lint-free cloth

dampened with isopropyl alcohol or acetone.

Remove all dust and particles.

4.

Mark the starting location on the mounting surface where the tape scale will be applied.

Page 8

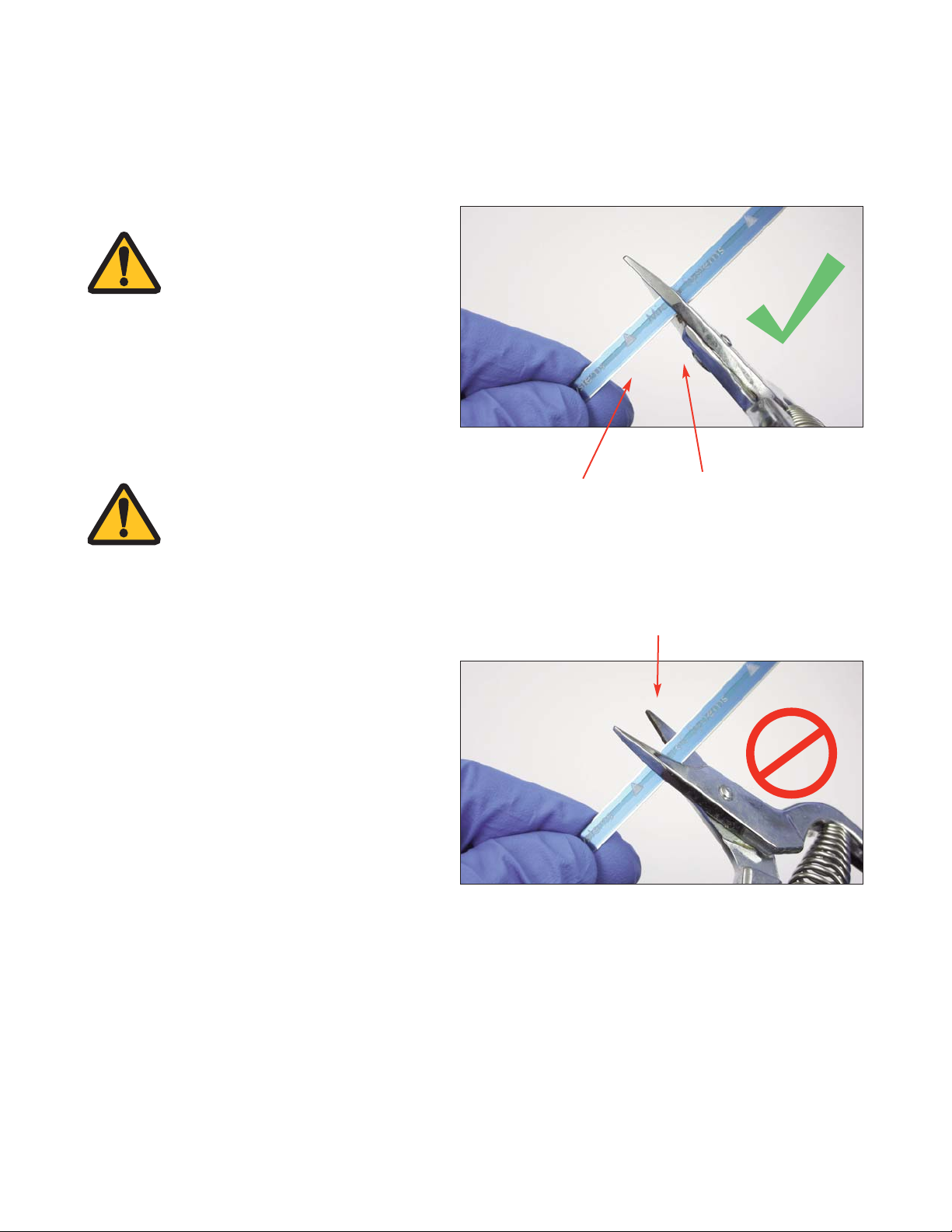

Cutting the CET™ Scale

1.

Uncoil the tape scale and cut it to the

required length using shears.

Note: check the interface drawing to make

sure the scale is cut to the right length.

Securely hold the tape scale close

to the shear (at an approximate

distance of 40mm [1½ inches])

near the point of cutting.

Orient the tape scale

perpendicular to the shear.

Cut the tape scale in a smooth,

continuous motion.

Shear held perpendicular to

the tape scale (NOT INCLINED)

Hand approximately at a

distance of 40mm-50mm

(1 1/2 inches to 2 inches)

from the cutting point

Shear held inclined,

not perpendicular,

to the tape scale

NOTE:

When working with any encoder

scale, it is important to use either

finger Cots or talc-free gloves

Page 9

CET™ Scale, MTE Top/Side Mount Configurations

Installation By Hand

2.

Removing/peeling the bottom

adhesive liner.

CET Scales have 3 layers, blue protective

film, steel scale, and adhesive backing.

Remove/peel back approximately 25mm

(1 inch) of the bottom adhesive liner, taking

care not to touch the adhesive or allow any

particulate contamination.

NOTE:

Do not peel the blue protective

film off at this time.

Adhesive liner peeled off about

25mm (1 inch) from one end

LEFT RIGHT

1.

Scale direction/orientation

Orient the scale such that the "arrowheads" on the blue protective film are pointing towards the mounting

surface reference edge “D” as shown in the interface drawings for your sensor model.

Refer to the correct model number Interface Drawing for reference edge “D” dimensions and sensor

orientation. Download the latest Interface Drawing at www.microesys.com/products/documentation

D

= Mounting Surface Reference Edge

NOTE:

For best system performance, talc-free gloves or finger cots should be worn during all

steps of tape scale installation.

Thoroughly clean the scale mounting surface and reference edge using a cotton swab

or lint-free cloth dampened with isopropyl alcohol or acetone. Remove all dust and

particles.

D

Page 10

CET™ Scale, MTE Top/Side Mount Configurations

Installation By Hand

4.

Place the CET™ Tape Scale against the mounting surface “D” reference edge.

Place the 25mm (1 inch) exposed adhesive end of the tape scale against the mounting surface “D” reference

edge as shown and press firmly on the end.

NOTE:

Adhesive exposed by removing the adhesive bottom liner can touch the mounting

surface only once.

3.

Flip the tape over with the 25mm (1 inch) exposed adhesive surface facing down. Be sure not to touch or

contaminate the exposed adhesive surface. Be sure the orientation arrows on the blue protective film point to

the “D” reference edge.

“D” reference edge as shown in the

MTE interface drawing.

Tape scale orientation arrows.

Page 11

CET™ Scale, MTE Top/Side Mount Configurations

Installation By Hand

5.

Install the CET Scale along the remaining length of the mounting surface.

Press the remaining tape on to the mounting surface with a sliding motion as shown below.

Pull the adhesive liner out of the way during the sliding motion.

NOTE:

Make sure that the tape scale is tight against the “D” reference edge.

Pull adhesive liner out of the way

during sliding motion

Sliding motion of finger along the

length of the tape

NOTE:

Be sure to keep the blue top protective film in place.

“D” reference edge as shown in the

interface drawing.

Page 12

CET™ Scale, MTE Top/Side Mount Configurations

Installation By Hand

6.

Once the scale is applied to the mounting surface, and before the blue protective film is removed, it is

recommended that even pressure be applied over the entire tape scale length by sliding a glove or cot

protected finger across the scale. The applied pressure will ensure that the adhesive is evenly and

permanently set.

7.

Peel off the blue protective film.

Start the peeling process using a sharp tool, being careful not to damage the scale. Pull off the remaining blue

protective film.

NOTE:

After removing the blue

protective film, the scale is

ready for use and will

perform to specification.

The encoder will not

function properly with the

blue protective film

installed. It must be

removed for proper encoder

operation.

Page 13

Applicator tool spring loaded contact

cylinder Up/Down position knob

CET scale entry

channel

Spring loaded

contact cylinder

1.

Overview of CET Scale Applicator Tool (Model Number: TSAT-CET)

The CET Scale Applicator Tool

mounts into the MTE’s sensor

mounting holes.

The orientation of the CET Applicator Tool

corresponds to the MTE encoder as shown below.

The benching surfaces correspond to the B and C

faces shown in the MTE interface drawing.

B

B

C

C

2.

Applicator Tool benching faces

Shown below is the MTE Sensor head mounted in

its fixture.

3.

Applicator Tool - mounting

The CET Applicator Tool mounted in the same

MTE Sensor fixture, ready for CET Scale

installation.

CET™ Scale, MTE Top Mount Configuration

Installation By Mounted Applicator Tool

NOTE:

For best system performance, talc-free gloves or finger cots should be worn during all

steps of tape scale installation.

Thoroughly clean the scale mounting surface and reference edge using a cotton swab or

lint-free cloth dampened with isopropyl alcohol or acetone. Remove all dust and particles.

Tool orientation

arrows

Page 14

CET™ Scale, MTE Top Mount Configuration

Installation By Mounted Applicator Tool

The correct end of the tape to insert is shown

below.

5.

Applicator Tool / CET Scale Orientation

Tape Scale orientation arrows

Tool orientation

arrows

Both Tape Scale arrows, and Applicator Tool

orientation arrows need to point in the same

direction, while the tape is being applied.

In the example above, the side of the tape scale

that needs to go into the tool entry channel first

is called the “correct” end.

Tape entry

channel

“Correct” end of tape to

insert into applicator tool.

While mounted in the MTE sensor’s fixture, CET

Scale is fed through the entry channel and pressed

onto the mounting surface with the spring loaded

contact cylinder.

The contact cylinder has two positions, Up and

Down, controlled by the black position knob on the

side of the Applicator Tool.

Up, allows clearance for feeding of the CET Scale

through the entry slot into the “start” position.

Down, locks the tape scale onto the “start” position.

Moving the Applicator Tool along in the Down

position will automatically press the CET Scale to

the mounting surface.

4.

Applicator Tool - bottom view

CET Scale

adhesive surface

CET Scale clear adhesive

backing, unravelling

Spring loaded

contact cylinder

6.

Install the Applicator Tool into the MTE Mount

Tighten the mounting screws.

Page 15

CET™ Scale, MTE Top Mount Configuration

Installation By Mounted Applicator Tool

Peel back about 50mm (2 inches) of clear adhesive backer tape.

8.

Tape Scale Insertion

Turn the tool contact cylinder knob to the UP

position.

Insert the “correct” end of the tape scale into the

applicator tool, making sure the clear backing tape

curls out of the way.

The orientation arrows on the Tape Scale and

Applicator Tool need to point in the same direction.

Also note, the “D” reference edge is determined

from the MTE interface drawing. The tape scale

orientation arrows always point to the “D” reference

edge. In the example, the dotted red line shown is

the measured “D” reference edge. When the tape

scale is finally installed, the orientation arrows will

be pointing to the calculated “D” reference edge.

Clear adhesive backer tape peeled

back about 50mm (2 inches).

Tool contact cylinder in

UP position

Tape slides into channel

under the dowel pin.

Tool orientation arrows

7.

Tape Scale Preparation

Using a sharp tool or fingernail, peel off a short

section of bottom adhesive backing, approximately

50mm (2 inches) from the “correct” end of the scale

to be inserted into the applicator tool.

Take care not to touch the adhesive or allow any

particle contamination.

Tape scale orientation arrows

NOTE:

Do not peel the blue

protective film off at

this time.

D

“D” datum edge

from MTE

interface drawing

Page 16

CET™ Scale, MTE Top Mount Configuration

Installation By Mounted Applicator Tool

9.

Tape Scale Insertion

Push the scale slowly into the Applicator Tool until the tape scale emerges from the side of the mounting fixture

to a desired end location. Press down on this exposed 3-5mm section of tape.

10.

Rotate Contact Cylinder Knob to Down

Turn the applicator tool contact cylinder knob to the DOWN position.

Turning the knob to the DOWN position, applies firm pressure to the tape scale under the applicator tool. This

action presses the adhesive side of the tape scale firmly onto the scale mounting surface.

Press down on end of tape.

Tool contact cylinder in DOWN position

Page 17

CET™ Scale, MTE Top Mount Configuration

Installation By Mounted Applicator Tool

11.

Apply the Tape Scale

Push the Applicator Tool and fixture assembly in the direction of tape application. Use a slow and steady motion.

Once the tool begins moving, it automatically separates the clear adhesive backing tape from the scale.

Pull the clear adhesive backing tape out of the way to prevent the backing tape from clogging the applicator tool.

Be sure to pull the

adhesive backing film out

of the way to prevent a

tool jam.

Pull clear adhesive backing

tape out the way as the

Applicator Tool is moved.

Applicator Tool and fixture direction of motion

CET Scale being applied

to mounting surface

Tool contact cylinder knob in the DOWN position

Page 18

CET™ Scale, MTE Top Mount Configuration

Installation By Mounted Applicator Tool

12.

Once the scale is applied to the mounting surface, and before the blue protective film is removed, it is

recommended that even pressure be applied over the entire tape scale length by sliding a glove or cot

protected finger across the scale. The applied pressure will ensure that the adhesive is evenly and

permanently set.

NOTE:

After removing the blue protective film, the scale is ready for use and will perform to

specification.

The encoder will not function properly with the blue protective film installed. It must be

removed for proper encoder operation.

13.

Peel off the blue protective film.

Start the peeling process using a sharp tool, being careful not to damage the scale. Pull off the remaining

blue protective film. Clean the tape scale using alcohol or acetone and a lint-free cotton cloth.

NOTE:

Make sure you have on finger cots

or talc-free gloves.

A

A

B

D

Page 19

CET™ Scale, MTE Side Mount Configuration

Installation By Mounted Applicator Tool

1.

MTE Side Mount Tape Scale Applicator Tool (Model Number: TSAT-SM-PPT)

The mounted application tool is needed for scale lengths greater than 1000mm. It is mounted in the same

fixture as the MTE Side Mount Sensor in the MTE Side Mount Bracket Kit (BK-SM-MTE) or customer

fabricated adaptor.

Tool orientation

arrows

Tool contact cylinder knob

Tape entry

channel

2.

TSAT-SM-PPT Side Mount Applicator Tool orientation to the “B” sensor mounting surface*.

The “B” MTE sensor benching surface is shown in the MTE interface drawing, along with the “D” tape scale

mounting edge. The corresponding “A” reference mounting surface of the Applicator Tool and Bracket Kit

adapter is shown below.

Tape Scale

Applicator Tool

Mounting Surface “A”

Mounting Surface for MTE Sensor/Bracket Kit and Tape Applicator Tool

MTE Side Mount

Bracket Kit,

Model Number:

BK-SM-MTE

*The MTE Side Mount Tape Scale Applicator Tool (model number: TSAT-SM-PPT), will only work

properly when mounted in the configuration shown in Step 2.

NOTE:

For best system performance, talc-free gloves or finger cots should be worn during all

steps of tape scale installation.

Thoroughly clean the scale mounting surface and reference edge using a cotton swab or

lint-free cloth dampened with isopropyl alcohol or acetone. Remove all dust and particles.

8.80±0.20

6.94±0.15

Bracket Kit

Mounting

Surface “A”

MTE Sensor

Page 20

CET™ Scale, MTE Side Mount Configuration

Installation By Mounted Applicator Tool

3.

Mount the Applicator Tool.

Mount the Applicator Tool in the Side Mount Bracket Kit/Sensor mounting holes. Rotate the knob that controls

the contact cylinder plunger to the UP position (See Step 6.). Use the red spacer (1.00mm) Z-height shim to

set up the approximate Z-height, to ensure proper Applicator Tool function.

4.

Note tape scale orientation with arrows and the “D” reference edge.

The applicator tool is shown mounted to the MTE/Bracket Kit Adaptor Sensor mount. Both Tape Scale arrows,

and Applicator Tool orientation arrows need to point in the same direction for proper configuration.

Also note, the “D” reference edge is determined from the MTE interface drawing. The tape scale orientation

arrows always point to the “D” reference edge. In the example below, the dotted red line shown is the

measured “D” reference edge. When the tape scale is finally installed, the orientation arrows will be pointing to

the calculated “D” reference edge.

In the example shown, the left side of the tape scale needs to go into the applicator tool entry channel first.

Tape Scale

orientation arrows

Tool orientation

arrows

D

Page 21

CET™ Scale, MTE Side Mount Configuration

Installation By Mounted Applicator Tool

5.

Peel off a short section of bottom adhesive backing approximately 50mm (2 inches).

Compact Encoder Tape (CET) Scales have 3 layers, blue protective film, steel scale, and adhesive backing.

Using a sharp tool or fingernail, initiate the peeling of the adhesive liner from the end of the tape scale that will

be inserted into the applicator tool entry channel.

6.

Turn Applicator Tool to the “Up” position and insert tape into applicator tool.

Rotate the knob that controls the contact cylinder plunger to the UP position. This allows you to insert the first

section of adhesive exposed tape, into the applicator tool.

Be sure that both the tape scale orientation arrows and the applicator tool arrows point in the same direction.

Tape Scale

orientation arrows

Tool

orientation arrows

Plunger in UP

position

Close-up of plunger knob in the UP

position. The position of the keyways

indicates UP or Down. Rotating the knob

will both move the plunger up or down.

Adhesive backing

liner

NOTE:

Do not peel the blue

protective film off at

this time.

Page 22

CET™ Scale, MTE Side Mount Configuration

Installation By Mounted Applicator Tool

7.

Insert a short section of tape scale into the tool, approximately 50mm (2 inches).

Insert the first short section of tape scale so that it emerges just past the plunger knob to a desired end

location. Press down on this exposed 3-5mm section of tape.

Plunger in the UP position

Press down on this

small section of tape

8.

Rotate the pressure plunger knob to the “Down” position.

Rotate the plunger knob so that the key-way notch is in the position shown.

Plunger knob in the

DOWN position

Close-up of plunger knob in the

DOWN position. Position of notch

indicates that the plunger is in the

DOWN position.

Page 23

CET™ Scale, MTE Side Mount Configuration

Installation By Mounted Applicator Tool

9.

Move the tool in a steady motion to apply the tape scale.

Push the applicator tool in the direction of tape application. Be sure to pull the adhesive backer out of the way

while the applicator is in motion.

Pull adhesive backer away from

tape applicator, while moving the

applicator tool.

Direction of motion of tape

applicator tool.

10.

Once the scale is applied to the mounting surface, and before the blue protective film is removed, it is

recommended that even pressure be applied over the entire tape scale length by sliding a glove or cot

protected finger across the scale. The applied pressure will ensure that the adhesive is evenly and

permanently set.

Page 24

CET™ Scale, MTE Side Mount Configuration

Installation By Mounted Applicator Tool

NOTE:

After removing the blue protective film, the scale is ready for use and will

perform to specification.

The encoder will not function properly with the blue protective film installed.

It must be removed for proper encoder operation.

11.

Peel off the blue protective film.

Start the peeling process using a sharp tool, being careful not to damage the scale. Pull off the remaining

blue protective film. Clean the tape scale using alcohol or acetone and a lint-free cotton cloth.

NOTE:

Make sure you have on finger cots

or talc-free gloves.

Page 25

End Cap Installation for CET™ Scales

Optional

1.

Epoxy Setup

• Mix the two-part epoxy and place it in a

syringe or on the end of a stick. Do not

use a cotton swab to apply the epoxy.

• Put epoxy on the end of the scale. Make

sure that the epoxy touches both the

mounting surface and the scale across

the width of the scale.

Only apply epoxy at the

ends of the tape scale. Do

not get any epoxy on the

tape scale in the

measuring area.

• Perform Step 2, immediately while the

epoxy is still in a liquid state.

2.

Installing the End Caps on the

Mounting Surface

• Remove the adhesive liner from end cap.

• Place the end cap on the top of the scale and

epoxy so that the end of the scale is in the

middle of the end cap.

• Press down lightly to ensure adhesion and

let cure for 24 hours.

Page 26

Final Cleaning, Inspection and Cure Time

Before using the encoder for servo control, clean the tape scale using alcohol or acetone and a lint-free cotton

cloth or swab. Finally, inspect the tape scale's surface for scratches, adhesive spots or smears in the

measuring length.

A cure time of 12 hours is required for the tape scale's pressure sensitive adhesive to achieve the best

performance and reliability.

Reworking to Correct Mistakes

Once installed, the tape scale cannot be moved or removed and reinstalled. Reworking will require removal

and discarding of the old tape and installation of a new one.

Page 27

Contacting MicroE

MicroE Systems is a world leader in optical encoder technology with

offices in major industrial centers around the globe.

To learn more about MicroE Systems products, visit:

www.microesystems.com.

Our products have been used by thousands of companies worldwide to

solve a wide range of motion control applications. Our advanced

encoder technology and application expertise has driven innovations in

the design of machinery, equipment and instrumentation in many

industries, including medical, industrial, robotics, automation, metrology,

semiconductor manufacturing, packaging equipment, entertainment,

energy, military, and scientific research.

MicroE Systems

125 Middlesex Turnpike

Bedford, MA 01730 USA

T 781-266-5700

F 781-266-5112

info@microesys.com

www.microesystems.com

© 2015 MicroE Systems

Loading...

Loading...