Microchip Technology Inc PIC16C62B-20I-SO, PIC16C62B-20I-SP, PIC16C72A-04I-SO, PIC16C72A-20-SO, PIC16C72A-20I-SO Datasheet

...

1998 Microchip Technology Inc.

Preliminary

DS35008A-page 1

M

Microcontroller Core Features:

• High-performance RISC CPU

• Only 35 single word instructions to learn

• All single cycle instructions except for program

branches which are two cycle

• Operating speed: DC - 20 MHz clock input

DC - 200 ns instruction cycle

• 2K x 14 words of Program Memory,

128 x 8 bytes of Data Memory (RAM)

• Interrupt capability

(up to 7 internal/external interrupt sources)

• Eight level deep hardware stack

• Direct, indirect, and relative addressing modes

• Power-on Reset (POR)

• Power-up Timer (PWRT) and

Oscillator Start-up Timer (OST)

• Watchdog Timer (WDT) with its own on-chip RC

oscillator for reliable operation

• Brown-out detection circuitry for

Brown-out Reset (BOR)

• Programmable code-protection

• Power saving SLEEP mode

• Selectable oscillator options

• Low-power, high-speed CMOS EPROM

technology

• Fully static design

• In-Circuit Serial Programming

• Wide operating voltage range: 2.5V to 5.5V

• High Sink/Source Current 25/25 mA

• Commercial, Industrial and Extended temperature

ranges

• Low-power consumption:

- < 2 mA @ 5V, 4 MHz

- 22.5 µ A typical @ 3V, 32 kHz

- < 1 µ A typical standby current

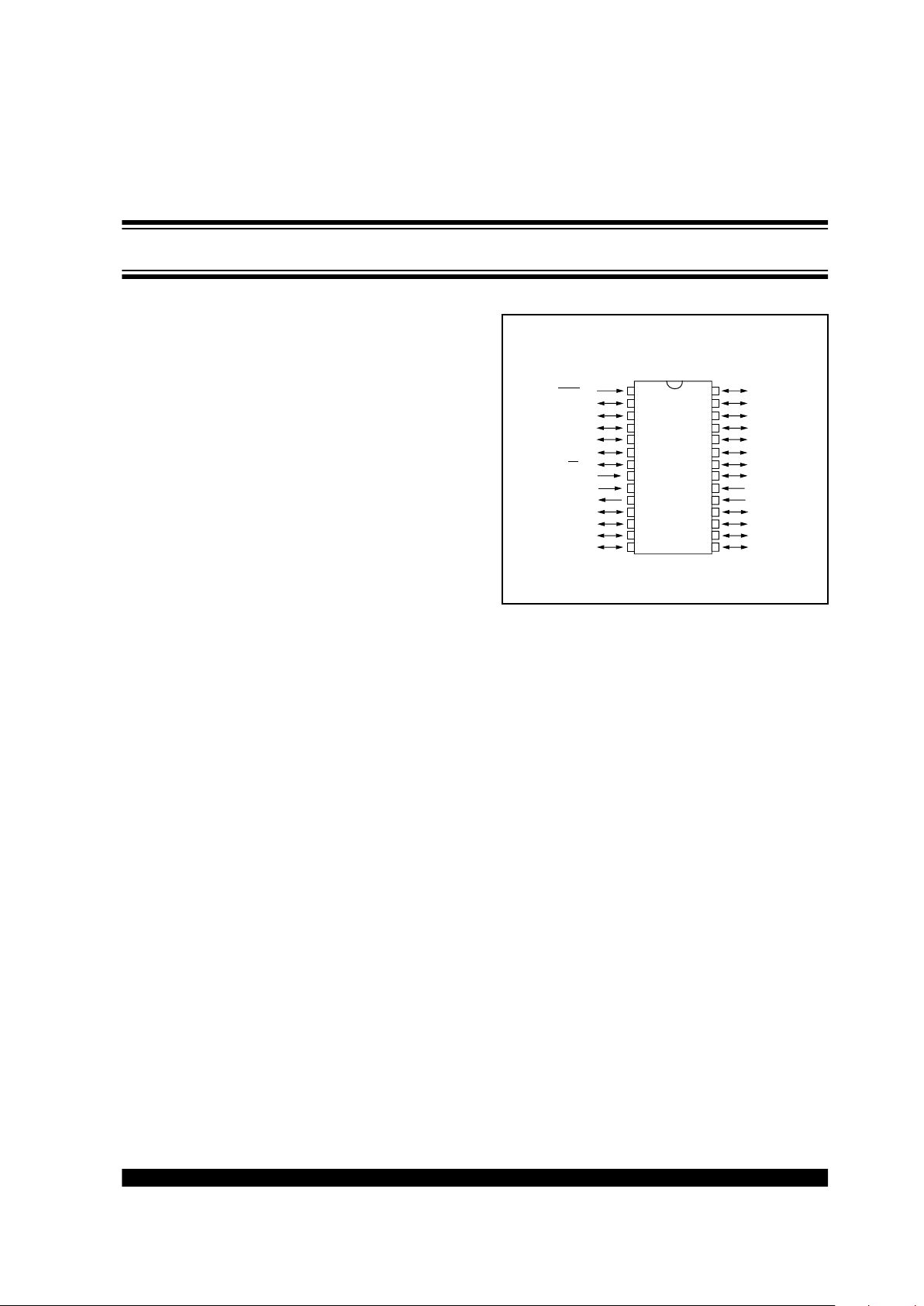

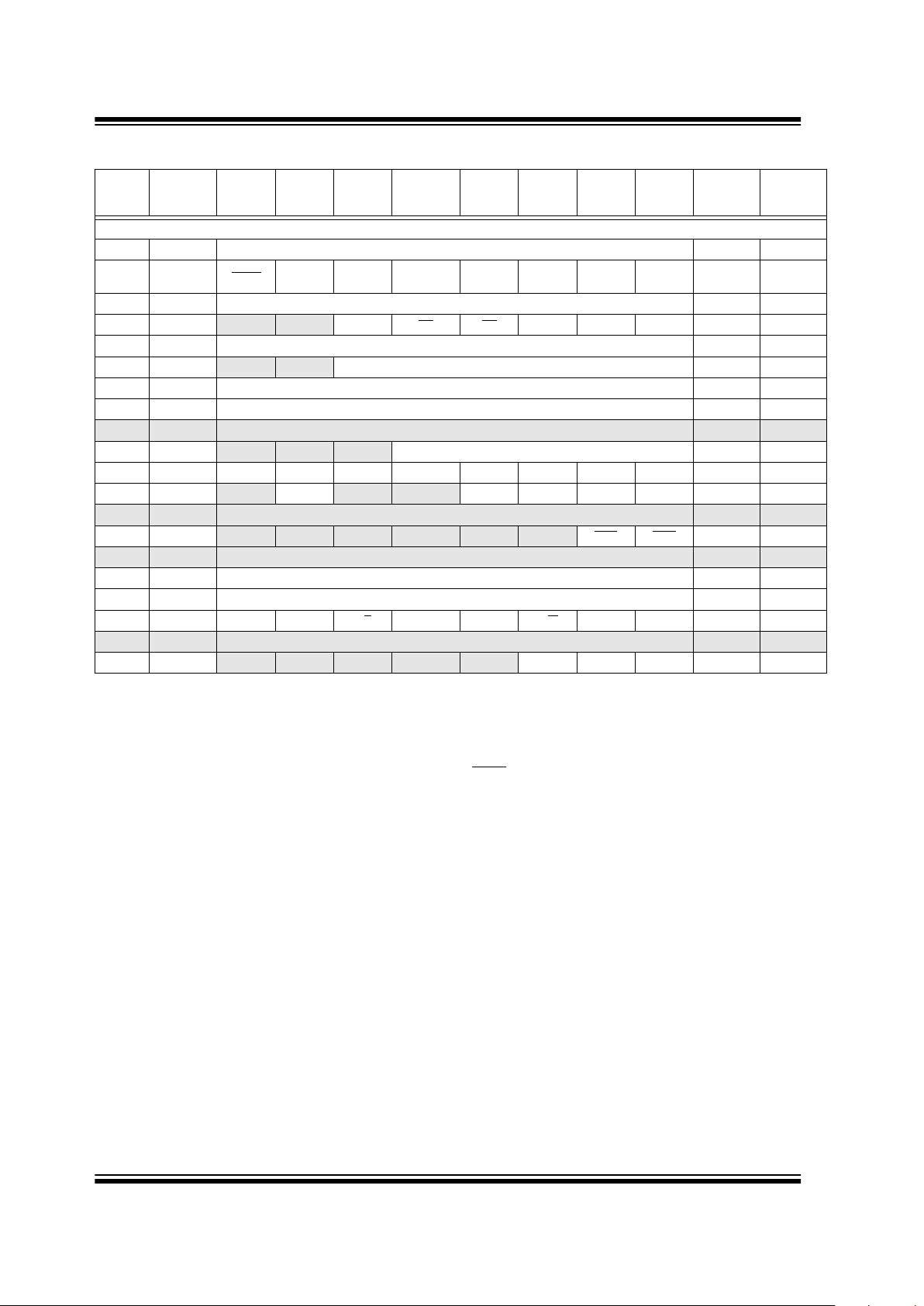

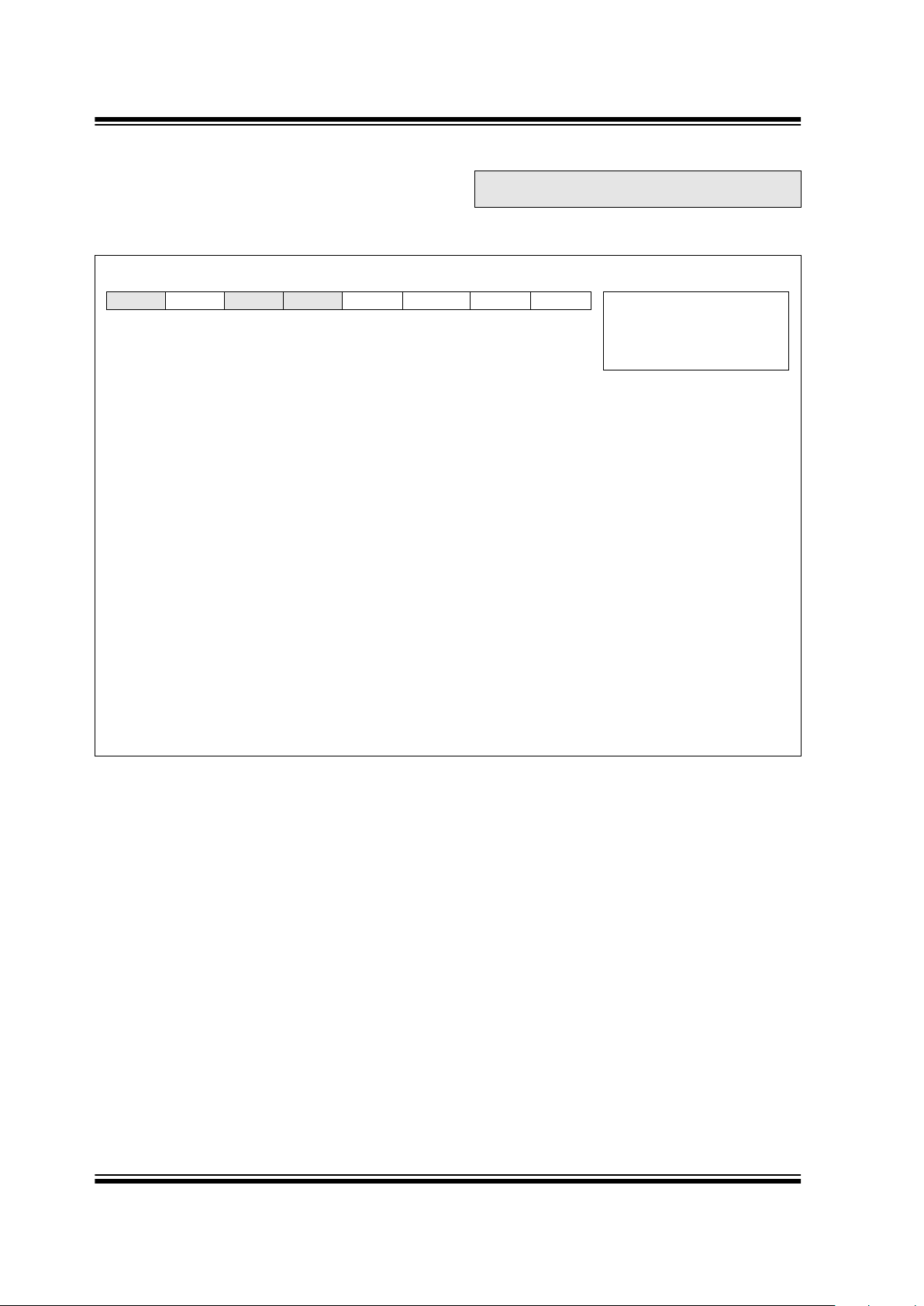

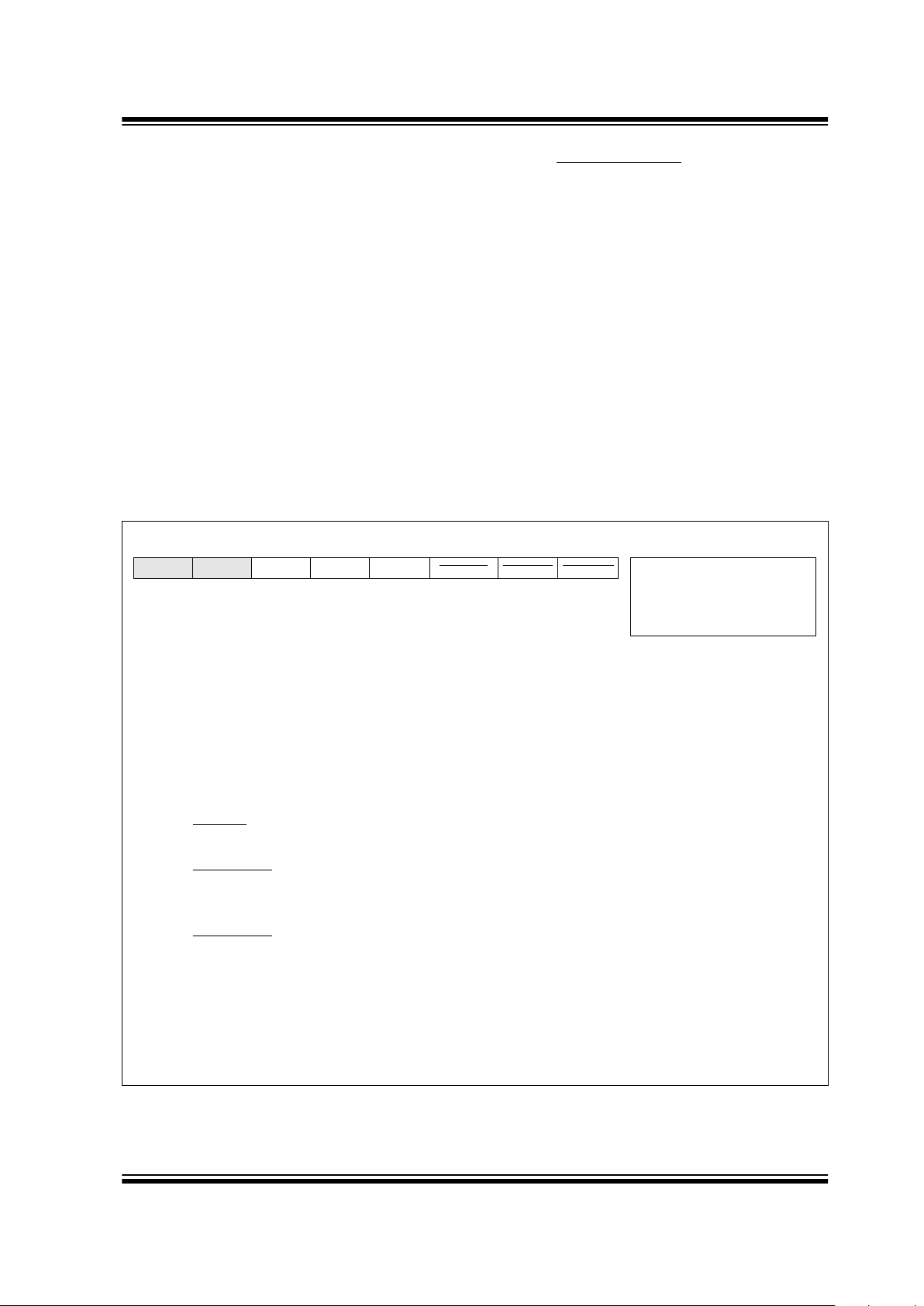

Pin Diagram

Peripheral Features:

• Timer0: 8-bit timer/counter with 8-bit prescaler

• Timer1: 16-bit timer/counter with prescaler,

can be incremented during sleep via external

crystal/clock

• Timer2: 8-bit timer/counter with 8-bit period

register, prescaler and postscaler

• Capture, Compare, PWM module

• Capture is 16-bit, max. resolution is 12.5 ns,

Compare is 16-bit, max. resolution is 200 ns,

PWM maximum resolution is 10-bit

• 8-bit multi-channel Analog-to-Digital converter

• Synchronous Serial Port (SSP) with Enhanced

SPI

and I

2

C

PIC16C72A

MCLR/VPP

RA0/AN0

RA1/AN1

RA2/AN2

RA3/AN3/VREF

RA4/T0CKI

RA5/SS/AN4

V

SS

OSC1/CLKIN

OSC2/CLKOUT

RC0/T1OSO/T1CKI

RC1/T1OSI

RC2/CCP1

RC3/SCK/SCL

RB7

RB6

RB5

RB4

RB3

RB2

RB1

RB0/INT

VDD

VSS

RC7

RC6

RC5/SDO

RC4/SDI/SDA

• 1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

SDIP, SOIC, SSOP, Windowed CERDIP

PIC16C62B/72A

28-Pin 8-Bit CMOS Microcontrollers

PIC16C62B/72A

DS35008A-page 2

Preliminary

1998 Microchip Technology Inc.

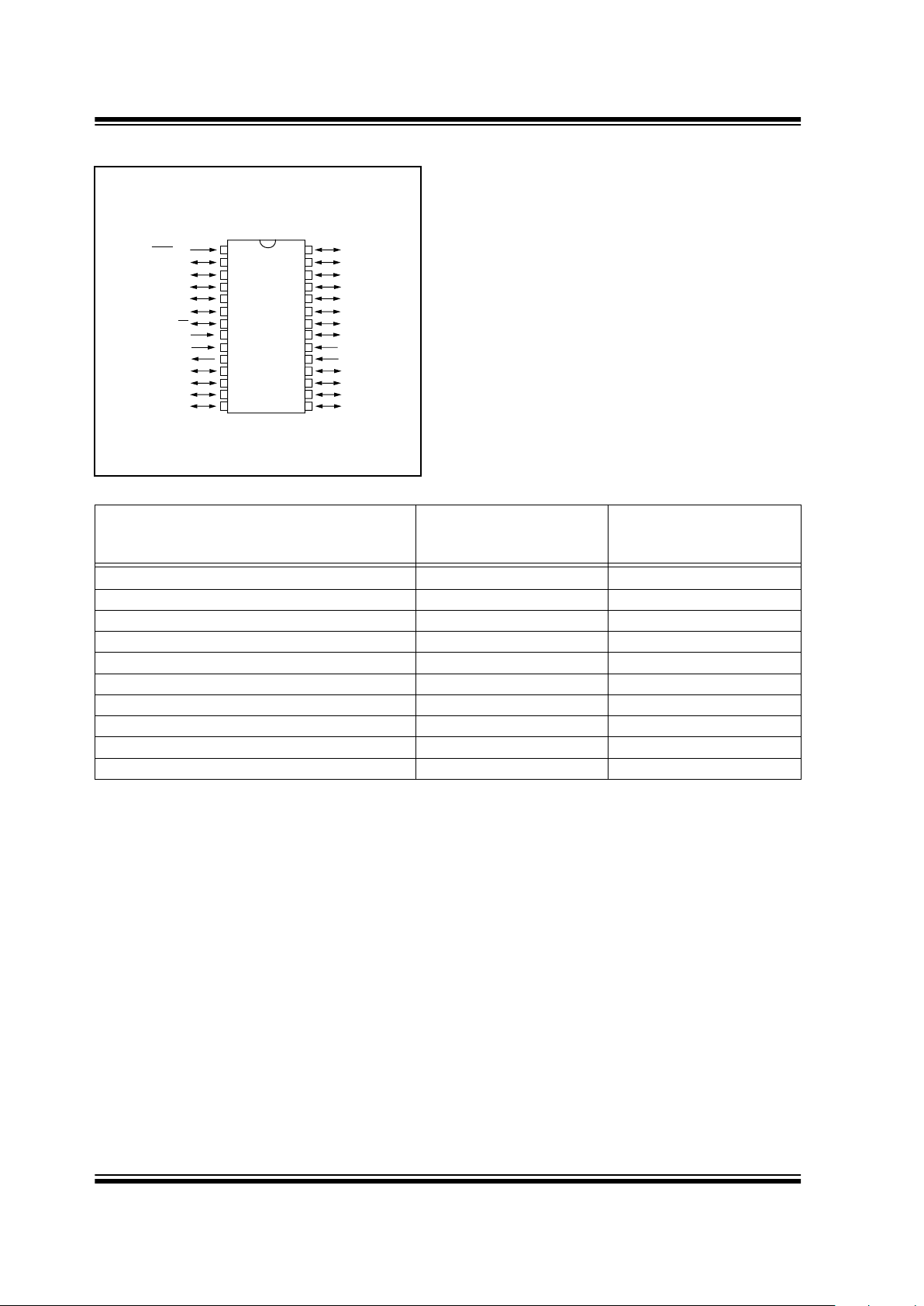

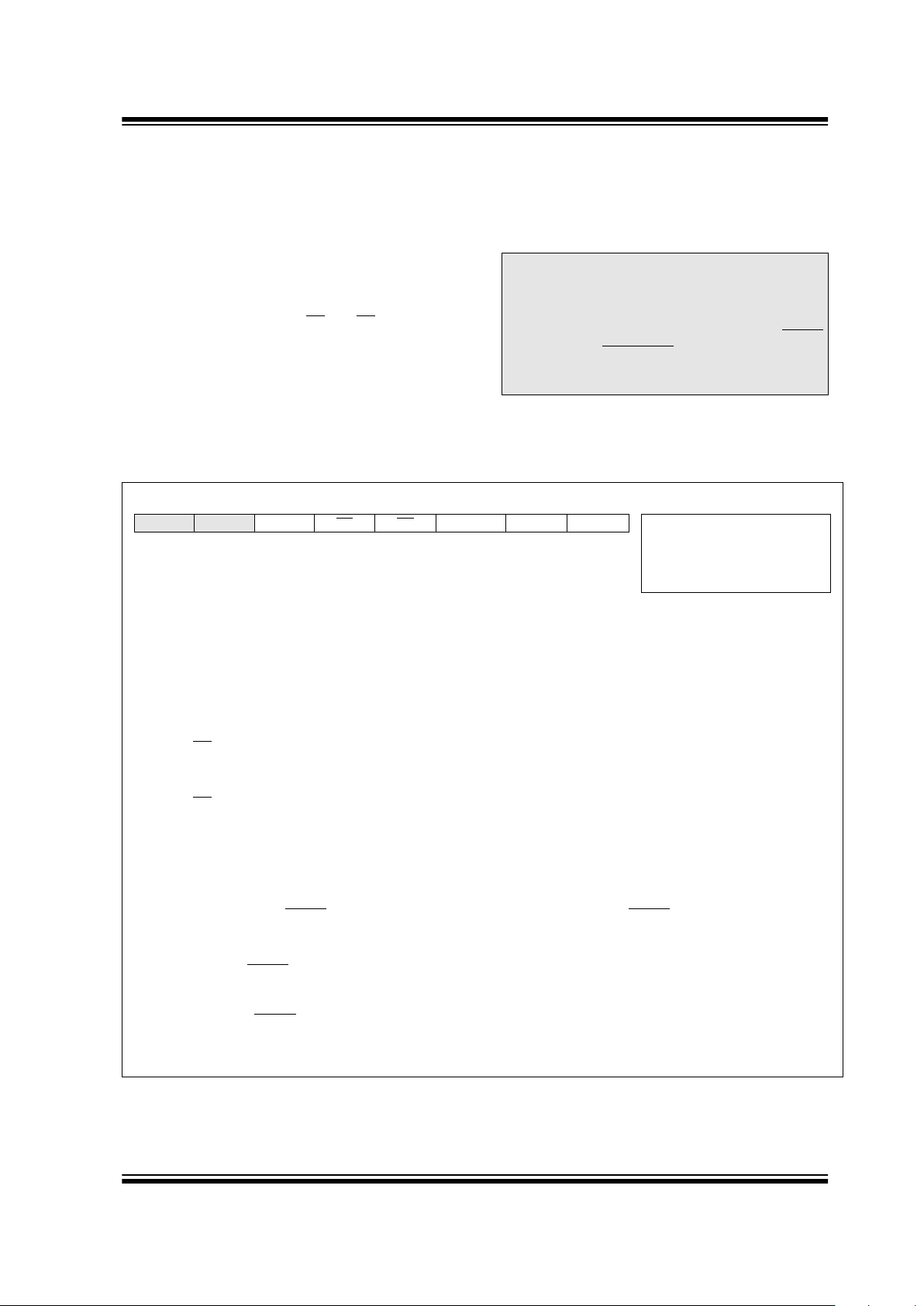

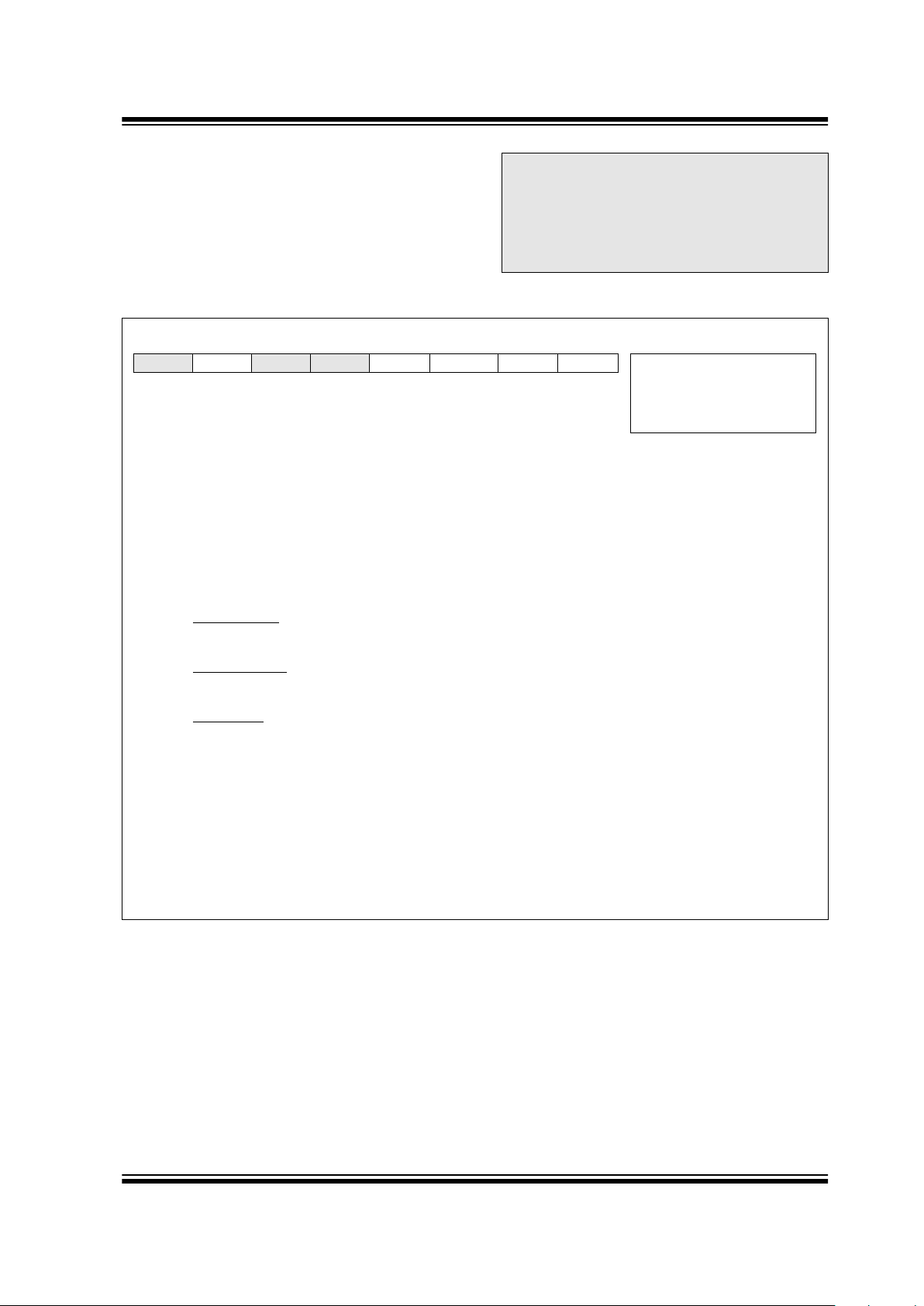

Pin Diagrams

PIC16C62B

MCLR/VPP

RA0

RA1

RA2

RA3

RA4/T0CKI

RA5/SS

VSS

OSC1/CLKIN

OSC2/CLKOUT

RC0/T1OSO/T1CKI

RC1/T1OSI

RC2/CCP1

RC3/SCK/SCL

RB7

RB6

RB5

RB4

RB3

RB2

RB1

RB0/INT

VDD

VSS

RC7

RC6

RC5/SDO

RC4/SDI/SDA

• 1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

SDIP, SOIC, SSOP, Windowed CERDIP

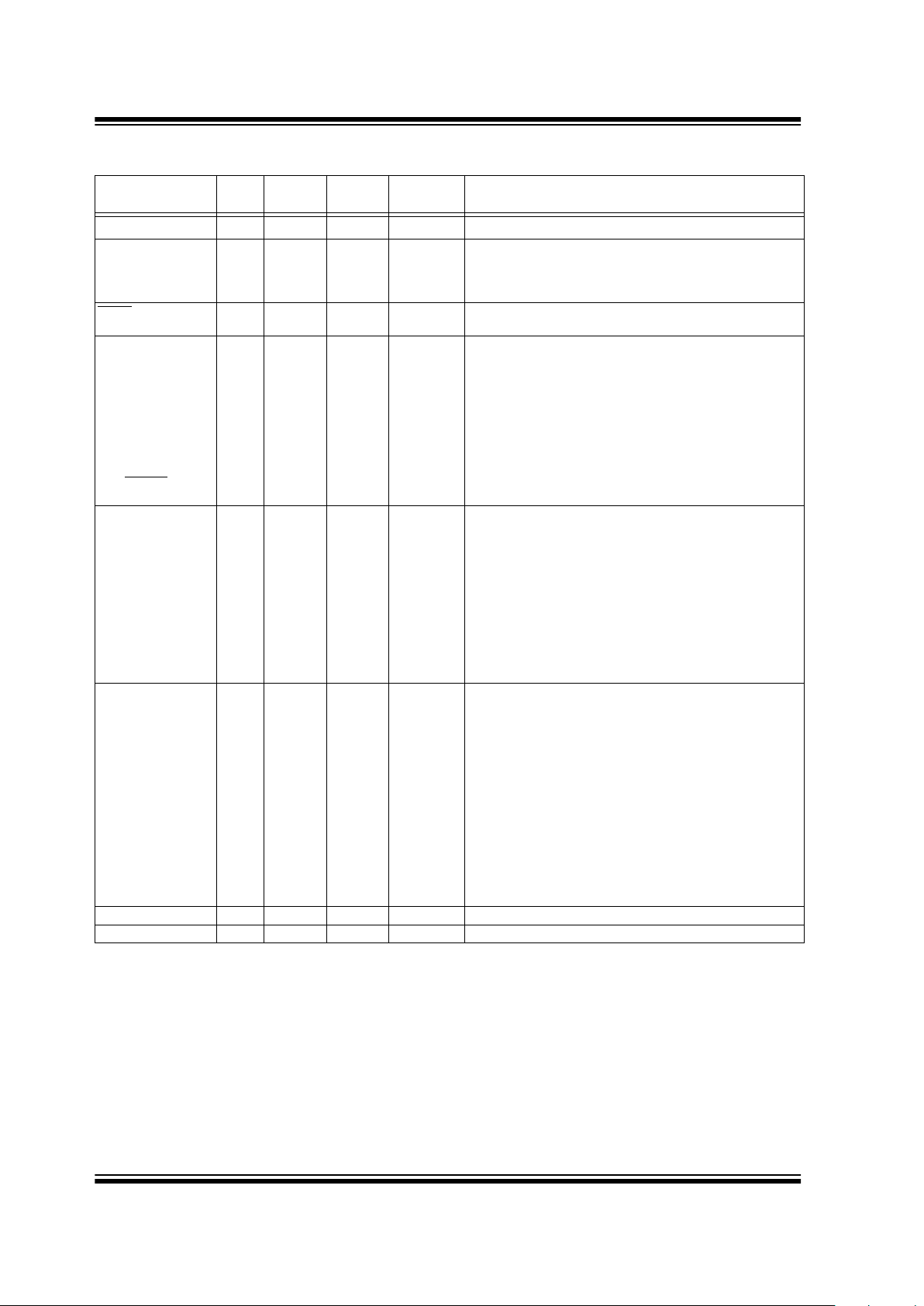

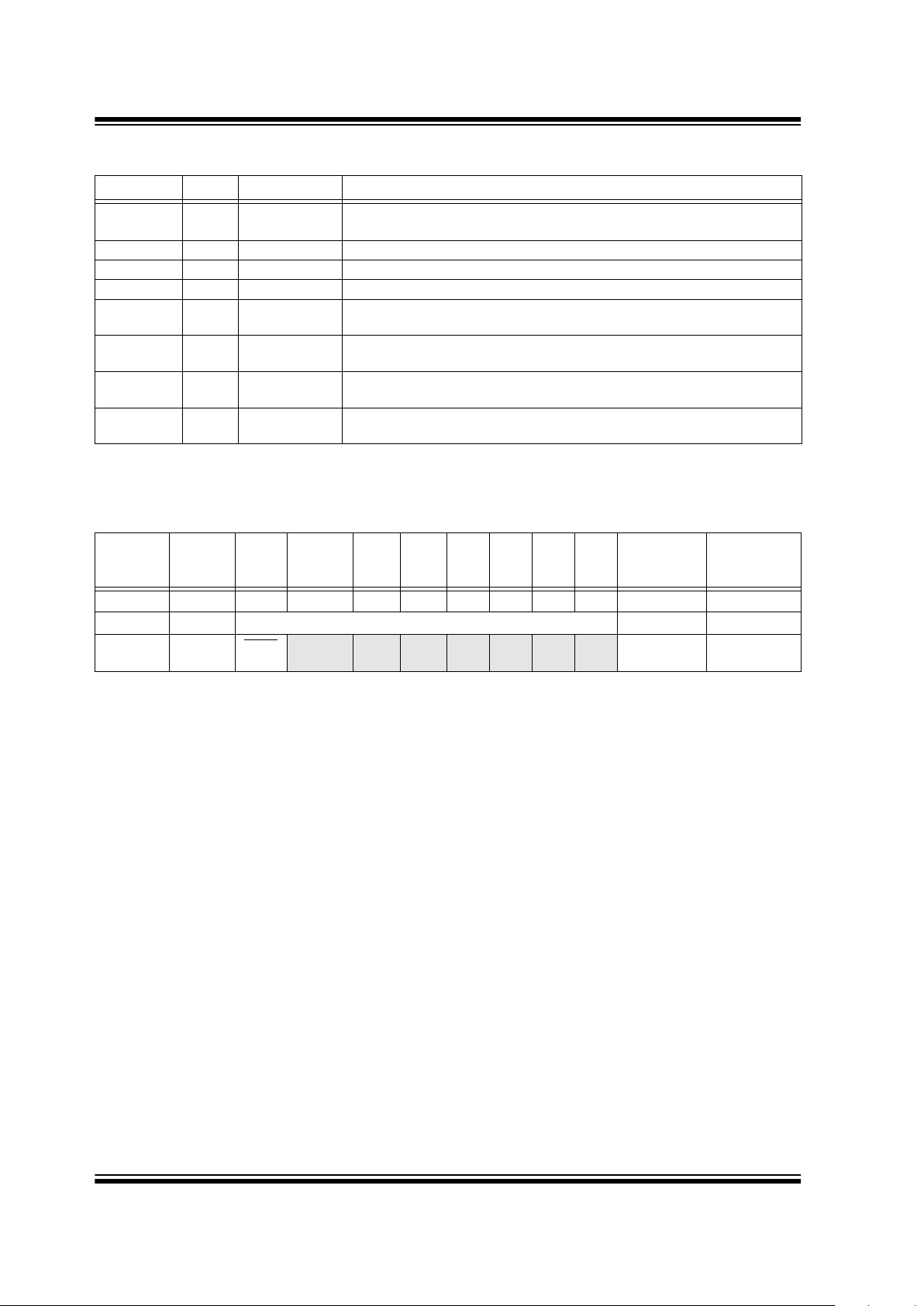

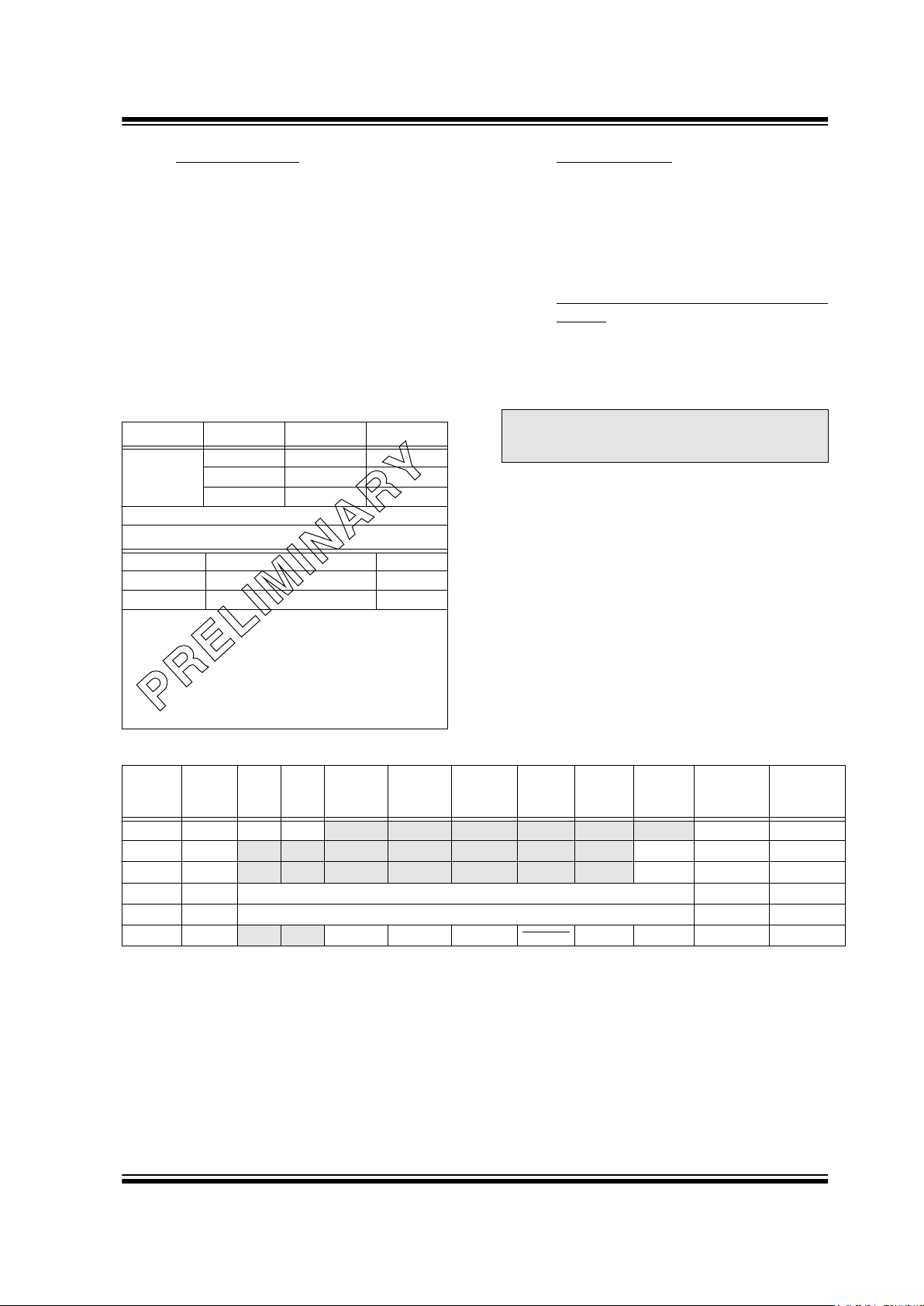

Key Features

PICmicro™ Mid-Range Reference Manual

(DS33023)

PIC16C62B PIC16C72A

Operating Frequency DC - 20 MHz DC - 20 MHz

Resets (and Delays) POR, BOR (PWRT, OST) POR, BOR (PWRT, OST)

Program Memory (14-bit words) 2K 2K

Data Memory (bytes) 128 128

Interrupts 6 7

I/O Ports Ports A,B,C Ports A,B,C

Timers 3 3

Capture/Compare/PWM modules 1 1

Serial Communications SSP SSP

8-bit Analog-to-Digital Module — 5 input channels

PIC16C62B/72A

1998 Microchip Technology Inc.

Preliminary

DS35008A-page 3

Table of Contents

1.0 Device Overview....................................................................................................................................................5

2.0 Memory Organization............................................................................................................................................7

3.0 I/O Ports .............................................................................................................................................................. 19

4.0 Timer0 Module.....................................................................................................................................................25

5.0 Timer1 Module.....................................................................................................................................................27

6.0 Timer2 Module.....................................................................................................................................................31

7.0 Capture/Compare/PWM (CCP) Module(s)..........................................................................................................33

8.0 Synchronous Serial Port (SSP) Module .............................................................................................................. 39

9.0 Analog-to-Digital Converter (A/D) Module...........................................................................................................49

10.0 Special Features of the CPU...............................................................................................................................55

11.0 Instruction Set Summary .....................................................................................................................................69

12.0 Development Support..........................................................................................................................................71

13.0 Electrical Characteristics .....................................................................................................................................75

14.0 DC and AC Characteristics Graphs and Tables..................................................................................................95

15.0 Packaging Information.........................................................................................................................................97

Appendix A: Revision History.....................................................................................................................................103

Appendix B: Conversion Considerations...................................................................................................................103

Appendix C: Migration from Base-line to Mid-Range Devices...................................................................................104

Index ........................................................................................................................................................................... 105

On-Line Support.......................................................................................................................................................... 109

Reader Response.......................................................................................................................................................110

PIC16C62B/72A Product Identification System..........................................................................................................111

To Our Valued Customers

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please check our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its liter ature number found on the bottom outside corner of any page.

The last character of the literature number is the version number. e.g., DS30000A is version A of document DS30000.

Errata

An errata sheet may exist for current devices, describing minor operational differences (from the data sheet) and recommended

workarounds. As de vice/documentation issues become known to us , we will publish an err ata sheet. The err ata will specify the revision of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip .com

• Your local Microchip sales office (see last page)

• The Microchip Corporate Literature Center; U.S. FAX: (602) 786-7277

When contacting a sales office or the literature center, please specify which device, revision of silicon and data sheet (include lit-

erature number) you are using.

Corrections to this Data Sheet

We constantly strive to improve the quality of all our products and documentation. We have spent a great deal of time to ensure

that this document is correct. However, w e realize that w e may have missed a fe w things . If you find any information that is missing

or appears in error, please:

• Fill out and mail in the reader response form in the back of this data sheet.

• E-mail us at webmaster@microchip.com.

We appreciate your assistance in making this a better document.

PIC16C62B/72A

DS35008A-page 4

Preliminary

1998 Microchip Technology Inc.

NOTES:

PIC16C62B/72A

1998 Microchip Technology Inc.

Preliminary

DS35008A-page 5

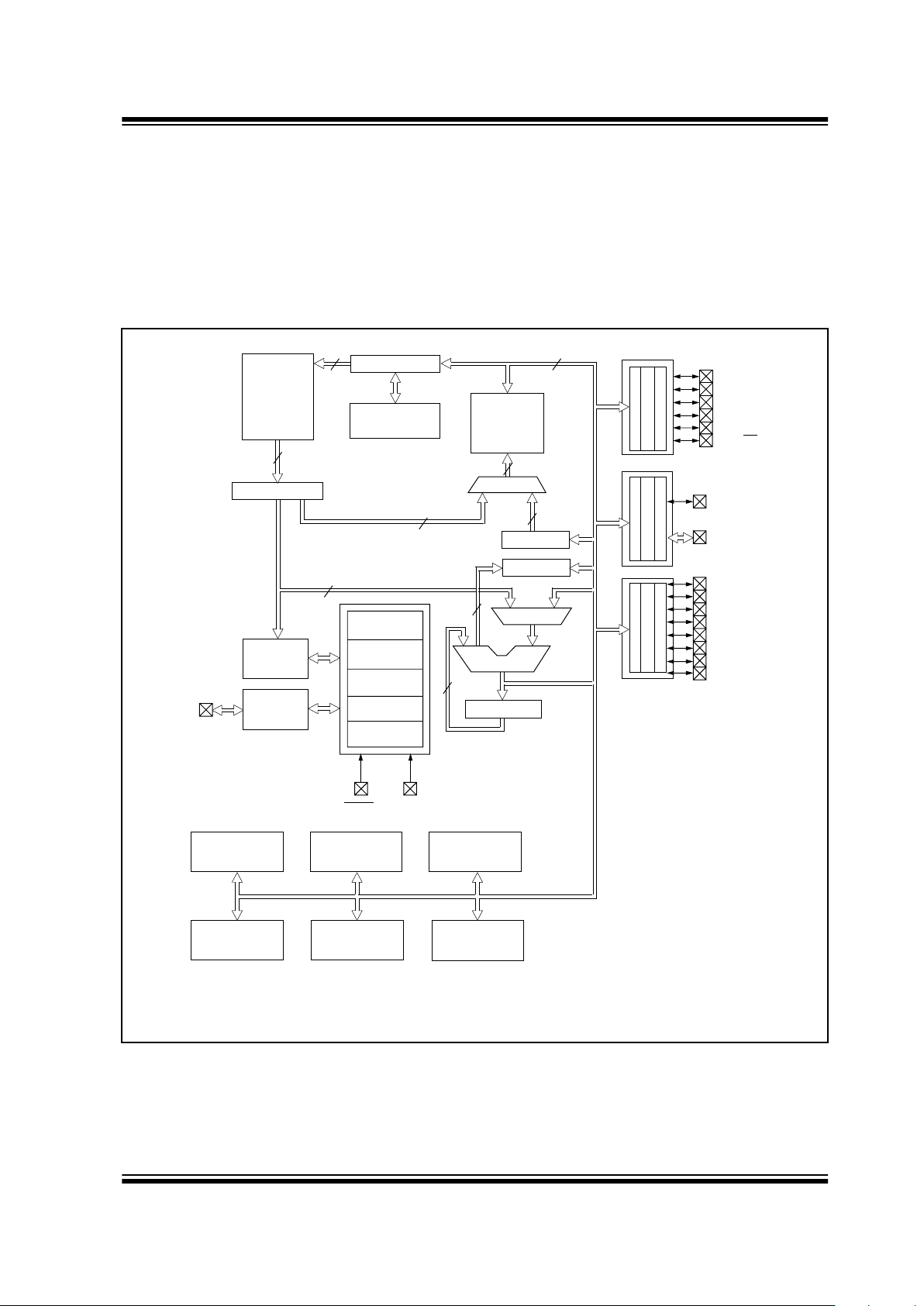

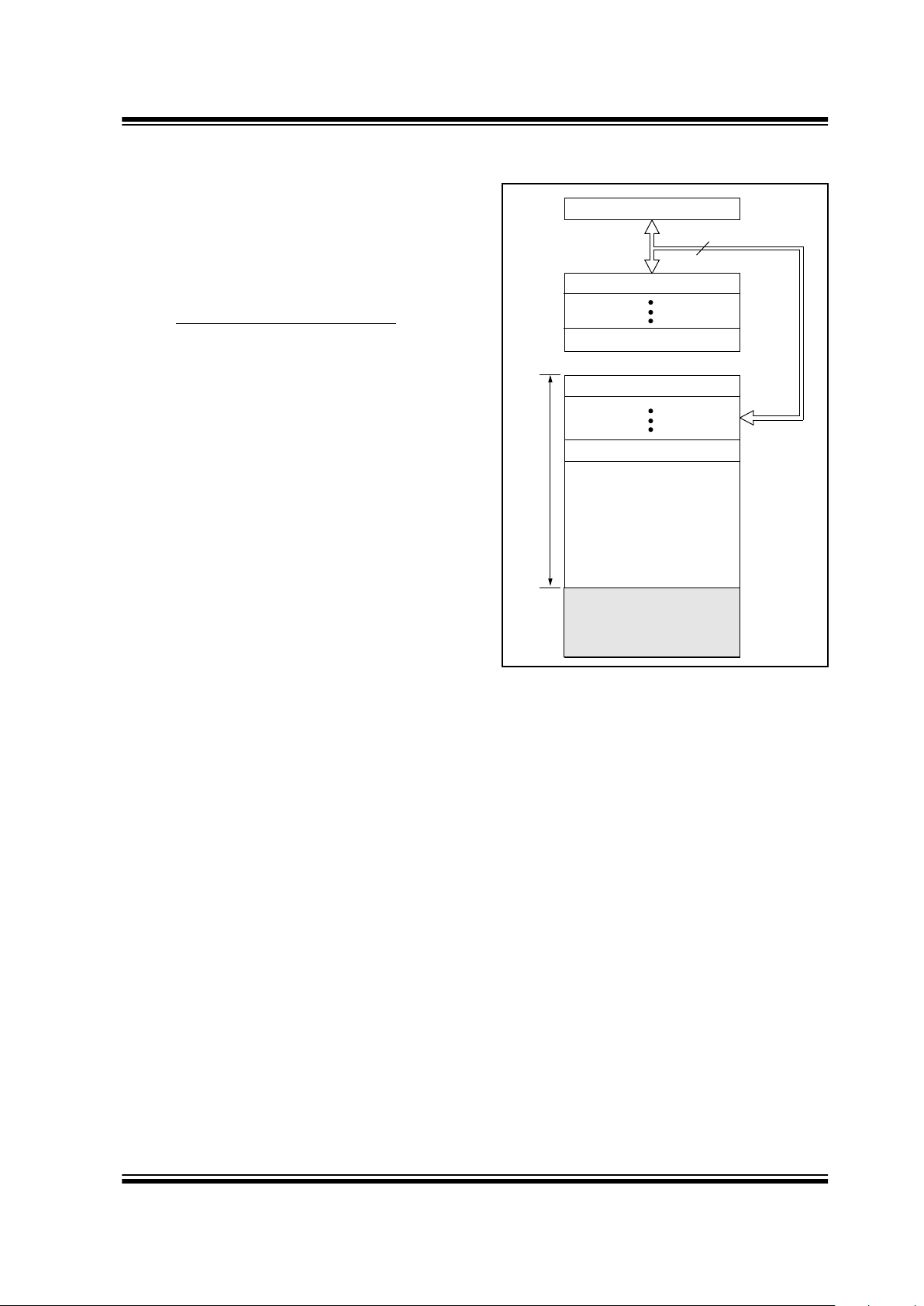

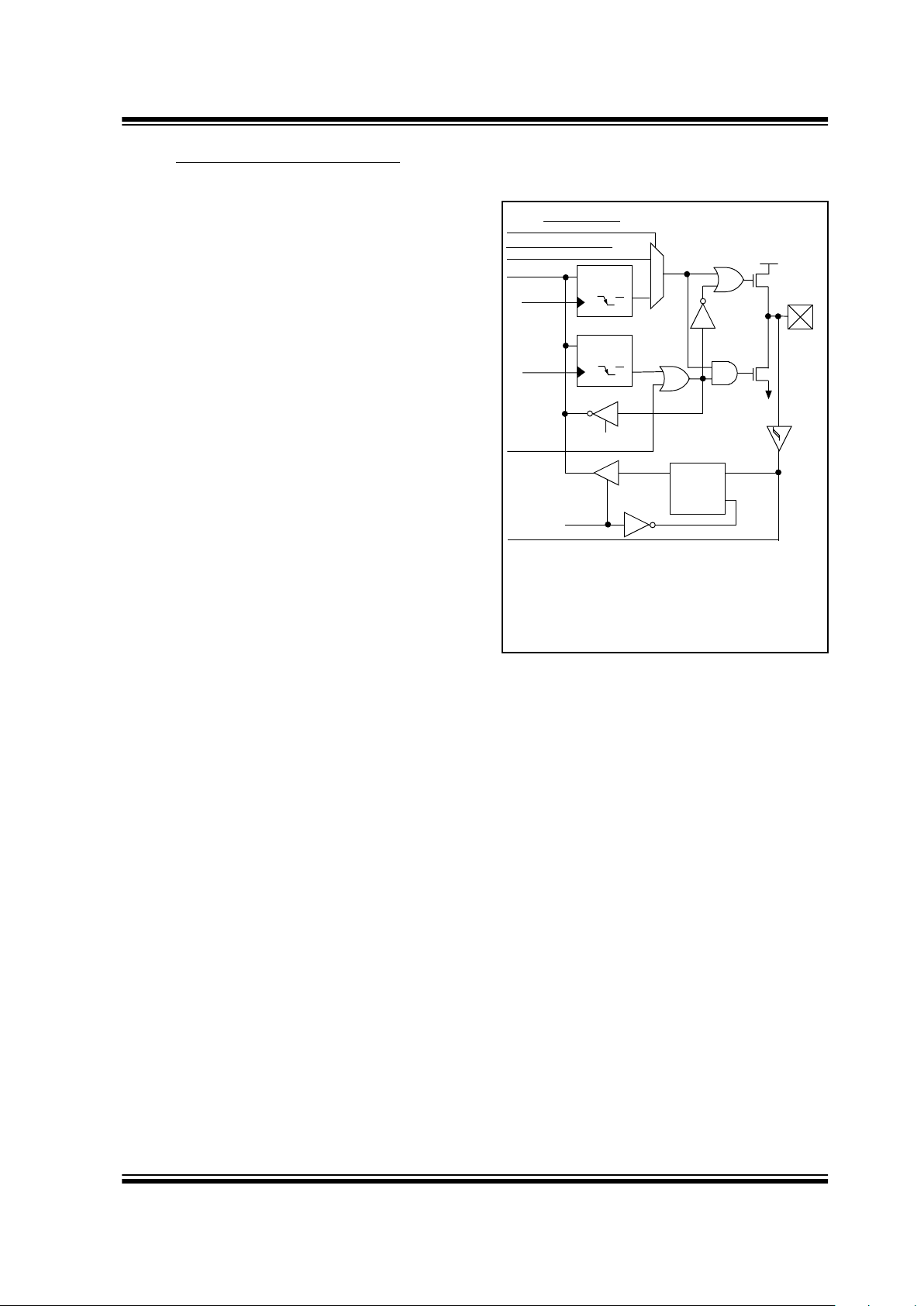

1.0 DEVICE OVERVIEW

This document contains device-specific information.

Additional information may be found in the PICmicro™

Mid-Range Reference Manual, (DS33023), which may

be obtained from your local Microchip Sales Representative or downloaded from the Microchip website. The

Reference Manual should be considered a complementary document to this data sheet, and is highly rec-

ommended reading for a better understanding of the

device architecture and operation of the peripheral

modules.

There are two devices (PIC16C62B, PIC16C72A) covered by this datasheet. The PIC16C62B does not have

the A/D module implemented.

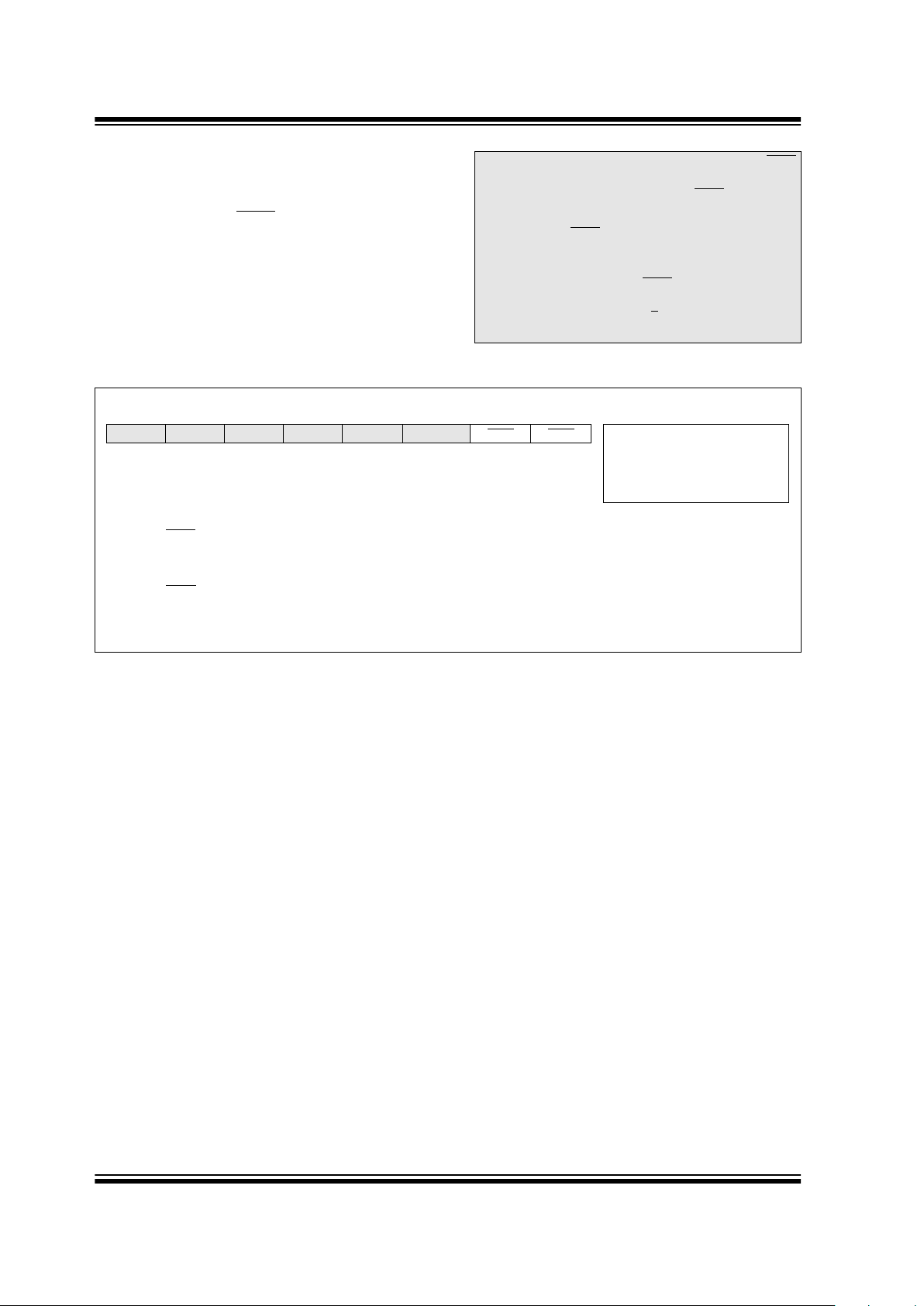

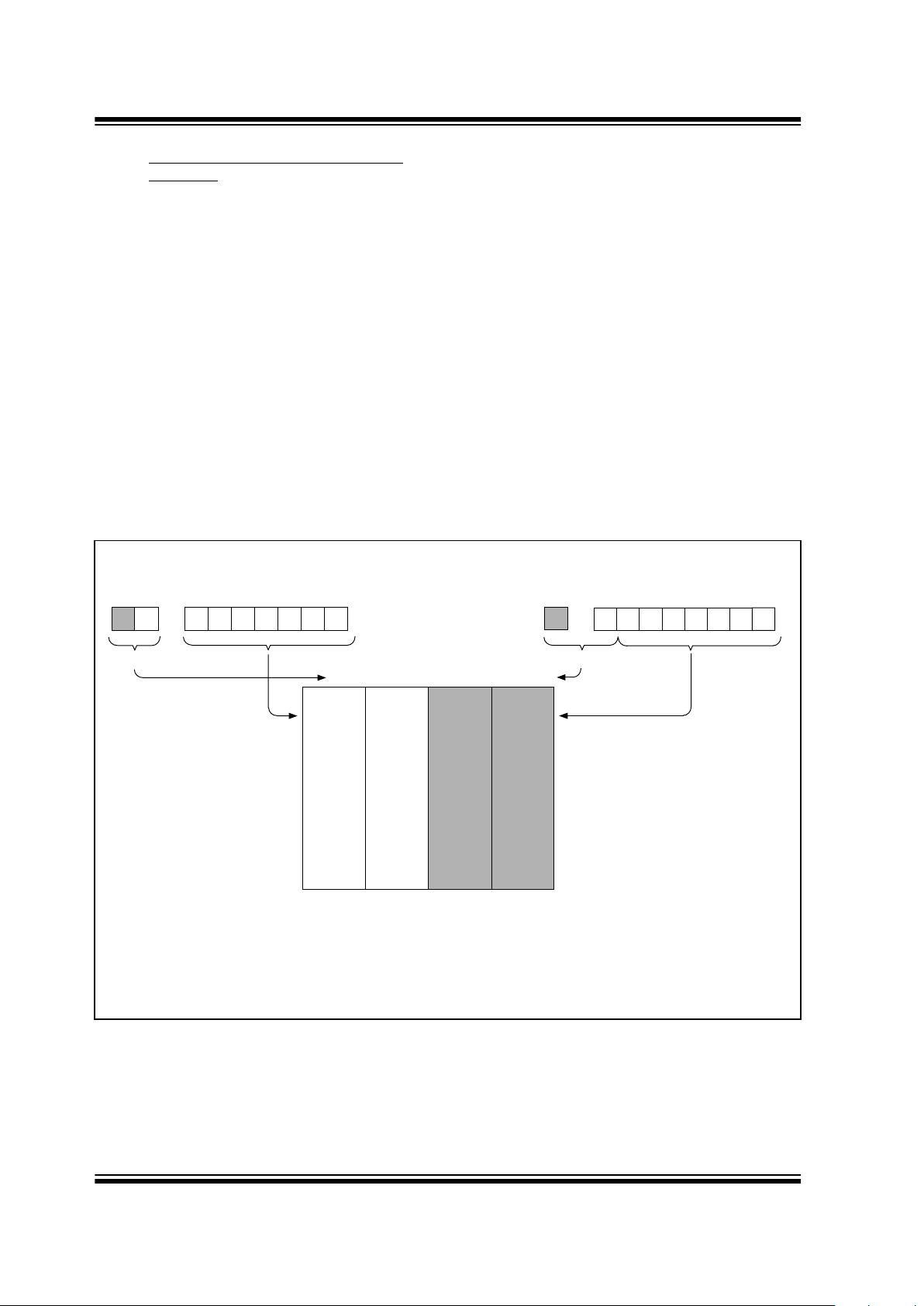

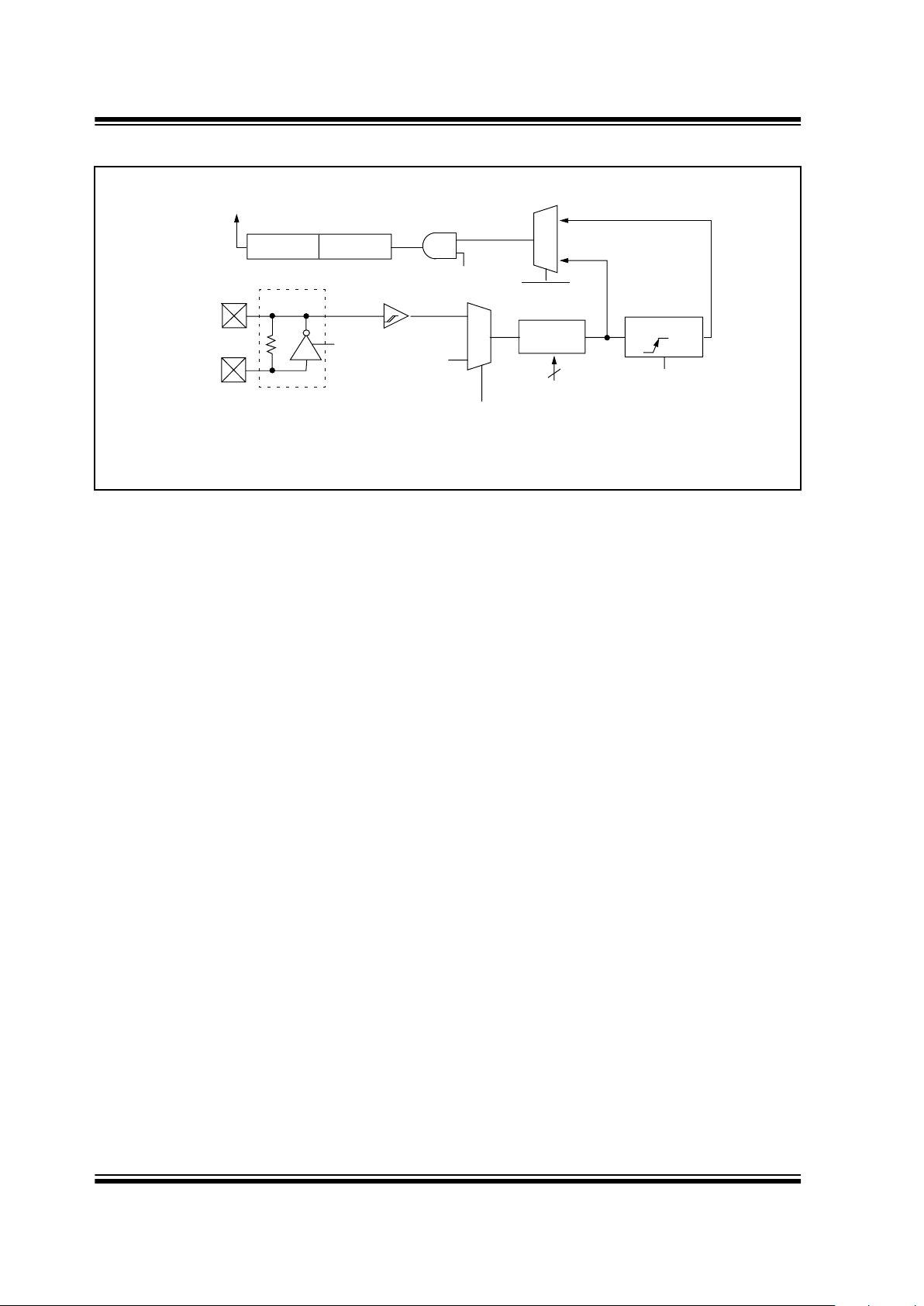

Figure 1-1 is the block diagram for both devices. The

pinouts are listed in Table 1-1.

FIGURE 1-1: PIC16C62B/PIC16C72A BLOCK DIAGRAM

EPROM

Program

Memory

13

Data Bus

8

14

Program

Bus

Instruction reg

Program Counter

8 Level Stack

(13-bit)

RAM

File

Registers

Direct Addr

7

RAM Addr

(1)

9

Addr MUX

Indirect

Addr

FSR reg

STATUS reg

MUX

ALU

W reg

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

Instruction

Decode &

Control

Timing

Generation

OSC1/CLKIN

OSC2/CLKOUT

MCLR

VDD, VSS

PORTA

PORTB

PORTC

RB0/INT

RB7:RB1

RC0/T1OSO/T1CKI

RC1/T1OSI

RC2/CCP1

RC3/SCK/SCL

RC4/SDI/SDA

RC5/SDO

RC6

RC7

8

8

Brown-out

Reset

Note 1: Higher order bits are from the STATUS register.

2: The A/D module is not available on the PIC16C62B.

CCP1

Synchronous

A/D

(2)

Timer0 Timer1 Timer2

Serial Port

RA4/T0CKI

RA5/SS

/AN4

(2)

RA3/AN3/VREF

(2)

RA2/AN2

(2)

RA1/AN1

(2)

RA0/AN0

(2)

8

3

2K x 14

128 x 8

PIC16C62B/72A

DS35008A-page 6

Preliminary

1998 Microchip Technology Inc.

TABLE 1-1 PIC16C62B/PIC16C72A PINOUT DESCRIPTION

Pin Name

DIP

Pin#

SOIC

Pin#

I/O/P

Type

Buffer

Type

Description

OSC1/CLKIN 9 9 I

ST/CMOS

(3)

Oscillator crystal input/external clock source input.

OSC2/CLKOUT 10 10 O — Oscillator crystal output. Connects to crystal or resonator in

crystal oscillator mode. In RC mode, the OSC2 pin outputs

CLKOUT which has 1/4 the frequency of OSC1, and denotes

the instruction cycle rate.

MCLR

/V

PP

1 1 I/P ST Master clear (reset) input or programming voltage input. This

pin is an active low reset to the device.

PORTA is a bi-directional I/O port.

RA0/AN0

(4)

2 2 I/O TTL RA0 can also be analog input0

RA1/AN1

(4)

3 3 I/O TTL RA1 can also be analog input1

RA2/AN2

(4)

4 4 I/O TTL RA2 can also be analog input2

RA3/AN3/V

REF

(4)

5 5 I/O TTL RA3 can also be analog input3 or analog reference voltage

RA4/T0CKI 6 6 I/O ST RA4 can also be the clock input to the Timer0 module.

Output is open drain type.

RA5/SS/AN4

(4)

7 7 I/O TTL RA5 can also be analog input4 or the slave select for the

synchronous serial port.

PORTB is a bi-directional I/O port. PORTB can be software

programmed for internal weak pull-up on all inputs.

RB0/INT 21 21 I/O TTL/ST

(1)

RB0 can also be the external interrupt pin.

RB1 22 22 I/O TTL

RB2 23 23 I/O TTL

RB3 24 24 I/O TTL

RB4 25 25 I/O TTL Interrupt on change pin.

RB5 26 26 I/O TTL Interrupt on change pin.

RB6 27 27 I/O TTL/ST

(2)

Interrupt on change pin. Serial programming clock.

RB7 28 28 I/O TTL/ST

(2)

Interrupt on change pin. Serial programming data.

PORTC is a bi-directional I/O port.

RC0/T1OSO/T1CKI 11 11 I/O ST RC0 can also be the Timer1 oscillator output or Timer1

clock input.

RC1/T1OSI 12 12 I/O ST RC1 can also be the Timer1 oscillator input.

RC2/CCP1 13 13 I/O ST RC2 can also be the Capture1 input/Compare1 out-

put/PWM1 output.

RC3/SCK/SCL 14 14 I/O ST RC3 can also be the synchronous serial clock input/output

for both SPI and I

2

C modes.

RC4/SDI/SDA 15 15 I/O ST RC4 can also be the SPI Data In (SPI mode) or

data I/O (I

2

C mode).

RC5/SDO 16 16 I/O ST RC5 can also be the SPI Data Out (SPI mode).

RC6 17 17 I/O ST

RC7 18 18 I/O ST

V

SS

8, 19 8, 19 P — Ground reference for logic and I/O pins.

V

DD

20 20 P — Positive supply for logic and I/O pins.

Legend: I = input O = output I/O = input/output P = power

— = Not used TTL = TTL input ST = Schmitt Trigger input

Note 1: This buffer is a Schmitt Trigger input when configured as the external interrupt.

2: This buffer is a Schmitt Trigger input when used in serial programming mode.

3: This buffer is a Schmitt Trigger input when configured in RC oscillator mode and a CMOS input otherwise.

4: The A/D module is not available on the PIC16C62B.

PIC16C62B/72A

1998 Microchip Technology Inc.

Preliminary

DS35008A-page 7

2.0 MEMORY ORGANIZATION

There are two memory blocks in each of these

PICmicros. Each block (Program Memory and Data

Memory) has its own bus so that concurrent access

can occur.

Additional information on device memory may be found

in the PICmicro Mid-Range Reference Manual,

(DS33023).

2.1 Pr

ogram Memory Organization

The PIC16C62B/72A PICmicros have a 13-bit program

counter capable of addressing an 8K x 14 program

memory space. Each device has 2K x 14 w ords of program memory. Accessing a location above the physically implemented address will cause a wraparound.

The reset vector is at 0000h and the interrupt vector is

at 0004h.

FIGURE 2-1: PROGRAM MEMORY MAP

AND STACK

PC<12:0>

13

0000h

0004h

0005h

07FFh

0800h

1FFFh

Stack Level 1

Stack Level 8

Reset V ector

Interrupt Vector

On-chip Program

Memory

CALL, RETURN

RETFIE, RETLW

User Memory

Space

PIC16C62B/72A

DS35008A-page 8

Preliminary

1998 Microchip Technology Inc.

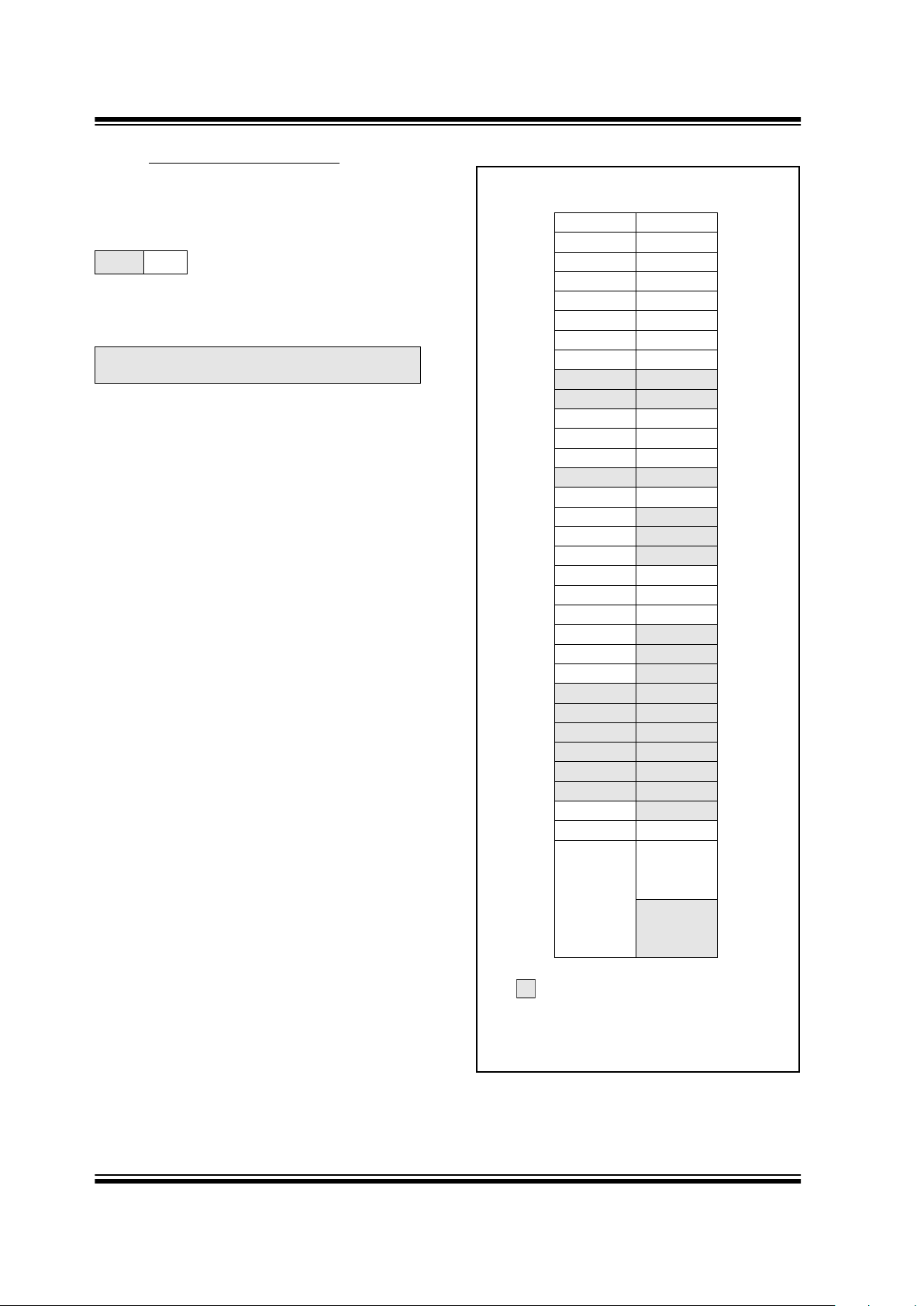

2.2 Data Memory Organization

The data memory is partitioned into multiple banks

which contain the General Purpose Registers and the

Special Function Registers. Bits RP1 and RP0 are the

bank select bits.

= 00 → Bank0

= 01 → Bank1

= 10 → Bank2 (not implemented)

= 11 → Bank3 (not implemented)

Each bank extends up to 7Fh (128 bytes). The lower

locations of each bank are reserved for the Special

Function Registers. Abo ve the Special Function Registers are General Purpose Registers, implemented as

static RAM. All implemented banks contain special

function registers. Some “high use” special function

registers from one bank may be mirrored in another

bank for code reduction and quicker access.

2.2.1 GENERAL PURPOSE REGISTER FILE

The register file can be accessed either directly , or indi-

rectly through the File Select Register FSR

(Section 2.5).

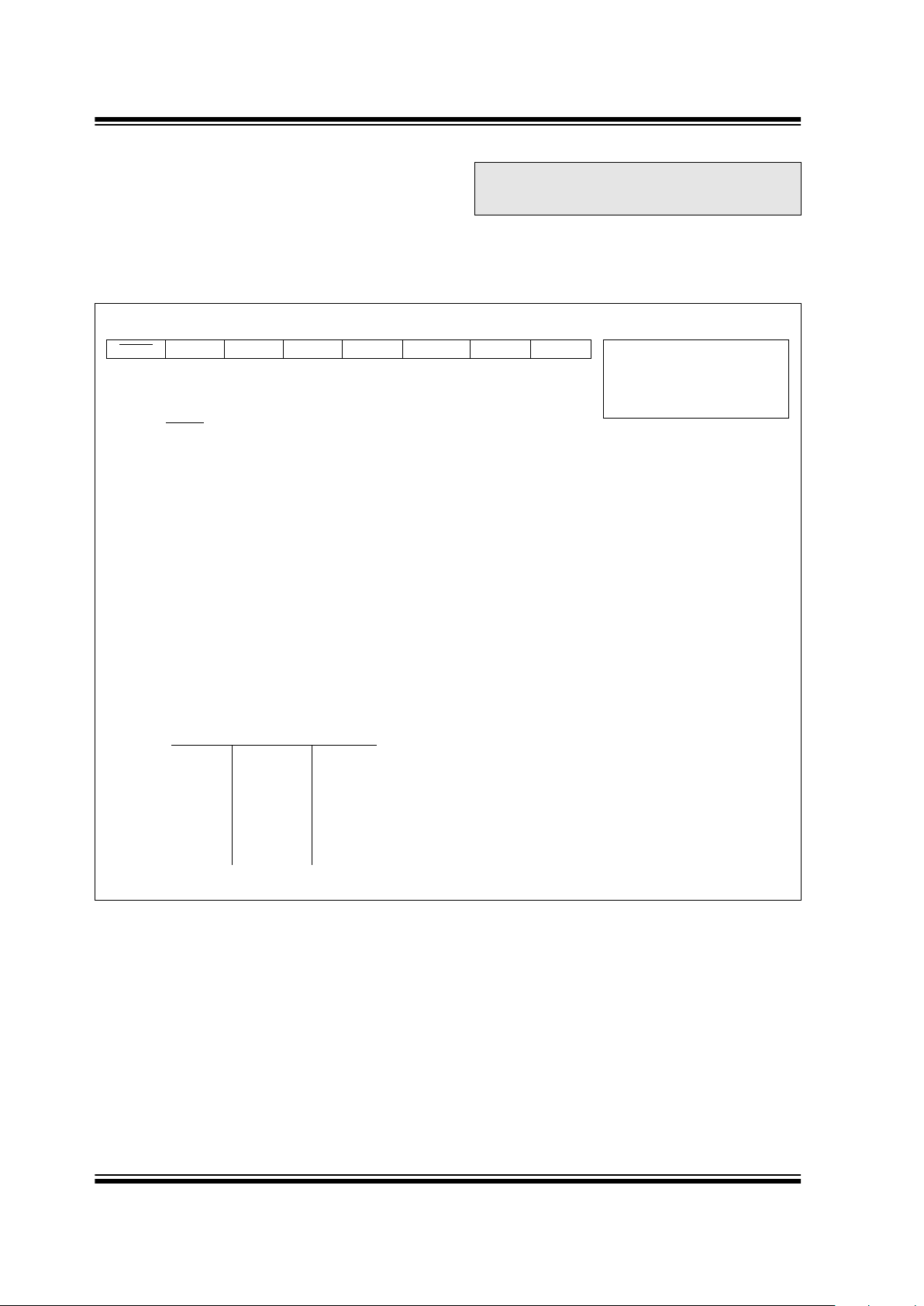

FIGURE 2-2: REGISTER FILE MAP

RP1

(1)

RP0 (STATUS<6:5>)

Note 1: Maintain this bit clear to ensure upward compati-

bility with future products.

Unimplemented data memory locations,

read as '0'.

Note 1: Not a physical register.

2: These registers are not implemented on the

PIC16C62B, read as '0'.

File

Address

File

Address

00h INDF

(1)

INDF

(1)

80h

01h TMR0

OPTION_REG

81h

02h PCL PCL 82h

03h STATUS STATUS 83h

04h FSR FSR 84h

05h PORTA TRISA 85h

06h PORTB TRISB 86h

07h PORTC TRISC 87h

08h 88h

09h 89h

0Ah PCLATH PCLATH 8Ah

0Bh INTCON INTCON 8Bh

0Ch PIR1 PIE1 8Ch

0Dh

8Dh

0Eh TMR1L PCON 8Eh

0Fh TRM1H 8Fh

10h T1CON 90h

11h TRM2 91h

12h T2CON PR2 92h

13h SSPBUF SSPADD 93h

14h SSPCON SSPSTAT 94h

15h CCPR1L 95h

16h CCPR1H 96h

17h CCP1CON 97h

18h 98h

19h 99h

1Ah 9Ah

1Bh 9Bh

1Ch 9Ch

1Dh 9Dh

1Eh ADRES

(2)

9Eh

1Fh ADCON0

(2)

ADCON1

(2)

9Fh

20h

General

Purpose

Registers

General

Purpose

Registers

A0h

BFh

C0h

7Fh FFh

Bank 0 Bank 1

PIC16C62B/72A

1998 Microchip Technology Inc.

Preliminary

DS35008A-page 9

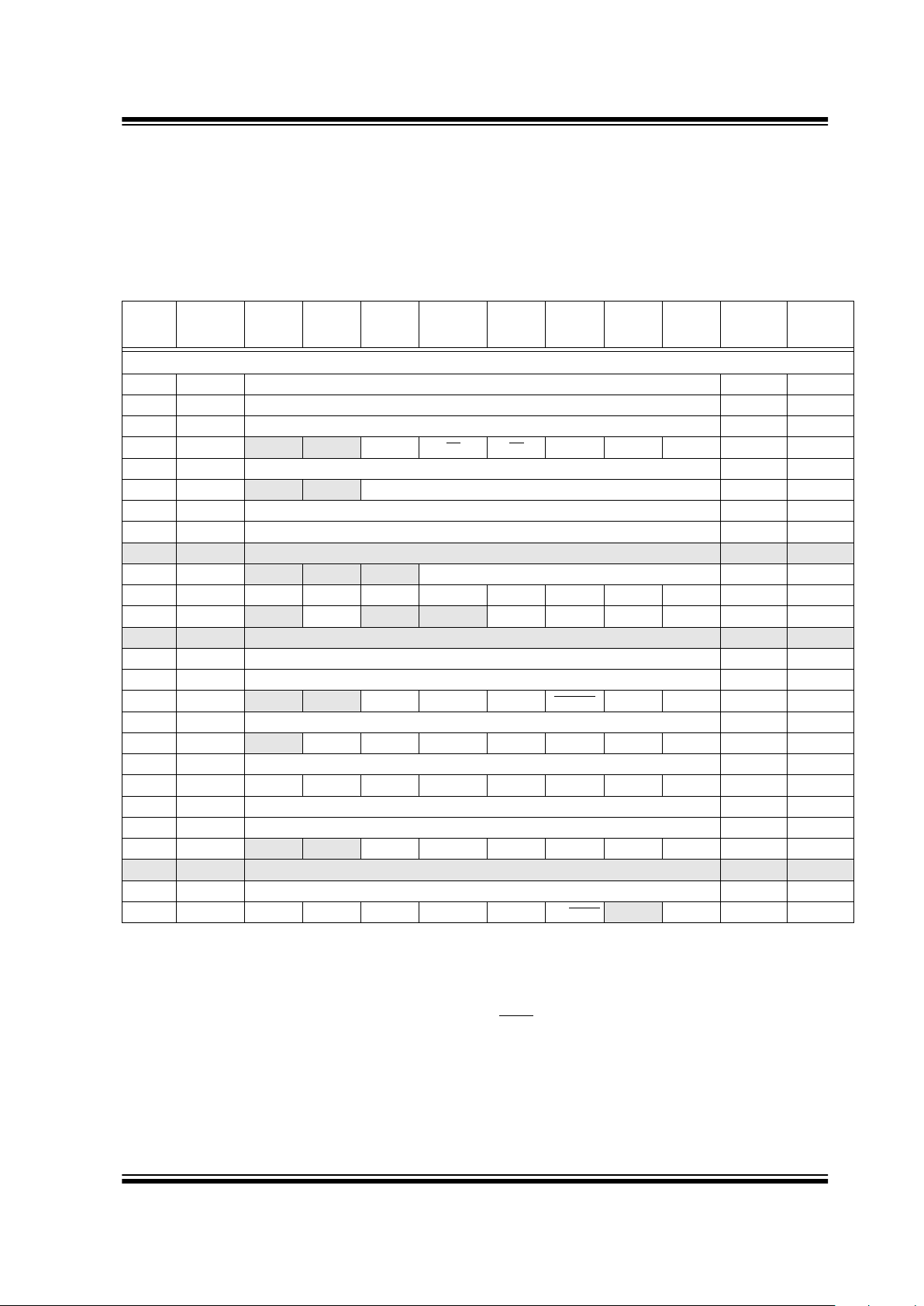

2.2.2 SPECIAL FUNCTION REGISTERS

The Special Function Registers are registers used by

the CPU and Peripheral Modules for controlling the

desired operation of the device. These registers are

implemented as static RAM. A list of these registers is

give in Table 2-1.

The special function registers can be classified into two

sets; core (CPU) and peripheral. Those registers associated with the core functions are described in detail in

this section. Those related to the operation of the

peripheral features are described in detail in that

peripheral feature section.

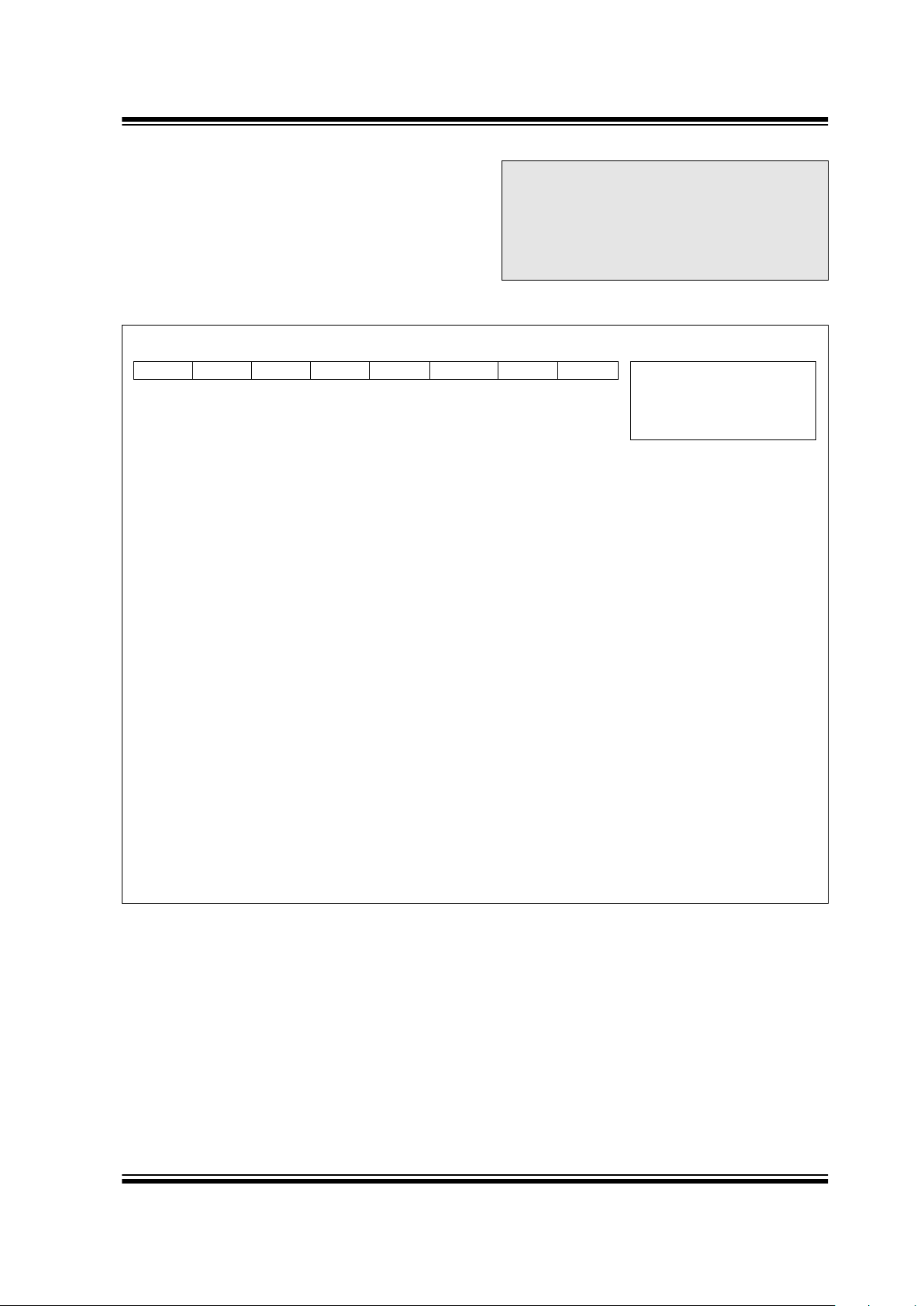

TABLE 2-1 SPECIAL FUNCTION REGISTER SUMMARY

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on:

POR,

BOR

Value on all

other resets

(4)

Bank 0

00h INDF

(1)

Addressing this location uses contents of FSR to address data memory (not a physical register)

0000 0000 0000 0000

01h TMR0 Timer0 module’s register

xxxx xxxx uuuu uuuu

02h PCL

(1)

Program Counter's (PC) Least Significant Byte

0000 0000 0000 0000

03h STATUS

(1)

IRP

(5)

RP1

(5)

RP0 T

O PD ZDCC

rr01 1xxx rr0q quuu

04h FSR

(1)

Indirect data memory address pointer

xxxx xxxx uuuu uuuu

05h PORTA

(6)

—

— PORTA Data Latch when written: PORTA pins when read

--0x 0000 --0u 0000

06h PORTB

(7)

PORTB Data Latch when written: PORTB pins when read

xxxx xxxx uuuu uuuu

07h PORTC

(7)

PORTC Data Latch when written: PORTC pins when read xxxx xxxx uuuu uuuu

08h-09h — Unimplemented — —

0Ah PCLATH

(1,2)

— — — Write Buffer for the upper 5 bits of the Program Counter ---0 0000 ---0 0000

0Bh INTCON

(1)

GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000u

0Ch PIR1 — ADIF

(3)

— — SSPIF CCP1IF TMR2IF TMR1IF -0-- 0000 -0-- 0000

0Dh — Unimplemented — —

0Eh TMR1L Holding register for the Least Significant Byte of the 16-bit TMR1 register xxxx xxxx uuuu uuuu

0Fh TMR1H Holding register for the Most Significant Byte of the 16-bit TMR1 register xxxx xxxx uuuu uuuu

10h T1CON — — T1CKPS1 T1CKPS0 T1OSCEN T1SYNC TMR1CS TMR1ON --00 0000 --uu uuuu

11h TMR2 Timer2 module’s register 0000 0000 0000 0000

12h T2CON — TOUTPS3 TOUTPS2 TOUTPS1 TOUTPS0 TMR2ON T2CKPS1 T2CKPS0 -000 0000 -000 0000

13h SSPBUF Synchronous Serial Port Receive Buffer/Transmit Register xxxx xxxx uuuu uuuu

14h SSPCON WCOL SSPOV SSPEN CKP SSPM3 SSPM2 SSPM1 SSPM0 0000 0000 0000 0000

15h CCPR1L Capture/Compare/PWM Register1 (LSB) xxxx xxxx uuuu uuuu

16h CCPR1H Capture/Compare/PWM Register1 (MSB) xxxx xxxx uuuu uuuu

17h CCP1CON — — CCP1X CCP1Y CCP1M3 CCP1M2 CCP1M1 CCP1M0 --00 0000 --00 0000

18h-1Dh — Unimplemented — —

1Eh ADRES

(3)

A/D Result Register xxxx xxxx uuuu uuuu

1Fh ADCON0

(3)

ADCS1 ADCS0 CHS2 CHS1 CHS0 GO/DONE — ADON 0000 00-0 0000 00-0

Legend: x = unknown, u = unchanged, q = value depends on condition, - = unimplemented, read as '0',

Shaded locations are unimplemented, read as '0'.

Note 1: These registers can be addressed from either bank.

2: The upper byte of the program counter is not directly accessible. PCLATH is a holding register for PC<12:8> whose contents

are transferred to the upper byte of the program counter.

3: A/D not implemented on the PIC16C62B, maintain as ’0’.

4: Other (non power-up) resets include: external reset through MCLR and the Watchdog Timer Reset.

5: The IRP and RP1 bits are reserved. Always maintain these bits clear.

6: On any device reset, these pins are configured as inputs.

7: This is the value that will be in the port output latch.

PIC16C62B/72A

DS35008A-page 10 Preliminary 1998 Microchip Technology Inc.

Bank 1

80h INDF

(1)

Addressing this location uses contents of FSR to address data memory (not a physical register) 0000 0000 0000 0000

81h

OPTION_

REG

RBPU

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

82h PCL

(1)

Program Counter's (PC) Least Significant Byte 0000 0000 0000 0000

83h STATUS

(1)

IRP

(5)

RP1

(5)

RP0 TO PD ZDCCrr01 1xxx rr0q quuu

84h FSR

(1)

Indirect data memory address pointer xxxx xxxx uuuu uuuu

85h TRISA — — PORTA Data Direction Register --11 1111 --11 1111

86h TRISB PORTB Data Direction Register 1111 1111 1111 1111

87h TRISC PORTC Data Direction Register 1111 1111 1111 1111

88h-89h — Unimplemented — —

8Ah PCLATH

(1,2)

— — — Write Buffer for the upper 5 bits of the Program Counter ---0 0000 ---0 0000

8Bh INTCON

(1)

GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000u

8Ch PIE1 — ADIE

(3)

— — SSPIE CCP1IE TMR2IE TMR1IE -0-- 0000 -0-- 0000

8Dh — Unimplemented — —

8Eh PCON — — — — — — POR BOR ---- --qq ---- --uu

8Fh-91h — Unimplemented — —

92h PR2 Timer2 Period Register 1111 1111 1111 1111

93h SSPADD Synchronous Serial Port (I2C mode) Address Register 0000 0000 0000 0000

94h SSPSTAT SMP CKE D/A P S R/W UA BF 0000 0000 0000 0000

95h-9Eh — Unimplemented — —

9Fh ADCON1

(3)

— — — — — PCFG2 PCFG1 PCFG0 ---- -000 ---- -000

Legend: x = unknown, u = unchanged, q = value depends on condition, - = unimplemented, read as '0',

Shaded locations are unimplemented, read as '0'.

Note 1: These registers can be addressed from either bank.

2: The upper byte of the program counter is not directly accessible. PCLATH is a holding register for PC<12:8> whose contents

are transferred to the upper byte of the program counter.

3: A/D not implemented on the PIC16C62B, maintain as ’0’.

4: Other (non power-up) resets include: external reset through MCLR and the Watchdog Timer Reset.

5: The IRP and RP1 bits are reserved. Always maintain these bits clear.

6: On any device reset, these pins are configured as inputs.

7: This is the value that will be in the port output latch.

TABLE 2-1 SPECIAL FUNCTION REGISTER SUMMARY (Cont.’d)

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on:

POR,

BOR

Value on all

other resets

(4)

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 11

2.2.2.1 STATUS REGISTER

The STATUS register, shown in Figure 2-3, contains

the arithmetic status of the ALU, the RESET status and

the bank select bits for data memory.

The STATUS register can be the destination for any

instruction, as with any other register. If the STATUS

register is the destination for an instruction that affects

the Z, DC or C bits, then the write to these three bits is

disabled. These bits are set or cleared according to the

device logic. Furthermore, the T

O and PD bits are not

writable. Therefore, the result of an instruction with the

STATUS register as destination may be different than

intended.

For example, CLRF STATUS will clear the upper-three

bits and set the Z bit. This leaves the STATUS register

as 000u u1uu (where u = unchanged).

It is recommended, therefore, that only BCF, BSF,

SWAPF and MOVWF instructions are used to alter the

STATUS register because these instructions do not

affect the Z, C or DC bits from the STATUS register. For

other instructions, not affecting any status bits, see the

"Instruction Set Summary."

FIGURE 2-3: STATUS REGISTER (ADDRESS 03h, 83h)

Note 1: These devices do not use bits IRP and

RP1 (STATUS<7:6>). Maintain these bits

clear to ensure upward compatibility with

future products.

Note 2: The C and DC bits operate as a borro

w

and digit borrow bit, respectively, in subtraction. See the SUBLW and SUBWF

instructions for examples.

R/W-0 R/W-0 R/W-0 R-1 R-1 R/W-x R/W-x R/W-x

IRP RP1 RP0 TO PD Z DC C R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: IRP: Register Bank Select bit (used for indirect addressing)

1 = Bank 2, 3 (100h - 1FFh) - not implemented, maintain clear

0 = Bank 0, 1 (00h - FFh) - not implemented, maintain clear

bit 6-5: RP1:RP0: Register Bank Select bits (used for direct addressing)

01 = Bank 1 (80h - FFh)

00 = Bank 0 (00h - 7Fh)

Each bank is 128 bytes

Note: RP1 = not implemented, maintain clear

bit 4: T

O: Time-out bit

1 = After power-up, CLRWDT instruction, or SLEEP instruction

0 = A WDT time-out occurred

bit 3: PD

: Power-down bit

1 = After power-up or by the CLRWDT instruction

0 = By execution of the SLEEP instruction

bit 2: Z: Zero bit

1 = The result of an arithmetic or logic operation is zero

0 = The result of an arithmetic or logic operation is not zero

bit 1: DC: Digit carry/borro

w bit (ADDWF, ADDLW,SUBLW,SUBWF instructions) (for borrow the polarity is reversed)

1 = A carry-out from the 4th low order bit of the result occurred

0 = No carry-out from the 4th low order bit of the result

bit 0: C: Carry/borro

w bit (ADDWF, ADDLW,SUBLW,SUBWF instructions)

1 = A carry-out from the most significant bit of the result occurred

0 = No carry-out from the most significant bit of the result occurred

Note: F or borro

w the polarity is reversed. A subtraction is executed by adding the two’s complement of the

second operand. For rotate (RRF, RLF) instructions, this bit is loaded with either the high or low order bit of

the source register.

PIC16C62B/72A

DS35008A-page 12 Preliminary 1998 Microchip Technology Inc.

2.2.2.2 OPTION_REG REGISTER

The OPTION_REG register is a readable and writable

register which contains various control bits to configure

the TMR0 prescaler/WDT postscaler (single assignable register known also as the prescaler), the External

INT Interrupt, TMR0, and the weak pull-ups on PORTB .

FIGURE 2-4: OPTION_REG REGISTER (ADDRESS 81h)

Note: To achieve a 1:1 prescaler assignment for

the TMR0 register, assign the prescaler to

the Watchdog Timer .

R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1

RBPU INTEDG T0CS T0SE PSA PS2 PS1 PS0 R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: RBPU: PORTB Pull-up Enable bit

1 = PORTB pull-ups are disabled

0 = PORTB pull-ups are enabled by individual port latch values

bit 6: INTEDG: Interrupt Edge Select bit

1 = Interrupt on rising edge of RB0/INT pin

0 = Interrupt on falling edge of RB0/INT pin

bit 5: T0CS: TMR0 Clock Source Select bit

1 = Transition on RA4/T0CKI pin

0 = Internal instruction cycle clock (CLKOUT)

bit 4: T0SE: TMR0 Source Edge Select bit

1 = Increment on high-to-low transition on RA4/T0CKI pin

0 = Increment on low-to-high transition on RA4/T0CKI pin

bit 3: PSA: Prescaler Assignment bit

1 = Prescaler is assigned to the WDT

0 = Prescaler is assigned to the Timer0 module

bit 2-0: PS2:PS0: Prescaler Rate Select bits

000

001

010

011

100

101

110

111

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

1 : 256

1 : 1

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

Bit Value TMR0 Rate WDT Rate

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 13

2.2.2.3 INTCON REGISTER

The INTCON Register is a readable and writable regis-

ter which contains various enable and flag bits for the

TMR0 register overflow, RB Port change and External

RB0/INT pin interrupts.

FIGURE 2-5: INTCON REGISTER (ADDRESS 0Bh, 8Bh)

Note: Interrupt flag bits get set when an interrupt

condition occurs regardless of the state of

its corresponding enable bit or the global

enable bit, GIE (INTCON<7>). User software should ensure the appropriate interrupt flag bits are clear prior to enabling an

interrupt.

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-x

GIE PEIE T0IE INTE RBIE T0IF INTF RBIF R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: GIE: Global Interrupt Enable bit

1 = Enables all un-masked interrupts

0 = Disables all interrupts

bit 6: PEIE: Peripheral Interrupt Enable bit

1 = Enables all un-masked peripheral interrupts

0 = Disables all peripheral interrupts

bit 5: T0IE: TMR0 Overflow Interrupt Enable bit

1 = Enables the TMR0 interrupt

0 = Disables the TMR0 interrupt

bit 4: IINTE: RB0/INT External Interrupt Enable bit

1 = Enables the RB0/INT external interrupt

0 = Disables the RB0/INT external interrupt

bit 3: RBIE: RB Port Change Interrupt Enable bit

1 = Enables the RB port change interrupt

0 = Disables the RB port change interrupt

bit 2: T0IF: TMR0 Overflow Interrupt Flag bit

1 = TMR0 register has overflowed (must be cleared in software)

0 = TMR0 register did not overflow

bit 1: INTF: RB0/INT External Interrupt Flag bit

1 = The RB0/INT external interrupt occurred (must be cleared in software)

0 = The RB0/INT external interrupt did not occur

bit 0: RBIF: RB Port Change Interrupt Flag bit

1 = At least one of the RB7:RB4 pins changed state (must be cleared in software)

0 = None of the RB7:RB4 pins have changed state

PIC16C62B/72A

DS35008A-page 14 Preliminary 1998 Microchip Technology Inc.

2.2.2.4 PIE1 REGISTER

This register contains the individual enable bits for the

peripheral interrupts.

FIGURE 2-6: PIE1 REGISTER (ADDRESS 8Ch)

Note: Bit PEIE (INTCON<6>) must be set to

enable any peripheral interrupt.

U-0 R/W-0 U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0

— ADIE

(1)

— — SSPIE CCP1IE TMR2IE TMR1IE R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: Unimplemented: Read as ‘0’

bit 6: ADIE

(1)

: A/D Converter Interrupt Enable bit

1 = Enables the A/D interrupt

0 = Disables the A/D interrupt

bit 5-4: Unimplemented: Read as ‘0’

bit 3: SSPIE: Synchronous Serial Port Interrupt Enable bit

1 = Enables the SSP interrupt

0 = Disables the SSP interrupt

bit 2: CCP1IE: CCP1 Interrupt Enable bit

1 = Enables the CCP1 interrupt

0 = Disables the CCP1 interrupt

bit 1: TMR2IE: TMR2 to PR2 Match Interrupt Enable bit

1 = Enables the TMR2 to PR2 match interrupt

0 = Disables the TMR2 to PR2 match interrupt

bit 0: TMR1IE: TMR1 Overflow Interrupt Enable bit

1 = Enables the TMR1 overflow interrupt

0 = Disables the TMR1 overflow interrupt

Note 1: The PIC16C62B does not have an A/D module. This bit location is reserved on these devices. Always maintain this

bit clear.

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 15

2.2.2.5 PIR1 REGISTER

This register contains the individual flag bits for the

Peripheral interrupts.

FIGURE 2-7: PIR1 REGISTER (ADDRESS 0Ch)

Note: Interrupt flag bits get set when an interrupt

condition occurs regardless of the state of

its corresponding enable bit or the global

enable bit, GIE (INTCON<7>). User software should ensure the appropriate interrupt flag bits are clear prior to enabling an

interrupt.

U-0 R/W-0 U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0

— ADIF

(1)

— — SSPIF CCP1IF TMR2IF TMR1IF R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: Unimplemented: Read as ‘0’

bit 6: ADIF

(1)

: A/D Converter Interrupt Flag bit

1 = An A/D conversion completed (must be cleared in software)

0 = The A/D conversion is not complete

bit 5-4: Unimplemented: Read as ‘0’

bit 3: SSPIF: Synchronous Serial Port Interrupt Flag bit

1 = The transmission/reception is complete (must be cleared in software)

0 = Waiting to transmit/receive

bit 2: CCP1IF: CCP1 Interrupt Flag bit

Capture Mode

1 = A TMR1 register capture occurred (must be cleared in software)

0 = No TMR1 register capture occurred

Compare Mode

1 = A TMR1 register compare match occurred (must be cleared in software)

0 = No TMR1 register compare match occurred

PWM Mode

Unused in this mode

bit 1: TMR2IF: TMR2 to PR2 Match Interrupt Flag bit

1 = TMR2 to PR2 match occurred (must be cleared in software)

0 = No TMR2 to PR2 match occurred

bit 0: TMR1IF: TMR1 Overflow Interrupt Flag bit

1 = TMR1 register overflowed (must be cleared in software)

0 = TMR1 register did not overflow

Note 1: The PIC16C62B does not have an A/D module. This bit location is reserved on these devices. Always maintain this

bit clear.

PIC16C62B/72A

DS35008A-page 16 Preliminary 1998 Microchip Technology Inc.

2.2.2.6 PCON REGISTER

The Power Control (PCON) register contains a flag bit

to allow differentiation between a Power-on Reset

(POR) to an external MCLR

Reset or WDT Reset.

Those devices with brown-out detection circuitry contain an additional bit to differentiate a Brown-out Reset

condition from a Power-on Reset condition.

FIGURE 2-8: PCON REGISTER (ADDRESS 8Eh)

Note: If the BODEN configuration bit is set, BOR

is ’1’ on Power-on Reset. If the BODEN

configuration bit is clear, BOR

is unknown

on Power-on Reset.

The BOR

status bit is a "don't care" and is

not necessarily predictable if the brown-out

circuit is disabled (the BODEN configuration bit is clear). BOR

must then be set by

the user and checked on subsequent

resets to see if it

is clear, indicating a

brown-out has occurred.

U-0 U-0 U-0 U-0 U-0 U-0 R/W-0 R/W-q

— — — — — — POR BOR R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7-2: Unimplemented: Read as '0'

bit 1: POR

: Power-on Reset Status bit

1 = No Power-on Reset occurred

0 = A Power-on Reset occurred (must be set in software after a Power-on Reset occurs)

bit 0: BOR

: Brown-out Reset Status bit

1 = No Brown-out Reset occurred

0 = A Brown-out Reset occurred (must be set in software after a Brown-out Reset occurs)

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 17

2.3 PCL and PCLATH

The program counter (PC) specifies the address of the

instruction to fetch for execution. The PC is 13 bits

wide. The low byte is called the PCL register. This register is readable and writable. The high byte is called

the PCH register. This register contains the PC<12:8>

bits and is not directly readable or writable. All updates

to the PCH register go through the PCLATH register.

2.3.1 STACK

The stack allows a combination of up to 8 program calls

and interrupts to occur. The stack contains the return

address from this branch in program execution.

Midrange devices have an 8 level deep x 13-bit wide

hardware stack. The stack space is not part of either

program or data space and the stack pointer is not

readable or writable. The PC is PUSHed onto the stack

when a CALL instruction is executed or an interrupt

causes a branch. The stack is POPed in the event of a

RETURN, RETLW or a RETFIE instruction execution.

PCLATH is not modified when the stack is PUSHed or

POPed.

After the stack has been PUSHed eight times, the ninth

push overwrites the value that was stored from the first

push. The tenth push overwrites the second push (and

so on).

2.4 Program Memory Paging

The CALL and GOTO instructions provide 11 bits of

address to allow branching within any 2K program

memory page. When doing a CALL or GOTO instruction

the upper bit of the address is provided by

PCLATH<3>. When doing a CALL or GOTO instruction,

the user must ensure that the page select bit is programmed so that the desired program memory page is

addressed. If a return from a CALL instruction (or interrupt) is executed, the entire 13-bit PC is pushed onto

the stack. Therefore, manipulation of the PCLATH<3>

bit is not required for the return instructions (which

POPs the address from the stack).

PIC16C62B/72A

DS35008A-page 18 Preliminary 1998 Microchip Technology Inc.

2.5 Indirect Addressing, INDF and FSR

Registers

The INDF register is not a physical register. Addressing INDF actually addresses the register whose

address is contained in the FSR register (FSR is a

pointer

). This is indirect addressing.

EXAMPLE 2-1: INDIRECT ADDRESSING

• Register file 05 contains the value 10h

• Register file 06 contains the value 0Ah

• Load the value 05 into the FSR register

• A read of the INDF register will return the value of

10h

• Increment the value of the FSR register by one

(FSR = 06)

• A read of the INDR register now will return the

value of 0Ah.

Reading INDF itself indirectly (FSR = 0) will produce

00h. Writing to the INDF register indirectly results in a

no-operation (although STATUS bits may be affected).

A simple program to clear RAM locations 20h-2Fh

using indirect addressing is shown in Example 2-2.

EXAMPLE 2-2: HOW TO CLEAR RAM

USING INDIRECT

ADDRESSING

movlw 0x20 ;initialize pointer

movwf FSR ; to RAM

NEXT clrf INDF ;clear INDF register

incf FSR ;inc pointer

btfss FSR,4 ;all done?

goto NEXT ;NO, clear next

CONTINUE

: ;YES, continue

An effective 9-bit address is obtained by concatenating

the 8-bit FSR register and the IRP bit (STATUS<7>), as

shown in Figure 2-9. However, IRP is not used in the

PIC16C62B/72A.

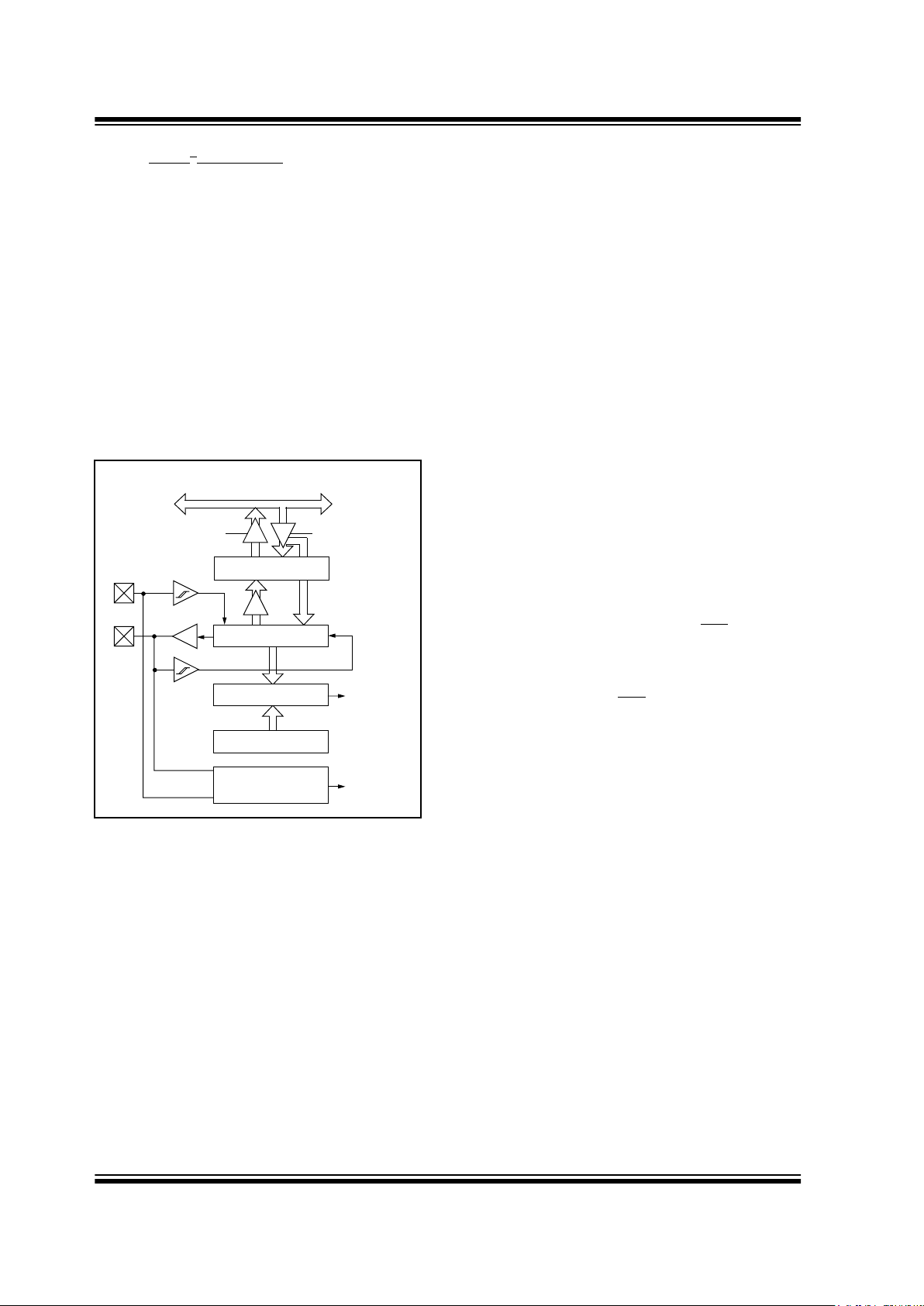

FIGURE 2-9: DIRECT/INDIRECT ADDRESSING

Note 1: For register file map detail see Figure 2-2.

2: Maintain clear for upward compatibility with future products.

3: Not implemented.

Data

Memory(1)

Indirect AddressingDirect Addressing

bank select location select

RP1:RP0 6

0

from opcode

IRP FSR register

7

0

bank select

location select

00 01 10 11

Bank 0 Bank 1 Bank 2 Bank 3

not used

FFh

80h

7Fh

00h

17Fh

100h

1FFh

180h

(2)

(2)

(3) (3)

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 19

3.0 I/O PORTS

Some pins for these I/O ports are multiplexed with an

alternate function for the peripheral features on the

device. In general, when a peripheral is enabled, that

pin may not be used as a general purpose I/O pin.

Additional information on I/O ports may be found in the

PICmicro™ Mid-Range Reference Manual,

(DS33023).

3.1 PORTA and the TRISA Register

PORTA is a 6-bit wide bi-directional por t. The corresponding data direction register is TRISA. Setting a

TRISA bit (=1) will make the corresponding PORTA pin

an input, i.e., put the corresponding output driver in a

hi-impedance mode. Clearing a TRISA bit (=0) will

make the corresponding PORTA pin an output, i.e., put

the contents of the output latch on the selected pin.

Reading the PORTA register reads the status of the

pins whereas writing to it will write to the port latch. All

write operations are read-modify-write operations.

Therefore a write to a port implies that the port pins are

read, this value is modified, and then written to the port

data latch.

Pin RA4 is multiplexed with the Timer0 module clock

input to become the RA4/T0CKI pin. The RA4/T0CKI

pin is a Schmitt Trigger input and an open drain output.

All other RA port pins have TTL input levels and full

CMOS output drivers.

On the PIC16C72A device, other PORTA pins are multiplexed with analog inputs and analog V

REF input. The

operation of each pin is selected by clearing/setting the

control bits in the ADCON1 register (A/D Control

Register1).

The TRISA register controls the direction of the RA

pins, even when they are being used as analog inputs.

The user must ensure the bits in the TRISA register are

maintained set when using them as analog inputs.

EXAMPLE 3-1: INITIALIZING PORTA

BCF STATUS, RP0 ;

CLRF PORTA ; Initialize PORTA by

; clearing output

; data latches

BSF STATUS, RP0 ; Select Bank 1

MOVLW 0xCF ; Value used to

; initialize data

; direction

MOVWF TRISA ; Set RA<3:0> as inputs

; RA<5:4> as outputs

; TRISA<7:6> are always

; read as '0'.

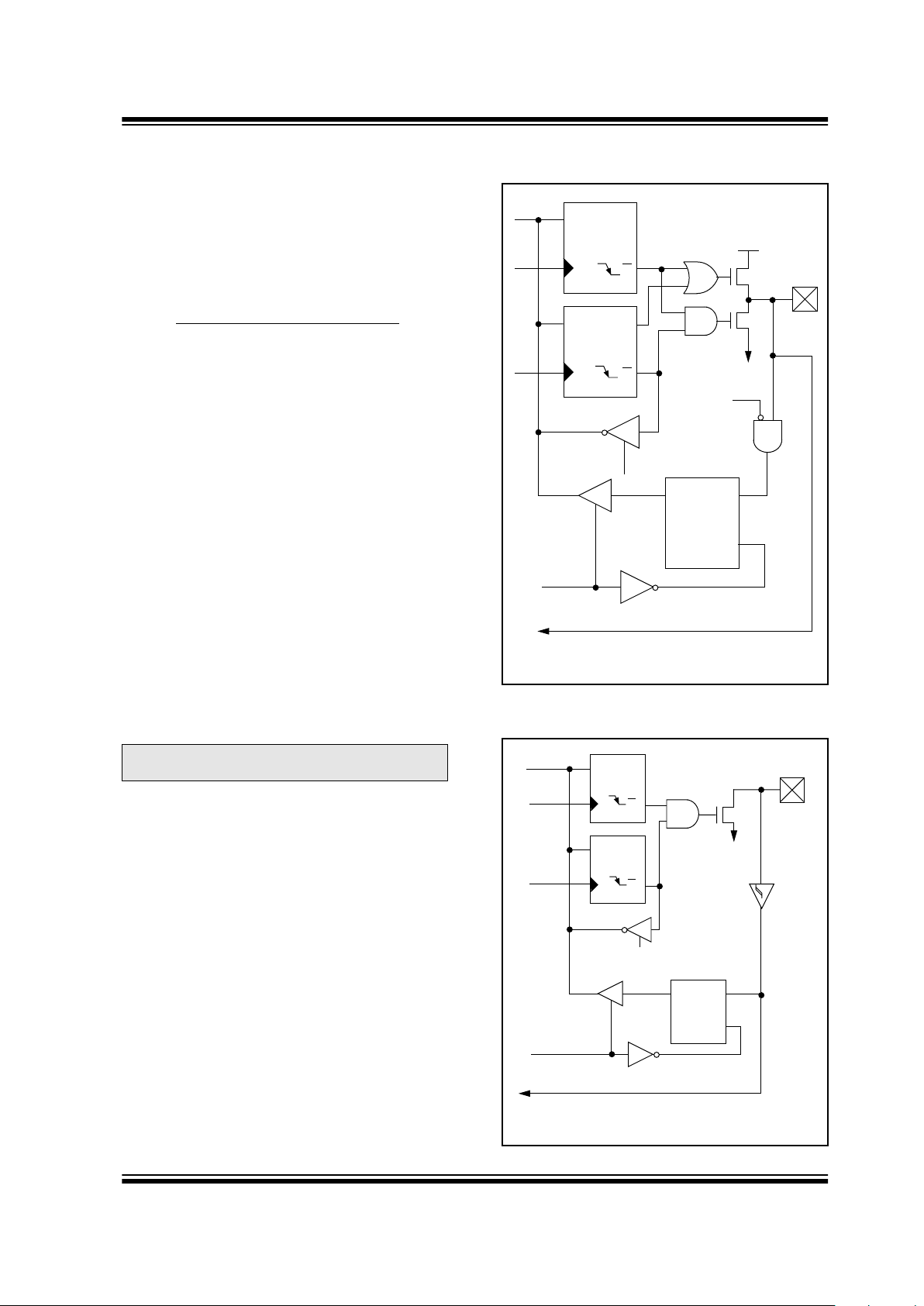

FIGURE 3-1: BLOCK DIAGRAM OF

RA3:RA0 AND RA5 PINS

FIGURE 3-2: BLOCK DIAGRAM OF

RA4/T0CKI PIN

Note: On a Power-on Reset, these pins are con-

figured as analog inputs and read as '0'.

Data

bus

QD

Q

CK

QD

Q

CK

QD

EN

P

N

WR

Port

WR

TRIS

Data Latch

TRIS Latch

RD TRIS

RD PORT

V

SS

VDD

I/O pin

(1)

Note 1: I/O pins have protection diodes to VDD

and V

SS.

Analog

input

mode

TTL

input

buffer

To A/D Converter (72A only)

(72B

only)

Data

bus

WR

PORT

WR

TRIS

RD PORT

Data Latch

TRIS Latch

RD TRIS

Schmitt

T rigger

input

buffer

N

V

SS

I/O pin

(1)

TMR0 clock input

QD

Q

CK

QD

Q

CK

EN

QD

EN

Note 1: Note 1: I/O pin has protection diodes to

V

SS only.

PIC16C62B/72A

DS35008A-page 20 Preliminary 1998 Microchip Technology Inc.

TABLE 3-1 PORTA FUNCTIONS

TABLE 3-2 SUMMARY OF REGISTERS ASSOCIATED WITH PORTA

Name Bit# Buffer Function

RA0/AN0 bit0 TTL Input/output or analog input

(1)

RA1/AN1 bit1 TTL Input/output or analog input

(1)

RA2/AN2 bit2 TTL Input/output or analog input

(1)

RA3/AN3/VREF bit3 TTL Input/output or analog input

(1)

or VREF

(1)

RA4/T0CKI bit4 ST

Input/output or external clock input for Timer0

Output is open drain type

RA5/SS/AN4 bit5 TTL Input/output or slave select input for synchronous serial port or analog input

(1)

Legend: TTL = TTL input, ST = Schmitt Trigger input

Note 1: On PIC16C72A only.

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on

POR,

BOR

Value on all

other resets

05h PORTA

(for PIC16C72A only)

— — RA5 RA4 RA3 RA2 RA1 RA0 --0x 0000 --0u 0000

05h PORTA

(for PIC16C62B only)

— — RA5 RA4 RA3 RA2 RA1 RA0 --xx xxxx --uu uuuu

85h TRISA

— — PORTA Data Direction Register --11 1111 --11 1111

9Fh ADCON1

(1)

— — — — — PCFG2 PCFG1 PCFG0 ---- -000 ---- -000

Legend: x = unknown, u = unchanged, - = unimplemented locations read as '0'. Shaded cells are not used by PORTA.

Note 1: On PIC16C72A only.

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 21

3.2 PORTB and the TRISB Register

PORTB is an 8-bit wide bi-directional port. The corresponding data direction register is TRISB. Setting a

TRISB bit (=1) will make the corresponding PORTB pin

an input, i.e., put the corresponding output driver in a

hi-impedance mode. Clearing a TRISB bit (=0) will

make the corresponding PORTB pin an output, i.e., put

the contents of the output latch on the selected pin.

EXAMPLE 3-1: INITIALIZING PORTB

BCF STATUS, RP0 ;

CLRF PORTB ; Initialize PORTB by

; clearing output

; data latches

BSF STATUS, RP0 ; Select Bank 1

MOVLW 0xCF ; Value used to

; initialize data

; direction

MOVWF TRISB ; Set RB<3:0> as inputs

; RB<5:4> as outputs

; RB<7:6> as inputs

Each of the PORTB pins has a weak internal pull-up. A

single control bit can turn on all the pull-ups. This is performed by clearing bit RBPU

(OPTION_REG<7>). The

weak pull-up is automatically turned off when the port

pin is configured as an output. The pull-ups are disabled on a Power-on Reset.

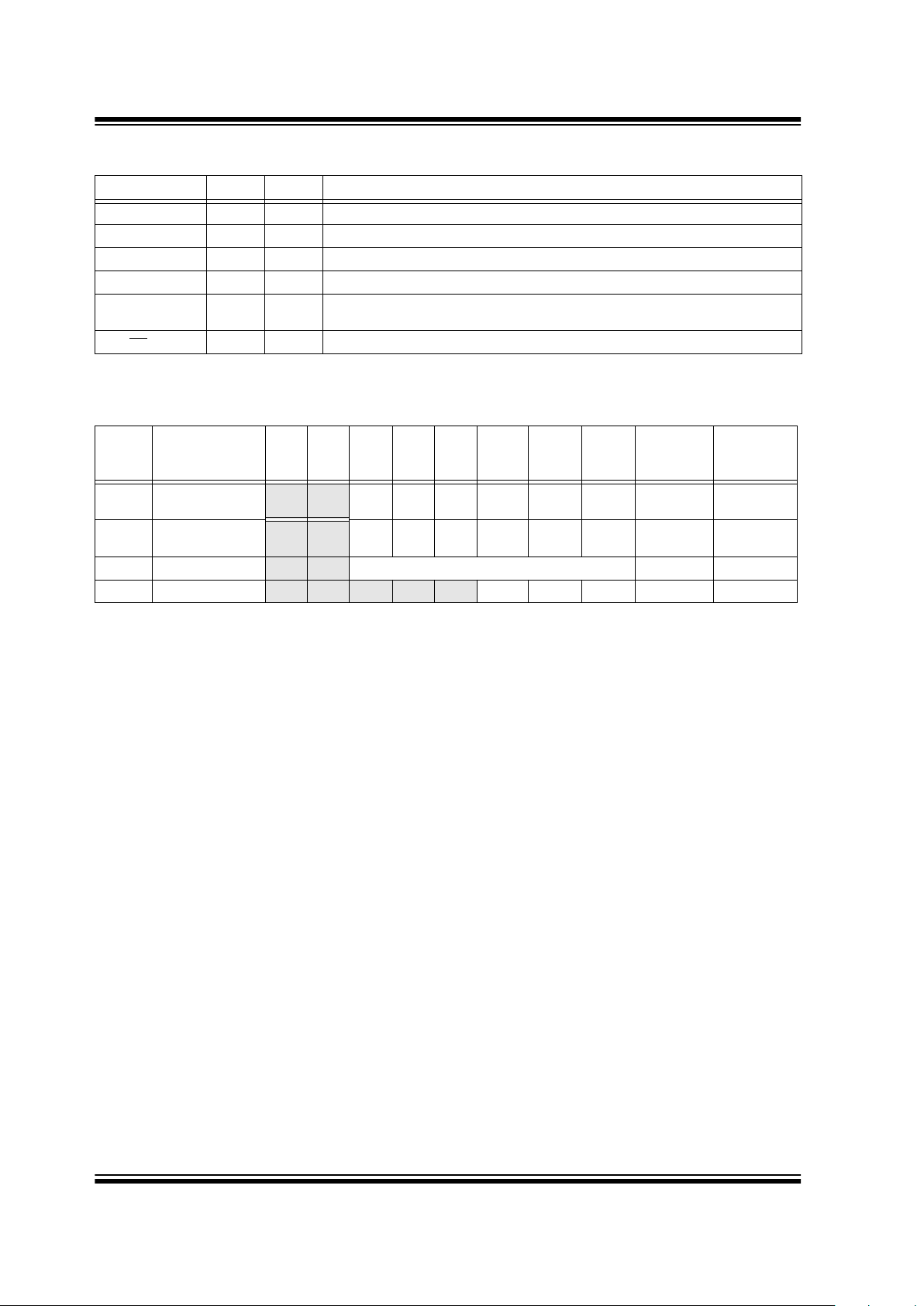

FIGURE 3-3: BLOCK DIAGRAM OF

RB3:RB0 PINS

Four of PORTB’s pins, RB7:RB4, have an interrupt on

change feature. Only pins configured as inputs can

cause this interrupt to occur (i.e. any RB7:RB4 pin configured as an output is excluded from the interrupt on

change comparison). The input pins (of RB7:RB4) are

compared with the old value latched on the last read of

PORTB. The “mismatch” outputs of RB7:RB4 are

OR’ed together to generate the RB Port Change Interrupt with flag bit RBIF (INTCON<0>).

This interrupt can wake the device from SLEEP. The

user, in the interrupt service routine, can clear the interrupt in the following manner:

a) Any read or write of PORTB. This will end the

mismatch condition.

b) Clear flag bit RBIF.

A mismatch condition will continue to set flag bit RBIF.

Reading PORTB will end the mismatch condition, and

allow flag bit RBIF to be cleared.

The interrupt on change feature is recommended for

wake-up on key depression operation and operations

where PORTB is only used for the interrupt on change

feature. Polling of PORTB is not recommended while

using the interrupt on change feature.

FIGURE 3-4: BLOCK DIAGRAM OF

RB7:RB4 PINS

Data Latch

RBPU

(2)

P

V

DD

QD

CK

QD

CK

QD

EN

Data bus

WR Port

WR TRIS

RD TRIS

RD Port

weak

pull-up

RD Port

RB0/INT

I/O

pin

(1)

TTL

Input

Buffer

Note 1: I/O pins have diode protection to V

DD and VSS.

2: To enable weak pull-ups, set the appropriate TRIS bit(s)

and clear the RBPU

bit (OPTION_REG<7>).

Schmitt T rigger

Buffer

TRIS Latch

Data Latch

From other

RBPU

(2)

P

V

DD

I/O

QD

CK

QD

CK

QD

EN

QD

EN

Data bus

WR Port

WR TRIS

Set RBIF

TRIS Latch

RD TRIS

RD Port

RB7:RB4 pins

weak

pull-up

RD Port

Latch

TTL

Input

Buffer

pin

(1)

Note 1: I/O pins have diode protection to VDD and VSS.

ST

Buffer

RB7:RB6 in serial programming mode

Q3

Q1

2: To enable weak pull-ups, set the appropriate TRIS bit(s)

and clear the RBPU bit (OPTION_REG<7>).

PIC16C62B/72A

DS35008A-page 22 Preliminary 1998 Microchip Technology Inc.

TABLE 3-3 PORTB FUNCTIONS

TABLE 3-4 SUMMARY OF REGISTERS ASSOCIATED WITH PORTB

Name Bit# Buffer Function

RB0/INT bit0 TTL/ST

(1)

Input/output pin or external interrupt input. Internal software

programmable weak pull-up.

RB1 bit1 TTL Input/output pin. Internal software programmable weak pull-up.

RB2 bit2 TTL Input/output pin. Internal software programmable weak pull-up.

RB3 bit3 TTL Input/output pin. Internal software programmable weak pull-up.

RB4 bit4 TTL Input/output pin (with interrupt on change). Internal software programmable

weak pull-up.

RB5 bit5 TTL Input/output pin (with interrupt on change). Internal software programmable

weak pull-up.

RB6 bit6 TTL/ST

(2)

Input/output pin (with interrupt on change). Internal software programmable

weak pull-up. Serial programming clock.

RB7 bit7 TTL/ST

(2)

Input/output pin (with interrupt on change). Internal software programmable

weak pull-up. Serial programming data.

Legend: TTL = TTL input, ST = Schmitt Trigger input

Note 1: This buffer is a Schmitt Trigger input when configured as the external interrupt.

2: This buffer is a Schmitt Trigger input when used in serial programming mode.

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on:

POR,

BOR

Value on all

other resets

06h PORTB RB7 RB6 RB5 RB4 RB3 RB2 RB1 RB0 xxxx xxxx uuuu uuuu

86h TRISB PORTB Data Direction Register 1111 1111 1111 1111

81h OPTION_

REG

RBPU INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

Legend: x = unknown, u = unchanged. Shaded cells are not used by PORTB.

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 23

3.3 PORTC and the TRISC Register

PORTC is an 8-bit wide bi-directional port. The corresponding data direction register is TRISC. Setting a

TRISC bit (=1) will make the corresponding PORTC pin

an input, i.e., put the corresponding output driver in a

hi-impedance mode. Clearing a TRISC bit (=0) will

make the corresponding PORTC pin an output, i.e., put

the contents of the output latch on the selected pin.

PORTC is multiplex ed with se v eral peripheral functions

(Table 3-5). PORTC pins have Schmitt Trigger input

buffers.

When enabling peripheral functions, care should be

taken in defining TRIS bits for each PORTC pin. Some

peripherals override the TRIS bit to make a pin an output, while other peripherals override the TRIS bit to

make a pin an input. Since the TRIS bit override is in

effect while the peripheral is enabled, read-modifywrite instructions (BSF, BCF, XORWF) with TRISC as

destination should be avoided. The user should ref er to

the corresponding peripheral section for the correct

TRIS bit settings.

EXAMPLE 3-1: INITIALIZING PORTC

BCF STATUS, RP0 ; Select Bank 0

CLRF PORTC ; Initialize PORTC by

; clearing output

; data latches

BSF STATUS, RP0 ; Select Bank 1

MOVLW 0xCF ; Value used to

; initialize data

; direction

MOVWF TRISC ; Set RC<3:0> as inputs

; RC<5:4> as outputs

; RC<7:6> as inputs

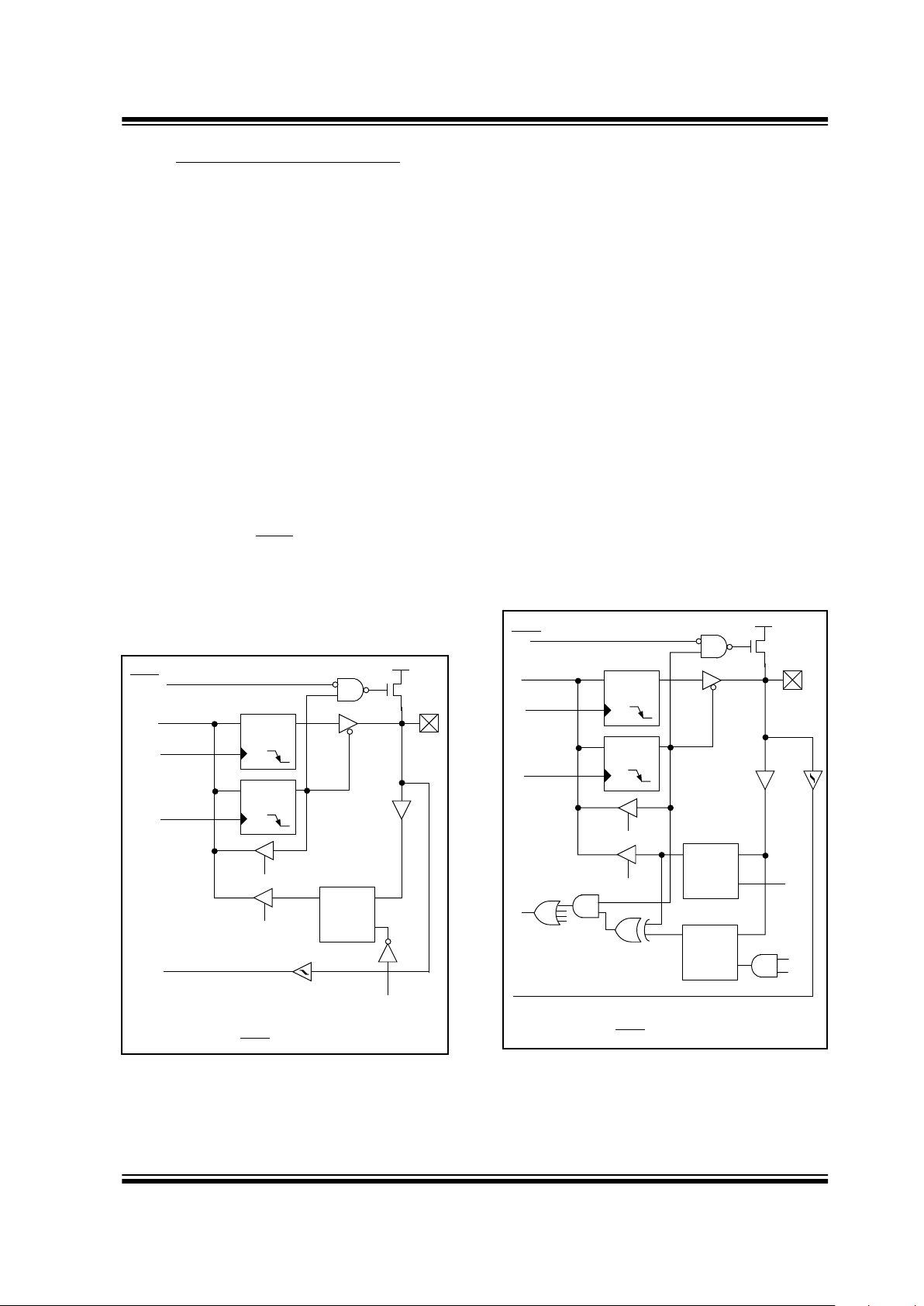

FIGURE 3-5: PORTC BLOCK DIAGRAM

(PERIPHERAL OUTPUT

OVERRIDE)

PORT/PERIPHERAL Select

(2)

Data bus

WR

PORT

WR

TRIS

RD

Data Latch

TRIS Latch

RD TRIS

Schmitt

T rigger

QD

Q

CK

QD

EN

Peripheral Data Out

0

1

QD

Q

CK

P

N

VDD

VSS

PORT

Peripheral

OE

(3)

Peripheral input

I/O

pin

(1)

Note 1: I/O pins have diode protection to VDD and VSS.

2: Port/Peripheral select signal selects between port

data and peripheral output.

3: Peripheral OE (output enable) is only activated if

peripheral select is active.

PIC16C62B/72A

DS35008A-page 24 Preliminary 1998 Microchip Technology Inc.

TABLE 3-5 PORTC FUNCTIONS

TABLE 3-6 SUMMARY OF REGISTERS ASSOCIATED WITH PORTC

Name Bit# Buffer Type Function

RC0/T1OSO/T1CKI

bit0

ST Input/output port pin or Timer1 oscillator output/Timer1 clock input

RC1/T1OSI bit1 ST Input/output port pin or Timer1 oscillator input

RC2/CCP1 bit2 ST Input/output port pin or Capture1 input/Compare1 output/PWM1

output

RC3/SCK/SCL bit3 ST

RC3 can also be the synchronous serial clock for both SPI and I

2

C

modes.

RC4/SDI/SDA bit4 ST

RC4 can also be the SPI Data In (SPI mode) or data I/O (I

2

C mode).

RC5/SDO bit5 ST Input/output port pin or Synchronous Serial Port data output

RC6 bit6 ST Input/output port pin

RC7 bit7 ST Input/output port pin

Legend: ST = Schmitt Trigger input

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on:

POR,

BOR

Value on all

other resets

07h PORTC RC7 RC6 RC5 RC4 RC3 RC2 RC1 RC0 xxxx xxxx uuuu uuuu

87h TRISC PORTC Data Direction Register 1111 1111 1111 1111

Legend: x = unknown, u = unchanged.

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 25

4.0 TIMER0 MODULE

The Timer0 module timer/counter has the following features:

• 8-bit timer/counter

• Readable and writable

• Internal or external clock select

• Edge select for external clock

• 8-bit software programmable prescaler

• Interrupt on overflow from FFh to 00h

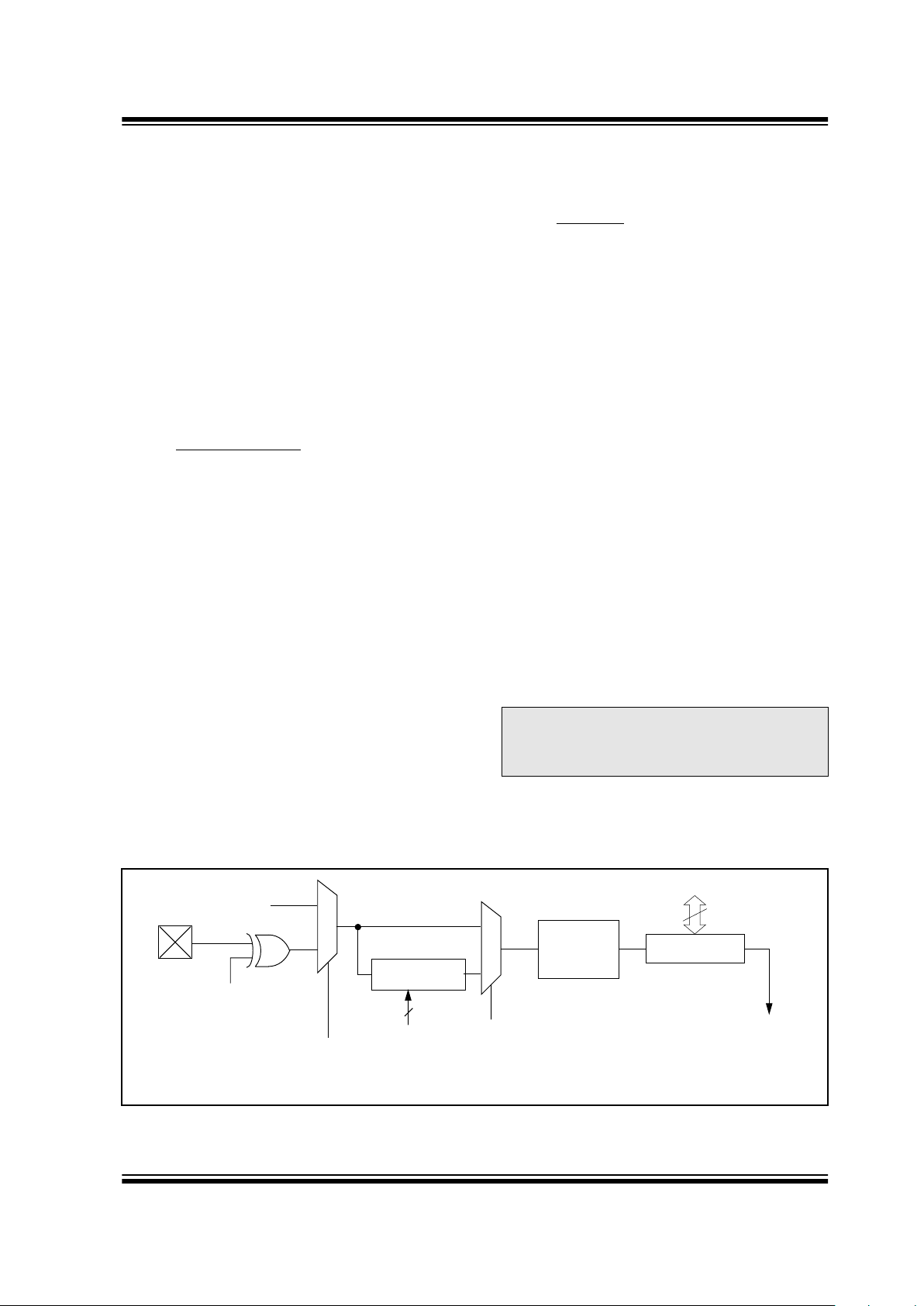

Figure 4-1 is a simplified block diagram of the Timer0

module.

Additional information on timer modules is available in

the PICmicro™ Mid-Range Reference Manual,

(DS33023).

4.1 Timer0 Operation

Timer0 can operate as a timer or as a counter.

Timer mode is selected by clearing bit T0CS

(OPTION_REG<5>). In timer mode, the Timer0 module will increment every instruction cycle (without prescaler). If the TMR0 register is written, the increment is

inhibited for the following two instruction cycles. The

user can work around this by writing an adjusted value

to the TMR0 register.

Counter mode is selected by setting bit T0CS

(OPTION_REG<5>). In counter mode, Timer0 will

increment either on every rising or falling edge of pin

RA4/T0CKI. The incrementing edge is determined by

the Timer0 Source Edge Select bit T0SE

(OPTION_REG<4>). Clearing bit T0SE selects the rising edge. Restrictions on the external clock input are

discussed below.

When an external clock input is used for Timer0, it must

meet certain requirements. The requirements ensure

the external clock can be synchronized with the internal

phase clock (T

OSC). Also, there is a delay in the actual

incrementing of Timer0 after synchronization.

Additional information on external clock requirements

is available in the PICmicro™ Mid-Range Reference

Manual, (DS33023).

4.2 Prescaler

An 8-bit counter is available as a prescaler for the

Timer0 module, or as a postscaler for the Watchdog

Timer, respectively (Figure 4-2). For simplicity, this

counter is being referred to as “prescaler” throughout

this data sheet. Note that there is only one prescaler

available which is mutually exclusively shared between

the Timer0 module and the Watchdog Timer. Thus, a

prescaler assignment for the Timer0 module means

that there is no prescaler for the Watchdog Timer, and

vice-versa.

The prescaler is not readable or writable.

The PSA and PS2:PS0 bits (OPTION_REG<3:0>)

determine the prescaler assignment and prescale ratio.

Clearing bit PSA will assign the prescaler to the Timer0

module. When the prescaler is assigned to the Timer0

module, prescale values of 1:2, 1:4, ..., 1:256 are

selectable.

Setting bit PSA will assign the prescaler to the Watchdog Timer (WDT). When the prescaler is assigned to

the WDT, prescale values of 1:1, 1:2, ..., 1:128 are

selectable.

When assigned to the Timer0 module, all instructions

writing to the TMR0 register (e.g. CLRF 1, MOVWF 1,

BSF 1,x....etc.) will clear the prescaler. When

assigned to WDT, a CLRWDT instruction will clear the

prescaler along with the WDT.

FIGURE 4-1: TIMER0 BLOCK DIAGRAM

Note: Writing to TMR0 when the prescaler is

assigned to Timer0 will clear the prescaler

count, but will not change the prescaler

assignment.

Note 1: T0CS, T0SE, PSA, PS2:PS0 (OPTION_REG<5:0>).

2: The prescaler is shared with Watchdog Timer (refer to Figure 4-2 for detailed block diagram).

RA4/T0CKI

T0SE

0

1

1

0

pin

T0CS

FOSC/4

Programmable

Prescaler

Sync with

Internal

clocks

TMR0

PSout

(2 cycle delay)

PSout

Data bus

8

PSA

PS2, PS1, PS0

Set interrupt

flag bit T0IF

on overflow

3

PIC16C62B/72A

DS35008A-page 26 Preliminary 1998 Microchip Technology Inc.

4.2.1 SWITCHING PRESCALER ASSIGNMENT

The prescaler assignment is fully under software con-

trol, i.e., it can be changed “on the fly” during program

execution.

4.3 Timer0 Interrupt

The TMR0 interrupt is generated when the TMR0 register overflows from FFh to 00h. This overflow sets bit

T0IF (INTCON<2>). The interrupt can be masked by

clearing bit T0IE (INTCON<5>). Bit T0IF must be

cleared in software by the Timer0 module interrupt service routine before re-enabling this interrupt. The TMR0

interrupt cannot awaken the processor from SLEEP

since the timer is shut off during SLEEP.

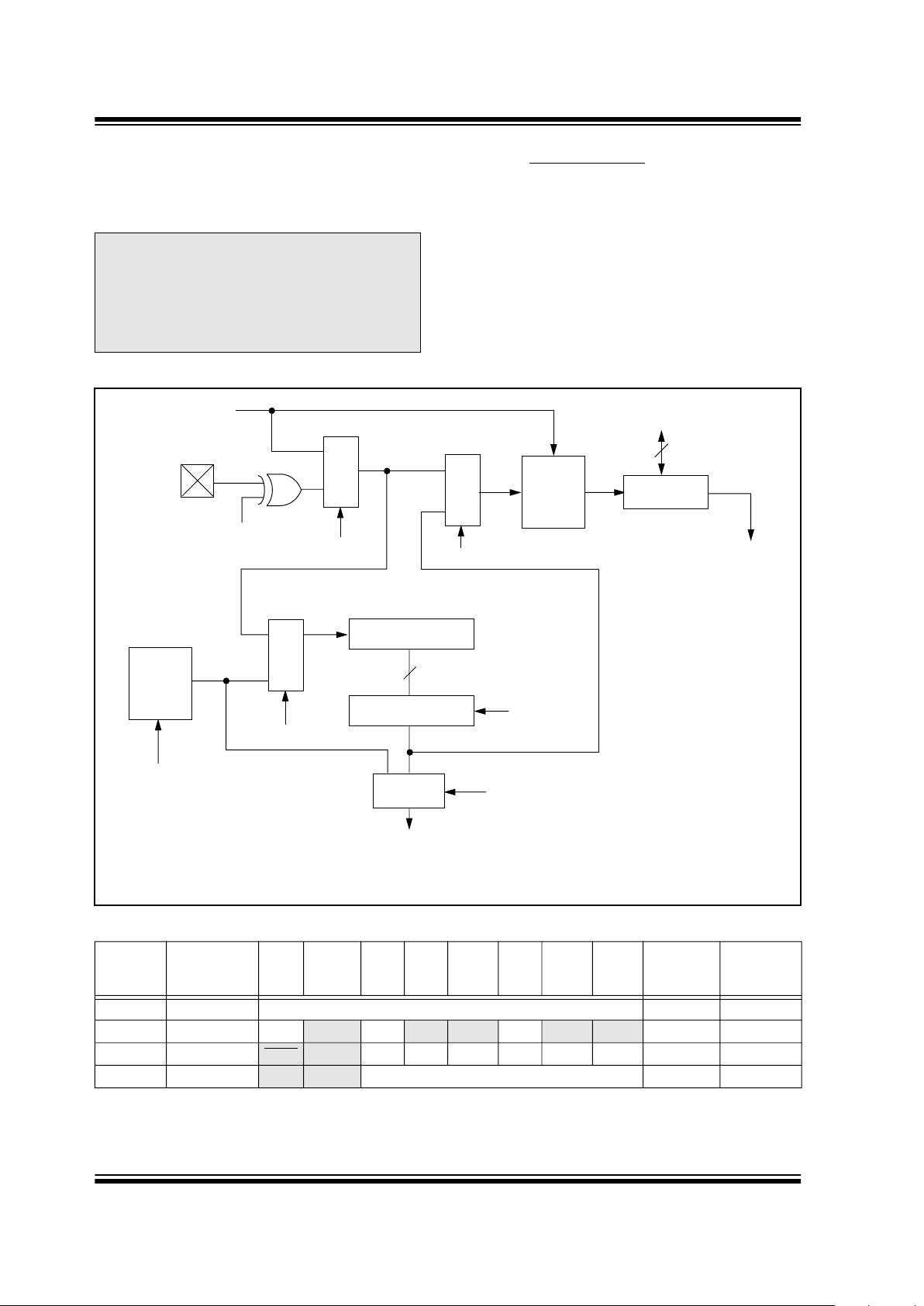

FIGURE 4-2: BLOCK DIAGRAM OF THE TIMER0/WDT PRESCALER

TABLE 4-1 REGISTERS ASSOCIATED WITH TIMER0

Note: To avoid an unintended device RESET, a

specific instruction sequence (shown in the

PICmicro Mid-Range Reference Manual,

DS33023) must be executed when changing the prescaler assignment from Timer0

to the WDT. This sequence must be

followed even if the WDT is disabled.

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on:

POR,

BOR

Value on all

other resets

01h TMR0 Timer0 module’s register xxxx xxxx uuuu uuuu

0Bh,8Bh INTCON GIE

PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000u

81h OPTION_REG RBPU INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

85h TRISA — — PORTA Data Direction Register --11 1111 --11 1111

Legend: x = unknown, u = unchanged, - = unimplemented locations read as '0'. Shaded cells are not used by Timer0.

RA4/T0CKI

T0SE

pin

M

U

X

CLKOUT (=Fosc/4)

SYNC

2

Cycles

TMR0 reg

8-bit Prescaler

8 - to - 1MUX

M

U

X

M U X

Watchdog

Timer

PSA

0

1

0

1

WDT

Time-out

PS2:PS0

8

Note: T0CS, T0SE, PSA, PS2:PS0 are (OPTION_REG<5:0>).

PSA

WDT Enable bit

M

U

X

0

1

0

1

Data Bus

Set flag bit T0IF

on Overflow

8

PSA

T0CS

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 27

5.0 TIMER1 MODULE

The Timer1 module timer/counter has the f ollowing features:

• 16-bit timer/counter

(Two 8-bit registers; TMR1H and TMR1L)

• Readable and writable (Both registers)

• Internal or external clock select

• Interrupt on overflow from FFFFh to 0000h

• Reset from CCP module trigger

Timer1 has a control register, shown in Figure 5-1.

Timer1 can be enabled/disabled by setting/clearing

control bit TMR1ON (T1CON<0>).

Figure 5-2 is a simplified block diagram of the Timer1

module.

Additional information on timer modules is available in

the PICmicro™ Mid-Range Reference Manual,

(DS33023).

5.1 Timer1 Operation

Timer1 can operate in one of these modes:

• As a timer

• As a synchronous counter

• As an asynchronous counter

The operating mode is determined by the clock select

bit, TMR1CS (T1CON<1>).

In timer mode, Timer1 increments every instruction

cycle. In counter mode, it increments on every rising

edge of the external clock input.

When the Timer1 oscillator is enabled (T1OSCEN is

set), the RC1/T1OSI and RC0/T1OSO/T1CKI pins

become inputs. That is, the TRISC<1:0> value is

ignored.

Timer1 also has an internal “reset input”. This reset can

be generated by the CCP module (Section 7.0).

FIGURE 5-1: T1CON: TIMER1 CONTROL REGISTER (ADDRESS 10h)

U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

— — T1CKPS1 T1CKPS0 T1OSCEN T1SYNC TMR1CS TMR1ON

R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7-6: Unimplemented: Read as '0'

bit 5-4: T1CKPS1:T1CKPS0: Timer1 Input Clock Prescale Select bits

11 = 1:8 Prescale value

10 = 1:4 Prescale value

01 = 1:2 Prescale value

00 = 1:1 Prescale value

bit 3: T1OSCEN: Timer1 Oscillator Enable Control bit

1 = Oscillator is enabled

0 = Oscillator is shut off

Note: The oscillator inverter and feedback resistor are turned off to eliminate power drain

bit 2: T1SYNC

: Timer1 External Clock Input Synchronization Control bit

TMR1CS = 1

1 = Do not synchronize external clock input

0 = Synchronize external clock input

TMR1CS = 0

This bit is ignored. Timer1 uses the internal clock when TMR1CS = 0.

bit 1: TMR1CS: Timer1 Clock Source Select bit

1 = External clock from pin RC0/T1OSO/T1CKI (on the rising edge)

0 = Internal clock (F

OSC/4)

bit 0: TMR1ON: Timer1 On bit

1 = Enables Timer1

0 = Stops Timer1

PIC16C62B/72A

DS35008A-page 28 Preliminary 1998 Microchip Technology Inc.

FIGURE 5-2: TIMER1 BLOCK DIAGRAM

TMR1H

TMR1L

T1OSC

T1SYNC

TMR1CS

T1CKPS1:T1CKPS0

SLEEP input

T1OSCEN

Enable

Oscillator

(1)

FOSC/4

Internal

Clock

TMR1ON

on/off

Prescaler

1, 2, 4, 8

Synchronize

det

1

0

0

1

Synchronized

clock input

2

RC0/T1OSO/T1CKI

RC1/T1OSI

Note 1: When the T1OSCEN bit is cleared, the inverter and feedback resistor are turned off. This eliminates power drain.

Set flag bit

TMR1IF on

Overflow

TMR1

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 29

5.2 Timer1 Oscillator

A crystal oscillator circuit is built in between pins T1OSI

(input) and T1OSO (amplifier output). It is enabled by

setting control bit T1OSCEN (T1CON<3>). The oscillator is a low power oscillator rated up to 200 kHz. It will

continue to run during SLEEP. It is primarily intended

for a 32 kHz crystal. Table 5-1 shows the capacitor

selection for the Timer1 oscillator.

The Timer1 oscillator is identical to the LP oscillator.

The user must provide a software time delay to ensure

proper oscillator start-up.

TABLE 5-1 CAPACITOR SELECTION

FOR THE TIMER1

OSCILLATOR

5.3 Timer1 Interrupt

The TMR1 Register pair (TMR1H:TMR1L) increments

from 0000h to FFFFh and rolls over to 0000h. The

TMR1 Interrupt, if enabled, is generated on overflow

which is latched in interrupt flag bit TMR1IF (PIR1<0>).

This interrupt can be enabled/disabled by setting/clearing TMR1 interrupt enable bit TMR1IE (PIE1<0>).

5.4 Resetting Timer1 using a CCP Trigger

Output

If the CCP module is configured in compare mode to

generate a “special event trigger" (CCP1M3:CCP1M0

= 1011), this signal will reset Timer1 and start an A/D

conversion (if the A/D module is enabled).

Timer1 must be configured for either timer or synchronized counter mode to take advantage of this f eature. If

Timer1 is running in asynchronous counter mode, this

reset operation may not work.

In the event that a write to Timer1 coincides with a special event trigger from CCP1, the write will take precedence.

In this mode of operation, the CCPR1H:CCPR1L registers pair effectively becomes the period register for

Timer1.

TABLE 5-2 REGISTERS ASSOCIATED WITH TIMER1 AS A TIMER/COUNTER

Osc Type Freq C1 C2

LP 32 kHz 33 pF 33 pF

100 kHz 15 pF 15 pF

200 kHz 15 pF 15 pF

These values are for design guidance only.

Crystals Tested:

32.768 kHz Epson C-001R32.768K-A ± 20 PPM

100 kHz Epson C-2 100.00 KC-P ± 20 PPM

200 kHz STD XTL 200.000 kHz ± 20 PPM

Note 1: Higher capacitance increases the stability

of oscillator but also increases the start-up

time.

2: Since each resonator/crystal has its own

characteristics, the user should consult the

resonator/crystal manufacturer for appropriate values of external components.

Note: The special event triggers from the CCP1

module will not set interrupt flag bit

TMR1IF (PIR1<0>).

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on

POR,

BOR

Value on

all other

resets

0Bh,8Bh INTCON GIE PEIE

T0IE INTE RBIE T0IF INTF RBIF

0000 000x 0000 000u

0Ch PIR1 — ADIF — — SSPIF CCP1IF TMR2IF TMR1IF

-0-- 0000 -0-- 0000

8Ch PIE1 — ADIE — — SSPIE CCP1IE TMR2IE TMR1IE

-0-- 0000 -0-- 0000

0Eh TMR1L Holding register for the Least Significant Byte of the 16-bit TMR1 register

xxxx xxxx uuuu uuuu

0Fh TMR1H Holding register for the Most Significant Byte of the 16-bit TMR1 register

xxxx xxxx uuuu uuuu

10h T1CON — — T1CKPS1 T1CKPS0 T1OSCEN T1SYNC TMR1CS TMR1ON

--00 0000 --uu uuuu

Legend: x = unknown, u = unchanged, - = unimplemented read as '0'. Shaded cells are not used by the Timer1 module.

PIC16C62B/72A

DS35008A-page 30 Preliminary 1998 Microchip Technology Inc.

NOTES:

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 31

6.0 TIMER2 MODULE

The Timer2 module timer has the following features:

• 8-bit timer (TMR2 register)

• 8-bit period register (PR2)

• Readable and writable (Both registers)

• Software programmable prescaler (1:1, 1:4, 1:16)

• Software programmable postscaler (1:1 to 1:16)

• Interrupt on TMR2 match of PR2

• SSP module optional use of TMR2 output to generate clock shift

Timer2 has a control register, shown in Figure 6-1.

Timer2 can be shut off by clearing control bit TMR2ON

(T2CON<2>) to minimize power consumption.

Figure 6-2 is a simplified block diagram of the Timer2

module.

Additional information on timer modules is available in

the PICmicro™ Mid-Range Reference Manual,

(DS33023).

FIGURE 6-1: T2CON: TIMER2 CONTROL REGISTER (ADDRESS 12h)

FIGURE 6-2: TIMER2 BLOCK DIAGRAM

U-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

— TOUTPS3 TOUTPS2 TOUTPS1 TOUTPS0 TMR2ON T2CKPS1 T2CKPS0 R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: Unimplemented: Read as '0'

bit 6-3: TOUTPS3:TOUTPS0: Timer2 Output Postscale Select bits

0000 = 1:1 Postscale

0001 = 1:2 Postscale

•

•

•

1111 = 1:16 Postscale

bit 2: TMR2ON: Timer2 On bit

1 = Timer2 is on

0 = Timer2 is off

bit 1-0: T2CKPS1:T2CKPS0: Timer2 Clock Prescale Select bits

00 = Prescaler is 1

01 = Prescaler is 4

1x = Prescaler is 16

Comparator

TMR2

Sets flag

TMR2 reg

output

(1)

Reset

Postscaler

Prescaler

PR2 reg

2

F

OSC/4

1:1 1:16

1:1, 1:4, 1:16

EQ

4

bit TMR2IF

Note 1: TMR2 register output can be software selected

by the SSP Module as a baud clock.

to

PIC16C62B/72A

DS35008A-page 32 Preliminary 1998 Microchip Technology Inc.

6.1 Timer2 Operation

Timer2 can be used as the PWM time-base for PWM

mode of the CCP module.

The TMR2 register is readable and writable, and is

cleared on any device reset.

The input clock (F

OSC/4) has a prescale option of 1:1,

1:4 or 1:16, selected by control bits

T2CKPS1:T2CKPS0 (T2CON<1:0>).

The match output of TMR2 goes through a 4-bit

postscaler (which gives a 1:1 to 1:16 scaling inclusive)

to generate a TMR2 interrupt (latched in flag bit

TMR2IF, (PIR1<1>)).

The prescaler and postscaler counters are cleared

when any of the following occurs:

• a write to the TMR2 register

• a write to the T2CON register

• any device reset (Power-on Reset, MCLR

reset,

Watchdog Timer reset, or Brown-out Reset)

TMR2 is not cleared when T2CON is written.

6.2 Timer2 Interrupt

The Timer2 module has an 8-bit period register PR2.

Timer2 increments from 00h until it matches PR2 and

then resets to 00h on the next increment cycle. PR2 is

a readable and writable register. The PR2 register is initialized to FFh upon reset.

6.3 Output of TMR2

The output of TMR2 (bef ore the postscaler) is fed to the

Synchronous Serial Port module which optionally uses

it to generate shift clock.

TABLE 6-1 REGISTERS ASSOCIATED WITH TIMER2 AS A TIMER/COUNTER

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on

POR,

BOR

Value on

all other

resets

0Bh,8Bh INTCON GIE PEIE

T0IE INTE RBIE T0IF INTF RBIF

0000 000x 0000 000u

0Ch PIR1

— ADIF — — SSPIF CCP1IF TMR2IF TMR1IF

-00- 0000 0000 0000

8Ch PIE1

— ADIE — — SSPIE CCP1IE TMR2IE TMR1IE

-0-- 0000 0000 0000

11h TMR2 Timer2 module’s register

0000 0000 0000 0000

12h T2CON

— TOUTPS3 TOUTPS2 TOUTPS1 TOUTPS0 TMR2ON T2CKPS1 T2CKPS0

-000 0000 -000 0000

92h PR2 Timer2 Period Register

1111 1111 1111 1111

Legend: x = unknown, u = unchanged, - = unimplemented read as '0'. Shaded cells are not used by the Timer2 module.

PIC16C62B/72A

1998 Microchip Technology Inc. Preliminary DS35008A-page 33

7.0 CAPTURE/COMPARE/PWM

(CCP) MODULE(S)

Each CCP (Capture/Compare/PWM) module contains

a 16-bit register which can operate as a 16-bit capture

register, as a 16-bit compare register or as a PWM

master/slave Duty Cycle register. Table 7-1 shows the

timer resources of the CCP module modes.

Capture/Compare/PWM Register 1 (CCPR1) is comprised of two 8-bit registers: CCPR1L (low byte) and

CCPR1H (high byte). The CCP1CON register controls

the operation of CCP1. All are readable and writable.

Additional information on the CCP module is available

in the PICmicro™ Mid-Range Reference Manual,

(DS33023).

TABLE 7-1 CCP MODE - TIMER

RESOURCE

FIGURE 7-1: CCP1CON REGISTER (ADDRESS 17h)

CCP Mode Timer Resource

Capture

Compare

PWM

Timer1

Timer1

Timer2

U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

— — CCP1X CCP1Y CCP1M3 CCP1M2 CCP1M1 CCP1M0 R = Readable bit

W =Writable bit

U = Unimplemented bit,

read as ‘0’

- n =Value at POR reset

bit7 bit0

bit 7-6: Unimplemented: Read as '0'

bit 5-4: CCP1X:CCP1Y: PWM Least Significant bits

Capture Mode: Unused

Compare Mode: Unused

PWM Mode: These bits are the two LSbs of the PWM duty cycle. The eight MSbs are found in CCPR1L.

bit 3-0: CCP1M3:CCP1M0: CCP1 Mode Select bits

0000 = Capture/Compare/PWM off (resets CCP1 module)

0100 = Capture mode, every falling edge

0101 = Capture mode, every rising edge

0110 = Capture mode, every 4th rising edge

0111 = Capture mode, every 16th rising edge

1000 = Compare mode, set output on match (CCP1IF bit is set)

1001 = Compare mode, clear output on match (CCP1IF bit is set)

1010 = Compare mode, generate software interrupt on match (CCP1IF bit is set, CCP1 pin is unaffected)

1011 = Compare mode, trigger special event (CCP1IF bit is set; CCP1 resets TMR1 and starts an A/D

conversion (if A/D module is enabled))

11xx = PWM mode

PIC16C62B/72A

DS35008A-page 34 Preliminary 1998 Microchip Technology Inc.

7.1 Capture Mode

In Capture mode, CCPR1H:CCPR1L captures the

16-bit value of the TMR1 register when an e v ent occurs

on pin RC2/CCP1. An event is defined as:

• every falling edge

• every rising edge

• every 4th rising edge

• every 16th rising edge

An event is selected by control bits CCP1M3:CCP1M0

(CCP1CON<3:0>). When a capture is made, the interrupt request flag bit CCP1IF (PIR1<2>) is set. It must

be cleared in software. If another capture occurs before

the value in register CCPR1 is read, the old captured

value will be lost.

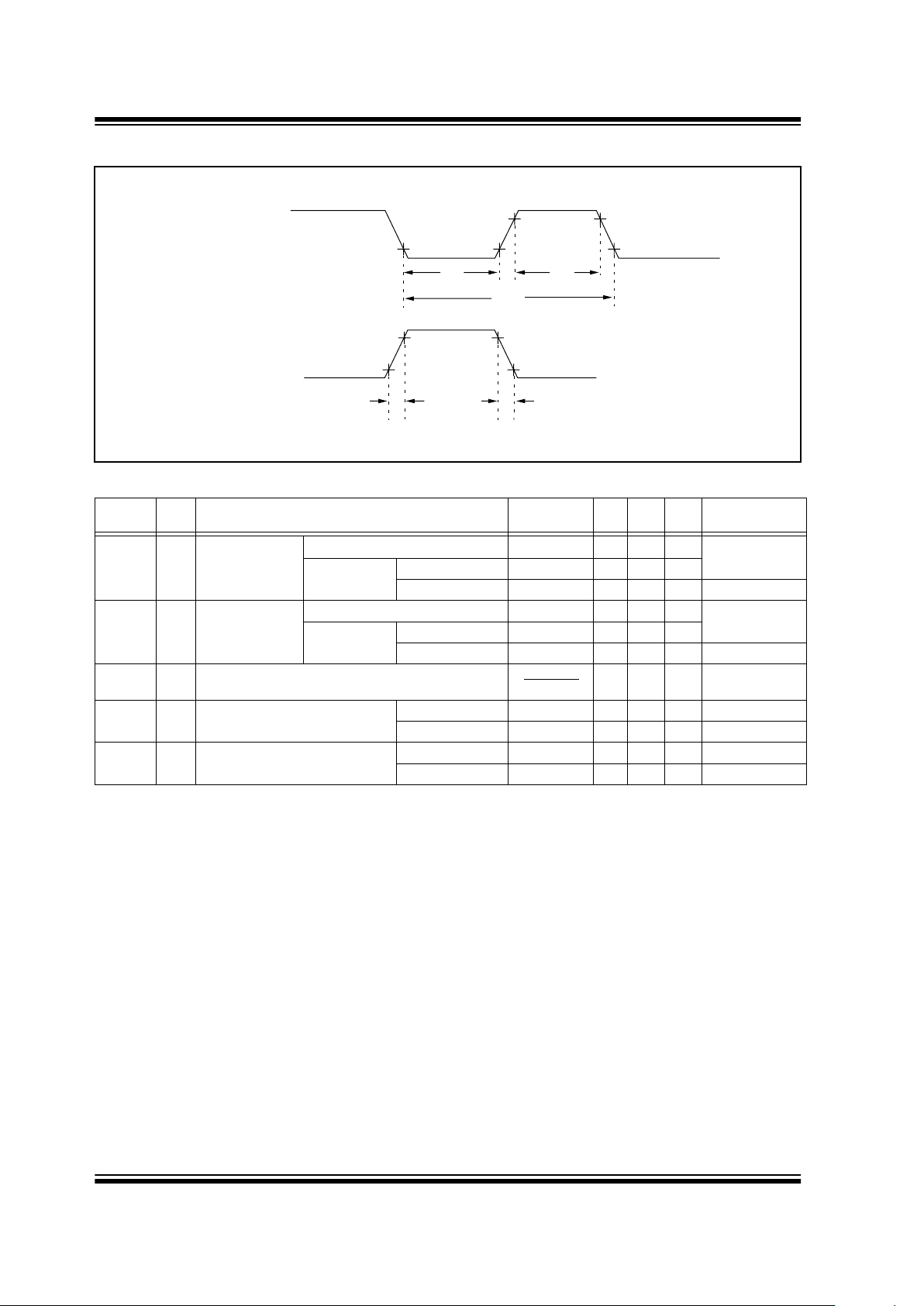

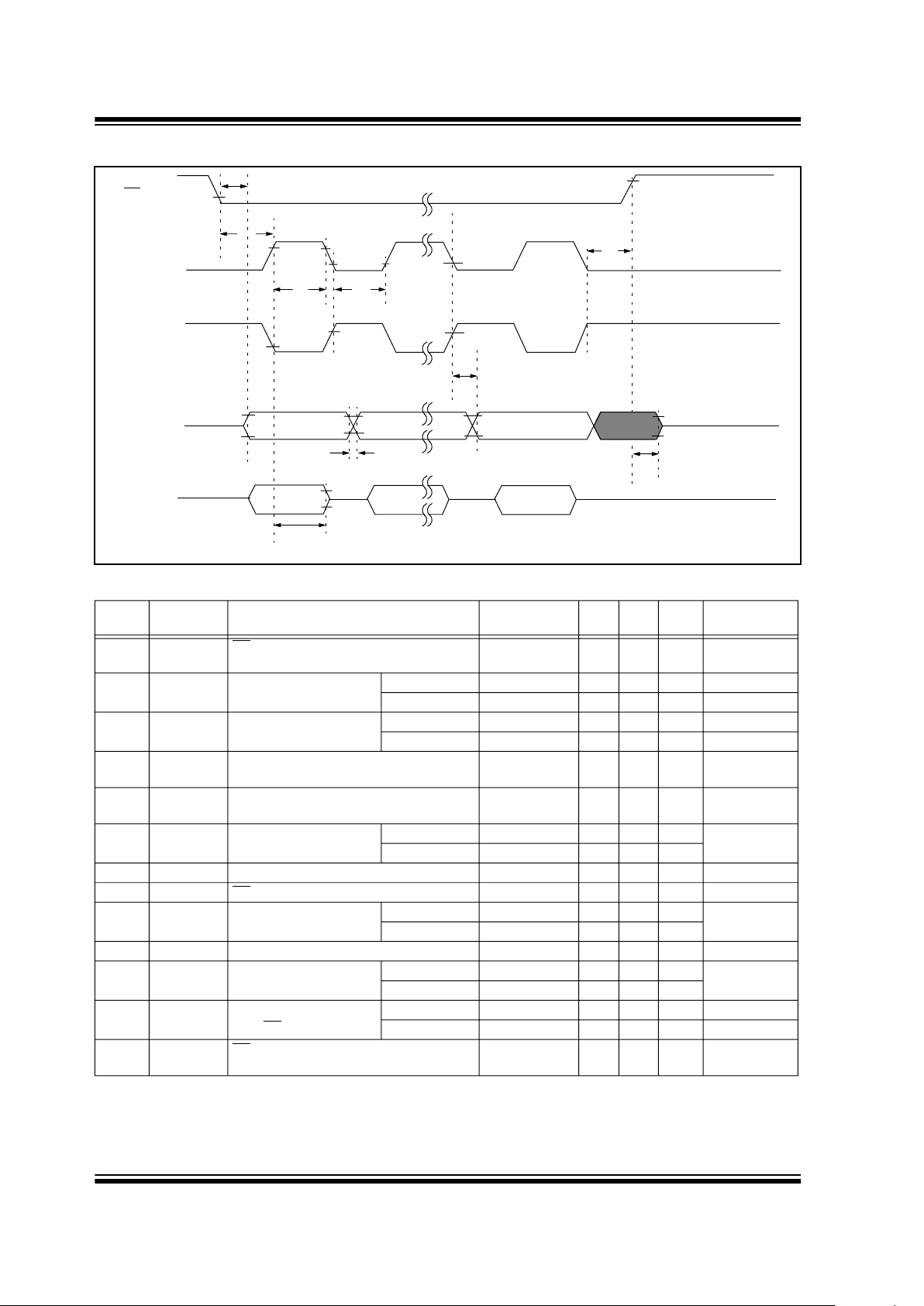

FIGURE 7-2: CAPTURE MODE

OPERATION BLOCK

DIAGRAM

7.1.1 CCP PIN CONFIGURATION

In Capture mode, the RC2/CCP1 pin should be config-

ured as an input by setting the TRISC<2> bit.

7.1.2 TIMER1 MODE SELECTION

Timer1 must be running in timer mode or synchronized

counter mode for the CCP module to use the capture

feature. In asynchronous counter mode, the capture

operation may not work.

7.1.3 SOFTWARE INTERRUPT

When the Capture mode is changed, a false capture

interrupt may be generated. The user should keep bit

CCP1IE (PIE1<2>) clear to avoid false interrupts and

should clear the flag bit CCP1IF following any such

change in operating mode.

7.1.4 CCP PRESCALER

There are four prescaler settings, specified by bits

CCP1M3:CCP1M0. Whenever the CCP module is

turned off, or the CCP module is not in capture mode,

the prescaler counter is cleared. This means that any

reset will clear the prescaler counter.

Switching from one capture prescaler to another may

generate an interrupt. Also, the prescaler counter will

not be cleared, therefore the first capture may be from

a non-zero prescaler. Example 7-1 shows the recommended method for switching between capture prescalers. This example also clears the prescaler counter

and will not generate the “false” interrupt.