Page 1

www.mgeups.com

Galaxy 3000

10 - 30 kVA

MGE UPS SYSTEMS

Upsilon STS

30A-60A-100A-160A

250A-400A-600A

Installation and user

manual

LE SAVOIR FAIRE MERLIN GERIN

R

E

D

I

V

O

R

P

R

E

W

O

P

E

L

B

I

T

P

U

R

R

E

T

N

I

N

U

E

H

T

34020113EN/AA - Page 1

Page 2

Page 2 - 34020113EN/AA

Page 3

Introduction

Thank you for selecting an MGE UPS SYSTEMS product to protect your electrical equipment.

The Upsilon STS range has been designed with the upmost care. We recommend that you take the time to read this

manual to take full advantage of the many features of your new equipment.

MGE UPS SYSTEMS pays great attention to the environmental impact of its products. Measures that have made Upsilon

STS a reference in environmental protection include:

◗ the eco-design approach used in product development,

◗ production on an industrial site certified ISO 14001,

◗ recycling of Upsilon STS at the end of its service life.

To discover the entire range of MGE UPS SYSTEMS products and the options available for the Upsilon STS range, we

invite you to visit our web site at www.mgeups.com or contact your MGE UPS SYSTEMS representative.

All products in the Upsilon STS range are protected by patents. They implement original technology not available to competitors of MGE

UPS SYSTEMS.

To take into account evolving standards and technology, equipment may be modified without notice. Indications concerning technical

characteristics and dimensions are not binding unless confirmed by MGE UPS SYSTEMS.

This document may be copied only with the written consent of MGE UPS SYSTEMS. Authorised copies must be marked "Upsilon STS

Installation and User Manual, nr 3402011300".

34020113EN/AA - Page 3

Page 4

Foreword

Using this document

Information may be found primarily by consulting:

◗ the contents,

◗ the index.

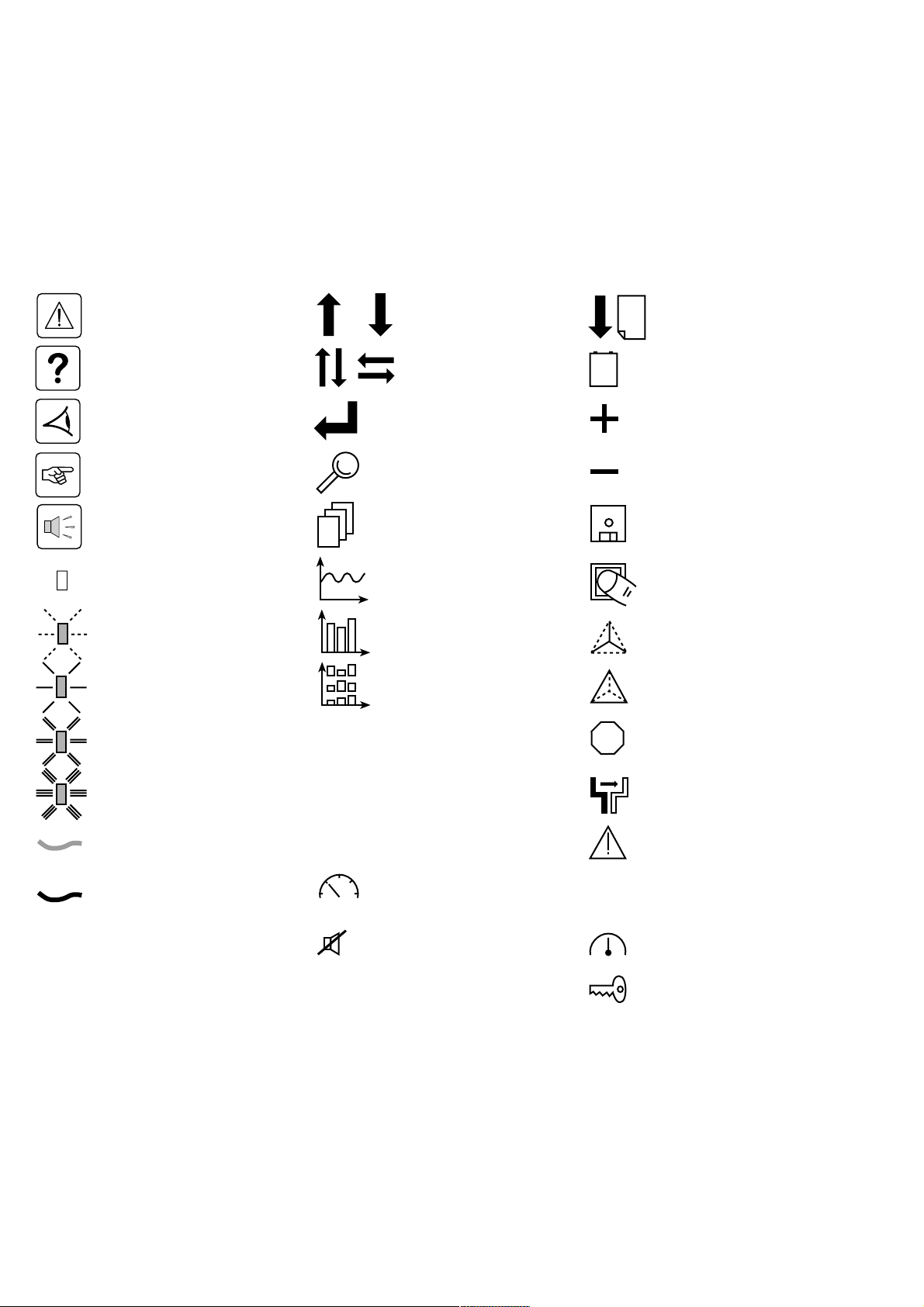

Pictograms

Document

Display

Important instructions that must

be followed

Information, advice, help

Visual indication

Action

Audio indication

LED off

LED flashing

LED on green

LED on orange

LED on red

Earth cables

Other cables

88.8

8.88

E

S

C

D

E

L

VOLT

Up / down selection

Other selection

Confirm

Details

Scrolling menu

Graphic display

Graphic display

Graphic display

Digital display

Return to previous display

Delete

Access to measurements

17

mai

STOP

0101

1010

0101

Go up or down one page

Select date for event log

consultation

Increase

Reduce

Save

Enter characters

Phase-to-neutral

measurements

Phase-to-phase

measurements

Interrupt manual transfer

without break

Transfer

Alarm

Status conditions

Page 4 - 34020113EN/AA

Buzzer off

Note: LEDs and switches are represented in their rest position. Transient conditions are indicated by dotted arrows.

Settings

Maintenance

Page 5

Contents

1. Presentation

1.1 Upsilon STS 30 - 60 - 100 - 160 - 250 A (cabinet 1400 mm high) .............................................. 7

1.2 Upsilon STS 30 - 60 - 100 - 160 - 250 - 400 - 600 A (cabinet 1900 mm high) .......................... 7

1.3 Access to control and connections .......................................................................................... 8

Upsilon STS 30 - 60 - 100 - 160 - 250 A (cabinet 1400 mm high) ................................................. 8

Upsilon STS 30 - 60 - 100 - 160 - 250 - 400 - 600 A (cabinet 1900 mm high)............................... 8

1.4 Man / machine interface ............................................................................................................... 9

1.5 Relay communication card ........................................................................................................ 10

1.6 JBus communication card ......................................................................................................... 10

2. Installation

2.1 Positioning .................................................................................................................................. 11

Upsilon STS 30 - 60 - 100 - 160 - 250 A (cabinet 1400 mm high) ............................................... 11

Upsilon STS 30 - 60 - 100 - 160 - 250 - 400 - 600 A (cabinet 1900 mm high)............................. 11

2.2 Power connections ..................................................................................................................... 12

Upsilon STS 30 to 250 A with input/output: 3 phases + PEN, ..................................................... 12

Upsilon STS 30 to 250 A with input: 3 phases + PEN, output: 3 phases + PE + Neutral ............ 12

Upsilon STS 30 to 250 A with input: 3 phases + PEN, output: 3 phases + PE ............................ 13

Upsilon STS 30 to 250 A with input/output: 3 phases + PE + Neutral ......................................... 13

Upsilon STS 30 to 250 A with input/output: 3 phases + PE ......................................................... 13

Upsilon STS 400 to 600 A with input/output: 3 phases + PEN .................................................... 14

Upsilon STS 400 to 600 A with input: 3 phases + PEN, output: 3 phases + PE + Neutral .......... 14

Upsilon STS 400 to 600 A with input: 3 phases + PEN, output: 3 phases + PE .......................... 15

Upsilon STS 400 to 600 A with input/output: 3 phases + PE + Neutral ....................................... 15

Upsilon STS 400 to 600 A with input/output: 3 phases + PE ....................................................... 15

Cable running for cables entering through the top of the Upsilon STS 30 to 250 A cabinet ........ 16

2.3 Connection of the emergency power off terminal block ......................................................... 16

2.4 Connection of the communication cards ................................................................................. 17

2.5 Connection of the JBUS communication card......................................................................... 17

2.6 Connection of the relay communication card .......................................................................... 18

3. Operation

3.1 Start-up ........................................................................................................................................ 19

3.2 Shutdown..................................................................................................................................... 19

3.3 Normal mode: operation on preferred source S1 .................................................................... 20

Operation on the preferred source ................................................................................................ 20

Automatic transfer to the alternate source .................................................................................... 20

Manual transfer to the alternate source ........................................................................................ 20

Manual transfer to an out-of-phase alternate source .................................................................... 21

3.4 Display screens........................................................................................................................... 22

3.5 Upsilon STS customization........................................................................................................ 23

3.6 Customization of the relay communication card ..................................................................... 24

4 Maintenance

4.1 Identification of anomalies......................................................................................................... 25

4.2 Transfer to the manual bypass .................................................................................................. 25

5 Environment ..................................................................................................................................... 26

34020113EN/AA - Page 5

Page 6

Contents

6 Appendix

6.1 Technical data ............................................................................................................................. 27

Output currents and voltage.......................................................................................................... 27

Thermal characteristics ................................................................................................................. 27

Noise level .................................................................................................................................... 27

Cable sizes ................................................................................................................................... 27

Recommended protection devices upstream of Upsilon STS ..................................................... 27

Permissible-overload curve........................................................................................................... 27

6.2 Simplified diagrams .................................................................................................................... 28

Upsilon STS simplified diagram ................................................................................................... 28

Simplified diagram of an installation ............................................................................................. 28

6.3 Glossary....................................................................................................................................... 29

6.4 Index............................................................................................................................................. 30

Page 6 - 34020113EN/AA

Page 7

1. Presentation

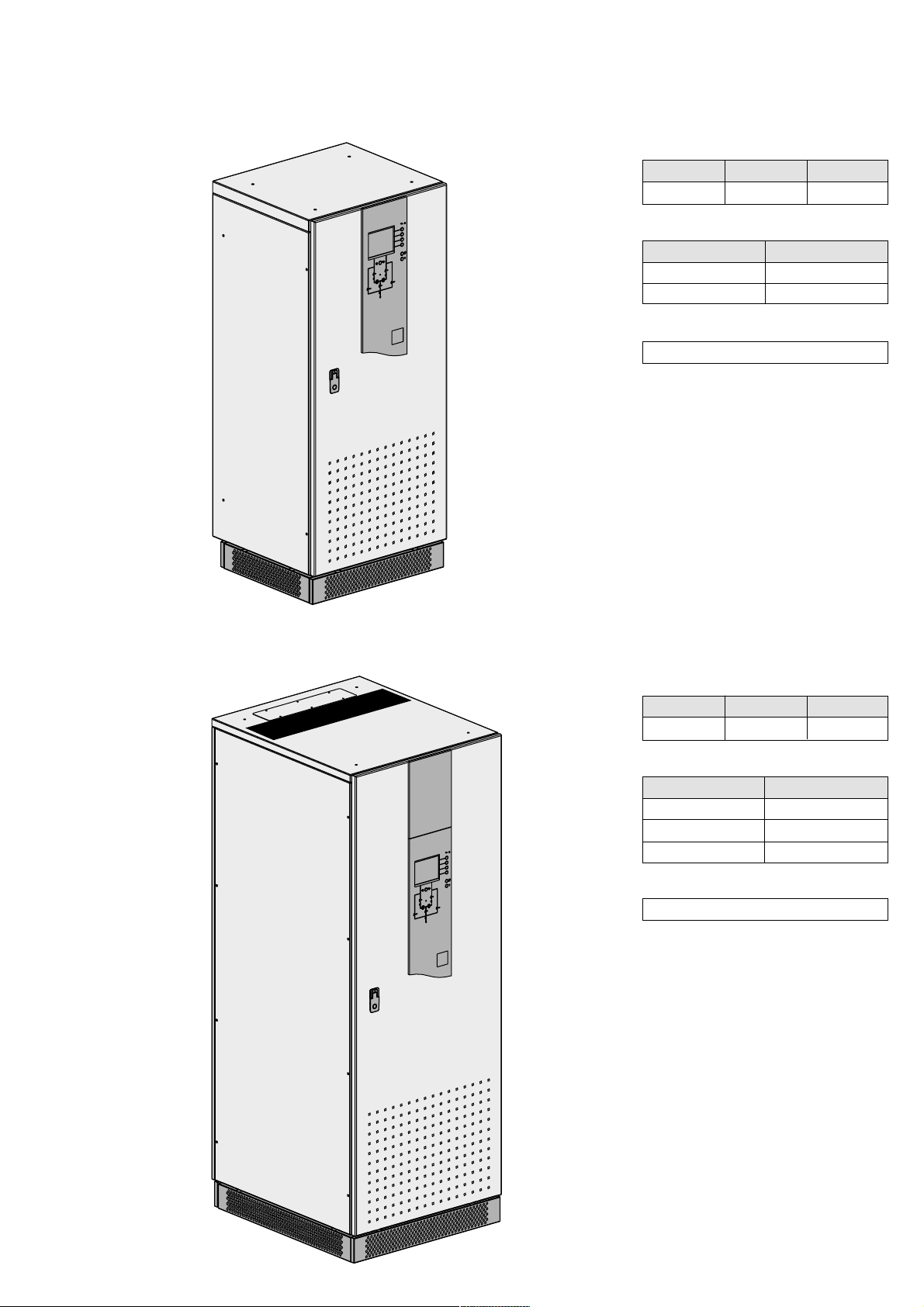

1.1 Upsilon STS 30 - 60 - 100 - 160 - 250 A (cabinet 1400 mm high)

Dimensions in mm

Height

1400

Weight in kg

Upsilon STS

30 - 60 - 100 A

160 - 250 A

Footprint

Width

600

0.45 m

Depth

500

157 kg

174 kg

2

1.2 Upsilon STS 30 - 60 - 100 - 160 - 250 - 400 - 600 A (cabinet 1900 mm high)

Dimensions in mm

Height

1900

Weight in kg

Upsilon STS

30 - 60 - 100 A

160 - 250 A

400 - 600 A

Footprint

Width

715

0.57 m

Depth

800

215 kg

225 kg

327 kg

2

34020113EN/AA - Page 7

Page 8

1. Presentation

1.3 Access to control and connections

Upsilon STS 30 - 60 - 100 - 160 - 250 A (cabinet 1400 mm high)

1

Switch Q1 for Source S1

2

Circuit breaker Q5 for control electronics

power supply

3

Circuit breaker Q6 for control electronics

power supply

4

Switch Q2 for Source S2

5

Communication card cage

6

Bypass switch Q1BP for Source S1

7

Output switch Q3

16

Emergency power off terminal block

8

Bypass switch Q2BP for Source S2

9

Source S2 connection

10

Output connections

11

Source S1 connection

12

Earth bar

13

Connection cover

Base panels

14

15

Adjustable foot pads

Upsilon STS 30 - 60 - 100 - 160 - 250 - 400 - 600 A (cabinet 1900 mm high)

1

Switch Q1 for Source S1

2

Circuit breaker Q5 for control electronics

power supply

Circuit breaker Q6 for control electronics

3

power supply

4

Switch Q2 for Source S2

5

Communication card cage

Bypass switch Q1BP for Source S1

6

7

Output switch Q3

8

Bypass switch Q2BP for Source S2

16

Emergency power off terminal block

9

Source S2 connection

10

Output connections

11

Source S1 connection

12

Earth bar

13

Connection cover

14

Base panels

Page 8 - 34020113EN/AA

Adjustable foot pad

15

Page 9

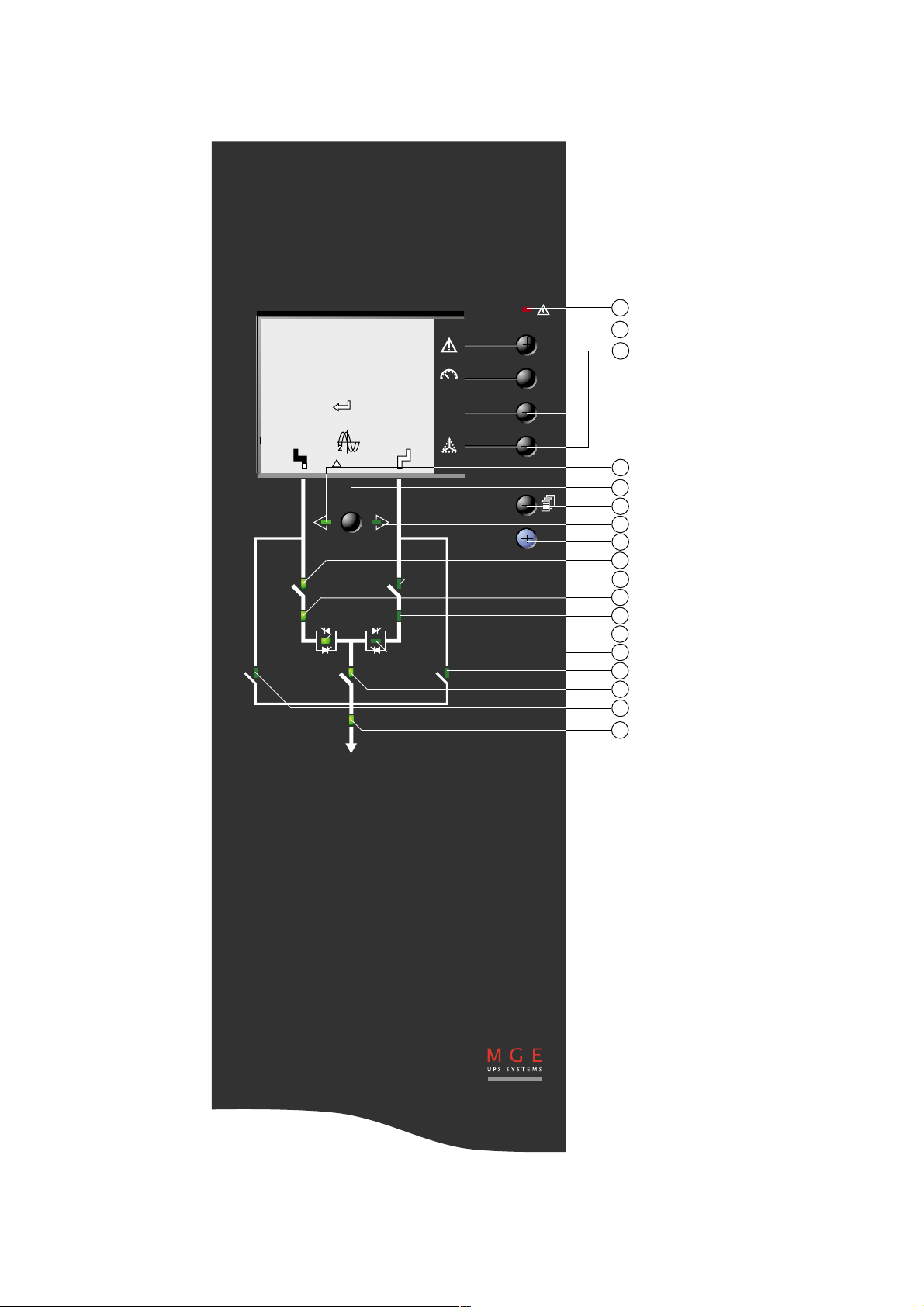

1.4 Man / machine interface

Menu

NORMAL OPERATION

Menu

I1 17 A I2 9 A I3 2 A

Source prioritaire

UPS galaxy

UPS galaxy

deuxième étage, salle 14

deuxième étage, salle 14

Q1BP

1 KW 6 KVA

Transfert

Alarme

Alarme

Mesures

Mesures

Etats

Etats

Historique

Historique

UPS 1

U12 413 V

U23 414 V

U31 414 V

50.0 Hz

Q1 Q2

PF 0.3

preferred

synchro

U12 412 V

U23 415 V

U31 413 V

50.0 Hz

Source secours

UPS galaxy

UPS galaxy

deuxième étage, salle 13

deuxième étage, salle 13

= 0°

Q3

load

charge

UPS 2

volt

Q2BP

1. Presentation

21

General alarm

22

Graphic display

23

Function buttons

Preferred source S1

24

25

Manual transfer button

26

Menu button

27

?

Preferred source S2

28

Help button

29

Status of switch Q1

30

Status of switch Q2

31

Status of source S1 (green, orange, red)

32

Status of source S2 (green, orange, red)

33

Status of static switch 1 (green, red)

34

Status of static switch 2 (green, red)

35

Status of bypass switch Q2BP

36

Status of switch Q3

37

Status of bypass switch Q1BP

Status of system output to the load (green,

38

red)

Upsilon STS

34020113EN/AA - Page 9

Page 10

1. Presentation

1.5 Relay communication card

2

1

B

A

1.6 JBus communication card

41

42

43

44

6

5

4

3

45

46

47

Screws to secure the cover

Card fixing holes

Protection cover

Openings for cables

Output terminal block

Input terminal block

Screws to block cables

48 RS232 connector

49

RS485 connector

Page 10 - 34020113EN/AA

Page 11

2.1 Positioning

Upsilon STS 30 - 60 - 100 - 160 - 250 A (cabinet 1400 mm high)

>250 mm

2. Installation

1 - Unclip the base panels 14 .

2 - Set the cabinet to a level position using

the adjustable foot pads 15 .

3 - Put the base panels 14 back in place.

Important: correct ventilation

requires at least 250 mm of free

space behind the cabinet.

14

15

Upsilon STS 30 - 60 - 100 - 160 - 250 - 400 - 600 A (cabinet 1900 mm high)

1 - Unclip the base panels 14 .

2 - Set the cabinet to a level position using

>350 mm

the adjustable foot pads 15 .

3 - Put the base panels 14 back in place.

Important: correct ventilation

requires at least 350 mm of free

space above the cabinet.

14

15

34020113EN/AA - Page 11

Page 12

2. Installation

2.2 Power connections

See section 6.1 for information on sizing protection devices and cables (Appendix, Technical data).

Two cables maximum may be used per phase.

Upsilon STS 30 to 250 A Input: 3 phases + PEN

Output: 3 phases + PEN

N L1 L2 L3 N L1 L2 L3 N L1 L2 L3

N

See section 1.3 for information on accessing

the connections.

Connections are made using lugs connected

to threaded studs (diameter 8 mm).

The cables are tied to the earth bar.

PEN

S1 S2

PEN PEN

275 mm

Upsilon STS 30 to 250 A Input: 3 phases + PEN

Output: 3 phases + PE + Neutral

N L1 L2 L3 N L1 L2 L3 N L1 L2 L3

N

PEN

S1 S2

PE PEN

275 mm

See section 1.3 for information on accessing

the connections.

Connections are made using lugs connected

to threaded studs (diameter 8 mm).

The cables are tied to the earth bar.

Page 12 - 34020113EN/AA

Page 13

Upsilon STS 30 to 250 A Input: 3 phases + PEN

Output: 3 phases + PE

N L1 L2 L3 N L1 L2 L3 N L1 L2 L3

N

2. Installation

See section 1.3 for information on accessing

the connections.

Connections are made using lugs connected

to threaded studs (diameter 8 mm).

The cables are tied to the earth bar.

PEN

S1 S2

PE PEN

275 mm

Upsilon STS 30 to 250 A Input: 3 phases + PE + Neutral

Output: 3 phases + PE + Neutral

See section 1.3 for information on accessing

the connections.

Connections are made using lugs connected

to threaded studs (diameter 8 mm).

The cables are tied to the earth bar.

N L1 L2 L3 N L1 L2 L3 N L1 L2 L3

N

PE

NN

PE PE

275 mm

S1 S2

Upsilon STS 30 to 250 A Input: 3 phases + PE

Output: 3 phases + PE

N L1 L2 L3 N L1 L2 L3 N L1 L2 L3

PE PE PE

275 mm

S1 S2

See section 1.3 for information on accessing

the connections.

Connections are made using lugs connected

to threaded studs (diameter 8 mm).

The cables are tied to the earth bar.

34020113EN/AA - Page 13

Page 14

2. Installation

See section 6.1 for information on sizing protection devices and cables (Appendix, Technical data).

A maximum of four cables may be used per phase.

Upsilon STS 400 to 600 A Input: 3 phases + PEN

Output: 3 phases + PEN

N L1 L2 L3 N L1 L2 L3 N L1 L2 L3

463

N

S1 S2

PEN

PEN PEN

mm

403

mm

See section 1.3 for information on accessing

the connections.

Connections are made using lugs connected

to two threaded studs per phase (diameter

10 mm).

The cables are tied to the earth bar.

Upsilon STS 400 to 600 A Input: 3 phases + PEN

Output: 3 phases + PE + Neutral

N L1 L2 L3 N L1 L2 L3 N L1 L2 L3

463

N

S1 S2

PEN

N

PE PEN

mm

403

mm

See section 1.3 for information on accessing

the connections.

Connections are made using lugs connected

to two threaded studs per phase (diameter

10 mm).

The cables are tied to the earth bar.

Page 14 - 34020113EN/AA

Page 15

Upsilon STS 400 to 600 A Input: 3 phases + PEN

Output: 3 phases + PE

N L1 L2 L3 N L1 L2 L3 N L1 L2 L3

463

mm

N

S1 S2

PEN

PE PEN

403

mm

2. Installation

See section 1.3 for information on

accessing the connections.

Connections are made using lugs

connected to two threaded studs per phase

(diameter 10 mm).

The cables are tied to the earth bar.

Upsilon STS 400 to 600 A Input: 3 phases + PE + Neutral

Output: 3 phases + PE + Neutral

See section 1.3 for information on accessing

the connections.

Connections are made using lugs connected

to two threaded studs per phase (diameter

N L1 L2 L3 N L1 L2 L3 N L1 L2 L3

NN N

S1 S2

PE PE PE

463

mm

403

mm

10 mm).

The cables are tied to the earth bar.

Upsilon STS 400 to 600 A Input: 3 phases + PE

Output: 3 phases + PE

See section 1.3 for information on

accessing the connections.

Connections are made using lugs

N L1 L2 L3 N L1 L2 L3 N L1 L2 L3

connected to two threaded studs per phase

(diameter 10 mm).

The cables are tied to the earth bar.

S1 S2

PE PE PE

463

mm

403

mm

34020113EN/AA - Page 15

Page 16

2. Installation

Cable running for cables entering through the top of the Upsilon STS 30 to 250 A

cabinet

Cable-running zone for cables entering

16

through the top

Cable gland plate that must be drilled to

17

cable size

2.3 Connection of the emergency power off terminal block

1 - Remove the jumper from terminal block

16 .

2 - Connect the emergency power off NC

contact to terminals 1 and 2.

3 - Tie the cable down as illustrated in

section 2.4.

Page 16 - 34020113EN/AA

2

1

16

Page 17

2.4 Connection of the communication cards

2. Installation

Tie the cables to the cable way on the door.

Do not run the control wires with

the power cables.

Two slots are available in the card

cage 5 for additional cards.

5

2.5 Connection of the JBUS communication card

JBUS/MODBUS

12345

6789

RS232:

Pin 2: Rxd (or Txd)

Pin 3: Txd (or Rxd)

Pin 5: Earth

RS485:

Pin 4: RPin 5: TPin 8: R+

Pin 9: T+

For information on using the

communication card, see the

JBUS communication card

manual.

Only one communication port

(the RS232 OR the RS485) may

be used at a time.

34020113EN/AA - Page 17

Page 18

2. Installation

2.6 Connection of the relay communication card

Before proceeding, disconnect all power sources connected to the card.

Do not mix very low safety voltage (VLSV) and non-VLSV circuits on the card outputs.

1 - Remove the screws 41 and the

protection cover 43 .

2 - Run the communication cables through

the openings 44 .

3 - Connect the cables to the input terminal

block 46 and the output terminal block 45 .

46

41

45

44

43

4 - Put the cover back in place and secure it

with the screws 41 .

5 - Secure the cables using the screws 47 .

6 - Note the position of the power sources

on the labels.

7 - Insert the card in its slot.

8 - Secure the card using the two screws

42 .

42

6

5

4

3

2

1

B

A

Page 18 - 34020113EN/AA

42

47

Source S2 status condition (active or inactive)

Source S1 status condition (active or inactive)

Overload status condition

STS fault

(fault on one of the sources or on the STS)

Load-supplied status condition

(presence or absence of power to the load)

General alarm

Characteristics of the output contacts:

6

Permissible voltage: 250 V AC, 30 V DC

Permissible current: 2 A

Cable: 4 x 0.93 mm2, Ø 6.6 mm ± 0.3 mm.

5

4

3

2

1

Characteristics of the input contacts:

Switched voltage: 5 V DC

Current drawn: 10 mA

Cable: 4 x 0.34 mm2, Ø 5 mm ± 0.5 mm.

Command to disable transfer (transfer to alternate

source inhibited)

Memorised faults reset command

BA

Page 19

3.1 Start-up

3. Operation

Make sure that the voltages and frequencies of the two sources S1 and S2 are identical.

Make sure that the voltages of the two sources S1 and S2 are the same as the rated voltage (400 V) of Upsilon STS,

otherwise see section 3.5 (Customization).

1 - Check that the two sources are

energised (voltage present).

2 - Set circuit breakers Q5 2 and Q6 3

to the ON position (position 1).

3 - Turn switch Q1BP 6 to the ON position

(position 1). LEDs 37 and 38 go on.

The load is supplied by Source 1 via the

bypass.

4 - Set switches Q1 1 and Q3 7 to the

ON position (position 1). LEDs 29 , 31 ,

and 36 go on.

5 - Turn switch Q1BP 6 back to the OFF

position (position 0). LED 37 goes off.

6 - Set switch Q2 4 to the ON position

(position 1). LEDs 30 and 32 go on.

The load is supplied by Source 1.

If LED 33 is red or off, if LEDs

31 and/or 32 are orange or

red: see section "Maintenance".

Q1 Q5 Q6 Q2

1

0

1

0

Q1BP Q2BPQ3

111

000

S1 S2

Q1 Q2

Q1BP

Q3

Q2BP

1

2

3

4

6

7

29

30

31

32

33

36

37

38

3.2 Shutdown

000

Q1 Q5 Q6 Q2

1

0

Q1BP Q2BPQ3

S1 S2

Q1 Q2

Q1BP

1

2

3

1

0

4

7

1 - Set switches Q1 1 , Q2 4 and Q3 7

to the OFF position (position 0).

2 - Set circuit breakers Q5 2 and Q6 3

to the OFF position (position 0).

All LEDs should go off.

The load is not supplied with power.

Dangerous voltage levels are

still present inside the Upsilon

111

STS cabinet, in the connection

zone.

Q2BPQ3

34020113EN/AA - Page 19

Page 20

3. Operation

3.3 Normal mode. Operation on preferred source S1

Operation on the preferred source

S1 S2

Q1 Q2

Q1BP

Q3

Q2BP

Automatic transfer to the alternate source

S1 S2

Q1 Q2

24

29

30

31

32

33

36

38

24

29

30

31

32

During normal operation on the preferred

source S1, LEDs 24 , 29 , 30 , 31 , 32 ,

33 , 36 and 38 are on in green.

If LED 38 is orange, there is an

overload.

If LED 38 is red, the load is no

more supplied.

The load is automatically transferred to the

source offering the highest level of power

quality.

For example, if the preferred source S1

goes outside tolerances, LED 31 goes

orange or red. The buzzer beeps.

Upsilon STS automatically transfers the

load to the alternate source S2. LEDs 24 ,

29 , 30 , 32 , 34 , 36 and 38 are on.

Q1BP

Q3

Q2BP

Manual transfer to the alternate source

S1 S2

Q1 Q2

Q1BP

Q3

Q2BP

34

36

38

25

27

Upsilon STS transfers the load

back to the preferred source S1 as

soon as it returns to within

tolerances.

To stop the buzzer, press the

function button marked .

1 - Press the manual transfer button 25 :

2 - Confirm the order by pressing the grey

function button 23 marked on the

screen.

LEDs 24 and 27 flash.

After the transfer, the green LED 27 goes

on.

The load is supplied by alternate Source 2.

Transfer is authorised only if the

two sources are within tolerances

(voltage, frequency) and their

phase displacement is within the

set limits. If these two conditions

are not met, the transfer order is

stored in memory and executed

when the voltages cross zero.

If transfer does not take place

within thirty minutes, the order is

cancelled.

Page 20 - 34020113EN/AA

Page 21

Manual transfer to an out-of-phase alternate source

3. Operation

S1 S2

Q1 Q2

Q1BP

When the two sources are not in phase, it is

possible to force manual transfer using the

commands on the screen, after entering a

password.

1 - Enter the password (see section 3.5,

Customization).

2 - Follow the instructions provided on the

screen.

Q3

Q2BP

34020113EN/AA - Page 21

Page 22

3. Operation

3.4 Display screens

Initial screen

DOWNGRADED MODE

I1 17 A I2 9 A I3 2 A

UPS 1

V1 244 V

V2 230 V

V3 232 V

50.0 Hz

1 KW 6 KVA

PF 0.3

preferred

synchro

= 64°

UPS 2

V1 232 V

V2 229 V

V3 230 V

50.0 Hz

MANUAL TRANSFERT

Transfer without break

Transfer with break

MAIN MENU

Transfer

Alarms

0101

1010

Status

0101

Measurements

VOLT

Setup

Maintenance

Transfer

Status

Main screen

E

S

C

Alarms

ALARMS

Measurements

STATUS

EVENT LOG

STATISTICS

SETUP

LANGUAGE

ADJUST DATE AND TIME

CONTRAST

BUZZER VOLUME

SOURCE NAMES

NEW PASSWORD

PERSONALIZATION

DRY CONTACT SETTINGS

CURRENT MEASUREMENTS

VOLTAGE MEASUREMENTS

FREQUENCY MEASUREMENTS

POWER MEASUREMENTS

LOAD MEASUREMENTS

Setup

Maintenance

MAINTENANCE

DISPLAY TEST

UNIT ON BYPASS

Page 22 - 34020113EN/AA

Page 23

3.5 Upsilon STS customization

1 - Press the menu button 26 .

2 - Select "Setup", then "Customization" using the function buttons 23 marked or .

3 - Confirm the order by pressing the function button 23 marked .

4 - Enter the password.

3. Operation

The password

ØØØ

is set in the factory.

Select "Setup", then "Password" to personalise the password.

PERSONALIZATION

Current settings

Nominal voltage

Overvoltage threshold

Undervoltage threshold

Nominal frequency

Overfrequency threshold

Underfrequency threshold

Phase sync tolerance

Retransfer

400 V

10%

10%

50 Hz

5%

5%

15°

YES

E

S

C

Return to preferred source after transfer

Nominal source voltage

Overvoltage threshold

Undervoltage threshold

Factory setting

Automatic

400 V

Un +10%

Un -10%

The monitoring parameters must

be identical for the two sources.

These parameters depend on the

tolerances of the connected loads.

Customization

Manual / Automatic

380 / 400 / 415 V

Un +5% to Un +20%

in 1% steps

Un -5% to Un -20%

in 1% steps

Nominal source frequency

Frequency tolerances

Phase error tolerance between the two sources

50 Hz

±5%

±15°

50 / 60 Hz

+1% to +10%

-1% to -10%

in 0.5% steps

±1° to ±45° in 1° steps

34020113EN/AA - Page 23

Page 24

3. Operation

3.6 Customization of the relay communication card

1.A

1.B

1.1

1.2

1.3

1.4

1.5

1.6

Inputs

Outputs

Factory setting

- Memorised faults reset command.

- Command to disable transfer.

Factory setting

- Load-supplied status condition (presence or

absence of power to the load).

- General alarm (fault on one of the sources or

on the Upsilon STS).

- Upsilon STS fault.

- Overload status condition.

- Source S1 status condition (active or inactive).

- Source S2 status condition (active or inactive).

Signals available on each contact

- Memorised faults reset command.

- Selection command for source S1.

- Selection command for source S2.

- Selection command for the authorised

automatic retransfer mode.

- Selection command for the inhibited automatic

retransfer mode.

- Command to authorise transfer.

- Command to disable transfer.

- EPO command (enables the opening

command for switches Q1 and Q2).

Signals available on each contact

- Load-supplied status condition (presence or

absence of power to the load).

- General alarm (fault on one of the sources or

on the Upsilon STS).

- Upsilon STS fault.

- Source S1 status condition (within or outside

tolerances).

- Source S2 status condition (within or outside

tolerances).

- Phase-error condition between the two

sources (within or outside tolerances).

- Source S1 status condition (active or inactive).

- Source S2 status condition (active or inactive).

- Preferred-source status condition (S1 inactive

and S2 active).

- Automatic-transfer status condition

(authorised or not).

- Overload status condition.

Page 24 - 34020113EN/AA

Page 25

4.1 Identification of anomalies

4. Maintenance

General-alarm

LED 21

-

-

-

-

-

S1 31 or S2 32

LED

-

-

-

-

Static-switch

LED 33 or 34

-

-

-

-

-

Buzzer

Beeps

Beeps

Beeps

Beeps

-

-

System output

LED 38

-

-

-

-

Meaning

Internal STS fault.

Source outside

tolerances, load still

supplied.

Source outside

tolerances, no voltage.

The load cannot be

supplied by this source.

Static-switch fault.

Overload.

Load not supplied.

The meaning of all these anomalies are detailed on the display:

Select the alarm: the corresponding informations are displayed.

4.2 Transfer to the manual bypass

Q1 Q5 Q6 Q2

1

0

Q1BP Q2BPQ3

000

Q1 Q5 Q6 Q2

1

0

Q1BP Q2BPQ3

000

Q1 Q5 Q6 Q2

1

0

Q1BP Q2BPQ3

000

1

0

111

1

0

111

1

0

111

Transfer to the manual bypass for source

S1:

4

6

1

7

1 - Manually transfer the load to source S1.

2 - Set switch Q2 4 to the OFF position

(position 0).

3 - Set switch Q1BP 6 to the ON position

(position 1).

The load is supplied by source S1 via the

bypass.

4 - Set switches Q1 1 and Q3 7 to the

OFF position (position 0).

The operation for source S2 is

identical, using switches Q2 and

Q2BP.

Interlocking of the bypass lines is

ensured by use of a single key that

must be inserted on the bypass

switch to be operated.

34020113EN/AA - Page 25

Page 26

5. Environment

This product has been designed to respect the environment

It does not contain CFCs or HCFCs.

It is manufactured on a production site certified ISO 14001.

UPS recycling at the end of service life

MGE UPS SYSTEMS undertakes to recycle, by certified companies and in compliance with all applicable regulations, all

products recovered at the end of their service life (contact your MGE UPS SYSTEMS branch office).

Packing

Packing materials must be recycled in compliance with all applicable regulations.

Page 26 - 34020113EN/AA

Web site: www.mgeups.com

Page 27

6.1 Technical data

Output currents and voltage

6. Appendix

Rated output current:

Input and output voltage:

◗ Rated operating voltage:

◗ Maximum voltage:

◗ Minimum voltage:

◗ Rated frequency:

Thermal characteristics

Heat losses

◗ at rated power:

◗ at 50% rated power:

Required ventilation:

(1) These characteristics are calculated for a voltage of 400 V and a power factor of 0.8.

(1)

Noise level

Noise in dB (ISO 3746):

Cable sizes

Cross-sectional area in mm2 :

30 A

:

195 W

150 W

350 m3/h

55 55 55 59 59 59 59

50 50 50 120 120 240 240

60 A 100 A 160 A 250 A 400 A 600 A

380 V / 400 V / 415 V

498 V (415 V +20%)

247 V (380 V -35%)

50 or 60 Hz (45 Hz minimum, 66 Hz maximum)

295 W

195 W

350 m3/h

430 W

260 W

350 m3/h

615 W

350 W

1600 m3/h

920 W

495 W

1600 m3/h

1420 W

735 W

2300 m3/h

2150 W

1070 W

2300 m3/h

Recommended protection devices upstream of Upsilon STS

Type of circuit breaker:

◗ TNS system:

◗ TNC system:

Trip unit:

Thermal setting:

Magnetic setting:

C60L 32A

curve C

1.05 In

10xIn

NS100H 4P 4D

NS100H 3P

STR22SE

≤1.05 In

≤10xIn

Permissible-overload curve

32 In

16 In

8 In

4 In

NS160H

4P 4D

NS160H

3P

STR22SE

≤1.05 In

≤10xIn

NS250H

4P 4D

NS250H

3P

STR22SE

≤1.05 In

≤10xIn

NS400H

4P 4D

NS400H

3P

STR23SE

≤1,05 In

≤10xIn

NS630H

4P 4D

NS630H

3P

STR23SE

≤1.05 In

≤10xIn

2 In

In

0.01 s 0.1 s 1 s 10 s 100 s 1000 s

◗ During an overload, transfer between sources is disabled.

◗ Overloads higher than 1.5 In are stored in memory. The alarm must be reset to return to normal operation.

t(s)

34020113EN/AA - Page 27

Page 28

6. Appendix

6.2 Simplified diagrams

Upsilon STS simplified diagram

S1 S2

Simplified diagram of an installation

Preferred sources

Source 1

Q1

Source 2

Upsilon STS

Static-switch

control/monitoring

Q2

Q3 Q2BPQ1BP

To the load

Alternate sources

Page 28 - 34020113EN/AA

Upsilon STSUpsilon STS

To the load

Upsilon STS

Page 29

6.3 Glossary

Alternate source Backup source that steps in if the preferred source fails.

JBUS communication card Internal card implementing the JBus protocol on a serial link to supply the user with

Load Device(s) or system(s) connected the Upsilon STS output.

Manual bypass Q1BP, Q3 and Q2BP switches, accessible to the user, that may be used to directly

Normal mode Operating mode during which the load is supplied by the preferred source.

Preferred source Source selected as the normal source of power.

Relay communication card Internal card implementing contacts to supply the user with system information.

Static switch Electronic switch ensuring instantaneous switching.

6. Appendix

system information.

supply the load from Source S1 or S2. The bypass enables servicing on the equipment

without interrupting the supply of power to the load.

34020113EN/AA - Page 29

Page 30

6. Appendix

6.4 Index

A

Alarms ............................................................................ 25

Anomalies ...................................................................... 25

B

Buzzer ............................................................................ 25

C

Cable sizes .................................................................... 27

Communication cards

JBUS ...................................................................... 10

Relay ...................................................................... 10

Connections

Access ...................................................................... 8

JBUS communication card ..................................... 17

Power cables .................................. 12, 13, 14, 15, 16

Relay communication card ..................................... 18

Through the top ...................................................... 16

Customization .......................................................... 23, 24

D

Dimensions ...................................................................... 7

Display ........................................................................... 22

F

Faults ............................................................................. 25

Frequency ...................................................................... 27

L

Layout of components ...................................................... 8

LEDs .......................................................................... 9, 25

Links

RS232 .................................................................... 10

RS485 .................................................................... 10

Losses ............................................................................ 27

M

Man / machine interface ................................................... 9

Manual bypass ............................................................... 25

O

Operating modes ..................................................... 20, 21

Overloads ....................................................................... 27

R

Recommended protection .............................................. 27

Recycling ....................................................................... 26

S

Safety rules ...................................................................... 3

Shutdown ....................................................................... 19

Start-up .......................................................................... 19

V

Ventilation ...................................................................... 27

Voltages ......................................................................... 27

W

Weight .............................................................................. 7

Page 30 - 34020113EN/AA

Loading...

Loading...