Operating Instructions........... page

Mode d’emploi ......................page

Instrucciones de manejo .... página

Instruções de serviço ......... página

5

10

16

22

170 26 8570 - 1112

KHE 56

MHE 56

2

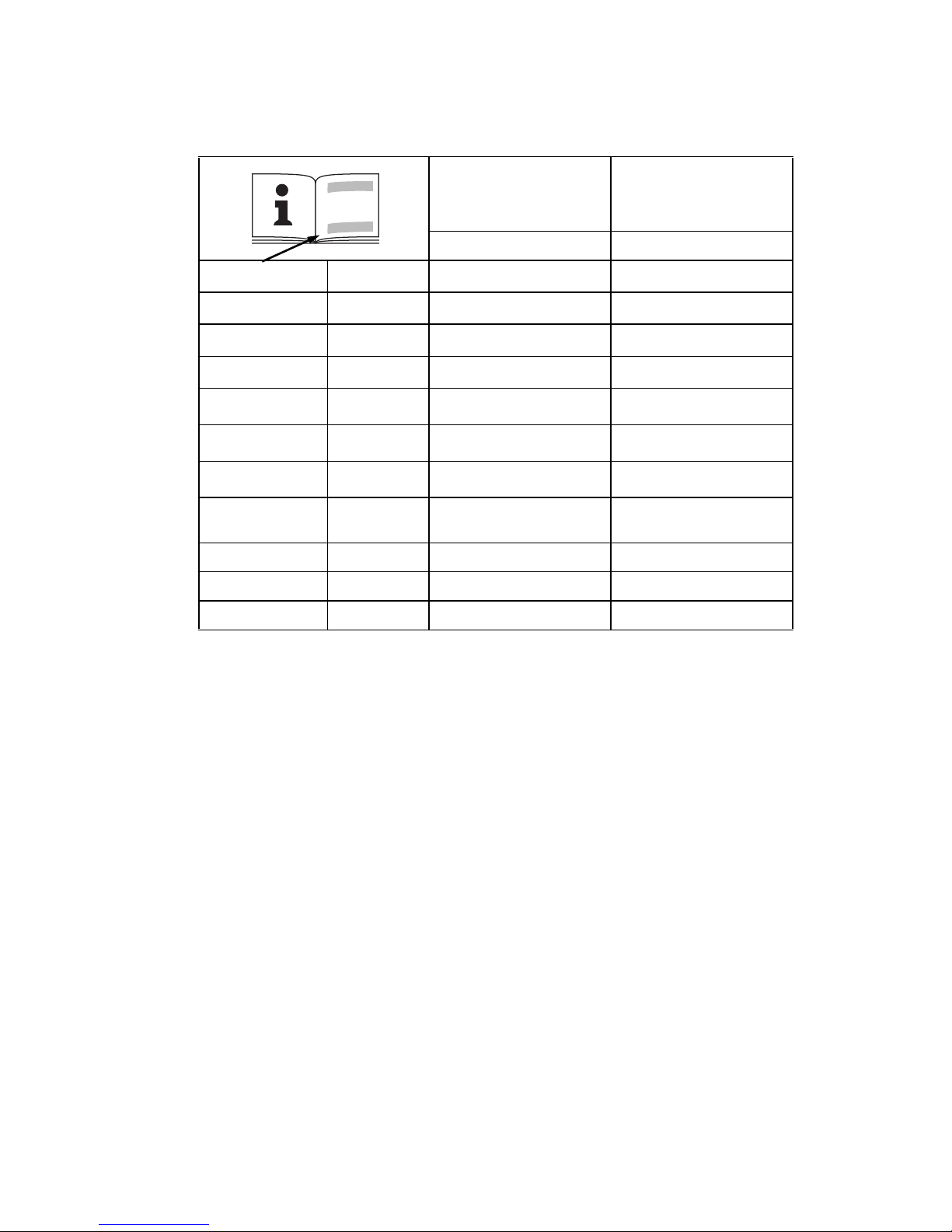

KHE 56 MHE 56

SDS-max SDS-max

P

1

W 1300 1300

P

2

W 650 650

T

in-lbs (Nm) 796 (90) -

n

1

/min 0 - 300 -

D

1

in (mm)

1

25

/32 (45)

-

D

2

in (mm)

3

15

/16 (100)

-

D

3

in (mm)

2

9

/

16

(65)

-

smax

/min

bpm

2840 2840

WJ 14 14

C- 12 12

mlbs (kg)14.8 (6,7) 13.9 (6,3)

14

© 2012

Metabowerke GmbH,

Postfach 1229

Metabo-Allee 1

D-72622 Nürtingen

Germany

3

1

3

2

4

5

6

7

7

b

a

8

8

9

10

12

13

14

15

89

10

12

13

11

14

15

KHE 56

MHE 56

4

A

B

6.31800

MHE 56

KHE 56

etc.

.

.

.

etc.

.

.

.

ENGLISH

5

ENG

1 Specified Use

2 General Safety Rules

3 Special Safety Rules

4 Functional Description

5 Special Product Features

6 Commissioning

6.1 Assembly of the bow handle or

additional handle

7Use

7.1 Adjusting the depth stop

(only for KHE 56)

7.2 Attaching and removing tools

7.3 Setting the operating mode

7.4 Adjusting the chisel position

7.5 Adjusting the impact force

7.6 Switching on and off

7.7 Metabo VibraTech (MVT)

8 Cleaning, Maintenance

9 Tips and Tricks

10 Troubleshooting

11 Accessories

12 Repairs

13 Environmental Protection

14 Technical Specifications

The KHE 56 is designed for hammer drilling and

chiselling in concrete, bricks, stone and similar

materials when used in combination with appropriate accessories.

The MHE 56 is designed for chiselling in concrete,

bricks, stone and similar materials when used in

combination with appropriate accessories.

The user bears sole responsibility for damage

caused by improper use.

Generally accepted accident prevention regulations and the enclosed safety information must be

observed.

General Power Tool Safety Warnings

WARNING

Read all safety warnings and

all instructions.

Failure to follow the warnings and instructions may result in electric shock,

fire and/or serious injury.

Save all warnings and

instructions for future reference! The term

"power tool" in the warnings refers to your mainsoperated (corded) power tool or battery-operated

(cordless) power tool.

1) Work area safety

a)

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b)

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

Power

tools create sparks which may ignite the dust

or fumes.

c)

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) Electrical safety

a)

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools.

Unmodified plugs

and matching outlets will reduce risk of electric shock.

b)

Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators, ranges and refrigerators.

There is an

increased risk of electric shock if your body is

earthed or grounded.

c)

Do not expose power tools to rain or wet

conditions.

Water entering a power tool will

increase the risk of electric shock.

d)

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts.

Damaged or

entangled cords increase the risk of electric

shock.

e)

When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Operating Instructions

Dear Customer,

Thank you for the trust you have placed in us by buying a Metabo power tool. Each Metabo power tool

is carefully tested and subject to strict quality controls by Metabo's quality assurance. Nevertheless, the

service life of a power tool depends to a great extent on you. Please observe the information contained

in these instructions and the enclosed documentation. The more carefully you treat your Metabo power

tool, the longer it will provide dependable service.

Contents

1 Specified Use

2 General Safety Rules

6

ENGLISH

ENG

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f)

If operating a power tool in a damp location

is unavoidable, use a residual current

device (RCD) protected supply.

Use of an

RCD reduces the risk of electric shock.

3) Personal safety

a)

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication.

A moment of

inattention while operating power tools may

result in serious personal injury.

b)

Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

c)

Prevent unintentional starting. Ensure the

switch is in the off-position before

connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your finger on the

switch or energising power tools that have the

switch on invites accidents.

d)

Remove any adjusting key or wrench

before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

e)

Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

f)

Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts.

Loose

clothes, jewellery or long hair can be caught in

moving parts.

g)

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used.

Use of dust collection can reduce

dust-related hazards.

4) Power tool use and care

a)

Do not force the power tool. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

b)

Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

c)

Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments,

changing accessories, or storing power

tools.

Such preventive safety mea ures reduce

the risk of starting the power tool accidentally.

d)

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e)

Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tool's operation. If

damaged, have the power tool repaired

before use.

Many accidents are caused by

poorly maintained power tools.

f)

Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g)

Use the power tool, accessories and tool

bits etc. in accordance with these instructions, taking into account the working

conditions and the work to be performed.

Use of the power tool for operations different

from those intended could result in a

hazardous situation.

5) Service

a)

Have your power tool serviced by a

qualified repair person using only identical

replacement parts.

This will ensure that the

safety of the power tool is maintained.

Wear ear protectors.

Exposure to noise can

cause hearingloss.

Use auxiliary handles supplied with the tool.

Loss of control can cause personal injury.

Hold power tools by insulated gripping

surfaces, when performing an operation where

the cutting tool may contact hidden wiring or its

own cord.

Cutting accessory contacting a "live"

wire may make exposed metal parts of the power

tool "live" and could give the operator an electric

shock.

Ensure that the spot where you wish to work is free

of

power cables, gas lines or water pipes

(e.g.

using a metal detector).

WARNING Read all safety warnings and

instructions.

Failure to follow all safety warnings and instructions may result in electric shock,

fire and/or serious injury.

Keep all safety instructions and information for

future reference.

3 Specific Safety Rules

ENGLISH

7

ENG

Before using this power tool, carefully read

through and familiarise yourself with all the

enclosed safety information (red booklet)

and the instructions. Keep all enclosed

documentation for future reference, and pass on

your power tool only together with this documentation.

For your own protection and for the

protection of your power tool pay attention to all parts of the text that are

marked with this symbol!

Pull the plug out of the plug socket before any

adjustments or servicing are performed.

Always work with the additional handle correctly

installed.

A damaged or cracked additional handle must be

replaced. Never operate a machine with a defective additional handle.

Always hold the machine with both hands using

the handles provided, stand securely and concentrate.

Always wear protective goggles, gloves, a dust

mask and sturdy shoes when working with this

tool.

Always work with the tool attached correctly. Pull

on the tool to check that it is seated correctly. (It

must be possible to move the tool a few centimetres in an axial direction.)

When working above ground level, make sure that

the area underneath is free.

Do not touch the tool or parts close to the tool

immediately after stopping work because they

may still be extremely hot and could cause skin

burns.

Always lay the power cable away from the back of

the machine.

Dust from material such as paint containing lead,

some wood species, minerals and metal may be

harmful. Contact with or inhalation of the dust may

cause allergic reactions and/or respiratory

diseases to the operator or bystanders.

Certain kinds of dust are classified as carcinogenic

such as oak and beech dust especially in conjunction with additives for wood conditioning (chromate, wood preservative). Material containing

asbestos must only be treated by specialists.

- Where the use of a dust extraction device is

possible it shall be used.

- The work place must be well ventilated.

- The use of a dust mask of filter class P2 is

recommended.

Follow national requirements for the materials you

want to work with.

SYMBOLS ON THE TOOL:

.... Class II Construction

V........ volts

A........amperes

Hz...... hertz

W.......watts

BPM ..beat per minute

~

.......alternating current

n

0

.......no load speed

rpm....revolutions per minute

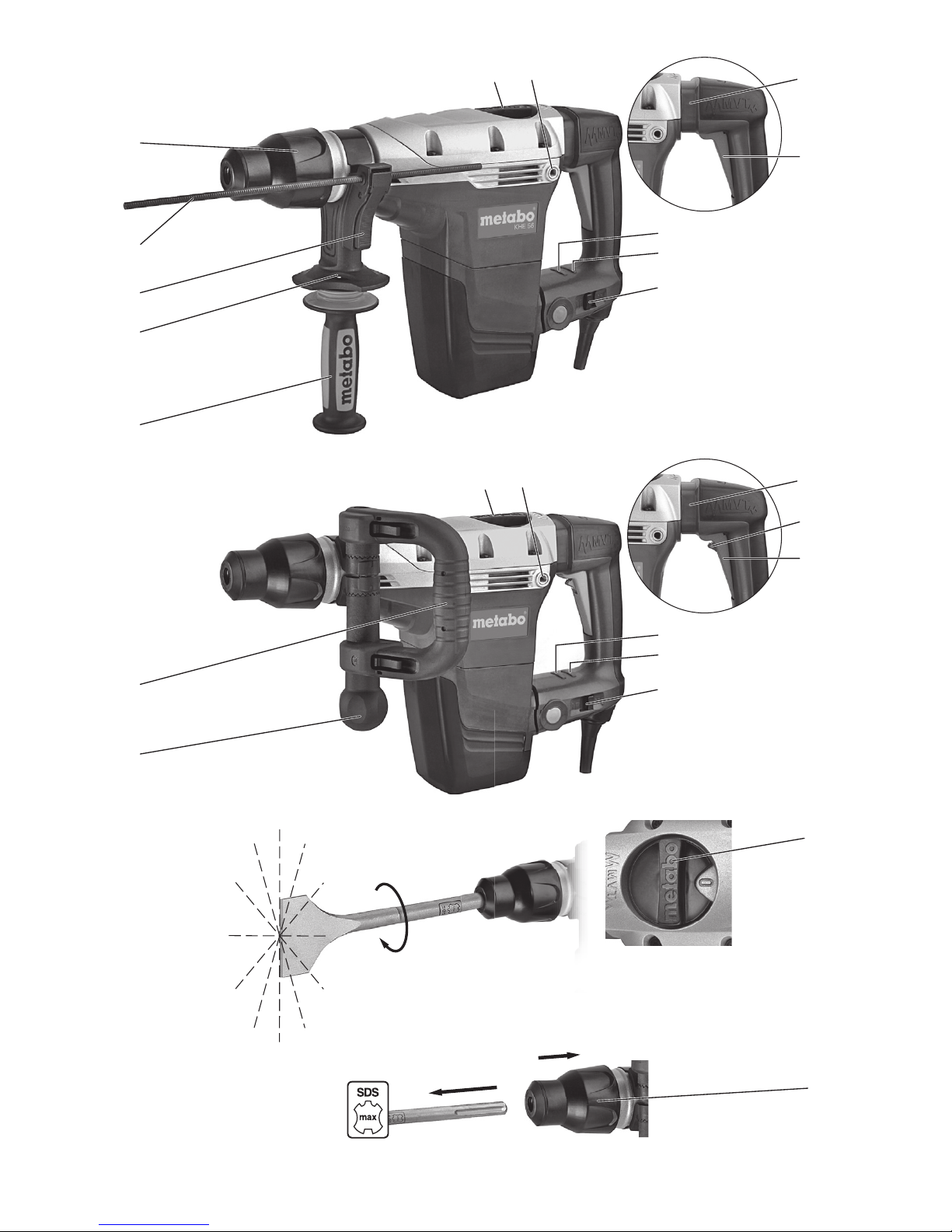

See page 3.

1 Clamping knob *

2 Bow handle *

3 Additional handle *

4 Additional handle holder *

5 Clamp lever for depth stop *

6 Depth stop *

7 Tool lock

8 Switch button

9 Thread for additional handle

10 Metabo VibraTech (MVT): integrated damping

system

11 Locking button for continuous activation *

12 Trigger switch

13 Carbon brush service indicator (lamp signal

for pending carbon brush change)

14 Operating indicator (light signal for mains

power supply)

15 Switch for optional impact reduction when

working on soft materials

* model-dependent

• Metabo VibraTech (MVT): integrated damping

system in the handles for reduced vibrations

and less stress on the hands

• Additional handle can be attached to the

housing at 2 different points

• Optional impact reduction of up to 30% for

working on softer materials such as brick

• Lockable switch for convenient operation

during continuous chiselling

• Electronic smooth start-up for precision drilling

• Low-weight cast magnesium gear housing

ensures excellent heat dissipation

• Service indicator e.g. for signalling pending

carbon brush changes and light signal for mains

power supply

4 Functional Description

5 Special Product Features

8

ENGLISH

ENG

Before plugging in, check to see that the

rated mains voltage and mains frequency,

as stated on the rating label, match with your

power supply.

Always use an extension cable with a minimum

diameter of 1.5 mm

2

. The extension cable must be

suitable for the machine power rating (see Technical Specifications). If using a roll of cable, always

roll up the cable completely.

6.1 Assembly of the bow handle or addi-

tional handle

For safety reasons, always use the bow

handle (2) or additional handle (3)

supplied.

MHE 56:

Release the clamping ring by turning the clamping

knob (1) anticlockwise. Adjust the bow handle (2)

to the required position and angle. Tighten the

clamping knob.

KHE 56:

Option 1

Open the clamping ring by turning the additional

handle (3) anticlockwise. Secure the additional

handle at the required angle. Tighten the additional

handle.

Option 2

Upright working position for reduced stress on the

back when working on floors:

The additional handle (3) can also be attached to

the motor housing. Unscrew the additional handle

from the handle holder (4), insert in one of the

threads (9) (on the left and right of the motor

housing) by hand and tighten.

7.1 Adjusting the depth stop

(only for KHE 56)

Press and hold the clamp lever (5). Set the depth

stop (6) to the required drilling depth and release

the clamp lever.

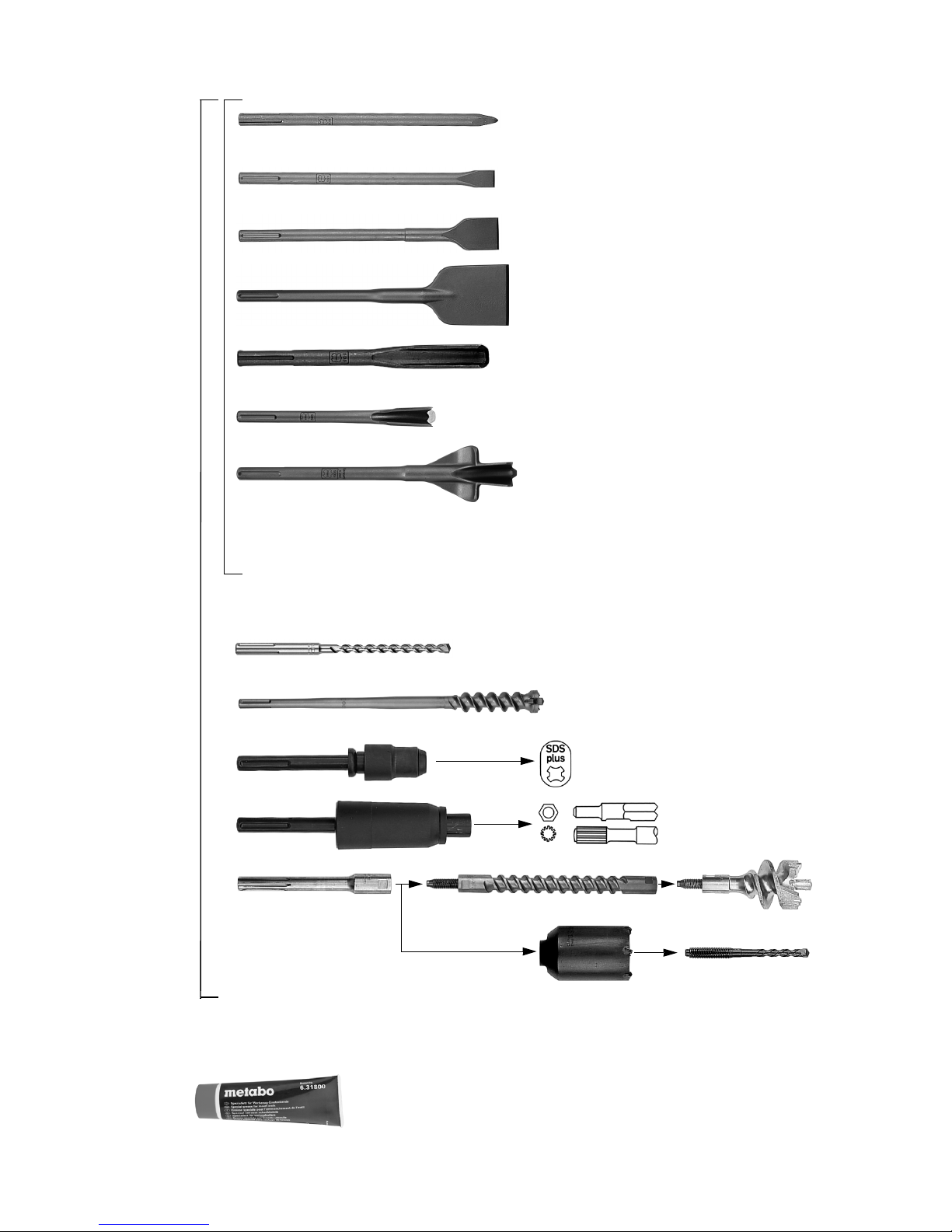

7.2 Attaching and removing tools

Before fitting tools, clean shank and apply

special grease enclosed with tool (accessories order no. 6.31800)! Use only SDS-max

tools.

Attaching tools:

Turn tool and insert until it engages. The tool is

automatically locked.

Pull on the tool to check that it is seated

correctly.

(It must be possible to move the

tool a few centimetres in an axial direction.)

Removing the tool:

Pull tool lock (7) backwards in direction indicated

by arrow (a) and remove tool (b).

7.3 Setting the operating mode

Turn the switch button (8) to select the desired

operating mode.

Hammer drilling (only for KHE 56)

Chiselling

When a chisel is fitted, only operate the

machine in the chiselling operating

mode

.

7.4 Adjusting the chisel position

The chisel can be secured in 12 different positions.

- Insert the chisel.

- Turn the switch button (8) to position .

- Turn the chisel to the required position.

- Turn the switch button (8) to position .

- Turn the chisel until it engages.

When a chisel is fitted, only operate the

machine in the chiselling operating

mode .

7.5 Adjusting the impact force

Slide the switch (15) to adjust the

impact force

(and speed)

setting.

Reduced impact force,

reduced speed

High impact force,

high speed

The correct setting depends on the task in hand.

Example: set the switch to "reduced impact force"

when working on soft, brittle material or trying to

minimise break-off.

Set the switch to "high impact force" when

working on harder materials.

7.6 Switching On and Off

Instantaneous activation (MHE 56, KHE 56):

To start the machine, press the trigger switch (12).

Release the trigger (12) to switch off.

Continuous operation

(MHE 56 only):

For continuous operation, the trigger switch (12)

can be locked using the lock button (11).

Press and release the trigger (12) again to switch

off.

6 Commissioning

7Use

Loading...

Loading...