Page 1

Merrychef

MD-SERIES

SERVICE MANUAL

Part No. 32Z3329 Issue No. 6

For all MD-Series models manufactured from January 2001

CAUTION MICROWAVE EMISSIONS

DO NOT BECOME EXPOSED TO EMISSIONS FROM THE MICROWAVE

GENERATOR OR PARTS CONDUCTING MICROWAVE ENERGY

Page 1 MD Series Ovens 32Z3329 Issue 6

SERVICE MANUAL

Page 2

Table of Contents

Safety Code...........................................................................3

Product Specifications ..........................................................4

Installation Instructions ..........................................................5

Error Codes and Diagnostics.................................................6

Power Output Testing to BS EN 60335-2-90.........................7

Power Output Testing............................................................8

Power Transformer Test........................................................8

High Voltage Capacitor Test..................................................9

High Voltage Rectifier Test....................................................9

Magnetron Test .....................................................................9

Exploded View ....................................................................10

Door Assembly ....................................................................11

Door Replacement and Adjustment.....................................12

Door Servicing .....................................................................13

Door Interlock operation ......................................................14

Membrane Panel Circuit ......................................................15

Input Wiring Details .............................................................16

Part Number Identification List ...................................... 17-18

Wiring Diagram ...................................................................19

Appendix 1: Cleaning procedure .........................................20

Appendix 2: Door interlock All Models before Jan 2007......21

Manual Corrections and Modifications ................................22

From January 2007 only the MD1800 Microwave Oven model is

being manufactured. All the other MD Series ovens are

discontinued.

Note that the MD1800 currently in production has a different door

interlock system to the earlier model and can be identified from the

handle which is solid and does not have the door catch release

mechanism on the inside face of the handle.

Merrychef Limited,

Station Road West,

Ash Vale, Aldershot,

Hampshire, GU12 5XA

United Kingdom

Tel: +44 (0)1252 371000 Fax: +44 (0)1252 371007

Internet address: http://www.merrychef.com

E-mail: sales@merrychef.com or service@merrychef.com

Page 2 MD Series Ovens 32Z3329 Issue 6

Page 3

SAFETY CODE

This manual is designed to assist engineers who have been on a recognised product familiarisation

and training course run by Merrychef Limited. It has been prepared to offer technical guidance for the

Merrychef MD Series Commercial Microwave Ovens.

Please remember that it is wiser not to attempt a service task if you are unsure of being able to

complete it competently, quickly, and above all safely.

To avoid injury to yourself, and to protect the appliance from possible damage, please follow this

Safety Code when servicing these ovens.

Before attempting to repair the oven, check it for microwave leakage.

Check that the oven is not emitting microwaves, even when supposedly not in operation.

Check that the oven is not operating continuously, whether the display indicates cooking

or not.

Always discharge the HT capacitors before working on the oven using a suitably

insulated 10 MΩ Resistor

Before removing the rear cover from the oven, ensure you do the following:

• Switch off the mains supply and remove the plug from the wall socket.

or

• If the oven is hard wired, ensure that the power is turned off at the isolator switch.

Note: the oven does NOT have an On/Off switch.

Upon completion of a service on an MD Series oven, or before reconnecting the appliance to the

mains supply for testing, check all of the following points:

• All internal electrical connections are correct.

• All wiring insulation is correct and is not touching a sharp edge.

• All Earth connections are electrically and mechanically secure.

• All four door safety interlocks are secure and mechanically sound.

• The door operation is smooth.

• The door activates all four of the door interlock switches in the correct order.

• All fuse-holder safety covers are correctly fitted.

Before finishing the service call, recheck the following points:

• All of the electronics are functioning correctly, and all of the touch pads are working.

• The power output of the oven is correct (see pages 7 & 8 ).

• Microwave emission is below permissible limit - 5mW/cm² (see BS EN 60335-2-90:).

• Oven has correct 50mm air gap all round. Air flow should not be restricted.

Page 3 MD Series Ovens 32Z3329 Issue 6

Page 4

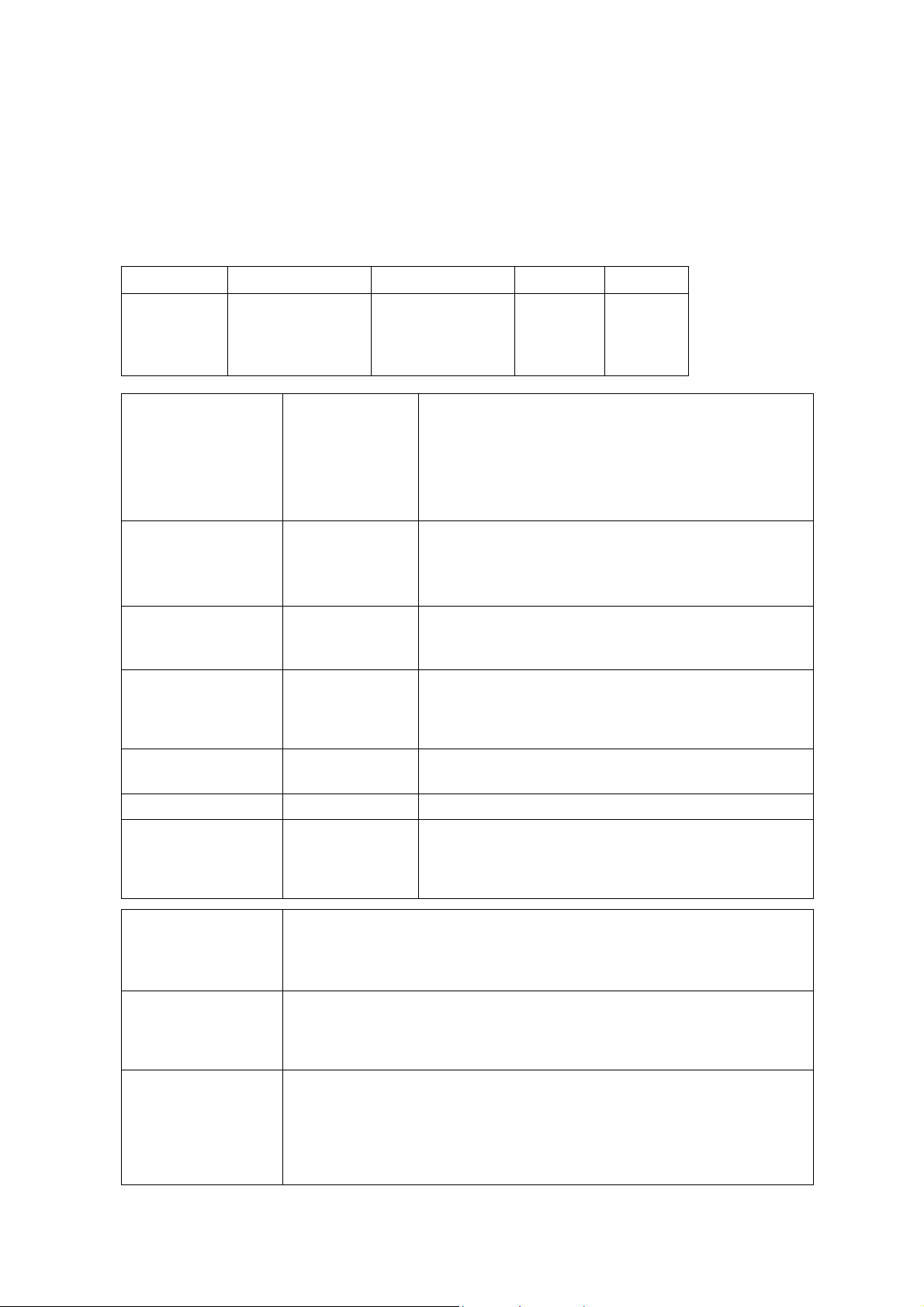

Product specifications

Model Number: MD + Power + Voltage + Frequency + Country

For example: MD1800C25EX

Model MD 1800 (1000W) , 220-230V, 50Hz, Export model

Only Model MD1800 is currently manufactured

Model prefix Voltage Frequency Country

MD

Power Requirements

Power Output

Microwave 100%

External Dimensions

Internal Dimensions

Model Number

750

1000

1400

1800

MD 075045CUK

MD1000C45UK

MD1000C25EX

MD1400C45UK

MD1400C25EX

MD1800C45UK

MD1800C25EX

MD0750

MD1000

MD1400

MD1800

Height

Width

Depth

Height

Width

Depth

Capacity

2 = 220-230V a.c.

4 = 230-240V a.c

230-240V ac 50 Hz 13.0A Single Phase 2 Wire + Earth

230-240V ac 50 Hz 13.0A Single Phase 2 Wire + Earth

220-230V ac 50 Hz 14.2A Single Phase 2 Wire + Earth

230-240V ac 50 Hz 13.0A Single Phase 2 Wire + Earth

220-230V ac 50 Hz 14.2A Single Phase 2 Wire + Earth

230-240V ac 50 Hz 13.0A Single Phase 2 Wire + Earth

220-230V ac 50 Hz 14.2A Single Phase 2 Wire + Earth

750W ( IEC 705 )

1000W ( IEC 705 )

1400W ( IEC 705 )

1800W ( IEC 705 )

335mm ( Plus 50mm minimum clearance above )

510mm ( Plus 50mm minimum clearance each side )

415mm ( Plus 50mm clearance behind )

210mm

330mm

330mm

23 litres (0.81 ft³)

5 = 50 Hz

6 = 60 Hz

UK

EX = export

Weight

Construction

Settings

Nett

Gross packed

Cavity & Casework 304 Stainless Steel

Microwave

Timer

30kg

35kg

100%, 75%, 50%, progressive Defrost

Up to 9 minutes 59 seconds

Up to 3 cooking stages of up to 9 minutes 59 seconds each

(Programmed)

Control System Wipe-clean touch pad operating microprocessor based control system.

Direct readout of time and power set.

10 Pre-programmed cooking sequences accessed by just two key

presses.

Safety Features Four door interlock switches.

Cavity Overheat Sensor.

Magnetron Overheat Sensor.

Additional Features

• Easy-to-use multistage programming.

• Manual and Pre-programmed mode always available

• Magnetron soft-start circuit for increased life and faster activation.

• Multiple product facility.

Page 4 MD Series Ovens 32Z3329 Issue 6

Page 5

Installation instructions

Power Supply Requirements

The oven should be connected to a suitable electricity supply, which can cope with the switchingon surge that occurs with certain types of catering equipment, such as microwaves. Because of

this requirement, we strongly recommend that a separate, suitably rated supply is installed for the

oven.

The supply for the oven should be fitted with a Type "C" circuit breaker, rated at 16A.

Positioning the Oven

In order to maintain adequate ventilation for air intake and exhaust, and to allow access for

cleaning filters, you must allow a minimum of 50mm clearance all around the oven. Air intake

temperature should not exceed 35°C - excessive temperature can lead to reduced operating duty

cycle or premature ageing of internal components.

ALWAYS Place containers in the cavity carefully - impact damage may chip the oven shelf

NEVER Install an oven above fryers, grills, griddles or any other major heat source

NEVER Stack machines on top of each other without using the stacking adapter provided

stacking adapter

maximum

3 ovens

in a stack

Page 5 MD Series Ovens 32Z3329 Issue 6

Page 6

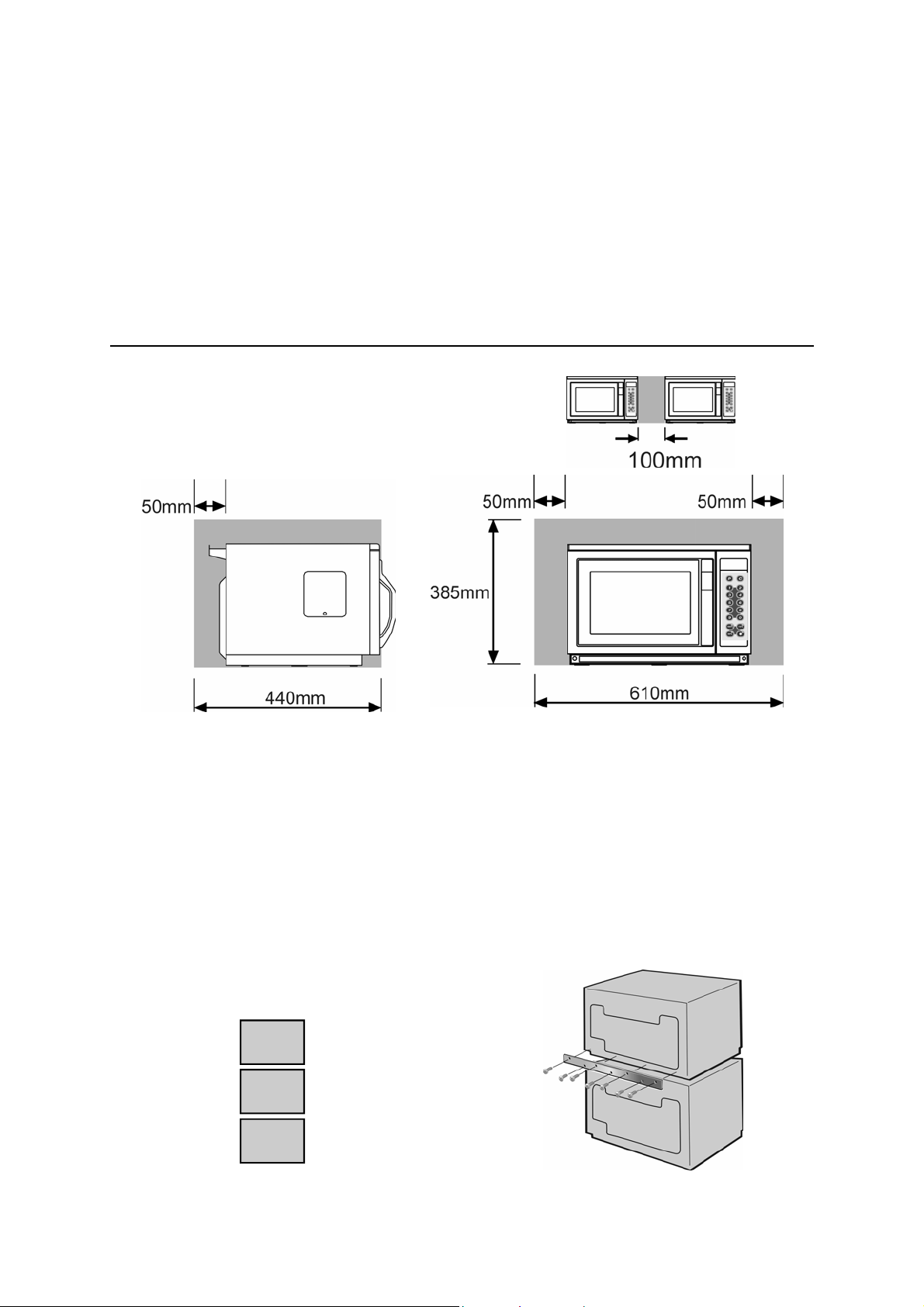

Error codes and diagnostics

The MD series oven will identify some of the most common problems by flashing an error message

code in the time display window.

These are the error messages, and suggestions for repairing them.

1

1

Door not fully shut

2

Possible electrical fault

No time has been set

2

Invalid time has been set.

3

Invalid program has been

set

4

Memory failure running a

Program

Close door fully

Check microswitch door circuit

Check microswitch connection

to PCB

Check ribbon cable

Check relay PCB & logic PCB

Set a time

Set a valid time

Use call-back to check program

Re-Program Pad,

if fault repeats replace logic

PCB

Page 6 MD Series Ovens 32Z3329 Issue 6

Page 7

Procedure A - Power Output Test in accordance with

BS EN 60335-2-90 Annex AA

This test is given in the BSI test standard for microwave ovens. It is reproduced below - not so that

you can follow it, but to show you why it is impractical in normal conditions. A simplified procedure,

which gives a good approximation to the BSI power output, is given in Procedure B which follows.

Note: This test can only be carried out on a COLD oven. If the oven has been operating, even for

only a few seconds, the power given will be lower than the oven rating. This test must also be

carried out at a stable voltage - the voltage in most kitchens varies considerably even within the

period of the test. If the oven has been operating, go to Procedure B.

You will need:

A thermometer capable of reading to ±0.1°C.

A cylindrical borosilicate glass container, 190mm diameter, with a wall thickness of

3mm or less.

A calculator.

A set of scales capable of reading 1kg to an accuracy of ± 1g.

A glass or plastic stirrer.

A jug capable of holding over 1 litre of water.

Drinkable water which is at a temperature of 10°C ± 1°C.

A “Variac” or similar variable transformer capable of supplying the oven to ensure

a stable voltage.

WARNING: The Borosilicate Glass container has thin walls and is therefore fragile

- take care not to break it during use.

Method

A cylindrical container of borosilicate glass is used for the test. It has a maximum thickness of

3mm, an external diameter of approximately 190mm and a height of approximately 90mm. The

mass of the container is determined.

At the start of the test, the oven and the empty container are at ambient temperature. Potable water

having an initial temperature of 10°C ± 1°C is used for the test. The temperature of the water is

measured immediately before it is poured into the container.

A quantity of 1000g ± 5g of water is added to the container and its actual mass obtained. The

container is then immediately placed in the middle of the oven shelf which is in its lowest normal

position. The appliance is supplied at rated voltage and operated at the maximum power setting.

The time for the water temperature to attain 20°C ± 2°C is measured. The oven is then switched off

and the final water temperature is measured within 60seconds.

NOTES:

1 The water is stirred before its temperature is measured.

2 Stirring and measuring devices are to have a low heat capacity.

The microwave power output is calculated from the formula:

P =

where

P is the microwave power output, in watts;

M

is the mass of the water, in grams;

W

M

is the mass of the container, in grams;

C

T

is the ambient temperature, in °C;

0

T

is the initial temperature of the water, in °C;

1

T

is the final temperature of the water, in °C;

2

t is the heating time in seconds, excluding the magnetron filament heat-up time.

4.187 MW (T2-T1) + 0.55 MC (T2-T0)

t

Page 7 MD Series Ovens 32Z3329 Issue 6

Page 8

Procedure B - Simplified Power Test

You will need:

A thermometer capable of reading to ±0.1°C.

A Polypropylene tray approximately 200mm x 200mm.

A measuring jug.

A calculator.

Water which is at a temperature of 10°C ± 2°C.

1 Measure 1 litre of cold water into the tray using the measuring jug.

2 Measure the water temperature, and record it as T[s].

3 Place the tray in the oven and close the door.

4 Turn the oven on.

5 Set the timer to 1:02.

6 Press the “100%” pad.

7 When the oven bleeps, open the door and remove the tray.

8 Stir the water thoroughly, and measure its temperature. Record this as T[e].

Calculation:

1 T[r] = T[e] - T[s].

2 Power = 78.5 x T[r]. Power is in Watts.

The power given by the above test should be within ±15% of the rated power.

Procedure C - Power Transformer Test

You will need:

A Digital Multi-meter (D.M.M.)

A Megger or similar resistance meter using 500V d.c.

1 Isolate the oven from the mains supply.

WARNING: High voltages and large currents are present at the secondary winding and filament

winding of the Power Transformer. It is very dangerous to work near this part when the

oven is on. NEVER make any voltage measurements at the High Voltage circuits,

including the magnetron filament.

WARNING: Even when the oven is not cooking, the Power Transformer has High Voltages present

because of the Soft Start circuit. Isolate the oven before testing.

2. Ensure that the High Voltage Capacitor is discharged before commencing work.

3. Remove all connections from the Power Transformer.

4. Using a D.M.M., check the continuity of the windings. Results should be as follows:

Mains winding between tags P & P

High Voltage winding

(between tag S & chassis)

Filament winding

between terminals F & F

Approx. 1.3 Ω

Approx. 82 Ω

Less than 1 Ω

5. Using a Megger, test the insulation resistance between:

Primary winding P and chassis

Filament winding F and chassis

One end of the High Voltage winding is connected to the chassis, so this is not tested.

Pass if over 10 MΩ

Pass if over 10 MΩ

Page 8 MD Series Ovens 32Z3329 Issue 6

Page 9

Procedure D - High Voltage Capacitor Test

You will need: A Digital Multi-meter (D.M.M.)

A Megger or similar resistance meter using 500V d.c.

WARNING: High voltages and large currents are present at the High Voltage Capacitor. It is very

dangerous to work near this part when the oven is on. NEVER make any voltage

measurements at the High Voltage circuits, including the magnetron filament .

WARNING: Even when the oven is not cooking, the High Voltage Capacitor has High Voltages

present because of the Soft Start circuit. Isolate the oven before testing.

1. Isolate the oven from the mains supply.

2. Ensure that the High Voltage Capacitor is discharged before

commencing work.

3. Remove all connections from the High Voltage Capacitor.

4. Using a D.M.M., check for continuity between the terminals &

compare results with table.

Between Terminals

Between Terminals and Case Pass if open circuit

5. Using a Megger, test the insulation resistance between the

terminals and the case.

Between Terminals and Case

Procedure E - High Voltage Rectifier Test

You will need:

A Megger or similar resistance meter using 500V d.c.

WARNING: High voltages and large currents are present at the High Voltage Rectifier. It is very

dangerous to work near this part when the oven is on. NEVER make any voltage

WARNING: Even when the oven is not cooking, the High Voltage Rectifier has High Voltages

1. Isolate the oven from the mains supply.

2. Ensure that the High Voltage Capacitor is

discharged before commencing work.

3. Remove all connections from the High Voltage

Rectifier.

4. Using the Megger, test for continuity in both

directions. Compare results with the table.

measurements at the High Voltage circuits, including the magnetron filament .

present because of the Soft Start circuit. Isolate the oven before testing.

Pass if approximately 10 MΩ

Pass if over 100 MΩ

Open Circuit both ways

Conducts one way only

Short Circuit both ways

Conducts one way, leaks the other

FAIL

PASS

FAIL

FAIL

Procedure F - Magnetron Test

You will need:

A Megger or similar resistance meter using 500V d.c.

A Magnetron can be tested for an open filament or a short circuit

by carrying out a continuity check.

1. Isolate the oven from the mains supply.

2. Ensure that the High Voltage Capacitor is discharged before

commencing work.

3. Remove all connections from the Magnetron.

4. A continuity check across the Filament terminals should be 1ohm or less

5. A continuity check between each filament terminal and the

metal outer should read open.

Page 9 MD Series Ovens 32Z3329 Issue 6

Page 10

Exploded view :

65

97

94

94

Door interlock details for Models

before January 2007,

MD1000, MD1400 & MD1800

See APPENDIX 2

96

MD1800 [January 2007]

95

98

94

Note: Models MD0750 & MD1000 have one Magnetron Assembly only ( Parts 51 & 61 )

Model Part

59 MD0750 (Tesco) HV Capacitor 0.74µF 30M0098

HV Capacitor 1.0µF 30M0059

51

MD0750 (Tesco)

61

MD1000

1 Magnetron only

Page 10 MD Series Ovens 32Z3329 Issue 6

Page 11

Door assembly MD-Series

Note that the MD1800 currently in production has a different door

interlock system to earlier MD Series models and can be identified

from the handle which is solid and does not have the door catch

release mechanism on the inside face of the handle.

14

80

16

14

5

6

4

3

1

5

Door Handle

Models before January 2007,

MD1000, MD1400 & MD1800

No Description MD1000,

1 Outer Handle 30M0001

2 Handle Bearing (4) 30M0002

3 Inner Handle 30M0003

4 Door Outer Skin 30M0004

5 Glass Locator 30M0005

6 Outer Door Glass 30M0006

7 Door Body 30M0007

8 Door Catch Bracket 30M0008

9 Door Catch (2) 30M0009

10 Door Catch Link Rod 30M0010

11 Door Spring 30M0011

13 Door Catch Crank 30M0013

14 Upper / Lower Hinge Plate 30M0014

15 Inner Door Film 30M0015

16 Choke Cover 30M0016

80 Door Assembly 11M0334

15

9

11

9

13

8

7

MD1400, MD1800

10

MD1800

From Jan 2007

30M4002

——-

30M4003

30M0004

30M0005

30M0006

30M0007

30M0008

30M4009

30M0010

30M4011

30M0013

30M0014

30M0015

30M0016

11M4334

Page 11 MD Series Ovens 32Z3329 Issue 6

Page 12

Door replacement and door adjustment

After any service work to the door, the oven should always be

checked for microwave leakage with a suitable meter

DOOR REPLACEMENT

1. Remove four screws holding the Upper and Lower Hinge Plate [14] to the oven cavity.

2. Remove Door Assembly [80] by pulling it forward.

3. On re-installing new door assembly, secure the upper and lower oven hinges with the

four mounting screws to the oven cavity.

4. Make sure the door is parallel with the bottom line of the oven cavity face and the

catches pass through the catch holes correctly. See door adjustment.

DOOR ADJUSTMENT

When removing and/or loosening hinges during door adjustment or replacement, the following

adjustment criteria must be met. The door is adjusted to meet the following three conditions by

keeping the hinge screws slack.

1. Adjust door interlock block to a position where it smoothly locates with the catches

through the catch holes.

2. Deviation of door alignment from horizontal line of cavity front is to be less than 1.0mm.

3. The door is positioned so that it touches the cavity front.

Reinstall outer case and check for microwave leakage around the door with an approved

microwave leakage meter

Page 12 MD Series Ovens 32Z3329 Issue 6

Page 13

Door servicing

CHOKE COVER REMOVAL

1. Insert a flat type screw driver into the gap

between the Choke Cover [16] and Door Body [7]

as shown below to free the engaging clips. A

protective piece of tape should be used so as not

to damage the door panel.

2. Lift up the Choke Cover.

DOOR COMPONENTS REMOVAL

Place the Door Assembly [80] on a soft cloth with the Choke Cover [16] facing up.

UPPER AND LOWER OVEN HINGE REMOVAL

1. Remove the Choke Cover, referring to "CHOKE COVER REMOVAL".

2. Release the Door Hinges [14] from the door panel.

DOOR HANDLE REMOVAL

1. Remove the two screws holding the Door Handle [1] to door.

2. Remove the Door Handle from the Door Body.

UPPER AND LOWER DOOR CATCH REMOVAL

1. Remove the Inner Handle [3] from the door assembly.

2. Remove the three screws holding the Door Catch Bracket [8] to the Door Body.

3. Release the Door Spring [11] from the tab of the Door Catch Link Rod [10] and Door

Catch Bracket.

4. Release the Catches [9] from Door Catch Link Rod and Door Catch Bracket.

DOOR OUTER SKIN REMOVAL

1. Set the four tabs of the Door Outer Skin [4] upright.

2. Remove the Door Outer Skin from the Door Body [7].

DOOR GLASS REMOVAL

1. Remove the four screws holding the two Glass Locators [5] to the Door Body [7].

Page 13 MD Series Ovens 32Z3329 Issue 6

Page 14

Door interlock operation

Door interlock operation

The door on the oven is monitored by four microswitches. Three of these are used in the

conventional “Primary, Secondary and Monitor” switch arrangement shown below, while the fourth

is a low-voltage switch linked directly to the control circuitry.

Door interlock arrangement

66d

L

Power In Power Out

N

The switches operate as follows:

1. Monitor Switch [66b , Top ]. As the door is closed, the monitor switch is opened.

2. Primary Interlock Switch [ 66a , Lower Middle ]. The Primary switch is then closed.

3. Secondary Interlock Switch [ 66c , Upper Middle ]. The Secondary Switch then closes.

4. Low voltage Switch [ 66d , Bottom ]. The Low voltage switch operates concurrently with

the Primary and Secondary switches.

When the door is opened, the switches operate in the reverse order.

66a

66c

66b

Page 14 MD Series Ovens 32Z3329 Issue 6

Page 15

Membrane panel circuit

You will need:

A Digital Multi-meter (D.M.M.)

Procedure:

1. Isolate the oven from the mains supply.

2. Remove the Logic Assembly from the

Control Panel Housing.

3. Unplug the membrane “tail” from the Logic

PCB Assembly.

4. Using a D.M.M., check for continuity

between the correct terminals when the

pads are pressed.

5. When the panel has been tested, re-

assemble and re-test the control housing.

Page 15 MD Series Ovens 32Z3329 Issue 6

Page 16

Input wiring details

Green/Yellow

Blue

26 Mains Cable Assy 31Z0220

35 Strain Relief Bush 31Z1036

60 Rear Panel 30M0060

67 Fuse Cover 20Z1080

74 16A Mains Filter 30Z0997

75 Fuse Holder 30Z0231

76 Fuse 13A Anti surge 30Z0168

Brown

Page 16 MD Series Ovens 32Z3329 Issue 6

Page 17

Part number identification chart 1

No Description MD1400 MD1800

Outer Handle 30M0001 30M0001 30M0001 30M4002

1

Handle Bearing (4) 30M0002 30M0002 30M0002 30M0002

2

Inner Handle 30M0003 30M0003 30M0003 30M4003

3

Door Outer Skin 30M0004 30M0004 30M0004 30M0004

4

Glass Locator 30M0005 30M0005 30M0005 30M0005

5

Outer Door Glass 30M0006 30M0006 30M0006 30M0006

6

Door Body 30M0007 30M0007 30M0007 30M0007

7

Door Catch Bracket 30M0008 30M0008 30M0008 30M0008

8

Door Catch (2)// Catch hook 30M0009 30M0009 30M0009 30M4009

9

Door Catch Link Rod 30M0010 30M0010 30M0010 30M0010

10

Door Spring 30M0011 30M0011 30M0011 30M4011

11

Oven Cavity 30M0012 30M0036 30M0036 30M0036

12

Door Catch Crank 30M0013 30M0013 30M0013 30M0013

13

Upper / Lower Hinge Plate 30M0014 30M0014 30M0014 30M0014

14

Inner Door Film 30M0015 30M0015 30M0015 30M0015

15

Choke Cover 30M0016 30M0016 30M0016 30M0016

16

Control Panel Cover ( see note 1) 30M0017 30M0017 30M0017 30M0017

17

Membrane Blue 11M0384 11M0384 11M0384 11M0384

18

Display Screen 30M0019 30M0019 30M0019 30M0019

19

Control Housing Moulding 30M0020 30M0020 30M0020 30M0020

20

Logic PCB Assy 11M0326 11M0326 11M0326 11M0326

21

Housing Support Bracket 30M0022 30M0022 30M0022 30M0022

22

Relay PCB Assy 11M0327 11M0327 11M0327 11M0327

23

10 Way Ribbon Cable Assy 11E0081 11E0081 11E0081 11E0081

24

Insulating Sheet 30M0025 30M0025 30M0025 30M0025

25

Mains Cable Assy 31Z0220 31Z0220 31Z0220 31Z0220

26

Mica Plate and Stirrer Assembly 30M0027 30M0027 30M0027 30M0027

27

28

Decorative Trim LH 30M0029 30M0029 30M0029 30M0029

29

Decorative Trim Top 30M0030 30M0030 30M0030 30M0030

30

Air Inlet Filter 30M0031 30M0031 30M0031 30M0031

31

Chassis 30M0032 30M0032 30M0032 30M0032

32

HV Transformer J1342 30M0035 ———— ———— ————

33

HV Transformer J1338 ———— 30M0033 30M0033 30M0033

Decorative Trim RH 30M0034 30M0034 30M0034 30M0034

34

Strain Relief Bush 31Z1036 31Z1036 31Z1036 31Z1036

35

Lamp Cover Film 30M0037 30M0037 30M0037 30M0037

37

Lamp 30M0038 30M0038 30M0038 30M0038

38

Lamp Holder 30M0039 30M0039 30M0039 30M0039

39

Lamp Bracket 30M0040 30M0040 30M0040 30M0040

40

Air Outlet Duct 30M0041 30M0041 30M0041 30M0041

41

Temp Sensor 30M0042 30M0042 30M0042 30M0042

42

Thermal Fuse 30M0043 30M0043 30M0043 30M0043

43

MD1000

Pre Jan 2007

Part No. Part No. Part No. Part No.

MD1800

From Jan 2007

Note 1. Part 17 supplied as MD 1800, remove label for MD1000 & MD1400

Page 17 MD Series Ovens 32Z3329 Issue 6

Page 18

Part number identification chart:

No Description MD1400 MD1800

Lamp Cover 30M0044 30M0044 30M0044 30M0044

44

45

46

47

48

49

51

52

56

57

58

60

61

62

63

64

65

66a-d

67

68

69

70

71

72

73

74

75

76

78

79

80

82

83

84

91

92

93

94

95

96

97

98

*Note: Model 0750 (Tesco) uses: HV Capacitor 0.74µF 30M0098 & HV Capacitor 1.0µF 30M0059

Back Case 30M0045 30M0045 30M0045 30M0045

Rear Air Guide 30M0046 30M0046 30M0046 30M0046

Upper Air Duct 30M0047 30M0047 30M0047 30M0047

Cooling Fan Assembly 30M0048 30M0048 30M0048 30M0048

Gold Resistor 30Z0235 30Z0235 30Z0235 30Z0235

Magnetron Thermostat 30M0051 30M0051 30M0051 30M0051

10A Fuse In-line Assembly 11M0330 11M0330 11M0330 11M0330

Fan Scroll 30M0056 30M0056 30M0056 30M0056

Main Capacitor Bracket 30M0057 30M0057 30M0057 30M0057

Capacitor Clamp 30M0058 30M0058 30M0058 30M0058

HV Capacitor 0.74µF ———— 30Z1329 ———— ————

HV Capacitor 0.88µF ———— 30Z1075 ———— ————

59*

HV Capacitor 1.0µF 30M0059 ———— 30M0059 30M0059

HV Capacitor 1.1µF ———— ———— 30Z1242 30Z1242

Rear Panel 30M0060 30M0060 30M0060 30M0060

Magnetron 30M0061 30M0061 30M0061 30M0061

Magnetron Air Splitter 30M0062 30M0062 30M0062 30M0062

Magnetron Cooling Duct 30M0063 30M0063 30M0063 30M0063

Cooling Duct Cover 30M0064 30M0064 30M0064 30M0064

Interlock Holder/ switch holder 30M0065 30M0065 30M0065 30M4065

Microswitch V5S010CB (4) 30Z1176 30Z1176 30Z1176 ————

Fuse Cover 20Z1080 20Z1080 20Z1080 20Z1080

Spring 1 30M0068 30M0068 30M0068 30M4066

Spring 2 30M0069 30M0069 30M0069 30M0069

Top Lever 30M0070 30M0070 30M0070 30M0070

Middle Lever/ Up lever 30M0071 30M0071 30M0071 30M4071

Bottom Lever/ Lower lever 30M0072 30M0072 30M0072 30M4072

Filter Bracket 40M0961 40M0961 40M0961 40M0961

16A Mains Filter 30Z0997 30Z0997 30Z0997 30Z0997

Fuse Holder 30Z0231 30Z0231 30Z0231 30Z0231

Fuse 13A Anti surge 30Z0168 30Z0168 30Z0168 30Z0168

HV Diode Assy 30M0078 30M0078 30M0078 30M0078

Self-Adhesive Foot 30M0079 30M0079 30M0079 30M0079

Door Assembly 11M0334 11M0334 11M0334 11M4334

Oven Shelf 30M0082 30M0082 30M0082 30M0082

HT Lead 1 30M0083 30M0083 30M0083 30M0083

HT Lead 2 ———— 30M0084 30M0084 30M0084

Mains Filter Bracket 40M0961 40M0961 40M0961 40M0961

Filter Shell Clip 30M0092 30M0092 30M0092 30M0092

Filter OIN Clip 30M0093 30M0093 30M0093 30M0093

Microswitch ———— ———— ———— 30M4073

Microswitch ———— ———— ———— 30M4072

Spring ———— ———— ———— 30M4066

Top lever ———— ———— ———— 30M4071

Lower lever ———— ———— ———— 30M4072

MD1000

Pre Jan 2007

Part No. Part No. Part No. Part No.

MD1800

From Jan

Page 18 MD Series Ovens 32Z3329 Issue 6

Page 19

Circuit diagram:

Page 19 MD Series Ovens 32Z3329 Issue 6

Page 20

APPENDIX 1: Cleaning procedure

For the oven to operate at peak efficiency, the cavity, door and the air filter must be

kept clean.

A daily cleaning routine will ensure that you comply with the required hygiene standards

and will help to maintain and prolong the efficiency of your oven.

Follow the SAFETY INSTRUCTIONS at the beginning of this manual.

• ALWAYS switch off at the electrical supply.

• As required, wipe out spillage's with disposable

paper wipes

• NEVER use steel wool, knives or harsh abrasives on

any part of the oven

As with all electrical appliances, it is wise to have the

electrical connections inspected periodically.

Cleaning the Air Filter

1. Remove the air filter from along the lower edge of the

oven.

2. Wash in clean, warm soapy water, rinse and pat dry.

Put the filter back into position.

Cleaning the oven cavity and door

1. Wipe down the sides and floor of the cavity with a damp

cloth.

2. Gently wipe the ceiling. Take care not to press upwards

as this could damage the stirrer cover.

Faults arising from neglect

or misuse including use

without clean filters in place

are not covered by the

guarantee. Service visits as

a result of such faults will be

chargeable.

DO NOT USE THE OVEN

WITHOUT A CLEAN AIR

FILTER IN POSITION

Cleaning the control panel and exterior surfaces

Wipe down regularly with a damp cloth.

Hints and Tips for stubborn stains in the oven cavity

1. Place a container of water (1.5 litres) into the centre of

the oven cavity.

2. Set timer to 9 minutes.

3. Set microwave power to 100%.

4. At end of steam cycle wipe out cavity with a clean cloth.

Replacing the Light Bulb

WARNING: Disconnect the oven from the electrical

supply before removing the light bulb cover

1 Undo screw on panel on side of the oven and remove

panel

2 Replace light bulb Part No. 33M0038 and replace panel

and tighten screw.

NOTE: Light bulbs are not covered by the warranty and can

be purchased by contacting Merrychef Service Dept.

Page 20 MD Series Ovens 32Z3329 Issue 6

Page 21

APPENDIX 2: Door interlock details

Models before January 2007, MD1000, MD1400 & MD1800

No Description Part No.

1 Outer Handle 30M0001

3 Inner Handle 30M0003

9 Door Catch (2) 30M0009

10 Door Catch Link Rod 30M0010

11 Door Spring 30M0011

13 Door Catch Crank 30M0013

65 Interlock/ Switch Holder 30M0065

66 a-d Microswitch V5S010CB 30Z1176

67 Fuse Cover 20Z1080

68 Spring 1 30M0068

69 Spring 2 30M0069

70 Top Lever 30M0070

71 Middle Lever 30M0071

72 Bottom Lever 30M0072

Page 21 MD Series Ovens 32Z3329 Issue 6

Page 22

Manual corrections and modifications

Whilst every effort has been made to ensure that the information contained in this manual is accurate

and complete, if you believe that an error has been made, or if you have any suggestions for how the

manual could be improved, please fill in and return this form. A review of any forms returned will be

made on a regular basis, and the manual will be updated if required.

Name

Address

Page on which error occurs- MD 1800:

Description of error

Suggestion for improvement to manual

Please return this form to: Service Department

Merrychef Ltd

Station Road West

Ash Vale

Aldershot

Hampshire

GU12 5XA

Or Fax it on: +44 (0) 1252 371007

E-Mail quality@merrychef.com

Page 22 MD Series Ovens 32Z3329 Issue 6

Loading...

Loading...