Page 1

User guide

Varset

Automatic low voltage

capacitor banks

Panels and cubicles

C1 panel C2 panel

A1 cubicle A3 cubicle

Page 2

DB108739

For all panels and cubicles.

DB108740

Reception

Presentation

Varset is an automatic capacitor bank in the form of:

b panels

b cubicles.

The cubicles can be fitted with harmonic filter reactors.

Reception of equipment

b the addressee is always responsible for the risks and perils of

transporting our goods

b we decline all responsibility for missing items or damage attributable to

the carrier. If need be, send your complaints by registered mail to the carrier

b make sure there are no missing items and that the equipment has not

been subject to a shock likely to have affected its insulation or operation

b check the electrical characteristics indicated on the rating plate

correspond to those on the order form

b in the event of a non-conformity, indicate the shipping note reference

when submitting your complaint.

For A3 cubicles.

DB108741

For A3 bis, A4 and A4 bis cubicles.

Handling

b unpack the equipment at the place where it is to be installed

b it is preferable to use a forklift truck

b for the A3 cubicle, handle in the vertical position using

2 lifting rings

b to handle A3 bis, A4 and A4 bis cubicles in the vertical position, 4 lifting

rings must be used

b avoid shocks and deformation to the equipment.

Storage

b store the devices in a dry and well ventilated place that is sheltered from

rain, water projections, chemical agents and dust

b storage temperature: -20 °C to +45 °C.

Warranty

The equipment is factory cabled and inspected. Any modification to the

equipment jeopardizes its warranty.

2 AAV31918_00

Page 3

Technical characteristics

b voltage, frequency, power, as per rating plate

b rating tolerances: -5, +10 %

b allowable voltage overload

(8 h out of 24 h as defined in IEC 831-1/2): 10 %

b insulation voltage: 690 V

v 50 Hz, 1 min withstand: 2.5 kV

b ambient temperature in premises:

v maximum temperature: 40 °C

v average temperature over a 24 hour period:

35 °C

v average temperature over a 1 year period:

25 °C

v minimum temperature: -5 °C

b maximum dissipated power:

v 2.7 W/kVAr for Classic cubicles

v 3.1 W/kVAr for Comfort cubicles

v 8.7 W/kVAr for Harmony cubicles

b protection degree: IP31 (apart for the ventilator

outlet: IP21D)

b load shedding (normal-standby)

b colour:

v sheet steel: RAL 9001

v base: RAL 7021

b compliant with IEC 60439-1

and IEC 61921.

Description

DB110688

Fig. 1: electrical layout diagram, Classic and Comfort cubicles.

DB110689

Fig. 2: electrical layout diagram, Harmony cubicles.

3AAV31918_00

Page 4

Description (cont.)

DB110699

C1 panel

Fig. 3: C1 and C2 panels.

DB110700

Fig. 4: A1 and A2 cubicles.

C2 panel

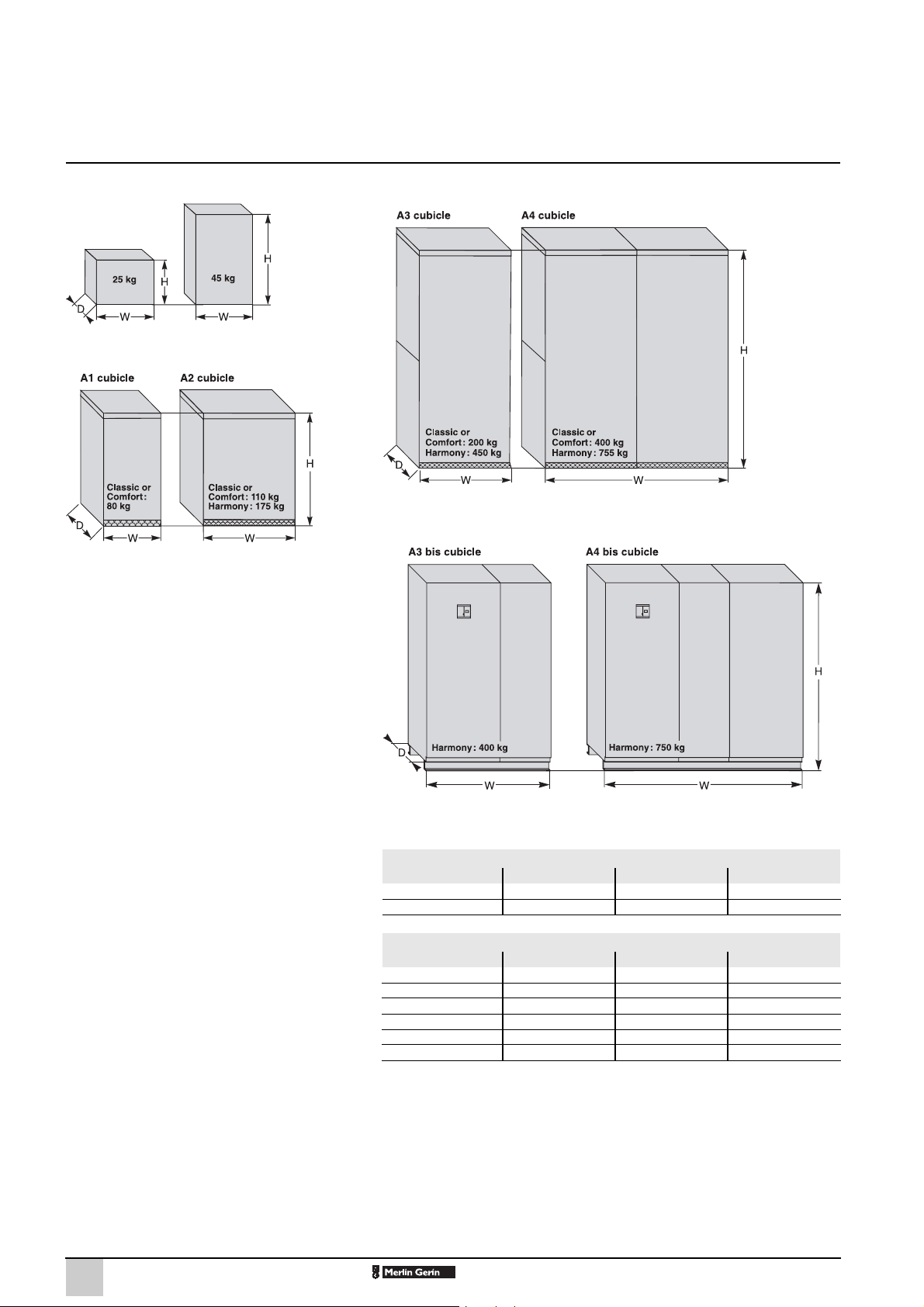

Sizes and weights (Figs. 3 to 7)

DB110701

Fig. 5: A3 and A4 cubicles.

DB110702

Fig. 6: A3 bis cubicle. Fig. 7: A4 bis cubicle.

Panel sizes (mm)

C1 panel 450 500 275

C2 panel 800 500 275

H W D

Cubicle sizes (mm)

A1 cubicle 1100 550 600

A2 cubicle 1100 800 600

A3 cubicle 2000 800 600

A3 bis cubicle 2000 1350 600

A4 cubicle 2000 1600 600

A4 bis cubicle 2000 2150 600

H W D

4 AAV31918_00

Page 5

DB110543

Fig. 8: C1 and C2 panels.

DB110498

Fig. 9: A1 cubicle.

Description (cont.)

Components

DB110497

DB110499

A : step switching control contactors

B : capacitors

C : current transformer connection terminal

D : control circuit protection fuses

E : power cable connection pads

F : ventilator depending on power rating

G : air vents

H : voltage transformer depending on range

I : harmonic filter reactors depending on range

J : main busbar

K : Varmetric controller

L : protective circuit-breaker depending on range

M : earthing.

DB110500

Fig. 10: Classic or Comfort A3 cubicle.

DB110577

DB110501

DB110578

Fig. 11: Harmony A3 cubicle.

5AAV31918_00

Page 6

Installation

Ambient air temperature

The ambient air temperature surrounding the electrical cubicle must be

within the following limits:

b maximum temperature: 40 °C

b average temperature over a 24 hour period: 35 °C

b average temperature over a 1 year period: 25 °C

b minimum temperature: -5 °C.

Ventilation rules

b place the equipment in well ventilated premises

b check maximum temperature limits are not exceeded when

the equipment is in operation (see the "ambient air temperature" paragraph

above)

b make sure the air vents are not covered

(minimum space 100 mm)

b ensure the equipment is sheltered from dust and humidity.

DB110694

Fig. 12: air flow.

6 AAV31918_00

Page 7

Electrical connections

The electrical connections are to be made as

shown in

the electrical diagrams, (page 3, Figs. 1 and 2)

Connection of the

current circuit

b current transformer / controller connection

cable cross-section: 2.5 mm2 minimum.

Installation of CT

(current transformer)

If there is an existing CT:

b ensure it is placed upstream of the installation,

capacitor bank included (Fig. 13)

b ensure it has a 5A secondary

b ensure it has a power rating greater than

5 VA

b connect the varmetric controller in series with

the existing circuit.

If a CT has to be fitted:

b the current transformer must be fitted to one

phase of the MLVS upstream of the capacitor

bank and the loads (motors, etc.) (Figs. 13, 14)

P1 to the transformer or source side

P2 to the load and capacitor bank side

b ensure it has a 5A secondary

b ensure it has a power rating greater than

5 VA.

Installation (cont.)

DB108778

Fig. 13: Installation electrical diagram.

DB108782

Fig. 14: 3-phase diagram of CT connection.

DB108755

.

CT connection

b identify the phase onto which the CT is placed

as phase L1 (Fig. 14)

b ensure that phase L1 of the capacitor bank is

connected to the busbar fitted with the CT (Fig.

14)

b connect the cables from the CT to the terminal

block, S1 to terminal K and S2 to terminal L (Fig.

15 and diagrams Figs. 1 and 2, page 3).

Earth connection

(Fig. 16)

The capacitor bank must be earthed using the

terminal intended for this purpose.

Load shedding

The terminals marked 1L3 and 2L3 are linked

using jumper A. To be able to shed load, replace

the jumper with one of the installation's normallyclosed contacts (Figs. 17, 18, 19).

Fig. 15: connection of CT to terminal block.

DB110511

Fig. 16: earth connection: horizontal

or vertical.

DB110509

Fig. 18: terminal block without load shedding. Fig. 19: terminal block with load shedding.

DB110695

Fig. 17: connection of load shedding contact.

DB110510

7AAV31918_00

Page 8

Installation (cont.)

Choice of cables

For an ambient temperature of 40 °C,

the temperature inside the cubicle can

reach 55°C.

Sizing current

The connection cables to the power factor

correction cubicle must be sized for the following

maximum continuous currents Imp:

Model Imp

Classic 1.36 In

Comfort 1.50 In

Harmony 135 Hz 1.10 In

Harmony 190 Hz 1.19 In

Harmony 215 Hz 1.31 In

Minimum sizing rules not taking into consideration any

correction factors: temperature, installation method.

Power factor correction cubicle nominal

current:

In =

Cross-section

It must be compatible with:

b the ambient temperature around the conductor

b the installation method (trunking, duct, etc.)

b the cable manufacturer's recommendations.

Q where U = mains supply voltage

U3

Q = reactive power

of the cubicle

Power circuit connection

DB110532

Fig. 20: power connection to circuit-breakers

(A3 bis, A4 bis, A2 Harmony).

DB110548

DB110531

Fig. 22: power connection to terminal blocks.

DB110597

Fig. 23: power connection to Polybloc.

DB108761

Connection methods

b to circuit-breakers (Fig. 20)

b to terminal blocks (Fig. 22)

b to connection pads (Figs. 21, 24)

b to Polybloc (Fig. 23).

Tightening torques

b cables connected to terminal blocks must be

tightened to 42 Nm max.

b cables connected to connection pads must be

tightened to 50 Nm max.

For cables connected to circuit-breakers,

refer to the user guide.

Fig. 21: power connection

to connection pads (A1 and A2 cubicles).

Fig. 24: power connection

to connection pads (A3 and A4 cubicles).

For A4 cubicles, the supply is spread over

two columns.

8 AAV31918_00

Page 9

DB108763

Controller front face.

Commissioning

Configuring the Varlogic controller

NR6/NR12

Setting the controller

The varmetric controller has been configured in accordance with the

capacitor bank's characteristics.

The only operations that have to be carried out during commissioning are:

Φ

b target cos

b current transformer ratio configuration.

Important:

b if supplied by a summing CT (installation with several incoming

transformers), it is the sum of the ratios of the different measurement CTs

that must be taken into consideration

b for an installation equipped with a generator set (load shedding),

the capacitor bank must be taken out of circuit, by breaking the supply to

the controller, before switching to the generator set.

See page 7, "connection of current circuit".

setting if necessary

Commissioning the capacitor bank

When first energised, the controller will immediately ask you to enter the

user language.

Choose the desired language using the keys and then validate by

pressing Enter.

The parameters needed for correct capacitor bank operation

are factory set.

Some parameters depend on the installation's characteristics

and must be modified on-site during commissioning

b target cos

b current transformer ratio in order to display the measured values correctly

b response current (C/K): this value is automatically searched for during the

checking phase.

The other parameters must not be changed.

In particular, the time delay must never be less than 50 s, otherwise

there is a risk the capacitor bank will incur serious damage and will no

longer be covered by the warranty.

b the "MIS.SERV" menu must be used to launch the commissioning

sequence. The sequence includes the configuration of cos

transformation ratio, as well as an automatic check that the parameters

entered are compatible with the installation's actual parameters.

Note : if an alarm appears during commissioning or when first used, refer to the

“faults and solutions” paragraph to determine its origin.

Φ

(default value = 1)

+

-

Φ

and the

Checking correct operation

b check that cos Φ corresponds to the required value

b if operating on full load, check the switched stepping functions correctly

b after several hours' operation, check the temperature in the premises.

For a better understanding of the parameters to be defined, refer to the

Glossary (Chapter 7) in the controller manual.

9AAV31918_00

Page 10

Commissioning (cont.)

DB108779

Commissioning a pre-configured capacitor bank.

What to do in the event of an error?

"Error codes" allow a diagnosis to be made and a solution to be found.

Refer to chapter 5.4 of the controller manual.

After checking the installation, re-launch the "MIS.SERV" sequence or the

commissioning with automatic configuration "REG.AUTO" sequence.

If the controller is not solicited for a long period when a menu is run, it may

display the message "I FAIBLE"

To return to the commissioning ("MIS.SERV") menu, or any other menu,

press and then scroll through the menus to obtain the one required.

esc

10 AAV31918_00

Page 11

Commissioning (cont.)

Configuring the Varlogic controller RT6

PB100045-55

Setting the controller

The varmetric controller has been configured in accordance with the

capacitor bank's characteristics.

The only operations that have to be carried out during commissioning are:

b target cos

b current transformer ratio configuration.

Important:

b if supplied by a summing CT (installation with several incoming

transformers), it is the sum of the ratios of the different measurement CTs

that must be taken into consideration

b for an installation equipped with a generator set (load shedding),

the capacitor bank must be taken out of circuit, by breaking the supply

to the controller, before switching to the generator set.

See page 7, "connection of current circuit".

Φ

setting if necessary

Commissioning the capacitor bank

The parameters needed for correct capacitor bank operation

are factory set.

Some parameters depend on the installation's characteristics

and must be modified on-site during commissioning

b target cos

b current transformer ratio in order to display the measured values correctly

b response current (C/k): this value is automatically searched for during the

C/k automatic setting sequence.

The other parameters must not be changed.

In particular, the time delay must never be less than 50 s, otherwise

there is a risk the capacitor bank will incur serious damage and will no

longer be covered by the warranty.

Φ

(default value = 1)

Checking correct operation

b check that cos Φ corresponds to the required value

b if operating on full load, check the switched stepping functions correctly

b after several hours' operation, check the temperature

in the premises.

For a better understanding of the parameters to be defined,

refer to the Varlogic RT6 manual.

11AAV31918_00

Page 12

Commissioning (cont.)

Automatic setting

of the C/k value

DB108812

DB110549

To start the C/k setting process,

simultaneously press

the UP and DOWN keys

.

Setting cos Φ

Start the SET menu by pressing the

SET key for 3 seconds.

AUtO

Display

Use the UP and DOWN keys to

select the cos

Φ LED.

The cos symbol is displayed.

Select the cos

Φ setting

by pressing the SET key.

The previously configured value is

displayed.

Choose a value between 0.85 and

1.00 using the UP-DOWN keys.

When the target value is displayed,

save it by pressing the SET key.

The RT6 then goes back to its

normal operating mode.

Selecting the transformer primary

current

DB108814

DB110550

Start the SET menu by pressing the

SET key for 3 seconds.

AUtO

Display

Select the CT LED using the

UP-DOWN keys. The CT symbol

is

displayed.

Select the transformer primary

current value by pressing the SET

key. The previously configured CT

value is displayed.

Choose a value between 5 and

10,000 using the UP-DOWN keys.

When the target value is displayed,

save it by pressing the SET key.

The RT6 then goes back to its

normal operating mode.

12 AAV31918_00

Page 13

Commissioning (cont.)

Varlogic NR6/NR12 faults and solutions

An operating problem, when commissioning

a capacitor bank, can generally be diagnosed from

the information supplied by the controller.

Controller display Possible causes Solutions

No display b no supply to controller v check for voltage at the controller's

b overvoltage v the controller has been damaged by a supply

Low (i.e. low current)

A3 or A5 alarm

(abnormal cos

(capacitive cos Φ) b incorrect voltage configuration v check the controller's voltage configuration (LL

Alarm A1 (lack of kVAr)

(1) The CT must be fitted on phase L1, upstream of the installation to be corrected. It must be checked that phase L1 at the point the CT is connected corresponds

to phase L1 inside the capacitor bank (e.g. by checking that the voltage between these two points = 0).

Φ

)

b non-compliant wiring v check the position of the CT in the (low current)

b CT oversized or too lower load v check the CT has been correctly chosen

b faulty CT v replace the CT

b bad connection v check the position of the CT

b presence of fixed capacitor bank(s) with low load

levels

b bad connection v check the position of the CT in the installation

b no auxiliary voltage v check the protection status of the auxiliary circuit

b incorrect C/K configuration v carry out the C/K automatic configuration again or

b target cos Φ occasionally not reached v deactivate alarm A1

b target cos Φ too high v readjust the target cos

b lack of reative power

(undersized capacitor bank)

terminals

v if there is no voltage reading, check circuit continuity

from the source: wiring, fuses, etc.

overvoltage.

Replace the controller

installation

v check the short-circuit jumper is present between

terminals K-L

in the installation

display)

v deactivate alarm A5

manually configure the calculated value

(1)

(1)

(1)

Φ

v add more capacitors

13AAV31918_00

Page 14

Commissioning (cont.)

Faults and solutions for Varlogic RT6

Errors and alarms

The alarm relay is activated if the following "errors" occur.

Overvoltage

If the voltage between phases equals or exceeds the pre-defined value

(programmable between 185...265 V for 240-275 V and between

320...460 V for 410-480 V), the RT6 waits for 1 minute. If the overvoltage is

still present at the end of this 1 minute period, the "OVER VOLTAGE" LED

lights-up. Depending on the programmed overvoltage protection

configuration, the RT6 switches all the capacitor steps or continues

to achieve power factor correction (refer to chapter 5.9 of the Varlogic RT6

manual).

Low power factor

When the power factor does not reach the target value, despite having

switched-in all the capacitor steps, the low power factor LED lights-up and

the alarm relay is activated after 1 minute.

Overcorrection

If the system is still capacitive despite having switched-out all the capacitor

steps, the "OVER COMPENSATION" LED lights-up and the alarm relay is

activated after 1 minute.

14 AAV31918_00

Page 15

DB110696

Fig. 25: on-line break.

DB110697

Maintenance

Personnel protection

Each capacitor is fitted with discharge resistors which reduce terminal

voltages to 50 V one minute after de-energising.

Before carrying out work on the equipment:

b remove its power supply

b wait until the compulsory discharge time has elapsed

b ensure each capacitor has been fully discharged by short-circuiting and

earthing the contactor terminals.

Discharging the capacitors

Warning:

refer to the capacitor bank's electrical diagram to identify the coupling mode

between the contactor and the capacitor.

b on-line break (Fig. 25).

To ensure capacitor discharge, successively short-circuit terminals: AB, AC

and BC

b break the triangle links (Fig. 26).

To ensure capacitor discharge, successively short-circuit terminals: AE, BF

and CD.

Fig. 26: break the triangle links.

Checks

One month after energising, check:

b contactor terminal tightening torques.

Each year check:

b general cleanliness of the equipment

b filters and ventilation system

b terminal tightening torques.

b proper working order of switching and protective devices

b temperature in the premises: -5 °C to +40 °C max

b capacitor capacitance, consult us if the capacitance value has

changed by more than 10 %.

Safety

All the operations described in this guide must be carried out whilst

respecting current safety standards, and under the responsibility

of a competent authority.

15AAV31918_00

Page 16

Maintenance (cont.)

Working on the current circuit

Before starting work

DB109732

Initial state.

A : separator

B : jumper

K : S1 terminal on CT

L : S2 terminal on CT

Fig. 27.

DB109735

DB109733

Remove the separator from

the circuit A.

After finishing work

DB109736

DB109734

Use the jumper B to link

DB109735

Final state.

terminals K and L

of the terminal block

(terminals S1

and S2 of the CT).

Warning

Risk of destroying the current transformer

if the secondary is open-circuit.

DB109737

DB109738

Initial state. Disconnect the jumper B

by lifting it up.

Fig. 28.

Schneider Electric Industries SAS

Rectiphase

399 rue de la Gare

74370 Pringy

France

Tel.: 33 (0)4 50 66 95 00

Fax: 33 (0)4 50 27 24 19

http://www.schneider-electric.com

http://www.merlin-gerin.com

No.AAV31918_00

As standards, specifications and designs change from time to time, please ask for confirmation

of the information given in the publication.

Creation: Schneider Electric, Ameg and Hardis Conseil

Publication: Schneider Electric

Printing: Coquand Imprimeur - made in France

Refit the separator A. Final state.

This document has been printed on ecological paper

© 2006 - Schneider Electric – All rights reserved

10-2006

Loading...

Loading...