Page 1

Varlogic NR6, NR12

Power factor controller

User manual

Page 2

Table of Contents

1. General...................................................................................................3

1.1 Safety...............................................................................................3

1.2 Description.......................................................................................3

2. Installation ..............................................................................................5

3. Display....................................................................................................6

4. Start-up Procedure.................................................................................6

5. Menu Operations....................................................................................7

5.1 General.............................................................................................7

5.2 Main Menu .......................................................................................9

5.3 Bank Pre-Configuration .................................................................11

5.4 Commissioning ..............................................................................13

5.5 Auto Setup of Parameters .............................................................14

5.6 Manual Setup of Parameters .........................................................15

5.7 Measurement Menu.......................................................................17

5.8 Parameter Update..........................................................................18

5.9 Alarms Menu..................................................................................19

5.10 Maintenance Menu ......................................................................20

6. Miscellaneous.......................................................................................23

6.1 Stepping Programs........................................................................23

6.2 Manual calculation of response value............................................26

6.3 High Voltage use of NR6/NR12......................................................27

7. Glossary ...............................................................................................29

8. Technical specifications .......................................................................31

2

USER´S MANUAL

Power Factor Controller NR6 / NR12

USER’S MANUAL

Page 3

3

USER´S MANUAL

1. General

1.1 Safety

The following precautions must be taken into account when installing and operating the controller

• The installation of the controller must be performed by a qualified electrician

• Do not touch the connectors when the controller is energized, make sure that

the operating voltage is disconnected before touching any parts located on the

rear side of the controller

• Do not open a live current circuit, this may cause dangerous overvoltages. Always

short circuit the current transformer (CT) before replacing or removing the controller

installed in a bank.

• Do not open the controller casing, there are no user serviceable parts inside

For better understanding of the terminology used, please refer to the Glossary

(chapter 7) at the end of this manual.

1.2 Description

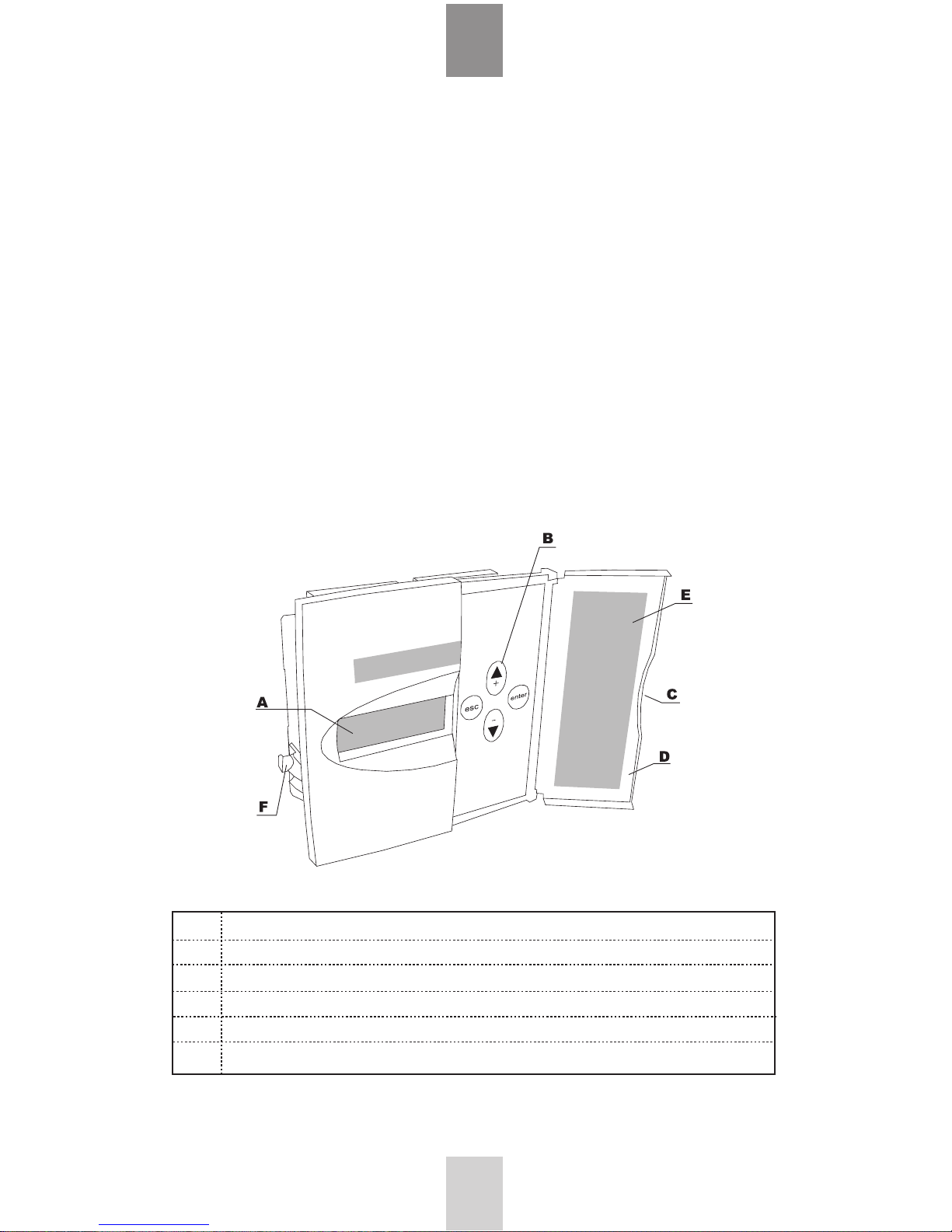

Front view:

Legend

A Display

B Keys

C Opening of door

D Door

E Alarm information

F Mounting bracket for panel mounting installation

Page 4

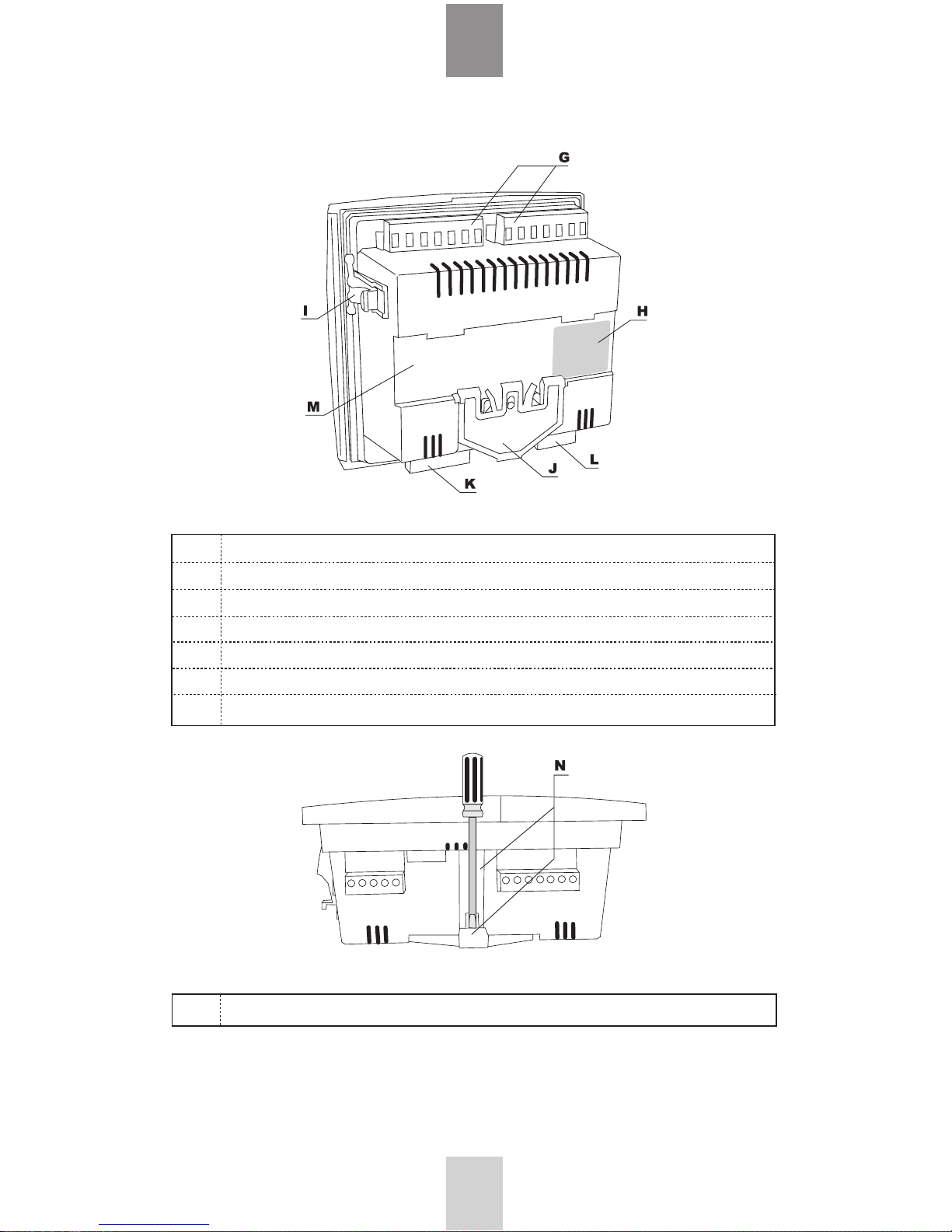

Rear view:

Legend

Side view:

Legend

See Chapter 8 for technical specifications.

4

USER´S MANUAL

G Step output connectors

H Specification label

I Mounting bracket for panel mounting installation

J Fixing spring for DIN-rail mounting

K Current/voltage connection inputs

L Fan and alarm outputs

M DIN-rail mounting installation area

N Screwdriver guide

Page 5

5

USER´S MANUAL

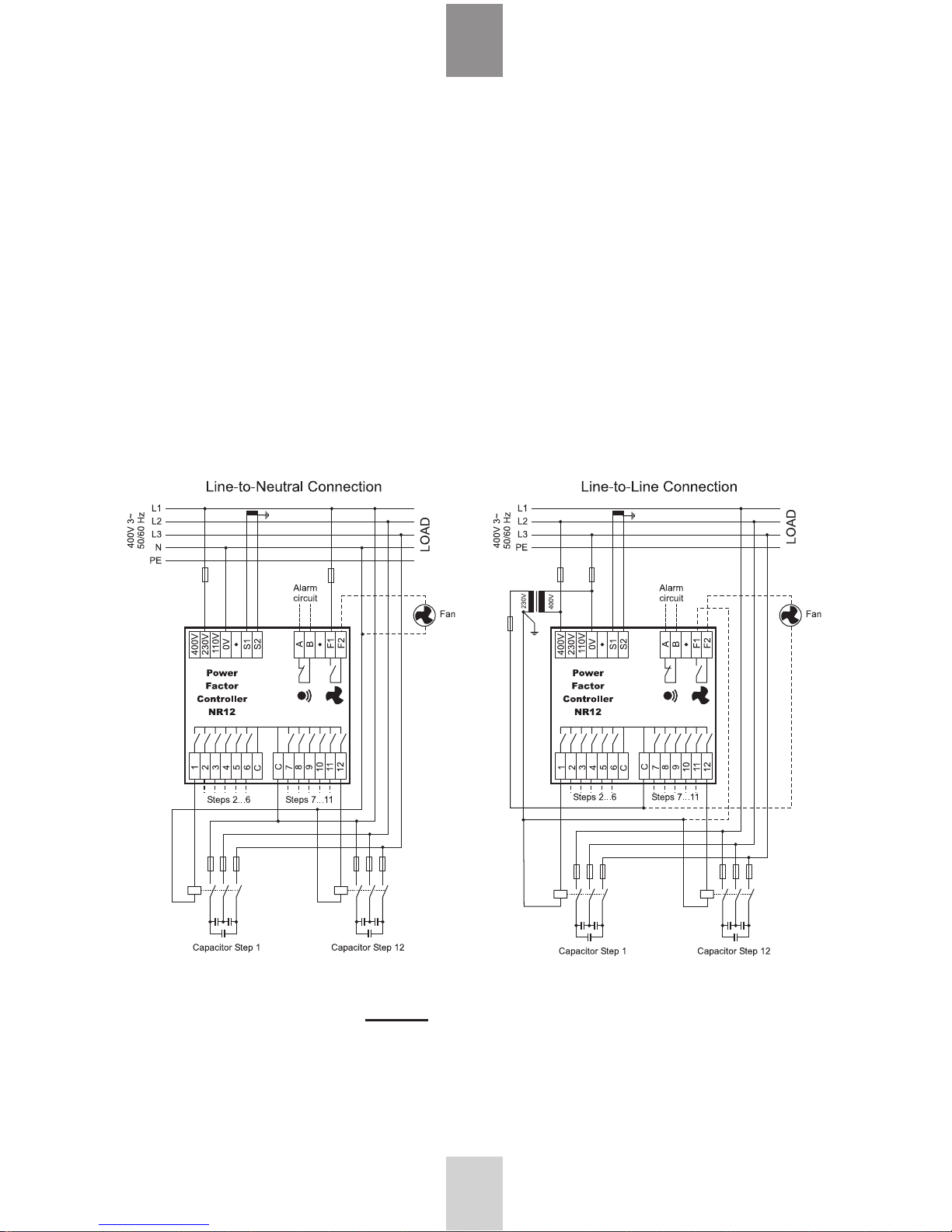

2. Installation

The controller is designed for either panel (cut-out 138 x 138 mm) or DIN-rail installation. It is

locked to the rail by a screwdriver-operated fixing spring and to a panel by a side fitting spring.

There are two ways of connecting the controller to the network.

Voltage LN (Line – Neutral) (CT on the same line phase)

Voltage LL (Line – Line) (CT on the third phase)

Incorrect connections can be automatically corrected by the controller when Auto Setup is

selected from the main menu.

Caution: For use in HV network, look first at chapter 6.3

Figure 1: Controller connections

Page 6

6

USER´S MANUAL

3. Display

The controller is equipped with a backlighted LCD-display.

Figure 2 : Display layout and symbols

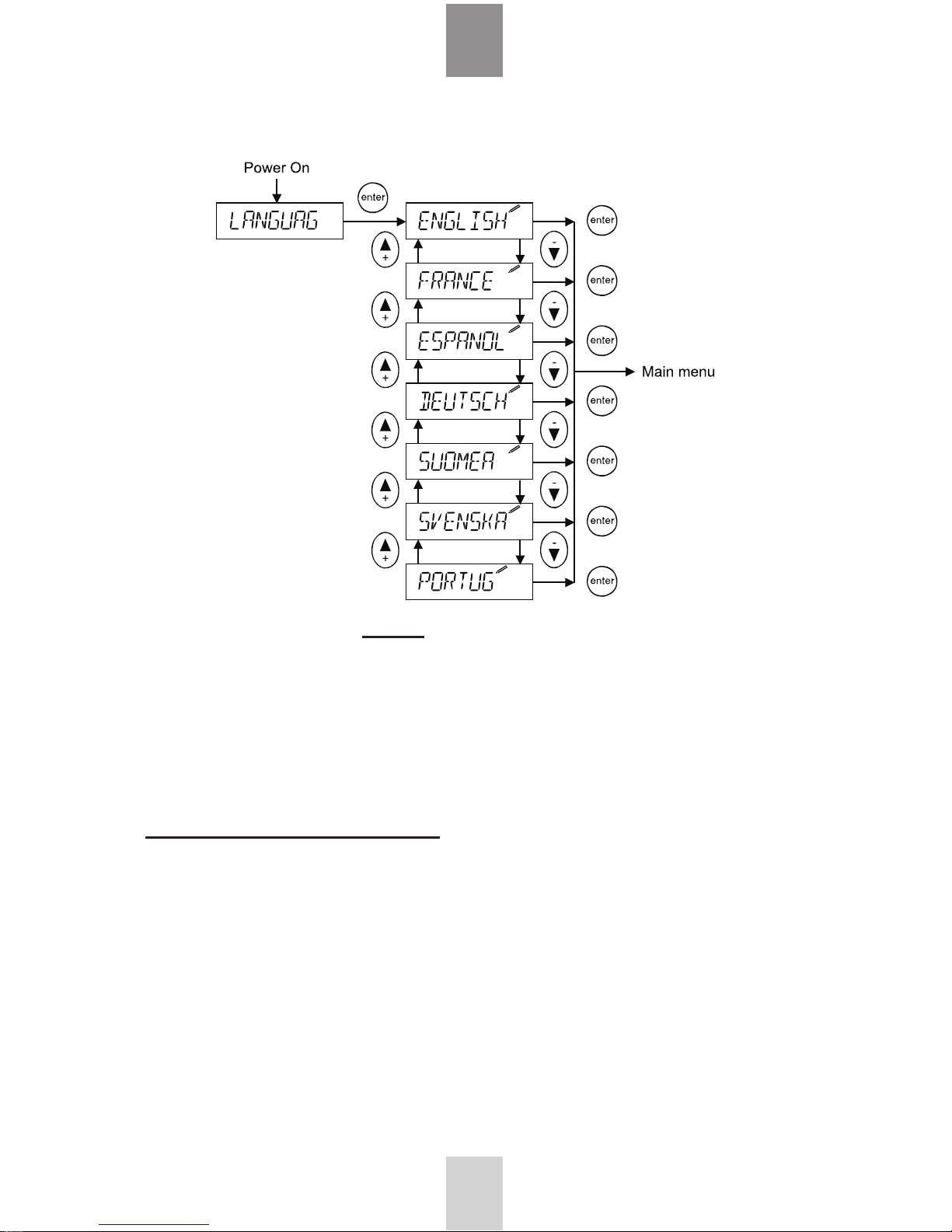

4. Start-up Procedure

Before connecting power, check the wiring of all controller terminals. Check carefully for correct

operating voltage. Selection of wrong voltage input can permanently damage the controller.

After the first power switch-on, the controller will automatically ask for the language setting of

the menu.

Page 7

7

USER´S MANUAL

Figure 3: Language setting dialog

5. Menu Operations

5.1 General

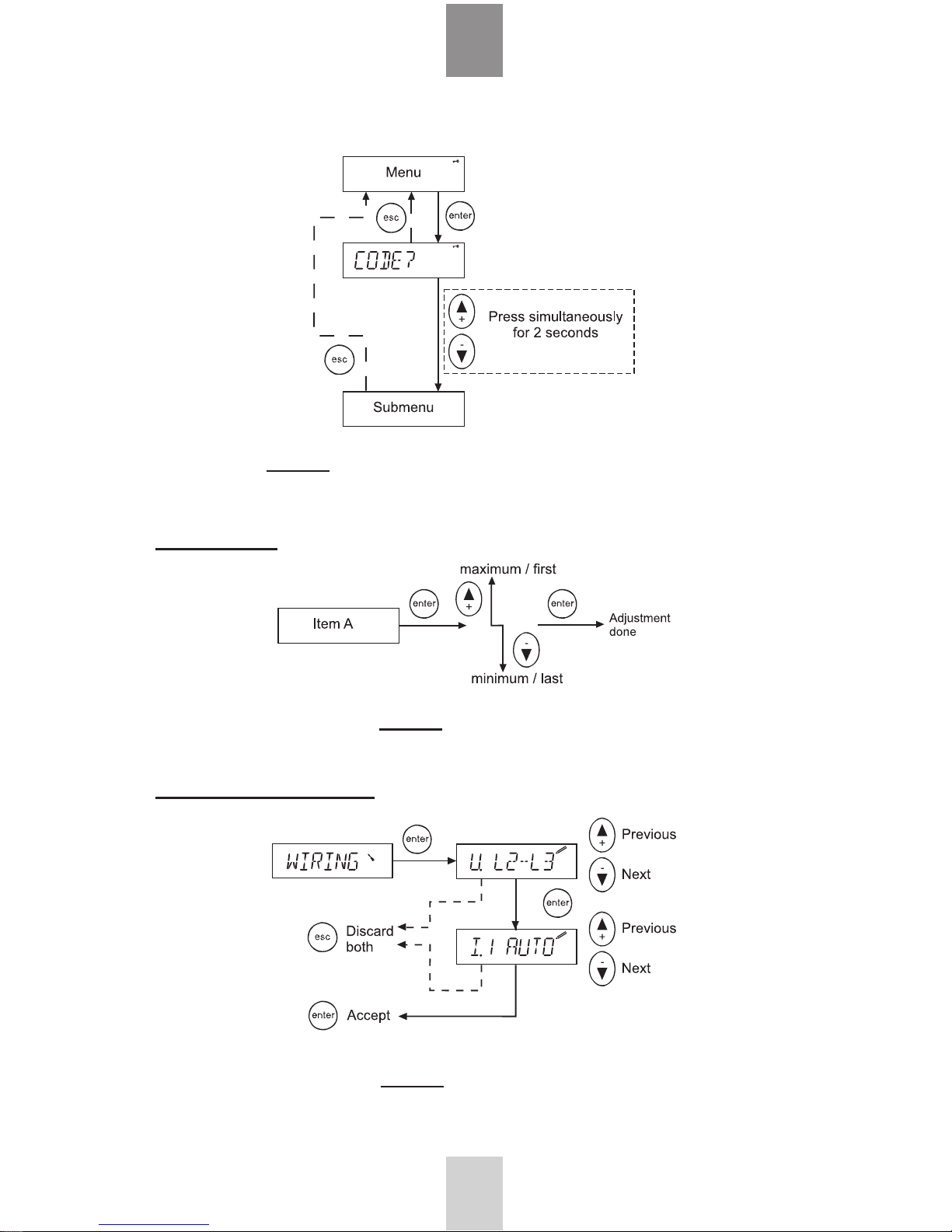

Navigation between different menu levels

As a precaution against accidental use, the access of certain menus has been protected by a

keylock, which is a special sequence of keystrokes enabling the use the particular menu item.

Page 8

Figure 4: General way of entering the menu with a keylock

Adjusting a value

Figure 5: Adjusting a value

Special case: The wiring editor

Figure 6: The wiring editor

8

USER´S MANUAL

Page 9

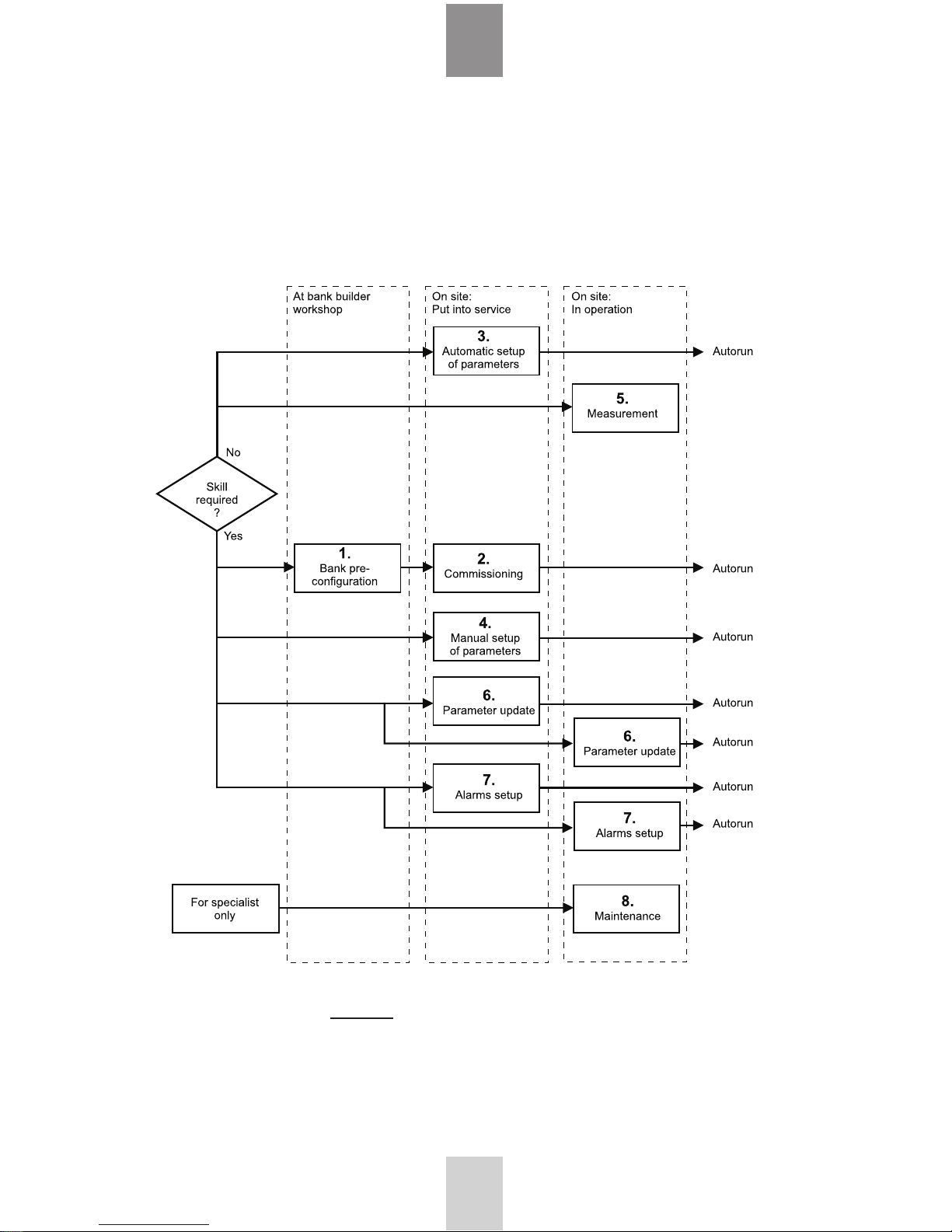

5.2 Main Menu

The main menu contains all basic submenus required to set up and operate the controller.

Which menu to choose?

Figure 7: Required skills and menu selection

If bank preconfiguration is properly done, commissioning does not require any special skill.

9

USER´S MANUAL

Page 10

10

USER´S MANUAL

Figure 8: Main menu

(1) Bank pre-configuration

When factory settings have not been changed, this

menu provides the bank builder the means of preconfiguring the bank at the workshop. After preconfiguration, this menu topic is replaced by

(2) Commissioning, by which the controller is taken

into service.

(3) Automatic setup of parameters

In the event that the controller has not been preconfigured, an inexperienced user can automatically

set up all the characteristics of the bank and bring it

into service.

(4) Manual setup of parameters

In the event that the controller has not been preconfigured, an experienced user can manually set up

all the characteristics of the bank and bring it into

service.

(5) Measurement

The measurement menu contains the most common

measurements taken from the network and provides

some information about the bank. This is a read-only

menu.

(7) Alarm settings

To adjust status and parameters of alarms.

(8) Maintenance

The maintenance menu provides some useful

information about the usage of the bank, capacitors

and contactors. Some auxiliary settings and action

have also been provided. This menu is basically

intended for use by the manufacturer’s maintenance

team.

(6) Parameter update

At any time, an experienced user can access the most

common operating parameters from this menu. Unlike

the configuration and setup sequences, this is a menu

allowing a free and unrestricted entry into all its items

and should be used when an occasional parameter

access is needed.

Page 11

11

USER´S MANUAL

5.3 Bank Pre-Configuration

This menu item is a forced sequence, meaning that all items must be accessed before the preconfiguration takes place.

NOTE: Do not use of the Bank Pre-Configuration menu for HV network

applications

The sequence can be interrupted by pressing key.

See Glossary (chapter 7) for parameters definitions.

Page 12

12

USER´S MANUAL

Figure 9: Bank pre-configuration

Page 13

5.4 Commissioning

A pre-configured controller is put into service by this menu. The sequence contains an automatic

parameter verification to check that the manually entered parameters agree with the network

used.

See Glossary (chapter 7) for parameter definitions.

NOTE: Do not use of the Commissioning menu for HV network applications

What to do in case of error ?

Error codes can help you to identify a problem and make corrections.

13

USER´S MANUAL

Figure 10: Commissioning

Page 14

Code Meaning

Unstable network: The controller is unable to

operate due to excessive load variations on the

network. CT oversized.

Step size too small: The effect of the 1

st

step

cannot be measured. CT oversized, wrong

wiring, inoperative steps.

Sequence not found: Step ratio does not match

available step sequences.

Step size too large: The ratio of measured step

compared with the 1

st

step is too large. Step

sequence cannot be resolved.

Non-relevant autosetup process with this bank

configuration

Reserved

Wiring verify error: Controller wiring not correct.

Step count error: The Number of Steps setting

is incorrect.

Step sequence error: The step size ratios differ

from the selected step sequence.

C/K value error.

14

USER´S MANUAL

5.5 Auto Setup of Parameters

The auto setup sequence is intended for inexperienced users so they can commission the bank

with minimal prior knowledge. The user need only input three of the most common parameters

and then launch an automatic search for the other parameters.

NOTE: The use of Auto Setup of Parameters menu is forbidden on HV network applications

In the event of error, see the Commissioning Menu (chapter 5.4).

Action to do

• Enter the parameter settings

manually using Parameter

Update menu.

• Rerun the commissioning

sequence

• Check wiring, CT, condition of

capacitor steps (1

st

step)

• Check the condition and sizes

of steps and contactors

• Check the condition and sizes

of steps and contactors

• Use manual setup to confirm

or correct the information

obtained by autosetup

• Check the wiring of voltageand current inputs

• Check the Wiring setting from

Parameter Update menu

• Check the Number of Steps

setting

• Check the number of steps in the

bank and the condition of steps

• Check Step Sequence setting

• Check step sizes used in the

bank

• Check the response value used

• Check the size of 1

st

step in the

bank

to

Page 15

15

USER´S MANUAL

Figure 11: Auto setup of parameters

5.6 Manual Setup of Parameters

The manual setup sequence is intended for experienced users. There are nine important

parameters to input before the controller can be taken into service. This sequence is

completed by an automatic verification of the parameters entered earlier in this sequence.

This menu item is a forced sequence, meaning that all items must be accessed before the

validation of the setup takes place.

The sequence can be interrupted by pressing key.

See Glossary (chapter 7), for parameter definitions.

In case of error, refer to the Commissioning Menu, chapter 5.4.

Page 16

16

USER´S MANUAL

Figure 12: Manual setup of parameters

Page 17

17

USER´S MANUAL

5.7 Measurement Menu

The measurement menu contains the most common measurements taken from the network.

This is a read-only menu sequence.

Figure 13: Measurement menu

Page 18

18

USER´S MANUAL

5.8 Parameter Update

The most common operating parameters can be accessed from this menu.

Unlike the configuration and setup sequences presented earlier in this text, this is a menu

allowing a free and unrestricted entry into all of its items and should be used when occasional

parameter access is needed.

See Glossary (chapter 7), for parameter definitions.

In case of error, refer to the Commissioning Menu, chapter 5.4.

Figure 14: Parameter update

Page 19

5.9 Alarms Menu

In Alarms menu, each individual alarm can be enabled or disabled.

Once an alarm condition is detected, the corresponding alarm number is shown at the upper

part of the display, and the alarm symbol is on. The alarm relay is also activated.

List of alarms:

Alarm contacts are

• closed when the controller is not energized

• opened when the controller is energized without alarm

• closed when the controller is energized with alarm

ALRM.SET

• informs on the status of each alarm : enabled or disabled

• allows enabling or disabling of each individual alarm by setting it ON or OFF. If an alarm

is set to OFF, it cannot cause an alarm under any condition. To allow a normal alarm

response, the appropriate alarm must be enabled, i.e. set ON.

Some alarm triggering levels can be adjusted

Alarm No 9 (overtemperature ), with temperature limit setting

Alarm No 10 (voltage distortion ), with THD(U) limit setting

An alarm can be reset by an extended pressure of key, this clears all passive alarms.

If alarm condition is still active, the alarm cannot be reset.

19

USER´S MANUAL

Alarm

No

.

1

2

3

4

5

6

7

8

9

10

Alarm Possible cause Controller action

Low power factor

Hunting

Abnormal Cos Phi

Low voltage

Overcapacitive

Wrong frequency

Overcurrent

Overvoltage

Overtemperature

Voltage distortion

• Wiring or LL/LN definition error

• Undersized bank

• Too small C/K value

• Wrong program choice

• Defective capacitors

(optimal program)

• Wiring mistake

• overcapacitive network

(welded contactors)

• Too low current

• Wiring or LL/LN definition error

• Improper use of

fixed steps

• Wrong or unstable network

frequency detected at startup

• Undersized CT

• Ambient temperature too high

• Defective coolingsystem

• Harmonic pollution

• Resonance

Pauses regulation for 10

minutes

Disconnection till voltage

returns

Stop regulation. No automatic restart

Temporary disconnection of steps

Temporary disconnection of steps

Temporary disconnection of steps

Page 20

20

USER´S MANUAL

Figure 15: Alarms menu

5.10 Maintenance menu

The maintenance menu provides useful information about the usage of the bank, capacitors

and contactors. Also, some auxiliary settings have been provided.

CAUTION: This menu access is dedicated to specialists.

CAUTION: In case of installation in a HV bank (with VT), you must adjust the default

factory settings. The reconnection delay must be changed to a larger

value (e.g. 600 secs) to prevent destruction of capacitors.

Page 21

21

USER´S MANUAL

Figure 16/1: Maintenance menu

Page 22

22

USER´S MANUAL

Figure 16/2: Maintenance menu

Page 23

23

USER´S MANUAL

6. Miscellaneous

6.1 Stepping programs

The controller's algorithm will try to reach the target cos inside a tolerance area dependant

upon the C/K value. It reaches the value by switching on or off available relevant steps.

The regulation step program choice is as follows:

a) Stack Program (linear) :

All capacitor steps are of equal size (ex :1.1.1.1). The operation sequence obeys to a last-in-

first-out (LIFO) principle. The first step connected will be the last one to be disconnected and

vice versa. See Fig. 17

b)

Normal program (2+ linear)

Normal program can be used on bank whose step ratio is 1.2.4.4.. The linear sequence starts

with the 3rd step. The two first steps are used as fine-tuning. The controller always start by

switching the first step then the second. Other steps are used successively See Fig. 18.

c)

Circular A program

All capacitor steps are of equal size (ex :1.1.1.1). The operation sequence obeys the first-in-firstout (FIFO) principle. The first step connected will be the first one to be disconnected and vice

versa. Then a circular sequence is followed. In order to operate correctly, the number of steps

programmed into the controller must strictly comply with the number of physical steps

See Fig. 19.

d) Circular B program (1+Circular)

Circular B program can be used on a bank whose step ratio is 1.2.2.2… The first step is used

as tuning after the activating limit is exceeded. The circular sequence starts with the 2nd step.

Figure 17: Stack program - Operation

sequence 1:1:1:1

Figure 18: Normal program - Operation

sequence 1:2:4:4

Step Step number

demand 1 2 3 4 5 6

+ X

+ X X

+ X X X

+ X X X X

+ X X X X X

+ X X X X X X

- X X X X X

- X X X X

- X X X

- X X

+ X X X

+ X X X X

+ X X X X X

- X X X X

- X X X

- X X

- X

Step Step number

demand 1 2 3 4 5 6

+ X

+ X X

+ X X X

+ X X X X

- X X X

- X X

+ X X X

+ X X X X

+ X X X X X

- X X X X

- X X X

- X X

- X

Page 24

24

USER´S MANUAL

e) Optimal Program :

The optimal program operates with many step configurations:

1.1.1.1.1 1.2.2.2.2 1.2.4.4.4 1.2.4.8.8 1.1.2.2.2

1.1.2.3.3 1.1.2.4.4 1.2.3.3.3 1.2.3.4.4 1.2.3.6.6

The target cos

power is reached using the fewest number of steps in minimal time. Like the

circular program, this algorithm equalises the usage of steps.

This program uses optimally selected steps sizes when approaching the target power and at

the same time the response delays are shortened, particularly if there is a large requirement for

kvar or if the network suddenly becomes capacitive.

Comparison between normal and optimal program:

Normal program will reach the cos

target value by successive connection/disconnection of

kvar corresponding to the smallest step value.

Optimal program will reach the target cos

value by successive connection/disconnection of

kvar corresponding to the highest relevant and available step value

Figure 20: Circular B program Operation sequence 1:2:2

Figure 19: Circular A program - Operation

sequence 1:1:1

Step Step number

demand 1 2 3 4 5 6

+ X

+ X X

+ X X X

+ X X X X

- X X X

- X X

+ X X X

+ X X X X

- X X X

- X X

+ X X X

+ X X X X

- X X X

Step Step number

demand 1 2 3 4 5 6

+ X

+ X X

+ X X X

- X X

+ X X X

+ X X X X

- X X X

- X X

- X

+ X X

+ X X X

+ X X X X

+ X X X X X

- X X X X

- X X X

- X X

Page 25

25

USER´S MANUAL

Figure 21: Regulation example - Optimal vs. Normal

Ind

Cap

+4

-4

-4

Steps on :

4

Steps on :

4+4+4+1

Steps on :

4+1

Compensated reactive power

Connection of steps

Disconnection of steps

+4

+1

t

Q

Uncompensated reactive power

Optimal Stepping Program

Step sizes : 1:2:4:4

+4

-4

Normal Stepping Program

Q

Ind

Cap

Step sizes : 1:2:4:4

+4

-4

Steps on :

4

Steps on :

4+4+4+4

Steps on :

4

-4

-1

+4

+1

+2

t

-4

+4

-2

Page 26

26

USER´S MANUAL

6.2 Manual calculation of response value

Normally the response value, more generally known as the C/K value, is set automatically as

a part of the Auto Setup sequence, but there are cases when these values must be entered

manually. The correct value can be calculated using an equation requiring the 1st step size

(in vars), line-to-line voltage of the network used (in volts) and the CT ratio as follows

where Q

1st

= size of 1

st

step in vars

U

LL

= line-to-line voltage in volts

I1/5A = CT ratio

Alternatively, the C/K value can be taken from the table below (valid for 400 V networks)

Table 1: C/K-values for 400 V network

By successive connections (or disconnections) of steps we adjust the reactive power between

two symmetrical limits corresponding to response value

n1/n

2

Smallest step (kvar)

12,5 20 25 30 40 50 60 100

100/5 0,91 1,44

150/5 0,60 0,96 1,20 1,44

200/5 0,45 0,72 0,90 1,08 1,44

250/5 0,36 0,58 0,72 0,87 1,16 1,44

300/5 0,30 0,48 0,60 0,72 0,96 1,20 1,44

400/5 0,36 0,45 0,54 0,72 0,90 1,08

500/5 0,29 0,36 0,43 0,58 0,72 0,87 1,44

600/5 0,30 0,36 0,4 0,60 0,72 1,20

800/5 0,27 0,36 0,45 0,54 0,90

1000/5 0,29 0,36 0,43 0,72

1500/5 0,24 0,29 0,48

2000/5 0,22 0,36

2500/5 0,29

3000/5 0,24

35

/

1

1

××

=

LL

st

UAI

Q

KC

Page 27

27

USER´S MANUAL

Figure 22: Compensation example and consequences

6.3 High Voltage use of NR6/NR12

This controller is primarily intended for LV network, but may be used in HV networks under

the commissioner’s full responsibility, if the following points are taken into account.

Connections must employ VT and CT with respect to the following figure.

In HV applications the power values displayed in Measurement Menu represent only the secondary

side values of the VT. To avoid potential misunderstandings, set the CT ratio to percentage

scale.

Safety (or reconnection) delay must be adapted to the value of the discharge resistors of the

capacitors, the most usual value is 10 minutes (600 seconds). The controller’s default response

delay is adapted for LV use. Using too short a response delay may damage the capacitors.

Important:

• the whole commissioning process must be performed using the Manual setup menu and

Parameter menu

• the commissioner should not use Bank Pre-Configuration and Commissioning menus

• the use of Auto Setup menu is strictly forbidden to prevent capacitor destruction

Page 28

28

USER´S MANUAL

Figure 23: HV use of the controller

Page 29

29

USER´S MANUAL

ALARMS Alarms Menu

ALRM.SET Alarm Setup (Enable/Disable)

AUTO Automatic search of C/K response value

AUTO.SET Automatic Setup Sequence

BANK.PRE Bank Pre-configuration Sequence Menu

BANK.TST Bank Test: each step is automatically connected

and disconnected in turn. This facilitates testing of

the operation of each capacitor step contactor.

See also Step Test.

CIRC.A Circular A stepping program

CIRC.B Circular B stepping program

C/K Response value, normally set up automatically by

the controller

CLR.STAT Clear Statistics

COMMISS Commissioning Sequence Menu

COS PHI Target cos value 0,8ind 1.00 0,9cap

CT Current Transformer primary setting, xxx/5 A 25/5 % 6000/5

DELAY Safety Delay or reconnection delay. Response 10s 50s 600s

delay is fixed 20% of reconnection delay. The

default value corresponds to capacitors with

internal discharge resistors 50V 1 min

ENGLISH Language names: English, for instance

ERR NN Error in parameter search or verify. NN= error number

FACTOR.S Restore Factory Settings

IGNORED The controller does not require the information

about step sequence for any program outside

Optimal. The controller defines it automatically.

I HIGH Current too high >115%

I

N

I LOW Current too low <2,5%

I

N

LANGUAG Language Selection for menus

LL Line to Line connection

LN Line to Neutral connection

LV Low Voltage

MAINTEN Maintenance Menu

MAN.SET Manual Setup Sequence Menu

MANUAL Manual setting of C/K response value. See further 0,01 0,50 1,99

MEASURE Measurements Menu

7. Glossary

Display

information

Long form text Min

value

Default

value

Max

value

Page 30

30

USER´S MANUAL

N.CONNEC Number of Connections

N.STEPS Number of used steps 1 6/12 12

NORMAL Normal, Standard stepping program

OPTIM Optimal program

PARAMET Parameters Menu

PROGRAM Selection of suitable stepping program between

(see 6.1 Stepping programs)

The controler’s algorithm will try to reach the target

cos

inside a tolerance area dependant upon the

C/K value. It reaches the value by switching on or off

available relevant steps.

Stack

Normal

Circular A

Circular B

Optimal

SEARCH Search (response value, step sizes, wiring...)

SERIAL.N Serial Number of the product (for internal

manufacturer use)

STACK Linear stepping program

STEP.SEQ Setting of Step Size Sequence

1.1.1.1.1 - 1.1.2.2.2 - 1.1.2.3.3 - 1.1.2.4.4 - 1.2.2.2.2 -

1.2.4.4.4 - 1.2.4.8.8 -1.2.3.3.3 - 1.2.3.4.4 - 1.2.3.6.6

This concerns the Optimal program.

Step sequence are predefined with other programs and

modification request are not then taken into account

STEP.TST Step Test: each step can be manually connected and

disconnected. This facilitates testing of the operation

of each capacitor step contactor. See also Bank Test.

TEMP.LIM Temperature Limit (adjustable) 20

°

C50°C60

°

C

Fan switch-on limit is 15°C lower than temperature limit.

THD.U Total Harmonic Distortion of Voltage

THD.U.LIM Maximum Harmonic Distortion of Voltage (adjustable) 5% 7% 20%

U LOW Voltage too low

<85%U

N

UPTIME Uptime (Power On Hours)

VERIFY Automatic verification of parameters

VERSION Software version number (for internal manufacturer use)

VOLTAGE Input Voltage reference value for voltage alarms 80V 400V 460V

WIRING Connections of voltage and current inputs.

Example: U.L2-L3

(Voltage connected between phase 2 and 3)

Example: I.1.AUTO

(Current connected to phase 1 with automatic polarity

selection)

Current polarity selections:

DIR = direct connection

INV = inverted connection

AUTO = automatic polarity (defined by controller)

Display

information

Long form text Min

value

Default

value

Max

value

Page 31

31

USER´S MANUAL

8. Technical specifications

Number of steps 6 or 12

Dimensions 155 x 155 x 70 mm

Frequency 48...52 Hz, 58...62 Hz

Measuring current 0...5 A

Measuring and supply voltages 88...130 V

185...265 V

320...460 V

Relay outputs 120 Vac/5A, 250 Vac/2A, 400 Vac/1A

110 Vdc/0,3A, 60 Vdc/0,6A, 24 Vdc/2A

Display LCD glass with 160 symbols, backlighted

Protection class IP41 front panel, IP20 rear part

Target cos

-range 0,85 ind...1,00...0,90 cap

Response limits, C/K 0,01...1,99 symmetrical

Reconnection delay 10...600 s

Response delay 20 % of reconnection delay, min. 10 s

Displayed measurements cos

, P, Q, S, THD(U), temperature

Installation method Panel installation, DIN-rail installation

Casing Impact resistant PC/ABS, UL94V-0

Operating temperature range 0...60°C

Alarm log List of 5 last alarms

Step counters Yes

Fan control with dedicated relay Yes

Accuracy (of FS) Is: 5%

Iq: 5%

U/I-samples: 5%

Phase: 5°

Distortion: ±3 dB (up to 11

th

)

Temperature: ±3°C

CT setting range 25/5...6000/5

Power outage detection Reaction time > 15 ms

Approvals IEC 61010-1

IEC 61000-6-2

IEC 61000-6-4

IEC 61326

Page 32

Schneider Electric Industries SAS

As characteristics and dimensions of our products are constantly

changing, please contact our offices for confirmation.

10/2003Rec NM39EN

Loading...

Loading...