Mercedes-Benz OM906LA Mercedes-Benz OM926LA

Repair manual

Service & Parts

1044-004

Table of contents

Introduction

General Information.................................................................................................................................

General repair instructions.....................................................................................................................

Torque settings........................................................................................................................................

CCN explanation

CCN (CLAAS Component Number)........................................................................................................

CCN (CLAAS Component Number)

Safety

General Information.................................................................................................................................

01 Engine

0102 Complete component.....................................................................................................................

0105 Engine suspension.........................................................................................................................

0110 Engine housing...............................................................................................................................

0115 Engine unit......................................................................................................................................

0120 Cylinder head / Valves / Idler gear................................................................................................

0125 Injection - / Fuel system.................................................................................................................

0130 Lubricating oil system....................................................................................................................

0135 Cooling system...............................................................................................................................

0140 Exhaust system..............................................................................................................................

0145 Air intake.........................................................................................................................................

0150 Engine attachment parts................................................................................................................

0155 Engine control.................................................................................................................................

0165 Exhaust gas treatment...................................................................................................................

1044-004

4

8

20

32

36

48

59

61

81

117

152

176

196

212

231

234

255

257

Index....................................................................................................................................

284

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 3

Introduction

General Information

Introduction

1044-004

General Information

Validity of manual

This manual applies to the Mercedes-Benz diesel

engines below:

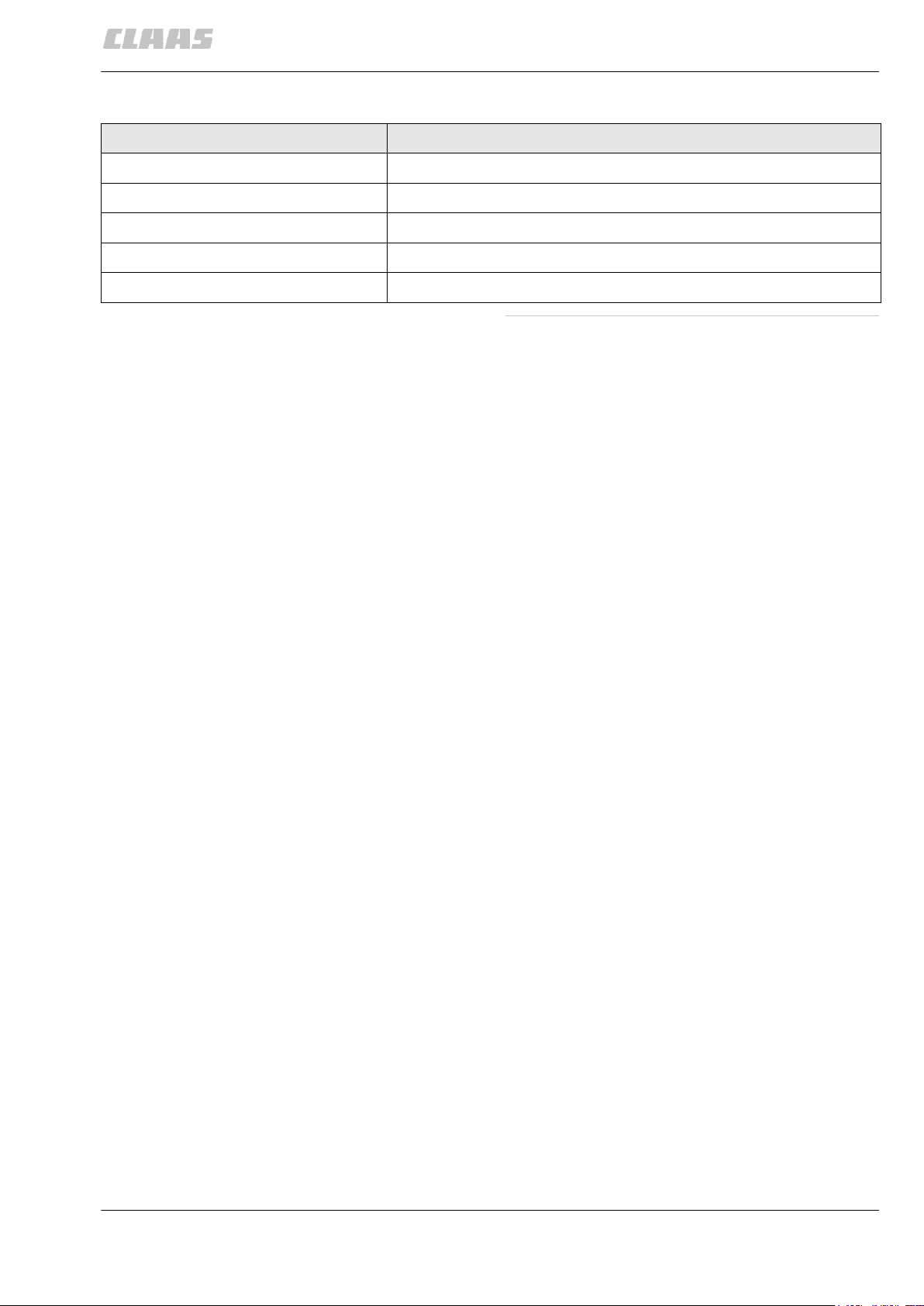

Engine Type design Engine no.

OM 906 LA 906.991 906.991-00-xxxxxx

OM 926 LA 926.929 926.929-00-xxxxxx

OM 926 LA 926.959 926.959-00-xxxxxx

OM 926 LA 926.970 926.970-xx-xxxxxx

Handling the manual

This repair manual should help you to maintain

ongoing operational capacity. The high value of the

harvesting machine is ensured through careful

maintenance and technical monitoring by customer

service.

This repair manual is a compilation of our service

technicians' and shop-floor experience.

162113-001

123139-005

The picture sequence demonstrates the steps in a

repair procedure. The text provides you with the

information required for making adjustments, using

special tools and further similar information.

Essential repairs are listed in such a way that even

individual and small repairs can be easily found and

followed.

Supplements are added to reflect the ongoing

technical development of the machines and the

manual is thereby continuously being updated as a

reference book.

As a precaution, always compare the setting values

and fill quantities with the most recent operator's

manual and the technical systems documents for the

respective machine.

Texts and figures

Pictures and graphics apply to all models covered by

this manual. Differences are highlighted by captions

below the figures.

In general, texts are short and apply to all models

covered by this manual. Differences are highlighted by

intermediate headings.

Different text categories can be easily identified by the

formatting. The following different formattings are

distinguished:

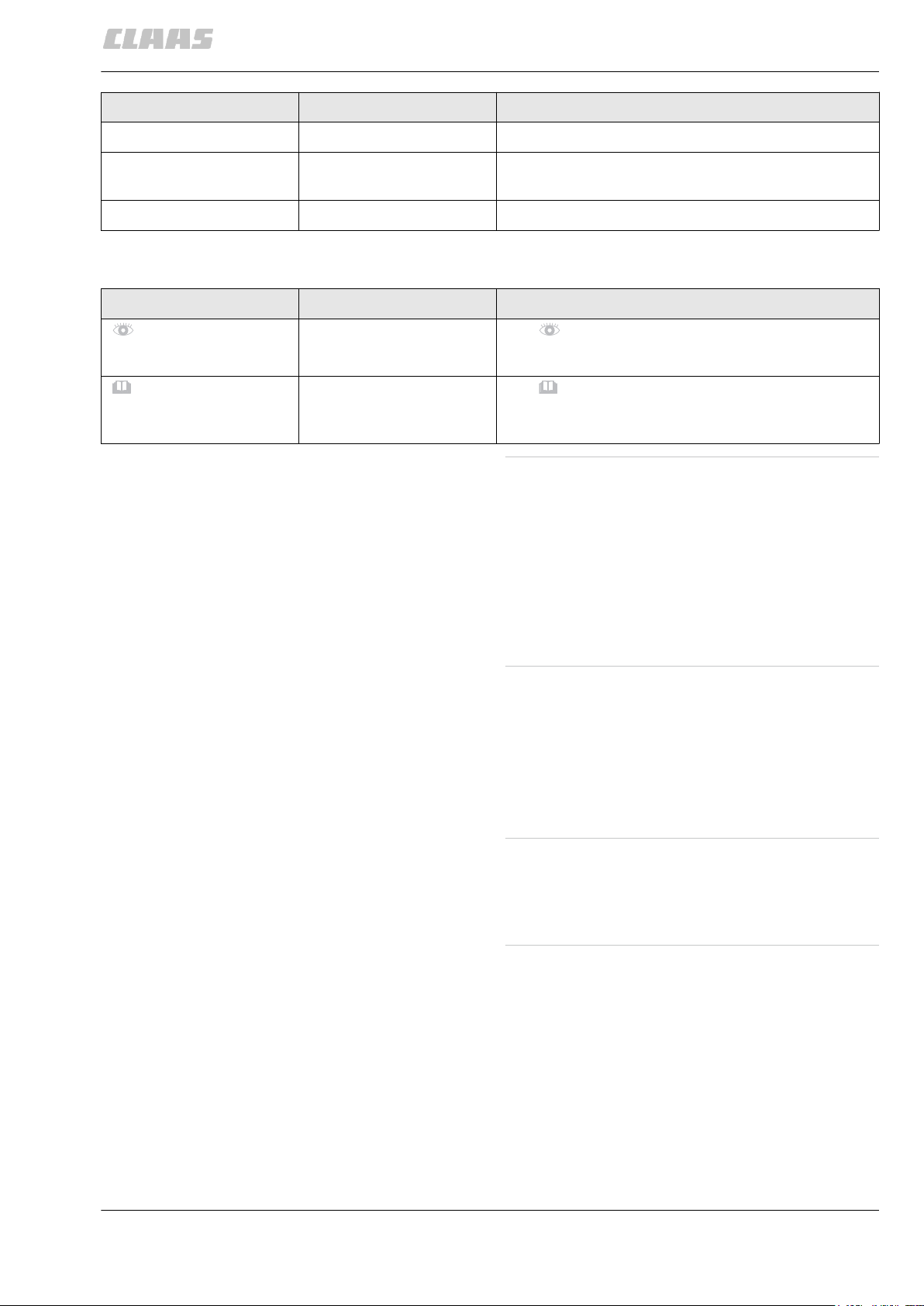

4 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Formatting Meaning Description

Description Descriptive text Further information on the subject.

Introduction

General Information

1044-004

Procedure

–

instructions

Process Operations which must be carried out one after the

other.

Result Result Result of the processes carried out.

References can be easily identified by corresponding

symbols. The following symbols are distinguished:

Symbol

Meaning Description

See index

The symbol indicates that further information on

this subject is available in other sections of this

manual.

See the index of the

Operator's Manual in

question

The symbol indicates that further information on

this subject is available in the Operator's Manual of

the machine or of the implement in question.

Document structure based on the assembly structure

The chapters of the present manual are subdivided

into assemblies as far as contents permit. The

structure of these assemblies is the same in all

chapters.

Different product groups have different assembly

structures. CLAAS makes every effort to keep this

assembly structures identical in any document.

Search and find

Due to the constantly recurring assembly structure,

the subject in question can be quickly found using the

table of contents or the header of this manual.

In addition, the index provided in this manual is a

useful tool for locating a subject. The index can be

found on the last pages of this manual.

Directions

Front, rear, right and left refer to the direction of

forward travel. If necessary, a direction arrow is used

for indicating the direction of travel in figures.

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 5

Introduction

General Information

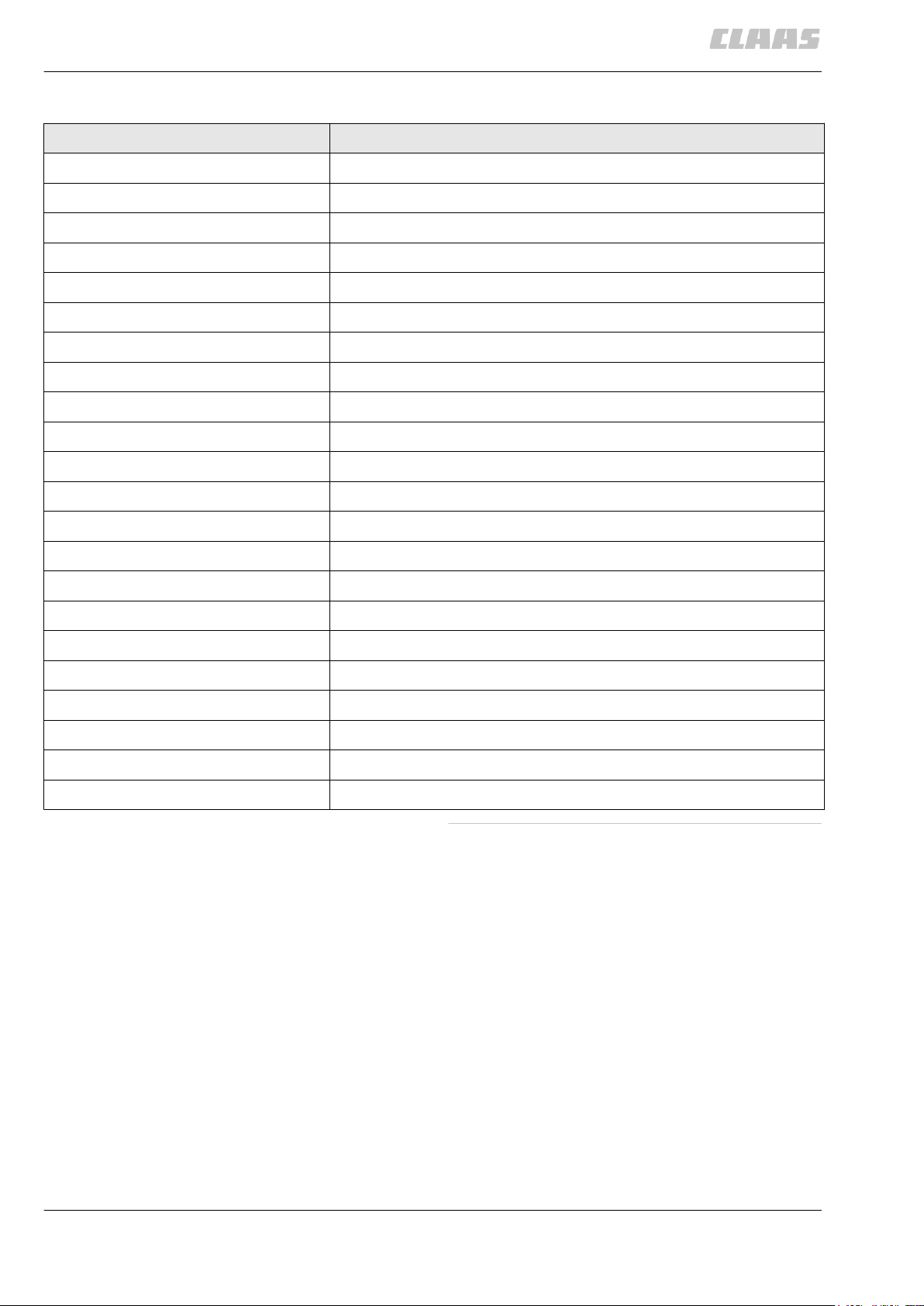

Abbreviations

Abbreviation Description

bar bar (unit for pressure)

approx. approximately

cm Centimetre

DIN German Standardization Institute

EC European Community

EN European Standard

GPS Satellite navigation system

h Hours

Ident no. Identification number of machine

ISO International Standardization Organisation

kg Kilogram

1044-004

kPa Kilopascal

km Kilometre

km/h Kilometres per hour

m Metre

mm Millimetre

Nm Newtonmetre

psi pound per square inch

StVZO German Regulations Authorizing the Use of Vehicles for Road Traffic

e.g. for instance

% percent

°C degrees Celsius (unit for temperature)

6 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

General Information

Technical terms

Technical term Description

recycle Re-use of used, defective or no longer required products

Season Recurring periods of a year

Ignition TDC Ignition top dead centre (diesel engine piston position)

Overlap TDC Valve overlap top dead centre (diesel engine piston position)

BDC Bottom dead centre (diesel engine piston position)

Your CLAAS Service Department

Introduction

1044-004

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 7

Introduction

General repair instructions

General repair instructions

Technical specifications

Information on proper repairs

1044-004

123153-002

Technical specifications, dimensions and weights are

non-binding. Technical specifications are subject to

modification in the course of technical development,

and all errors and omissions are excepted.

123192-003

Mark rotating machine components before

►

removing or dismounting them in order to ensure

well-balanced component seating on the correct

side after refitting.

The slots of expansion pins must always point to

►

the loaded side.

When they are installed with a 90° twist, they

come loose, fall out or shear off.

Replace cotter pins, locking wires, sheet retention

►

devices, lock washers and spring washers in the

repair process.

Align sprockets and V-belt pulleys with one

►

another.

Observe the information in the hydraulic system

►

chapter when working on the hydraulic system.

Do not mix different oil grades.

►

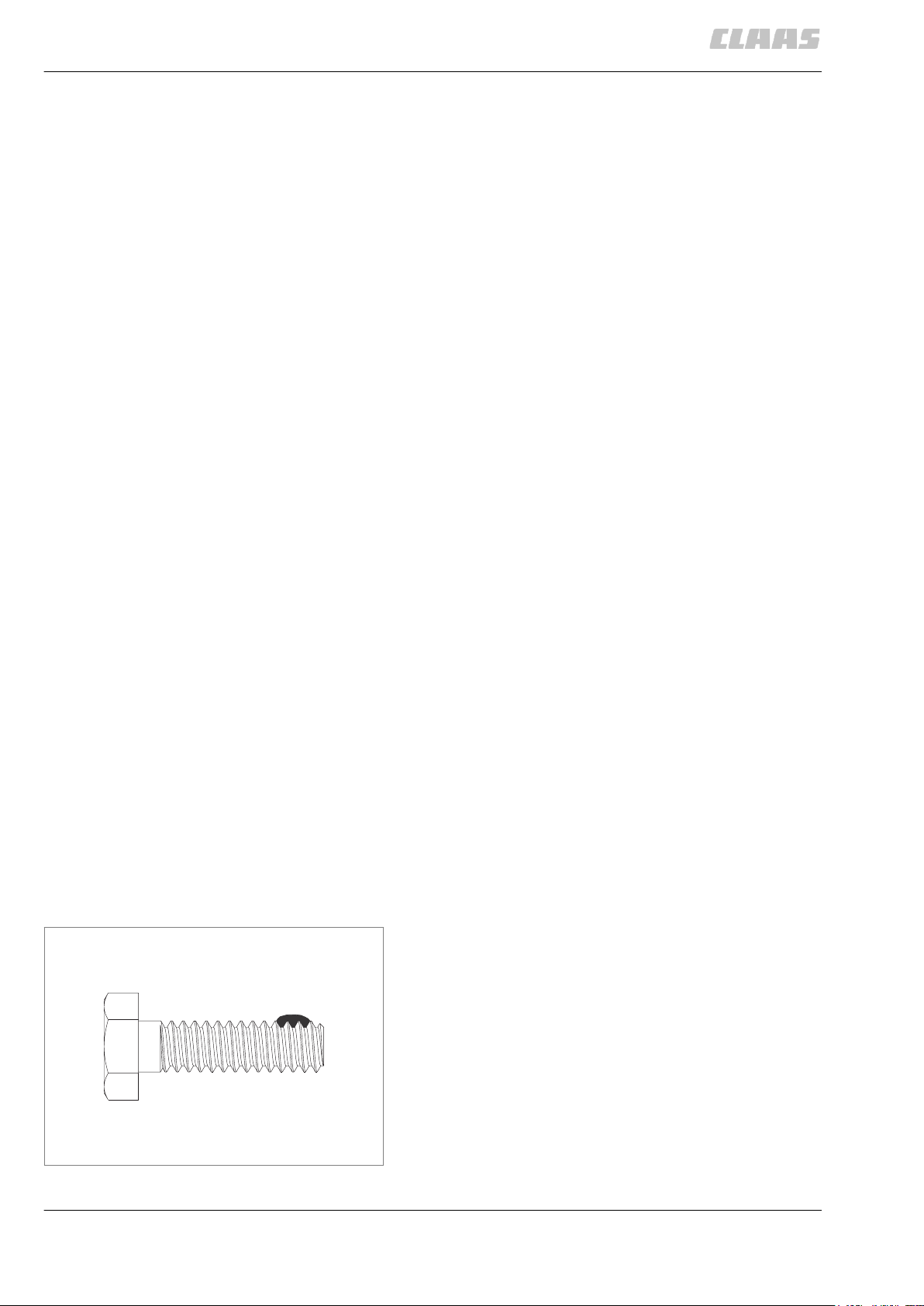

Self-locking bolts

Liquid locking compound

151599-001

Self-locking bolts must not come in contact with

sealing compound.

Tighten self-locking bolt speedily up to the

►

specified torque.

► The full hardening time can be reduced by

heating-up, e.g. to 15 minutes at + 70 °C.

► The full load capacity is achieved after

24 hours at + 20 °C.

When unscrewing self-locking bolts, unscrew

►

them quickly.

Use liquid locking compound (glue) only at the

►

spots described in the Repair Manual.

The surfaces to be joined must be absolutely

►

clean and free of grease.

► A suitable cleaner and an activator possibly

delivered along with the glue can be used for

cleaning.

No cleaner residues may remain on the surfaces

►

to be joined.

This applies in particular to tapped holes with a

bottom.

► Let the surfaces dry well before applying the

1

glue.

123164-004

120820-003

8 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Steel roller chains

A

x

1

Introduction

General repair instructions

Apply the glue only in the areas shown in the

►

figure if possible.

When applying the glue at an unfavourable spot

or when applying too much glue, the joint may

tear off when loosening.

Observe the glue producer's instructions for use

►

and application!

A joint secured by liquid locking compound can be

loosened by heating up to approx. 200 °C.

120771-004

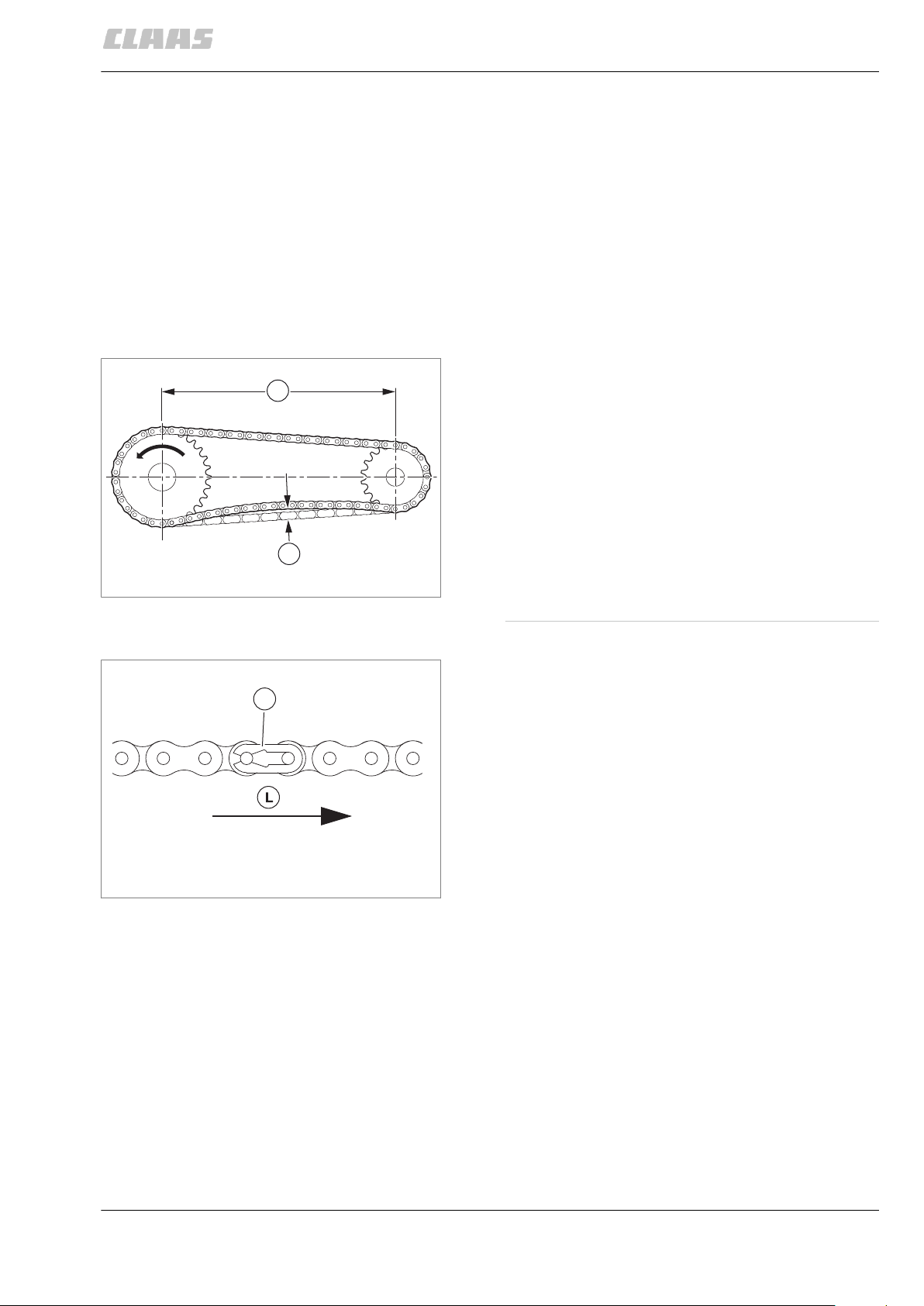

Tensioning

Checking the tension of steel roller chains:

Apply a small load to the tight span.

►

Push down the slack span in the middle between

►

the sprockets with your thumb.

You should be able to push down the slack span

around 2 % of the spacing between the axles.

1044-004

13827-006

123668-001

Example:

Axle spacing (A) = 500 mm

Pushing distance (x) of slack span = approx. 10 mm

2

Chain connector

The closed side of chain connector (1) must point

►

in running direction (L)!

3

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 9

1

2

4

3

2

1

4

5

4

3

2

1

Introduction

General repair instructions

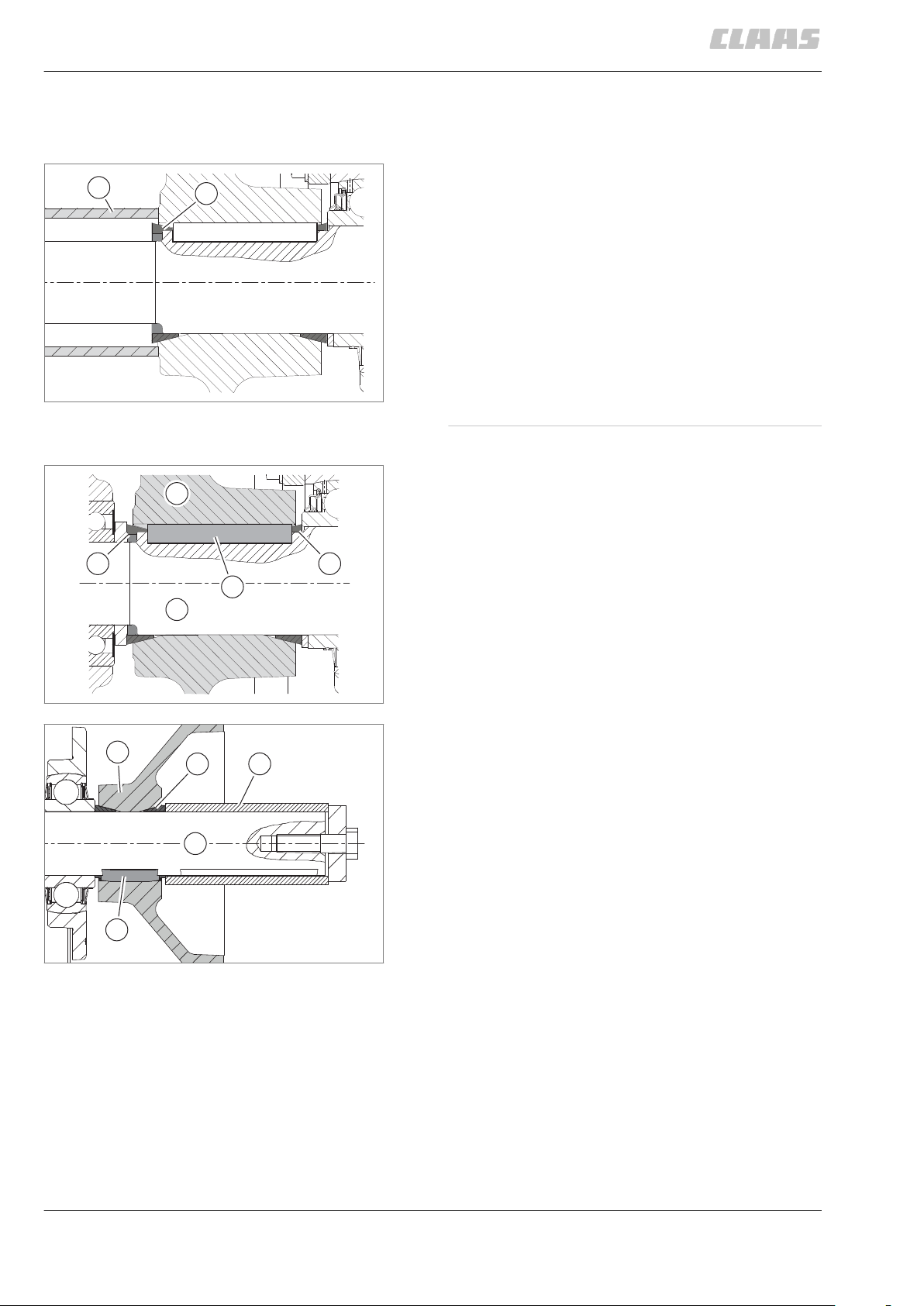

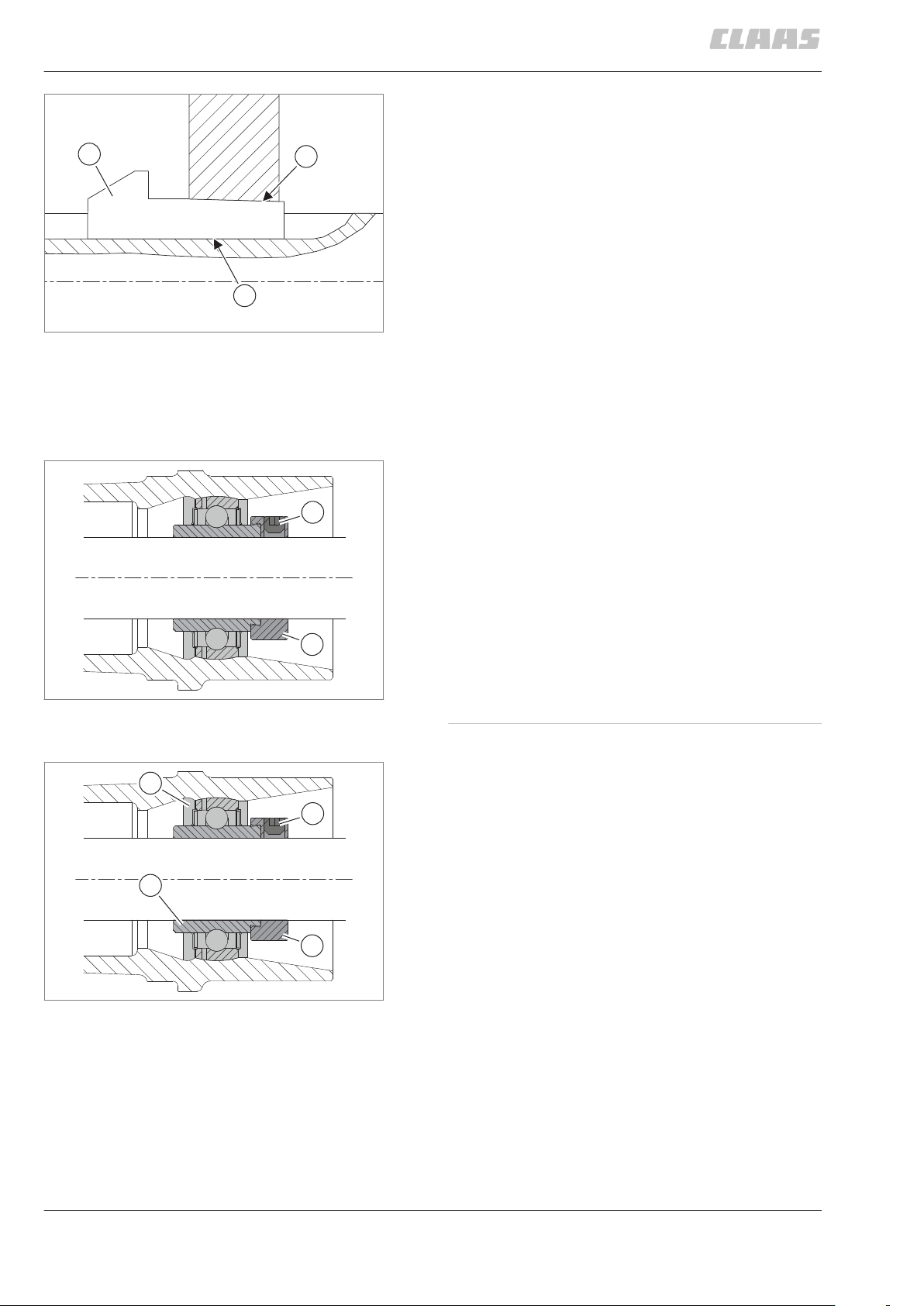

Taper ring fasteners

Dismounting

Slacken off tapered ring (1) with a blow.

►

► Use an auxiliary tool (2) if required.

1044-004

120801-005

154769-001

154486-001

4

Installation

NOTICE! Sticking together at the taper ring fasteners.

The joint cannot be loosened or comes off only with

difficulty.

► Do not install parts with tough grease.

Clean shaft (1), hub (2), parallel key (3) and

►

tapered rings (4) thoroughly and apply some

CLAAS AGRIGREASE LC 00 / 000.

Tighten to the specified torque.

►

► In case of several taper ring fasteners fitted

behind one another, tighten those

5

separately.

► Use an auxiliary tool (5) if required.

13975-003

154768-001

10 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

6

Gib head key joints

2

1

2

1

2

1

General repair instructions

Dismounting

Slacken off gib head key (1) with a blow if

►

possible.

► Use an auxiliary tool (2) if required.

Introduction

1044-004

123163-004

154811-001

154813-001

7

Drive out the gib head key (2) with a key

►

drawer (1).

► Ensure that the key drawer is used as shown

in the figure.

8

154812-001

Installation

The gib head key (1) comes in raw condition as a

spare part and must be machined to suit the

application by milling or grinding.

9

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 11

2

1

3

1

2

4

3

2

1

Introduction

General repair instructions

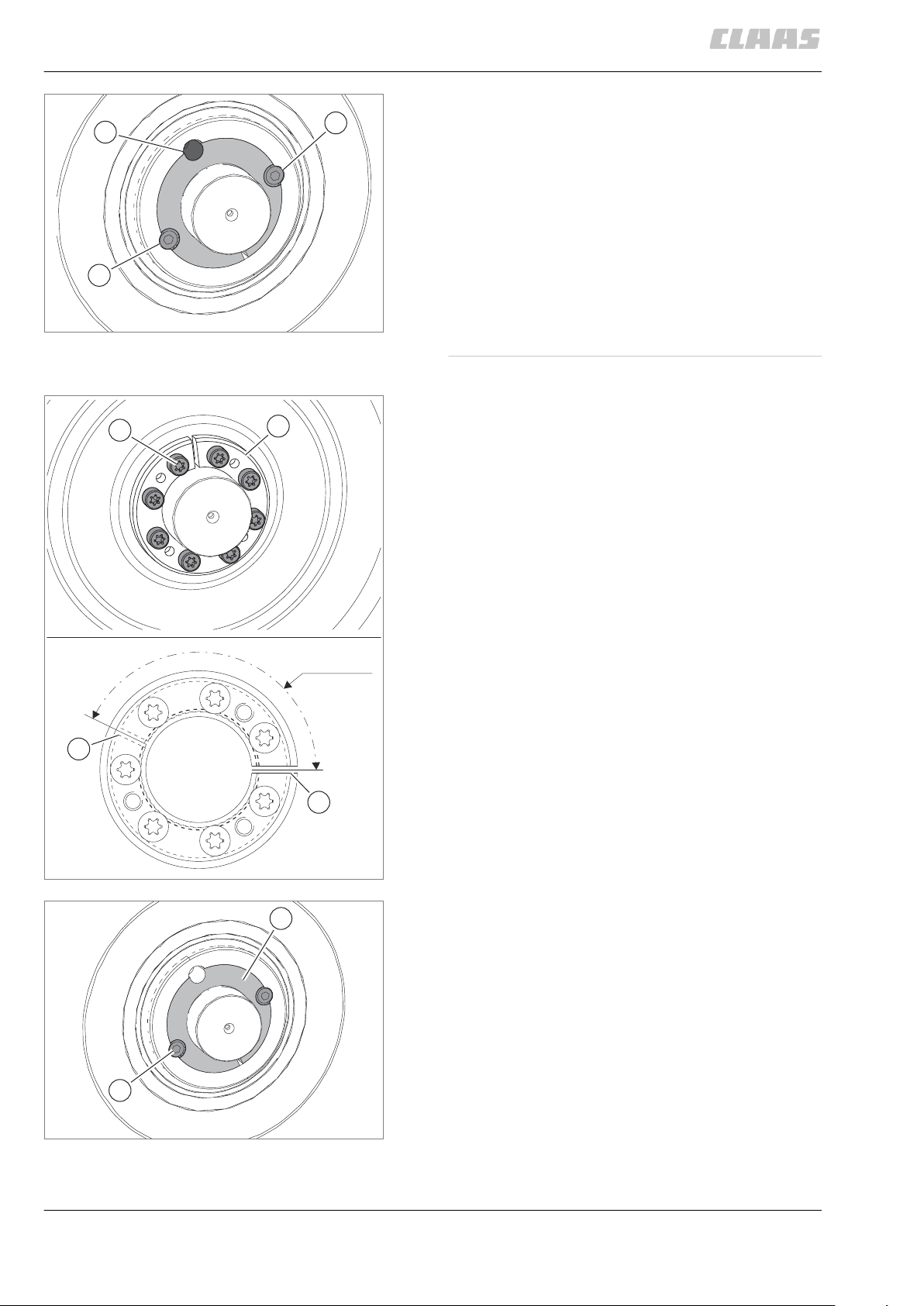

Lock collar bearing

154492-001

Grind the gib head key (1) to suit the application

►

at surface (2).

► Surface (3) must not be machined.

Clean shaft, hub and keyway to be free of grease,

►

paint and rust prior to assembly.

NOTICE! Excessive force employed when installing

the gib head key. Damage to the gib head key joint.

The gib head key cannot be removed any more.

► Drive in the gib head key carefully with a suitable

and not too heavy hammer.

Ensure that the gib head key is driven in only so

►

10

far that it can still be removed without problems,

using a key extractor.

Dismounting

Slacken off set screw (1).

►

Drive off eccentric ring (2) against the shaft's

►

sense of rotation.

Remove bearing.

►

1044-004

85675-003

123167-002

154814-001

Installation

11

Tighten lock collar bearing (1) on the shaft by

►

twisting eccentric ring (2) over the inner bearing

race (3).

► Arrest the eccentric ring with moderate force

in the sense of rotation of the shaft.

► To make dismounting easier, the inner race

and the shaft can be coated with

CLAAS AGRIGREASE LC 00 / 000.

Tighten set screw (4).

►

12

154500-001

12 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Adapter sleeve bearings

3

2

1

3

2

1

3

1

2

General repair instructions

Dismounting

Loosen the tab of sleeve nut (3).

►

Slacken off sleeve nut by some turns only.

►

► Ensure that the thread is still completely

engaged.

Slacken off expansion pin (2) with a firm blow.

►

Pull off adapter sleeve bearing (1) completely.

►

Introduction

1044-004

120831-003

Chuck bushing

154510-001

154510-001

13

Installation

►

►

►

►

►

►

14

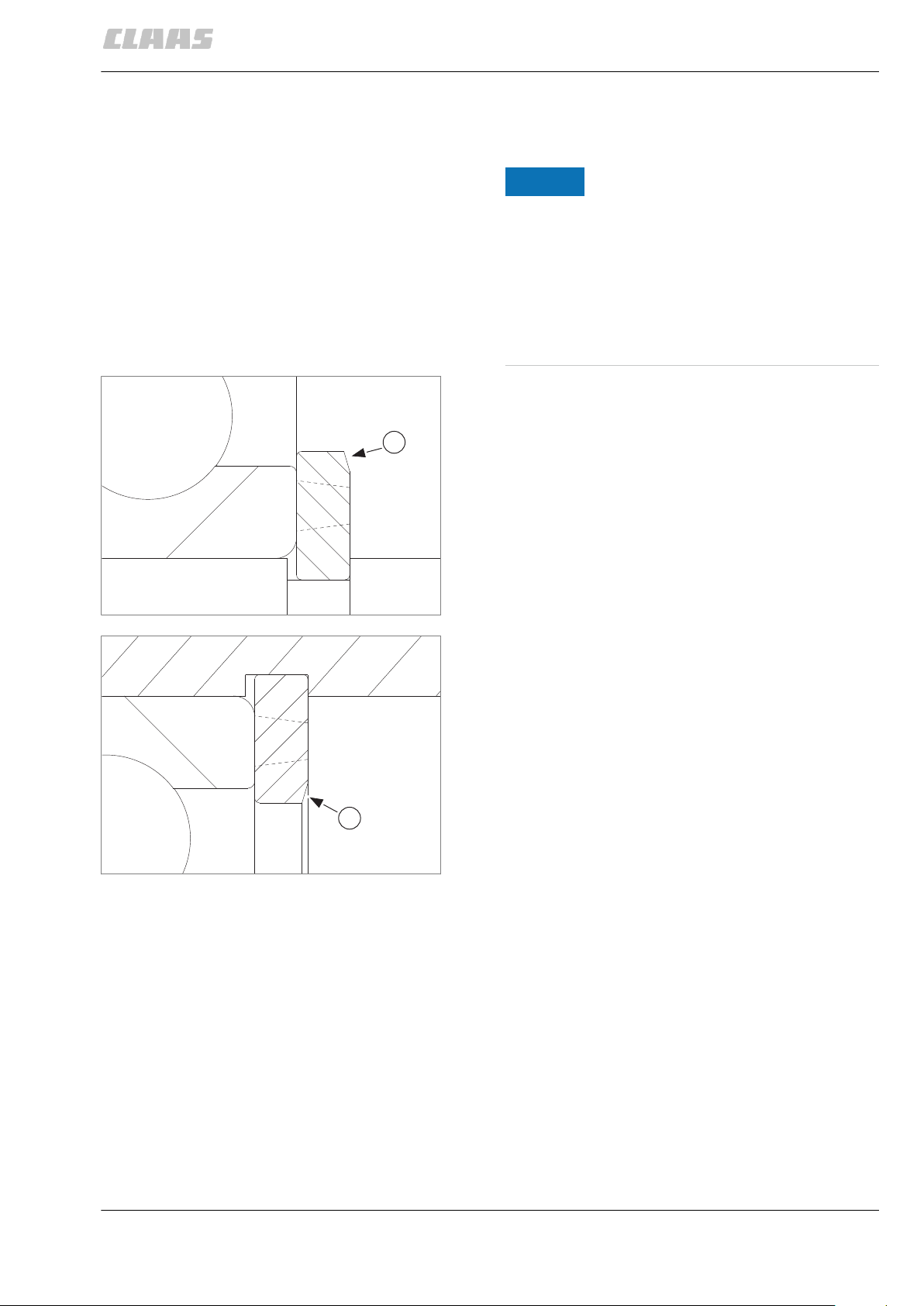

Dismounting

►

►

►

Clean expansion pin (2) and shaft and check easy

movement of the sleeve nut (3).

Install adapter sleeve bearing (1) according to the

conical inside ring (2).

Tighten the sleeve nut with the suitable special

tool and to the prescribed torque.

Continue tightening the sleeve nut to the specified

degrees.

Tighten sleeve nut until the nearest tab can be

applied.

Secure sleeve nut with the tab.

144598-002

Unscrew bolts (1).

Screw in bolts (1), or longer bolts if required at (2).

► Screw in bolts until the chuck bushing (3)

comes loose.

► Apply a little oil to bushing if necessary.

Remove the chuck bushing if required.

Version 1 154820-002

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 13

15

3

1

1

1

2

3

4

max. 180°

1

2

Introduction

General repair instructions

1044-004

Version 2 154836-002

16

Installation

Clean chuck bushing (1) and shaft thoroughly.

►

Insert chuck bushing.

►

► Ensure that slots (3) and (4) are mounted

with the maximum possible angle offset.

Tighten bolts (2) evenly crosswise in three steps.

►

► Observe the specified torques of the

respective steps.

17

Version 1

185680-001

18

Version 2 154844-002

14 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Circlips

1

1

Introduction

General repair instructions

1044-004

144716-004

144718-002

NOTICE

Overspreading the circlip.

Plastic material deformation.

No safe fixing of component.

► Spread circlip only as far as needed for

installation and dismounting.

► Do not use any circlip already overspread before.

Insert circlips as shown in the figures.

►

► Ensure that chamfer (1) does not make

contact with the component to be secured.

► If required, make circlip engage with a slight

blow.

Circlip DIN 471 155144-001

Circlip DIN 472 155145-001

19

20

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 15

3

2

1

4

3

2

1

Introduction

General repair instructions

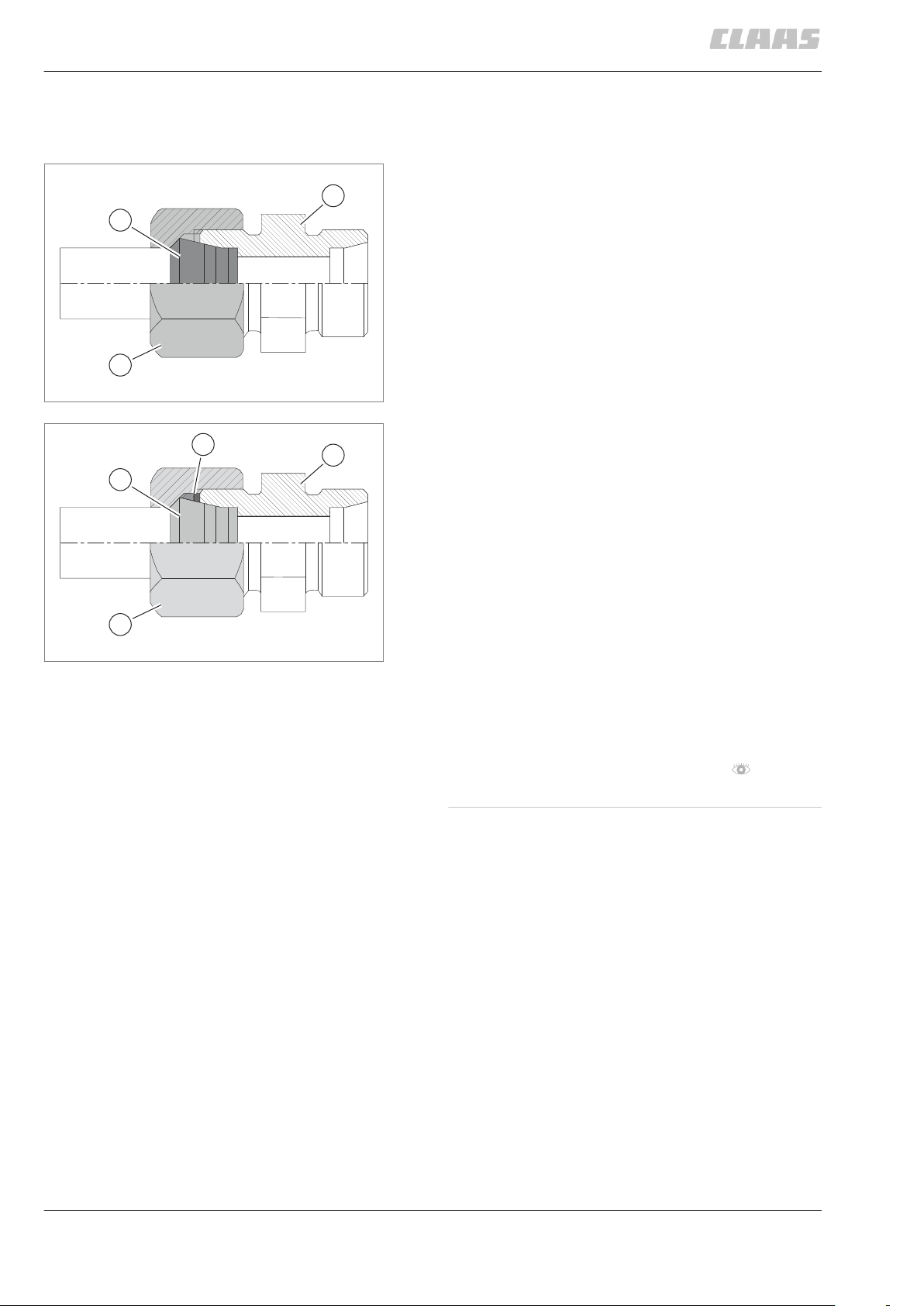

Ferrule fittings

Ferrule without seal 154515-001

Ferrule with seal 154516-001

Screwing in

►

►

►

►

►

21

►

►

►

22

►

►

1044-004

120840-004

Cut off the corresponding tube at right angles.

► Do not use a pipe cutter.

In case of pipe bends, the straight pipe end up to

where the bending radius starts must be at least

twice the height of the union nut.

Slightly deburr the pipe end on the inside and

outside.

► Do not chamfer the pipe end.

Clean the pipe end.

Push the union nut (1) and the ferrule (2) on the

pipe.

Push the pipe against the stop in the connector

(3) and tighten the union nut until the ferrule

seizes the pipe.

This pressure point can be felt because increased

power is needed from here.

The pipe must be fixed securely during assembly

and must not rotate.

Tighten the union nut by half a rotation beyond

the first pressure point.

Check the incision at the cutting edge.

A visible collar must fill the space ahead of the

ferrule face end.

The ferrule may rotate, but axial displacement

must not be possible.

Insert the pre-assembled pipe into the well-oiled

threaded joint.

Screw on the union nut until the power needed to

do this clearly increases.

After that, continue to screw the union nut on for

half a turn beyond that point.

► Observe the tightening torques. Page

23

Non-tight ferrule connection

If a connection leaks, loosen the union nut until

►

some oil escapes.

Then tighten according to instructions.

►

Replace the seal (4) if required.

►

16 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Sealing cone fittings

32

1

XXX / 250 bar / 13/07

XXX / 250 bar

/ 13

/07

1

1

XXX / 250 bar / 13/07

32

Introduction

General repair instructions

Apply seal (1) on the sealing cone (2).

►

Tighten the union nut (3) a third of a turn beyond

►

the point where resistance is felt.

► Observe the tightening torques! Page

24

1044-004

123189-002

Hydraulic hoses

154527-001

23

NOTICE

Failure of hydraulic hose lines due to ageing.

Uncontrolled lowering of machine parts.

► Replace hydraulic hose lines 6 years after

manufacture at the latest.

To facilitate identifying of hydraulic hoses, each hose

has the CLAAS part number printed on it.

Check hydraulic hoses before initial

►

commissioning and thereafter at least once a

year.

In the case of damage and ageing, replace

►

hydraulic hoses.

The date of manufacture can be seen on the hose

fittings (1).

120856-007

124582-003

(2) = year (e.g. 12 = 2012)

(3) = month (e.g. 07 = July)

24

40202-004

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 17

Introduction

General repair instructions

5727-002

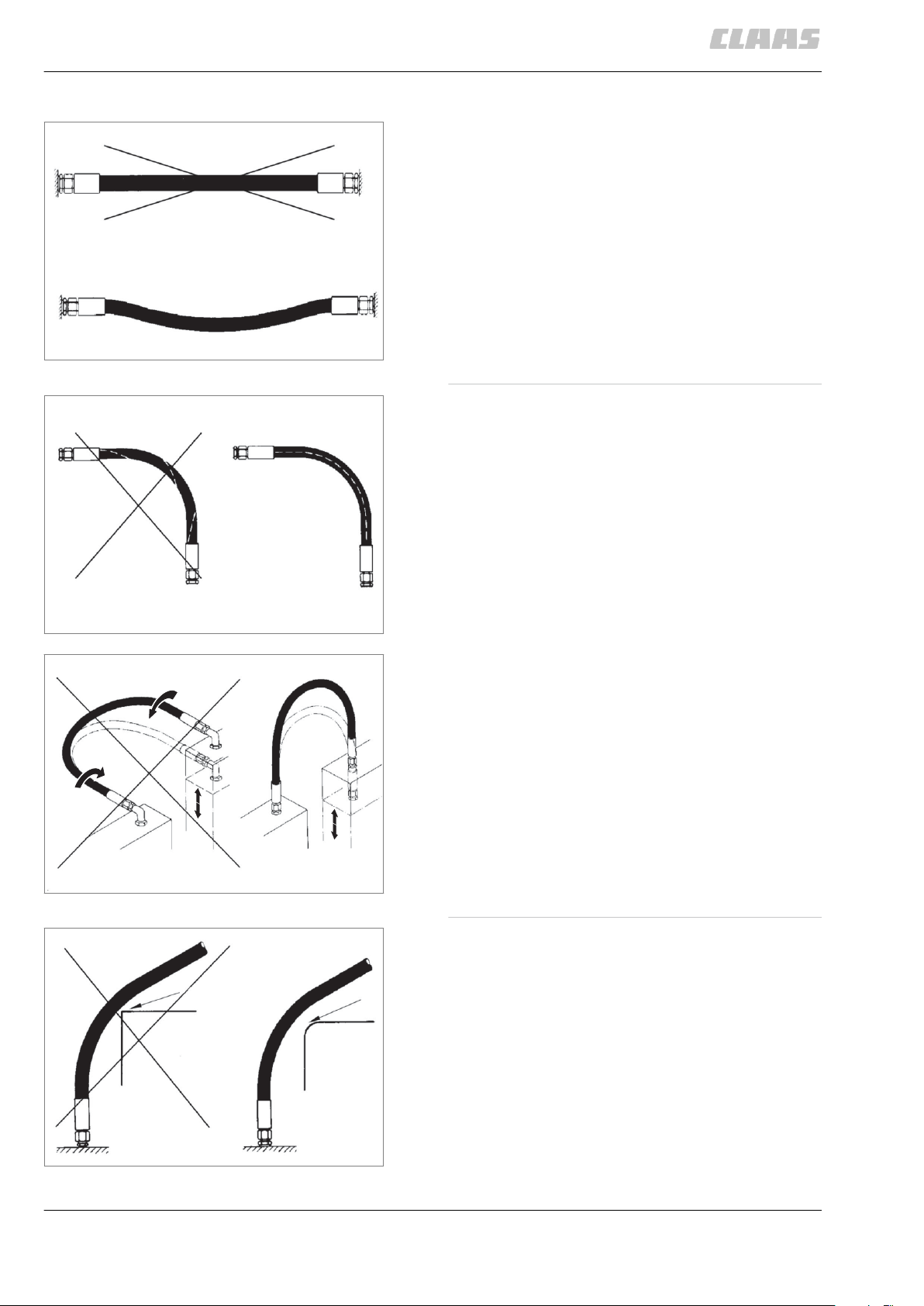

Hose placement

NOTICE! Hoses laid in a straight line get shorter as

the hydraulic pressure is built up. Valves may be torn

off.

► Always install hoses with a slight slack.

Install hoses so that no tension or compression

►

loads will occur in any operating conditions.

► Check: If you shake the hose line in the

middle between two brackets/connectors

(e.g. clamps), the overall play of the hose

line should be at least 1 cm.

25

Do not install hose with a twist.

►

► Particularly if there is movement at the hose

line.

1044-004

13989-003

5728-002

5729-002

5726-002

26

27

28

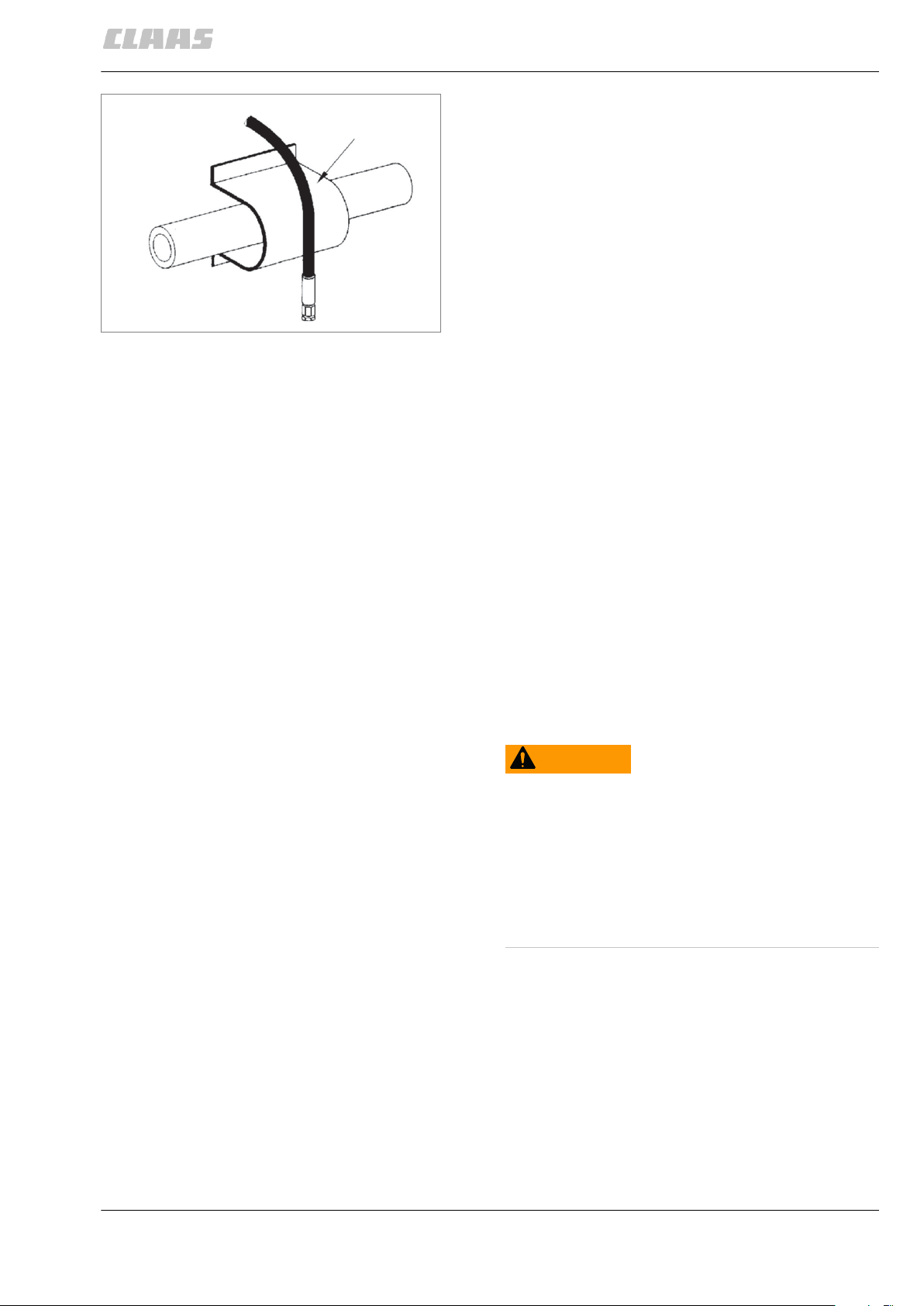

Avoid external mechanical impacts on hoses.

►

► Avoid chafing the hoses against each other

or against components through proper

placement and fastening.

► Keep an adequate distance from

components.

► Keep sharp-edged components covered at

all times.

When high outside temperatures are involved,

►

install hose lines at a sufficient distance from

components radiating heat.

► If necessary, protect hose by a protective

guard.

18 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Introduction

General repair instructions

1044-004

Treatment of sealing faces

Spare parts

5730-002

29

157962-002

Close all oil, coolant and fuel bores thoroughly prior to

treating the sealing faces.

Ensure that when treating sealing faces of

components containing oil, coolant and fuel, no

abrasives are used. Loose particles cause pollution

and damage.

Ensure that no seal residues, rust, lime and

combustion residues end up in open components

(gearbox halves).

Remove sealing residues, rust, lime and combustion

residues only using scraping tools or cleaning agents.

123155-004

11210-003

WARNING

Use of unauthorised spare parts.

Death or serious injury.

► Spare parts must at least comply with the

technical standards required by the manufacturer

of the implement!

► We recommend using genuine CLAAS spare

parts.

Please quote the machine identification number

►

when ordering spare parts or making technical

enquiries.

CLAAS will assume no liability whatsoever for

damage incurred as a result of the use of non-genuine

CLAAS parts, accessories, and ancillary equipment.

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 19

Introduction

Torque settings

Torque settings

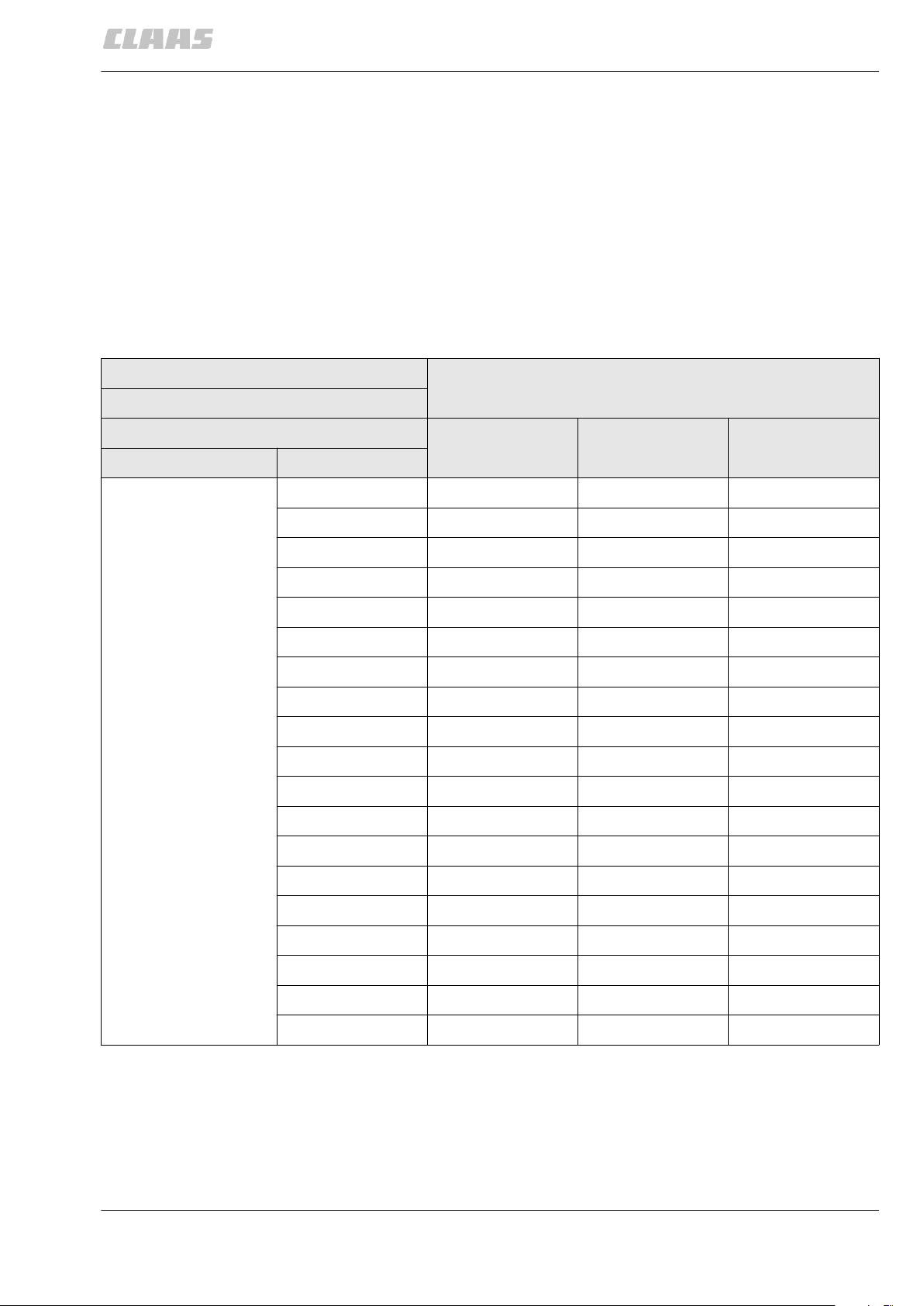

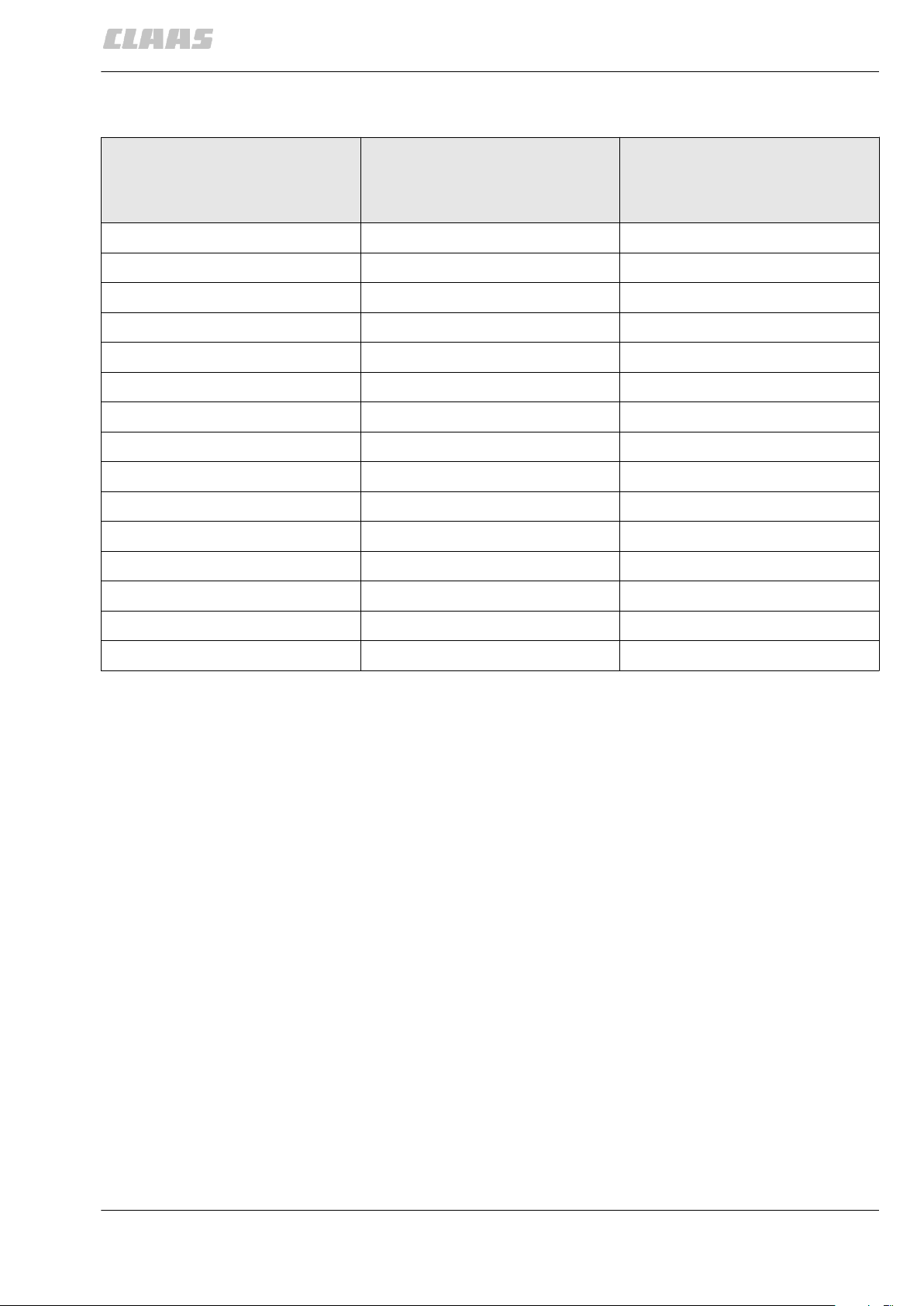

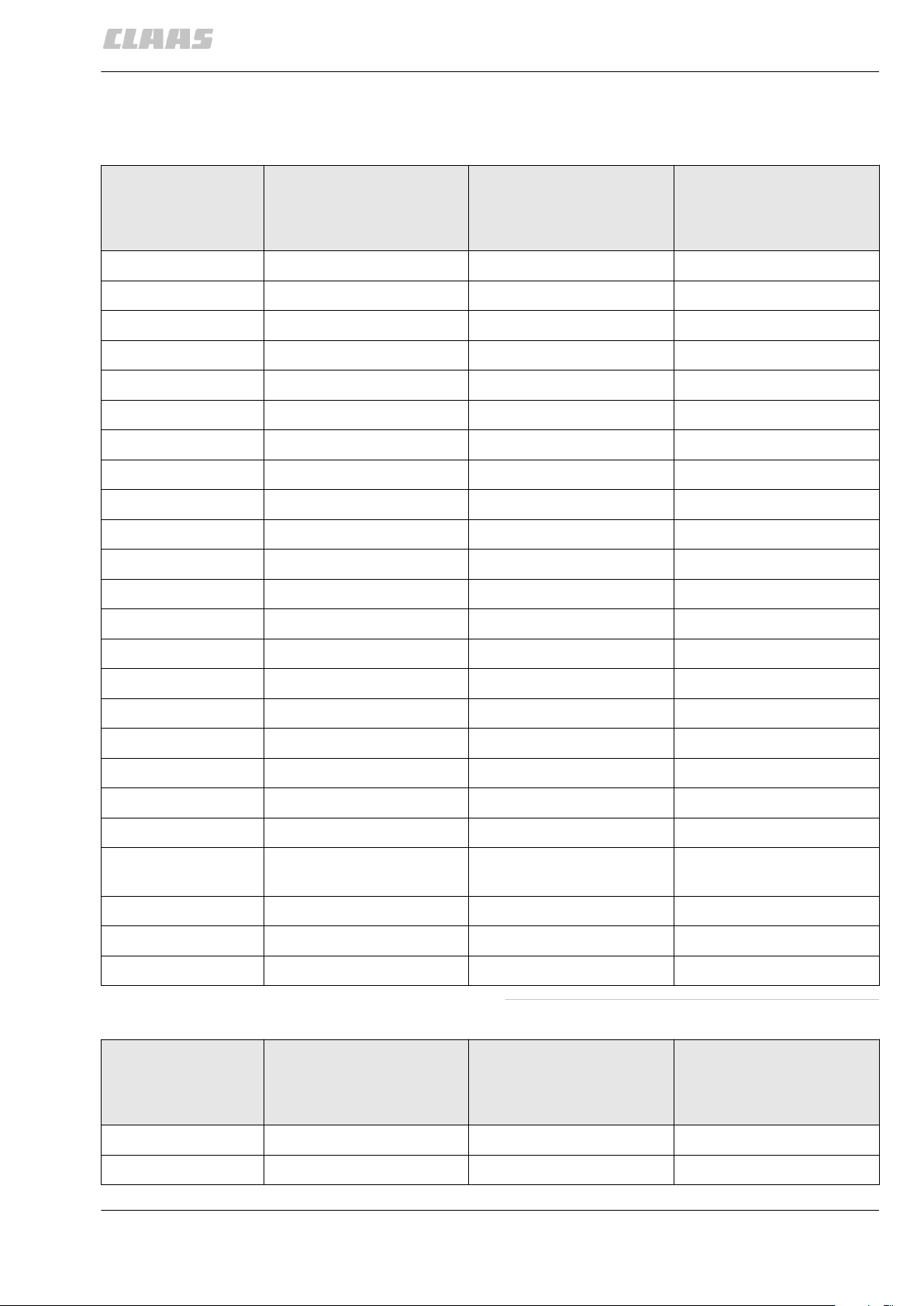

Tightening torques for metric standard threads

The tightening torques specified below apply only

when:

A friction coefficient of µ tot = 0.14 is achieved in

–

connection with thread lubricant.

To achieve this, a surface protection agent such

as A3C+L, Dacromet or Termosil is

recommended.

No other tightening torque is specified in the

–

descriptive text.

No additional screw retention is used, such as

–

MK-type bolts or liquid locking compound.

Tightening torque in Nm at a friction coefficient

1044-004

123194-003

Bolts and nuts

Strength class 8.8 10.9 12.9

Dimensions

M 4 2.9 4.3 5

M 5 5.8 8.5 10

M 6 10 14.5 17

M 8 24.5 36 42

M 10 48.5 71 83.5

Hex. bolts

ISO 4014 to ISO 4018

M 12 83.5 123 144

M 14 133 196 229

M 16 207 304 355

Cheese-head screws

M 18 296 422 494

ISO 4762

Hex. nuts

ISO 4032

M 20 417 594 695

M 22 570 813 951

M 24 718 1022 1196

M 27 1058 1506 1763

μ tot = 0.14

M 30 1437 2046 2395

M 33 1944 2770 3240

M 36 2500 3561 4167

M 39 3237 4610 5394

20 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Torque settings

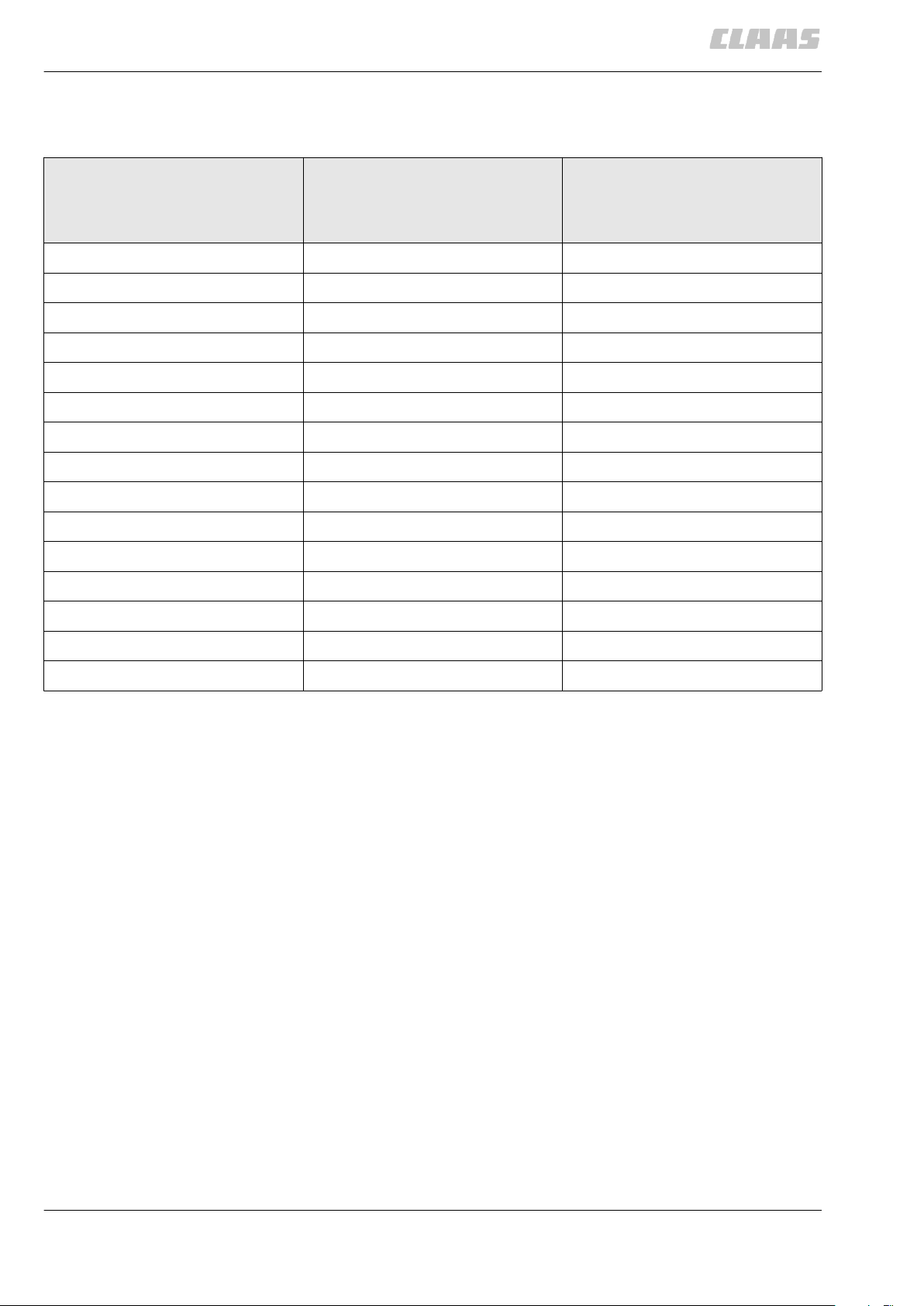

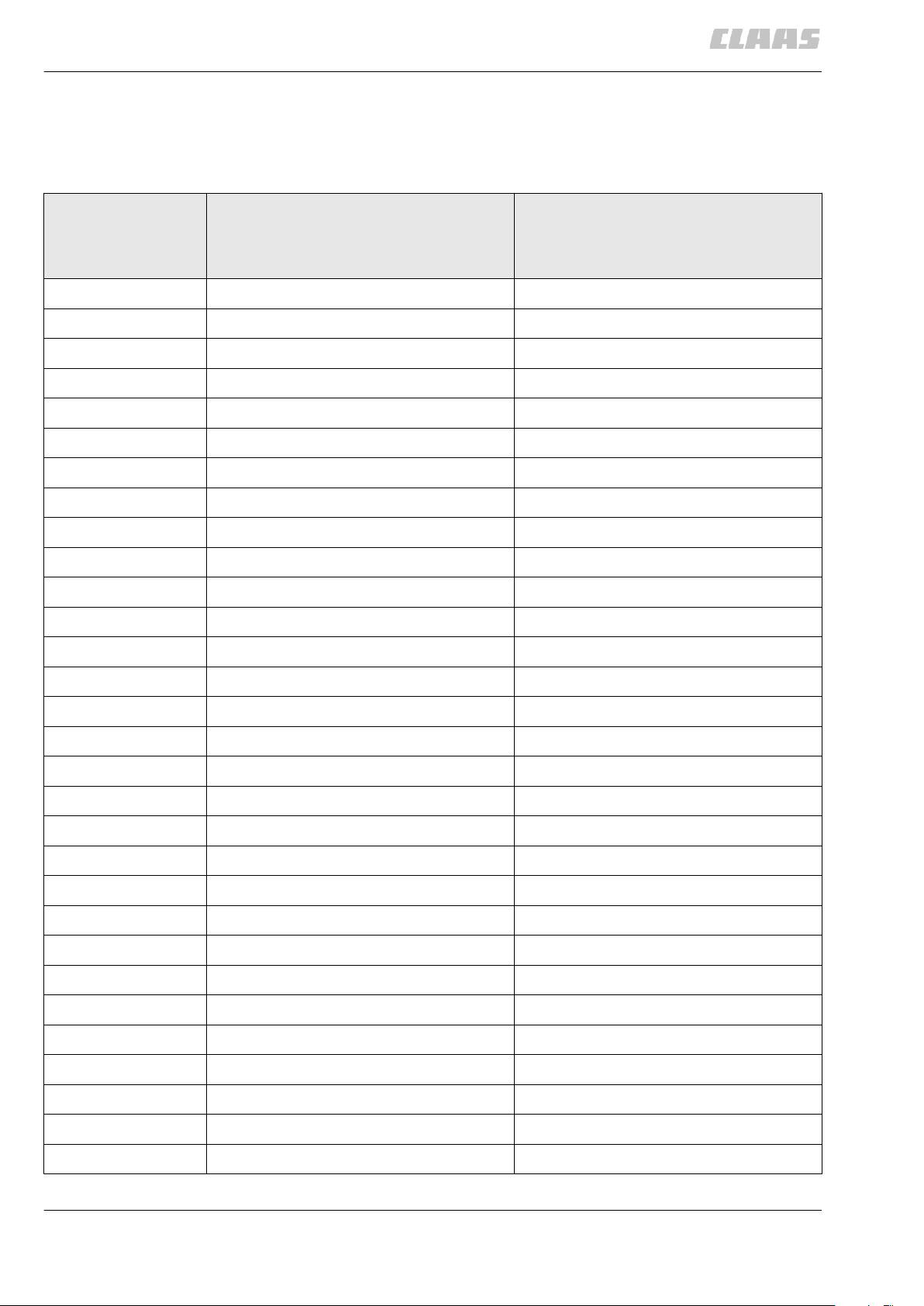

Tightening torques for metric fine thread screws

The tightening torques specified below apply only

when:

A friction coefficient of µ tot = 0.14 is achieved in

–

connection with thread lubricant.

To achieve this, a surface protection agent such

as A3C+L, Dacromet or Termosil is

recommended.

No other tightening torque is specified in the

–

descriptive text.

No additional screw retention is used, such as

–

MK-type bolts or liquid locking compound.

Tightening torque in Nm at a friction coefficient

Introduction

1044-004

123196-003

Bolts and nuts

Strength class 8.8 10.9 12.9

Dimensions

M 8 x 1 26 38.5 45

M 10 x 1 54 79 92.5

M 10 x 1.25 51 74.5 88

M 12 x 1.25 90.5 134 156

M 12 x 1.5 87 128 150

M 14 x 1.5 143 210 246

M 16 x 1.5 219 323 378

Hex. bolts

ISO 8765, ISO 8876

M 18 x 1.5 331 470 551

M 18 x 2 313 446 522

M 20 x 1.5 459 655 766

Hex. nuts

ISO 4032

M 22 x 1.5 622 886 1037

M 24 x 1.5 809 1152 1348

M 24 x 2 778 1108 1297

μ tot = 0.14

M 27 x 1.5 1173 1672 1956

M 27 x 2 1135 1617 1892

M 30 x 2 1580 2251 2634

M 33 x 2 2116 3015 3528

M 36 x 2 2773 3951 4623

M 39 x 2 3557 5067 5930

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 21

Introduction

Torque settings

1044-004

123198-002

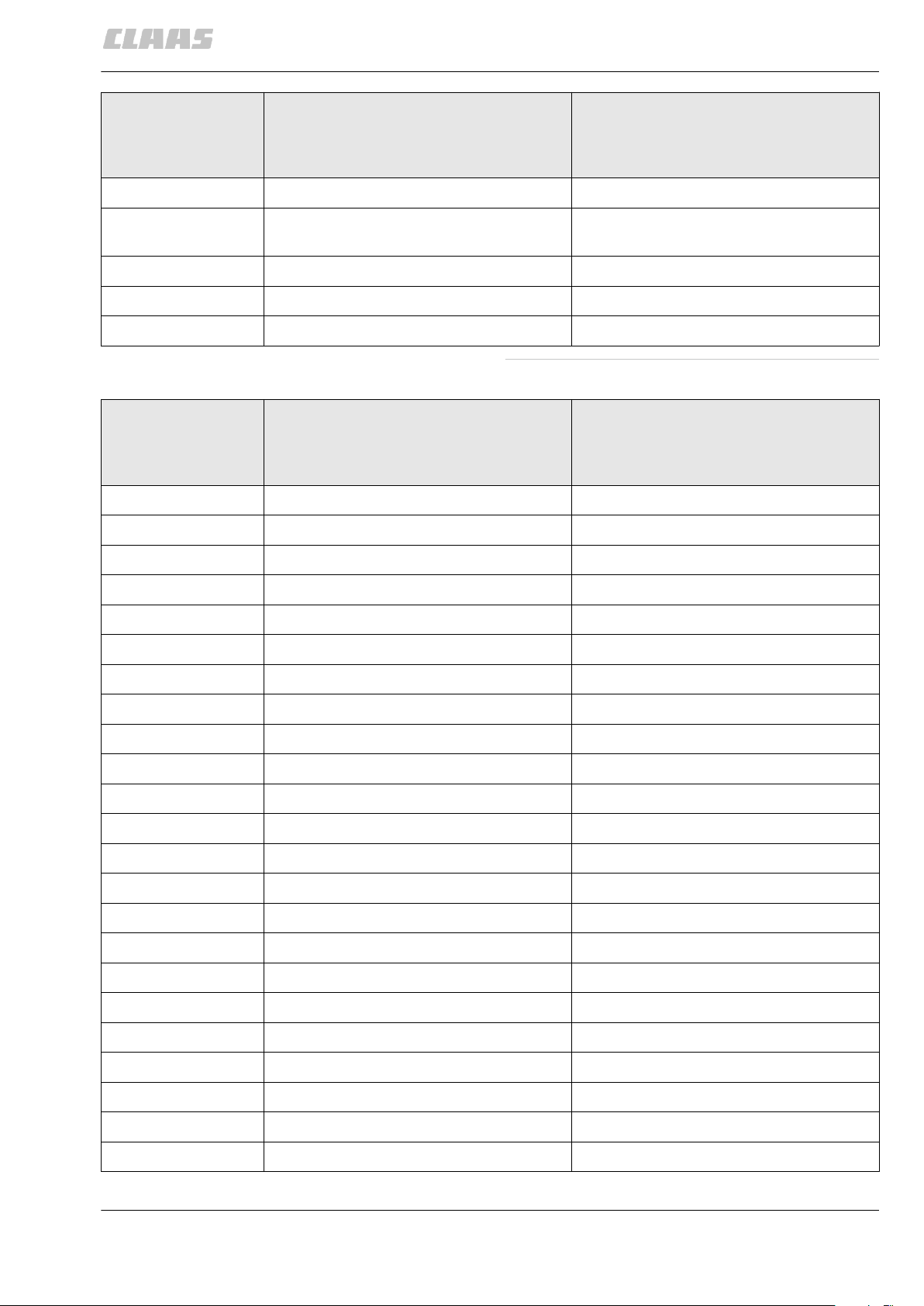

Tightening torques for hydraulic screw fittings and air conditioner screw fittings with sealing cone and O-ring according to DIN 3865

Outside pipe diameter

in mm

6 10 15

8 15 25

10 25 35

12 35 50

15 50 -

16 - 80

18 80 -

20 - 110

22 110 -

25 - 160

28 160 -

30 - 210

35 210 -

Tightening torque

(light series)

in Nm

Tightening torque

(heavy series)

in Nm

38 - 320

42 320 -

22 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Tightening torques for hydraulic screw fittings with ferrule according to DIN 3861

Introduction

Torque settings

1044-004

123197-002

Outside pipe diameter

in mm

6 15 25

8 25 35

10 35 50

12 50 80

15 80 -

16 - 110

18 110 -

20 - 160

22 160 -

25 - 210

28 210 -

30 - 320

35 320 -

Tightening torque

(light series)

in Nm

Tightening torque

(heavy series)

in Nm

38 - 400

42 400 -

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 23

Introduction

Torque settings

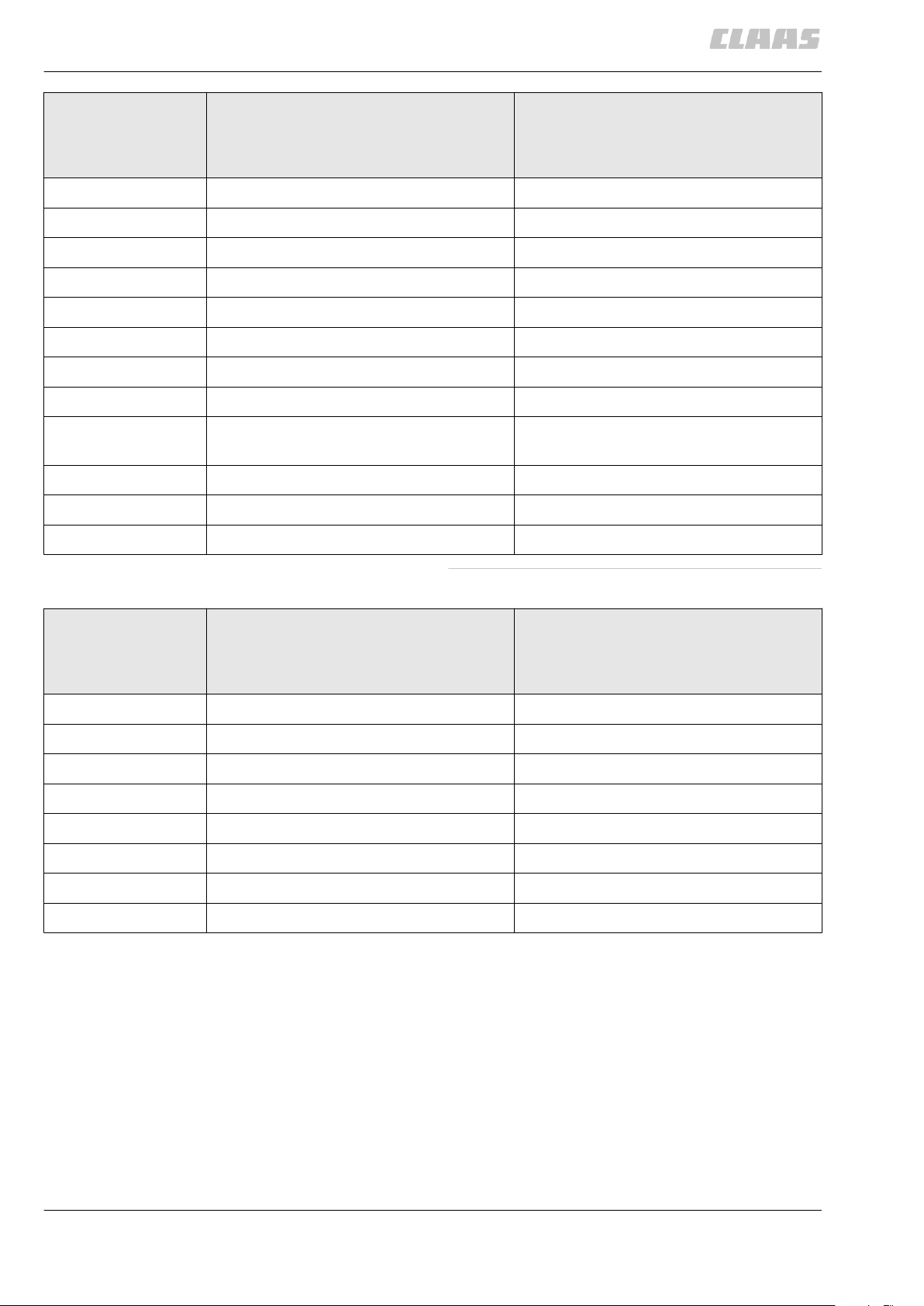

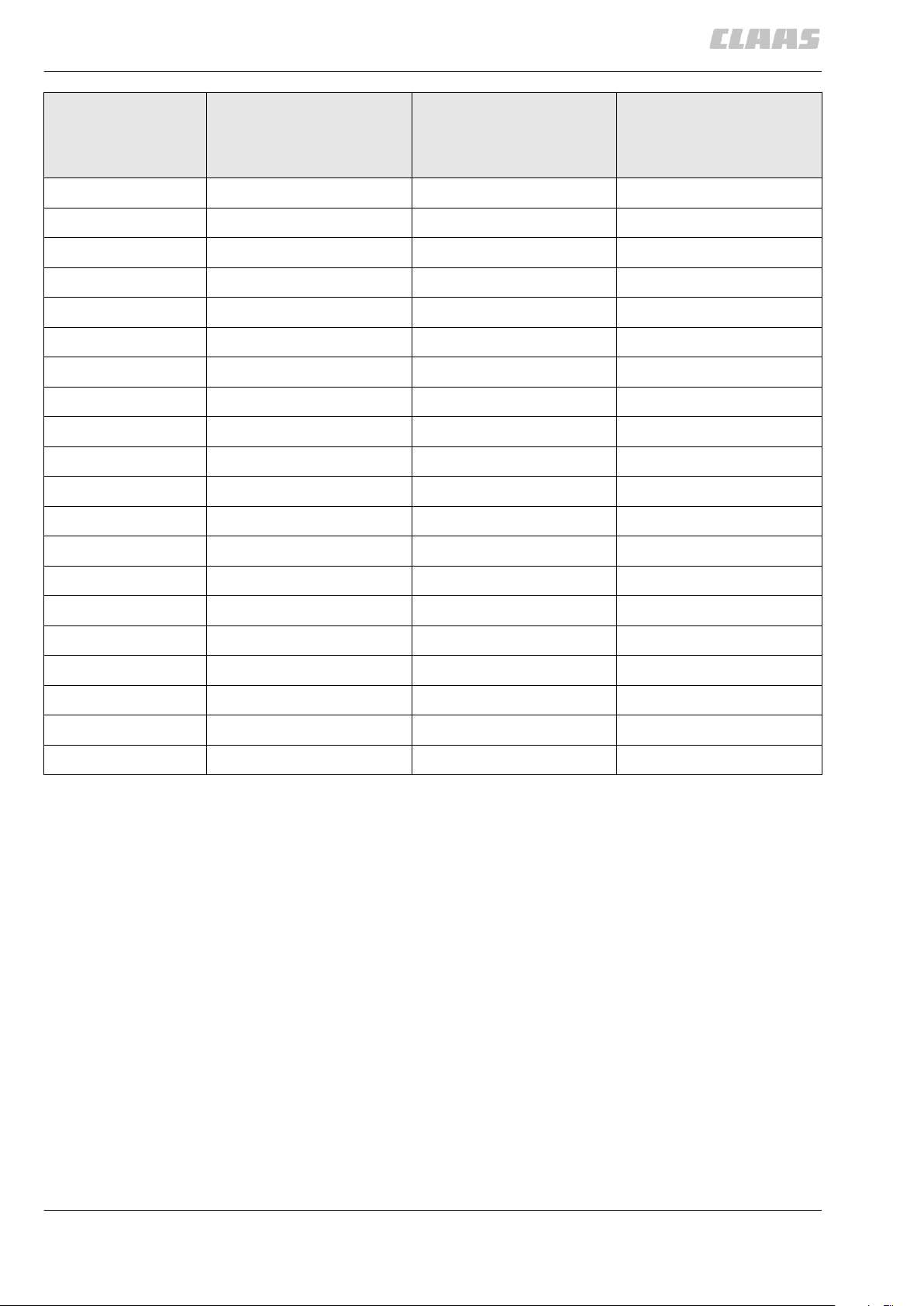

Tightening torques for SDS hydraulic male connectors

Shape B with sealing edge (cutting edge)

Shape E with soft ring seal

1044-004

123200-004

Dimension Tightening torque

(light series)

in Nm

Tightening torque

(heavy series)

in Nm

M5 - -

M6 - -

M8 x 1 - -

M10 x 1 18 -

M12 x 1.5 30 35

M14 x 1.5 45 55

M16 x 1.5 60 70

M18 x 1.5 70 110

M20 x 1.5 - 140

M22 x 1.5 140 170

M26 x 1.5 180 220

M27 x 2 190 250

M33 x 2 300 300

M42 x 2 500 550

M48 x 2 550 600

G 1/8 A 20 25

G 1/4 A 35 40

G 3/8 A 70 90

G 1/2 A 100 150

G 3/4 A 180 270

G 1 A 250 350

G 1-1/4 A 450 500

G 1-1/2 A 550 600

7/16 - 20 (11.1 mm) - -

1/2 - 20 (UNF) - -

9/16 - 18 (14.3 mm) - -

3/4 - 16 (19.1 mm) - -

7/8 - 14 (22.2 mm) - -

24 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Introduction

Torque settings

1044-004

Dimension Tightening torque

(light series)

in Nm

Tightening torque

(heavy series)

in Nm

1-1/16 - 12 (27 mm) - -

1-5/16 - 12

- -

(33.3 mm)

1-5/8 - 12 (UNF) - -

1-7/8 - 12 (UNF) - -

2 - 12 (UNF) - -

Shape F with O-ring and plug

Dimension Tightening torque

(light series)

in Nm

Tightening torque

(heavy series)

in Nm

M5 2.8 -

M6 5.2 -

M8 x 1 7 -

M10 x 1 11 -

M12 x 1.5 15 15

M14 x 1.5 25 25

M16 x 1.5 35 35

M18 x 1.5 50 50

M20 x 1.5 - 55

M22 x 1.5 80 80

M26 x 1.5 110 110

M27 x 2 110 160

M33 x 2 160 210

M42 x 2 210 320

M48 x 2 320 420

G 1/8 A - -

G 1/4 A - -

G 3/8 A - -

G 1/2 A - -

G 3/4 A - -

G 1 A - -

G 1-1/4 A - -

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 25

Introduction

Torque settings

1044-004

Dimension Tightening torque

(light series)

in Nm

Tightening torque

(heavy series)

in Nm

G 1-1/2 A - -

7/16 - 20 (11.1 mm) 15 20

1/2 - 20 (UNF) 20 25

9/16 - 18 (14.3 mm) 30 30

3/4 - 16 (19.1 mm) 35 60

7/8 - 14 (22.2 mm) 70 90

1-1/16 - 12 (27 mm) 85 100

1-5/16 - 12

150 170

(33.3 mm)

1-5/8 - 12 (UNF) 250 300

1-7/8 - 12 (UNF) 300 350

2 - 12 (UNF) 350 400

Shape H with O-ring and chamber ring

Dimensions

Tightening torque

(light series)

in Nm

G 1/8 A 20 20

G 1/4 A 40 40

G 3/8 A 75 75

G 1/2 A 85 85

G 3/4 A 180 180

G 1 A 310 310

G 1-1/4 A 450 450

G 1-1/2 A 540 540

Tightening torque

(heavy series)

in Nm

26 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Tightening torques for hydraulic swivel fittings

Introduction

Torque settings

1044-004

123204-003

Dimensions Tightening torque

(light series)

in Nm

Tightening torque

(heavy series)

in Nm

M10 x 1 20 30

M12 x 1.5 35 40

M14 x 1.5 45 50

M16 x 1.5 60 70

M18 x 1.5 75 80

M20 x 1.5 - 100

M22 x 1.5 125 130

M26 x 1.5 130 -

M27 x 2 130 140

M33 x 2 300 300

M42 x 2 500 500

M48 x 2 600 600

G 1/8 A 20 -

G 1/4 A 40 40

G 3/8 A 65 70

G 1/2 A 90 100

G 3/4 A 130 130

G 1 A 270 380

G 1-1/4 A 500 600

G 1-1/2 A 600 700

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 27

Introduction

Torque settings

Tightening torques for hollow screws DIN 7643

Dimensions Tightening torque

M8 x 1 8

M10 x 1 15

M12 x 1.5 27

M14 x 1.5 38

M16 x 1.5 45

M18 x 1.5 58

M22 x 1.5 95

M26 x 1.5 130

M30 x 1.5 183

1044-004

123206-002

in Nm

28 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Tightening torques for direction-adjustable SDE hydraulic male connectors

Shape F with O-ring

Introduction

Torque settings

1044-004

123202-004

Dimensions Tightening torque

(very light series)

in Nm

Tightening torque

(light series)

in Nm

Tightening torque

(heavy series)

in Nm

M8 x 1 - - -

M10 x 1 20 15 -

M12 x 1.5 - 25 35

M14 x 1.5 - 35 45

M16 x 1.5 - 40 55

M18 x 1.5 - 45 90

M20 x 1.5 - - 140

M22 x 1.5 - 60 170

M26 x 1.5 - 100 190

M27 x 2 - 100 190

M33 x 2 - 160 310

M42 x 2 - 210 330

M48 x 2 - 260 420

7/16 - 20 (11.1 mm) - 15 20

1/2 - 20 (UNF) - 30 40

9/16 - 18 (14.3 mm) - 35 45

3/4 - 16 (19.1 mm) - 55 60

7/8 - 14 (22.2 mm) - 80 90

1-1/16 - 12 (27 mm) - 100 100

1-5/16 - 12

- 150 170

(33.3 mm)

1-5/8 - 12 (UNF) - 290 340

1-7/8 - 12 (UNF) - 325 415

2 - 12 (UNF) - 350 450

Shape H with O-ring and chamber ring

Dimensions

Tightening torque

(very light series)

Tightening torque

(light series)

Tightening torque

(heavy series)

in Nm

in Nm

in Nm

M8 x 1 10 - -

M10 x 1 20 18 -

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 29

Introduction

Torque settings

1044-004

Dimensions Tightening torque

(very light series)

in Nm

Tightening torque

(light series)

in Nm

Tightening torque

(heavy series)

in Nm

M12 x 1.5 - 30 35

M14 x 1.5 - 45 55

M16 x 1.5 - 60 80

M18 x 1.5 - 70 105

M20 x 1.5 - - 140

M22 x 1.5 - 125 125

M26 x 1.5 - 180 180

M27 x 2 - 180 180

M33 x 2 - 300 380

M42 x 2 - 450 500

M48 x 2 - 600 600

G 1/8 A 20 20 25

G 1/4 A - 35 45

G 3/8 A - 70 75

G 1/2 A - 100 100

G 3/4 A - 180 180

G 1 A - 300 300

G 1-1/4 A - 450 450

G 1-1/2 A - 540 540

30 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Tightening torques for brake line screw fittings

Dimensions Tightening torque

M10 x 1 14+2

Tightening torques for worm drive hose clamps

Introduction

Torque settings

1044-004

123207-004

Shape F union screws

Shape FS union screws with chime

in Nm

123209-003

8515-001

Width of clip Tightening torques for new hoses

when installing for the first time

Tightening torques for retightening

or reassembling

7.9 mm (0.31 inch) 0.9 ± 0.2 Nm (8 ± 2 lb in) 0.7 ± 0.2 Nm (6 ± 2 lb in)

13.5 mm (0.53 inch) 4.5 ± 0.5 Nm (40 ± 4 lb in) 3.0 ± 0.5 Nm (27 ± 4 lb in)

15.9 mm (0.63 inch) 7.5 ± 0.5 Nm (65 ± 4 lb in) 4.5 ± 0.5 Nm (40 ± 4 lb in)

Tightening torque for spring-loaded worm drive hose clamps

30

123211-002

37503-001

Width of clip

Clamp diameter Tightening torque

12 mm 60 - 80 mm 5 + 0.5 Nm

12 mm 70 - 90 mm 5 + 0.5 Nm

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 31

31

CCN explanation

CCN (CLAAS Component Number)

CCN explanation

1044-004

CCN (CLAAS Component Number)

General

Electric systems standard

Pos. Component

A Terminal / module

B Sensor

C Electric / electronic devices

E Lighting

G Voltage source

H Signalling device / lamp

120555-004

The CCN (CLAAS Component Number) arises from a

CLAAS standard for hydraulic and electric systems.

This standard is based on the hydraulic and electric

functions on the machine.

146587-001

In the electric systems standard, the components are

subdivided according to their function, using letters.

J Information units (required for function diagnosis)

M Motor (electric)

P Gauge

R Potentiometer / resistor

S Switches / pushbuttons - Cab operation

T Switches - Terminal operation

U Switches - External operation

V Electronic component

W Antenna

X Connectors

Y Solenoid coil

Z Actual value switch

32 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Hydraulic system standard

Pos. Component

1000 Oil reservoir / oil filter / oil cooler

2000 Pump / motor

3000 Hydraulic cylinder

4000 Restrictor / orifice plate

5000 Pressure accumulator

6000 Valve - mechanically actuated

7000 Valve - hydraulically actuated

8000 Couplings / connections

CCN explanation

CCN (CLAAS Component Number)

1044-004

146588-001

In the hydraulic systems standard, the components

are subdivided according to their function, using

number ranges.

9000 Measuring point / gauge

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 33

CCN (CLAAS Component Number)

CCN (CLAAS Component Number)

CCN (CLAAS Component Number)

1044-004

34 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

CCN (CLAAS Component Number)

CCN Index

1044-004

CCN Index

A

A015 see A6-MB.............................................................................................................................................52, 256

A032 see A95-MB.................................................................................................................................................275

A113-MB NOx sensor with control unit................................................................................................................. 229

A6-MB MR/PLD control unit............................................................................................................................52, 256

A95-MB Exhaust gas treatment module............................................................................................................... 275

B

B10-MB Fuel temperature sensor...........................................................................................................................52

B111-MB Sensor

Charge air temperature and pressure......................................................................................................52, 232

B115-MB Exhaust temperature sensor

Upstream of catalyst...................................................................................................................................... 229

B116-MB Exhaust temperature sensor

Downstream of catalyst..................................................................................................................................229

B11-MB Oil temperature sensor..................................................................................................................... 52, 190

B128-MB Dosing unit air pressure sensor...................................................................................................... 52, 279

B129-MB Urea pressure sensor..................................................................................................................... 52, 279

B12-MB Oil pressure sensor...........................................................................................................................52, 190

B130-MB Urea temperature sensor................................................................................................................ 52, 279

B14-MB Oil level sensor................................................................................................................................... 52, 63

B15-MB Crankshaft position sensor................................................................................................................. 52, 77

B16-MB Camshaft position sensor......................................................................................................................... 52

B350 see A113-MB...............................................................................................................................................229

B351 see B115-MB...............................................................................................................................................229

B352 see B116-MB...............................................................................................................................................229

B360 see B129-MB.........................................................................................................................................52, 279

B65-MB Coolant temperature sensor............................................................................................................. 52, 201

G

G002 see G2-MB.......................................................................................................................................... 241, 246

G003 Alternator 24 V............................................................................................................................................ 246

G2-MB alternator 12 V.................................................................................................................................. 241, 246

M

M021 see M1-MB..................................................................................................................................................236

M047 see M25-MB........................................................................................................................................260, 267

M1-MB Electric starting motor...............................................................................................................................236

M25-MB Urea pump......................................................................................................................................260, 267

R

R25-MB Urea diffusor heater................................................................................................................................ 279

Y

Y107-MB Urea heater valve..........................................................................................................................260, 264

Y109-MB Urea dosing valve........................................................................................................................... 52, 279

Y10-MB Plug-on pump valve................................................................................................................................ 168

Y11-MB Plug-on pump valve................................................................................................................................ 168

Y487 see Y109-MB.........................................................................................................................................52, 279

Y488 see Y107-MB.......................................................................................................................................260, 264

Y6-MB Plug-on pump valve.................................................................................................................................. 168

Y7-MB Plug-on pump valve.................................................................................................................................. 168

Y8-MB Plug-on pump valve.................................................................................................................................. 168

Y9-MB Plug-on pump valve.................................................................................................................................. 168

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 35

Safety

General Information

Safety

1044-004

General Information

Of special importance

Identification of warning and danger signs

123229-002

In order to prevent accidents, the information provided

in this repair manual must be read and observed by all

persons who use, maintain, repair, service or monitor

the machine.

Read the section on safety in particular.

123231-004

We have marked all points of this Repair Manual

involving your safety and the safety of the front

attachment or of the machine with the signs below.

Please pass all safety precautions on to other users

as well.

9-003

WARNING

Nature and source of danger

Consequences: probable incidence of serious injury or

death

► Countermeasures

CAUTION

Nature and source of danger

Consequences: probable incidence of slight injuries

► Countermeasures

NOTICE

Nature and source of danger

Consequences: probable incidence of material

damage

► Countermeasures

11-003

13-003

36 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Safety

General Information

1044-004

16-003

Information

Nature and source of information

Consequences: inefficient use

► Measures

18-001

Environment!

Nature and source of danger

Consequences: damage to the environment

► Countermeasures

The warning and information signs on the machine

provide important information for hazard-free

operation. Observing these warnings and information

serves your safety!

Regulations for avoiding accidents with personal injuries

General

In addition to this manual, the Repair Manual for

–

the machine must always be observed.

Observe all general rules concerning safety and

–

accident prevention.

Testing, adjusting and repair work may be carried

–

out only by CLAAS sales partners.

Testing, adjusting and repair work

WARNING

Pinch point from pre-loaded components.

Serious injuries.

► Never move your hands between pre-loaded

components.

Secure the engine when removing it.

–

Keep the engine, ladders, stairs, bridges and their

–

surroundings free of oil and grease.

Switch off the battery isolating switch while

–

working in built-in condition.

Ensure that the engine is not started accidentally

–

by unauthorised persons.

157730-003

1497-002

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 37

Safety

General Information

1044-004

Engine operation

160525-002

CAUTION

Bruises and burns when intervening into the starting

process or while the engine is running.

Danger of injury

► Wear closed and tight-fitting working clothes.

► Do not touch any hot or rotating parts.

173-002

CAUTION

Contact with hot liquids or machine parts.

Danger of burns

► Wear suitable protective clothing.

► Let liquids or machine parts cool down.

► Comply with instructions.

Suspended loads

57765-002

WARNING

Lifting heavy components.

Risk of death or serious injury.

► Use a lifting tool with a sufficient bearing load.

► Use a lifting tool that operates reliably.

► Use the lifting tool on solid and even ground.

► Attach the lifting tool to the component at the

intended or a suitable position.

► Only use faultless and sufficiently dimensioned

lifting accessories.

► Protect lifting accessories against sharp corners

and edges, for example using protectors.

Do not lift heavy components with your body's

►

force.

Ensure that no persons are present beneath

►

suspended loads.

38 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

General Information

Working on piping and hoses

WARNING

Fire / explosion hazard when handling fuel.

Death or serious injury.

► No fires, sparks, open light and no smoking.

► Fill fuel only into suitable containers.

► Wear protective clothing.

CAUTION

Contact with hot liquids.

Risk of burns.

Safety

1044-004

157932-002

125670-003

► Release pressure on the system/wait for pressure

to drop.

► Leave liquids to cool.

► Wear suitable protective clothing.

124851-001

Environment!

Lubricants, operating utilities and fuels escape into the

environment.

Environmental pollution.

► Collect and store lubricants, operating utilities and

fuels in suitable containers and ensure proper

disposal.

Neither retighten nor open any piping and hoses

►

under pressure.

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 39

Safety

General Information

1044-004

Work on the Common Rail System

161964-002

NOTICE

Unprofessional installation on Common Rail system.

Damage to Common Rail system.

► All work on components of the Common Rail

system may be carried out only by specially

trained personnel.

► Prior to starting work, the engine must be

standing still for at least 5 minutes in order to

relieve the pressure in the pressure pipe or

pressure reduction must be controlled with the

CDS.

► Absolute cleanliness must be ensured during all

work in all areas.

► Prior to any work on the clean side of the fuel

system, the engine and the engine compartment

must be cleaned (e.g. steam jet cleaner) with the

fuel system remaining closed.

► Absolutely avoid moisture.

► Slackened-off inlet connectors must always be

replaced.

► Plugs once used for high-pressure lines, pressure

pipe and injectors must not be re-used.

► Observe the sequence specified in the description

when tightening the injectors, high-pressure lines,

pressure pipe and inlet connector.

161966-002

NOTICE

Unclosed components.

Damage to the Common Rail system.

► Dismount only one fuel line at a time.

► Close the component connections immediately

with new and clean caps.

Working on the electric system

Start the engine only with firmly connected

►

batteries.

Do not disconnect the batteries while the engine

►

is running.

Do not use any quick-charging devices for starting

►

the engine.

► Assist-starting only with separate batteries.

The connections of control units may be

►

disconnected and connected only with the electric

system switched off.

40 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

General Information

Incorrect polarity of the control units may cause

►

their destruction.

Always tighten the connections on the injection

►

system to the specified tightening torques.

When temperatures above 80 °C must be

►

expected, the control units must be removed.

Use only suitable testing lines for measurements

►

on connectors.

Observe the manufacturer's regulations for

►

batteries.

Wear protective clothing when handling batteries.

►

Do not tilt the batteries, acid might escape.

►

Measure the voltage only with a suitable

►

measuring device.

Electrolytic gas may form in closed battery boxes.

►

► Be particularly careful after the engine has

run for an extended period and after charging

the battery with a charger.

When disconnecting the batteries, non-

►

disconnected continuous consumers may

generate sparks that ignite the gas.

► Vent the battery box sufficiently prior to

disconnecting.

Avoid short-circuits by wrong polarity or placing

►

metal objects on the battery terminals.

Disconnect batteries when the engine has been

►

shut down and recharge every four weeks.

Safety

1044-004

Working on the hydraulic system

64831-003

WARNING

Residual oil pressure in hoses / hydraulic

components.

Serious injury of eyes / of skin.

► Relieve the residual oil pressure in the hydraulic

system.

11741-003

NOTICE

Serious damage to hydraulic circuit components.

► Before installing hydraulic system components,

the entire hydraulic circuit and the hydraulic

system components remaining on the machine

must be flushed.

► The entire hydraulic system must be free of dirt

and foreign objects.

► Replace the hydraulic oil filter.

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 41

Safety

General Information

Electric welding

Observe the welding information sheets.

►

Disconnect the batteries.

►

Fit earthing point of the welder close to the

►

welding spot.

Disconnect the control units.

►

Painting work

During painting work, electronic components may

►

be exposed to high temperatures (up to 95 °C)

only for a short time.

Disconnect the batteries.

►

Remove sensitive electric components.

►

Screw fittings of high-pressure lines must not be

►

painted. Danger of introducing dirt in case of

repairs.

Working with urea solution

1044-004

124844-004

CAUTION

Contact with urea solution.

Danger of injury.

► Wash your skin thoroughly with water and soap.

See a doctor if necessary.

► Flush eyes thoroughly with plenty of water. See a

doctor if necessary.

► Flush mouth and drink plenty of water. See a

doctor if necessary.

149012-002

NOTICE

Foreign substances pollute the system

Damage to exhaust gas system.

► Keep foreign substances and residual quantities

of diesel fuel out of this system.

► Increased cleanliness requirements during

installation work.

42 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

NOTICE

Surfaces get in contact with urea solution.

Component corrosion.

► Flush the surfaces concerned with plenty of water

immediately.

Information on how to avoid damage and premature wear

General

Engines are built exclusively for the intended use

–

according to the shipping package.

Unauthorised modifications on the engine will

–

exclude any liability of the manufacturer for any

resulting damage.

Manipulations on the injection and control system

may also influence the output and waste gas

behaviour.

Meeting the statutory environmental protection

requirements is no longer guaranteed in this

condition.

If any trouble occurs during operation, locate and

–

remove the reason immediately.

Clean the engine thoroughly before starting

–

repairs.

- Ensure that no dirt, sand or foreign objects

Only use genuine CLAAS spare parts.

–

Never let the engine run dry.

–

Never let the engine run without coolant.

–

Fit a corresponding note on engines that are not

–

ready for operation.

Use only operating utilities approved by CLAAS.

–

Do not fill in engine oil beyond the maximum level

–

mark.

Safety

General Information

1044-004

124885-005

157737-001

end up inside the engine.

157745-001

Liability limitation

General

All information and notes in this manual were

►

compiled considering the standards and

regulations in force, the state of the art and many

years of experience.

CLAAS will not assume any liability for damage

►

caused by:

► failure to comply with this manual

► use not in line with the intended use

► use of non-trained personnel

► unauthorised conversions

► technical modifications

► use of non-approved spare part and

operating utilities

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 43

Safety

General Information

Shutting down and storage

Shutting down the engine for an extended period

►

of time requires temporary corrosion protection.

Regulations for avoiding health and environmental damage

Precautionary measures for protection against health and environmental damage

Avoid extended, excessive or repeated skin

►

contact with operating utilities, auxiliary operating

utilities, diluents or solvents.

Protect your skin by suitable skin protection

►

agents or protective gloves.

Do not use any operating utilities, auxiliary

►

operating utilities, diluents or solvents for cleaning

of skin.

► Wash polluted skin thoroughly with water and

soap.

Change oil-soaked clothing and shoes.

►

Do not put any oil-soaked rags into the pockets of

►

your working clothes.

1044-004

157747-001

Information for working on the diesel engine

Disposal of operating utilities and auxiliary operating utilities

Observe the regulations of the local authorities.

►

Ensure that no operating utilities will end up in the

►

soil, sewer or in waters.

Different operating utilities must be collected and

►

disposed of in different containers.

Use tight containers for draining operating utilities.

►

► Ensure that food or drink containers are

never used - danger of confusion.

Ensure that operating utilities are correctly

►

disposed of.

► Operating utilities count among the water-

hazardous substances!

Accident protection

Fuel jets may cut the skin.

►

Fire hazard due to fine spraying of fuel.

►

Avoid standing near the running engine.

►

Never slacken off the screw fittings of fuel lines

►

while the engine is running.

The lines may be under very high pressure (up to

1800 bar).

The engine must have been stopped for at least 5

►

minutes before slackening off the fuel lines.

► Check the line pressure values with the CDS

if necessary.

Do not touch live parts of electric connections

►

while the engine is running.

157748-002

44 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Safety

General Information

1044-004

Persons wearing a pacemaker must not come

►

closer than 20 cm to the running engine.

Any modifications of the original engine cabling

►

may result in exceeding threshold values of the

pacemaker regulations.

Cleanliness

Diesel injection components consist of high-precision

parts that are subject to extreme loads. In view of this

high-precision equipment, maximum cleanliness must

be ensured during all work on the fuel system. Even

dirt particles measuring more than 0.002 mm may

make components fail.

Before starting work, absolutely comply with the rules

below:

Clean engine and engine compartment before

►

starting the work.

► Ensure that the fuel system is closed here.

► When using a jet cleaner, do not aim directly

on electric components or fit covers.

Clean tools and working materials before starting

►

work.

► Use only undamaged tools.

Cover up engine compartment areas where dirt

►

particles may come off with a new and clean dust

film.

Wash your hands before starting dismounting and

►

put on fresh working clothing.

Carry out a visual inspection for leaks and

►

damage on the fuel system.

Remove any loose dirt particles such as paint

►

chips and insulation material with a suitable

suction device.

When removing and installing components, no

►

materials such as cloths, cardboard or wood may

be used as these materials may lose particles and

fibres.

Carefully remove paint chippings resulting from

►

slackening off bolts before completely removing

the bolts.

Place the engine in a clean area of the workshop

►

where no work is carried out that raises dust.

Avoid air motion (possible raising of dust by

►

starting engines, workshop ventilation or heating

system, air draught etc.).

Clean and dry the area of the still closed fuel

►

system with compressed air.

► After opening the clean-side fuel system, use

of compressed air for cleaning is no longer

allowed.

Use only non-fluff cleaning cloths on the fuel

►

system.

Close connecting openings of all removed parts of

►

the clean-side fuel system immediately with

suitable caps.

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 45

Safety

General Information

► Caps must be packed dust-tight before use

and must be disposed of after using them

once.

Keep components carefully in a clean and closed

►

container.

► Never use pre-used cleaning or testing

liquids for these components.

New parts may be taken out of their original

►

packaging only just before using them.

Carry out work on removed components only at a

►

workplace equipped for this purpose.

If removed parts are dispatched, always use the

►

original packaging of the new part.

Installation instructions

Piping of all kinds must not be bent, risk of

►

cracking!

Regulations for flawless installation of flat seals:

►

► Only use genuine CLAAS seals.

► Sealing faces must be undamaged and

clean.

► Do not use any sealants or glues.

► Tighten bolts evenly to the specified torque.

Regulations for flawless installation of round

►

seals:

► Only use genuine CLAAS seals.

► Sealing faces must be undamaged and

clean.

► Always wet O-rings with engine oil according

to the manufacturer's specification when

installing.

1044-004

Engine overhaul

The service life of an engine is influenced by very

different factors. Specifying a certain number of

operating hours for basic overhauls is therefore not

possible.

Opening an engine or a basic overhaul is not

appropriate as long as the engine has good

compression values and the following operating

values have not significantly changed as compared

with those measured and accepted upon

commissioning:

Charge pressure.

►

Exhaust gas temperature.

►

Coolant and lubricating oil temperature.

►

Oil pressure and oil consumption.

►

Smoke behaviour.

►

The criteria below have major influence on the

engine's service life:

Correct setting of output, depending on the type of

►

use.

Proper installation.

►

46 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Safety

General Information

1044-004

Acceptance of installation by authorised

►

personnel.

Regular maintenance according to the

►

maintenance schedule.

Selection and quality of lubricating oil, fuel and

►

coolant according to the manufacturer's

specifications.

Putting into operation after an engine overhaul

Pre-fill the engine with engine oil after finishing repair,

i.e. in dry condition, before putting it back into

operation. This process can also be applied when

establishing damage and reasons.

On all engines that have not been pre-filled with

lubricating oil, the danger of premature damage to the

bearing surface is very big because the lubrication oil

fed by the oil pump from the oil sump takes relatively

long before it reaches the individual bearings.

Such initial damage will not necessarily make the

bearings fail, but can affect bearing function and

reduce the service life.

First aid measures

Pre-filling the engine with engine oil:

Page 178

Inhaling:

Give the person fresh air and consult a doctor

–

depending on his or her symptoms.

Remove the person from the danger area.

–

Contact with the eyes:

Rinse the eyes thoroughly with large amounts of

–

water for several minutes. Consult a doctor if

required.

Contact with the skin:

Wash thoroughly with plenty of water and soap,

–

remove polluted and soaked clothing immediately,

consult a doctor if the skin is irritated (e.g.

reddening).

Swallowing:

Do not induce vomiting; consult a doctor

–

immediately.

123242-003

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 47

01 Engine

0102 Complete component

01 Engine

1044-004

0102 Complete component

Type design

The engines of the OM 906 LA and OM 926 LA series

are available in three different versions.

These are differentiated by the different type designs:

Series Type design Exhaust gas level Note!

OM 906 LA

OM 926 LA

OM 926 LA 926.959

Engine data

Designation

Dry weight 530 kg

Wet weight 573 kg

906.991

926.929

926.970

Tier 3 / Stage IIIA

Tier 4i / Stage IIIB

OM 906 LA

Value

162116-001

162117-001

Engine type In-line engine

Number of cylinders 6

Cylinder bore 102 mm

Cylinder stroke 130 mm

Cubic capacity 6.370 cm³

Direction of rotation of engine when viewing the flywheel Left

OM 926 LA

Designation

Value

Dry weight 530 kg

Wet weight 573 kg

Engine type In-line engine

Number of cylinders 6

Cylinder bore 106 mm

Cylinder stroke 136 mm

Cubic capacity 7.200 cm³

Direction of rotation of engine when viewing the flywheel Left

48 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Engine description

8

7

6

5

4

3

2

1

Engine components

01 Engine

0102 Complete component

1044-004

162119-002

188319-001 32

Designation

1 Valve cover Page 118

2 Urea heater valve

Page 263

Applies to: Type designs 926.959 and 926.970

3 Cylinder head Page 121

4 Flywheel Page 111

5 Compressor Page 251

6 Plug-on pump Page 167

7 MR/PLD control unit Page 256

8 Fuel filter Page 175

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 49

1

2

3

4

5

6

7

8

9

10

11

12

01 Engine

0102 Complete component

1044-004

188320-001 33

Designation

1 Intake housing Page 232

2 Oil filter housing Page 184

3 Coolant pump Page 201

4 Fuel pump Page 172

5 Oscillation damper Page 109

6 Alternator 24 V

Page 245

Applies to: Type designs 926.959 and 926.970

7 Alternator 12 V Page 240

8 Oil cooler Page 189

9 Exhaust turbo charger Page 218

10 Electric starting motor

11 Exhaust manifold Page 213

12 Urea dosing unit

Applies to: Type designs 926.959 and 926.970

Page 277

50 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Sensors

4

32

1

5

6

7

8

9

10

11

12

13

01 Engine

0102 Complete component

1044-004

188321-001 34

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 51

01 Engine

0102 Complete component

Value CCN Remark / designation

1 B65-MB Coolant temperature sensor Page 201

1044-004

2 A6-MB

MR/PLD control unit Page 256

(A015)

3 B16-MB Camshaft position sensor

4 B15-MB Crankshaft position sensor Page 77

5 B111-MB Charge air temperature and pressure sensor Page 232

6 B14-MB Oil level sensor Page 63

7 B12-MB Oil pressure sensor Page 189

8 B11-MB Oil temperature sensor Page 189

9 Y109-MB

Urea dosing valve Page 279

(Y487)

10 B128-MB Dosing unit air pressure sensor Page 279

11 B130-MB Urea temperature sensor Page 279

12 B129-MB

Urea pressure sensor Page 279

(B360)

13 B10-MB Fuel temperature sensor

Tightening torques not specified, see section on tightening torques

52 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Ignition order

65

4

3

2

1

01 Engine

0102 Complete component

1044-004

188322-001 35

The piston (1) is at the ignition top dead centre

(ignition TDC) when the synchronous piston (6) is at

the valve overlap top dead centre (overlap TDC).

The intake valves and the exhaust valves are relieved

at the ignition top dead centre.

When at the overlap top dead centre, the intake

valves and the exhaust valves are loaded.

Piston position

Cylinder / injection order

Overlap TDC 1 5 3 6 2 4

Ignition TDC 6 2 4 1 5 3

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 53

01 Engine

0102 Complete component

Cranking the engine

1044-004

162184-002

The engine can be cranked by hand both in built-in

condition and in removed condition.

Depending on the variant, different special tools are

available for this.

In order to avoid damage to the special tool, it is

–

important to use the respective special tool only

for the specified application!

This is why this chapter is sub-divided into two

sections:

Cranking the engine in built-in condition: Page

56

Cranking the engine in removed condition: Page

58

54 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

01 Engine

0102 Complete component

1044-004

Special tool for built-in engine

The following tools of special tool kit 00 0181 932 0

are needed:

Special tool Pcs.

1 Cranking tool

00 0181 751 0

2 Spacer sleeve

00 0953 440 0

3 Hex. bolt

180243-001

36

ISO 4017 M16x80

00 0237 841 0

Compose special tools using the table below,

depending on the machine in question:

Machine Special tool Part number

TUCANO Page

56

Cranking tool

Spacer tube

Hex. bolt

00 0181 751 0

00 0953 440 0

00 0237 841 0

Special tools for removed engine

Special tool Pcs.

1

3

3

1x

3x

3x

147485-001

1 Cranking tool

37

1

00 1992 902 0

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 55

CC

C

2

01 Engine

0102 Complete component

Cranking the engine in built-in condition

TUCANO

Remove bracket (2).

►

1044-004

173942-001

38

170310-001 39

Screw on special tool (1) ( Page 55) through

►

openings (C) of the cranking tool.

56 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

1

1

01 Engine

0102 Complete component

1044-004

173943-001

188340-001

40

41

Crank engine at (1) until the desired crankshaft

►

position is reached.

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 57

1

1

01 Engine

0102 Complete component

Cranking the engine in removed condition

Unscrew plate (1).

►

1044-004

180254-001

180255-001

42

Using the special tool: Page 55

Fit special tool at (1).

►

Crank engine until the desired crankshaft position

►

is reached.

43

58 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

0105 Engine suspension

01 Engine

0105 Engine suspension

1044-004

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 59

2

1

01 Engine

0105 Engine suspension

Lifting eyes

Technical specifications

1044-004

162197-001

188362-001 44

1 Crankcase lifting eyes, front

Value CCN Remark / designation

See coolant pump

Page 201

2 210 Nm Crankcase lifting eyes, rear

Tightening torques not specified, see section on tightening torques

60 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

0110 Engine housing

01 Engine

0110 Engine housing

1044-004

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 61

01 Engine

0110 Engine housing

Oil sump

1044-004

162348-001

Special tool

Special tool (I) Pcs.

39225-002

1 Sealing compound

00 0217 602 0

45

1

62 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Technical specifications

5

4

3

2

1

01 Engine

0110 Engine housing

1044-004

188475-001 46

Value CCN Remark / designation

1 19 kg Oil sump

2 Seal

3 25 Nm Oil pan mounting bolts

4 65 Nm Oil drain plug

5 65 Nm B14-MB Oil level sensor

Tightening torques not specified, see section on tightening torques

Removal

Drain the engine oil.

►

See the Operator's Manual of the machine in

question.

Remove the alternator. Page 247

►

Applies to type designs:

926.959

926.970

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 63

1

2

B14-MB

1

1

2

1

01 Engine

0110 Engine housing

Unscrew the oil level dipstick (1).

►

1044-004

188494-001

188495-001

47

48

Disconnect cable connector from sensor (B14-

►

MB) at (1) and unscrew at (2).

Unscrew oil drain hose (1).

►

188496-001

Unscrew all bolts (2) and remove oil pan (1).

►

► Ensure that no more cables or lines are

attached to the oil pan.

50

49

188497-001

64 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Remove seal (1) from the oil pan.

1

1

►

01 Engine

0110 Engine housing

1044-004

188498-001

188498-001

51

Installation

Clean all sealing faces. Page 19

►

Place a new seal (1) on the oil pan.

►

52

Use special tool (I). Page 62

Clean all sealing faces. Page 19

►

Apply special tool (I) at the separating

►

points (arrows) with the timing housing and the

front housing cover.

188499-001

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 65

53

2

1

1

2

B14-MB

1

1

01 Engine

0110 Engine housing

Bolt down oil pan (1) with bolts (2).

►

Tightening torque: Page 63

1044-004

188497-001

188496-001

54

55

Bolt down oil drain hose (1).

►

Tightening torque: Page 63

Connect cable connector to sensor (B14-MB)

►

at (1) and screw on at (2).

188495-001

Bolt down oil level dipstick (1).

►

57

56

188494-001

66 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

0110 Engine housing

Top up engine oil.

►

See the Operator's Manual of the machine in

question.

Install the alternator. Page 247

►

Applies to type designs:

926.959

926.970

01 Engine

1044-004

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 67

01 Engine

0110 Engine housing

Crankshaft front seal

1044-004

162370-003

Special tool

Special tool (I) Pcs.

237684-001

1 Installation tool

00 1995 525 0

58

1

68 00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014

Technical specifications

3

2

1

1

2

3

01 Engine

0110 Engine housing

1044-004

188520-001 59

1 Radial seal

Value CCN Remark / designation

Observe the installation position.

Coat the inner contact face slightly with engine

oil.

Replace the seal with every installation.

2 Crankshaft Page 98

3 Oil pump Page 193

Tightening torques not specified, see section on tightening torques

Removal

Remove the oscillation damper. Page 109

►

00 0296 433 2 - RHB Dieselmotor OM906/926LA - 10/2014 69

1

2

1

4

3

2

1

4

01 Engine

0110 Engine housing

Drill two Ø 3 mm holes into seal (1).

►

Screw two self-tapping screws 4.8x25 mm into the

►

bores.

Pull out the seal (1) at the self-tapping screws.

►

1044-004

188521-001

188536-001

60

61