®

OM 904-926 LA BlueTec

Operating Instructions

, OM 904-926 LA

Symbols

$

%

!

i

X

YY

(Y page)

Warning

Environmental note

Possible vehicle damage

Tip

Instructions

Continuation symbol

Page reference

Welcome to the world of Mercedes-Benz

Familiarise yourself

with your engine and read

the Operating Instructions before you use the

engine. This will help you to avoid endangering yourself or others.

The standard equipment and product description of your engine may vary, depending on

individual specifications. This is described on

the engine data card.

Mercedes-Benz constantly updates its

engines to the state of the art.

Mercedes-Benz reserves the right to make

changes to the following:

R

design

R

equipment

R

technical features

You cannot therefore base any claims on the

data, illustrations or descriptions in this manual.

The manual/instructions are comprised of:

R

Operating Instructions

R

Maintenance Booklet

Always keep these documents together with

the engine/vehicle/device. These documents should be passed on to the new owner

if you sell the engine/vehicle/device.

i

You can find out about your engine's

important functions in German and English

in the online Owner's Manual at: http://

www.mercedes-benz.de/betriebsanleitungen

The technical documentation team at

Daimler AG wishes you safe and pleasant

motoring.

9265840681

É9265840681ÁËÍ

Contents

3

Index ....................................................... 4

General information .............................. 7

At a glance ........................................... 13

Safety ................................................... 29

Driving mode/working mode ............. 33

Maintenance and care ........................ 45

Notes on maintenance ....................... 59

Decommission and protection ........... 79

Breakdown assistance ....................... 85

Technical data ..................................... 99

Index

4

A

Adaptation module .............................. 21

AdBlue®/DEF

Components .................................... 19

Consumption ................................... 41

Refuelling

Replacing the filter ...........................

......................................... 42

69

Service product ............................... 54

ADM (FR (drive control) unit) ............. 21

Antifreeze ............................................. 73

B

Bio-diesel fuel

see FAME fatty acid methyl ester fuel

Bleeding the fuel system .................... 86

Bleeding the fuel system manually ... 86

BlueTec

®

Exhaust gas aftertreatment ................ 9

Sensors ............................................ 19

BlueTec® exhaust gas aftertreatment

AdBlue® service product .................. 54

Braking

Continuous brake ............................ 40

C

Capacities .......................................... 104

Care products ...................................... 55

Charge current .................................... 37

Checking the fluid level ...................... 34

Cleaning and care

Engine cleaning ................................

56

High-pressure cleaning .................... 55

Notes on care .................................. 55

Cold-start aid

....................................... 27

Consumption

AdBlue®/DEF .................................. 41

Fuel .................................................. 41

Oil (engine) ...................................... 41

Continuous brake ................................ 26

Coolant ................................................. 34

Mixing ratio ...................................... 48

Renewing ......................................... 75

Service product ............................... 48

Coolant (engine)

Topping up

....................................... 76

Coolant additive .................................. 48

Cooling system

Degreasing ....................................... 76

Flushing ........................................... 76

Correct use ............................................ 9

Corrosion inhibitor/antifreeze

agent .................................................... 48

Cranking device ................................... 64

D

Data card ............................................

Decommissioning

................................ 81

100

Decommissioning the engine ............. 80

DEF/AdBlue

®

see AdBlue®/DEF service products

Description of the engine ................... 21

Diesel

Flow improvers ................................ 52

Fuels ................................................ 50

Low outside temperatures ............... 52

refuelling .......................................... 41

Sulphur content table ...................... 51

Dimensions ........................................ 101

Disposal of service products .............. 46

Draining the coolant ........................... 75

Draining the fuel prefilter ................... 86

Driving tips .......................................... 40

E

Electronic engine control ................... 38

Emergency mode .................................

Emergency running program

................ 8

87

Engine

Capacities ...................................... 104

Changing the oil and oil filter ........... 62

Checking for leaks and general

condition .......................................... 77

Cleaning ........................................... 55

Data ............................................... 101

Data card ....................................... 100

Data plate ...................................... 100

Diagnostics (indicator lamp) ............ 94

Oil consumption ............................... 41

Operating data ............................... 104

Index

5

Protective treatment ........................ 81

Re-commissioning ........................... 83

Rectifying faults ............................... 89

Running-in period ............................. 40

Starting

Stopping .......................................... 39

Engine brake

Condition and setting ....................... 72

Function ........................................... 26

Engine control unit .............................. 22

Engine data ........................................ 101

Engine data card ............................... 100

Engine description .............................. 21

Engine model designation ................ 100

Engine oil

Adding ............................................. 63

For winter operation ........................ 46

Mixing .............................................. 48

Oil change ........................................ 47

Siphoning and draining .................... 62

Topping up ....................................... 48

Engine oil consumption ...................... 41

Engine overview .................................. 14

Engine type plate .............................. 100

Exhaust gas aftertreatment indica-

tor lamp ................................................ 95

............................................ 36

F

Filling up the pressure reservoir ....... 71

Flow improvers .................................... 52

FR (drive control) unit

see ADM

Fuel

Additives

Consumption ................................... 41

Diesel ............................................... 50

FAME fatty acid methyl ester fuel .... 53

refuelling .......................................... 41

Sulphur content table ...................... 51

Fuel filter .............................................. 67

Fuel grade ............................................ 50

.......................................... 52

G

Genuine Mercedes-Benz

parts ................................................... 7, 8

Getting started .................................... 35

H

High-pressure cleaning ....................... 55

I

Identification plate ............................ 100

Indicator and warning lamps

BlueTec® exhaust gas aftertreat-

ment ................................................ 25

Installation ........................................... 10

L

Lines and hoses

Checking for leaks ........................... 77

M

Maintenance ........................................ 56

Mercedes-Benz Service Centre

see Qualified specialist workshop

Modifications and changes .................. 7

O

Oil (engine)

For winter operation ........................ 46

Oil change ........................................

Scope of use

Oil change ............................................ 62

Oil filter replacement .......................... 62

Oil pressure ......................................... 38

Operating data ................................... 104

Operating restriction override ........... 39

Operating safety .................................... 7

Operational monitoring ...................... 37

Organisational measures ................... 30

Original parts ......................................... 7

Overview, sensors ............................... 18

Overview of maintenance work ......... 60

Overview of work plans ...................... 60

.................................... 47

47

P

Personnel ............................................. 30

Poly-V-belt

Checking condition .......................... 66

Damage patterns ............................. 66

Routing ............................................ 97

Index

6

Preparing for starting operation

see Starting operation

Protection of the environment ............. 7

Protective treatment .......................... 81

Q

Qualified specialist workshop ........... 11

R

Re-commissioning ............................... 83

Refuelling

AdBlue®/DEF .................................. 42

Fuels ................................................ 41

Replacing the fuel filter

Replacing the fuel prefilter ................. 68

Replacing the poly-V-belt .................... 97

Requirements of the personnel ......... 30

Roadside Assistance ........................... 86

Running the vehicle in ........................ 40

...................... 69

S

Safety and

gram ....................................................... 8

Safety precautions .............................. 30

Service products

AdBlue®/DEF .................................. 54

Coolant ............................................ 48

DEF/AdBlue® .................................. 54

Diesel fuel ........................................ 50

Disposal ........................................... 46

Disposing of AdBlue®/DEF .............. 55

Engine oil ......................................... 46

FAME fatty acid methyl ester fuel .... 53

Flow improvers ................................ 52

Fuel additives ................................... 52

Purity of AdBlue®/DEF .................... 55

Storing AdBlue®/DEF ...................... 55

Specialist workshop ............................ 11

Starting

see Starting (engine)

Starting (engine) .................................. 36

Starting the engine for the first

time ...................................................... 35

Stopping and switching off the

engine ................................................... 39

emergency running pro-

Sulphur content of fuel ....................... 51

T

Technical data ................................... 101

Dimensions .................................... 101

Filling capacities

Operating data ............................... 104

Weights .......................................... 101

Tightening torques ............................ 105

Torque reduction ............................... 106

Transport ................................................ 9

Troubleshooting .................................. 94

............................ 104

V

Valve clearance

Checking and adjusting ................... 63

Valve clearance special tool ...............

64

W

Warning and indicator lamps

Charge indicator .............................. 25

Cold-start aid ................................... 25

Electronics

Weights .............................................. 102

Winter diesel ........................................ 52

Winter operation ................................. 43

....................................... 25

General information

7

Environmental note

Environmental note

H

Daimler AG has a declared policy of comprehensive environmental protection.

The objectives are to use the natural resources which form the basis of our existence on

this planet sparingly and in a manner which

takes the requirements of both nature and

humanity into account.

You

by operating your engine in an environmentally responsible manner.

The fuel consumption and wear and tear of an

engine depend upon the conditions under

which it is operated. For this reason, you

should:

R

R

R

R

Always have maintenance work carried out at

a qualified specialist workshop, e.g. a

Mercedes-Benz or MTU Service Centre.

can help to protect the environment

also

not warm up the engine in neutral

switch off the engine during operation-related delays

monitor the fuel consumption

carry out the specified maintenance work.

Operating safety and vehicle approval

Operating safety

The operating

safety of an engine depends on

its professional installation in the overall system (e.g. the vehicle or working machinery).

As the operator of the engine, you also affect

its safe operation.

Through compliance with the prescribed

maintenance intervals, you fulfil part of the

requirements for safe operation of the

engine.

However, safe operation of the engine also

depends upon its proper use, which includes,

for example, regular checks of the oil level.

WARNING

G

Accidents can occur as a result of engine

damage caused by improper use of the

engine.

Therefore,

instructions included in the Owner's Manual.

WARNING

G

Faulty or incomplete maintenance work, as

well as disregarded maintenance intervals,

can decrease the engine's operating life,

cause engine damage and lead to accidents.

Therefore,

instructions included in the Owner's Manual.

follow the engine operating

please

follow the engine operating

please

Notes on electronic systems

WARNING

G

If work on electronic equipment and its software

carried out incorrectly, this equipment

is

could stop working. The electronic systems

are networked via interfaces. Tampering with

these electronic systems could cause malfunctions in systems which have not been

modified. Malfunctions such as these can

seriously jeopardise the vehicle's operating

safety and therefore your own safety.

Other work or modifications incorrectly carried out on the vehicle could also jeopardise

operating safety.

Some safety systems only function when the

engine is running. You should therefore never

switch off the engine when driving.

Conversion parts and modifications to the engine

WARNING

G

Unauthorised changes to the engine can

reduce its functionality and safety, lead to

accidents and consequently to personal

injury.

tion to the engine carried out at a qualified

specialist workshop which has the necessary

have maintenance or modifica-

Always

Z

General information

8

specialist knowledge and tools to carry out

the work required. Mercedes-Benz recommends that

Service Centre for this purpose.

!

Unauthorised intervention in the injection

you use a Mercedes-Benz or MTU

system and the engine electronics can

affect the performance and emissions of

the engine. Compliance with factory settings and legal environmental protection

conditions can then no longer be guaranteed.

The implied warranty does not cover damage

resulting from unauthorised modifications to

the engine.

Safety/emergency running program

The engine is equipped with an electronic

control system, which monitors both the

engine and itself (self-diagnosis).

When the

electronic control system detects a

malfunction, one of the following measures is

automatically implemented after an appraisal

of the malfunction:

R

The corresponding warning lamp displays

the faults occurring during operation

(Y page 25).

R

In conjunction with the electronic engine

control, fault codes can be shown on a display.

R

The system switches to a suitable backup

function for the continued, albeit restricted

operation of the engine (e.g. constant

emergency running speed).

WARNING

G

If maintenance and repair work on the engine

is

carried out correctly, the operation and

not

safety may be affected, which can result in

accidents and personal injury.

Always have work on or modifications to the

engine carried out at a qualified specialist

workshop that has the necessary special

skills and tools for the work required.

Mercedes-Benz recommends a MercedesBenz or MTU Service Centre.

The Daimler diagnostic tester can be

attached to the 14-pin diagnostic socket on

the equipment,

or to the service plug according to the EU Directive. Both the malfunction

message memory and the saved engine data

can be read by this device.

Warning lamp electronics (example)

Genuine Mercedes-Benz parts

Make sure of the suitability of the replacement parts

for your engine. Parts that lead to

a modification of the engine/vehicle/equipment are considered in many countries to

render the general operating permit invalid.

Such modifications include, for example:

R

modifications that change the approved

equipment type/vehicle type, as defined by

the general operating permit.

R

modifications that could endanger road

users or persons in the vicinity of the vehicle/equipment.

R

modifications that change the exhaust or

noise level.

The use of unapproved parts can adversely

affect safety levels.

Environmental note

H

For more economic repairs, Mercedes-Benz

offers Mercedes-Benz reconditioned assembly and

parts as part of the recycling process.

The same quality standards and warranty

apply as to new parts.

General information

9

You can find more information on recommended conversion

parts and accessories, as well

as permitted technical modifications at a

Mercedes-Benz or MTU Service Centre

(Y page 11).

Always state the engine number with the

model designation when ordering genuine

Mercedes-Benz parts. You can find the numbers on the identification plate of your engine

(Y page 100) and on the engine data card

(Y page 100).

BlueTec® exhaust gas aftertreatment

The engines meet the requirements of the

relevant emissions

level and are correspond-

ingly certified.

Compliance with emissions laws and regulations is a condition of the operating permit for

the vehicle/equipment.

Engines with BlueTec® exhaust gas aftertreatment must be operated with AdBlue®/

DEF in order to meet the emissions laws and

regulations.

The operating permit is invalidated if the vehicle/equipment is operated without AdBlue®/

DEF. The legal consequence of this is that

operation of the vehicle/equipment is no longer permitted. This may be an offence or a

breach of road traffic regulations in certain

countries. Special concessions granted

either at the time of purchase or to reduce

operating costs of the vehicle/equipment,

e.g. reduced taxes or tolls, may also be rendered retroactively invalid. This can be the

case in the country of registration. Or also in

another country where you operate the vehicle/equipment.

This normally affects the following operating

states:

R

driving without AdBlue®/DEF

R

the permissible nitrogen oxide (NOx)

thresholds are exceeded

R

there is a fault or emissions-relevant malfunction in the monitoring or exhaust gas

aftertreatment system

can

You

find details in the “Engine diagnostics

indicator lamp” section(Y page 94).

Fault detected in the monitoring system

If the monitoring system detects a fault in the

BlueTec® exhaust gas aftertreatment, operation is limited in accordance with the relevant

regulations (Y page 37).

Correct use

The engine may only be installed as contractually specified.

The manufacturer of the end product is

responsible for the correct installation and

compatibility of

the engine in the overall sys-

tem.

The engine may not be modified. If the engine

is modified, Mercedes-Benz and MTU do not

accept responsibility for any damage arising

as a result.

Correct use of the engine requires adherence

to the instructions in this Owner's Manual.

This also requires compliance with the maintenance intervals and the professional execution of maintenance work in accordance

with this Owner's Manual.

Transport

Legal requirements

If the engine/vehicle/equipment is not operated within the limits of the emissions laws

and regulations, it can lead to sanctions.

WARNING

G

The engine can detach and cause injuries if it

overturns or falls out.

Z

General information

10

R

To lift the engine, only use lifting points

attached to the engine.

R

Only use Mercedes-Benz transport equipment intended for this purpose.

R

Only lift and transport the engine in the

installation position. Also, observe the maximum permitted angle of 30° while lifting

the engine in and out of vehicles.

Lifting point flywheel-side (example)

Lifting point belt-side (example)

Installation

The engine may only be installed as contractually specified.

The manufacturer of the end product is

responsible for the correct installation and

compatibility of

the engine in the overall sys-

tem.

Observe the sections "Correct use"

(Y page 9) and "Modification and changes to

the engine" (Y page 7).

The Operating Instructions contains information required

for installation in the "Technical

Data" section" (Y page 101).

Please consult a Mercedes-Benz or MTU

Service Centre if you have any questions

(Y page 11).

Information on the implied warranty

A well-developed network of Mercedes-Benz

and MTU

Service Centres is available to carry

out maintenance work.

Mercedes-Benz and MTU Service Centres:

R

have special equipment and tools as well

as specialists who receive continuous

training

R

guarantee that your engine is repaired and

maintained thoroughly and expertly

R

carry out all repairs within the framework

of the engine warranty and the implied warranty

R

carry out all maintenance work expertly

R

confirm in the Maintenance Booklet that

the maintenance work has been carried out

at the required time

R

handle warranty claims that are admissible

according to the sales contract

Please observe the instructions and recommendations as well as the maintenance services in the Maintenance Booklet. Please

observe these instructions even if you let a

third party use and care for your engine. This

is the only way to ensure that you do not lose

your entitlements.

If the prescribed maintenance work is not

carried out, claims can only be decided after

the manufacturer has inspected the claim.

General information

11

During the engine warranty period in particular, have

the prescribed maintenance service

carried out as follows:

R

regularly

R

punctually

R

at a qualified specialist workshop which

has the necessary specialist knowledge

and tools to carry out the work required.

Mercedes-Benz recommends that you use

a Mercedes-Benz or MTU Service Centre

for this purpose. In particular, work relevant to safety or on safety-related systems

must be carried out at a qualified specialist

workshop.

If there are legal requirements on exhaust gas

aftertreatment, please note that:

R

maintenance on the engines must be carried out according to specific regulations

and using special measuring devices.

R

it is prohibited to modify or tamper with

components relevant to emissions.

All Mercedes-Benz and MTU Service Centres

are aware of the relevant regulations.

Maintenance work does not include repair

work. Repair work requires a separate order.

You may also consult a Mercedes-Benz or

MTU Service Centre for further information.

Always have the following work on the vehicle

carried out

R

work relevant to safety

R

service and maintenance work

R

repair work

R

modifications such as installations or con-

at a qualified specialist workshop:

versions

R

work on electronic components

Please have warranty and ex gratia work carried out at authorised workshops/Service

Centres.

R

For on-highway applications, contact a

Mercedes-Benz Service Centre.

R

For off-highway applications, contact an

MTU or MTU-authorised Mercedes-Benz

partner.

Qualified specialist workshop

A qualified specialist workshop has the necessary specialist knowledge, tools and qualifications to

carry out the work required on the

engine to a professional standard. This is

especially important for work relevant to

safety.

A qualified specialist workshop must carry

out the required service, maintenance and

repair work and document it according to the

specifications of Daimler AG. Failure to comply with these specifications could lead to the

loss of warranty entitlements.

Mercedes-Benz recommends that you use a

Mercedes-Benz or MTU Service Centre.

Z

12

Exterior view ....................................... 14

General information ............................ 21

13

At a glance

Exterior view

14

Exterior view

Engine overview

At a glance

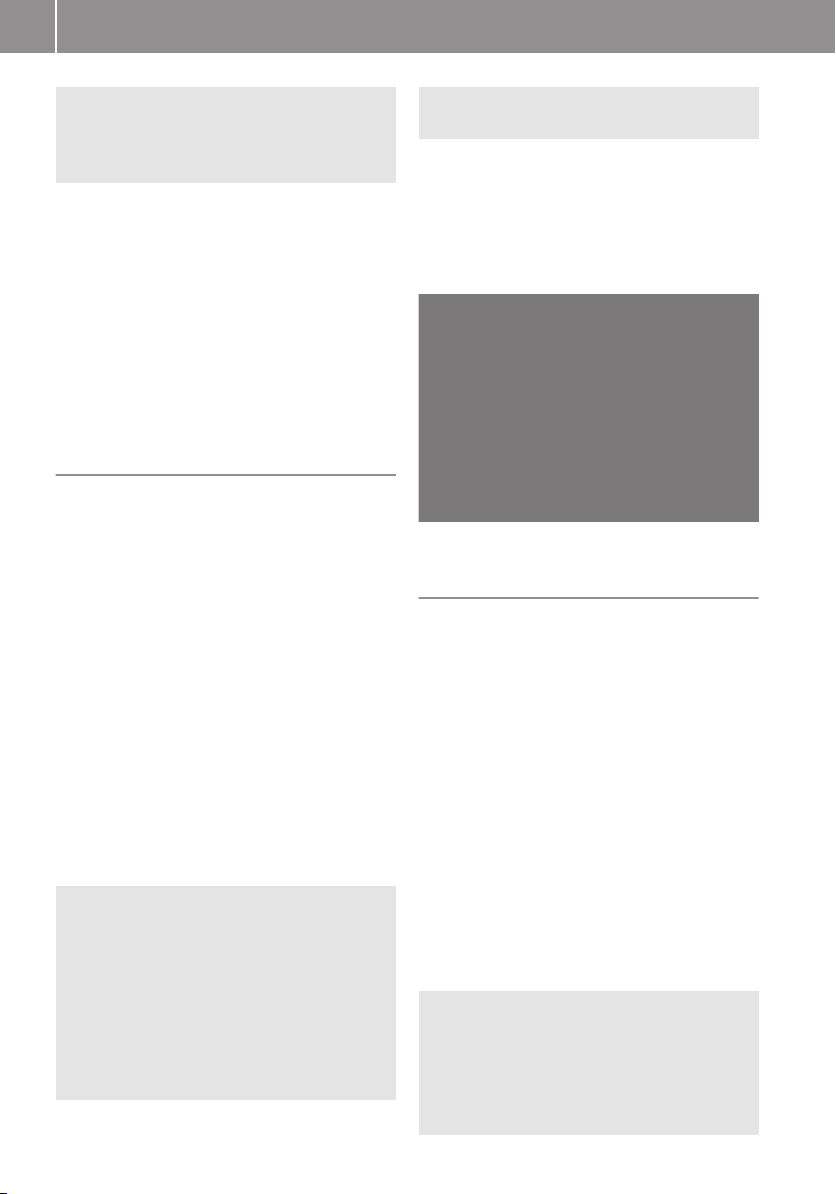

Engine overview OM 904 LA

:

Filler neck

;

Stop button

=

Start button

?

Air compressor

A

Power-steering pump

B

Engine control (MR) control unit

C

Oil dipstick

D

Refrigerant compressor

E

Tensioning pulley

F

Coolant pump

G

Fuel prefilter

H

Fuel filter

Exterior view

15

At a glance

Engine overview OM 904 LA

:

AdBlue®/DEF metering unit

;

Charge air pipe of the charge-air cooler

=

Charge air pipe to the charge-air cooler

?

Crankcase ventilation hose

A

Oil filter

B

Tensioning pulley

C

Alternator

D

Starter

E

Intake air inlet

F

Engine brake

Exterior view

16

At a glance

Engine overview OM 906 LA

:

Filler neck

;

Stop button

=

Start button

?

Air compressor

A

Power-steering pump

B

Engine control (MR) control unit

C

Oil dipstick

D

Refrigerant compressor

E

Tensioning pulley

F

Fuel filter

G

Coolant pump

H

Fuel prefilter

I

Coolant outlet to the radiator

Exterior view

17

At a glance

Engine overview OM 906 LA

:

AdBlue®/DEF metering unit

;

Charge air pipe of the charge-air cooler

=

Charge air pipe to the charge-air cooler

?

Crankcase ventilation hose

A

Oil filter

B

Tensioning pulley

C

Alternator

D

Starter

E

Intake air inlet

F

Exhaust gas turbocharger

G

Engine brake

Exterior view

18

Sensors overview

Sensors, general

At a glance

Example: OM 926 LA

:

Oil temperature

;

Oil pressure

=

Coolant temperature

?

Charge-air temperature/charge-air pressure

A

TDC sensor (on camshaft gear)

B

Crankshaft position sensor (on flywheel)

C

Oil level

D

Fuel temperature

AdBlue®/DEF components

Exterior view

19

At a glance

BlueTec® sensors, overview OM 924 LA

:

Valve preheating, AdBlue®/DEF system

;

Silencer

=

Temperature and humidity sensor (air filter, clean air side)

?

Metering unit

A

Temperature sensor downstream of catalytic converter

B

NOx sensor

C

Temperature sensor upstream of catalytic converter

D

SCR frame module

E

Supply unit

F

AdBlue®/DEF filter

G

AdBlue®/DEF tank

Exterior view

20

At a glance

BlueTec® sensors, overview OM 926 LA

:

Valve preheating, AdBlue®/DEF system

;

Silencer

=

Temperature and humidity sensor (air filter, clean air side)

?

Metering unit

A

Temperature sensor downstream of catalytic converter

B

NOx sensor

C

Temperature sensor upstream of catalytic converter

D

SCR frame module

E

Supply unit

F

AdBlue®/DEF filter

G

AdBlue®/DEF tank

General information

21

At a glance

BlueTec® sensors and test connection on the metering unit. Example: OM 926 LA

:

AdBlue®/DEF pressure sensor

;

AdBlue®/DEF temperature sensor

=

Pressure sensor for compressed air

?

Metering unit test connection

A

Metering unit heater

B

Metering valve

General information

Description of the engine

The engine is a water-cooled four-stroke diesel engine with direct injection.

The cylinders

inder has two inlet valves and one outlet

valve.

Each cylinder has its own fuel injection pump

(unit pump) with a short high-pressure fuel

injection line to the multi-hole nozzle at the

centre of the combustion chamber. The unit

are arranged in a row. Each cyl-

pumps sit directly in the crankcase and are

driven by the camshaft.

The engine is equipped with exhaust gas turbocharger and intercooler as standard. The

engine can

brakes (brake valve and constant throttle

valves).

It is a low-emission engine. Start of injection,

injection period and injection quantity are

controlled entirely electronically.

be equipped with optional engine

General information

22

Electronic drive control

The engine has a fully electronic control system which,

along with the engine and its associated sensors, consists of the following components:

R

the engine control unit (MR) and

R

the drive control unit (FR) and/or other

At a glance

vehicle-specific control units, e.g. ADM

R

SCR frame module (only for engines with

BlueTec® exhaust gas aftertreatment)

The control units are interconnected by a

CAN line (Controller Area Network line) which

facilitates the exchange of all necessary data.

In addition to the engine and the BlueTec

exhaust gas aftertreatment, the electronic

engine control also monitors itself. Depending on the malfunctions/failures that occur,

a safety and emergency mode (Y page 8) may

be automatically selected.

For vehicle engines, the electronic engine

control only allows the engine to be started

when the transmission is in neutral.

Engine control unit (engine resident)

The engine control unit is on the left side of

the engine.

These values are analysed together with data

the

from

engine sensors. They are compared

with the charts or characteristic curves

stored in the engine control unit.

Data from the sensors derives from, e.g.:

R

charge-air pressure and charge-air temperature

R

coolant temperature

R

fuel temperature

R

oil pressure

Start of injection, injection period and injection quantity are calculated on this basis and

the unit pump is controlled via the solenoid

valve accordingly.

®

If BlueTec® exhaust gas aftertreatment is

available, the associated sensors are also

analysed and the AdBlue®/DEF dosage is

controlled.

i

To obtain a replacement engine control

unit, you will require all the data on the

control unit type plate.

Example: OM 926 LA engine control unit

The engine control unit processes values

from the

FR (drive control) unit and the ADM.

These are, for example, the value from the

position sensor (accelerator pedal), the

engine brake or engine start/stop, etc.

Control unit type plate

:

Data record

;

Certification no.

=

Engine number

?

Equipment code

General information

23

FR (drive control) unit or ADM (on the

equipment)

The engine can be adapted to the various

operation-specific requirements

using the FR

(drive control) unit or the adaptation module

ADM.

Example: FR (drive control) unit

Various operation specific data such as

engine idling speed, maximum working

engine speed or speed limiter are stored in

the FR (drive control) unit or the ADM.

The FR (drive control) unit or the ADM

receives data from:

R

user (values from the position sensor,

engine start/stop)

R

engine brake switch

R

other systems (e.g. acceleration skid control)

R

engine control unit (e.g. oil pressure and

coolant temperature)

Values for the engine control (MR control

unit) are derived from this and conveyed via

the CAN line.

The FR (drive control) unit or the ADM controls various displays, e.g. the electronics

warning lamp, the engine brake and the constant throttle valve.

If the electronic engine control detects a

fault, the fault code is saved in the control

units. It

can be read out with the corresponding diagnostic testers (STAR DIAGNOSIS or

minidiag2).

In addition, the ^ electronics warning

lamp is switched on.

i

Mercedes-Benz diagnostic

testers can be

connected to the 14-pin diagnostic socket

on the equipment or with the EU compliant

service connector. Both fault memory and

stored engine data can be read out using

this equipment.

SCR frame module (on the frame)

SCR frame module

The SCR frame module reads signals and

transmits them

via the CAN line to the engine

control unit.

The following signals are read:

R

Temperature sensor upstream of the SCR

catalytic converter

R

Temperature sensor downstream of the

SCR catalytic converter

R

NOx sensor downstream of the SCR catalytic converter

R

Combination sensor for level and temperature in the AdBlue®/DEF tank

R

Combination sensor for humidity and air

charge temperature

Example: diagnostic socket

At a glance

General information

24

At a glance

Example: EU compliant service connector

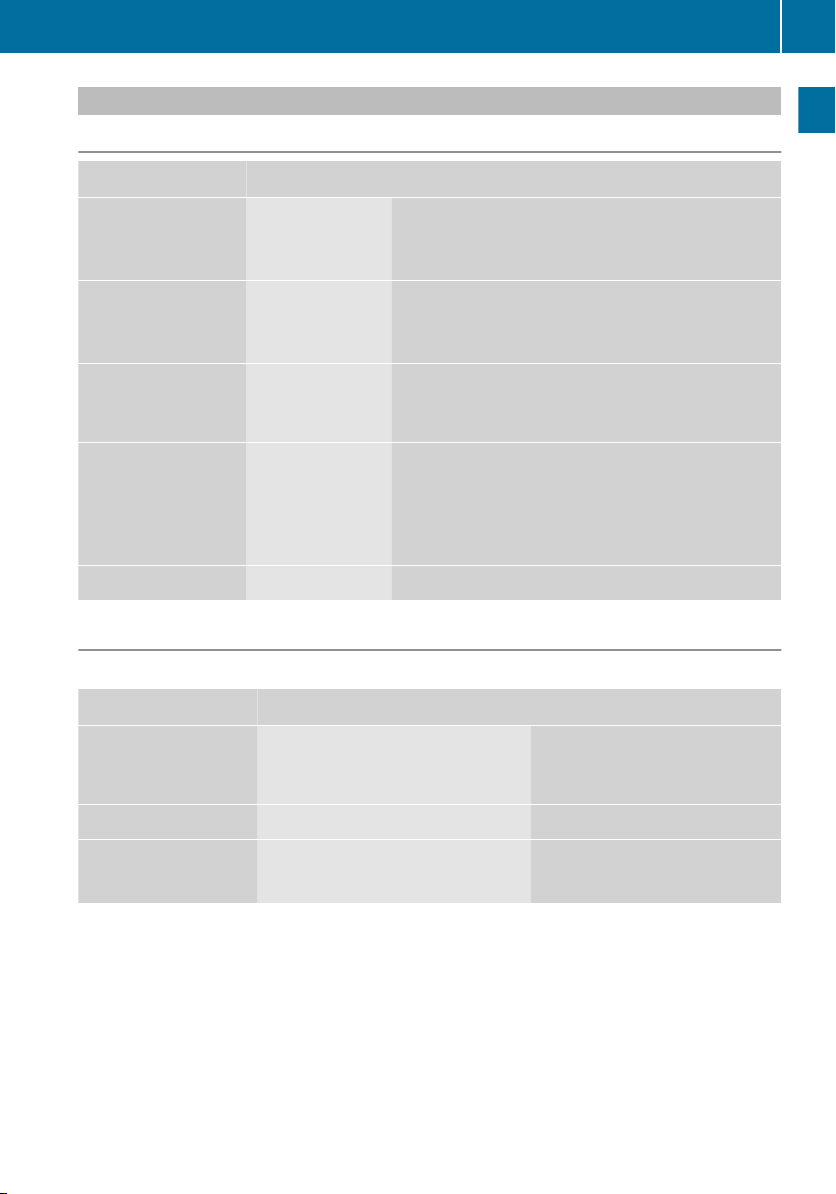

Warning and indicator lamps

Engine, general

General information

25

Symbol

;

1

Reason for display/displayed message

Fault lamps Impermissible operating conditions

Text in the engine

symbol: "CHECK"

;

STOP lamp

Serious fault

2

Text in the engine

symbol: "STOP"

k

#

Electronic

engine control

malfunction

Charge current

(power generation)

Lights up in the event of an electronic engine control malfunction. Engine may only be operated in

emergency mode.

Lights up in the event of a charge current (power

generation) malfunction.

If the warning lamp does

not go out after starting the engine, or if it goes

on while the engine is running, the alternator or

poly-V-belt is faulty.

%

BlueTec® exhaust gas aftertreatment on-highway version

Cold-start aid Lights up if the cold-start aid is active.

3

The following indicator lamps could be available on the instrument panel:

Symbol

þ

1

Reason for display/displayed message

AdBlue®/DEF level

Fault message/action required

(warning before reduction in

operating performance)

;

È

NOx bulb

Engine indicator lamp Exhaust system fault

Reduction in operating perform-

Active torque limitation

ance

At a glance

1

Symbols may vary depending on the vehicle/equipment version.

2

In addition, a warning tone may sound.

3

On-highway: vehicles with MOT approval.

General information

26

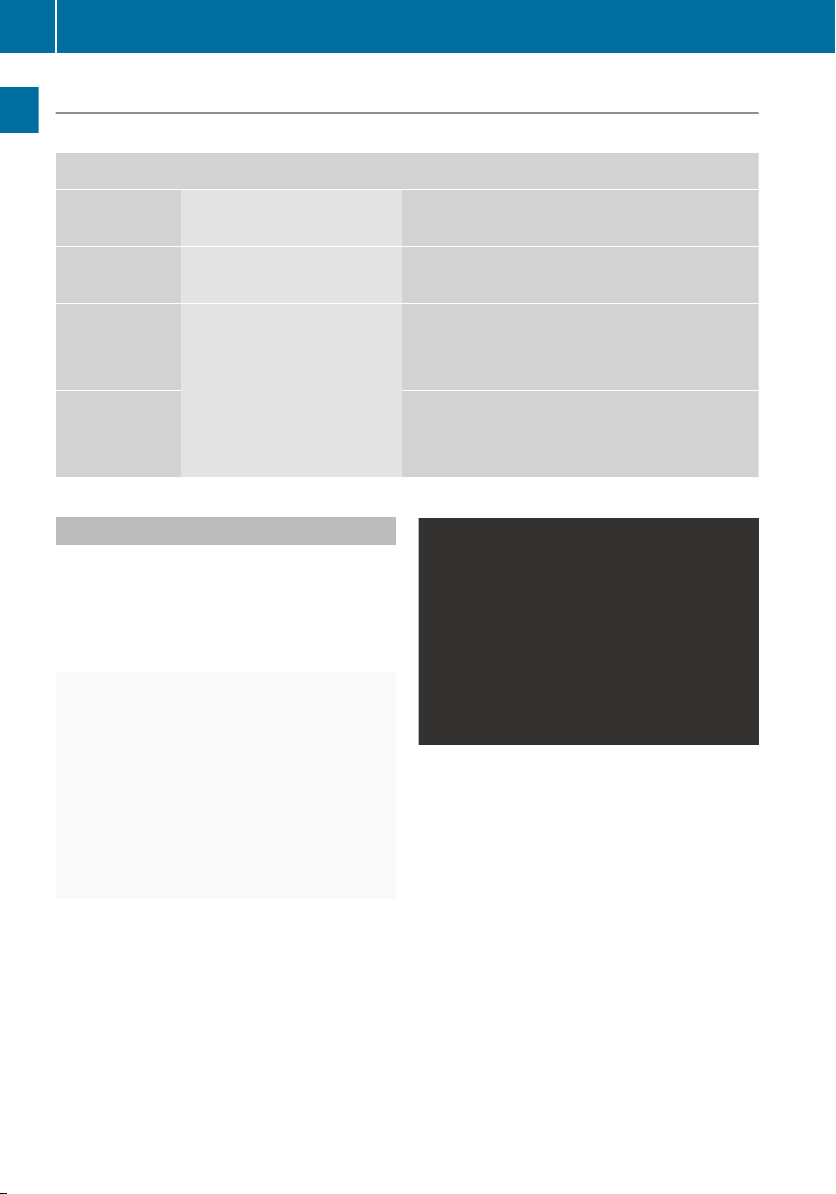

BlueTec® exhaust gas aftertreatment off-highway version

4

The following indicator lamps could be available on the instrument panel:

Symbol

þ

1

Reason for display/displayed message

AdBlue®/DEF level

Fault message/action required (warning

before reduction in operating performance)

At a glance

!

È

lights up

Check engine/exhaust gas

aftertreatment

Torque/speed limiter

2

active

Fault and misuse (failure in the monitoring

system)

Slight reduction in operating performance

(level 1)

È

flashes

Significant reduction in operating performance

(level 2)

Continuous brake

If increased braking power is required, the

engine can be equipped with a brake valve

downstream from the exhaust gas turbocharger in

conjunction with constant throttle

valves.

OM 926 LA constant throttle valve

:

;

The brake valve uses exhaust back pressure

to increase braking power. The constant

throttle

OM 904 LA/OM 924 LA constant throttle valve

:

Constant throttle valve

;

Pneumatically-actuated line

compression pressure in the power stroke

(third stroke), whilst the compression (second stroke) is not significantly affected.

The constant throttle valve is an additional

valve in the cylinder head. When open, the

constant throttle valve establishes a connection between the combustion chamber and

4

Off-highway: vehicles without MOT approval.

1

Symbols may vary depending on the vehicle/equipment version.

2

In addition, a warning tone may sound.

Constant throttle valve

Hydraulically-actuated line

valves

bring about a reduction of the

General information

27

exhaust port. This brings about the desired

decompression during the power stroke.

When the engine brake is activated, the constant throttle valves are opened. For

OM 904/OM 924 engines, the actuation is

pneumatic. For OM 906/OM 926

engines,

the actuation is hydraulic. The brake valve on

the exhaust gas turbocharger is also closed.

The engine brake is actuated by the FR (drive

control) unit (Y page 23) or the ADM.

The engine brake is always deactivated below

900 rpm. This prevents the engine from stalling. The engine brake is automatically deactivated even if the position sensor (e.g. accelerator pedal) is in use.

i

In emergency mode (constant engine

speed), the engine brake can only be activated in overrun mode at increased engine

speed. Once the constant engine speed is

reached, the engine brake is automatically

deactivated again.

Cold-start aid

The cold-start

aid makes it easier to start the

engine at low outside temperatures (below

–15 †); it is activated when the outside temperature falls below –4 †.

Environmental note

H

At outside temperatures below about –4 †

the cold-start aid minimises emissions (after

starting

load on the starter motor and batteries and

enables the engine to be started more rapidly.

For this reason you should only start the

engine after the % indicator lamp goes out.

engine). In addition, it reduces the

the

The cold-start aid is automatically deactivated if:

R

the engine

is not started within 30 seconds

of the % indicator lamp going out.

R

the engine is started while the % indicator lamp is still lit.

R

the coolant temperature reaches around

0 † while the engine is running.

At a coolant temperature above approximately –4 †, the % indicator lamp goes

out after approximately 2 seconds (function

check). At a coolant temperature below

approximately –4 †, the % indicator lamp

goes out after approximately 20 seconds.

Have the cold-start aid checked and repaired

at a qualified specialist workshop. MercedesBenz recommends that you use a MercedesBenz or MTU Service Centre for this purpose

(Y page 11). Work relevant to safety or on

safety-related systems must be carried out at

a qualified specialist workshop.

At a glance

X

To activate the cold-start aid: turn the

vehicle key

to the drive position in the igni-

tion lock.

The % indicator lamp lights up in the

instrument panel.

X

After the % indicator lamp goes out,

start the engine within 30

seconds.

Z

28

Safety precautions .............................. 30

Staff qualifications ............................. 30

Organisational measures ................... 30

29

Safety

Organisational measures

30

Safety precautions

Damage to the engine can also lead to personal injury.

In order to avoid engine damage,

the following safety precautions must be

adhered to.

Safety

Safety precautions

R

Only start

the engine when the batteries

are firmly attached.

R

Do not disconnect the batteries when the

engine is running.

R

Do not use a rapid charger to start the

engine.

R

Only perform the jump-starting procedure with separate batteries.

R

Note, the battery terminals must be disconnected when rapid charging the batteries.

R

Observe the operating instructions of the

rapid battery charger.

R

Please note, when carrying out electric

welding work, that the batteries must be

disconnected and both of the cables ("+"

and "-") must be firmly attached to each

other.

R

The control unit connectors may only be

connected/disconnected when the electrical system is switched off.

R

Incorrect control unit-power supply

polarity (e.g. by connecting up the batteries incorrectly) can cause irreparable

damage to the control units.

R

Tighten diesel injection system connections to the prescribed tightening torque.

R

If temperatures above 80 † are to be

expected (e.g. in a drying oven), the control unit on the engine must be removed.

R

Only use the appropriate testing probes

when taking measurements from electrical connectors (e.g. a Mercedes-Benz

connection set). Telephones and twoway radio devices that are not connected

to an external aerial, can cause malfunc-

tions in the vehicle electronics and thus

endanger the operating safety of the

engine.

Staff qualifications

WARNING

G

If maintenance and repair work on the engine

is

carried out correctly, the operation and

not

safety may be affected, which can result in

accidents and personal injury.

Always have work on or modifications to the

engine carried out at a qualified specialist

workshop that has the necessary special

skills and tools for the work required.

Mercedes-Benz recommends a MercedesBenz or MTU Service Centre.

The engine should only be operated, maintained and repaired by trained personnel who

have been briefed and authorised by the operator. The minimum legal age for personnel

carrying out maintenance and repair work

must be observed.

Organisational measures

The responsibilities for operation, maintenance and

repairs are to be determined by the

operator. Give the Operating Instructions and

the Maintenance Booklet to the personnel

that are charged with operating or carrying

out work on the engine.

WARNING

G

Before operating the engine, please read

these

Operating

read the operating instructions of the vehicle

or the machine to which the engine is fitted.

You may not recognise dangers and may

injure yourself or others.

Instructions. Please also first

Instruct personnel on how to operate the

engine using the Operating Instructions.

When doing so, put special emphasis on

safety-relevant information. This is particu-

larly important for personnel that only work

occasionally on the engine.

Always keep the Operating Instructions and

the Maintenance Booklet readily accessible,

in the area of engine operation.

In addition to the Operating Instructions,

other general, country-specific, legal and

other binding

tion and environmental protection must be

adhered to.

regulations on accident preven-

Organisational measures

31

Safety

Z

32

Operation ............................................. 34

Continuous brake ................................ 40

Driving tips .......................................... 40

Refuelling ............................................. 41

Winter operation ................................. 43

33

Driving mode/working mode

Operation

34

Operation

Preparation for operation

At the factory, the engine is filled with 5W30

initial operation oil that complies with Sheet

225.6 of the Mercedes-Benz Specifications

for Service Products.

These high-quality engine oils are beneficial

running-in process. They also allow you

to the

to make the first oil change in accordance

with the applicable oil change intervals for

normal operation. This eliminates the need

for special initial operation oils and the additional oil change otherwise required.

The extended maintenance intervals can only

be observed if engine oils complying with

Sheet 228.5 of the Mercedes-Benz Specifications for Service Products are used.

Driving mode/working mode

X

If the engine is at normal operating temperature: wait about one minute. If the

engine is

X

Check the engine oil level with oil dip-

cold: wait about 5 to 10 minutes.

stick ;. The oil level should be between

the upper and lower marks on oil dipstick ;.

X

If necessary, add oil via filler neck :.

Do not add too much oil when topping up.

Topping up with too much oil can result in

damage to the engine or the catalytic converter. Drain or siphon off excess oil.

Adding coolant

X

Information on coolant mixture ratio

(Y page 76).

X

Filling the cooling system (Y page 48).

Refuelling

Use summer or winter fuel depending on the

season (Y page 50).

!

When refuelling ensure that conditions

are clean and do not allow water to enter

the tank and thus contaminate the fuel.

Example: OM 926 LA

:

Filler neck

;

Oil dipstick

Engine oil level

Check the engine oil level on a regular basis,

e.g. every week or each time you refuel.

X

Park the vehicle/equipment on a horizontal

surface.

X

Engage the parking brake.

X

Switch off the engine.

Refuelling with AdBlue®/DEF

Only use AdBlue®/DEF that complies with

DIN 70070/ISO

22241. Do not use any additives. If AdBlue®/DEF comes into contact

with painted or aluminium surfaces when filling the tank, rinse the affected surfaces

immediately with plenty of water.

Bleeding the fuel system

The bleeding of a fuel system that has been

run dry takes place when the engine is next

started

refuelling. Automatic continuous

after

bleeding takes place in the filter.

i

The battery must be sufficiently charged

when the engine is started in order for the

fuel system to be bled.

i

Use the integrated hand pump

(Y page 68) to bleed the heated-fuel prefilter with

water separator mounted on the

vehicle or equipment.

Starting the engine for the first time

Preparation

Carry out the work listed under "Preparing for

operation" before operating the engine for

the first time (Y page 34).

Observe the information contained in the

equipment/vehicle manufacturer's

operating

instructions.

X

Connect a power supply.

X

Switch on the ignition.

X

Start the engine using the key in the ignition

lock or the start button on the engine. Do

not depress the accelerator or clutch pedal

while doing so. For equipment, the neutral

position must be engaged.

As a safety function, the electronic engine

control system facilitates the possibility of

only allowing the engine to be started when

the transmission or equipment is in neutral.

WARNING

G

Make sure you do not touch any hot or moving

engine components (e.g. exhaust manifold,

poly-V-belt, fan) when the engine is running.

You could injure yourself.

Be aware of the road and traffic situation

when working on public roads and secure

your position accordingly.

WARNING

G

There is a danger of limbs being caught, pulled

in

thereby crushed or severed by rotating

and

engine parts.

Operation

Therefore you should:

R

R

R

G

When opening the coolant expansion tank,

there is a risk of scalding due to hot coolant

spraying

expansion tank are pressurised when the

engine is at operating temperature. Wear

gloves and eye protection.

Only open the coolant expansion tank when

the coolant temperature is below 50 †.

G

Coolant contains glycol and is therefore toxic.

Do not swallow the coolant. See a doctor

immediately if you swallow coolant.

Make sure that coolant does not come into

contact

contact with eyes, rinse immediately with

plenty of clean water. Clean affected areas of

skin and clothing with soap and water immediately. Change any affected clothing immediately.

Starting the engine for the first time

X

To check coolant level: leave the engine

running at a moderate engine speed for

around five minutes.

X

If the coolant temperature is less than

50 †, check the coolant level again. Add

coolant.

If a heating system is connected to the cooling system, all heating system valves must be

opened while the cooling system is being topped up. Otherwise, there might be too little

safe distance between yourself and

keep a

rotating engine parts, including when the

engine is being started.

wait until all engine parts have stopped

moving before carrying out any work on the

engine.

wear work clothing which is fastened and

close-fitting. Wear a hair net if necessary.

Remove jewellery such as watches and

necklaces.

WARNING

The cooling system and coolant

out.

WARNING

skin, eyes or clothing. In case of

with

35

Driving mode/working mode

Z

36

Operation

coolant in the coolant circuit after it is filled.

Only close

the heating system valves once the

engine has been running for a brief period

and, where applicable, the coolant has been

topped up.

X

Check the engine for leaks.

X

Check all hose fittings, hose clamps and

pipe connections on the engine as well as

the oil feed and return lines on the exhaust

gas turbocharger for leaks and firm seating.

X

Around five minutes after switching off the

engine, check the engine oil level with the

dipstick.

The oil level should be between the upper

and lower marks on the dipstick.

X

Check the seating of the bracket secured

to the engine.

X

Check the tightness of bolts on the exhaust

manifold, engine mountings, coolant pump,

starter motor and air compressor.

Driving mode/working mode

Starting and stopping the engine with

the key

X

To start the engine: turn the key in the

ignition lock to drive position 2.

X

Vehicles/equipment with a hot-water auxiliary heater: preheat the engine at outside

temperatures below −20 † before starting.

X

Vehicles/equipment with cold-start aid:

wait until the % indicator lamp in the

instrument cluster goes out.

X

Turn the key to start position 3 in

the ignition lock. While doing so, do not depress

the accelerator pedal. For equipment, keep

the idling function active.

X

When the engine has started, release the

key.

Depending on the vehicle/equipment, the

idling speed is automatically adjusted to

around 600 rpm. Depending on the nature

work to be performed, higher engine

of the

idling speeds are also possible.

X

If the engine does not start, interrupt the

starting procedure after no more than

30 seconds.

X

Turn the key in the ignition lock back to the

stop at key position g.

X

Repeat the starting procedure after approximately

X

After three starting attempts, wait approx-

one minute.

imately three minutes before trying again.

X

Observe the oil pressure gauge immediately after having started the engine.

Example: ignition lock

g

To insert/remove the vehicle key

1

Steering unlocked/radio position

2

Drive position (ignition)

3

Start position

X

Secure the vehicle/equipment against rolling away.

X

Shift the transmission to neutral or engage

neutral on the equipment.

!

After starting the engine, let it run at

engine idling

speed until the oil pressure is

displayed. If no oil pressure is displayed

after approximately 10 seconds, switch off

the engine. Determine the cause. The operating safety of the engine is jeopardised.

Starting and stopping the engine with

the start/stop button

X

Switch on the ignition.

X

Shift to neutral.

i

The start

button will not function if a gear

is engaged or the equipment is in an operating position.

Operation

37

Engine with one button

X

To start the engine: press

start/stop but-

ton :.

The engine starts and runs at engine idling

speed.

X

To start the engine and increase the

engine speed: press and hold start/stop

button :.

The engine

starts and runs at engine idling

speed. After about three seconds, the

engine speed increases.

X

Hold down start/stop button : until the

desired engine speed is reached.

After releasing start/stop button :, the

engine

continues

to run at the currently set

speed. The engine speed can be increased

up to the limiting speed.

X

To stop the engine: press start/stop button : again.

The engine switches off.

X

To start the engine: press start button ;.

The engine

starts and runs at engine idling

speed.

X

To increase the engine speed: while the

engine is running, press start button ;

again and hold it down until the desired

engine speed is reached.

After releasing start button ;, the engine

run at the currently set speed.

continues

to

The engine speed can be increased up to

the limiting speed.

X

To stop the engine: while the engine is

running, press stop button :.

The engine switches off.

X

To turn the engine over without starting

it: press and hold start button ; and stop

button : at the same time.

The engine turns over without starting.

X

Release start button ; and stop button :.

The engine remains at a standstill.

Operational monitoring

Charge current

The charge current indicator lamp must go

out after the engine has started.

Driving mode/working mode

Engine with two buttons

Example: charge current indicator lamp

If the #

indicator lamp does not go out, or

if it lights up while the engine is running,

switch off the engine and check the poly-Vbelt.

Z

38

Operation

!

Make sure that the poly-V-belt contact

surfaces are not damaged (e.g. torn), oily

or glazed, as this could cause the poly-Vbelt to slip. Do not run the engine without

a poly-V-belt.

Otherwise, the alternator and

coolant pump are not driven, which results

in engine damage.

Further information can be found in the

“Checking the poly-V-belt for wear”

(Y page 66) and “Replacing the poly-V-belt”

sections (Y page 97).

Electronic engine control

The electronics warning lamp must go out

after the engine has started.

Driving mode/working mode

Example: electronics warning lamp

If the electronics warning lamp does not go

out, or if it lights up while the engine is running, there is a malfunction in the electronic

engine control system.

Each malfunction

its own fault code. Temporary faults are also

stored.

Fault codes can be read using the MercedesBenz diagnostic tester STAR DIAGNOSIS or

minidiag2 (Y page 8). If the electronics warning lamp lights up while the engine is running,

read or determine the fault code.

is stored in the system with

Oil pressure

!

Once the

operating temperature has been

reached, the engine oil pressure may not

drop below the following values:

R

2.5 bar at rated speed

R

0.5 bar at idling speed

If the oil pressure falls below these values,

stop the engine and trace the cause.

Operating restrictions with on-highway

applications

The electronics monitor:

R

the display, level and quality of the

AdBlue®/DEF reducing agent

R

the efficiency of the catalytic converter in

accordance with the permitted thresholds

for nitrogen oxide emissions (NOx).

Requirements for vehicles

The engine output can be automatically

the

reduced

first time the vehicle is stationary

if:

R

the AdBlue®/DEF reservoir is empty

R

the permitted thresholds for nitrogen oxide

(NOx) emissions are exceeded.

Torque reduction

If the AdBlue®/DEF is used up or if there is a

fault, the indicator lamp in the instrument

panel lights up or flashes. The display also

shows a message. The engine output is only

reduced after a fault is detected and confirmed after up to four journeys.

The degree of torque reduction depends on

the vehicle category:

R

vehicles above 7.5 t: torque reduction by

approximately 40%

R

vehicles below 7.5 t: torque reduction by

approximately 25%

Fault in the monitoring system

If a fault is detected in the electronic monitoring of the exhaust gas aftertreatment sys-

Operation

39

tem, the torque is reduced automatically after

36 operating hours of the engine.

Operating restrictions for off-highway

engines

Minor operating restriction

The available torque is reduced within a

period of 10 minutes. The torque is reduced

across the entire engine speed range to 80%

of the maximum torque (see the diagram

below).

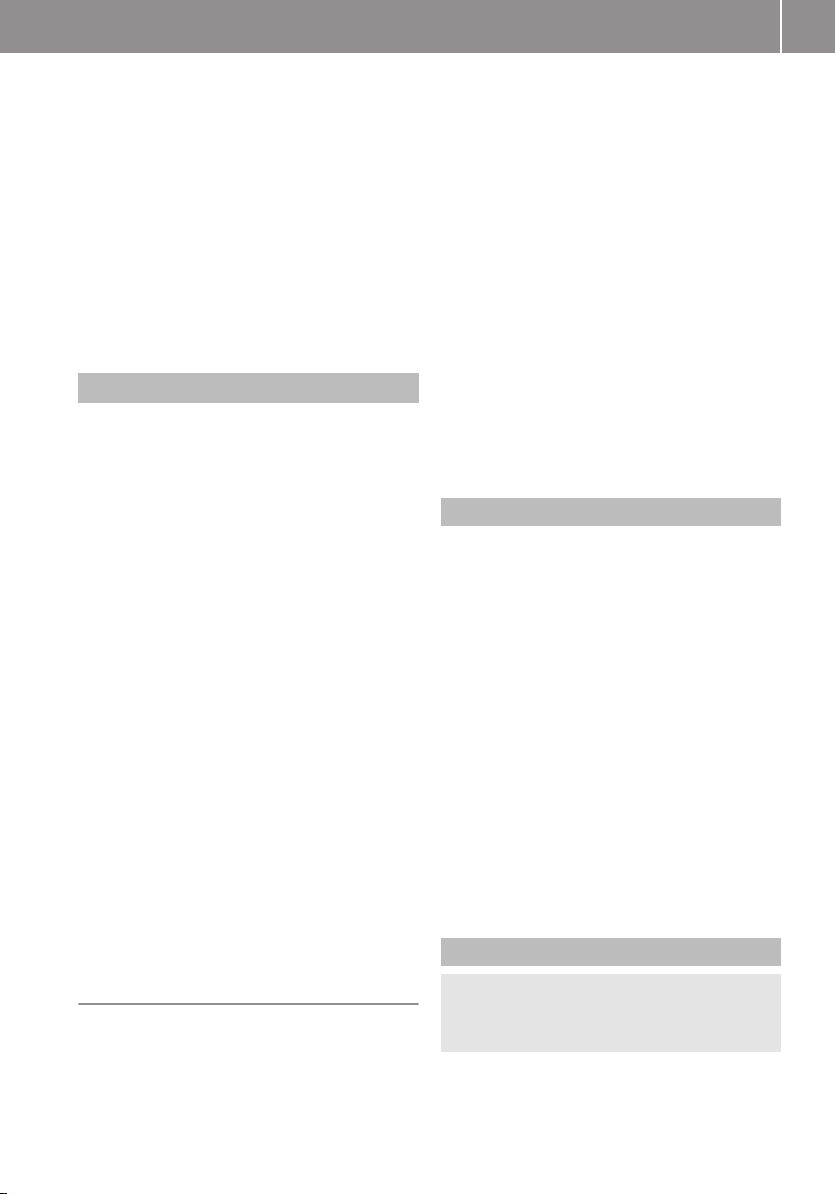

Reduction in output during minor operating restriction

Major operating restriction

The transition between a minor and a major

operating restriction

is achieved by a gradual

reduction in engine speed and torque. The

reduction takes place over a period of 60

minutes.

R

The engine torque is reduced from 80% of

the rated value by 1% per minute to 20% of

the rated value.

R

Simultaneously, the engine speed is

reduced over the period of 60 minutes from

the initial value to 1000 rpm.

Emergency override

A button is optionally available for overriding

the operating restriction in an emergency.

The override function makes the full engine

output available for up to 30 minutes and can

be used a maximum of three times. The override can only be activated between the start

of the operating restriction system and the

end of the major operating restriction. The

override function is also used to reset the

operating restriction after the fault is corrected. This

is the case, for example, after filling

up with AdBlue®/DEF of the correct quality.

Deleting the fault memory

A fault stored in the fault memory because of

the operating restriction system cannot be

deleted with a conventional reading device.

Faults can only be deleted using the Daimler/

MTU maintenance system.

Repeated violations

In the event of repeated violations, the periods for the trigger signals and continuous

reduction are shortened. When a fault is eliminated (for example the NOx sensor is

replaced or reconnected), the operating

restrictions are reset. Normal operation can

be resumed. If a fault occurs again because

of the operating restriction system within

40 hours, the periods of the operating restriction system are shortened.

Example: if a fault reoccurs within 40 hours

of the first elimination, the time until the operating restriction comes into effect is halved.

If the same fault occurs within 40 hours of the

second fault being rectified, the times are

shortened to a quarter.

Stopping and switching off the engine

WARNING

G

When switching off the equipment or parking

the vehicle, make sure that the exhaust system does not come into contact with combustible objects, e.g. dry leaves, grass or

other highly flammable materials.

X

Park the vehicle/equipment.

X

Secure the vehicle/equipment against rolling away.

X

Shift the transmission into neutral/decouple the drive system.

Z

Driving mode/working mode

40

Driving tips

Let the engine idle for approximately two

minutes before switching off the engine if:

R

the coolant temperature is very high (over

90 †).

R

the engine

X

To switch off the engine: turn the vehicle

has been operated at full output.

key in the ignition lock back to the stop at

position u.

X

Press the start/stop button on the engine

or on the engine shutoff device on the

equipment.

X

Safeguard the vehicle/equipment against

rolling away.

!

Stop the engine immediately if:

R

the oil pressure falls or fluctuates significantly.

R

the power output or engine speed

decreases and the position of the position sensor (accelerator) remains constant.

Driving mode/working mode

R

heavy smoke is emitted from the

exhaust.

R

the coolant or engine oil temperature

rises steeply.

R

abnormal noises suddenly come from

the engine or exhaust gas turbocharger.

i

When you switch off the engine, BlueTec® exhaust gas aftertreatment automatically

the exhaust system with fresh

flushes

air. Residues of AdBlue®/DEF on the

metering unit or the injection nozzle might

otherwise impair the function of BlueTec

exhaust gas aftertreatment. Depending on

the engine's previous operating load, BlueTec® exhaust gas aftertreatment may flush

the exhaust system several times.

When BlueTec® exhaust gas aftertreatment

flushes the exhaust system, an air valve is

activated. You may then hear a hissing

sound. This hissing sound does not indicate

a leak in the compressed-air system.

Continuous brake

The airbrake

and the constantly open throttle

valves are employed as continuous brakes.

WARNING

G

Do not activate the continuous brake (engine

brake/retarder) on slippery road surfaces.

The wheels may otherwise become locked

and the vehicle could skid.

You can utilise the engine's braking effect,

particularly

R

activate the continuous brake

R

shift to a lower gear in good time

long downhill gradients, if you:

on

Driving tips

Running-in

Equipment

Observe the equipment manufacturer's running-in notes.

Vehicles

The running-in period of the engine has a significant effect on the vehicle, especially for

the:

R

service life

R

operating reliability

R

economy

Observe the following notes during the run-

®

ning-in period up to 2000 km (30 operating

hours):

R

avoid subjecting the engine to full load.

R

run-in the engine with care using differing

speeds and engine revs.

R

avoid high engine revs.

R

do not drive at more than ¾ of the maximum road speed for each gear.

R

change gear in good time.

R

do not shift down to brake the vehicle.

R

in the case of vehicles with automatic

transmission, do not press the accelerator

Refuelling

41

pedal beyond the point of resistance (kickdown) and only engage the shift ranges 4,

3, 2, or 1 when driving slowly.

After 2000

km (30 operating hours), you can

gradually bring the vehicle up to full road and

increased engine speeds.

Fuel consumption

General information

Fuel consumption depends on:

R

the type

of fuel used (diesel fuel, fatty acid

methyl ester FAME fuel)

R

the machine version

R

the operating mode

R

the operating conditions

R

the attached equipment (e.g. hydraulic

pumps, mowers, etc.)

For these reasons, exact details about any

single engine's fuel consumption cannot be

provided.

Machine version

The following components influence fuel consumption:

R

tyres (e.g. tyre pressure, tyre condition)

R

body type

R

drive train (e.g. transmission ratio)

R

additional equipment (e.g. automatic climate control, auxiliary heating)

Operating mode

Your operating mode can help to keep the fuel

consumption down:

R

anticipate road and traffic conditions.

R

avoid frequent acceleration and braking.

R

stay within the economical engine speed

range.

Operating conditions

Fuel consumption can increase due to poor

operating conditions.

Observe the following notes:

R

avoid driving in mountainous terrain.

R

do not allow the engine to idle when the

vehicle is stationary.

R

do not drive with unnecessary weight.

R

avoid frequent cold starts.

R

avoid frequent short journeys.

AdBlue® consumption

AdBlue®/DEF consumption

is between 4 and

8% of the fuel consumption, depending on

engine use.

Engine oil consumption

After running in the engine, oil consumption

may reach 0.5% of the vehicle's fuel consumption.

More arduous operating conditions and

increased distance covered could result in

engines exceeding this oil consumption

value.

Refuelling

Fuels

Important safety notes

WARNING

G

Fuel is highly flammable. Therefore, fire,

naked flames and smoking are prohibited

when handling fuel.

Deactivate the auxiliary heating when refuelling to prevent fuel vapours from igniting on

the auxiliary heating exhaust system.

Fuel is toxic and constitutes a health hazard.

Therefore, you should make sure that:

Driving mode/working mode

Z

42

Refuelling

R

fuel does not come into contact with skin,

eyes or clothing.

R

you do not inhale fuel vapours.

R

children are kept away from fuel.

If you or anyone else comes into contact with

fuel:

R

wash eyes immediately with plenty of clean

water if fuel comes into contact with the

eyes and consult a doctor.

R

clean affected areas of skin with soap and

water immediately.

R

change out of clothing which has come into

contact with fuel immediately.

R

if fuel is swallowed, a doctor should be consulted immediately.

WARNING

G

Do not use petrol to refuel vehicles with a diesel

would result in damage to the fuel system and

engine, which could lead to a vehicle fire.

Driving mode/working mode

!

AdBlue®/DEF is not a fuel additive and

Do not mix diesel with petrol. This

engine.

must not be added to the diesel tank. If

AdBlue®/DEF gets into the diesel tank, this

could lead to engine damage.

!

Do not use petrol to refuel vehicles with a

diesel engine. Even small amounts of petrol

result in damage to the fuel system and

engine.

!

If you fill the tank with the wrong fuel by

accident, do not start the engine. Otherwise, the fuel lines may be contaminated.

Notify a qualified specialist workshop and

have the fuel tank and fuel lines fully

drained.

!

Do not add any special fuel additives to

the diesel fuel or fatty acid methyl ester

FAME fuel.

Special fuel additives can lead to:

R

malfunctions

R

damage to the catalytic converter

R

engine failure

You will find further information on fuel in the

"Service products" section (Y page 50).

Environmental note

H

If fuels are handled improperly, they pose a

danger to persons and the environment. Do

not

the surface waters, the ground water or into

the ground.

fuels to run into the sewage system,

allow

Before filling the tank

X

Switch off the engine.

X

Secure the vehicle/equipment against rolling away.

X

Switch off the auxiliary heating system.

X

Observe the fuel grade (Y page 50).

!

If you are refuelling the vehicle from

drums or canisters, filter the fuel before

refuelling.

This prevents malfunctions in the fuel system caused by contaminated fuel.

i

Regularly check

the fuel prefilter with the

heated water separator for condensation

(Y page 86).

AdBlue®/DEF

Important safety notes

WARNING

G

If the AdBlue®/DEF tank

temperatures, ammonia vapours may escape.

Ammonia vapours have a pungent odour and

particularly irritate:

R

skin

R

mucous membranes

R

eyes

The vapours may cause a burning sensation

in the eyes, nose and throat as well as irritation of the throat and watering eyes.

Avoid inhaling ammonia vapours.

cap is opened at high

Winter operation

43

WARNING

G

AdBlue®/DEF must not come into contact

with skin, eyes or clothing.

R

If AdBlue®/DEF comes into contact with

your eyes

clean water immediately.

R

If AdBlue®/DEF is swallowed, immediately

rinse your mouth out with a lot of clean

water and drink plenty of water.

R

Change clothing that is soiled with

AdBlue®/DEF immediately.

R

If allergic reactions occur, consult a doctor

immediately.

Keep AdBlue®/DEF out of the reach of children.

!

The BlueTec® exhaust gas aftertreatment

or skin, rinse affected areas with

will cease to function correctly if you:

R

fill the AdBlue®/DEF reservoir with

cleaning agent or other service products

or fuels

R

mix in additives

R

dilute AdBlue®/DEF

Only use AdBlue®/DEF in accordance with

DIN 70070/ISO 22241.

Notify a qualified specialist workshop in the

event of incorrect filling.

You will find further information on AdBlue®/

DEF in the "Service products" section

(Y page 54).

Environmental note

H

Dispose of AdBlue®/DEF in an environmentally responsible manner.

Before filling the tank

X

Switch off the engine.

X

Secure the vehicle/equipment against rolling away.

X

Switch off the auxiliary heating system.

Bleeding the fuel system

If the fuel system is run dry, the system will

be bled the next time the engine is started

after refuelling. Automatic continuous bleeding takes place in the filter.

The battery

must be sufficiently charged during the starting procedure to ensure that the

fuel system can be bled.

Bleed the heated fuel prefilter with water separator mounted on the vehicle or equipment

using the integrated hand pump

(Y page 86).

Winter operation

Cold-start aids

The following

notes should be observed at the

start of the cold season.

Fuel

WARNING

G

There is an increased risk of fire when handling

fire, naked flames and sparks, and refrain

from smoking when handling fuels.

as they are highly flammable. Avoid

fuels

Use cold-resistant diesel fuel (Y page 50).

Jump-starting

WARNING

G

The use of liquid or gaseous starting aids can

cause explosions. This may result in severe

injuries.

Do not use liquid or gaseous starting aids

such

as

ether or Startpilot to start the engine.

Engine oil

When changing the oil, select an engine oil

that is

compatible with the SAE classification