New Generation of 4-Cylinder

Inline Engines, OM 651

Introduction into Service Manual

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Daimler AG · Technical Information and Workshop Equipment (GSP/OI) · D-70546 Stuttgart

Mercedes-Benz Service

Introduction of New Generation of 4-Cylinder

Inline Engines, OM 651

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Information and copyright

Ordering workshop information

All printed workshop information from GSP / OI, such as Introduction into Service

Manuals, System Descriptions, Function Descriptions, Technology Guides, Technical Data Manuals and adhesive labels, can be ordered as follows:

Within Germany

Through our GSP / OI Shop on the Internet

Link: http: / / gsp-ti-shop.de

or alternatively

E-mail: customer.support@daimler.com

Phone: +49-(0)1805 / 010-7979

Fax: +49-(0)1805 / 010-7978

Outside Germany

Please get in touch with the contact person responsible for your market.

Product portfolio

You can also find comprehensive information on our complete product portfolio

in our Internet portal.

Link: http: / / open.aftersales.daimler.com

Questions and suggestions

If you have any questions or suggestions concerning this product, please write to

us.

E-mail: customer.support@daimler.com

Fax: +49-(0)18 05 / 0 10-79 78

or alternatively

Address: Daimler AG

GSP / OIS

HPC R822, W002

D-70546 Stuttgart

© 2008 by Daimler AG

This document, including all its parts,

is protected by copyright.

Any further processing or use requires the prev

ious written consent of

Daimler AG, Department GSP / OIS, HPC R822, W002, D-70546 Stuttgart.

This applies in particular to reproduction, distribution, alterati

on, translation,

microfilming and storage and / or processing in electronic systems, including

databases

and online services.

Image no. of title image: P01.00-3119-00

Order no. of this publication: 6516 1364 02

08 / 2008

– This printout will not be recorded by the update service. Status: 09 / 2008 –

3

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

Contents

Preface 5

Overview

Brief description 6

Engine data 7

Highlights 8

Engine views 9

System comparison 10

At a glance 11

Mechanical system

Crankcase 12

Cylinder head 13

Oil pan 14

Crankshaft assembly 15

Valve assembly 17

Gear drive 18

Belt drive 19

Combustion

Common rail injection 20

Charging 24

Air supply 29

Exhaust system 32

Exhaust system 34

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Contents

4

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

Cooling and lubrication

Engine cooling 36

Engine lubrication and oil circuit 38

Oil pump 40

Coolant pump 41

Electrical and electronic systems

Engine control unit 42

Glow system 43

Pneumatic system

Vacuum control 44

Environmental protection

Emission reduction 46

Service information

New features 48

Special tools

Engine 50

Abbreviations 55

Index 56

– This printout will not be recorded by the update service. Status: 09 / 2008 –

5

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

Preface

Dear Reader,

This Introduction into Service Manual presents the

new 4-cyli

nder inline diesel engine 651 from

Mercedes-Benz.

It allows you to familiarize yourself with the technical

hi

ghlights of this new engine in advance of its market

launch. This brochure primarily intended to provide

information for people employed in service, maintenance and repair as well as for aftersales staff. It is

as

sumed that the reader is already familiar with the

Mercedes-Benz model series and major assemblies

currently on the market.

In terms of the contents, the emphasis in this Introduction into Service Manual is on presenting new and

modified

components, systems, system components

and their functions.

This Introduction into Service Manual aims to provide

an overview of th

e technical innovations and an insight

into their complicated designs.

However, this Introduction into Service Manual is not

intended as a basis for repair work or technical diagnosis. For such needs, more extensive information is

avai

lable in the Workshop Information System (WIS)

and in the Diagnosis Assistance System (DAS).

WIS is updated monthly. Therefore, the

information

available there reflects the latest technical status of

our vehicles.

The contents of this brochure are not updated and no

provision is

made for supplements. We will publicize

modifications and new features in the relevant WIS

documents. The information presented in this Introduction into Service manual may therefore differ from

the more up-to-date information found in the WIS.

All information relating to technical data, equipment

a

nd options is valid as of the copy deadline in July 2008

and may therefore differ from the current production

configuration.

Daimler AG

Technical Information and Workshop Equipment

(GSP / OI)

– This printout will not be recorded by the update service. Status: 09 / 2008 –

6

Overview

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

Brief description

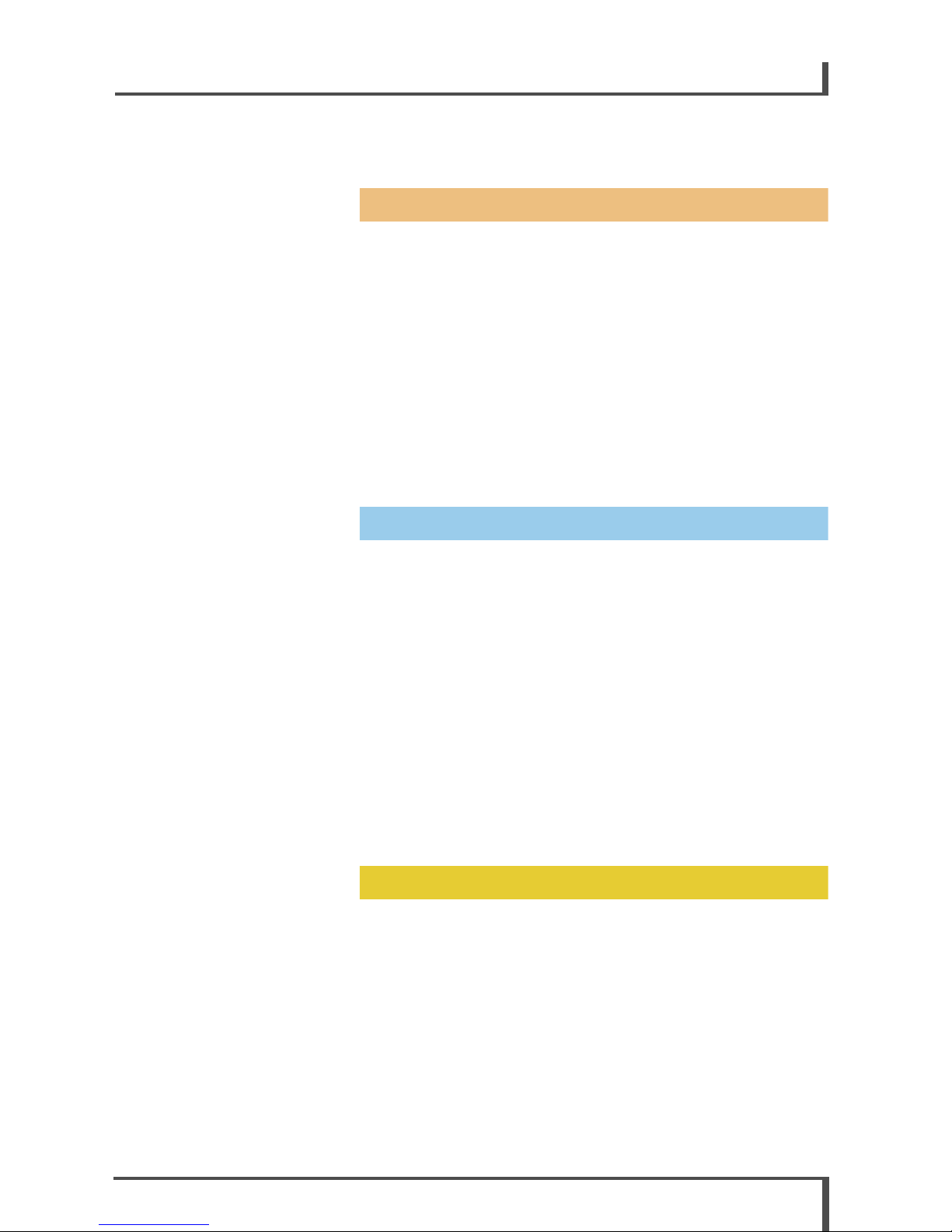

Engine model series 651

The new generation of the 4-cylinder diesel engine

651 equipped with the second-generation Common

Rail Direct Injection (CDI) system from Delphi will be

launched on the market as of October 2008.

Engine 651 has a rated output of 150 kW with a

displacement of 2,

143 cm

3

and a consumption of just

5.4 liters of diesel fuel per 100 kilometers. Despite

this high output and an engine torque of 500 Nm,

emissions of CO

2

have been further reduced. In addi-

tion, the engine meets the future Euro 5 standard.

A central feature of the new engine is its dual stage

turboc

harging system. The system combines a small

high-pressure turbocharger with a large low-pressure

turbocharger. Engine 651 also features two

Lanchester balance shafts to make the engine run

more smoothly.

In order to meet the new legal requirements of the

Eur

o NCAP crash tests with respect to improved

pedestrian protection, the gear drive has been located

on the output side together with the chain drive. The

increased space between the engine and engine hood

reduces the risk of injury for pedestrians.

Engine 651

2.2 l displacement and 150 kW output. Installed in the

C-Class as of October 2008.

Engine 138

2.6 l displacement and 33 kW output. Installed in the

Mercedes-Benz 260 D, the world's first diesel passenger

car, in 1936.

i Note

A detailed description of the new CDI system can

be found in the System Description for engine 651.

Order number: 6516 1363 02

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Overview

7

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

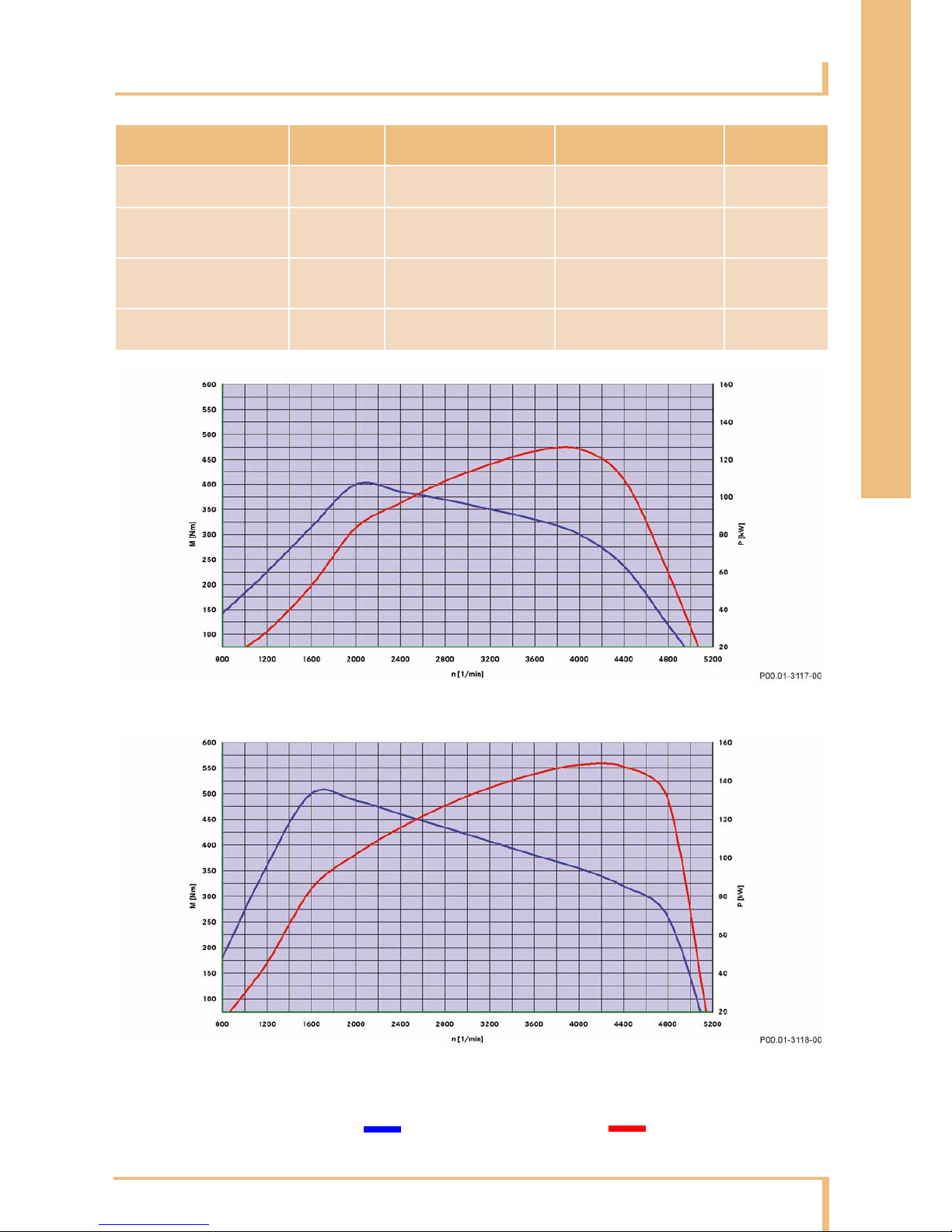

Engine data

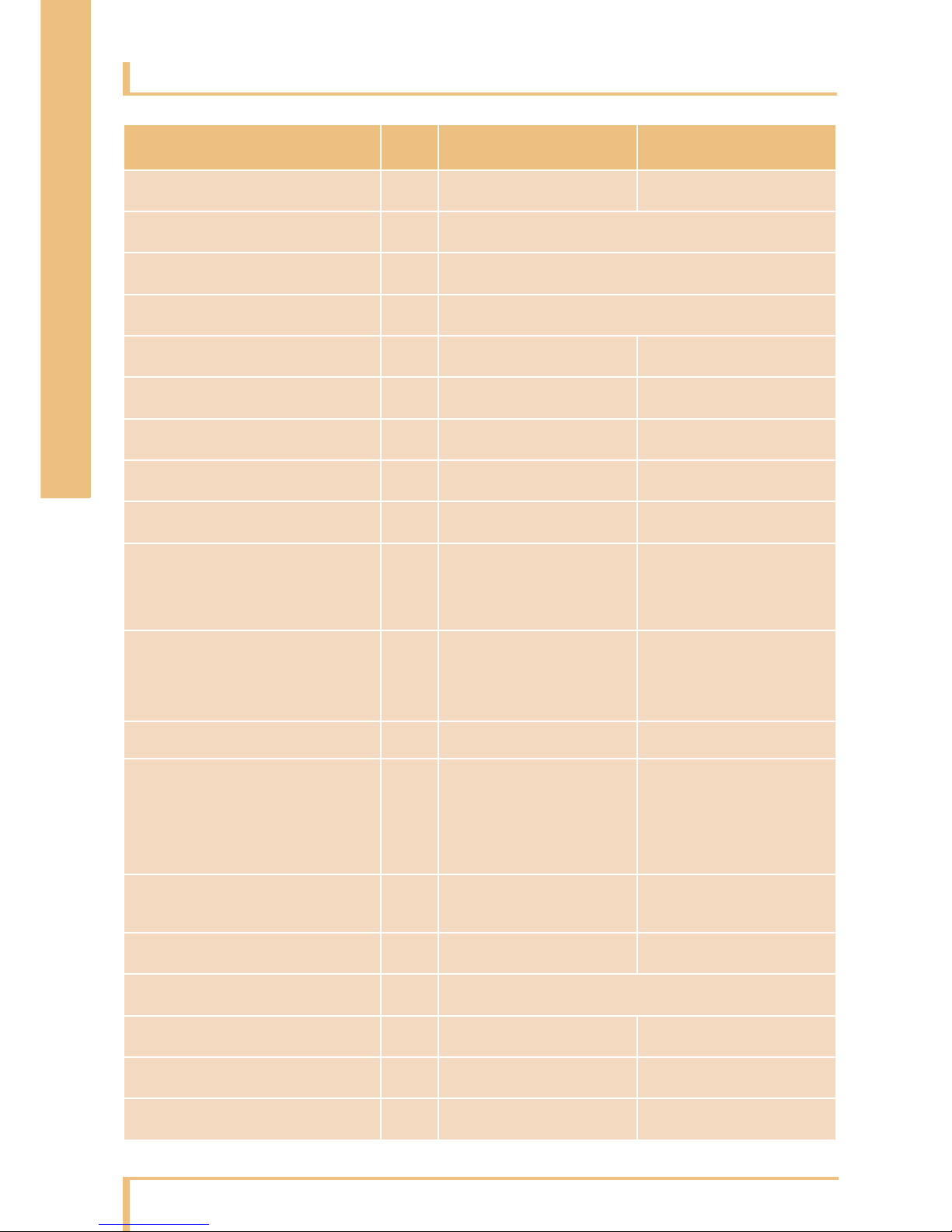

Comparison Engine 646.821 EVO Engine 651.911 Difference

Displacement cm

3

2,148 2,143 –0.2%

Rated output kW

at rpm

125

3,800

150

4,200

+20%

Rated torque Nm

at rpm

400

2,000

500

1,600…1,800

+25%

Maximum rpm rpm 4,900 5,200 +6%

Engine 646.821 EVO

Engine 651.911

n Engine speed M Torque

POutput

– This printout will not be recorded by the update service. Status: 09 / 2008 –

8

Overview

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

Highlights

New features

Based on the use of the latest innovative technologies,

engine 651 sets a new standard in terms of output and

torque characteristics, economy, exhaust emission

levels and smooth running. The engine features a

number of new developments which cannot be found

in this combination in any other series-produced

passenger car diesel engine.

Technology

The most important technical features of the new

engine are:

• Dual stage turbocharging with fixed geometry

• Directly actuated piezo injectors

• Gear drive in combination with a chain drive on the

output side

• Intake air-cooled engine control unit

on air filter housing

• Main bearing bridge with integrated

Lanchester housing

• Two Lanchester balance shafts

• Drive gear friction welded to crankshaft

• Vibration dampers

(quadruple bolted)

• Universal timing case cover for adaptation to

va

rious transmission models

• Major assembly carrier with variable arrangement

as per vehicle

concept

• Two knock sensors

• Two-piece oil pan (noise optimized)

• Oil pan bottom section made of plastic

Thermal management

The new thermal management system consists of:

• Shutoff-capable coolant pump

• Cylinder head with two-piece water jacket

• Shutoff-capable oil spray nozzles combined with

pisto

n crown cooling

• Oil pump volume-controlled at clean oil side

i Note

Further information on repairing and maintaining

engine 651 can be found in the Workshop Information System (WIS).

i Note

Friction-welded connections involve connecting

two parts together by force. The application of friction and pressure produces a fixed connection

without the use of welding consumable.

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Overview

9

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

Engine views

Engine 651: Side view from right

Engine 651: Side view from left

– This printout will not be recorded by the update service. Status: 09 / 2008 –

10

Overview

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

System comparison

Comparison Engine 646.821EVO

C 220 CDI

Engine 651.911

C 250 CDI

Market launch 06 / 2006 10 / 2008

Combustion system Diesel direct injection

No. of cylinders 4

Engine configuration Inline

Bore mm 88.3 83.0

Stroke mm 88.3 99.0

Compression ratio e 16.5:1 16.2:1

Camshafts – drive Duplex chain Simplex chain

Camshafts – number 2 2

Valve actuation Cup tappet

with hydraulic valve

clearance compensation

Roller-type cam follower

with hydraulic valve

clearance compensation

Turbocharger type 1-stage turbocharging with

variable turbine geometry

2-stage turbocharging with

fixed geometry

Boost pressure control Electric Pneumatic

Measures for low-emission

combustion

Intake port shutoff,

exhaust gas recirculation

(EGR) with separate EGR

cooler

Intake port shutoff, EGR

cooling and EGR bypass

Fuel injector – type Solenoid injector Directly controlled piezo

injector

Fuel injector – diameter mm 17 19

Firing order 1-3-4-2

Oil pump – drive Simplex chain Gear drive

Alternator – current rating A 200 180

Engine weight DIN (dry) approx. kg 190 203

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Overview

11

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

At a glance

Objective Measures on engine 651

Optimized comfort Stiffer crankcase with full-length crankshaft bearing bridge

Wide crankshaft main bearing; friction-optimized with center bearing

Two low-positioned Lanchester balance shafts for smooth engine running

Plastic cylinder head cover with integrated ventilation

Maintenance-free, long-life simplex chain as camshaft drive

Engine cover with adjusted acoustic damping

Improved fuel

economy

Optimized flow conditions (air ducting, intake ports)

Dual stage turbocharging

Optimized charge air cooling and exhaust gas recirculation cooling

Reduction in friction through gear drive and balance shafts mounted

on roller bearings

Compliance with

exhaust emissions

standards (Euro 5

standard)

Optimized shape of combustion chamber

7-hole injection nozzles

More precise injection times

Optimized air ducting

Exhaust gas recirculation (EGR) with EGR pre-cooler and EGR cooler, EGR valve and

switched EGR bypass

Electric intake air throttling

Shutoff-capable coolant pump and shutoff-capable oil spray nozzles

Exhaust system with oxidation catalytic converter and diesel particulate filter

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Crankcase

12

Mechanical system

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

General

When engine 651 was developed, the design of the

crankcase was based on an overall concept with optimized spatial features. Accordingly, the gear drive

with

the oil pump drive and the Lanchester balance

shafts are positioned on the output side. The cast iron

crankcase is manufactured by sand casting.

The new design concept provides the following advantages:

•4 cm shorter crankcase compared to predecessor

version

• Improved pedestrian protection through

positioning of gear drive and

camshaft drive on

output side

• Universal timing case cover for adaptation to

various transmis

sion models

Crankcase

1 Crankcase 2 Oil spray nozzle shutoff valve

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Mechanical system

13

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

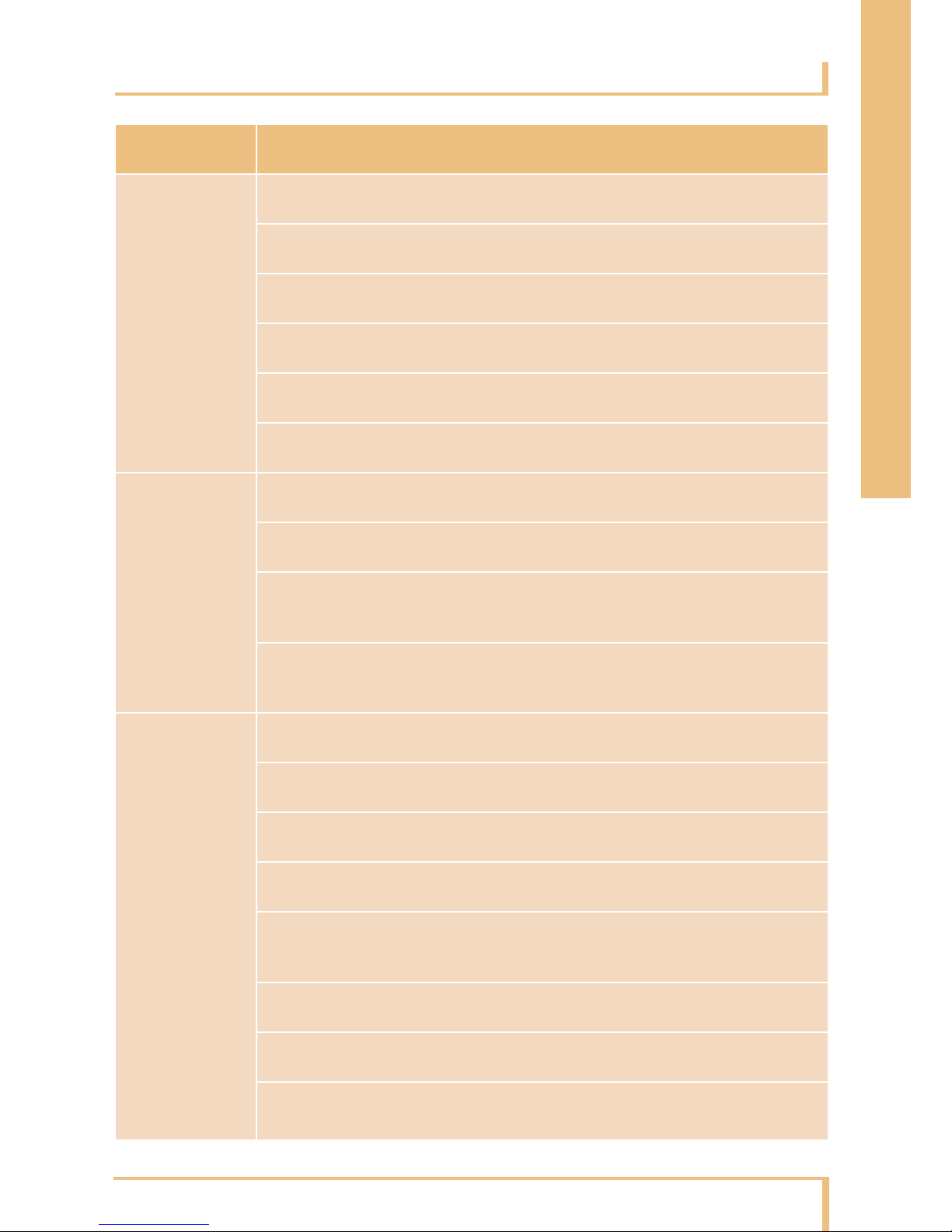

Cylinder head

General

The cylinder head is made of high-strength aluminum.

It is equipped with two camshafts and four valves per

cylinder. The cylinder head cover is made of plastic

with integrated ventilation. The cylinder head is characterized by the following new features:

• Maximum ignition pressure of 200 bar (previously

160

bar)

• Tangential and spiral intake ports

• Bore for piezo injector of 19 mm diameter

The upper duct of the two-piece water jacket supplies

the cylinder

head with coolant. The advantages of the

two-piece water jacket include:

• Greater structural rigidity

• Better heat dissipation

• Improved thermal management

The improved thermal management system is particularly beneficial in those areas which are exposed to

very

high temperatures. The high ignition pressure of

200 bar is only made possible by targeted cooling of

the individual components. The increased pressure

potential and optimized injection quantity are responsible for the high engine torque of 500 Nm and the

en

gine output of 150 kW.

Cross-section of cylinder head

1 Ventilation

2 Main bearing bridge

3 Cylinder head cover

4Glow plug

5 Exhaust valve

6 Piezo injector

7 Intake valve

8 Valve spring

9 Valve clearance compensation

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Oil pan

14

Mechanical system

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

Special design features

• Two-piece design

• Lower section of oil pan made of plastic

•Noise-optimized

• Service-optimized and cost-optimized replacement

parts

• Bolts secured to prevent them being lost

• Installation can be checked via special pins on seal

Oil pan

1 Upper section of oil pan

2Seal with pins

3 Lower section of oil pan (plastic)

4 Bolts with retainer (anti-loss)

i Note

Temporary level fluctuations are balanced out by the volume of the housing and the size of the drain bores

in the oil level check switch. This prevents unnecessary warning messages e.g. triggered by cornering.

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Mechanical system

15

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

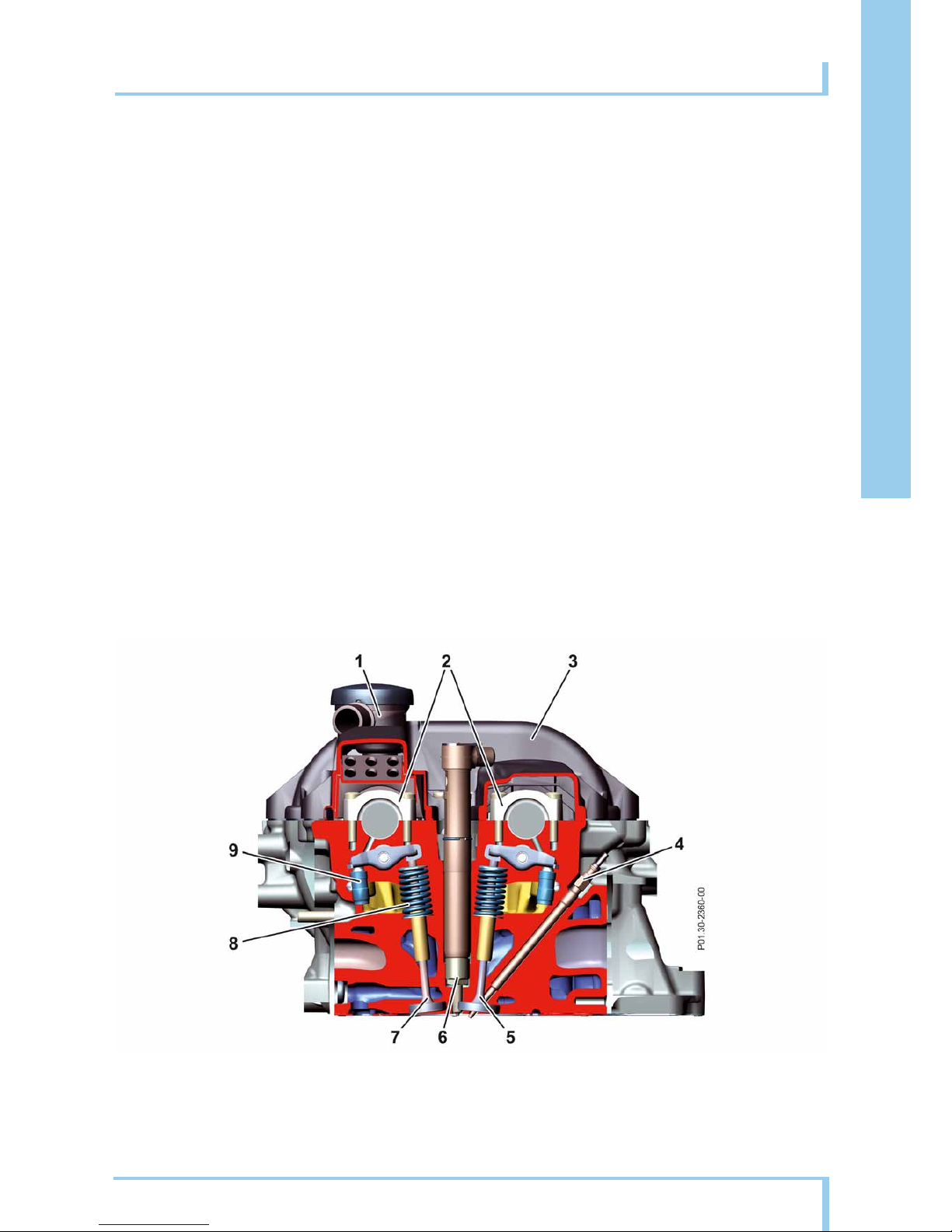

Crankshaft assembly

Crankshaft

The forged crankshaft with eight counterweights is

supported by five bearings for effective vibration

damping. The radiuses of the crank pins are rolled to

give them high strength. In addition, the connection

between the drive gear and crankshaft is friction

welded.

The vibration damper is fixed to the crankshaft with a

fourfold threaded connection.

Connecting rods

The weight-optimized connecting rods are made of

forged steel and are cracked at the level of the bearing

shells.

Balance shafts

Two Lanchester balance shafts are integrated in the

main bearing bridge and mounted on three roller bearings. They are driven in opposite directions by the gear

drive to counteract the inertia forces of the second

order which are generated. This ensures smooth

engine running.

i Note

The aluminum pistons run in friction-optimized cast-iron cylinder barrels. On this engine, they are all manufactured uniformly. There is therefore no differentiation between A, B or X sizes on this engine.

Crank assembly with gear drive

1 Oil and vacuum pump drive gear

2 Crankshaft gear

3Crankshaft

4 High-pressure pump drive gear

5 Intermediate gears

(tensioning gears)

6Piston

7 Connecting rod

8Vibration damper

9 Lanchester drive gears

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Crankshaft assembly

16

Mechanical system

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

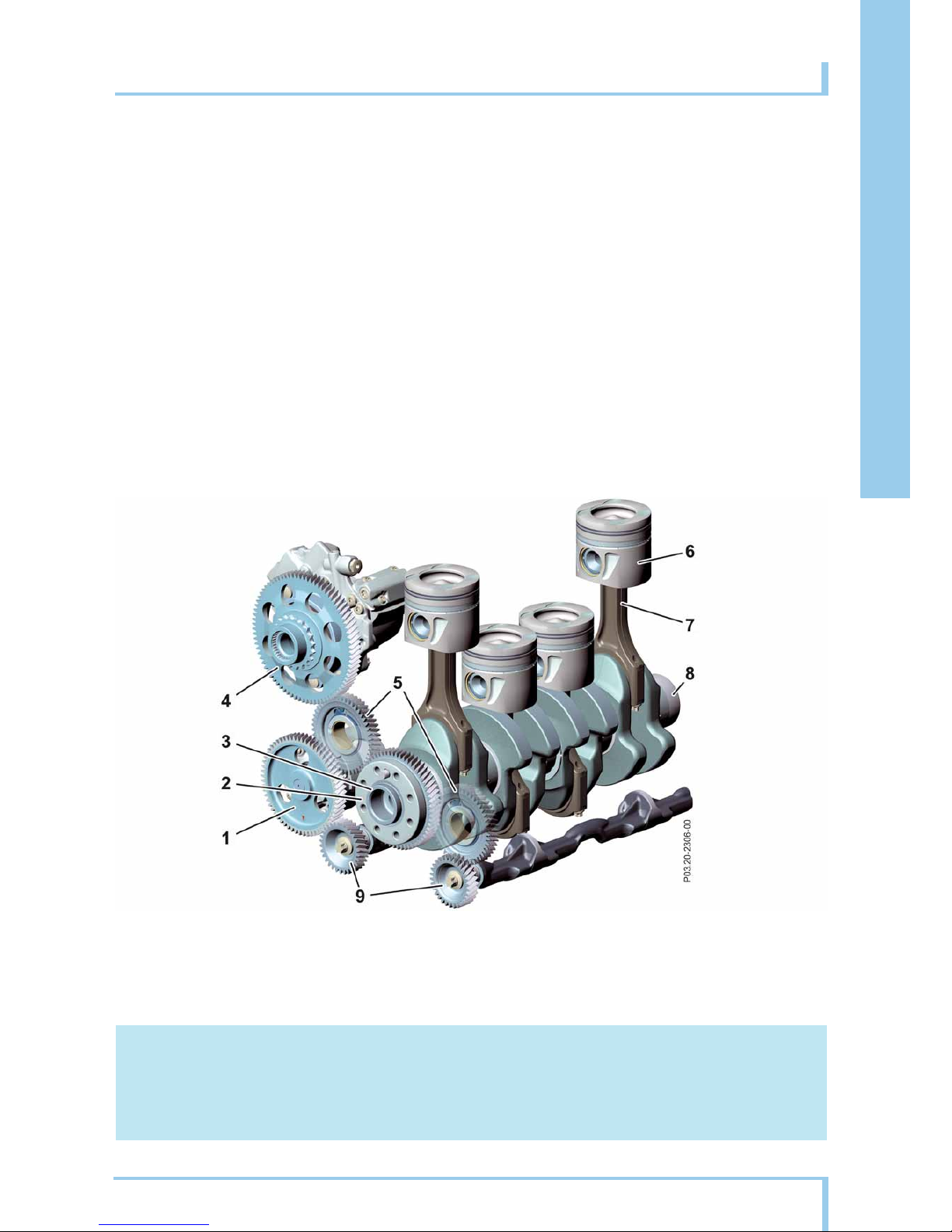

Camshafts

The gear drive drives the camshaft sprockets and the

connected camshafts via a timing chain. The maintenance free timing chain is tried and tested and has

proven longevity. The

cams are fixed to the camshaft

by means of internal high-pressure forming (IHU).

Camshaft sprocket

The camshaft sprocket is connected to the camshaft

by a center bolt. The center bolt of the camshaft has a

left-hand thread.

Sensor wheel

The sensor wheel is fixed to the exhaust camshaft. In

combination with the Hall sensor, the sensor wheel

makes it possible to determine the camshaft position

and rpm.

The Hall sensor generates a magnetic field through a

buil

t-in permanent magnet. The magnetic field is periodically interrupted by an orifice plate on the sensor

wheel while the engine is running. The

signal which

this generates is used by the CDI control unit and

serves as a substitute signal for emergency engine

operation if the position sensor for the crankshaft

fails.

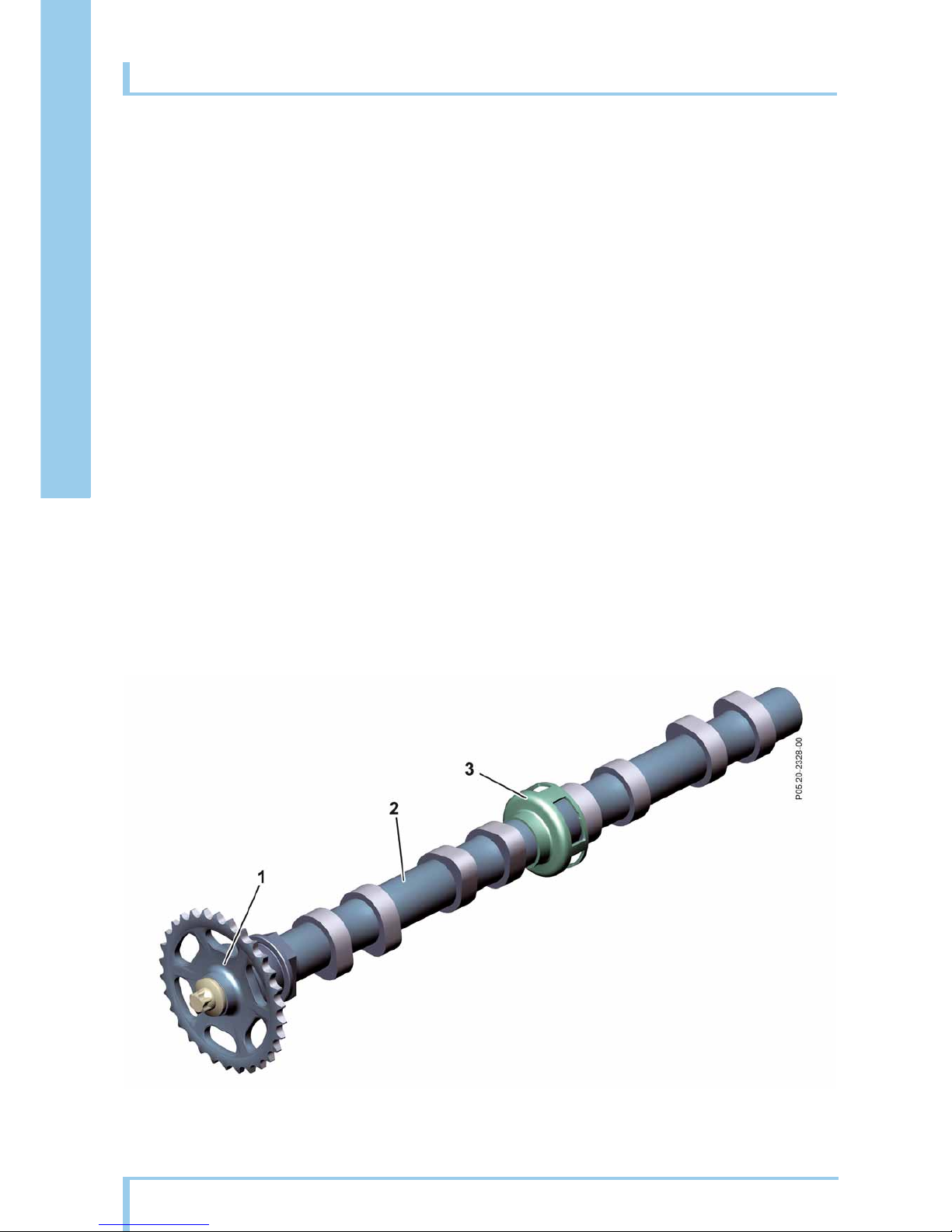

Exhaust camshaft with sensor wheel

1 Drive gear 2 Exhaust camshaft 3 Sensor wheel with orifice plate

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Mechanical system

17

Introduction of New Generation of 4-Cylinder Inline Engines, OM 651

q

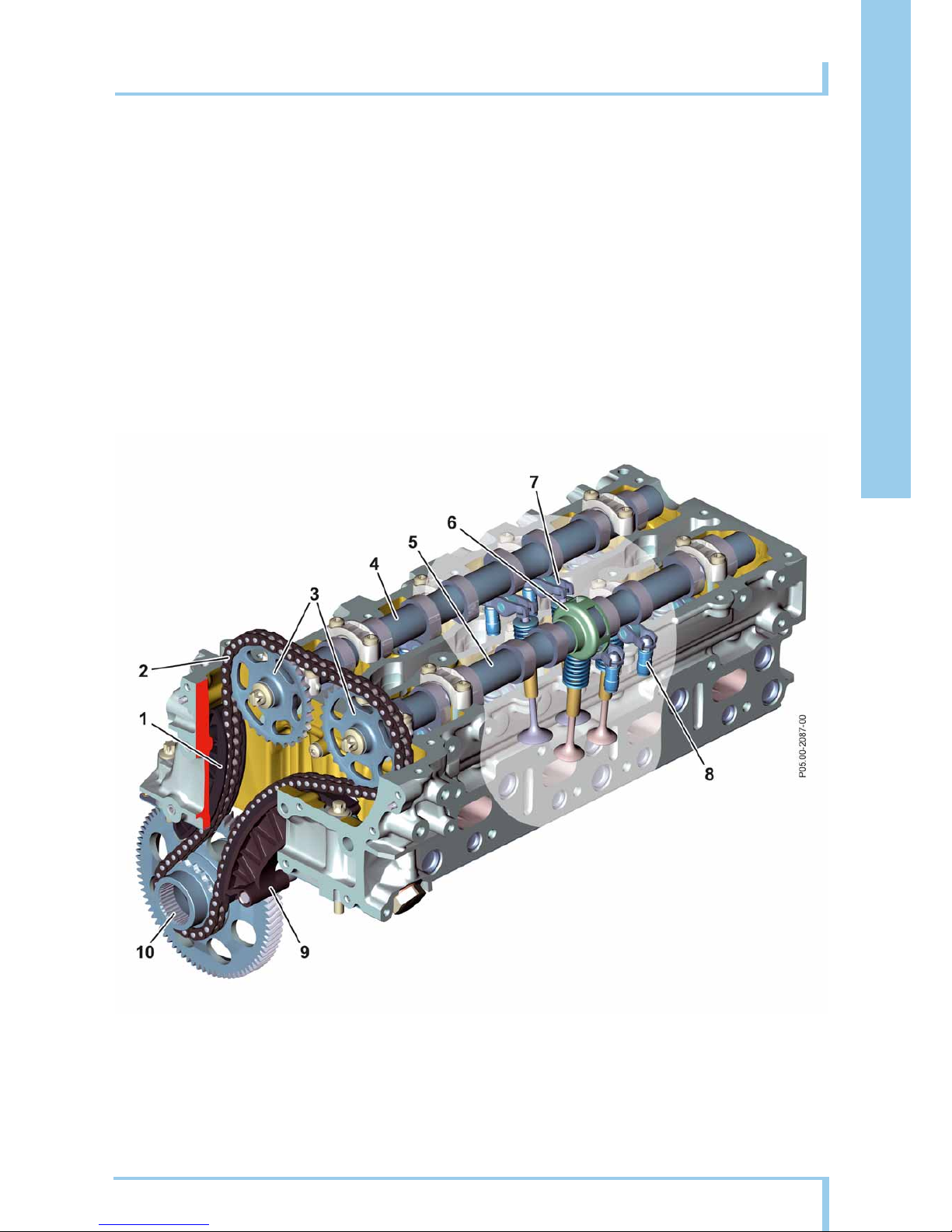

Valve assembly

Valve assembly with hydraulic valve clearance compensation

The valve assembly was modified with the aim of optimizing friction and reducing the moved masses.

The camshafts control two intake valves and two

exhaust

valves per cylinder. This valve timing system

uses low-friction roller-type cam followers with

hydraulic valve clearance compensation.

Valve assembly

1 Slide rail

2 Timing chain

3 Camshaft drive gears

4Intake camshaft

5Exhaust camshaft

6 Sensor wheel with orifice plate

7 Roller-type cam followers

8 Hydraulic valve clearance compensator

9 Chain tensioner

10 Timing chain drive gear

– This printout will not be recorded by the update service. Status: 09 / 2008 –

Loading...

Loading...