Order no. 6462 9807 02 Part no . 5 41 58 4 09 81 EN Edition A, 0 8/03

Bild in der Größe

215x70 m m ein fügen

OM 501 LA – OM 502 LA engin es

Operating Ins tructions

Than k you fo r ch oosing this

Mercedes- Benz engine.

Please get to know your new MercedesBenz en gine first. Make sure y ou read the

Operati ng Ins truc tions in parti cular befor e

using the engine for the first time. In this

way you can ensure succes sful and safe

use. At the same time you will avoid endanger ing your self a nd others when o perat ing

the engine.

Items of special equipment are mar ked

with an asterisk *. The equipment in your

Mercedes-Benz d rive train may vary, depending on the version. Mercedes-Benz is

constantly updating its engines to the

state of the art. You cannot, therefore,

base a ny claims on the data, illust rations

or descriptions in these Operating Instructions.

For further information contact a

Mercedes-Benz Service Centre.

The Operating Ins tructions and Maintenance Booklet bel ong with the engine. You

should therefore always keep them with

the engine and pass them on to the new

owner if y ou sell it.

The technical documentation team at

DaimlerChrys ler AG wishes you every

suc cess .

Contents

Introduction

The aim of these Operating

Instructions . . . . . . . . . . . . . . . . . . . . . 5

Sym bo ls . . . . . . . . . . . . . . . . . . . . . . . . 6

Protection of the environment . . . . . . 7

Op erat ing s af ety . . . . . . . . . . . . . . . . . 8

Correct use. . . . . . . . . . . . . . . . . . . . 9

1At a glance

OM 501 LA overview . . . . . . . . . . . . . 12

OM 502 LA overview . . . . . . . . . . . . . 16

Location of senso rs . . . . . . . . . . . . . . 20

Engi ne pl ate . . . . . . . . . . . . . . . . . . . . 22

2 Before commissioning

General remarks . . . . . . . . . . . . . . . . 26

Type designation . . . . . . . . . . . . . . 26

Engine data card. . . . . . . . . . . . . . . 26

Description of the engine . . . . . . . . 27

Flame-start system*. . . . . . . . . . . . 28

Engine exhaust brake/ cons tantly-

open throttle valves* . . . . . . . . . . . 29

Telligent® engine system . . . . . . . . 31

Transport/installation . . . . . . . . . . . 35

3Safety

Safety precautions. . . . . . . . . . . . . . . 38

Personnel requirements . . . . . . . . . . 39

Commissioning parts and

modifications . . . . . . . . . . . . . . . . . . . 40

Safety/emergency running

programs . . . . . . . . . . . . . . . . . . . . . . 41

Replacement parts. . . . . . . . . . . . . . . 42

4Operation

Co mmi ssioning . . . . . . . . . . . . . . . . . . 44

P re paration . . . . . . . . . . . . . . . . . . . 44

Initial comm issioning . . . . . . . . . . . 46

Sta rting the eng ine . . . . . . . . . . . . . 49

Mo nito ring en gine oper ati on . . . . . . 51

Charge curr en t . . . . . . . . . . . . . . . . 51

Telligent® engine system . . . . . . . . 52

Oil pre ss ure . . . . . . . . . . . . . . . . . . 52

Flame-s tart syste m* . . . . . . . . . . . . 53

Stopping the engine. . . . . . . . . . . . . . 54

Wint er operation . . . . . . . . . . . . . . . . 55

Cleaning /protective treatment . . . . 57

Cl eaning the eng ine . . . . . . . . . . . . 57

Cleaning the cooling system. . . . . . 58

P ro te c tive trea tment . . . . . . . . . . . . 60

Service products . . . . . . . . . . . . . . . . 61

D ie se l fuel s . . . . . . . . . . . . . . . . . . . 62

Engine oils . . . . . . . . . . . . . . . . . . . 64

Coolant. . . . . . . . . . . . . . . . . . . . . . 65

5 M aint en anc e

Main te nan ce i nst r uctio ns . . . . . . . . . 68

Overview of w ork plans . . . . . . . . . . . 69

Main ten anc e s ervice. . . . . . . . . . . . 69

Ad ditional work. . . . . . . . . . . . . . . . 69

Additional work during every

3rd maintenanc e service . . . . . . . . 69

Wo rk plan s . . . . . . . . . . . . . . . . . . . . . 70

Engine: Checking for leaks and

gener al condition . . . . . . . . . . . . . . 70

Lines and hoses on the engine:

Checking for leaks and general

condition. . . . . . . . . . . . . . . . . . . . . 70

Engine: Oil change and filter

replacement . . . . . . . . . . . . . . . . . . 71

Adjusting the valve clearance. . . . . 74

Fuel connections. . . . . . . . . . . . . . . 78

Fuel pr efil te r with he at ed wat er

separator*: Replacing the filter

element. . . . . . . . . . . . . . . . . . . . . . 79

Replacing the fuel filter element. . . 81

Intake pi pe between air cleaner

and engine: Checki ng for leaks and

gener al condition . . . . . . . . . . . . . . 83

Contents

Poly-V-belt : Checking the condition 83

Engine brake*: Checking t he

condition and adjustment. . . . . . . . 88

Engine cooling s ystem: Checking

and cor recting the fluid level and

the antifreeze/ corrosion inhibitor . 90

Cooling and heating system:

Checking for leaks and general

condition. . . . . . . . . . . . . . . . . . . . . 91

Renewing coolant . . . . . . . . . . . . . . 93

6 Practical advice

Malfunctions, causes and solutions 96

Jump-starti ng . . . . . . . . . . . . . . . . . . 104

7Technical data

Engi ne da ta . . . . . . . . . . . . . . . . . . . . 1 06

Test values and adjustment values 109

Tightening torques. . . . . . . . . . . . . . 110

8 Glossary and index

Technical terms . . . . . . . . . . . . . . . . 113

Index . . . . . . . . . . . . . . . . . . . . . . . . . 115

The aim of these Operating Instructions

These Operating Instructions are intended

to a ssi st you i n all situatio ns wi th your new

engine. Each section has a print register to

help you find the information you require

quickly:

1At a glance

This section gives you an overview of the

layout of important components i n the engine.

2 Getting started

This contains the basic i nformation you

require for i nitial operation. I f this is y our

first Mercedes-Benz engine, you shoul d

read this section fir st.

3Safety

4 Controls in detail

Here you will fi nd all the informati on you

will need w hen you are operating the engine.

5Operation

This is where you will find m ore detailed in formation about maintenance work.

6 Practical advice

Here you will fi nd practical hel p for possible problems.

7Technical data

All the important techni cal data for the engine is listed here.

Introduction

The aim of these Operating Instru ctions

The engine documentation comprises the

fol lo win g:

these Operating Instructions

the Maintenance Booklet

Specifications for Service Produc ts

You may receive additional supp lements

depending on the equipment.

This section contains important aspects

with r egard to safety in the use of the

Mercedes-Benz OM 501 LA and

OM 502 LA engines.

8 Glossary and index

The glossary of technical terms explains

the mos t important tec hnical terms.

The index is intended to help you find infor mation quickly.

5

Introduction

Symbols

You will find the following symbols used in

these Operating Instructions:

* This aster isk i ndicates special

equipment. Since not all models

hav e the same standard equipment, the layout of your engine may

differ from certain descriptions and

illust rations.

Wa rnin g G

A warning draws your attention to possible

risks of accident and injury to yourself and

others.

You sho uld th eref ore always read an d observe all warning notices.

Environm ental n ote H

An environmen tal no te gi ves yo u tips o n the

protection of the environment.

!

This note draws your attention to possible hazards to your engine.

i

This tip contains advice or further information you may find useful.

This symbol means that you have to do

so mething.

A number of these symbols one after

the other indicates a sequence of action s.

page This symbol indicates the page

on which you will find further information on t he subject.

This continuation symbol indi-

cates an interrupted sequence

of actions that w ill be continued

on the next page.

-> This symbol in the gl ossary of

technical terms means that the

term following the arrow is also

explained.

6

Protection of the environment

Introduction

Protecti on of the e nvir on men t

Environmental note H

DaimlerChrysler's declared policy is one of

integrated envir onmen tal pro tection. This

policy start s at the ro ot cause s and encompasses in its management decisions all the

conseq ue nce s f or t h e e nvironmen t which

could arise from production processes or

the products themselves.

The objectives are for the natural resources

which f orm t he b asis of our e xistence on this

planet to be used sparingly and in a manner

which takes the requirements of b oth nature

and huma nity in to ac count.

Ope ra te the en gine in an env ironme ntally responsible manner, and you will help to protect the environment.

F uel con sump tion and e ng ine wear de pen d

on the op erating conditions.

Th ere fore y ou sh ould:

n ot warm up the engine in idling mode

switch off the engine during operation-

associated waiting times

check fuel consumption

c arry out the specified maintenance

work regularly

7

Introduction

Operating safet y

The operating safety of an engine firstly depends on its proper installation into the

comp le te sy stem (e. g. vehicl e, m achi ne,

etc.). Secondly, as operator or service personnel, you also have a direct in fluence on

the safe operation of the engine.

Some of the requiremen ts for operating

the engine safely can be achieved b y adhering to t he specified maintenance inter vals and ensuring that the required

maintenance work is carried out correctly.

However, s afe engine operation also depends on correct servicing, such as checking the engine oil level at regular i ntervals.

Risk of accident G

Impro per op erat ion of the en gine, e .g. exceeding the permitted maximum engine

spee d in o verrun mode or operating the en gine wi th to o l ittle oil , can cause eng ine

dama ge. En gin e damag e can le ad to an increase in the risk of accide nt.

The refo re, obs erv e th e notes on oper ating

the engine in these Operating Instructions.

Risk of accide nt G

Faulty maintenance work or failure to carry

ou t main te na nce wor k , e. g. not cha ng ing

the oil filter or not observing the correct

main te na nce int e rva l, ca n c ause en gin e

da mage . E ng ine da ma ge can lea d to an increase in the risk o f accident.

Therefore, observe the notes on engine

maintenance in these Operating Instructions.

8

Introduction

Operating safety

Risk of accident G

Work incorrectly carried out on electronic

components and its software could impair

the functioning of these components. Since

the electronic systems are networked, this

might also affect systems that h ave not

be en mod ifie d.

Always have work on or modifications to

elec tro nic comp onents carried out at a qualified specialist workshop which has the necessary specialist knowledge and to ols to

carry out the work required.

Mercedes-Benz recommends that you use a

Mercedes-Benz Service Centre for this purpo se.

Correct use

The engine i s only designed for installation

in accordance w ith the specifications determined in the contract.

The manufacturer of the end product is

pers onally respo nsible for t he compl ete

system of the end product, and in particular for the correct installation and compatibi lity of t his engine with the compl ete

system.

The engine must not be modified.

DaimlerChr ysler accepts no respon sibil ity

for damage caused as the result of modifications.

Correct use of the engine includes adhering to thes e Op er at ing Instructions, adhering to the maintenance i ntervals and

performing maintenance wo rk correctly in

accordance with these Operating Instructions.

9

10

At a glance

OM 501 LA overview

OM 502 LA overview

Location of sensors

Engine plate

1

11

At a glance

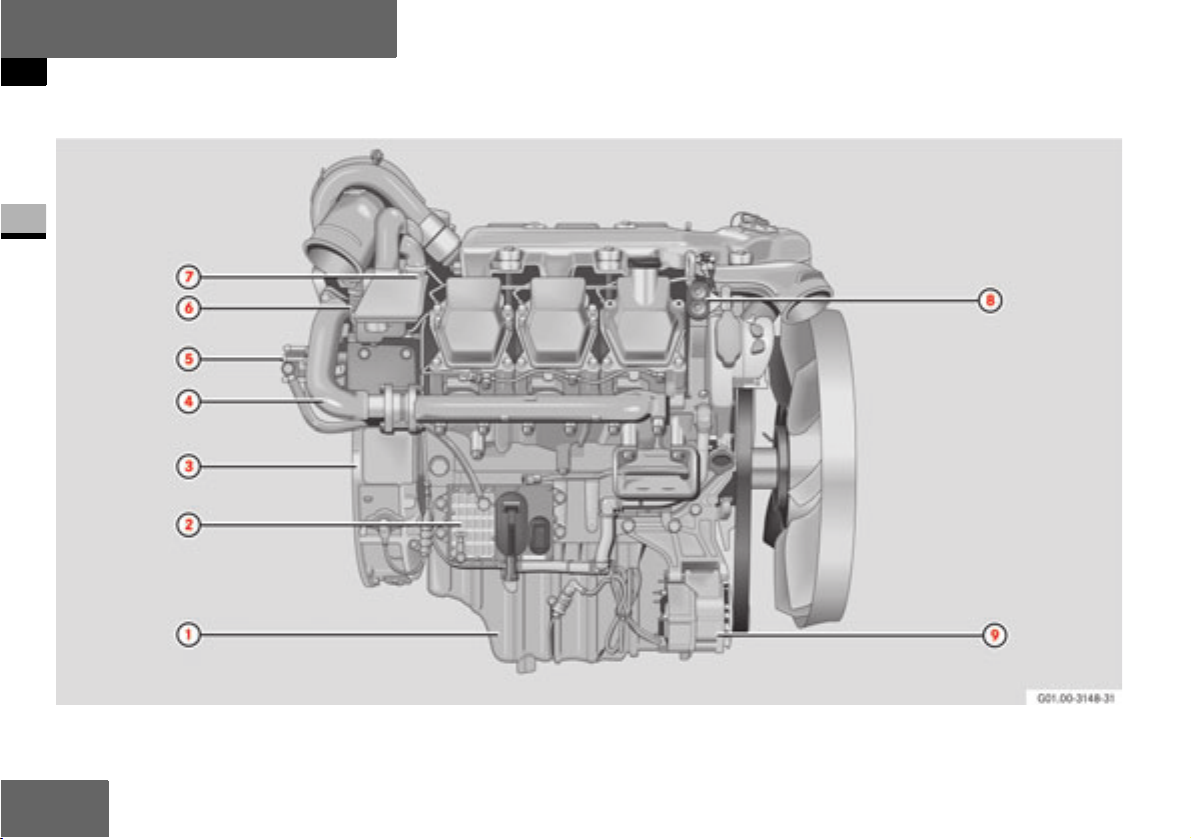

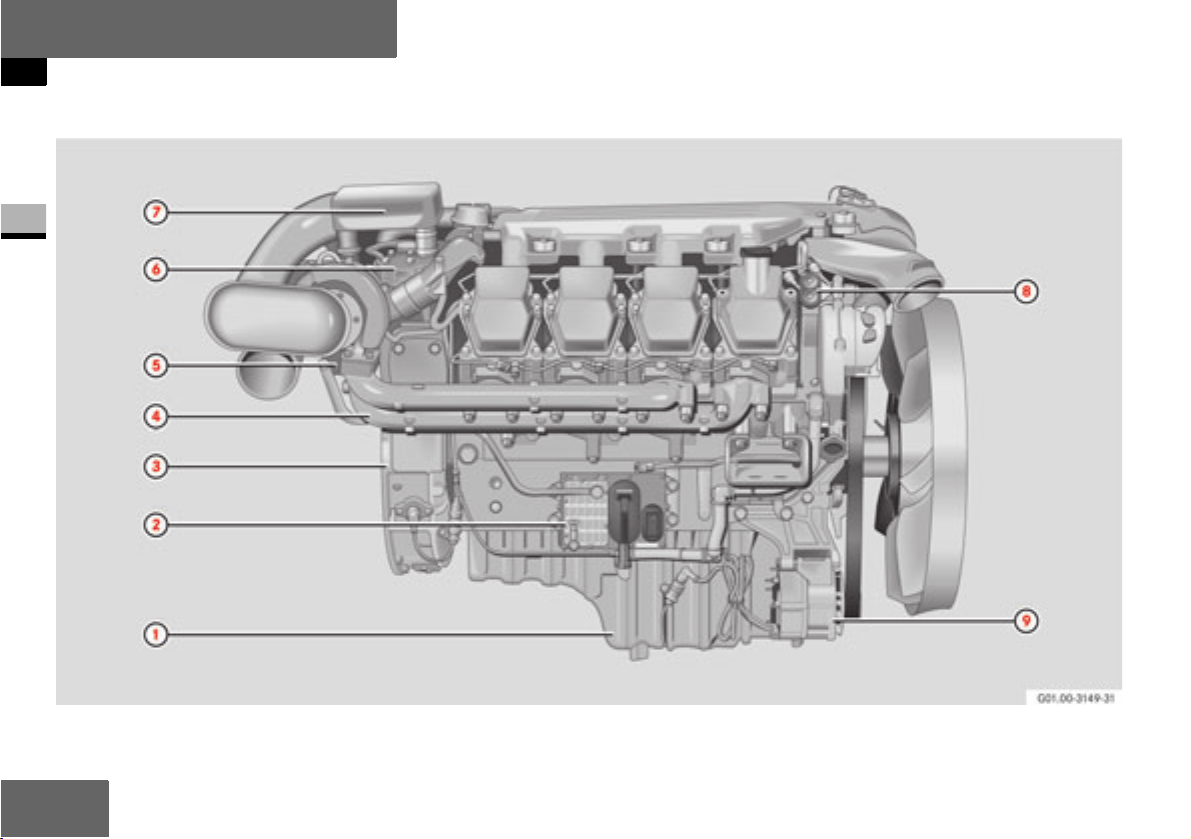

OM 501 LA overview

1

12

1 Fan

2 Coolant pump

3 Charge-air pres sure pipe (with flame-

start sy stem*) from charg e-ai r cooler

4 Charge-air pres sure pipe to charge-air

cooler

5 Oi l fil le r nec k

6 Exhaust gas turbocharger

7 Crankcase ventilation system oil trap

8 Exhaust pipe (with engine b rake throt-

tle valve*)

9 Oi l fil te r

a Fuel filter

b St arter motor

c Dipstick

At a glance

OM 501 LA o verview

1

13

At a glance

OM 501 LA overview

1

14

1 Oi l sump

2 Engine control unit

3 Flywheel housing

4 Exhaust manifold

5 Fuel pump (with flange-mounted

power-steering pump*)

6 A ir compressor*

7 Resonator* (onl y in conjunction

with air compressor)

8 Start-Stop buttons

9 Alternator

At a glance

OM 501 LA o verview

1

15

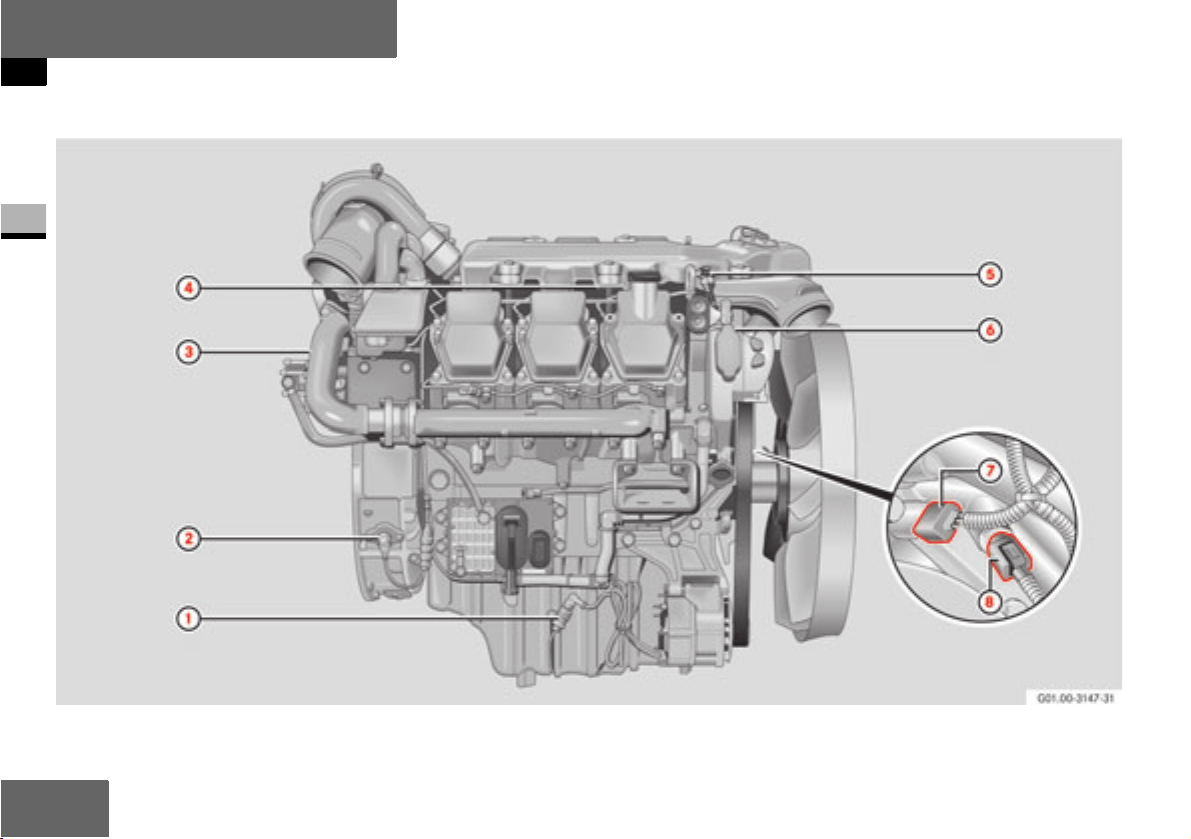

At a glance

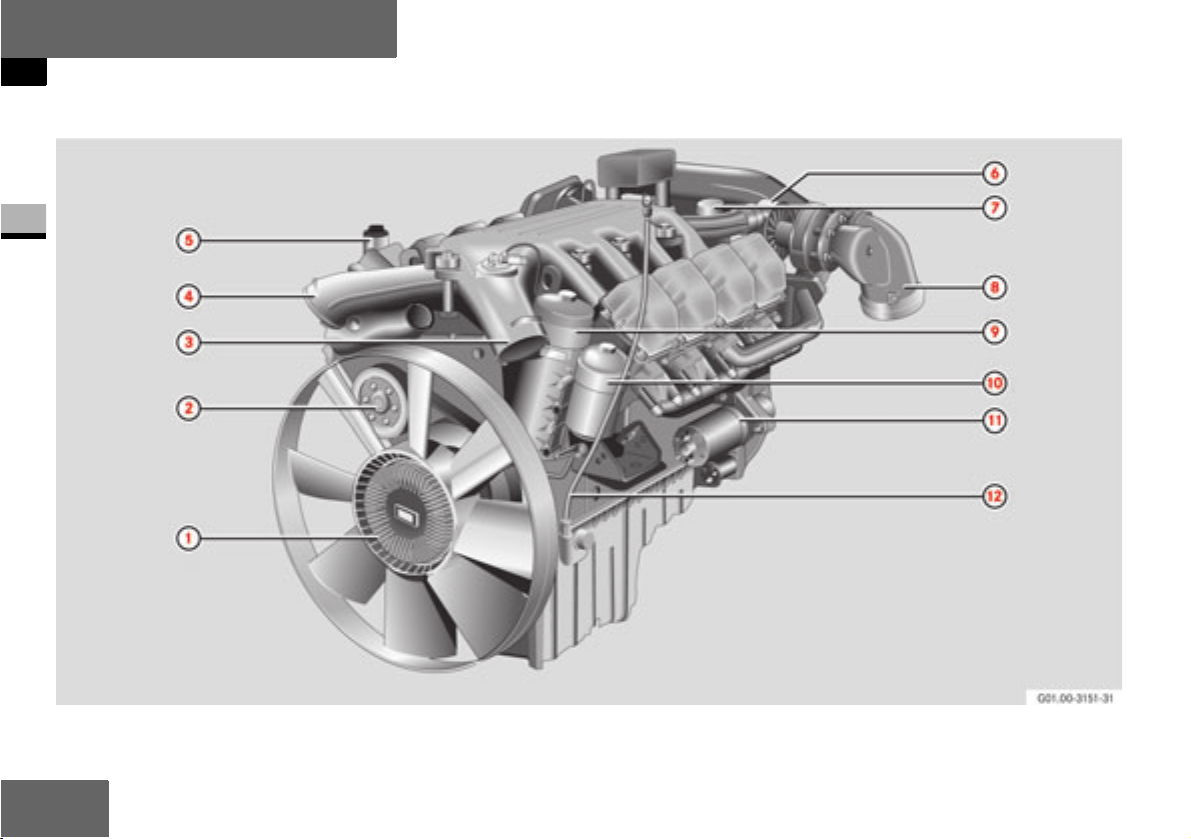

OM 502 LA overview

1

16

1 Fan

2 Coolant pump

3 Charge-air pres sure pipe (with flame-

start sy stem*) from charg e-ai r cooler

4 Charge-air pres sure pipe to charge-air

cooler

5 Oi l fil le r nec k

6 Exhaust gas turbocharger

7 Crankcase ventilation system oil trap

8 Exhaust pipe (with engine b rake throt-

tle valve*)

9 Oi l fil te r

a Fuel filter

b St arter motor

c Dipstick

At a glance

OM 502 LA o verview

1

17

At a glance

OM 502 LA overview

1

18

1 Oi l sump

2 Engine control unit

3 Flywheel housing

4 Exhaust manifold

5 Fuel pump (with flange-mounted

power-steering pump*)

6 A ir compressor*

7 Resonator* (onl y in conjunction

with air compressor)

8 Start-Stop buttons

9 Alternator

At a glance

OM 502 LA o verview

1

19

At a glance

Location of sensors

1

20

1 Oi l l evel sen sor

2 Crankshaft position sensor (on the

flywheel)

3 Cylinder 1 TDC sensor (on the cam-

shaft sproc ket)

4 Fuel temperature sensor

5 Combined charge-air pressure and

temperature sensor

6 Coolant temperature sensor

7 Oi l pr essur e sensor

8 Oil temperature sensor

At a glance

Location of s ensor s

1

21

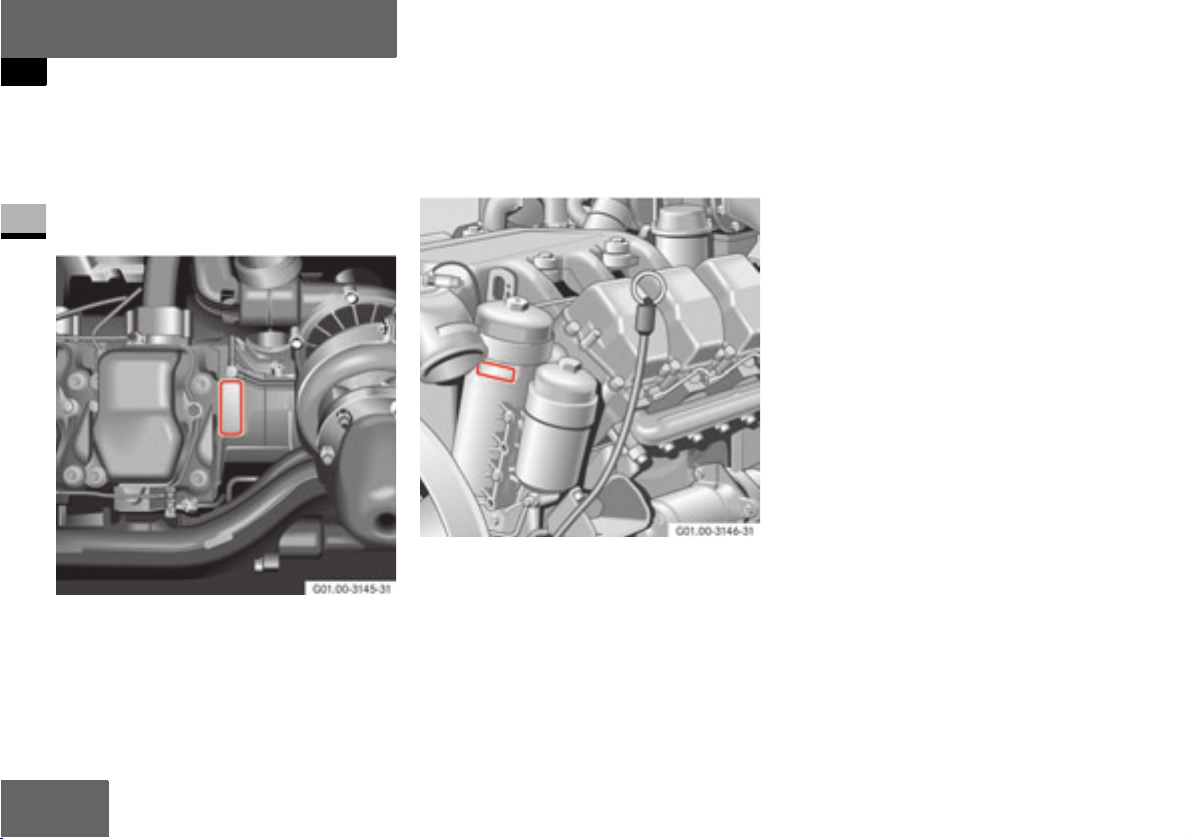

At a glance

Engine plate

Location

The engine plate is located on the left-hand

side of the engine, on the engine block af-

1

ter the l as t cylinder.

Engine plate, left-hand side of engine, flywhee l end

A second engine plate is mounted on the

front of the oil filter casing.

Engine plate, left-hand side of engi ne, fan

end

22

Information on the engine plate

On motor vehicles, t he engine plate shows

the engine model designation 1 and the

full engine number 2 along with the manufacturer' s name.

In addition to this, engines for mobil e machines and equipment carry the engine series designation and approval number.

At a glance

Engine plate

1

Engine plate

1 Engine mo del designation

2 Engine number

23

24

Before commissioning

General remarks

Transport / installa tion

2

25

Before commissioning

Genera l rem arks

Type designation

OM 501 L A

OM Oil engine (diesel

2

en gi ne)

501 Engine model

L Charge-air co oling

AExhaust gas turbo-

cha rger

1

Engine mode l 501 : 6-cyli nde r,

eng ine model 502: 8-cylinder

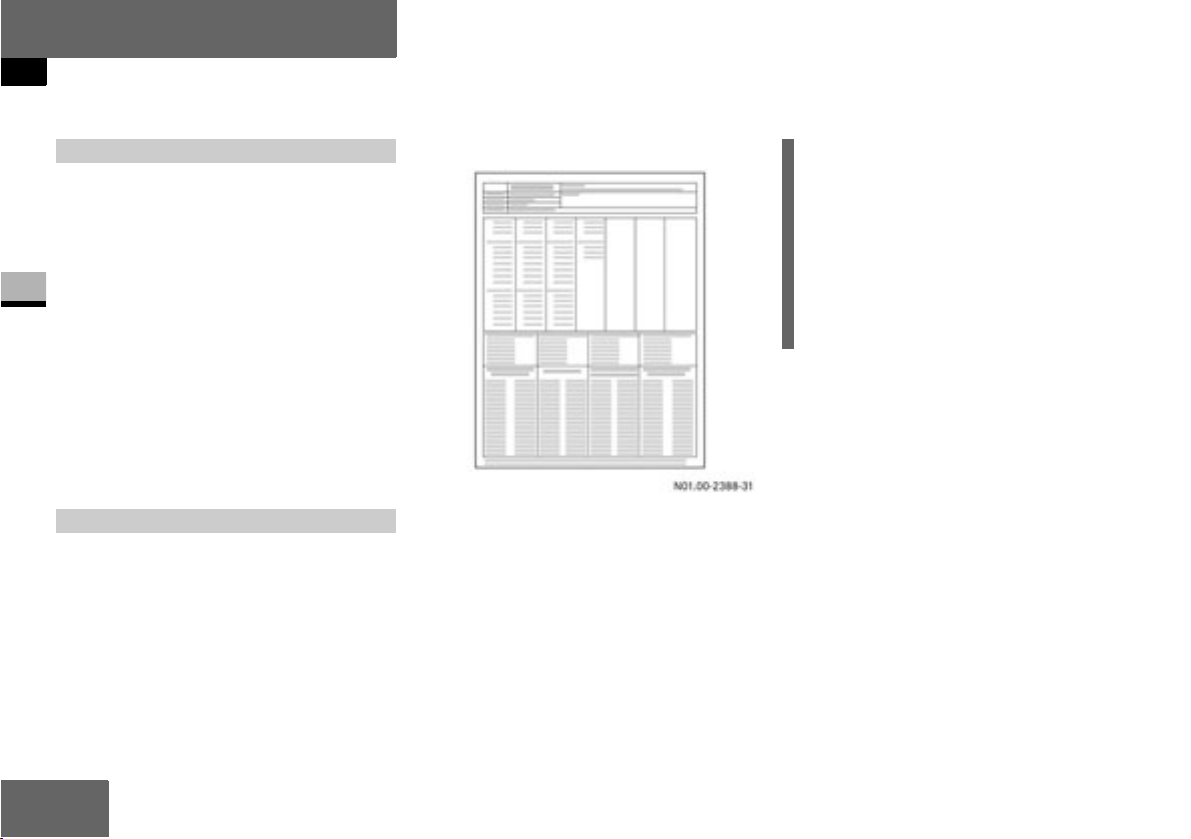

Engi ne da ta card

The en gine d ata c ard (DIN A4 sheet) forms

an i ntegral part of the documents belonging to the engine and should always be

kept w ith the Maintenance Booklet. It contains details about the engine's construction, including special equipment features.

The engine data card must be produced for

the procurement of genuine parts.

i

The engine data card describes the

scope of delivery from the supplying

factory; later changes to the scope of

delivery are not included on the data

card.

1

Engine data card

Always keep the engine data card with

the Maintenance Booklet.

26

Before commissioning

General remarks

Descr iption of th e engine

The OM 501 LA and OM 502 LA engines

are water-cooled 4-stroke direct injection

diesel engines.

The 6 or 8 cylinders are arranged in a

90° V and have separate fuel-injection

pumps (unit pumps) with a short highpressure fuel injection line to the multihole

injection nozzle located centr ally in relation to th e combustion chamber. The unit

pu mp s are moun t ed dir ectly on th e cra nkcase and is dr iven by the camshaft. Each

cylinder has two inlet valves and two exhaust valves.

The OM 501 LA and OM 502 LA engines

are equipped with an exhaust gas turb ocharger and a charge-air cooler as standard. The engine can be optionally equipped

with an engine brake* (throttle valve and

constantly-open throttle valves) and a

flame- sta rt sy stem .

Thanks to their fully electronic control system for controll ing the injection quantity

and injection timing v ia solenoid valves,

thes e are part icularly low-emiss ion engines.

The control system comprises an engineresident control unit, an engine control

(MR) wit h inte gra ted heat excha nger fo r

cooling by means of the forward fuel flow

and an application-related contr ol unit , a

vehicle control (FR) or an adaptation module (ADM), all interconnected via the Controller Area Network (CAN).

2

27

Before commissioning

Genera l rem arks

Flame-start system*

T h e flam e- s tar t s yst em i s a cold - start a i d

for starting at low outside temperatures. It

reduces the white smoke emission after

the engine is st arted. In addition, it reduces the strain on the starter motor and bat-

2

teries by shortening the startup ti me.

Flame-start system

Fuel can be ignited by a flame heater plug

mounted in the charge-air duct intake. The

fuel is supplied to the fl ame heater plug via

a solenoid valv e with a dosing jet.

Flame- sta rt sys te m i ndicato r lamp (exa mpl e)

The flame-start system is primed after a

preglow time (m aximum 20 seconds)

which is dependent on the outside temperature. After this time the flame-start system indicator lamp goes out.

Once the engine has started, the flamestart sys tem is suppli ed w ith fuel by t he engine's fuel delivery pump.

28