Introduction of engine OM 471 and

– This printout will not be recorded by the update service. Status: 09 / 2011 –

exhaust aftertreatment

Introduction into Service Manual

Mercedes>Benz Service

– This printout will not be recorded by the update service. Status: 09 / 2011 –

Introduction of engine OM 471 and

exhaust aftertreatment

Technical status

01.09.2011

Daimler AG . Technical Information and Workshop Equipment(GSP/OI)

D$70546 Stuttgart

Information and copyright

– This printout will not be recorded by the update service. Status: 09 / 2011 –

Product portfolio

You can also find comprehensive information about our

complete product portfolio on our Internet portal:

Link: http://aftersales.mercedes>benz.com

Questions and suggestions

If you have any questions or suggestions concerning this product, please write

to us.

E>Mail: customer.support@daimler.com

Telefax: +49>(0)18 05/0 10>79 78

or alternatively

Address: Daimler AG

GSP/OIS,

HPC R822, W002

D>70546 Stuttgart

(Germany)

©

2011 by Daimler AG

This document, including all its parts, is protected by copyright.

Any further processing or use requires the previous written consent of

Daimler AG, Department GSP/OIS, HPC R822, W002, D>70546 Stuttgart.

This applies in particular to reproduction, distribution, alteration, translation,

microfilming and storage and/or processing in electronic systems, including

databases and online services.

Image no. of title image: W00.01>1015>00

Order no. of this publication: 6517 1260 02 > HLI 000 000 02 82

09/11

SN00.00>W>0001>01HD Preface

– This printout will not be recorded by the update service. Status: 09 / 2011 –

Preface

The intention behind this brochure is to introduce you to the new

6>cylinder inline diesel engine OM 471 along with the new

exhaust aftertreatment system (EATS).

This brochure is intended for the technical personnel entrusted

with the maintenance and repair of Mercedes>Benz trucks.

The content of this brochure is split up into:

•

as>built configuration descriptions

•

function descriptions

•

component descriptions

All the data listed in this brochure correspond with the technical

status as per September 2011.

Any changes or supplements hereto will be published in the

Workshop Information System (WIS) only.

Additional documents for the OM 471 engine and the EATS, such

as maintenance and repair instructions or wiring diagrams are

also available in the Workshop Information System (WIS).

Mercedes>Benz

W‘rth plant, GSP/TTM

September 2011

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

1

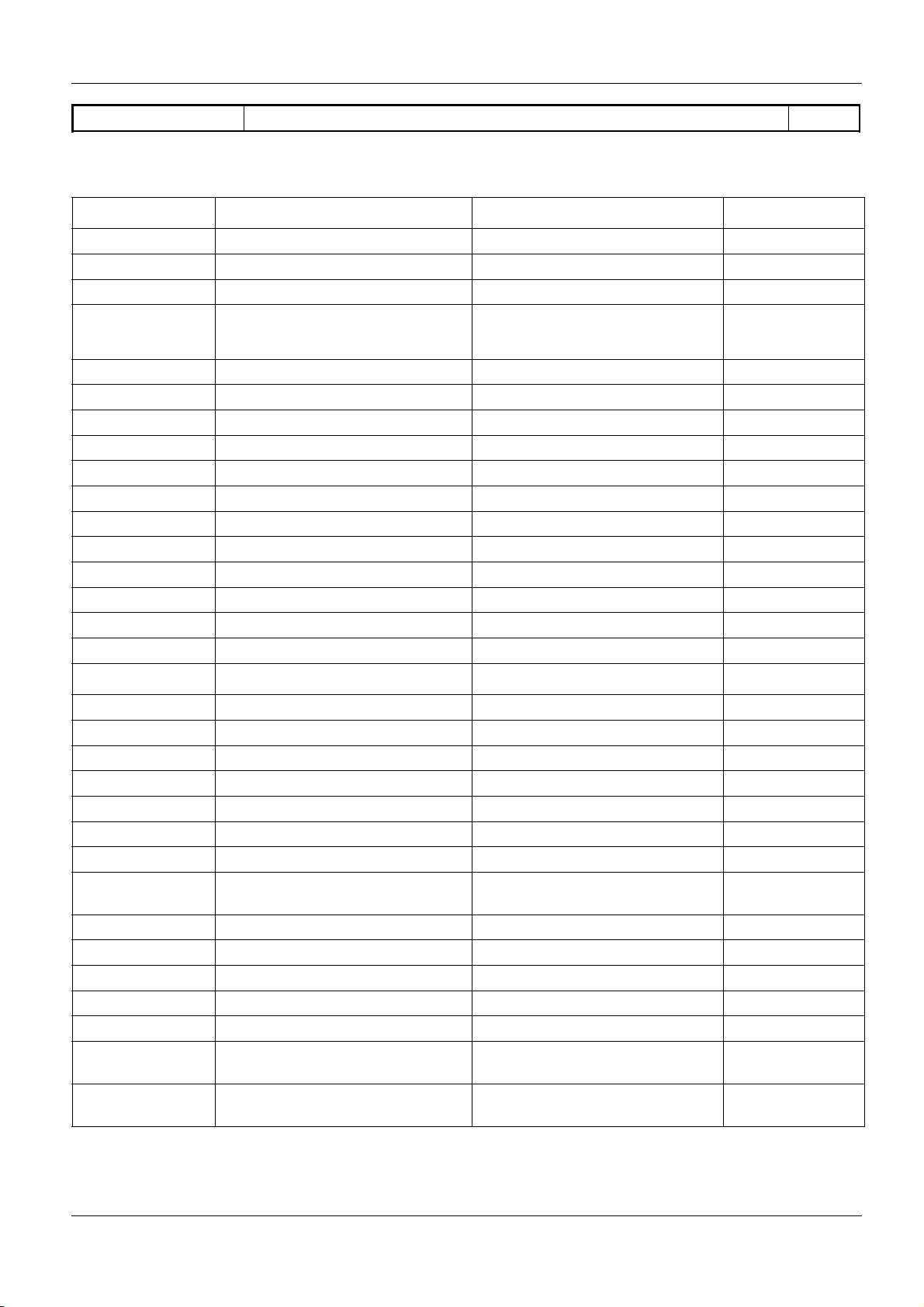

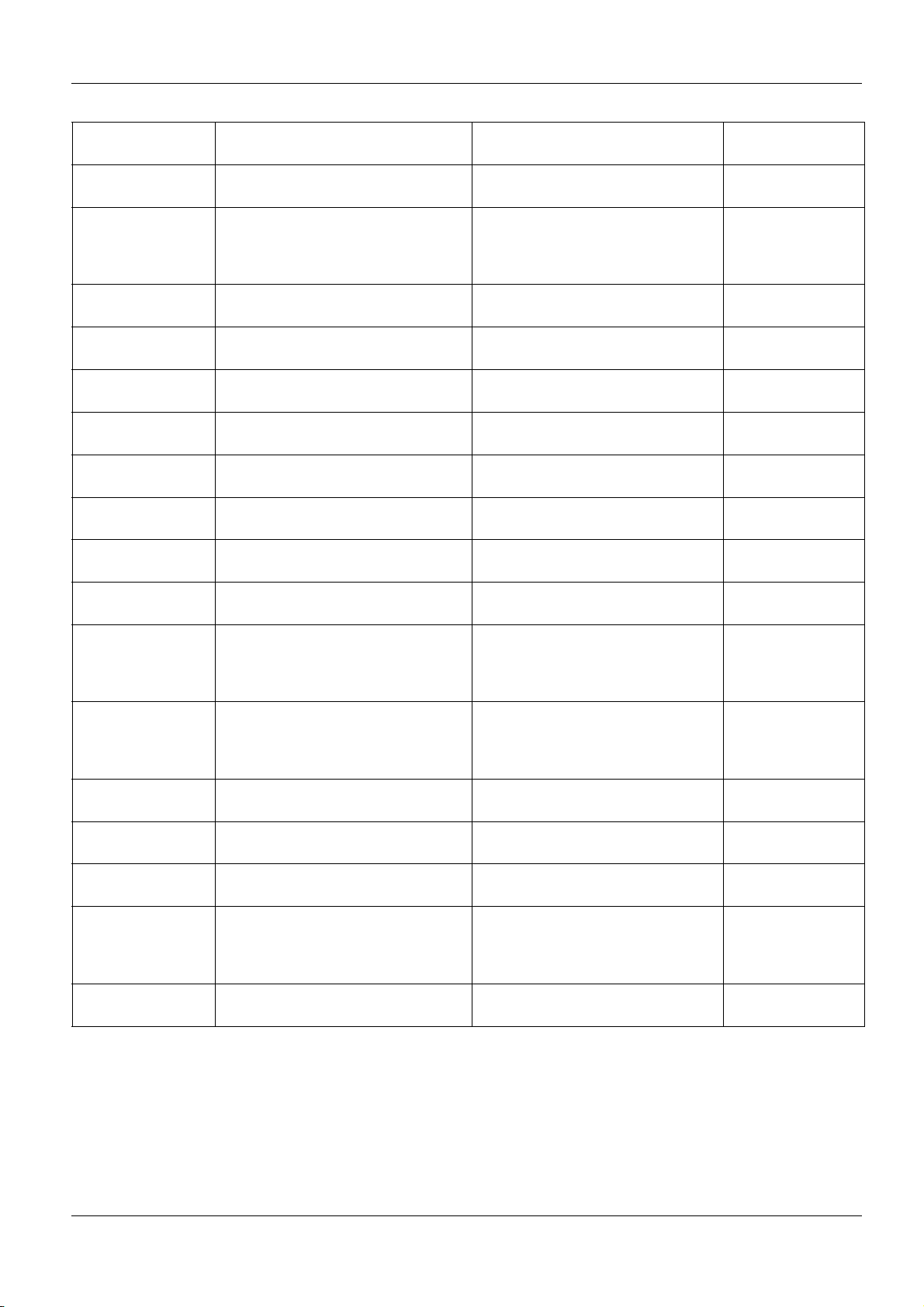

Contents

– This printout will not be recorded by the update service. Status: 09 / 2011 –

SN00.00>W>0110HA

ENGINES 471.9

Overview of as>built configuration and function descriptions 2.8.11

Overview of new features

Engine OM!471

Technical data of diesel engine OM 471

As>built configuration

descriptions

Cylinder head cover, as>built configuration

Cylinder head, as>built configuration

Cylinder head gasket, as>built configuration

Crankcase as>built configuration

Connecting rod, as>built configuration

Piston, as>built configuration

Crankshaft, as>built configuration

Valve control; as>built configuration

Gear drive, as>built configuration

Camshaft, as>built configuration

Belt drive, as>built configuration

Page 10

Page 11

Page 12

Page 13

Page 18

Page 19

Page 21

Page 22

Page 23

Page 24

Page 29

Page 31

Page 32

Function descriptions

Crankcase ventilation system function

Charging, function

Engine management, function

Engine management, overall network

Engine management, behavior in the event

of malfunctions

Start procedure, function

Idle speed control, function

Working speed control, function

Driving, function

Engine shutoff procedure, function

Determination of the engine speed and

crankshaft angle, function

Determination of the compression stroke at

cylinder 1, function

Page 34

Page 35

Page 37

Page 39

Page 40

Page 42

Page 44

Page 46

Page 48

Page 50

Page 53

Page 54

2

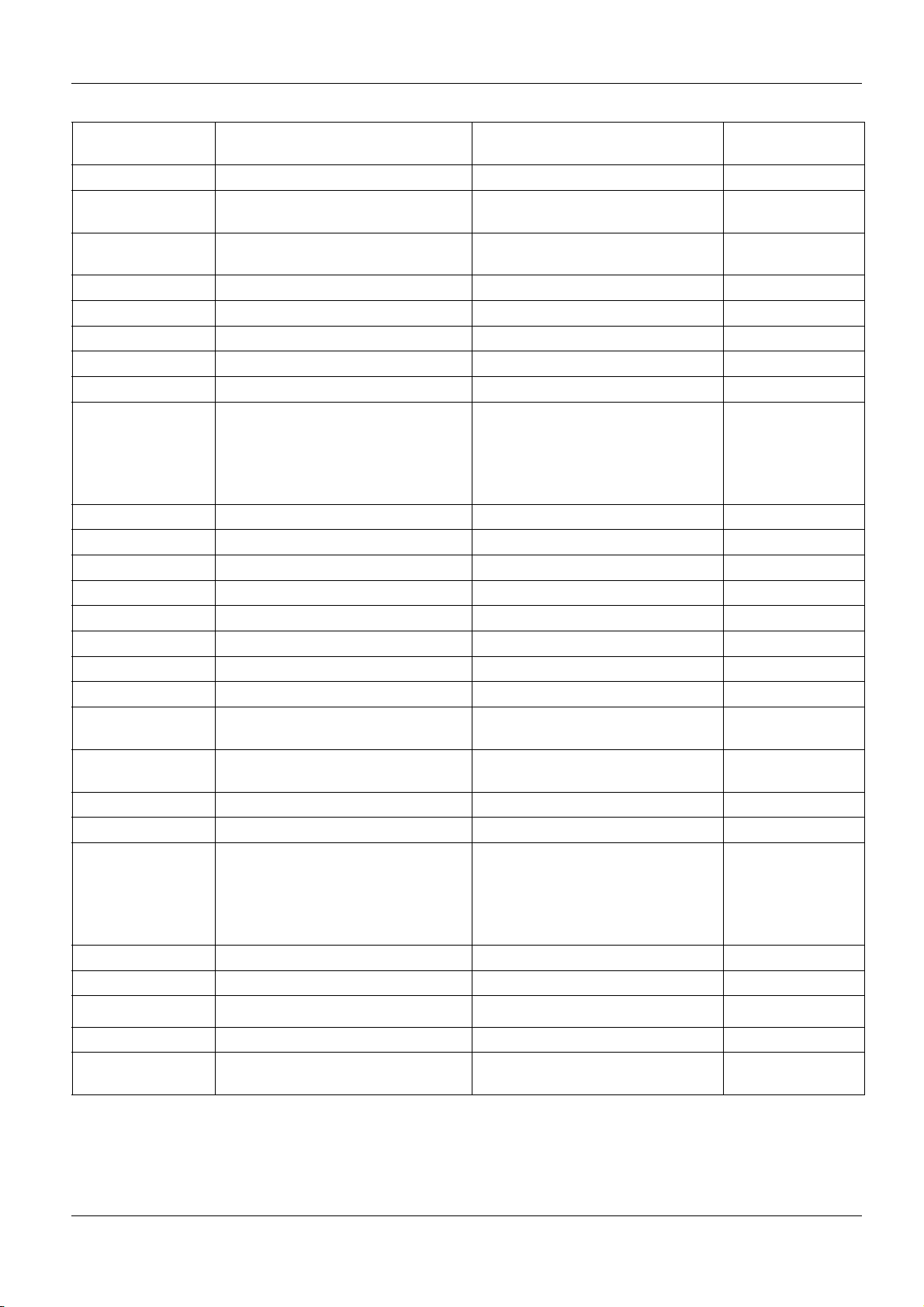

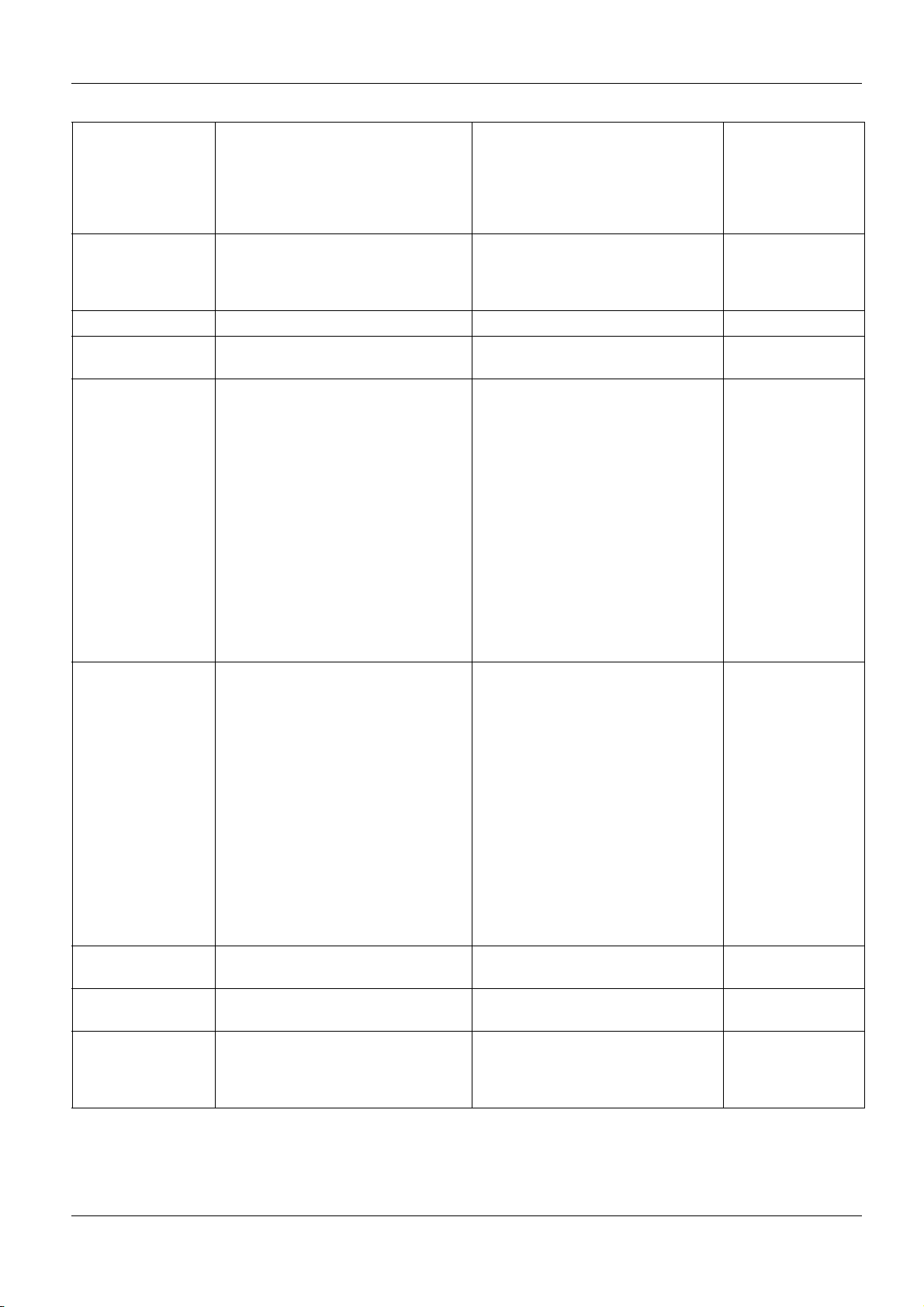

Contents

– This printout will not be recorded by the update service. Status: 09 / 2011 –

Determination of coolant temperature,

function

Determination of air mass, function

Determination of the fuel temperature,

function

Function of the specified engine torque

calculation

Engine brake, function

Exhaust gas recirculation, function

Exhaust aftertreatment, function Vehicles with code (M5R) Engine version

EEV and vehicles with code (M5Y) Engine

version Euro V

Vehicles with code (M5Z) Engine version

Euro VI

Exhaust aftertreatment, overall network

Engine oil circuit, function

Engine oil circuit, diagram

Page 55

Page 56

Page 57

Page 58

Page 60

Page 66

Page 68

Page 73

Page 79

Page 80

Page 82

Coolant circuit, function

Coolant circuit, diagram

Engine cooling thermal management,

function

Engine cooling thermal management,

overall network

Fuel supply, function

Fuel low pressure circuit function Vehicles with code (M5R) Engine version

Fuel high pressure circuit function

i Only in vehicles with code (M7T)

Coolant pump, controlled.

EEV and vehicles with code (M5Y) Engine

version Euro V

Vehicles with code (M5Z) Engine version

Euro VI

Component descriptions

Central gateway control unit (CGW),

component description

A2

Page 83

Page 86

Page 87

Page 90

Page 91

Page 93

Page 96

Page 100

Page 101

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

3

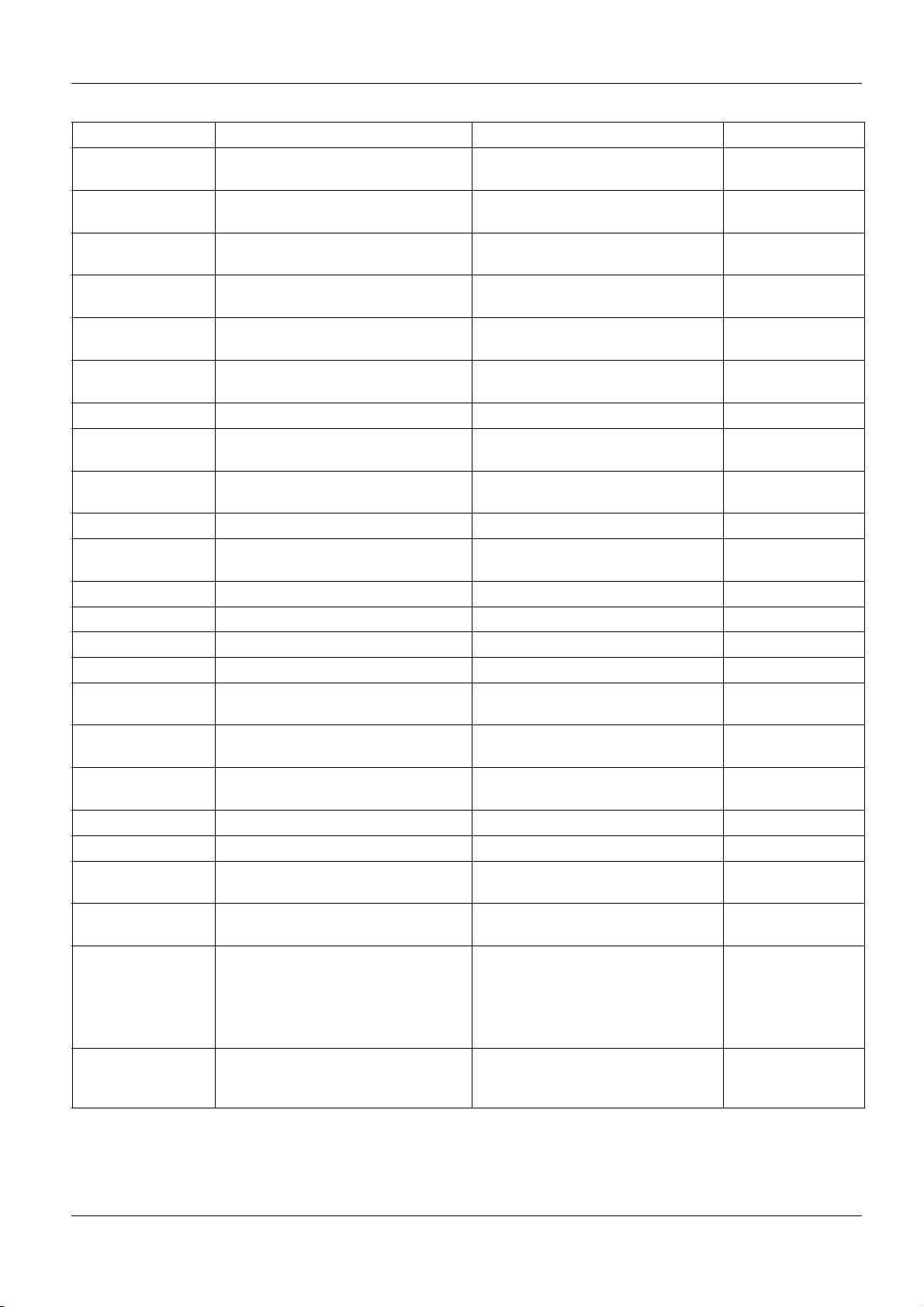

Contents

– This printout will not be recorded by the update service. Status: 09 / 2011 –

Component description drive control (CPC)

control unit

Component description for engine

management (MCM) control unit

Electronic Brake Control control unit (EBS),

component description

Parameterizable special module (PSM)

control unit component description

Battery disconnect switch control unit,

component description

Radiator shutters, component description A54, A55

A3

A4

A10b, A10c

A22

A33

i Only in vehicles with one of the

following codes:

•

Code (E5T) ADR model class EX/II,

including AT

•

Code (E5U) ADR model class EX/III,

including EX/II and AT

•

Code (E5V) ADR model class FL,

including EX/II, EX/III and AT

•

Code (E5X) ADR model class AT

•

Code (E5Z) Accessories, ADR

•

Code (E9D) Preinstallation, for bipolar

battery disconnect switch

•

Code (E9E) ADR preinstallation, without

chassis shielding

Page 102

Page 103

Page 105

Page 106

Page 107

Page 109

i Only in vehicles with code (M7K)

Radiator shutters.

EATU output NOx sensor, component

description

Pump module, component description A58, M25

Exhaust aftertreatment (ACM) control unit,

component description

AdBlue metering device, component

description

EATU input NOx sensor, component

description

A57, A57 b1

Vehicles with code (M5R) Engine version

EEV and vehicles with code (M5Y) Engine

version Euro V

Vehicles with code (M5Z) Engine version

Euro VI

A60

Vehicles with code (M5R) Engine version

EEV and vehicles with code (M5Y) Engine

version Euro V

Vehicles with code (M5Z) Engine version

Euro VI

A67

A70, A70 b1

Vehicles with code (M5R) Engine version

EEV and vehicles with code (M5Y) Engine

version Euro V

Page 110

Page 112

Page 115

Page 117

Page 119

Page 121

Page 123

4

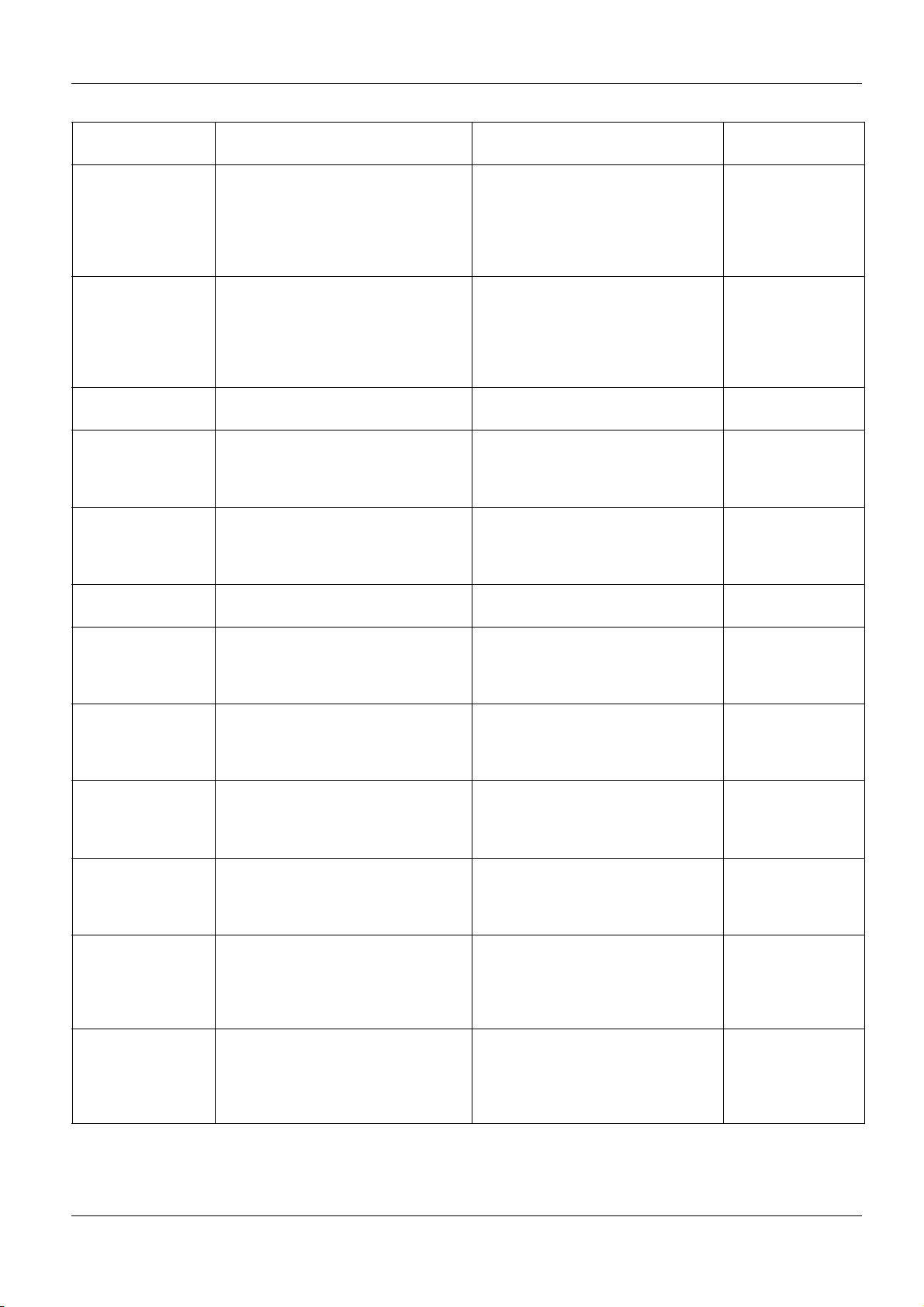

Contents

– This printout will not be recorded by the update service. Status: 09 / 2011 –

Auxiliary heater heating unit, component

description

Auxiliary heater coolant circulation pump,

component description

Travel and speed sensor, component

description

Exhaust pressure sensor upstream of diesel

oxidation catalytic converter, component

description

Exhaust pressure sensor downstream of

diesel particulate filter, component

description

Component description for accelerator

pedal sensor

Exhaust temperature sensor upstream of

diesel oxidation catalytic converter,

component description

Exhaust temperature sensor downstream of

diesel oxidation catalytic converter, top,

component description

Exhaust temperature sensor downstream of

diesel oxidation catalytic converter, bottom,

component description

Exhaust temperature sensor downstream of

diesel particulate filter, component

description

Exhaust temperature sensor upstream of

SCR catalytic converter, component

description

Exhaust temperature sensor downstream of

SCR catalytic converter, component

description

Vehicles with code (M5Z) Engine version

Euro VI

A901

i Only in vehicles with code (D6M)

Auxiliary water heater, cab or code (D6N)

Auxiliary water heater, cab and electric

motor.

A901 M2

i Only in vehicles with code (D6M)

Auxiliary water heater, cab or code (D6N)

Auxiliary water heater, cab and electric

motor.

B18

B37

i Only for vehicles with code (M5Z)

Engine version Euro VI.

B38

i Only for vehicles with code (M5Z)

Engine version Euro VI.

B44

B67

i Only for vehicles with code (M5Z)

Engine version Euro VI.

B68

i Only for vehicles with code (M5Z)

Engine version Euro VI.

B69

i Only for vehicles with code (M5Z)

Engine version Euro VI.

B70

i Only for vehicles with code (M5Z)

Engine version Euro VI.

B72

i Only in vehicles with code (M5R) Engine

version EEV and in vehicles with code

(M5Y) Engine version Euro V.

B73

Vehicles with code (M5R) Engine version

EEV and vehicles with code (M5Y) Engine

version Euro V

Page 125

Page 128

Page 130

Page 131

Page 132

Page 133

Page 134

Page 135

Page 136

Page 137

Page 138

Page 139

Page 140

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

5

Contents

– This printout will not be recorded by the update service. Status: 09 / 2011 –

AdBlue fill level sensor/temperature sensor,

component description

Coolant pressure control sensor, component

description

Component description for crankshaft

position sensor

Component description for camshaft

position sensor

Component description for fuel

temperature sensor

Oil pressure sensor, description of

components

Component description for engine oil fill

level sensor

Component description for exhaust coolant

temperature sensor

Component description for intake coolant

temperature sensor

Charge air pressure and temperature sensor

in charge air pipe, component description

Turbine wheel rpm sensor, component

description

Component description for temperature

sensor downstream of air filter

Charge air temperature sensor in charge air

housing, component description

Exhaust gas recirculation differential

pressure sensor, component description

Component description for rail pressure

sensor

Diesel fuel metering device, component

description

Fuel filter module pressure sensor,

component description

Vehicles with code (M5Z) Engine version

Euro VI

B74

B87

i Only in vehicles with code (B3H)

Secondary water retarder.

B600

B601

B602

B604

B605

B606

B607

B608

B610

i Only for vehicles with code (M5Z)

Engine version Euro VI.

B611

i Only for vehicles with code (M5Z)

Engine version Euro VI.

B617

B621

B622

B625, B626, Y628, Y629

i Only for vehicles with code (M5Z)

Engine version Euro VI.

B638

Page 141

Page 142

Page 144

Page 145

Page 146

Page 147

Page 148

Page 149

Page 150

Page 151

Page 152

Page 153

Page 154

Page 155

Page 156

Page 157

Page 158

Page 159

6

Contents

– This printout will not be recorded by the update service. Status: 09 / 2011 –

Component description for coolant pump B640, Y631

i Only in vehicles with code (M7T)

Coolant pump, controlled.

No component description was created for

vehicles with a rigid coolant pump.

Residual heat pump, component description M20

i Only in vehicles with code (D6I)

Residual heat utilization.

Tachograph (TCO) component description P1

Electronic ignition lock (EIS), component

description

EMERGENCY OFF switch, component

description

EMERGENCY OFF switch frame, component

description

Engine start and engine stop button,

component description

Heating shutoff valve, component

description

Coolant pressure control solenoid valve,

component description

S1

S30

i Only in vehicles with one of the

following codes:

•

Code (E5T) ADR model class EX/II,

including AT

•

Code (E5U) ADR model class EX/III,

including EX/II and AT

•

Code (E5V) ADR model class FL,

including EX/II, EX/III and AT

•

Code (E5X) ADR model class AT

•

Code (E5Z) Accessories, ADR

•

Code (E9D) Preinstallation, for bipolar

battery disconnect switch

•

Code (E9E) ADR preinstallation, without

chassis shielding

S31

i Only in vehicles with one of the

following codes:

•

Code (E5T) ADR model class EX/II,

including AT

•

Code (E5U) ADR model class EX/III,

including EX/II and AT

•

Code (E5V) ADR model class FL,

including EX/II, EX/III and AT

•

Code (E5X) ADR model class AT

•

Code (E5Z) Accessories, ADR

•

Code (E9D) Preinstallation, for bipolar

battery disconnect switch

•

Code (E9E) ADR preinstallation, without

chassis shielding

S600

Y49

Y53

i Only in vehicles with code (B3H)

Secondary water retarder.

Page 160

Page 162

Page 163

Page 164

Page 165

Page 166

Page 167

Page 168

Page 169

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

7

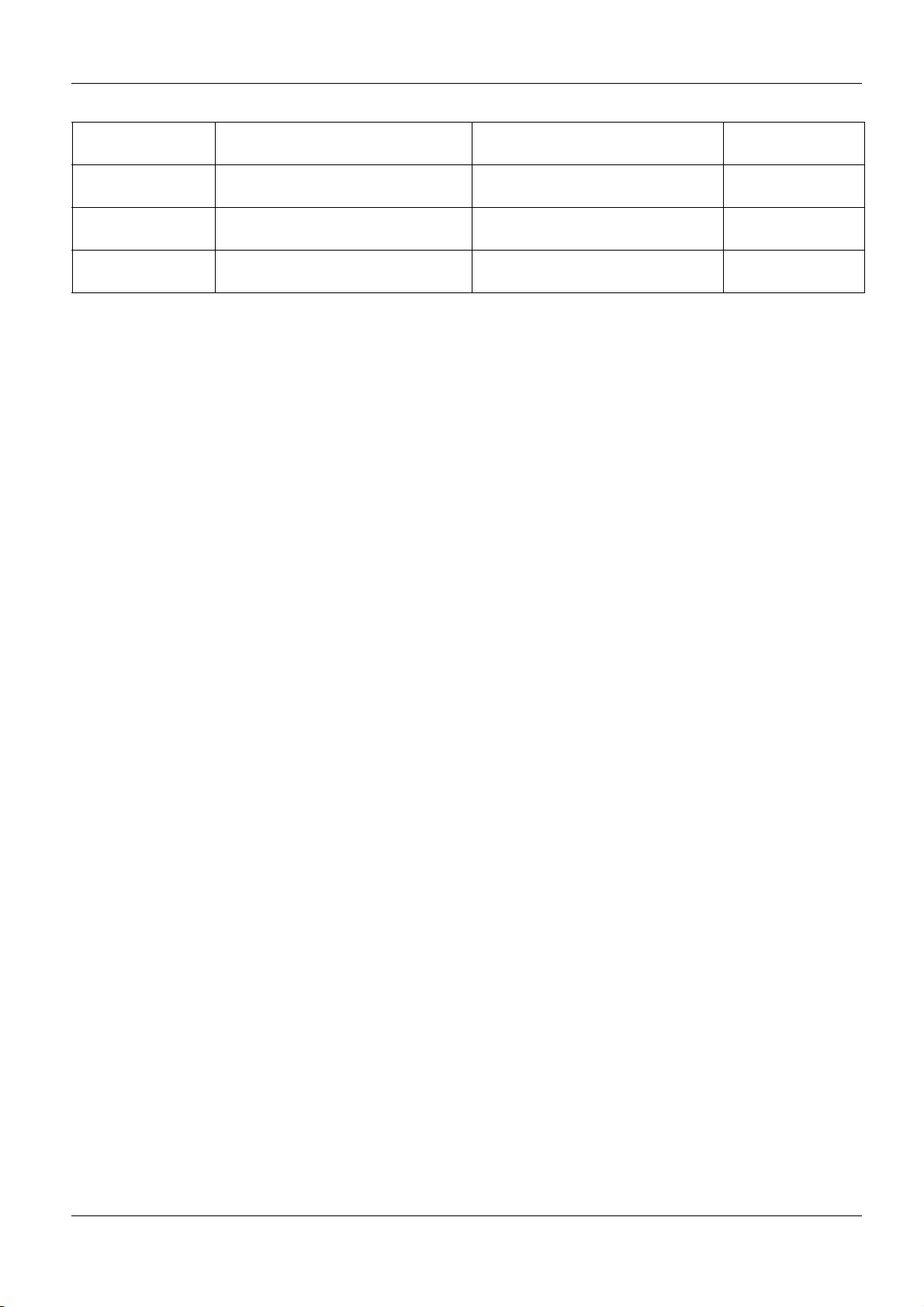

Contents

– This printout will not be recorded by the update service. Status: 09 / 2011 –

Component description for fuel injectors Y608. to Y613

Component description for the

electromagnetic viscous coupling

Component description for exhaust gas

recirculation controller

Component description for engine brake

solenoid valve

AdBlue“ heater coolant solenoid valve,

component description

Component description for boost pressure

regulator

Component description for quantity control

valve

Oil separator component description

Component description for fuel system high

pressure pump

Pressure limiting valve, component

description

Component description for turbocharger

Component description for exhaust gas

recirculation cooler

Component description for AdBlue tank

Component description for oil pump

Oil/coolant module, component description

Oil thermostat, component description

Component description for oil/water heat

exchanger

Component description for coolant

thermostat

Retarder, component description i Only in vehicles with code (B3H)

Component description for fuel pump

Component description for fuel cooler

Component description for fuel filter

module

Diesel oxidation catalytic converter,

component description

Component description for SCR catalytic

converter

Exhaust aftertreatment unit, component

description

Y616, Y616 b1

Y621

Y624, Y625

Y627

Y636

Y642

Secondary water retarder.

i Only for vehicles with code (M5Z)

Engine version Euro VI.

Vehicles with code (M5R) Engine version

EEV and vehicles with code (M5Y) Engine

version Euro V

Vehicles with code (M5Z) Engine version

Euro VI

Vehicles with code (M5R) Engine version

EEV and vehicles with code (M5Y) Engine

version Euro V

Page 170

Page 174

Page 176

Page 178

Page 180

Page 181

Page 182

Page 183

Page 184

Page 185

Page 186

Page 187

Page 188

Page 189

Page 191

Page 193

Page 194

Page 195

Page 197

Page 203

Page 204

Page 205

Page 208

Page 209

Page 211

Page 213

8

Contents

– This printout will not be recorded by the update service. Status: 09 / 2011 –

Diesel particulate filter of exhaust

aftertreatment unit, component description

Nozzle unit for DPF regeneration,

component description

Heating system heat exchanger, component

description

Vehicles with code (M5Z) Engine version

Euro VI

i Only for vehicles with code (M5Z)

Engine version Euro VI.

i Only for vehicles with code (M5Z)

Engine version Euro VI.

Page 215

Page 218

Page 220

Page 221

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

9

Engine

– This printout will not be recorded by the update service. Status: 09 / 2011 –

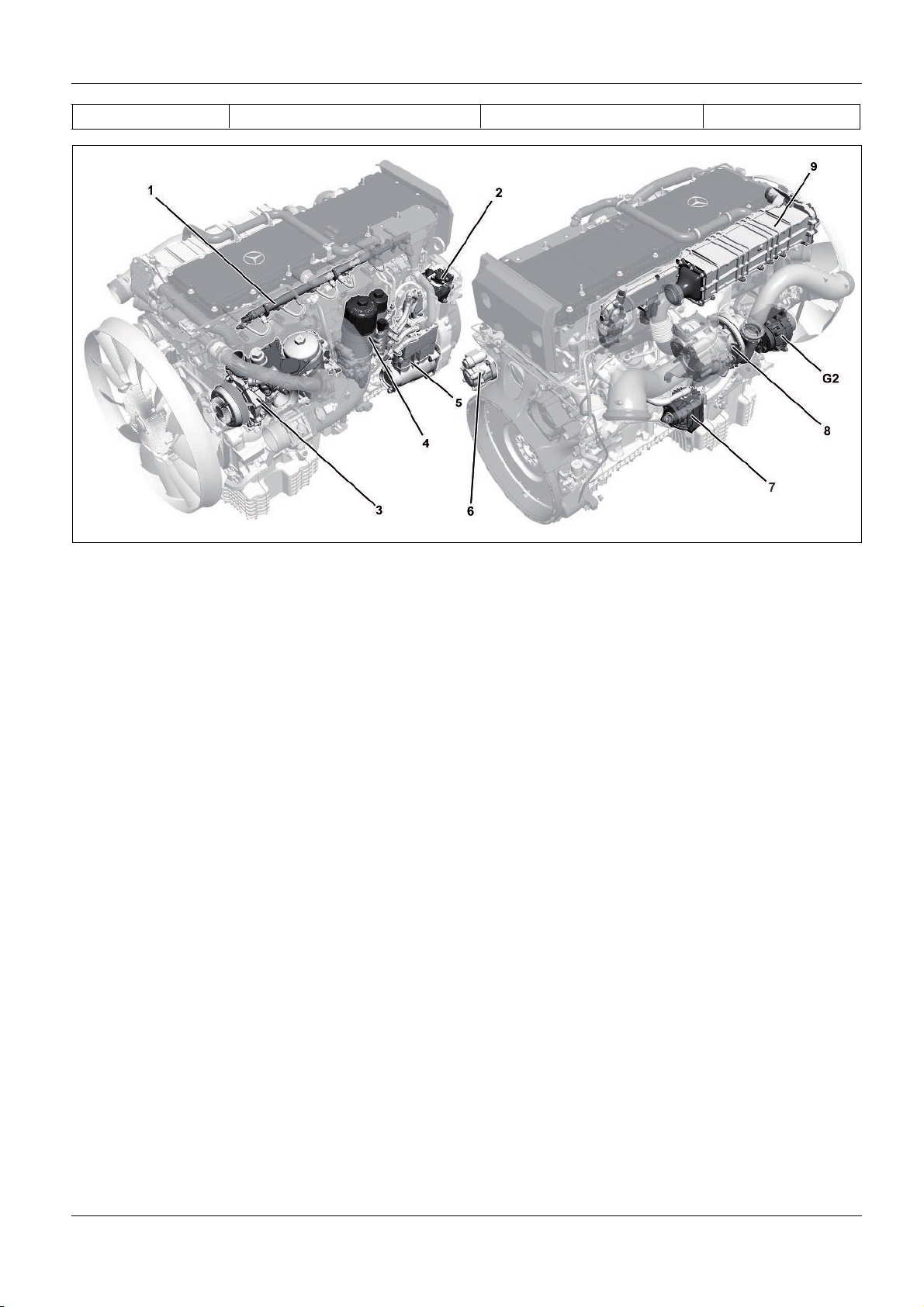

SN00.00>W>0002>04H Engine OM!471

1 Amplified Pressure Common>Rail

System (APCRS)

2 Diesel fuel>metering device (for

regeneration of diesel particulate

filter (DPF))

3 Oil/coolant module

The engine OM 471 is the first 6>cylinder inline engine with two

overhead camshafts to be used in a Mercedes>Benz commercial

vehicle.

Both camshafts are driven by a gear drive which is located at the

output side of the engine. The position of this drive gear makes a

major contribution to reducing noise emission.

The extremely compact design of the engine is based on the

optimized cylinder liner concept in which the overhead seat is

located at the bottom in the crankcase > this design measure

allows the gap between the cylinders to be reduced considerably.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

The positive properties of the new engine have been made

possible by a variety of new technical developments:

•

The new injection system, the amplified pressure common

rail system (APCRS) (1), is the first common rail system to be

used in Mercedes>Benz commercial vehicles that minimizes

the quantity of fuel required for combustion. The advantage

of this system lies in the fact that the rail and high>pressure

lines have a relatively low pressure of 900 bar, and the fuel

pressure required for injecting into the injector is generated,

which has a particularly positive effect on material loads and

therefore on component longevity.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

4 Fuel filter module

5 Compressor

6 Power steering pump

7 Oil separator for crankcase

ventilation system

8 Turbocharger

W01.10>1090>09

9 Cooled and regulated exhaust gas

recirculation (AGR)

G2 Generator

The OM 471 engine is available in four output stages between 310

and 375 kW.

Advantages of new 6>cylinder inline engine:

•

Lower fuel consumption in relation to high output

•

Smooth running characteristics, whereby only four

counterweights are required on the crankshaft

•

Excellent application capability for the various emissions

standards

•

Implementation of particularly high combustion pressures of

up to 230 bar

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

•

The completely redesigned engine brake system has an even

higher braking power.

•

The cooled and regulated exhaust gas recirculation (EGR) (9)

and the diesel particulate filter (DPF) as well as the modified

oil separator of the crankcase ventilation system (7) ensure

that tomorrow's emissions regulations can also be met.

•

The regulated coolant pump installed in the oil/coolant

module (3), which has already been installed in Actros

vehicles, also contributes to fuel economy.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

i With each maintenance and repair work to the engine as well

as to the ancillary assemblies and detachable parts comes the

danger of property damage caused by soiling and foreign bodies.

The high pressure diesel injection system, the intake system and

the oil circuit, in particular, are at risk here.

10

To avoid any damage, when conducting repair work not only the

specified special tools must be used along with observance of the

WIS repair instructions, but in addition to this special care must be

given to cleanliness at the workbay.

Additional information is available in the document

AH00.00>N>5000>01H.

Technical data

– This printout will not be recorded by the update service. Status: 09 / 2011 –

SN00.00>W>0002>05H Technical data of diesel engine OM 471

General information

OM 471

Displacement (l) 12,8

No. of cylinders 6 (in line)

Valve control DOHC

Valve number for each cylinder

(intake/exhaust)

Idle speed (rpm) 560

Compression ratio (f) 17,3

Stroke (mm) 156

Stroke:bore ratio 1,18

Weight (kg) approx. 1200

Power categories

Output (kW) 310 330 350 375

Output (horsepower) 421 449 476 510

Torque (Nm) 2100 2200 2300 2500

2/2

OM 471 with

code M3A

OM 471 with

code M3B

OM 471 with

code M3C

OM 471 with

code M3D

Piston

OM 471

Diameter (mm) 132

Overall height (mm) 113

Compression height (mm) 75

Shank length 71,65

Piston pin

OM 471

Inside diameter (mm) 23.5

Outside diameter (mm) 58

Length (mm) 88

Fuel system

OM 471

Rail pressure, max. (bar) 900

Crankshaft bearing

OM 471

Diameter (mm) 114

Width (mm) 36

Connecting rod

OM 471

Length (mm) 268

Connecting rod bearing

OM 471

Diameter (mm) 95

Width (mm) 36,4

Crankcase, cylinder liner (wet)

OM 471

Cylinder diameter (mm) 132

Cylinder distance (mm) 165

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

11

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

GF01.20>W>0801H

ENGINES 471.9

1 Cylinder head cover

2 Prefilter

3 Elastomer element

4 Elastomer seal

x Direction of travel

Cylinder head cover, as>built configuration 1.7.11

The cylinder head cover (1) consists of plastic and, on the one

hand, prevents ingress of water and foreign objects into the valve

assembly. On the other hand it seals the camshaft case to the

outside using an elastomer seal (4) and prevents escape of the

engine oil used to lubricate the valve assembly.

A prefilter (2) is integrated in the cylinder head cover (1). The

prefilter (2) ensures that the engine oil which is swirled by the

valve assembly and mixes with the blow>by gases is roughly

separated before the blow>by gases are passed on to the oil

separator for the crankcase ventilation system.

W01.20>1046>76

For acoustic decoupling of the cylinder head cover (1) an

elastomer element (3) is inserted in all through holes which serve

to attach the cylinder head cover (1) to the camshaft case. The

elastomer elements (3) reduce noise emissions and possible

damage which can occur due to vibrations.

12

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

GF01.30>W>0800H

Cylinder head, as>built configuration 1.7.11

ENGINES 471.9

The engine OM 471 has a one>piece cylinder head.

There are two intake valves and two exhaust valves for each

cylinder in the cylinder head. The narrow engine design means

that overall a symmetrical location of the valves can ensue. This

symmetrical valve pattern is optimum for the combustion.

Tightening procedure for cylinder head

bolts

1 > 38 Cylinder head bolt (M15¥2) 40 Bolt (M10)39 Bolt (M10)

Cylinder head bolts

In order to ensure that the correct bolts are used when installing

the cylinder head, on each bolt head there is an embossing which

provides information on the thread strength of the respective

cylinder head bolt.

The cylinder head bolts have the M15 2 thread and therefore have

the embossing "15".

All the cylinder head bolts must be tightened in four stages as per

a set tightening pattern. The tightening torques and the

tightening angle can be obtained from the repair instructions.

W01.30>1105>78

As the cylinder head bolts elongate due to assembly, the shank

length for each bolt which has already been used once must be

measured before it is reassembled.

The relevant bolt must be replaced when the permissible shank

length is exceeded.

i The cylinder head bolts are no longer assembled when the

valve assembly is mounted. The valve assembly must be removed

before dismantling the cylinder head.

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

13

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

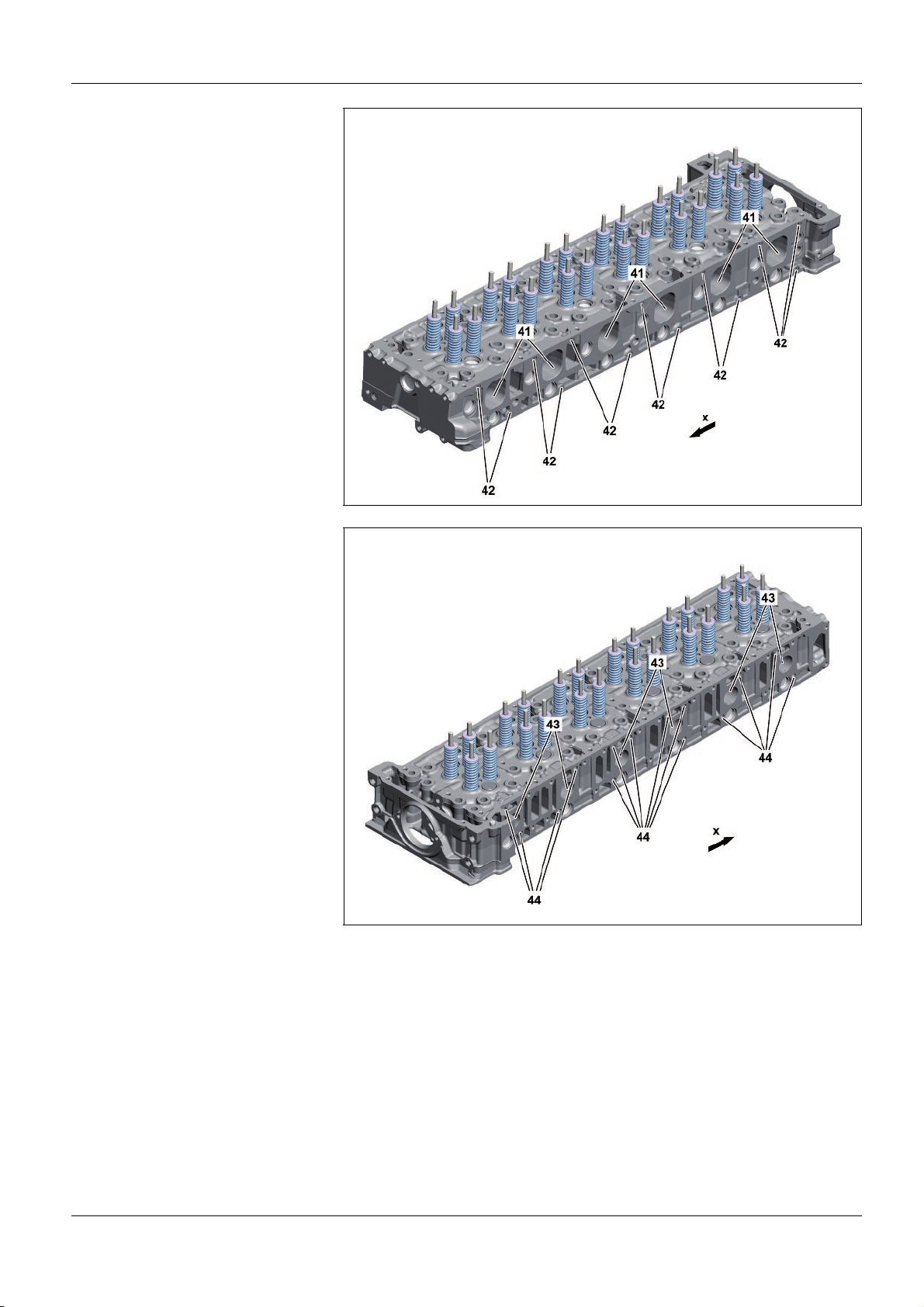

41 Intake ports

42 Threaded holes for the charge air

manifold attachment

x Direction of travel

43 Exhaust ducts

44 Threaded holes for the charge air

manifold attachment

W01.30>1122>76

x Direction of travel

W01.30>1123>76

14

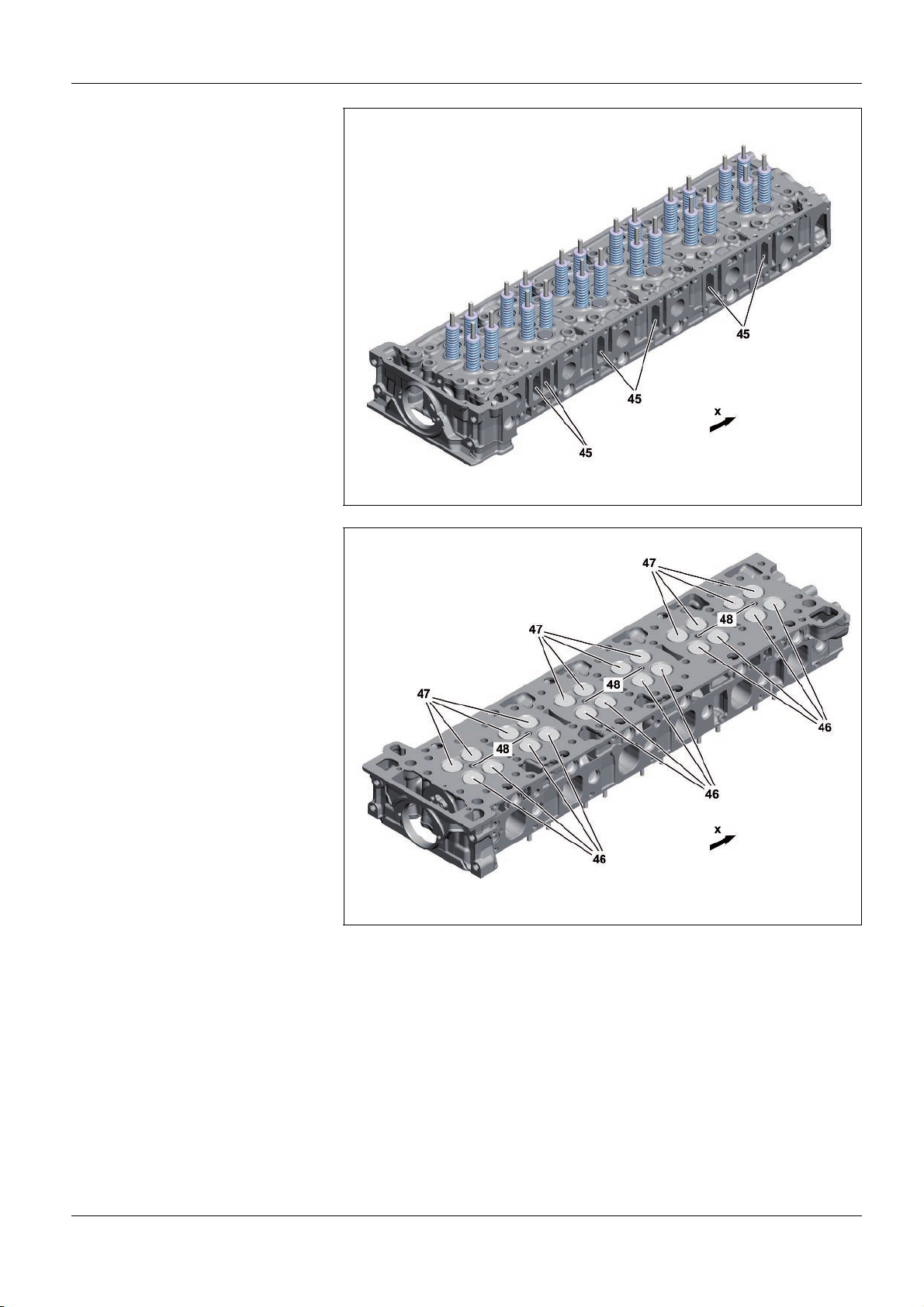

45 Connectors for coolant collector block

– This printout will not be recorded by the update service. Status: 09 / 2011 –

x Direction of travel

46 Inlet valves

47 Exhaust valves

48 Bores for the fuel injectors

As>built configurations

W01.30>1124>76

x Direction of travel

W01.30>1125>76

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

15

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

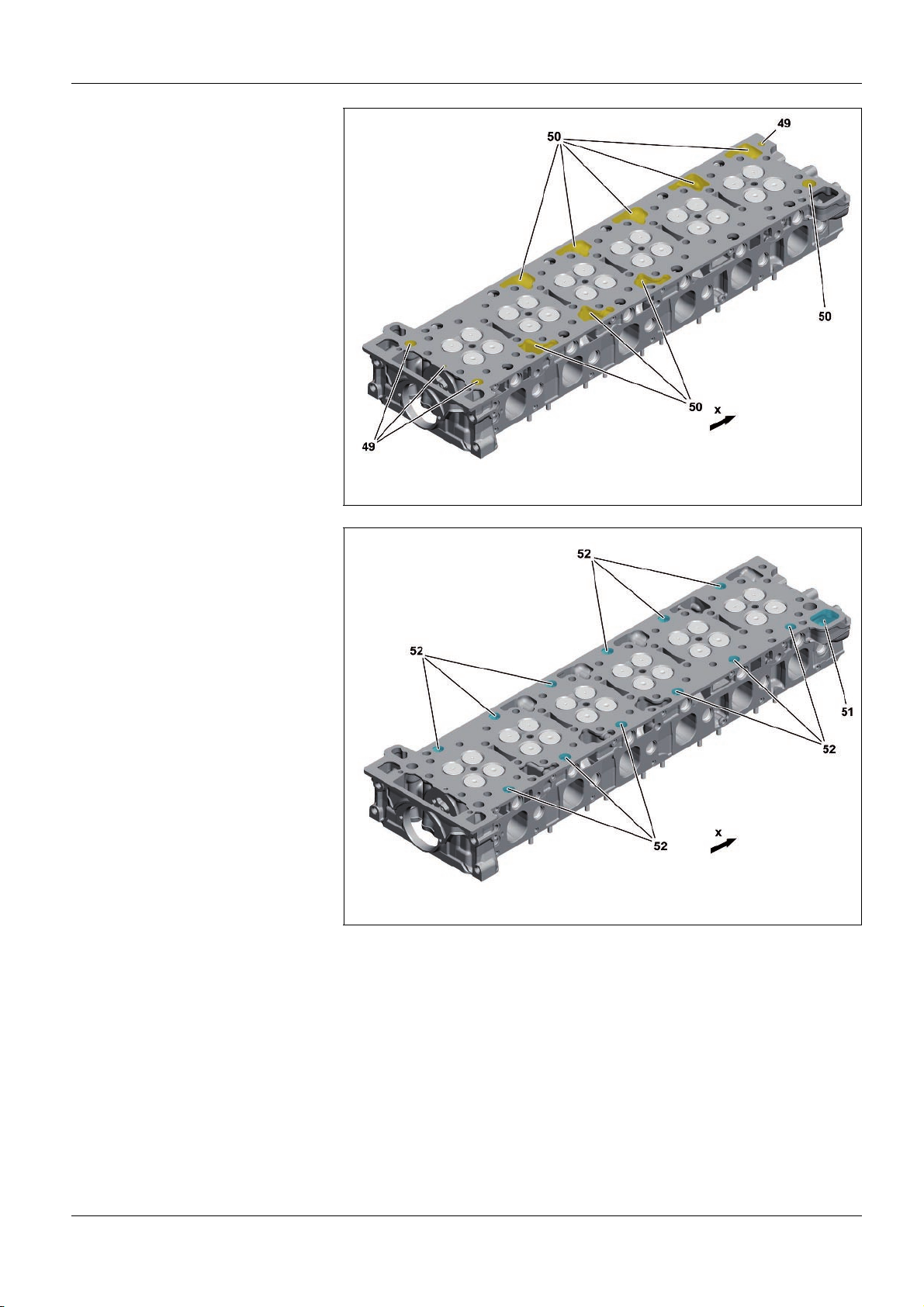

49 OiI overflow holes from cylinder

crankcase to cylinder head

50 Oil return flow openings or oil return

flow holes from cylinder head to

cylinder crankcase

x Direction of travel

51 Coolant short>circuit channel from

cylinder head to cylinder crankcase

52 Coolant overflow holes from cylinder

crankcase to cylinder head

W01.30>1126>76

x Direction of travel

W01.30>1127>76

16

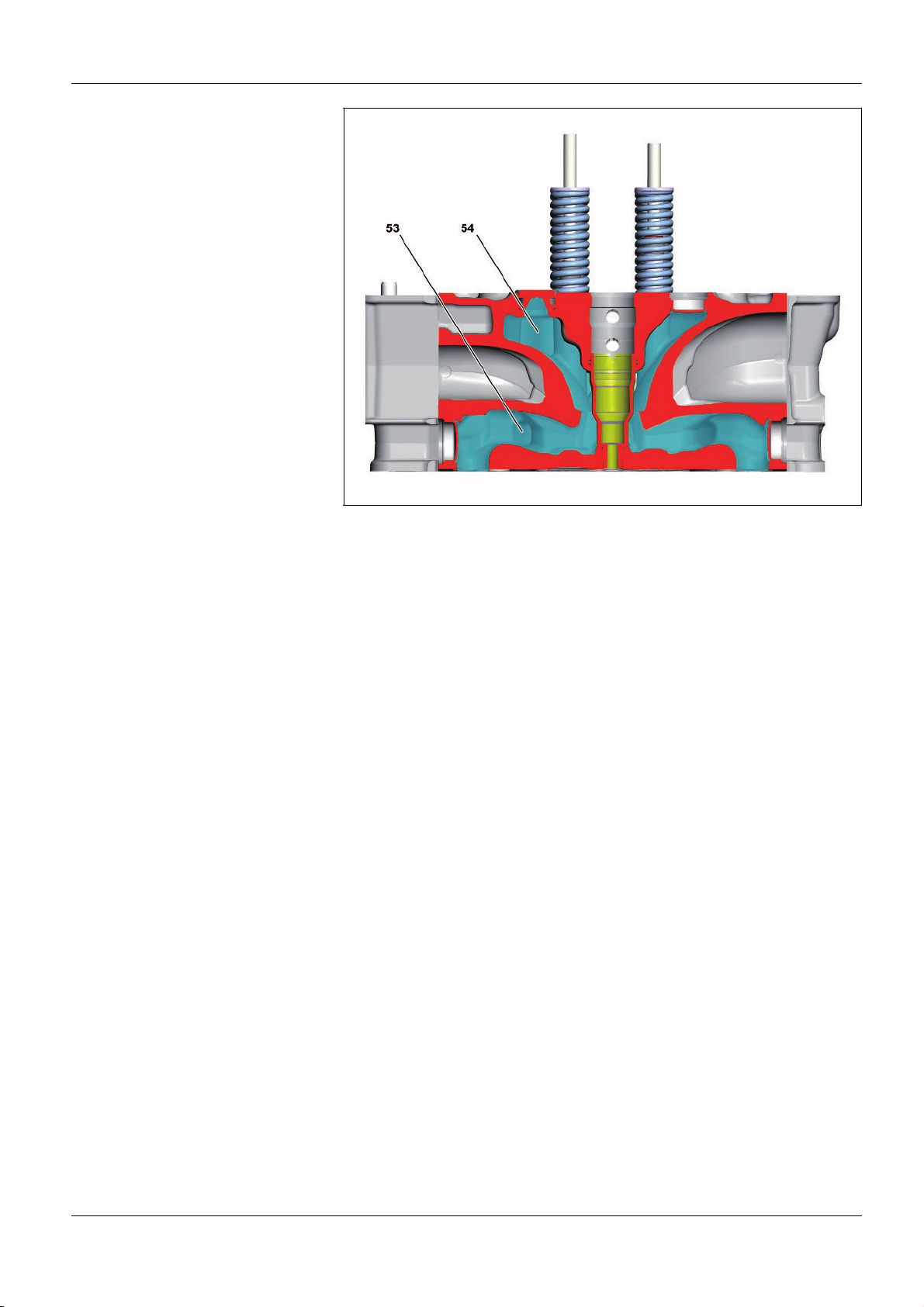

Cooling levers

– This printout will not be recorded by the update service. Status: 09 / 2011 –

53 Lower cooling level

54 Upper cooling level

Cooling

The cylinder head has a divided coolant jacket. This means that

the coolant, after it has flushed around the cylinders, flows into

the cylinder head on the inlet side and on the exhaust side. The

advantage is that the coolant first flushes around the fuel

injectors and valve seat rings in the lower cooling level (53) of the

cylinder head.

As>built configurations

W01.30>1128>76

After this the coolant flows into the upper cooling level (54) of the

cylinder head and cools the valve guides. The coolant is collected

there and directed outwards.

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

17

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

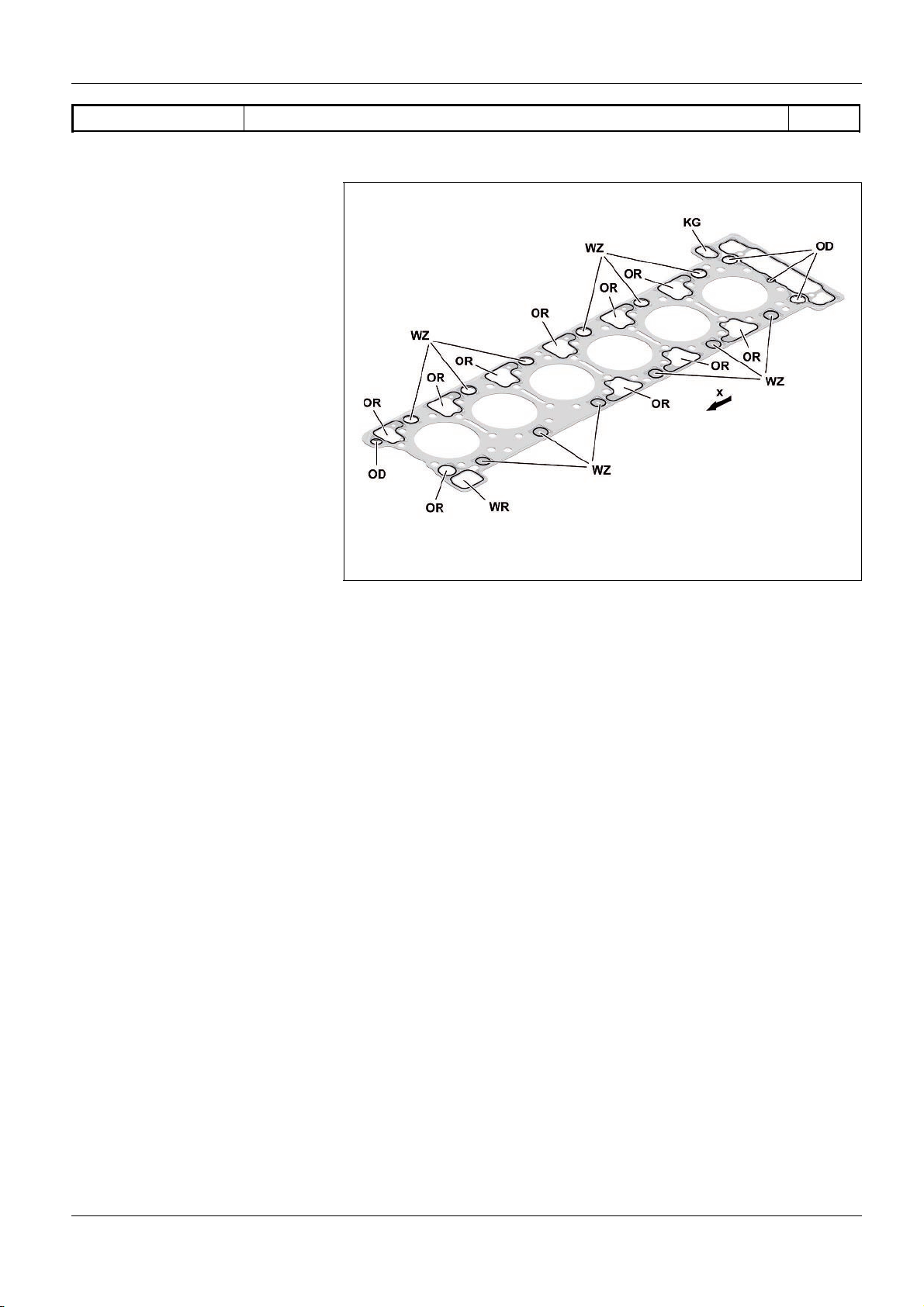

GF01.30>W>0801H

Cylinder head gasket, as>built configuration 1.7.11

ENGINES 471.9

Upper side of the cylinder head seal

OD Engine oil feed openings

OR Engine oil return opening

WR Coolant bypass duct opening

WZ Coolant feed opening

KG Opening for the blow>by duct to the

crankcase ventilation system

x Direction of travel

The cylinder head gasket consists of a number of layers of stainless

steel.

The cylinder head gasket at the engine oil feed openings (OD) and

at the coolant feed opening (WZ) is fitted with raised elastomer

elements through which the seal between the cylinder head and

the cylinder crankcase is improved.

W01.30>1120>06

18

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

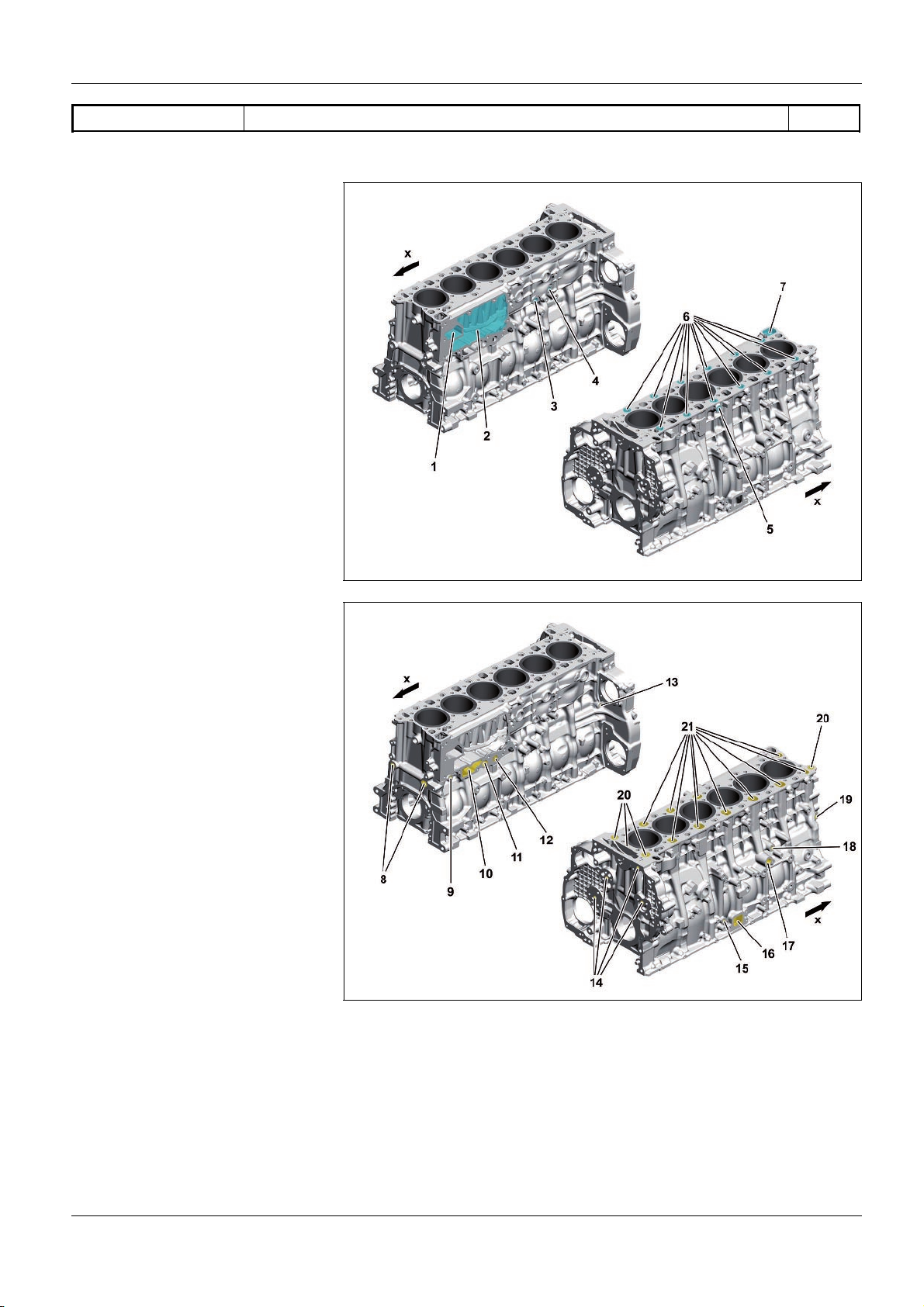

GF01.40>W>0802H

Crankcase as>built configuration 1.7.11

ENGINES 471.9

Crankcase from above, shown with coolant

ducts

1 Coolant bypass duct

2 Recess for oil>water heat exchanger

3 Coolant connection for fuel cooler

4 Coolant connection for compressor

5 Coolant connection for exhaust gas

recirculation positioner

6 Coolant overflow holes to the cylinder

head

7 Coolant return from the cylinder head

x Direction of travel

Crankcase from above, shown with oil

ducts

8 Oil hole closed longitudinally

9 Connection for the oil pressure sensor

10 Oil return duct from oil filter (for

changing the oil filter)

11 Oil feed from oil/coolant module

(from oil filter) to crankcase

12 Oil feed from crankcase (from the oil

pump) to

oil/coolant module

13 Oil hole closed off laterally

14 Bores for oil supply to the gear drive

15 Connection for oil supply of the

centrifuge on the oil separator to the

crankcase ventilation system

16 Oil return duct from oil separator for

crankcase ventilation system

17 Oil return duct from turbocharger

18 Connection for oil supply to the

turbocharger

19 Oil hole closed off laterally

W01.40>1144>76

W01.40>1145>76

20 OiI overflow holes to the cylinder

head

21 Oil return ducts from cylinder head

x Direction of travel

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

19

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

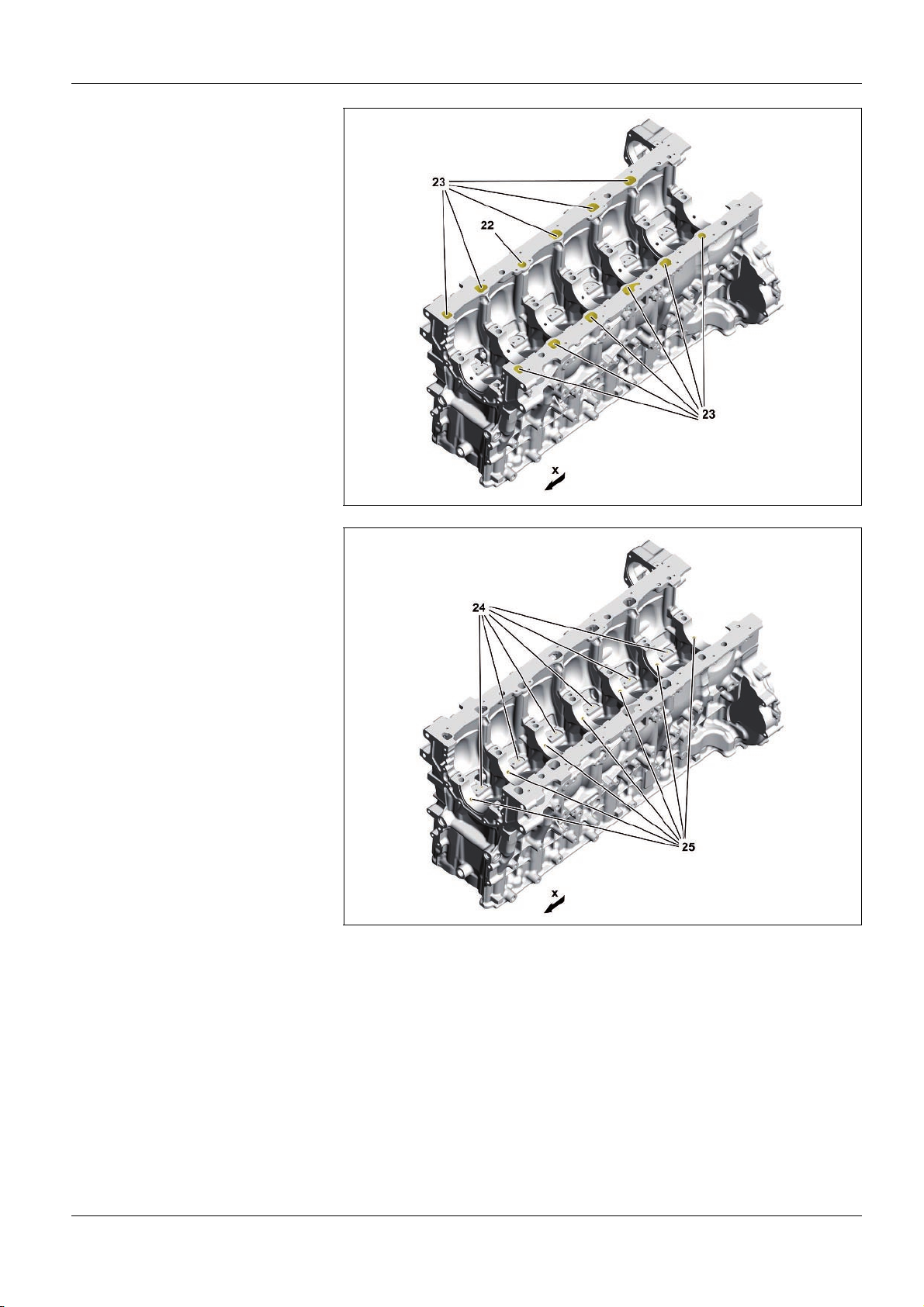

Crankcase from below, shown with oil

ducts

22 Oil return duct to oil/coolant module

23 Oil return ducts to oil pan

x Direction of travel

Crankcase from below, shown with oil

ducts

24 Bores for oil supply to the oil spray

nozzles

25 Bores for oil supply to the main

bearing, crankshaft and connecting

rod bearing

W01.40>1146>76

x Direction of travel

The crankcase consists of cast iron and is characterized by the

following features:

f a high rigidity and low noise emissions due to the vertical

and horizontal reinforcements, as well as due to the design

form of the oil return ducts

f a compact design due to the low distance from the cylinder

The crankcase also has 1.5 mm recesses at the sealing surface to

the cylinder head for all coolant overflow holes to the cylinder

head (6) and for all oil overflow holes to the cylinder head (20).

These serve to receive the respective elastomer elements in the

cylinder head gasket.

W01.40>1147>76

The following major assemblies and components are located on

the crankcase:

Right>hand side

f Turbocharger

f Starter

f Oil separator for crankcase ventilation system

Left>hand side

f Oil/coolant module

f Engine management (MCM) control unit

f Fuel filter module

f Fuel high pressure pump

f Compressor, power steering pump

20

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

GF03.10>W>0800H

Connecting rod, as>built configuration 1.7.11

ENGINES 471.9

1 Connecting rod

2 Connecting rod small end (small)

3 Connecting rod bushing

4 Connecting>rod shank

5 Connecting rod big end

6 Connecting rod bearing shells

7 Connecting rod bearing cap

8 Stretch bolt

The connecting rods are forged in steel and are characterized by

their high strength.

The connecting point between the connecting rod (1) and the

connecting rod bearing cap (7) is cracked. This has the advantages,

amongst other things, that one has no offset after screwing

together both parts and the connecting rod bearing cap (7)

cannot slip.

A connecting rod bushing (3) is pressed into a small connecting

rod small end (2).

W03.10>1119>76

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

21

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

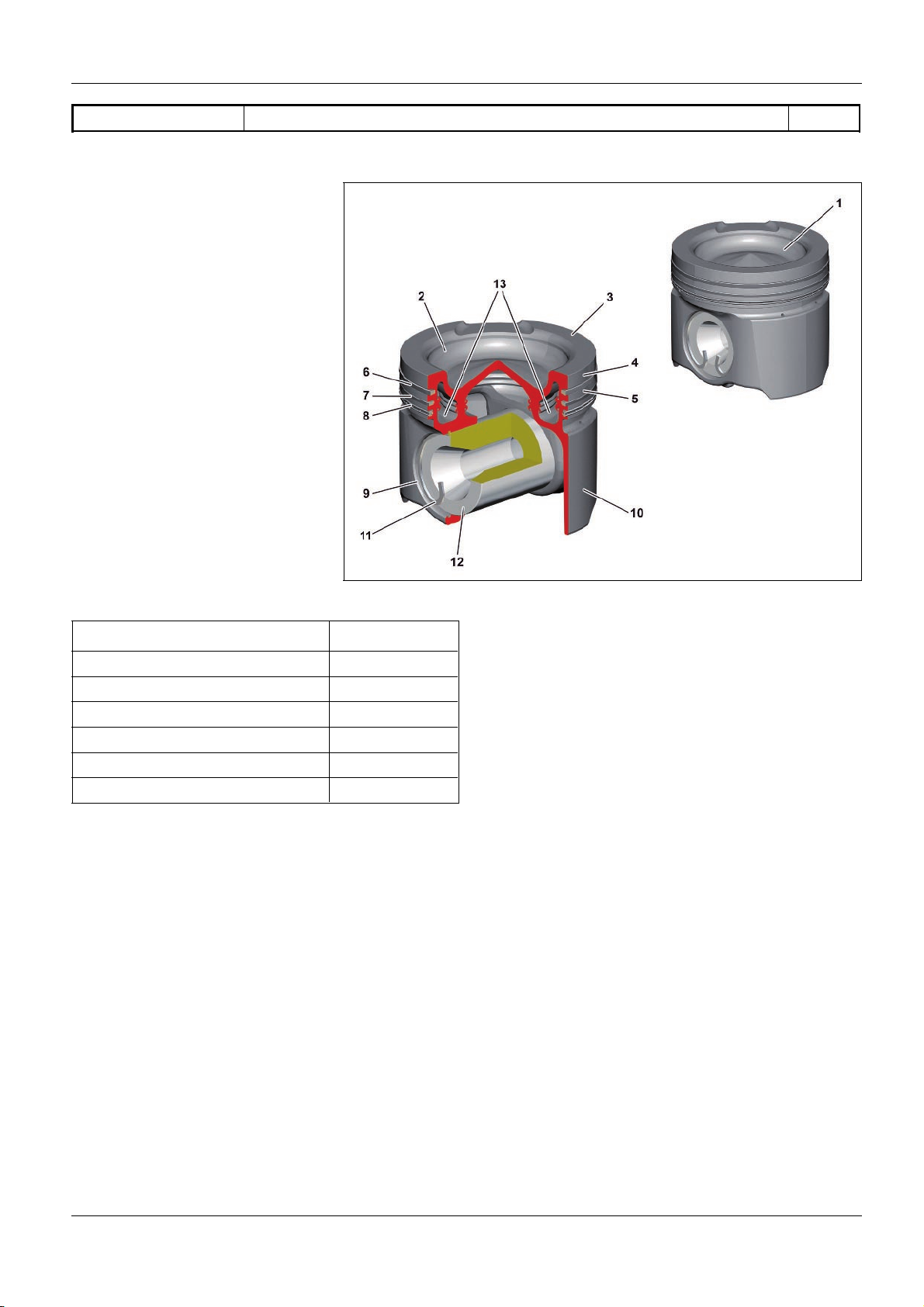

GF03.10>W>0801H

ENGINE 471.9

1 Piston

2 Combustion recess

3 Piston crown

4 Top land

5 Piston ring zone

6 1st piston ring

7 2nd piston ring

8 Oil scraper ring

9 Bolt eye

10 Piston skirt

11 Piston bolt circlip

12 Piston pin

13 Cooling duct

Piston, as>built configuration 2.8.11

Feature

OM 471

Version Two piece

Material Steel

Weight (with spring steel sheet) 3,339 KG

Piston diameter 132 mm

Bolt diameter 58 mm

Surface friction optimized

Piston (1)

The piston (1) consists of a forged upper section and a forged

lower section, which are connected to each other by means of a

friction weld.

Piston crown (3)

The piston crown (3) is fitted with a combustion recess (2).

Through the combustion recess (2) the clearance volume is

partially transferred into the piston (1).

Top land (4)

The top land (4) protects the 1st piston ring (6) against excessively

heating during the combustion process.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

W03.10>1124>76

Piston ring zone (5)

The 1st piston ring (6), the 2nd piston ring (7) and the oil scraper

ring (8) are located in the piston ring zone (5).

The 1st piston ring (6), the 2nd piston ring (7) take on the task of

fine sealing to the crankcase.

The oil scraper ring (8) wipes off excess oil on the cylinder wall and

leads the oil back into the oil pan.

Piston skirt (10)

The piston skirt (10) serves to guide the piston (1) into the cylinder

liner. It transfers the lateral forces to the cylinder wall.

Located in the piston skirt (10) is the bolt eye (9) which supports

the piston pin (12).

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

22

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

Cooling

The piston (1) is cooled via an oil spray nozzle for each cylinder

located in the crankcase.

The oil spray nozzle continuously sprays engine oil into an

injection opening in the cooling duct (13). Due to the coaxial spray

direction of the oil spray nozzle the greatest possible throughput

of engine oil is achieved in the cooling duct (13) and thus cooling

of the piston is improved significantly.

One further opening which is located on the opposite side serves

as a drain.

Additional bores in the cooling duct (13) serve to achieve better

lubrication of the piston pin (12) and the connecting rod bearing

bushing.

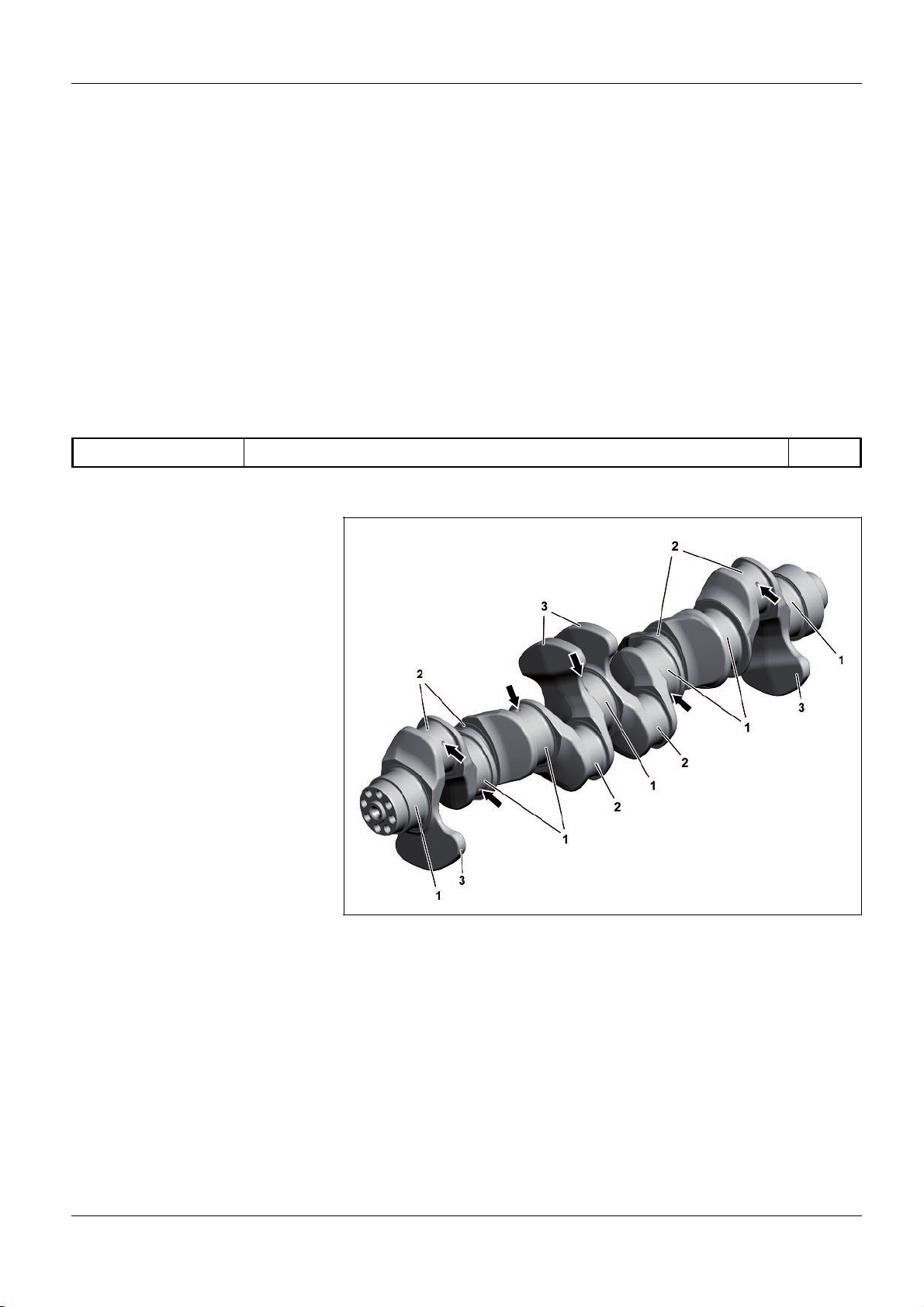

GF03.20>W>0800H

Crankshaft, as>built configuration 2.8.11

ENGINE 471.9

1 Crankshaft bearing journals

2 Connecting rod bearing journals

3 Counterweight

Protecting the contact surfaces

In order to protect the contact surfaces the friction, above all in

the startup phase of the engine, is reduced by the applied

protective coatings. This allows a longer working life and engine

damage is avoided by the emergency running characteristics

which result from the coating if the lubrication is faulty.

Arrows Oil holes

The crankshaft is mounted in the crankcase with 7 crankshaft

bearing journals (1).

Counterweights (3) are forged onto the webs to avoid vibrations

arising.

The crankshaft bearing journals (1) and the connecting rod

journals (2) are inductively hardened and ground in the surface

layer.

W03.20>1216>06

There are oil holes (arrows) on the crankshaft bearing journals (1)

and on the connecting rod journal (2) over which the crankshaft

bearing and connecting rod bearing are lubricated.

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

23

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

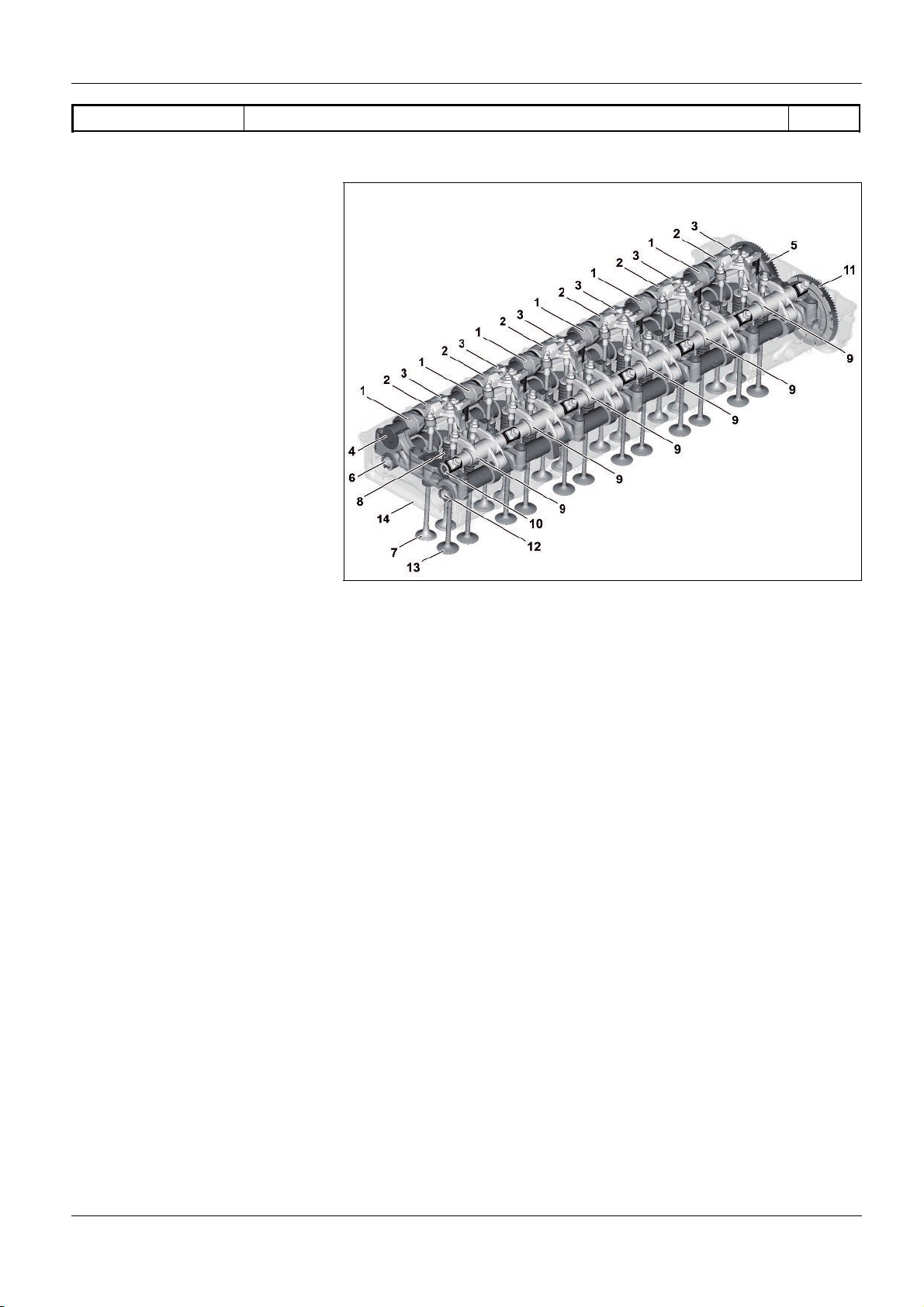

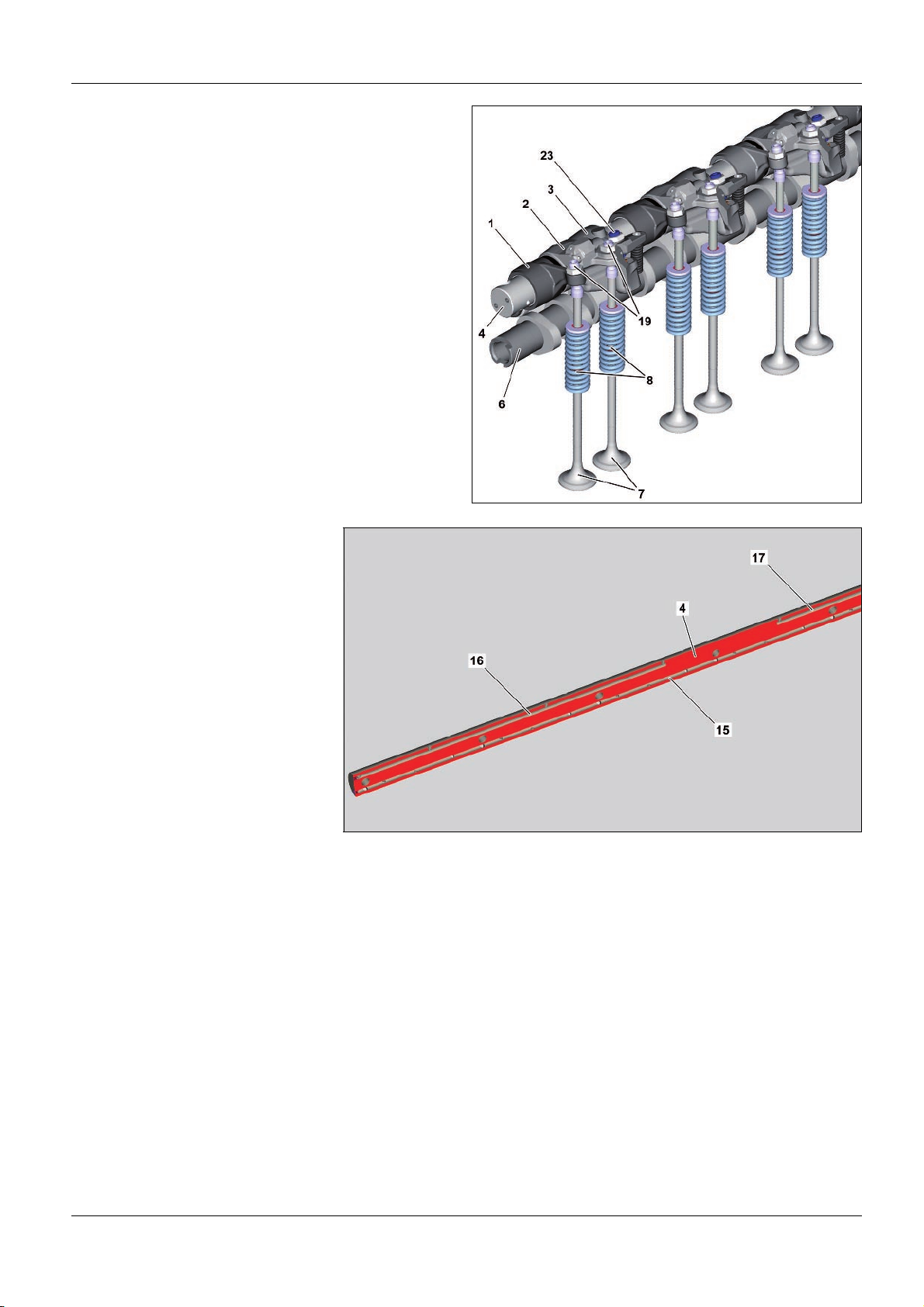

GF05.00>W>0800H

Valve control; as>built configuration 1.7.11

ENGINES 471.9

Valve control overall

1 Exhaust rocker arm

2 Exhaust rocker arm with

hydroelement

3 Brake rocker arm

4 Exhaust rocker arm spindle

5 Drive gear for exhaust camshaft

6 Exhaust camshaft

7 Outlet valve

8 Valve spring

9 Intake rocker arm

10 Intake rocker arm spindle

11 Drive gear for intake camshaft

12 Intake camshaft

13 Inlet valve

14 Camshaft frame

The gas exchange system in the combustion chambers is

controlled via the valve control.

Components of the valve control include:

•

Two upper recumbent camshafts > the intake camshaft (12)

and the exhaust camshaft (6), which are driven by the gear

drive via the pinion gear drive for the intake camshaft (11) or

via the pinion gear drive for the exhaust camshaft (5)

•

Two rocker arm spindles > the intake rocker arm spindle (10)

and the exhaust rocker arm spindle (4) on which the intake

rocker arm (9) or exhaust rocker arm (1), the exhaust rocker

arm with hydroelement (2) as well as the brake rocker arm

(3) are mounted

•

Two exhaust valves (7) and two intake valves (13) per

cylinder which are located symmetrically and pressed onto

their seat via the valve springs (8) if they are not actuated by

the corresponding rocker arm.

W05.00>1033>06

24

Valve control on the exhaust side

– This printout will not be recorded by the update service. Status: 09 / 2011 –

1 Exhaust rocker arm

2 Exhaust rocker arm with hydroelement

3 Brake rocker arm

4 Exhaust rocker arm spindle

6 Exhaust camshaft

7 Exhaust valves

8 Valve springs

19 Adjusting elements for adjusting the valve clearance

23 Adjusting element for engine brake

Design of the exhaust rocker arm spindle

(4)

4 Exhaust rocker arm spindle

15 Lubricating oil duct

16 Oil duct for cylinders 1 and 3

17 Oil duct for cylinders 4 and 6

As>built configurations

W05.00>1034>82

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

W05.00>1035>75

25

As>built configurations

– This printout will not be recorded by the update service. Status: 09 / 2011 –

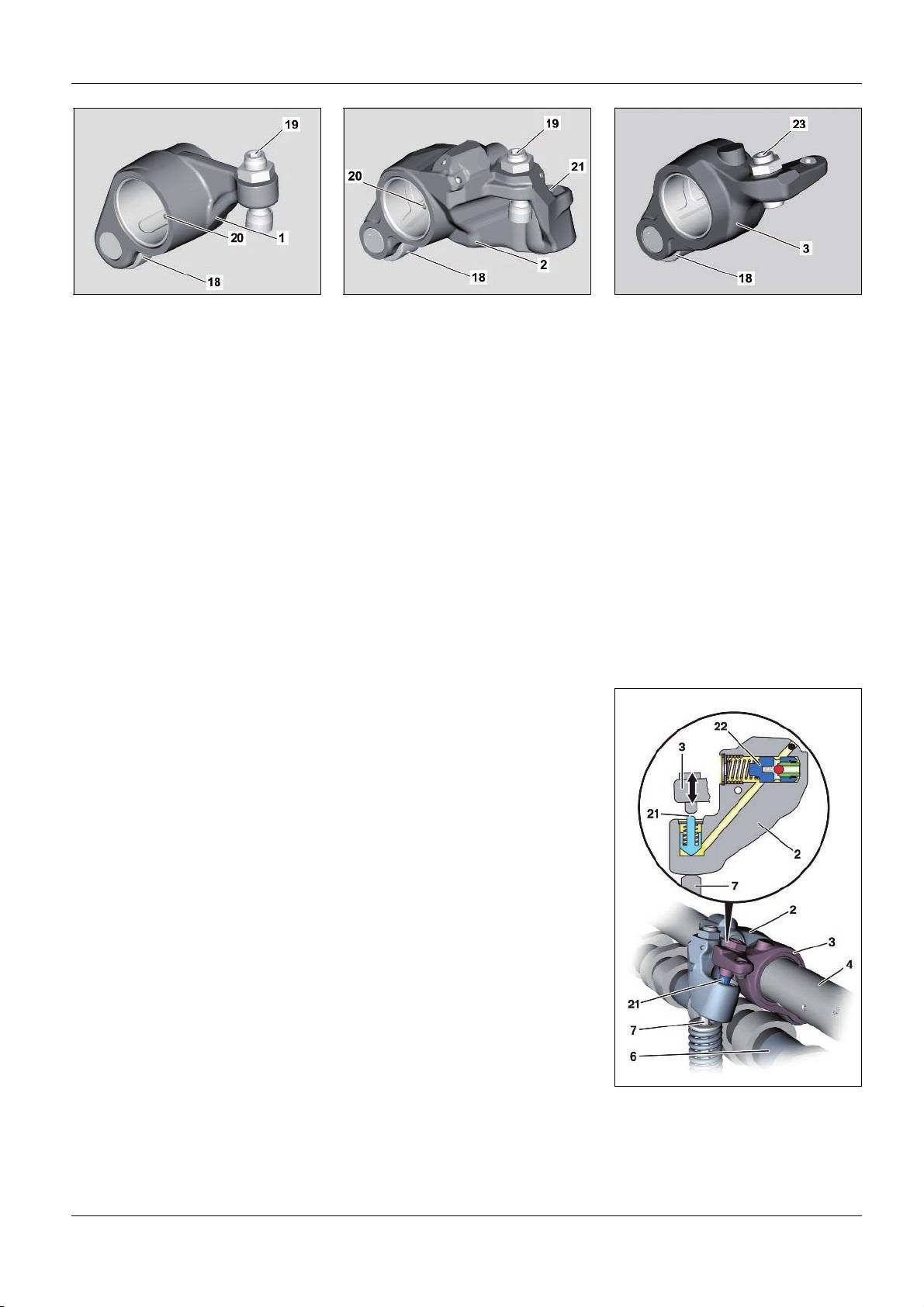

W05.00>1036>01 W05.00>1037>01 W05.00>1038>01

Design of the rocker arm

1 Exhaust rocker arm

18 Rocker arm roller

19 Adjusting element for adjusting the

valve clearance

20 Oil inlet hole

2 Exhaust rocker arm with

hydroelement

18 Rocker arm roller

19 Adjusting element for adjusting the

valve clearance

20 Oil inlet hole

21 Piston

3 Brake rocker arm

18 Rocker arm roller

23 Adjusting element for engine brake

The valve control of the exhaust side is characterized by the fact

that every cylinder has three rocker arms > one exhaust rocker arm

(1), one exhaust rocker arm with hydroelement (2) and one brake

rocker arm (3).

All rocker arms are fitted with a rocker arm roller (18). Use of

rocker arm rollers (18) means that wear between the respective

actuation cams of the exhaust camshaft (6) and the corresponding

rocker arm is reduced. The noise emission of the valve assembly is

also reduced.

Exhaust valve control for a deactivated engine brake

2 Exhaust rocker arm with hydroelement

3 Brake rocker arm

4 Exhaust rocker arm spindle

6 Exhaust camshaft

7 Outlet valve

21 Piston

22 Check valve

Rotational movement of the camshaft is converted into linear travel by the exhaust cam on

the exhaust camshaft (6) and transferred to the associated exhaust rocker arm on the

exhaust rocker arm spindle (4). The exhaust rocker arms steer the linear travel in turn onto

the respective exhaust valves (7) which are opened and then closed again by the valve

springs.

Because the pistons (21) are pressed by a spring to their lower limit stop when the engine

brake is deactivated, no contact takes place between the brake rocker arms (3) and the

exhaust rocker arms with hydroelement (2) and the brake rocker arms (3) run in idle. This

serves to prevent any unnecessary piston (21) motion and therefore any unnecessary wear.

The exhaust rocker arm (1) and exhaust rocker arm with

hydroelement (2) are each equipped with an adjusting element

for adjusting the valve clearance (19). The clearance between the

brake rocker arm (3) and exhaust rocker arm with hydroelement

(2) is set using the adjusting element for the engine brake (23).

The exhaust rocker arm (1), exhaust rocker arm with

hydroelement (2) and brake rocker arm (3) are mounted rotatable

on the exhaust rocker arm spindle (4).

The exhaust rocker arm spindle (4) is made out of solid material

due to the higher loads in the engine brake system and is fitted

with oil ducts > a lubricating oil duct (15) and two oil ducts for

operation of the engine brake.

26

W05.00>1024>73

Exhaust valve control for an activated engine brake

– This printout will not be recorded by the update service. Status: 09 / 2011 –

2 Exhaust rocker arm with hydroelement

3 Brake rocker arm

4 Exhaust rocker arm spindle

6 Exhaust camshaft

7 Outlet valve

21 Piston

22 Check valve

When in engine brake operation up to six exhaust valves (7), one per cylinder are opened as

follows, according to the engine brake stage, by the brake cam of the exhaust camshaft (6):

The corresponding exhaust rocker arms with hydroelement (2) have oil pressure applied to

them in engine brake operation via the oil inlet hole (20). If the corresponding brake rocker

arm (3) now presses on the piston (21), the check valve (22) is closed by the increased oil

pressure. Depressurization is prevented and the downward movement of the respective

brake rocker arm (3) is transmitted by the piston (21) onto the associated exhaust rocker arm

with hydroelement (2) which opens the respective exhaust valve (7).

As>built configurations

W05.00>1025>73

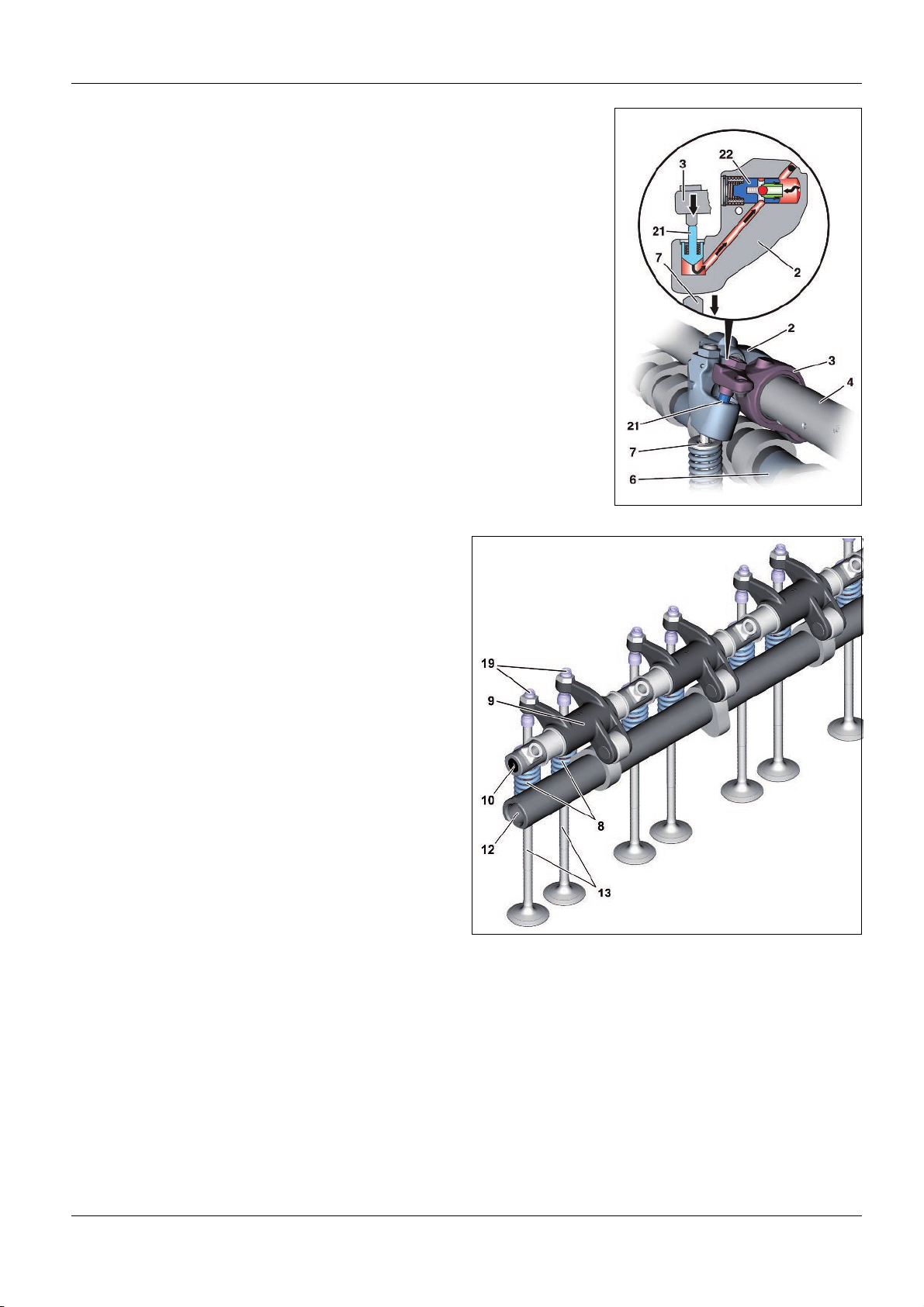

Valve control on the inlet side

8 Valve springs

9 Intake rocker arm

10 Intake rocker arm spindle

12 Intake camshaft

13 Inlet valves

19 Adjusting elements for adjusting the valve clearance

W05.00>1039>82

i

Introduction of engine OM 471 and exhaust aftertreatment > 09/2011 >

27

Loading...

Loading...