Mercedes-Benz OM 900, OM 457 LA Service manual

As at 04/03

Powersystems • Industrial Engines

Maintenance and Repair

Series 457, 500 and 900

Advanced Training

Powersystems • Industrial Engines

Maintenance and Repair Series 457,

This document is provided for training purposes only and is not subject to the normal updates.

Printed in Germany

ã 2003 Copyright DaimlerChrysler AG

Herausgeber: Global Training

This documentation and all its constituent parts are subject to copyright. Any reproduction or re-

use requires written permission from DaimlerChrysler AG in advance. This especially applies to

any duplication, dissemination, editing, translation, and microfilming of this documentation, or

storage and/or processing on electronic systems, databases and online services.

1511 1209 02 - 1stedition 04.03 236 As at 04/03

Note:

The term "employee" always refers to both

male and female staff.

Content 07.05.2003

Title Side

Welcome ..................................................................................................................................................................................................................................................1

Engine model series OM 457 LA..............................................................................................................................................................................................................2

Engine OM 457 LA ...................................................................................................................................................................................................................................4

Series 457<>Cylinder head....................................................................................................................................................................................................................11

Series 457<>Cylinder head - cross section (transverse and longitudinal) ............................................................................................................................................12

Series 457 LA<>Port assignments in the cylinder head gasket ............................................................................................................................................................13

Series 457<>Cylinder head bolts - tightening instructions....................................................................................................................................................................14

Series 457<>Setting valve play .............................................................................................................................................................................................................16

Series 457<>Removing/installing the nozzle holder combination........................................................................................................................................................19

Series 457<>Valve cover and valve cover gasket .................................................................................................................................................................................25

Series 457<>Oil pan ..............................................................................................................................................................................................................................26

Series 457<>Pump-line-nozzle injection system ...................................................................................................................................................................................27

Series 457<>Removing/installing the MR/PLD unit pump...................................................................................................................................................................28

Series 457<>Pistons..............................................................................................................................................................................................................................35

Series 457<>Lubrication schematic diagram ........................................................................................................................................................................................36

Series 457<>Oil spray nozzle.................................................................................................................................................................................................................38

Series 457<>Crankcase and cylinder liner ............................................................................................................................................................................................39

Series 457<>Camshaft ..........................................................................................................................................................................................................................40

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Content

I1

Series 457<>Fuel system ......................................................................................................................................................................................................................42

Series 457<>Fuel pump.........................................................................................................................................................................................................................45

Series 457<>Fuel prefilter with heated water separator .......................................................................................................................................................................46

Series 457<>Planetary drive starter ......................................................................................................................................................................................................48

Series 457<>Fan drive and fan systems................................................................................................................................................................................................50

Series 457<>Air compressor .................................................................................................................................................................................................................52

Series 457<>Turbocharger BR S400 .....................................................................................................................................................................................................53

Series 457<>Engine oil and filter change ..............................................................................................................................................................................................54

Series 457<>Replacing the fuel filter ....................................................................................................................................................................................................56

Series 457<>Fuel filter with water separator - replacing the filter element..........................................................................................................................................58

Series 457<>Air cleaner, engine coolant service ..................................................................................................................................................................................60

Series 500<>Engine models ..................................................................................................................................................................................................................62

Series 500<>Technical features ............................................................................................................................................................................................................64

Series 500<>Cylinder head - port assignment ......................................................................................................................................................................................70

Series 500<>Cylinder head....................................................................................................................................................................................................................71

Series 500<>Cylinder head mounting ...................................................................................................................................................................................................73

Series 500<>Cylinder head gasket ........................................................................................................................................................................................................74

Series 500<>EURO 2 and EURO 3 cylinder heads compared ...............................................................................................................................................................75

Series 500<>Valve assembly.................................................................................................................................................................................................................77

Series 500<>Pump-line-nozzle injection system (PLD) .........................................................................................................................................................................83

Series 500<>Removing/installing the MR/PLD unit pump...................................................................................................................................................................91

Series 500<>EURO 2 and EURO 3 pistons ......................................................................................................................................................................................... 101

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Content

I2

Series 500<>Connecting rod .............................................................................................................................................................................................................. 102

Series 500<>Crankcase...................................................................................................................................................................................................................... 103

Series 500<>Cylinder liners................................................................................................................................................................................................................ 104

Series 500<>EURO 2 and EURO 3 cylinder liners compared ............................................................................................................................................................. 107

Series 500<>Crankcase ventilation system ....................................................................................................................................................................................... 108

Series 500<>Fuel system ................................................................................................................................................................................................................... 112

Series 500<>Oil cooler and oil filter housing – component locations................................................................................................................................................ 124

Series 500<>Oil circuit ....................................................................................................................................................................................................................... 128

Series 500<>Engine oil system........................................................................................................................................................................................................... 129

Series 500<>Oil spray nozzle.............................................................................................................................................................................................................. 130

Series 500<>Water guide ................................................................................................................................................................................................................... 134

Series 500<>Thermostat location....................................................................................................................................................................................................... 136

Series 500<>Supercharging system and charge air ducting .............................................................................................................................................................. 137

Series 500<>Engine oil and filter change ........................................................................................................................................................................................... 140

Series 500<>Cleaning the fuel prefilter / filter insert ........................................................................................................................................................................ 144

Series 500<>-Fuel prefilter with water separator - replacing the filter element ................................................................................................................................ 146

Series 500<>Replacing the oil separator insert ................................................................................................................................................................................. 148

Series 500<>Replacing the fuel filter - air cleaner - coolant .............................................................................................................................................................. 150

Engines OM 904 and 906 ................................................................................................................................................................................................................... 152

Engine series 900 ............................................................................................................................................................................................................................... 153

Series 900<>Technical features ......................................................................................................................................................................................................... 156

Series 900<>Port assignments in the cylinder head gasket .............................................................................................................................................................. 159

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Content

I3

Series 900<>Tightening instructions for cylinder head bolts ............................................................................................................................................................. 160

Series 900<>Valve control.................................................................................................................................................................................................................. 162

Series 900<>Setting valve play .......................................................................................................................................................................................................... 164

Series 900<>Pump-line-nozzle injection system (PLD) ...................................................................................................................................................................... 167

Series 900<>Crankcase...................................................................................................................................................................................................................... 185

Series 900<>Ölspritzdüsen - Unterschiede ........................................................................................................................................................................................ 188

Series 900<>Pistons and piston rings ................................................................................................................................................................................................ 189

Series 900<>Connecting rod .............................................................................................................................................................................................................. 190

Series 900<>Pistons and connecting rod - modifications .................................................................................................................................................................. 191

Series 900<>Engine oil circuit ............................................................................................................................................................................................................ 192

Series 900<>Removing/installing the oil pan .................................................................................................................................................................................... 196

Series 900<>Fuel system ................................................................................................................................................................................................................... 200

Series 900<>Supercharging system and charge air ducting .............................................................................................................................................................. 212

Series 900<>Removing/installing the coolant thermostatic control ................................................................................................................................................. 216

Series 900<>Engine oil and filter change ........................................................................................................................................................................................... 218

Series 900<>Cleaning the fuel prefilter - filter insert ......................................................................................................................................................................... 221

Series 900<>Fuel prefilter with water separator - replacing the filter element ................................................................................................................................. 223

Series 900<>Replacing the fuel filter - air cleaner - coolant .............................................................................................................................................................. 226

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Content

I4

Welcome 07.05.2003

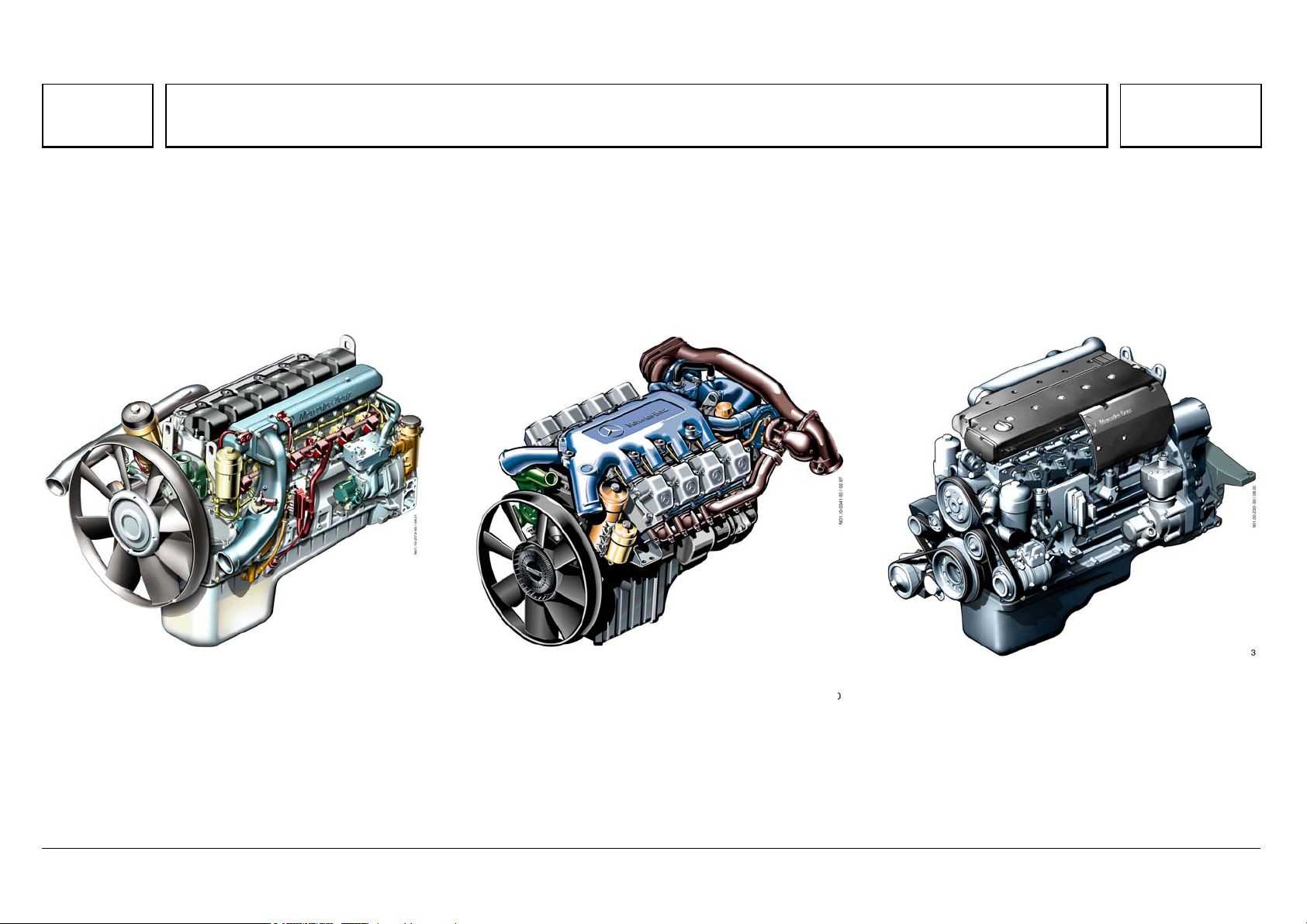

OM 457 LA OM 502 LA OM 906 LA

N01.10-2073-50 N01.10-0341-50 N01.00-2301-50

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Welcome

1

Series 500<>Engine models 07.05.2003

V

A

V

A

V

The 500 engine model series is future-ready, and

comes in V6 and V8 cylinder variants with 2 litre

swept volume per cylinder.

The sales designation is formed in the same way

as the 400 model series:

Model series 500

6-cylinder engine: OM 501 LA

8-cylinder engine: OM 502 LA

At the same time, the OM 457 LA engine was

developed with the same basic design as the Vengines.

The Series 2000 V12 and V16 MTU engines are

derived from the BR 500, and are intended for

industrial applications.

6

OM 501 L

= 12l VH= 16l

H

OM 501 LA

OM 501 LA

8

OM 502 L

Turbocharger

Charge air cooler

1=6-cylinder V-engine

2=8-cylinder V-engine

Model series 500

Diesel engine

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Engine models

62

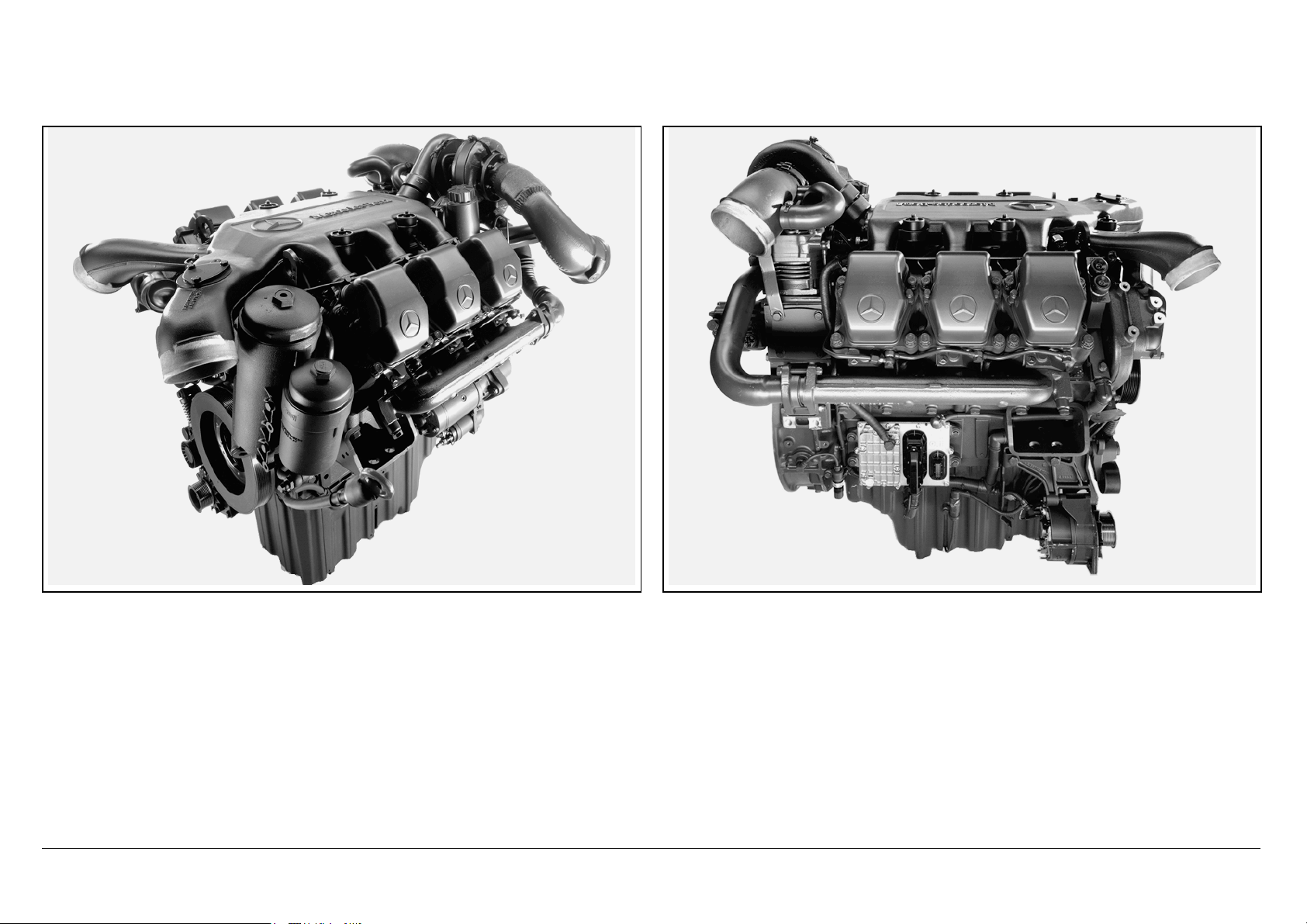

N01.10-2026-11 N01.10-2028-11

The development of the 500 series encapsulates all the knowledge and experience gained from the 1 million V-engines manufactured since 1969, when

production of the OM 403 V10 engine began.

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Engine models

63

Series 500<>Technical features 07.05.2003

Þ Outstanding power output and torque characteristics over the whole

rpm range

Þ Dynamic start-off characteristics and pulling power

Þ Attractive power/weight ratio

Þ Low fuel consumption

Þ Enormous potential: the V6 engines meet the requirements of the highly

popular 400 HP Class

Þ High-pressure direct injection, pump-line-nozzle system with peak

pressures up to 1,800 bar.

Þ Electronic engine control (MR) with electronic system fixed to the

engine, and extensive engine protection functions

Þ Direct injection with centrally positioned 6-hole injection nozzle.

Þ 4-valve technology

Þ Useful engine brake rpm well over rated rpm, up to 2400 rpm

Þ Meets the emission legislation of EURO 3 and EUROMOT/EPA Level 2

Þ Viscous fan clutch, electromagnetic fan clutch and high-speed fan

drive on the most powerful engines

Þ Rated engine speed 1,800 rpm or 2000 rpm

Þ Low maintenance requirement

Þ Long maintenance intervals

Þ Engine oil and fuel filter located at the front, for easy maintenance

Þ Maintenance-free belt drive

Þ Can run on FAME / RME (rape methyl ester) or biodiesel, and engine oil

changes are halved

Þ High reliability and long runtime

Þ Low number of component variants, as many parts are the same on both

6 and 8 cylinder engines

Þ Rear engine power take-off ex works

Þ Turbocharger with charge air cooling

Þ V8 with 2 turbochargers

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Technical features

64

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Technical features

65

Overview of BR 500 engines with EURO 3 certification

Engine

model

No. of

cylinders/

Output (rpm) Torque (rpm) Cylinder bore Cylinder

stroke

Displace

ment

Dimensions

L x W x H

Weight Power/weight

ratio

layout

[kW/HP (at rpm)] [Nm (at rpm)] [mm] [mm] [l] [mm] [kg] [kg/kW]

OM 501 LA 6 Cyl./V 230/313 (1800) 1530 (1080) 130 150 11.95 1190x1020x1130 885 3.85

OM 501 LA 6 Cyl./V 260/354 (1800) 1730 (1080) 130 150 11.95 1190x1020x1130 885 3.40

OM 501 LA 6 Cyl./V 290/394 (1800) 1850 (1080) 130 150 11.95 1190x1020x1130 885 3.05

OM 501 LA 6 Cyl./V 300/408 (2000) 1900 (1080) 130 150 11.95 1190x1020x1130 885 2.95

OM 501 LA 6 Cyl./V 315/428 (1800) 2000 (1080) 130 150 11.95 1190x1020x1130 885 2.81

OM 502 LA 8 Cyl./V 320/435 (2000) 1900 (1080) 130 150 15.93 1530x1195x1080 1125 3.52

OM 502 LA 8 Cyl./V 350/476 (2000) 2100 (1080) 130 150 15.93 1530x1195x1080 1125 3.21

OM 502 LA 8 Cyl./V 350/476 (1800) 2300 (10809 130 150 15.93 1530x1195x1080 1125 3.21

OM 502 LA 8 Cyl./V 370/503 (2000) 2300 (1080) 130 150 15.93 1530x1195x1080 1125 3.04

OM 502 LA 8 Cyl./V 390/530 (1800) 2400 (1080) 130 150 15.93 1530x1195x1080 1125 2.88

OM 502 LA 8 Cyl./V 420/571 (1800) 2700 (1080) 130 150 15.93 1530x1195x1080 1125 2.68

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Technical features

66

Overview of BR 500 engines with EUROMOT/EPA Level 2 certification

Engine

model

No. of

cylinders/

Output (rpm) Torque (rpm) Cylinder bore Cylinder

stroke

Displace

ment

Dimensions

L x W x H

Weight Power/weight

ratio

layout

[kW/HP (at rpm)] [Nm (at rpm)] [mm] [mm] [l] [mm] [kg] [kg/kW]

OM 501 LA 6 Cyl./V 230/313 (1800) 1530 (1080) 130 150 11.95 1190x1020x1130 885 3.85

OM 501 LA 6 Cyl./V 260/354 (1800) 1730 (1080) 130 150 11.95 1190x1020x1130 885 3.40

OM 501 LA 6 Cyl./V 290/394 (1800) 1850 (1080) 130 150 11.95 1190x1020x1130 885 3.05

OM 501 LA 6 Cyl./V 315/428 (1800) 2000 (1080) 130 150 11.95 1190x1020x1130 885 2.81

OM 502 LA 8 Cyl./V 330/449 (1800) 2150 (1200) 130 150 15.93 1530x1195x1080 1125 3.40

OM 502 LA 8 Cyl./V 350/476 (1800) 2300 (1200) 130 150 15.93 1530x1195x1080 1125 3.21

OM 502 LA 8 Cyl./V 350/476 (2000) 2100 (1200) 130 150 15.93 1530x1195x1080 1125 3.21

OM 502 LA 8 Cyl./V 380/517 (1800) 2400 (1200) 130 150 15.93 1530x1195x1080 1125 2.96

OM 502 LA 8 Cyl./V 420/571 (1800) 2700 (1200) 130 150 15.93 1530x1195x1080 1125 2.68

OM 502 LA 8 Cyl./V 448/609 (1800) 2700 (1200) 130 150 15.93 1530x1195x1080 1125 2.51

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Technical features

67

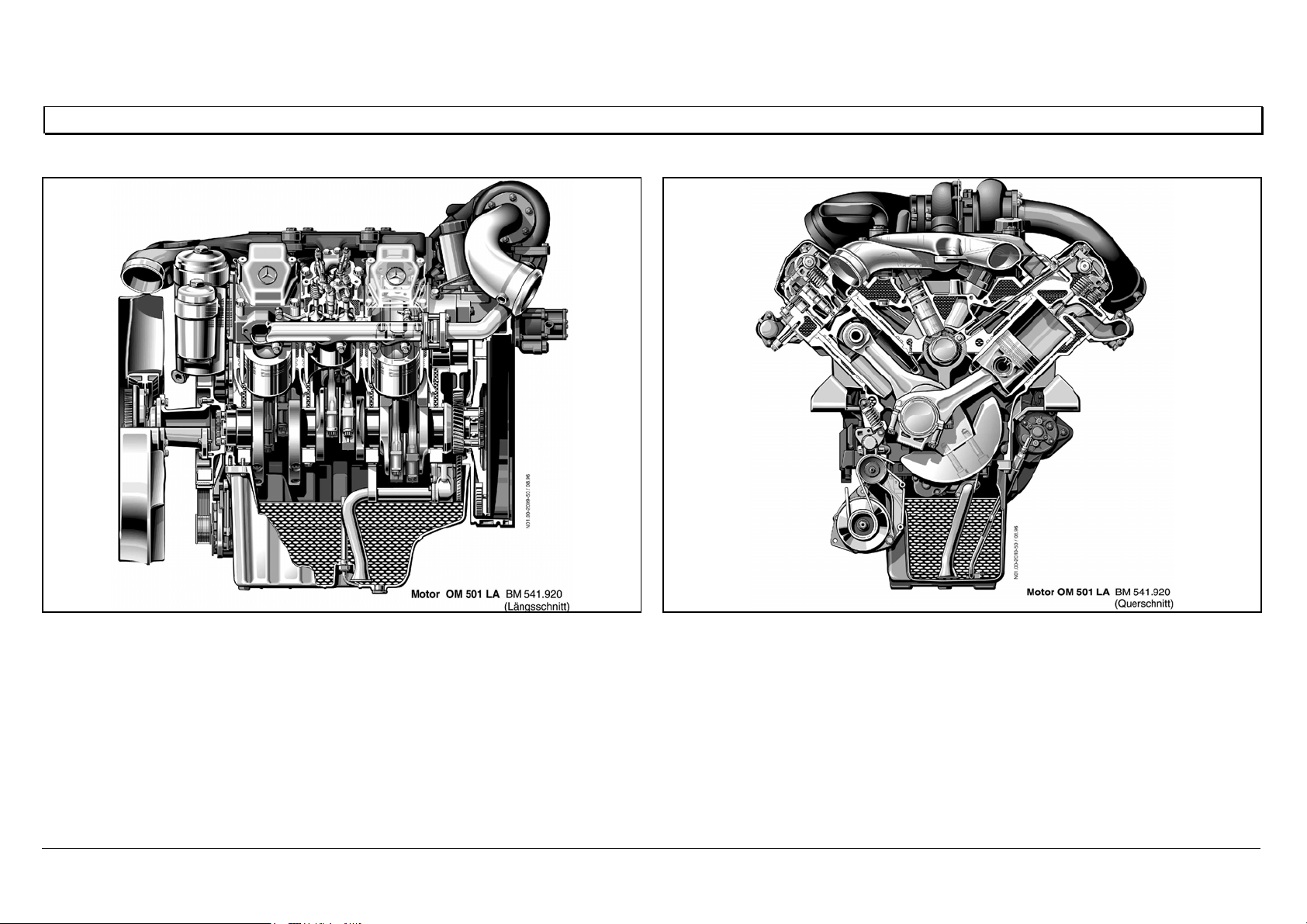

Engine OM 501 LA in cross section

N01.00-2009-50 N01.00-2010-50

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Technical features

68

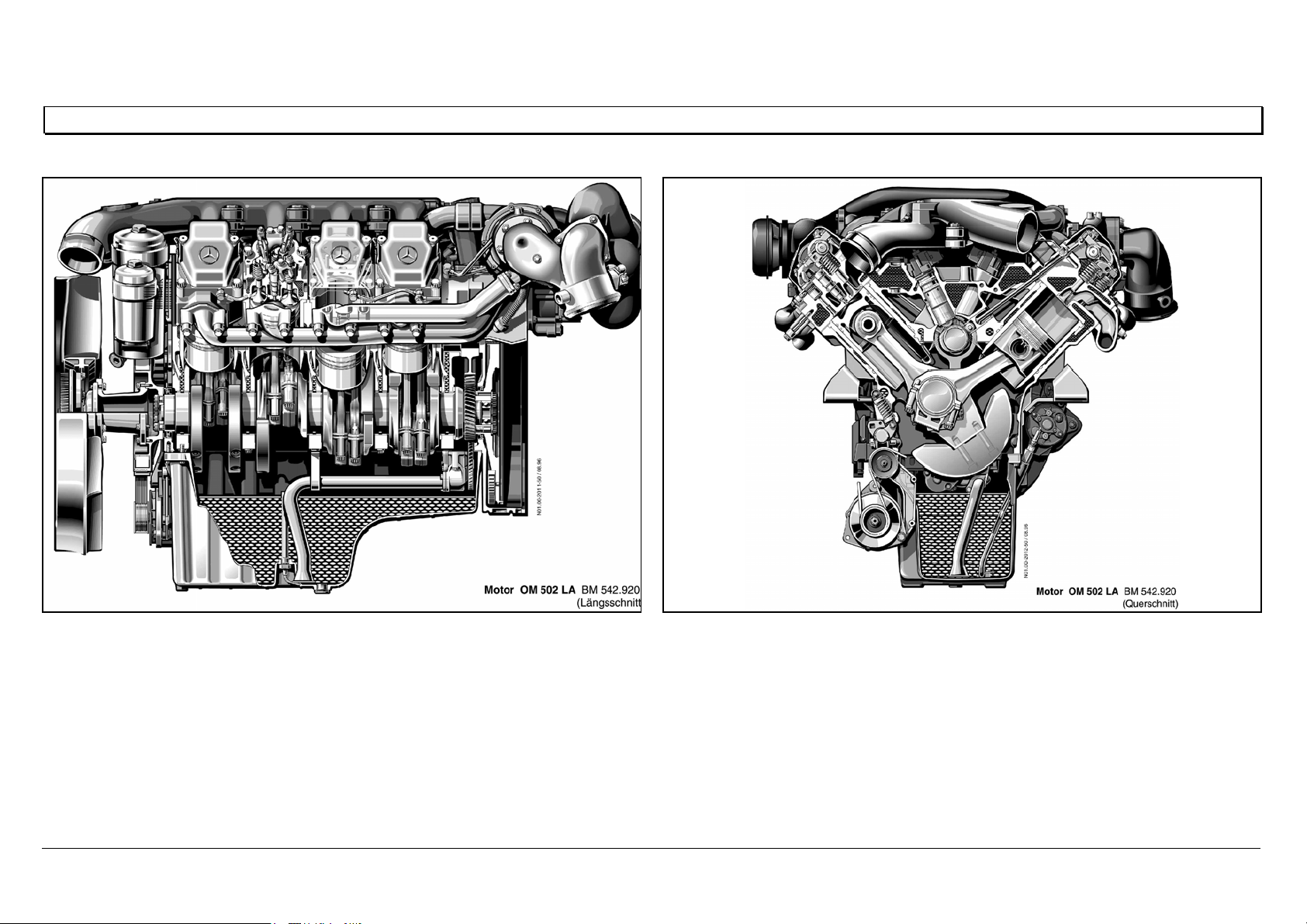

Engine OM 502 LA in cross section

N01.00-2011-50 N01.00-2012-50

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Technical features

69

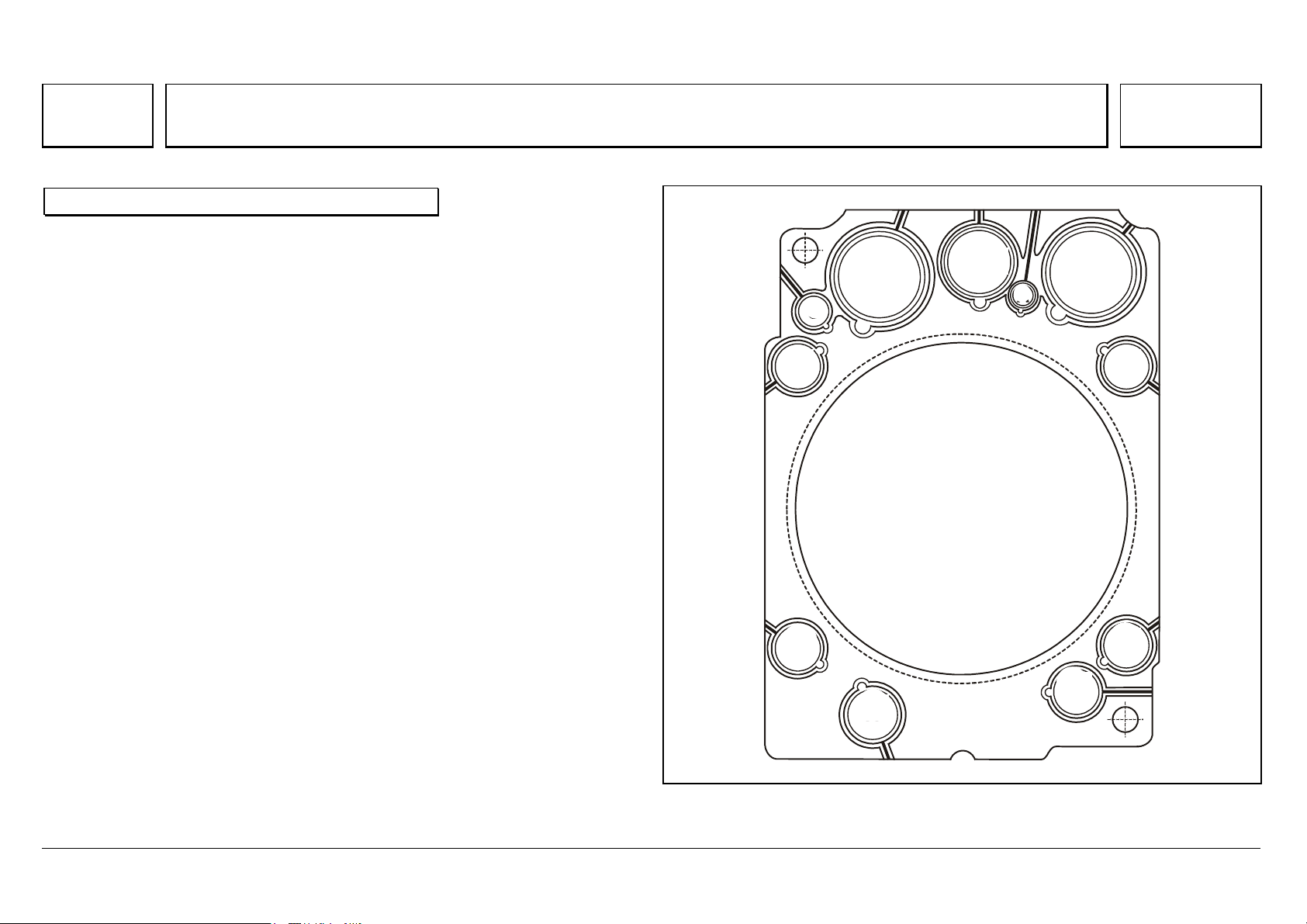

Port assignment

Series 500<>Cylinder head - port assignment 07.05.2003

A Coolant

BBolts

CPressure oil

D Oil return

E Plunger, oil return

A

E

E

A

C

B

B

B

B

B

D

A

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Cylinder head - port assignment

N01.30-2024-12

70

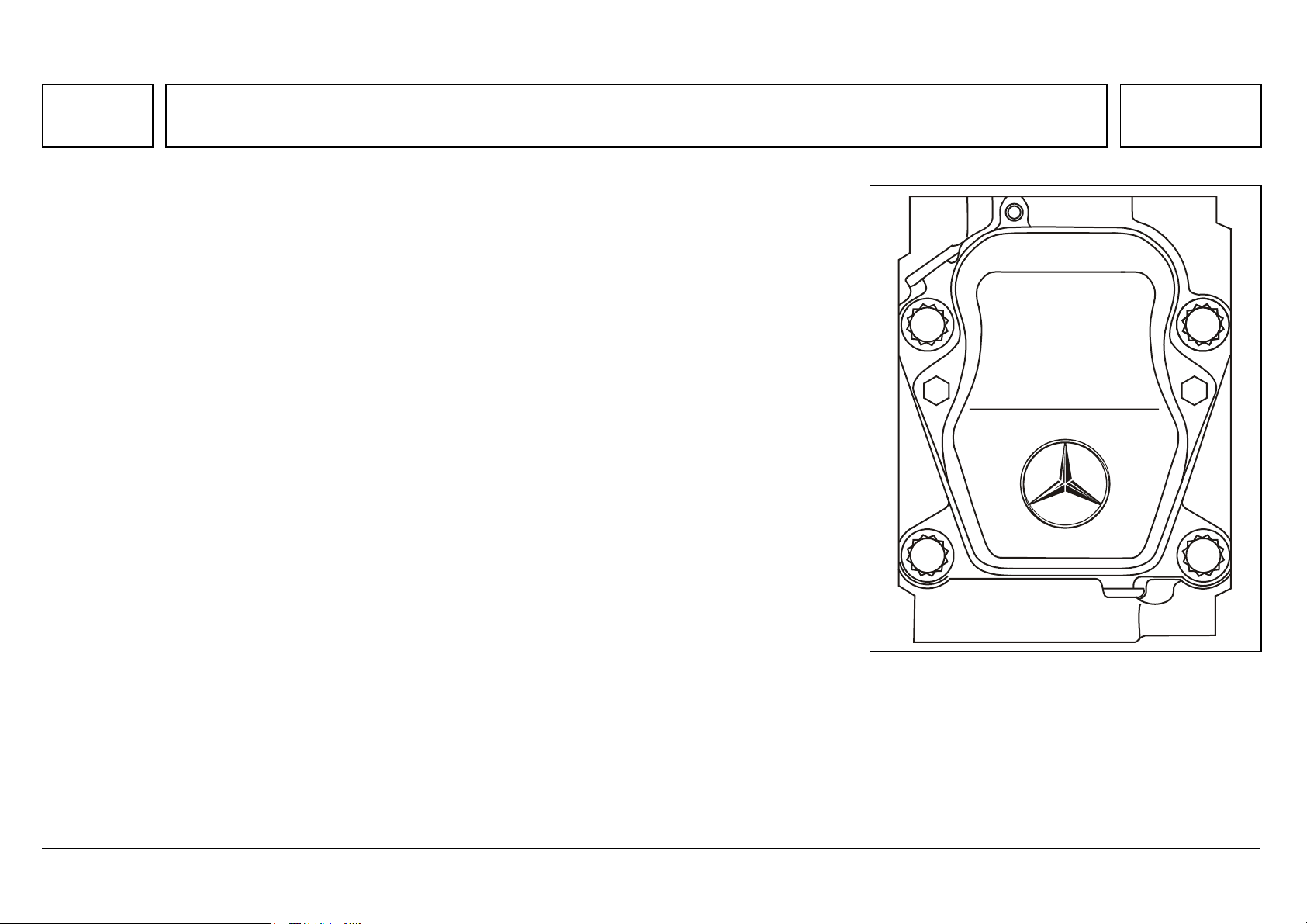

Series 500<>Cylinder head 07.05.2003

The individual cylinder heads are made of high-quality molybdenum/cast iron alloy. Each has four stretchthread bolts (M18x2), with which it is bolted to the crankcase.

The optimal position for the injection nozzle is the vertical position at the center of the combustion

chamber.

This ideal arrangement can only be achieved by using multi-valve technology.

This consists in arranging the valves in pairs (2 intake, 2 exhaust) around the injection nozzle.

A fifth valve is required for the constant throttle or the decompression valve/engine brake.

In both cases, these are linked to the exhaust port through an exactly adjusted hole.

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Cylinder head

N01.30-2025-02

71

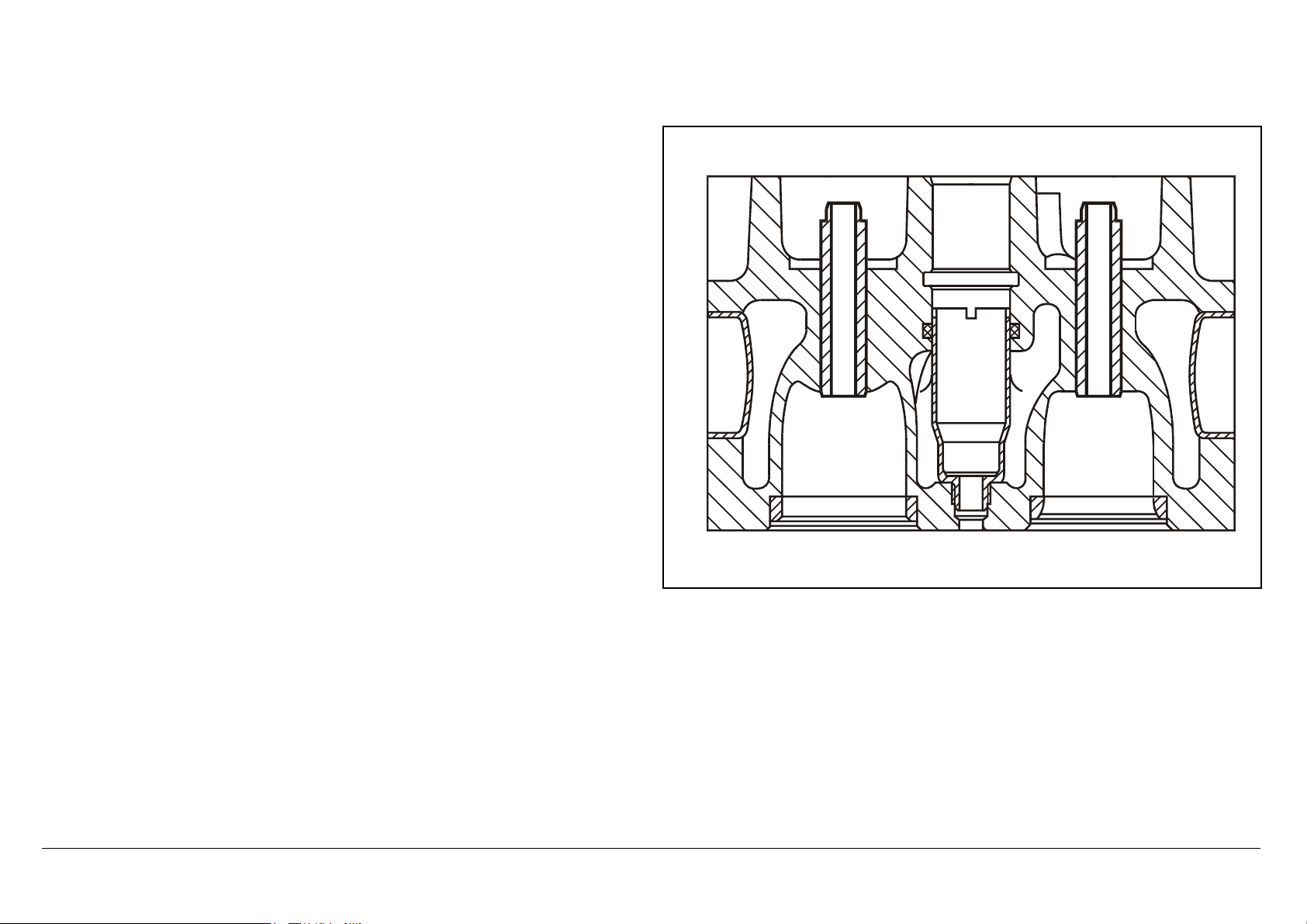

The high-temperature, wear-resistant valve seat rings are inserted deep-frozen

into the floor panel.

The nozzle holder is inserted in a protective sleeve, which is washed around

by coolant and thus individually cooled.

The nozzle protective sleeve is sealed by an O-ring against coolant escape,

and by the thread and face against gas escape.

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Cylinder head

N07.03-2035-11

72

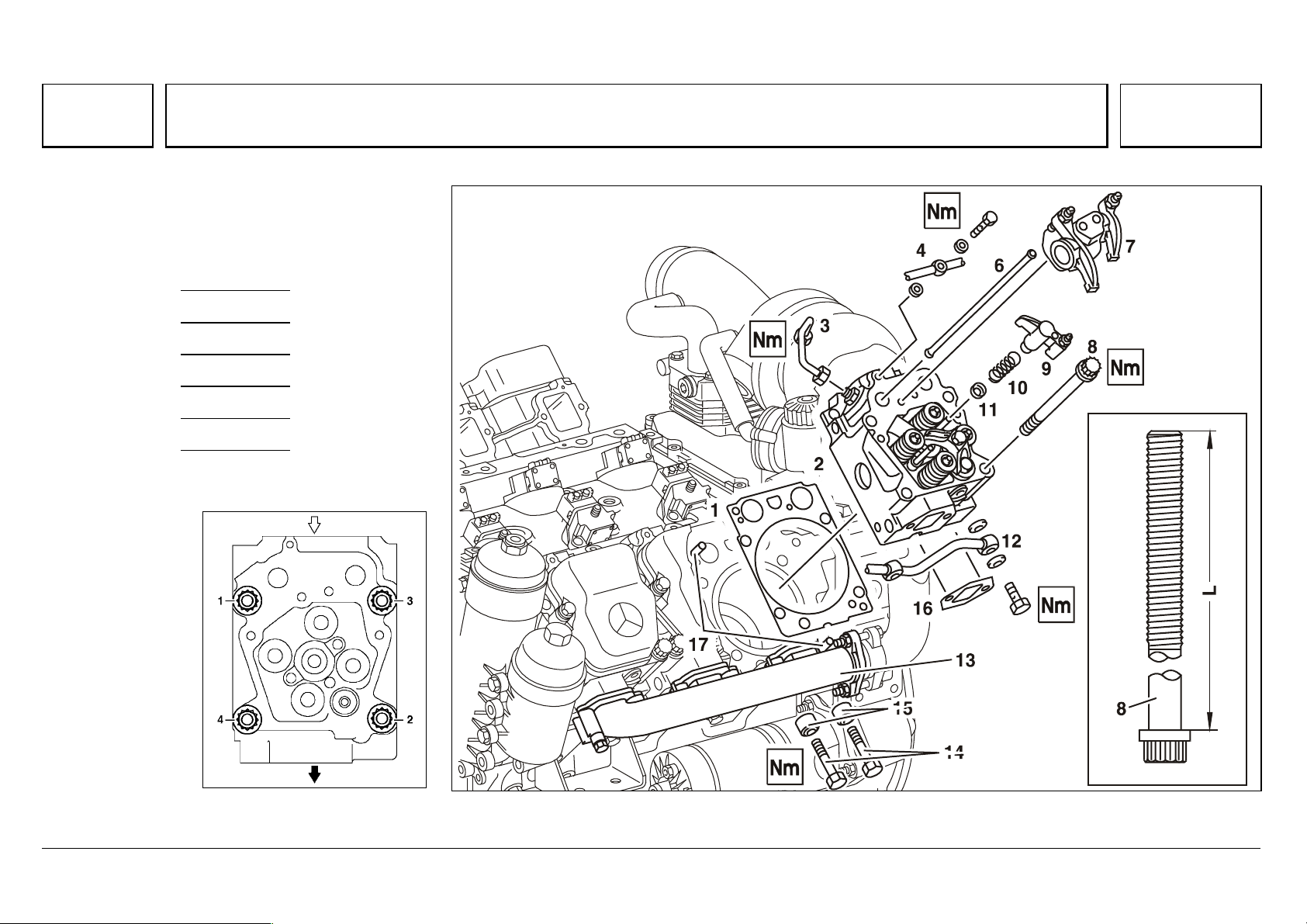

Series 500<>Cylinder head mounting 07.05.2003

The cylinder head is tightened in 6 stages.

The cylinder head bolts do not require

retightening.

Step 1 10 Nm

Step 2 50 Nm

Step 3 100 Nm

Step 4 200 Nm

Step 5 90 °

Step 6 90 °

1 L T 212 mm

W01.30-0009-02 W01.30-0010-06

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Cylinder head mounting

73

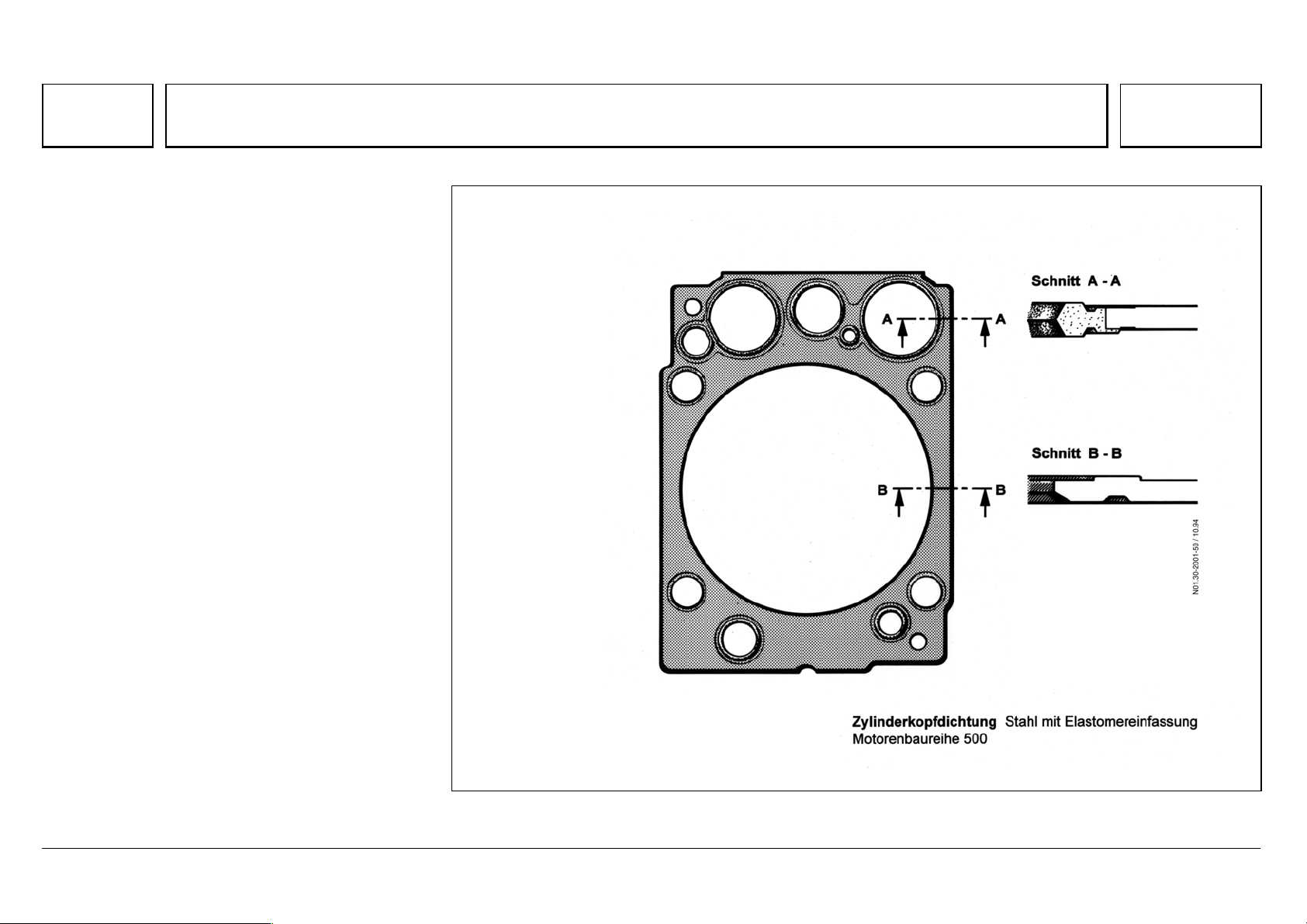

Series 500<>Cylinder head gasket 07.05.2003

Each cylinder head has a stainless steel insert

gasket with scorched elastomer binding, which

does not require retightening.

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Cylinder head gasket

N01.30-2001-50

74

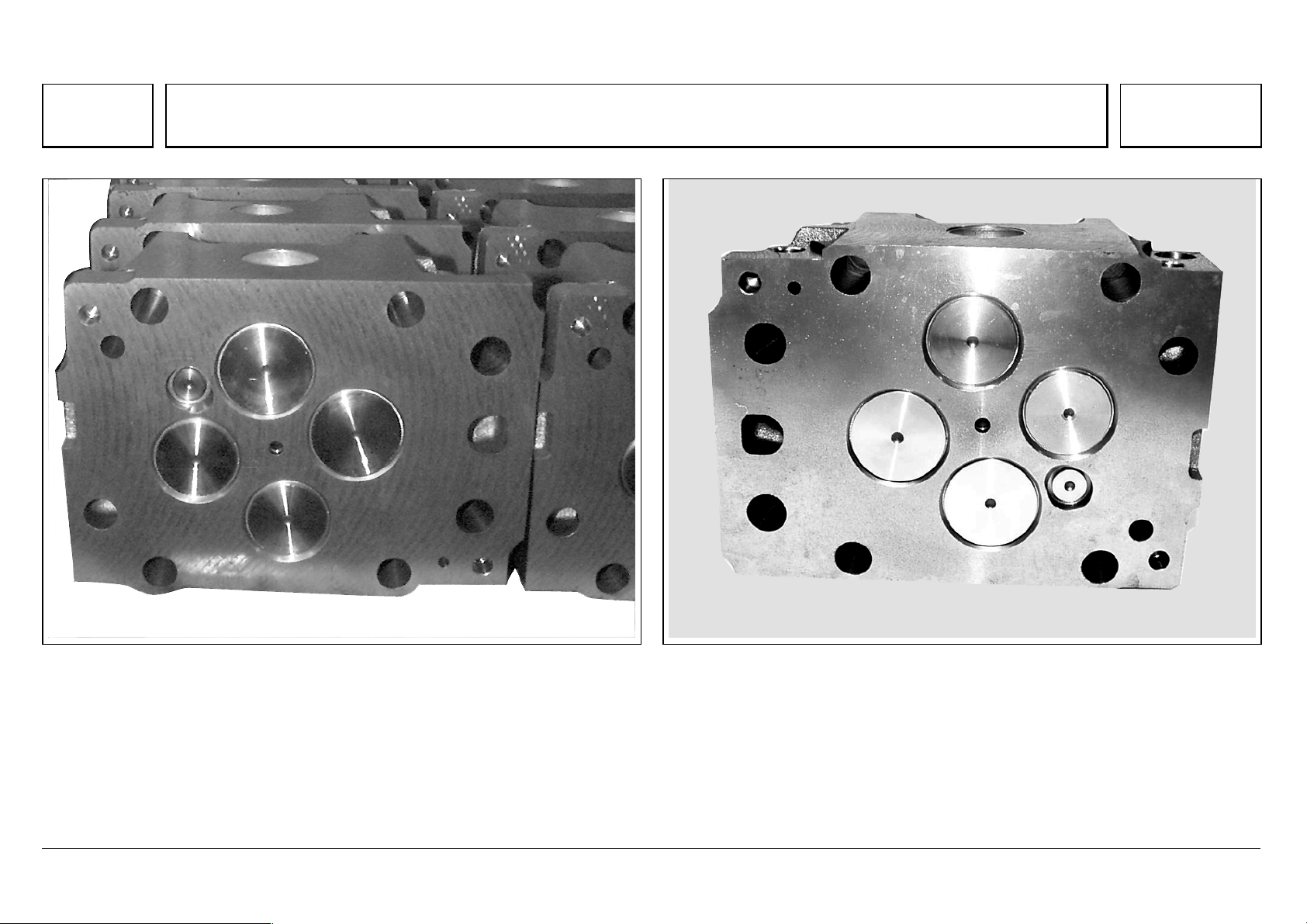

Series 500<>EURO 2 and EURO 3 cylinder heads compared 07.05.2003

Cylinder head old version, as of 04/99

In the previous Euro 2 version, the cover surfaces were milled.

Since 2000, as part of the "Euro 3" package of measures, the cylinder head

surfaces are turned, to a specific surface quality.

N01.30-2065-11

Cylinder head, Euro 3 version

The new cylinder heads should be ground to a minimum height of 113.5 mm,

by face grinding only. The surface quality (peak-to-valley height and

corrugation depth) is to be observed in all cases.

Since 06/2000, this also applies to all Euro 2 V8 and 315 kW V6 engines,

and from January 2001 to all other V6 engines.

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>EURO 2 and EURO 3 cylinder heads compared

N01.30-2064-11

75

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>EURO 2 and EURO 3 cylinder heads compared

76

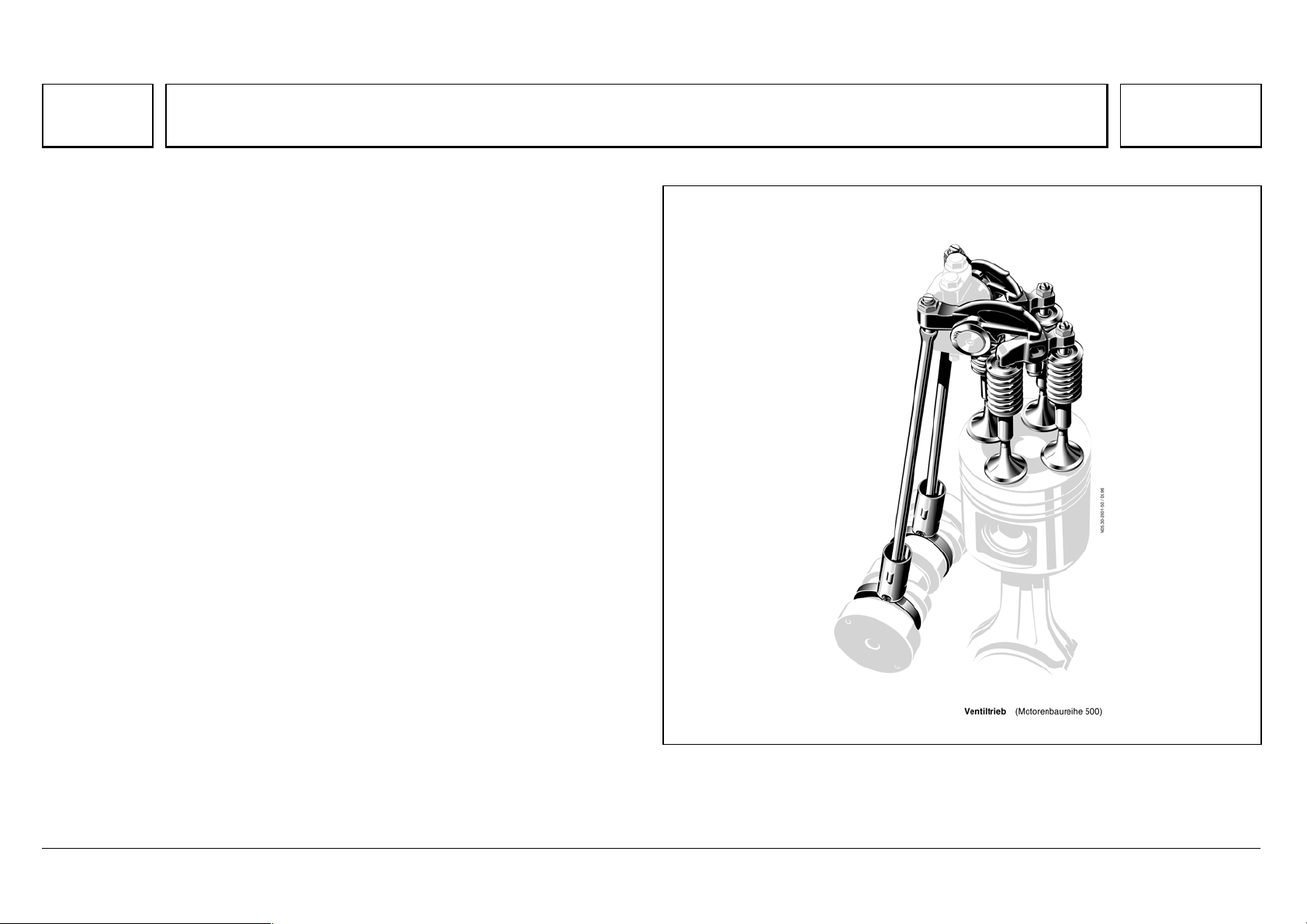

Series 500<>Valve assembly 07.05.2003

Gas exchange is improved by 4-valve technology, thus contributing

considerably to lower fuel consumption with lower emissions.

The intake and exhaust valves are controlled by means of roller tappets, push

rods and intake and exhaust rocker arms which are set in a groove in the

crankcase with a sliding block, and which operate the intake/exhaust valve

pairs through a valve bridge.

The rocker arm spindle complete with preassembled rocker arms and rocker

arm bearing bracket is bolted to the cylinder head.

To keep wear in the whole valve assembly to a minimum throughout its

lifetime, the contact surfaces of the valve, valve bridge, the rocker arm thumb,

the upset ball socket of the push rod, and the ball head of the adjusting

screw, are induction hardened. This is to allow them to support the actuation

forces of the high-temperature valve springs, and the effects of inertial forces

and cylinder pressures.

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Valve assembly

N05.30-2001-50

77

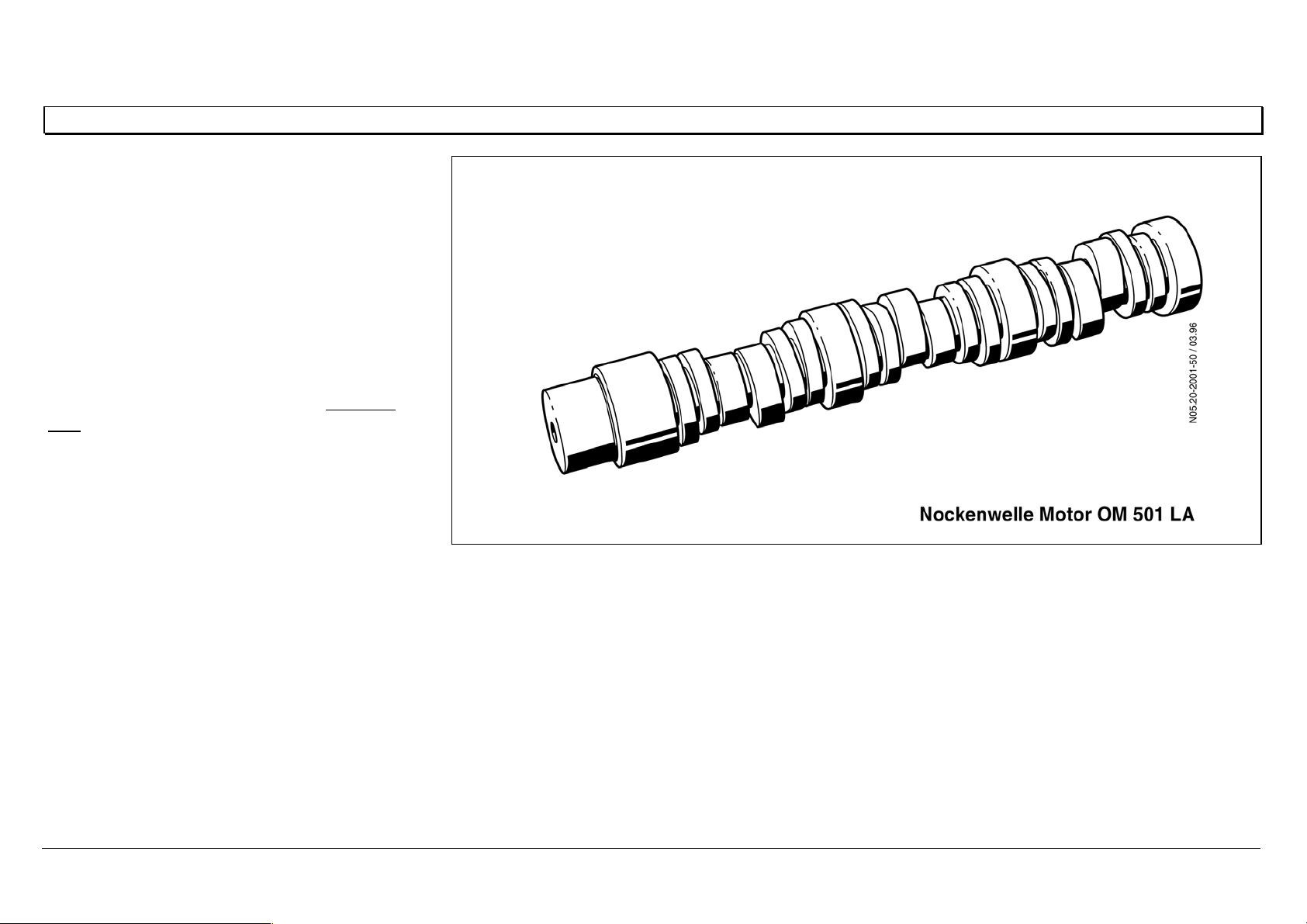

Camshaft

The camshaft is made of high-strength material,

with induction-hardened running surfaces, and

has 4 bearings in the OM 501 LA, 5 bearings in

the OM 502 LA.

Between the bearings are 4 valve timing cams

and 2 injection cams for each opposing cylinder

pair.

The slide ways of the timing cams for the valve

and injection roller tappets are supplied with lube

oil through additional oil holes in the piston jet

pipe.

N05.20-2001-50

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Valve assembly

78

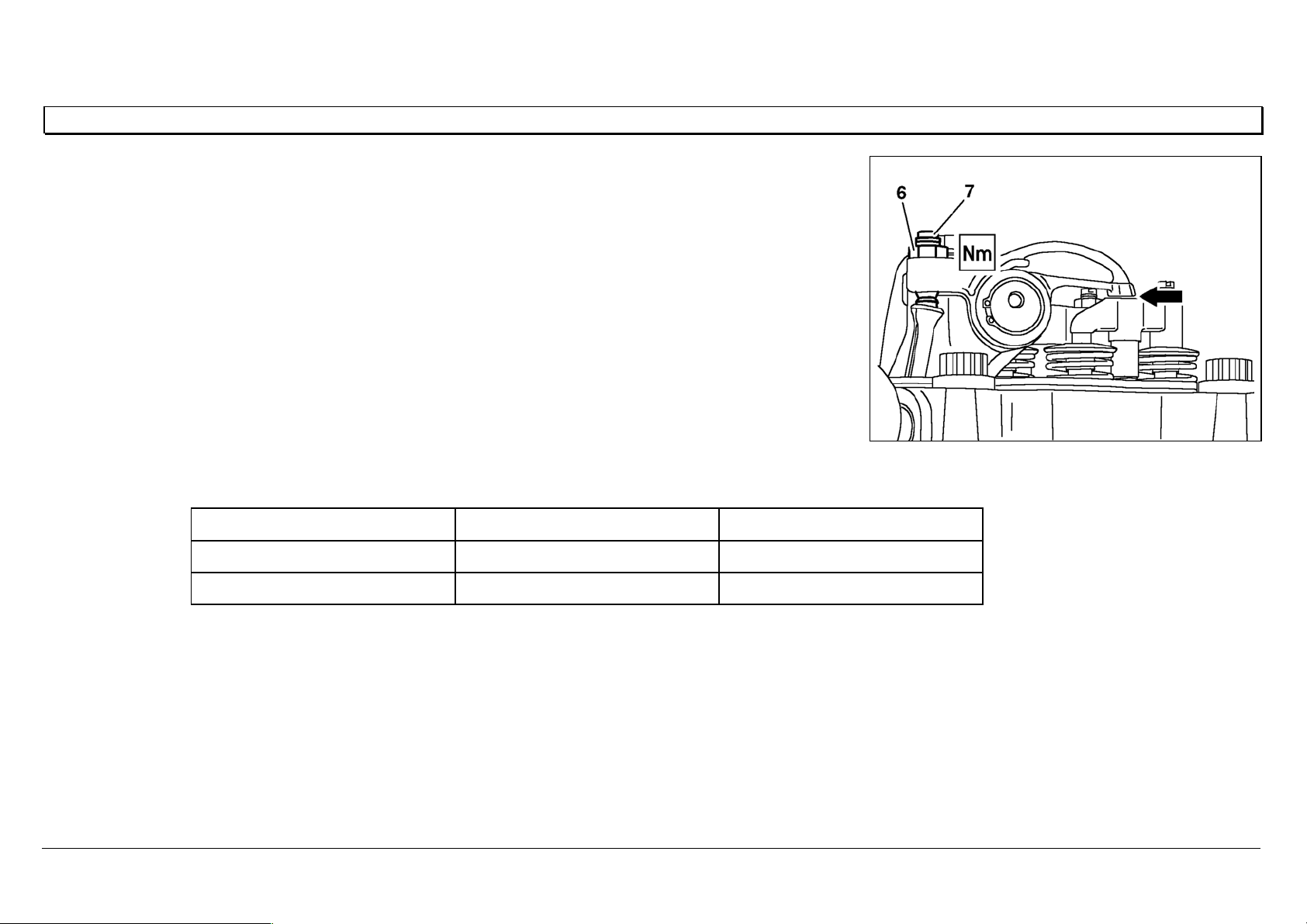

Adjusting the valve play

The valve play checking and setting procedure is the same as for the BR 400, and there are two methods.

Method 1

Set the intake and exhaust valves for each cylinder, according to the injection sequence.

The cylinder to be set must be at ignition TDC, the parallel cylinder at valve overlap TDC.

With this method, the crankshaft must be turned six times in the 6-cylinder engine, and eight times in the

8-cylinder engine.

Method 2

Set the intake and exhaust valves in two crankshaft positions.

Adjust when cylinder 1 is at ignition TDC.

Adjust when cylinder 1 is at overlap TDC.

N05.30-0302-01 P

Valve Play

Intake 0.40 + 0.20 / - 0.10

Exhaust 0.60 + 0.20 / - 0.10

The valve play test tolerance applies only for checking valve play.

If valve play is outside the tolerance range, the specified value must be set.

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Valve assembly

Tolerance

79

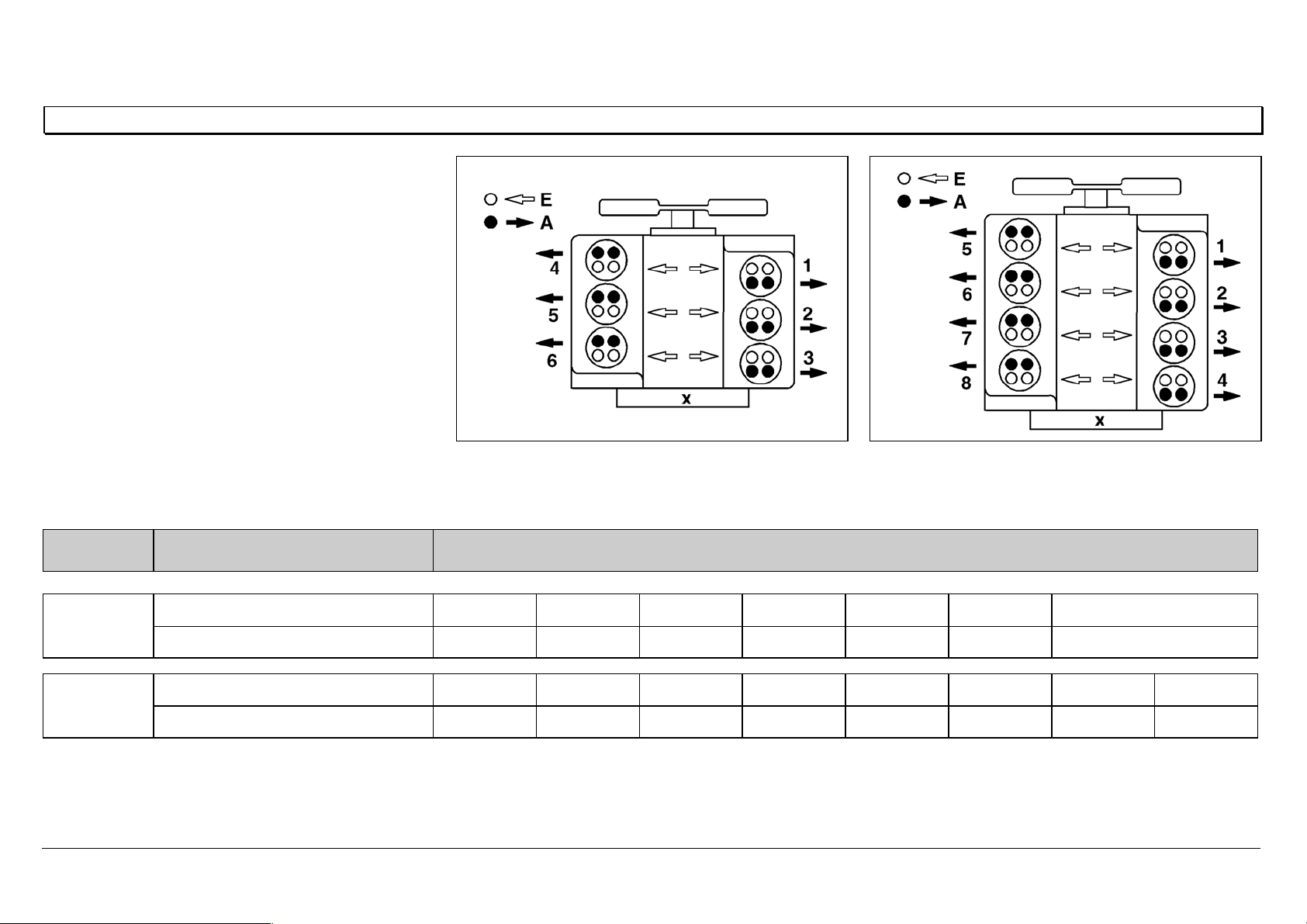

General notes on valve adjustment

Method 1

Set the intake and exhaust valves for each

cylinder, according to the injection sequence.

The cylinder to be set must be at ignition TDC, and

the parallel cylinder at valve overlap TDC.

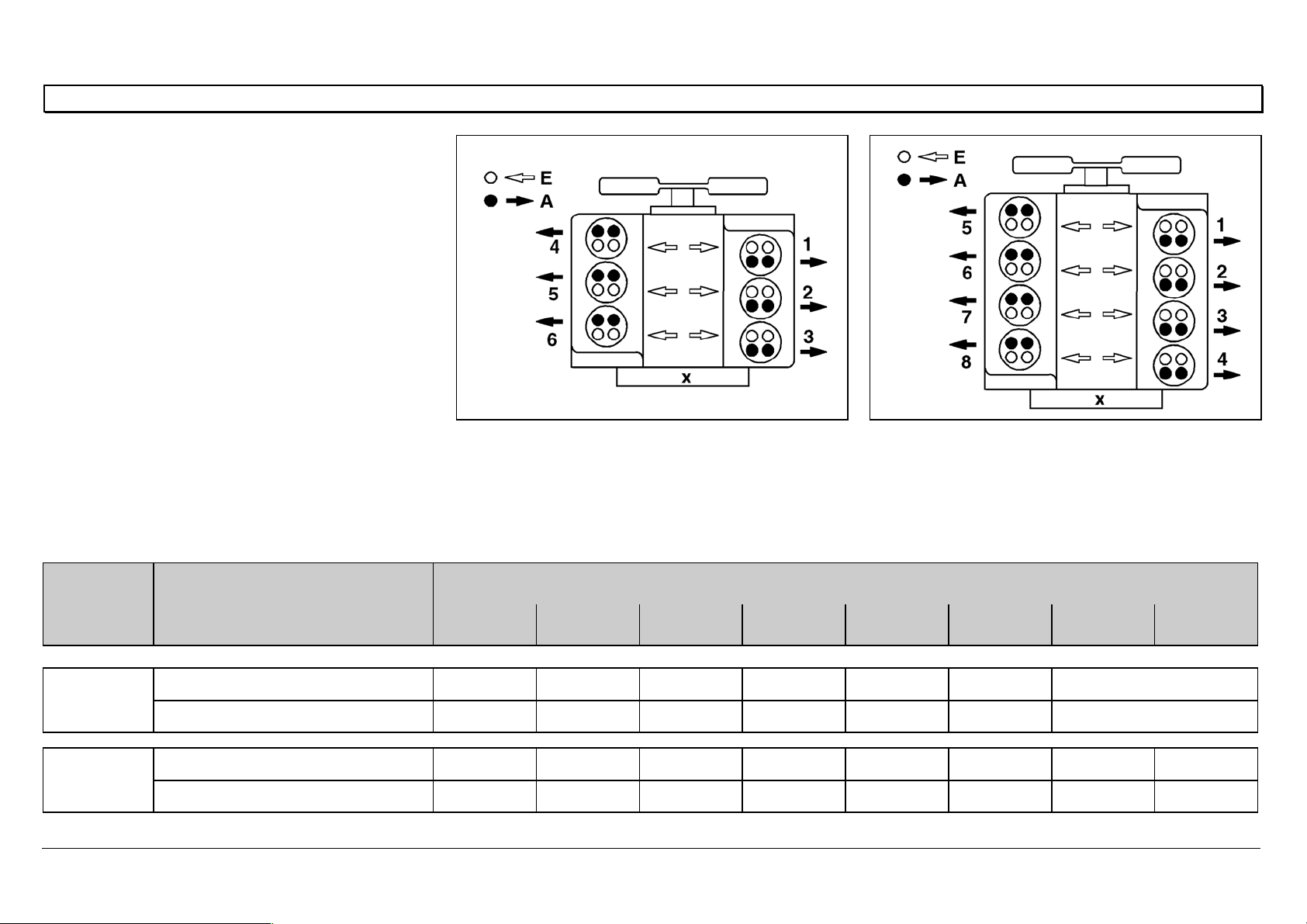

AExhaust valve

E Intake valve

X Flywheel side

N01.00-0200-01 N01.00-0201-01

Engine Crankshaft position Cylinder/injection sequence

6-cylinder Ignition TDC142536

Valve overlap536142

8-cylinder

Ignition TDC15726348

Valve overlap63481572

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Valve assembly

80

General notes on valve adjustment

Method 2

Set the intake and exhaust valves at two

crankshaft positions, as shown in the table.

AExhaust valve

E Intake valve

X Flywheel side

N01.00-0200-01 N01.00-0201-01

6-cylinder

First set cylinder 5 at valve overlap TDC (cylinder

1 at ignition TDC), then cylinder 1 at valve

overlap TDC (cylinder 5 at ignition TDC).

8-cylinder

First set cylinder 6 at valve overlap TDC (cylinder

1 at ignition TDC), then cylinder 1 at valve

overlap TDC (cylinder 6 at ignition TDC).

Engine Crankshaft position Cylinder/injection sequence

1 2 3 4 5 6 7 8

6-cylinder

Cylinder 5 valve overlap I / E E I E - I

Cylinder 1 valve overlap - I E I I / E E

8-cylinder

Cylinder 6 valve overlap I / E E I I E - E I

Cylinder 1 valve overlap - I E E I I /E I E

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Valve assembly

81

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Valve assembly

82

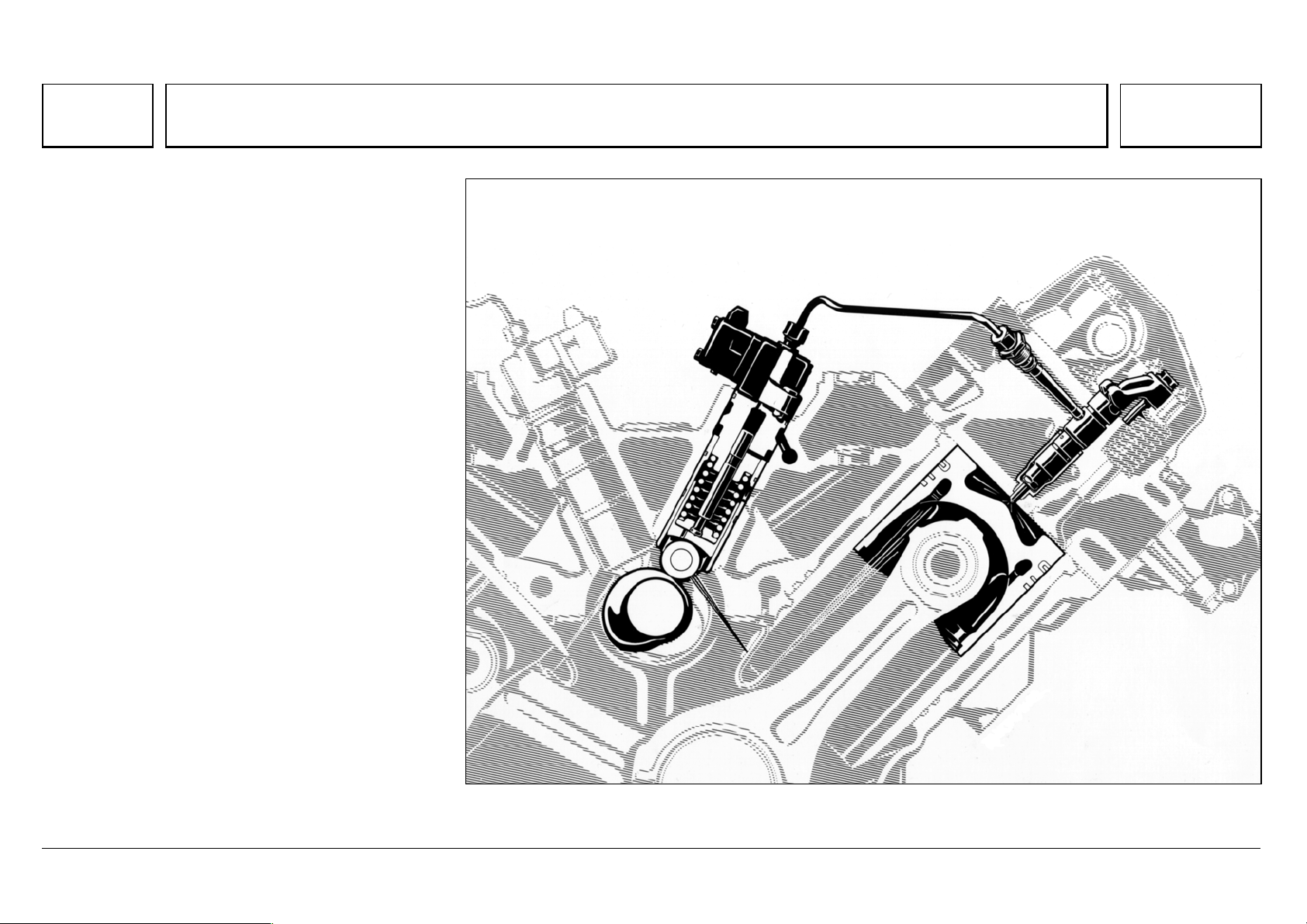

Series 500<>Pump-line-nozzle injection system (PLD) 07.05.2003

Engines of the OM 500 model series use the direct

fuel injection process.

The injection process is performed by the newly

developed pump-line-nozzle (PLD) system,

controlled by an electronic engine management

system that has also been newly developed.

In the PLD system, fuel is delivered to the injection

nozzle by individual unit pumps over short, rigid

high-pressure injection lines, and through the

pressure pipe connection screwed into the cylinder

head.

The connection to the nozzle and nozzle holder is

located centrally at the cylinder, and is integrated

with, and removable from, the cylinder head.

A unit pump fitted for each cylinder is located

directly on the crankcase.

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Pump-line-nozzle injection system (PLD)

N07.02-2018-50

83

The electronic engine management system controls the injection timing point and quantity injected individually per cylinder, by means of solenoid valves.

Separation of the high pressure pump and injection nozzle made it necessary to develop a high pressure injection line of special tube material with a surface

hardened by internal high pressure forming, able to support continuous injection pressures over 2000 bar.

With high pressure injection (peak pressures up to 1800 bar) together with the central, vertically positioned nozzle with 8 or 6 injection orifices and flat

combustion chamber cavity in the piston, outstanding particulate values are achieved.

Advantages over the Pump-Nozzle system

¦ No overhead camshaft

- therefore lower space requirement and reduced engine height

- lower noise emission

¦ On the V-engine, only one camshaft needed, which controls both cylinder banks.

- Weight saving

¦ Locating the camshaft in the center of the crankcase means there is optimal power absorption. With an overhead camshaft, measures would be

necessary for strengthening the cylinder head.

¦ Easy to repair

- Individual cylinder heads, which are all identical

- Compact unit pumps, which are simple to replace

- Inexpensive replacement due to separate pump and nozzle

05/03 Powersystems • Industrial Engines Maintenance and Repair Series 457, 500 and 900 Advanced Training

Series 500<>Pump-line-nozzle injection system (PLD)

84

Loading...

Loading...