TM 55-2420-224-14

TECHNICAL MANUAL

TRANSPORTABILITY GUIDANCE

SMALL

EMPLACEMENT EXCAVATOR (SEE)

(NSN 2420-01-160-2754)

HIGH MOBILITY ENTRENCHER (HME)

(NSN 2420-01-228-8610)

HIGH MOBILITY MATERIAL HANDLER (HMMH)

(NSN 2420-01-205-8636)

Approved for public release; distribution is unlimited

HEADQUARTERS, DEPARTMENT OF THE ARMY

18 FEBRUARY 1990

T

ECHNICAL MANUAL

N

O. 55-2420-224-14

TM 55-2420-224-14

HEADQUARTERS

DEPARTMENT OF THE ARMY

ASHINGTON, DC 18 February 1990

W

TRANSPORTABILITY GUIDANCE

SMALL EMPLACEMENT EXCAVATOR

(NSN 2420-01-160-2754)

HIGH MOBILITY ENTRENCHER (HME)

(NSN 2420-01-228-8610)

HIGH MOBILITY MATERIAL HANDLER (HMMH)

(NSN 2420-01-205-8636)

C

HAPTER

C

HAPTER

S

ECTION

C

HAPTER

C

HAPTER

C

HAPTER

S

ECTION

C

HAPTER

S

ECTION

I.

INTRODUCTION

Purpose and Scope

Reporting of Recommendations and Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definitions of Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.

TRANSPORTABILITY DATA

I.

GENERAL

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transportability Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II.

CHARACTERISTICS AND RELATED DATA

General Transportability Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reduced Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unusual Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hazardous and Dangerous Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.

SAFETY

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specific Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.

AIR TRANSPORTABILITY GUIDANCE

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Use of Aircraft Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reparation of Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transport by US Aircraft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transport by LVAD and LAPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helicopter Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.

HIGHWAY TRANSPORTABILITY GUIDANCE

I.

GENERAL

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety

II.

III.

6.

I.

II.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELF-PROPELLED MOVEMENT

General . . . . . . . . . . . . . . . . . . . . . . . .

Preparation of the SEE, HME, and HMMH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRANSPORT BY TRACTOR-TRAILER OR SEMITRAILER

General

Transport on M345 Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MARINE AND TERMINAL TRANSPORTABILITY GUIDANCE

GENERAL

Scope . . . . . . . . . . . . .

Safety

Water Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOADING AND SECURING

General Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Cargo and Barge-Type (LASH and SEABEE) Ships . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Roll-on/Roll-off (RORO), Seatrain, Landing, and Attack Cargo Ships . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paragraph

1-1

1-2

1-3

2-1

2-2

2-3

2-4

2-5

2-6

2-7

3-1

3-2

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

5-1

5-2

5-3

5-4

5-5

5-6

6-1

6-2

6-3

6-4

6-5

6-6

Page

1-1

1-1

1-1

2-1

2-1

2-1

2-7

2-6

2-6

2-6

3-1

3-1

4-1

4-1

4-1

4-1

4-1

4-1

4-2

4-2

5-1

5-1

5-1

5-1

5-1

5-1

6-1

6-1

6-1

6-1

6-1

6-5

i

TM 55-2420-224-14

CHAPTER 7.

ECTION I.

S

II.

III.

APPENDIX A.

Figure

B.

2-1

2-2

2-3

2-4

2-5

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

5-1

6-1

6-2

6-3

6-4

7-1

7-2

7-3

7-4

7-5

Paragraph

RAIL TRANSPORTABILITY GUIDANCE

GENERAL

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Use of Railcard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRANSPORT ON CONUS RAILWAYS

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the SEE or Variants on a General-Purpose Flatcar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the SEE or Variants on Special-Purpose Flatcars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRANSPORT ON FOREIGN RAILWAYS

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transport on Foreign-Service Flatcars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONVERSION TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF ILLUSTRATIONS

Small emplacement excavator (SEE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High mobility material handler (HMMH). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transportability drawing, left-side and rear views of the small emplacement excavator . . . . . . . . . . . . . . . . . .

Transportability drawing, left-side and rear views of the high mobility entrenched . . . . . . . . . . . . . . . . . . . . . .

Transportability drawing, left-side and rear views of the high mobility material handler . . . . . . . . . . . . . . . .

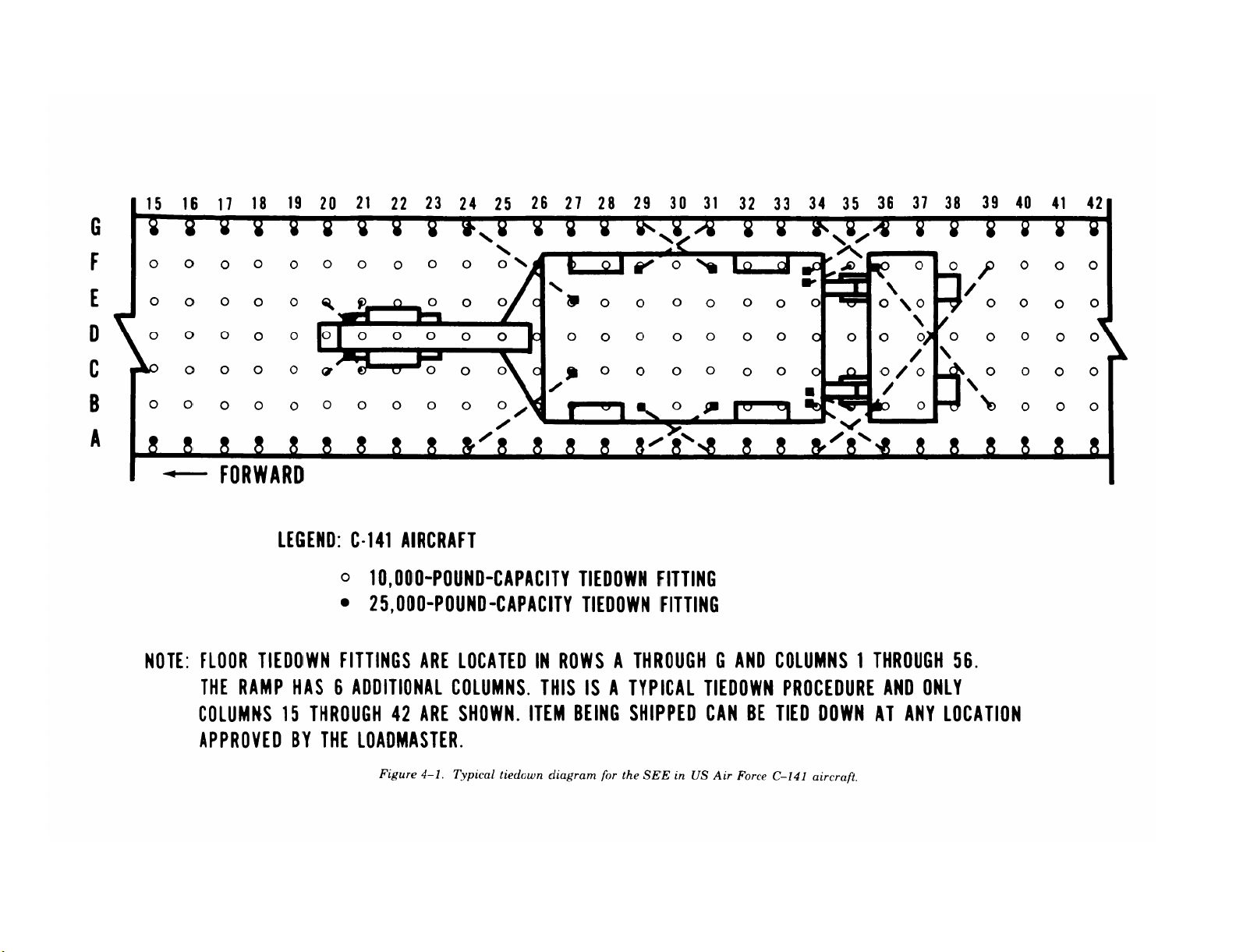

Typical tiedown diagram for the SEE in US Air Force C-141 aircraft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical tiedown diagram for the HME in US Air Force C-130 aircraft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical tiedown diagram for the HMMH in US Air Force C-5 aircraft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEE being lifted with single-hook method by CH-47 helicopter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEE being lifted with dual-hook method by CH-47 helicopter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEE being lifted by CH-54 helicopter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front sling legs preparation on SEE (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Right rear sling leg preparation on SEE (rear view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Left rear sling leg preparation on SEE (rear view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical tiedown diagram for the SEE, HME, and HMMH on an M345 trailer (side view) . . . . . . . . . . . . . . . .

Typical four-leg sling-lifting diagram for the SEE, HME, and HMMH with wire rope . . . . . . . . . . . . . . . . . . .

Typical blocking and tiedown of the SEE, HME, and HMMH in general-cargo and barge-type vessels . . . .

Typical loading of the SEE, HME, and HMMH on a LASH lighter with wire rope, cable clamps,

turnbuckles, and blocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical tiedown of the SEE, HME, and HMMH on a RORO vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical blocking and tiedown for the SEE and HME on a CONUS general-purpose flatcar (side view) . . . .

Typical blocking and tiedown for the SEE and HME on a CONUS general-purpose flatcar (rear view) . . . .

Typical blocking and tiedown detail diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical tiedown for the SEE and variants on a CONUS conventional wood-deck, chain-tiedown flatcar

(side view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical tiedown for the SEE and variants on a CONUS conventional wood-deck, chain-tiedown flatcar

(rear view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

Page

7-1

7-1

7-1

7-1

7-1

7-1

7-7

7-7

A-1

B-1

Page

2-2

2-3

2-4

2-5

2-6

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-12

5-2

6-2

6-3

6-6

6-7

7-2

7-3

7-4

7-8

7-9

LIST OF TABLES

Table

5-1

5-2

6-1

6-2

7-1

7-2

7-3

ii

Bill of Materials for Blocking and Tiedown of the SEE, HME, and HMMH on the M345 Trailer (Fig 5-1)

Application of Materials for Blocking and Tiedown of the SEE, HME, and HMMH on the M345 Trailer

(Fig 5-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bill of Materials for Blocking and Tiedown of a Typical SEE, HME, and HMMH in a General-Cargo

Vessel (Fig 6-2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application of Materials for Blocking and Tiedown

General-Cargo Vessel (Fig 6-2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bill of Materials for Blocking and Tiedown of the SEE and HME on a CONUS General-Purpose Flatcar

(Figs 7-1 and 7-2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application of Materials for Blocking and Tiedown of the SEE and HME on a CONUS General-Purpose

Flatcar (Figs 7-1 and 7-2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application of Chain Tiedowns for Securing the HMMH on HTTX or Similar Type of Flatcars (Figs 7-4

and 7-5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of a Typical SEE, HME, and HMMH in a

Page

5-3

5-3

6-4

6-4

7-5

7-5

7-6

CHAPTER 1

INTRODUCTION

TM 55-2420-224-14

1-1. Purpose and Scope

This manual provides transportability guidance for

logistical handling and movement of the small

emplacement excavator (SEE), high mobility entrencher (HME), and high mobility material handler (HMMH). It contains information considered

appropriate for safe transport of the SEE and its

variants. The information includes significant

technical and physical characteristics, as well as

safety considerations,

movement by the various transport modes. Where

considered necessary, metric equivalents appear in

parentheses following the dimensions or other

measurements. This manual is for transportation

officers and other personnel responsible for moving

the SEE, HME, and HMMH, or for providing

transport services.

required for worldwide

1-2. Reporting of Recommendations

and Comments

Users of this manual are encouraged to submit

comments and to recommend changes for its im-

provement. Comments and recommendations

should be prepared on DA Form 2028 (Recommended Changes to DA Publications and Blank

Forms) and forwarded to Commander, Military

Traffic Management Command Transportation Engineering Agency, ATTN: MTTE-TRS, PO Box

6276, Newport News, VA 23606–0276. Electrically

transmitted messages should be addressed

MTMCTEA FT EUSTIS VA//MTTE-TRS//.

1-3. Definitions of Warnings,

to CDR

Cau-

tions, and Notes

Throughout this manual, warnings, cautions, and

notes emphasize important or critical guidance.

They are used for the following conditions:

a. Warning. Instructions that, if not followed,

could result in injury to or death of personnel.

b. Caution. Instructions that, if not strictly observed, could result in damage to or destruction of

equipment.

c. Note. An operating procedure or condition

that must be emphasized.

1-1

CHAPTER 2

TRANSPORTABILITY DATA

Section I. GENERAL

TM 55-2420-224-14

2-1. Scope

This chapter provides transportability characteris-

tics of the SEE, HME, and HMMH.

2-2. Description

The SEE, HME, and HMMH are commercial items

of construction equipment. The tractor portion of

the equipment is a light truck chassis equipped

with a diesel engine, multispeed range transmission, and offroad flotation tires. The tractor has a

45-mile-per-hour (72-km/h) highway convoy speed

as well as a full drive rough-terrain capability.

a. The SEE tractor configuration consists of the

basic tractor with a 3/4-cubic-yard-capacity front

end loader and rear-mounted backhoe. The backhoe has a 7-cubic-foot-capacity bucket, as shown in

figure 2-1.

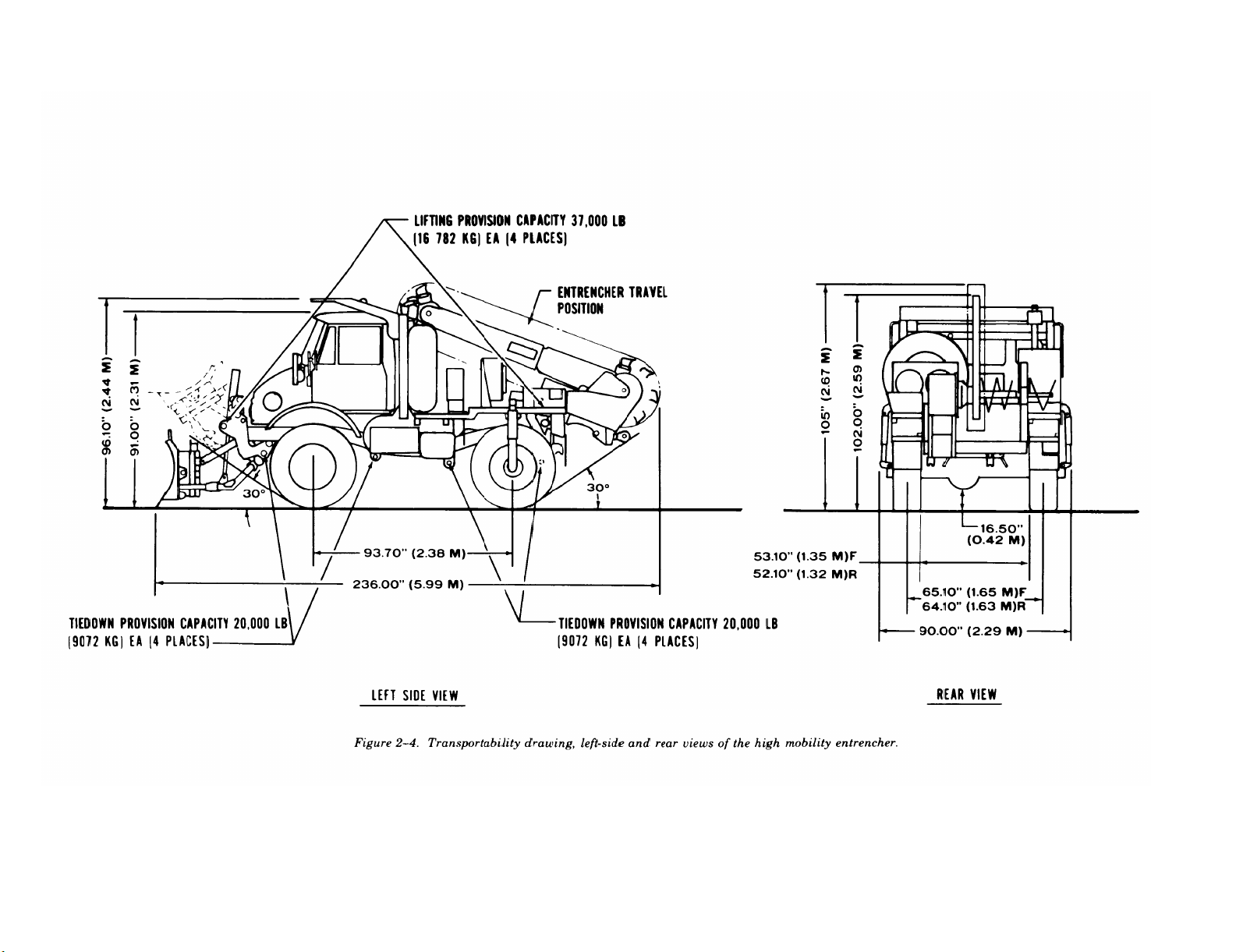

b. The HME variant consists of the same basic

tractor as the SEE, but with a dozer blade (85

inches wide and 32 inches high) on the front end

and an entrencher on the rear. No photograph is

available at this time.

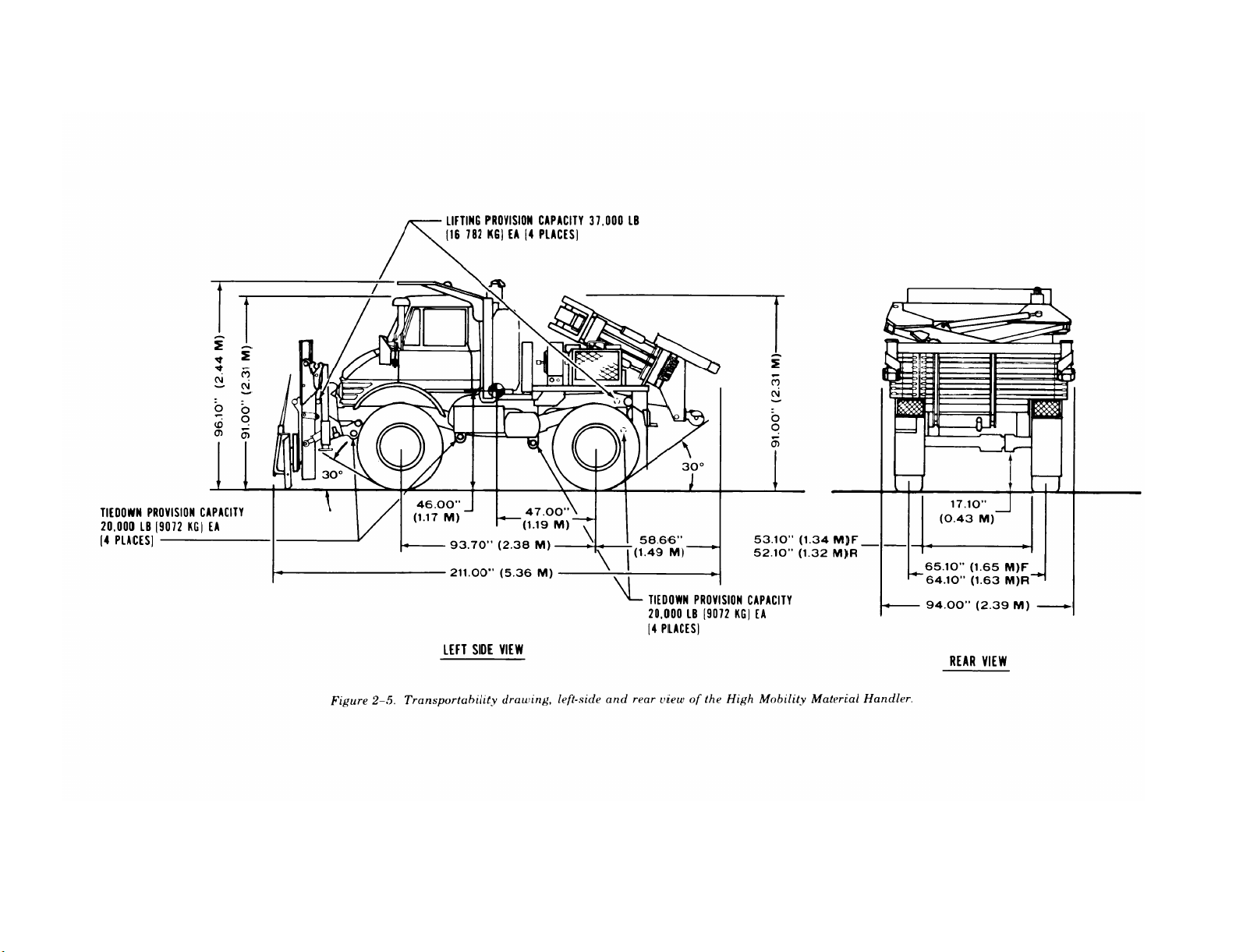

c. The HMMH variant consists of the same

basic tractor as the SEE, but with a 4,000-pound

(1814-kg)-capacity forklift mounted to the front

and a 6,000 pound (2722-kg)-capacity crane at-

tached to the rear of the vehicle, as shown in

figure 2-2.

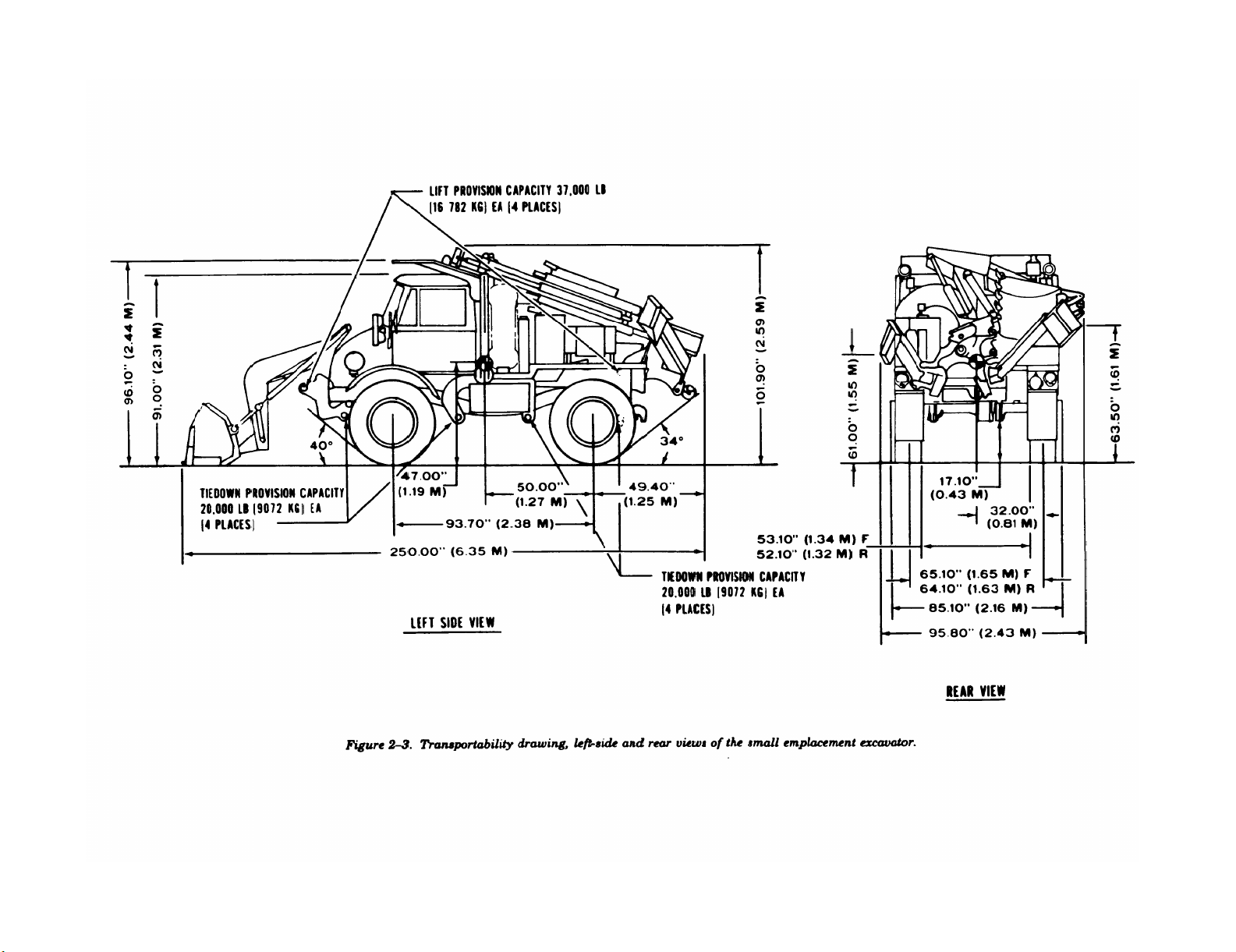

2-3. Transportability Drawings

Figures 2-3 through 2-5 are detailed side- and

rear-view transportability drawings of the SEE,

HME, and HMMH with dimensions, tiedown and

lifting provisions, and load-rating capacities.

2-1

2-2

TM 55-2420-224-14

Figure 2-1.

TM 55-2420-224-14

2-3

Figure 2-2.

2-4

TM 55-2420-224-14

Figure 2-3.

2-5

TM 55-2420-224-14

Figure 2-4.

2-6

TM 55-2420-224-14

Figure 2-5.

TM 55-2420-224-14

Section II. CHARACTERISTICS AND RELATED DATA

2-4. General Transportability Characteristics

Data contained here apply to the model numbers or national stock numbers (NSN) shown. Changes in

model numbers or NSN may affect the loadability of the item as related to the guidance in this manual.

a. Small Emplacement Excavator.

National stock number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line item number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Length:

Operational configuration (maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Width:

Operational configuration (maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Height:

Operational configuration (maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Area:

Operational configuration (maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Travel configuration . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Volume:

Operational configuration (maximum)

Travel configuration . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight:

Front axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Total weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tires:

Number/size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact area:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed/range:

Maximum speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ground clearances–differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

b. High Mobility Entrenched.

National stock number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line item number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Length, travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Width, travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Height, travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Area, travel configuration.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Volume, travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight:

Front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Total weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tires:

Number/size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2420-01-160-2754

T34437

340.2 in. (8.64 m)

250.0 in. (6.35 m)

95.8 in. (2.43 m)

95.8 in. (2.43 m)

96.1 in. (2.44m)

101.9 in. (2.59 m)

226.3 ft2 (21.05 m2)

166.3 ft2 (15.47 m2)

1,720.7 ft3 (48.73 m3)

1,412.3 ft3 (39.99 m3)

8,760 lb (3973 kg)

7,160 lb (3248 kg)

15,920 lb (7221 kg)

4 ea 12.5 x 20

50 psi (344.40 kpa)

45 psi (310.30 kpa)

2

89.9 in.

95.5 in.

(0.06 m2)

2

(0.06 m2)

45 mph (72.41 km/h)

10 hours

17.1 in. (0.43 m)

2420-01-228-8610

T34437

236.0 in. (5.99 m)

90.0 in. (2.29 m)

105.0 in. (2.67 m)

2

147.5 ft

1,290.6 ft

(13.71 m2)

3

(36.55 m3)

7,830 lb (3551 kg)

7,670 lb (3479 kg)

15,500 lb (7030 kg)

4 ea 12.5 x 20

55 psi (379.72 kpa)

55 psi (379.72 kpa)

2-7

TM 55-2420-224-14

Contact area:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed/range:

Maximum speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ground clearances–differential. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45 mph (72.41 km/h)

c. High Mobility Material Handler.

National stock number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line item number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Length, travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Width, travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Height, travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Area, travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Volume, travel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight:

Front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Total weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tires:

Number/size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact area:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed/range:

Maximum speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ground clearances–differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

137.7 ft

1,130.0 ft

45 mph (72.41 km/h)

77.9 in.2 (0.05 m2)

2

76.0 in.

2420-01-205-3636

211.0 in. (5.36 m)

8,018 lb (3637 kg)

7,632 lb (3462 kg)

15,650 lb (7099 kg)

55 psi (379.72 kpa)

55 psi (379.72 kpa)

79.5 in.

76.1 in.

(0.04 m2)

10 hours

16.5 in. (0.42 m)

Z90450

94.0 in. (2.39 m)

96.1 in. (2.44 m)

2

(12.80 m2)

3

(30.89 m3)

4 ea 12.5 x 20

2

(0.05 m2)

2

(0.04 m2)

10 hours

17.1 in. (0.43m)

2-5. Reduced Configuration

Lower cost shipping can be obtained by reducing

each SEE, HME, and HMMH to its minimum

dimensions for terminal handling and ocean transport. Both side mirrors are to be folded in, and the

rear-mounted attachment is placed in the travel

position.

2-6. Unusual Characteristics

These vehicles have no unusual characteristics

that would require special attention be given to

temperature,

atmospheric pressure, or humidity

variations during their exposure to normal transportation environments.

2-7. Hazardous and Dangerous Characteristics

Under usual circumstances, the SEE, HME, and

HMMH will not present any hazardous or dangerous characteristics during exposure to normal

transportation environments.

NOTE

Those regulations and/or transportation

procedures normally associated with vehicles containing diesel fuel apply.

2-8

CHAPTER 3

SAFETY

TM 55-2420-224-14

3-1. General

General safety considerations and precautions for

movement are as follows:

a. Check each vehicle to ensure that all loose

items are properly secured.

b. When backing a vehicle, ensure that no

personnel or obstacles are in danger of being hurt

or damaged by the vehicle.

WARNING

Fire extinguishers must be readily available during all loading and unloading

operations.

WARNING

When vehicle engine is operating, provide

proper ventilation during loading and unloading operations.

of carbon monoxide fumes could be fatal.

Prolonged inhalation

3-2. Specific Safety Requirements

Appropriate chapters of this manual contain pertinent safety requirements by individual mode.

3-1

TM 55-2420-224-14

CHAPTER 4

AIR TRANSPORTABILITY GUIDANCE

4-1. Scope

This chapter provides air transportability guidance

for movement of the SEE, HME, and HMMH. It

covers significant technical and physical characteristics and safety considerations. Also, it prescribes

the materials required to prepare, load, and un-

load the SEE, HME, and HMMH when transported in the C–130, C–141, and C–5 US Air Force

aircraft and the Boeing 747 Civil Reserve Air

Fleet (CRAF) aircraft.

4-2. Maximum Use of Aircraft Capacity

Additional cargo, including personnel within allowable load limits and restrictions prescribed by

pertinent safety regulations, may be transported

with these vehicles on US Air Force aircraft.

4-3. Applicability

a. US Air Force Aircraft. When prepared for

loading as described in paragraph 4-5, the SEE,

HME, and HMMH are transportable in C-130,

C-141, and C-5 aircraft.

b. Tiedown Devices.

HMMH will be tied down according to section IV

of applicable procedures in TO 1C-XXX–9.

c. Loadmaster. The loadmaster will ensure that

the loaded equipment is secured according to

restraint criteria outlined in TO 1C–XXX–9.

Air Force aircraft loads in this manual

are illustrated to a minimum restraint of

3 g forward, 1.5 g aft, 1.5 g lateral and 2

g vertical. (Reference 1C-XXX-9 and

MIL-STD-1791.)

The SEE, HME, and

NOTE

4-4. Safety

In addition to safety precautions

chapter 3, the following precautions

SEE, HME, and HMMH:

a. Ensure that the fuel tanks are

one-fourth or more than three-fourths full.

b. Check each vehicle carefully to ensure that

all loose items are properly secured.

c. Check each vehicle to ensure there are no

fluid leaks.

d. Check all tiedown provisions and attached

structural members for any damage.

e. Check tire pressure to ensure tires are at

recommended highway pressure.

contained in

apply for the

not less than

f. Check batteries to ensure they are protected

against short circuits and secured so that leakage

of acid cannot occur (reference TM 38–250, para

8-47a). Also, check the fuel tanks and hydraulic

systems to ensure they comply with TM 38–250.

WARNING

Fire extinguishers must be readily available during all loading and unloading.

WARNING

Provide proper ventilation during loading.

Prolonged inhalation of exhaust fumes

could be fatal.

WARNING

Do not allow the vehicle to exceed 3 miles

per hour (walking speed) inside the aircraft or on the loading ramps.

4-5. Preparation of Equipment

a. Fold both mirrors and secure them with rope

to the roll over protection structure (ROPS).

b. Secure rear attachments with 1/2-inch wire

rope (safety cable) and two clips, when shipped in

the travel position.

tight) around the ROPS (or tiedown provision as

directed) and rear attachment to restrain the

attachment in case the mechanical lock is not

engaged or fails.

Install wire rope taut (not

4-6. Transport by US Aircraft

a. The SEE, when shipped in C–130 and C–141

aircraft, will have the backhoe attachment in the

operational configuration. The SEE should be

backed into the C-130 and C-141 aircraft using

two qualified operators. One driver operates the

tractor and the other operates the backhoe, adjust-

ing height during loading and unloading opera-

tions. Each SEE requires two stacks of parking

shoring (2 x 6 inches x 4 feet, two per stack)

between the front end loader and the aircraft floor.

Also, place two stacks of shoring (2 x 6 inches x 4

feet, two per stack) under lowered bucket and

aircraft floor.

b. The HME and HMMH, when shipped in

C–130 and C–141 aircraft, must be in the travel

configuration.

(1) HME. Install 1/2-inch wire rope (safety

cable) through ROPS and over entrenched attach-

ment, forming a loop. Secure the loop by pulling

and installing the wire rope taut (not tight) with

two 1/2-inch clips. Each HME requires two stacks

4-1

TM 55-2420-224-14

of parking shoring (2 x 6 inches x 4 feet, two per

stack) between the front dozer blade and the

aircraft floor.

(2) HMMH. Install 1/2-inch wire rope (safety

cable) around top crane arm and through left

center tiedown provision on chassis, forming a

loop. Secure the loop by pulling the wire rope taut

(not tight) and installing two 1/2-inch clips. Repeat

same procedure for right side, except loop wire

rope through right provision on chassis. Each

HMMH requires two stacks of parking shoring (2

x 6 inches x 5 feet, two per stack) between the

front forklift tines and the aircraft floor. Also the

rear outriggers are to be secured with 1/2-inch

wire rope (safety cable) looped around each outrigger and secured with two 1/2-inch clips.

c. The C–5 aircraft can transport the SEE,

HME, and HMMH in the travel configurations.

(1) SEE. Install 1/2-inch wire rope (safety

cable) taut (not tight) around the ROPS and the

backhoe attachment and secure with two 1/2-inch

clips. Also, install on right outrigger a 1/2-inch

wire rope (safety cable) taut (not tight) through the

bucket tiedown provisional and around outriggers.

Repeat procedures for left outrigger. Each SEE

requires two stacks of parking shoring (2 x 6

inches x 4 feet, two per stack) between the front

end loader and the aircraft floor.

(2) HME and HMMH. To transport the HME

and HMMH in the C–5 aircraft, follow the same

procedures in paragraph 4-6b.

d. The shoring is required to protect the aircraft

floor and any downward motion of the front or

rear implements on the aircraft floor.

e. All shoring material will be furnished by the

shipper and installed as directed by the aircraft

loadmaster.

f. The aircraft commander or his/her representa-

tive ensures that the vehicles are loaded/unloaded

and properly secured in the aircraft according to

the criteria in section IV of the appropriate technical order.

g. Typical tiedown diagrams (figs 4-1 through

4–3) are based on acceptable methods. They can be

used as a guide for loading and securing the SEE,

HME, and HMMH aboard aircraft and also for

preparing a vehicle for air transport. The tiedowns

are part of the aircraft equipment.

4-7. Transport by LVAD and LAPE

The SEE is certified for low altitude parachute

extraction (LAPE) from US Air Force C–130 aircraft and certified for low velocity airdrop (LVAD)

from US Air Force C-130 and C-141 aircraft.

Preparation and procedures for LAPE and LVAD

airdrops are described in FM 10–539 and TO

13C7-1-17.

4-8. Helicopter Transport

The SEE is within the external lift capability of

the CH–47D helicopter in either single-hook (fig

4–3) or dual-hook (fig 4–4) configuration at airspeeds of 100 knots. The load is also suitable for

external transport by the CH–54 helicopter (fig

4-5) at airspeeds of 95 knots.

a. Materials.

(1) Sling set (25,000-pound capacity) – one

each.

(2) Nylon cord, Type III-as required.

(3) Cotton webbing–as required.

(4) Tape, adhesive, pressure-sensitive, 2-inch

roll—as required.

(5) Felt, padding, sheet–four each (for cush-

ioning material).

b. Preparation.

(1) Ensure that the front end loader assembly

travel locks at the ends of both front end loader

boom cylinders are properly pinned in place.

(2) Secure steering wheel, doors, and all loose

equipment with cord and tape as necessary.

(3) Fold side mirrors inboard and tie or tape

as required.

(4) Tape windshield wipers to windshield.

(5) Securely tie and tape engine compartment

hood.

(6) Tie or tape the hydraulic lines and hoses

close to the forward lifting provisions to prevent

possible entanglement during hookup.

c. Rigging Procedures.

(1) Place apex fitting on top of the falling

object protection system (FOPS). Route the outer

sling legs (1 and 2) to the front of the SEE and the

inner sling legs (3 and 4) to the rear of the SEE.

NOTE

Sling legs 1 and 3 should be the same side

of the load.

(2) Loop the chain ends of sling legs 1 and 2

through the respective front lifting provisions, and

insert link 3 into the grabhook. Wrap a felt sheet

around the chain ends of the sling legs and secure

with tape or nylon cord (fig 4–7).

(3) Loop the chain end of sling leg 3 through

the right rear lifting provision (closest to the

backhoe bucket) and insert link 10 into the grabhook. Wrap a felt sheet (cushioning material)

around the chain end of

with tape or nylon cord.

links (fig 4-8).

the sling leg and secure

Tape or tie excess chain

4-2

4-3

TM 55-2420-224-14

Figure 4-1.

4-4

TM 55-2420-224-14

Figure 4-2.

4-5

TM 55-2420-224-14

Figure 4-3.

4-6

TM 55-2420-224-14

Figure 4-4.

TM 55-2420-224-14

4-7

Figure 4-5.

4-8

TM 55-2420-224-14

Figure 4-6.

4-9

TM 55-2420-224-14

Figure 4-7.

TM 55-2420-224-14

4-10

Figure 4-8. Right rear sling leg preparation on SEE.

TM 55-2420-224-14

(4) Loop the chain end of sling leg 4 through

the left rear lifting provision (closest to backhoe

operator’s seat), and insert link 5 into the grabhook. Wrap a felt sheet (cushioning material)

around the chain end of the sling leg and secure

with tape or nylon cord (fig 4-9).

(5) Cluster and tie or tape (breakaway technique) all sling legs above the FOPS to prevent

entanglement during hookup.

(6) Dual-hook procedures are identical except

two apex fittings are used—one for sling legs 1 and

2 and one for sling legs 3 and 4.

d. Hookup.

(1) vehicle should fly with rear end forward.

(2) Hookup team sits or squats on FOPS,

facing aft. The assistant hookup person discharges

static electricity with the static probe. The hookup

person places the apex fitting on the aircraft cargo

hook. Both persons carefully dismount and remain

beside the load as the helicopter removes slack

from the sling legs. When a successful hookup is

assumed, the hookup team briskly exits the area

underneath the helicopter.

(3) Dual-hook procedures are similar except

the hookup persons place two apex fittings on two

different cargo hooks. Apex fitting 1 goes onto the

forward cargo hook and apex fitting 2 goes onto

the rearward cargo hook. Do not use the center

aircraft hook.

4-11

TM 55-2420-224-14

4-12

Figure 4-9. Left rear sling leg preparation on SEE.

TM 55-2420-224-14

CHAPTER 5

HIGHWAY TRANSPORTABILITY GUIDANCE

Section I.

5-1. Scope

This chapter provides highway transportability

guidance for movement of the SEE, HME, and

HMMH. It covers significant technical and physical characteristics, as well as safety considerations. It also prescribes the materials and guidance required to prepare, load, and tie down these

vehicles.

5-2. Safety

In addition to safety precautions in chapter 3,

movement within CONUS is subject to all safety

Section II. SELF-PROPELLED MOVEMENT

5-3. General

The SEE, HME, and HMMH are self-deployable

throughout CONUS, Alaska, and Hawaii without

permits. Also, they are transportable worldwide.

However, they may need a permit for exceeding

the length limits in 17 countries, height limits in

34 countries, weight limits in 4 countries, and

width in 18 countries. Legal limitations for foreign

countries are identified in the Limits of Motor

Vehicle Sizes and Weights, International Road

Federation, Geneva, Switzerland.

GENERAL

laws, rules, and regulations that apply to commercial carriers. In overseas areas, movements are

governed by the theater and local regulations.

CAUTION

Do not allow the SEE, HME, and HMMH

to exceed 3 miles per hour (walking speed)

during loading and unloading operations.

CAUTION

Do not disconnect trailer from transporter

during loading and unloading.

5-4. Preparation of the SEE, HME, and

HMMH

When transported under their own power, the

SEE, HME, and HMMH must have the front and

rear implements raised to the travel position and

safety cable installed as described in paragraph

4-5b.

Section III. TRANSPORT BY TRACTOR-TRAILER OR SEMITRAILER

5-5. General

The SEE, HME, and HMMH can be transported

over highways by tractor-trailer or tractor-

semitrailer. All variants can be transported by

both the M915A1/M345 and the M915A1/M269A1

tractor-trailer/semitrailer, and larger, combina-

tions. Highway shipments may be made using

either military or commercial lowbed semitrailers

of adequate capacity and size. The tiedown proce-

dures for transport on trailer or semitrailer will be

similar to those described in paragraph 5-6.

5-6. Transport on M345 Trailer.

a. General. The SEE, HME, and HMMH are to

be loaded on the M345 trailer as shown in figure

5-1.

b. Material. Adequate tiedown chains, binders,

and materials for blocking are listed in table 5-1.

Applications of tiedowns and blocking are listed in

table 5-2.

c. Loading.

WARNING

At no time during loading and unloading

operations should personnel, other than

the guide and the driver of the SEE,

HME, or HMMH, be on the trailer bed.

WARNING

5-1

5-2

TM 55-2420-224-14

Figure 5-1.

TM 55-2420-224-14

Table 5-1. Bill of Materials

and HMMH

Item

*Chains

Load binders

*1/2-inch wire rope with U-bolt clamps (4 ea) and thimbles (4 ea) may be substituted for 1/2-inch chain.

120-inch-long x 1/2-inch-diameter, high-test chain (working load limit 9,200

pounds), type I, grade C, class 2; welded steel, Fed Spec RR-C–271; with two

grabhooks equal to or better than the strength of the chain

Double-hook, heavy-duty, eccentric takeup with chain grabhooks for 1/4- to

1/2-inch chain, working load limit 9,200 pounds, type II, class 1, style C; Fed

Spec GGG-B-325B

for Blocking

on the M345

Description

and Tiedown of the SEE, HME,

Trailer (Fig 5-1)

Table 5-2. Application of Materials for Blocking and Tiedown of the SEE, HME,

and HMMH on the M345 Trailer (Fig 5-1)

Item

A

B

No. Required

4

4 Load binder. Secure grabhooks to chains, and remove slack with eccentric takeup.

Chain. Run one end of chain through tiedown provision and the other end through

trailer tiedown ring. Secure both ends of chain to load binder (item B) and then secure

the load binder. Wire-tie load binder handle in closed position. (Repeat procedure at all

four tiedown provisions.)

Application

Approximate

Quantity

4

4

5-3

TM 55-2420-224-14

CHAPTER 6

MARINE AND TERMINAL TRANSPORTABILITY GUIDANCE

Section I. GENERAL

6-1. Scope

This chapter provides marine and terminal transportability guidance for movement of the SEE,

HME, and HMMH. It covers significant technical

and physical characteristics, as well as safety

considerations. Also it prescribes the materials

required to prepare, lift, tie down, and discharge

the SEE, HME, and HMMH.

6-2. Safety

In addition to the safety precautions contained in

chapter 3, the following areas should be noted as

applicable:

a. Fire extinguishers must be available during

all loading and unloading operations.

b. Vessel equipment and gear should be in-

spected for damage and wear before being used.

c. Slings, chains, cables, and other items used in

loading, discharge, and tiedown operations shall be

inspected for condition and adequate capacity.

Section II. LOADING AND SECURING

6-4. General Rules

a. Stowage. When possible, the SEE, HME, and

HMMH should receive the protection of below-deck

stowage. The SEE, HME, and HMMH can be

loaded as deck cargo provided the tractors have

protective covering. In general, good stowage of

the SEE, HME, and HMMH means they are

placed as close together as practical, with minimum space between outer vehicles and sweat-

boards. Also, their brakes are set with brake lever

wire-tied, and the transmission is placed in neutral.

b. Lifting. The SEE, HME, and HMMH have

four lifting provisions each. Two are over both rear

wheels and two are on the front frame. Typical

four-leg lifting diagrams are shown in figure 6-1.

c. Loading. The SEE, HME, and HMMH will be

loaded on seagoing cargo vessels in its travel

configuration. They may be loaded in the travel

configuration aboard landing craft, beach dis-

charge lighters, and amphibious lighters under

their own power or by a crane with a 10-ton

capacity (minimum), They can also be driven or

towed aboard roll-on/roll-off vessels or onto the

decks of barges.

d. Personnel should be cautioned not to walk

under vehicle being lifted.

e. Lifting provisions and connected structural

members on each vehicle shall be inspected to

ensure that they are complete and not damaged.

f. All lifts should have at least one tag line

attached to a tiedown fitting to control the sway of

the SEE, HME, and HMMH while suspended.

6-3. Water Shipment

The vehicles can be transported by a large variety

of inland-waterway carriers and lighters and by all

seagoing cargo vessels.

NOTE

The methods described in this chapter for

lifting and securing the SEE, HME, and

HMMH are suggested procedures. Other

methods of handling and stowing may be

used provided they will ensure safe delivery without damage.

6-5. General Cargo and Barge-Type

(LASH and SEABEE) Ships

CAUTION

Vehicle fuel tanks must be drained and

purged, and battery terminals must be

disconnected and taped.

a. Lighterage. The SEE, HME, and HMMH are

transportable on all Army lighterage vessels except the LARC V. Transporting the SEE, HME,

and HMMH by lighterage to or from vessels

requires blocking. Also, use tiedown restraints

when transporting the tractors for extended distances or through rough water.

b. Securing, Requirements for securing the vehicles aboard general-cargo vessels are basically the

same as for barge-type vessels. The wheels of the

vehicles are blocked in front, in rear, and on both

sides. Then the vehicles are lashed with wire rope

or chains to bulkheads, stanchions, or padeyes.

Figure 6–2 shows typical blocking and tiedown

details, and table 6-1 lists the materials for

blocking and tiedown. Application of materials is

shown in table 6–2.

6-1

TM 55-2420-224-14

6-2

Figure 6-1. Typical four-leg sling-lifting diagram for the SEE, HME, HMMH with wire rope.

6-3

TM 55-2420-224-14

Figure 6-2.

TM 55-2420-224-14

Table 6-1. Bill of Materials for Blocking and Tiedown of a Typical SEE, HME,

Item

and HMMH in General-Cargo Vessel (Fig 6-2)

Approximate

Description Quantity

Turnbuckles

Lumber

Nails Common, steel; flathead; bright or cement-coated; Fed Spec FF-N-105B: 40d

Wire rope

Clamps

Eye-and-jaw type, 3/4-inch diameter x 10-inch takeup or equal

Douglas-fir, or comparable, straight-grain, free from material defects; Fed Spec

MM-L-751H: 4- x 6-inch

6- x 8-inch

(Does not include lumber for side blocking)

6 x 19, IWRC; improved plow steel; performed, regular-lay; table X, Fed Spec

RR-W-410C: 1/2-inch

Wire rope, U-bolt clips, saddled, single-grip, steel, Crosby heavy-duty, or equal;

Fed Spec FF-C-450: 1/2-inch

8 linear feet

101 linear feet

80 feet

Table 6-2. Application of Materials for Blocking and Tiedown of a Typical SEE, HME, and

HMMH in General-Cargo Vessel (Fig 6-2)

Item

A 2

B

No. Required

4

Application

Side blocking. Each consists of 6- x 8- x

of tractor against outside of tires.

End blocking. Each consists of 6- x 8against front and rear of front wheels and rear wheels. Toenail to item A with four 40d

nails, two in the side and two in each end.

260-inch* lumber. Place one piece on each side

x 100-inch* lumber. Place on top of item A,

6

90

21

C

D

E

F

G

H

I

*Approximate lengths may be cut-to-suit.

8

6

21

4

as required

6

2

Backup cleats. Each consists of 4- x 6- x 12-inch lumber. Place one on top of each item

A against item B. Toenail to item A with four 30d nails, one in each side and two in the

ends.

Wire rope. Form a complete loop through each shackle and the eye of a turnbuckle.

Overlap wire rope ends at least 24 inches.

Clamps. Place three on each wire rope at the overlapped area and space 3 inches apart,

with a minimum of 6 inches from ends of wire rope. Evenly tighten clamps to a torque

of 65 foot-pounds.

Turnbuckles. Attach jaw end to padeye in deck. Tighten as required.

Bracing. Consists of 6- x 8-inch lumber, cut-to-fit. Brace as required against adjacent

vehicle blocking, cargo, or vessel bulkhead. Secure each end of each piece to adjacent

blocking by toenailing with four 40d nails. Lumber and nails for this requirement are

not included in table 6-1.

Padeye. Six required on floor of vessel.

Shoring. Each consists of 6- x 8- x 36-inch lumber. Place under front bucket on both

left and right side of center of bucket. Secure shoring to bucket with wire.

6-4

TM 55-2420-224-14

c. Stowage in Barges. Figure 6–3 shows the

arrangement for stowing six SEES or variants in

barge-type vessels. The vehicles should be loaded

symmetrically in sequences about the centerline of

the barge. They should be loaded in a manner to

counterbalance variations in centers of gravity.

6-6. Roll-On/Roll-Off (RORO), Seatrain, Landing, and Attack Cargo Ships

NOTE

When the SEE, HME, and HMMH are

loaded onto vessels that are adequately

ventilated by power blowers, such as

RORO vessels, the fuel need not be

drained and batteries need not be disconnected.

a. Loading. The SEE, HME, and HMMH can be

driven or towed aboard RORO vessels.

b. Securing. RORO, seatrain, landing, and attack cargo ships have patented lashing gear (Peck

and Hale equipment is often used) and permanent

fittings on their decks. Four Peck and Hale lashings, size 35M, should be used to tie down each

SEE, HME, and HMMH; two lashings, crossed,

from the forward tiedown points with shackles and

two lashings, crossed, from the aft tiedown points

with shackles to the "cloverleaf" deck sockets or

bulkhead fitting. Blocking and bracing is not

required with adequate patented lashing gear (fig

6-4). Use Peck and Hale lashing, type 4M or 35M;

one lashing from front bucket (SEE) or dozer blade

(HME) tiedown point and across the bucket or

blade to the "cloverleaf" deck sockets or bulkhead.

Lower forklift implement (HMMH) on shoring,

secure with lashing across tines from deck sockets.

6-5

6-6

TM 55-2420-224-14

Figure 6-3.

6-7

TM 55-2420-224-14

Figure 6-4.

TM 55-2420-224-14

CHAPTER 7

RAIL TRANSPORTABILITY GUIDANCE

Section I.

7-1. Scope

This chapter provides rail transportability guidance for movement of the SEE, HME, and HMMH.

It covers technical and physical characteristics and

safety considerations. It also prescribes the mate-

rial and guidance

required to prepare, load, and

Section II. TRANSPORT

7-3. General

The transportability guidance contained in this

section applies when the SEE or variants are

transported on CONUS railways. Consideration is

given to single and multiple movements on the

types of flatcar normally used to move this vehicle.

The SEE or variants can be transported on a

50-inch-high deck railcar without restriction

throughout CONUS.

7-4. Preparation.

a. The SEE will be in the travel configuration

for rail transport.

cable) with two clamps will be installed taut (not

tight) around the ROPS and the backhoe attachment for a safety device if the locking device fails.

Outriggers are tied, with 1/2-inch wire rope and

two clamps, in their retracted position to prevent

extension during transport. Foam padding will be

tied around the hydraulic cylinders on the backhoe

attachment for protection against damage during

rail shipment.

b. The HME will be in the travel configuration

for rail transport.

cable) with two clamps will be installed taut (not

tight) around the ROPS and entrenched implement

for a safety device if the locking device fails.

c. The HMMH will also be in the travel configuration for rail transport. Secure rear crane implement with a 1/2-inch wire rope (safety cable)

looped around crane arm and through right side

center tiedown provision on chassis for a safety

device if the locking device fails. Repeat same

procedure on left side. Also the outriggers are tied,

A 1/2-inch wire rope (safety

A 1/2-inch wire rope (safety

GENERAL

tie down the SEE, HME, and HMMH on open-top

flatcars.

7-2. Maximum Use of Railcars

Additional cargo,

offering the SEE or variants

transported with the SEE or

as approved by the activity

—

for transport, may be

variants.

ON CONUS RAILWAYS

with 1/2-inch wire rope and

retracted position to prevent extension during

transport. Tie felt padding around the hydraulic

cylinders on the backhoe implement for protection

against damage during rail shipment.

two clamps, in their

7-5. Loading the SEE or Variants on a

General-Purpose Flatcar

a. The SEE or variants may be placed in the

tiedown position on a railcar by a crane (refer to

para 6–4b for lifting instructions), or it may be

driven or towed onto the railcar provided a suit-

able ramp or bridge is available.

CAUTION

Do not allow the SEE or variant to exceed

3 miles per hour (walking speed) during

loading or unloading operations.

b. Loads shown in figures 7–1 and 7–2 are

based on a flatcar that is 9 feet 4 inches wide.

Table 7-1 is a bill of materials and table 7-2 is

the application of materials for securing the SEE

or variants on general-purpose flatcars.

7-6. Loading the SEE or Variants on

Special-Purpose Flatcars

The loads shown in figures 7-4 and 7-5 are based

on the use of CONUS conventional wood-deck

chain-tiedown flatcars. These cars are equipped

with special heavy-duty tiedown anchors and chain

assemblies contained in a channel along each side

of the car and on each side of the center sill. Table

7–3 presents application of chain tiedowns for

securing the HMMH.

7-1

7-2

TM 55-2420-224-14

Figure 7-1.

TM 55-2420-224-14

Figure 7–2. Typical blocking and tiedown for the SEE and HME on a CONUS general-purpose flatcar (rear view).

7-3

7-4

TM 55-2420-224-14

Figure 7-3.

TM 55-2420-224-14

Table 7-1. Bill of Materials for Blocking and Tiedown of the SEE and HME on a CONUS

General-Purpose Flatcar (Figs 7-1 and 7-2)

Approximate

Item

Lumber

Description

Douglas-fir, or comparable, straight-grain, free from material defects; Fed

Spec MM-L-751H:

2- x 4-inch

2- x 6-inch

2- x 12-inch

6- x 8-inch

Quantity

36 linear feet

12 linear feet

16 linear feet

16 linear feet

Nails

Thimbles

Clamps

Protective

material

Wire rope

Cushioning

material

Common, steel; flathead; bright or cement-coated; Fed Spec FF-N-105B:

12d

20d

30d

40d

Standard, open-type: 1/2-inch

Wire rope, U-bolt clips, saddle, single-grip, steel, Crosby heavy-duty, or equal;

Fed Spec FF-C-450: 1/2-inch

5/8-inch

Waterproof paper, burlap, or other suitable material

6 x 19, IWRC; improved plow steel; preformed regular lay; table X, Fed Spec

RR-W-410C: 1/2-inch

Felt, Padding, Sheet

20

58

40

40

18

42

18

as required

200 feet

2 Each

Table 7-2. Application of Materials for Blocking and Tiedown of the SEE and HME on a CONUS

General-Purpose Flatcar (Figs 7-1 and 7-2)

Item

A

B

C

D

E

F

G

No. Required

8

4

1

8

42

18

Brake wheel clearance. Minimum clearance required is 6 inches above, in back of, and

on both sides of, and 4 inches underneath wheel.

Blocks (detail 1, fig 7–3). Each consists of one piece of 6- x 8- x 24-inch lumber, cut as

wheel, and nail heel of block with five 40d nails.

Side blocks. Each consists of one piece of 2- x 6- x 36-inch lumber and three pieces of 2-

x 4- x 36-inch lumber (detail 2, fig 7-3). Nail one edge of the 2- x 6- x 36-inch piece to

the bottom 2- x 4- x 36-inch piece with five 12d nails. Then, place against tire and

cushioning material (item D) and nail to car floor through the 2- x 4- x 36-inch piece

with four 20d nails. Nail the other two 2- x 4- x 36-inch pieces to the one below in the

same manner.

Protective material. Place bottom portion under item C. The top portion should extend 2

inches above item C (detail 2, fig 7–3).

Wire rope. Each to consist of one piece 1/2-inch wire rope, length as required (about 18

feet). Form a complete loop between tiedown provision and the appropriate stake pocket

(detail 3, fig 7-3). Wire rope ends should overlap a minimum of 24 inches.

Clamps, 1/2-inch. Except for items H, J, K, and M, place four 1/2-inch clips on each

1/2-inch wire rope at the overlapped area, and space 3 inches apart, with a minimum of

6 inches from ends of cable. For items H, J, K, and M, place two 1/2-inch clips on each

1/2-inch wire rope at the overlap area, and space 3 inches apart, with a minimum of 6

inches from ends of cable. Tighten the nuts on the 1/2-inch clips to a torque of 65

foot-pounds.

Thimbles, 1/2-inch. Place one at the bottom of each stake pocket and at each tiedown

provision.

Application

7-5

TM 55-2420-224-14

Table 7-2 – Continued

Item

H

I

J

K

L

M

N

No. Required Application

1

2

1

2

18

1

2

Wire rope, 1/2-inch (about 20 feet). Run end through stake pocket, forming a loop.

Secure with two 1/2-inch clips. Run opposite end through both tiedown provisions on

front loader and through stake pocket, forming second loop. Secure with two 1/2-inch

clips.

Shoring. Each consists of one piece of 2- x 6- x 72-inch lumber. Raise front bucket and

place one piece of lumber longitudinal, about 6 inches from each side of bucket. Nail

each piece of lumber to railcar floor with five 20d nails. Lower bucket on top of

blocking.

Wire rope, 1/2-inch (about 10 feet). Run through ROPS and over backhoe attachment,

forming a loop. Secure with two 1/2-inch clamps. Wire rope around ROPS and backhoe

attachment arm shall be taut but not tight.

Wire rope, 1/2-inch, about 10 and 15 feet long. For the right outrigger, run the 10-foot

piece through the bucket tiedown provision and around the outrigger. With the wire

rope taut but not tight, secure with two 1/2-inch clips. Using the 15-foot piece, repeat

the procedure for the left outrigger.

Clips, 5/8-inch. Place one clip on each thimble (item G) at each stake pocket and tiedown

provision to secure wire rope and thimble together (detail 3, fig 7-3).

Wire rope, 1/2-inch, about 15 feet long. Run through ROPS and over entrenched

attachment, forming a loop. Secure with two 1/2-inch clamps. Wire rope (safety cable)

shall be taut (not tight).

Cushioning material. Wrap each hydraulic cylinder with felt padding and tie with rope.

General Instructions

1. Set handbrakes and wire or block them in place.

2. Place and wire-tie gearshift levers in the neutral position.

3. Use an applicable-sized come-along mechanical hoist, or equal tensioning device, to tension wire rope.

4. See General Rules 1, 2, 3, 4, 5, 7, 9, 11, 12, 13, 14, 15, 19, 19A, 19B, and 19C in Section 1 of the Rules Governing the Loading of

Commodities on Open-Top Cars and Trailers, published by the Association of American Railroads. These rules provide applicable

guidelines and are mandatory in application.

5. Properly tighten the wire rope clamp nuts by using a proper sized torque wrench. After the nuts have been initially tightened,

strike the “U” side of each clamp several times with a hammer to ensure proper seating into the dead end line, repeatedly and

alternately tightening each clip nut to acquire final torque.

NOTE

Use a staggered nailing pattern to nail lumber or laminated lumber to the floor or a railcar.

Adjust the nailing pattern for an upper piece of lumber, as required, so that a nail for that piece is

not driven into or immediately adjacent to a nail in the lower piece of lumber.

Table 7-3. Application of Chain Tiedowns for Securing the HMMH on HTTX or

Similar Type of Flatcars (Figs 7-4 and 7-5)

Item

A

B

C

D 2

No. Required

8

1

Application

Brake wheel clearance. Minimum clearance required is 6 inches above, in back of, and

on both sides of, and 4 inches underneath wheel.

Tiedown chains (furnished with railcar), 1/2-inch diameter alloy steel chain, extra

strength, proof-tested to at least 27,000 pounds for vehicles over 25,000 pounds.

Wire rope (safety cable), 1/2-inch (about 10 feet). Run around both forklift tines and

through both front lifting provisions, forming a loop. Secure with two 1/2-inch clamps.

Wire rope shall be taut but not tight.

Wire rope (safety cable). Run one piece of 1/2-inch wire rope (safety cable about 16 feet

long) around top of crane arm and through left center tiedown provision on chassis,

forming a loop. Secure with two 1/2-inch clamps. Wire rope (safety cable) shall be taut

but not tight. Repeat same procedure for right side, except loop wire rope (safety cable)

through right tiedown provision on chassis.

7-6

Table 7-3 – Continued

TM 55-2420-224-14

Item

E

F

G

No. Required

1 Wire rope (safety cable), 1/2-inch (about 18 feet). Run wire rope (safety cable) around left

and right outriggers on rear crane implement, forming a loop. Secure with two 1/2-inch

clamps. Wire rope (safety cable) shall be taut but not tight.

3 Clamps, 1/2-inch. Place two on wire rope at the overlap area, and space 3 inches apart,

with a minimum of 6 inches from ends of cable, and tighten.

2 Blocking. Each to consist of one piece, 2- x 6- x 48-inch lumber. Raise front forklift

tines and place one piece laterally across both rub rails and lower tines on top of

blocking and secure blocking to tines with wire.

Application

General Instructions

1. Shippers should specify cars equipped with tiedown devices in the quantity shown in table 7–3 when ordering specialized railway

equipment. When carriers furnish cars without the requested tiedown equipment (chains and tensioning devices), chains and

turnbuckles of appropriate size and strength will be used for tiedown of vehicles. Load binders are not to be used in place of

turnbuckles to tension tiedown chains.

2. The HMMHs must face in the same direction and be uniformly spaced along the length of the car to allow sufficient space at each

end of the car and between the HMMHs for tiedown. Apply tiedowns parallel to each other at the same end of the HMMH and from

the HMMH tiedown point to the car tiedown point. The angle of the tiedown should be as close to 45° as possible.

3. Handbrakes are to be set and wired or blocked in place.

4. Gearshift levers must be placed and wire tied in the neutral position.

5. Open hooks must be secured with wire over opening to prevent the hook from becoming disengaged from the chain link to which it

is attached.

6. Turnbuckles used to tighten chains must be wired or locked to prevent them from turning during transit unless turnbuckles are

equipped with self-locking devices.

7. General rules 1, 2, 3, 4, 5, 7, 9, 11, 12, 13, 14, 15, 19, 19A, 19B, and 19C in Section 1 of Rules Governing the Loading of

Commodities on Open-Top Cars and Trailers, published by the Association of American Railroads, provide further details and are

mandatory in application.

Section III. TRANSPORT

7-7. General

The transportability guidance contained in this

section applies when the SEE, HME, and HMMH

is transported on foreign railways. Consideration

is given to single and multiple SEE and variant

movements on the type of rail cars normally used

to move this type of equipment. The SEE and

variants on flatcars are within the Gabarit International De Chargement (GIC) limits and can

move unrestricted in Canada, Mexico, and Europe.

Because of the various designation systems and

clearances used by different countries, evaluation

of transport capability must be on an individual

basis.

ON FOREIGN RAILWAYS

7-8. Transport on Foreign-Service Flatcars

The SEE, HME, and HMMH can be transported on

most foreign-service flatcars. The tractors should

be transported in their reduced configurations.

They can be moved, without restrictions, on standard flatcars throughout Europe. Materials required for blocking and tiedown on foreign-service

flatcars are essentially the same as those used for

rail transport within CONUS. Detailed guidance is

contained in the 4th Transportation Command

Pamphlet 55–2, Tiedown Guide for Rail Move

ments. This pamphlet can be obtained from the 4th

Transportation Command, Oberursel, Germany,

7-7

7-8

TM 55-2420-224-14

Figure 7-4.

TM 55-2420-224-14

Figure 7-5. Typical tiedown for the SEE and variants on a CONUS conventional wood-deck, chain-tiedown flatcar (rear view).

7-9

Common Metric Abbreviations

1.

m = meter

decimeter

dm =

centimeter

cm =

mm = millimeter

2.

Linear Measure

1 mi= 1,609.35 m

1 yd

= 0.9144 m

1 ft = 0.3048 m

1 in.

= 0.0254 m

1 m= 10 dm = 100 cm = 1,000 mm

Surface Measure

3.

1 sq yd = 0.8361 sq m

1 sq ft = 0.0929 sq m

1 sq in. = 0.00065 sq m

4.

Cubic Measure

1 cu yd

1 cu ft = 0.02831 cu m

1 cu in. = 0.000016 cu m

= 0.76455 cu m

APPENDIX A

CONVERSION TABLES

kilogram

kg =

km =

t

kilometer

= metric tons

km =

1

m = 1.0936 yd

1

m = 3.2808 ft

1

1

m

1

sq m

1

sq m

1

sq m = 1,550 sq in.

1

cu m = 1.31 cu yd

1

cu m = 35.30 cu ft

1

cu m

0.6214 mi

= 39.3700 in.

= 1.196 sq yd

= 10.764 sq ft

= 61,023 cu in.

TM 55-2420-224-14

5.

Weight

1 STON = 907.185 kg

1 lb = 0.45359 kg

1 kg = 2.2046 lb

The following simplified conversion factors are

6.

accurate to within 2 percent for quick computations:

a. Inches to centimeters. Multiply in. by 10 and

divide by 4.

b. Yards to meters. Multiply yd by 9 and divide

by 10.

c. Miles to kilometers. Multiply mi by 8 and

divide by 5.

d. Pounds to kilograms. Multiply lb by 5 and

divide by 11.

Paragraph 7-37, FM 55-15 and paragraph 2-15,

TM 55–450-15 contain additional detailed conver-

sion factors.

7. The following conversions are provided for

guidance when procuring lumber, wire rope, or

wire in areas that use the metric system. Lumber

sizes are rounded off to nearest 1/2 cm.

a. Lumber.

(1) 2-in. x 4-in. x desired length = 5-cm x

10-cm x desired length.

1

MT = 1,000 kg

1

MT = 2,204.62 lb

(2) 1-in. x 6-in. x desired length = 2.5-cm x

15-cm x desired length.

(3) 6-in. x 8-in. x desired length = 15-cm x

20-cm x desired length.

(4) 1-in. x 12-in. x desired length = 2.5-cm x

30-cm x desired length (length normally expressed

in ft or m).

b. Wire rope.

(1) 3/8-in. dia = 9.5-mm dia

(2) 1/2-in. dia

(3) 5/8-in. dia

(4) 3/4-in. dia = 19.0-mm dia

(5) 7/8-in. dia

(6) 1-in. dia = 25.4-mm dia

(7) 1-1/4-in. dia = 31.7-mm dia

(8) 1-1/2-in. dia = 38.1-mm dia

Round off to next higher whole mm of available

wire rope sizes.

c. Wire. No. 8 gauge annealed (11/64-in. dia) =

4.37-mm dia. Round off as in b above.

= 12.7-mm dia

= 15.8-mm dia

= 22.2-mm dia

A-1

1.

Army Regulations (AR)

55-29

55-80

55-162

55-355

70-44

70-47

385-40

746-1

Field Manuals (FM)

2.

55-9

55-15

55-17

3.

Supply Bulletins (SB)

700-20

TM 55-2420-224-14

APPENDIX B

REFERENCES

Military Convoy Operations in CONUS

Highways for National Defense

Permits for Oversize, Overweight, or Other Special Military Move-

ments on Public Highways in the United States

Military Traffic Management Regulation

DOD Engineering for Transportability

Engineering for Transportability

Accident Report and Records

Packaging of Army Materiel for Shipment and Storage

Unit Air Movement Plan

Transportation Reference Data

Terminal Operations Coordinator’s Handbook

Army Adopted/Other Items Selected for Authorized/List of Reportable

Items

4.

Technical Bulletins (TB)

55-46-1

Technical Manuals

5.

38-236 (AFP 71-8)

55-500

55-600

55-601

55-2200-001-12

Technical Orders (TO)

6.

1-1B-40

1C-5A-9

1C-130-9

1C-141B-9

7.

Other Publications and Source of Procurement

a. Code of Federal Regulations. Title 49 — Transportation, Parts 170-179.

Available from:

Superintendent of Documents

US Government Printing Office

Washington, DC 20402

Standard Characteristics (Dimensions, Weight, and Cube) for Trans-

portability of Military Vehicles and Other Outsize/Overweight

Equipment

Preparation of Freight for Air Shipment

Marine Equipment Characteristics and Data

Transportation Services at Continental United States (CONUS) Instal-

lations

Railcar Loading Procedures

Transportability Guidance:

Application of Blocking, Bracing, and Tiedown Materials for Rail

Transportation.

Koehing Commercial Parts Manual

Koehing Commercial Maintenance with Supplemental Operator

Maintenance and Repair and Instruction Manual

Handbook of Weight and Balance Data

Loading Instructions, USAF-Series C-5A Airplane

Loading Instructions, USAF-Series C-130 Airplane

Loading Instructions, USAF-Series C-141 Airplane

B-1

TM 55-2420-224-14

b. Association of American Railroads, Rules Governing the Loading of Commodities on Open-Top Cars

and Trailers.

Section No. 1 – General Rules

Section No. 6 – Rules Governing the Loading of Department of Defense

Material on Open-Top Cars

Available from: Association of American Railroads

50 F Street NW

Washington, DC 20001

c. American Trucking Associations, Inc.

2200 Mill Road

Alexandria, VA 22314-4654

B-2

TM 55-2420-224-14

By Order of the Secretary of the Army:

CARL E. VUONO

Official:

WILLIAM J. MEEHAN II

Brigadier General, United States Army

The Adjutant General

DISTRIBUTION: