Memmert UF 30 Instruction Manual

UN UF

IN IF

SN SF

OPERATING INSTRUCTIONS

100% ATMOSAFE. MADE IN GERMANY.

www.memmert.com | www.atmosafe.net

Manufacturer and customer service

Memmert GmbH + Co. KG

Willi-Memmert-Straße 90–96

D-91186 Büchenbach Deutschland

Phone: +49 (0)9122 925-0

Fax: +49 (0)9122 14585

E-mail: sales@memmert.com nternet: www.memmert.com

Customer service: |

|

|

Service hotline: |

+49 (0)9171 |

9792 91 |

Service fax: |

+49 (0)9171 |

9792 979 |

E-mail: |

service@memmert.com |

|

When contacting customer service, always quote the product serial number on the nameplate

(see page 12).

Shipping address for repairs:

Memmert GmbH + Co. KG Kundenservice Willi-Memmert-Str. 90-96 DE-91186 Büchenbach

Germany

Please contact our customer service before sending appliances for repair or before returning equipment, otherwise, we have to refuse acceptance of the shipment.

© 2013 MEMMERT GmbH + Co. KG

Date 06/2013

We reserve the right to make changes

About this manual

About this manual

Purpose and target group

This manual describes the setup, function, transport, operation and maintenance of universal ovens UN/UF, sterilisers SN/SF and incubators IN/IF. It is intended for use by trained personnel of the owner who have the task of operating and/or maintaining the respective appliance.

If you are asked to work on the appliance, read this manual carefully before starting. Familiarise yourself with the safety regulations. Only perform work that is described in this manual. If there is something you do not understand, or certain information is missing, ask your superior or contact the manufacturer. Do not do anything without authorisation.

Versions

The appliances are available in different configurations and sizes. If specific equipment features or functions are available only for certain configurations, this is indicated at the relevant points in this manual.

Due to individual configurations and sizes, illustrations in this manual may be slightly different from the actual appearance. Function and operation are identical.

Other documents that have to be observed:

For operation of the appliance with MEMMERT AtmoCONTROL, observe the separate software manual

For service and repair (see page 43), please refer to the separate service manual

Storage and forwarding

This instruction manual belongs with the appliance and should always be stored where persons working on the appliance have access to it. It is the responsibility of the owner to ensure that persons who are working or will work on the appliance are informed as to the whereabouts of this instruction manual. We recommend that it is always stored in a protected location close to the appliance. Make sure that the instruction manual is not damaged by heat or humidity. If the appliance is sold on or transported and then set up again at a different location, the operating instructions must go with it.

You will find the current version of our operating manual as pdf file if you go to www.memmert.com/de/service/downloads/bedienungsanleitung/.

3

Contents

Contents

1. |

Safety regulations |

6 |

|

1.1 |

Terms and signs used |

6 |

|

1.1.1 |

Terms used |

6 |

|

1.1.2 |

Signs used |

6 |

|

1.2 |

Product safety and dangers |

7 |

|

1.3 |

Requirements of the operating personnel |

7 |

|

1.4 |

Responsibility of the owner |

8 |

|

1.5 |

Intended use |

8 |

|

1.6 |

Changes and alterations |

9 |

|

1.7 |

Behaviour in case of malfunctions and irregularities |

9 |

|

1.8 |

Switching off the appliance in an emergency |

9 |

|

2. |

Construction and description |

10 |

|

2.1 |

Construction |

10 |

|

2.2 |

Function |

1 |

|

2.3 |

Material |

1 |

|

2.4 |

Electrical equipment |

1 |

|

2.5 |

Connections and interfaces |

12 |

|

2.5.1 |

Electrical connection |

12 |

|

2.5.2 |

Communication interface |

12 |

|

2.6 |

Designation (nameplate) |

12 |

|

2.7 |

Technical data |

13 |

|

2.8 |

Applied directives and standards |

14 |

|

2.9 |

Ambient conditions |

15 |

|

2.10 |

Scope of delivery |

15 |

|

2.11 |

Optional accessories |

15 |

|

3. |

Delivery, transport and setting up |

16 |

|

3.1 |

Safety regulations |

16 |

|

3.2 |

Delivery |

16 |

|

3.3 |

Transport |

16 |

|

3.4 |

Unpacking |

16 |

|

3.4.1 Checking for completeness and transport damage |

16 |

||

3.4.2 Disposing of packaging material |

16 |

||

3.5 |

Storage after delivery |

17 |

|

3.6 |

Setting up |

17 |

|

3.6.1 |

Prerequisites |

17 |

|

3.6.2 |

Installation options |

18 |

|

3.6.3 |

Tilt protection |

19 |

|

4. |

Putting into operation |

20 |

|

4.1 |

Connecting the appliance |

20 |

|

4.2 |

Switching on |

20 |

|

4

|

|

|

Contents |

5. |

Operation and control |

21 |

|

5.1 |

Operating personnel |

2 |

|

5.2 |

Opening the door |

2 |

|

5.3 |

Loading the appliance |

22 |

|

5.4 |

Operating the appliance |

22 |

|

5.4.1 |

ControlCOCKPIT |

22 |

|

5.4.2 |

Basic operation |

24 |

|

5.4.3 |

Operating modes |

24 |

|

5.4.4 |

Manual mode |

25 |

|

5.4.5 |

Timer operation |

25 |

|

5.5 |

Temperature monitoring |

26 |

|

5.5.1 |

Electronic temperature monitoring |

26 |

|

5.5.2 Mechanical temperature monitoring: Temperature limiter (TB) |

28 |

||

5.5.3 |

Function |

28 |

|

5.6 |

Ending operation |

28 |

|

6. |

Malfunctions, warning and error messages |

29 |

|

6.1 |

Warning messages of the temperature monitoring function |

29 |

|

6.2 |

Malfunctions, operating problems and appliance errors |

30 |

|

6.3 |

Power failure |

30 |

|

7. |

Menu mode |

31 |

|

7.1 |

Overview |

3 |

|

7.2 |

Basic operation in menu mode using the example of language selection |

32 |

|

7.3 |

Setup |

33 |

|

7.3.1 IP address and subnet mask |

33 |

||

7.3.2 |

Unit |

34 |

|

7.3.3 Temperature monitoring (Alarm Temp and Max Alarm) |

35 |

||

7.3.4 |

Timer Mode |

36 |

|

7.3.5 Type of the slide-in unit (Grid or Shelf) |

37 |

||

7.4 |

Date and time |

38 |

|

7.5 |

Calibration |

39 |

|

8. |

Sterilisers SF/SN |

42 |

|

8.1 |

Intended use |

42 |

|

8.2 |

Note in accordance with Medical Devices Directive |

42 |

|

8.3 |

Guidelines for sterilisation |

42 |

|

9. |

Maintenance and service |

43 |

|

9.1 |

Cleaning |

43 |

|

9.1.1 Working chamber and metal surfaces |

43 |

||

9.1.2 |

Plastic parts |

43 |

|

9.1.3 |

Glass surfaces |

43 |

|

9.2 |

Regular maintenance |

43 |

|

9.3 |

Repairs and service |

43 |

|

10. |

Storage and disposal |

44 |

|

10.1 |

Storage |

44 |

|

10.2 |

Disposal |

44 |

|

Index |

|

45 |

|

5

Safety regulations

1.Safety regulations

1.1 Terms and signs used

In this manual and on the appliance itself, certain common terms and signs are used to warn you of possible dangers or to give you hints that are important in avoiding injury or damage. Observe and follow these hints and regulations to avoid accidents and damage. These terms and signs are explained below.

1.1.1 Terms used

"Warning" is used whenever you or somebody else could be injured if you do not observe the accompanying safety regulation.

"Caution" is used for information that is important for avoiding damage.

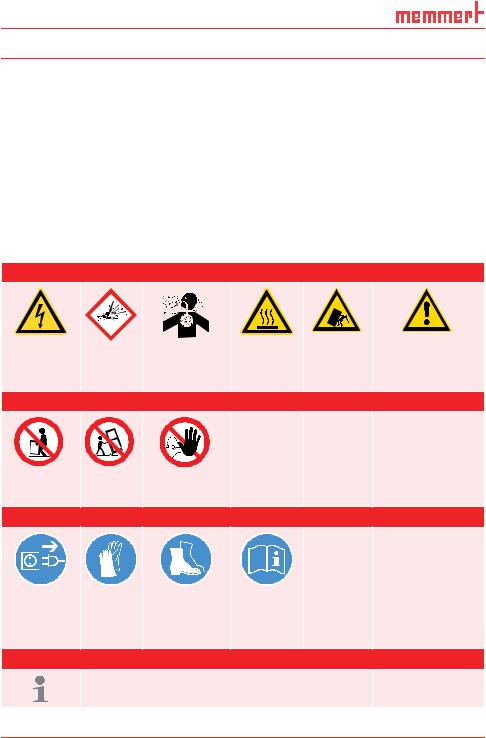

1.1.2 Signs used

Warning signs (warning of a danger)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Danger of |

|

|

|

Danger |

|

|

|

Dangerous |

|

Danger of |

|

Danger of |

|

|

|

Hazard area |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

of |

|

|

||||||||||||||||||||||

|

electrocution |

|

|

|

|

|

|

|

|

|

gases / |

burns |

toppling |

Observe the opera- |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

vapour |

|

|

|

|

|

|

|

|

ver |

|

|

|

|

|

|

|||

|

|

|

|

explosion |

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ting instructions |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Prohibition signs (forbidding an action)

Do not lift |

|

Do not |

|

|

Do not enter |

||

|

|

|

|

|

|

|

|

|

|

|

tilt |

|

|

||

Regulation signs (stipulating an action)

Disconnect |

|

|

|

Wear |

|

|

Wear safety |

|

|

|

Observe |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

the mains |

|

|

gloves |

|

|

boots |

|

|

information |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

plug |

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

in separate |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

manual |

|

|

|

|

Other icons

Important or useful additional information

6

Safety regulations

1.2Product safety and dangers

The appliances described in this manual are technically sophisticated, manufactured using high-quality materials and subject to many hours of testing in the factory. They contain the latest technology and comply with recognised technical safety regulations. However, there are still risks involved, even when the appliances are used as intended. These are described below.

Warning!

After removing covers, live parts may be exposed. You may receive an electric shock if you touch these parts. Disconnect the mains plug before removing any covers. Only electrical technicians may work on the electrical equipment of the appliances.

Warning!

When loading the appliance with an unsuitable load, poisonous or explosive vapours or gases may be produced. This could cause the appliance to explode, and persons could be severely injured or poisoned. The appliance may only be loaded with materials/test objects which do not form any toxic or explosive vapours when heated up (see also "Intended use" on page 8).

Warning!

Depending on operation, the surfaces in the working chamber and the chamber load may still be very hot after the appliance is switched off. Touching these surfaces can cause burns. Wear heatresistant protective gloves or wait until the appliance cools down. To do so, pull the handle bar until the door springs open into its ventilating position (see page 21).

Warning!

In case of appliances of a certain size, you can get accidentally locked in, which is life-threatening. Do not climb into the appliance!

1.3Requirements of the operating personnel

The appliance may only be operated and maintained by persons who are of legal age and have been instructed accordingly. Personnel who are to be trained, instructed or who are undergoing general training may only work with the appliance under the continuous supervision of an experienced person.

Repairs may only be performed by qualified electricians. The regulations in the separate service manual must be observed.

7

Safety regulations

1.4Responsibility of the owner

The owner of the appliance

is responsible for the flawless condition of the appliance and for its proper operation in accordance with its intended use (see page 8);

is responsible for ensuring that persons who are to operate or service the appliance are qualified to do this, have been instructed accordingly and are familiar with the operating instructions at hand;

must know about the applicable guidelines, requirements and operational safety regulations, and train staff accordingly;

is responsible for ensuring that unauthorised persons have no access to the appliance;

is responsible for ensuring that the maintenance plan is adhered to and that maintenance work is carried out properly (see page 43);

has to ensure that the appliance and its surroundings are kept clean and tidy, for example through corresponding instructions and inspections;

is responsible for ensuring that personal protective clothing is worn by operating personnel, e.g. work clothes, safety shoes and protective gloves.

1.5Intended use

This appliance is exclusively intended for heating up non-explosive substances and objects.

Any other use is improper, and may result in hazards and damage.

The appliance is not explosion-proof (does not comply with the German workplace health & safety regulation VBG 24). The appliance may only be loaded with materials and substances which cannot form any toxic or explosive vapours at the set temperature and which cannot explode, burst or ignite.

The appliance may not be used for drying, vaporising and branding paints or similar materials the solvents of which could form an explosive mixture when combined with air. If there is any doubt as to the composition of materials, they must not be loaded into the appliance. Potentially explosive gas-air mixtures must not form, neither in the working chamber nor in the direct vicinity of the appliance.

Steriliser SF

The appliance’s intended use is the sterilisation of medical material through dry heated air at atmospheric pressure (also see page 42).

Appliances IF/UF for use as medical device

For appliances IF and UF with extended overtemperature protection (option A6, recognisable due to standard DIN 12880-2007-Kl.:3.1 on the nameplate) subject to the 93/42/EEC directive (Directive of the council on harmonisation of the laws of the member states relating to medical devices), the intended use is defined as follows: The appliance’s intended use is the warming of non-sterile cloths and covers.

8

Safety regulations

1.6Changes and alterations

No unauthorised changes or alterations may be made to the appliance. No parts may be added or inserted which have not been approved by the manufacturer.

Unauthorised modifications or changes result in the CE declaration of conformity losing its validity and the appliance must no longer be operated.

The manufacturer is not liable for any damage, danger or injuries that result from unauthorised changes or alterations, or from non-observance of the regulations in this manual.

1.7Behaviour in case of malfunctions and irregularities

The appliance may only be used in a flawless condition. If you as the operator notice irregularities, malfunctions or damage, immediately take the appliance out of service and inform your superior.

You can find information on correcting malfunctions from page 29.

You can find information on correcting malfunctions from page 29.

1.8Switching off the appliance in an emergency

Push the On/Off switch on the control panel (Fig. 1) and disconnect power plug. This disconnects the appliance from the power supply at all poles.

Warning!

Depending on the operation performed , the surfaces

in the working chamber and the chamber load may still be very hot after the appliance is switched off. Touching these surfaces can cause burns. Wear heatresistant protective gloves or wait until the appliance cools down. To do so, pull the handle bar until the door springs open into its ventilating position (see page 21).

Fig. 1

Switch off the appliance by pressing the On/ Off switch

9

Setup and description

2.Construction and description

2.1 Construction

1

2 |

8 |

3

7

|

|

4 |

5 |

|

6 |

Fig. 2 |

Construction |

|

|

|

|

1 |

ControlCOCKPIT with capacitive function |

4 |

Steel grid |

||

|

keys (see page 23) |

|

5 |

Working chamber |

|

2 |

On/Off switch (see page 20) |

|

6 |

Nameplate (covered, see page 12) |

|

3 |

Working chamber fan (for |

|

7 |

Door handle (see page 21) |

|

|

UF/IF/SF appliances only) |

|

8 |

Turn control with confirmation key |

|

10

Setup and description

2.2Function

Appliances of the UN, SN and IN type series feature

natural circulation

(convection). For the UF, SF and IF type series, air is circulated by a fan at the working chamber rear panel

Fig. 3, No. 1). It increases the air flow and provides stronger horizontal forced air circulation than natural convection.

In both the convection and fan ventilated appliances, supply air (2) is preheated in a pre-heating chamber

(3). Through the ventilation slits in the side panel of the working chamber, the preheated air is introduced into the interior of the chamber. The supply and exhaust air (5) volume (air change) is controlled by the

air flap (4) on the rear panel of the appliance.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 3 |

Function |

|

|

||||

1Fan

2Fresh air

3Pre-heating chamber

4Air flap

5Exhaust air

2.3Material

For the outer housing, MEMMERT deploys stainless steel (Mat.No. 1.4016 – ASTM 430) and for the interior, stainless steel (Mat.No. 1.4301 – ASTM 304) is used, which stands out through its high stability, optimal hygienic properties and corrosion-resistance towards many (but not all!) chemical compounds (caution for example with chlorine compounds).

The chamber load for the appliance must be carefully checked for chemical compatibility with the materials mentioned. A material resistance table can be requested from the manufacturer.

2.4Electrical equipment

Operating voltage and current consumption: See nameplate

Protection class I, i.e. operating insulation with PE conductor in accordance with EN 61010

Protection type IP 20 acc. to EN 60 529

Interference suppression acc. to EN 55011 class B Appliance fuse: Fusible link 250 V/15 A quick-blow

The temperature controller is protected with a miniature fuse 100 mA (200 mA at 115 V)

1

Setup and description

2.5Connections and interfaces

2.5.1 Electrical connection

This appliance is intended for operation on an electrical power system with a system impedance Z ax of a maximum of 0.292 ohm at the point of transfer (service line). The operator must ensure that the appliance is operated only on an electrical power system that meets these requirements. If necessary, you can ask your local energy supply company what the system impedance is.

Observe the country-specific regulations when connecting (e.g. in Germany DIN VDE 0100 with residual current circuit breaker).

2.5.2 Communication interface

The Ethernet interface is intended for appliances which meet the requirements of IEC 60950-1.

Via Ethernet interface, the appliance can be connected to a network to read out protocol logs with AtmoCONTROL, the optional appliance software. The Ethernet interface is located on the rear of the appliance (Fig. 4).

For identification purposes, each appliance connected must have its own unique IP address. Setting the IP address is described on page 33

With an optional USB to Ethernet converter, |

Fig. 4 |

Ethernet interface |

|

the appliance can be directly connected to a |

|||

|

|

||

computer / laptop (see "Optional accessories" |

|

|

|

on page 15). |

|

|

2.6 Designation (nameplate)

The nameplate (Fig. 5) provides information about the appliance model, manufacturer and technical data. It is attached to the front of the appliance, on the right side under the door (see page 10).

1

2

3

4

5

Typ: UN 260 |

F.-Nr.: 0109.0088 |

230 V~ |

14.8 A 50/60 Hz 3400 W |

DIN12880-Kl.3.1 |

Nenntemp.: 300 °C |

10

10

9

9  8

8

7

|

|

6 |

|

|

Fig. 5 |

Nameplate (example) |

|

|

|

1 |

Type designation |

6 |

Address of manufacturer |

|

2 |

Operating voltage |

7 |

Disposal note |

|

3 |

Applied standard |

8 |

Temperature range |

|

4 |

Protection type |

9 |

Connection / power ratings |

|

5 |

CE conformity |

10 Appliance number |

||

|

|

|

|

|

12 |

|

|

|

|

<![endif]>13

Appliance size |

|

|

|

30 |

55 |

75 |

110 |

160 |

260 |

450 |

750 |

<![if ! IE]> <![endif]>.2 |

Appliance width D |

[mm] |

|

|

585 |

585 |

585 |

745 |

745 |

824 |

1224 |

1224 |

<![if ! IE]> <![endif]>7 |

|

|

|

||||||||||

Appliance height E |

[mm] |

|

|

707 |

787 |

947 |

867 |

1107 |

1186 |

1247 |

1726 |

<![if ! IE]> <![endif]>Technical |

Appliance depth G |

(footprint) [mm] |

|

434 |

514 |

514 |

584 |

584 |

684 |

784 |

784 |

||

|

|

|||||||||||

Depth of door lock [mm] |

|

|

|

|

|

|

56 |

|

|

|

|

|

Appliance depth F (including door handle) [mm] |

490 |

570 |

570 |

640 |

640 |

740 |

840 |

840 |

|

|||

Working chamber width A [mm] |

|

400 |

400 |

400 |

560 |

560 |

640 |

1040 |

1040 |

<![if ! IE]> <![endif]>data |

||

Working chamber height B |

[mm] |

|

320 |

400 |

560 |

480 |

720 |

800 |

720 |

1200 |

||

|

|

|||||||||||

Working chamber depth C |

[mm] |

|

250 |

330 |

330 |

400 |

400 |

500 |

600 |

600 |

|

|

Chamber volume [litres] |

|

|

32 |

53 |

74 |

108 |

16 |

256 |

449 |

749 |

|

|

Weight [kg] |

|

|

|

48 |

57 |

66 |

78 |

96 |

110 |

170 |

217 |

|

|

N/IF |

115 V, 50/60 Hz |

1600 |

850 |

1100 |

1100 |

1100 |

1100 |

1500 |

1800 |

|

|

|

230 V, 50/60 Hz |

1600 |

1000 |

1250 |

1400 |

1600 |

1700 |

1800 |

2000 |

|

||

|

|

|

|

|||||||||

Power [W] |

|

|

230 V, 50/60 Hz |

1600 |

2000 |

2500 |

2800 |

3200 |

3400 |

|

|

|

|

UN/UF/SN/SF |

115 V, 50/60 Hz |

1600 |

1700 |

2200 |

2200 |

2200 |

2200 |

|

|

|

|

|

|

|

400 V, 50/60 Hz |

|

|

|

|

|

|

58002 |

70002 |

|

|

N/IF |

230 V, 50/60 Hz |

7,0 |

4,3 |

5,4 |

6, |

7,0 |

7,4 |

7,8 |

8,7 |

|

|

|

115 V, 50/60 Hz |

13,9 |

7,4 |

9,6 |

9,6 |

9,6 |

9,6 |

13,0 |

15,7 |

|

||

Current consumption |

|

|

||||||||||

|

230 V, 50/60 Hz |

7,0 |

8,7 |

10,9 |

12,2 |

13,9 |

14,8 |

|

|

|

||

[A] |

|

|

|

|

|

|||||||

UN/UF/SN/SF |

115 V, 50/60 Hz |

13,9 |

14,8 |

19, |

19, |

19, |

19, |

|

|

|

||

|

|

|

|

|||||||||

|

|

|

400 V, 50/60 Hz |

|

|

|

|

|

|

3 x 8,42 |

3 x 10,22 |

|

max. number of sliding shelves |

|

3 |

4 |

6 |

5 |

8 |

9 |

8 |

14 |

|

||

max. load per sliding shelve [kg] |

|

|

|

|

|

30 |

|

|

|

|

||

max. load per appliance [kg] |

|

60 |

80 |

120 |

175 |

210 |

|

300 |

|

|

||

|

|

N/IF |

|

|

|

|

+20 to +80 °C3 |

|

|

|

||

Setting temperature range |

UN/UF |

|

|

|

|

+20 to +300 °C3 |

|

|

|

|||

|

|

SN/SF |

|

|

|

|

+20 to +250 °C3 |

|

|

|

||

Adjustment precision |

N/IF |

|

|

|

|

|

0.1 K |

|

|

|

|

|

UN/UF/SN/SF |

|

|

|

up to 100 °C: 0.1 K, above 100 °C: 0.5 K |

|

|

||||||

|

|

|

|

|

|

|

||||||

See Fig. 6 on page 14. 2 3 x 230 V without zero

3 With the interior lighting on, the minimum temperature might not be reached.

<![endif]>description and Setup

Setup and description

D

56

C

<![if ! IE]><![endif]>E

<![if ! IE]><![endif]>B

|

|

|

|

|

|

|

G |

|

|

|

A |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||||

|

|

|

|

|

||||||

|

|

|

|

|

F |

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Fig. 6 Dimensions (see table on page 13)

2.8 Applied directives and standards

Directive 2004/108/EC amended (Directive of the council on harmonisation of the laws of the member states on electromagnetic compatibility). Fulfilled standards:

DIN EN 61326:2004-05, EN 61326:1997, EN 61326/A1:1998, EN 61326/A2:200 EN 61326/A2:2003

Directive 2006/95/EC amended (Directive of the council on harmonisation of the laws of member states relating to electrical equipment designed for use within certain voltage limits). Standards complied with:

DIN EN 61 010-1 (VDE 0411 Part 1):2002-08

DIN EN 61 010-2-010 (VDE 0411 Part 2-010):2004-06

EN 61 010-1:2001, EN 61 010-2-010:2003

When used as a medical device

Directive 93/42/EEC (Directive of the Commission on the harmonisation of the legal regulations of the member states on medical devices)

Directive 2004/108/EC amended (Directive of the council on harmonisation of the laws of the member states on electromagnetic compatibility). Standards complied with:

DIN EN 61326:2004-05, EN 61326:1997, EN 61326/A1:1998, EN 61326/A2:200 EN 61326/A2:2003

14

Setup and description

2.9 Ambient conditions

The appliance may only be used in enclosed rooms and under the following ambient conditions:

Ambient temperature |

|

|

|

+5 |

|

C to +40 |

|

C |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

Humidity rh |

max. 80 %, non-condensing |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Overvoltage category |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Pollution degree |

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|||||||||||||

Altitude of installation |

|||||||||||||||||

|

max. 2,000 m above sea level |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The appliance may not be used in areas where there is a risk of explosion. The ambient air must not contain any explosive dusts, gases, vapours or gas-air mixtures. The appliance is not explosion-proof.

Heavy dust production or aggressive vapours in the vicinity of the appliance could lead to sedimentation in the interior and, as a consequence, could result in short circuits or damage to electrical parts. For this reason, sufficient measures to prevent large clouds of dust or aggressive vapours from developing should be taken.

2.10 Scope of delivery

Power cable Tilt protection

One or two sliding steel grids (load capacity 30 kg each)

The operating instructions at hand

Calibration certificate

2.11 Optional accessories

AtmoCONTROL software for reading out and processing of protocol log files

USB to Ethernet converter (Fig. 7). Makes

it possible to connect the appliance's network interface (see page 12) to the

USB port of a computer / laptop.

Reinforced, sliding steel grids with a load capacity of 60 kg each (for appliance size

110 and larger)

Fig. 7 Converter USB to Ethernet

15

Loading...

Loading...