Memmert SV 29, SV 45 User Manual

page 1

Shaking device

SV 14 / 22

SV 29 / 45

Operating Instuctions

page 2

General notes, safety notes, notes on electrical equipment

and electromagnetic compatibility, as well as

notes on maintenance of the unit are to be found in the

Operating Instructions for the waterbath.

Brief technical description

The shaking device permits controlled shaking of beakers or test tubes in a waterbath.

The shaking device performs a reversing linear movement with a frequency of approx. 35 to 160 strokes

per minute. The shaking speed is controlled electronically and can be adjusted in 10 speed steps. The stroke

is approx. 15 mm.

The ambient conditions for its operation are the same as for the basic units.

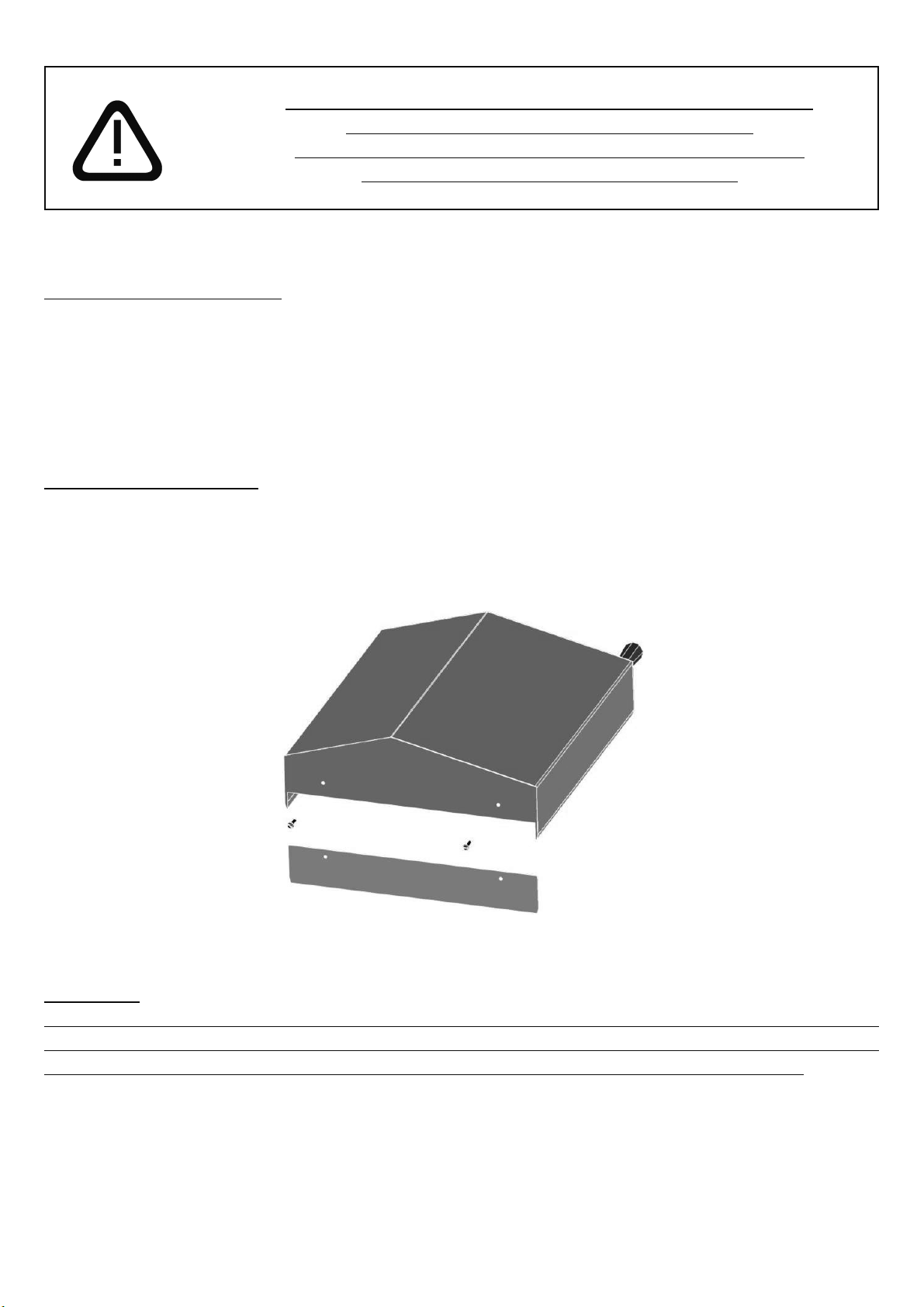

Inserting and removing

The bath can be operated without shaking device if required. After the shaking device and the support

basket has been removed, the side panel supplied should be secured to the gable cover by means of the

two screws in orded to ensure optimum sealing of the cover. Fitting the shaking device has to take place

in the reverse order.

Safety note

If the shaking device has to remain in a waterbath that is switched on, it has to remain switched on as

well! The shaking speed can be set to a standstill! When being switched off, the overpressure steam

blockage is out of action and condensate may pass into the housing of the shaking device!

page 3

Starting up

Mains supply

The mains cable must be arranged so that it can not come anywhere into contact with hot surfaces of the unit.

Filling the waterbath

In order to protect the stainless steel shaking

device it is necessary to use deionised water as

the thermofluid. The bath must be filled so that

the liquid level is between the two level marks on

the right inside the tank (with the shaking device

carrying its load)!

Note!

Depending on the loading of the shaking device and the shaking speed selected, it is possible

for the bath liquid or the (possibly noxious) shaken liquid to slop over. In that case the

shaking speed or the liquid level have to be suitably adjusted but without going below the

minimum liquid level.

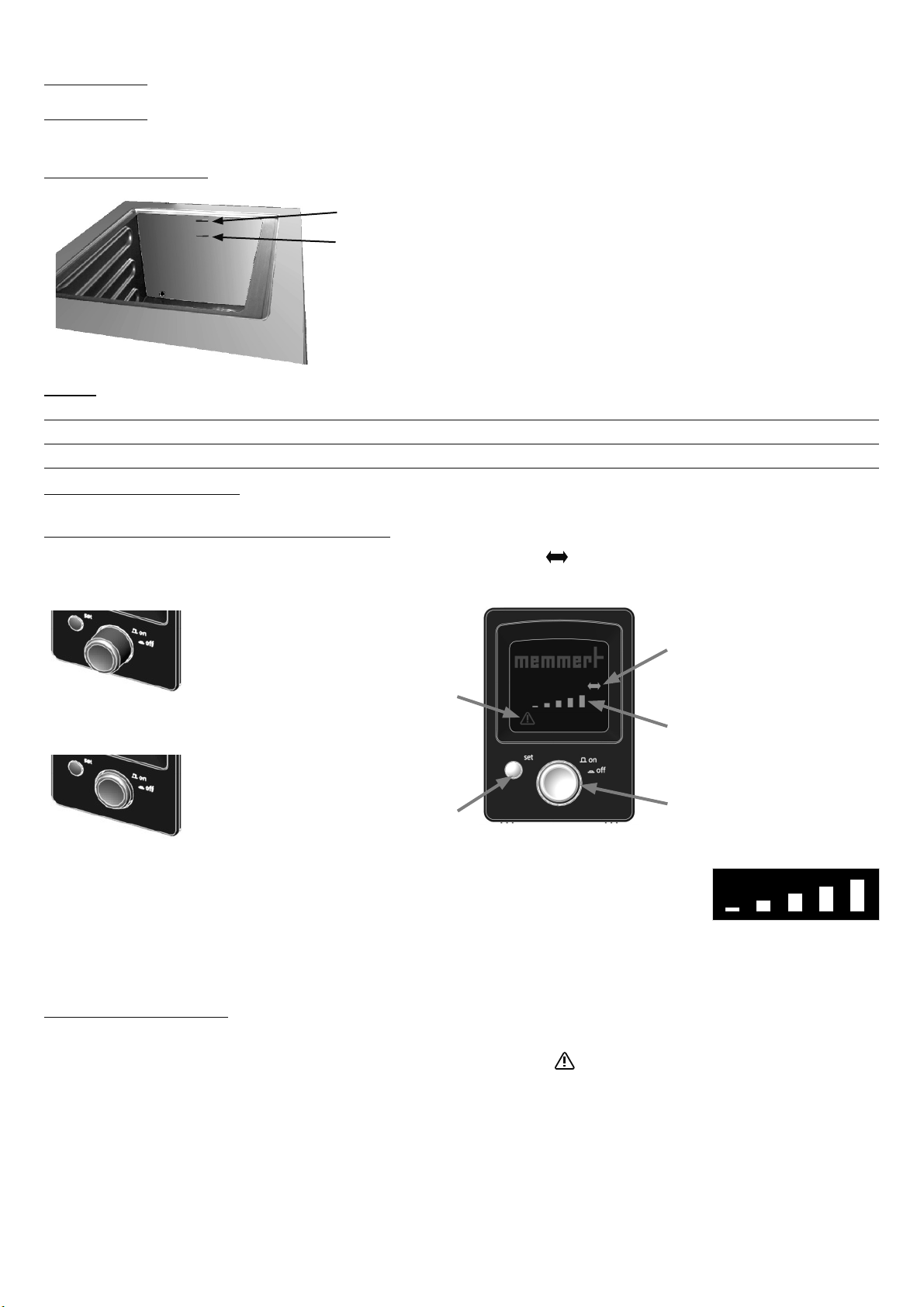

Switching on and setting the shaking speed

The unit is switched on by pressing the push/turn control. The

symbol indicates that the unit is ready

for operation.

Quick stop on overload

The unit incorporates a quick stop on overload as a safety device.

Operation of this safety device can be recognised by the symbol

lighting up.

In this case it is necessary to check whether there is any overloading or whether some object has been

trapped in the system.

After the overload has been removed, the shaking device can be restarted by briefly pressing the SET key

and setting the shaking speed again.

Fault:

overload/

blockage

SET key

Shaking device

ready for operation

Shaking

speed

Max. level

Min. level

35

50

145

160

120

130

90

105

65

80

Bar dark approx.:

Bar bright approx.:

Unit is switched on.

Unit is switched off.

After the shaking device has been switched on, the setpoint for

the shaking speed is always set to 0 strokes per minute.

The shaking speed is selected by rotating the push/turn control

while holding down the SET key.

strokes per minute

push/turn

control

Loading...

Loading...