Page 1

Introduction 1

Congratulations on choosing to buy a Delta® product. By doing so you now have

the assurance and peace of mind that comes with purchasing a product made by

one of the leading manufacturers.

All products brought to you by Delta® are manufactured to the highest standards

of performance and safety, and, as part of our philosophy of customer service and

satisfaction, are backed by our comprehensive 3 Year Warranty.

Please fill in and return the Warranty Card to the address provided.

We hope you will enjoy using your purchase for many years to come.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

3

Page 2

Overview 2

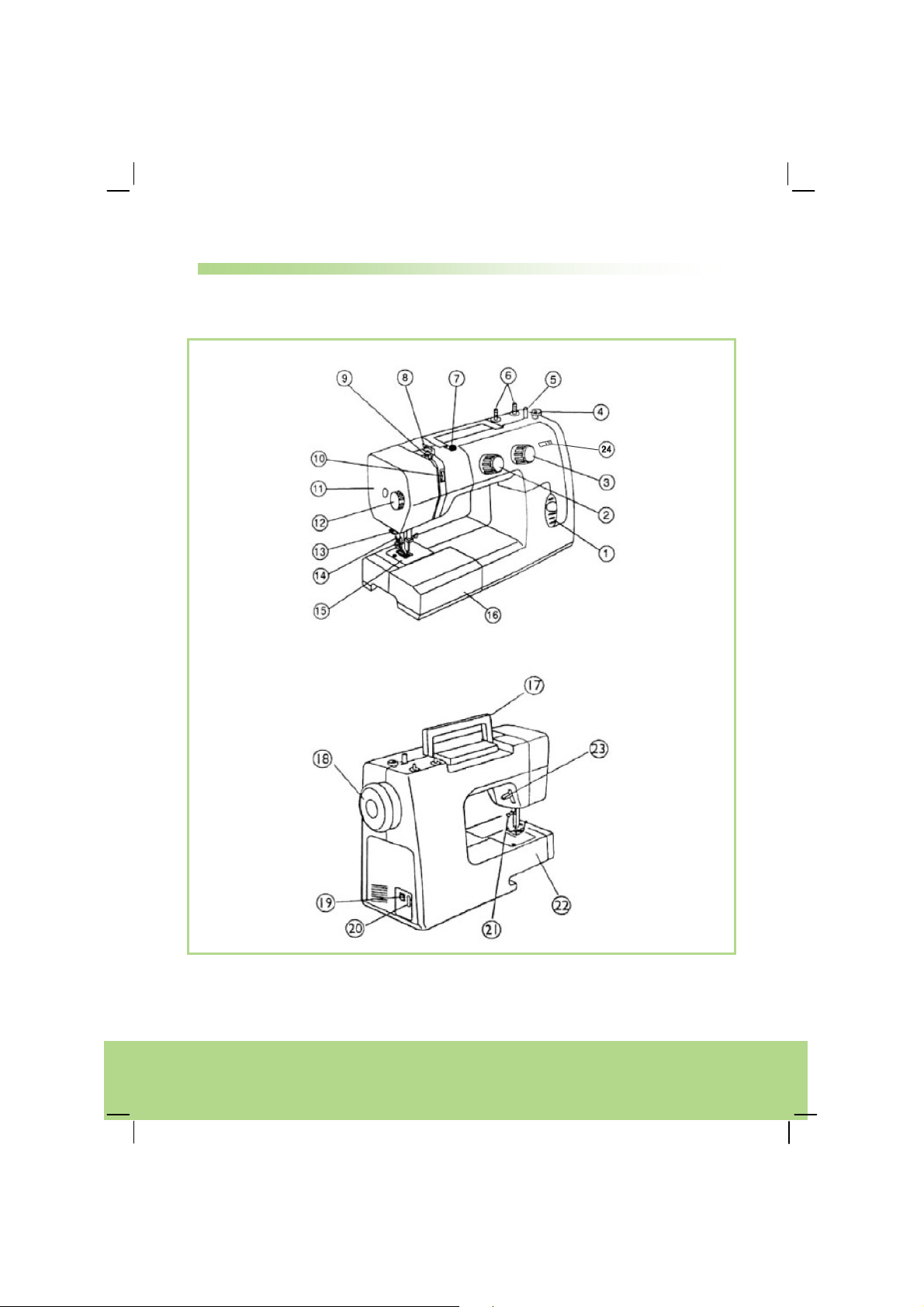

Main components

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

4

Page 3

Caption of figure on page 4

1. Reverse lever

2. Stitch type selection dial

3. Stitch length regulator

4. Bobbin winder

5. Bobbin spindle

6. Spool holders

7. Winder tension disc

8. Thread guide

9. Thread take-up lever

10. Thread tension disc

11. Front flap / bulb cover

12. Sewing foot pressure selection dial

13. Ripper

14. Sewing foot

15. Needle plate

16. Extendable cloth plate with accessories box

17. Handle

18. Hand wheel

19. Main switch (motor and light)

20. Plug housing for foot pedal

21. Sewing foot holding screw

22. Free arm

23. Sewing foot lever

24. Double needle (twin needle) button

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

5

Page 4

General Information 3

Please read these operating instructions thoroughly and follow the

safety notes in particular before using the appliance for the first time!

Anything done to or with this appliance should only be undertaken as

described in the operating instructions.

Keep these instructions in a safe place for further use. If you pass on

this sewing machine to a third party, please include these instructions.

Areas of use / Purpose of use

• This appliance is intended solely for household use.

• This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the

appliance.

• The sewing machine should never be allowed to get wet – there is the danger

of electric shocks!

• When the sewing machine is on, never leave it unattended. Do not use the

machine out of doors.

• The appliance can only be operated using the supplied foot pedal model

HKT7.

Included in the box

Check that nothing is missing from the packaging and inform us of any missing

parts within 14 days after purchase. The delivery of the sewing machine you have

purchased includes:

1. Sewing machine

2. Table extension with accessory box

3. Foot pedal

4. Cover hood

5. Operating instructions and guarantee documents

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

6

Page 5

Accessories

Sewing foots

1 2

3 4 5

6

1) Standard foot (straight stitch/zigzag stitch) (already attached)

2) Zip sewing foot

3) Buttonhole sewing foot

4) Button sewing foot

5) Hemming foot

6) Blind stitch foot

Other accessories

7

10

7) Guiding plate

8) Buttonhole knife (disconnecting knife) with brush

9) Screwdrivers (small and large)

10) Spare bobbin (4)

11) Finger protector (already attached)

12) Selection of needles (5 universal needles and 1 twin needle)

13) Oilcan

8

11

9

12

13

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

7

Page 6

Safety instructions 4

Keep electrical equipment out of reach of children

Children are not aware of the dangers posed by electrical equipment.

Never allow children to use the sewing machine unsupervised. Remember that

needles can also cause injury even when the machine has been turned off.

Keep the packaging out of the reach of children. There is a risk of suffocation.

Mains cable and mains connection

• Only connect the appliance to a power socket (230 V ~ 50 Hz) that is easy to

reach and is close to the place where you have set up the appliance.

• The power socket must be freely accessible so that you can unplug the

appliance quickly, if necessary.

• When you unplug the appliance, always take hold of the plug itself, not the

cable.

Fully unwind the cable during operation of the appliance.

• The mains cable and extension cable must be positioned so that no one can

trip over them.

• Never expose the cable to hot surfaces.

• When you perform the following activities, switch off and unplug the sewing

machine: Threading, changing the needle, setting the sewing foot, replacing

the light bulb, cleaning and maintenance work, when you have finished

sewing, and if your work is interrupted.

Never undertake your own repairs

• If the plug, cable or appliance is damaged, pull the mains plug immediately.

• If the sewing machine or mains cable has visible damage, the appliance must

not be used, in order to avoid risks.

Warning

Never try to open and/or repair the appliance yourself. There is a

risk of electric shock! If there is a fault contact our Service Centre

or other suitable specialist workshop.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

8

Page 7

Handling the appliance safely

• Place the sewing machine on a sturdy, level work surface.

• During operation, the air vents must not be blocked: Do not allow any objects

(e.g. dust, threads, etc.) to enter the vents.

• Only use the accessories supplied.

• Only use special sewing machine oil to oil the appliance. Do not use any other

liquids.

• Be careful when using the moving parts of the machine, in particular the

needle. There is the risk of injury even when the machine has been turned off.

• When sewing, make sure that your fingers are never underneath the needle

holding screw.

• Do not use bent or blunt needles.

• When sewing, do not hold the fabric tight or pull the fabric. The needles could

break.

• When you have finished sewing, always move the needle to its highest

position.

Cleaning and storage

• Before cleaning, remove the plug from the mains socket. Use a dry, soft cloth

to clean the appliance. Avoid the use of chemical solutions and cleaning

products because these may damage the appliance surface or markings.

• Always store the sewing machine using the cover hood provided to protect

the machine from dust.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

9

Page 8

Getting Started 5

Electrical connections

The power switch turns both the machine and the sewing light on.

• Put the coupler plug of the supplied foot pedal into the connector housing on

the machine and then put the mains plug into the socket.

Only use the supplied foot pedal model HKT7.

Once you have finished working or before you start maintenance, always turn off

and unplug the machine.

Foot pedal

The foot pedal controls the sewing speed.

Note:

The tighter the switch is pressed, the faster stitching

goes.

Sewing light bulb

The sewing light bulb you will find

behind the front flap.

Warning!

Before carrying out any maintenance

work, please always turn off and unplug

the machine.

• Remove the cover of the screw and

unscrew.

• Take off the front flap.

• Hold the bulb and screw off to the left

to take out the bulb.

• Hold the bulb and screw on to the

right to fit over a new bulb.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

10

Page 9

• Place the front flap and screw it tight.

Note:

The maximum permitted light bulb power rating in 15W. Light bulbs are available

from specialist retailers.

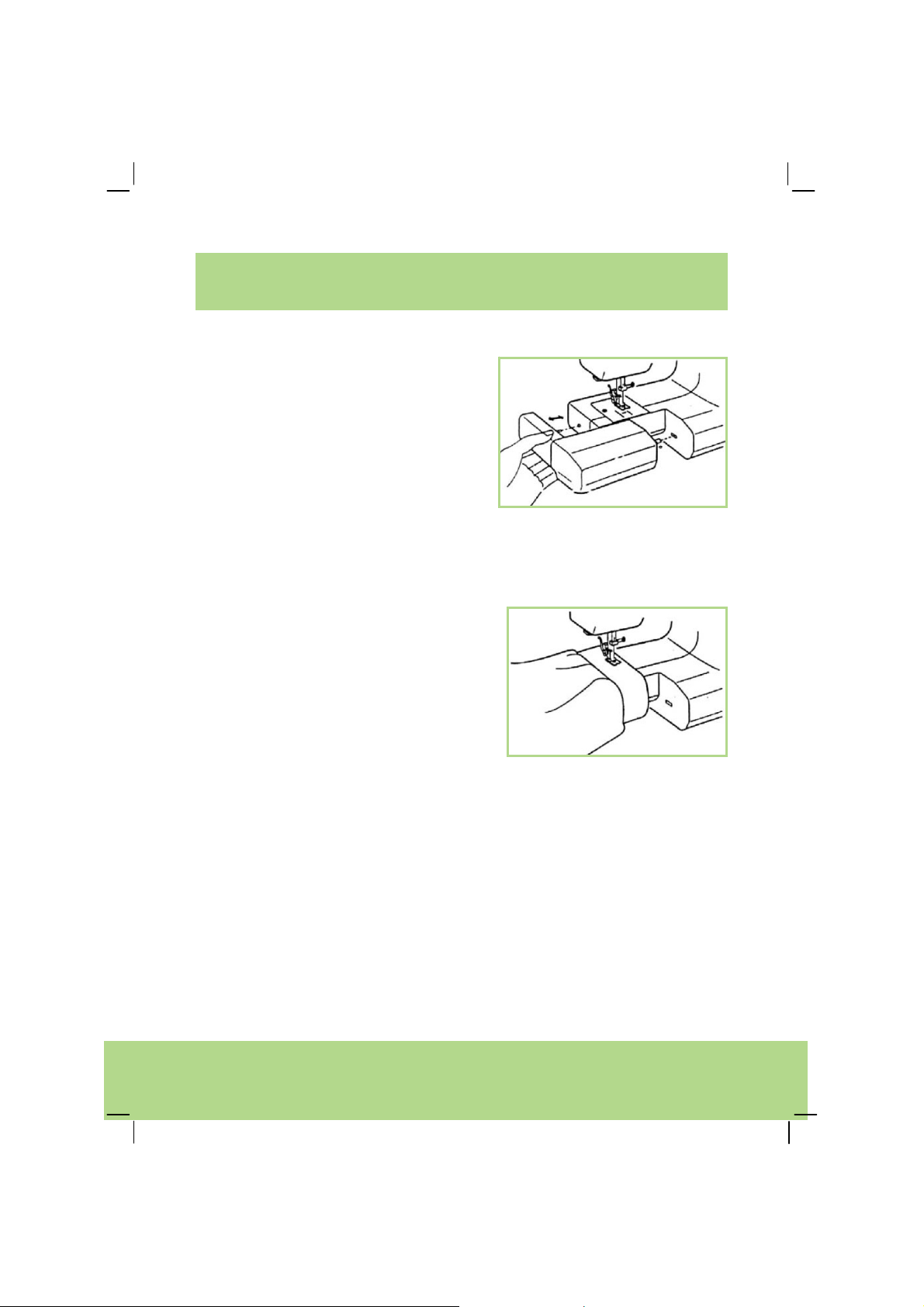

Extendable cloth plate

The machine has a free arm and is supplied

with an extendable cloth plate.

• Carefully pull the extendable cloth plate

to the left to disassemble it.

• To attach the cloth plate, carefully place

it to the projection guide in front and

back and push it to the right until it

catches.

Merits and application of free-arm cloth plate stitching

Sewing with free arm cloth plate avoids that

cloth piled up in front of needle while sewing

pockets, tucks and waist edges. Sew sleeves,

waist edges, trouser legs or other roundshaped costumes. Sew darn knees, elbows

and children clothes.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

11

Page 10

Accessories box

The accessories box is integrated in the table

extension.

• To open it, simply lift the lid of the table

extension towards you.

Spool holders

You can push down the spool holder for transporting or packing the machine.

• Pull up the spool holder when sewing before sewing

• Press the spool holder down before the machine is packed

Note

In case that the thread in use is tangling easily with spool holder or is knotting,

you can pull the thread through the hole.

Finger protector

This accessory prevents your hand from accidentally getting under the needle.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

12

Page 11

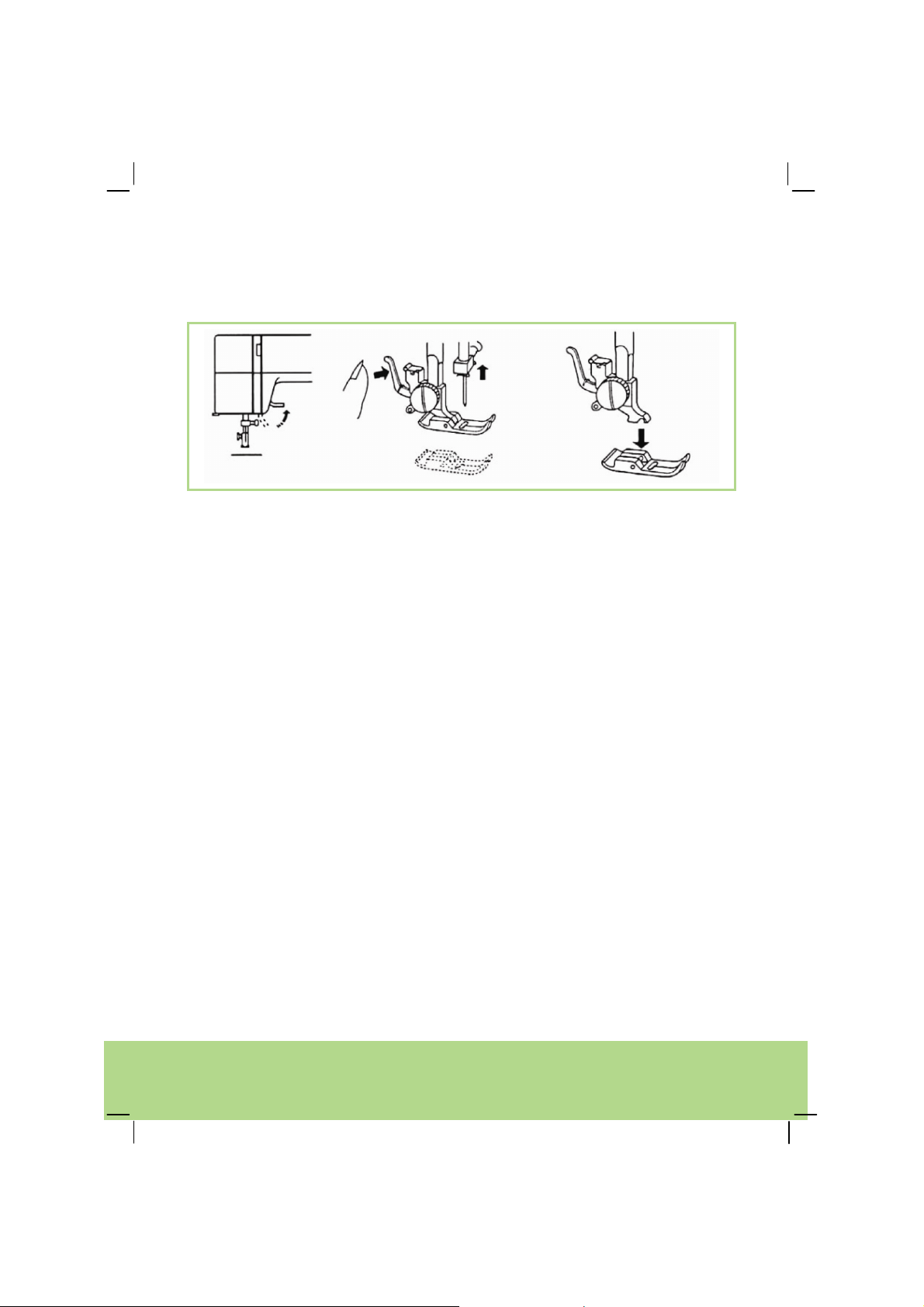

Removing the sewing foot

• Turn the hand wheel towards you until the needle has reached its highest

position.

• If the sewing foot is down, raise it by pushing up the sewing foot lever.

• Push up the sewing foot release lever behind the sewing foot holder to

release the foot. The sewing foot drops out.

• Attach the desired sewing foot so that the pin on the foot is directly under the

groove of the foot holder. Lower the sewing foot lever.

• Now push the sewing foot release lever upwards. The sewing foot

automatically clicks into place.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

13

Page 12

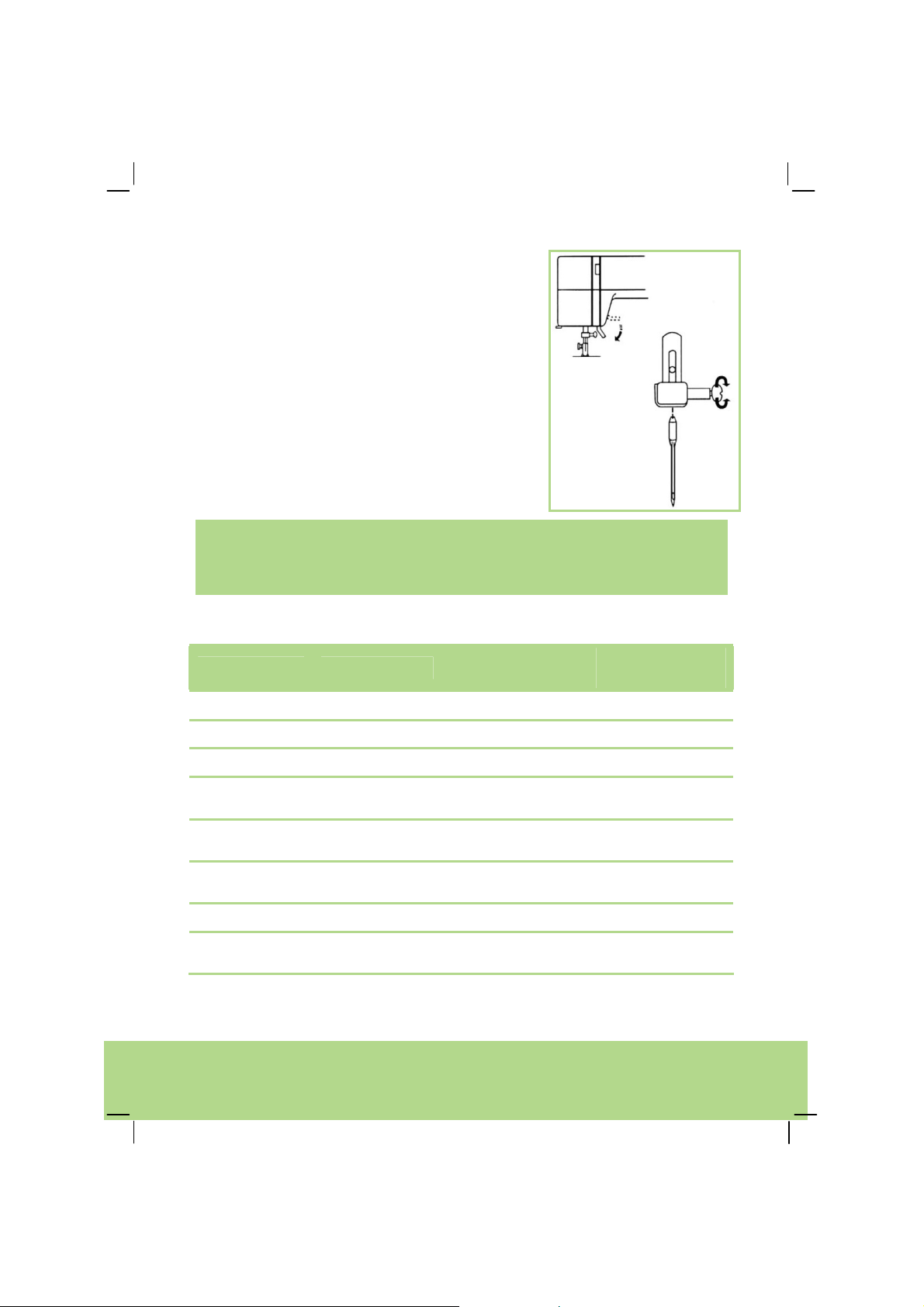

Replacing the needle

` Turn the hand wheel towards you until the needle

has reached its highest position.

` Lower the sewing foot.

` Loosen the needle holding screw by turning it

anticlockwise.

` Remove the needle from the needle holder.

` Insert a new needle with the flat side facing

backwards. Push the needle upwards until it can go

no further.

` Tighten the needle holding screw again.

Note:

Regular checking is necessary to ensure that the needle is never twisted or blunt.

Knitting materials, like silk or silk fabrics may frequently encounter knots and

skipping stitches, which are often caused by the damaged needles.

Thread and needle chart

Needle size Material

60 (#7) Fine silk 70 – 80 100 – 140

70 (#10) Crepe 70 – 80 100 – 140

80 (#12) Poplin, Pure Silk 50 – 60 80 – 100

80 – 90 (#12 –

14)

90 – 100 (#14 –

16)

90 – 100 (#14 –

18)

Elastic stitching

70 (#10)

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

Woollen cloth,

Cotton

Wool 30 – 40 50 – 60

Jeans materials 30 45 – 50

Knitting

materials

Cotton thread

Specification

40 – 50 60 - 70

70 – 80 100 - 140

Silk thread

Specification

14

Page 13

Remove and insert the bobbin case

Open the bobbin case cover (1).

1. Turn the hand wheel towards you until the needle has reached its highest

position.

2. Hold on the bobbin exit (2) and pull out of the bobbin case of the machine.

3. Press the bobbin case handle (3) to the innermost to ensure joining when

loading it into the bobbin case.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

15

Page 14

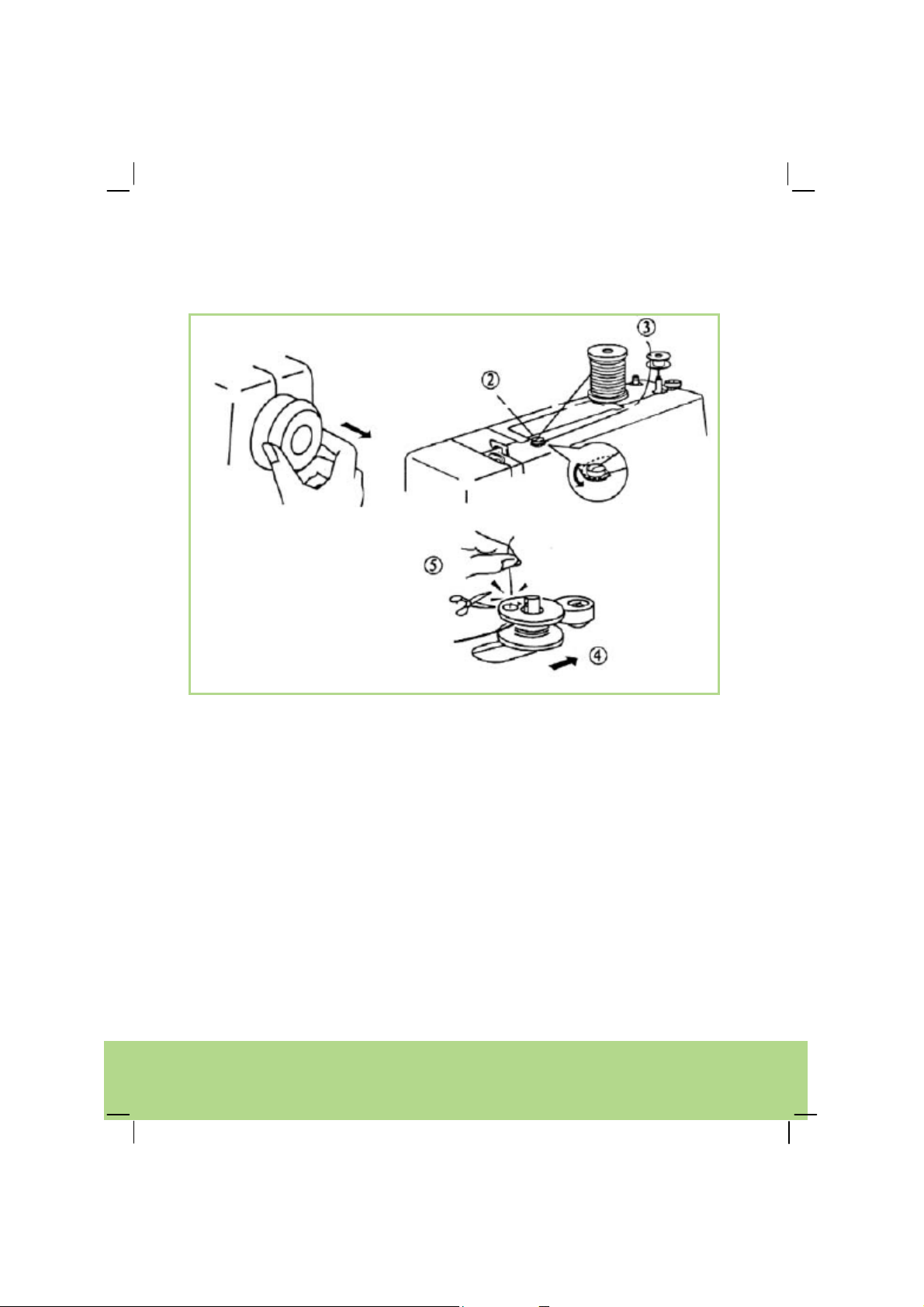

Winding thread to the bobbin

You can use the sewing machine to wind thread on to the bobbins easily. To do

so, take the thread from the spool through the thread guide to the bobbin.

1

1. Pull out the hand wheel slightly to prevent the needle from moving while

you wind thread on to the bobbin. Pull one of the spool holders completely

out and place a cotton reel on it.

2. Draw thread from the spool through the bobbin winder-tension disc.

3. Pull thread through the hole in the bobbin and insert the bobbin into the

bobbin shaft.

4. Turn the bobbin to the right.

5. Hold the end of the thread and press down the foot pedal. Stop after several

turns. Cut the excess thread close to the bobbin.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

16

Page 15

6. Press down again the foot pedal. Wind thread on to the bobbin until the

bobbin is full. Stop the machine. Push the shaft to the left and cut the thread.

7. Push the hand wheel to the left to close contact. (original position).

The needle will now move when you press the foot pedal.

Threading the bobbin case

1 2 3

1. Load bobbin in bobbin case. Make sure that you pull out the thread in the

direction indicated by the arrowhead (clockwise).

2. Pull thread into the slit of bobbin case.

3. Then pull thread through the bobbin tension-regulator spring to the outlet

hole.

Note: Make sure, that you pull around 10 cm of thread out of the bobbin.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

17

Page 16

Threading the upper thread

Please read the following instructions carefully as an incorrect sequence or thread

guiding can lead to broken threads, missed stitches and gathered fabric. A

diagram of how to guide the thread is provided on the front flap; you can also use

this drawing as a guideline.

1. Lower sewing foot and turn the hand wheel towards you until the needle has reached

its highest position.

2. Place a cotton reel on the spool holder and make sure the thread comes from

behind the cotton reel.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

18

Page 17

3. Lead the thread through the pre-tension (1).

4. Pass the thread along the right guide to the bottom and put it under the

thread tension disc.

5. Pass the thread upwards and pull up the thread tightly, which pushes up the

inner guide spring.

6. Insert the thread from the right side into the hook of thread take-up lever (3).

7. Now guide the thread along the left guide towards the needle and pass it

through the upper thread hook (4).

8. Then pass the thread further down and through the second thread hook (5).

9. Pass the thread through the eye of the needle (6) from the front to the back

and leave a thread end of around 10 cm.

Note

An upper thread tension of 3 is ideal for most applications.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

19

Page 18

Draw up the lower thread

2

1) Lift sewing foot and hold the upper thread lightly with your left hand.

2) Keep turning forward the hand wheel until thread take-up Iever is at its

highest position. Pull the upper thread upwards slightly to draw up the

lower thread.

3) Pull both threads out and pass them under the sewing foot toward the

back. Leave 5 cm of both threads.

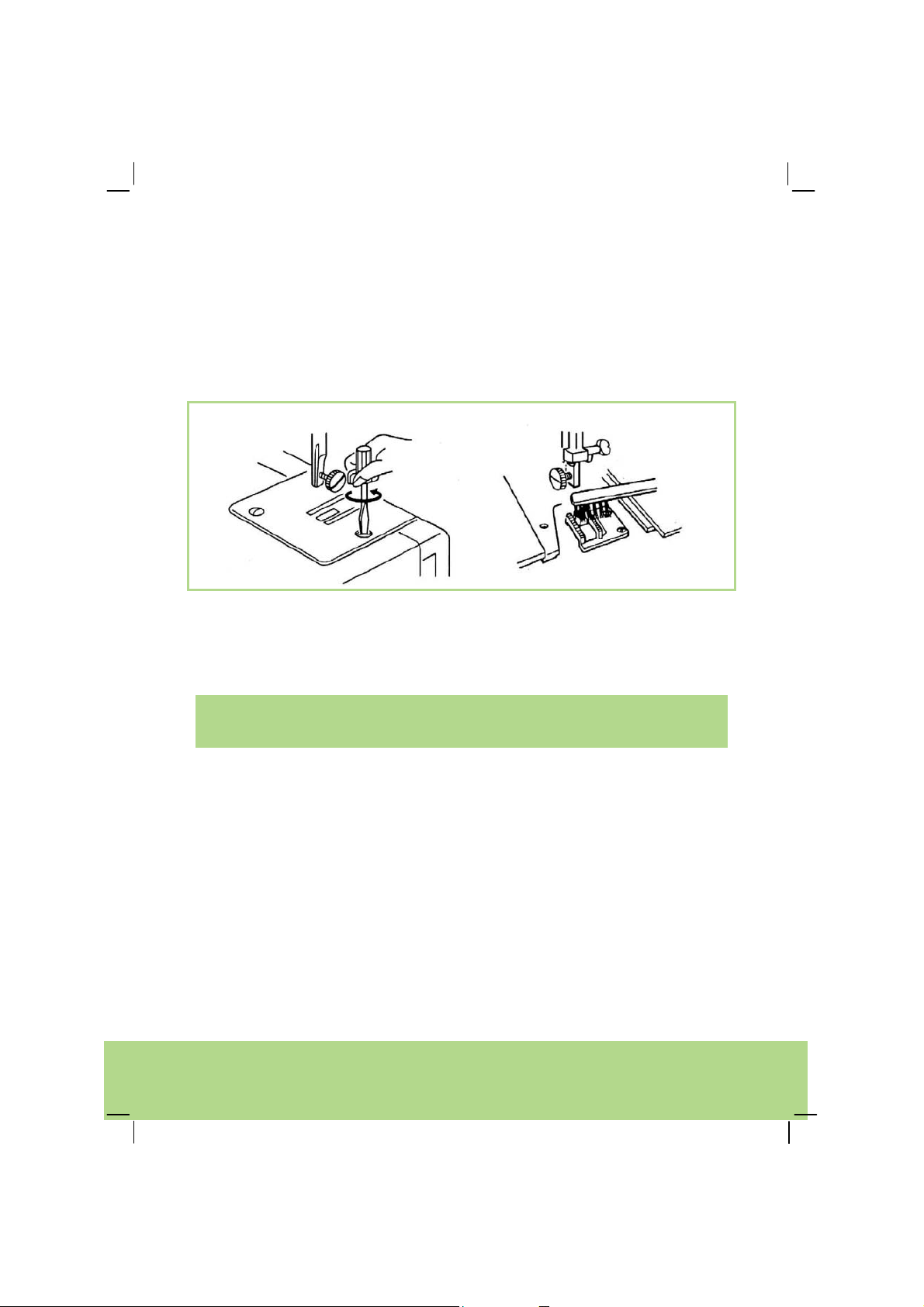

Fit the guiding plate

For several stitch type it is recommeded to use the

guiding plate.

1. Lower sewing foot, release the screw of the

fixed sewing foot and push forward the

guiding plate between the screw and

footplate groove.

2. Fix the screw and make sure that the stopper of guiding plate should be

installed in the middle of footplate.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

20

Page 19

Settings 6

Adjusting the upper thread tension

While doing straight stitching, both upper and lower threads must be knotted

between the two layers of garment.

Adjust selection dial of thread tension disc within the window.

Select upper thread tension

The lower the number is, the lower the

tension will be.

The tension you require depends on the strength and thickness of the fabric, the

number of layers of fabric you want to sew and the type of stitch you choose.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

The higher the number is, the

higher the tension will be.

21

Page 20

Tension of upper thread in case of zigzag stitching

In order to achieve good effect of zigzagging, the tension

of upper thread should be less than that of straight

stitching.

The upper thread should be visible from the reverse.

Selecting Double Needle

Turn double needle (twin needle) switch to position if you require sewing

double stitches.

Turn double needle (twin needle) switch to

single stitches, otherwise the stitches would be narrower.

position if you require sewing

Select the stitch type

On this sewing machine, you can select a number of different stitch types.

1. Turn the hand wheel towards you until the needle is pulling out from fabric.

2. Select the desired stitch type by turning the stitch type selection dial. (Please see

„Relationship between stitch types and settings“ on page 24)

Width of stitches changes seamlessly from positions 3 to 5.

When sewing elastic stitches and double action stitches

regulator must set to position +

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

1

- -.

- the stitch length

1

22

Page 21

Select stitch length

` Turn the stitch length regulator to the desired stitch length. (Please see the stitch

types on page 24)

When you would like to sew elastic stitches or double action stitches

turn the stitch length regulator to position +

double needle as well.

- -. They can be used with

1

1

-

Position „

Range from 0.5 to 4 can be used of zigzag stitching.

” is the correct range of adjustment for making buttonholes.

How to make the elastic stitches better?

In case the elastic stitch turns out to be unsatisfactory, you may turn the selection

dial to “ - " and in this way, stitches would be thicker while turning to “+" they

would be more sparse.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

23

Page 22

Relationship between stitch types and settings

Note: Always raise the needle to its highest position before selecting the pattern.

Stitch type

selection dial

1

Stitch

Patterns for

sewing

buttonholes

Straight stitch

Needle

position:

middle

Stitch

length

regulator

0,5 - 1 3 - 5

1,5 - 4 2 - 6

Upper

thread

tension

Straight stitch

2

3

4

5

6

7

Needle

position: left

Zigzag

Zigzag

Zigzag

Sewn zigzag

(overlock)

Elastic

blind-stitch

1,5 - 4 2 - 6

1 - 4

1 - 2

1 - 4

1 - 2

1 - 4

1 - 2

1-2 4 - 6

1- 3 4 - 6

2 - 6

4 - 6

2 - 6

4 - 6

2 - 6

4 - 6

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

24

Page 23

Stitch type

selection dial

8

9

10

1

2

Stitch

Stitch

Elastic blind-

stitch small

Shell-stitch 2 6 - 8

Elastic stitch 1 4 - 6

Triple straight

stitch

Needle

position:

middle

Triple straight

stitch

Needle

position: left

length

regulator

1 - 3 4 - 6

1 or 2 4 – 6

1 or 2 4 - 6

Upper

thread

tension

3

4

5

6

7

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

Triple Zigzag

Triple Zigzag

Triple Zigzag

Honeycomb

stitch /

Smoking

stitch

Elastic

decorative

stitch

+

1 -

+

1 -

+

1 -

+

1 -

+

1 -

-

2 - 6

-

2 - 6

-

2 - 6

-

2 - 6

-

2 - 6

25

Page 24

Stitch type

selection dial

8

9

Stitch

Elastic

decorative

stitch

Stretch-

overlock

(elastic)

Double-

overlock

(elastic)

Stitch

length

regulator

+

1 -

+

1 -

+

1 -

Adjusting the lower thread tension

The lower thread tension rarely needs to be adjusted, as it was

setting by the manufacturer for general sewing work.

The lower thread tension is correct if you can pull the thread out

of the bobbin easily but with a slight resistance.

However, the lower thread needs to be adjusted for particularly

lightweight or heavy fabrics.

You set the lower thread tension by using the regulating screw

on the bobbin case. Adjust the screw using the small

screwdriver provided.

-

-

-

Upper

thread

tension

2 - 6

2 - 6

2 - 6

`

Remove the bobbin case:

Low tension: Turn the screw anticlockwise

Higher tension: Turn the screw clockwise.

Checking the lower thread tension

The easiest way of checking the lower thread tension is by sewing a medium

zigzag stitch on the fabric in question.

Use the appropriate needle and threads.

You can get a clearer picture by using different colours for the upper and lower

threads.

Sew a few zigzag stitches.

The thread tension is correct if the lower threads are not visible on the top surface

of the fabric.

Make sure that you always sew even stitches (see diagram on the left).

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

26

Page 25

Stitching reverse

Use reverse stitches to reinforce the first and last stitches.

If the reverse button is pressed down, the machine will do reverse stitching.

If you want to change to forward stitching simply release the reverse lever.

Raising and lowering the feed dog

1. Open the bobbin case cover (1).

2. Lower the feed dog by pulling down the shaft of lower teeth lever (2) and moving it to

the right until it catches. Feed dog dischargs into the machine. (indicated by the

arrow head as shown in the illustration)

3. Raise the feed dog by pulling down the lower teeth lever (2) and moving it to position

“A”

Note: For ordinary sewing, feed dog shall be raised.

Feed dog discharged

Fabric is not

transported

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

Feed dog raised

Fabric is transported

27

Page 26

Adjusting the sewing foot pressure

You need a higher sewing foot pressure when sewing multi-layer or thick fabrics.

You need a lower sewing foot pressure when sewing normal and lightweight

fabrics.

An incorrect sewing foot pressure results in poor fabric feed, poor material

guidance and imperfect stitches.

For ordinary sewing, foot pressure selection dial is present at "3".

The foot pressure drops to "2" when sewing appliqués, mesh fabrics and

embroidery.

As for chiffon, lace, yarn and other miscellaneous fine materials, you may put the

dial to "3". When sewing cotton flannel and braided stretch textile adjust to "1".

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

28

Page 27

Sewing 7

Start sewing

Test the stitching on a swatch before using a stitch type for your actual work.

1. Raise sewing foot and put cloth beside leg

wire of needle plate.

2. Turn forward the hand wheel and lower the

needle down into the fabric. Lower sewing

foot and make sure that thread passed

backward. Step down foot pedal.

3. Fabric will go along leg wire and it is carried

forward automatically by feed dog.

4. In order to make end of thread firm, please

press the reverse stitch button and do

several reverse stitches.

Removing fabric from the sewing

machine

When you finish sewing, make sure that the

needle is at its highest position. To remove the

fabric, raise the sewing foot and pull out the

fabric from the back of the machine.

Changing the sewing direction

1. Stop the machine and turn the hand wheel towards you until the needle is in

the fabric.

2. Raise the sewing foot and turn the fabric around the needle to change the

direction as desired.

3. Lower the sewing foot and continue sewing.

Cutting the thread

Cut the thread using the thread cutter behind the sewing foot or with a pair of

scissors. Leave around 15 cm of the thread hanging from the eye of the needle.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

29

Page 28

Using the strips of leg wire on the needle plate

The Strips of leg wire on the needle plate is of

great help to maintaining width between the

needle and the thread.

Instruction: these data conform to the distance

between strips of leg wire and the needle.

Caption of figure

(1) Strips of leg wire

(2) Comer

(3) Needle plate

(4) Hole of needle plate

(5) The width of sewing to the center of needle

Figure on the needle

plate

Spacing in cm 1.0 1.5 2.0 1.0 1.3 1.6 1.9

10 15 20 3/8 4/8 5/8 6/8

Sewing a right angle

While doing right stitches, a space of 1.6

cm should be kept apart from the edge of

fabric

1. When the edge of fabric is aligned

with the corner, stop the machine

2. Turn the hand wheel towards you

until the needle is dropping into the

fabric.

3. Raise the presser foot, turn the fabric

around the needle to change direction until its edge is aligned with the strip

of leg wire of 5/8 (1.6 cm).

4. Lower the presser foot and sew in the new direction.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

30

Page 29

Using the Stitch Types 8

Straight stitch

Sewing foot......................................................................... Standard foot

Stitch type .......................................................................................... 1 or 2

Stitch length ..................................................................................... 1.5 – 4

Upper thread tension ........................................................................2 – 6

Suitable for general sewing and for top stitching.

Zigzag stitch

Sewing foot......................................................................... Standard foot

Stitch type ............................................................................................. 3 - 5

Stitch length .........................................................................................1 – 4

Upper thread tension ........................................................................2 – 6

The stitch is used for making over-lock so that thread at the edge of cloth shall

not fall apart.

Before you use the zigzag stitch, sew a few straight stitches to reinforce the

stitching.

TIPS FOR ZIGZAG STITCHES

For a better zigzag stitch, the upper thread tension must be lower than for

straight stitches.

The upper thread should be slightly visible on the underside of the fabric.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

31

Page 30

Sewn Zigzag

Sewing foot......................................................................... Standard foot

Stitch type ................................................................................................... 6

Stitch length .........................................................................................1 – 4

Upper thread tension ........................................................................2 – 6

The stitch is used for synthetic materials and other materials that get folds easily.

It also suits over-lock to avoid threads falling apart. It is fit for sewing elastic bends

and darning. Leave a strip of hemming-stitch with 1.5 cm. Cut off the strip of

hemming-stitching after sewing.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

32

Page 31

Blind stitch for blind hemming

Sewing foot................................... Standard foot with guiding plate

....................................................................................... or blind stitch foot

Stitch type ............................................................................................ 7 – 8

Stitch length .........................................................................................1 – 3

Upper thread tension ........................................................................4 – 6

Use a thread colour that exactly matches the fabric.

If you are sewing very light or transparent fabrics, use a transparent nylon thread.

1. Fold the fabric as illustrated.

2. Fit the guiding plate or use the blind stitch foot.

3. Sew on the fold, as illustrated. The straight stitches should be on the hem,

and only the points of the zigzag stitches should extend into the upper fold

of the fabric.

4. Remove the fabric from the machine and straighten it out.

The folded-out fabric now has a blind-hem.

Note: You can adjust the edge guide to the crease line of the outer fabric by

turning the screw of the foot.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

33

Page 32

Shell hem

Used for decorative hemming. It is particularly suitable for fabrics cut on the bias.

Sewing foot......................................................................... Standard foot

Stitch type ............................................................................................ 7 – 8

Stitch length .........................................................................................1 – 3

Upper thread tension ........................................................................4 – 6

Fold the fabric as illustrated and position

the sewing foot along the folded edge of

the fabric.

The needle should be positioned in

relation to the right-hand edge of the

fabric so that the stitches loop over the

outer edge of the hem.

Elastic stitch

Sewing foot......................................................................... Standard foot

Stitch type ................................................................................................ 10

Stitch length ................................................................................................1

Upper thread tension ........................................................................4 – 6

The stitches are most suitable for sewing

elastic cords over 3 mm of children's sleeves.

Tighten the elastic cord after sewing.

Such stitches are also suitable for sewing

heavyweight fabrics. Seamlessly fold the two

fabrics and stitch them together.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

34

Page 33

Triple straight stitch

Sewing foot......................................................................... Standard foot

Stitch type ..................................................................................... 1 oder 2

Stitch length .............................................................................+

Upper thread tension ........................................................................2 – 6

Two stitches forward and then one stitch

backward will make the stitching firm. Prior to

stitching garment pıeces, make a sample by using

pins. Such stitches are most suitable for sewing

crotches.

1 -

-

Triple zigzag stitch

Sewing foot......................................................................... Standard foot

Stitch type ............................................................................................. 3 - 5

Stitch length .............................................................................+

Upper thread tension ........................................................................2 – 6

If you want to sew stretch fabrics, this stitch enables you to avoid broken threads.

It is also suitable for stitches subject to greater strain.

A seam with this stitch is three times as strong as a

normal seam and is far more elastic.

The seam therefore stretches with the fabric

without the thread breaking.

The stitch is also suitable for sewing patches

(including leather patches) on jeans.

1 -

-

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

35

Page 34

Honeycomb stitch (smoking stitch)

Sewing foot......................................................................... Standard foot

Stitch type ................................................................................................... 6

Stitch length .............................................................................+

Upper thread tension ........................................................................4 – 6

Straight stitch the tucked side with

spacing of 1 cm. Select "4” for its

stitch length.

Knot the thread on one side. Tighten

lower thread and make tucks with

even spaces.

Fix the thread on the other side. Make

a reticulate and decorative stitching

along the middle of tucks.

Then, extract the tuck stitches.

Note: Decrease upper thread tension will make tuck decoration easy.

1 -

-

Overlock stitch (feather stitch)

Sewing foot......................................................................... Standard foot

Stitch type ................................................................................................... 9

Stitch length .............................................................................+

Upper thread tension ........................................................................4 – 6

You can use this stitch for an attractive and lasting

stitch to trim the edges of materials that fray easily.

Position the fabric under the foot so that the stitch

is made over the edge. Lower the sewing foot and

start sewing, guiding the fabric gently.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

1 -

-

36

Page 35

Double overlock stitch (overlock-overcast stitch)

Sewing foot......................................................................... Standard foot

Stitch type ................................................................................................ 10

Stitch length .............................................................................+

Upper thread tension ........................................................................4 – 6

Fold in both sides with 1.5 cm each and iron it.

The folded sides should be fixed to non-woven

textiles with spacing of 0.3 cm. Slowly stitch and

make sure that each stitch should reach the

folding edges.

1 -

-

Sewing buttonhole

(1) (2)

Sewing foot.....................................................................Buttonhole foot

Stitch type ..................................................................

Stitch length .............................................................................0.5 - 1

Upper thread tension .........................................................................3 - 5

Stitch width is to be chosen arbitral with in between 0 and 1 range according to

variation of stitch length.

(1) For thicker stitching, adjust selection dial to "O".

Satin stitches suit lightweight material.

(2) For thicker stitching, adjust selection dial to "1”.

Loose stitches suit heavyweight material.

Note: Make trial stitching on some small cloth to find out the optimum effect.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

37

Page 36

1. Make the marks of buttonhole carefully on the

material.

2. Pull forward slide (A), keep the mark (C) on it in

conformity to the initial mark (B),The mark on

the presser foot should be aligned with that of

the material. Lower the sewing foot.

Instruction:

marks on the slide should be carved in cm.

3. Adjust stitch selection dial to

forward until comes to the marks in front of the

buttons and then stop sewing with needle

pausing at top left.

4. Adjust stitch selection dial to

stitches before stopping sewing with needle

pausing at top right.

5. Adjust stitch selection dial to

backward until come to the marks at the back of

buitons and then stop sewing with needle

pausing at top right.

6. Adjust stitch selection dial to

stitches before stopping sewing with needle

pausing at top left.

7. After sewing: buttonholes, take out fabrics.

Insert a pin at the back hole of buttonhole so that the end of thread of

buttonhole will not be cutting off. Cut out the buttonhole carefully with a

buttonhole cutter.

Note: Pin a safety pin in front of the top bar to stop you cutting through it.

. Keep stitching

. Make 4-6

. Keep stitching

. Make 4-6

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

38

Page 37

Buttonholes with decorative stitching

1. Raise the foot plate of buttonholes sewing hang the laid in threads on the

positioning cam (1) at the back of presser foot,

2. Draw forward the end of additional thread under the presser foot and place it

under the centre of presser foot.

3. Hold tightly the additional thread and hook the fork in front of the sewing

foot.

4. Bring the needle into the fabrics before starting sewing and lower the presser

foot.

5. Slowly step down foot controller buttonholes, with each face of buttonholes

encasing the laid-in threads

6. Take out fabrics and clip sewing thread.

7. Pull the laid-in threads from left side and hold it tightly.

8. The end of thread should be wound to darning needle. Draw the thread to

the back and clip.

Note: While cutting out buttonholes, pay attention to the instruction on page

Fehler! Textmarke nicht definiert..

Sewing on buttons and hooks

Sewing foot................................... button sewing foot (transparent)

Stitch type ............................................................................................. 3 - 5

Stitch length ................................................................................................0

Upper thread tension ........................................................................1 – 3

Feed dog...................................................................................discharged

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

39

Page 38

You can use the transparent blue sewing foot to sew on buttons, hooks and eyes

easily.

Use the stitch type selection dial to select a zigzag stitch width that corresponds

to the distance between the holes.

1. Align both holes of the button with groove slots while placing the left hole of

button directly under the needlepoint. Low sewing foot

2. Check if the button is positioned correctly by turning the hand wheel

manually. The needle must exactly enter the holes of the button, otherwise

the needle may be damaged. If necessary, change the width of the zigzag

stitch.

3. At a low speed, sew about 6 to 7 stitches per hole.

4. If the button has four holes, move the fabric and button: then sew 6 to 7

stitches in the other two holes. Once you have removed the fabric pass a

generous length of the upper thread to the underside of the fabric and knot

it to the lower thread there.

Sewing buttons with a shank

In the case of heavy fabrics, a button shank is often needed.

1. Place a needle or, for a thicker shank, a matchstick on the button and then

proceed to sew as for a normal button.

2. After about 10 stitches, remove the material from the machine.

3. Remove the needle or matchstick.

4. Leave a longer length of upper thread, pass it through the button and wind it

around the threads to create a shank, then pass it through to the underside

of the fabric and knot it to the lower thread.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

40

Page 39

Sewing in zips

Sewing foot..................................................................... Zip sewing foot

Stitch type ................................................................................................... 1

Stitch length ...................................................................................... 1.5 - 4

Upper thread tension .........................................................................4 - 6

Depending on which side of the zip band you are sewing, the sewing foot must

always be on the fabric.

For this reason, the sewing foot is attached on either the left-hand or right-hand

side, and not in the middle like all other sewing feet.

1. Raise the sewing foot and needle to its

highest position to switch the sewing

foot.

2. Place the zip on the fabric and place

the workpiece in position under the

foot.

3. To sew the right-hand side of the zip,

attach the zip sewing foot so that the

needle sews on the left-hand side (1).

4. Sew the right-hand side of the zip,

creating the stitches as close as

possible to the teeth. (1)

5. Sew the zip in with a bridge around 0.5

centimetres below the teeth.

6. To sew the left-hand side of the zip,

change the foot position on the sewing

foot holder.

7. Proceed in the same way as for the

right-hand side of the zip (2).

8. Before the foot reaches the slider on

the zip band, lift the foot up and open

the zip, keeping the needle in the

material. (3)

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

41

Page 40

Pad stitching

Sewing foot......................................................................... Standard foot

Stitch type ................................................................................................... 5

Stitch length ...................................................................................... 0.5 - 1

Upper thread tension ........................................................................1 – 4

Sewing foot pressure................................................................................2

1. Adhere tightly the decorative parts to the fabrics or iron it with solvable nonwoven textiles.

2. Stitch around the decorative parts and make sure that suture beyond the

decorative parts should disappear.

3. Insert the needle into the cloth when encountering corner.

4. Raise the presser foot and pivot the cloth to the left or right.

Note: After sewing, adjust foot pressure selection dial to position “3”.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

42

Page 41

Rolled hemming

Sewing foot....................................................................... Hemming foot

Stitch type ................................................................................................... 5

Stitch length ..........................................................................................1 - 4

Upper thread tension ........................................................................2 – 6

You can use the roll hem/hemming sewing foot

to easily hem fine to medium materials, e.g.

blouses, silk scarves and flounces. Hemming

using the roll hemmer stops the edges from

fraying and creates a clean, durable edge.

1. Raise the sewing foot and needle to its

2. Fold the start of the hem around 2 mm in

3. Insert this folded hem into the coil of the roll

4. Carefully and slowly, sew a few stitches,

5. If the start of the hem was pulling into the

6. Always hold the edge of the fabric somewhat

7. • Make sure that the fabric does not slip

Note:

The hem can be inserted in the hemming foot more easily if you hold the end of

the fabric at a slight angle.

Before you start sewing, fix the hem with safety pins or iron down the start of the

hem.

For this work, you need to use suitable materials and have some experience in

order to obtain the best results.

highest position and replace the existing foot

with the hemming foot.

with a double fold.

hemming foot.

preferably by turning the hand wheel.

foot, carefully start sewing the hem.

over the left-hand side of the sewing foot, to

stop the fabric slipping out of the coil.

under the right-hand side of the sewing foot.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

43

Page 42

Sewing with a twin needle

The twin needle is available from well-stocked specialist retailers.

When buying a twin needle, make sure that the distance between the two

needles is no more than 2.5 mm.

By using the twin needle you can create attractive, two-coloured patterns if you

use different coloured threads when sewing.

Sewing foot......................................................................... Standard foot

Stitch type ......................................................................................... 1 – 10

Stitch length ......................................................................1 – 4 /

Upper thread tension .........................................................................2 - 6

1. Attach the twin needle in the same way as you would a single needle (see

page 14).

2. Place two equally fully cotton reels on the removable spool holders.

3. Pass the two threads through the thread holder in the same way as

4. for a single thread.

5. Guide both threads through the upper thread tension discs making sure that

one thread goes to the right of the central disc and the second thread goes

to the left of the disc.

6. Insert both threads in the thread guide.

7. Insert one thread through the eye of the needle on the right-hand side, and

one thread on the left-hand side.

Note:

To sew a corner using the twin needle, take the needle out of the fabric, as

otherwise the twin needle may bend or break.

1 -

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

44

Page 43

Maintenance and Cleaning 9

Warning

Before carrying out any maintenance, cleaning or replacement work, please

always turn off and unplug the machine.

Cleaning pendular shuttle

Take out the pendular shuttle:

(1) Bobbin case (5) Shuttle carrier

(2) Shuttle lever (6) Centre pin

(3) Shuttle retaining ring (7) Slot

(4) Pendular shuttle

`

Raise needle to its highest position and lift shuttle cover. Remove the bobbin case

from the machine.

` Uncover shuttle lever and draw out the shuffle retaining ring.

` Clean the feed dog with a brush and soft and dry cloth.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

45

Page 44

Installation of the pendular shuttle:

` Hold shuttle centre pin and fit carefully back into the shuttle carrier.

` Refit shuttle-retaining ring and make sure that the following centre pin fixes in the

slot of the shuttle carrier.

` Lock retaining ring by turning levers back into starting position. Refit bobbin case

with bobbin.

Cleaning feed dog

` Remove the needle and sewing foot. Remove the screw on the left hand side of the

needle plate with a screwdriver. Remove the needle plate.

` Clean the teeth of feed dog with a fine brush and refit the needle plate.

` Fit the sewing foot and the needle, the machine is now ready for sewing

Note:

In case of frequent use, it is recommended to clean the feed dog frequently to

obtain the first rate effect of needlework.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

46

Page 45

Oiling the machine

Note:

Apply only one or two drops of machine oil, or cloth will be stained.

If the machine should not run well after being out of use for a long period, apply a

few drops of oil before running it and the machine gets full operating ability.

Oiling the machine behind the front flap

Remove the cover (1), screw (2) and front flap (3).

Oiling is required for the positions marked in the illustration.

Oiling the pendular shuttle

Open the bobbin cover case (4).

Oiling is required for the positions marked in the illustration

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

47

Page 46

Disposal 10

Packaging

Your sewing machine is wrapped in packaging to protect it against

transportation damage. Packaging is raw material and can be re-used

or added to the recycling system.

Device

At the end of its useful life, the sewing machine should not be disposed

of with the household rubbish. Seek the advice of your local authority

on correct, environmentally friendly disposal.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

48

Page 47

Troubleshooting 11

If faults occur, please read the operating instructions to determine whether you

have followed all the instructions correctly. Please only contact our customer

services if none of the solutions provided is successful.

Malfunctions Cause Remedy

Upper thread breaks.

Lower thread breaks.

Needle breaks.

Upper thread is not guided

correctly.

Upper thread tension is too

tight.

Needle is bent or dull.

Needle is not inserted correctly. See page 14

Fabrics are not pulled backward

after sewing.

Thread thickness does not fit to

the needle.

Lower thread is not threat

properly in the shuttle hook.

Fibres block the bobbin case

handle.

Bobbin case is damaged and

does not work.

Needle is not inserted correctly. See page 14

Needle is bent or dull.

Needle clamp screw goes loos.

Upper thread tension is too

tight.

See page 18

See page 21

Insert a new

needle.

See page 27

See page 14

See page 15

Clean the

bobbin case.

Change the

bobbin case.

Insert a new

needle.

Screw the

needle clamp

screw again.

See page 21

Fabrics are not pulled backward See page 27

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

49

Page 48

Malfunctions Cause Remedy

Machine skips stitches

Fabric puckers or gathers

of seam

after sewing.

Needle is too thin to stitch the

cloth.

Pattern selection dial I not

turned properly.

Needle is not inserted correctly. See page 14

Needle is bent or dull.

Neither needle nor thread fit for

sewing.

Upper threading is incorrect. See page 18

Upper thread tension is too

tight.

Threading is incorrect.

Sewing foot pressure is to high. See page 28

Stitches are too big to sew the

cloth.

Non-woven lining under the

cloth is required for stitching

very thin cloth.

See page 14

See page 22

Insert a new

needle.

See page 14

See page 21

See pages 15

and 18

Put a nonwoven lining

under the cloth.

Upper thread tension is too low. See page 21

Thread makes loops

Fabric does not feed

properly

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

The combination of needle size,

thread size and fabric is

incorrect, either too thick or too

thin.

Fibres block the feed dog. See page 46

Feed dog is discharged. See page 27

Stitches are too small. See page 23

See page 14

50

Page 49

Malfunctions Cause Remedy

Stitch length is „0“. See page 23

Fabric feeds irregular

Machine does not work.

Machine does not run

free.

Machine is noisy and

works slowly

Thread ends in shuttle track. See page 45

Hand wheel is in winding

position.

Main power switch is turned off. See page 10

Thread tangled it the bobbin

case handle.

Hand wheel is in winding

position.

Insufficient oiling See page 47

Thread tangled it the bobbin

case handle.

Fibres block the feed dog. See page 46

Insufficient oiling See page 47

See page 16

See page 45

See page 16

See page 45

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

51

Page 50

Technical Specifications 12

Sewing machine

Nominal voltage: 220 - 240 V ~ 50 Hz

Nominal consumption: total 85 W

Motor 70 W

Light 15 W

Light socket E14

Stitch speed: max. 800 stitches per minute

Foot pedal:

Model: HKT7

Nominal voltage: 200 - 240 V ~ 50 Hz

Safety class: II

Subject to technical changes.

Helpline No. UK/ North Ireland 0871 37 61 020 Rep. Ireland 1-800-992 508

Web Support www.medion.co.uk

Model Number: MD 11871

52

Loading...

Loading...