Page 1

Operating & Maintenance Manual

Group: Chiller

Part Number: 10000199900

Date: Sept 2010

Supercedes: July 2010

OM 1051-2

Pathfinder™ Air-Cooled Chillers

AWS 150A through AWS 530A (Includes Optional Compressor VFD Models)

50/60 Hertz,

R-134a

Software Version: 2507500205

© 2010 McQuay International

Page 2

Table of Contents

INTRODUCTION ........................................................3

OPERATING LIMITS: ...............................................4

E

CONOMIZER CONTROL

L

IQUID INJECTION

L

IQUID LINE SOLENOID VALVE

C

APACITY OVERRIDES – LIMITS OF OPERATION

........................................... 42

.................................................... 42

............................... 43

...... 43

CONTROLLER FEATURES .....................................4

GENERAL DESCRIPTION........................................5

C

ONTROL PANEL LAYOUT

P

OWER PANEL LAYOUT

E

CONOMIZER COMPONENTS

CONTROLLER DESCRIPTION ...............................9

H

ARDWARE STRUCTURE

S

YSTEM ARCHITECTURE

SEQUENCE OF OPERATION ................................11

CONTROLLER OPERATION.................................15

S

ETPOINTS

UNIT FUNCTIONS....................................................22

C

ALCULATIONS

U

NIT AVAILABILITY

U

NIT MODE SELECTION

U

NIT CONTROL STATES

U

NIT STATUS

I

CE MODE START DELAY

E

VAPORATOR PUMP CONTROL

N

OISE REDUCTION

L

EAVING WATER TEMPERATURE

U

NIT CAPACITY CONTROL

U

NIT CAPACITY OVERRIDES

CIRCUIT FUNCTIONS ............................................34

................................................................18

.........................................................22

............................................................24

....................................................25

..........................................5

..............................................6

.......................................7

.............................................9

...........................................10

.................................................22

............................................23

............................................23

..........................................24

.................................25

(LWT) R

........................................28

.....................................30

ESET

.......26

ALARMS AND EVENTS ......................................... 44

S

IGNALING ALARMS

C

LEARING ALARMS/FAULTS

D

ESCRIPTION OF ALARMS

A

LARM LISTING

U

NIT FAULTS

U

NIT WARNINGS

C

IRCUIT FAULTS

C

IRCUIT PROBLEMS

A

LARM LOGGING

E

VENT LOG

.............................................................. 55

................................................ 44

.................................... 44

........................................ 45

....................................................... 45

........................................................... 47

...................................................... 48

...................................................... 49

................................................. 54

..................................................... 55

USING THE CONTROLLER.................................. 56

N

AVIGATING

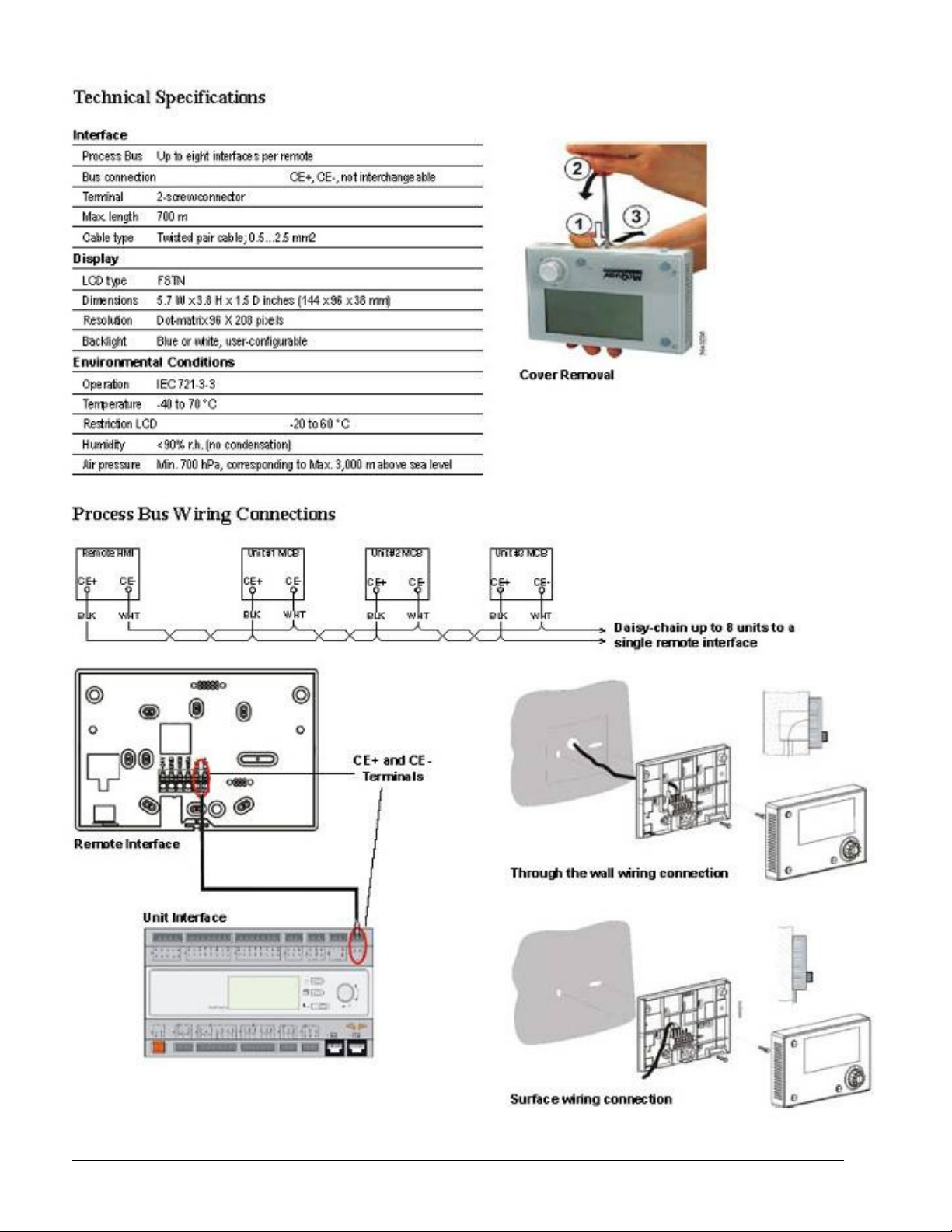

OPTIONAL REMOTE USER INTERFACE ......... 61

............................................................ 57

OPTIONAL COMPRESSOR VFD.......................... 63

F

AULTS AND MINOR FAULTS/ALARMS

C

LEARING

N

AVIGATING

OPTIONAL POWER FACTOR CORRECTION

CAPACITORS........................................................... 67

START-UP AND SHUTDOWN ............................... 68

T

EMPORARY SHUTDOWN

E

XTENDED (SEASONAL) SHUTDOWN

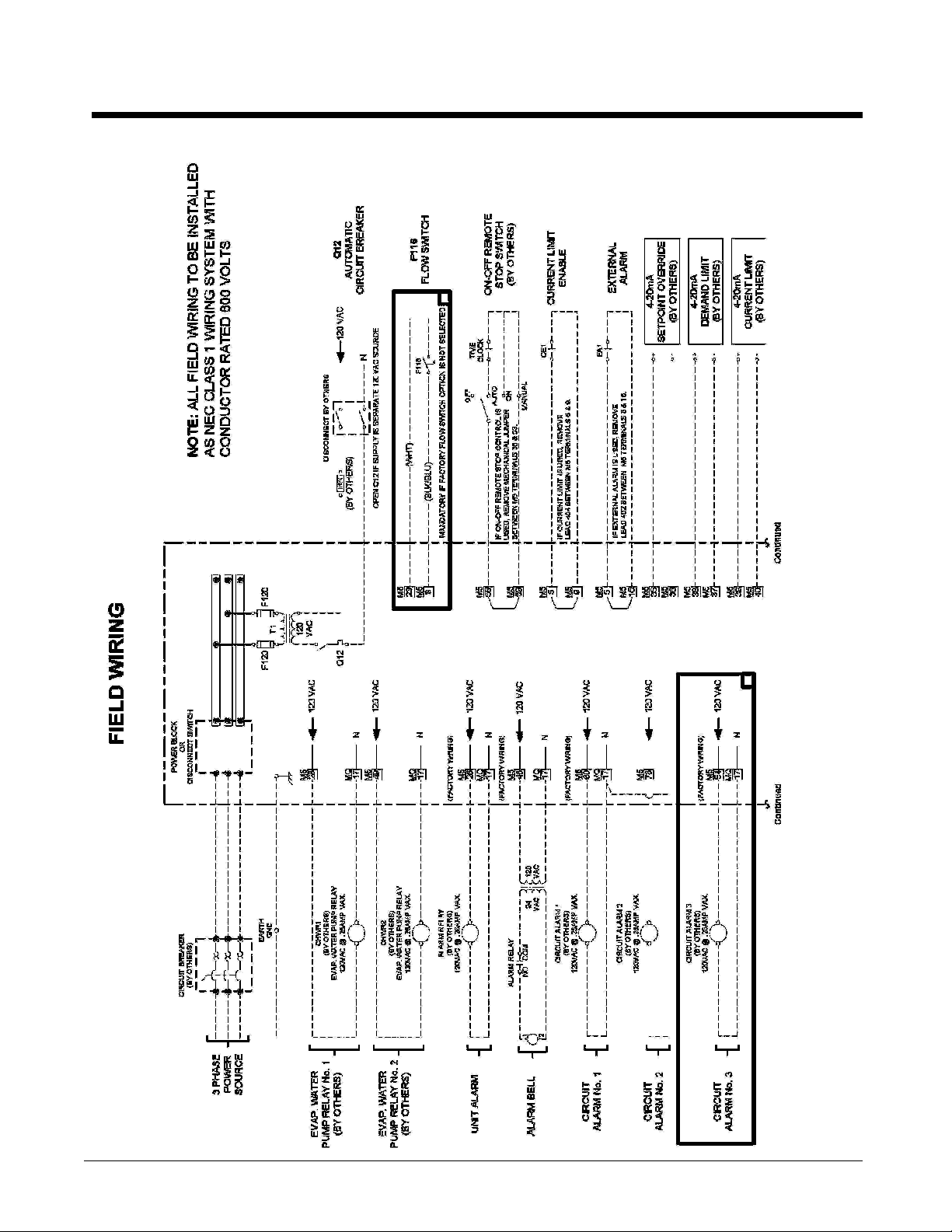

FIELD WIRING DIAGRAM ................................... 71

VFD F

VFD F

AULTS

.......................................... 63

AULT CODES

......................................... 68

.................... 63

............................ 63

....................... 69

C

ALCULATIONS

C

IRCUIT CONTROL LOGIC

C

IRCUIT STATUS

C

OMPRESSOR CONTROL

C

ONDENSER FAN CONTROL

F

AN CONTROL WITHOUT

F

AN CONTROL WITH

EXV C

ONTROL

.........................................................34

.........................................35

.......................................................36

............................................37

......................................38

VFD ..................................38

VFD.........................................40

.........................................................40

Modbus

Manufactured in an ISO Certified Facility

SYSTEM MAINTENANCE ..................................... 73

P

REVENTATIVE MAINTENANCE SCHEDULE

APPENDIX ................................................................ 78

D

EFINITIONS

............................................................ 78

.............. 77

Unit controllers are LONM

optional LONW

ORKS

ARK

certified with an

communications module

2010 McQuay International. Information covers the McQuay International products at the time of publication and we reserve the right to make

changes in design and construction at anytime without notice. The following are trademarks or registered trademarks of their respective

companies: BACnet from ASHRAE; LONM

from McQuay International; Excel from Microsoft Corp.

2 OM 1051-2

ARK and LONWORKS

from Echelon Corporation; McQuay, MicroTech III, Guardister, and Open Choice

Page 3

Introduction

This manual provides setup, operating, troubleshooting and maintenance information for the

Daiken McQuay Pathfinder chillers.

Dangers indicate a hazardous situation which will result in death or serious injury if not avoided.

Warnings indicate potentially hazardous situations, which can result in property damage, severe

Cautions indicate potentially hazardous situations, which can result in personal injury or equipment

Software Version:

The unit software and BSP (Board Support Package) versions can be viewed using the

keypad/display. From the Main Menu, turn the knob to the right until you reach the About Chiller

menu and press Enter (the knob). The software version is displayed as "App Version =". Scroll

down in this menu (turn knob to the right), the BSP version will also be displayed ("BSP

Version=").

H

AZARD IDENTIFICATION INFORMATION

!

DANGER

!

WARNING

personal injury, or death if not avoided.

!

CAUTION

damage if not avoided.

• App Version 2507500205 for units with or without the optional compressor VFDs

!

WARNING

Electric shock hazard: can cause personal injury or equipment damage. This equipment must

be properly grounded. Connections to, and service of, the MicroTech III control panel must be

performed only by personnel who are knowledgeable in the operation of this equipment .

!

CAUTION

Static sensitive components. A static discharge while handling electronic circuit boards can

cause damage to the components. Discharge any static electrical charge by touching the bare

metal inside the control panel before performing any service work. Never unplug any cables,

circuit board terminal blocks, or power plugs while power is applied to the panel.

NOTICE

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with this instruction manual, can cause interference to

radio communications. Operation of this equipment in a residential area can cause

harmful interference, in which case the user will be required to correct the interference at

the user’s own expense. McQuay International Corporation disclaims any liability

resulting from any interference or for the correction thereof.

OM 1051-2 3

Page 4

Operating Limits:

• Maximum standby ambient temperature, 130°F (55°C)

• Maximum operating ambient temperature is 115°F (46°C), or 125°F (52°C) with the addition

of the optional high ambient package

• Minimum operating ambient temperature (standard), 35°F (2°C)

• Minimum operating ambient temperature (with optional low-ambient control), 0°F (-18°C)

• Leaving chilled water temperature, 39.2°F to 59.0°F (4.0°C to 15.0°C)

• Leaving chilled fluid temperatures with glycol, 24.8°F to 59.0°F (-4.0°C to 15.0°C). Normal

unloading.

• Leaving temperature in ICE mode, 17.6°F to 39.2°F (-8.0°C to 4°C). No unloading.

• Operating Delta-T range, 6°F to 16°F (3.3°C to 8.9°C)

• Maximum operating inlet fluid temperature, 76°F (24°C)

• Maximum non-operating inlet fluid temperature, 100°F (38°C)

Controller Features

Readout of the following temperature and pressure readings:

• Entering and leaving chilled water temperature

• Saturated evaporator refrigerant temperature and pressure

• Saturated condenser temperature and pressure

• Outside air temperature

• Suction and discharge line temperatures − calculated superheat for discharge and suction

lines

• Oil pressure

Automatic control of primary and standby chilled water pumps. The control will start one of the

pumps (based on lowest run-hours) when the unit is enabled to run (not necessarily running on a

call for cooling) and when the water temperature reaches a point of freeze possibility.

Two levels of security protection against unauthorized changing of setpoints and other control

parameters.

Warning and fault diagnostics to inform operators of warning and fault conditions in plain

language. All events and alarms are time and date-stamped for identification of when the fault

condition occurred.

Twenty-five previous alarms are available.

Remote input signals for chilled water reset, demand limiting, and unit enable.

Test mode allows the service technician to manually control the controllers’ outputs and can be

useful for system checkout.

Building Automation System (BAS) communication capability via LonTalk, Modbus, or

BACnet standard protocols for all BAS manufacturers-simplified with McQuay’s Open

Choices feature.

Pressure transducers for direct reading of system pressures. Preemptive control of low evaporator

pressure conditions and high discharge temperature and pressure to take corrective action prior to

a fault trip.

4 OM 1051-2

Page 5

General Description

Switch

Switch

The control panel is located on the front of the unit at the compressor end. There are three doors. The

control panel is behind to left-hand door. The power panel is behind the middle and right-hand doors.

General Description

The MicroTech III control system consists of a microprocessor-based controller and a number of extension

modules, which vary depending on the unit size and conformation. The control system provides the

monitoring and control functions required for the controlled, efficient operation of the chiller.

The operator can monitor all critical operating conditions by using the screen located on the main controller.

In addition to providing all normal operating controls, the MicroTech III control system will take corrective

action if the chiller is operating outside of its normal design conditions. If a fault condition develops, the

controller will shut a compressor, or the entire unit, down and activate an alarm output.

The system is password protected and only allows access by authorized personnel. Except that some basic

information is viewable and alarms can be cleared without a password. No settings can be changed.

Additional information about the Daikin McQuay Pathfinder Chiller is available in Catalog 600 and IM

997, which can be found on www.mcquay.com.

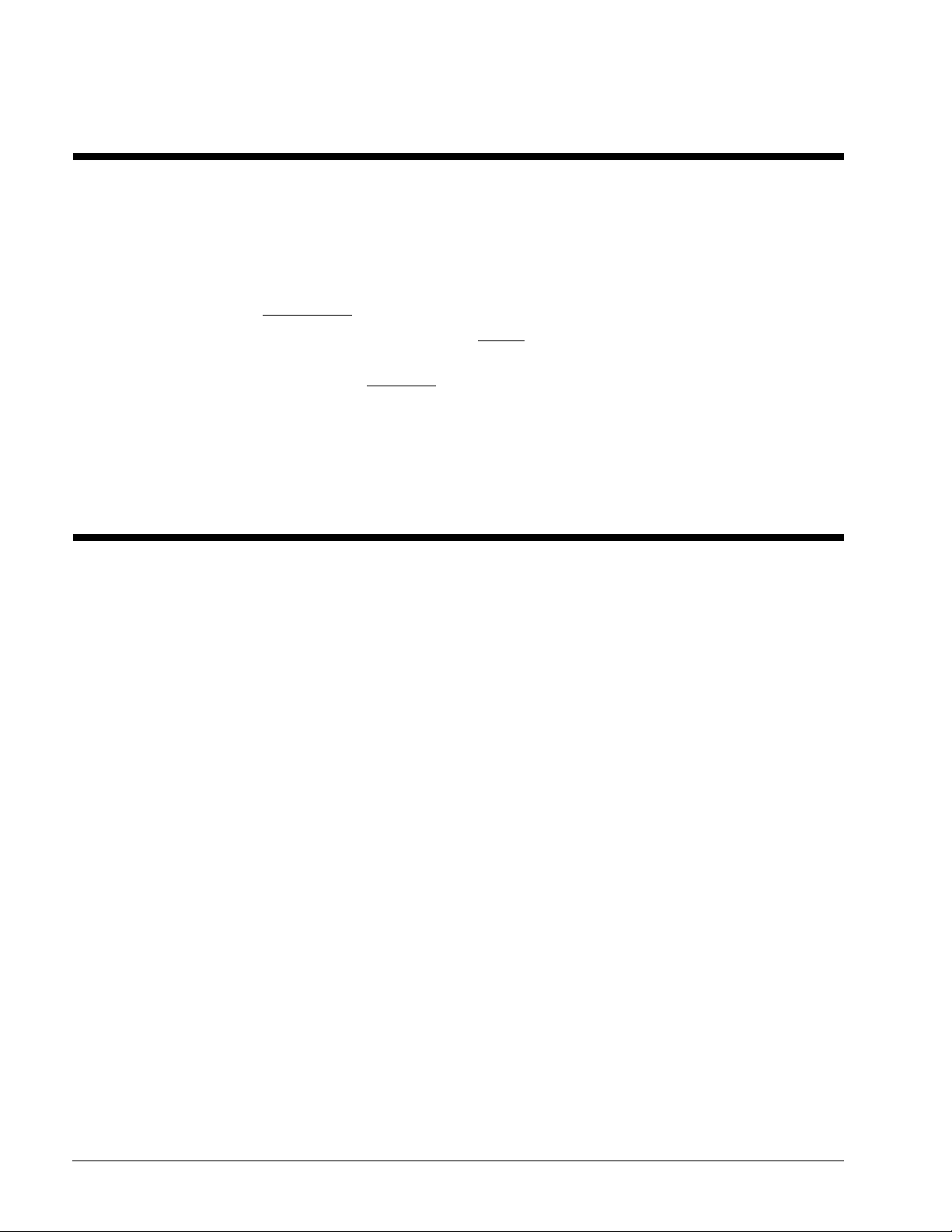

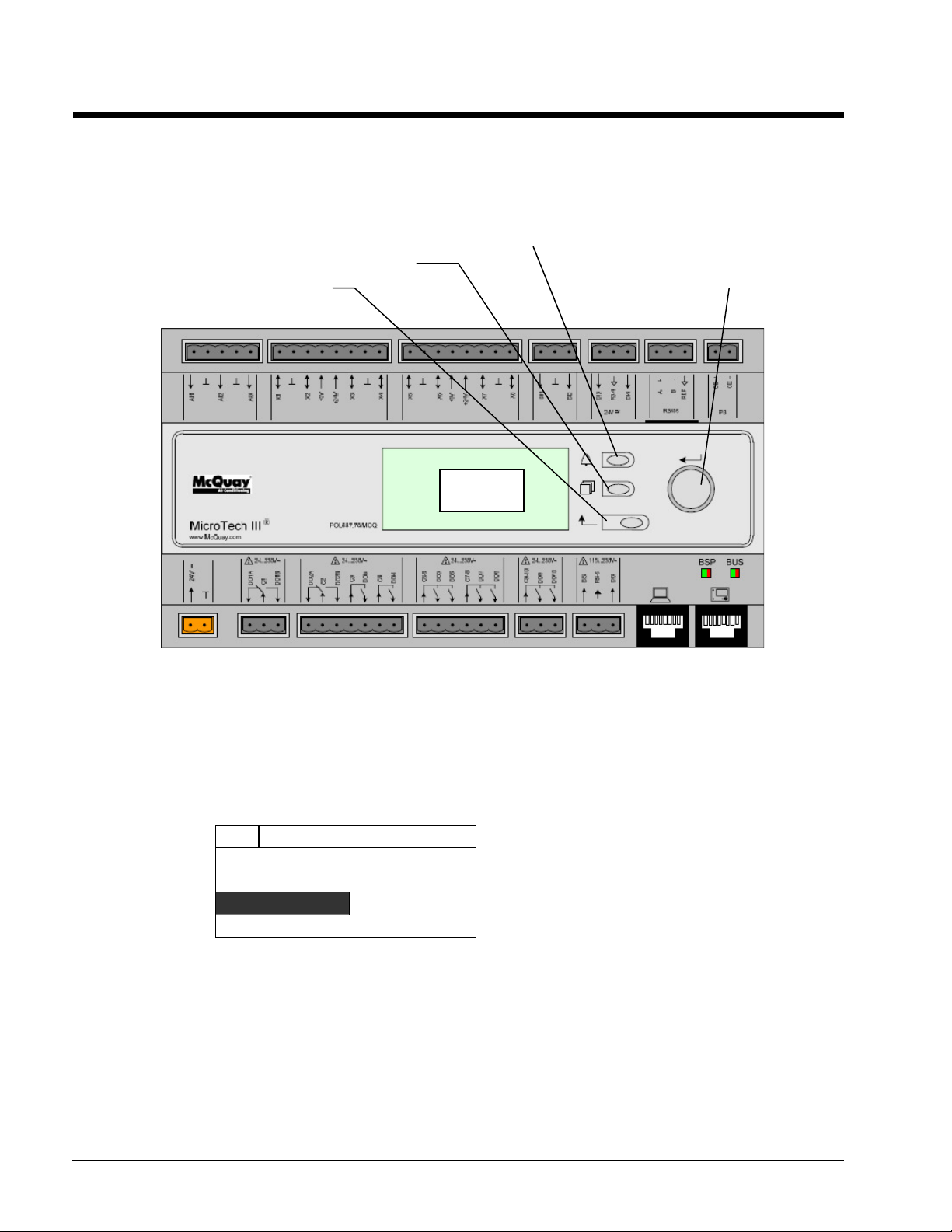

Control Panel Layout

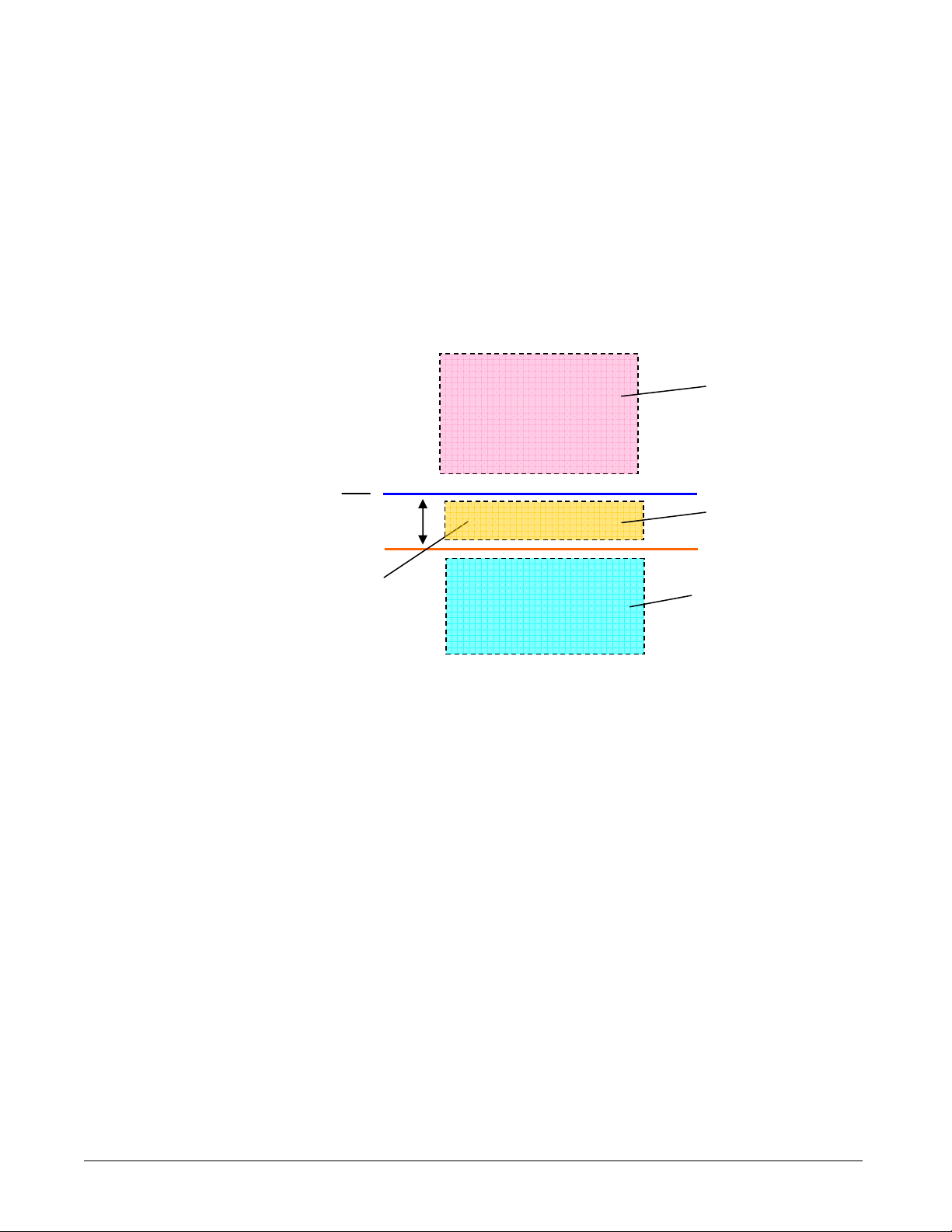

Figure 1, Control Panel Components, Three-Circuit Unit, w/o VFD

Controller

Fuse

Emergency

Switch

Relay

Control

Circuit

Breaker

Unit On/Off

Circuit #1

Pumpdown

Circuit #2

Pumpdown

Switch

Circuit #3

Pumpdown

Switch

Alarm & Limit

Extension

Module

MicroTech III

Main

Controller

Fan Control

Extension

Modules

Emergency

Switch

Located on

Front Door

OM 1051-2 5

Page 6

NOTES:

Fan

Circuit Breaker

s

1 per Fan

,

Circuit #

1

Circuit Breaker

Circuit Breaker

1. The Emergency Switch Relay de-energizes all circuit’s control power when activated, causing an

immediate compressor and fan shutdown. The red emergency button switch is located on the

front of the control panel door.

2. The control power transformer is located in the power panel adjacent to the control panel.

3. Additional extension (aka expansion) modules are located elsewhere on the chiller.

4. See the VFD section for a description of the panel used with the VFD option as it is considerably

different from the standard panel.

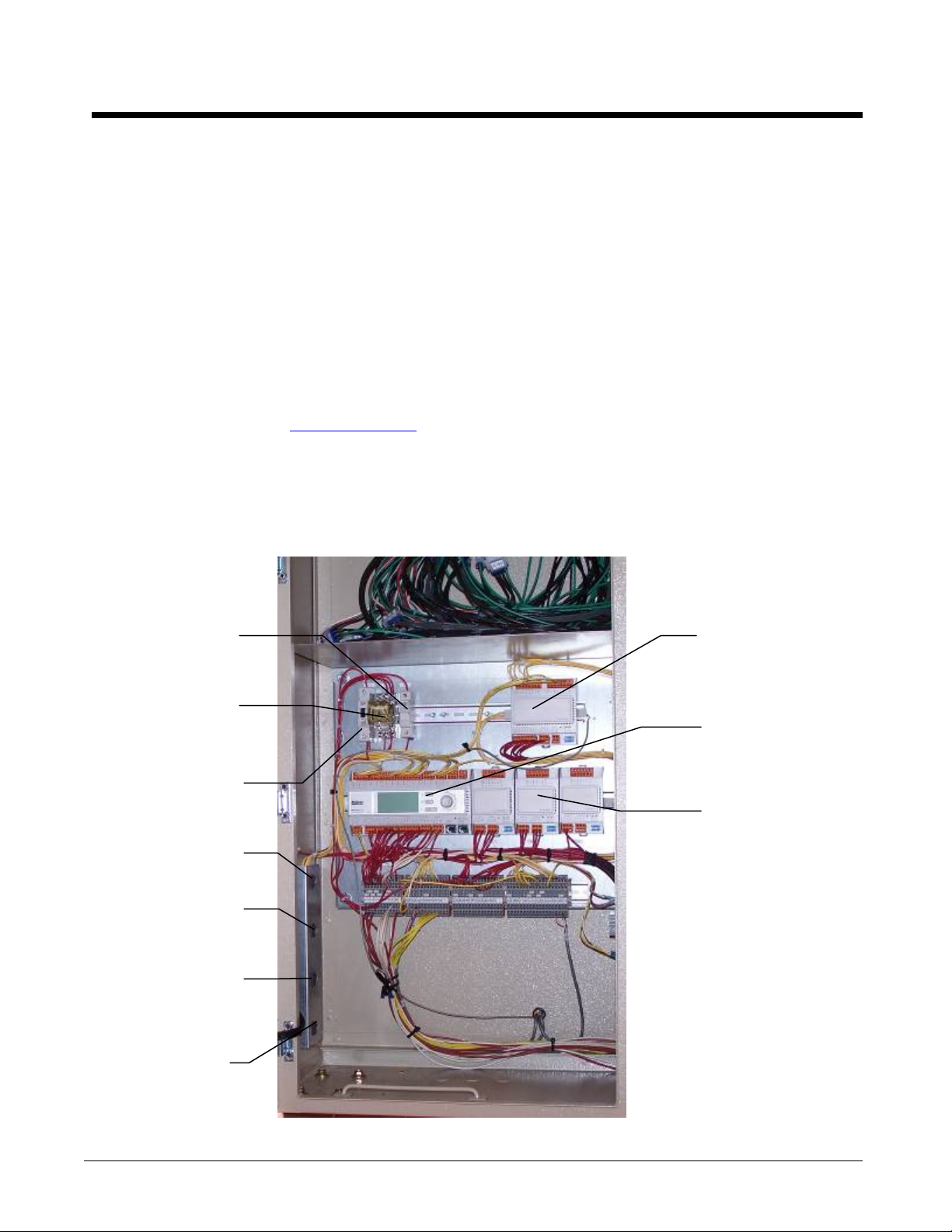

Power Panel Layout

The power panel is at the front of the unit, behind the two doors to the right.

Figure 2, Power Panel, Three-Circuit Units, w/o VFD

Fan Contactors

Fan Contactors

1 per Fan, Circuit #2

Fan Contactors

1 per Fan, Circuit #3

Compressor #1

Circuit Breaker

Single Point

Disconnect Switch with

Compressor #3

Compressor #2

6 OM 1051-2

Line/120V

Transformer

Incoming Power

Connections

NOTE: See the VFD section of this manual for a description of the power used with the VFD option

as it is considerably different from the standard panel.

Page 7

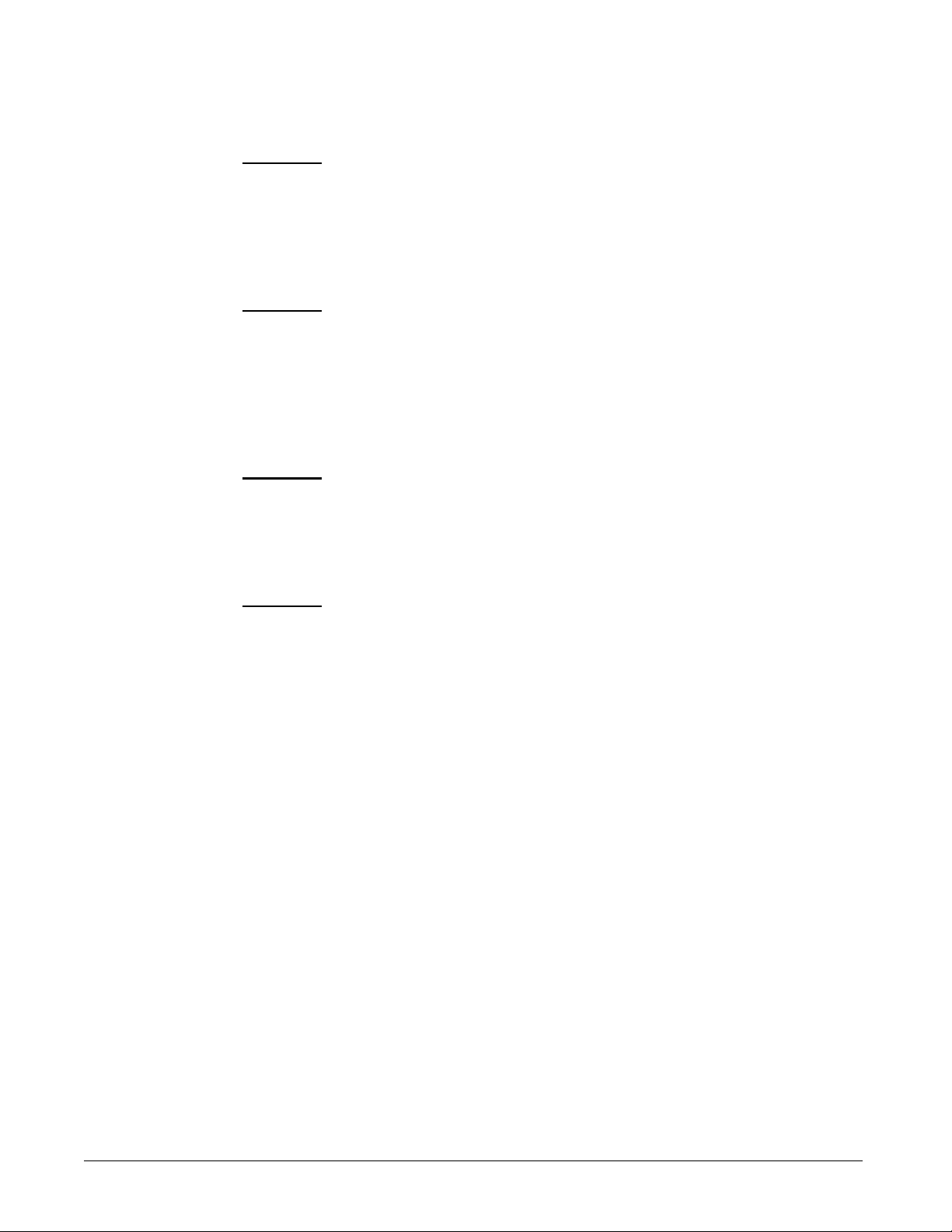

Economizer Components

The chiller may or may not have economizers depending on design capacity

requirements. An economizer is a well-proven device to increase a refrigerant circuit’s

capacity and efficiency.

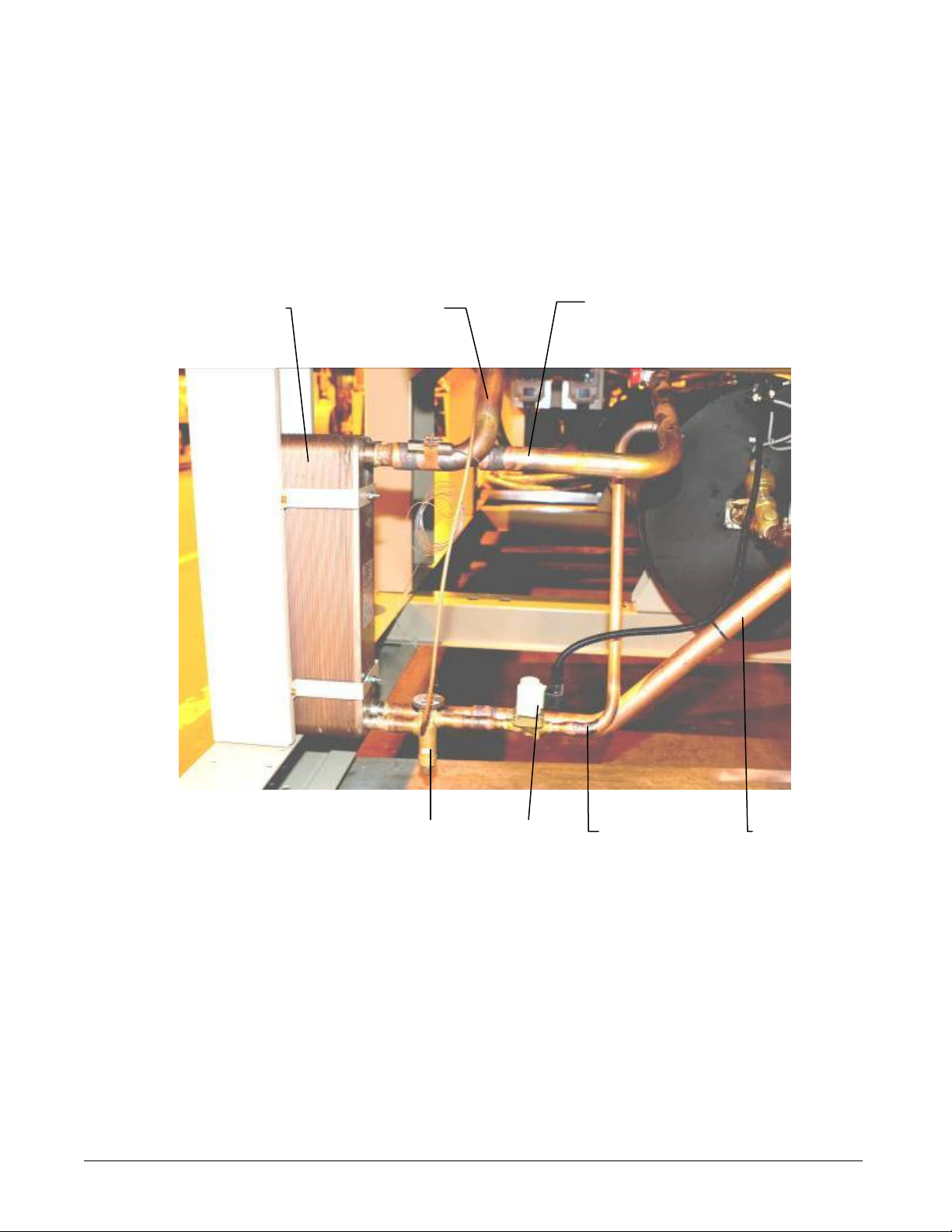

Figure 3, Economizer Components

Brazed-plate

Heat Exchanger

Gas to Comp.

Interstage

Liquid from

Condenser

TXV LLSV

Warm liquid from the condenser is fed into the economizer where it is cooled by flashing off

liquid also from the condenser. The flash gas is piped to a compressor interstage point.

Lowering the liquid refrigerant temperature to the evaporator decreases its enthalpy (heat

content) and results in a greater amount of heat absorption from the chilled water.

OM 1051-2 7

Liquid Feed

to

Economizer

Liquid Feed

to

Evaporator

Page 8

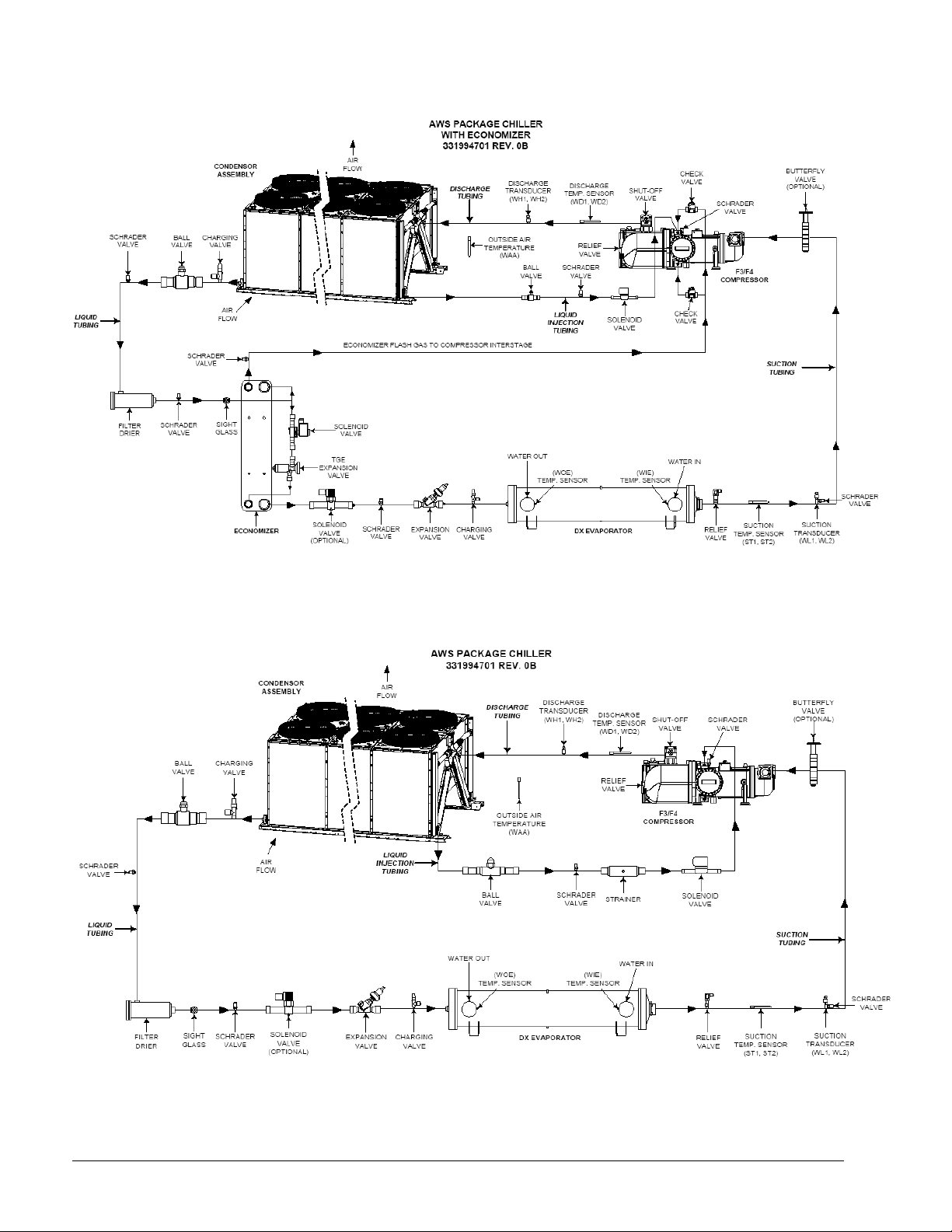

Figure 4, Piping Schematic with Economizer Circuit, One Circuit Shown

Figure 5, Piping Schematic without Economizer Circuit, One Circuit Shown

8 OM 1051-2

Page 9

Controller Description

Hardware Structure

The MicroTech III control system for Pathfinder chillers consists of a main unit controller with a

number of extension input/output I/O modules attached depending on the chiller size and

configuration.

One of the optional BAS communication modules may be included.

An optional Remote Operator Interface panel may be included, connected with up to nine

Pathfinder units.

The MicroTech III controllers used on Pathfinder chillers are not interchangeable with previous

MicroTech II controllers.

MicroTech III unit controller

Remote Operator Interface

BACnet/

MSTP

Communication

MODbus LON

BACnet/IP

Extension I/O Modules

OM 1051-2 9

Page 10

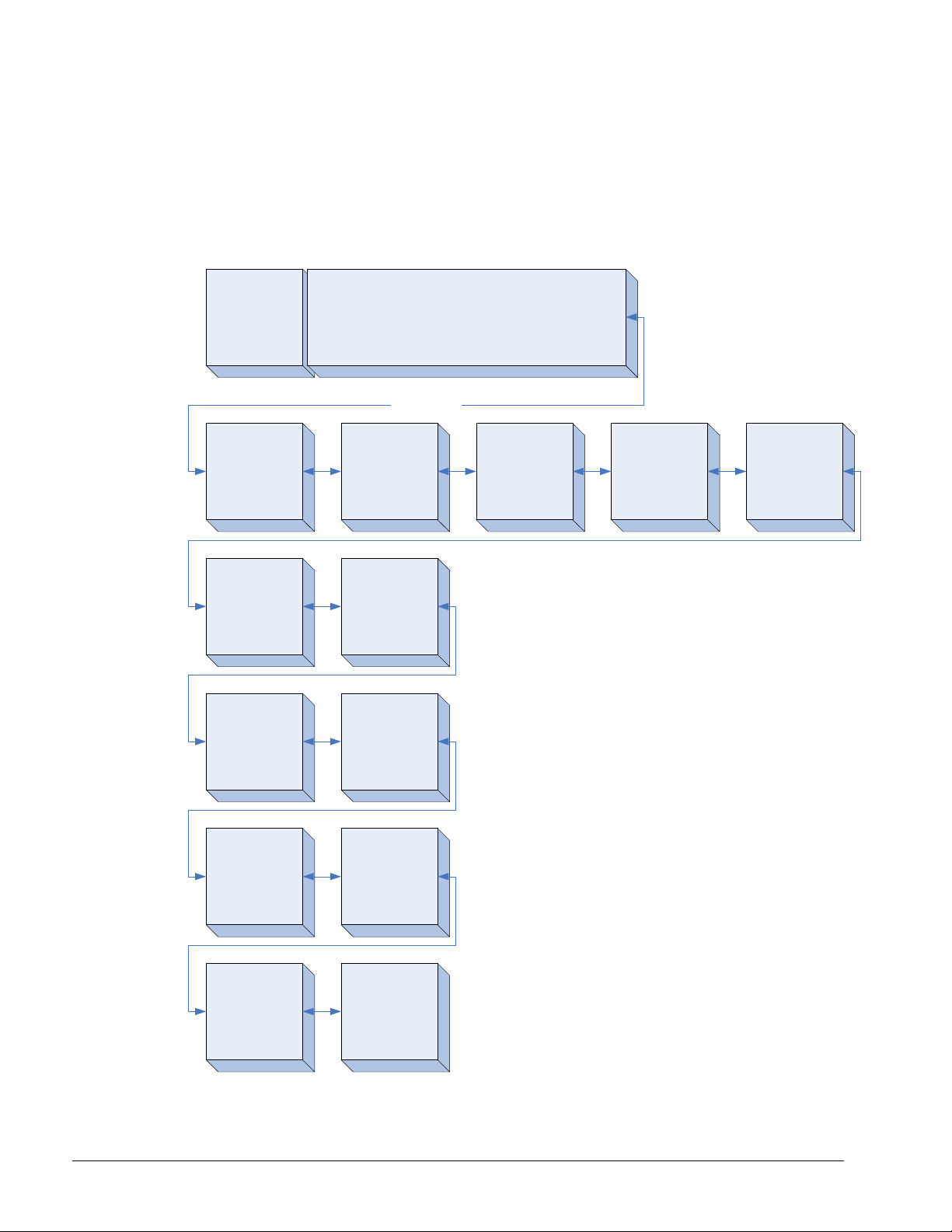

System Architecture

The overall controls architecture uses the following:

• One MicroTech III main controller

• I/O extension modules (sometimes referred to as “controllers”) as needed depending

on the configuration of the unit

• Optional BAS interface as selected

Figure 6, System Architecture

BAS Interface

(BACnet, Lon,

Modbus)

MicroTech III Main Controller

Peripheral Bus

I/O Extension

Alarm/Limiting

I/O Extension

Compressor 1

I/O Extension

Compressor 2

I/O Extension

Compressor 3

I/O Extension

Fans Circuit 1

and 2

I/O Extension

EXV 1

I/O Extension

EXV 2

I/O Extension

EXV 3

I/O Extension

Fans Circuit 3

I/O Extension

Fans Circuit 3

and 4

I/O Extension

Fans Circuit 4

I/O Extension

Compressor 4

I/O Extension

EXV 4

10 OM 1051-2

Page 11

Sequence of Operation

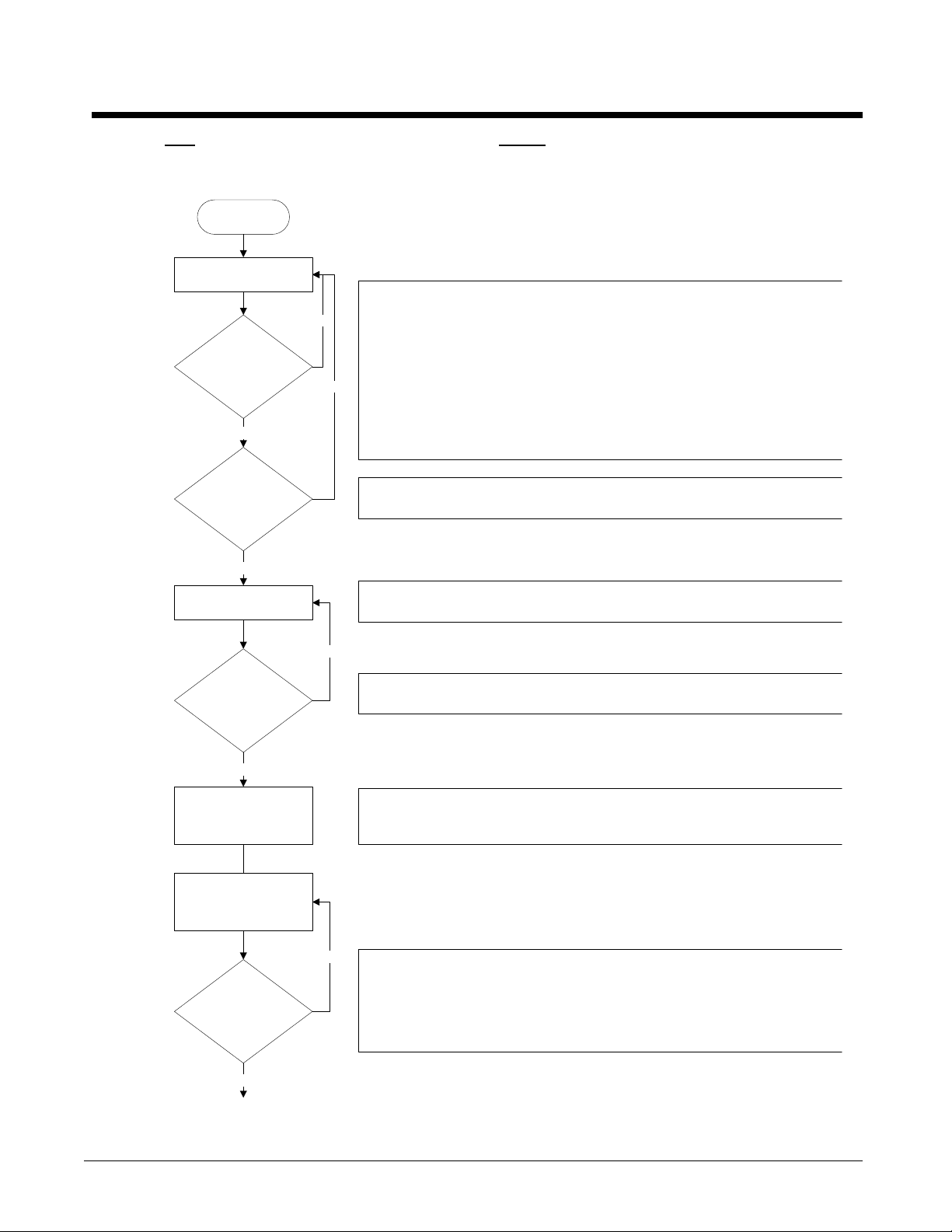

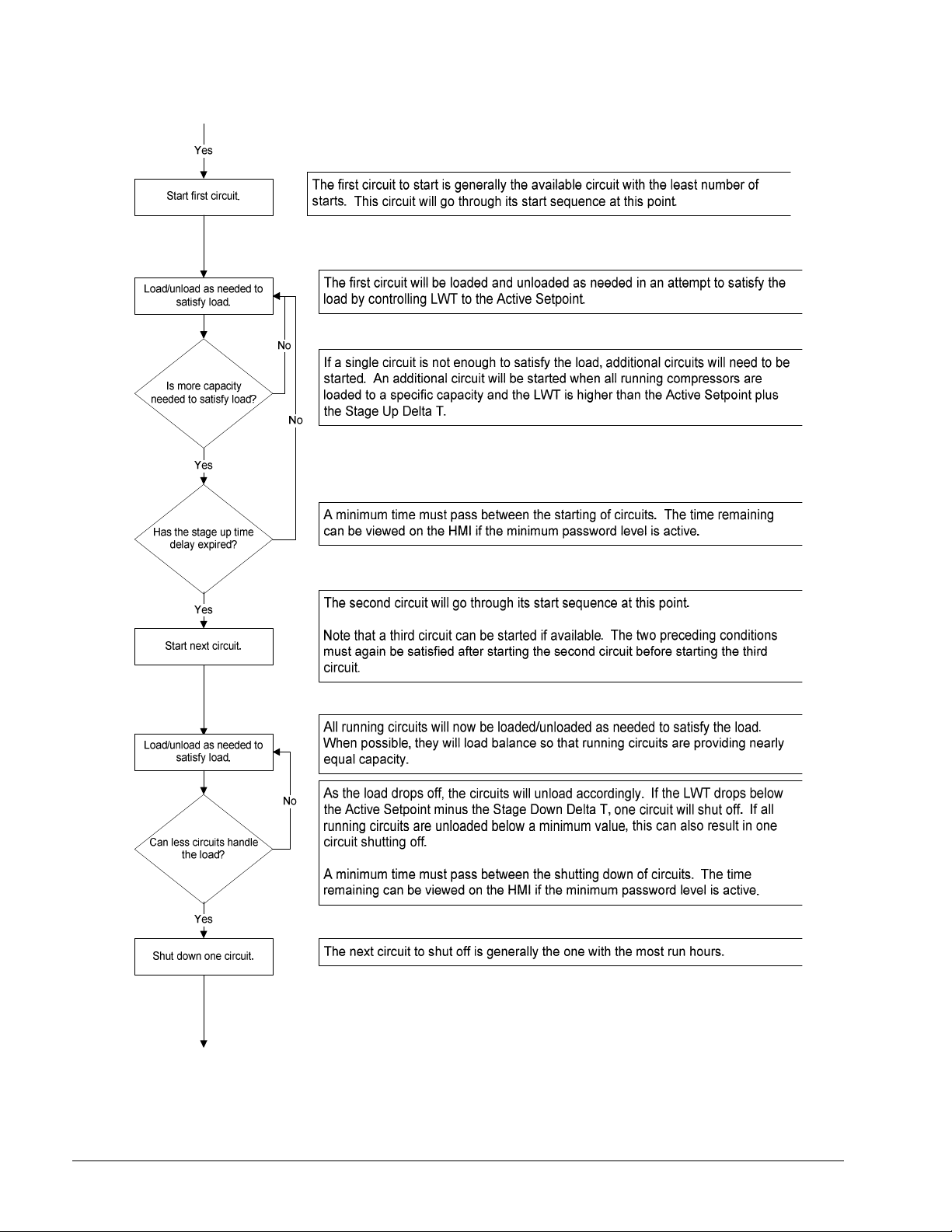

Figure 7, Unit Sequence of Operation (see Figure 9 for circuit sequence of operation)

Unit power up

Unit in Off state

Is unit enabled?

Yes

Is low ambient lockout

active?

No

Evaporator pump output on

AWS Chiller Sequence of Operation in Cool Mode

The chiller may be disabled via the unit switch, the remote switch, the keypad

enable setting, or the BAS network. In addition, the chiller will be disabled if all

No

circuits are disabled, or if there is a unit alarm. If the chiller is disabled, the unit

status display will reflect this and also show why it is disabled.

If the unit switch is off, the unit status will be Off:Unit Switch. If the chiller is

disabled due to network command, the unit status will be Off:BAS Disable. When

Yes

the remote switch is open, the unit status will be Off:Remote Switch. When a unit

alarm is active, the unit status will be Off:Unit Alarm. In cases where no circuits

are enabled, the unit status will be Off:All Cir Disabled. If the unit is disabled via

the Chiller Enable set point, the unit status will be Off:Keypad Disable.

Low ambient lockout will prevent the chiller from starting even if it is otherwise

enabled. When this lockout is active, the unit status will be Off:Low OAT Lock.

If the chiller is enabled, then the unit will be in the Auto state and the evaporator

water pump output will be activated.

No

Is flow present?

Yes

Wait for chilled water loop to

recirculate.

Keep pump output on while

chiller is enabled and either

running or ready to run.

Is there enough load to

start chiller?

Yes

The chiller will then wait for the flow switch to close, during which time the unit

status will be Auto:Wait for flow.

After establishing flow, the chiller will wait some time to allow the chilled water loop

to recirculate for an accurate reading of the leaving water temperature. The unit

status during this time is Auto:Evap Recirc.

No

The chiller is now ready to start if enough load is present. If the LWT is not higher

than the Active Setpoint plus the Start Up Delta T, the unit status will be Auto:Wait

for load.

If the LWT is higher than the Active Setpoint plus the Start Up Delta T, the unit

status will be Auto. A circuit can start at this time.

OM 1051-2 11

Page 12

12 OM 1051-2

Page 13

OM 1051-2 13

Page 14

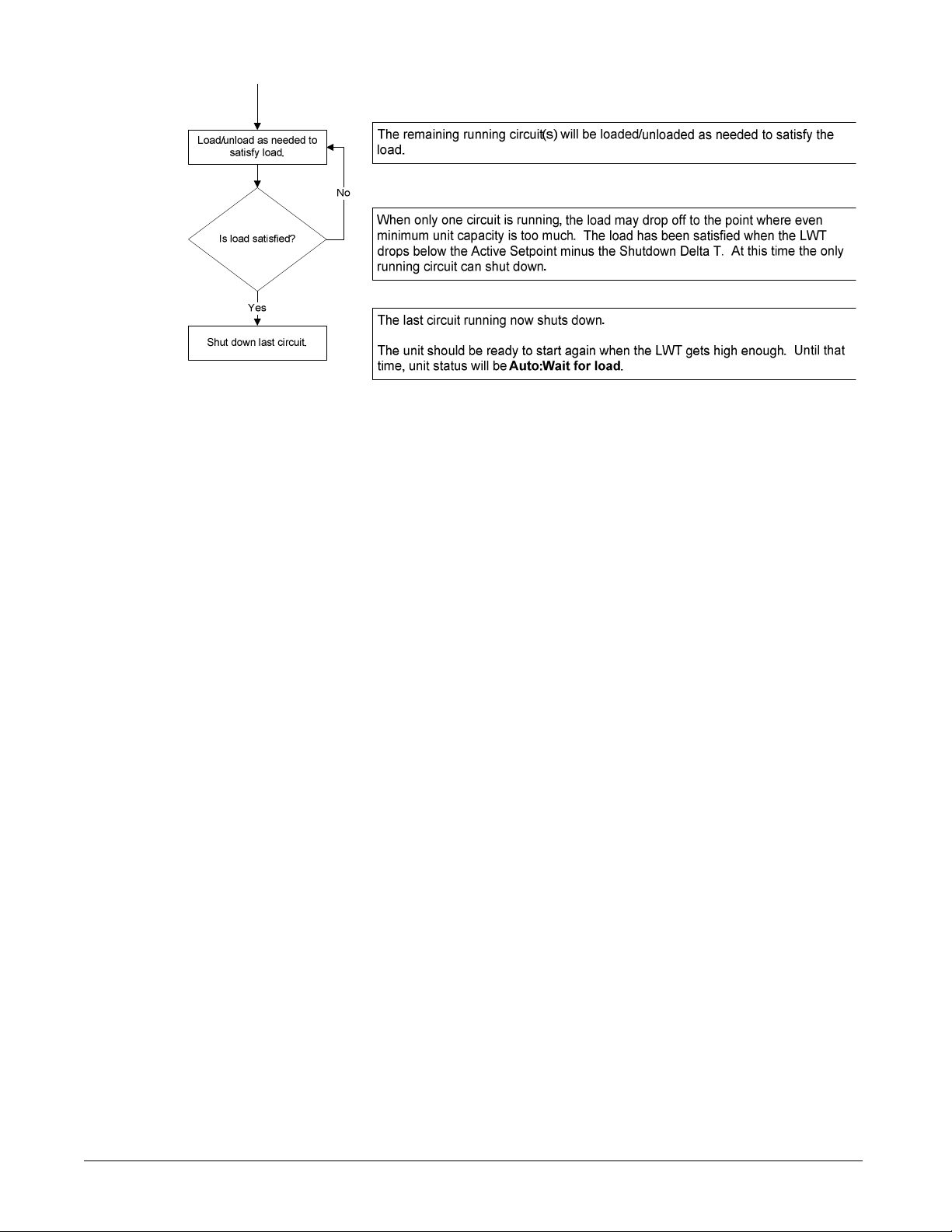

Figure 8, Circuit Sequence of Operation

Unit power up

Circuit is in Off state

Is circuit is enabled to

start?

Yes

Are compressor cycle

timers active?

No

Is compressor oil sump

ready?

No

AWS Sequence of Operation - Circuits

When the circuit is in the Off state the EXV is closed, compressor is off, and all fans

are off.

The circuit must be enabled before it can run. It may be disabled for several

reasons. When the circuit switch is off, the status will be Off:Circuit Switch.

If the BAS has disabled the circuit, the status will be Off:BAS Disable. If the circuit

Yes

has an active stop alarm then the status will be Off:Cir Alarm. If the circuit has

been disabled via the circuit mode set point, the status will be Off:Cir Mode

Disable.

No

A minimum time must pass between the previous start and stop of a compressor

and the next start. If this time has not passed, a cycle timer will be active and the

circuit status will be Off:Cycle Timer.

If the compressor is not ready due to refrigerant in the oil, the circuit cannot start.

The circuit status will be Off:Refr In Oil.

Yes

Circuit is ready to start

Is circuit commanded to

start?

Yes

Run circuit

Is circuit commanded to

shut down?

Yes

Pumpdown circuit

No

No

If the compressor is ready to start when needed, the circuit status will be

Off:Ready.

When the circuit begins to run, the compressor will be started and the EXV, fans,

and other devices will be controlled as needed. The normal circuit status at this

time will be Run.

When the circuit is commanded to shut down, a normal shut down of the circuit will

be performed. The circuit status during this time will be Run:Pumpdown. After

the shut down is completed, the circuit status will normally be Off:Cycle Timer

initially.

14 OM 1051-2

Page 15

Controller Operation

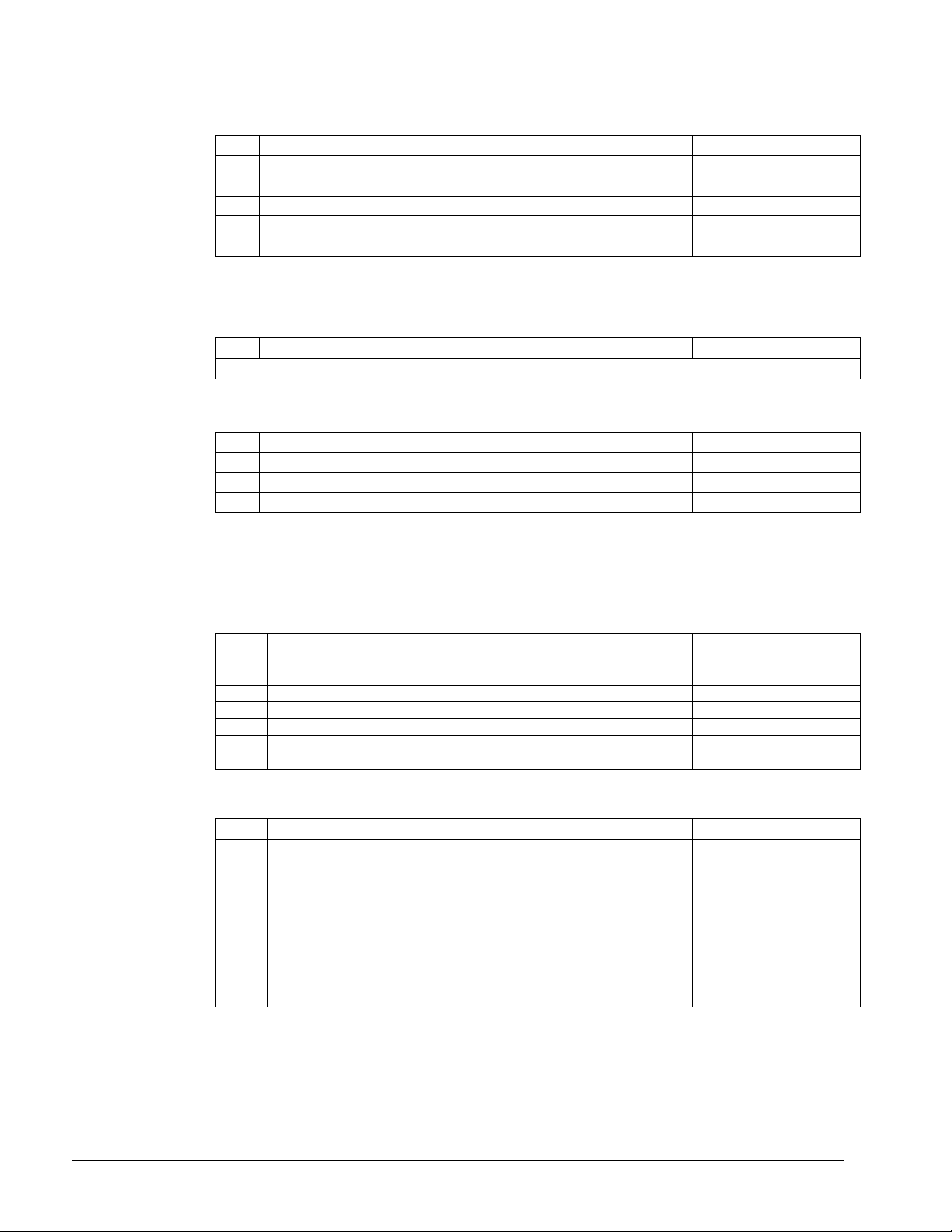

MicroTech III Inputs/Outputs

I/O for the unit control and for circuits one and two are found on CP1.

The chiller may be equipped with two or three compressors.

Analog Inputs

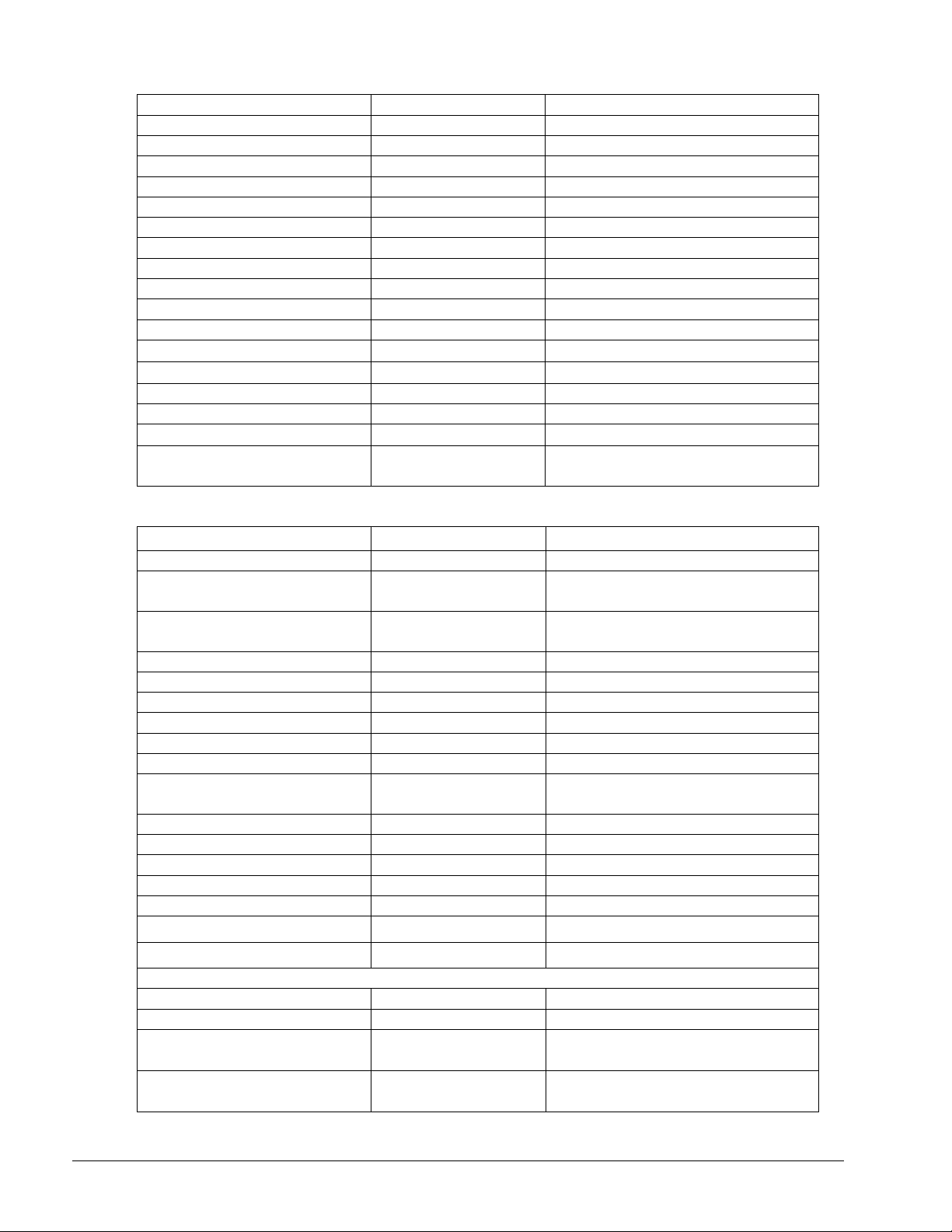

# Description Signal Source Expected Range

AI1 Evaporator Entering Water Temp NTC Thermister (10K@25°C) -50°C – 120°C

AI2 Evaporator Leaving Water Temp NTC Thermister (10K@25°C) -50°C – 120°C

AI3 Evaporator #1 Leaving Water Temp (*) NTC Thermister (10K@25°C) -50°C – 120°C

X1 Evaporator #2 Leaving Water Temp (*) NTC Thermister (10K@25°C) -50°C – 120°C

X2 Outside Ambient Temperature NTC Thermister (10K@25°C) -50°C – 120°C

X4 LWT Reset 4-20 mA Current 1 to 23 mA

*Evaporator #1 LWT and Evaporator #2 LWT will only be used when unit is configured with

four circuits

Analog Outputs

# Description Output Signal Range

X5 Fan VFD #1 0-10VDC 0 to 100% (1000 steps resolution)

X6 Fan VFD #2 0-10VDC 0 to 100% (1000 steps resolution)

X7 Fan VFD #3 0-10VDC 0 to 100% (1000 steps resolution)

X8 Fan VFD #4 0-10VDC 0 to 100% (1000 steps resolution)

Digital Inputs

# Description Signal Off Signal On

DI1 Unit PVM Fault No Fault

DI2 Evaporator Flow Switch No Flow Flow

DI3 Double Setpoint/ Mode Switch Cool mode Ice mode

DI4 Remote Switch Remote off Remote on

DI5 Unit Switch Unit off Unit on

DI6 Emergency Stop Unit off/rapid stop Unit on

Digital Outputs

# Description Output OFF Output ON

DO1 Evaporator Water Pump Pump Off Pump On

Alarm Active

DO2 Unit Alarm Alarm not Active

DO3 Circuit #1 Fan Step #1 Fan Off Fan On

DO4 Circuit #1 Fan Step #2 Fan Off Fan On

DO5 Circuit #1 Fan Step #3 Fan Off Fan On

DO6 Circuit #1 Fan Step #4 Fan Off Fan On

DO7 Circuit #2 Fan Step #1 Fan Off Fan On

DO8 Circuit #2 Fan Step #2 Fan Off Fan On

DO9 Circuit #2 Fan Step #3 Fan Off Fan On

DO10 Circuit #2 Fan Step #4 Fan Off Fan On

(Flashing= circuit

alarm)

OM 1051-2 15

Page 16

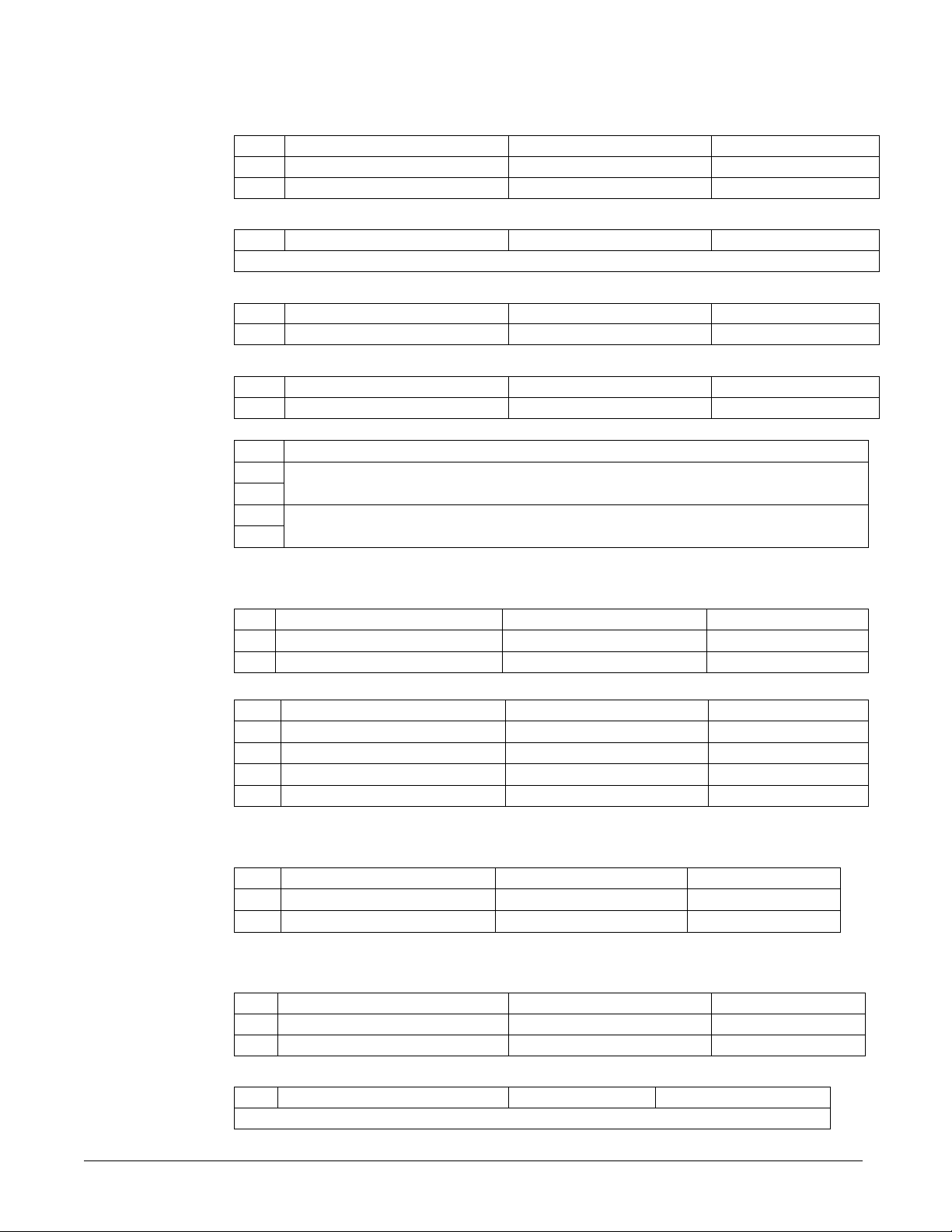

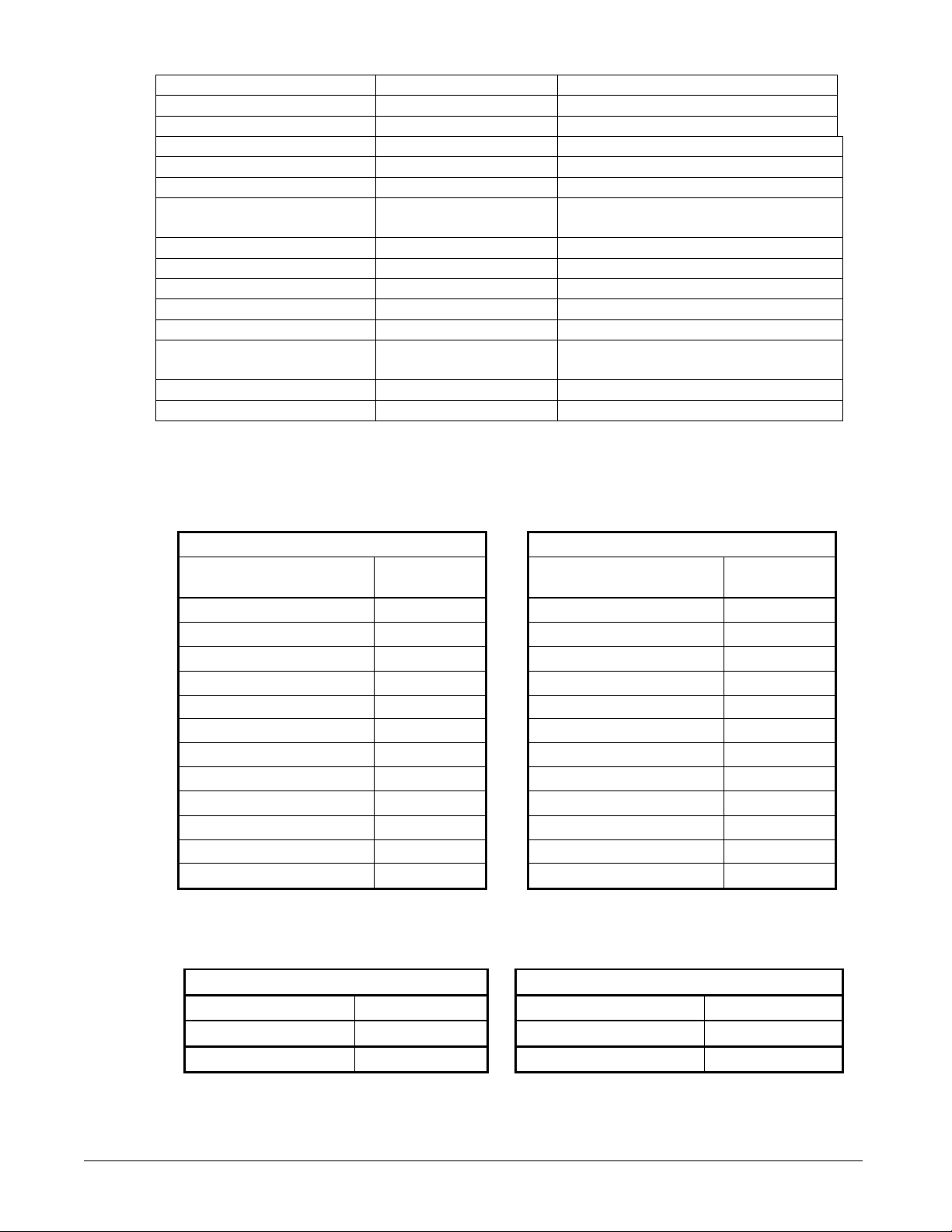

Expansion I/O Compressor #1 to #3

Analog Inputs

# Description Signal Source Expected Range

X1 Discharge Temperature NTC Thermister (10K@25°C) -50°C – 125°C

X2 Evaporator Pressure Ratiometric 0.5-4.5 Vdc -100 kPa to 700 kPa

X3 Oil Pressure Ratiometric 0.5-4.5 Vdc 0 kPa to 3000 kPa

X4 Condenser Pressure Ratiometric 0.5-4.5 Vdc 0 kPa to 3000 kPa

X7 Motor Temperature See note below

Note: European chillers will have the PTC thermistor in the compressor motor connected

to this input. X7 is configured as an NTC 10k input for European chillers.

Analog Outputs

# Description Output Signal Range

Not Needed

Digital Inputs

# Description Signal Off Signal On

X6 Starter Fault Fault No fault

X7 Motor Protection See note below

DI1 High Pressure Switch Fault No fault

Note: US chillers will use the motor protection board connected to this input. X7 is

configured as a digital input for US chillers.

Digital Outputs

Europe Configuration

# Description Output Off Output On

DO1 Start Compressor Compressor Off Compressor On

DO2 Economizer Solenoid Closed Solenoid Open

DO3 Non-modulating Slide Load/Unload Solenoid Closed Solenoid Open

DO4 Liquid Injection Solenoid Closed Solenoid Open

DO5 Modulating Slide Load Solenoid Closed Solenoid Open

DO6 Modulating Slide Unload Solenoid Closed Solenoid Open

X5 Modulating Slide “turbo” Solenoid Closed Solenoid Open

U.S. Configuration

# Description Output Off Output On

DO1 Start Compressor Compressor Off Compressor On

DO2 Economizer Solenoid Closed Solenoid Open

DO3 Non-modulating Slide Load Solenoid Closed Solenoid Open

DO4 Non-modulating Slide Unload Solenoid Closed Solenoid Open

DO5 Modulating Slide Load Solenoid Closed Solenoid Open

DO6 Modulating Slide Unload Solenoid Closed Solenoid Open

X5 Modulating Slide ‘Turbo’ Solenoid Closed Solenoid Open

X8 Liquid Injection Solenoid Closed Solenoid Open

16 OM 1051-2

Page 17

I/O EXV Circuit #1 to #3

Analog Inputs

# Description Signal Source Expected Range

X2 Suction Temperature NTC Thermister 10K@25°C) -50°C – 120°C

X3 Slide Position LVDT 4 to 20 mA 0% to 100%

Analog Outputs

# Description Output Signal Range

Not Needed

Digital Inputs

# Description Signal Off Signal On

DI1 Low Pressure switch Fault No fault

Digital Outputs

# Description Output Off Output On

DO1 Liquid Line Solenoid Closed Solenoid Open

Stepper Motor Output

# Description

M1+

M1-

M2+

M2-

EXV Stepper Coil 1

EXV Stepper Coil 2

Extension I/O Fan Module Circuit #1 & 2

Digital Inputs

# Description Output Off Output On

DI1 PVM/GFP Circuit #1 Fault No fault

DI2 PVM/GFP Circuit #2 Fault No fault

Digital Outputs

# Description Output Off Output On

DO1 Circuit #1 Fan Step #5 Fan Off Fan On

DO2 Circuit #1 Fan Step #6 Fan Off Fan On

DO3 Circuit #2 Fan Step #5 Fan Off Fan On

DO4 Circuit #2 Fan Step #6 Fan Off Fan On

Extension I/O Fan Module Circuit #3

Digital Outputs

# Description Output Off Output On

DO1 Circuit #3 Fan Step #5 Fan Off Fan On

DO2 Circuit #3 Fan Step #6 Fan Off Fan On

Extension I/O Unit Alarm & Limiting

Analog Inputs

# Description Signal Source Range

X3 Demand Limit 4-20 mA 1 to 23 mA

X4 Unit Current 4-20 mA 1 to 23 mA

Analog Outputs

# Description Output Signal Range

Not Needed

OM 1051-2 17

Page 18

Digital Inputs

# Description Signal Off Signal On

X1 External Alarm/Event

X2 Current Limit Enable No Limiting Limiting

X5 Circuit Switch #1 Circuit Off Circuit On

X6 Circuit Switch #2 Circuit Off Circuit On

X7 Circuit Switch #3 Circuit Off Circuit On

External Device

Failure

External Device OK

Digital Outputs

# Description Output Off Output On

DO1 Evaporator Water Pump #2 Pump Off Pump On

DO2 Open

DO3 Circuit #1 Alarm No Alarm Alarm

DO4 Circuit #2 Alarm No Alarm Alarm

DO5 Circuit #3 Alarm No Alarm Alarm

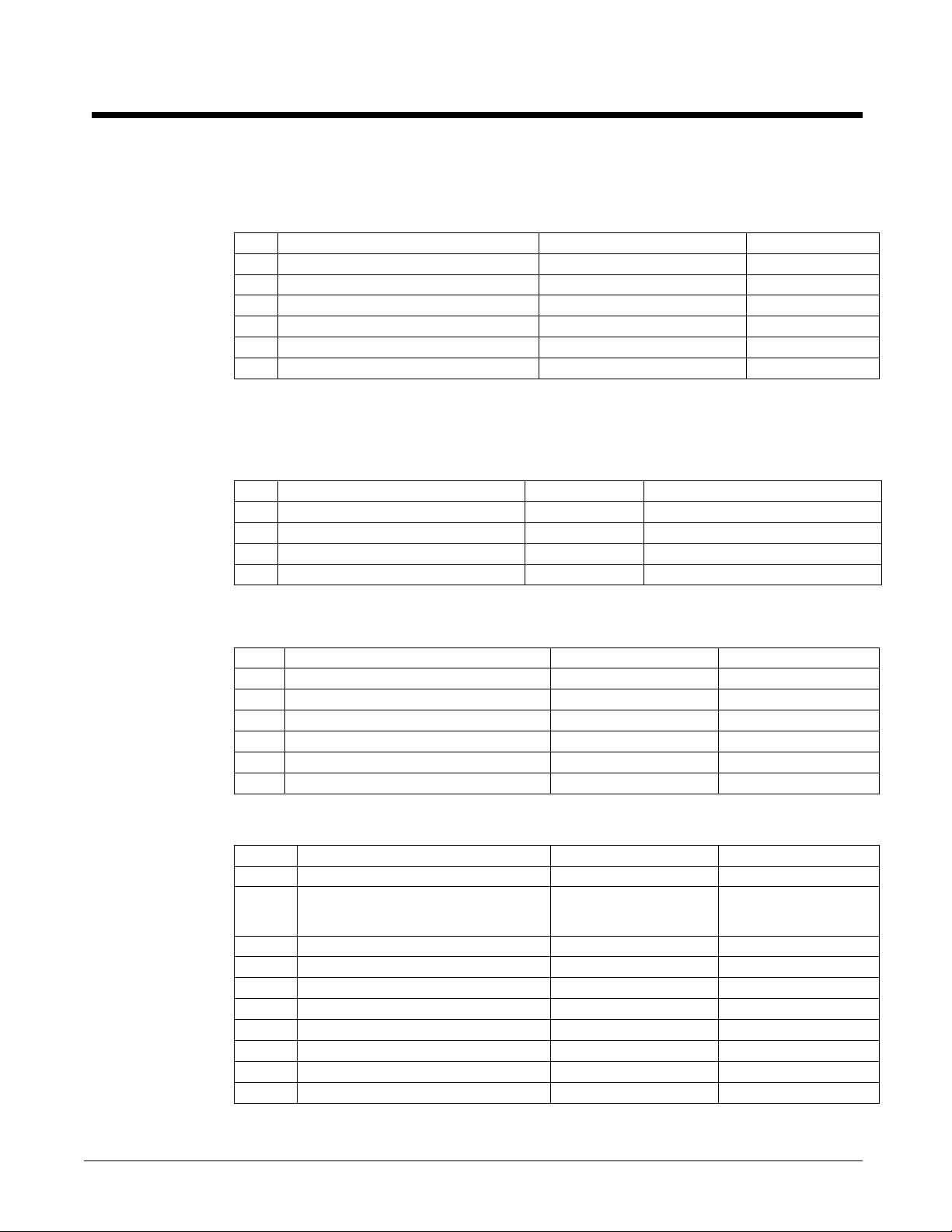

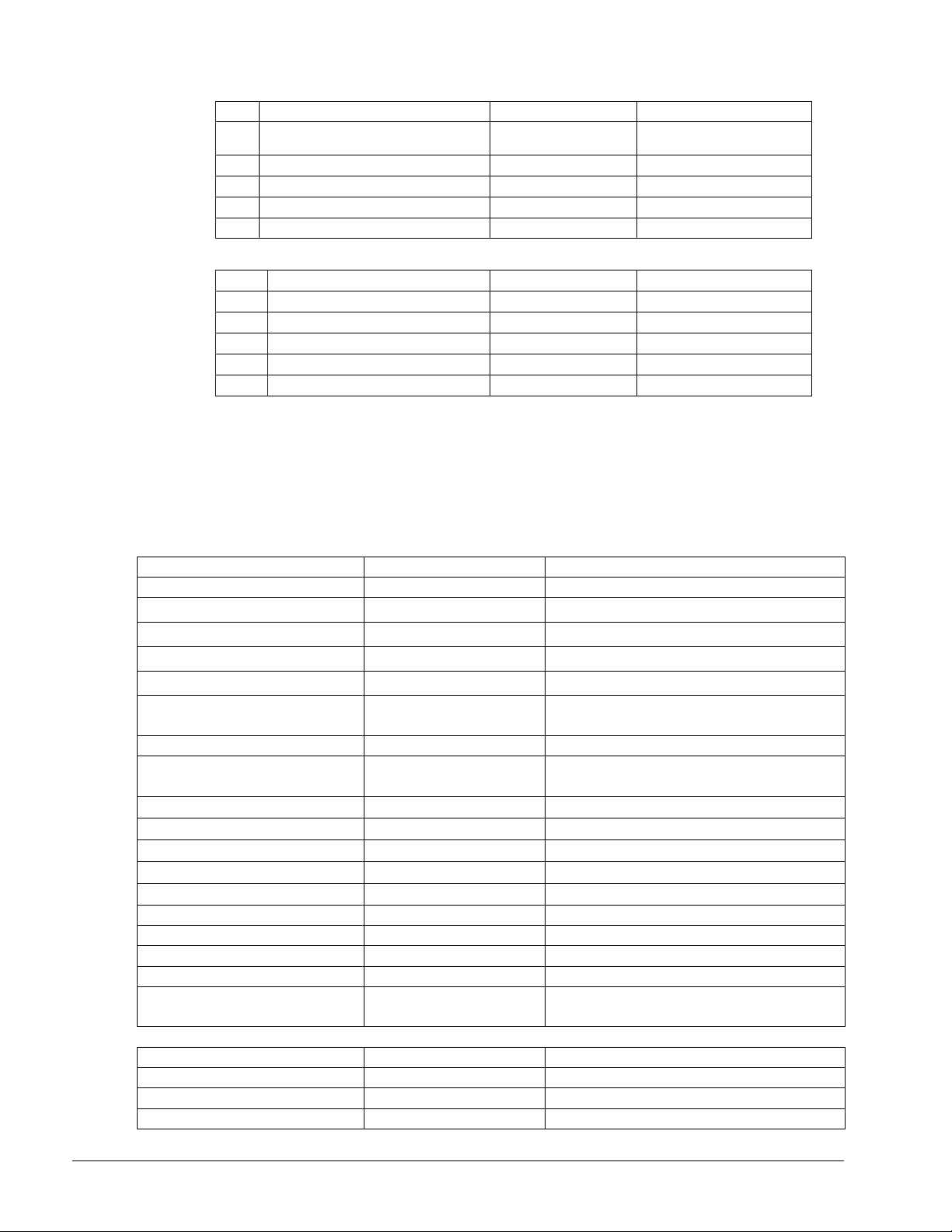

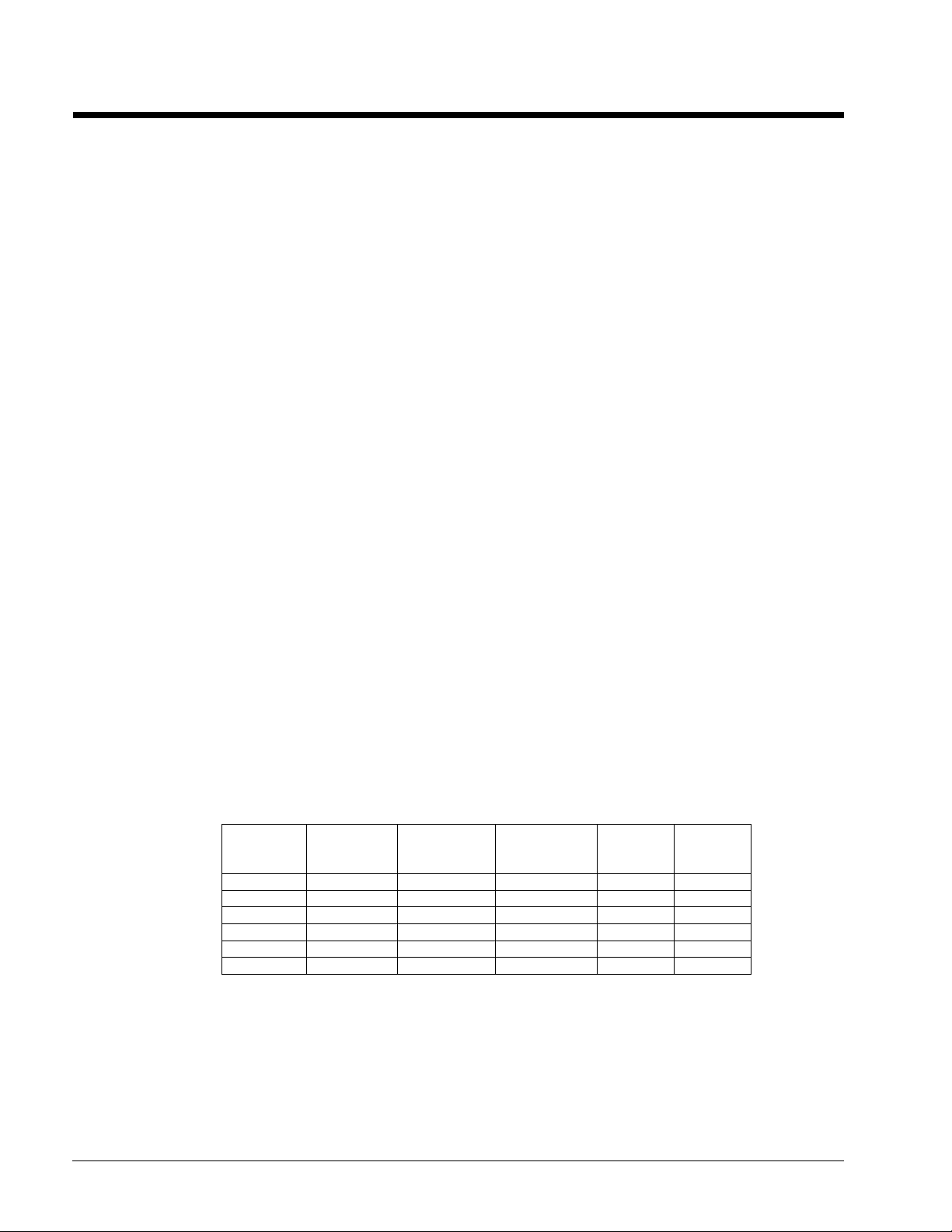

Setpoints

The following parameters are remembered during power off, are factory set to the Default value,

and can be adjusted to any value in the Range column.

Read and write access to these setpoint is determined by the Global HMI (Human Machine

Interface) Standard Specification.

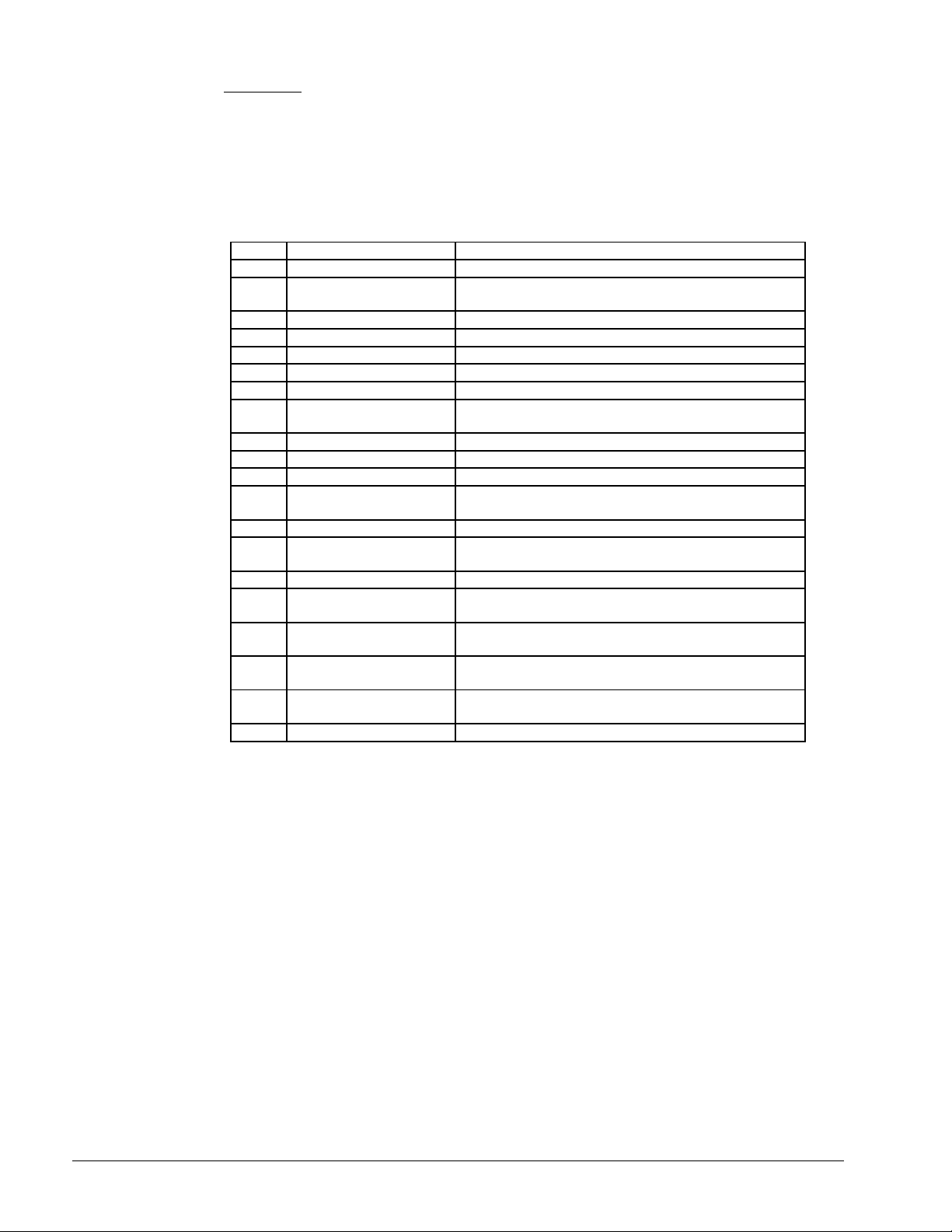

Table 1, Setpoint Default and Range

Description Default Range

Unit

Manufacturing Location

Frequency

Voltage

Unit Enable

Unit Status after Power

Failure

Not Selected

60 Hz

460 V

Enable

Not Selected, Europe, USA

50, 60

230, 380, 400, 460, 575

Disable, Enable

Enable Disable, Enable

Control source Local Local, Network

Available Modes Cool

Cool LWT 1

Cool LWT 2

Cool LWT 1 with Glycol

Cool LWT 2 with Glycol

Ice LWT

7.0°C (44.6°F)

7.0°C (44.6°F)

7.0°C (44.6°F)

7.0°C (44.6°F)

-4.0°C (24.8°F)

4.0°C to 15.0°C (39.2°F to 59.0°F)

4.0°C to 15.0°C (39.2°F to 59.0°F)

-4.0°C to 15.0°C (24.8°F to 59.0°F)

-4.0°C to 15.0°C (24.8°F to 59.0°F)

Cool, Cool w/Glycol

Cool/Ice w/Glycol, Ice, Test

-8.0°C to 4.0°C (17.6°F to 39.2°F)

Startup Delta T 2.7 deg C (4.9 deg F) 0 to 5.0 deg C (0 to 9.0 deg F)

Shut Down Delta T 1.5 deg C (2.7 deg F) 0 to 1.7 deg C (0 to 3.1 deg F)

Stage Up Delta T 0.5 deg C (0.9 deg F) 0 to 1.7 deg C (0 to 3.1 deg F)

Stage Down Delta T 0.7 deg C (1.3 deg F) 0 to 1.7 deg C (0 to 3.1 deg F)

Max Pulldown

1.7 deg C/min

(3.1 deg F/min)

0.3 to 2.7 deg C/min

(0.5 to 4.9 deg F/min)

Continued next page.

Description Default Range

Nominal Evap Delta T 2 Cir 5.6 deg C (10.1 deg F) 3.3 to 8.9 deg C (5.9 to 16.0 deg F)

Nominal Evap Delta T 3 Cir 5.6 deg C (10.1 deg F) 3.3 to 10 deg C (5.9 to 18.0 deg F)

Variable Evap Flow No No, Yes

18 OM 1051-2

Page 19

Evap Recirc Timer 30 sec 0 to 300 seconds

Pump Control #1 Only

#1 Only, #2 Only, Auto,

#1 Primary, #2 Primary

LWT Reset Type None None, 4-20mA, OAT

Max Reset 5.0 deg C (9.0 deg F) 0 to 10.0 deg C (0 to 18.0 deg F)

Start Reset Delta T 5.0 deg C (9.0 deg F) 0 to 10.0 deg C (0 to 18.0 deg F)

Max Reset OAT

Start Reset OAT

15.5°C (59.9°F)

23.8°C (74.8°F)

10.0°C to 30.0°C (50°F to 86.0 °F)

10.0°C to 30.0°C (50°F to 86.0 °F)

Soft Load Off Off, On

Begin Capacity Limit 40% 20-100%

Soft Load Ramp 20 min 1-60 minutes

Demand Limit Off Off, On

Current @ 20mA 800 A 0 to 2000 A

Current limit Setpoint 800 A 0 to 2000 A

# of Circuits 2 2, 3

Ice Delay Timer 12 hrs 1-23 hours

Clear Ice Timer No No, Yes

PVM Multi Point Single Point, Multi Point , None(SSS)

Noise Reduction Disabled Disabled, Enabled

Noise Reduction Start Time 21:00 18:00 – 23:59

Noise Reduction End Time 6:00 5:00 – 9:59

Noise Reduction Offset 5.0 deg C (9.0 deg F) 0 to 14.0 deg C (0 to 25.2 deg F)

Evap LWT Sensor Offset 0 deg C (0 deg F) -5.0 to 5.0 deg C (-9.0 to 9.0 deg F)

Evap EWT Sensor Offset 0 deg C (0 deg F) -5.0 to 5.0 deg C (-9.0 to 9.0 deg F)

OAT Sensor Offset 0 deg C (0 deg F) -5.0 to 5.0 deg C (-9.0 to 9.0 deg F)

Compressors-Global

Start-start timer 20 min 15-60 minutes

Stop-start timer 5 min 3-20 minutes

Pumpdown Pressure 100 kPa (14.5 psi) 70 to 280 kPa (10.2 to 40.6 psi)

Pumpdown Time Limit 120 sec 0 to 180 sec

Light Load Stage Down 40% 26 to 50%

High Load Stage Up 80% 50 to 100%

Stage Up Time 5 min 0 to 60 min

Stage Down Time 3 min 3 to 30 min

Stage Delay Clear No No, Yes

Soft Load Off Off, On

Max # Comps Running 2 2,3

Sequence # Cir 1 1 1-3

Sequence # Cir 2 1 1-3

Sequence # Cir 3 1 1-3

Liquid Injection Activation

85.0°C (185.0°F)

50.0°C to 110.0°C (122.0°C to 230.0°F)

Liq. Line Solenoid Valves No No, Yes

Slide Position Sensors Yes No, Yes

Continued next page.

OM 1051-2 19

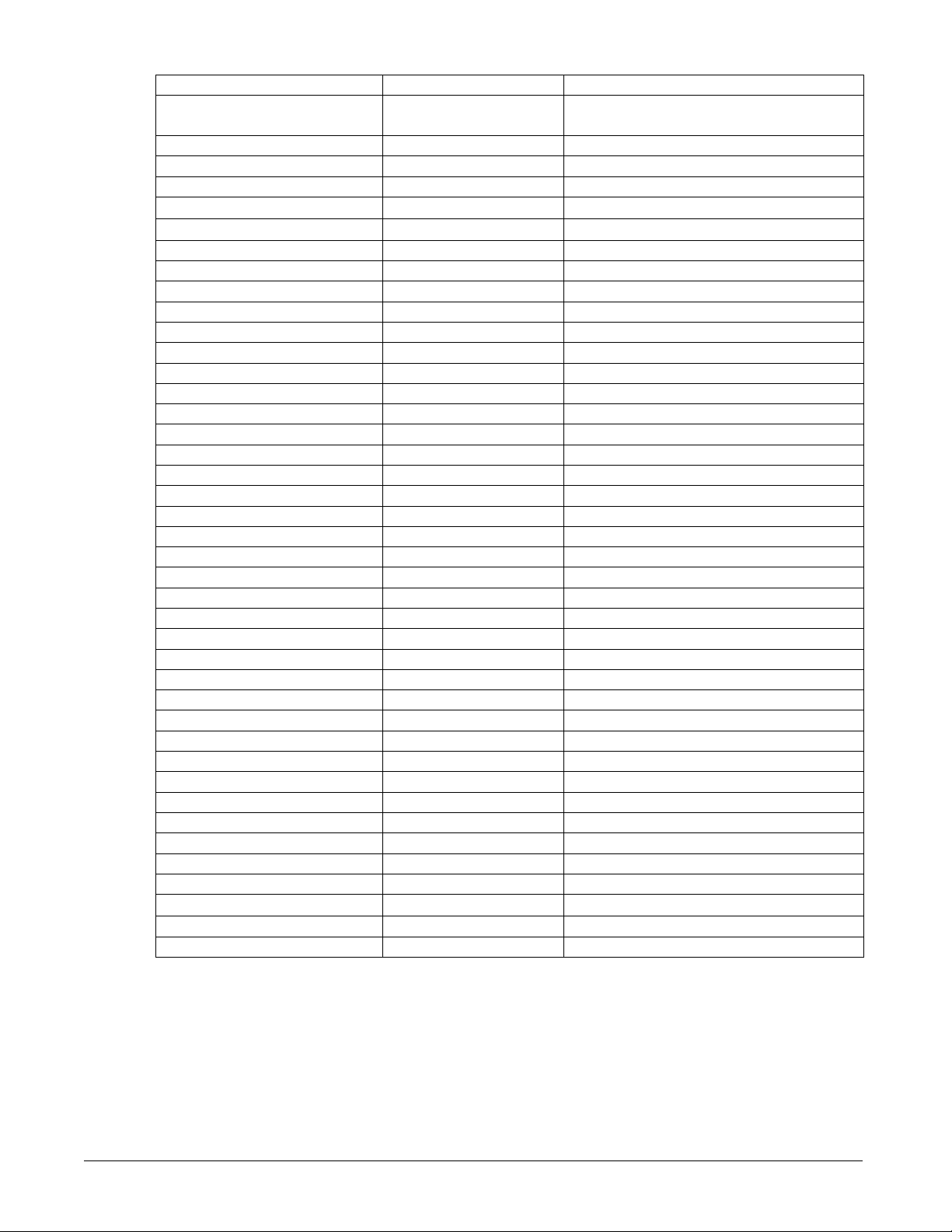

Page 20

Description Default Range

Alarm Limits

Low Pressure-Unload 160 kPa (23 psi) 160 kPa to 310 kPa (23 psi to 48 psi)

Low Pressure-Hold 180 kPa (26 psi) 180 kPa to 310 kPa (26 psi to 48 psi)

Low Press-Unload w/ Glycol 160 kPa (23 psi) 0 kPa to 310 kPa (0 psi to 48 psi)

Low Press-Hold w/Glycol 180 kPa (26 psi) 0 kPa to 310 kPa (0 psi to 48 psi)

High Oil Press Diff Delay 30 sec 10-180 sec

High Oil Press Differential 250 kPa (36 psi) 0 to 415 kPa (0 to 60 psi)

High Discharge Temperature 110.0°C (230.0°F) 65.0 to 110.0 °C (149.0 to 230.0°F)

High Cond Pressure Delay 5 sec 0 to 30 sec

Low Pressure Ratio Delay 90 sec 0 to 180 sec

Start Time Limit 60 sec 20 to 180 sec

Evap. Water Freeze

Evap. Water Freeze w/ Glycol

2.2°C (36.0°F)

2.2°C (36.0°F)

1.1°C to 6.0°C (34.0°F to 42.8°F)

-18.0°C to 6.0°C (-0.4°F to 42.8°F)

Evaporator Flow Proof 15 sec 5 to 15 sec

Recirculate Timeout 3 min 1 to 10 min

Low OAT Lockout

Low OAT Lockout/with

Fan VFD

12.0°C (53.6°F)

12.0°C (53.6°F)

2.0°C to 15.0°C (35.6°F to 59.0°F)

-23.0°C to 15.0°C (-9.4°F to 59.0°F)

The following setpoints exist individually for each circuit:

Description

Default Range

Circuit mode Enable Disable, enable, test

Compressor Size for Non-VFD HSA204

Compressor Size for VFD HSV204

HSA192, HSA204, HSA215

HSA232, HSA241, HSA263

HSV204, HSV215

HSV232, HSV241, HSV263

Economizer (VFD Only) With With, Without

Capacity Control Auto Auto, Manual

Manual Capacity See Note 1 0 to 100%

Clear Cycle Timers No No, Yes

EXV control Auto Auto, manual

Service Pumpdown No No, Yes

Economizer Enable Capacity

(VFD Model Only)

40% 40 to 75%

Evap pressure Sensor offset 0 kPa (0 psi) -100 to 100 kPa (-14.5 to 14.5 psi)

Cond pressure Sensor offset 0 kPa (0 psi) -100 to 100 kPa (-14.5 to 14.5 psi)

Oil pressure Sensor Offset 0 kPa (0 psi) -100 to 100 kPa (-14.5 to 14.5 psi)

Suction temp Sensor Offset 0 deg C (0 deg F) -5.0 to 5.0 deg C (-9.0 to 9.0 deg F)

Discharge temp offset 0 deg C (0 deg F) -5.0 to 5.0 deg C (-9.0 to 9.0 deg F)

Slide sensor mA @ minimum

Slide sensor mA @ maximum

4 mA 4 to 22 mA

20 mA 4 to 22 mA

Fans

Fan VFD enable Enable Disable, Enable

Number of fans 5 5 to 12

Saturated Condenser Temp

Target Min

Saturated Condenser Temp

Target Max

32.0°C (89.6°F)

43.0°C (109.4°F)

20.0°C to 50.0°C (68.0°F to

122.0°F)

32.0°C to 50.0°C (89.6°F to

122.0°F)

Continued next page.

20 OM 1051-2

Page 21

Description Default Range

Fan Stage 0 Up Deadband 2.5 deg C (4.5 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 1 Up Deadband 2.5 deg C (4.5 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 2 Up Deadband 4.0 deg C (7.2 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 3 Up Deadband 5.0 deg C (9.0 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 4 Up Deadband 4.0 deg C (7.2 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 5 to 12

Up Deadband

4.0 deg C (7.2 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 1 Down Deadband 10.0 deg C (18.0 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 2 Down Deadband 4.0 deg C (7.2 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 3 Down Deadband 3.5 deg C (6.3 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 4 Down Deadband 3.0 deg C (5.4 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 5 Down Deadband 2.5 deg C (4.5 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan Stage 6 to 12

Down Deadband

2.5 deg C (4.5 deg F) 1.0 to 10.0 deg C (1.8 to 18 deg F)

Fan VFD Max Speed 100% 90 to 110%

Fan VFD Min Speed 25% 20 to 60%

Dynamic Default Values

The fan staging dead bands have different default values based on the VFD enable setpoint.

When the VFD enable setpoint is changed, a set of default values for the fan staging dead bands

is loaded as follows:

Fan VFD is Enabled

Setpoint

Default

loaded (oF)

Stage 0 On Deadband 4.5 Stage 0 On Deadband 7.2

Stage 1 On Deadband 4.5 Stage 1 On Deadband 9.0

Stage 2 On Deadband 7.2 Stage 2 On Deadband 9.9

Stage 3 On Deadband 9.0 Stage 3 On Deadband 10.8

Stage 4 On Deadband 7.2 Stage 4 On Deadband 11.7

Stage 5 On Deadband 7.2 Stage 5 On Deadband 11.7

Stage 2 Off Deadband 7.2 Stage 2 Off Deadband 18

Stage 3 Off Deadband 6.3 Stage 3 Off Deadband 14.4

Stage 4 Off Deadband 5.4 Stage 4 Off Deadband 9.9

Stage 5 Off Deadband 4.5 Stage 5 Off Deadband 7.2

Stage 6 Off Deadband 4.5 Stage 6 Off Deadband 7.2

The low pressure settings have different default values based on the Manufacturing Location

setpoint. When the manufacturing location is configured, the default values for these setting are

loaded as shown below:

US Chiller

Setpoint Default loaded

Low Evap Press.Unload 160 kPa (23.2 psi) Low Evap Press. Unload 160 kPa (23.2 psi)

Low Evap Press.-Hold 180 kPa (26.1 psi) Low Evap Pressure-Hold 180 kPa (26.1 psi)

Fan VFD is Disabled

Setpoint

Default

loaded (oF)

European Chiller

Setpoint Default loaded

OM 1051-2 21

Page 22

Unit Functions

Calculations

EWT Slope

EWT slope is calculated such that the slope represents the change in EWT over a time frame

of one minute.

Pulldown Rate

The slope value calculated above will be a negative value as the water temperature is

dropping. A pulldown rate is calculated by inverting the slope value and limiting to a

minimum value of 0°C/min.

Unit Availability

The unit is available to start if the following conditions are true:

1. Unit switch is closed

2. If unit mode is ice and the ice timer has timed out.

3. No unit alarms exist

4. Emergency stop input is closed

5. At least one circuit is enabled

6. Unit enable setpoint is Enable

7. If remote control is connected and remote unit switch is closed

8. If Control Source = Network, BAS Enable = True

Enabling and disabling the chiller is accomplished using setpoints and inputs to the chiller.

The unit switch, remote switch input, and Unit Enable Setpoint all are required to be on for

the unit to be enabled when the control source is set to local. The same is true if the control

source is set to network, with the additional requirement that the BAS request must be on.

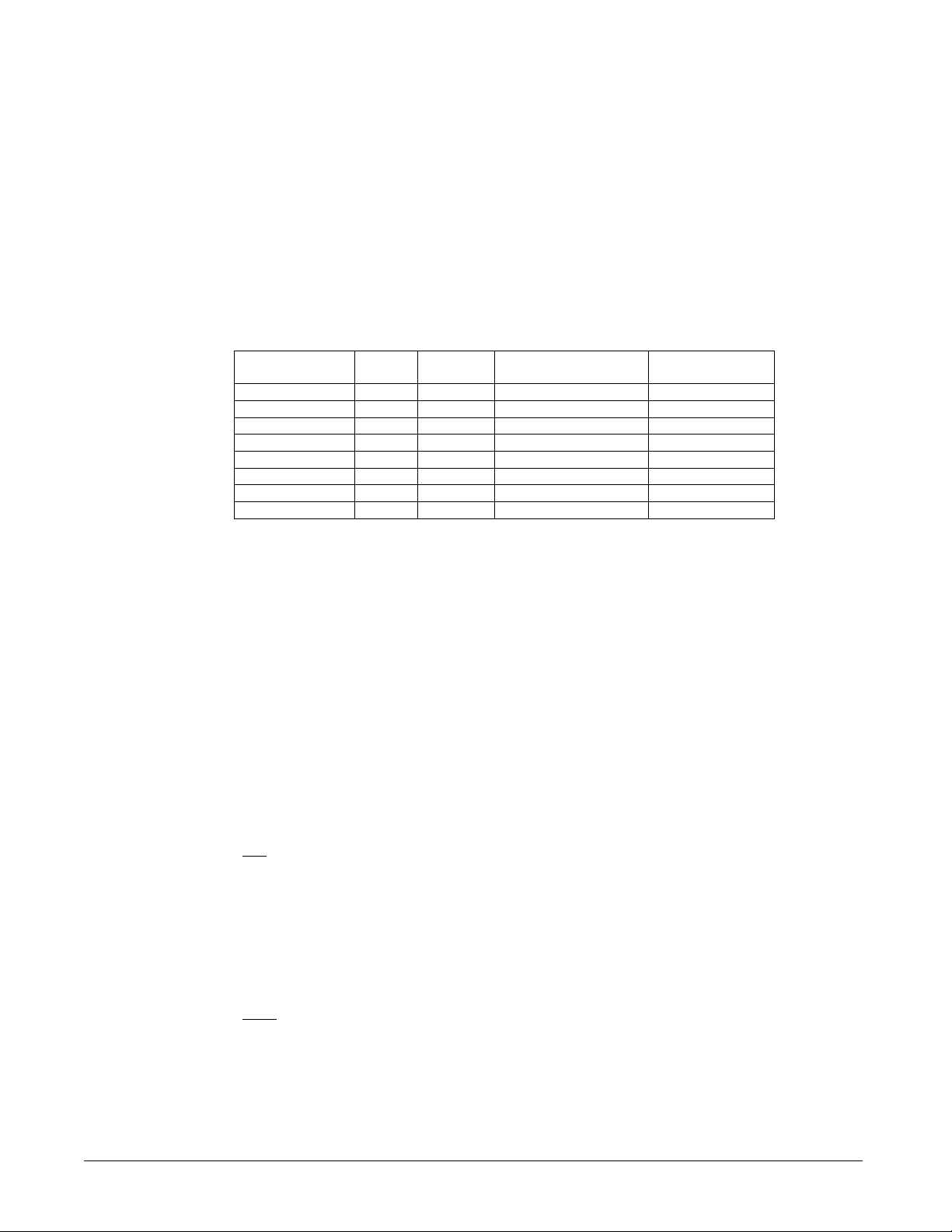

Unit is enabled according to the following table.

NOTE: An x indicates that the value is ignored.

Table 2, Enable Combinations

Unit

Switch

Off x x x x Off

x x Off x x Off

x x x Off x Off

On Local On On x On

x Network x x Off Off

On Network On On On On

Control

Source

Setpoint

Remote

Switch Input

Unit Enable

Setpoint

BAS

Request

Unit

Enable

All of the methods for disabling the chiller, discussed in this section, will cause a normal

shutdown (pumpdown) of any running circuits.

When the controller is powered up, the Unit Enable Setpoint will be initialized to ‘Disable’ if

the Unit Enable Init Setpoint is set to ‘Disable’.

.

22 OM 1051-2

Page 23

Unit Mode Selection

The operating mode of the unit is determined by setpoints and inputs to the chiller. The

Available Modes Setpoint determines what modes of operation can be used. This setpoint

also determines whether the unit is configured for glycol use. The Control Source Setpoint

determines where a command to change modes will come from. A digital input switches

between cool mode and ice mode if they are available and the control source is set to local.

The BAS mode request switches between cool mode and ice mode if they are both available

and the control source is set to network.

The Available Modes Setpoint must only be changed when the unit switch is off. This is to

avoid changing modes of operation inadvertently while the chiller is running.

Unit Mode is set according to the following table.

Table 3, Mode Combinations

Control Source

Setpoint

x x x Cool Cool

x x x Cool w/Glycol Cool

Local Off x Cool/Ice w/Glycol Cool

Local On x Cool/Ice w/Glycol Ice

Network x Cool Cool/Ice w/Glycol Cool

Network x Ice Cool/Ice w/Glycol Ice

x x x Ice w/Glycol Ice

x x x Test Test

Notes

1. “x” Indicates that the value is ignored.

2. If the Available Modes Setpoint is set to an option ‘w/Glycol’, then glycol operation should be

enabled for the unit. Glycol operation should only be disabled when the Available Modes

Setpoint is set to ‘Cool’.

Mode

Input

BAS

Request

Available Modes

Setpoint

Unit Mode

Glycol Configuration

If the Available Modes Setpoint is set to an option w/Glycol, then glycol operation is

enabled for the unit. Glycol operation must be disabled only when the Available Modes

Setpoint is set to Cool.

Unit Control States

The unit will always be in one of three states:

• Off – Unit is not enabled to run.

• Auto – Unit is enabled to run.

• Pumpdown – Unit is doing a normal shutdown.

Off. The unit should be in the Off state if any of the following are true:

• A unit alarm is active

• All circuits are unavailable to start (cannot start even after cycle timers have expired)

• The unit mode is ice, all circuits are off, and the ice mode delay is active

• Manufacturing Location is not set

• Either manufacturing location or number of circuits have been changed and controller

has not been rebooted

Auto. The unit should be in the Auto state if all of the following are true:

• Manufacturing location is set and controller has been rebooted

• Unit enabled based on settings and switches

• If unit mode is ice, the ice timer has expired

• No unit alarms are active

• At least one circuit is enabled and available to start

OM 1051-2 23

Page 24

Pumpdown. The unit should be in Pumpdown until all running compressors finish

pumping down if any of the following are true:

• Unit is disabled via settings and/or inputs in section Unit Availability.

• Unit pumpdown alarm is triggered

Unit Status

The displayed unit status is determined by the conditions in the following table:

Table 4, Unit Status

Enum

0 Auto Unit State = Auto

1 Off: Ice Mode Tmr

2 Off: OAT Lockout Unit State = Off and Low OAT Lockout is active

3 Off: All Cir Disabled Unit State = Off and all compressors unavailable

4 Off: Unit Alarm Unit State = Off and Unit Alarm active

5 Off: Keypad Disable Unit State = Off and Unit Enable Setpoint = Disable

6 Off: Remote Sw Unit State = Off and Remote Switch is open

7 Off: BAS Disable

8 Off: Unit Sw Unit State = Off and Unit Switch = Disable

9 Off: Test Mode Unit State = Off and Unit Mode = Test

10 Auto: Noise Reduction Unit State = Auto and Noise Reduction is active

11 Auto: Wait for Load

12 Auto: Evap Recirc Unit State = Auto and Evaporator State = Start

13 Auto: Wait for flow

14 Auto: Pumpdn Unit State = Pumpdown

15 Auto: Max Pulldn

16 Auto: Unit Cap Limit

17 Auto: Current Limit

18 Off. Cfg Chg, Rst Ctlr

19 Off Mfg Loc Not Set Mfg Location is not set

Status Conditions

Unit State = Off, Unit Mode = Ice, and Ice Delay =

Active

Unit State = Off, Control Source = Network, and BAS

Enable = false

Unit State = Auto, no circuits running, and LWT is

less than the active setpoint + startup delta

Unit State = Auto, Evaporator State = Start, and Flow

Switch is open

Unit State = Auto, max pulldown rate has been met or

exceeded

Unit State = Auto, unit capacity limit has been met or

exceeded

Unit State = Auto, unit current limit has been met or

exceeded

Unit configuration setpoint has changed, and reboot

of controller is required

Ice Mode Start Delay

Compressor Staging in Ice Mode

The first compressor will start when evaporator LWT is higher than the target plus the

Startup Delta T setpoint.

When at least one compressor is running, the other compressors will start only when

evaporator LWT is higher than the target plus the Stage Up Delta T setpoint.

All compressors will be staged off when evaporator LWT is less than the target.

Stage Up Delay

A fixed stage up delay of one minute between compressor starts is used in this mode.

When at least one compressor is running, the other compressors will start as quickly as

possible with respect to the stage up delay.

An adjustable start-to-start ice delay timer will limit the frequency with which the chiller

may start in Ice mode. The timer starts when the first compressor starts while the unit is

in ice mode. While this timer is active, the chiller cannot restart in Ice mode. The time

delay is user adjustable.

24 OM 1051-2

Page 25

The ice delay timer may be manually cleared to force a restart in ice mode. A setpoint

specifically for clearing the ice mode delay is available. In addition, cycling the power to

the controller will clear the ice delay timer.

Evaporator Pump Control

State

Three evaporator pump control states for control of the evaporator pumps:

• Off - No pump on.

• Start – Pump is on, water loop is being recirculated. Recirc timer runnning

• Run – Pump is on, water loop has been recirculated. Recirc timer has timed out

Off The control state is Off when all of the following are true:

• Unit state is Off

• LWT is higher than the Evap Freeze setpoint or LWT sensor fault is active

• EWT is higher than the Evap Freeze setpoint or EWT sensor fault is active

Start. The control state is Start when any of the following are true:

• The unit state is auto

• LWT is less than the Evap Freeze setpoint and LWT sensor fault isn’t active

• EWT is less than the Evap Freeze setpoint and EWT sensor fault isn’t active

Run. The control state is Run when

• The flow switch input has been closed for a time greater than the Evaporator

Recirculate setpoint.

• The flow switch fault is not active

Pump Selection

The pump output used is determined by the Evap Pump Control setpoint. This setting

allows the following configurations:

• #1 only – Pump 1 will always be used

• #2 only – Pump 2 will always be used

• Auto – The primary pump is the one with the least run hours, the other is used as

a backup

• #1 Primary – Pump 1 is used normally, with pump 2 as a backup

• #2 Primary – Pump 2 is used normally, with pump 1 as a backup

Primary/Standby Pump Staging

The standby pump will be on if either of the following are true:

• Pump state is Run and the flow switch is open for Evap Proof Time/2

• Pump start is start and Recirculate timeout has expired.

Auto Control

If auto pump control is selected, the primary/standby logic above is still used. When the

evaporator is not in the run state, the run hours of the pumps will be compared. The

pump with the least hours will be designated as the primary at this time.

Noise Reduction

Noise Reduction is an operating mode designed to reduce unit sound levels by decreasing

compressor and fan operating time. It is used during the night when the cooling load is

usually reduced and the ambient temperature is lower.

Noise Reduction always requires the Noise Reduction setpoint to be set to ‘enable’. If it

is set to ‘disable’, it will not activate for any reason.

Assuming this functionality is enabled, there are two ways it can become active:

OM 1051-2 25

Page 26

• If the unit mode is cool, and the unit controller clock time is between the Noise

Reduction start time and end time

• Control Source setpoint is set to network, and the BAS command is ‘enable’

When Noise Reduction is active, the Maximum Reset is applied to the cool LWT

setpoint. However, if any reset type is selected, that reset will continue to be used rather

than the Maximum Reset. Also, the saturated condenser target for each circuit will be

offset by the Noise Reduction Condenser Target Offset.

Leaving Water Temperature (LWT) Reset

LWT Target

The LWT Target varies based on settings and inputs and is selected as follows:

Table 5, Leaving Water Temperature Targets

Control Source

Setpoint

Local

Network X X

Local

Network X X

Local

Network

Local x x Ice Setpoint

Network x x

Mode

Input

OFF X Cool Setpoint 1

ON X Cool Setpoint 2

OFF X Cool Setpoint 1

ON X Cool Setpoint 2

OFF x Cool Setpoint 1

ON x Ice Setpoint

x COOL BAS Cool Setpoint

x ICE

BAS

Request

Available Modes

Setpoint

COOL

COOL w/Glycol

COOL/ICE w/Glycol

ICE w/Glycol

Base LWT Target

BAS Cool Setpoint

BAS Cool Setpoint

BAS Ice Setpoint

BAS Ice Setpoint

Leaving Water Temperature (LWT) Reset

The base LWT target may be reset if the unit is in Cool mode and it is configured for a

reset. The type of reset to be used is determined by the LWT Reset Type setpoint.

When the active reset increases, the Active LWT Target is changed at a rate of

0.2 degrees F every 10 seconds. When the active reset decreases, the Active LWT Target

is changed all at once.

After resets are applied, the LWT target can never exceed a value of 60°F.

Reset Type – None

The Active Leaving Water variable is set equal to the current LWT setpoint.

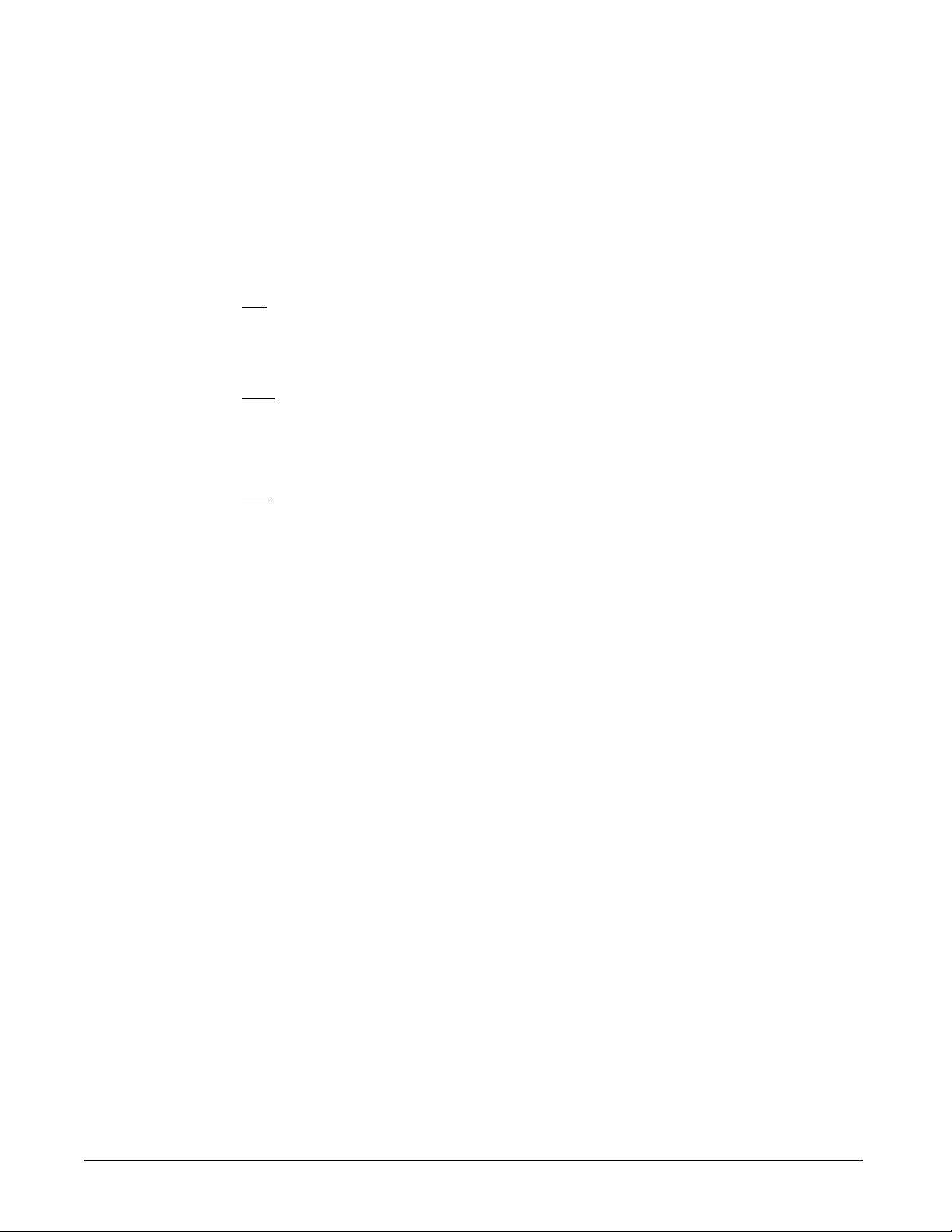

Reset Type – Return Chilled Water

The Active Leaving Water variable is adjusted by the return water temperature.

Return Reset

LWT set Point+Max Reset

Active

LWT

(oF)

(54)

Max Reset

(10)

LWT Set Point

(44)

0

Evap Delta T (oF)

Start Reset Delta T

26 OM 1051-2

Page 27

The active setpoint is reset using the following parameters:

1. Cool LWT setpoint

2. Max Reset setpoint

3. Start Reset Delta T setpoint

4. Evap Delta T

Reset varies from 0 to Max Reset setpoint as the Evaporator EWT – LWT (Evap delta t)

varies from the Start Reset Delta T set-point to 0.

4-20 mA External Signal Reset

The Active Leaving Water variable is adjusted by the 4 to 20 mA reset analog input.

Parameters used:

1. Cool LWT setpoint

2. Max Reset setpoint

3. LWT Reset signal

Reset is 0 if the reset signal is less than or equal to 4 mA. Reset is equal to the Max Reset

Delta T setpoint if the reset signal equals or exceeds 20 mA. The amount of reset will

vary linearly between these extremes if the reset signal is between 4 mA and 20 mA. An

example of the operation of 4-20 reset in Cool mode follows.

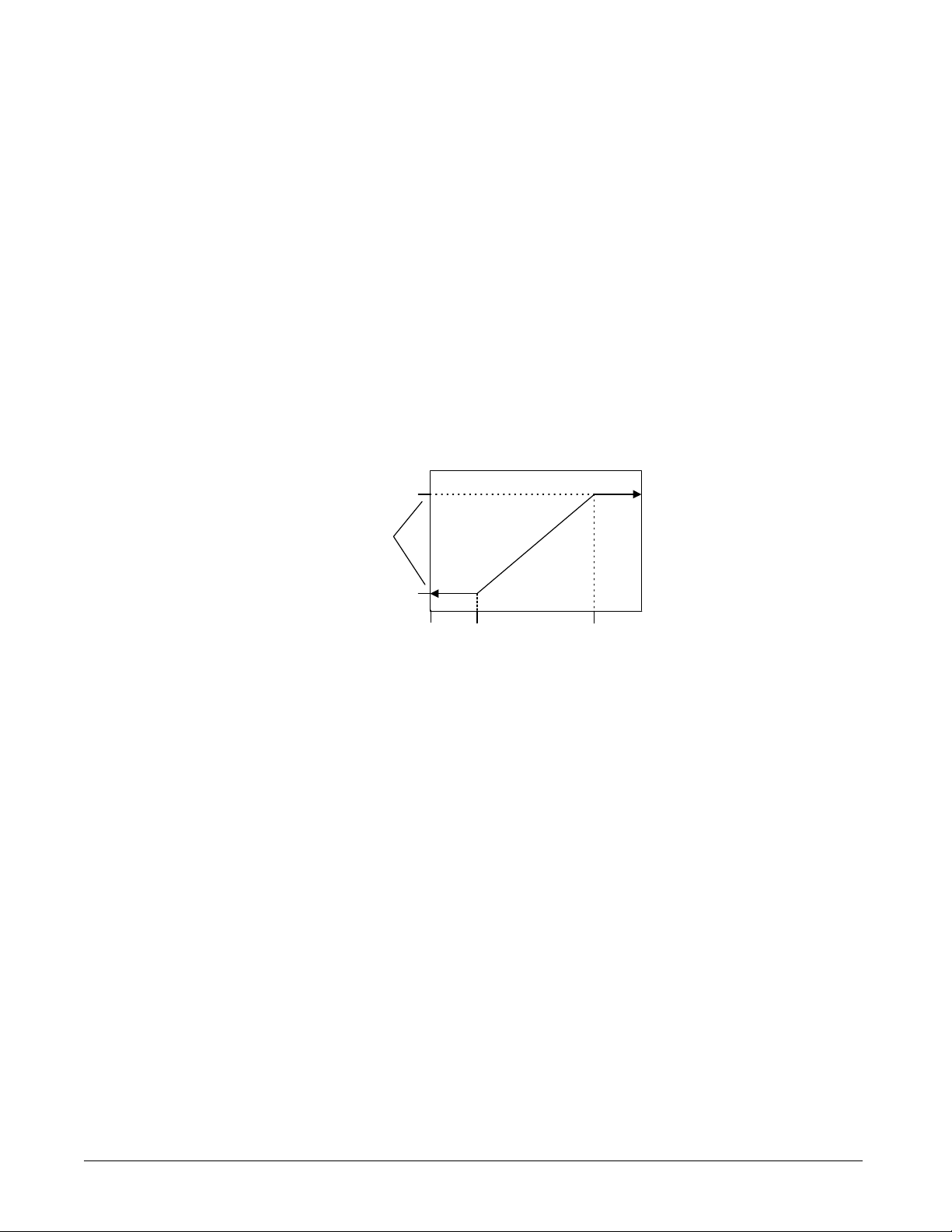

4-20 mA Reset - Cool Mode

(54)

Active

LWT

(oF)

Max Reset

(10)

Cool LWT Set

Point (44)

4

0

Reset Signal (mA)

20

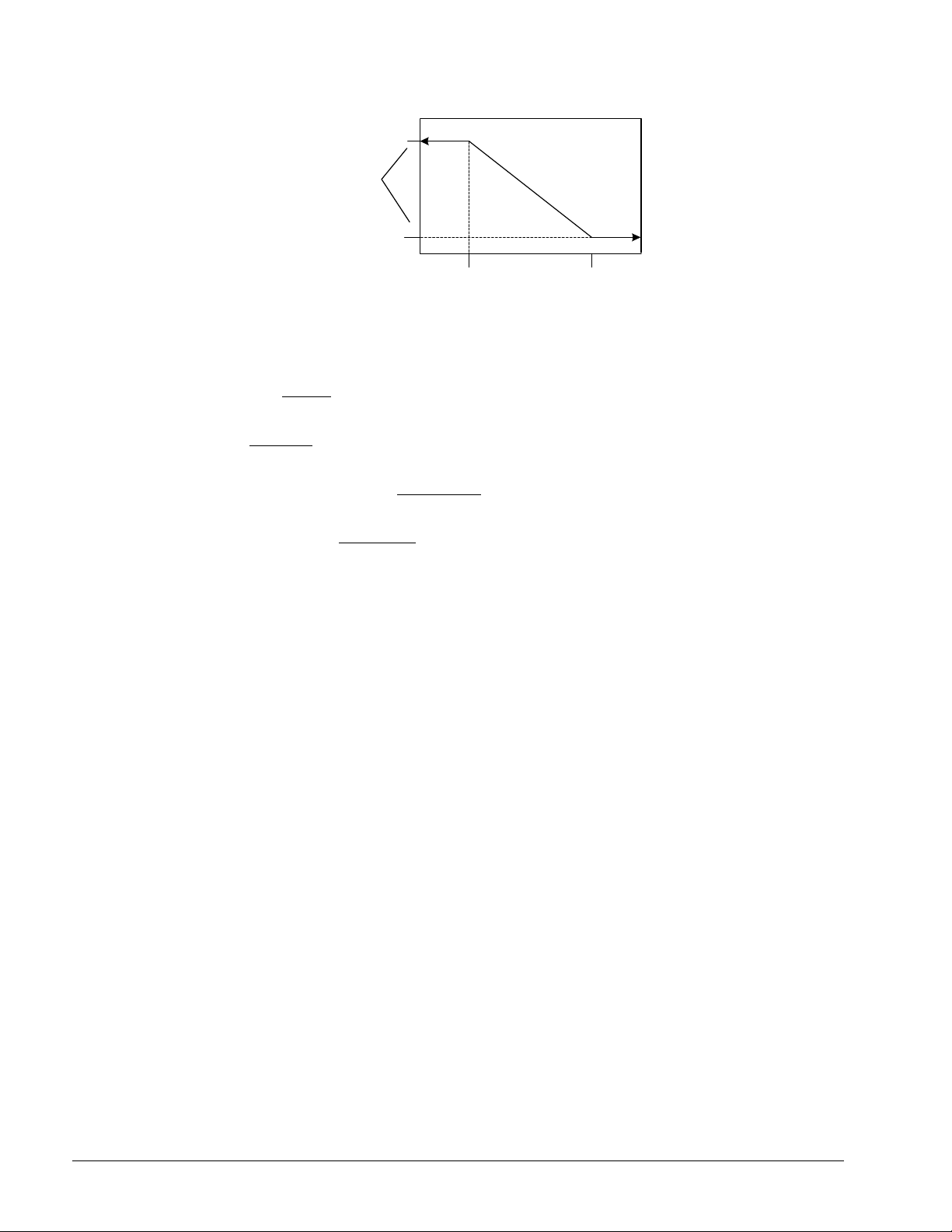

Outside Air Temperature (OAT) Reset

The Active Leaving Water variable is reset based on the outdoor ambient temperature.

Parameters used:

1. Cool LWT setpoint

2. Max Reset setpoint

3. Start Reset OAT setpoint

4. Max Reset OAT setpoint

5. OAT

Reset is 0 if the outdoor ambient temperature is greater than Start Reset OAT setpoint.

From Start Reset OAT setpoint down to Max Reset OAT the reset varies linearly from no

reset to the max reset at Max Reset OAT setpoint. At ambient temperatures less than

Max Reset OAT setpoint, reset is equal to the Max Reset setpoint.

OM 1051-2 27

Page 28

Cool LWT+Max Reset

(54)

OAT Reset

Active

LWT

(oF)

Max Reset

(10)

Cool LWT Set-Point

(44)

60

OAT (oF)

75

Unit Capacity Control

Compressor Staging in Cool Mode

The first compressor on the unit is started when evaporator LWT is higher than the target

plus the Startup Delta T setpoint.

An additional compressor is started when Evaporator LWT is higher than the target plus

the Stage Up Delta T setpoint.

When multiple compressors are running, one will shut down if evaporator LWT is lower

than the target minus the Stage Down Delta T setpoint.

All running compressors will shut down when the evaporator LWT is lower than the

target minus the Shut Down Delta T setpoint.

Stage Up Delay

A minimum amount of time will pass between compressors starting, which is defined by

the Stage Up Delay setpoint. This delay will only apply when at least one compressor is

running. If the first compressor starts and quickly fails on an alarm, another compressor

will start without this minimum time passing.

Required Load for Stage Up

An additional compressor will not be started until all running compressors are at a

capacity higher than the Load Stage Up setpoint, or running in a limited state.

Light Load Stage Down

When multiple compressors are running, one will shut down if all running compressors

are at a capacity lower than the Load Stage Down setpoint and the evaporator LWT is less

than the target plus the Stage Up Delta T setpoint. A minimum amount of time will pass

between compressors stopping as a result of this logic, which is defined by the Stage

Down Delay setpoint.

Light Load Shut Down

When the following conditions are met, the last compressor running on the chiller will be

shut down:

• One compressor running

• Evaporator Delta T < 0.25*(Nominal Evap Delta T Setpoint/Number of Circuit

Setpoint) for longer than five minutes

• Variable Evap Flow Setpoint = No

Maximum Circuits Running

If the number of compressors running is equal to the Max Circuits Running setpoint, no

additional compressors will be started.

When multiple compressors are running, one will shut down if the number of

compressors running is more than the Max Circuits Running setpoint.

28 OM 1051-2

Page 29

Staging Sequence

This section defines which compressor is the next one to start or stop. In general,

compressors with fewer starts will normally start first, and compressors with more run

hours will normally stop first. Compressor staging sequence can also be determined by an

operator defined sequence via setpoints.

Next To Start

The next compressor to start must meet the following requirements:

Lowest sequence number of those compressors available to start

• -if sequence numbers are equal, it must have the least starts

• -if starts are equal, it must have least run hours

• -if run hours are equal, it must be the lowest numbered compressor

Next To Stop

The next compressor to shut down must meet the following requirements:

Lowest sequence number of the compressors that are running

• -if sequence numbers are equal, it must have the most run hours

• -if run hours are equal, it must have the fewest starts

• -if starts are equal, it must be the lowest numbered compressor

Compressor Capacity Control in Cool Mode

In Cool mode, evaporator LWT is controlled to a temperature within a calculated

variation range of the target under constant flow conditions by controlling capacity of the

individual compressors. The allowed variation is plus or minus 4% of nominal

evaporator delta t.

Compressors are loaded with a fixed step scheme. The rate of capacity adjustment is

determined by the time between capacity changes. The farther away from the target, the

faster compressors will be loaded or unloaded.

The logic projects ahead to avoid overshoot, such that the overshoot does not cause the

unit to shut off due to evaporator LWT dropping below the target minus the Shutdown

Delta T setpoint while there is still a load on the loop at least equal to the minimum unit

capacity.

Capacity of the compressors is controlled so that when possible their capacities are

balanced.

Circuits that are running in manual capacity control or running with active capacity

limiting events are not considered in the capacity control logic.

The compressor capacities are adjusted one at a time while maintaining a capacity

imbalance that does not exceed 12.5%.

Load/Unload Sequence

This section defines which compressor is the next one to load or unload.

Next To Load

The next compressor to load meets the following requirements:

Lowest capacity of the running compressors that can load up

• if capacities are equal, it must have the lowest sequence number of the compressors

that are running

• if the sequence numbers are equal, it must have the least starts

• if run starts are equal, it must have the least hours

• if starts hours are equal, it must be the lowest numbered compressor

OM 1051-2 29

Page 30

Next To Unload

The next compressor to unload must meet the following requirements:

Highest capacity of the running compressors

• if capacities are equal, it must have the lowest sequence number of the compressors

that are running

• if sequence numbers are equal, it must have the most run hours

• if run hours are equal, it must have the least starts

• if starts are equal, it must be the lowest numbered compressor

Compressor Capacity Control in Ice Mode

In Ice mode, running compressors are loaded up simultaneously at the maximum possible

rate that allows for stable operation of the individual circuits.

Unit Capacity Overrides

Unit capacity limits are used to limit total unit capacity in Cool mode only. Multiple

limits may be active at any time, and the lowest limit is always used in the unit capacity

control.

Soft load, demand limit, and network limit use a deadband around the actual limit value,

such that unit capacity increase is not allowed within this deadband. If unit capacity is

above the deadband, capacity is decreased until it is back within the deadband.

• For 2 circuit units, the deadband is 7%.

• For 3 circuit units, the deadband is 5%.

Soft Load

Soft Loading is a configurable function used to ramp up the unit capacity over a given

time. The setpoint that control this function are:

• Soft Load – (ON/OFF)

• Begin Capacity Limit – (Unit %)

• Soft Load Ramp – (seconds)

The Soft Load Unit Limit increases linearly from the Begin Capacity Limit set-point to

100% over the amount of time specified by the Soft Load Ramp set-point. If the option is

turned off, the soft load limit is set to 100%.

Demand Limit

The maximum unit capacity can be limited by a 4 to 20 mA signal on the Demand Limit

analog input, usually from a BAS, on the unit controller. This function is only enabled if

the Demand Limit setpoint is set to ON and the control is in the COOL mode.

As the signal varies from 4 mA up to 20 mA, the maximum unit capacity changes from

100% to 0%. The unit capacity shall be adjusted as needed to meet this limit, except that

the last running compressor cannot be turned off to meet a limit lower than the minimum

unit capacity.

Network Limit

The maximum unit capacity can be limited by a network signal. This function is only

enabled if the unit control source is set to network. The signal will be received through

the BAS interface on the unit controller.

As the signal varies from 0% up to 100%, the maximum unit capacity changes from 0%

to 100%. The unit capacity is adjusted as needed to meet this limit, except that the last

running compressor cannot be turned off to meet a limit lower than the minimum unit

capacity.

30 OM 1051-2

Page 31

Current Limit

unload area

Unload area

Current Limit control is enabled only when the current limit enable input is ON.

Unit current is calculated based on the 4-20 mA input that receives a signal from an

external device. The current at 4 mA is assumed to be 0, and the current at 20 mA is

defined by a setpoint. As the signal varies from 4 to 20 mA, the calculated unit current

varies linearly from 0 amps to the amp value defined by the setpoint.

The current limit uses a deadband centered around the actual limit value, such that unit

capacity increase is not allowed when current is within this deadband. If unit current is

above the deadband, capacity is decreased until it is back within the deadband. The

current limit deadband is 5% of the current limit.

Figure 9, Current Limit Operation

Current Limit

Hold area

5% of HMI setpoint

Free to load or

Maximum LWT Pulldown Rate

The maximum rate at which the leaving water temperature can drop is limited by the

Maximum Rate setpoint, only when the LWT is less than 59°F (15°C).

If the pulldown rate is higher than the Maximum Pulldown Rate set point minus 0.1°C,

the unit capacity should not be increased.

If the pulldown rate is higher than the Maximum Pulldown Rate set point plus 0.1°C, the

unit capacity should be reduced until the rate is less than that value.

High Water Temperature Capacity Limit

If the evaporator LWT exceeds 77°F (25°C), compressor load will be limited to a

maximum of 80%. Compressors will unload to 80% or less if running at greater than

80% load when the LWT exceeds the limit. This feature is to keep the circuit running

within the capacity of the condenser coil.

Pumpdown

The circuit state should be Pump down when any of the following conditions are true.

1. Normal shut down alarm exists in Run state.

2. LWT error is less than Shut down delta T in case of 1 circuit running

3. LWT error is less than Stage down delta T in case of 2 circuit running

4. Unit state is Pumpdown

5. Circuit switch is Off

OM 1051-2 31

Page 32

Cycle Timer

A minimum time between starts of the compressor and a minimum time between shutdown and

start of the compressor shall be enforced.

The time values are set by global circuit setpoints. These cycle timers shall be enforced even

through cycling of power to the chiller.

These timers may be cleared via a setting on the HMI.

Start-to-start time is the time period from when a compressor starts until it starts again.

Stop-to-start is the time period from when a compressor stops until it restarts.

Table 6, Cycle Time Settings

Function Default

Start - Start time 20 min 15 min 60 min

Stop - Start time 5 min 3 min 20 min

minimum maximum

Range

Circuit Start-up Delta T, Shut-down Delta T

To avoid excessive ON/OFF compressor cycling when the capacity required is very low.

The first compressor on the unit will be started when evaporator LWT is higher than the LWT

target plus the Startup Delta T setpoint.

An additional compressor will be started when evaporator LWT is higher than the target plus

the Stage Up Delta T setpoint.

When multiple compressors are running, one will shut down if Evaporator LWT is lower than

the target minus the Stage Down Delta T setpoint.

All running compressors will shut down when the evaporator LWT is lower than the target

minus the Shut Down Delta T setpoint.

Circuit Pulldown Rate

The pulldown rate is established to control the capacity of the compressor so that it does not

pull down the chilled water temperature too fast and overshoot the LWT target and to avoid

excessive compressor cycling.

The maximum rate at which the leaving water temperature can drop is limited by the

Maximum Rate setpoint, only when the LWT is less than 15°C (59°F).

If the pulldown rate is higher than the Maximum Pulldown Rate setpoint minus 0.1°C, the unit

capacity will not be increased.

If the pulldown rate is higher than the Maximum Pulldown Rate setpoint plus 0.1°C, the unit

capacity will be reduced until the rate is less than that value.

Non-VFD models

EWT slope is calculated such that the slope represents the estimated change in EWT over a

time frame of one minute. This slope is used to determine the compressor capacity

VFD models

Compressor capacity is controlled by compressor speed and a sophisticated algorithm is used

to determine rate.

32 OM 1051-2

Page 33

Unit Capacity Control

Non-VFD models

An estimate of total unit capacity is needed for applying unit capacity limits. Unit

capacity will be based on the estimated circuit capacities.

The unit capacity is the average of the estimated circuit capacities.

In Cool mode, evaporator LWT is controlled to a temperature within a calculated

variation range of the target under constant flow conditions by controlling capacity of the

individual compressors. The allowed variation is plus or minus 4% of nominal

evaporator delta t.

Compressors are loaded with a fixed step scheme. The rate of capacity adjustment is

determined by the time between capacity changes. The farther away from the target, the

faster compressors will be loaded or unloaded.

The logic will project ahead to avoid overshoot, such that the overshoot does not cause

the unit to shut off due to evaporator LWT dropping below the target minus the Shutdown

Delta T setpoint while there is still a load on the loop at least equal to the minimum unit

capacity.

Capacity of the compressors is controlled so that when possible their capacities are

balanced.

Circuits that are running in manual capacity control or running with active capacity

limiting events are not considered in the capacity control logic.

The compressor capacities are adjusted one at a time while maintaining a capacity

imbalance that does not exceed 12.5%.

VFD models

The purpose of this logic is as follows.

• To avoid load/unload hunting.

• To reach LWT target at appropriate speed.

• To avoid unnecessary shut downs.

• To keep LWT within +/-0.1C of LWT target as possible.

Compressor capacity is controlled by compressor speed and a sophisticated algorithm is

used to determine the rate considering the various parameters affecting capacity.

OM 1051-2 33

Page 34

Circuit Functions

Calculations

Refrigerant Saturated Temperature

Refrigerant saturated temperature is calculated from the pressure sensor readings for each

circuit. A function provides the converted value of temperature to match values published

data for R134a:

-within 0.18°F (0.1°C) for pressure inputs from 0 to 300 psi (0 to 2070kPa)

-within 0.36°F (0.2°C) for pressure inputs from -11.6 to 0 psi (80 kPa to 0 kPa)

Evaporator Approach

The evaporator approach is calculated for each circuit. The equation is as follows:

Evaporator Approach = LWT – Evaporator Saturated Temperature

Condenser Approach

The condenser approach is calculated for each circuit. The equation is as follows:

Condenser Approach = Condenser Saturated Temperature - OAT

Suction Superheat

Suction superheat is calculated for each circuit using the following equation:

Suction superheat = Suction Temperature – Evaporator Saturated Temperature

Discharge Superheat

Discharge superheat is calculated for each circuit using the following equation:

Discharge superheat = Discharge Temperature – Condenser Saturated

Temperature

Oil Differential Pressure

Oil Differential Pressure is calculated for each circuit with this equation:

Oil Differential Pressure = Condenser Pressure - Oil Pressure

Maximum Saturated Condenser Temperature

The maximum saturated condenser temperature calculation is modeled after the

compressor operational envelope.

If Sat Evap Temp < 32°F (0°C) then

Max Sat Cond Temp = 1.596(Sat Evap Temp) +155°F (68.3°C)

Otherwise, Max Sat Cond Temp = 155°F (68.3°C)

High Saturated Condenser – Hold Value

High Cond Hold Value = Max Saturated Condenser Value – 5°F (2.78°C)

High Saturated Condenser – Unload Value

High Cond Unload Value = Max Saturated Condenser Value – 3°F (1.67°C)

Condenser Saturated Temperature Target

The saturated condenser temperature target is calculated by using the following equation:

Sat condenser temp target raw = 0.8332(evaporator sat temp) + 95.0°F (35.0 °C)

This value is then limited to a range defined by the Condenser Saturated Temperature

Target min and max setpoint. These setpoint simply cut off the value to a working range,

and this range can be limited to a single value if the two setpoint are set to the same value.

34 OM 1051-2

Page 35

Circuit Control Logic

Circuit Availability

A circuit is available to start if the following conditions are true:

• Circuit switch is closed

• No circuit alarms are active

• Circuit Mode setpoint is set to Enable

• BAS Circuit Mode setpoint is set to Auto

• No cycle timers are active

• Discharge Temperature is at least 9°F (5°C) higher than Oil Saturated Temperature

Starting

The circuit will start if all these conditions are true:

• Adequate pressure in the evaporator and condenser (see No Pressure At Start Alarm)

• Circuit Switch is closed

• Circuit Mode setpoint is set to Enable

• BAS Circuit Mode setpoint is set to Auto

• No cycle timers are active

• No alarms are active

• Staging logic requires this circuit to start

• Unit state is Auto

• Evaporator pump state is Run

Circuit Startup Logic

Circuit startup is the time period following the starting of the compressor on a circuit.

During the startup, the low evaporator pressure alarm logic is ignored. When the

compressor has been running at least 20 seconds and the evaporator pressure rises above

the low evaporator pressure unload setpoint, the startup is complete.

If the pressure does not rise above the unload setpoint and the circuit has been running

longer than the Startup Time setpoint, then the circuit is turned off and an alarm triggered.

If the evaporator pressure drops below the absolute low pressure limit then the circuit is

turned off and the same alarm triggered.

Low OAT Restart Logic

Low OAT restart logic allows multiple start attempts in low ambient conditions. If the

condenser saturated temperature is less than 60°F (14.6°C) when the compressor starts,

the startup is considered to be a ‘low OAT start’. If a low OAT start is not successful the

circuit is shut down, but no alarm is triggered for the first two attempts of the day. If a

third low OAT start attempt fails, then the circuit is shut down and the Low OAT Restart

Alarm is triggered.

The restart counter is reset when a startup is successful or the Low OAT Restart alarm is

triggered.

Stopping

Normal Shutdown

A normal shutdown requires the circuit to pumpdown before the compressor is turned off.

This is done by closing the EXV, and closing the liquid line solenoid (if present) while

the compressor is running.

OM 1051-2 35

Page 36

The circuit will do a normal shutdown (pumpdown) if any of the following are true:

• Staging logic requires this circuit to stop

• Unit State is Pumpdown

• A pumpdown alarm occurs on the circuit

• Circuit switch is open

• Circuit Mode setpoint is set to Disable

• BAS Circuit Mode setpoint is set to Off

The normal shutdown is complete when any of the following are true:

• Evaporator Pressure is less than the Pumpdown Pressure setpoint

• Service Pumpdown setpoint is set to Yes and Evaporator Pressure is less than

5 psi (34.5 kPa)

• Circuit has been pumping down for longer than the Pumpdown Time Limit setpoint

Rapid Shutdown

A rapid shutdown requires the compressor to stop and the circuit to go to the Off state

immediately.

The circuit will do a rapid shutdown if either of these conditions occurs at any time:

• Unit State is Off

• A rapid stop alarm occurs on the circuit

Circuit Status

The displayed circuit status is determined by the conditions in the following table:

Table 7, Circuit Status

Enum Status Conditions

0 Off:Ready Circuit is ready to start when needed.

1 Off:Stage Up Delay Circuit is off and cannot start due to stage up delay.

2 Off:Cycle Timer Circuit is off and cannot start due to active cycle timer.

3 Off:BAS Disable Circuit is off and cannot start due to BAS command.

4 Off:Keypad Disable Circuit is off and cannot start due to keypad disable.

5 Off:Circuit Switch Circuit is off and circuit switch is off.

6 Off:Refr In Oil Sump

7 Off:Alarm Circuit is off and cannot start due to active circuit alarm.

8 Off:Test Mode Circuit is in test mode.

9 EXV Preopen Circuit is in preopen state.

10 Run:Pumpdown Circuit is in pumpdown state.

11 Run:Normal Circuit is in run state and running normally.

12 Run:Disch SH Low

13 Run:Evap Press Low

14 Run:Cond Press High

15 Run: High LWT Limit

16 Run: High VFD Amps

17 Off: Max Comp Starts

Circuit is off and Discharge Temperature – Oil

Saturated Temperature at gas pressure <= 5°C

Circuit is running and cannot load due to low discharge

superheat.

Circuit is running and cannot load due to low evaporator

pressure.

Circuit is running and cannot load due to high

condenser pressure.

Circuit is running and cannot load due to high

evaporator leaving water temperature.

Circuit is running and cannot load due to high

compressor VFD current output.

Circuit is off and cannot start due to four starts in the

last hour. Remaining time displayed.

36 OM 1051-2

Page 37

Compressor Control

The compressor runs only when the circuit is in a start, run or pumpdown state. The

compressor will not be running any time the circuit is off or during preopening the EXV.

Compressor State

The compressor will always be in one of the following states

Name Meaning

Off Comp off.

Start Comp in Start control.

Run Comp in automatic or manual capacity control.

Pump down Comp in shut down control.

Compressor Off

The control state will be Off when the circuit state is Off.

Compressor Start

The purpose of this logic is:

• To avoid the suction pressure dropping too much at start.

• To prohibit loading until circuit state is stable.

The control state should be Start up when the circuit state is Start. Start up is controlled

by logic considering EXV preopen time, compressor start time, suction superheat and

other parameters.

Capacity Control, Non-Compressor VFD Models

After starting, the compressor capacity target should be the minimum of 10%, and no

attempt to increase compressor capacity should be made until the compressor has been

running at least three minutes and the minimum discharge superheat has been established

for at least 30 seconds. After this condition is met, the compressor capacity target shall

move via steps to a minimum running capacity even if unit capacity control commands do

not require the compressor to load up. This minimum running capacity target is 26% for

European chillers and 25% for US chillers.

Once the compressor has been loaded to the minimum running capacity target, the

capacity target shall always be at least equal to this value while the compressor is

running.

Changes to the capacity target shall be performed as needed to meet unit capacity

requirements based on load and unload commands (see unit capacity control section). For

European chillers, the standard capacity target step is 4%, and for US chillers it is 5%.

A minimum time of 20 seconds should pass between capacity changes other than the

capacity transitions from 50% to 60% or from 60% to 50%. For those capacity

transitions, a minimum time of 30 seconds should pass before capacity is changed again.

OM 1051-2 37

Page 38

Capacity Control, Compressor VFD Models