Page 1

AAF-HermanNelson

Classroom Unit Ventilators

Models AVS, AVB, AVV and AVR Floor Units

Catalog UV1600

C

Page 2

Contents

Introduction 3

AAF-HermanNelson Classroom Unit Ventilators 3

The Model AV Floor Unit 4

Features & Benefits 5

Quiet Operation With Our GentleFlo Delivery 5

The Right Amount of Fresh Air and Cooling 6

Precise Temperature and Dehumidification Control 7

Low Installation Costs 9

Low Operating Costs 10

Easy To Maintain 11

Built To Last 13

MicroTech II Controls 15

MicroTech II Controls For Superior Performance, Easy Integration 15

Control Modes and Functions 17

Advanced Control Options 19

System Components 21

Accessories 25

Wall Louvers & Grilles 25

Ventimatic™ Shutter Room Exhaust Ventilation 26

Storage Cabinets, Sink & Bubbler 27

End Panels, Filler Sections & Sub-Bases 28

Application Considerations 29

Why Classrooms Overheat 29

Meeting IAQ Requirements 31

Following ASHRAE Control Cycle II 31

Meeting ARI 840 Requirements 32

Meeting IBC Seismic Requirements 33

Face & Bypass Temperature Control 34

Modulating Valve Temperature Control 36

Coil Selection 37

DX Split Systems 38

Window Downdraft Protection 40

Digital Ready Systems 43

Field-Installed Controls By

Others & Digital Ready Controls 43

Unit Installation 48

Unit Arrangements: 16-5/8" Deep 51

Unit Arrangements: 21-7/8" Deep 52

Coil Selection 55

Quick Selection Procedure 55

Coil Selection Procedure 56

Chilled Water Selection Example 58

Hot Water Heating Selection 60

Steam Heating Selection 63

Electric Heating Selection 64

Direct Expansion Cooling Coil Selection 65

Valve Selection 66

Face and Bypass End-Of-Cycle Valve Sizing & Piping 66

Modulating Valve Sizing & Piping 68

Steam Valve Sizing & Piping 70

General Data 72

AV General Data 72

Available Unit Ventilator Combinations 73

Available Coil Combinations 75

Details & Dimensions 76

Coil Connections 76

Condensate Drain Connections 79

16-5/8” (422 mm) Deep Unit Arrangements 80

21-7/8" Deep Arrangements 82

End Panels 87

Valve Dimensions 88

Wall Intake Louvers & Grilles 89

Ventimatic Shutter Assembly 90

Sink & Bubbler Cabinet 91

Filler Sections & Utility Compartment 92

Shelf Storage Cabinets 93

Finned Tube Radiation Cabinets 95

Wiring Diagrams 96

Typical MicroTech II Wiring Diagrams 96

Typical Digital Ready Wiring Diagram 99

Typical Controls By Others Wiring Diagram 100

Guide Specifications 101

AAF-HermanNelson Unit Ventilator Model AV Guide Specifications 101

The ventilation rate of AAFHermanNelson unit

ventilators is certified and

tested per Air Conditioning

and Refrigeration Institute

(ARI) Standard 840.

McQuay is a registered trademark and MicroTech II, Digital Ready, GentleFlo, ServiceTools,

Microsoft is a registered trademark and Windows is a trademark of Microsoft Corporation.

and Protocol Selectability are trademarks of McQuay International.

Copyright © 2005 McQuay International. All rights reserved throughout the world.

C

Page 3

Introduction

Introduction

AAF-HermanNelson Classroom Unit Ventilators

Low Installation Costs

New construction installations are easily accomplished

with AAF-HermanNelson unit ventilators because they

avoid the added cost and space required for expensive

ductwork. Retrofit installations are also economical

because new units fit the same space occupied by

existing ones. Multiple control options—including

MicroTech II controls with Protocol Selectability™, or

For more than 85 years, schools have relied on

AAF-HermanNelson unit ventilators to keep classrooms

comfortable. Students learn more readily in a quiet, wellventilated environment. That’s why Herman Nelson

invented the unit ventilator and why we remain

committed to meeting the changing requirements of

schools with the highest quality products available.

We realize that keeping expenditures down is a high

priority for school administrators and school boards.

AAF-HermanNelson unit ventilators are inexpensive to

install and operate, and they are designed and built to

provide decades of trouble-free service.

Quiet Operation

AAF-HermanNelson unit ventilators are engineered and

manufactured to deliver quiet, continuous comfort. We

developed our GentleFlo™ air moving system to minimize

operating sound levels—even as demands for more fresh

air require units to operate longer and work harder.

The Right Amount of Fresh Air and Cooling

AAF-HermanNelson unit ventilators deliver required

amounts of fresh air to meet ventilation requirements,

and added cooling capacity to maintain consistent

comfort for students and teachers. Our Economizer

Operation, Demand Control Ventilation (DCV) and Part

Load, Variable Air options allow you to closely match

comfort requirements and reduce operating costs.

Precise Temperature and Dehumidification Control

AAF-HermanNelson unit ventilators feature precise

temperature and dehumidification control to keep

students and teachers comfortable while making

maximum use of “free” outdoor-air cooling to reduce

operating costs. They utilize a draw-thru air design that

contributes to even heat transfer and uniform discharge

air temperatures into the classroom. Coupled with face

and bypass air control and our MicroTech

passive dehumidification control strategies, they provide

precise control of temperature and humidity levels.

II™ active and

Digital Ready™ features—provide easy, low cost

integration into the building automation system of your

choice.

Low Operating Costs

When running, AAF-HermanNelson unit ventilators can

use as little electricity as two 100-watt light bulbs. They

take maximum advantage of “free” cooling opportunities

to reduce operating costs. During unoccupied periods

and at night, units operate sparingly to conserve energy.

Easy To Maintain, Modular Design

AAF-HermanNelson Unit Ventilators are designed to

provide easy access for maintenance and service

personnel to all serviceable components. Most tasks are

easily handled by a single person.

Built To Last

Our proven institutional design can withstand the rigors

of the classroom environment. It features an extra-sturdy

chassis and double-wall damper on the inside; scuffresistant finishes and tamper prevention features on the

outside. In fact, many units installed over 30 years ago

continue to provide quiet, reliable classroom comfort.

MicroTech II Control For Superior Performance, Easy Integration

AAF-HermanNelson unit ventilators can be equipped

with MicroTech II™ unit controllers for superior

performance. Factory integrated and tested controller,

sensor, actuator and unit options promote quick, reliable

start-up and minimize costly field commissioning. Our

Protocol Selectability feature provides easy, low-cost

integration into most building automation systems. Select

BACnet

communications to communicate control and monitoring

information to your BAS, without the need for costly

gateways. Unit controllers are L

the optional L

®

, LonTalk® or Metasys® N2 Open

ONWORKS

®

communication module.

ONMARK

®

certified with

AAF-HermanNelson Model AV Unit Ventilators 3

Page 4

Introduction

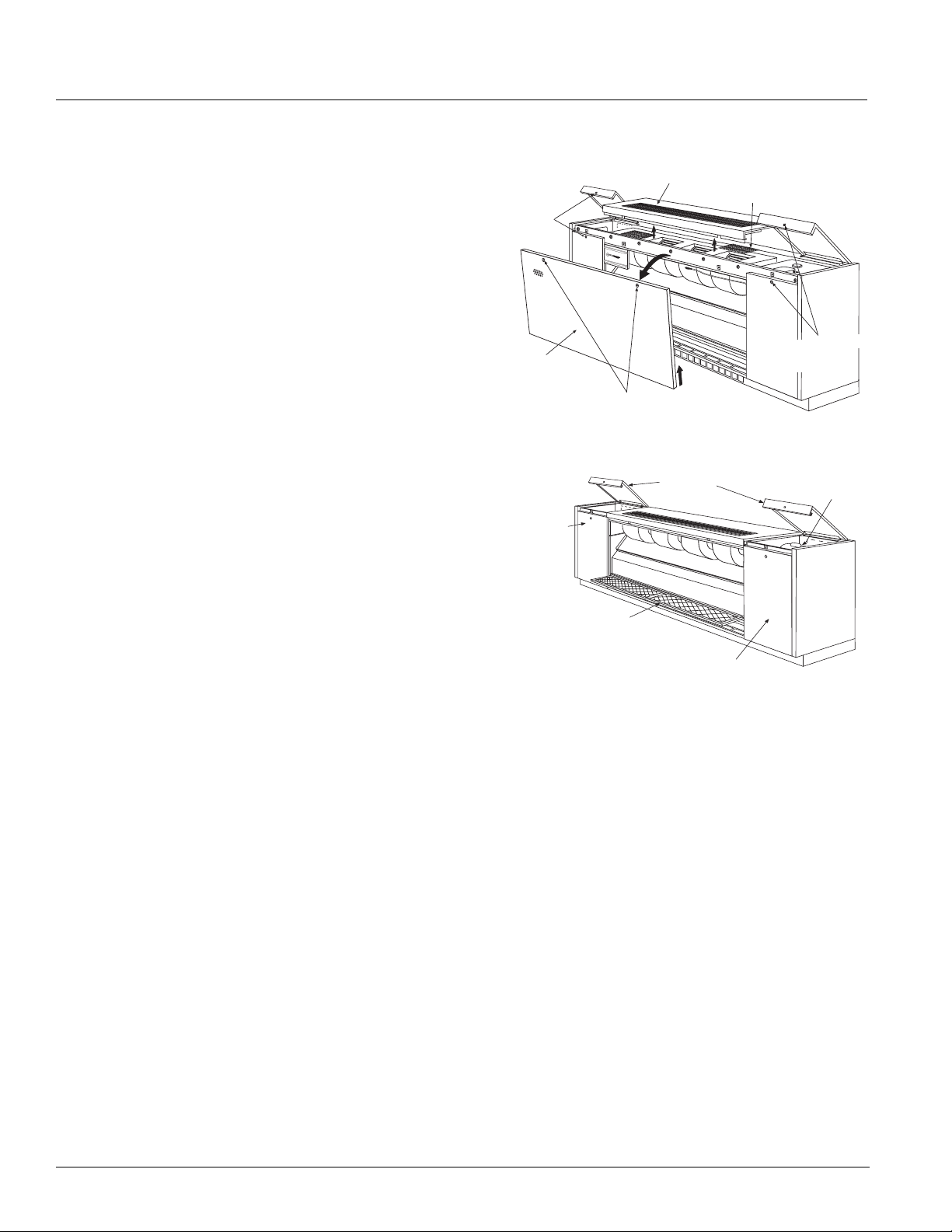

The Model AV Floor Unit

Our Model AV is a vertical, floor-standing unit that utilizes

remotely-supplied chilled water or refrigerant for cooling,

and hot water, steam or electric heat for heating. The

Model AV also can be supplied as a heating/ventilating

unit only or as a cooling/ventilating unit only.

The Model AV is just right for new construction and for

retrofit applications. Older buildings with baseboard

Hinged Top Access Doors

Welded OnePiece Chassis

Sampling

Chamber

Draw-Thru

Air Flow

Quiet, Aerodynamic Fans

radiant heat or other hydronic heating systems can be

easily adapted to work efficiently with Model AV units.

Chilled-water or refrigerant cooling can be added to

provide year-round comfort. The major features of this

model are shown below and described in more detail on

the following pages.

Fan Motor Out

Of Airstream

MicroTech II Controls

Composite

Drain Pan

Sectionalized

Access Panels

Face And Bypass

Damper Design

• Welded One-Piece Chassis offers

superior strength, durability, and vibration reduction.

• Unique Draw-Thru Design provides

uniform air distribution across the coil

for even discharge air temperatures.

• Quiet, Aerodynamic Fans utilize

GentleFlo technology for exceptionally

quiet unit operation.

• Modular Fan Section improves

balance, alignment and simplifies

maintenance.

• Fan Motor Located Out Of Air

Stream and away from heating coil

reduces heat exposure to prolong life.

• Face And Bypass Damper Design

provides superior dehumidification

and reduces chance of coil freeze-up

Advanced Heat

Transfer Coil

• Certified Ventilation Performance

per ARI-840.

• MicroTech II Controls provide supe-

rior comfort control and easy

integration into the building automation system of your choice.

• Advanced Heat Transfer Coil design

provides extra capacity.

• Sturdy Cabinet Construction

includes hidden reinforcement, a nonglare textured surface, and a tough,

scuff- and mar-resistant finish to make

the top sturdy enough to support

maintenance personnel.

• Sectionalized Front Access Panels

provide easy access to unit interior.

Panels are easily removed by a single

person. Front side panels can be

removed while unit is running.

Single Full-Length

Air Filter

Sturdy Cabinet

• Two Hinged Top Access Doors pro-

vide easy access to motor and end

bearing. Special tamper-resistant fasteners deter unauthorized access.

• Sampling Chamber for unit-mounted

sensor provides accurate sensing of

room temperature.

• Indoor Room Air Damper blocks

unwanted gusts of outdoor air on

windy days. Its nylon bearings are

quiet and maintenance free.

• Insulated Double-Wall Outdoor Air

Damper seals tightly without twisting.

• Single Full-length Air Filter is effi-

cient and easy to replace. All air

delivered to classroom is filtered.

• UL/cUL Listed

4 McQuay Catalog 1600

Page 5

Features & Benefits

Features & Benefits

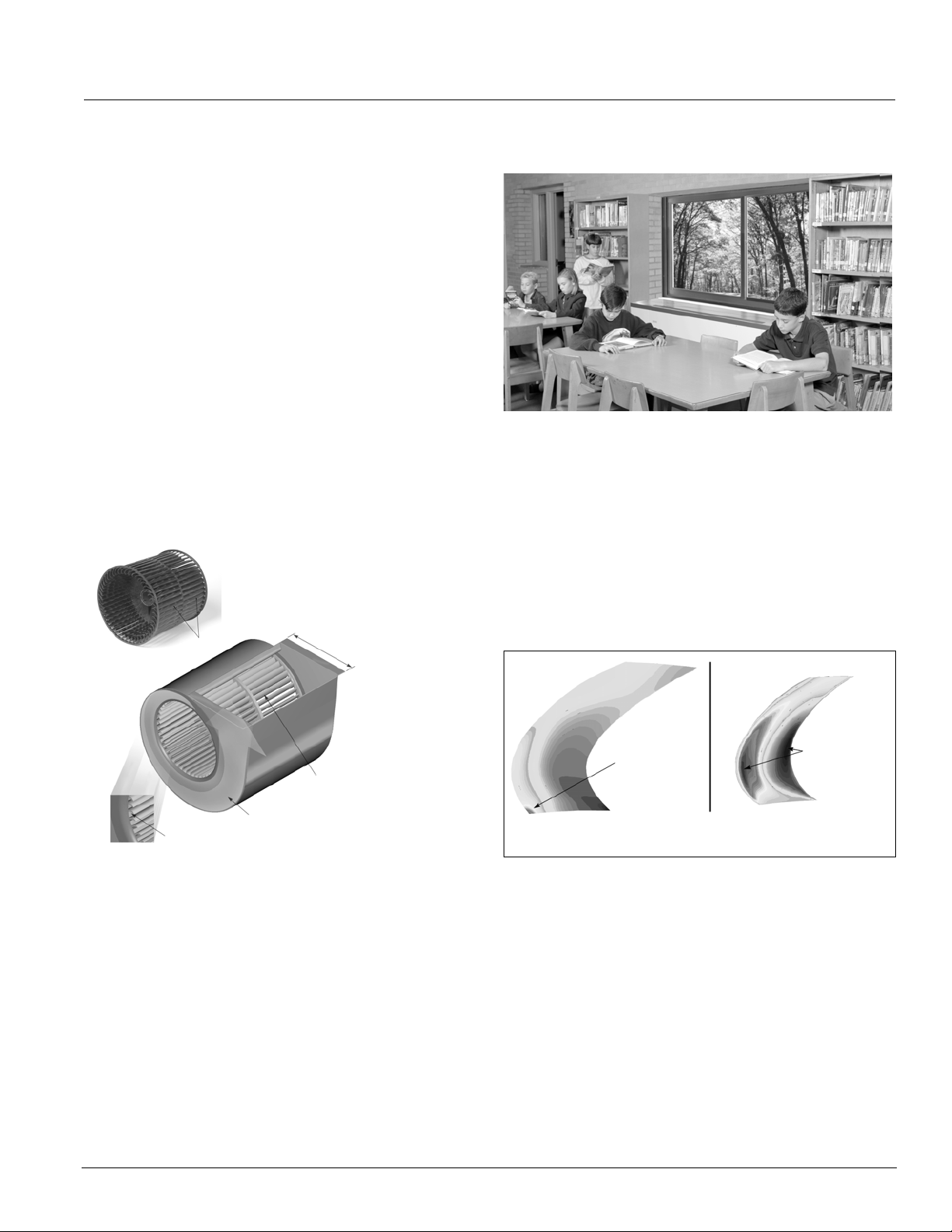

Quiet Operation With Our GentleFlo Delivery

AAF-HermanNelson unit ventilators are engineered and

manufactured to deliver quiet, continuous comfort. We

developed our GentleFlo™ air moving system to

minimize operating sound levels—even as demands for

more fresh air require units to operate longer and work

harder. GentleFlo features include:

• Fan wheels are large, wide and rotate at a low speed

to reduce fan sound levels. They are impact-resistant

and carefully balanced to provide consistent

performance.

• Offset, aerodynamic fan wheel blades move air

efficiently (

• Precision tolerances help reduce flow and pressure

turbulence, resulting in lower sound levels.

• Fan housings incorporate the latest logarithmicexpansion technology for smoother, quieter air flow

(

Figure 2).

Figure 1. GentleFlo Fan Technology

Figure 1).

Expanded discharge air

opening

• A large, expanded discharge opening minimizes air

resistance, further lowering sound levels.

• Modular fan construction contributes to equal outlet

velocities and promotes quiet operation.

• Fan shafts are of ground and polished steel to

minimize deflections and provide consistent, long-term

operation.

• Fan assemblies are balanced before unit assembly,

then tested after assembly (and rebalanced if

necessary) to provide stable, quiet operation.

Figure 2. GentleFlo Reduces Turbulence

Minimal

Offset aerodynamic blades

Logarithmic expansion

housing

Precision Tolerances

AAF-HermanNelson Model AV Unit Ventilators 5

GentleFlo fan blade design

turbulence

Typical fan blade design

High turbulence

Page 6

Features & Benefits

The Right Amount of Fresh Air and Cooling

AAF-HermanNelson unit ventilators deliver required

amounts of fresh air to meet ventilation requirements and

added cooling capacity to maintain consistent comfort for

students and teachers. Our Economizer Operation,

Demand Control Ventilation (DCV) and Part Load,

Variable Air options allow you to match classroom

comfort requirements even more closely, and reduce

operating costs.

This means that you can be confident that your school is

meeting ventilation standards for Indoor Air Quality and

that your students are receiving adequate air to be

attentive to instruction. At the same time, you are saving

money in early morning hours, between classes or after

hours when classrooms are heated and cooled but not

always fully occupied.

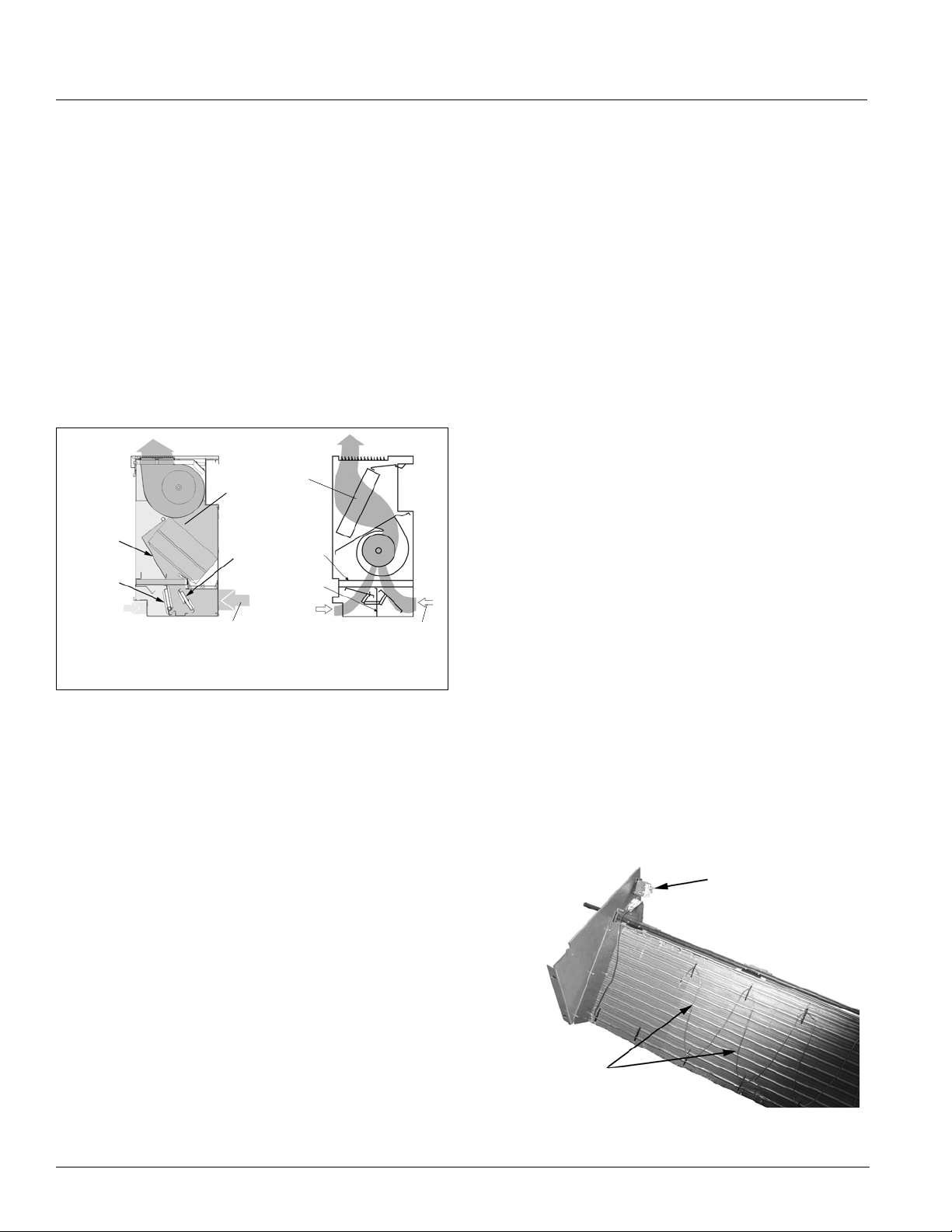

Economizer Operation

It is well recognized that cooling, not heating, is the main

thermal challenge in school classrooms. The typical

classroom is cooled by outdoor air over half the time,

even in cold climates. It is therefore essential that unit

ventilators efficiently deliver outdoor air when classroom

conditions call for “free” or economizer cooling.

With AAF-HermanNelson unit ventilators, you can have

outdoor air whenever it is needed. Economizer operation

is facilitated by the outdoor air damper, which

automatically adjusts the above-minimum outside air

position to provide free cooling when the outdoor air

temperature is appropriate (

with MicroTech II controls, three levels of economizer

control are available (see

Figure 3. Full Economizer Mode

100% Outdoor Air Into Classroom

Figure 3). On units equipped

page 17).

Part-Load Variable Air Control

Part Load Variable Air control can be used in conjunction

with face and bypass damper temperature control to

automatically adjust the unit ventilator fan speed based

upon the room load and the room temperature. This

MicroTech II control option provides higher latent cooling

capabilities and quieter operation during non-peak load

periods by basing indoor fan speed upon room load.

Lower fan speeds in conjunction with our GentleFlo fan

technology (see page

page 5) contributes to a very quiet

classroom environment.

Room-temperature PI control loops determine the speed

of the fan, which varies according to the room load. It

also provides a built-in delay to prevent overshooting for

better comfort control. The outdoor air damper’s

minimum-air position is adjusted with the fan speed to

bring in a constant amount of fresh air.

Demand Control Ventilation

AAF-HermanNelson unit ventilators can be equipped to

use input from a CO

based on actual occupancy instead of a fixed design

occupancy. This Demand Controlled Ventilation (DCV)

system monitors the amount of CO

outdoor air is introduced to maintain good air quality. The

system is designed to achieve a target ventilation rate

(e.g., 15 cfm/person) based on actual occupancy.

By using DCV to monitor the actual occupancy pattern in

a room, the system can allow code-specific levels of

outdoor air to be delivered when needed. Unnecessary

over-ventilation is avoided during periods of low or

intermittent occupancy, leading to improved energy

efficiencies and cost savings.

controller to ventilate the space

2

so enough fresh

2

Face &

Bypass

Damper

Room Air

Damper

6 McQuay Catalog 1600

Filter

Outdoor Air

Damper

Outdoor Air

Page 7

Features & Benefits

Precise Temperature and Dehumidification Control

AAF-HermanNelson unit ventilators provide precise

temperature and dehumidification control to keep

students and teachers comfortable while making

maximum use of “free” outdoor-air cooling to reduce

operating costs. They utilize a draw-thru fan design that

contributes to even heat transfer and provides uniform

discharge air temperatures into the classroom. Coupled

with face and bypass damper air control and/or our

MicroTech

II active and passive dehumidification control

strategies, they provide precise control of temperature

and humidity levels under both part-load and full-load

conditions.

Draw-Thru Design For Even Discharge Temperatures

The AAF-HermanNelson Draw-Thru design sets our unit

ventilators apart from most competitive models. With this

system, fans draw air through the entire heat transfer

element (

concentrated areas of the coil element. The result is

more uniform discharge air temperatures into the

classroom and more efficient unit ventilator operation.

Figure 4. Draw-Thru Design Provides Even Discharge Air

Figure 4) rather than blowing it through highly

Uniform Discharge Air (Shaded)

Motor

Fans

Condenser

Ta bl e s 1 and 2 below compare the composition of the air

streams through the coil and air streams bypassing the

coil at various bypass air percentages for draw-thru and

blow-thru unit ventilators using 450 cfm of outdoor air. At

both 0% bypass air and 100% bypass air, no difference

exists in the composition of the air streams. However, at

all other bypass air percentages (part load), significant

differences are evident.

For instance, compare the 1500 cfm draw-thru (Ta bl e 1)

and blow-thru (Tab le 2) units at 70% bypass air. At this

point, the draw-thru unit still has all of the outdoor air

going through the coil. Meanwhile, the blow-thru unit is

bypassing 70% (315 cfm) of the humid outdoor air

directly into the classroom.

Table 1: AAF-Herman Nelson 1500 CFM Draw-Thru Unit

Bypass Air Stream CFM Cold Air Stream CFM

Tot al

% Bypass Air

0 1500 0 0 0 1500 1050 450

10 1500 150 150 0 1350 900 450

20 1500 300 300 0 1200 750 450

30 1500 450 450 0 1050 600 450

40 1500 600 600 0 900 450 450

50 1500 750 750 0 750 300 450

60 1500 900 900 0 600 150 450

70 1500 1050 1050 0 450 0 450

80 1500 1200 1050 150 300 0 300

90 1500 1350 1050 300 150 0 150

100 1500 1500 1050 450 0 0 0

Bypass

Total Unit CFM

From

Room

From

Outdoors

Tot al

Coil

From

Room

From

Outdoors

Table 2: 1500 CFM Blow-Thru Unit

Face & Bypass Design For Better Temperature and Humidity Control

When coupled with our draw-thru design, face and

bypass damper air control offers maximum

dehumidification and optimal temperature control. That’s

because indoor and outdoor air streams can be

separated until it is optimal to mix them.

During most part-load conditions, humid outdoor air is

directed through the cold coil (coil surface below the dew

point) where moisture is removed. Room air is bypassed

around the coil, since it has already been dehumidified.

This arrangement allows for maximum condensate

removal. Humid outdoor air is not bypassed around the

coil until the total amount of cooling air required is less

than the total amount of fresh outdoor air required in the

% Bypass Air

0 1500 0 0 0 1500 1050 450

10 1500 150 105 45 1350 945 405

20 1500 300 210 90 1200 840 360

30 1500 450 315 135 1050 735 315

40 1500 600 600 0 900 450 450

50 1500 750 525 225 750 525

60 1500 900 630 270 600 420 180

70 1500 1050 735 315 450 315 135

80 1500 1200 840 360 300 210 90

90 1500 1350 945 405 150 105 45

100 1500 1500 1050 450 0 0 0

Bypass Air Stream CFM Cold Air Stream CFM

Tot al

Bypass

Total Unit CFM

From

Room

From

Outdoors

Tot al

Coil

From

Room

From

Outdoors

225

room.

AAF-HermanNelson Model AV Unit Ventilators 7

Page 8

Features & Benefits

This illustrates that the most effective way to maintain an

acceptable humidity level with a chilled-water unit

ventilator system is to use a face and bypass damper,

draw-thru unit.

Why Blow-Thru Designs Don’t Measure Up

Blow-thru designs cannot provide comfort like this. With

blow-thru designs, the humid outside air is pre-mixed

with the room air before it can go through the coil

(

Figure 5). Dehumidification occurs only to the portion of

the air that is directed unevenly through the cooling coil.

The air that bypasses the coil is largely humid outdoor

air, resulting in unconditioned air being bypassed and

creating poor comfort conditions.

Figure 5. Draw-Thru Vs. Blow-Thru Design

Coil

Face &

Bypass

Damper

Room Air

Damper

Room Air

AAF-HermanNelson

Draw-Thru Design

Outdoor

Air Damper

Outdoor Air

With a blow-thru design the positive pressure of the fan

discharge can create areas across the coil of varying

temperatures and airflow. In addition, blow-thru face and

bypass damper construction picks up heat by wiping the

coil, creating overheating conditions. The sound level in

a blow-thru design also varies based upon the position of

the face and bypass damper.

Coil

Filter

RA/OA

Divider

Room Air

Outdoor Air

Blow-Thru Design

See “Active Dehumidification Control (Reheat)” on page

20 for more information.

Passive Dehumidification (Optional)

On units with face and bypass damper air control and

MicroTech II part-load variable air control, passive

dehumidification can be used under high humidity

conditions to keep classrooms comfortable. A unitmounted humidity sensor and fan speed changes are

utilized to improve latent cooling by keeping the air in

closer contact with the cold coil for passive

dehumidification.

This occurs in the unoccupied mode as the unit operates

to satisfy the unoccupied temperature and humidity set

points with the outside damper closed. The face and

bypass damper is placed in a minimum face position to

promote high latent cooling. The unit fan continues to

operate on low speed until the load is satisfied. This is

very helpful in high humidity areas where high night time

humidity can be absorbed in the building during off

hours.

Increased Coil Freeze Protection

AAF-HermanNelson units equipped with face and

bypass damper control provide extra protection from coil

freeze-up. That’s because there is a constant flow of hot

water through the coil, and water that is flowing typically

does not freeze. Additionally, all AAF-HermanNelson

units feature a double-walled, insulated outdoor air

damper with airtight mohair seals to prevent unwanted

coil air from entering the unit.

Furthermore, a low-temperature freezestat is factory

installed on all units with hydronic coils. Its serpentine

capillary tube senses temperatures across the leaving air

side of the coil, allowing the unit controller to react

quickly to low-temperature conditions.

Active Dehumidification (Reheat)

In high-humidity applications where valve-controlled,

Figure 6. Freezestat

Freezestat

reheat units are used, the Active Dehumidification

Control (ADC) sequence should be considered. During

excessive humidity conditions, a humidity sensor directs

the unit to continue cooling past the room setpoint to

remove excess moisture. Hydronic heat or electric heat

is then used to reheat the discharge air to maintain

acceptable room temperatures.

MicroTech II controls minimize the amount of reheat

needed to maintain relative humidity below a preset limit.

Capillary Tube

Reheat is used only when required and in the most

energy-efficient manner possible.

8 McQuay Catalog 1600

Page 9

Features & Benefits

Low Installation Costs

AAF-HermanNelson unit ventilators have many features

that make them economical to purchase and to install in

both new construction and retrofit applications. It is this

attention to detail and understanding of school

applications that make them the system of choice.

Perfect For Both New & Retrofit Applications

New construction installations are easily accomplished

with AAF-HermanNelson unit ventilators because they

avoid the added cost and space required for expensive

ductwork. Further savings can be realized because

piping installations use less space than duct systems.

This is important in existing buildings and also in new

construction where floor-to-floor heights can be reduced,

saving on overall building costs.

Retrofit installations are also economical because new

units fit the same space occupied by existing ones. Using

AAF-HermanNelson unit ventilators, central equipment,

such as chillers, can be sized smaller using building

diversity. This results in a low capital-cost system.

Built In Flexibility

AAF-HermanNelson unit ventilators include features that

make them easy to set up and reconfigure as needed to

meet special requirements. These features include:

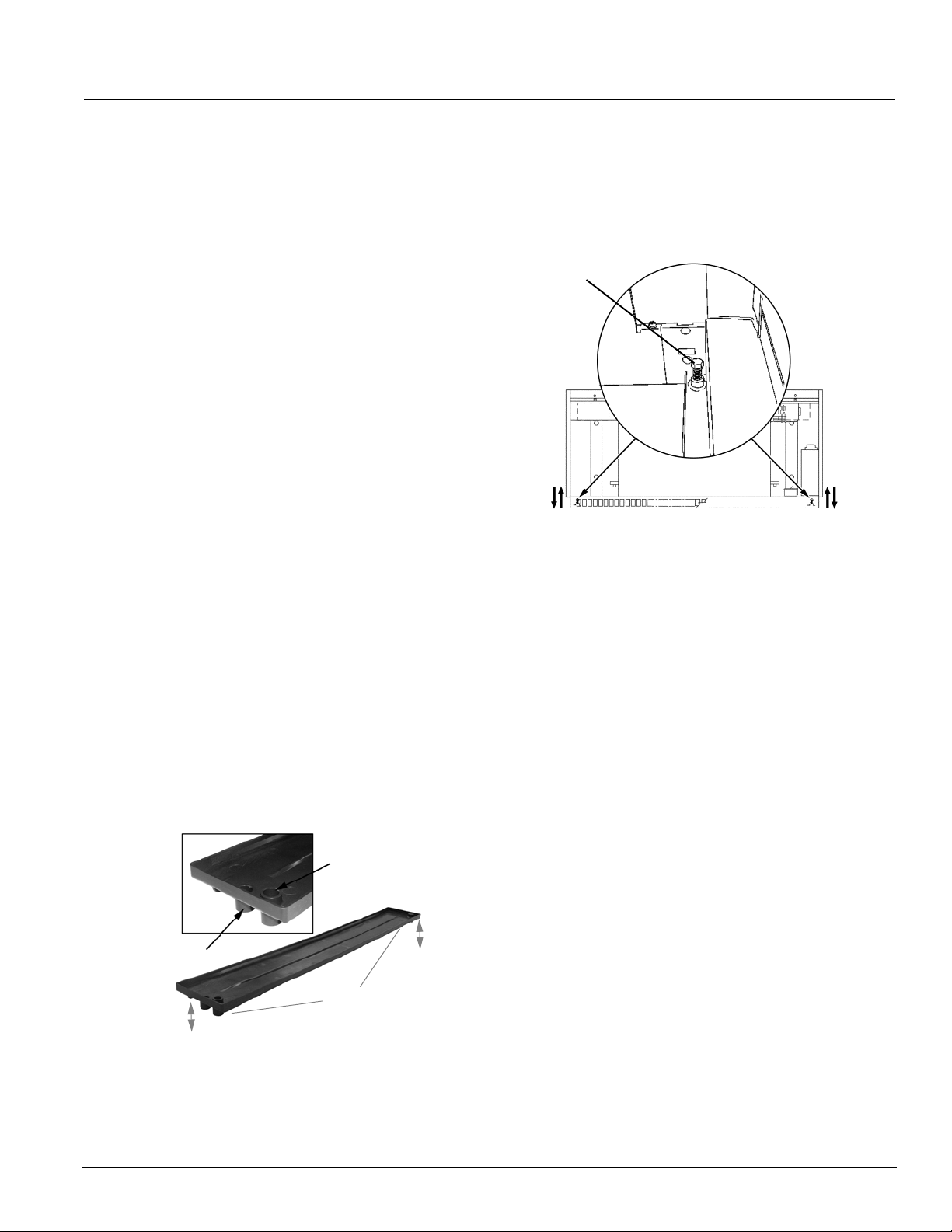

• Reversible Drain Connections All units come with a

composite drain pan that has drain connections on

either end (

connection is also provided. The drain-side connection

can be selected in the field. The direction in which the

drain pan slants can also be field-modified.

Figure 7. Composite Drain Pan, Reversible Connections

• Add Cooling At A Later Date Because we recognize

that some schools may wish to add cooling at a later

date, even heating-only units are shipped standard

with a composite drain pan.

Figure 7). A secondary, overflow drain

Secondary Overflow

Drain Connection

Primary Drain

Connection

Connect Drains On Either

End, Slant Pan To Either

End, Can Field-Modify

• Adjustable Leg Levelers Adjustable leg levelers are

furnished on the front legs of all floor units to

compensate for floor irregularities (

Figure 8. Adjustable Leg Levelers

Leg Leveler

Figure 8).

• Built-in Pipe Tunnel A built-in pipe tunnel allows field

crossover of hot-water or chilled-water piping,

electrical conduit or refrigeration tubing (see Unit

Arrangements beginning on page

51).

• Built-In Wire Race A built-in metal wire race runs from

one end of the unit to the other to provide extra

protection for wires and protect them from unit air.

Controls Flexibility

Multiple control options—including MicroTech II controls

with our Protocol Selectability feature—provide easy, low

cost integration of AAF-HermanNelson unit ventilators

into the building automation system of your choice (see

page 15). You can also operate these units individually or

in a master-slave control configuration.

With MicroTech II controls, you select BACnet, LonTalk

or Metasys

and monitoring information to your BAS, without the

need for costly gateways. Unit controllers are L

certified with the optional L

module.

Controls and communication modules can be factory

provided or field-installed by others. Factory integrated

and tested controller, sensor, actuator and unit options

promote quick, reliable start-up and minimize costly field

commissioning.

You can also use our Digital Ready option, where we

factory-install and pre-wire control sensors and actuators

and the controller is field-installed by others. See

Ready Systems” on page 43.

N2 communications to communicate control

ONMARK

ONWORKS communication

“Digital

AAF-HermanNelson Model AV Unit Ventilators 9

Page 10

Features & Benefits

Low Operating Costs

Schools consume more than 10% of the total energy

expended in the United States for comfort heating and

cooling of buildings. As energy costs increase, educators

are placed in a difficult position: caught between rising

costs, lower budgets and the requirements to raise

educational standards.

Fortunately, the technology and the system exists for

schools to take control of their energy expenditures while

providing a comfortable environment for learning. And

that system is the AAF-HermanNelson unit ventilator.

Consider these realities of school environments:

• Most heating energy in schools is expended to heat

unoccupied spaces. Because lights, computers and

students give off considerable heat, occupied spaces

require little supplemental heat.

• The removal of heat is usually required in occupied

classrooms, even when outside temperatures are

moderately cold (i.e., 35-40°F).

Then consider how AAF-HermanNelson unit ventilators,

located in each classroom, take advantage of these

realities to lower operating costs:

• They provide individual classroom control and comfort.

• They can be cycled on when the room is occupied and

cycled off when it is not.

• They bring in fresh air from directly outside the

classroom for high indoor air quality.

• During most of the school year, they use outdoor air to

keep classrooms comfortable without the expense of

mechanical cooling.

• They have their own air-moving device—a fan and 1/4

hp motor—which uses about as much energy as two

100-watt light bulbs. Compare this to the energy

consumed by the 20-plus-hp motors used in

centralized systems to cool both occupied and

unoccupied spaces (at about 1 hp of energy consumed

per room).

MicroTech II Control Options Further Reduce Operating Costs

Many of the MicroTech II control options available with

AAF-HermanNelson unit ventilators can further reduce

operating costs. For example:

• Economizer Operation Economizer operation

automatically adjusts the above-minimum outside air

position to provide free cooling when the outdoor air

temperature is appropriate.

• Demand Control Ventilation By using CO2 levels to

monitor the actual occupancy pattern in a room, the

system can allow code-specific levels of outdoor air to

be delivered when needed without costly overventilation during periods of low or intermittent

occupancy (

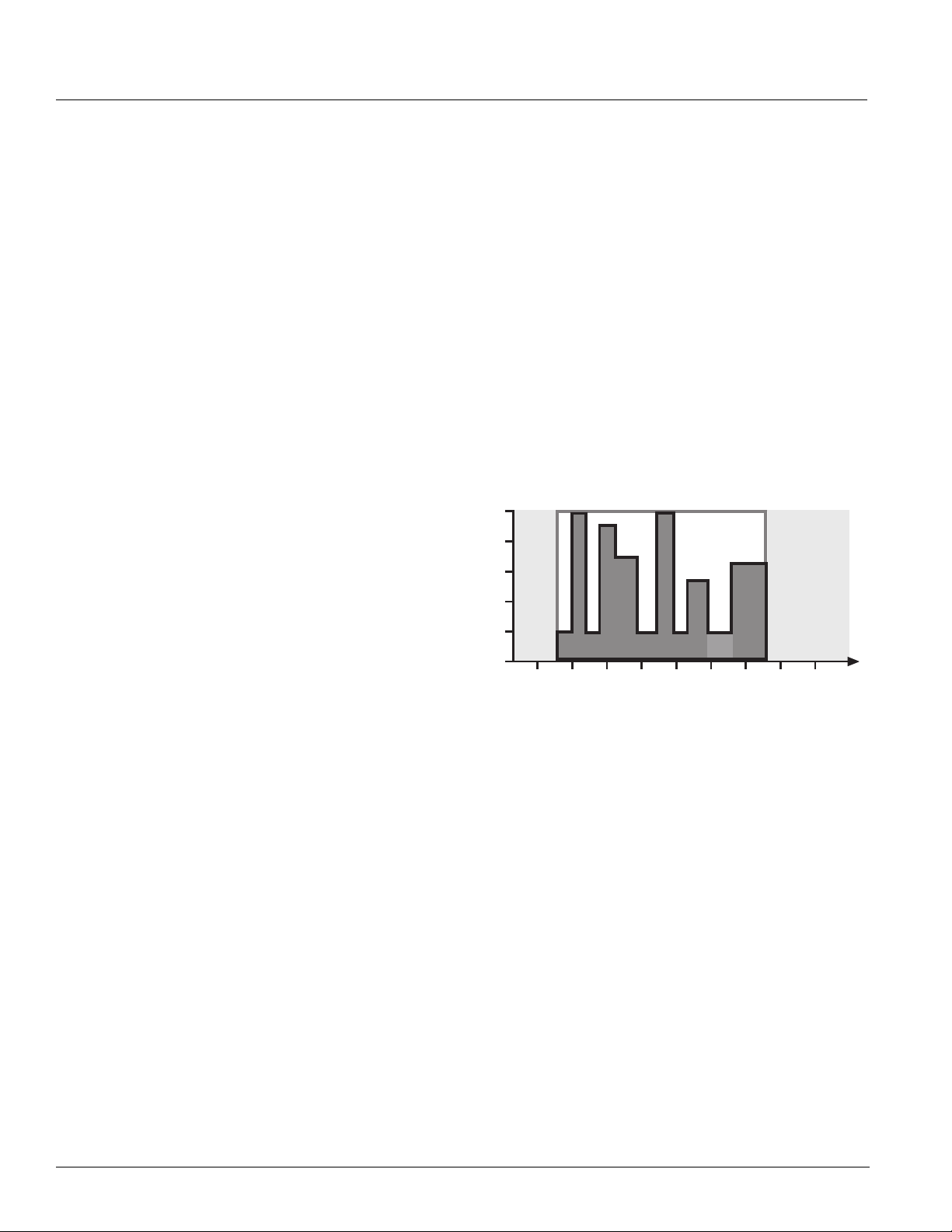

Figure 9. Energy Savings with Demand Control Ventilation

100%

20%

• Occupancy Mode Operation Units can be

programmed to operate only sparingly during

unoccupied periods and at night to conserve energy.

Figure 9).

Energy Savings

with DCV

Unoccupied

After Hours

DCV's fresh air for indoor air quality

6:00 8:00 10:00 12:00 2:00 4:00 6:00 8:00 10:00

School Hours

Cleaning

Unoccupied

10 McQuay Catalog 1600

Page 11

Features & Benefits

Easy To Maintain

AAF-HermanNelson Unit Ventilators are designed to

provide easy access for maintenance and service

personnel to all serviceable components. Most

maintenance tasks are easily handled by a single

person.

Modular Fan Deck

The entire fan deck is easily removed as a single unit.

This provides ready access to fan wheels, motors,

bearings and other components for service, cleaning or

repair.

The fan deck’s rotating element has one large, selfaligning, oilable end bearing and two oilable motor

bearings for smoother operation. The location of these

bearings at the ends of the shaft (out of the airstream)

enables easy access and long life.

Figure 10. Long-life bearings

Even “permanently” lubricated motors are supplied with

recommended lubrication charts calling for lubrication

every seven years. Maintenance instructions of the

motor manufacturer should be followed closely.

Heavy-Duty Discharge Grille

The discharge grille on the top of the unit is made from

extra-strength steel bar stock, promoting long life

(

Figure 11). It can be removed to facilitate cleaning of

fans and fan housings. A built-in 10-degree angle

provides proper air throw to blanket the room for proper

air circulation and comfort.

Figure 11. Heavy-Duty Steel Discharge Grille

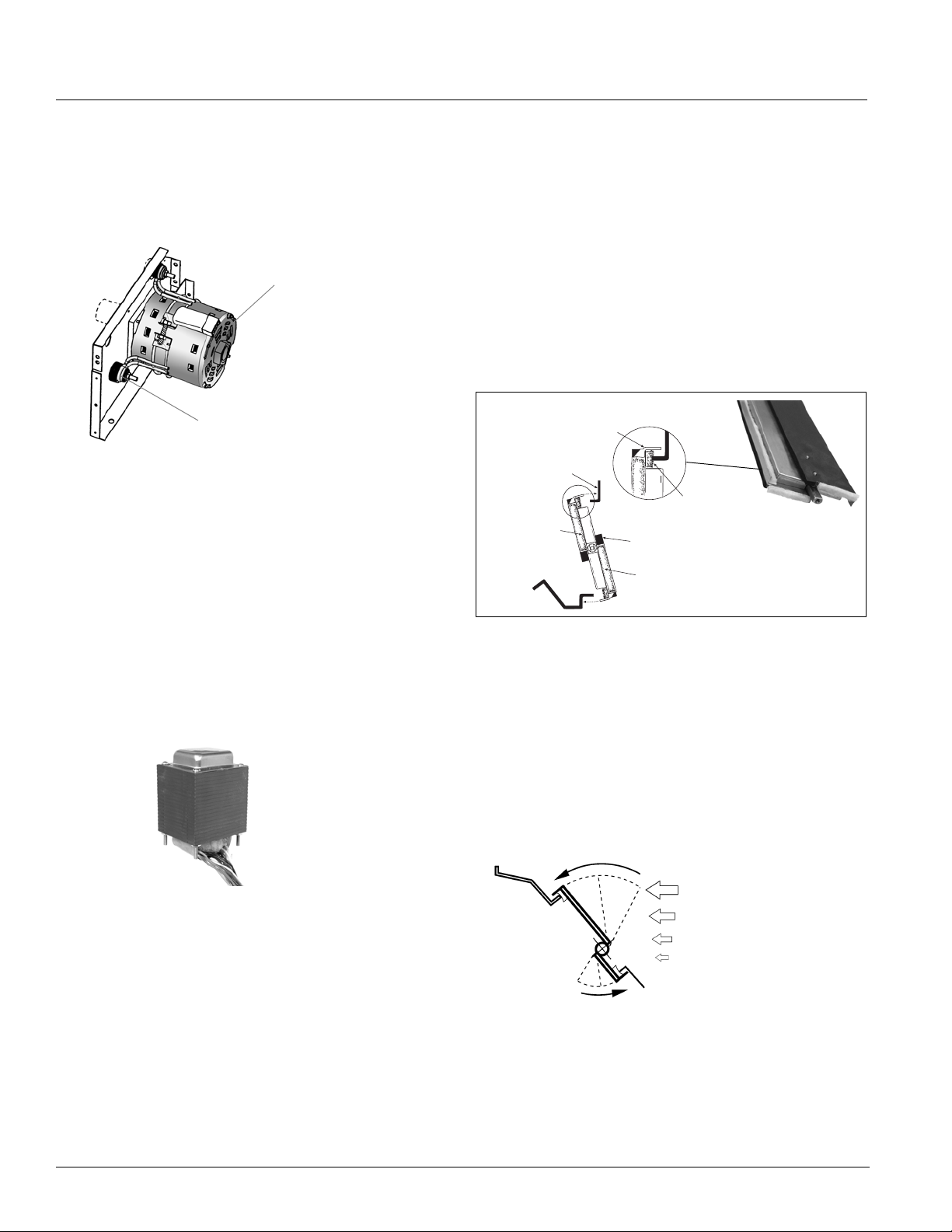

Easy Motor Removal

Unlike with many competitive models, the motor in

AAF-HermanNelson unit ventilators is separate from the

fan assembly and is located out of the airstream at the

end of the fan shaft—away from the hot coil—for easier

maintenance and removal. Locating the motor away from

the coil (

motor life. Our direct-coupled motor and self-aligning

motor mount facilitate motor change-out. The motor

comes with a molex plug that fits all sizes and further

simplifies removal.

Figure 12) has the added benefit of extending

Figure 12. Modular Fan Deck

Heavy-Duty Discharge Grille

Modular Fan Deck

AAF-HermanNelson Model AV Unit Ventilators 11

Motor & Bearings Located

Out Of Airstream

Page 12

Features & Benefits

Tamper-Resistant Fasteners

Front panels and top access doors are held in place by

tamper-resistant, positive-positioning fasteners. They are

quickly removed or opened with the proper tool, but deter

unauthorized access to the unit’s interior (

Figure 13).

Sectionalized Access Panels And Doors

All floor units have three separate front panels and

hinged top access doors, sized for convenient handling

by a single person (

Figure 13). The result is easy,

targeted access to the component that needs servicing:

• Two 12 inch-wide end panels provide easy access to

piping, temperature control components and the fan

switch. Unlike units with full-length front panels, these

can be removed without disturbing the normal

operation of the unit.

• Hinged top access doors provide easy access into the

end compartments to facilitate convenient servicing of

the motor and shaft bearing.

• A short, center front panel provides easy access to the

filter and discharge grille.

Single-Filter Design

With AAF-HermanNelson’s single-filter design, filter

change-out takes only seconds. Uneven dust loading is

eliminated, which is common to units with separate filters

for room and outdoor air, or that use a metal partition to

separate filtering of indoor and outdoor air. The result

can be longer filter life, which means less maintenance

and fewer filters consumed.

Three filter types are offered:

• Single-use filters which feature Amerglas media and

are designed to be used once and discarded. These

are standard on all but electric heat units.

• Permanent metal filters which may be removed for

cleaning and reused numerous times. These are

standard on electric heat units.

• Renewable media filters, which consist of a heavyduty, painted-metal structural frame and renewable

Amerglas media.

Figure 13. Easy Access With Tamper-Resistant Fasteners

Discharge Grille

Doors

Right Front

Access Panel

Discharge Screen

Tamper-Resistant

Fasteners

Fan

Motor

Ta m pe r -

Resistant

Fasteners

Center Front Access

Panel

Tamper-Resistant

Fasteners

Top Access

Left Front

Access Panel

Renewable

Media Filter

12 McQuay Catalog 1600

Page 13

Features & Benefits

Built To Last

Our industrial-strength design provides the durability to

withstand the rigors of the classroom environment. Its

solid construction and rugged finish promotes continued

alignment, structural strength and long-lasting beauty

decades after the unit is installed. In fact, many units

installed over 30 years ago continue to provide quiet,

reliable classroom comfort.

Heavy Duty Frame Construction

AAF-HermanNelson’s exclusive, unitized frame

(

Figure 14) is far superior to the fastener-type

construction used by other manufacturers. Loosened

fasteners can cause vibration, rattles and sagging

panels. With unitized construction, there are no fasteners

(screws or bolts) to come loose.

Other design features that promote trouble-free

operation and long life include:

• A corrosion-resistant, galvanized-steel frame.

• Extra-strength, steel-bar discharge grille.

• Heavy-gauge-metal cabinet access panels and doors.

• An extra-strength pipe tunnel that stiffens the structure

while adding aerodynamic air flow within the unit.

• Hidden reinforcement that provides additional built-in

support for the top section as well as better support for

the fan deck assembly.

• A rigid exterior that is strong enough to support

maintenance personnel without fear of damaging the

unit.

Rugged Exterior Finish

The superior finish of the unit ventilator’s cabinets fosters

long-lasting beauty as well as resistance to abuse and

corrosion. We apply the very highest standards at every

step of the finishing process to provide lasting quality:

• High-quality furniture steel is carefully inspected before

painting. Scratches and marks that might show through

are removed.

• After fabrication, the metal undergoes a five-stage

cleaning and phosphatizing process to provide a good

bonding surface and reduce the possibility of peeling

or corrosion.

• A specially formulated, environmentally friendly,

thermosetting urethane powder is applied

electrostatically to the exterior panels. This film is

oven-cured to provide correct chemical cross-linking

and to obtain maximum scuff- and mar-resistance.

• The top of the unit is finished with a textured, non-glare

and scuff-resistant, charcoal bronze electrostatic paint.

End and front panels are available in a pleasing array

of architectural colors.

• The Oxford brown steel kickplate is coated and baked

with a thermosetting urethane powder paint to blend

with floor moldings and provide years of trouble-free

service.

• Each unit is painstakingly inspected before boxing,

then encapsulated in a clear plastic bag, surrounded

by an extra-heavy-duty cardboard box and secured to

a skid to help provide damage-free shipment.

Figure 14. Heavy-Duty, Welded Chassis

Unitized Frame

Welded

Construction

AAF-HermanNelson Model AV Unit Ventilators 13

Energy-Efficient

Fan Motor

Page 14

Features & Benefits

Durable, Energy Efficient Fan Motors

AAF-HermanNelson unit ventilators are equipped with

115/60/1 NEMA motors that feature low operating current

and wattage (

Figure 15. Energy-Efficient Fan Motor

Additional features of these motors include:

• Split-capacitor (PSC) design with automatic reset and

thermal-overload protection.

• No brushes, contacts or centrifugal starting switches—

the most common causes of motor failure.

• A built-in, decoupled isolation system to reduce

transmission of vibrations for quieter operation.

• A multi-tap, auto-transformer (Figure 16) provides

multiple fan motor speed control through the speed

switch. The motor is independent of supply voltage,

which allows stocking of one motor (school districtwide) for various voltage applications.

Figure 16. Multi-Tap Auto-Transformer

Figure 15).

Energy Efficient

NEMA Motor

Decoupled Isolation

System

Additional features include:

• Face and bypass dampers have a twist-free

reinforced aluminum construction for durability.

Aluminum is used because it is lightweight and

noncorrosive, resulting in low torque and easy

movement.

• Outdoor air dampers are made of galvanized steel to

inhibit corrosion, with double-wall welded construction

for rigidity and encapsulated insulation (

Figure 17).

Additional insulation is provided on the exterior of the

outdoor air damper blade and on the outdoor air entry

portion of the unit.

Figure 17. Outdoor Damper Seals Out Cold Weather

Turned Metal

Damper Blade

Turned Metal

Damper Stop

Wool Mohair

End Seal

Full-Length

Wool Mohair Damper

Additional

Insulation

Wool Mohair End

Seal

• Room air dampers are free-floating and designed to

prevent intermittent gusts of cold air from blowing

directly into the classroom on windy days (

Figure 18).

They are constructed of aluminum with built-in rigidity.

The metal forming technique that is employed resists

twisting and incorporates a full-length counter weight

for easy rotation. The simple principle of an area

exposed to a force is used to automatically close the

damper, rather than open it, when gusts of cold air

occur.

Figure 18. Room Air Damper Auto-Closed By Wind Gusts

Wind

Gust

Durable Damper Design

All dampers in AAF-HermanNelson Unit Ventilators use

the turned-metal principle on their long closing edges

(

Figure 17). Positive sealing is provided by embedding

the edge into wool mohair (no metal to metal contact).

There are no plastic gaskets to become brittle with time,

sag with heat or age, or require a difficult slot fit to seal.

Nylon damper bearings foster quiet, maintenance-free

operation.

14 McQuay Catalog 1600

Page 15

MicroTech II Controls

MicroTech II Controls

MicroTech II Controls For Superior Performance, Easy Integration

AAF-HermanNelson unit

ventilators equipped with

MicroTech

provide superior performance

and easy integration into your

building automation system of

choice. MicroTech II benefits

include:

• Factory integrated and tested

controller, sensor, actuator and unit options promote

quick, reliable start-up and minimize costly field

commissioning.

• High-performance features and advanced control

options can quickly pay for themselves in saved energy

costs and more comfortable classrooms.

• Select from three control levels: stand-alone, masterslave or network control.

• For network control applications, our Protocol

Selectability feature provides easy, low-cost integration

of AAF-HermanNelson unit ventilators into most

building automation systems.

• Flexible BAS network communication options guard

against controls obsolescence, keeping MicroTech II

controls viable for the life of your AAF-HermanNelson

equipment.

II unit controllers can

If a school has more than one zone, separate, remote

time clocks are used to regulate each zone. In this case,

the remote-mounted time clock energizes or deenergizes an external, 24-volt or 120-volt control circuit

which operates the unit-mounted day/night relays in that

zone.

Master-Slave Control

Designate the master and slave units and we will factory

configure and install the controllers so they are set up for

a local peer-to-peer network between units (leaving only

the network wiring between these units to be field

installed).

Slave units can be field-configured to be dependent or

independent as follows:

• Dependent slave units follow the master unit

completely. They are ideal for large spaces that have

even loads across the space (such as some libraries).

• Independent slave units (default) use master setpoints

and slave sensors. The slave follows the master unit

modes, such as heat or cool, but has the flexibility to

provide the conditioning required for its area within the

space. Independent slave units perform better in

spaces where loads vary from one area of the space to

the other (such as stairwells or cafeterias).

Three Control Levels

MicroTech II unit controllers provide the flexibility to

operate AAF-HermanNelson unit ventilators on any of

three levels:

• As stand-alone units, with control either at the unit or

from a wall sensor.

• In a master-slave relationship, where slave units follow

the master unit for some or all functions.

• Controlled as part of a network using a centralized

building automation system.

Stand-Alone Control

When operating in stand-alone mode, the MicroTech II

controller performs complete room temperature and

ventilation control. Units can be operated in occupied,

unoccupied, stand-by, or bypass (tenant override)

modes. Occupied/unoccupied changeover can be

accomplished:

• Manually by a unit-mounted day/night switch.

• Automatically by a unit-mounted day/night time clock.

• Automatically by a remote-mounted time clock that

operates unit-mounted day/night relays.

Network Control

MicroTech II unit controllers provide easy integration into

your building automation system of choice. All factoryinstalled options are handled by the unit controller. This

simplifies the transmission of monitoring and setpoint

data to the building automation system.

You select BACnet, LonTalk or Metasys N2 Open

communications to communicate control and monitoring

information to your BAS, without the need for costly

gateways (see

page 22). Unit controllers are LONMARK certified with the

optional LONWORKS communication module.

Flexible network communication options via our Protocol

Selectability feature help you avoid control obsolescence

over the life of your AAF-HermanNelson equipment.

“Optional Communication Modules” on

AAF-HermanNelson Model AV Unit Ventilators 15

Page 16

MicroTech II Controls

A Wide Variety of Input, Output & Alarm Data Points Available

A wide variety of data is available from AAFHermanNelson unit ventilators when equipped with

MicroTech II unit controllers in a network situation. They

classroom and notify your building automation system of

alarm conditions regardless of the protocol you select.

See

"Table 3: Network Operation - Typical Data Points"

below for a list of inputs, outputs and alarm functions

available.

provide a clear picture of just what's happening in each

Table 3: Network Operation - Typical Data Points

Read/Write Attributes Read Only Attributes

• Application Mode

• Auxiliary Heat

Enable

• Compressor

Enable

• Emergency

Override

• Energy Hold Off

• Heat/Cool Mode

• Occupancy

Override

• Outdoor Air

Humidity

• Reset Alarm

• Reset Filter Alarm

• Setpoint Offset

• Source (Water In)

Temperature

• Space CO2

• Space Humidity

• Space

Temperature

• Binary Input 1 Status

• Binary Output 1 Status

• Binary Output 2 Status

• Compressor Run Time

• Chiller Water Valve

Position

• Discharge Air

Temperature

• Discharge Air

Temperature Setpoint

• Effective Setpoint

• Effective Space

Temperature

• Fan Speed

• F & BP Damper

Position

• Local Setpoint

• Outdoor Air Damper

Position

• Space Fan Runtime

• Unit Ventilator

Controller State

• Water-out Temperature

• WH or CW/HW Valve

Position

1.

Not all data points or alarms listed will be available in all unit ventilator configurations. Humidity and CO2 points require the use of optional sensors.

1

Read/Write

Setpoint Attributes

• Econ. IA/OA Enthalpy

Differential Setpoint

• Econ. IA/OA Temp.

Differential. Setpoint

• Econ. Outdoor Air

Enthalpy Setpoint

• OAD Min. Position

Low-Speed Setpoint

• OAD Min. Position

Med.-Speed Setpoint

• Occupied Cooling

Setpoint

• Occupied Heating

Setpoint

• Space CO2 Setpoint

• Space Humidity

Setpoint

• Standby Cooling

Setpoint

• Unoccupied Cooling

Setpoint

• Unoccupied Heating

Setpoint

• UV Software

Application Version

Typical Alarms

• Indoor Air Temperature Sensor

Failure

• DX Pressure Fault

• Compressor Envelope Fault

• Condensate Overflow Indication

• Indoor Air Coil DX Temperature

Sensor Failure

• Outdoor Air Temperature Sensor

Failure

• Discharge Air Temperature Sensor

Failure

• Outdoor Air Coil DX Temperature

Sensor Failure (or)

• Water Coil DX Temperature

Sensor Failure

• Water-out Temperature Sensor

Failure (or)

• Water-in Temperature Sensor

Failure

• Space Humidity Sensor Failure

• Outdoor Humidity Sensor Failure

• Space CO2 Sensor Failure

• Source Temperature (Water-in)

Inadequate Indication

• Change Filter Indication

16 McQuay Catalog 1600

Page 17

MicroTech II Controls

Control Modes and Functions

AAF-HermanNelson unit ventilators equipped with

MicroTech

operate in a variety of modes based on the current

situation in the room and the status of the unit ventilator.

Changes in mode can be triggered manually, via network

signals, by sensor readings, or by date and time.

External inputs and outputs can be used to change

modes, communicate data to network controls or change

the functional operation of the unit.

Occupancy Modes

MicroTech II unit controllers can be set up to change

modes based on room occupancy. Four different

occupancy modes are provided, as described below.

Occupied Mode

This is the normal daytime operation mode. The

controller maintains a room set point using the outside air

capability and other functions.

Note: For non-school applications, the unit can also be

Unoccupied Mode

This is the night setback operating mode, in which the

unit responds to a new room set point and cycles to

maintain the condition. The fan comes on when heating

or cooling is needed and runs until the load is satisfied.

The outdoor air damper is closed during this mode.

When a cooling load is satisfied by a refrigerant system,

the compressor is de-energized and the unit ventilator

indoor fan continues to run for a fixed period of time to

remove coldness from the evaporator coil. This reduces

the potential for low refrigerant temperatures to exist on

the evaporator coil.

II unit controllers can be programmed to

configured to cycle the fan in response to the room load.

In this case, the fan would normally be in the Off Mode

until heating or cooling is required. The outside air

damper is always closed when the fan is off. When the

fan starts, the outside air damper opens to the required

position, usually minimum position.

can be made in 1-minute increments from 1 minute to

240 minutes through ServiceTools™ (see

network.

page 24) or a

Economizer Modes

Economizer operation is facilitated by the outdoor air

damper, which automatically adjusts the above-minimum

outside air position to provide free cooling when the

outdoor air temperature is appropriate. Three levels of

economizer control are available:

Basic Economizer Operation: The MicroTech II

controller compares the inside and outside temperatures.

If the temperature comparison is satisfactory, then freeair economizer operation is used to cool the space.

Reheat units also come configured with an indoor

humidity sensor.

Expanded Economizer Operation: In addition to

comparing inside and outside temperatures, outdoor

relative humidity is measured to calculate outside air

enthalpy. If the enthalpy set point is not exceeded, and

the temperature comparison is satisfactory, then free

economizer operation is used to cool the space. This

helps to minimize the entrance of humid outside air.

Leading-Edge Economizer Operation: The MicroTech II

controller compares both indoor and outdoor

temperatures and indoor and outdoor relative humidities.

Then it calculates both inside and outside air enthalpy to

determine if free economizer operation can cool the

space with non-humid outside air. This is a true enthalpy

economizer—a first for unit ventilators.

Night Purge Mode

Under this mode, the unit is configured to purge the room

space for one hour for various reasons (odor or fume

removal, drying, etc.).During Night Purge the outside air

damper is open full and the fan is run on high speed. No

“normal” heating or cooling takes place (the emergency

heat set point is maintained) and the exhaust fan, if the

room is so equipped, is signaled to turn on.

Stand By Mode

In this mode, the unit maintains the occupied mode set

point temperature with the outdoor air damper closed.

The fan runs continuously unless it is configured to cycle

in response to the load.

Bypass Mode

This is a tenant override operating mode in which the unit

is placed back into the Occupied Mode for a

predetermined time. The default is 120 minutes. Settings

AAF-HermanNelson Model AV Unit Ventilators 17

Freeze Prevention Mode

This mode helps protect the unit ventilator from freezing

air conditions. Control functions vary depending on the

type of temperature control used by the unit, as follows:

Face and bypass control units: Upon sensing a potential

freezing air temperature condition leaving the heating

coil, the unit will automatically protect itself by shutting

the outside air damper and opening the EOC valve. The

face and bypass damper is allowed to operate normally

to control the space. The fan continues to run to remove

the cold air. Once accomplished, the freezestat is reset,

Page 18

MicroTech II Controls

the outside air damper opens to the minimum position

and the unit commences its normal mode of operation.

Valve control units: Upon sensing a potential freezing

air temperature condition leaving the heating coil, the

unit will automatically protect itself by shutting the outside

air damper and opening the hot water valve to a

minimum of 50% (more if required to heat the room). The

fan speed will be staged down to low speed and then

turned off. When the freezestat is reset, the outside air

damper opens to the minimum position and the fan runs

at low speed for a minimum of 10 minutes. It then will

stage up if needed to satisfy the room set point. This

reduces the potential to overheat a room recovering from

a potential freeze condition.

Note: Valve selection and coil sizing is critical for proper

operation. Face and bypass control is recommended for

proper humidity and freeze protection.

Emergency Heat Mode

If the unit is left in a mode that does not normally allow

heating (such as Off, Fan Only, Cool, or Night Purge)

and the room temperature falls below 55°F, the unit will

heat the space to above 55°F and then return to the

previously set mode of operation. This mode of operation

can be field configured and/or be disabled.

External Input Functions

The unit ventilator controller is provided with three (3)

binary inputs that allow a single set of dry contacts to be

used as a signal to it. Input signal choices are described

below. Multiple units can be connected to a single set of

dry contacts.

Note: Not all of the functions listed can be used at the same

time. The unit ventilator controller is provided with

configuration parameters that can be adjusted to select

which function will be used for these inputs where

multiple functions are indicated below. For wiring

examples see installation manual IM

Unit Ventilator Controller.

Unoccupied Input Signal

This input signals the unit ventilator controller to go into

unoccupied or occupied mode. When the contacts close,

the unit ventilator controller goes into unoccupied mode;

when the contacts open, it goes into occupied mode.

Additional variables can affect occupancy mode and

override this binary input. See

“Occupancy Modes” on

page 17.

Dewpoint/Humidity Input Signal (Optional)

This input signals the unit ventilator controller to go into

active dehumidification mode. When the contacts close

747: MicroTech II

(high humidity) the controller will go into active

dehumidification; when the contacts open (low humidity)

it will stop active dehumidification.

Remote Shutdown Input Signal

This input signals the unit ventilator controller to go into

shutdown mode. When the contacts close, the controller

goes into shutdown mode; when the contacts open, it

returns to normal operation.

Ventilation Lockout Input Signal

This input signals the unit ventilator controller to close

the outdoor air damper. When the contacts close

(ventilation lockout signal) the controller closes the

outdoor damper; when the contacts open, it returns to

normal outdoor damper operation.

Exhaust Interlock Input Signal

This input signals the unit ventilator controller that an

exhaust fan within the space has been energized. The

controller then repositions the outdoor air damper to a

user-adjustable minimum position. When the contacts

close (exhaust fan on signal) the controller uses the

value defined by the Exhaust Interlock OA Damper Min

Position Setpoint as the new minimum outdoor air

damper position regardless of the indoor air fan speed.

When the contacts open, it returns to normal outdoor

damper operation.

External Output Functions

The unit ventilator controller is provided with three (3)

binary outputs to perform the functions described below.

These are relay type outputs that are intended to be

used with signal level voltages only (24 VAC max).

Note: Not all of the functions listed can be used at the same

time. The unit ventilator controller is provided with

configuration parameters that can be adjusted to select

which function will be used for these outputs when

multiple functions are indicated below. For wiring

examples, see installation manual IM

Unit Ventilator Controller.

Lights On/Off Signal

This relay output provides one set of NO dry contacts

that can be used to signal the operation of the room

lights. When the unit ventilator controller is in occupied,

standby or bypass occupancy modes, the relay output

will signal the lights on (contacts closed); when the

controller is in unoccupied occupancy mode the relay

output will signal the lights off (contacts open).

747: MicroTech II

18 McQuay Catalog 1600

Page 19

MicroTech II Controls

Fault Signal

This relay output provides NO, NC, and Common

connections that can be used to signal a fault condition.

When a fault exists, the unit ventilator controller

energizes this relay output. When the fault or faults are

cleared, it de-energizes this relay output.

Exhaust Fan On/Off Signal

This relay output provides one set of NO dry contacts

that can be used to signal the operation of an exhaust

fan. When the outdoor air damper opens more than the

Energize Exhaust Fan OA Damper Setpoint, the relay

output will signal the exhaust fan on (contacts closed).

When the outdoor damper closes below this setpoint, the

relay output will signal the exhaust fan off (contacts

open).

Auxiliary Heat Signal

This relay output provides one set of NO dry contacts

that can be used to operate an auxiliary heat device. The

unit ventilator controller by default is configured to

operate a NO auxiliary heat device (de-energize when

heat is required) such as a wet heat valve actuator with a

spring setup to open upon power failure. However, the

Auxiliary Heat Configuration variable can be used to set

the controller to use an NC auxiliary heat device

(energize when heat is required) such as electric heat.

fan operation under normal operating conditions, in

conjunction with our GentleFlo fan technology (see

5page 5) contributes to a very quiet classroom

envionment.

page

Demand-Controlled Ventilation (Optional)

AAF-HermanNelson unit ventilators can be equipped to

use input from a CO

based on actual occupancy instead of a fixed design

occupancy. This Demand Controlled Ventilation (DCV)

system monitors the amount of CO

students and teachers so that enough fresh outdoor air is

introduced to maintain good air quality. The system is

designed to achieve a target ventilation rate (e.g., 15

cfm/person) based on actual occupancy.

By using DCV to monitor the actual occupancy pattern in

a room, the system can allow code-specific levels of

outdoor air to be delivered when needed. Unnecessary

over-ventilation is avoided during periods of low or

intermittent occupancy.

With DCV you can be confident that your school is

meeting ventilation standards for Indoor Air Quality and

that your students are receiving adequate air to be

attentive to instruction. At the same time, you are saving

money in early morning hours, in between classes, or

after hours when classrooms are heated and cooled but

not always fully occupied.

controller to ventilate the space

2

produced by

2

Advanced Control Options

MicroTech II controls make possible a number of

advanced control options that can quickly pay for

themselves in saved energy costs and more comfortable

classrooms, as described below.

Part Load Variable Air Control

Part Load Variable Air control can be used in conjunction

with face and bypass damper temperature control to

automatically adjust the unit ventilator fan speed based

upon the room load and the room-temperature PI control

loop. This MicroTech II control option provides higher

latent cooling capabilities and quieter operation during

non-peak load periods by basing indoor fan speed upon

room load.

During low-load or normal operation (about 60% of the

time) the fan will operate on low speed. When the load

increases to an intermediate demand, the fan will

automatically shift to the medium-speed setting. Under

near-design or design-load conditions, the fan will

operate on high speed. A built-in, 10-minute delay helps

minimize awareness of fan speed changes. Low-speed

As Simple as a Thermostat

Demand Controlled Ventilation is easy to apply. When

DCV is ordered, a CO

and configured for operation. The system does the rest.

If desired, the ventilation control setpoint can be adjusted

through the MicroTech II Controller.

sensor is mounted on the unit

2

Acceptance By Codes And Standards

ASHRAE Standard 62-2004 Ventilation for Indoor Air

Quality recognizes CO

controlling ventilation based on occupancy. The

ASHRAE standard has been referenced or adopted by

most regional and local building codes. This standard

references ventilation on a per-person basis.

Using CO2 control will sometimes lower the absolute

amount of outside air delivered into a room but will

maintain the per-person rate. For example, if a

classroom is designed for 30 students, the ventilation

rate is 450 cfm (30 students X 15 cfm/student). However,

when there are only ten students in the classroom, the

CO

control will adjust ventilation to 150 cfm (10 students

2

X 15 cfm/student). A minimum base ventilation rate

(typically 20% of design levels) is provided when in the

based DCV as a means of

2

AAF-HermanNelson Model AV Unit Ventilators 19

Page 20

MicroTech II Controls

occupied mode. This provides outdoor air to offset any

interior source contamination while allowing for proper

space pressurization.

Active Dehumidification Control (Reheat)

In high-humidity applications where valve-controlled,

reheat units are used, the Active Dehumidification

Control (ADC) sequence should be considered. During

excessive humidity conditions, a humidity sensor directs

the unit to continue cooling past the room setpoint to

remove excess moisture. Hydronic heat or electric heat

is then used to reheat the discharge air to maintain

acceptable room temperatures.

MicroTech II controls minimize the amount of reheat

needed to maintain relative humidity below a preset limit.

Reheat is used only when required and in the most

energy-efficient manner possible.

Active Dehumidification comes standard on units

equipped with MicroTech

configuration and valve-control temperature modulation.

The MicroTech ADC humidity sensor is unit-mounted. It

issues a signal proportional to the classroom’s humidity

level (unlike humidistats which issue an open-close

signal). This enables a control sequence that manages

both the temperature and the relative humidity.

When the relative humidity exceeds a preset value, the

modulating chilled-water valve opens fully to dehumidify

the mixture of outdoor and return air entering the cooling

coil. The reheat modulating water valve then opens, or

electric heat is engaged, to reheat the air leaving the

cooling coil, as required to maintain the classroom

setpoint.

Active dehumidification starts when the indoor relative

humidity exceeds the preset relative humidity upper

setpoint and continues until the room humidity falls 5%

below the endpoint. During active dehumidification,

economizer operation is disabled (and the outdoor air

damper is reset to its minimum position) unless the

outdoor air temperature is below 55°F. It is maintained

until dehumidification is completed. When the indoor

humidity level is satisfied, the MicroTech II controller

reverts to its normal sequences to satisfy the classroom

temperature setpoint.

II controls, a reheat

closer contact with the cold coil for passive

dehumidification.

This only occurs in the unoccupied mode as the unit

operates to satisfy the humidity set point with the outside

damper closed. The face and bypass damper is placed in

a minimum face position to promote high latent cooling.

The unit fan continues to operate on low speed until the

load is satisfied. This is very helpful in high humidity

areas where high night time humidity can be absorbed in

the building during off hours.

DX Split System Control

On unit ventilators equipped with direct-expansion (DX)

coils, the unit ventilator controller is configured to operate

the compressor as secondary (mechanical) cooling when

economizer cooling is available, and as primary cooling

when economizer cooling is not available. Addtiional DX

control features include:

Compressor Envelope: This helps protect the

compressor from adverse operating conditions that can

cause damage and or shortened compressor life. It ends

compressor operation if coil temperatures exceed the

defined operating envelope.

Compressor Cooling Lockout: The unit ventilator

controller is configured to lock out compressor cooling

when the outdoor air temperature falls below the

compressor cooling lock out setpoint. Below this

temperature setpoint only economizer cooling will be

available.

Minimum On And Off Time: The unit ventilator controller

is provided with minimum-on and minimum-off timers to

prevent adverse compressor cycling (3-minutes default).

Compressor Start Delay Variable: This variable is

intended to be adjusted as part of the start-up procedure

for each unit. It is used to prevent multiple unit

compressors from starting at the same time after a power

failure or after an unoccupied-to-occupied changeover.

Each unit should be configured at start-up with a slightly

different (random) delay, or groups of units should be

provided with different delays.

Passive Dehumidification Control

On units with face and bypass damper control, a chilledwater coil and MicroTech II part-load variable air control,

passive dehumidification can be used under high

humidity conditions to keep classrooms comfortable. A

unit-mounted humidity sensor and a low fan speed are

utilized to improve latent cooling by keeping the air in

20 McQuay Catalog 1600

Page 21

MicroTech II Controls

System Components

The main components of the MicroTech II system are:

• The Unit Ventilator Controller (UVC)

• The Local User Interface (LUI)

• Optional plug-in network communication modules

In addition, unit ventilators equipped with MicroTech II

controllers feature factory-mounted sensors and

actuators for system control and feedback.

Unit Ventilator Controller

The MicroTech II UVC is a DDC, microprocessor-based

controller designed to provide sophisticated comfort

control of an economizer-equipped AAF-HermanNelson

unit ventilator. In addition to normal operating control, it

provides alarm monitoring and alarm-specific component

shutdown if critical system conditions occur. Each UVC is

factory wired, factory programmed and factory run-tested

for the specific unit ventilator model and configuration

ordered by the customer.

Figure 19. MicroTech II Control Board

Terminal Connections

Plug-In Control Module

Figure 20. User Interface Touch Pad

The User Interface has individual touch-sensitive printed

circuit board mounted buttons, and comes with a built-in

menu structure (Hidden Key and Password Protected) to

change many of the common operating variables.

Four Operating Mode States

Four different user operating mode states can be chosen

on the LUI:

Heat: Heating and economizer operation only.

Cool: Cooling and economizer operation only.

Fan Only: Fan only operation.

Auto: The unit automatically switches between heating,

cooling and economizer operation to satisfy the room

load conditions. The current unit state is also displayed.

Local User Interface

A built-in LUI touch pad with digital LED Display is

located in the right hand compartment below the top right

access door. In addition to the Operating Mode States

and Fan Functions, the Touch Pad will digitally display:

• The room set point temperature.

• The current room temperature.

• Any fault code for quick diagnostics at the unit.

Four Fan States

Four fan states are provided on all units: high, medium

low and Auto speed modulation. The Auto speed

function (part load, variable air) varies the fan speed

automatically to meet the room load whether the unit is in

heating, cooling or economizer mode.

All this is accomplished with a standard, single-speed

NEMA frame motor. A built-in 10-minute delay helps

minimize awareness of speed changes. During low-load

or normal operation (about 60% of the time) the fan will

operate at low speed. The low speed operation, along

with GentleFlo fan technology, contributes to a very quiet

classroom environment.

When the load increases to an intermediate demand, the

fan automatically shifts to the medium speed setting. At

near-design or design-load conditions the fan will

operate on high speed.

With four fan states and GentleFlo fan technology, there

is no need to oversize units or worry about

uncomfortable conditions.

AAF-HermanNelson Model AV Unit Ventilators 21

Page 22

MicroTech II Controls

Optional Communication Modules

Optional communication modules provide control and

monitoring information to your building automation

system without the need for costly gateways. Available

communication protocols include BACnet, LonTalk and

Metasys N2 Open. The communication modules for each

are described below.

Figure 21. Typical 2" x 4" Communication Module

BACnet MS/TP Communication Module

This module allows the UVC to inter-operate with

systems that use the BACnet (MS/TP) protocol with a

conformance level of 3. It meets the requirements of the

ANSI/ASHRAE 135-1995 standard for BACnet systems.

LonWorks SCC Communication Module

This module supports the LonWorks SCC (Space

Comfort Communication) profile number 8500-10. Unit

controllers are LonMark certified with this optional

LonWorks communication module.

Metasys N2 Communication Module

This module provides N2 Open network communication

capability to the UVC for communication with Johnson

Metasys systems.

Figure 22. Wall-Mounted Temperature Sensors

Standard Expanded Deluxe

Standard Sensor: This sensor has no remote setpoint

adjustment capability.

Expanded Sensor: This sensor has a remote room

setpoint adjustment of ±3°F (±1.5°C) from the room

setpoint established on the unit ventilator’s local user

interface touch pad. Five temperature settings are

provided on each side of center.

Deluxe Sensor : This sensor has a remote room setpoint

adjustment of from 54°F (12°C) to 82°F (28°C) with a

midpoint setting of 68°F (20°C).

Note: McQuay does not recommend using the Deluxe Sensor

with DX systems due to its wide operating range and

potential problems with the refrigerant system.

Humidity Sensors

On units equipped with humidity sensors, the UVC is

configured to use a 0-100% RH, 0

VDC, capacitive

humidity sensor. Humidity sensors are available as unitmounted only. The humidity sensors are used with units

capable of passive or active dehumidification, or with

units using an outdoor enthalpy economizer or an indoor/

outdoor enthalpy economizer.

Sensors

The UVC is configured to use passive Positive

Temperature Coefficient (PTC) unit-mounted and wallmounted sensors. These sensors vary their input

resistance to the UVC as the sensed temperature

changes.

CO2 Sensor for Demand Controlled Ventilation

On units equipped for Demand Controlled Ventilation

(DCV) the UVC is configured to use a 0-2000 PPM, 0-10

VDC, single beam absorption infrared gas sensor. CO

2

sensors are available as unit mounted only. An air

collection probe (pitot tube and filter) is installed in the

return air of the unit.

Remote Wall-Mounted Temperature Sensors

MicroTech II unit ventilators offer three choices for

Figure 23. CO2 Sensor For Demand Control Ventilation

remote wall-mounted room sensors (

Figure 22). Each

has a tenant override capability and comes with an

international, quick-fastening connection capability.

22 McQuay Catalog 1600

Page 23

MicroTech II Controls