Page 1

Installation and Maintenance Data IM 473-1

Group: Unit Ventilator

Part Number: 106101901

Date: June 1999

Louver & VentiMatic Shutter

Installation For AAF-HermanNelson® Classroom Unit Ventilators

(Models AVS, AVV, AVR, AHF , AHV, AHR, ARQ and ERQ)

Horizontal

Blade Louver

Ventimatic Shutter

Vertical

Blade Louver

Uncrating and Inspection

Upon receipt of the equipment, check carton for visible damage. Make a notation on the shipper's delivery ticket before

signing. If there is any evidence of rough handling, the

cartons should be opened at once to check for concealed

damage. If any is found, notify the carrier within 48 hours to

establish a claim and request their inspection and a report.

The Warranty Claim Department should be contacted.

Inspect the carton for any specific tagging numbers indi-

cated by the factory per a request from the installing contractor.

©1999 AAF-HermanNelson IM 473-1 (Rev. 6/99)

Check the number against the plans to be sure that the

unit will be installed in the correct location.

Note: Installation and maintenance must be performed by

qualified personnel who are familiar with local codes and

regulations, and are experienced with this type of equipment.

Caution: Sharp edges are a potential injury hazard. Avoid

contact with them.

®

Page 2

Installation Instructions

The louver supplied with these instructions is designed to let

in fresh air and to prevent water such as driving rain from

getting past the louver and into the unit. A weathertight seal

must be accomplished to keep unwanted air and moisture

from entering the occupied space. It is important to properly

install the louver per the instructions below.

1. If the fresh air opening has not yet been made, refer to

Figures 1 through 4 for the recommended locations.

Consult approved architectural plans for exact location.

2. Once the location has been selected, cut the opening in

the wall so that it is slightly larger than the louver being

installed.

3. If the opening has already been made, measure it to be

sure there is a minimum of

1

⁄2" (13mm) clearance around

all sides. Note that for masonry installations, a lintel

must be installed above all louvers. The louver is not

designed to replace the lintel.

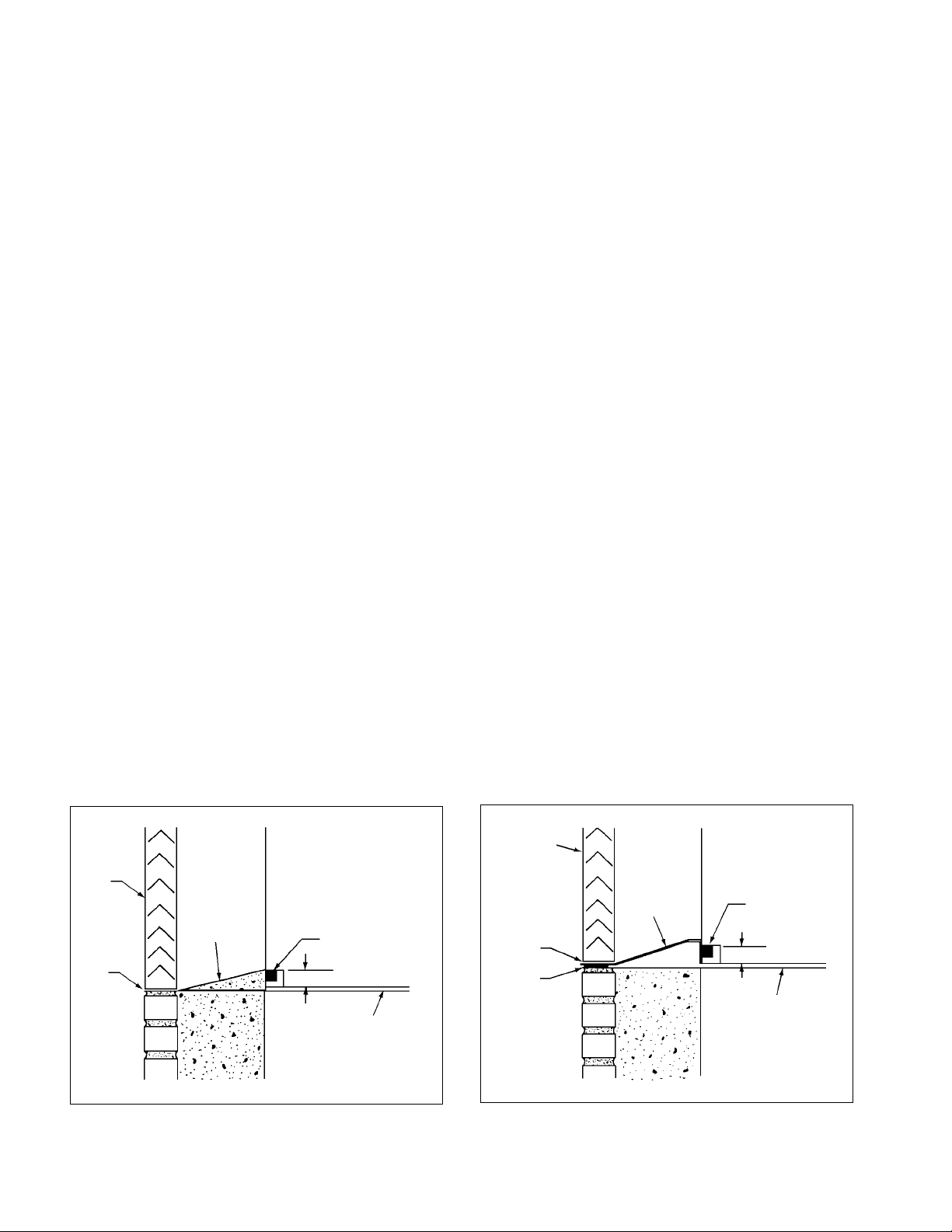

4. Before setting the louver, construct a sloping mortar

base to drain unwanted moisture to the outside. A

typical method is shown in Detail A. The mortar base

should be 1" (25mm) thick at the unit and taper toward

the louver. The 1" (25mm) thick mortar at the unit also

acts as backing against which the open cell gasket of the

unit can seal.

If it's not possible to make a mortar base as described above, then field supplied flashing must be

installed. A typical installation using flashing is shown in

Detail B. This flashing should terminate flush with the

exterior of the building. Place a bead of caulk under the

flashing to prevent moisture from wicking back to the

unit. Do not caulk the joint between the louver and

the flashing. This joint is designed to let unwanted

moisture escape.

5. Before setting the louver, make sure the drain lip (vertical) or drain holes (horizontal) are at the bottom and the

bird screen is towards the unit.

6. Place a heavy bead of caulk along the top and two sides

of the louver. Leave the bottom of the louver uncaulked

so that if moisture gets into the area between the louver

and the unit, it may drain outside unrestricted.

7. Place the louver in the opening so that it is recessed a

minimum

1

⁄16" (2mm) beyond the building facade or as

directed by the architect.

8. Mechanical fasteners may be desired or required to

further secure the louver in the wall. Employ a method

that is appropriate to the installation.

9. After the louver is solidly in place, run a bead of caulk

around the perimeter of the louver to seal it weathertight.

Caution: Do not plug the weep holes of the horizontal

louver nor the drip line of the vertical blade louver. This

will restrict the flow of unwanted moisture to the outside.

10. If flashing is used in place of a mortar base, caulk the

flashing where it meets the inside of the opening between the louver and the unit. This will prevent moisture

from getting under the flashing and into the occupied

space.

Detail A

Louver

No

Caulk

Page 2 / IM 473

Wall Unit

Cement Mortar;

Pitch Away

From Unit

1" (25mm)

Typical Installation Methods

Detail B

Louver

Unit Gasket

Floor

No

Caulk

Caulk

(By Others)

Wall Unit

Flashing

(By Others)

1" (25mm)

Unit Gasket

Floor

Page 3

Figure 1. 165⁄8" (422mm) Deep Unit with Open Pipe

Tunnel & Standard Louver Application

Figure 2. 16

Tunnel & High Louver Application with Chased

Wall

5

⁄8" (422mm) Deep Unit with Open Pipe

Piping

Lintel

(By

Others)

Louver

Floor Line

Cement

Mortar;

Pitch Away

From Unit

1"

(25mm)

Important: Gasket sealing

surface is required.

Figure 3. 217⁄8" (556mm) Deep Adapter Back Unit With

Standard Louver Application

Piping

Lintel

(By

Others)

Louver

Not Less

Than 3" (76mm)

Not More

Than 21" (533mm)

Cement Mortar;

Pitch Away

From Unit

Piping

1" (25mm)

Important: Gasket sealing

surface is required.

Floor Line

Figure 4. 217⁄8" (556mm) Deep Adapter Back Unit with

High Louver Application

Lintel

(By

Others)

Piping

Lintel

(By

Others)

Piping

Louver

Cement Mortar;

Pitch Away

From Unit

1" (25mm)

Important: Gasket sealing

surface is required.

Floor

Line

Louvers With Flanges

1. If the louver is supplied with flanges, follow steps 1

through 5 on page 2. Additionally, place a bead of caulk

on the inside of the top and side flanges that come in

contact with the building facade. Do not caulk the bottom

flange.

2. Place the louver in the opening and push it tight against

the building. Fasten it to the exterior of the building using

appropriate fasteners for the installation.

3. Seal the top and sides with a waterproof caulk to make it

weathertight. Do not caulk the bottom of the louver. To do

so may trap unwanted moisture behind the flange.

Louver

Cement

Mortar;

Pitch Away

From Unit

Not More

Than 28"

(711mm)

Piping

Floor

Line

Lining the Wall Opening

Thick wall applications require additional treatment of the

opening. The portion of the wall between the louver and the

unit will act as a plenum to bring outdoor air into the unit

ventilator. This plenum area should be lined using

of mortar or other suitable material. There are instances

where the specification requires a metal sleeve connection

between the louver and the unit. If a sleeve is used, properly

caulk it to insure a weathertight seal.

1

⁄2" (13mm)

IM 473 / Page 3

Page 4

VentiMatic Shutter Assembly

The VentiMatic shutter is a continuously variable, gravity

actuated, room exhaust vent which operates in direct response to positive static air pressure. It is a one-way shutter

that opposes any flow of air into the room. The Ventimatic

shutter allows a slight positive pressure in the room which

completely eliminates any unwanted friction.

When using the VentiMatic shutter exhaust system, it is

important that the VentiMatic shutter and the unit ventilator

wall louvers be mounted on the same wall. This will neutralize

the effect of the wind, forcing excess air into the room

through the unit ventilator louver because the same pressure

will work to keep the VentiMatic shutter closed and prevent

air from exhausting through it.

The VentiMatic shutter is generally mounted on a wall

exhaust louver. For larger units with 100% ventilation dampers, two VentiMatic shutters may be mounted side-by-side

on the same exhaust louver. The size and appearance of the

wall louvers used with the unit ventilator and VentiMatic

shutter, with or without decorative grilles, are identical.

Recommended

BC

24 27 2 4

(610) (659) (613) (267)

36 39 36

(914) (991) (918) (267)

48 51 48

(1219) (1295) (1222) (267)

60 63 60

(1524) (1600) (1527) (267)

72 75 72

Wall Openings

For Wall Louvers

Length Height 24" Shutter 36" Shutter cfm L/s

1

⁄8 101⁄2

1

⁄8 101⁄2

1

⁄8 101⁄2

1

⁄8 101⁄2

1

⁄8 191⁄2

(1829) (1905) (1832) (495)

As Directed

By Architect

Bird

Screen

Do Not

Block Drain

Holes With

Caulk or

Mortar

Notes:

1. Horizontal blade wall louver shown. Vertical blade wall louver also avail-

7"

(178mm)

Less

Than 9"

(229mm)

Cement Mortar

Maximum Number of VentiMatic

VentiMatic Shutters Shutter(s)

Which Can Be Mounted Air Capacity

On Standard Louver Maximum

1 0 500 236

0 1 750 354

2 0 1000 472

1 1 1250 590

0 2 1500 708

Cement Mortar

3⁄4" (19mm) Approx.

Steel Interior Wall

(Optional) See Note 3

Not

125⁄8"

(314mm)

3

⁄4" (19mm) Approx.

C

able with VentiMatic shutter.

2. Optional exterior grille matches unit ventilator wall louver in material and

design. Mounted on wall louvers.

3. Optional steel interior wall grille should be used to conceal the interior wall

opening whenever the VentiMatic shutter is not located behind shelf

cabinets or DraftStop enclosure. Hardware to mount the interior wall grille

is not included.

Aluminum Wall Louver

Assembly With Bird Screen

(See Note 1)

41⁄8"

(105mm)

237⁄8" (606mm)

357⁄8" (911mm)

Decorative Exterior Grille

Also Available (See Note 2)

103⁄8"

(264mm)

3" (76mm)

B

2" (51mm)

Single VentiMatic Shutter & Wall Louver

Aluminum Wall Louver

Assembly with Bird Screen

103⁄8"

(264mm)

(See Note 1)

B

Decorative Exterior Grille

Also Available (See Note 2)

Two VentiMatic Shutters & Wall Louver

or

3'' (76mm)

Center Cover

Steel

VentiMatic

Shutter

Assembly

VentiMatic

Shutter Ass'y

Installation

1. Install the louver per appropriate instructions found on pages 2 and 3.

2. Make sure all moving parts will operate unobstructed. Install interior grille if furnished.

AAF-HermanNelson

4900 Technology Park Boulevard, Auburn, NY 13021-9030 USA, (315) 253-2771

Printed on recycled paper containing at least 10% post-consumer material.

©1999 AAF-HermanNelson

Page 4 / IM 473-1 (Rev. 6/99)

Loading...

Loading...