Page 1

ULLETIN

INSTALLATION AND

MAINTENANCE DATA

NO. IM 104

REVISED MAY 1967

-2

AMD-AMB

AIRCONS”

AIR COOLED CONDENSERS

I

.13600

INDUSTRIAL PARK BLVD., MINNEAPOLIS, MINNESOTA 55427 1 PHONE: 377-9750

AREA CODE: 612

I

Page 2

TABLE OF CONTENTS

GENERAL INFORMATION

ASSEMBLY OF UNITS

INSTALLATION OF UNITS

DIMENSIONAL DATA

PIPING

PIPING DIAGRAMS

..........................

...............

GENERAL

.........

............

.........

.............

4-5

6-7

INFORMATION

INSPECTION

When the equipment is received, items should be

carefully checked against the bill of lading to

sure all crates and cartons have been received.

All units should be carefully inspected for damage

when received. Visible or concealed damage should

be reported immediately to the carrier and a claim

filed for damage. All motor nameplates should be

checked to be sure they agree with the power supply

available.

be

RIGGING AND MOVING UNITS

The exact method of handling and setting the Aircon

depends on available equipment, size of unit, final

location, and other variables. It is therefore up to the

judgment of the riggers and movers to determine the

specific method of handling each unit. All units are

shipped on heavy skids and all vertical airflow units

have rigging holes in the legs. In addition, all the

larger units have rigging holes in each end of the

base channels for aiding in handling of the units.

See Figure 2 for suggested rigging.

Under no circumstances should the coil headers or

return bends

be

used in moving

these units.

LOCATION

A. General -The

marily for outdoor location. The fan motors are

enclosed within the cabinet for their protection

on AMB units. Motors are totally enclosed type

McQuay

Aircon is designed pri-

2

RECEIVER AND OPERATING

CHARGE.

ELECTRICAL WIRING.

3

3

START UP

OPERATION

MAINTENANCE.

8

REPLACEMENT PARTS

on

AMD

doors, the air leaving the unit should be discharg-

the

ed to

warmed air through the unit.

B.

AMD & AMB Horizontal Aircons.

type

flow

(inlet air side) facing the prevailing winds. Where

strong winds are common, it is recommended that

a wind deflector be used to discharge the air ver-

tically

capacity during varying wind conditions. The wind

deflector should be installed on the fan side of

the

unit. The wind deflector is shipped knocked

down,

units

are

tance

tween unit and wall. If it is absolutely necessary

to have the unit positioned so that the air discharge

the wall a distance of not less than

d

iameter

C.

AMD & AMB Vertical Aircons.

type units should be

fan diameter from a wall or other obstruction. If

two or

area, at least one fan diameter distance should be

maintained between adjacent units. Sufficient

free area should be left around and below unit to

avoid air restriction

required

not

......................

.......................

......................

.................

units. If the unit is to be installed in-

outdoors to prevent

units should be installed with the coil

from

the unit, so as to prevent loss of

complete

installed with coil facing a wall, a dis-

of

at least

is

of the fan.

more

with assembly instructions. If

24”

should be maintained be-

toward a wall. it should be

units are to be positioned in the same

for vertical

9-10

............

.12-19

...........

re-circulation

Horizontal air

Vertical air flow

located no closer

to

coil. Wind deflectors are

Aircons.

of the

spaced

1-1/2

times the

than one

from

11

12

19

20

--

Page 2

Page 3

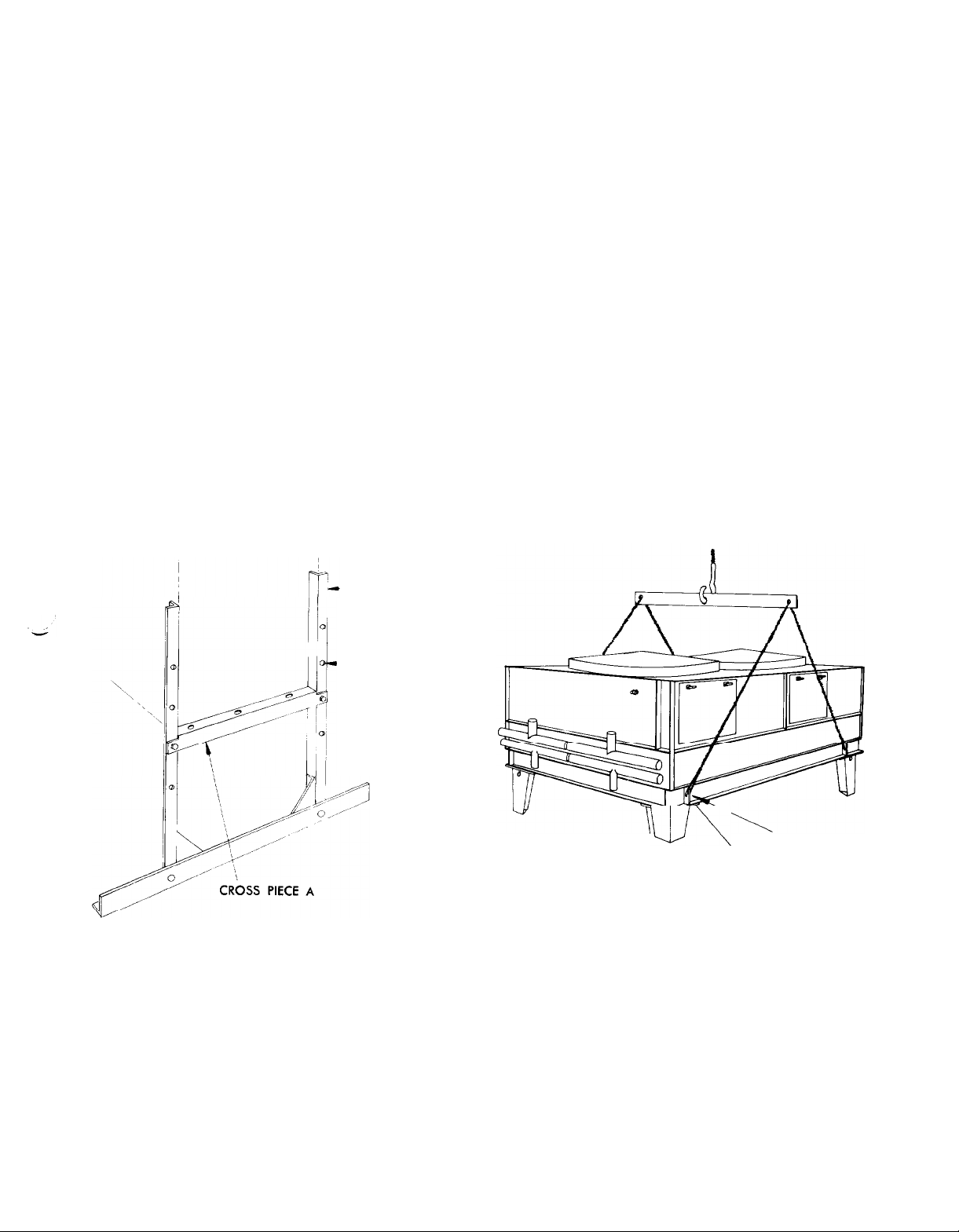

ASSEMBLY OF UNITS

GENERAL

‘-

Aircons

except for the mounting legs, wind deflectors, and

head pressure control packages. Mounting legs and

wind deflectors are furnished with

nuts and washers.

LEG ASSEMBLY (Horizontal

AMD

tional sets of holes for mounting. These holes are

furnished so that the legs can be positioned on the

unit at different leg heights. The location of cross

piece “A”,

of the unit above

On horizontal air flow units, the electric damper

motor, when furnished, is to bc installed on the under

are usually shipped completely assembled,

necessary

Aircons)

units are furnished with legs that have addi-

shown in Figure 1, determines the height

the

base.

bolts,

side of the damper section at the end nearest the

damper arm. See Figure 11, Page 16.

LEG ASSEMBLY

The legs of the vertical air flow units

adjustable. The legs are most easily assembled to

the unit when the unit is still in the upright position,

as

shipped.

work by 4 bolts furnished with the unit.

On vertical airflow units, when face dampers and

electric damper motors are used, it is necessary that

the leg

damper motor bracket be assembled to the corner

nearest the damper arm on the damper section. See

Figure 10, Page 16.

Each leg is fastened to the angle frame-

furnished

with the additional holes for the

(vertical Aircons)

are

not

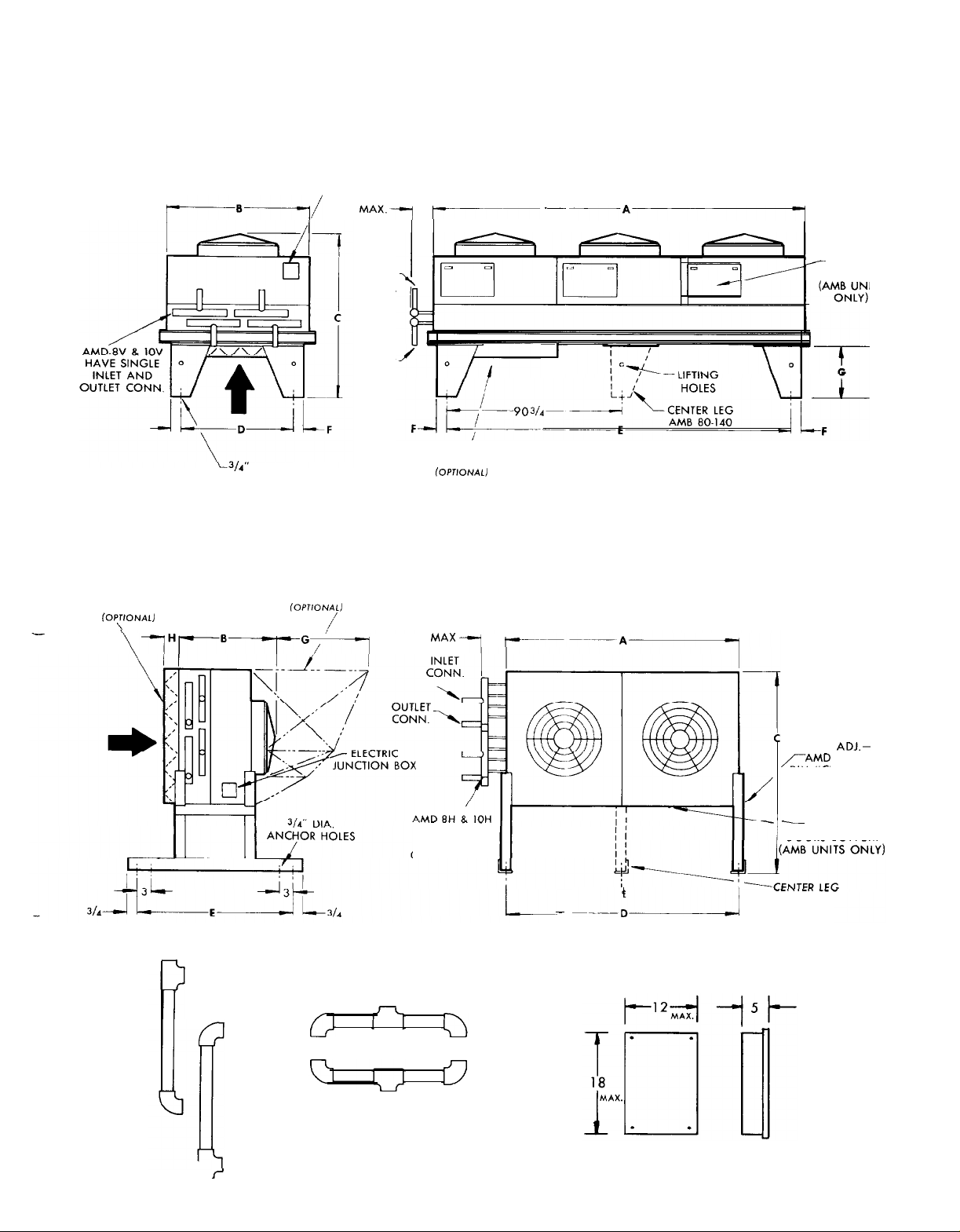

FIGURE 1

HORIZONTAL

LEG ASSEMBLY

VERTICAL LEG

HOLES FOR

HEIGHT ADJUSTMENT

(AMD

ANGLE B

MODELS)

FIGURE 2 SUGGESTED RIGGING

U--\

AMB 50 THRU

8 THRU 30

AMD

20 THRU 45

AMB

140

INSTALLATION OF UNITS

The Aircon must be installed level to insure proper

drainage of liquid refrigerant and oil. Mounting holes

3/4"

diameter are provided on all models. See

ures 3

and 4. Sleepers are normally required when

distribution of load is necessary.

ished

with single section coils as standard on

two

(2)

smaller sizes, the

section coils of equal capacity are furnished as

AMD-8

Aircons

and

AMD-10.

Fig-

are furn-

the

Two

standard on all other sizes. All models are available

with coils circuited for use with multiple compressors. On

furnished with reference numbered tags for

cation relat

sions

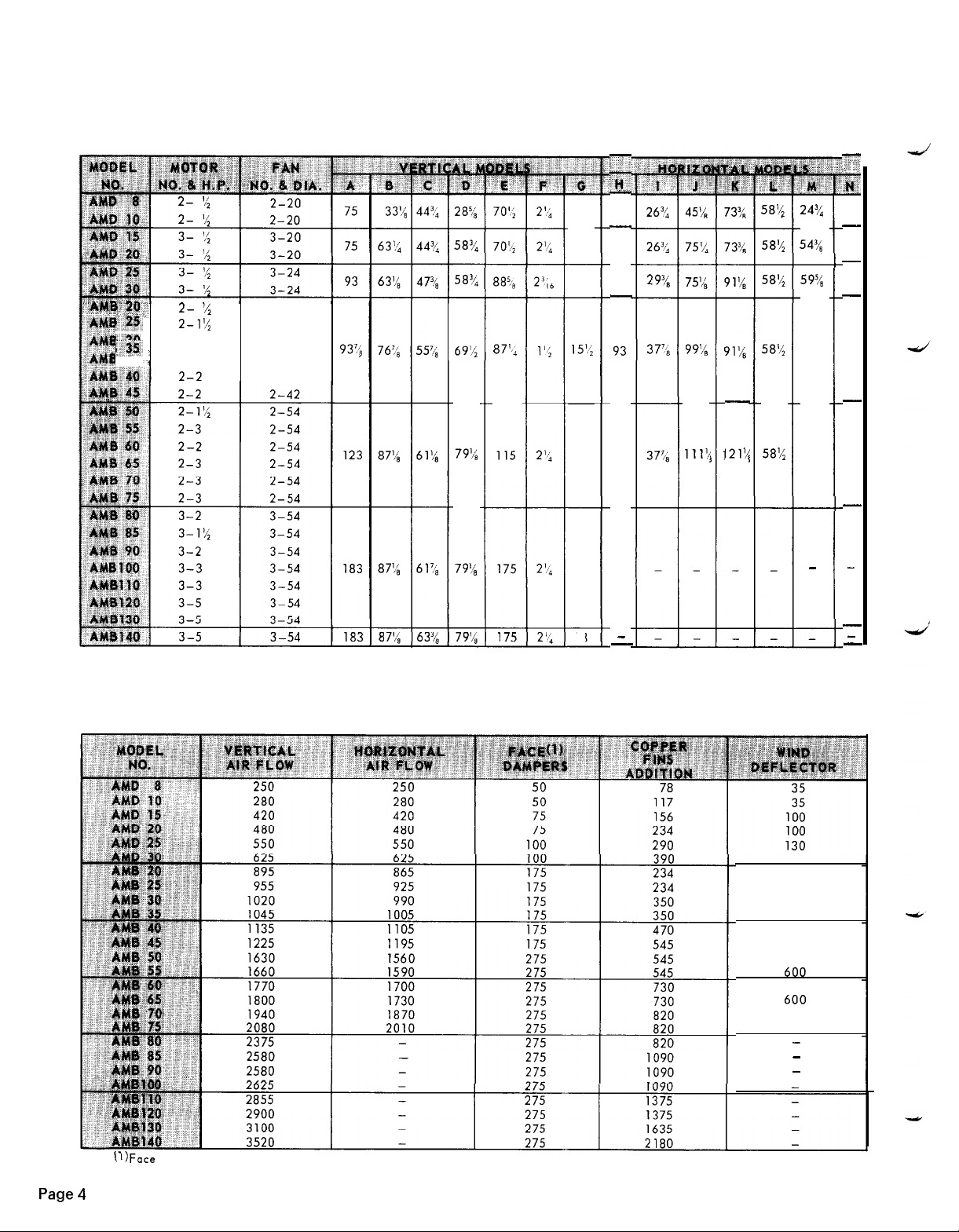

See Tables 1 & 2.

multi-section Aircons, each section is

identifi-

ing

to the proper compressor. For dimen-

and

weights of horizontal and vertical

Aircons,

Page 3

Page 4

DIMENSIONAL DATA

TABLE 1

2- ::

r:g,

I:$&

ij.$%

2-l'/,

2-l

:

2-2

2-42

2-42

2-42

2-42

2-42

DIMENSIONAL AND PHYSICAL DATA

n

:,,L’

g?

-

75

18

-

18

18

15'.;

18

18

75

93

-

123

_

937;

58%

58?~

87',

79'ii

29?<

377,, 99:/,

111'4

-

121%

58'4

58'4

58'/;

58'/,

58s;

24:/,

54%

59%

72

a4

-

z

r,;

10

-

10

-

-

-

-

10

10

10

-

1’~

TABLE 2

-

18

-

NET WEIGHTS-LBS. (APPROX.)

(WITHOUT REFRIGERANT CHARGE)

130

160

160

160

160

160

160

600

600

600

600

600

600

-

_

-

-

-

Page 4

('IFace

damper on one fan section only.

Page 5

DIMENSIONAL DATA

FIGURE 3

,p-B---_l/

=/i’

DIA.

ANCHOR HOLES

FIGURE 4

INLET FACE

DAMPER

(OPTIONAL)

-

\

WIND DEFLECTOR

f0prf0~At)

VERTICAL AIR FLOW TYPE

ELECTRIC

JUNCTION BOX

4

MAX.7

INLET

CONN

OUTLET

CONN.

,--p

INLET

FACE DAMPERS

~~PTIoNAL)

ONE SECTION

ONLY

HORIZONTAL AIR

i

4

MAX _cl

--~ pAp

I

NOTE:

RIGHT HAND UNIT SHOWN

LEFT HAND UNIT AVAILABLE

FLOW TYPE

NOTE

RIGHT HAND UNIT SHOWN

LEFT HAND UNIT AVAILABLE

I

ACCES:

DOOR!

HOT

GAS

HORIZONTAL

r’

CONNECTION

MANIFOLDS

VERTICAL

UNITS

UNITS

HAVE SINGLE

INLET AND

OUTLET CONN

LEGS

,,/-AMD

DIM “C” MAY BE

INCREASED 6”

_

ACCESS

DOORS BOTTOM

_

_--_:,I

AMB 50.75

CONTROL PANELS

FANTROL AND DAMPERTROL

ADJ.-

UNITS

Page 5

Page 6

PIPING

GENERAL

The design of refrigerant piping for air cooled

densers involves a number of considerations not commonly associated with other types of condensing

equipment. The following text is intended for

a general guide to sound, economical and trouble-free

piping of air cooled condensers.

A.

Discharge

lines involves two objectives:

1. To minimize refrigerant pressure drop, since

high pressure losses

ser horsepower per ton of refrigeration.

2. To maintain sufficiently high gas velocity to

carry oil through to the

receiver at all loading conditions.

B.

Liquid

to allow free drainage of refrigerant from

denser coil to the receiver. If this is not done,

the liquid will build up in

denser coil,reduce the effective surface and

cause increased operating head

line should

may cause gas binding in the receiver. The liquid

line should be sized so the liquid velocity from

the condenser coil to the receiver

100 feet per minute. Beyond this velocity the

flow of liquid prevents air or other

si bles from passing back through the liquid line

into the condenser coil.

Line

C.

Sizing-Table No. 3 should be used as a

guide to proper sizing of discharge and liquid

lines. The discharge

on tons of refrigeration resulting in a line

sure drop per 100 feet. of equivalent, pipe length

corresponding to 2 degrees F change

temperature. The liquid

based on a maximum of 100

denser to receiver liquid velocity.

Lines

-The proper design of discharge

cause

Lines

-The liquid line must be

the

be

free of any

traps

line

capacities are based

line

capacities shown are

increased compres-

condenser

bottom of the

pressure.

or loops which

does

not exceed

non-conden-

in

feet

per minute con-

con-

use

as

coil and

designed

the

con-

con-

This

pres-

saturation

TYPICAL ARRANGEMENTS

In this case the design of the discharge line is

very critical

tion, the gas velocity might be too low at reduced

loads to carry oil up through the discharge line

condenser

and

size

would increase the gas velocity sufficiently

reduced

at

ing at

sized.

pressure drop. This condition can

one of’

1.

The d

the

and an

the

pressor.

2. A

shown

be sized to carry the oil at minimum load conconditions and line

that at the full load condition both lines would

have sufficient flow velocity to carry the oil to

the condenser.

B.

Figure 7, Page 8, illustrates another very common

application where the Aircon is located

tially

cciver. The principal problem encountered with

this arrangement is that there is frequently insufficient

liquid refrigerant from the condenser coil to the

receiver.

To guard against gas binding in the receiver

and liqu

are common to this arrangement, the receiver

should

let as possible. The liquid line should be free of

any

traps

runs,

ceiver.

If properly sized for full load condi-

coil. Reducing the discharge line

1 oad conditions; however, when operat-

full

load. the line would be greatly under-

and thereby

two

following

i schargc l

desired pressure drop at full load condition

oi 1 separator installed at the bottom of

trap

in the discharge 1 inc from the com-

double

in Figure 6, Page 8. Line “A” should

the

same

vertical

id

be

located as far below the condenser out-

or loops and if there are any horizontal

they

should be pitched down toward the re-

create an excessive refrigerant

be

overcome in

ways:

ine

may be properly

riser discharge line may he used as

"B"

should be sized so

level

as the compressor and

distance to allow free drainage of

buildup in the condenser coil, which

sized

on

essen-

for

re-

Page 6

Figure 5, Page 8 illustrates a typical piping ar-

A..

rangement involving a remote Aircon located at a

higher elevation, as commonly encountered when

the Aircon is on a roof and the compressor and

receiver are on grade level or in a

ment room.

basement

equip-

8,

C. Figure

application where two or more separate

are piped together to a single compressor.

1. It is very important that the two Aircons have

Page 8, illustrates a third very common

the

same capacity so that the refrigerant pres-

sure

drop

through each unit is equal.

Aircons

Page 7

PIPING

The piping should be arranged so that the

2.

lengths of run to and from each Aircon are

equal.

The above two points are particularly important

3.

in applications where the refrigerant receiver is

directly beneath the air cooled condensers. If

two unlike air cooled condensers or unequal

piping is used, the resultant

unequal

refrigerant

pressure drop may cause liquid to build up in

one of the condenser coils thereby reducing its

effective capacity.

D. Notice that in all illustrations

the

discharge line

is looped at the bottom and top of’ the vertical run.

This is done to

prevent

oil and

condensed

refrigerant from flowing back into the compressor and

causing damage. The highest point in the discharge

be

line should always

above the highest point in

the condenser coil; and it is recommended a

ging vent be provided at this point to

release

condensibles from the system.

It is also very important that the piping be arranged such that no excessive strain on the piping

or unit components can result. There seems to

general disregard for this factor. Typical examples

are the connecting of two condensers in

connected header to header without any offsets in

line,

the interconnecting

or running of a line direct-

ly from a coil connection through a wall or floor

the

and then scaling tightly between

line and the

opening. Provide sufficient flexibility to allow

pur-

non-

be a

parallel,

for

vibration, thermal expansion, and gradual base or

bui lding

The discharge line should include a loop to a level

E.

movement.

above the header of the condenser coil. When the

Aircon is located above the compressor, the discharge line should loop to the floor near the compressor before rising to the condenser coil. This

reduces the possibility of refrigerant condensing

the l ine

in

during the off cycle, and draining back

to the head of the compressor. Also, any oil travel-

the

ing up

head of’

Maintain gravity drainage in the liquid line from

F.

the condenser coil to the

binding is a condition usually caused by an

Gas

G.

undersized

receiver.

the

pipe wall will not drain back to the

the

compressor during off periods.

receiver.

liquid

line

between the condenser and

or because of traps in this same line.

Air or other non-condcnsibles also may cause

binding.

Multiple

H.

Aircons

may be connected in parallel

to product a condensing system of almost un-

l

imi ted capacity. When Aircons are connected in

parallel,

pressure drop to each Aircon.

included

the

piping should be equivalent for equal

A

drop leg should be

between each liquid manifold of sufficient

height to prevent back-up of liquid into the coil of

the unit with the lower pressure drop. The pressure

drop through each Aircon should be essentially the

same to distribute the load equally.

TABLE 3

REFRIGERANT LINE CAPACITIES (TONS)

19.2 IS.7

I-

27.2 21.8

47.3 39.0

73.2 61 .O

t

33.0255.0

(I) Line sizes based on pressure drop equivalent to 2 degrees per

IOC’

length.

Page 8

PIPING DIAGRAMS

FIGURE 5

CONDENSER

LIQUID LINE

FIGURE 6

-

DISCHARGE

TRAP

FJzEQ!%

FIGURE 7

LINE

COMPRESSOR

LIQUID LINE

!

c=LLI&

/DISCHARGE

LINE B

fl

DISCHARGE

LINE A

d

DISCHARGE LINE

CONDENSER

FIGURE 8

r

I

I

CONDENSER

J

-\

r

TRAP

b;

I

I

,/-‘\

? \

:

_-DISCHARGE LINE

r

I I

I

Page 8

LIQUID LINE

/

(_

RECEIVER )

-

74!==&

COMPRESSOR

Page 9

RECEIVER AND OPE

RATING CHARGE

A.

The refrigerant receiver should be installed in a

warm location to insure sufficient refrigerant pres-

sure for proper expansion valve operation immediately upon start of a system. This is particularly

important where systems are required to operate in

low ambient temperatures, otherwise special con-

trols for low ambient start may be required. The

receiver should not be installed in a space ordinarily warmer than where the compressor is located.

Otherwise, there is danger of migration of

ant to the compressor during extended off periods.

be

The sizing of the receiver should

determined by

totalling the refrigerant charge required for each

component in the system. i.e., Evaporator, piping,

condenser coil and receiver operating charge. The

total volume of the condenser and the receiver

should be at least 20% greater than this calculated

total charge. The refrigerant charge for each size

Aircon is shown in Table No.

If the system includes Seasontrol head pressure

B.

4

control, one additional consideration is necessary

in determining the system operating charge. Since

Seasontrol operates on the principle of maintaining

a fixed condensing capacity of the Aircon coil by

backing up liquid refrigerant in the coil, additional

refrigerant is required, and also a larger receiver

is required. When calculating the necessary re-

frigerant charge with Seasontrol application, multi-

ply the normal charge in Table No.

4

by appropri-

ate factor selected in Table No. 5, Page 10.

If the system with Seasontrol is to be charged

c.

when the condenser ambient is lower than 75 F,

McQuay

1.

recommends the following procedure.

Add a nominal charge to the system, that would

be estimated as a typical summer charge.

Block off enough of the condenser coil face to

2.

bring the head pressure up to 125 psi (assuming

use of R-12). By bringing the head pressure up

to 125 psi, the Seasontrol will open and prevent

being

any refrigerant from

held up in the condenser.

Check the liquid line sight glass. If the system

3.

is short, add refrigerant until sight glass clears.

Then add customary reserve charge. This then

would be normal summer charge.

4. The additional amount of refrigerant that must

be added to the system for winter or cold weather operation is determined by Tables 4

additional charge required is equal to the dif-

charge

ference between the winter

as determined from Table 5, Page 10 for the particular

design condition, and the summer charge indicated in Table 4.

refriger-

&

5. The

5. When the system is being charged and the ambient is high enough to normally bring the head

pressure up to 125 psi or higher, disregard

Paragraph “2”

When the condenser is operating at full capacity,

D.

at ambient temperature above 75 F, there should

be no liquid refrigerant flooded back in the condenser coil. The additional refrigerant introduced

into the system with the use of the Seasontrol

be

system must

stored in the receiver during sum-

mer operation. Therefore, the receiver must be

sized accordingly.

E.

Because of the rather large refrigerant charge

required in an air cooled condenser system, es-

pecially when using the Seasontrol system, it is

usually necessary to put additional oil into the

system. The amount of oil to be added varies

considerably

with the make of compressor used,

and whether the system is furnished with an oil

separator. The compressor oil level should be

watched carefully on initial start up of the system.

TABLE 4

REFRIGERANT CHARGE (LBS. R-l

(Summer operation above 60F without Seasontrol)

FACETtlSE

.88

R-500; .93-R-502:

21’))

@HARCE

ryxR

.21

.31

.21

.31

.33

.45

.25

.25

.38

.38

.50

.63

.54

.54

.68

.68

1.86

1.02

.77

1.02

1.02

1.02

1.29

1.29

1.52

2.04

,O

R-22;

Page 9

Page 10

RECEIVER AND OPERATING CHARGE

TABLE 5

SEASONTROL REFRIGERANT CHARGE FACTOR(‘)

(Multiply summer charge by factor for total charge)

I

2.6

3.5

4.2

4.7

5.1

5.5

5.7

2.5

3.3

3.8

4. I

4.5

.o

4.7

5.1

5.5

5.8

6.1

I.0

I

.o

I

3.0

4.1

4.7

5.2

5.6

5.9

6.2

6.4

I

.o

I

.6

/

1.7

2.8

4.2 ~

4.7

5.1

5.4

5.6

2.6

4. I

4.8

5.5

5.8

6.1

6.3

6.6

I

I.0

I .6

2.9

/

,

4.5

5.0 5.8 6.7

5.3 6.1

5.8

6.0

I

I

/

I

5.6

6.2

6.4

6.1

6.4

6.6

1.6

::‘,

5.5 6.5

I

6.7

6.9

7.1

I

7.2

7.4

4.4

5.3

6.0

6.9

7.0

7.2

y-

“j.

L

.i

(I)

Based on minimum condensing temperature of: 9OF for 30, 25, 20 Design T

SAMPLE PROBLEM

GIVEN:

AMB25

lbs. R-12. (Refer table

Aircon with normal summer charge of 12

4).

FIND:

(A)

Refrigerant charge with Seasontrol on system

designed on 30” TD, and 30 F minimum ambient.

(B)

Refrigerant charge of system above with com-

pressor

TABLE 6

having cylinder unloading to

WEIGHT OF REFRIGERANT IN COPPER

33-l/3%.

(LBS. PER 100 LINEAL FEET)

SOLUTION:

(A)

(B)

.D.:

3.5

4.2

4.7

5.4

5.4

80F

for

4.9

5.3

5.6

5.9

6.2

IO, 5 Design T.D.

15,

6.1

6.4

6.6

6.8

7.0

Seasontrol refrigerant charge factor from table

5

is 4.2. Therefore total charge = 4.2 x 12.0

=

50.3 lbs.

Cylindcxr

as reducing the design T.D. to 10 degrees

TD x

unloading to

331/3’:‘0

:{3-11’3% = 10” TD).

has same effect

Factor for

(30”

10OT.D.

and 30 F minimum ambient is 6.1. Therefore

total charge = 6.1 s 12.0 = 73.2 lbs.

LINES*)

Page

(2) Type L copper

10

tubing.

Page 11

ELECTRICAL WIRING

A.

The electrical installation should be in accordance with National Electrical Code, local

and regulations. Proper fuse protection should D.

be provided for the fan motors. Wiring Diagrams

shown are only basic and do not show fuses, disconnect switches, etc., which must be provided in

the field.

B.

c.

Aircons

The

fan is driven

have either two or three fans. Each

by

a separate motor.

All standard motors have internal inherent overload protectors. Therefore,

contactors

can be used

instead of starters requiring thermal protectors,

eliminating the problem of furnishing the proper

heating elements. Also. the cost of a contactor is

codes

somewhat less than that of a corresponding magnetic starter.

All

standard

AMD

(direct drive)

units have single

phase. 220 volt permanent split capacitor fan

motor

s.

These motors are factory wired into a

combination capacitor enclosure and junction box.

All standard

E.

driven

fan)

Aircons

AMB

(belt

furnished with three phase, 208/220-440 volt,

fan motors. The motors are wired into a common

junction box. See Figure 9. The motors must be

checked out for proper rotation. Unless the unit

order specifically calls for the lower voltage connection, the motors will be factory wired for the

higher voltage as a precautionary measure.

are

FIGURE 9

AMB UNIT

ELECTRICAL CONNECTIONS AND LOCATIONS

I

i

A.

FAN MOTOR CONNECTION TO OUTSIDE. JUNCTION BOX

LOCATED INSIDE.

AMB UNIT

6.

TYPICAL ACCESSORY KIT PANEL LOCATION. RUN MOTOR

CONNECTIONS DIRECTLY INTO CONTROL PANEL.

\

AMD UNIT

u/I

FAN MOTOR CAPACITOR AND JUNCTION BOX.

A.

AMD UNIT

uI

B. TYPICAL ACCESSORY KIT LOCATION.

Page

11

Page 12

START UP

Check for proper fan rotation. Air is drawn through

the coil on all Aircons. Be sure the fans turn freely.

Check belt alignment and tension. Front edge of fan

blade should extend approximately one third into fan

OPERATION

WINTER OPERATION

HEAD PRESSURE CONTROL

A.

The capacity of an air cooled condenser varies

with the difference between the entering air dry

bulb temperature and the condensing temperature

of the refrigerant. Since air temperature in some

regions varies as much as 100 degrees from summer to winter, some means must be employed to

keep the condensing temperature sufficiently high

to insure proper operation of the refrigerant ex-

pansion valve during low ambient operation.

B.

The low limit of the head pressure is dependent

upon the required pressure drop across the ther-

mostatic expansion valve, and for normal air con-

ditioning applications, should be maintained above

a condensing temperature corresponding to 70 F.

This, in effect, corresponds to a normal lower

limit of about 60 F ambient, air. Since air conditioning is not normally required at these lower

ambient air

control may not always be necessary. However, for

those applications which are of such a nature that

operation is required below 60 F ambient air

temperature,

denser head pressure control to meet specific job

requirements

“Fantrol”,

temperatures,

McQuay

and

“Dampertrol” and “Scasontrol.”

FANTROL METHOD

Fantrol

is an automatic winter control method and

will maintain a condensing pressure within reasonable

limits by cycling one fan on a two fan Aircon, or two

fans in sequence on a three fan Aircon in

outside air temperature entering the condensing coil.

FANTROL OPERATION

A. Fantrol control package consists of a weathertight

enclosure with motor starting contactor with 220V

holding coil, line voltage

minal strip suitably marked to correspond with

motor leads at the Aircon junction box. Thermo-

stat(s) and contactor are factory wired to terminal

condenser head pressure

offers three methods of con-

engineer/owner preference:

response

thermostat(s)

to

and ter-

shroud. Be sure all air or other non-condensibles are

purged from the refrigerant circuits through purge

valve located at the high point in the discharge line

piping.

strip as shown in Diagrams 1 and 2. Simple elec-

trical hookup of power from fused disconnect to

(220V)

contactor, control circuit

ing coil and motors to terminal strip is all the field

wiring that is required. The control package is to

be mounted at the Aircon with the therm o stat

bulb(s) located to sense the air temperature entering the condenser coil.

B.

This control is suitable for outside temperatures

above those shown in Table 8, Page 14. The

thermostat(s)

first fan when the condensing temperature is reduced to approximately 90 F. Table

lists the theoretical thermostat settings and minimum outdoor air temperature for several system

design TD’s. These settings arc theoretical since

they do not take into account variation in load.

should be field- set to shut off the

to contactor hold-

7,

Page 14,

FAN CYCLING-HEAD

PRESSURE CONTROL

A.

One

of

the

more obvious advantages of multiple

fan condensers over single fan units is the simple

inexpensive

and

reduction may be achieved. On a two fan unit,

stopping one fan reduces the condensing capacity

approximately

to

unit, stopping two fans, reduces the condensing

capacity

Fan motors are internal inherent overload

B.

cd, and

individual fan motors cycled by use of two pole,

heavy

and 2.

Thermostats are nominally set to maintain con-

C.

densing

a low of about

mostats

settings shown in Table 7, Page 14, will ordinar-

ily give

Where operation at ambicnts below the range shown

D.

on Table

Seasontrol

to

are

duty

temperatures

varies

satisfactory

way in which controlled capacity

55% of full rating. On a three fan

approximately 40% of full rating.

protect-

started by a single contactor, with the

thermostats. See Wiring Diagrams 1

between a high of 120 F arid

80

F. The final setting of the ther-

with system design conditions. The

operation.

9,

Page 14, are required, dampers or

may be added.

Page 12

Page 13

OPERATION

b

DIAGRAM 1

230-60-

1

I

;

CONTACTOR

I

I

I

FANTROL AMD MODELS

.--_-

220v INTERLOCK TO START

--__

WITH COMPRESSOR

DIAGRAM 2

208-2201440-60-3

I

I

I

CONTACTOR

I

i

! I I

I

I

Ml

0

FANTROL AMB MODELS

FAN MOTORS

t--

THERMOSTAT

I

ON 3 FAN

UNITS ONLY

Page 13

Page 14

OPERATION

TABLE 7 FANTROL THERMOSTAT SETTINGS

(I) Settings are for normal air conditioning application. For other applications thermostats can be adjusted to maintain ade-

quate condensing pressure within limits of table.

(F)(l)

TABLE 8 FANTROL HEAD PRESSURE CONTROL DATA

45

63

72

35

54

15

27

40

52

65

49

56

63

69

76

53

57

62

66

71

42

49

55 67

61

67 74

66

68

71

73

75

61

64

70

3-a

‘Q

r

Page 14

TABLE 9 DAMPERTROL HEAD PRESSURE CONTROL

-30

-30

-10

15

40

-30

-30

-22

5

34

(2) Minimum outside air temperature based on

or two fans on three fan units.

(3) Minimum outside air temperature is based on

city and 80F condensing temperature at 50% and 25% compressor capacity.

Dampertrol

maintaing

used in

90F condensing temperature at 100% and 75% compressor capa-

conjunctior

with

Fantrol

cycling one fan on two fan units

DATAt2)

-30 24

-I4

I5

24 52

42

63

30

38

46

55

32

42

61

fre

ti

Page 15

OPERATION

DAMPERTROL METHOD

The dampertrol method utilizes the principle of

modulating the air flow through the condenser coil

and is used in conjunction with fan cycling control

to maintain the required head pressure.

DAM PERTROL “A”

A.

The electric motor type control is the conventional

method of’ controlling dampers on

use

of’ this

system

permits adjustment of both

head pressure range and differential.

B.

This

damper

control is to be used with fan cycling

Aircons.

The

control where a lower minimum range of ambient

operation

VARIATIONS OF DAMPERTROL

A.

Dampcrtrol is avail able in two arrangements:

1. Dampertrol A, which employs an electric

damper motor.

2.

Dampcrtrol B, which is direct refrigerant

sure operated.

B.

Dampertrol A utilizes a modulating pressure control,

damper motor, etc.,

and is intended for appli-

cations where head pressure is to be maintained

to close tolerance and where field adjustment is

desirable.

c.

Dampertrol

tuated damper operator and

B

employs a refrigerant pressure ac-

eliminates

the

electric wiring, pressure switches, etc. It is

tory installed and greatly

ordinarily required for

reduces the

damper

control

field labor

tions. Dampertrol B has a fixed operating range

and will modulate head pressure over a range of

170-250

psi for R-22 and

100-160

for R-12.

pres-

need

for

fac-

installa-

required and where range and differential adjustment is desired.

C.

Wiring

with damper operation. The thermostat or thermo-

stats are adjusted to cycle according to the

trol instructions. The damper control is then set to

modu l ate

sired

minimum operating range of this system under

various conditions.

D.

The adjustment, of both the range and differential

is

not at

motor and the damper arm should be adjusted so

that at the low pressure end of the motor arm

travel

an

11, Page

ting

produce

precaut ionary

than obtainable with fan cycling only is

Diagram 3

the dampers and thereby maintain the de-

head

pressure. Table 9 shows the effective

made

at the modulating pressure control and

the motor

the

face

inch from closed

16,

the face

shows a system for fan cycling

The linkage between the damper

damper remains open about

position. See Figures 10 and

for typical damper linkage. Permit-

dampers to close completely may

excessive overload of the fan motor. As a

measure. it is advisable to set the

Fan-

3/8

of

damper blades at the minimum opening that will not

DAMPERTROL COMPONENTS

Damper Section -The damper section consists of

inlet dampers of opposed balanced blade type. located

to cover one fan section of the Aircon.

excessively

ammeter).

will

on

under l ow ambient conditions the motors will

stand considerable overloading.

overload the motor, (by use of an

It is to be noted also that the damper

ly be

closed

at quite low ambient, and

DIAG

RAM 3 DAM PERTROL “A”

DAMPERTROL PANEL FANTROL PANEL

115/230-60-1

t

MOD. PRESS I ; HIGH PRESS.

TRANS.

TO COMPRESSOR

lNTERLOCK

DAMPERTROL A PANEL FOR AMB TWO FAN UNIT SHOWN.

THREE FAN UNITS AND AMD (SINGLE PHASE) UNITS

SIMILAR.

1

I

I

,’

22_o_v-

/-

CONTACTOR

THERMOSTAT

Page 15

Page 16

OPERATION

FIGURE 10

THE DAMPER MOTOR IS SHIPPED IN

“CLOSED” POSITION (AS SHOWN).

AFTER THE MOTOR IS WIRED IT WILL

ASSUME “CLOSED” POSITION IF TER-

MINALS “R

IT WILL ASSUME “OPEN” POSITION .

IF “R TO 8” IS SHORTED.

“A” SHOULD BE 45“ WHEN DAMPERS

ARE IN FULLY CLOSED POSITION.

“B”

MOTOR IS TO THE END OF ITS CCW

TRAVEL.

TO W” ARE SHORTED.

SHOULD BE

5i’!h”

WHEN DAMPER

DAMPER MOTOR ASSEMBLY-VERTICAL

*

;“i-;_,

BALL JOINT SHOULD’ BE

LOCATED NEAR MIDDLE

POSITION OF SLOT.

ss-.

& ‘2,. _

.>.rp.,-

.

. .

.. ‘+z.._

!

~

1

I

,__

_- ,e

MOTOR HOOD

FIGURE

THE DAMPER MOTOR IS SHIPPED IN

“CLOSED” POSITION (AS SHOWN).

AFTER THE MOTOR IS WIRED IT WILL

ASSUME “CLOSED” POSITION IF TERMINALS “R TO W” ARE SHORTED.

IT WILL ASSUME “OPEN” POSITION

IF “R TO B” IS SHORTED.

“A” SHOULD BE

ARE IN FULLY CLOSED POSITION.

“B”

SHOULD BE

MOTOR IS TO THE END OF ITS CCW

TRAVEL.

11

45’

WHEN DAMPERS

10’

WHEN DAMPER

DAMPER MOTOR

ASSEMBLY-HORIZONTAL

BALL JOINT SHOULD BE

LOCATED NEAR MIDDLE

POSITION OF SLOT.

Page 16

DAMPER MOTOR

Page 17

OPERATION

DAMPERTROL “B”

A.

Dampertrol “B” consists of a refrigerant pressure

actuated damper operator, factory mounted to the

damper frame, as illustrated in Figure 12. Interconnecting tubing is connected from receiver or

condenser outlet to damper operator.

B.

The pressure operator positions the dampers in

response to pressure of the refrigerant leaving the

condenser. One side of the piston is loaded by a

bellows operated by

posite side of the piston is spring opposed. When

refrigerant pressure is reduced to 250 psi for K-22

or 160 psi for R-12, dampers begin to close and

continue to modulate until completely closed when

refrigerant pressure is reduced to

or

100

psi for R-12.

The control is suitable for ambient temperatures

as shown in Table 9, Page 14.

c.

The pressure operator is factory installed on the

Aircon. However, the

connection from the operator to the system is not

made. The pressure connect ion may be made to the

top of the receiver, to the liquid line between the

refrigerant

l/4”

pressure. The op-

170

psi for R-22

O.D. pressure line

condenser and receiver, or to the liquid header.

However, if used in conjunction with

the connection must be made between the liquid

line Scasontrol valve and the condenser. The connection should not be made to the hot gas line or

the

hot gas header because of effect of possible

objectionable pulsations sometimes present on the

entering side of the condenser.

A shut off valve in the line between the operator

D.

system

and

is recommended.

Seasontrol,

DAMPERTROL-PRESSURE OPERATOR

Upon starting of the system check the position of

the damper blades. The damper blades should be open

3 /8"

about

stroke. The differential range of this operator is quite

wide so that the dampers will not be completely open

until the system reaches a fairly high head pressure.

The

out away from the cylinder with increase in pressure.

at the closed end of the damper operator

direct

ion of the stroke is such that the stroke is

FIGURE 12 DAMPERTROL “B”

HEADER END

L

PRESSURE LINE CONNECTION

TO LIQUID OUTLET OR RECEIVER

Page 17

Page 18

OPERATION

SEASONTROL METHOD

A.

The Seasontrol III system of head pressure control

is based on liquid refrigerant flooding back into

the condenser and thereby cutting down its effective condensing capacity.

B.

The Seasontrol III system is an improved head

pressure control incorporating two modulating

valves. A check valve is recommended as shown in

14

Figures 13 and

to the condenser during the off cycle. This valve

is a field supplied item. This system operation is

independent of difference of elevation

condenser and receiver. It, therefore, permits

receiver and condenser to be more conveniently

located

The main or liquid line valve is normally closed,

C.

and opens on pressure rise in the condenser. This

valve is located in the liquid line between the

condenser and receiver.

open and closes on pressure rise. This valve is

the compressor and the liquid line between the

D.

to suit specific job conditions.

The secondary gas or by-pass valve is normally

located in the line between the discharge line from

liquid Seasontrol valve and the receiver (See

Figures 13

The system operates as follows:

1. On system start up, the by-pass valve is normally open and the main or liquid valve is

closed. Hot gas moves from the compressor,

part going into the condenser, and part going

through the bypass circuit through the

to prevent refrigerant migration

between

& 14).

the

the

open

valve and into the receiver. The by-pass gas

goes directly into the receiver to maintain or

build up pressure in the receiver as liquid

leaves. As the compressor continues to run. hot

gas condenses in the condenser and raises the

on

liquid level since the main valve

side of the condenser is still closed. As the

liquid level rises: the condensing capacity of

the

condenser decreases and as a result the

head

pressure rises. The by-pass gas maintains

or

raises

the pressure in the receiver. As the

pressure

point of the valve, the liquid valve starts modulating towards the

liquid to leave the condenser and flow into the

receiver.

starts modulating towards the closed position

limiting the hot gas flow into the receiver. The

modul ating

per l

proper head pressure.

tem is ordinarily used to extend the range of a

fan

conjunction with the Seasontrol reduces the

amount of the refrigerant charge required for a

spcci fic

Refer to Refrigerant Charge Table 4, Page

and Refrigerant Charge Factor Table 5, Page

10.

in the condenser rises to the control

open

position, permitting

At the

iquid

On multi-fan condensers. the Seasontrol sys-

cycling

minimum design temperature condition.

same

time

the

of the two valves maintain the

lcvcl

in the condenser to maintain

system. The use of fan cycling in

the leaving

by-pass valve

pro-

9,

Page 18

FIGURE 13

DISCHARGE LINE

--

1

LIQUID LINE

0

CHECK

RECEIVER

MODELS AA

GAS VALVE

4, ,

“AfVE

CHECK VALVES NOT FURNISHED, TO BE FIELD INSTALLED

I

&

BA

AIRCON

LIQUID VALVE

FIGURE 14

MODELS CA

&

LARGER

Page 19

OPERATION

TABLE 10

25

50

75

125

.- 200

( I ) Net refrigeration effect at evaporator.

TABLE 11

SEASONTROL

SEASONTROL

IO

Ill

CONNECTIONS

III

VALVE SELECTION

AA-22

BA-22

CA-22

DA-22

E

B-22

F

B-22

,

I

I

TABLE 12

Valves are supplied set as Indicated for R-12 or R-22

R-502.

For R-500 valves must be adjusted in the field. Order

R-12 model and

IO AA-12

20

40

60

I

00

175

BA-12

CA-12

DA-12

EB-12

F

B-12

VALVE SETTINGS (PSIG)

adJust

at

time

of Installation.

MAINTENANCE

GENERAL

A.

Type AMD and

maintenance.

the fan shaft bearings, motor bearings, and occas-

ionally clean the surface of the coil. During the

initial break-in period, it is advisable to check the

belt tension after the first

Usually, by this time. the belts have acquired their

permanent stretch and further adjustments should

not be necessary. It is advisable, however, to recheck the belt tension at. 3 month intervals, and if

necessary, make any adjustments.

B.

The fan shaft mandrel does not require lubrication

at the time the unit is put into service. The fan

bearings

shaft

STANDARD OIL COMPANY,

Lithium Grease.

The Aircon coil will require a periodic cleaning

c.

and this can

cleaner or a pressurized air stream.

AMB Aircons

require a minimum of

All that is required is to lubricate

48

hours of operation.

should be greased once a year using

AMCO

Multi-Purpose

DO NOT

BE

accomplished by a brush, vacuum

OVERLUBRUCATE

MOTOR

A.

All

I motors are ball bearing, pre-lubricated and do

not require the addition of grease at the time of

installation. Periodically. the ball bearings should

be cleaned and the grease renewed to gain the

ultimate in service from the motor bearings.

B.

Extreme

matter from entering the ball bearings. It is also

important to avoid overgreasing. Only a high

grade,

characteristics

littlc

the

prefcrrably

aration of oil and soap under operating and storage

conditions. and freedom from abrasive matter, acid

alkali and moisture.

Specific gwasing

C.

the tag attached to the motor and should be gener-

ally

care must be exercised to prevent foreign.

clean

mineral grease having the following

should be used: Consistency: a

stiffer than that of

operat

ing temperature range; melting point

over

150 C (302

vaselinc,

maintained over

F); freedom from sep-

instructions are to be found on

greasing

Page 19

Page 20

REPLACEMENT PARTS

When writing to

McQuay

for service or replacement

parts, refer to the model number and serial number of

the unit as stamped on the Serial Plate, attached to

the unit. If replacement parts are required, mention

date

the

of installation of the unit and the date of

failure, along with an explanation of the malfunctions

and a description of the replacement parts required.

Refer to Replacement Parts List No. RPL 400.

“Bulletin illustrations cover the general appearance of

the right to make changes in design and construction at any time without notice.”

McQuay

products at time of publication and we reserve

@

Loading...

Loading...