Page 1

Installation & Maintenance Data

IM 548-3

Group: Chillers

Part Number: 573864Y-01

Date: October 1996

SeasonPak

®

Packaged Air Cooled Water Chiller

with Screw Compressor

Models ALS-125A thru 380A

©1996 McQuay International

®

Page 2

Table of Contents

Introduction ....................................................................... 3

General Description ....................................................... 3

Nomenclature ................................................................. 3

Inspection ...................................................................... 3

Installation and Start-up ............................................... 3-17

Handling ..................................................................... 3-6

Location ......................................................................... 6

Service Access .............................................................. 6-9

Vibration Isolators .................................................. 10-12

Water Piping ........................................................... 13-14

Flow Switch .................................................................. 14

Water Connections ....................................................... 15

Refrigerant Charge ....................................................... 15

Glycol Solutions ...................................................... 15-16

Evaporator Water Flow and Pressure Drop ............. 16-17

Physical Data .............................................................. 17-20

Major Components .......................................................... 21

Compressor Staging Sequence .................................... 21-23

Dimensional Data ...................................................... 24-27

Field Wiring ................................................................ 28-46

General ......................................................................... 28

Overload Dial Setting ................................................... 29

Wire Sizing Ampacities............................................30-35

Compressor and Condenser Fan Motors ................. 35-38

Customer Wiring.....................................................39-43

Electrical Data Notes .................................................... 44

Electrical Legend .......................................................... 45

Evaporator Freeze Protection ........................................ 45

Typical Field Wiring .................................................... 46

Unit Layout and Principles of Operation ................... 47-51

Major Component Locations ....................................... 47

Control Center ........................................................ 48-49

Sequence of Operation ............................................ 50-51

Refrigerant Piping Schematic ....................................... 51

Start-up and Shutdown ............................................... 52-54

Pre Start-up .................................................................. 52

Start-up ................................................................... 52-53

Temporary Shutdown................................................... 53

Start-up After Temporary Shutdown ...................... 53-54

Extended Shutdown ..................................................... 54

System Maintenance ................................................... 54-55

General ......................................................................... 54

Compressor Maintenance ............................................. 54

Fan Motor Bearings ...................................................... 54

Electrical Terminals ...................................................... 54

Condensers ................................................................... 55

Refrigerant Sightglass.................................................... 55

Lead-Lag ....................................................................... 55

Service ......................................................................... 55-61

Compressor Solenoids .................................................. 56

Filter-Driers ............................................................. 56-57

Liquid Line Solenoid Valve .......................................... 57

Liquid Injection Solenoid Valve ................................... 57

Electronic Expansion Valve .......................................... 58

Electronic Expansion Valve Operation ......................... 59

Evaporator .................................................................... 59

Refrigerant Charging ............................................... 59-61

In Warranty Return Material Procedure ......................... 61

Compressor .................................................................. 61

Components Other Than Compressors ........................ 61

Appendix ..................................................................... 61-77

Standard Controls: .................................................. 61-62

Thermistor sensors ..................................................... 61

Sensor locations .................................................... 62-65

Liquid presence sensor ................................................ 65

High condenser pressure control .................................. 65

Mechanical high pressure safety control ..................65-66

Compressor motor protection ...................................... 66

FanTrol head pressure control ............................... 66-68

Low ambient start ..................................................... 68

Phase/voltage monitor ................................................68

Compressor short cycling protection ............................. 69

Optional Controls: .................................................. 69-77

SpeedTrol head pressure control.................................. 69

Reduced inrush start .................................................. 69

Hot gas bypass ...................................................... 69-70

Wind baffles and hail guards ................................ 70-75

ALS controls, settings & functions .............................. 76

Troubleshooting chart ................................................ 77

Periodic Maintenance Log ............................................... 78

Limited Warranty ............................................................ 79

Page 2 / IM 548

IMPORTANT

See freeze protection references under the heading “Water Piping” on page 11.

“FanTrol”, “McQuay”, “SeasonPak”, “MicroTech” and “SpeedTrol” are registered trademarks of McQuay International, Minneapolis, MN.

©1996 McQuay International. All rights reserved throughout the world.

“Bulletin illustrations cover the general appearance of McQuay International products at the time of publication

and we reserve the right to make changes in design and construction at any time without notice.”

Page 3

Introduction

General Description

McQuay type SeasonPak® air cooled water chillers are complete, self-contained automatic refrigerating

units that include the latest in engineering components arranged to provide a compact and efficient

unit. Each unit is completely assembled, factory wired, evacuated, charged, tested and comes complete

and ready for installation. Each unit consists of multiple air cooled condensers with integral subcooler

sections, multiple accessible semi-hermetic single-screw compressors, replaceable tube multiple circuit

shell-and-tube evaporator, and complete refrigerant piping. Liquid line components included are

manual liquid line shutoff valves, charging valves, filter-driers, liquid line solenoid valves, sightglass/

moisture indicators, and electronic expansion valves. Other features include compressor heaters, an

evaporator heater for low ambient water freeze protection, automatic one time pumpdown of refrigerant

circuit upon circuit shutdown, and an advanced fully integrated microprocessor control system.

The electrical control center includes all safety and operating controls necessary for dependable automatic

operation, (the high and low pressure controls and the chiller heater thermostat are external from the electrical

control center.) Thermal overload protected condenser fan motors are fused in all three conductor legs

and started by their own three-pole contactors. Compressors are protected by solid state overload

protection and over temperature protection. Field installed fused disconnect offers additional

protection.

Nomenclature

A L S - 155 A

Air cooled Design vintage

Liquid refrigerant Nominal capacity (tons)

injected

Screw compressor

water chiller

Inspection

When the equipment is received, all items should be carefully checked against the bill of lading to insure

a complete shipment. All units should be carefully inspected for damage upon arrival. All shipping

damage must be reported to the carrier and a claim must be filed with the carrier. The unit’s serial plate

should be checked before unloading the unit to be sure that it agrees with the power supply available.

Physical damage to unit after acceptance is not the responsibility of McQuay International.

Note: Unit shipping and operating weights are available in the physical data tables.

Installation and Start-up

Note: Installation and maintenance are to be performed only by qualified personnel who are familiar

with local codes and regulations, and experienced with this type of equipment.

Sharp edges and coil surfaces are a potential injury

hazard. Avoid contact with them.

Start-up by McQuayService is included on all units sold for installation within the USA and Canada.

Two week prior notification of start-up is required. The contractor should obtain a copy of the Start-up

Scheduled Request Form from the sales representative or from the nearest office of McQuayService.

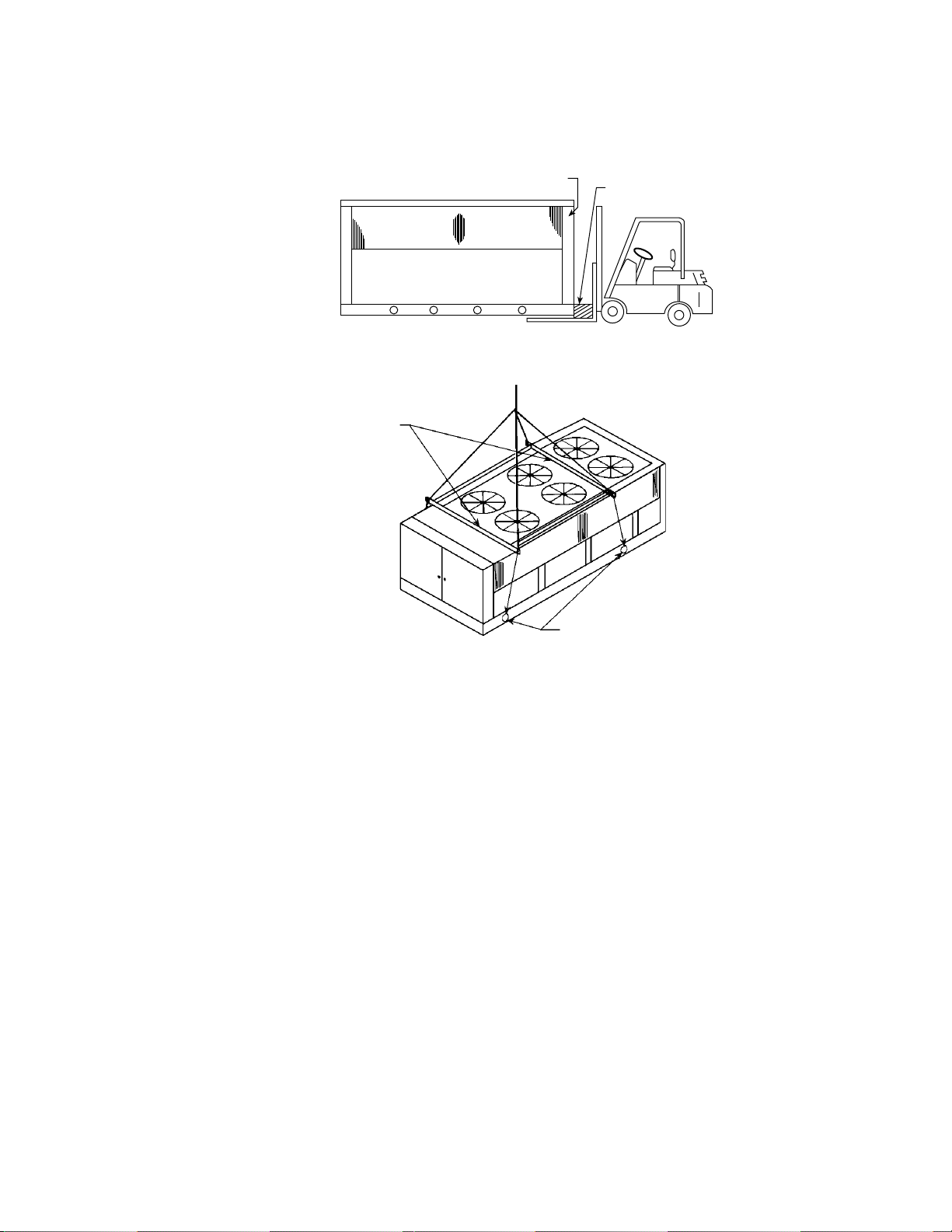

Handling

Care should be taken to avoid rough handling or shock due to impact or dropping the unit. Do not

push or pull the unit from anything other than the base, and block the pushing vehicle away from the

unit to prevent damage to the sheetmetal cabinet and end frame (see Figure 1).

Never allow any part of the unit to fall during unloading or moving as this may result in serious

damage.

IM 548 / Page 3

Page 4

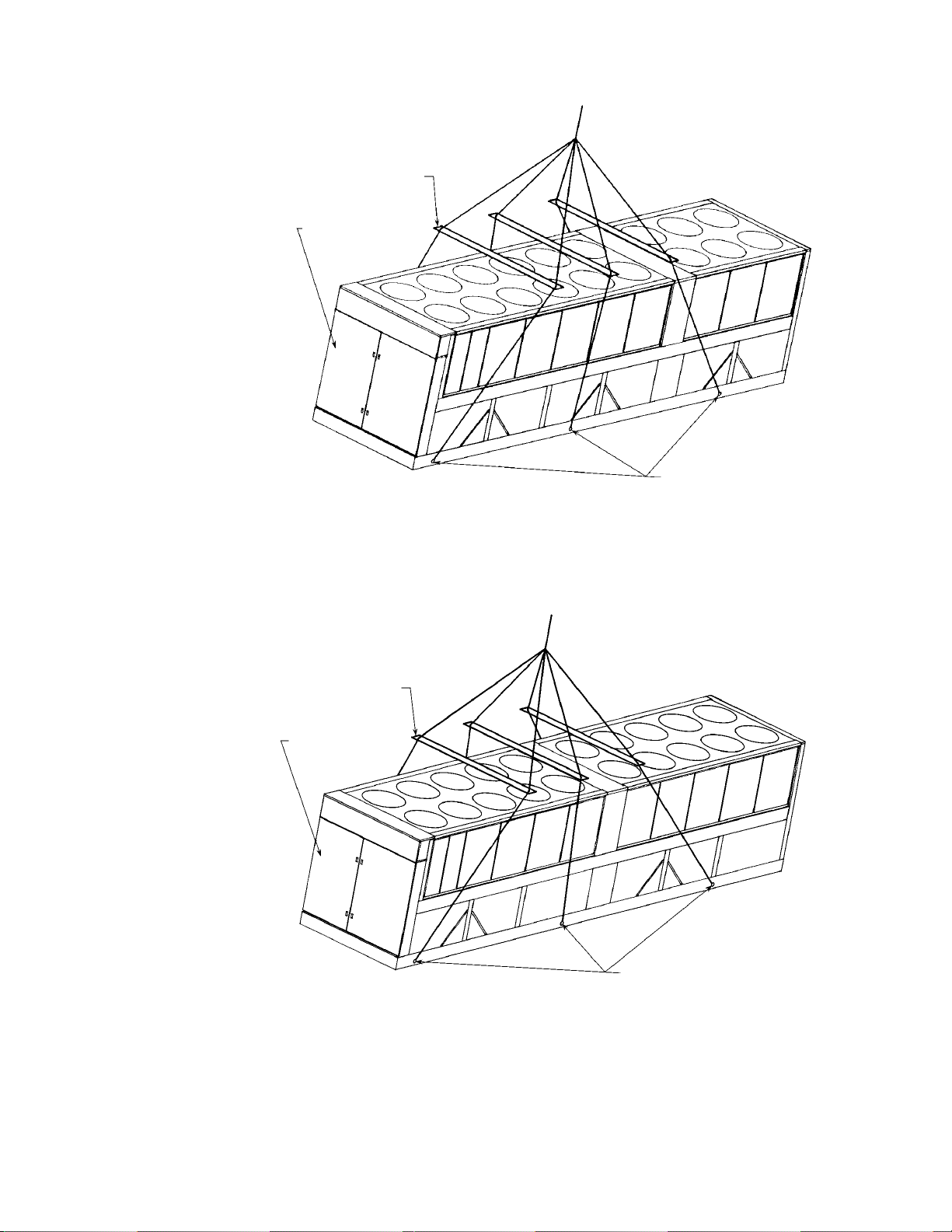

To lift the unit, 21/2" (64 mm) diameter lifting holes are provided in the base of the unit. Spreader bars

and cables should be arranged to prevent damage to the condenser coils or unit cabinet (see Figures 2, 3,

4 and 5).

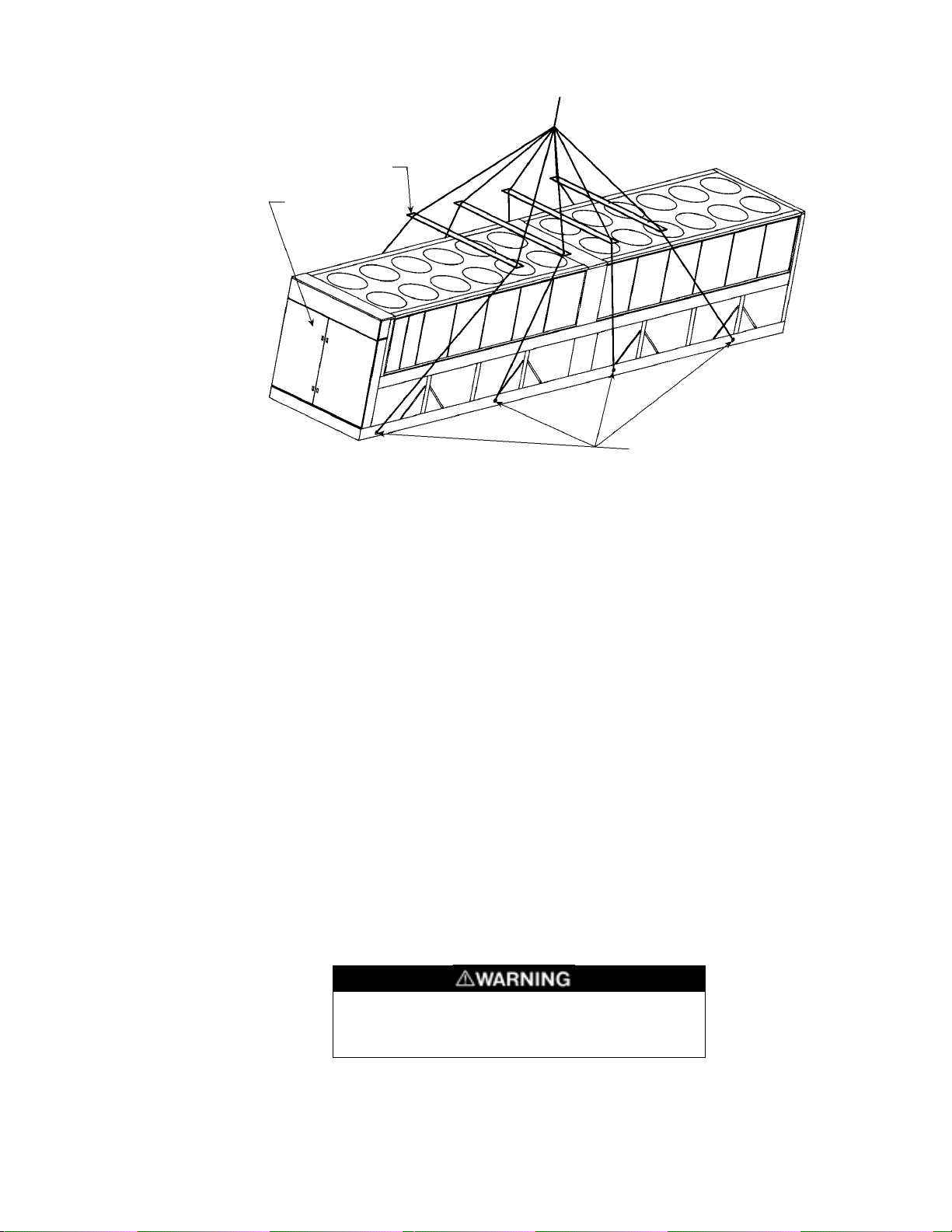

Figure 1. Suggested pushing arrangement

Control panel end

Blocking required

across full width

Figure 2. Suggested lifting arrangement (125 thru 195)

Unit Models ALS125 thru 204

Speader bar

recommended

(Use caution)

Must use these rigging holes.

(Note control box location)

Lift only as shown

Note: Number of fans may vary from this diagram, but lifting method remains the same.

Page 4 / IM 548

Page 5

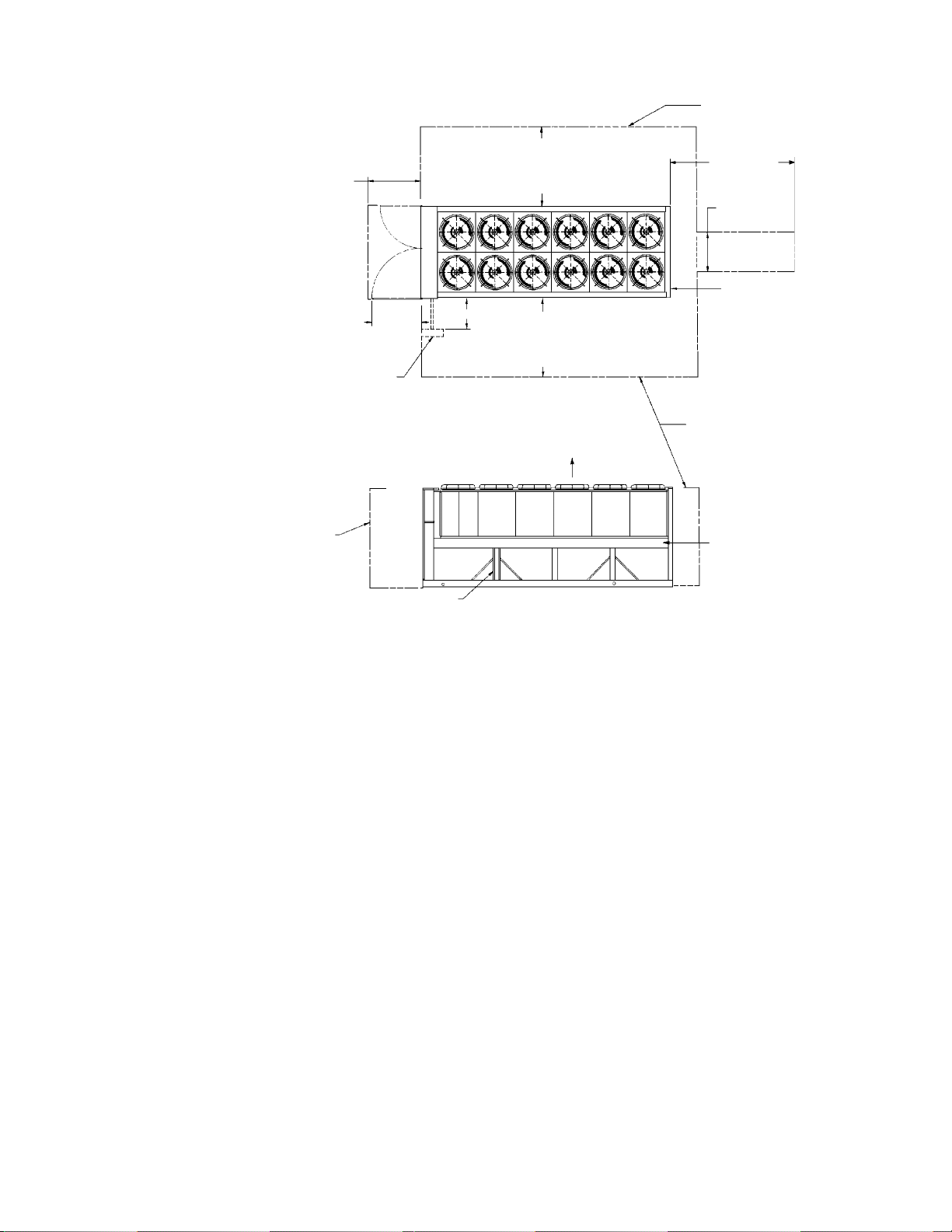

Figure 3. Suggested lifting arrangement (205 thru 280)

Spreader bars must be used

to prevent cabinet damage.

Locate bars above unit to

clear fan grilles. Minimum

distance across unit

between cables or chains

at bars is 90 inches.

Control box end

Unit Models ALS205 thru 280

Unit weights:

16,250 lbs. with aluminum fin coils

18,750 lbs. with copper fin coils

All (6) rigging holes must be used.

(Note control box locations)

Lift only from (6) base points as shown

Note: Number of fans may vary from this diagram, but lifting method remains the same.

Figure 4. Suggested lifting arrangement (300 thru 340)

Spreader bars must be used

to prevent cabinet damage.

Locate bars above unit to

clear fan grilles. Minimum

distance across unit

between cables or chains

at bars is 90 inches.

Control box end

Unit Models ALS300 thru 340

Unit weights:

20,400 lbs. with aluminum fin coils

24,075 lbs. with copper fin coils

All (6) rigging holes must be used.

(Note control box locations)

Lift only from (6) base points as shown

Note: Number of fans may vary from this diagram, but lifting method remains the same.

IM 548 / Page 5

Page 6

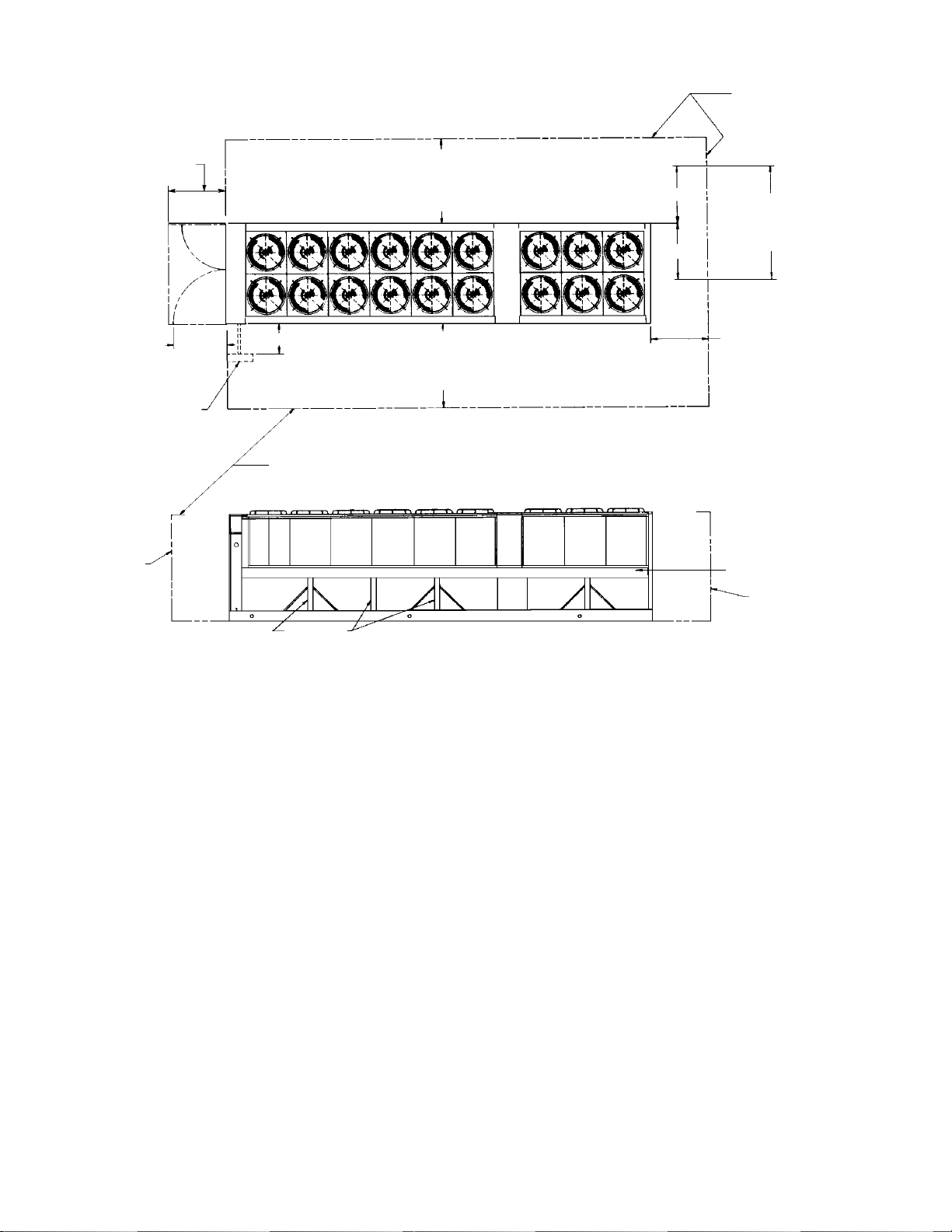

Figure 5. Suggested lifting arrangement (360 thru 380)

Spreader bars must be used

to prevent cabinet damage.

Locate bars above unit to

clear fan grilles. Minimum

distance across unit

between cables or chains

at bars is 90 inches.

Control box end

Note: Number of fans may vary from this diagram, but lifting method remains the same.

All (8) rigging holes must be used.

(Note control box locations)

Lift only from (8) base points as shown

Unit Models ALS360 thru 380

Unit weights:

22,100 lbs. with aluminum fin coils

22,506 lbs. with copper fin coils

Location

Care should be taken in the location of the unit to provide proper airflow to the condenser, minimizing

effects on condensing pressure.

Due to the vertical condenser design of the ALS125A thru ALS380A chillers, it is recommended that

the unit is oriented so that prevailing winds blow parallel to the unit length, thus minimizing the effects

of condensing pressure on performance. If the unit is installed with no protection against prevailing winds

it is recommended that wind baffles be installed.

Using less clearances than shown in Figures 6, 7 and 8 will cause discharge air recirculation to the

condenser and could have a significant and detrimental effect on unit performance.

Service Access

Each end of the unit must be accessible after installation for periodic service work. Compressors, filterdriers, and manual liquid line shutoff valves are accessible on each side of the unit adjacent to the

control box. High pressure and low pressure transducers are mounted on the compressor. The cooler

barrel heater thermostat is located on the cooler. Compressor overloads, microprocessor, and most other

operational, safety and starting controls are located in the unit control box.

On all ALS units the condenser fans and motors can be removed from the top of the unit. The complete

fan/motor assembly can be removed for service. The fan blade and fan motor rain shield must be

removed for access to wiring terminals at the top of the motor.

Disconnect all power to the unit while servicing

condenser fan motors. Failure to do so may cause

bodily injury or death.

Page 6 / IM 548

Page 7

Figure 6. Clearance requirements (125 thru 204)

5'-0" if open fence

4'-0" working

clearance per

National Electric

Code Article

110-16

Field installed

disconnect switch,

locate so as not to

block service access

to unit components

3'-9"

door

swing

2'-0" min.

or 50% open wall

6'-0" if solid wall

(see note 3 for pit)

5'-0" if open fence

or 50% open wall

6'-0" if solid wall

(see note 3 for pit)

No obstructions allowed

above unit at any height

Top View

Air flow.

No obstructions.

Recommended area required

for unit operation, air flow

and maintenance

10'-0" clearance for

evaporator

service or removal

3'-0" gate

or opening

centered on

unit width

2'-0" min.

See notes 2 & 4

concerning wall height

Wall

or fence

See note 5

Elevation

See note 6

Notes:

1. Minimum side clearance between two units is 12 feet.

2. Unit must not be installed in a pit or enclosure that is deeper or taller than the height of the unit

unless extra clearance is provided per note 4.

3. Minimum clearance on each side is a 8 feet when installed in a pit no deeper than unit height.

4. Minimum side clearance to solid wall or building taller than unit height is 8 feet provided no solid

wall above 6 feet tall is closer than 12 feet to opposite side of unit.

5. Removable post for compressor service access must not be blocked at either side of unit.

6. Do not mount electrical conduits, etc. above the side rail on either side of unit.

7. There must be no obstruction of the fan discharge.

IM 548 / Page 7

Page 8

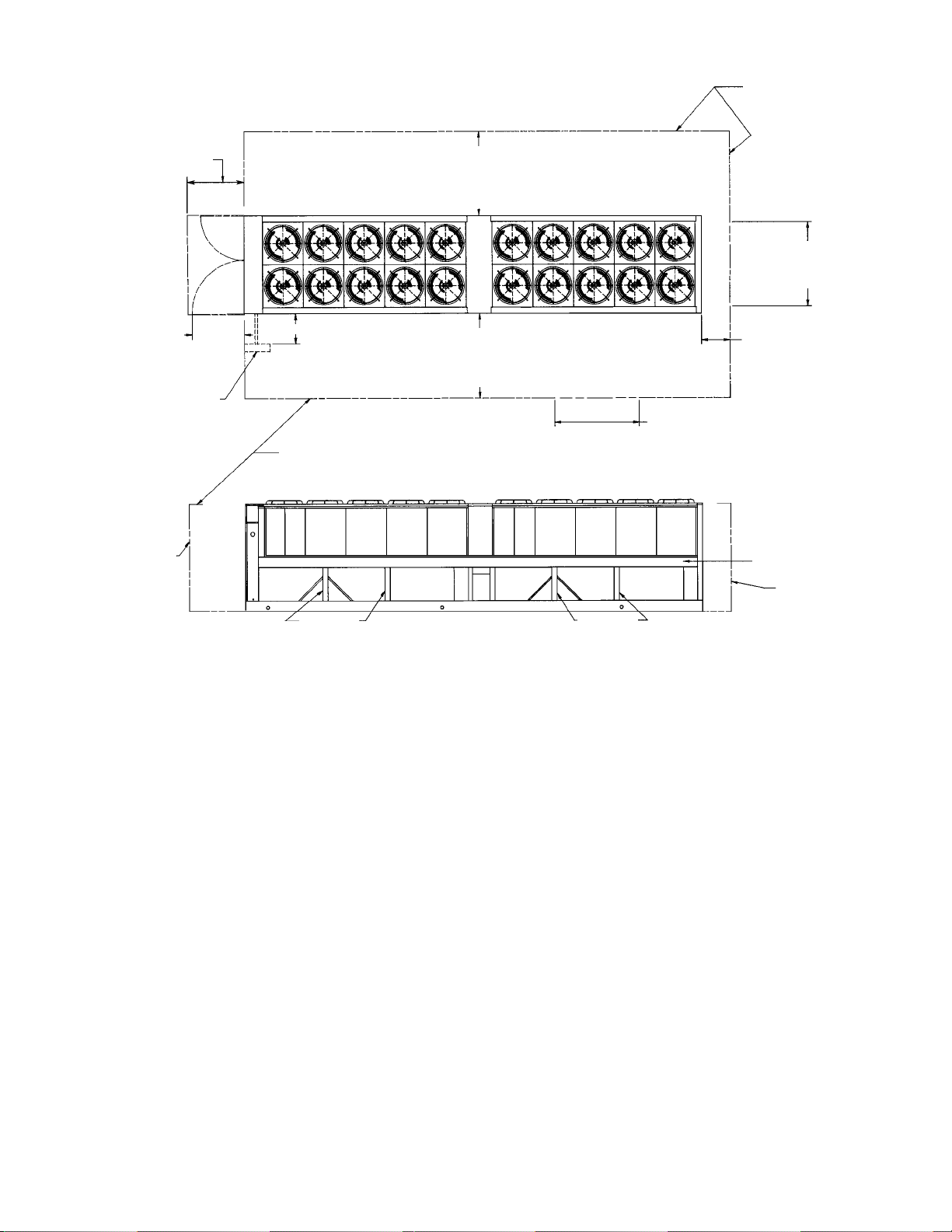

Figure 7. Clearance requirements (205 thru 280)

4'-0" working

clearance per

National Electric

Code Article 110-16

Control

Center

5'-0" if open fence

or 50% open wall

6'-0" if solid wall

(see note 3 for pit)

No obstructions.

Recommended area

required for unit

operation, air flow

and maintenance

access

8'-0" gate or access

opening centered on

corner of unit for

evaporator removal

3'-9"

door

swing

Field installed

disconnect switch,

locate so as not to

block service access to

unit components

Wall

or fence

2'-0" min.

See notes 2 & 4

concerning wall

height at unit sides

See note 5

5'-0" if open fence

or 50% open wall

6'-0" if solid wall

(see note 3 for pit)

Top View

Air Flow.

No obstructions allowed

above unit at any height

d

Side View

2'-0" min. for unit

operation.

4'-0" min. for major

component removal.

10'-0" min. for evaporator

removal (see access

opening dimension above)

See note 6

Wall or

fence

Notes:

1. Minimum side clearance between two units is 12 feet.

2. Unit must not be installed in a pit or enclosure that is deeper or taller than the height of the unit

unless extra clearance is provided per note 4.

3. Minimum clearance on each side is a 8 feet when installed in a pit no deeper than unit height.

4. Minimum side clearance to solid wall or building taller than unit height is 8 feet provided no solid

wall above 6 feet tall is closer than 12 feet to opposite side of unit.

5. Removable post for compressor service access must not be blocked at either side of unit.

6. Do not mount electrical conduits, etc. above the side rail on either side of unit.

7. There must be no obstruction of the fan discharge.

Page 8 / IM 548

Page 9

Figure 8. Clearance requirements (300 thru 380)

4'-0" working

clearance per

National Electric

Code Article 110-16

Control Center

3'-9"

door

swing

Field installed

disconnect switch, locate so

as not to block service access

to unit components

2'-0" min.

See notes 2 & 4

concerning wall

height at unit sides

5'-0" if open fence

or 50% open wall

6'-0" if solid wall

(see note 3 for pit)

5'-0" if open fence

or 50% open wall

6'-0" if solid wall

(see note 3 for pit)

Top View

Air Flow.

No obstructions allowed

above unit at any height

d

Alternate access

opening at side

opposite water

connections

No obstructions.

Recommended area

required for unit

operation, air flow

and maintenance

access

6'-0" gate or access

opening centered on

corner of unit for

evaporator removal

2'-0" min. for unit

operation.

4'-0" min. for major

component removal.

10'-0" min. for evaporator

removal (see access

opening dimension above)

Wall

or fence

See note 6

Wall or

fence

See note 5

Side View

See note 5

Notes:

1. Minimum side clearance between two units must be 12 feet.

2. Unit must not be installed in a pit that is deeper or enclosure higher than the height of the unit

unless extra clearance is provided per notes 3 and 4.

3. Minimum clearance on each side is a 8 feet when installed in a pit no deeper than unit height.

4. Minimum side clearance to solid wall or building higher than unit height is 8 feet. In addition, the

opposite side of the unit must be at least 12 feet away from a solid wall higher than 6 feet.

5. The removable posts for compressor or evaporator service access must not be blocked at either side of

unit.

6. Do not mount electrical conduits, etc. above the side rail on either side of unit.

IM 548 / Page 9

Page 10

Vibration Isolators

Vibration isolators are recommended for all roof mounted installations or wherever vibration

transmission is a consideration. Figure 9 (125 thru 204), Figure 10 (205 thru 280), Figure 12 (300 thru

340) and Figure 13 (360 thru 380) show isolator locations in relation to the unit control center. Table 2

(125 thru 204), Table 3 (205 thru 280), Table 5 (300 thru 340) and Table 6 (360 thru 380) give the

isolator loads at each location shown in Figures 9, 10, 12 and 13. Figure 11 gives dimensions that are

required to secure each McQuay isolator section to the mounting surface.

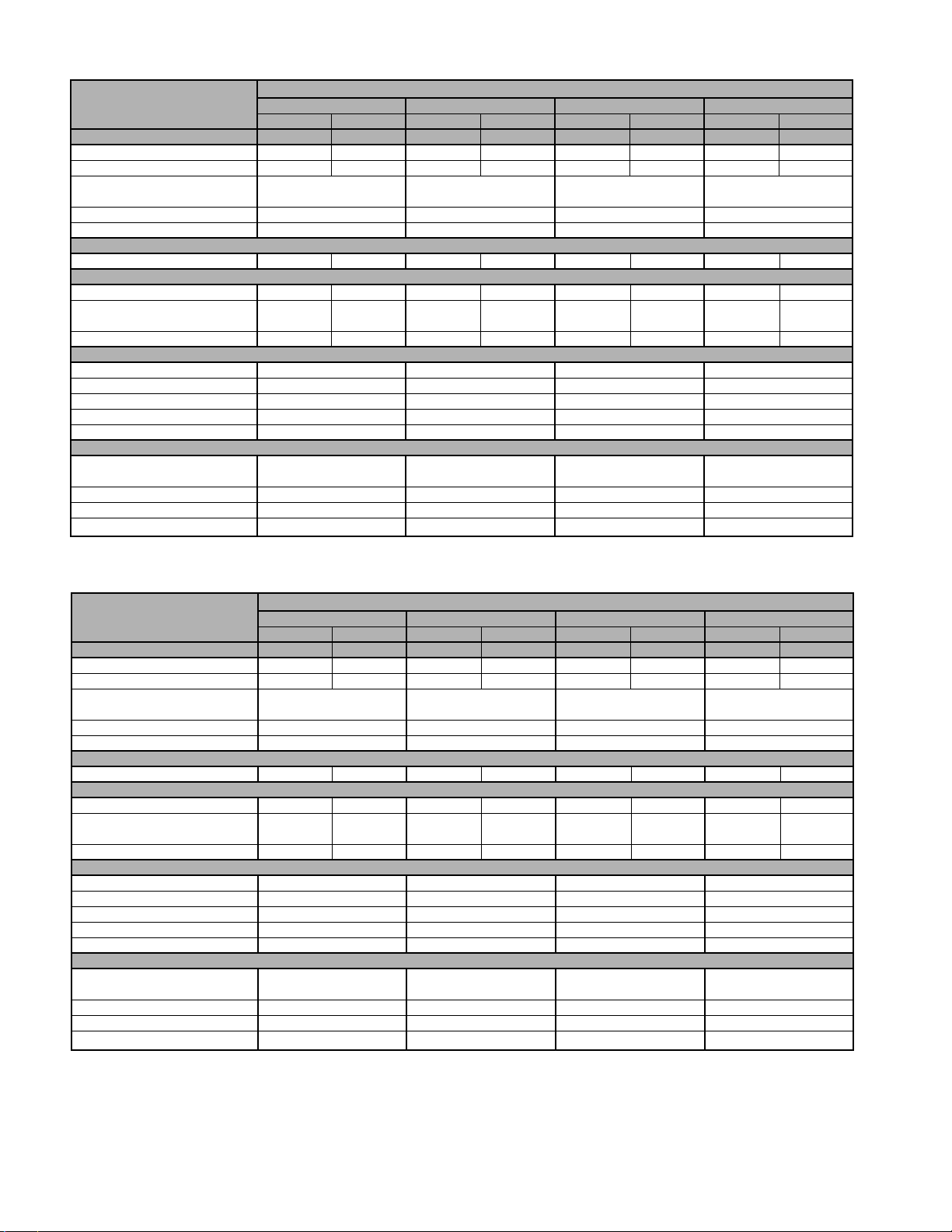

Table 1. Vibration isolators (spring)

COLOR

ALS UNIT SIZE TYPE OF

125-280 CP2-32 White 0047792932 2600 (1180)

STRIPE

MCQUAY PART

NUMBER

RECOMMENDED

MAXIMUM LOAD

LBS. (KG)

Note: The same isolators are used when the chiller is

supplied with the optional copper finned condenser coils.

The spring is fully compressed at approximately 3900 lbs

(1769 kg).

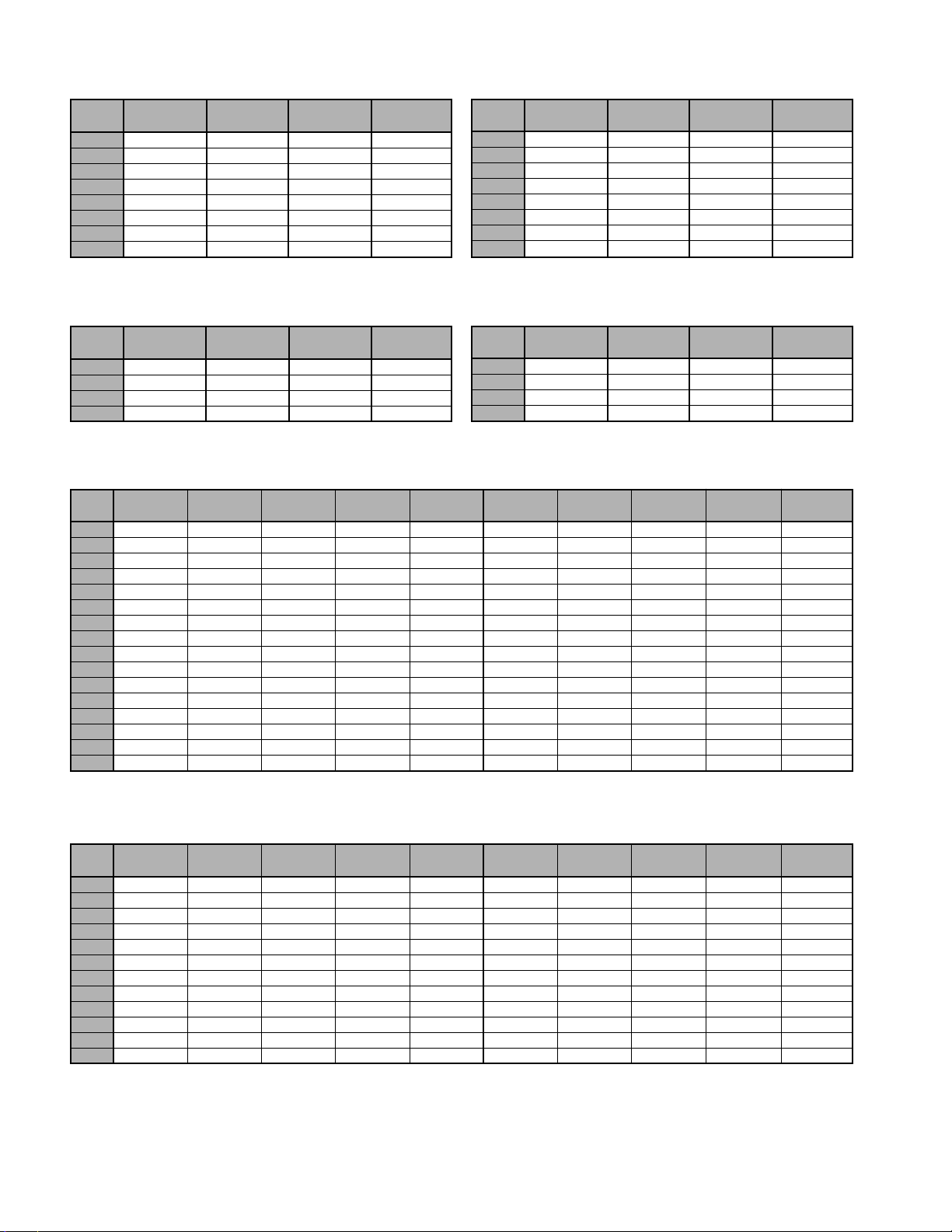

Table 2. Isolator loads (125A thru 204A)

ALS

UNIT

SIZE

125A 1625 (737) 2065 (937) 1270 (576) 1625 (737) 2065 (937) 1270 (576)

140A 1680 (762) 2145 (973) 1350 (612) 1680 (762) 2145 (973) 1350 (612)

155A 1720 (780) 2205 (1000) 1410 (640) 1720 (780) 2205 (1000) 1410 (640)

170A 1730 (785) 2220 (1007) 1425 (647) 1730 (785) 2220 (1007) 1425 (647)

175A 1880 (853) 2350 (1066) 1395 (633) 1880 (853) 2350 (1066) 1395 (633)

185A 1880 (853) 2350 (1066) 1395 (633) 1880 (853) 2350 (1066) 1395 (633)

195A 1920 (871) 2440 (1107) 1440 (653) 1920 (871) 2440 (1107) 1440 (653)

204A 2081 (944) 2644 (1199) 1560 (707) 2081 (944) 2644 (1199) 1560 (707)

ISOLATOR LOADS AT EACH MOUNTING LOCATION

LBS (KG)

1 23456

Table 3. Isolator loads (205 thru 280)

ALS

UNIT

SIZE

205A 1790 (812) 1840 (834) 2040 (925) 1370 (621) 950 (431) 1630 (739) 2020 (916) 1640 (744) 1650 (748) 1000 (454)

220A 1790 (812) 1850 (839) 2050 (930) 1370 (621) 950 (431) 1630 (739) 2030 (921) 1650 (748) 1660 (753) 1000 (454)

235A 1820 (825) 1880 (853) 2080 (943) 1370 (621) 960 (435) 1670 (757) 2060 (934) 1680 (762) 1660 (753) 1000 (454)

250A 1820 (825) 1880 (853) 2080 (943) 1380 (626) 960 (435) 1670 (757) 2060 (934) 1680 (762) 1670 (757) 1000 (454)

265A 1820 (825) 1880 (853) 2080 (943) 1380 (626) 960 (435) 1670 (757) 2060 (934) 1680 (762) 1670 (757) 1000 (454)

280A 1830 (830) 1890 (857) 2080 (943) 1380 (626) 960 (435) 1680 (762) 2070 (939) 1690 (766) 1670 (757) 1000 (454)

12345678910

ISOLATOR LOADS AT EACH MOUNTING LOCATION

LBS (KG)

Page 10 / IM 548

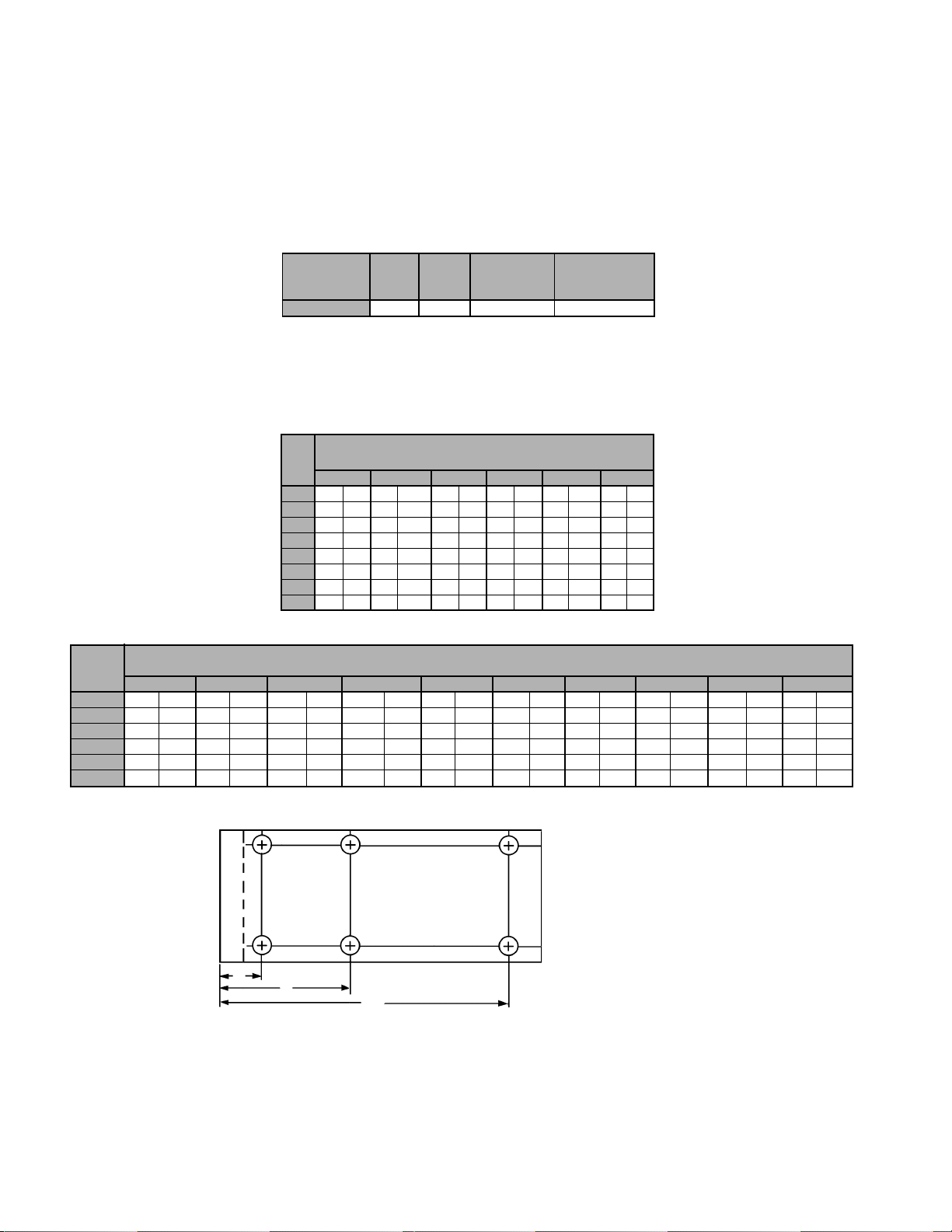

Figure 9. Isolator locations (125A thru 204A)

4

Control Center

1

A

B

5

2

C

6

A = 13" (330 mm)

B = 95" (2413 mm)

C = 215" (5461 mm) ALS125A-155A

250" (6350 mm) ALS170A-204A

3

Page 11

Figure 10. Isolator locations (205 thru 280)

67 8 9 10

12 3 4 5

Control Center

A

▼

▼

B

▼

▼▼▼

A = 13" (330 mm)

B = 95" (2413 mm)

C = 177" (4496 mm)

D = 259" (6579 mm)

E = 341" (8661 mm)

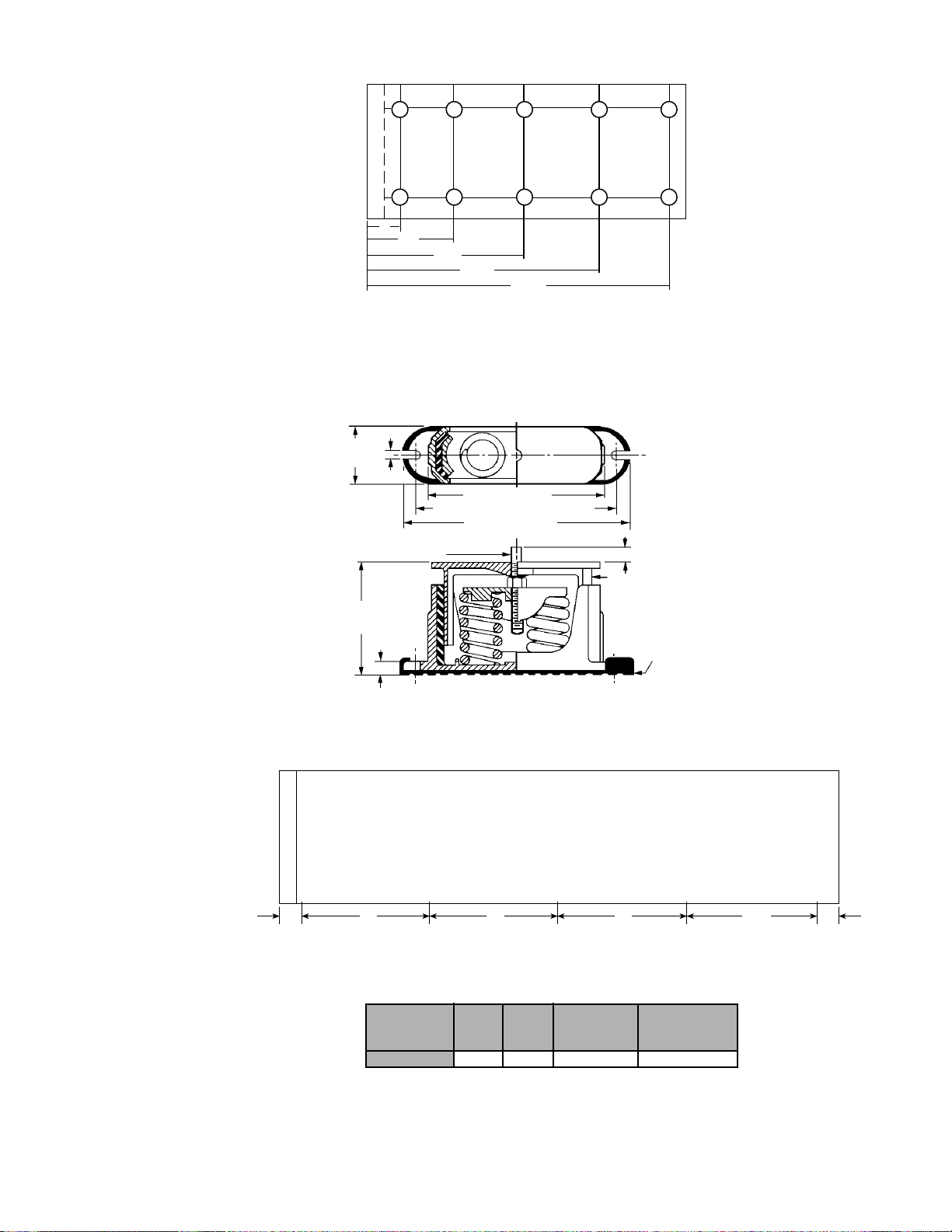

Figure 11. Spring flex isolator

3"

(76.2 mm)

3

⁄8"(15.8mm)

1

⁄2" (12.7 mm) dia.

positioning pin

6" free ht.

(152.4 mm)

9

⁄16" (14.1 mm)

++

++

▼

C

D

+ + +

+++

▼

E

73⁄4" (196.8 mm)

91⁄4" (234.9 mm) C-C FDTN. bolt

1

⁄2" (266.70 mm)

10

9

⁄16"(14.1mm)

▼

▼

5

⁄8" (15.8 mm)

Adjust mounting so that

upper housing clears

lower housing by at least

1

⁄4" (6.3 mm) and not

more than

1

⁄2" (12.7 mm)

1

⁄4" (6.3 mm)

acoustical non-skid

neoprene pad

Figure 12. Vibration isolator (300 thru 340)

•

1

Control Center

2

•

82 82 82

•

3

4

•

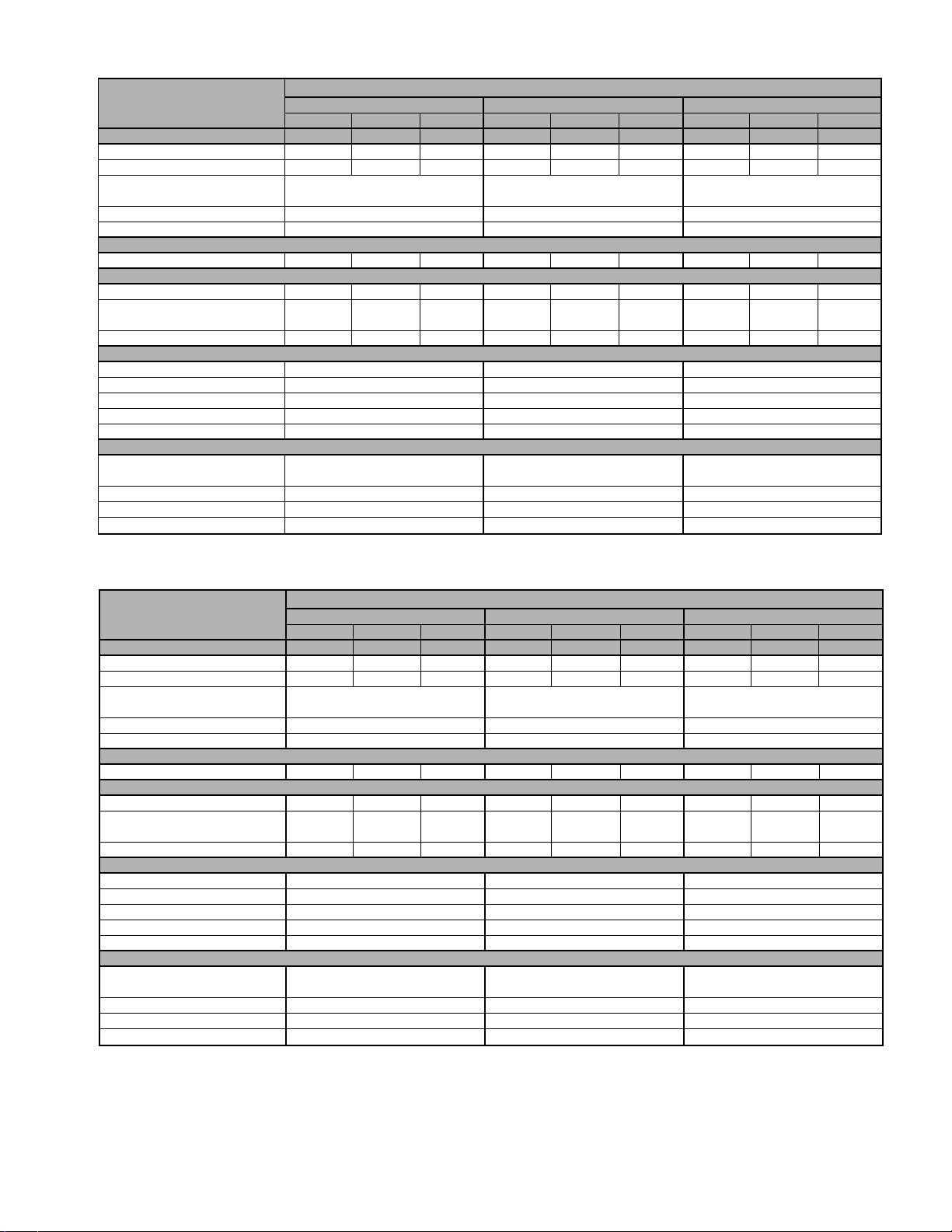

Table 4. Vibration isolators (spring)

ALS UNIT SIZE TYPE OF

300A-340A CP2-32 White 047792932 3000 (1360)

Note:

The same isolators are used when the chiller is supplied with the optional

copper finned condenser coils. The spring is fully compressed at

approximately 3900 lbs (1769 kgs).

COLOR

STRIPE

•

5

6

•

MCQUAY PART

NUMBER

•

7

8

•

RECOMMENDED

MAXIMUM LOAD

LBS (KG)

116.7

•

9

10

•

1413

IM 548 / Page 11

Page 12

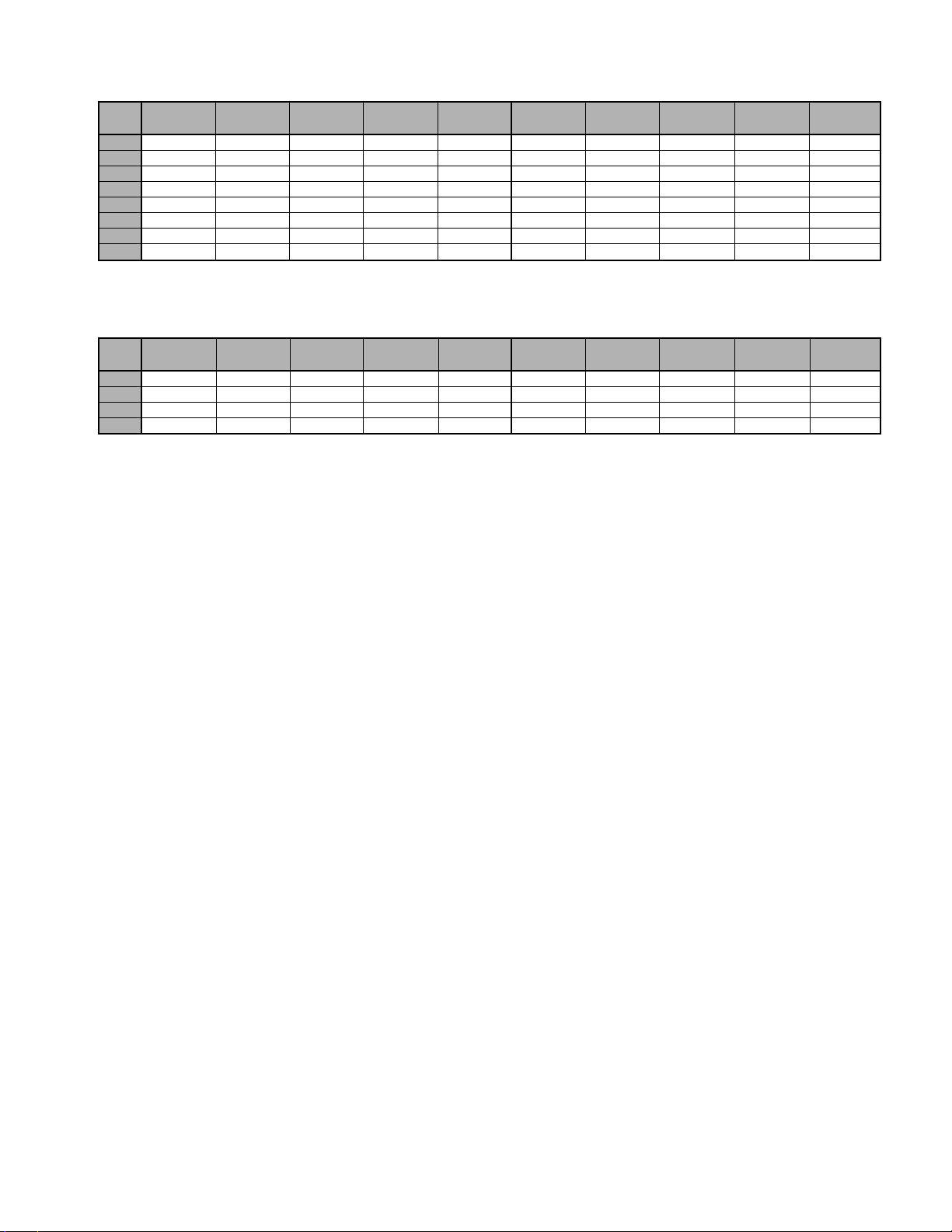

Table 5. Operating weight loads (300 thru 340)

ALS

UNIT WEIGHT

SIZE

300A

315A

330A

340A

Note: 1. Unit to be supported at (5) isolator mounting locations per side, 10 total, as indicated.

2. Add approximately 370 lbs (168 kgs) at each isolator location for units with optional copper finned condenser coils.

3. Unit to be level in both directions within 1⁄8 inch (3 mm) per 10 feet (3 m).

4. See dimensional drawing 073124701 for exact location of isolator support holes in base frame.

OPERATING WEIGHT LOAD AT ISOLATOR LOCATIONS, LBS (KGS) FOR UNITS WITH ALUMINUM FINNED COILS

12345 678910

1780 (807) 2060 (934) 2530 (1147) 2530 (1147) 2560 (1161) 2560 (1161) 2170 (984) 2170 (984) 1445 (655) 1445 (655) 21250 (9637)

1780 (807) 2060 (934) 2530 (1147) 2530 (1147) 2560 (1161) 2560 (1161) 2170 (984) 2170 (984) 1445 (655) 1445 (655) 21250 (9637)

1780 (807) 2060 (934) 2540 (1152) 2540 (1152) 2570 (1166) 2570 (1166) 2180 (989) 2180 (989) 1450 (658) 1450 (658) 21320 (9669)

1780 (807) 2060 (934) 2540 (1152) 2540 (1152) 2570 (1166) 2570 (1166) 2180 (989) 2180 (989) 1450 (658) 1450 (658) 21320 (9669)

OPERATING

LBS (KGS)

Figure 13. Vibration isolator (360 thru 380)

•

1

Control Center

2

•

13

•

3

4

•

•

5

6

•

•

7

8

•

•

9

10

•

10482 82 82 82

•

11

12

•

14

Table 6. Vibration isolators (spring)

ALS UNIT SIZE TYPE OF

COLOR

STRIPE

360A-380A CP2-32 White 047792932 3000 (1360)

MCQUAY PART

NUMBER

RECOMMENDED

MAXIMUM LOAD

LBS (KG)

Note: The same isolators are used

when the chiller is supplied with the

optional copper finned condenser

coils. The spring is fully compressed

at approximately 3900 lbs (1769 kgs).

Table 7. Weights (360 thru 380)

ALS OPERATING WEIGHT

UNIT SIZE LBS (KGS)

360A 22920 (10394)

370A 22970 (10417)

380A 23020 (10440)

Table 8. Operating weight loads (360 thru 380)

ALS

UNIT

SIZE

360A

1780 (807) 2060 (934) 2530 (1147) 2530 (1147) 2540 (1152) 2540 (1152) 1670 (757) 1670 (757) 1720 (780) 1720 (780) 1080 (490) 1080 (490)

370A

1780 (807) 2060 (934) 2540 (1152) 2540 (1152) 2550 (1156) 2550 (1156) 1675 (760) 1675 (760) 1720 (780) 1720 (780) 1080 (490) 1080 (490)

380A

1780 (807) 2060 (934) 2550 (1156) 2550 (1156) 2560 (1161) 2560 (1161) 1680 (762) 1680 (762) 1720 (780) 1720 (780) 1080 (490) 1080 (490)

Note: 1. Unit to be supported at (6) isolator mounting locations per side, 12 total, as indicated.

2. Add approximately 370 lbs (168 kgs) at each isolator location for units with optional copper finned condenser coils.

3. Unit to be level in both directions within 1⁄8 inch (3 mm) per 10 feet (3 m).

4. See dimensional drawing 073124801 for exact location of isolator support holes in base frame.

OPERATING WEIGHT LOAD AT ISOLATOR LOCATIONS, LBS (KGS) FOR UNITS WITH ALUMINUM FINNED COILS

123 456 78 9101112

Page 12 / IM 548

Page 13

Water Piping

Due to the variety of piping practices, it is advisable to follow the recommendations of local authorities.

They can supply the installer with the proper building and safety codes required for a safe and proper

installation.

Basically, the piping should be designed with a minimum number of bends and changes in elevation to

keep system cost down and performance up. It should contain:

1. Vibration eliminators to reduce vibration and noise transmission to the building.

2. Shutoff valves to isolate the unit from the piping system during unit servicing.

3. Manual or automatic air vent valves at the high points of the system. Drains at the low parts in the

system.

4. Some means of maintaining adequate system water pressure (e.g., expansion tank or regulating valve).

5. Temperature and pressure indicators located at the unit to aid in unit servicing.

6. A strainer or some means of removing foreign matter from the water before it enters the pump. It

should be placed far enough upstream to prevent cavitation at the pump inlet (consult pump

manufacturer for recommendations). The use of a strainer will prolong pump life and thus keep

system performance up.

7. A strainer should also be placed in the supply water line just prior to the inlet of the evaporator.

This will aid in preventing foreign material from entering and decreasing the performance of the

evaporator.

8. The shell-and-tube cooler has a thermostat and heating cable to prevent freeze-up, due to low

ambient, down to -20°F (-28.8°C). It is suggested that the heating cable be wired to a separate 110V

supply circuit. As shipped from the factory, it is factory wired to the control circuit. Any water

piping to the unit must also be protected to prevent freezing.

9. If the unit is used as a replacement chiller on a previously existing piping system, the system should

be thoroughly flushed prior to unit installation and then regular chilled water analysis and chemical

water treatment is recommended immediately at equipment start-up.

10. The total water quantity in the system should be sufficient to prevent frequent “on-off” cycling. A

reasonable minimum quantity would allow for a complete water system turnover in not less than 15

minutes.

11. In the event glycol is added to the water system, as an afterthought for freeze protection, recognize

that the refrigerant suction pressure will be lower, cooling performance less, and water side pressure

drop greater. If the percentage of glycol is large, or if propylene is employed in lieu of ethylene

glycol, the added pressure drop and loss of performance could be substantial.

12. For operations requiring the ice mode feature, logic in MicroTech will adjust the freezestat to a

pressure equivalent to 13.5°F (7.5°C) below the leaving evaporator water temperature. However, if a

different freezestat pressure value is desired, the freezestat can be manually changed through

MicroTech. Refer to IM549 for additional information.

If a separate disconnect is used for the 110V supply

to the cooler heating cable, it should be clearly

marked so that it is not accidentally shut off during

cold seasons.

Prior to insulating the piping and filling the system, a preliminary leak check should be made.

Piping insulation should include a vapor barrier to prevent moisture condensation and possible damage

to the building structure. It is important to have the vapor barrier on the outside of the insulation to

prevent condensation within the insulation on the cold surface of the pipe.

IM 548 / Page 13

Page 14

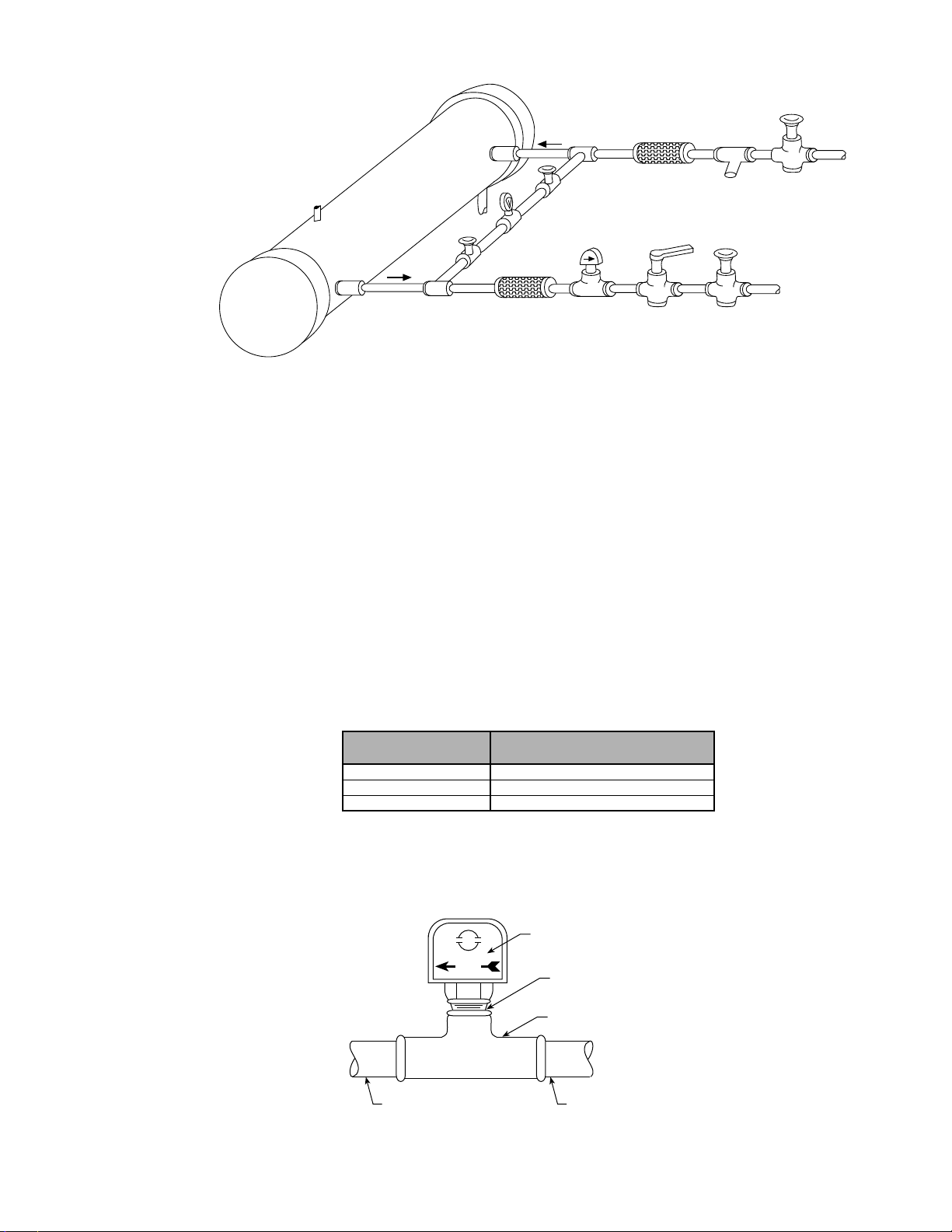

Figure 14. Typical field water piping

Inlet

Refrigerant

Connections

this end

Vent

Outlet

Drain

Valved

Pressure

Gauge

Vibration

Eliminator

Flow

Switch

Vibration

Eliminator

Balancing

Valve

Water

Strainer

Gate

Valve

Gate

Valve

Flow Switch

A water flow switch must be mounted in either the entering or leaving water line to insure that there

will be adequate water flow to the evaporator before the unit can start. This will safeguard against

slugging the compressors on start-up. It also serves to shut down the unit in the event that water flow is

interrupted to guard against evaporator freeze-up.

A flow switch is available from McQuay under ordering number 0017503300. It is a “paddle” type switch

and adaptable to any pipe size from 1" (25mm) to 8" (203mm) nominal. Certain minimum flow rates are

required to close the switch and are listed in Table 9. Installation should be as shown in Figure 15.

Electrical connections in the unit control center should be made at terminals 62 and 63. The normally

open contacts of the flow switch should be wired between these two terminals. Flow switch contact quality

must be suitable for 24 VAC, low current (16ma). Flow switch wire must be in separate conduit from

any high voltage conductors (115 VAC and higher).

Table 9. Flow switch minimum flow rates

Page 14 / IM 548

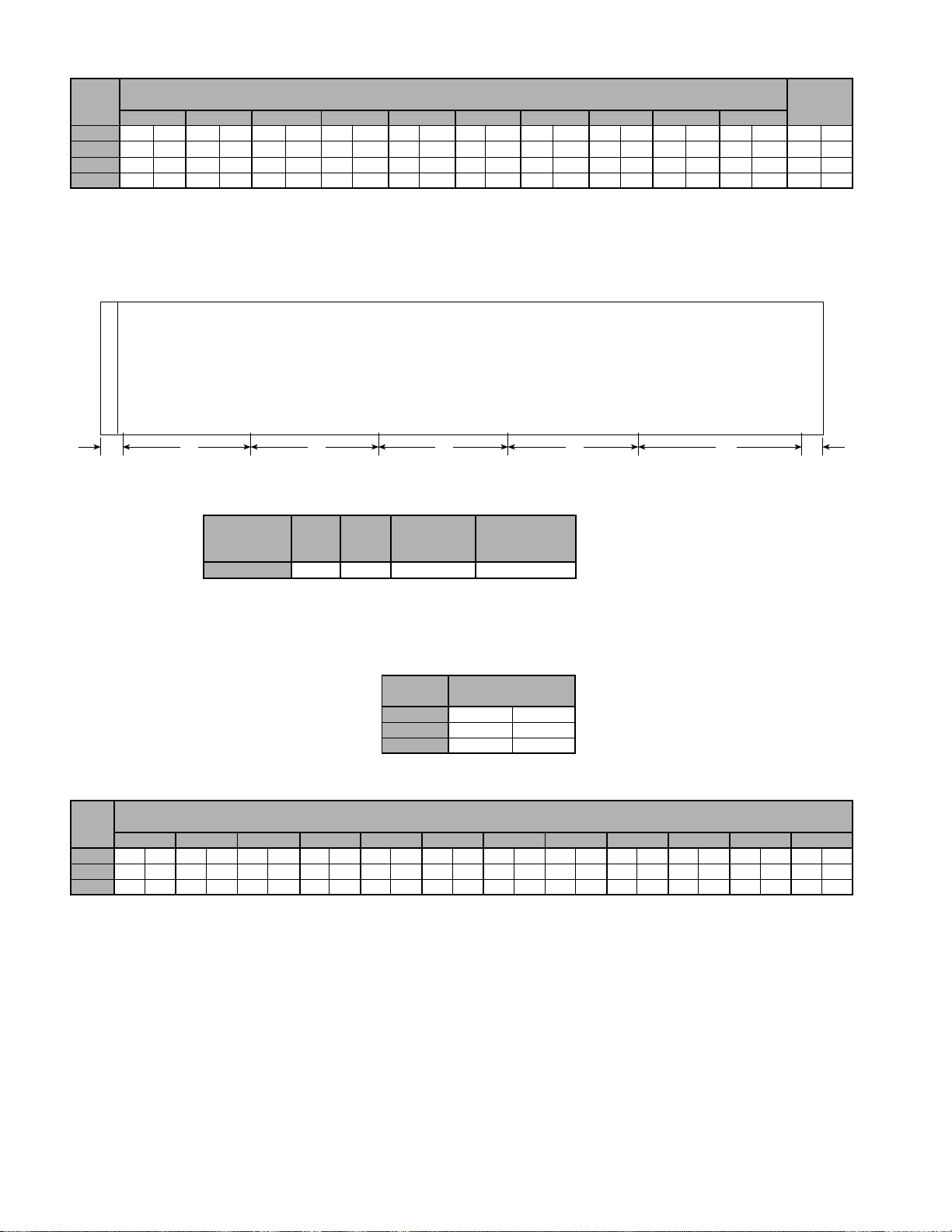

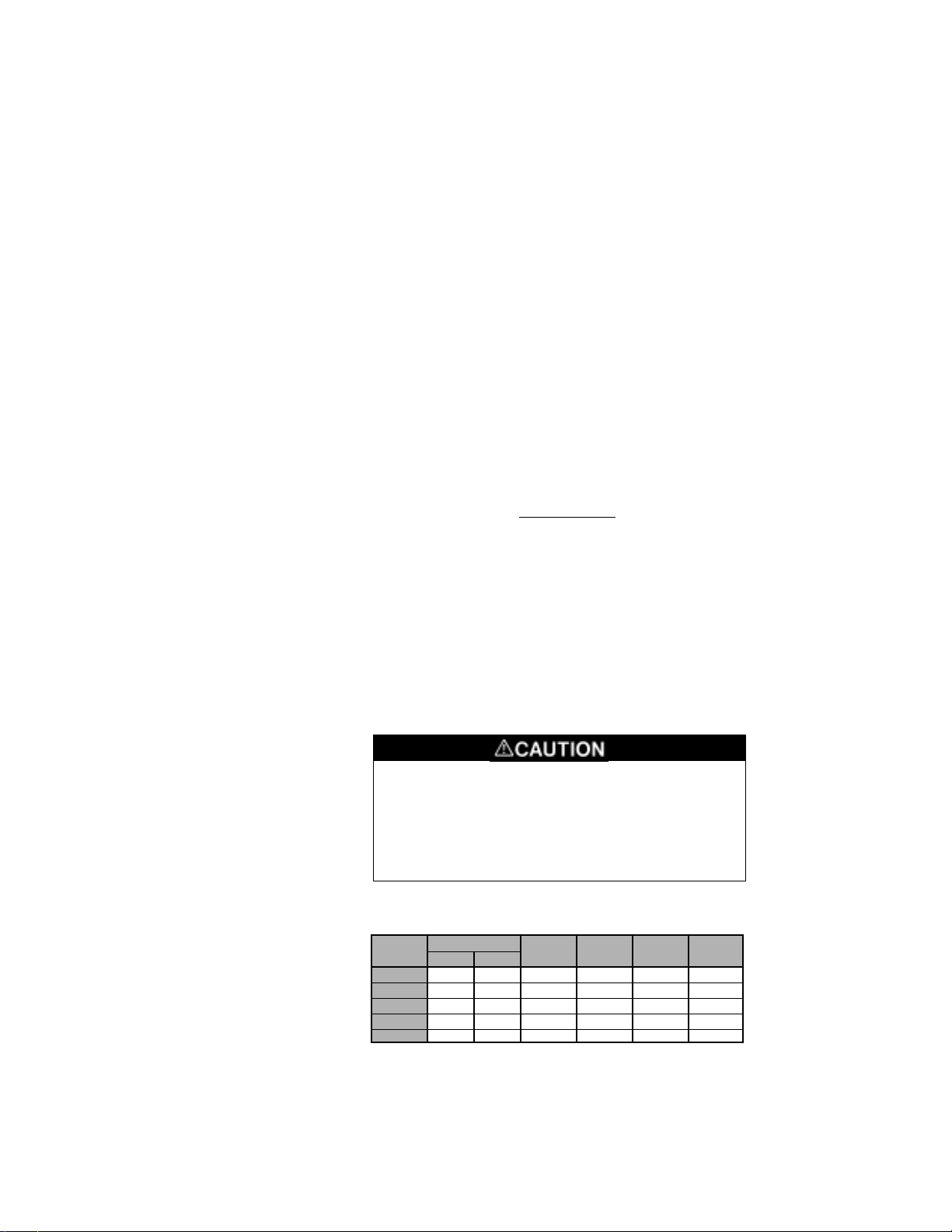

Figure 15. Flow switch

NOMINAL PIPE SIZE MINIMUM REQUIRED FLOW TO

INCHES (MM) ACTIVATE SWITCH - GPM (LPS)

5 (127) 58.7 (3.7)

6 (152) 79.2 (5.0)

8 (203) 140 (8.8)

Note: Water pressure differential switches are not recommended for

outdoor applications.

Flow direction

marked on switch

Flow

5" pipe dia.–

minimum after switch

1.00" NPT flow

switch connection

Te e

5" pipe dia.–

minimum before switch

Page 15

Water Connections

Water piping to the cooler can be brought up through the bottom of the unit or through the side

between the vertical supports. The dimensional data on pages 20-23 gives the necessary dimensions and

locations for all piping connections.

Note: On unit size 175A thru 204A there is a diagonal brace off of a vertical support which will

interfere with the water connection if brought in from the side. This brace can be removed, but only

after the unit is in place.

Refrigerant Charge

All units are designed for use with HCFC-22 and are compatible with HCFC alternatives and are

shipped with a full operating charge. The operating charge for each unit is shown in the Physical Data

Tables on pages 17-20.

Glycol Solutions

The system glycol capacity, glycol solution flow rate, and pressure drop through the cooler may be

calculated using the following formulas and tables.

Note: The procedure below does not specify the type of glycol. Use the derate factors found in Table 10

for corrections when using Ethylene glycol and those in Table 11 for Propylene glycol.

1. Capacity — Cooling capacity is reduced from that with plain water. To find the reduced value

multiply the chiller’s water system tonnage by the capacity correction factor to find the chiller’s

capacity in the glycol system.

2. Flow — To determine flow (or delta-T) knowing delta-T

(or flow) and cap:

Glycol flow = 24 x cap (glycol) x flow factor

delta-T

3. Pressure drop — To determine pressure drop through the cooler, when using glycol, enter the water

pressure drop graph on page 13 at the actual glycol flow. Multiply the water pressure drop found

there by the PD factor to obtain corrected glycol pressure drop.

4. To determine glycol system kW, multiply the water system kW by factor called Power.

Test coolant with a clean, accurate glycol solution hydrometer (similar to that found in service stations)

to determine the freezing point. Obtain percent glycol from the freezing point table below. On

glycol applications it is normally recommended by the supplier that a minimum of 25% solution by

weight be used for protection against corrosion.

Do not use an automotive grade antifreeze. Industrial

grade glycols must be used. Automotive antifreeze

contains inhibitors which will cause plating on the

copper tubes within the chiller evaporator. The type

and handling of glycol used must be consistent with

local codes.

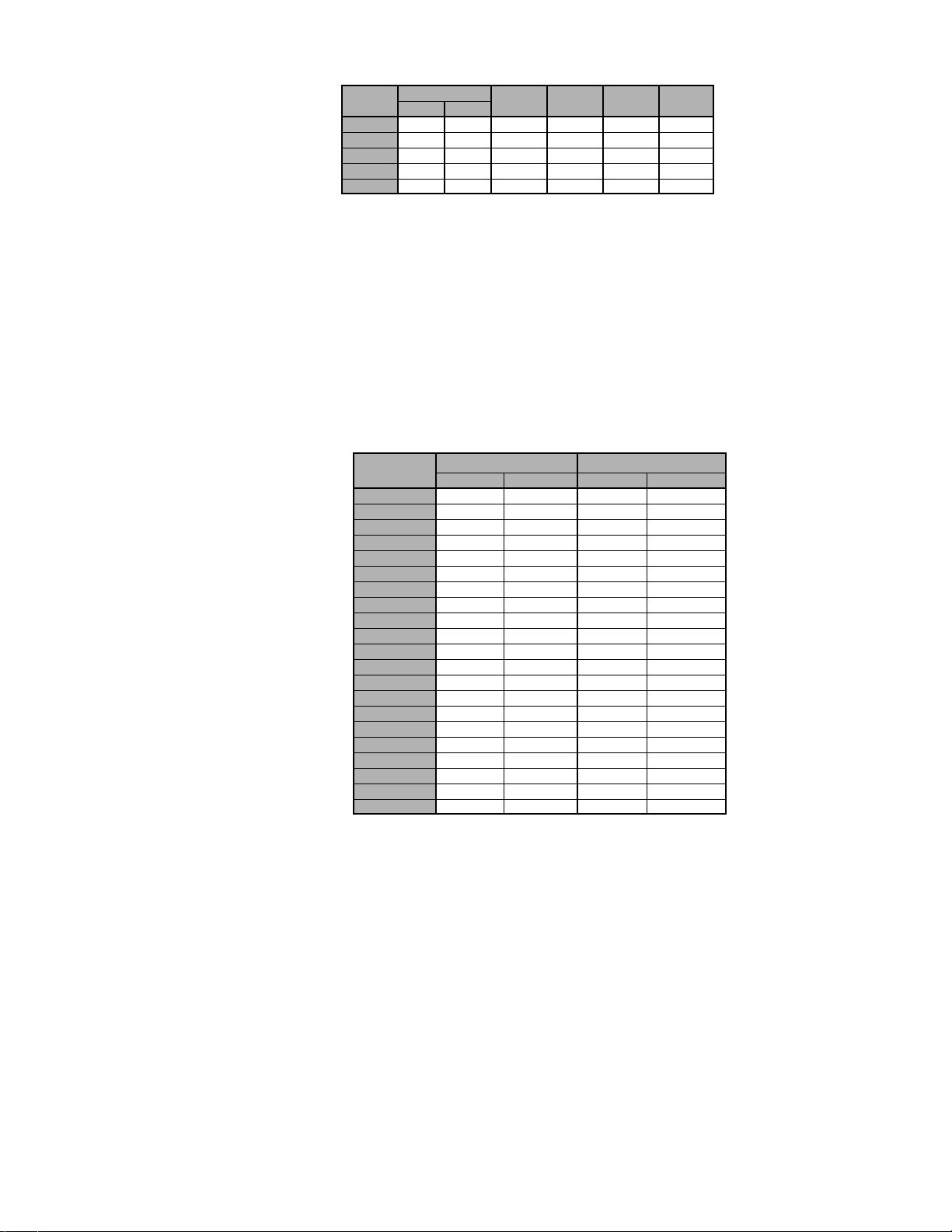

Table 10. Ethylene glycol

%

P.G.

10 26 -3 0.991 0.996 1.013 1.070

20 18 -8 0.982 0.992 1.040 1.129

30 7 -14 0.972 0.986 1.074 1.181

40 –7 -22 0.961 0.976 1.121 1.263

50 –28 -33 0.946 0.966 1.178 1.308

FREEZE PT.

°F °C

CAP POWER FLOW PD

IM 548 / Page 15

Page 16

Table 11. Propylene glycol

%

P.G.

10 26 -3 0.987 0.992 1.010 1.068

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

40 –5 -21 0.946 0.971 1.078 1.366

50 –27 -33 0.929 0.965 1.116 1.481

FREEZE PT.

°F °C

CAP POWER FLOW PD

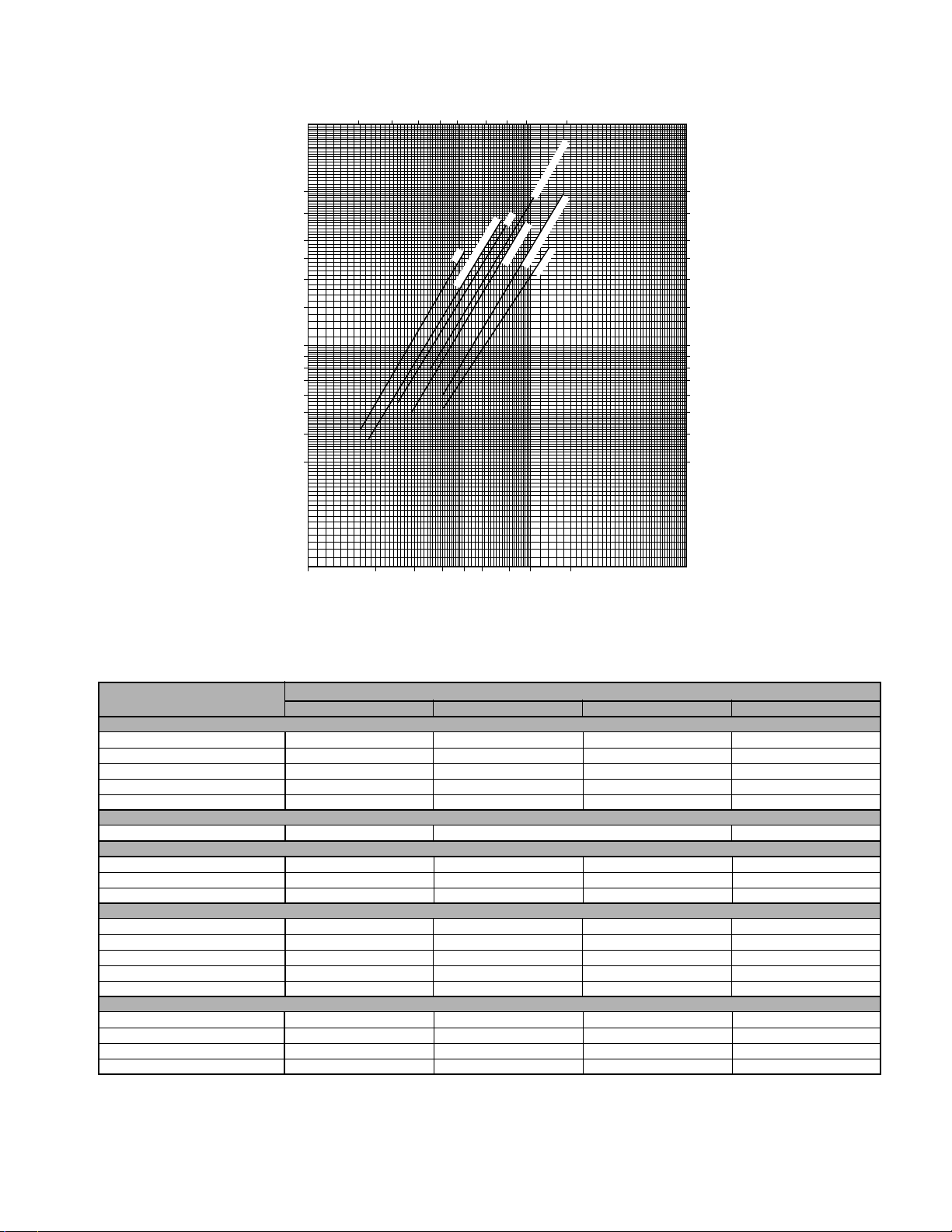

Evaporator Water Flow and Pressure Drop

Balance the chilled water flow through the evaporator. The flow rates must fall between the minimum and

maximum values shown in Table 12. Flow rates below the minimum values shown will result in laminar

flow which will reduce efficiency, cause erratic operation of the electronic expansion valve and could

cause low temperature cutouts. On the other hand flow rates exceeding the maximum values shown can

cause erosion on the evaporator water connections and tubes.

Measure the chilled water pressure drop through the evaporator at field installed pressure taps. It is

important not to include valves or strainers in these readings.

Variable chilled water flow through the evaporator while the compressor(s) are operating is not

recommended. MicroTech control set points are based upon a constant flow and variable temperature.

Table 12. Min/max evaporator flow rates

ALS UNIT

SIZE

125 186 11.8 497 31.4

140 209 13.2 557 35.2

155 231 14.6 617 39.0

170 253 16.0 675 42.7

175 256 16.2 683 43.2

185 274 17.3 730 46.1

195 284 18.0 767 48.5

204 303 19.1 808 51.0

205 309 19.5 825 52.1

220 335 21.2 893 56.4

235 356 22.5 950 60.0

250 376 23.8 1000 63.2

265 391 24.7 1043 66.0

280 408 25.8 1088 68.8

300 440 27.8 1173 74.1

315 459 29.0 1222 77.1

330 479 30.2 1276 80.6

340 493 31.1 1313 82.9

360 523 33.0 1395 88.1

370 540 34.1 1438 90.8

380 559 35.3 1490 94.1

MIN. FLOW RATE MAX. FLOW RATE

GPM LPS GPM LPS

Page 16 / IM 548

Page 17

Figure 16. Evaporator water pressure drop

50

40

30

25

20

O)

2

15

10

9

8

7

6

Pressure Drop (ft. of H

5

4

3

10 15 20 25 30 40 50 60 90

Flow (LPS)

195

125

140, 155, 170, 175, 185

205, 220, 235

204, 250, 265, 280

330, 340, 360, 370, 380

300, 315

150

120

90

75

60

45

30

27

24

21

18

15

12

9

Pressure Drop (kPa)

100 200 300 400

600 800 1000 1500

500

Flow (GPM)

Physical Data

Table 13. Unit sizes 70 thru 100

DATA

070A 080A 090A 100A

BASIC DATA

Unit Capacity @ ARI Conditions, tons 68.7 81.9 93.2 98.7

Unit Operating Charge R-22, lbs. 150 160 180 190

Cabinet Dimensions, L x W x H, in. 124.5 x 83.4 x 93.3 124.5 x 83.4 x 93.3 159.1 x 83.4 x 93.3 159.1 x 83.4 x 93.3

Unit Operating Weight, lbs. 5725 6175 6825 7300

Unit Shipping Weight, lbs. 5500 5900 6500 6900

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal Capacity, tons 65 80 95 95

CONDENSERS, HIGH EFFICIENCY FIN & TUBE TYPE WITH INTEGRAL SUBCOOLER

Coil Face Area, ft.

2

115.6 115.6 154.1 154.1

Finned Height x Finned Length, in. 160 x 104 161 x 104 160 x 138.7 160 x 138.7

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of Fans — Fan Diameter, in. 6 - 28 6 - 28 8 - 28 8 - 28

No. of Motors — hp 6 - 1.5 6 - 1.5 8 - 1.5 8 - 1.5

Fan & Motor RPM 1140 1140 1140 1140

Fan Tip Speed, fpm 8357 8357 8357 8357

Total Unit Airflow, ft3/sec 54120 54120 72160 72160

EVAPORATOR, DIRECT EXPANSION, BAFFLED SHELL & THRU TUBE

Shell Diameter — Tube Length (in. - ft.) 12 - 08 14 - 08 14 - 10 16 - 10

Water Volume, gallons 24.3 32.6 41.3 43.6

Max. Water Pressure, psi 175 175 175 175

Max. Refrigerant Pressure, psi 225 225 225 225

ALS MODEL NUMBER

IM 548 / Page 17

Page 18

Table 14. Unit sizes 125 thru 170

DATA 125A 140A 155A 170A

BASIC DATA

Unit capacity @ ARI conditions, tons (kW) 62.2 (218) 62.2 (218) 64.4 (226) 75 (263) 77.1 (271) 77.1 (271) 79 (278) 89.7 (315)

Unit operating charge R-22, lbs. (kg) 140 (63.5) 140 (63.5) 140 (63.5) 150 (68.1) 150 (68.1) 150 (68.1) 150 (68.1) 160 (72.6)

Cabinet dimensions L x W x H, in. (mm)

Unit operating weight, lbs. (kg) 9920 (4500) 10350 (4700) 10670 (4840) 10750 (4880)

Unit shipping weight, lbs. (kg) 9600 (4355) 9900 (4490) 10250 (4650) 10350 (4700)

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal tons, (kW) 65 (230) 65 (230) 65 (230) 80 (280) 80 (280) 80 (280) 80 (280) 95 (335)

CONDENSERS, HIGH EFFICIENCY FIN & TUBE TYPE WITH INTEGRAL SUBCOOLER

Coil face area, sq. ft. (m2) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7)

Finned height x finned length, in. (mm)

Fins per inch x rows deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of fans – fan diameter, in. (mm) 10 – 28 (711) 10 – 28 (711) 12 – 28 (711) 12 – 28 (711)

No. of motors – hp (kW) 10 – 1.5 (1.1) 10 – 1.5 (1.1) 12 – 1.5 (1.1) 12 – 1.5 (1.1)

Fan & motor rpm, 60 1140 1140 1140 1140

60 Hz fan tip speed, fpm 8357 8357 8357 8357

60 Hz total unit airflow, cfm 90200 90200 108240 108240

EVAPORATOR, DIRECT EXPANSION, BAFFLED SHELL & THRU TUBE

Shell diameter – tube length 14 – 10 16 – 10 16 – 10 16 – 10

in. (mm) – ft. (mm) (356 – 3048) (406 – 3048) (406 – 3048) (406 – 3048)

Water volume, gallons (L) 36.1 (136.7) 45.6 (172.6) 43.6 (165.0) 43.6 (165.0)

Max. water pressure, psi (kPa) 175 (1207) 175 (1207) 175 (1207) 175 (1207)

Max. refrigerant pressure, psi (kPa) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

CKT. 1 CKT. 2 CKT. 1 CKT. 2 CKT. 1 CKT. 2 CKT. 1 CKT. 2

228.7 x 83.4 x 92.5 228.7 x 83.4 x 92.5 228.7 x 83.4 x 92.5 228.7 x 83.4 x 92.5

(5809 x 2118 x 2350) (5809 x 2118 x 2350) (5809 x 2118 x 2350) (5809 x 2118 x 2350)

80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208

(2032 x 5283) (2032 x 5283) (2032 x 5283) (2032 x 5283) (2032 x 5283) (2032 x 5283) (2032 x 5283) (2032 x 5283)

ALS MODEL NUMBER

Table 15. Unit sizes 175 thru 204

DATA 175A 185A 195A 204A

BASIC DATA

Unit capacity @ ARI conditions, tons (kW) 80.4 (282) 90.6 (318) 91.2 (320) 91.2 (320) 94.6 (332) 94.6 (332) 101 (355) 101 (355)

Unit operating charge R-22, lbs. (kg) 160 (72.6) 160 (72.6) 160 (72.6) 160 (72.6) 170 (77.1) 170 (77.1) 195 (88.4) 195 (88.4)

Cabinet dimensions 263.4 x 83.4 x 92.5 263.4 x 83.4 x 92.5 263.4 x 83.4 x 92.5 263.4 x 83.4 x 92.5

L x W x H, in. (mm) (6690 x 2118 x 2350) (6690 x 2118 x 2350) (6690 x 2118 x 2350) (6690 x 2118 x 2350)

Unit operating weight, lbs. (kg) 11250 (5100) 11250 (5100) 11500 (5218) 12570 (5701)

Unit shipping weight, lbs. (kg) 10850 (4920) 10850 (4920) 11100 (5036) 11980 (5433)

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal tons, (kW) 80 (280) 95 (335) 95 (335) 95 (335) 95 (335) 95 (335) 95 (335) 95 (335)

CONDENSERS, HIGH EFFICIENCY FIN & TUBE TYPE WITH INTEGRAL SUBCOOLER

Coil face area, sq. ft. (m2) 135.0 (12.5) 135.0 (12.5) 135.0 (12.5) 135.0 (12.5) 135.0 (12.5) 135.0 (12.5) 135.0 (12.5) 135.0 (12.5)

Finned height x finned length, in. (mm)

Fins per inch x rows deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 12 x 4 12 x 4

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of fans – fan diameter, in. (mm) 14 – 28 (711) 14 – 28 (711) 14 – 28 (711) 14 – 28 (711)

No. of motors – hp (kW) 14 – 1.5 (1.1) 14 – 1.5 (1.1) 14 – 1.5 (1.1) 14 – 2.0 (1.5)

Fan & motor rpm, 60 1140 1140 1140 1140

60 Hz fan tip speed, fpm 8357 8357 8357 8357

60 Hz total unit airflow, cfm 126280 126280 126280 138908

EVAPORATOR, DIRECT EXPANSION, BAFFLED SHELL & THRU TUBE

Shell diameter – tube length 16 – 10 16 – 10 18 – 10 20 – 10

in. (mm) – ft. (mm) (406 –3048) (406 – 3048) (457 – 3048) (508 – 3048)

Water volume, gallons (L) 43.6 (165.0) 43.6 (165.0) 57.3 (216.9) 69.6 (263.5)

Max. water pressure, psi (kPa) 175 (1207) 175 (1207) 175 (1207) 175 (1207)

Max. refrigerant pressure, psi (kPa) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

CKT. 1 CKT. 2 CKT. 1 CKT. 2 CKT. 1 CKT. 2 CKT. 1 CKT. 2

80 x 243 80 x 243 80 x 243 80 x 243 80 x 243 80 x 243 80 x 243 80 x 243

(2032 x 6172) (2032 x 6172) (2032 x 6172) (2032 x 6172) (2032 x 6172) (2032 x 6172) (2032 x 6172) (2032 x 6172)

ALS MODEL NUMBER

Page 18 / IM 548

Page 19

Table 16. Unit sizes 205 thru 235

DATA 205A 220A 235A

BASIC DATA

Unit capacity @ ARI conditions, tons (kW) 64.4 (226) 66.1 (232) 75.8 (266) 66.1 (232) 78.2 (275) 79.0 (277) 79.3 (279) 79.3 (279) 79.0 (277)

Unit operating charge R-22, lbs. (kg) 140 (63.5) 140 (63.5) 150 (68.1) 140 (63.5) 150 (68.1) 150 (68.1) 150 (68.1) 150 (68.1) 150 (68.1)

Cabinet dimensions 355 x 83.4 x 94.5 355 x 83.4 x 94.5 355 x 83.4 x 94.5

L x W x H, in. (mm) (9017 x 2118 x 2400) (9017 x 2118 x 2400) (9017 x 2118 x 2400)

Unit operating weight, lbs. (kg) 15930 (7224) 15980 (7247) 16180 (7338)

Unit shipping weight, lbs. (kg) 15250 (6916) 15330 (6952) 15530 (7043)

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal tons, (kW) 65 (230) 65 (230) 80 (280) 65 (230) 80 (280) 80 (280) 80 (280) 80 (280) 80 (280)

CONDENSERS, HIGH EFFICIENCY FIN & TUBE TYPE WITH INTEGRAL SUBCOOLER

Coil face area, sq. ft. (m2) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7)

Finned height x finned length, in. (mm)

Fins per inch x rows deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of fans – fan diameter, in. (mm) 16 – 28 (711) 16 – 28 (711) 18 – 28 (711)

No. of motors – hp (kW) 16 – 1.5 (1.1) 16 – 1.5 (1.1) 18 – 1.5 (1.1)

Fan & motor rpm, 60 1140 1140 1140

60 Hz fan tip speed, fpm 8357 8357 8357

60 Hz total unit airflow, cfm 144320 144320 162360

EVAPORATOR, DIRECT EXPANSION, BAFFLED SHELL & THRU TUBE

Shell diameter – tube length 20 – 10 20 – 10 20 – 10

in. (mm) – ft. (mm) (508 – 3048) (508 – 3048) (508 – 3048)

Water volume, gallons (L) 81 (306.6) 76 (287.7) 76 (287.7)

Max. water pressure, psi (kPa) 175 (1207) 175 (1207) 175 (1207)

Max. refrigerant pressure, psi (kPa) 225 (1552) 225 (1552) 225 (1552)

CKT. 1 CKT. 2 CKT. 3 CKT. 1 CKT. 2 CKT. 3 CKT. 1 CKT. 2 CKT. 3

80 x 208 80 x 208 160 x 104 80 x 208 80 x 208 160 x 104 80 x 208 80 x 208 160 x 104

(2032 x 5283) (2032 x 5283) (4064 x 2642) (2032 x 5283) (2032 x 5283) (4064 x 2642) (2032 x 5283) (2032 x 5283) (4064 x 2642)

ALS MODEL NUMBER

Table 17. Unit sizes 250 thru 280

DATA 250A 265A 280A

BASIC DATA

Unit capacity @ ARI conditions, tons (kW) 80.2 (282) 79.0 (277) 91 (320) 80.2 (282) 89.7 (315) 91 (320) 91.4 (321) 89.7 (315) 91 (320)

Unit operating charge R-22, lbs. (kg) 150 (68.1) 150 (68.1) 160 (72.6) 150 (68.1) 160 (72.6) 160 (72.6) 160 (72.6) 160 (72.6) 160 (72.6)

Cabinet dimensions 355 x 83.4 x 94.5 355 x 83.4 x 94.5 355 x 83.4 x 94.5

L x W x H, in. (mm) (9017 x 2118 x 2400) (9017 x 2118 x 2400) (9017 x 2118 x 2400)

Unit operating weight, lbs. (kg) 16200 (7347) 16200 (7347) 16250 (7370)

Unit shipping weight, lbs. (kg) 15600 (7075) 15600 (7075) 15650 (7098)

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal tons, (kW) 80 (280) 80 (280) 95 (335) 80 (280) 95 (335) 95 (335) 95 (335) 95 (335) 95 (335)

CONDENSERS, HIGH EFFICIENCY FIN & TUBE TYPE WITH INTEGRAL SUBCOOLER

Coil face area, sq. ft. (m2) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7)

Finned height x finned length, in. (mm)

Fins per inch x rows deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of fans – fan diameter, in. (mm) 18 – 28 (711) 18 – 28 (711) 18 – 28 (711)

No. of motors – hp (kW) 18 – 1.5 (1.1) 18 – 1.5 (1.1) 18 – 1.5 (1.1)

Fan & motor rpm, 60 1140 1140 1140

60 Hz fan tip speed, fpm 8357 8357 8357

60 Hz total unit airflow, cfm 162360 162360 162360

EVAPORATOR, DIRECT EXPANSION, BAFFLED SHELL & THRU TUBE

Shell diameter – tube length 20 – 10 20 – 10 20 – 10

in. (mm) – ft. (mm) (508 – 3048) (508 – 3048) (508 – 3048)

Water volume, gallons (L) 69.6 (263.5) 69.6 (263.5) 69.6 (263.5)

Max. water pressure, psi (kPa) 175 (1207) 175 (1207) 175 (1207)

Max. refrigerant pressure, psi (kPa) 225 (1552) 225 (1552) 225 (1552)

CKT. 1 CKT. 2 CKT. 3 CKT. 1 CKT. 2 CKT. 3 CKT. 1 CKT. 2 CKT. 3

80 x 208 80 x 208 160 x 104 80 x 208 80 x 208 160 x 104 80 x 208 80 x 208 160 x 104

(2032 x 5283) (2032 x 5283) (4064 x 2642) (2032 x 5283) (2032 x 5283) (4064 x 2642) (2032 x 5283) (2032 x 5283) (4064 x 2642)

ALS MODEL NUMBER

IM 548 / Page 19

Page 20

Table 18. Unit sizes 300 thru 340

ALS MODEL NUMBER

DATA 300A 315A 330A 340A

BASIC DATA

Unit capacity @ ARI conditions, tons (kW) 66.9 (235) 66.9 (235) 79.7 (280) 79.7 (280) 66.9 (235) 79.2 (278) 79.7 (280) 79.7 (280) 79.2 (278) 79.2 (278) 80.3 (282) 80.3 (282) 79.2 (278) 79.2 (278) 80.3 (282) 89.4 (314)

Unit operating charge R-22, lbs. (kg) 155 (70.3) 155 (70.3) 160 (72.6) 160 (72.6) 155 (70.3) 160 (72.6) 160 (72.6) 160 (72.6) 160 (72.6) 160 (72.6) 160 (72.6) 160 (72.6) 160 (72.6) 160 (72.6) 160 (72.6) 170 (77.1)

Cabinet dimensions 389.7 x 83.4 x 94.5 389.7 x 83.4 x 94.5 389.7 x 83.4 x 94.5 389.7 x 83.4 x 94.5

L x W x H, in. (mm) (9898 x 2118 x 2400) (9898 x 2118 x 2400) (9898 x 2118 x 2400) (9898 x 2118 x 2400)

Unit operating weight, lbs. (kg) 21250 (9637) 21250 (9637) 21320 (9669) 21320 (9669)

Unit shipping weight, lbs. (kg) 20300 (9206) 20300 (9206) 20400 (9252) 20400 (9252)

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal tons, (kW) 65 (230) 65 (230) 80 (280) 80 (280) 65 (230) 80 (280) 80 (280) 80 (280) 80 (280) 80 (280) 80 (280) 80 (280) 80 (280) 80 (280) 80 (280) 95 (335)

CONDENSERS, HIGH EFFICIENCY FIN & TUBE TYPE WITH INTEGRAL SUBCOOLER

Coil face area, sq. ft. (m2) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9) 96.3 (8.9)

Finned height x finned length, in. (mm)

Fins per inch x rows deep 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of fans – fan diameter, in. (mm) 20 – 28 (711) 20 – 28 (711) 20 – 28 (711) 20 – 28 (711)

No. of motors – hp (kW) 20 – 2.0 (1.5) 20 – 2.0 (1.5) 20 – 2.0 (1.5) 20 – 2.0 (1.5)

Fan & motor rpm, 60 1140 1140 1140 1140

60 Hz fan tip speed, fpm 8357 8357 8357 8357

60 Hz total unit airflow, cfm 198440 198440 198440 198440

EVAPORATOR, DIRECT EXPANSION, BAFFLED SHELL & THRU TUBE

Shell diameter – tube length 24 – 10 24 – 10 24 – 10 24 – 10

in. (mm) – ft. (mm) (609 – 3048) (609 – 3048) (609 – 3048) (609 – 3048)

Water volume, gallons (L) 112 (424) 112 (424) 107 (405.0) 107 (405.0)

Max. water pressure, psi (kPa) 175 (1207) 175 (1207) 175 (1207) 175 (1207)

Max. refrigerant pressure, psi (kPa) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

CKT. 1 CKT. 2 CKT. 3 CKT. 4 CKT. 1 CKT. 2 CKT. 3 CKT. 4 CKT. 1 CKT. 2 CKT. 3 CKT. 4 CKT. 1 CKT. 2 CKT. 3 CKT. 4

80 x173 80 x173 80 x173 80 x173 80 x173 80 x173 80 x173 80 x173 80 x173 80 x173 80 x173 80 x173 80 x173 80 x173 80 x173 80 x173

(2032x 4394) (2032 x4394) (2032 x4394) (2032 x 4394) (2032 x4394) (2032 x4394) (2032x4394) (2032x4394) (2032x 4394) (2032x 4394) (2032x 4394) (2032 x4394) (2032 x4394) (2032 x 4394) (2032 x4394) (2032 x4394)

Table 19. Unit sizes 360 thru 380

DATA 360A 370A 380A

BASIC DATA

Unit capacity @ ARI conditions, tons (kW) 80.9 (284) 80.9 (284) 93.4 (328) 93.4 (328) 80.9 (284) 91.8 (323) 93.4 (328) 93.4 (328) 92.3 (325) 92.3 (325) 93.9 (330) 93.9 (330)

Unit operating charge R-22, lbs. (kg) 175 (79.4) 175 (79.4) 180 (81.6) 180 (81.6) 175 (79.4) 180 (81.6) 180 (81.6) 180 (81.6) 180 (81.6) 180 (81.6) 180 (81.6) 180 (81.6)

Cabinet dimensions 459 x 83.4 x 94.5 459 x 83.4 x 94.5 459 x 83.4 x 94.5

L x W x H, in. (mm) (11659 x 2118 x 2400) (11659 x 2118 x 2400) (11659 x 2118 x 2400)

Unit operating weight, lbs. (kg) 22920 (10395) 22970 (10417) 23020 (10440)

Unit shipping weight, lbs. (kg) 22000 (9977) 22050 (10000) 22100 (10023)

COMPRESSORS, SCREW, SEMI-HERMETIC

Nominal tons, (kW) 80 (280) 80 (280) 95 (335) 95 (335) 80 (280) 95 (335) 95 (335) 95 (335) 95 (335) 95 (335) 95 (335) 95 (335)

CONDENSERS, HIGH EFFICIENCY FIN & TUBE TYPE WITH INTEGRAL SUBCOOLER

Coil face area, sq. ft. (m2)

Finned height x finned length, in. (mm)

Fins per inch x rows deep 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4 12 x 4

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

No. of fans– fan diameter, in. (mm) 24 – 28 (711) 24 – 28 (711) 24 – 28 (711)

No. of motors – hp (kW) 24 – 2.0 (1.5) 24 – 2.0 (1.5) 24 – 2.0 (1.5)

Fan & motor rpm, 60 1140 1140 1140

60 Hz fan tip speed, fpm 8357 8357 8357

60 Hz total unit airflow, cfm 238128 238128 238128

EVAPORATOR, DIRECT EXPANSION, BAFFLED SHELL & THRU TUBE

Shell diameter – tube length 24 – 10 24 – 10 24 – 10

in. (mm) – ft. (mm) (609 – 3048) (609 – 3048) (609 – 3048)

Water volume, gallons (L) 107 (405.0) 107 (405.0) 107 (405.0)

Max. water pressure, psi (kPa) 175 (1207) 175 (1207) 175 (1207)

Max. refrigerant pressure, psi (kPa) 225 (1552) 225 (1552) 225 (1552)

CKT. 1 CKT. 2 CKT. 3 CKT. 4 CKT. 1 CKT. 2 CKT. 3 CKT. 4 CKT. 1 CKT. 2 CKT. 3 CKT. 4

115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7) 115.6 (10.7)

80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208

(2032x 5283) (2032 x5283) (2032 x5283) (2032 x5283) (2032 x5283) (2032 x5283) (2032 x5283) (2032 x5283) (2032 x5283) (2032 x5283) (2032 x5283) (2032 x5283)

ALS MODEL NUMBER

Page 20 / IM 548

Page 21

Major Components

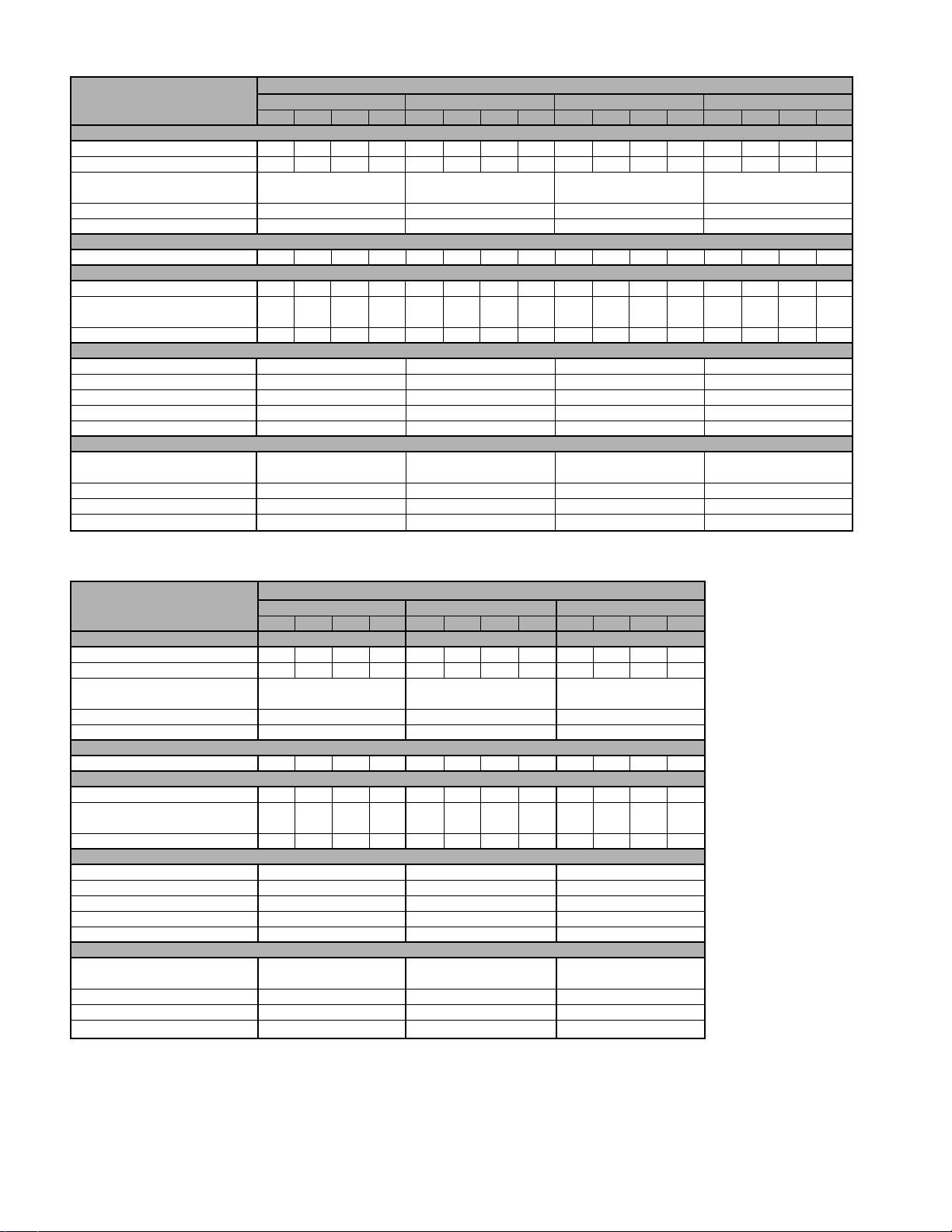

Table 20. Unit sizes 125 thru 380

UNIT SIZE

125A 155 155 — — 1410-1 100 100 — — M1-M5 M2-M6 — —

140A 155 167 — — 1610-1 140 140 — — M1-M5 M2-M6 — —

155A 167 167 — — 1610-1 140 140 — — M1-M5 M2-M6 — —

170A 167 175 — — 1610-1 170 170 — — M1-M5 M2-M6 — —

175A 167 175 — — 1610-1 170 170 — — M1-M5 M2-M6 — —

185A 175 175 — — 1610-1 170 170 — — M1-M5 M2-M6 — —

195A 175 175 — — 1810-1 170 170 — — M1-M5 M2-M6 — —

204A 175 175 — — 2010-1 170 170 — — M1-M5 M2-M6 — —

205A 155 155 167 — 2010-3 140 140 140 — M1-M5 M2-M6 M3-M7 —

220A 155 167 167 — 2010-2 140 140 140 — M1-M5 M2-M6 M3-M7 —

235A 167 167 167 — 2010-2 140 140 140 — M1-M5 M2-M6 M3-M7 —

250A 167 167 167 — 2010-1 140 140 140 — M1-M5 M2-M6 M3-M7 —

265A 167 175 175 — 2010-1 170 170 170 — M1-M5 M2-M6 M3-M7 —

280A 175 175 175 — 2010-1 170 170 170 — M1-M5 M2-M6 M3-M7 —

300A 155 155 167 167 2410-2 140 140 140 140 M1-M5 M2-M6 M3-M7 M4-M8

315A 155 167 167 167 2410-2 140 140 140 140 M1-M5 M2-M6 M3-M7 M4-M8

330A 167 167 167 167 2410-1 140 140 140 140 M1-M5 M2-M6 M3-M7 M4-M8

340A 167 167 167 175 2410-1 140 140 170 170 M1-M5 M2-M6 M3-M7 M4-M8

360A 167 167 175 175 2410-1 140 140 170 170 M1-M5 M2-M6 M3-M7 M4-M8

370A 167 175 175 175 2410-1 170 170 170 170 M1-M5 M2-M6 M3-M7 M4-M8

380A 175 175 175 175 2410-1 170 170 170 170 M1-M5 M2-M6 M3-M7 M4-M8

COMPRESSOR EVAPORATOR ELECTRONIC EXPANSION CONTACTOR DESIGNATION

IDENTIFICATION VESSEL SIZE VALVE SIZE FOR COMPRESSOR

Compressor Staging Sequence

Two compressors available (125 thru 204)

Table 21. Staging up Table 22. Staging down

STAGE

1 —— 0%

2 50% 0% 25.0%

3 75% 0% 37.5%

4 50% 50% 50.0%

5 75% 50% 62.5%

6 75% 75% 75.0%

7 100% 75% 87.5%

8 100% 100% 100.0%

LEAD LAG 1 UNIT

COMPRESSOR COMPRESSOR CAPACITY

STAGE

1 25% 0% 12.5%

2 50% 0% 25.0%

3 75% 0% 37.5%

4 50% 50% 50.0%

5 75% 50% 62.5%

6 75% 75% 75.0%

7 100% 75% 87.5%

8 100% 100% 100.0%

COMPRESSOR COMPRESSOR CAPACITY

One compressor available

Table 23. Staging up Table 24. Staging down

STAGE

1 ——0%

250% 0% 25.0%

3 75% 0% 37.5%

4 50% 0% 50.0%

LEAD LAG 1 UNIT

COMPRESSOR COMPRESSOR CAPACITY

STAGE

1 25% 0% 12.5%

2 50% 0% 25.0%

3 75% 0% 37.5%

4 100% 0% 50.0%

COMPRESSOR COMPRESSOR CAPACITY

Three compressors available (205 thru 280)

Table 25. Staging up Table 26. Staging down

STAGE

1 ——— 0%

250% 0% 0% 16.7%

3 75% 0% 0% 25.0%

4 50% 50% 0% 33.3%

5 75% 50% 0% 41.7%

6 75% 75% 0% 50.0%

7 75% 50% 50% 58.3%

8 75% 75% 50% 66.7%

9 75% 75% 75% 75.0%

10 100% 75% 75% 83.3%

11 100% 100% 75% 91.6%

12 100% 100% 100% 100.0%

LEAD LAG 1 LAG 2 UNIT

COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY

STAGE

1 25% 0% 0% 8.3%

2 50% 0% 0% 16.7%

3 75% 0% 0% 25.0%

4 50% 50% 0% 33.3%

5 75% 50% 0% 41.7%

6 50% 50% 50% 50.0%

7 75% 50% 50% 58.3%

8 75% 75% 50% 66.7%

9 75% 75% 75% 75.0%

10 100% 75% 75% 83.3%

11 100% 100% 75% 91.6%

12 100% 100% 100% 100.0%

LEAD LAG 1 LAG 2 UNIT

COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY

LEAD LAG 1 UNIT

LEAD LAG 1 UNIT

IM 548 / Page 21

Page 22

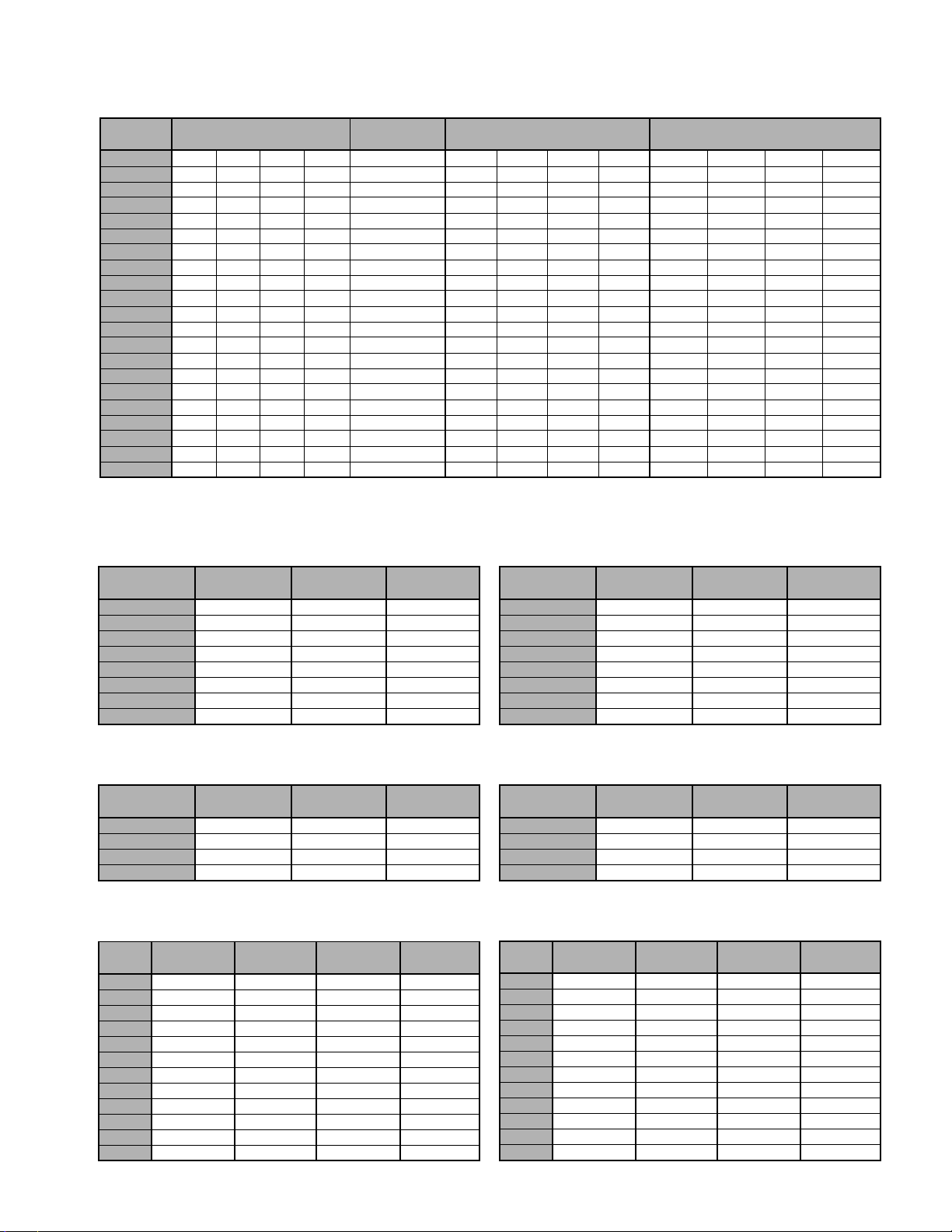

Two compressors available

Table 27. Staging up Table 28. Staging down

STAGE

1 ——— 0%

250% 0% 0% 16.7%

3 75% 0% 0% 25.0%

4 50% 50% 0% 33.3%

5 75% 50% 0% 41.7%

6 75% 75% 0% 50.0%

7 100% 75% 0% 58.3%

8 100% 100% 0% 66.7%

LEAD LAG 1 LAG 2 UNIT

COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY

STAGE

1 25% 0% 0% 8.3%

2 50% 0% 0% 16.7%

3 75% 0% 0% 25.0%

4 50% 50% 0% 33.3%

5 75% 50% 0% 41.7%

6 75% 75% 0% 50.0%

7 100% 75% 0% 58.3%

8 100% 100% 0% 66.7%

LEAD LAG 1 LAG 2 UNIT

COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY

One compressor available

Table 29. Staging up Table 30. Staging down

STAGE

1 ——— 0%

250% 0% 0% 16.7%

3 75% 0% 0% 25.0%

4 100% 0% 0% 33.3%

LEAD LAG 1 LAG 2 UNIT

COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY

STAGE

1 25% 0% 0% 8.3%

2 50% 0% 0% 16.7%

3 75% 0% 0% 25.0%

4 100% 0% 0% 33.3%

LEAD LAG 1 LAG 2 UNIT

COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY

Four compressors available (300 thru 380)

Table 31. Staging up Staging down

STAGE

1 ——— —

2 50% 0% 0% 0% 12.5% 50% 0% 0% 0% 12.5%

3 75% 0% 0% 0% 18.8% 75% 0% 0% 0% 18.8%

4 50% 50% 0% 0% 25.0% 50% 50% 0% 0% 25.0%

5 75% 50% 0% 0% 31.3% 75% 50% 0% 0% 31.3%

6 75% 75% 0% 0% 37.5% 50% 50% 50% 0% 37.5%

7 75% 50% 50% 0% 43.8% 75% 50% 50% 0% 43.8%

8 75% 75% 50% 0% 50.0% 50% 50% 50% 50% 50.0%

9 75% 75% 75% 0% 56.3% 75% 50% 50% 50% 56.3%

10 75% 75% 50% 50% 62.5% 75% 75% 50% 50% 62.5%

11 75% 75% 75% 50% 68.8% 75% 75% 75% 50% 68.8%

12 75% 75% 75% 75% 75.0% 75% 75% 75% 75% 75.0%

13 100% 75% 75% 75% 81.3% 100% 75% 75% 75% 81.3%

14 100% 100% 75% 75% 87.5% 100% 100% 75% 75% 87.5%

15 100% 100% 100% 75% 93.8% 100% 100% 100% 75% 93.8%

16 100% 100% 100% 100% 100.0% 100% 100% 100% 100% 100.0%

LEAD LAG 1 LAG 2 LAG 3 UNIT LEAD LAG 1 LAG 2 LAG 3 UNIT

COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY

0.0% 25% 0% 0% 0% 6.3%

Three compressors available

Table 32. Staging up Staging down

STAGE

1 —— ——

2 50% 0% 0% 0% 12.5% 50% 0% 0% 0% 12.5%

3 75% 0% 0% 0% 18.8% 75% 0% 0% 0% 18.8%

4 50% 50% 0% 0% 25.0% 50% 50% 0% 0% 25.0%

5 75% 50% 0% 0% 31.3% 75% 50% 0% 0% 31.3%

6 75% 75% 0% 0% 37.5% 50% 50% 50% 0% 37.5%

7 75% 50% 50% 0% 43.8% 75% 50% 50% 0% 43.8%

8 75% 75% 50% 0% 50.0% 75% 75% 50% 0% 50.0%

9 75% 75% 75% 0% 56.3% 75% 75% 75% 0% 56.3%

10 100% 75% 75% 0% 62.5% 100% 75% 75% 0% 62.5%

11 100% 100% 75% 0% 68.8% 100% 100% 75% 0% 68.8%

12 100% 100% 100% 0% 75.0% 100% 100% 100% 0% 75.0%

LEAD LAG 1 LAG 2 LAG 3 UNIT LEAD LAG 1 LAG 2 LAG 3 UNIT

COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY

0.0% 25% 0% 0% 0% 6.3%

Page 22 / IM 548

Page 23

Two compressors available

Table 33. Staging up Staging down

STAGE

1 ————

2 50% 0% 0% 0% 12.5% 50% 0% 0% 0% 12.5%

3 75% 0% 0% 0% 18.8% 75% 0% 0% 0% 18.8%

4 50% 50% 0% 0% 25.0% 50% 50% 0% 0% 25.0%

5 75% 50% 0% 0% 31.3% 75% 50% 0% 0% 31.3%

6 75% 75% 0% 0% 37.5% 75% 75% 0% 0% 37.5%

7 100% 75% 0% 0% 43.8% 100% 75% 0% 0% 43.8%

8 100% 100% 0% 0% 50.0% 100% 100% 0% 0% 50.0%

LEAD LAG 1 LAG 2 LAG 3 UNIT LEAD LAG 1 LAG 2 LAG 3 UNIT

COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY

0.0% 25% 0% 0% 0% 6.3%

One compressor available

Table 34. Staging up Staging down

STAGE

1 —— — —

2 50% 0% 0% 0% 12.5% 50% 0% 0% 0% 12.5%

3 75% 0% 0% 0% 18.8% 75% 0% 0% 0% 18.8%

4 100% 0% 0% 0% 25.0% 100% 0% 0% 0% 25.0%

LEAD LAG 1 LAG 2 LAG 3 UNIT LEAD LAG 1 LAG 2 LAG 3 UNIT

COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR CAPACITY

0.0% 25% 0% 0% 0% 6.3%

IM 548 / Page 23

Page 24

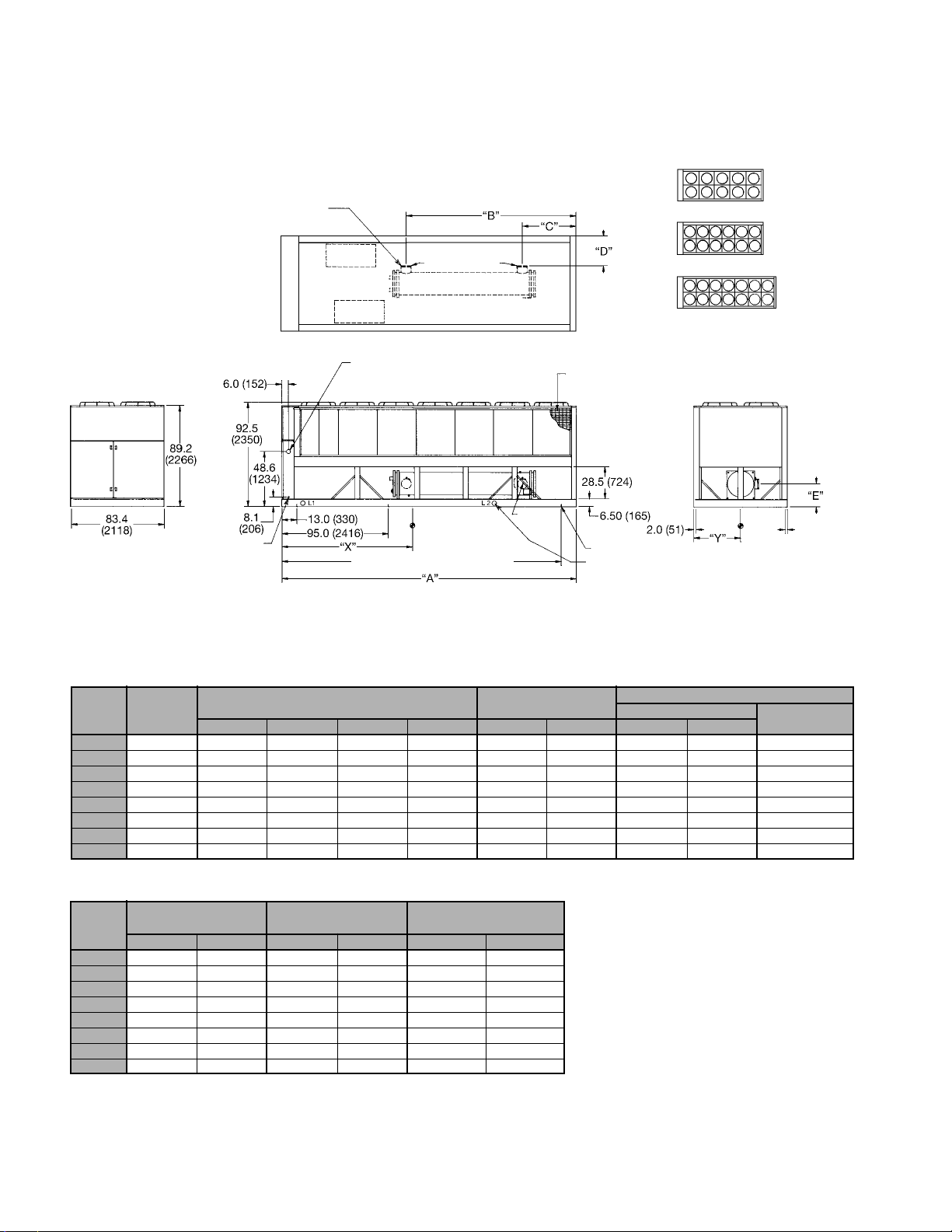

Dimensional Data

Figure 17. Unit sizes 125 thru 204

6.0 (152) for ALS125A-195A

8.0 (203) for ALS204A

Victaulic connections furnished

with grooves for victaulic

couplings by others

Air

discharge

d

Note:

1. All dimensions in inches (mm).

2. All units have (2) independent

refrigerant circuits.

3. Remove diagonal brace in way of water

outlet at installation for ALS204A only.

Compressor

#1

Compressor

#2

Power entry location this side only.

2 additional knockouts 6.0 (152)

above and below this opening

for multiple power supply

Inlet

Evaporator

2 refrigerant circuits

Outlet

Optional coil

guards

Air

discharge

d

ALS125A

ALS140A

ALS155A

ALS170A

ALS175A

ALS185A

ALS195A

ALS204A

Control

center

Power

center

Control wiring

entry knockouts

1

⁄2 (13)

for

conduit both

sides of unit

2.150 (5464) for ALS125A-170A

249.7 (6345) for ALS175A-204A

Note

#3

Unit mounting holes

2.5 (64) dia. lifting holes (4) located

from control center end (both sides)

18.6 (472) to L1 (all units) and 174.6

(4435) to L2 (ALS125A-170A) or 189.9

(4823) (ALS175A-204A).

Table 35. Unit sizes 125 thru 204

ALS

UNIT STANDARD UNIT

SIZE

125A 228.7 (5809) 117.6 (2987) 13.8 (351) 28.7 (729) 19.4 (493) 104.3 (2649) 41.7 (1059) 9920 (4500) 9600 (4355) 1652 (750)

140A 228.7 (5809) 118.5 (3010) 12.9 (328) 28.7 (729) 19.4 (493) 104.3 (2649) 41.7 (1059) 10350 (4700) 9900 (4490) 1652 (750)

155A 228.7 (5809) 118.5 (3010) 12.9 (328) 28.7 (729) 19.4 (493) 105.2 (2672) 41.7 (1059) 10670 (4840) 10250 (4650) 1652 (750)

170A 228.7 (5809) 118.5 (3010) 12.9 (328) 28.7 (729) 19.4 (493) 105.2 (2672) 41.7 (1059) 10750 (4880) 10350 (4700) 1652 (750)

175A 263.4 (6690) 153.2 (3891) 47.6 (1209) 28.7 (729) 19.4 (493) 113.1 (2873) 41.7 (1059) 11250 (5100) 10850 (4920) 1930 (876)

185A 263.4 (6690) 153.2 (3891) 47.6 (1209) 28.7 (729) 19.4 (493) 113.1 (2873) 41.7 (1059) 11250 (5100) 10850 (4920) 1930 (876)

195A 263.4 (6690) 153.2 (3891) 47.6 (1209) 27.3 (693) 20.4 (518) 115.2 (2926) 41.7 (1059) 11500 (5218) 11100 (5036) 1930 (876)

204A 263.4 (6690) 152.2 (3866) 48.5 (1232) 25.7 (653) 20.2 (513) 116.5 (2959) 41.7 (1059) 12570 (5701) 11980 (5433) 2025 (918)

LENGTH EVAPORATOR CENTER OF GRAVITY

A B C D E X Y OPERATING SHIPPING

UNIT WEIGHTS LBS (KGS)

ADDITIONAL WT.

FOR COPPER FINS

Table 35. Unit sizes 125 thru 204 (continued)

ALS

UNIT

SIZE

125A 2 65/65 10 1.5 140 (63.5) 140 (63.5)

140A 2 65/80 10 1.5 140 (63.5) 150 (68.1)

155A 2 80/80 12 1.5 150 (68.1) 150 (68.1)

170A 2 80/95 12 1.5 150 (68.1) 160 (72.6)

175A 2 80/95 14 1.5 160 (72.6) 160 (72.6)

185A 2 95/95 14 1.5 160 (72.6) 160 (72.6)

195A 2 95/95 14 1.5 170 (77.1) 170 (77.1)

204A 2 95/95 14 2.0 195 (88.5) 195 (88.5)

COMPRESSOR FANS

QTY. NOM. TONS QTY. H.P. SYSTEM #1 SYSTEM #2

OPERATING REFRIGERANT

CHARGE (R-22) LBS (KGS)

2.0 (51)

Typ.

spacing

for 1.0 (25)

diameter

isolator

mounting

hole

locations (6)

Page 24 / IM 548

Page 25

Figure 18. Unit sizes 205 thru 280

8" (203 mm) victaulic connections

furnished with grooves for victaulic

couplings by others

Note:

1. All dimensions in inches (mm).

2. All units have (3) independent refrigerant circuits.

222.1 (5641)

Compressor

#1

Inlet Outlet

Evaporator

3 refrigerant circuits

118.4 (3007)

13.7 (348)

ALS205A

ALS220A

ALS235A

ALS250A

ALS265A

ALS280A

Air

discharge

d

Control

center

Power

center

83.4

(2118)

Control wiring entry knockouts

for /

1

6.0 (152)

91.2

(2316)

1666)

94.5

(2400)

10.1

(256)

2" (13 mm) conduit

both sides of unit

65.6

Compressor

13.0 (330)

95.0 (2413)

177.0 (4496)

#2

Power entry location this side only.

2 additional knockouts 6" (152 mm)

above and below this opening for

multiple power supply

Compressor

“X”

259.0 (6579)

355.0 (9017)

#3

341.0 (8661)

Optional coil

guards

28.5 (724)

8.5 (216)

2.0 (51)

Unit mounting holes (10)

2.5" (64 mm) dia.

lifting holes (6)

located 18.6" (472 mm),

150.0" (3810 mm) and

293.0" (7442 mm) from

control center end (both sides)

Air

discharge

d

“Y”

22.0 (559)

2.0 (51 mm)

typ. spacing

for 1" (25 mm)

dia. isolation

mounting

holes (10)

Table 36. Unit sizes 205 thru 280

CENTER OF GRAVITY UNIT WEIGHTS

ALS

UNIT

SIZE

X Y OPERATING SHIPPING

IN. MM IN. MM LBS. KGS. LBS. KGS. LBS. KGS. LBS. KGS. LBS. KGS. LBS. KGS.

ADDITIONAL WEIGHT FOR

UNITS WITH COPPER FIN COILS

205A 146.7 3,726 41.7 1,059 15,930 7,224 15,250 6,916 2,478 1,124 3 65/65/80 16 1.5 140 63.5 140 63.5 150 68.1

220A 146.7 3,726 41.7 1,059 15,980 7,247 15,330 6,952 2,478 1,124 3 65/80/80 16 1.5 140 63.5 150 68.1 150 68.1

235A 146.7 3,726 41.7 1,059 16,180 7,338 15,530 7,043 2,478 1,124 3 80/80/80 18 1.5 150 68.1 150 68.1 150 68.1

250A 146.7 3,726 41.7 1,059 16,200 7,347 15,600 7,075 2,478 1,124 3 80/80/95 18 1.5 150 68.1 150 68.1 160 72.6

265A 146.7 3,726 41.7 1,059 16,200 7,347 15,600 7,075 2,478 1,124 3 80/95/95 18 1.5 150 68.1 160 72.6 160 72.6

280A 146.7 3,726 41.7 1,059 16,250 7,370 15,650 7,098 2,478 1,124 3 95/95/95 18 1.5 160 72.6 160 72.6 160 72.6

COMPRESSORS FANS OPERATING REFRIGERANT CHARGE (R-22)

QTY. NOM. TONS QTY. H.P.

SYSTEM #1 SYSTEM #2 SYSTEM #3

IM 548 / Page 25

Page 26

Figure 19. Unit sizes 300 thru 340

8.0 (203) victaulic connections

furnished with grooves for victaulic

couplings by others

Note:

1. All dimensions in inches (mm).

2. All units have (4) independent refrigerant circuits.

189.8 (4821)

86.1 (2187)

discharge

Control

center

Air

d

Power

center

83.4

(2118)

for /

both sides of unit

6.0 (152)

94.5

(2400)

91.2

(2316)

10.1

(256)

Control wiring

entry knockouts

1

2

(13) conduit

65.6

(1666)

Compressor

#1

Compressor

#2

Power entry location this side only.

2 additional knockouts 6 (152) above and below

this opening for multiple power supply

13.0 (330)

95.0 (2413)

177.0 (4496)

Compressor

#3

Compressor

#4

“X”

259.0 (6579)

375.7 (9543)

Inlet

Evaporator

4 refrigerant circuits

389.7 (9898)

Outlet

2.5 (64) dia. lifting holes (6)

located 18.6 (472), 167.0 (4242)

and 320.0 (8128) from control

center end (both sides)

Unit isolator/mounting hole locations (10)

23.4 (594)

Optional

coil guards

8.5 (216)

discharge

2.0

“Y”

28.5 (724)

Air

d

22.0 (559)

2.0 (51)

typ. spacing

for 1.0 (25) diameter

isolator/mounting

hole locations (10)

Table 37. Unit sizes 300 thru 340

CENTER OF GRAVITY UNIT WEIGHTS

ALS

UNIT X Y OPERATING SHIPPING

SIZE

IN. MM IN. MM LBS. KGS. LBS. KGS. LBS. KGS.

ADD’L WEIGHT FOR UNITS

WITH COPPER FIN COILS

300A 166.9 4239 41.7 1059 21,250 9637 20,300 9206 3,671 1665 4 65/65/80/80 20 2.0 155 70.3 155 70.3 160 72.6 160 72.6

315A 166.9 4239 41.7 1059 21,250 9637 20,300 9206 3,671 1665 4 65/80/80/80 20 2.0 155 70.3 160 72.6 160 72.6 160 72.6

330A 166.9 4239 41.7 1059 21,320 9669 20,400 9252 3,671 1665 4 80/80/80/80 20 2.0 160 72.6 160 72.6 160 72.6 160 72.6

340A 166.9 4239 41.7 1059 21,320 9669 20,400 9252 3,671 1665 4 80/80/80/95 20 2.0 160 72.6 160 72.6 160 72.6 170 77.1

COMPRESSORS FANS OPERATING REFRIGERANT CHARGE (R-22)

QTY.

NOM.

TONS

QTY. HP

SYST. #1 SYST. #2 SYST. #3 SYST. #4

LBS. KGS. LBS. KGS. LBS. KGS. LBS. KGS.

Page 26 / IM 548

Page 27

Figure 20. Unit sizes 360 thru 380

Note:

1. All dimensions in inches (mm).

2. All units have (4) independent refrigerant circuits.

3. Remove brace in way of water outlet at installation.

discharge

Control

center

Air

d

Power

center

83.4

(2118)

entry knockouts

for

both sides of unit

6.0 (152)

94.5

(2400)

91.2

(2316)

(256)

Control wiring

1

/2 (13) conduit

8.0 (203) victaulic connections

furnished with grooves for victaulic

couplings by others

Compressor

#1

Compressor

#2

Power entry location this side only.

2 additional knockouts 6 (152) above and below

this opening for multiple power supply

65.6

(1666)

10.1

13.0 (330)

95.0 (2413)

177.0 (4496)

Compressor

“X”

259.0 (6579)

#3

Compressor

#4

341.0 (8661)

445.0 (11303)

459.0 (11659)

259.2 (6584)

155.5 (3950)

Inlet Outlet

Evaporator

4 refrigerant circuits

Note #3

2.5 (64) dia. lifting holes (8)

located 18.6 (472), 146.6 (3724)

274.6 (6975) and 403.8 (10257)

from control center end (both sides)

Unit isolator/mounting hole locations (12)

23.4 (594)

Optional

coil guards

28.5 (724)

8.5 (216)

Air

discharge

d

2.0

“Y”

2.0 (51)

typ. spacing for

1.0 (25) diameter

isolator/mounting

hole locations (12)

22.0 (559)

Table 38. Unit sizes 360 thru 380

CENTER OF GRAVITY UNIT WEIGHTS

ALS

UNIT X Y OPERATING SHIPPING

SIZE

IN. MM IN. MM LBS. KGS. LBS. KGS. LBS. KGS.

ADD’L WEIGHT FOR UNITS

WITH COPPER FIN COILS

360A 185.0 4699 41.7 1059 22,92010395 22,000 9977 4,406 1998 4 80/80/95/95 24 2.0 175 79.4 175 79.4 180 81.6 180 81.6

370A 185.0 4699 41.7 1059 22,97010417 22,050 10000 4,406 1998 4 80/95/95/95 24 2.0 175 79.4 180 81.6 180 81.6 180 81.6

380A 185.0 4699 41.7 1059 23,02010440 22,100 10023 4,406 1998 4 95/95/95/95 24 2.0 180 81.6 180 81.6 180 81.6 180 81.6

COMPRESSORS FANS OPERATING REFRIGERANT CHARGE (R-22)

QTY.

NOM.

TONS

QTY. HP

SYST. #1 SYST. #2 SYST. #3 SYST. #4

LBS. KGS. LBS. KGS. LBS. KGS. LBS. KGS.

IM 548 / Page 27

Page 28

Field Wiring

General

Wiring must comply with all applicable codes and ordinances. Warranty is voided if wiring is not in

accordance with specifications. An open fuse indicates a short, ground, or overload. Before replacing a

fuse or restarting a compressor or fan motor, the trouble must be found and corrected.

Copper wire is required for all power lead terminations at the unit and copper must be used for all other

wiring to the unit.

ALS units may be ordered with main power wiring for either single or multiple point power connection.

If single point power connection is ordered, a single large power terminal block is provided and wiring

within the unit is sized in accordance with the National Electrical Code. A single field supplied

disconnect is required. An optional factory mounted transformer for the 115 volt control circuit may be

provided.

If multiple point power wiring is ordered, two power connections (125 thru 204) and (300 thru 380) or

three power connections (205 thru 280) are required and wiring within the unit is sized in accordance

with the National Electrical Code. A separate circuit is required for the 115 volt control circuit. Separate

field supplied disconnects are required for each electrical circuit.

It may be desirable to have the unit cooler heater on a separate disconnect switch from the main unit

power supply so that the unit may be shut down without defeating the freeze protection provided by the

cooler heater.

ALS unit compressors are single direction rotation

compressors. For this reason proper phasing of

electrical power is important. Electrical phasing must

be A, B, C for electrical phases 1, 2 and 3

(A=L1,B=L2,C=L3). Units supplied with single point

factory power connections will include one

MotorSaver® phase failure, phase reversal protective

device that will prevent operation of the unit with

incorrect power phasing. The MotorSaver is factory

wired and tested. Do not alter the wiring to the

MotorSaver.

Page 28 / IM 548

Multiple point power wired units will include two (125 thru 204) and (300 thru 380) or three (205 thru

280) MotorSaver safety controls (one for each power supply), and the contractor is cautioned to not apply

power until the phasing is verified with a phase sequence meter.

Internal power wiring to the compressors for the

single point versus the multiple point option are

different. It is imperative that the proper field wiring

be installed according to the way the unit is built.

Page 29

Overload Dial Setting

For units with 1 contactor and 1 overload per compressor: