Page 1

Installation and Maintenance Manual IM 549

Packaged Water Chiller with Screw Compressors

Models: ALS125A thru 204A

ALS205A thru 280A

ALS300A thru 380A

PFS150A thru 200A

Group: Chiller

Part Number: 5714335Y

Date: August 1996

©1996 McQuay International

®

Page 2

Table of Contents

Introduction ....................................................................... 4

General Description ........................................................... 4

Control Panel Features ....................................................... 5

Software Identification ....................................................... 5

Controller Layout ............................................................... 6

Component Data ............................................................... 6

Microprocessor Control Board...................................... 6

Analog/Digital Input Board (ADI Board) ........................ 7

Output Board ................................................................. 7

Electronic Expansion Valve Board (EXV Board)............ 7

Analog Output Board (AOX Board) ............................... 8

Keypad/Display.............................................................. 8

Sensors And Transducers ................................................... 9

Standard Sensors .......................................................... 9

Optional Sensor Packages ............................................ 9

Thermistor Sensors ....................................................... 9

Pressure Transducers.................................................. 11

Liquid Presence Sensor .............................................. 11

Sensor Locations ............................................................... 12

Analog Inputs............................................................... 13

Digital Inputs................................................................15

Analog Outputs............................................................ 16

Digital Outputs ............................................................. 17

Installation ....................................................................... 18

Controller Calibration................................................... 18

Field Wiring .................................................................. 18

Analog Sensors and Transducers .......................... 18

Digital Input Signals ................................................ 18

Digital Outputs ........................................................ 18

Interlock Wiring ....................................................... 18

External Alarm Circuit ............................................. 18

Power Wiring........................................................... 18

Power Supplies ....................................................... 18

Demand Limit and Chilled Water Reset Signals .... 18

Communication Ports ............................................. 18

Modem Kit............................................................... 19

Telephone Line for Remote Modem Access.......... 1 9

Unit Sequence of Operation............................................. 19

Off Conditions.............................................................. 19

Start-up........................................................................ 1 9

Waiting for Load .......................................................... 19

Start Requested........................................................... 19

Prepurge ...................................................................... 1 9

Opened EXV................................................................. 20

Low Ambient Start ....................................................... 20

Cool Stage (0 through 8) ............................................. 20

Compressor Control ......................................................... 20

Normal Compressor Staging Logic............................. 20

Project-Ahead Calculation .......................................... 21

Interstage Timer........................................................... 21

Anti-Cycle Timer .......................................................... 21

Compressor Heater Control ........................................ 21

Lead-Lag Of Refrigerant Circuits..................................... 22

Automatic Lead-Lag .................................................... 22

Manual Lead-Lag......................................................... 22

Electronic Expansion Valve .............................................. 22

Overview ...................................................................... 22

Exv Superheat Control ................................................ 22

Forced EXV Position Change ...................................... 22

EXV Evaporator Pressure Control ............................... 23

Chilled Water Reset Options ........................................... 23

Chilled Water Reset (Remote 4-20mA) ....................... 23

Ice Mode ...................................................................... 23

Network Reset ............................................................. 23

Return Water Reset ..................................................... 24

Remote Demand Limit................................................. 24

Network Demand Limit................................................ 24

Soft Loading ................................................................ 24

Max Pull Down............................................................. 24

Condenser Fan Control................................................... 24

Condenser Fan Staging............................................... 24

Head Pressure Control ................................................ 24

Lift Pressure Calculation ............................................. 25

Lift Pressure Dead Band ............................................. 25

Condenser Fan Stage Up ............................................ 26

High Pressure Stage Up .............................................. 26

Condenser Fan Stage Down ....................................... 26

SpeedTrol Logic .......................................................... 26

Pumpdown ....................................................................... 26

Automatic Pumpdown ................................................. 26

Manual Pumpdown................................................. 2 7

Service Pumpdown................................................. 27

Safety Systems .................................................................. 27

System Alarms............................................................. 27

Loss of Chw Flow ........................................................ 27

Bad Phase/Voltage ................................................. 27

No 5VDC @AI#5 ...................................................... 27

Chilled Water Freeze Protect.................................. 27

Bad Leaving Chilled Water Sensor......................... 27

Circuit Alarms .............................................................. 27

Mechanical High Pressure...................................... 27

High Condenser Pressure....................................... 27

High Condenser Pressure Stage Down.................. 27

High Condenser Pressure Stage Hold ................... 28

No Liquid Start........................................................ 2 8

No Liquid Run ......................................................... 28

Can’t Start - Low Evaporator Pressure .................. 28

Low Evaporator Pressure ....................................... 28

Freeze Protect Stage Down and

Freeze Stat Protect ................................................. 28

Failed Pre-Purge ..................................................... 28

Failed EXV or Low Refrigerant Charge................... 28

Failed Low Ambient Start ....................................... 2 8

Can't Pump Down................................................... 28

Bad Evaporator Pressure Sensor ........................... 28

Bad Condenser Pressure Sensor ........................... 28

Wait Flooded........................................................... 28

Wail Flooded ........................................................... 28

MicroTech Controller Test Procedures ........................... 29

Service Test (Digital Outputs)...................................... 29

Service Test (Digital Inputs)......................................... 29

2 IM 549

Page 3

Keypad/Display ............................................................... 29

Overview ...................................................................... 29

Status Category........................................................... 2 9

Control Category ......................................................... 29

Alarm Category............................................................30

Display Format............................................................. 30

MicroTech Component Test Procedures & ALS Units ...... 30

Status LED Diagnostics............................................... 30

Red LED Remains On ............................................. 30

Red and Green LEDs Off ........................................ 30

Troubleshooting Power Problems............................... 30

Troubleshooting Communications Problems ............. 31

Troubleshooting the Keypad/Display Interface .......... 31

Display is Hard to Read .......................................... 31

Back Light Not Lit ................................................... 31

Display Is Blank or Garbled .................................... 31

Troubleshooting Analog Inputs ................................... 32

Analog Input Not Read by the MCB....................... 32

Troubleshooting Digital Inputs .................................... 32

Digital Input Not Read by the MCB........................ 32

Troubleshooting Analog Outputs ................................ 32

Analog Output Device Is Not Operating Correctly ... 32

Troubleshooting Output Boards.................................. 33

One LED Out ........................................................... 33

All LEDs Out............................................................ 3 3

LED Lit, Output Not Energized ............................... 33

Output Energized, LED Not Lit ............................... 33

Contact Chatter ...................................................... 33

Troubleshooting Solid-State Relays............................ 34

MCB Replacement ...................................................... 34

Connecting The Communications Trunk .................... 35

Communications Cable Check............................... 35

Level-1 Controller Connection................................ 35

Level-2 Controller Connection................................ 35

Keypad Key Functions ..................................................... 36

Keypad Password........................................................ 36

Category Group ........................................................... 36

Menu Group................................................................. 3 7

Item Group................................................................... 3 7

Action Group................................................................ 37

Example of Keypad Operation .................................... 37

Personal Computer Specification ..................................... 37

MicroTech Menu Structure ............................................. 38

Status Menus............................................................... 38

Control Menus ............................................................. 38

Alarm Menus................................................................ 38

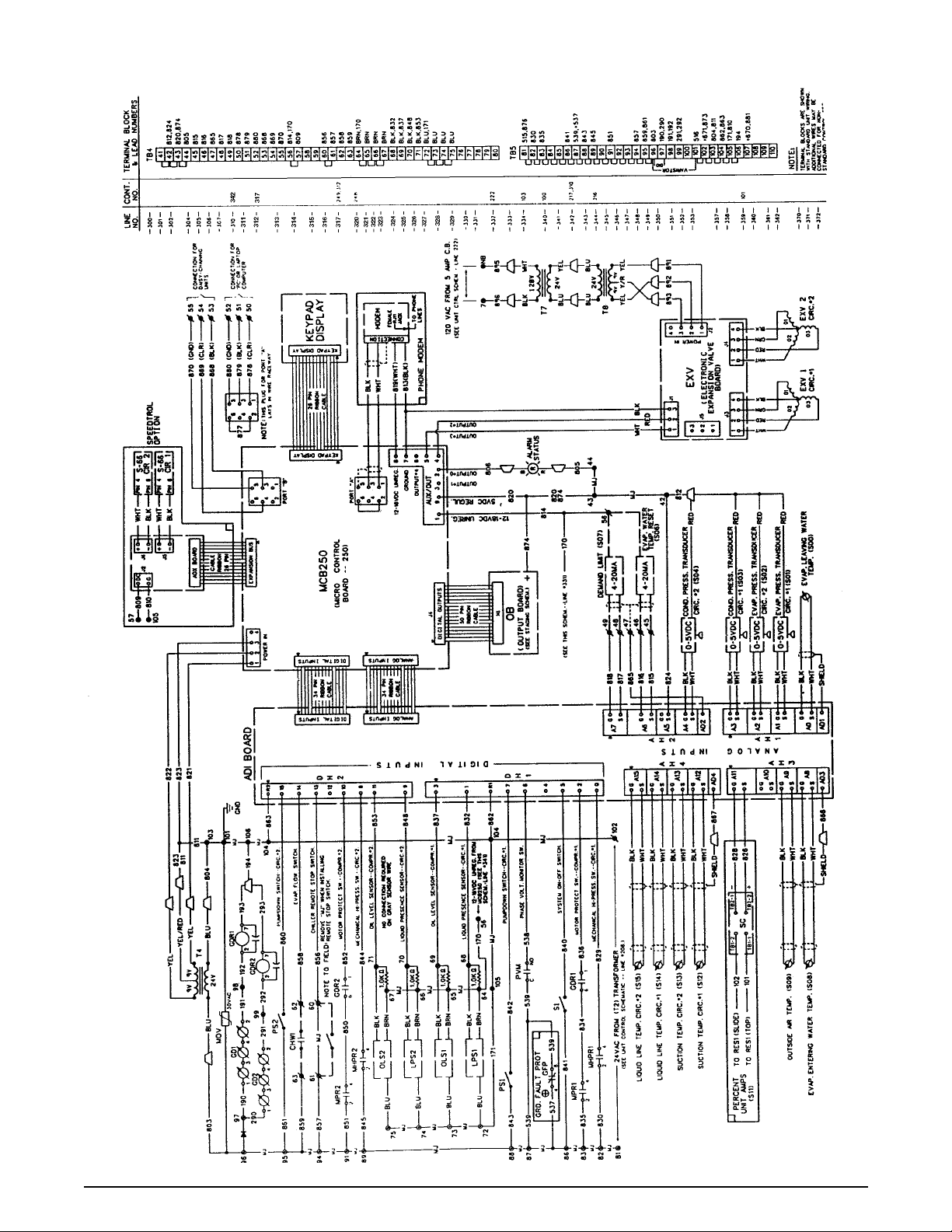

Schematics And Drawings ................................................ 60

Control Cabinet Layout ............................................... 60

Wiring Legend.............................................................. 63

PFS Unit Control.......................................................... 64

PFS 8-Stage Output .................................................... 65

PFS MicroTech ............................................................ 66

ALS Unit Control.......................................................... 67

ALS 8-Stage Output .................................................... 68

ALS MicroTech ............................................................ 69

ALS Field Wiring .......................................................... 70

IM 549 3

Page 4

Introduction

This manual provides installation, setup and troubleshooting

information for the MicroTech controller provided on McQuay

screw compressor chillers. Please refer to installation manual

IM548 for unit application information as well as water and

refrigerant piping details. All operating descriptions contained in this manual are based on MicroTech controller

software version SC2-X18B, SC3XX19 and SC4XX19A. Chiller

operating characteristics and menu selections may vary with

other versions of controller software. Contact McQuayService

for software update information.

!

CAUTION

This equipment generates, uses and can radiate radio

frequency energy and if not installed and used in accordance with the instructions manual, may cause interference to radio communications. It has been tested and

found to comply with the limits for a class A digital

device, pursuant to part 15 of the FCC rules. These

limits are designed to provide reasonable protection

against harmful interference when the equipment is

operated in a commercial environment.

Operation of this equipment in a residential area is

likely to cause harmful interference in which case the

user will be required to correct the interference at his

own expense. McQuay International disclaims any liability resulting from any interference or for the correction thereof.

!

CAUTION

The McQuay MicroTech control panel contains static

sensitive components. A static discharge while handling electronic circuit boards may cause damage to

the components.

To prevent such damage during service involving

board replacement, McQuay recommends discharging

any static electrical charge by touching the bare metal

inside the panel before performing any service work.

!

CAUTION

Excessive moisture in the control panel can cause

hazardous working conditions and improper equipment operation.

When servicing equipment during rainy weather conditions, the electrical devices and MicroTech components housed in the main control panel must be

protected.

The MicroTech controller is designed to operate within an

ambient temperature range of minus 40 to plus 185°F and a

maximum relative humidity of 95% (non-condensing).

General Description

The MicroTech Unit Control Panel, available on all McQuay

ALS and PFS products, contains a Model 250 Microprocessor based controller which provides all monitoring and

control functions required for the safe, efficient operation of

the unit. The operator can monitor all operating conditions by

using the panel’s built in 2 line by 16 character display and

keypad or by using an IBM compatible computer running

McQuay Monitor software. In addition to providing all normal

operating controls, the MicroTech controller monitors all

safety devices on the unit and will shut the system down and

close a set of alarm contacts if an alarm condition develops.

Important operating conditions at the time an alarm occurs

are retained in the controller’s memory to aid in troubleshooting and fault analysis. The system is protected by a password

scheme which only allows access by authorized personnel.

A valid password must be entered into the panel keypad by

the operator before any set points may be altered.

Table 1.

Unit Identification

ALS Air Cooled Chiller with Screw Compressors

PFS Water Cooled Chiller with Screw Compressors

4 IM 549

Page 5

Control P anel Featur es

●

Flexible control of leaving chilled water with convenient

reset capability.

●

Enhanced head pressure control on air cooled units

resulting in increased total unit SEER.

●

Convenient, easy to read 2 line by 16 character display for

plain English readout of operating temperatures and

pressures, operating modes or alarm messages.

●

Keypad adjustment of unit safeties such as low water

temperature cutout, high pressure cutout, suction pressure cutout, and freeze protection. The operator can use

the keypad to monitor various operating conditions, set

points or alarm messages.

●

Security password protection against unauthorized changing of set points and other control parameters.

●

Complete plain English diagnostics to inform the operator

of system warnings and alarms. All alarms are time and

date stamped so there is no guessing of when the alarm

Software Identification

Controller software is factory installed and tested in each

panel prior to shipment. The software is identified by a

program code which is printed on a small label attached to

the controller. The software version may also be displayed

on the keypad/display by viewing the last menu item in the

Misc. Setup menu.

condition occurred. In addition, the operating conditions

that existed at the instant of shutdown can be recalled to

aid in isolating the cause of the problem.

●

Soft loading feature to reduce electrical consumption and

peak demand charges during chilled water loop pulldown.

●

Easy integration into building automation systems via

separate 4-20 milliamp signals for chilled water reset and

demand limiting. McQuay’s Open Protocol feature is fully

supported.

●

Flexible internal time clock for on/off scheduling.

●

Communications capabilities for local system monitoring,

changing of set points, trend logging, remote reset, alarm

and event detection, via IBM compatible PC. The optional

modem kit supports the same features from an off-site PC

running McQuay Monitor software.

●

Special service modes may be used to override automatic

unit staging during system checkout and service.

The software “version” is the 5th & 6th digit of the software

number. In the example, the version is “17” and the revision

to the software is “G”.

Revisions are released in alphabetical order.

Hardware Software

Screw Chiller

Number of Compressors

Refrigerant

Type 2 = R22

Type 3 = R134a

SC 3 2 E 19 A

Revision

Version

English

IM 549 5

Page 6

Controller Layout

All major MicroTech components are mounted inside the

control section side of the unit’s control cabinet. The individual components are interconnected by ribbon cables,

shielded multi-conductor cables or discrete wiring. Power

for the system is provided by transformers T-2 and T-4. All

field wiring must enter the control cabinet through the

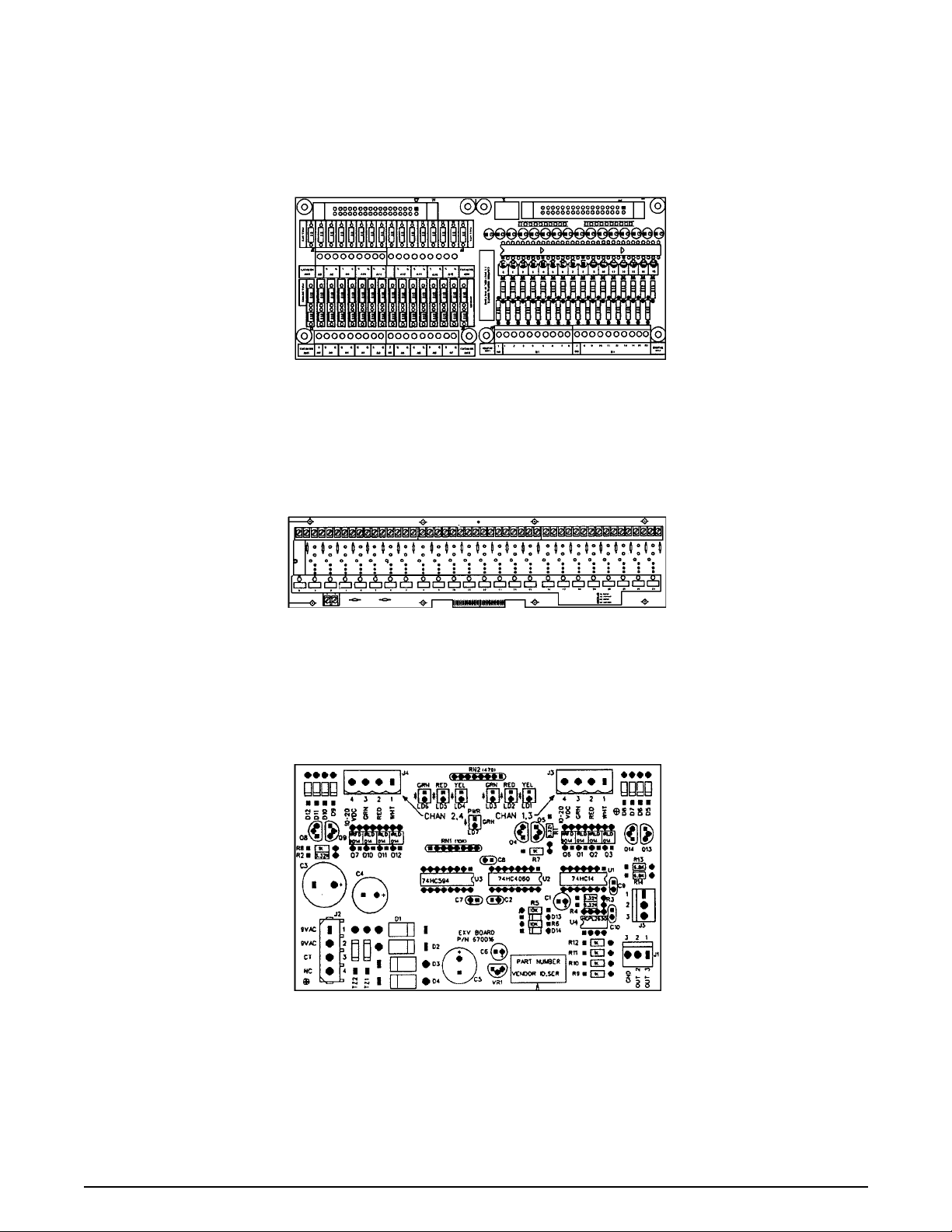

Figure 1. Typical control cabinet layout — 2 compressor unit

Keypad

F1 CB F2

NB

High voltage wireway

T4

T8

wireway

High voltage

TB3 TB2

T2

T7

ADX EXV

Low voltage wireway

Modem

MDBI

Low voltage wireway

TB4 TB5

Low voltage wireway

Fax alarm

option

ADI

Mech. relays

High voltage wireway

Output

board

Low voltage wireway

Low voltage wireway

GD1

GD2

RES1

SC

knockouts provided and be terminated on field wiring terminal strips. The standard ALS keypad/display is located inside

the control cabinet for protection from the weather while the

PFS Keypad/Display is accessible through the exterior of the

control cabinet. See Figure 1 for typical control cabinet layout.

FB6

M11 M12 M13 M15 M23 M25

T10

M21 M22 M14 M24

OL5

CB5 CB1

M5 M1

FB8FB7

OL1

C1

FB9

PVM

FB10

C2

FB11

T1

CT1

OL2 OL6

CB2

M2 M6

FB5

GRD

PB1

CB6

GFP

S

GFP

R

Component Data

Microprocessor Control Board (MCB1)

The Model 250 Microprocessor Control Board contains the

electronic hardware and software required to monitor and

control the unit. It receives input from the ADI Board and

sends commands to the Output Board to maintain the unit’s

optimum operating mode for the current conditions. Status

lights are mounted on the control board to indicate the

operating condition of the microprocessor.

6 IM 549

Figure 2. MCB1

Page 7

Analog/Digital Input Board (ADI Board)

The ADI Board provides low voltage power for the temperature and pressure sensors. It also provides electrical isolation between the Microprocessor Control Board and all 24V

switch inputs. LEDs are furnished on the board to give a

Figure 3. ADI

Output Board

The Output Board contains up to 24 solid state relays which

are used to control all compressors, condenser fans, solenoid valves and alarm annunciation.

Figure 4. Output board

visual indication of the status of all digital inputs. All analog

and digital signals from sensors, transducers and switches

are received by the ADI Board and then sent to the Microprocessor Control Board for interpretation.

It receives control signals from the Microprocessor Con-

trol Board through a 50 conductor ribbon cable.

Electronic Expansion Valve Board (EXV Board)

Each EXV Board will directly control up to two electronic

expansion valves. The boards may be cascaded together for

Figure 5. EXV board

units with more than two EXV’s. Control instructions for the

board are generated by the M250 controller.

IM 549 7

Page 8

Analog Output Board (AOX Board) (With Optional SpeedTrol)

The AOX Board converts control instructions from the M250’s

expansion bus into an analog control signal suitable for

Figure 6. AOX board

driving a variable speed condenser fan. Each AOX Board is

factory set via jumper to provide an output signal of 0 - 10 VDC.

Keypad/Display

The Keypad/Display is the primary operator interface to the

unit. All operating conditions, system alarms and set points

can be monitored from this display and all adjustable set

points can be modified from this keyboard if the operator has

entered a valid operator password.

Figure 7. Keypad display

8 IM 549

Page 9

Sensors and Transducers

Standard Sensors

Evaporator Leaving Water Temperature

Evaporator Refrigerant Pressure, Circuit #1, 2, 3 & 4

Condenser Refrigerant Pressure, Circuit #1, 2, 3 & 4

Saturated Suction Temperature, Circuit #1, 2, 3 & 4

Optional Sensor Packages

Water cooled units only:

Entering Condenser Water Temperature

Leaving Condenser Water Temperature

Thermistor Sensors

MicroTech panels use a negative temperature coefficient

thermistor for temperature sensing. A normal sensor will

measure 3000 ohms at 77°F.

Liquid Line Temperature, Circuit #1, 2, 3 & 4

(Provides direct display of subcooling and superheat)

Entering Evaporator Water Temperature

Ambient O.A. Temperature

Air and water cooled units:

Percent Unit Amps on 2 Compressor Units

(Percent total unit amperage including compressors and

condenser fans. Does not include externally powered equipment such as water pumps.)

Percent Compressor Amps On 3 Compressor Units And

Percent Circuit Amps (1 & 3, 2 & 4) On 4 Compressor Units.

Figure 8. Thermistor sensor

Stainless steel

tubing

Potting

Thermistor

Shielded

cable

IM 549 9

Page 10

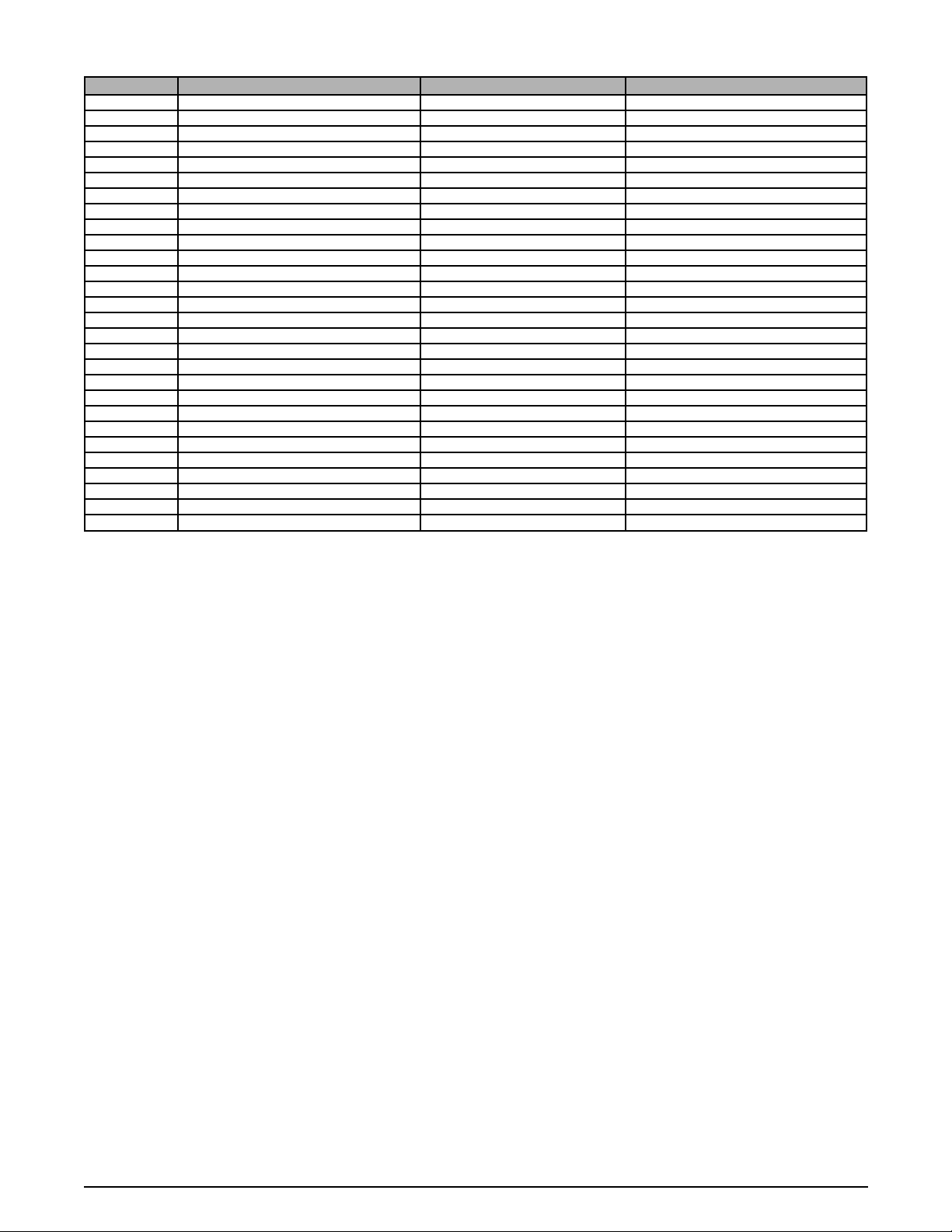

Table 2. MicroTech thermistors

°F Ohms Volts °F Ohms Volts °F Ohms Volts

15 16,104 4.145 77 3000 2.373 139 761 0.932

16 15,627 4.124 78 2927 2,343 140 746 0.917

17 15,166 4.102 79 8357 2.313 141 731 0.902

18 14,720 4.080 80 2789 2.283 142 717 0.888

19 14,288 4.057 81 2723 2.253 143 703 0.874

20 13,871 4.034 82 2658 2.223 144 689 0.859

21 13,467 4.011 83 2595 2.194 145 676 0.846

22 13,076 3.988 84 2534 2.164 146 662 0.831

23 12,698 3.964 85 2474 2.135 147 649 0.818

24 12,333 3.940 86 2416 2.106 148 637 0.805

25 11,979 3.915 87 2360 2.077 1490 625 0.792

26 11,636 3.890 88 2305 2.049 150 613 0.779

27 11,304 3.865 89 2251 2.020 151 601 0.766

28 10,983 3.839 90 2199 1.992 152 589 0.753

29 10,672 3.814 91 2149 1.965 153 578 0.741

30 10,371 3.788 92 2099 1.937 154 567 0.729

31 10,079 3.761 93 2051 1.909 155 556 0.717

32 9797 3,734 94 2004 1.882 156 546 0.706

33 9523 3.707 95 1959 1.855 157 535 0.694

34 9258 3.608 96 1914 1.828 153 525 0.683

35 9002 3.653 97 1871 1.802 159 516 0.673

36 8753 3.625 98 1829 1.775 160 506 0.661

37 8512 3.597 99 1788 1.750 161 496 0.650

38 8278 3.569 100 1747 1.724 162 487 0.640

39 8052 3.540 101 1708 1.698 163 478 0.629

40 7832 3.511 102 1670 1.673 164 469 0.619

41 7619 3.482 103 1633 1.648 165 461 0.610

42 7413 3.453 104 1597 1.624 166 452 0.599

43 7213 3.424 105 1562 1.600 167 444 0.590

44 7019 3.394 106 1528 1.576 168 436 0.580

45 6831 3.365 107 1494 1.552 169 428 0.571

46 6648 3.335 108 1461 1.528 170 420 0.561

47 6471 3.305 109 1430 1.505 171 413 0.553

48 6299 3.274 110 1398 1.482 172 405 0.544

49 6133 3.244 111 1368 1.459 173 398 0.535

50 5971 3.213 112 1339 1.437 174 391 0.527

51 5814 3.183 113 1310 1.415 175 384 0.518

52 5662 3.152 114 1282 1.393 176 377 0.510

53 5514 3.121 115 1254 1.371 177 370 0.501

54 5371 3.078 116 1228 1.350 178 364 0.494

55 5231 3.059 117 1201 1.328 179 357 0.485

56 5096 3.028 118 1176 1.308 180 351 0.478

57 4965 2.996 119 1151 1.287 181 345 0.471

59 4714 2.934 121 1103 1.247 183 333 0.456

60 4594 2.902 122 1080 1.227 184 327 0.448

61 4477 2.871 123 1058 1.208 185 321 0.441

62 4363 2.839 124 1036 1.189 186 316 0.435

63 4253 2.808 125 1014 1.170 187 310 0.427

64 4146 2.777 126 993 1.151 188 305 0.421

65 4042 2.745 127 973 1.133 189 299 0.413

66 3941 2.714 128 953 1.115 190 294 0.407

67 3842 2.682 129 933 1.076 191 289 0.400

68 3748 2.651 130 914 1.079 192 284 0.394

69 3655 2.620 131 895 1.062 193 280 0.389

70 3565 2.589 132 877 1.045 194 275 0.382

71 3477 2.558 133 859 1.028 195 270 0.376

72 3392 2.527 134 842 1.012 196 266 0.371

73 3309 2.496 135 825 0.995 197 261 0.364

74 3328 2.465 136 809 0.980 198 257 0.359

75 3150 2.434 137 792 0.963 199 252 0.353

76 3074 2.404 138 777 0.948 200 248 0.348

10 IM 549

Page 11

Pressure Transducers

These transducers are selected for a specific operating

range and provide an output signal which is proportional to

the sensed pressure. The typical range for evaporator sensors is 0 to 150 psig with a resolution of 0.1 psig. Condenser

pressure sensors have a range of 0 to 450 psi and a resolution

Figure 9.

Red dot – condenser

Blue dot – evaporator

Liquid Presence Sensor

The presence of liquid refrigerant is determined by a liquid

level sensor mounted at the liquid injection port in the

compressor casting. Whenever the glass prism sensor tip is

of 0.5 psig. The pressure transducers require an external 5

VDC power supply to operate which is provided by the

MicroTech controller. This connection should

power any additional devices.

in contact with liquid, the sensor output signal will be high

(>7VAC). If no liquid is detected, the output will be low

(0VAC).

not be used to

Figure 10.

IM 549 11

Page 12

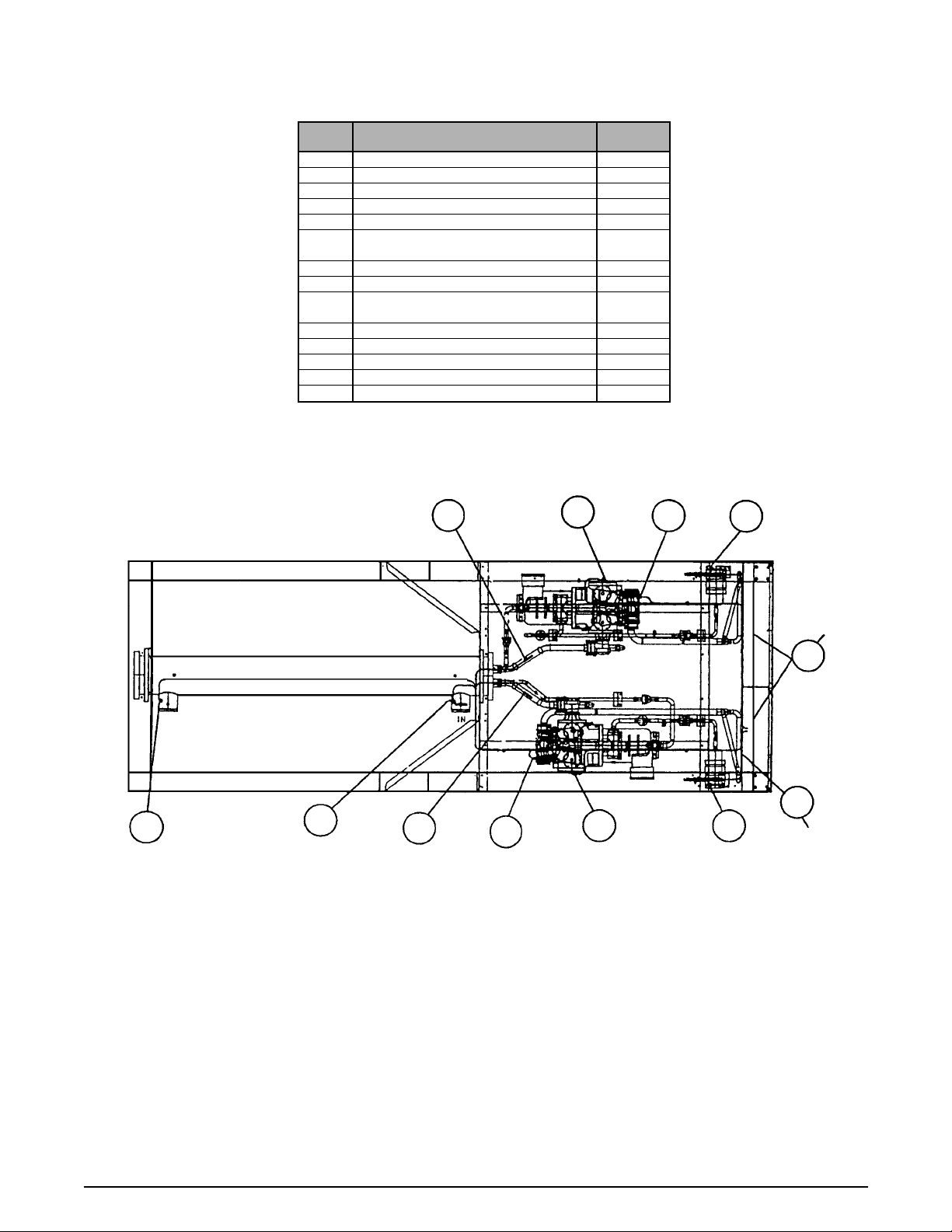

Sensor Locations – 2 Compressor Unit

Table 3.

Sensor Description

S00 Evaporator Leaving Water Temperature 605830-03

S01 Evaporator Pressure Transducer Circuit #1 658168B-011

S02 Evaporator Pressure Transducer Circuit #2 658168B-011

S03 Condenser Pressure Transducer Circuit #1 658168B-021

S04 Condenser Pressure Transducer Circuit #2 658168B-021

Evaporator Water Temperature Reset

S06

(Outdoor Air or Zone)

S07 Demand Limit N/A

S08 Evaporator Entering Water Temperature 705830B-02

Condenser Entering Water Temperature

S09

(or Outside Air)

S11 Total Unit Amps

S12 Suction Temperature Circuit #1 705830B-02

S13 Suction Temperature Circuit #2 705830B-01

S14 Liquid Line Temperature Circuit #1 705830B-01

S15 Liquid Line Temperature Circuit #2 705830B-02

Figure 11.

Part

Number

N/A

705830B-01

S00

Out

S08

S12

S13

S03

S02

S01 S14

S15S04

Inside of

control box

on power

& control

panels

S11

S09

Back of

control box

12 IM 549

Page 13

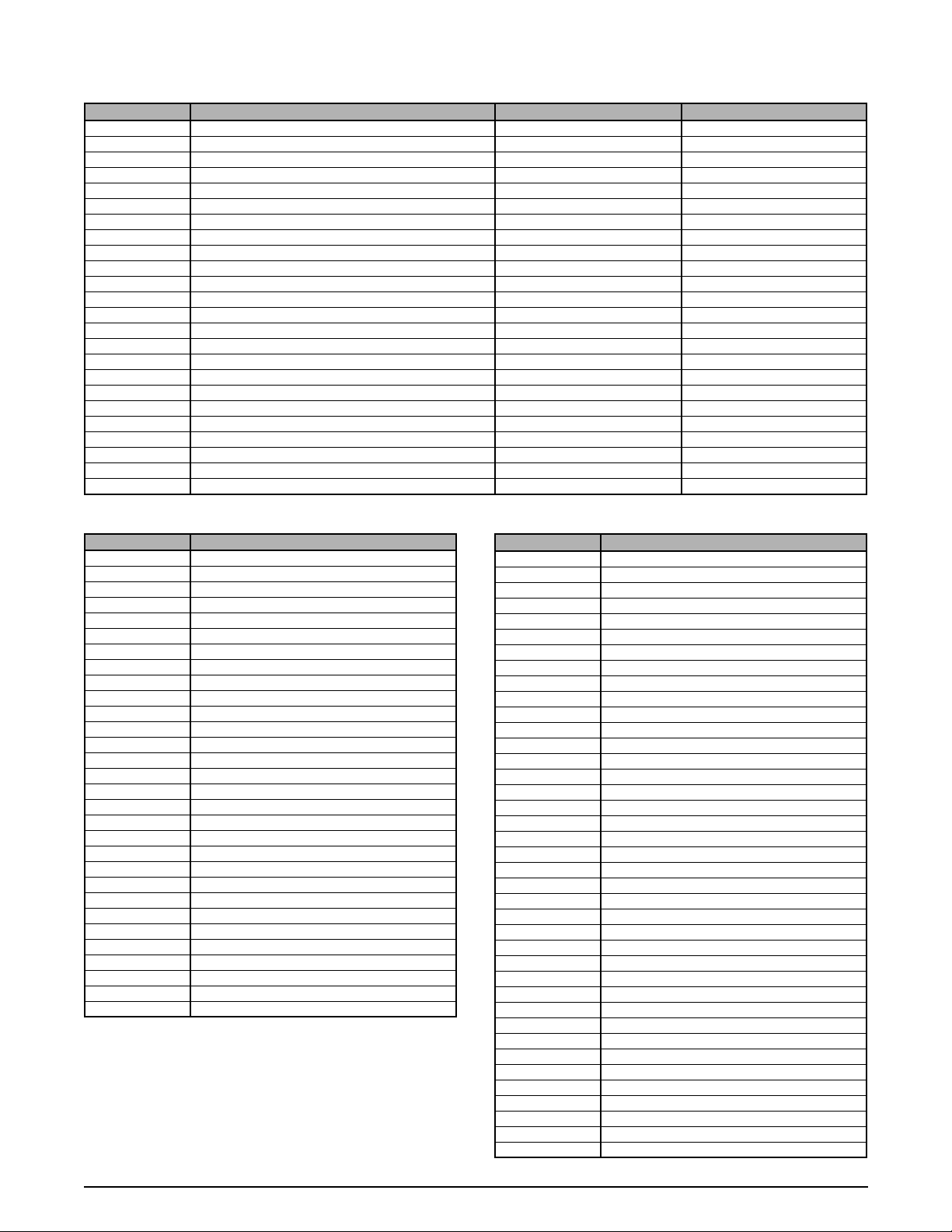

Analog Inputs

Analog inputs are used to read the various temperature and

pressure sensors installed on the chiller as well as any

customer supplied 4-20mA reset signals. The controller’s

Table 4a. Analog inputs — 2 compressor units

No. Description Sensor Location

S00 Evaporator Leaving Water Temp Leaving chilled water nozzle

S01 Evap Pressure Transducer, Cir #1 Common cir #1 suction line

S02 Evap Pressure Transducer, Cir #2 Common cir #2 suction line

S03 Cond Pressure Transducer, Cir #1 Compressor #1 discharge cover

S04 Cond Pressure Transducer, Cir #2 Compressor #2 discharge cover

S05 Transducer Power Voltage Ratio (Internal)

S06 Reset-Evap Water Temperature External 4-20 mA signal

S07 Demand Limit External 4-20 mA signal

S08 Entering Evaporator Water Temp Entering chilled water nozzle

S09 O.A.T. (Ent Cond Water Temp) Back of the control box

S10 Condenser Leaving Water Temp Leaving condenser water nozzle

S11 Percent Unit Amps Signal converter board

S12 Suction Temperature Circuit #1 Well brazed to the cir #1 suction line

S13 Suction Temperature Circuit #2 Well brazed to the cir #2 suction line

S14 Liquid Line Temperature Circuit #1 Well brazed to the cir #1 liquid line

S15 Liquid Line Temperature Circuit #2 Well brazed to the cir #1 liquid line

internal regulated 5 VDC and 12 VDC supplies provide the

correct operating voltage for the sensors.

Table 4b. Analog inputs — 3 compressor units

Sensor

Number

S00 Evaporator Leaving Water Temperature

S01 Low Pressure Transducer Circuit #1

S02 Low Pressure Transducer Circuit #2

S03 High Pressure Transducer Circuit #1

S04 High Pressure Transducer Circuit #2

S06 Evaporator Water Temperature Reset (Field Supplied)

S07 Demand Limit (Field Supplied)

S08 Evaporator Entering Water Temperature

S09 Outside Air Temperature

S10 Percent Circuit Amps Circuit #1

S11 Percent Circuit Amps Circuit #2

S12 Suction Temperature Circuit #1

S13 Suction Temperature Circuit #2

S14 Liquid Line Temperature Circuit #1

S15 Liquid Line Temperature Circuit #2

S16 Low Pressure Transducer Circuit #3

S17 High Pressure Transducer Circuit #3

S18 Suction Temperature Circuit #3

S19 Liquid Line Temperature Circuit #3

S20 Discharge Temperature Circuit #1

S21 Discharge Temperature Circuit #2

S22 Discharge Temperature Circuit #3

S23 Percent Circuit Amps Circuit #3

Description

Table 4c. Analog inputs — 4 compressor units

Sensor

Number

S00 Evaporator Leaving Water Temperature

S01 Low Pressure Transducer Circuit #1

S02 Low Pressure Transducer Circuit #2

S03 High Pressure Transducer Circuit #1

S04 High Pressure Transducer Circuit #2

S06 Evaporator Water Temperature Reset (Field Supplied)

S07 Demand Limit (Field Supplied)

S08 Evaporator Entering Water Temperature

S09 Outside Air Temperature

S10 Percent Circuit Amps Circuit #1 & 3

S11 Percent Circuit Amps Circuit #2 & 4

S12 Suction Temperature Circuit #1

S13 Suction Temperature Circuit #2

S14 Liquid Line Temperature Circuit #1

S15 Liquid Line Temperature Circuit #2

S16 Low Pressure Transducer Circuit #3

S17 High Pressure Transducer Circuit #3

S18 Suction Temperature Circuit #3

S19 Liquid Line Temperature Circuit #3

S20 Low Pressure Transducer Circuit #4

S21 High Pressure Transducer Circuit #4

S22 Suction Temperature Circuit #4

S23 Liquid Line Temperature Circuit #4

Description

IM 549 13

Page 14

Sensor Locations – 3 Scr ew Compressor Unit

Sensor Locations – 4 Scr ew Compressor Unit

14 IM 549

Page 15

Digital Inputs

Note: All digital inputs are 24 VAC.

At 7.5 VAC to 24 VAC the digital input contacts are

considered closed, and the signal level is high.

Below 7.5 VAC, the contacts are considered open, and

the signal level is low.

Table 5a. Digital inputs — 2 compressor unit

Number Description Lo Signal Hi Signal

0 Mechanical High Pressure Switch, Circuit #1 Alarm Normal

1 Liquid Presence Switch, Compressor #1 Alarm Normal

2 Motor Protect, Compressor #1 Alarm Normal

3 Oil Level Sensor, Compressor #1 Alarm Normal

4 (Reserved)

5 System Switch (S1) Stop Run

6 Phase Voltage Monitor Alarm Normal

7 Pump Down Switch, Circuit #1 Normal Pumpdown

8 Mechanical High Pressure Switch, Circuit #2 Alarm Normal

9 Liquid Presence Switch, Compressor #2 Alarm Normal

10 Motor Protect, Compressor #2 Alarm Normal

11 Oil Level Sensor, Compressor #2 Alarm Normal

12 (Reserved)

13 Unit Remote Stop Switch Stop Run

14 Evap Water Flow Switch Alarm Normal

15 Pump Down Switch, Circuit #2 Normal Pumpdown

Table 5b. Digital inputs — 3 compressor unit

No. Description Led Off Led On

0 Mechanical High Pressure Switch, Cir #1 Alarm Normal

1 Liquid Presence Sensor Compr #1 No Liquid Liquid

2 Motor Prot Compr #1 Alarm Normal

3 Not Used — —

4 Not Used — —

5 System On-Off Switch Off On

6 Phase Volt Monitor Compr #1 Alarm Normal

7 PumpDown Switch Compr #1 Normal Pump DN

8 Mechanical High Pressure Switch Cir #2 Alarm Normal

9 Liquid Presence Sensor Compr #2 No Liquid Liquid

10 Motor Prot Compr #2 Alarm Normal

11 Not Used — —

12 Not Used — —

13 Remote Start Stop Switch Stop Start

14 Evap Water Flow Switch No Flow Flow

15 PumpDown Switch Compr #2 Normal PumpDn

16 Mechanical High Pressure Switch Cir #3 Alarm Normal

17 Liquid Presence Sensor Compr #3 No Liquid Liquid

18 Motor Prot Compr #3 Alarm Normal

19 Not Used — —

20 Not Used — —

21 Phase Volt Monitor Compr #2 Alarm Normal

22 Phase Volt Monitor Compr #3 Alarm Normal

23 PumpDown Switch Compr #3 Alarm Normal

IM 549 15

Page 16

Table 5c. Digital inputs — 4 compressor unit

No. Description Led Off Led On

0 Mechanical High Pressure Switch, Cir #1 Alarm Normal

1 Liquid Presence Sensor Compr #1 No Liquid Liquid

2 Motor Prot Compr #1 Alarm Normal

3 Not Used — —

4 Not Used — —

5 System On-Off Switch Off On

6 Phase Volt Monitor Compr #1 Alarm Normal

7 PumpDown Switch Compr #1 Normal Pump DN

8 Mechanical High Pressure Switch Cir #2 Alarm Normal

9 Liquid Presence Sensor Compr #2 No Liquid Liquid

10 Motor Prot Compr #2 Alarm Normal

11 Not Used — —

12 Not Used — —

13 Remote Start Stop Switch Stop Start

14 Evap Water Flow Switch No Flow Flow

15 PumpDown Switch Compr #2 Normal PumpDn

16 Mechanical High Pressure Switch Cir #3 Alarm Normal

17 Liquid Presence Sensor Compr #3 No Liquid Liquid

18 Motor Prot Compr #3 Alarm Normal

19 Not Used — —

20 Not Used — —

21 Phase Volt Monitor Multi Point Alarm Normal

22 Not Used — —

23 PumpDown Switch Compr #3 Normal PumpDn

0 Mechanical High Pressure Switch Cir #4 Alarm Normal

1 Liquid Presence Sensor Compr #4 No Liquid Liquid

2 Motor Prot Compr #4 Alarm Normal

3 Not Used — —

4 Not Used — —

5 Not Used — —

6 Not Used — —

7 PumpDown Switch Compr #4 Normal PumpDn

Analog Outputs

Table 6. Analog outputs

No. Description Signal Range

0 SpeedTrol, Circuit #1 0-10 VDC

1 SpeedTrol, Circuit #2 0-10 VDC

2 SpeedTrol, Circuit #3 0-10 VDC

3 SpeedTrol, Circuit #4 0-10 VDC

16 IM 549

Page 17

Digital Outputs

Table 7a. Digital outputs — 2 compressor unit

No. Description Off On

0 Alarm LED and Contact (Programmable) (Programmable)

1 Chilled Water Pump Stop Run

2 EXV Serial Data 1

3 EXV Serial Data 2

4 MCR relay, Compr #1 Stop Run

5 Top Solenoid, Compr #1 Hold Load

6 Bottom Right Solenoid, Compr #1 Hold Load

7 Bottom Left Solenoid, Compr #1 Hold Load

8 MCR Relay, Compr #2 Stop Run

9 Top Solenoid, Compr #2 Hold Load

10 Bottom Right Solenoid, Compr #2 Hold Unload

11 Bottom Left Solenoid, Compr #2 Hold Load

12 Condenser Fan #1, Circ #1 (M12) Off On

13 Condenser Fan #2, Circ #1 (M13) Off On

14 Condenser Fan #3, Circ #1 (M14) Off On

15 Condenser Fan #4, Circ #1 (M15) Off On

16 Condenser Fan #1, Circ #2 (M22) Off On

17 Condenser Fan #2, Circ #2 (M23) Off On

18 Condenser Fan #3, Circ #2 (M24) Off On

19 Condenser Fan #4, Circ #2 (M25) Off On

20 Liquid Solenoid Valve, Cir #1 Close Open

21 Liquid Solenoid Valve, Cir #2 Close Open

22 (Spare)

23 (Spare)

Table 7b. Digital outputs — 3 compressor unit Table 7c. Digital outputs — 4 compressor unit

Relay Description

0 Alarm Circuit

1 Chilled Water Pump Relay

2 EXV Control

3 EXV Control

4 Compr #1 Contactor

5 Compr #1 Top Solenoid Valve

6 Compr #1 Bottom Right Solenoid Valve (feed)

7 Compr #1 Bottom Left Solenoid Valve (vent)

8 Compr #2 Contactor

9 Compr #2 Top Solenoid Valve (feed)

10 Compr #2 Bottom Right Solenoid Valve (feed)

11 Compr #2 Bottom Left Solenoid Valve (vent)

12 Condenser Fan Contactor M-12

13 Condenser Fan Contactor M-13

14 Condenser Fan Contactor M-14

15 Condenser Fan Contactor M-15

16 Condenser Fan Contactor M-22

17 Condenser Fan Contactor M-23

18 Condenser Fan Contactor M-24

19 Condenser Fan Contactor M-25

20 Compr #3 Contactor

21 Compr #3 Top Solenoid Valve (feed)

22 Compr #3 Bottom Right Solenoid Valve (feed)

23 Compr #3 Bottom Left Solenoid Valve (vent)

24 Condenser Fan Contactor M-32

25 Condenser Fan Contactor M-33

26 Condenser Fan Contactor M-34

27 Condenser Fan Contactor M-35

28 Hot Gas Bypass - SV5

29 Hot Gas Bypass - SV6

Relay Description

0 Alarm Circuit

1 Chilled Water Pump Relay

2 EXV Control

3 EXV Control

4 Compr #1 Contactor

5 Compr #1 Top Solenoid Valve

6 Compr #1 Bottom Right Solenoid Valve (feed)

7 Compr #1 Bottom Left Solenoid Valve (vent)

8 Compr #2 Contactor

9 Compr #2 Top Solenoid Valve (feed)

10 Compr #2 Bottom Right Solenoid Valve (feed)

11 Compr #2 Bottom Left Solenoid Valve (vent)

12 Condenser Fan Contactor M-12

13 Condenser Fan Contactor M-13

14 Condenser Fan Contactor M-14

15 Condenser Fan Contactor M-15

16 Condenser Fan Contactor M-22

17 Condenser Fan Contactor M-23

18 Condenser Fan Contactor M-24

19 Condenser Fan Contactor M-25

20 Compr #3 Contactor

21 Compr #3 Top Solenoid Valve (feed)

22 Compr #3 Bottom Right Solenoid Valve (feed)

23 Compr #3 Bottom Left Solenoid Valve (vent)

24 Condenser Fan Contactor M-32

25 Condenser Fan Contactor M-33

26 Condenser Fan Contactor M-34

27 Condenser Fan Contactor M-35

28 Hot Gas Bypass — SV5

29 Hot Gas Bypass — SV6

30 Not Used

31 Compr #4 Contactor

32 Compr #4 Top Solenoid Valve (feed)

33 Compr #4 Bottom Right Solenoid Valve (feed)

34 Compr #4 Bottom Left Solenoid Valve (vent)

35 Condenser Fan Contactor M-42

36 Condenser Fan Contactor M-42

37 Condenser Fan Contactor M-42

38 Condenser Fan Contactor M-42

IM 549 17

Page 18

Installation

Controller Calibration

The control software is installed and tested by the factory

prior to shipping therefore no periodic calibration of the

controller is required. All control and safety set points will be

checked and adjusted if necessary by the McQuayService

Field Wiring

start-up technician prior to starting the unit. The MicroTech

controller contains default set points which will be appropriate for most common installations.

Analog sensors and transducers

All sensors and transducers required for normal chiller operation are installed and wired by the factory. Any optional

analog signals provided by the installing contractor require

twisted, shielded pair wire (Belden #8760 or equal).

Digital input signals

Remote contacts for all digital inputs such as the chilled

water flow switch and the remote start/stop switch must be

dry contacts suitable for the 24 VAC control signals produced by the screw chiller control panel.

Digital outputs

Devices wired to the digital outputs typically be an optional

Chilled Water Pump control relay or an Alarm Annunciator.

The MicroTech output device is a normally open solid state

relay with an on board, replaceable 5 amp fuse. The model

250 controller activates a solid state relay by sending a

“trigger” signal to the output board via the attached ribbon

cable. The relay responds to the trigger by lowering it’s

resistance which allows current to flow through its “contacts”. When the controller removes the trigger signal, the

relay’s resistance becomes very high, causing the current

flow to stop. The status of all outputs are shown by individual

red LEDs for ease of determining output status.

Interlock wiring

All interlock wiring to field devices such as flow switches and

pump starters is provided by the installing contractor. Refer

to the Field Wiring Drawing as well as the unit wiring schematics and typical application drawings at the end of this

manual for details.

External alarm circuit

The MicroTech panel can activate an external alarm circuit

when an alarm or pre-alarm condition is detected. A 24VAC

voltage source is available at field wiring terminal #107 to

power an external alarm device such as a bell, light or relay.

An alarm annunciator rated for a maximum load of 1.8 Amps

at 24VAC is to be provided and wired by the installing

contractor. The normal and alarm states for the 24VAC alarm

signal are programmable by the operator. Available settings are:

Pre-alarm annunciation: Close-or-Open-or-Blink

Alarm annunciation: Close-or-Open

Power wiring

115VAC power for the control transformer is derived from the

3-phase power connection provided by the electrical contractor.

A separate disconnect for the cooler heating tape and

control circuit transformer may be supplied as options on

some installations. Wiring for these circuits is to be provided

by the installing contractor and should conform to the National Electrical Code and all applicable local building codes.

Power supplies

There are several internal power supplies used by the controller and its associated circuitry. The regulated 5 VDC

power on terminal #42 is used to support the analog inputs

on the ADI Board and should not be used to operate any

external devices. An unregulated 12 VDC power supply is

available on field wiring terminal #56 and an unregulated 24

VAC supply is provided at terminal #81. Both of these may be

used for powering external devices such as low current

relays and lights.

Demand limit and chilled water reset signals

Separate 4-20 milliamp signals for remote chilled water reset

and demand limit can be provided by the customer and

should be connected to the appropriate terminals on the field

wiring strip inside the control cabinet. The optional demand

limit and chilled water reset signals are 4 to 20 milliamp DC

signals. The resistive load used to condition the milliamp

input signals is a 249 ohm resistor factory mounted on the

ADI Board.

Communication ports

Communication port “A” is provided on the MicroTech controller for connection to an IBM compatible computer for

local or remote system monitoring (Belden 8762 or equivalent). The network uses the RS232 communication standard

with a maximum cable length of 50 feet. All communication

network wiring utilizes low voltage shielded twisted pair

cable. See the Personal Computer Specification section of

this manual for specific hardware requirements.

Communication port “B” is used to link the unit controller

into a MicroTech network using the RS-485 communication

standard. Refer to the field wiring drawing in this manual for

details.

18 IM 549

Page 19

Modem Kit

An optional modem kit may be installed for remote monitoring of the chiller from an off-site PC running McQuay’s

Monitor software. The kit comes complete with modem,

wiring harness and installation instructions.

Remote monitoring of the MicroTech controller requires a

dedicated telephone line supplied by the equipment owner.

The McQuay Monitor software package used to establish a

remote connection to the modem kit must be purchased

separately.

Unit Sequence of Operation

Telephone line for remote modem access

A voice quality, direct dial telephone line is required if remote

access and monitoring of the unit controller is desired. The

phone line should be terminated with a standard RJ-11

modular phone plug.

The following sequence of operation is typical for McQuay

ALS air cooled and PFS water cooled chillers. The sequence

Off Conditions

With power supplied to the unit, 115 VAC power is applied

through the control fuse F1 to the compressor crankcase

heaters, the compressor motor protector circuits, the primary of the 24V control circuit transformer and optionally,

the evaporator heater (HTR5). The 24V transformer provides

power to the MicroTech controller and related components.

With 24V power applied, the controller will check the position

of the front panel System Switch (S1). If the switch is in the

“stop” position the chiller will remain off and the display will

indicate the operating mode to be OFF:SystemSw. The

controller will then check the PumpDown Switches. If any

switch is in the “stop” position, that circuit’s operating mode

will be displayed as OFF:RemoteComm if this operating

Start-up

If none of the above “Off” conditions are true, the MicroTech

controller will initiate a start sequence and energize the

chilled water pump output relay. The display will indicate

Starting as the operating mode. The chiller will remain in the

Waiting For Flow mode until the field installed flow switch

Waiting for Load

Once flow is established the controller will sample the chilled

water temperature and compare it against the Leaving Chilled

Water Set point, the Control Band and the Load Delay which

have been programmed into the controller’s memory. If the

leaving chilled water temperature is above the Leaving

may vary depending on various options which may be

installed on the chiller.

mode is in effect. If an alarm condition exists which prevents

normal operation of both refrigerant circuits, the chiller will be

disabled and the display will indicate OFF:AllCompAlarm.

The MicroTech controller allows the operator to manually

set the chiller to an off mode via the keypad. The display

indicates this operating mode with the message

OFF:ManualMode.

Assuming none of the above “Off” conditions are true, the

controller will examine the internal time schedule to determine if the chiller should start. The operating mode will be

OFF:TimeClock if the time schedule indicates an “off” time

period.

indicates the presence of chilled water flow. If flow is not

proven within 30 seconds, the alarm output will be activated

and the chiller will continue to wait for proof of chilled water

flow. When chilled water flow is re-established, the alarm will

be automatically cleared.

Chilled Water Set point plus + the adjustable Control Band

plus the Start-up Delta Temperature Set point, the controller

will select the refrigerant circuit with the lowest number of

starts as the lead circuit and initiate the compressor start

sequence.

Start Requested

In the Start Requested Mode, the electronic expansion valve

is assumed to be fully closed. The MicroTech controller will

read the evaporator pressure to ensure at least 4 psi of

refrigerant pressure is present. If the evaporator pressure is

less than 4 psi the compressor will not be enabled and the

display will read “NoStart-LoEvap”.

Prepurge

In order to purge the compressor of any liquid refrigerant that

may be present, the lead compressor is operated at 50%

capacity while the electronic expansion valve is held fully

closed. The refrigerant circuit will continue to run in this

mode until either the evaporator refrigerant pressure drops

IM 549 19

to less than 40 psi or 45 seconds has elapsed. If the

evaporator pressure does not drop to 40 psi within the 45

seconds, the compressor will stop and the display will read

“Failed Prepurge”. The alarm output will be activated.

Page 20

Opened EXV

With the evaporator pressure less than 40 psi and the

compressor still running, the electronic expansion valve will

be driven open to 200 steps. If the evaporator pressure rises

above the freeze stat set point, the chiller will advance to

Low Ambient Start

If the difference between the freeze stat set point and the

evaporator refrigerant pressure is greater than 12 psi, the low

ambient start timer will be set to 180 seconds. The compressor will continue to run for 180 seconds from the moment the

expansion valve is opened in an attempt to build up the

evaporator pressure. If the difference between the freeze

stat set point and the evaporator refrigerant pressure is

greater than 12 psi, the following calculation will be used to

set the low ambient start timer:

Cool Stage

Circuit capacity at initial start will be 50%. Once the chiller

has started, the MicroTech controller will add or subtract

cooling capacity to maintain the chilled water set point. The

current cooling stage will be displayed on the keypad/display.

Cool Staging Mode. If the circuit is in Cool Staging Mode and

after 20 seconds, the evaporator pressure remains below the

freeze state set point but is greater than 2 psi, the controller

will transition to Low Ambient Start Mode.

Low Ambient Timer = 360 - (Pressure Difference x 15)

If the calculated low ambient timer value is greater than

360, the compressor will be stopped, the alarm output will

be activated and the display will indicate

“FailLowAmbStart”.

Automatic chiller staging may be overridden by selecting

“Manual Cooling” as the operating mode and then choosing

the desired cooling stage.

Compressor Control

Normal Compressor Staging Logic

The Compressor Staging Logic uses an adjustable control

band and interstage timers to determine the correct number

of cooling stages to activate. A project-ahead temperature

calculation provides stable operation. The total number of

cooling stages for each circuit is dependent upon the “number of cooling stages” set point.

Compressor Staging Sequence

Four Compressors Available

Staging Up Staging Down

Stage

10 75% 75% 50% 50% 62.5% 75% 75% 50% 50% 62.5%

11 75% 75% 75% 50% 68.8% 75% 75% 75% 50% 68.8%

12 75% 75% 75% 75% 75.0% 75% 75% 75% 75% 75.0%

13 100% 75% 75% 75% 81.3% 100% 75% 75% 75% 81.3%

14 100% 100% 75% 75% 87.5% 100% 100% 75% 75% 87.5%

15 100% 100% 100% 75% 93.8% 100% 100% 100% 75% 93.8%

16 100% 100% 100% 100% 100.0% 100% 100% 100% 100% 100.0%

Lead Lag 1 Lag 2 Lag 3 Unit Lead Lag 1 Lag 2 Lag 3 Unit

Compressor Compressor Compressor Compressor Capacity Compressor Compressor Compressor Compressor Capacity

1 — — — — 0.0% 25% 0% 0% 0% 6.3%

2 50% 0% 0% 0% 12.5% 50% 0% 0% 0% 12.5%

3 75% 0% 0% 0% 18.8% 75% 0% 0% 0% 18.8%

4 50% 50% 0% 0% 25.0% 50% 50% 0% 0% 25.0%

5 75% 50% 0% 0% 31.3% 75% 50% 0% 0% 31.3%

6 75% 75% 0% 0% 37.5% 50% 50% 50% 0% 37.5%

7 75% 50% 50% 0% 43.8% 75% 50% 50% 0% 43.8%

8 75% 75% 50% 0% 50.0% 50% 50% 50% 50% 50.0%

9 75% 75% 75% 0% 56.3% 75% 50% 50% 50% 56.3%

20 IM 549

Page 21

Three Compressors Available

Staging Up Staging Down

Stage

10 100% 75% 75% 0% 62.5% 100% 75% 75% 0% 62.5%

11 100% 100% 75% 0% 68.8% 100% 100% 75% 0% 68.8%

12 100% 100% 100% 0% 75.0% 100% 100% 100% 0% 75.0%

Lead Lag 1 Lag 2 Lag 3 Unit Lead Lag 1 Lag 2 Lag 3 Unit

Compressor Compressor Compressor Compressor Capacity Compressor Compressor Compressor Compressor Capacity

1 — — — — 0.0% 25% 0% 0% 0% 6.3%

2 50% 0% 0% 0% 12.5% 50% 0% 0% 0% 12.5%

3 75% 0% 0% 0% 18.8% 75% 0% 0% 0% 18.8%

4 50% 50% 0% 0% 25.0% 50% 50% 0% 0% 25.0%

5 75% 50% 0% 0% 31.3% 75% 50% 0% 0% 31.3%

6 75% 75% 0% 0% 37.5% 50% 50% 50% 0% 37.5%

7 75% 50% 50% 0% 43.8% 75% 50% 50% 0% 43.8%

8 75% 75% 50% 0% 50.0% 75% 75% 50% 0% 50.0%

9 75% 75% 75% 0% 56.3% 75% 75% 75% 0% 56.3%

Two Compressors Available

Staging Up Staging Down

Stage

Lead Lag 1 Lag 2 Lag 3 Unit Lead Lag 1 Lag 2 Lag 3 Unit

Compressor Compressor Compressor Compressor Capacity Compressor Compressor Compressor Compressor Capacity

1 — — — — 0.0% 25% 0% 0% 0% 6.3%

2 50% 0% 0% 0% 12.5% 50% 0% 0% 0% 12.5%

3 75% 0% 0% 0% 18.8% 75% 0% 0% 0% 18.8%

4 50% 50% 0% 0% 25.0% 50% 50% 0% 0% 25.0%

5 75% 50% 0% 0% 31.3% 75% 50% 0% 0% 31.3%

6 75% 75% 0% 0% 37.5% 75% 75% 0% 0% 37.5%

7 100% 75% 0% 0% 43.8% 100% 75% 0% 0% 43.8%

8 100% 100% 0% 0% 50.0% 100% 100% 0% 0% 50.0%

One Compressor A vailable

Staging Up Staging Down

Stage

Lead Lag 1 Lag 2 Lag 3 Unit Lead Lag 1 Lag 2 Lag 3 Unit

Compressor Compressor Compressor Compressor Capacity Compressor Compressor Compressor Compressor Capacity

1 — — — — 0.0% 25% 0% 0% 0% 6.3%

2 50% 0% 0% 0% 12.5% 50% 0% 0% 0% 12.5%

3 75% 0% 0% 0% 18.8% 75% 0% 0% 0% 18.8%

4 100% 0% 0% 0% 25.0% 100% 0% 0% 0% 25.0%

Project-Ahead Calculation

The Project-Ahead Calculation provides protection against

an overshoot condition when the chilled water temperature

is outside the control band. During cooling mode, if the

Chilled Water Temperature is above the control band and the

rate of temperature reduction is so great that in 120 seconds

the chilled water temperature will be below the control band,

the controller will stage down. The Project-Ahead Calculation also moderates the controllers response to a rapid

increase in leaving water temperature.

Interstage Timer

The minimum time delay between stage up commands is set

by the interstage timer set point (default=210 sec). The

interstage timer for stage down commands is 1⁄3 of the stage

up timer.

Anti-Cycle Timer

Anti-cycle timers are used to protect the compressors from

excessive starts and high motor winding temperature. The

anti-cycle timers are 5 minutes stop-to-start and 15 minutes

start-to-start.

Compressor Heater Control

Compressor Heater Control for PFS units is based on the

suction line superheat. If the superheat reading drops below

IM 549 21

3°F, the heater will be energized. The heater will be deenergized when the superheat rises above 8°F.

Page 22

Lead-Lag of Refrigerant Circuits

The following compressor control rules are enforced in the

control software.

●

The MicroTech controller will never turn on the lag compressor until the lead compressor is at 75% capacity or

greater and additional cooling capacity is required.

Automatic Lead-Lag

The controller provides automatic lead-lag of refrigeration

circuits based on compressor operating hours and the number of starts. The circuit with the fewest number of starts will

Manual Lead-Lag

The operator may override automatic circuit selection by

manually selecting the lead circuit via the keypad.

When the set point equals “auto”, the lead compressor is

selected by the MicroTech controller based upon which

Electronic Expansion Valve

Overview

McQuay screw compressor chillers are supplied with Sporlan

SE-series electronic expansion valves. The MicroTech controller generates valve positioning signals to maintain refrigerant circuit superheat to within 1.5°F of the superheat set

point. Valve positioning signals are converted to actuator

●

The Micro Tech controller will not turn off the lag compres-

sor until the lead compressor is running at 50% capacity,

the lag compressor is running at 25% capacity and a

reduction in cooling capacity is required.

be started first. If circuits are operating and a stage down is

required, the circuit with the most operating hours will cycle

off first.

circuit has the least operating hours. Regardless of the mode

selected, if the lead circuit cannot operate due to an alarm

condition or if off on cycle timers, the controller will switch to

the lag circuit.

step pulses by the EXV board which in turn drive the valve’s

3-phase DC stepper motor open or closed as required. A

control range of 0 steps (full closed) to 760 steps (full open)

is available to provide precise control of the valve position.

EXV Superheat Control

The electronic expansion valve position will be adjusted to

maintain the refrigerant circuit’s superheat set point. Superheat set points are based on refrigerant circuit capacity. For

circuit capacity of 25% to 50%, the superheat set point will

be 8.0°F. For circuit capacity of 75% to 100%, the superheat

set point will be 10.0°F.

When the chiller control panel is powered up, the expansion valve will be driven closed 800 steps. This ensures that

the valve is fully closed prior to a call for cooling. When all

refrigerant circuit safeties are satisfied, the controller will

initiate a start sequence. When the start sequence reaches

“open solenoid”, the expansion valve will be driven open to

the First Open set point (default=200 steps). The current

Forced EXV Position Change

With an increase in circuit capacity, the electronic expansion

valve position will be opened by a fixed percentage of its

current position. This change will not occur if the superheat

is less than 4°F below the superheat set point.

Table 8a.

When Staging Up

From To Open

25% 50% 65%

50% 75% 50%

75% 100% 25%

suction line temperature is compared against the Suction

Line Temperature set point (evaporator temp plus superheat

spt) to calculate superheat error (Err). The current suction line

temperature is also compared with the previous reading to

calculate delta superheat error (DErr). These two error values

are used to determine the magnitude and direction of the

expansion valve positioning signal. A new valve positioning

signal is calculated every 10 seconds, however, the interval

at which these signals are issued to the EXV board is

dependent on the magnitude of the required positional

change. If no change is required, the interval will be 60

seconds.

With a decrease in circuit capacity, the electronic expansion

valve position will be closed by a fixed percentage of its

current position.

Table 8b.

When Staging Down

From To Close

100% 75% 18%

75% 50% 40%

50% 25% 60%

22 IM 549

Page 23

EXV Evaporator Pressure Control

The electronic expansion valve control will maintain a constant superheat for suction line temperature up to 60°F. For

suction line temperatures greater than 61°F, the expansion

valve control logic will maintain a constant evaporator temperature to avoid overloading the compressor motor. The

Chilled Water Reset Options

Chilled Water Reset (Remote 4-20mA)

The controller resets the chilled water set point based on an

external 4 to 20mA signal. At 4 mA or less, no reset will occur.

At 20mA, the chilled water set point will be reset by an

Figure 12.

100

80

60

40

control point will be the Evap Temp set point (default=50°F)

and the control method will be the standard MicroTech Step

and Wait algorithm. When the suction line temperature drops

below 57°F, the MicroTech logic will resume normal superheat control.

amount equal to the value stored in the Maximum Reset set

point. The reset schedule is linear and may be calculated using

Figure 12.

20

Percent of maximum reset

0

01234567 89

External 0-10mA signal

Ice Mode

The MicroTech controller has dual chilled water set points

when ice mode is selected. With an external reset signal of

4mA or less, the chilled water reset will be zero. If the external

reset signal is greater than 4mA, maximum reset will be in

Table 9.

Set Point Monitors Default Ice Mode

FreezeStat Low Evap Pressure 54 psig to the leaving solution

FreezeH20 Leaving Solution 36° F to the leaving solution

StpPumpDn Final Pumpdown 34 psig the FreezeStat set point

Network Reset

The reset mode can be set to “network” if chilled water reset

via communications network is desired. The chiller controller

10 11 12 13 14 15 16 17 18 19 20

effect. For installations requiring operation in ice mode, the

following set points should be adjusted to accommodate the

reduced system temperature and pressures.

A pressure value equivalent

temperature minus 10°F

A temperature value equal

temperature minus 4°F

A pressure valve equal to

minus 10 psi

receives a signal from the network master panel in the range

of 0% to 100% of maximum reset.

IM 549 23

Page 24

Return W ater Reset

When return water is selected as the reset mode, the

MicroTech controller will adjust the leaving chilled water set

point to maintain a constant return water temperature equal

to the return water set point. The return water temperature is

sampled every 5 minutes and a proportional correction is

Remote Demand Limit

The controller will limit the total number of stages based on

an external 4 to 20mA signal regardless of the amount of

cooling actually required. A 4mA or less signal will enable all

Network Demand Limit

Unit demand limit via network communication may be selected if desired. The chiller controller receives a demand

Soft Loading

The soft loading feature limits the number of cooling stages

which may be energized by the controller to prevent unnecessary electrical demand and possible over-shoot of the

desired leaving chilled water temperature. Soft loading is

typically used during morning start-up. When the controller

Max Pull Down

The controller can limit the rate at which the chilled water

loop temperature is reduced. Whenever the rate of tempera-

made to the leaving chilled water set point. The corrected

leaving water set point is never set to a value greater than the

return water set point and is never set to a value less than the

actual leaving chilled water set point.

stages while a 20mA signal will allow only 1 stage to operate.

The effect of the reset signal may be calculated by using

Figure 13.

limit signal from the network master panel in the range of 0%

to 100% with 0 equaling no limit.

enters the “Cool Staging” mode of operation, the controller

will start a count down timer to indicate how long the unit has

been in the cool staging mode. The maximum number of

cooling stages will be limited to the soft load set point until

the soft load count down timer equals zero.

ture decrease exceeds the maximum pull down set point, no

additional cooling stages will be activated.

Condenser Fan Control

Condenser Fan Staging

The first condenser fan staging will be started in conjunction

with the first compressor to provide initial head pressure

control. The MicroTech controller continuously monitors the

lift pressure referenced to several head pressure control set

points and will adjust the number of operating condenser

Head Pressure Control (Air Cooled Units Only)

For each circuit, the first stage of condenser fans will be

wired in parallel with the compressor output so that they are

energized with the compressor. For chillers with optional

SpeedTrol, the first condenser fan stage will receive a control

signal from the AOX board which in turn modulates the

Johnson Controls S66DC-1 to provide variable speed fan

operation. Each circuit has 3 additional digital outputs available for refrigerant head pressure control. Each output will

energize an additional bank of condenser fans with each

bank consisting of 1 or 2 fans depending on the size of the

unit. Each output energizes additional heat rejection due to

increased air flow across the air cooled condenser regard-

fans as required to maintain proper head pressure.

For PFS water cooled units, the condenser pump will be

started in conjunction with the first compressor to provide

head pressure control.

less of the number of fans. If the outdoor ambient temperature is greater than 60°F when the unit is started, one

additional condenser fan stage will be energized. If the

outdoor ambient temperature is greater than 80°F, two

additional fan stages will be energized.

ALS unit EERs are maximized by not allowing the last

condenser fan stage to operate when the unit capacity is

25% and the condenser pressure is below 200 psi. The last

fan stage will operate if the condenser pressure is above 220

psi at 25% unit capacity.

24 IM 549

Page 25

Lift Pressure Calculation

The minimum acceptable lift pressure is determined by the

expansion valve. At low tonnage capacities, a minimum lift

pressure of approximately 60 psid must be maintained. At

higher tonnage capacities, a higher lift pressure must be

maintained to provide proper refrigerant flow through the

expansion valve. Refer to the following table for the lift

pressure values maintained at various unit capacities. Individual head pressure set points are provided at 25%, 50%,

and 100% circuit capacity to optimize chiller operation. For

operation at 75% capacity and greater with outdoor air

temperatures less than 60°F, the minimum lift will automatically be reset downward. The maximum available reset at

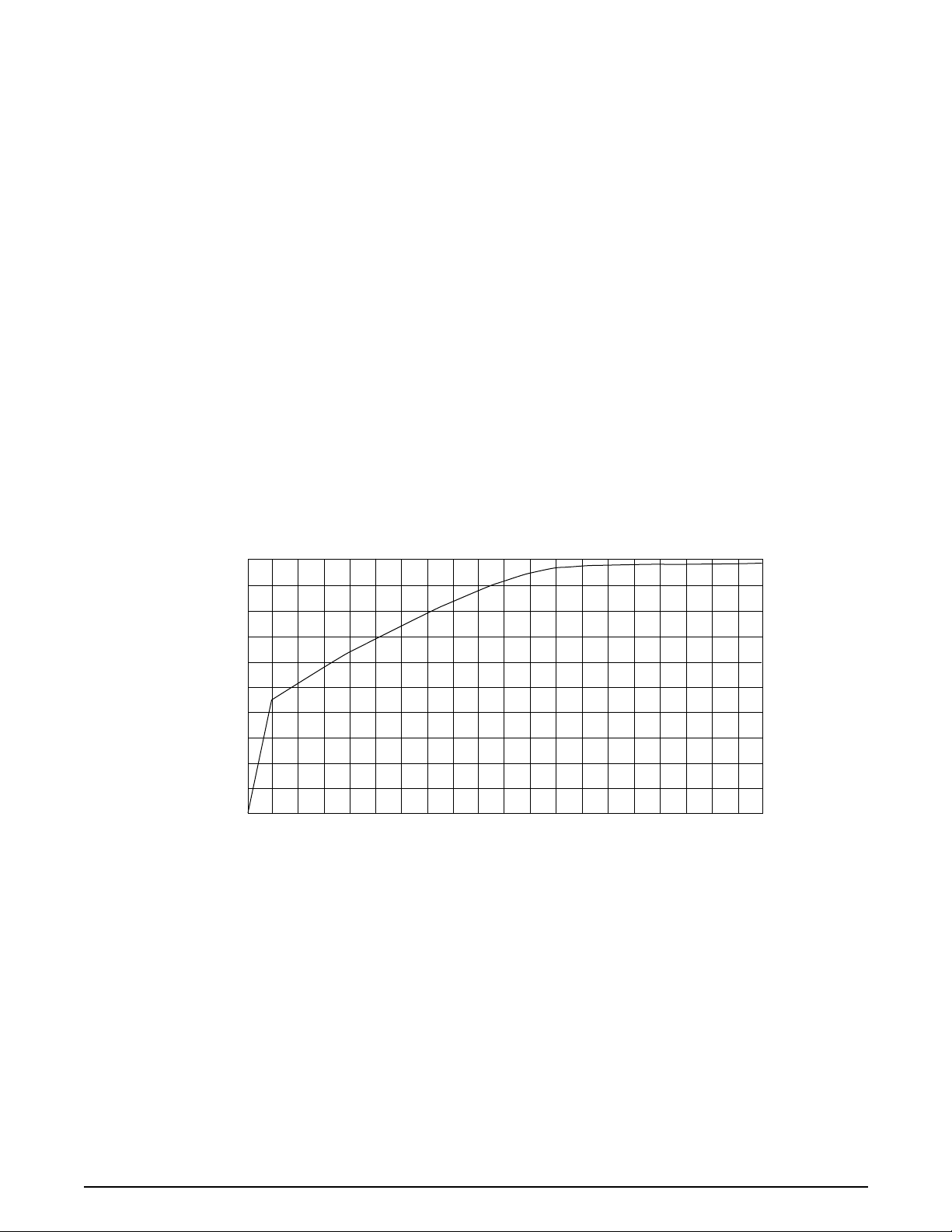

Figure 13.

100% capacity is 40 psid while the maximum reset at 75%

capacity is 20 psid.

Table 10.

Capacity Set Point

25% 60 psig 60-100

50% 70 psig 70-100

75% 105 psig Fixed

100% 140 psig 100-140

Adjustment

Range

140

105

69

60

Minimum lift (psig)

25% 50% 75% 100%

Compressor capacity

Lift Pressure Dead Band

The MicroTech controller establishes a dead band above the

minimum lift pressure that varies with circuit capacity. If the

lift pressure is within the dead band, no fan staging will occur.

Min list SPT at 100%

Min lift at OAT >=60°

Min lift at OAT >=0°

Area of reset

based on OAT

Low limit for

min lift SPT

at 100%

Condenser fan staging will occur as follows for lift pressures

above or below the dead band.

Table 11a.

Deadband Table – No SpeedTrol

Unit Capacity Stage 0 Stage 1 Stage 2 Stage 3 Stage 4 Stage 5 Stage 6

100% 120 100 60 40 30 25 20

75% 120 70 50 30 25 20 20

50% 60 50 30 20 15 15 15

25% 50 30 20 10 10 10 10

Table 11b.

Deadband Table – With SpeedTrol

Unit Capacity Stage 0 Stage 1 Stage 2 Stage 3 Stage 4 Stage 5 Stage 6

100% 40 40 40 40 30 25 20

75% 40 40 40 30 25 20 20

50% 70 30 30 20 15 15 15

25% 80 30 20 10 10 10 10

IM 549 25

Page 26

Condenser Fan Stage Up

Every four seconds, the controller records the difference

between the maximum condenser pressure (as defined by

the minimum lift plus the dead band) and the actual condenser refrigerant pressure. This value is added to the

previously recorded values and when the accumulated total

High Pressure Stage Up

The controller logic will bring on multiple condenser fan

Condenser Fan Stage Down

Every four seconds, the controller records the difference

between the minimum condenser pressure and the actual

condenser refrigerant pressure. This value is added to the

previously recorded values and when the accumulated total

is equal to or greater than the stage down set point, the

SpeedTrol Logic

When the SpeedTrol option is installed, the MicroTech controller will generate an analog signal via the AOX board to

directly control the S66DC-1 variable speed fan motor control. The control signal is proportional to the condenser

pressure’s relative position within the lift pressure dead

band. Minimum and maximum fan speed is defined by the

is equal to or greater than the stage up set point, the

controller starts an additional fan stage. The accumulated

total is set to zero whenever a fan stage change occurs or the

condenser pressure falls inside the dead band. Fan stages 5

or 6 will not be enabled unless the circuit capacity is greater

than 50%.

stages if a rapid rise in pressure is detected.

controller decrements a fan stage. The accumulated total is

set to zero whenever a fan stage change occurs or the

condenser pressure rises inside the dead band. Fan stages

5 or 6 will automatically be disabled whenever the circuit

capacity falls to 50% or less.

minimum and maximum lift pressure set points so that when

the condenser pressure is below the dead band, the fan

speed will be set to 0% and when the condenser pressure is

above the dead band, the fan motor speed will be set to

100%.

Figure 14.

100%

90%

80%

70%

60%

50%

40%

30%

SpeedTrol motor voltage

20%

10%

0%

109 876543210

Input voltage from AOX board

Pumpdo wn

Automatic Pumpdown

As the system chilled water requirements diminish, the

compressors will be unloaded. As the system load continues

to drop, the electronic expansion valve will be driven to 0

steps, (closed) and the refrigerant circuit will go through a

PumpDown sequence. As the evaporator pressure falls below the StopPumpDownPres set point while pumping down,

the compressors and condenser fans will stop. If the evaporator pressure is greater than the StopPumpDownPres set

point after 180 seconds have elapsed, the compressor will

stop and the display will read “Can’t Pump Down”. The alarm

output will be activated.

26 IM 549

Page 27

Manual Pumpdown

When the compressor is running and the circuit pumpdown

switch is moved from the Auto position to the Stop position,

the circuit will pumpdown and stop when the evaporator

pressure falls below the “StopPumpdownPressure” set point.

When the compressor is not running and the circuit

pumpdown switch is moved from the Auto position to the

Stop position, the controller will initiate a pumpdown only if

the evaporator pressure is above the “Begin Pumpdown

Pressure” set point. The compressor will stop when the

Service Pumpdown

The normal pumpdown sequence will stop when the evaporator pressure equals the Stop Pumpdown set point pressure. A control set point called FullPumpDown has been

provided which will allow an extended pumpdown for service

purposes.

The default value for the FullPumpDown set point is “No”.

By changing this setting to “Yes”, the circuit will attempt to

pump down to 2 psi during the next pumpdown cycle. If 2 psi

Safety Systems

evaporator pressure falls below the “Stop Pumpdown Pressure” set point.

An additional pumpdown sequence can be performed by

moving the pumpdown switch to the Auto position for approximately 3 seconds and then back to the Stop position. If

the evaporator pressure is above the “Begin Pumpdown

Pressure” set point, the controller will initiate a pumpdown

sequence and the compressor will stop when the evaporator

pressure falls below the “StopPumpdownPressure” set point.

cannot be obtained, the compressor will stop after 300

seconds have elapsed. The set point will be set to “No”

automatically at the end of the cycle.

Note: All pumpdown modes are disabled if the system

switch (S1) is in the Stop position.

Note: Compressor capacity during a pumpdown sequence

will be 50%.

System Alarms

Alarm conditions which are common to both refrigerant

circuits are considered to be system alarms. On a system

alarm, the MicroTech controller will shut down both compressors and energize the alarm output.

Loss of Chw flow

On a loss of chilled water flow for three consecutive seconds

while the chiller is in cooling mode, all operating refrigerant

circuits will pump down and stop. The display will read “Loss

of ChW Flow”. When chilled water flow resumes, the chiller

will initiate a normal start sequence.

Bad phase/voltage

The factory mounted voltage protection device will signal the

MicroTech controller if the incoming 3-phase power is not

within acceptable limits. The controller will immediately shut

the chiller down. When the voltage protection device indi-

Circuit Alarms

Alarm conditions which are unique to each refrigerant circuit

are considered to be circuit alarms. On a circuit alarm, the

MicroTech controller will shut down the affected circuit’s

compressor and energize the alarm output.

Mechanical high pressure

Closure of the HP1 or HP2 relay contacts indicates an

abnormally high compressor discharge pressure. The latching mechanical high pressure switch must be reset before

the MicroTech alarm can be cleared.

The mechanical high pressure switches should be set to

trip at the following pressures.

ALS Units . . . 400 psi

PFS Units . . . 380 psi

cates that the incoming power is back within acceptable

limits, normal chiller operation will resume.

No 5VDC @AI#5

The controller continuously monitors the output of both

internal 5VDC power supplies and calculates their ratio. If the

microprocessor is not receiving an acceptable volts ratio

signal, the unit will be shut down. The voltage present at

analog input #5 must be between 4.15 and 4.94 VDC.

Chilled water freeze protect