Page 1

Installation and Operating Manual

Leaving Water Controller, AS-UNT33n-1

Applied to ALR C/D/E and WHR D/E

IOM UNT33n

Group: Chiller

Date: May 2000

Supersedes: IM 552

© 1996 McQuay International

Page 2

Table of Contents

Introduction........................................................................................3

Specifications.....................................................................................4

Installation..........................................................................................5

Dimensional Data................................................................................6

Electrical Data.....................................................................................7

Operation...........................................................................................9

Additional Features............................................................................11

Settings And Adjustments.................................................................. 12

System Checkout and Troubleshooting .............................................. 13

Zone Terminal User's Guide.............................................................. 16

Zone Terminal Glossary.................................................................... 21

"McQuay" is a registered trademarks of McQuay International

"Illustrations and information cover McQuay International products at the time of publication and we reserve the right to make

changes in design and construction at anytime without notice"

2 IOM UNT33

1996 McQuay International

Page 3

Introduction

This controller is the standard controller on ALR "C", "D" or “E” vintage and WHR "D" or "E"

vintage packaged chillers where control of leaving water temperature is desired. On these units with

the controller factory installed, the control is pre-set and calibrated and should not need any

adjustment other than the control setpoint.

For further information on the AS-UNT33n-1 Microprocessor based leaving water controller and

accessories contact McQuay International for specification sheets for each individual control.

The controller and sensor covered in this Installation and Operating Manual is also available as a

substitute replacement for earlier ALR and WHR units.

General Description

The AS-UNT33n-1 Microprocessor-based Leaving Water Control is designed to control multiple

capacity steps of cooling from a single sensor.

The AS-UNT33n-1 operation is based on an adjustable Setpoint and Control Band as shown in the

OPERATION section of this document. If the leaving chilled water temperature begins to rise to the

desired Setpoint plus Control Band/2 (upper limit) , Cooling Stage 1 brings on the first stage of cooling.

Additional stages of cooling will follow as long as the leaving water temperature remains above the

upper limit of the Control Band. As the leaving water temperature begins to drop to Setpoint minus

Control Band/2 (lower limit), cooling stages will begin to de-energize.

There will be no energizing or de-energizing of cooling stages as long as the leaving water temperature

is between the upper and lower limits of the Control Band.

As a rule, anytime the leaving water temperature is above the upper limit of the Control Band, stages

will be energized, and anytime the leaving water temperature falls below the lower limit of the Control

Band, stages will be de-energized.

At the initial start of the unit a time delay will occur. There is a 60 second Interstage On Delay

between stages. Each stage incorporates minimum on and off timers with a maximum cycle rate of six

cycles per hour.

CAUTION-Offering this control

device is not intended to imply that

rapid cycling of compressors is

condoned. If an application

produces rapid cycling, the control

and/or the application must be

reviewed and altered to prevent

compressor failure.

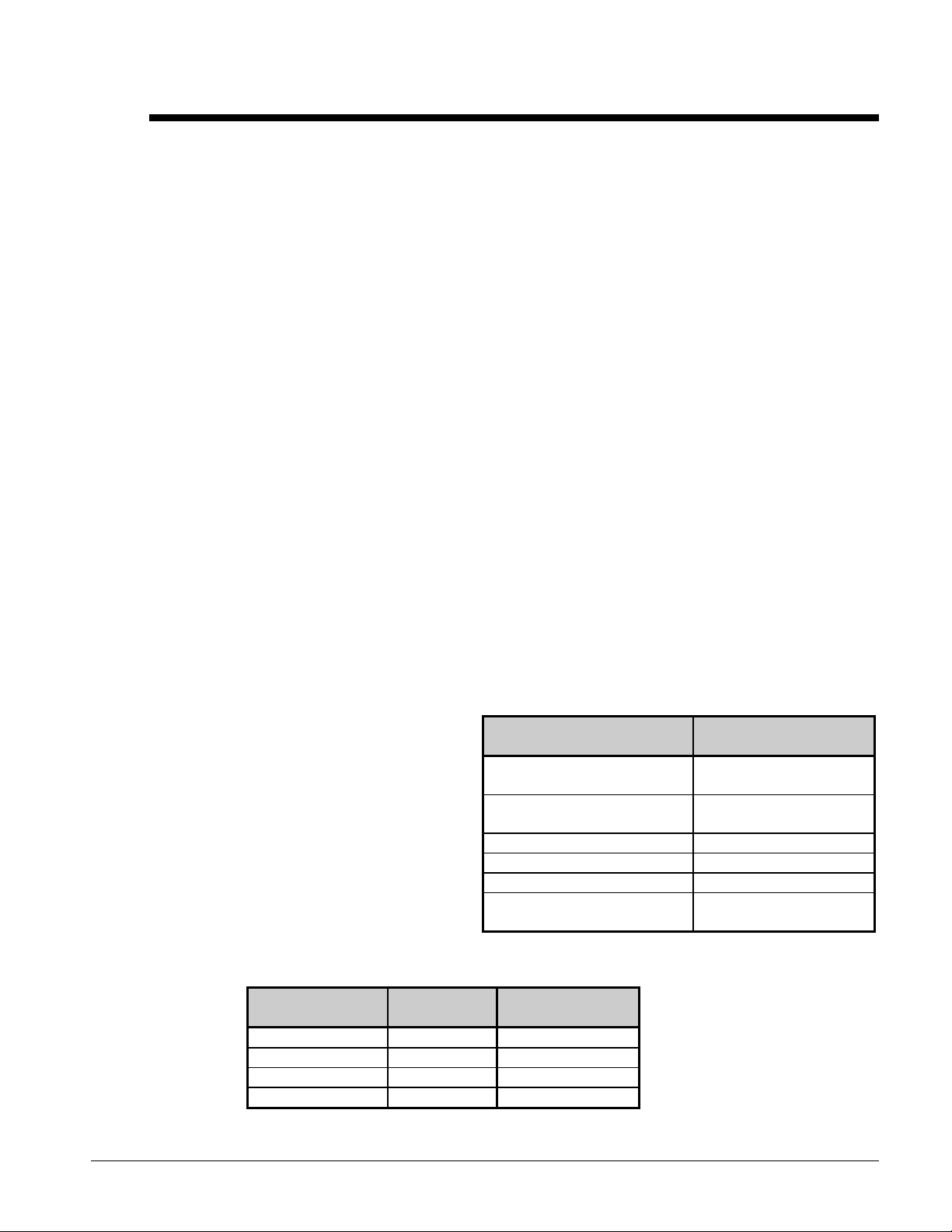

Table 1, Standard Control Characteristics

DESCRIPTION

AS-UNT-33n-1

Setpoint Range

Control Band Range

Interstage On Delay Between Stages 60 seconds

Minimum Off Time (each stage) 5 minutes

Minimum On Time (each stage) 60 seconds

Soft Start During Start-up

10°F to 60°F (-12°C to

+15°C) Adjustable

0°F to 10°F (0°C to 6°C)

Adjustable

50% command over 5

minutes

SETTING

Table 2, Controller Specific Characteristics

CONTROLLER

DESCRIPTION

AS-UNT330-1 4 or 6 Honeywell

AS-UNT332-1 8 Honeywell

AS-UNT334-1 4 or 6 Johnson Controls

AS-UNT336-1 8 Johnson Controls

IOM UNT33 3

NUMBER OF

STAGES

LEAVING WATER

SENSOR

Page 4

Specifications

Electrical Ratings:

Input voltage and frequency (terminals

24 VAC–COMMON) 20 to 30 VAC at 50/60 Hz

(50 Hz requires download.)

Power Consumption:

25 VA at 24 VAC and 50/60 Hz

Input Signal:

Honeywell sensor—positive temperature

coefficient of 4.8 ohms/Degree F; resistance of

3484 ohms at 77°F.

Johnson Controls sensor—positive temperature

Number of Stages Selection:

Refer to Table 5, Figure 1 for stage selection

Temperature Ranges:

Ambient: -40°F to +150°F.

Humidity Rating:

5 to 90% RH non-condensing.

Leaving Water Sensor:

The Honeywell C7173Al017, Honeywell

C7170A1010, or Johnson Controls TE-6300-300

senses Leaving Water Temperature on control

terminals AI3 and AI3 COM.

coefficient of 3 ohms/Degree F; resistance of 1000

ohms at 70°F.

.

Table 3, Contact Rating

CONTACT VOLTAGE (V) INRUSH (VA) RUNNING (VA)

N.O. 24 240 60

N.C. 24 75 30

N.O. 120/240 750 75

N.C. 120/240 240 40

Table 4, Accessories

Model No.

Johnson TE-6313P-1 070312301 1 Outdoor Air Sensor Used for reset of Leaving Water Setpoint.

Johnson TE-6300-300 070312401 1 Immersion Sensor (30 ft. cord) Senses Leaving or Return Water Temperature.

Sensor Well 047441506 1 Immersion Well Used with TE-6300-300.

Johnson TE-6410S2000

Johnson AS-ZTU3301

Honeywell

C7173A1017

Honeywell

C7170A1010

Honeywell 121371A 048442403 1 Copper Immersion Well Used with C7173A1017 or C7170A1010.

Honeywell 121371E 048442404 1 Stainless Steel Immersion Well Used with C7173A1017 or C7170A1010.

Johnson AS-KIT100-0 1 Resistor Test Kit Used for field diagnostics.

McQuay

Part No.

070312801

070312701 1 Zone Terminal

048442405 1 Immersion Sensor (30 ft. cord) Sensing of Leaving Water Temperature.

048442402 1 Immersion Sensor (10 ft. cord) Sensing of Leaving Water Temperature.

Quantit

y

depends on

# of zones

Description Application

Zone Temperature Sensor Used for zone temperature reset.

Used for monitoring and local control of

designated points.

4 IOM UNT33

Page 5

Installation

AS-UNT330-1

STANDARDS COMPLIANCE

The UNT Controller complies with the following standards:

* CSA C22.2 No. 205* UL 916 * IEEE 472

* IEEE 446 * VDE 0871 Class B * IEEE 587 Category A

* IEEE 518 * FCC Part 15, Subpart A, Cl. J * NEMA ICS 2, Part 2-230

All wiring must comply with local codes and ordinances:

1. Disconnect power before making connections to avoid electrical shock or equipment damage.

2. Check ratings given in the specification and on the product to make sure the controller fits the application.

3. Choose a location for the AS-UNT33n-1 controller that is not exposed to the weather and where controls,

connections, and the zone bus phone jack are accessible.

4. Mount the controller with three No. 8 screws through the mounting holes in the base. (See Figure 2.)

5. Install immersion well and sensor bulb in the Leaving Chilled Water piping as instructed by the installation manual

for the unit being controlled.

6. Connect 24 VAC to terminals marked 24 VAC and COM. CAUTION: Never spark the 24 V power leads to check for

power.

CAUTION: Do not run low-voltage wiring in the same conduit as line-voltage wiring (30 VAC or above) or

wiring that switches power to highly inductive loads (such as contactors, coils, motors, or generators).

7. Wire the compressor and capacity controls steps to the individual controller relay terminals as shown in the unit

wiring diagram.

8. Adjust SW1 and SW2 on AI2 for the appropriate number of cooling stages. The AS-UNT330-1/AS-UNT334-1 is

factory set for 6 stages by Johnson Controls. The AS-UNT332-1/AS-UNT336-1 is factory set for 8 stages.

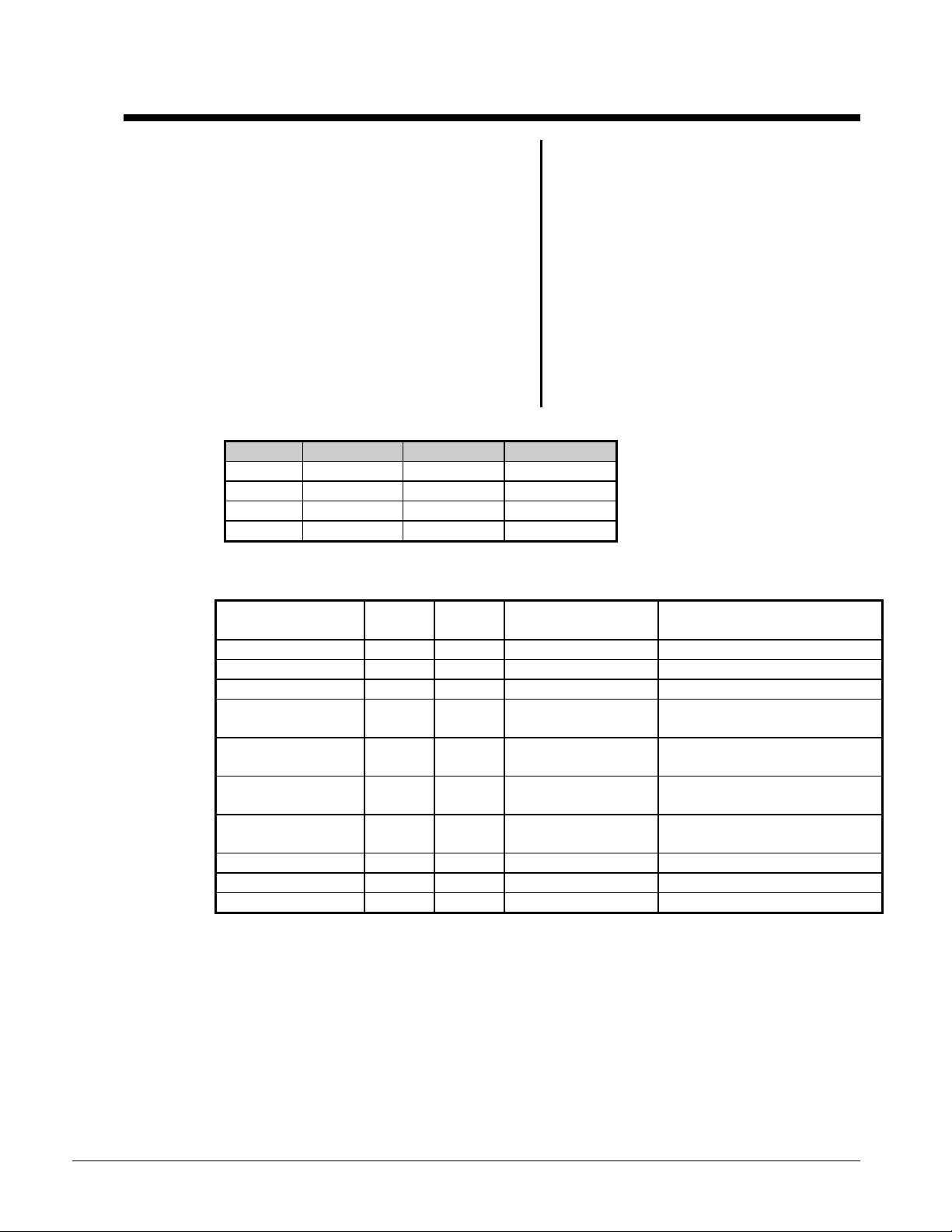

Table 5, Dipswitch Settings

Dipswitch Settings

Factory

Set

Stage

Select

Factory Set

AS-UNT33n-1 AI 1 AI 2 AI 3 AI 4 AI 5 AI 6

AS-UNT330-1 SW2 10 V • • • •

AS-UNT334-1 2 V • •

4 stage

SW1 T •

(set by others) V • • • • •

AS-UNT330-1 SW2 10 V • • • •

AS-UNT334-1 2 V • •

6 Stage

SW1 T • •

(Factory Set) V • • • •

AS-UNT332-1 SW2 10 V • • • • •

AS-UNT336-1 2 V •

8 Stage

SW1 T • •

(Factory Set) V • • • •

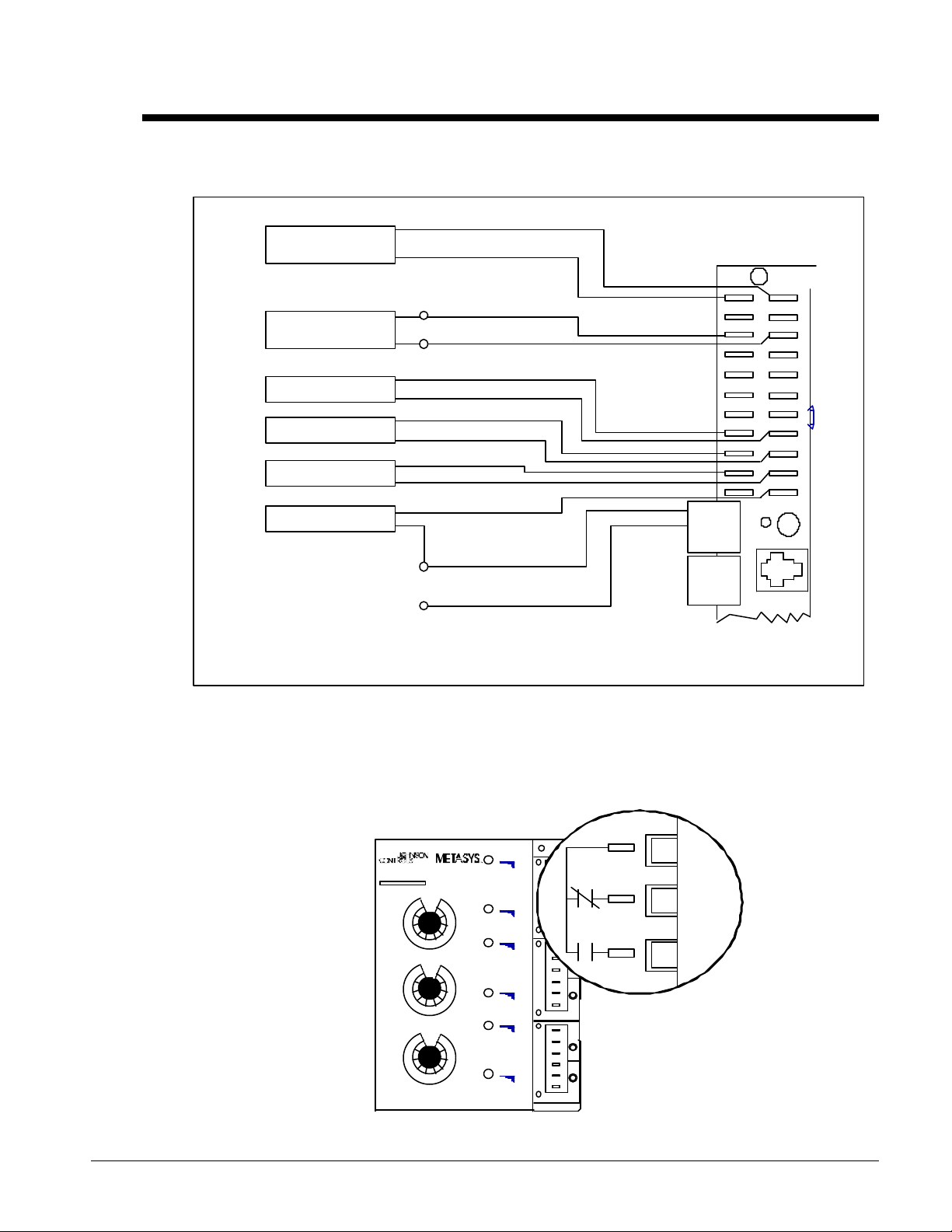

Figure 1, Analog Input Switches

C

D

V

5

1

+

A N A LO G I N PU TS

B IN A R Y IN

COM

PW R

I N

2 4V

B IN A R Y CO M

A C

BIN ARY INA NAL OGIN PUTS

BINA RY OUT PUT S

ANAL O G I N PU TS

1 2 3 4 5 6 1 2 3 4

A N A L OG I N P U TS

CO MM ON

B IN A RY OU TP U T

1 2 3 4 5 6 7 8

2 4V A C TO L OA D S

IOM UNT33 5

Page 6

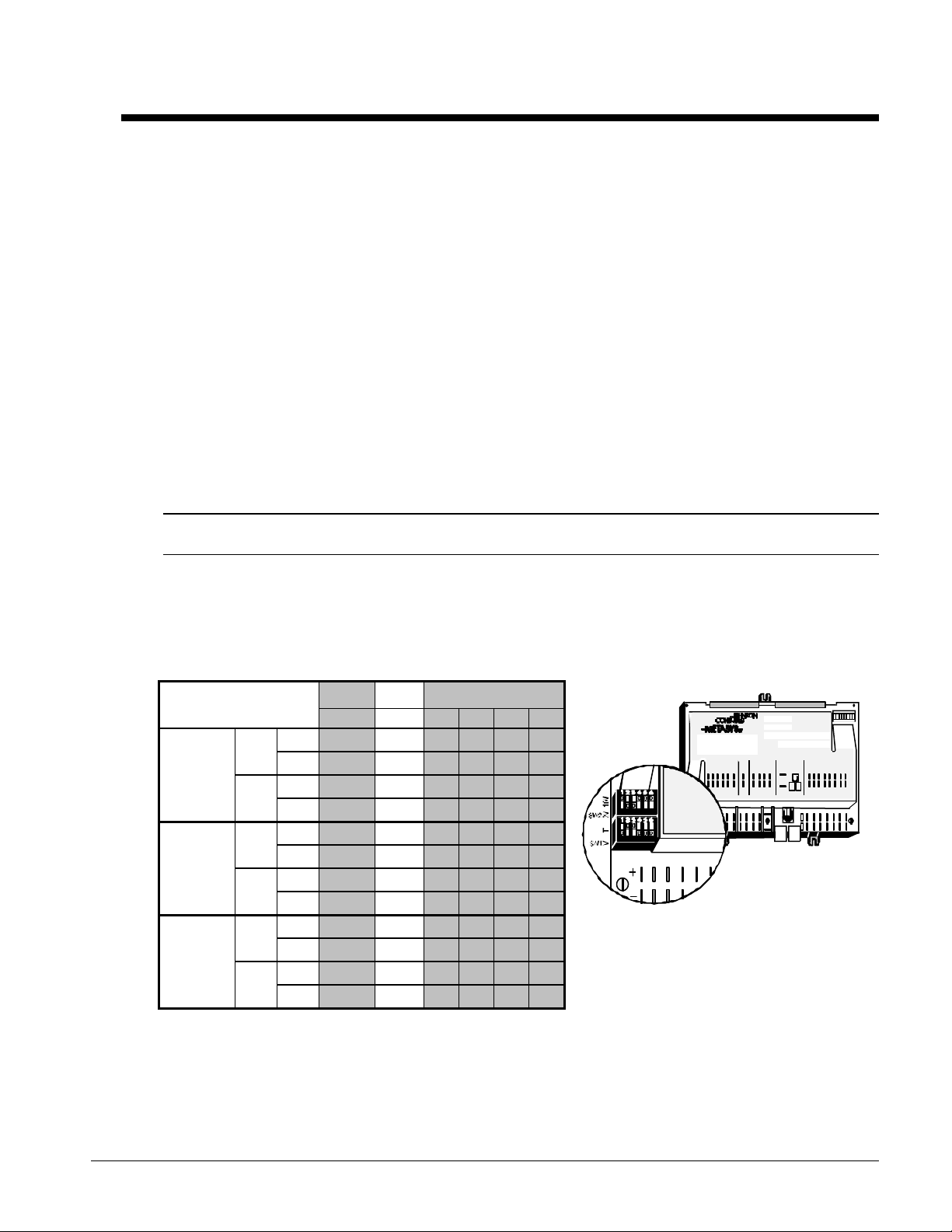

Dimensional Data

Figure 2, Dimensional Data

These relays are for the

7th and 8th stages.

COOL 8

COOL 7

7.78

8.95

SW2

SW1

ANALOG INPUTS BINARY IN

1.245.80

C

B

A

C

B

A

BINARY OUTPUTS

McQuay

RECIPROCATING

CHI LLER CONTROL

SETPOIN T

RESET

CON TROL BAND

COOL 6

COOL 5

COOL 4

COOL 3

COOL 2

COOL 1

C

B

A

C

B

A

C

B

A

C

B

A

C

B

A

C

B

A

8.95

9.23

0.89

14.90

= mounting holes

5.16

2.23

0.74

2.17

2.77

0.25

6 IOM UNT33

Page 7

Electrical Data

Sensor for Outdoor, Return Water, or Zone Temperature Reset options are connected to AI-1 and AI-CM.

Figure 3, Wiring Diagram

Note: See Additional Features on page 11 for explanation.

DEMAND LIMIT*

(1)

(2)

0-10 VDC

LEAVING

WATER SENSOR

SHUTDOWN*

COMP LEAD/LAG*

ICE MODE*

FLOW INTERLOCK

Indicates

*

optional

feature.

24VAC

(+)

AI CM

25

26

528

529

(-)

AI CM

AI CM

AI CM

AI CM

AI CM

+15VDC

24VAC

24VAC

24VAC

24VAC

24 C OM Z

VAC B U S

P5 P6

AI1

AI2

AI3

AI4

AI5

AI6

+15VDC

BI1

BI2

BI3

BI4

ANALOG INPUTS BINARY IN

DS

REF N 2 N 2

18

28

512/518

519

- +

P4

(1)

(2) Field connections must be made between TB3-18 and BI-4 for unit to operate.

NNotes:

1. Sensor for Outdoor, Return Water, or Zone Temperature Reset options are connected to Al-1 and Al-CM.

2. Field connections must be made between TB3-18 and Bl-4 for unit to operate.

3. If a time clock is desired, it should be installed between 24 VAC and Bl1. The time clock switch should be installed as follows:

Open to Run and Close to Stop.

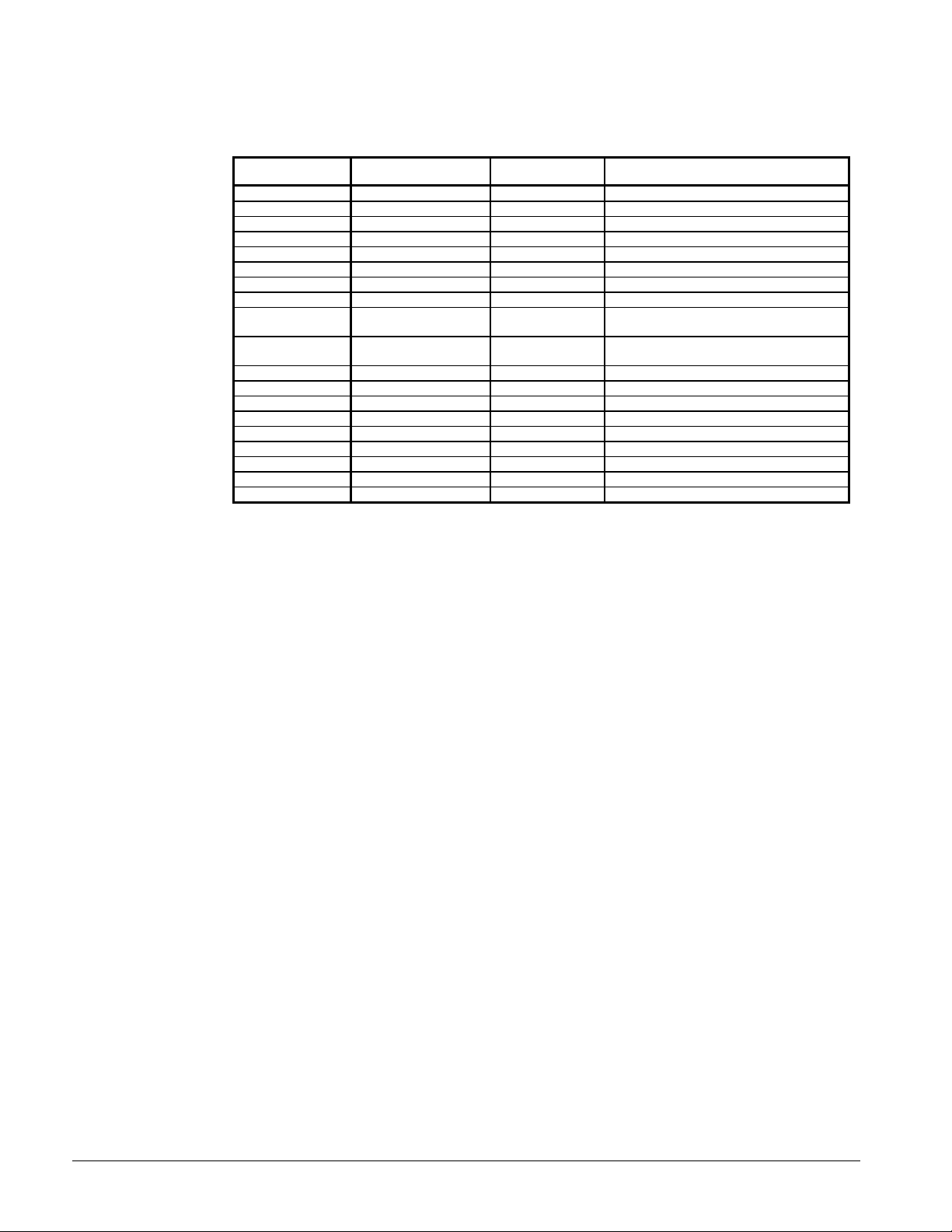

Figure 4, Stage Relay Configuration

M cQuay

C ONT ROL BA ND

S ET PO I NT

RE SET

RECIPROCATING

CHILLER CONT ROL

COO L 6

COO L 5

COO L 4

COO L 3

COO L 2

COO L 1

C

B

A

C

B

A

C

B

A

C

B

A

C

B

A

C

B

A

C

B

A

Stage Relays

COM

NC

NO

Note: Refer to Unit Wiring

Diagram for Stage

Wiring.

IOM UNT33 7

Page 8

Table 6, Wiring Location Cross Reference

Lead #

512 TB3-18 to TB3-29 (4,6,8 Stages) Not Needed (See Note 1 and 2)

518 TB3-29 to "TR" " TB3-18 to 24 VAC

519 "TR" " Common

522 Ground " Not Needed

524 "7" " Not Needed (See Note 3)

525 TB3-23 to TB3-24 " Not Needed

526 "6" " Not Needed (See Note 3)

527 "P" to "P1" " Not Needed or Zone Terminal Adjust

528 "T" "

529 "T1" "

400 OHM Resister "7" to "8" 4 Stages

600 OHM Resister "7" to "8" 6 Stages See Table 5

800 OHM Resister "7" to "8" 8 Stages

523 Ground 8 Stages Not Needed

535 "1" " Not Needed

536 "2" " Not Needed

537 "3" " Not Needed

538 "4" " Not Needed

539 "5" " Not Needed

Note 1: To install Flow Switch Contacts, connect between TB3-18 and UNT BI-4.

Note 2: To install Time Clock Contacts, connect between TB3-18 and UNT BI-1.

Note 3: The options are as follows. (Option A is standard; options B, C, and D require field download. See "Features Requiring

Configuration and/or Field Adjustment" section for more information):

A. The standard is Demand Limit Input. 0-10VDC signal is required. Connect leads to AI-1 and AI-CM on the

controller.

B. Johnson Controls Outdoor Air Sensor if Outdoor Air Reset is used.

C. Johnson Controls Zone Temperature Sensor if Zone Temperature Reset is used.

D. Johnson Controls Return Water Sensor if Return Water Reset is used.

Honeywell (H/W)

W7100G

Stages

AI-3 (JCI or H/W Leaving Water Sensor. See

Johnson Controls (JCI)

AS-UNT33n-1

appropriate sensor section)

AI-CM (JCI or H/W Leaving Water Sensor.

See appropriate sensor section)

8 IOM UNT33

Page 9

Operation

AS-UNT33n-1

LEAVING

WATER

CONTROL

COOLER

ZONE

TEMPERATURE

OR

OUTDOOR AIR

RESET

(optional)

PUMP

RETURN

WATER SENSOR

(optional)

LEAVING

WATER

SENSOR

COOLING LOAD

RETURN

WATER

LEAVING

WATER

Chiller System

Figure 5, Chiller System

Chiller systems are used to

provide cold water for comfort

cooling or process applications.

Control of the compressor

operation to supply that chilled

water may be initiated by sensing

return water temperature or

leaving water temperature. If

precise control of leaving water

temperature is desired a ASUNT33n-1 controller is

recommended.

LEAVING WATER TEMPERATURE CONTROL

OPERATION

Leaving water temperature will be

controlled to the actual leaving water

setpoint. The actual leaving water setpoint

will be a function of what mode of

operation the controller is in and if a reset

option is used. The Control Band

potentiometer located on the front of the

controller is used to determine the Actual

Leaving Dead Band and Prop Band.

Actual Leaving Dead Band: Control Band

(AI6)/2.

Actual Leaving Prop Band: Dead Band *

Number of Stages.

Example:

Control Band = 4 Deg F

Number of Stages = 6

Dead Band = 4/2 = 2 Deg F

Prop Band = 2 * 6 = 12 Deg F

As the leaving water temperature rises above the actual leaving water setpoint, but within the leaving

dead band, there will be no increase in the Compressor Command. As the leaving water temperature

continues to rise above the Dead Band and into the Prop Band, the Compressor Command will be

increased. When Leaving Integration Gain is used, a Proportional Plus Integral command will be

calculated. As the Compressor Command increases, stages of cooling capacity will be energized.

Minimum on, off, interstage times, and cycles per hour attributes will control the stages.

As the leaving water temperature decreases towards the actual leaving water setpoint, the Compressor

Command will be decreased. Upon reentering the Dead Band, the current Compressor Command will

be maintained. If the Leaving Water Temperature falls below the Actual Leaving Water Setpoint

(using the same Dead Band), the Compressor Command will again start to decrease.

Figure 6, Leaving Water Control

Algorithm Operation

57

PB

47

45

43

LWSP

DB

DB

Control

Band

IOM UNT33 9

Page 10

The "Control Band" is the non-staging area of the control. Anytime the Leaving Water Temperature is

outside of the Control Band limits, staging will occur. Anytime the Leaving Water Temperature is within the

Control Band limits, no staging occurs. As shown in Figure 6, with a 45°F Setpoint and a 4°F Control Band

setting, stages of cooling energize when the Leaving Water is 47°F or higher. Stages de-energize when the

Leaving Water is 43°F or lower (4°F difference). All stages will remain in their current state between 43°F

and 47°F.

AS-UNT33n-1 LED OPERATION

The AS-UNT33n-1 has one LED for each staged output. The LED on the AS-UNT33n-1 will light

simultaneously as that stage relay energizes. If the LED is not lit, the stage is not energized. When a stage

relay energizes, the normally closed contacts open, and the normally open contacts close.

JOHNSON CONTROLS LEAVING WATER SENSOR

Note: Johnson Controls or Honeywell Leaving Water Sensors may be used with the AS-UNT33n-1. Refer

to Table 4, page 4. A description of the Honeywell sensor follows the description of the Johnson Controls

sensor. Accuracy can be determined by measuring sensor resistance and making a comparison to the

temperature and resistance chart. The thin-film nickel sensor has a reference resistance of 1000 ohms at

70°F (21°C) and a change in resistance of approximately 3 ohms/ °F (5 ohms/°C). See Table 7 for resistance

values at selected temperatures.

Table 7, Johnson Controls Leaving Water Sensor, TE-6300-300

Temperature Resistance (Ohms) Temperature Resistance (Ohms)

°° F °° C Nickel °° F °° C Nickel

0 -18 803 70 21 1000

10 -12 830 80 27 1030

20 -7 858 90 32 1060

30 -1 885 100 38 1090

40 4 914 110 43 1121

50 10 942 120 49 1152

60 16 971

HONEYWELL LEAVING WATER SENSOR

The C7173A and C7170A are sensors for use in applications requiring a broad temperature sensing range.

Unlike thermistors, the C7173A and C7170A have a positive temperature coefficient (PTC); resistance

increases as the temperature increases. As shown in Table 8, the resistance curve increases by 4.8 ohms

per degree F temperature rise [8.6 ohms/C].

Resistance in the sensor wiring positively offsets the temperature sensed by 1 degree F every 4.8 ohms

[8.6 ohms/C] of resistance. Use short wire lengths or larger gauge wire when longer lengths are

necessary.

With an accurate thermometer (+/-l°F [.5°C]), measure the fluid temperature at the sensor location,

allowing time for the thermometer to stabilize before reading. Use an ohmmeter to measure the resistance

across the sensor wires. Then verify sensor accuracy with the temperature/resistance values in Table 8.

Table 8, Honeywell Temperature/Resistance Table for C7173A, Leaving Water Sensor

TEMP

°° F

23 3224.8 32 3268.0 41 3311.2 50 3354.4 59 3397.6 68 3440.8 77 3484.0 86 3527.2

24 3229.6 33 3272.8 42 3316.0 51 3359.2 60 3402.4 69 3445.6 78 3488.8 87 3532.0

25 3234.4 34 3277.6 43 3320.8 52 3364.0 61 3407.2 70 3450.4 79 3493.6 88 3536.8

26 3239.2 35 3282.4 44 3325.6 53 3368.8 62 3412.0 71 3455.2 80 3498.4 89 3541.6

27 3244.0 36 3287.2 45 3330.4 54 3373.6 63 3416.8 72 3460.0 81 3503.2 90 3546.4

28 3248.8 37 3292.0 46 3335.2 55 3378.4 64 3421.6 73 3464.8 82 3508.0 91 3551.2

29 3253.6 38 3296.8 47 3340.0 56 3383.2 65 3426.4 74 3469.3 83 3512.8 92 3556.0

30 3258.4 39 3301.6 48 3344.8 57 3388.0 66 3431.2 75 3474.4 84 3517.6 93 3560.8

31 3263.2 40 3306.4 49 3349.6 58 3392.8 67 3436.0 76 3479.2 85 3522.4 94 3565.6

OHMS

TEMP

°° F

OHMS

TEMP

°° F

OHMS

TEMP

°° F

OHMS

TEMP

°° F

OHMS

TEMP

°° F

OHMS

TEMP

°° F

OHMS

TEMP

°° F

OHMS

10 IOM UNT33

Page 11

Additional Features

The following features are also included with the controller algorithm operation. Where there is a

point number specified after the feature name (e.g., AI3), a sensor or contact closure input is required.

LEAVING WATER LOW LIMIT

If the Leaving Water sensor reads a reliable value below an adjustable Leaving Water Low Limit

(LWLL) for more than 3 seconds, the compressor command will be forced to 0% immediately. Once the

Leaving Water Temperature rises above the LWLL by a LWLL Differential (LWLLD), a normal control

sequence will be initiated. Default values are 15°F for the LWLL and 5°F for the LWLLD. Leaving

Water Low Limit will effect compressor commands only.

The default value for the Leaving Low Limit and Differential is adjustable through the Zone Terminal,

HVAC PRO Software, or Johnson Controls Facility Management System.

DEMAND LIMIT INPUT - ANALOG INPUT (AI1)

Demand Limit Input will effect the control strategy as follows. This AI will inversely limit the

Compressor Command for external demand limiting control strategies. As the input goes from 0 - 10

VDC, the Compressor Command will be proportionally limited from 100% to 0%. For example, if the

Demand Limit Input is 5 VDC, the Compressor Command cannot exceed 50%, if 8 VDC is present, the

maximum Compressor Commands will be 20% and so on. The Demand Limiting function can operate

when the control is in the Occupied mode only. Demand Limiting will not occur while in the Ice Mode.

CAUTION: For the Demand Limit Input feature, use only 0-10 VDC input.

COOLING DIAGNOSTICS

The Leaving Water Temperature sensor will be used to determine a drop in Leaving Water

Temperature over time whenever a stage is energized. When a stage is energized, if the Leaving Water

Temperature does not drop by 1°F in five minutes, this is considered a Cooling "Stage Failure." This

failure point can be monitored with the use of a Zone Terminal or Johnson Controls Facility

Management System. Once a Failure has occurred for a particular stage, the alarm can only be cleared

by producing the change in temperature over time or by cycling power.

SHUTDOWN MODE (BI-1)

When shutdown mode is enabled, all stages will be de-energized.

COMPRESSOR LEAD/LAG CONTROL (BI2)

If Lead/Lag Control is desired, a BI (Binary Input) point can be configured to initiate the mode of

operation. When BI2 is open, circuit 1 is the lead. When BI2 is closed, circuit 2 is the lead. The lead

circuit will not change unless all stages are off.

ICE MODE (BI3)

When Ice Mode is enabled, the controller will control Leaving Water Temperature to Ice Mode

Setpoint (default is 23°F). This mode can be enabled or disabled through a BI (Binary Input) hardware

point.

When Ice Mode is enabled, the current Leaving Water Temperature will be compared to the Ice Mode

Setpoint. If it is above the Setpoint, the Compressor Command will be forced to 100%. When the

Leaving Water Temperature drops below the Ice Mode Setpoint, the Compressor Command will be

forced to 0%. These are the only two levels of Compressor Command during Ice Mode. Once the

Compressor Command has fallen to 0% or the Ice Mode is de-activated, the control will return to the

Chiller On or Shutdown Mode. The control will not cycle to maintain an Ice Mode Setpoint.

Whatever triggered Ice Mode must be released before Ice Mode can be triggered again.

The default value for the Ice Mode Setpoint is adjustable through the Zone Terminal, HVAC PRO

Software, or Johnson Controls Facility Management System.

IOM UNT33 11

Page 12

FLOW INTERLOCK INPUT (BI4)

After a transition from Shutdown Mode or Restart Delay the controller will wait 10 seconds for a

verification of Pump Status. If Pump Status is verified during this time, normal control will occur. If

Pump Status is not verified, a "Pump Failure" point will be initiated.

If Pump Status had previously been verified, and then is lost for a period of three seconds, the

Compressor Commands will be forced to zero. If Pump Status is lost for a period of 10 seconds (Pump

Status Delay Timer), the Pump Failure Alarm will be initiated. Once Pump Status is again verified,

normal control will occur and the Alarm will be cleared.

Settings and Adjustments

SETPOINT KNOB

HVAC Applications-Typical Setpoints for HVAC applications range from 42°F to 50°F [5°C to 10°C].

These Setpoints may change due to many factors, including desired space temperature,

required/desired humidity conditions, etc.

CONTROL BAND KNOB

Set for the desired Control Band in accordance with the following formula. Increasing the Control

Band slows down the response of the AS-UNT33n-1, and increases the temperature deviation.

Lowering the Control Band speeds up the response of the AS-UNT33n-1, while decreasing the

temperature deviation from Setpoint.

The Control Band Setpoint should be as narrow as possible without causing hunting or rapid cycling.

If instability, hunting or rapid cycling occurs, widen the Control Band Setpoint. McQuay International

recommends the following formula for calculating the minimum Control Band Setpoint:

Temperature drop across vessel (∆T) at full load/number of stages + .5°F.

Example:

10°F∆T/4 stages of cooling +.5°F = 3°F Control Band.

RESET KNOB

This adjustment adds to the Leaving Water Setpoint, when the control is factory downloaded to

incorporate an Outdoor Air, Zone Temperature, or Return Water Reset function. The standard

application does not include reset; therefore, this Setpoint is disregarded in the algorithm.

12 IOM UNT33

Page 13

System Checkout and Troubleshooting

LWR

B

LWSPOALLOAHLOAR

B

(OALL=OAHL-OARB

)

Equipment needed:

1. Digital Voltmeter 2. Resistor Harness (AS-KIT100-0) included with controller

Table 9, Troubleshooting

Step Action Verification

1 Disconnect power to AS-UNT33n-1.

2 Disconnect compressor and unloader line voltage power. Check for 0 VAC at compressor and unloader contactors or

3 Remove Fast-On for Control Band input from AI6 and

connect resistors as shown.

relays.

AI CM

AI6

+15VDC

4

Set Setpoint knob on AS-UNT33n-1 to 10oF (-12oC).

5 Turn 24 VAC power on to the AS-UNT33n-1. Check for 24 VAC power at AS-UNT33n-1

6 After approximately 70 seconds, all stages will be

7

8 All stages should now be turned off quickly in a

9 Remove power from AS-UNT33n-1 terminals. Check for 0 VAC at compressor and unloader contactors or

10 Reconnect all wiring as originally installed.

11 Reconnect AS-UNT33n-1 power supply, close

energized quickly in an ascending order.

Move Setpoint to 60oF (16oC).

descending order.

compressor disconnects and place Setpoints as desired.

All LED's should be ON. The number of stage LED's illuminated

should correspond to the control model number. If there is a

discrepancy, the stage selection DIP switch (AI2) should be

checked for proper settings. Refer to page 2, Figure 1, Table 5.

All LED's should be OFF.

relays.

System is now operational.

FEATURES REQUIRING FACTORY CONFIGURATION AND/OR FIELD

ADJUSTMENT

RESET OPTIONS

One of the following three reset

options can be selected: Outdoor Air

Reset, Zone Temperature Reset, and

Return Water Reset. The reset

options described below operate on

identical strategies. The main

differences are Setpoints and sensor

locations.

Leaving Water Setpoint and Leaving

Water Reset Band are adjusted using

the Setpoint adjustment knobs on the

front of the AS-UNT33n-1.

Outdoor Air, Zone Temperature, and

Return Water High Limits and their respective Reset Bands are values that can be adjusted by use of a

Zone Terminal, HVAC PRO Software, or Johnson Controls Facility Management System.

Ramping Strategy

Figure 7, Outdoor Air Reset

IOM UNT33 13

Page 14

This ramping strategy applies to all three reset options. When a reset function is used, a Ramping of

sensor

sensor

sensor

sensor

sensor

sensor

sensor

sensor

sensor

Nine sensors wired in

a series/parallel

arrangement for large

areas.

AI1

AI1 COM

the Compressor Command is also used. Two adjustable variables setup the ramp as needed. These

are Ramp Output and Ramp Time.

The Ramp is used to meter the Proportional Command into the Sequencer when conditions don't

require a quick startup of all stages. For example, if the Outdoor Air Temperature (OAT) is at Outdoor

Air Low Limit (OALL), with OALL being equal to Outdoor Air High Limit minus Outdoor Air Reset

Band (OAHL - OARB), the stages do not need to be energized as quickly as they do if the OAT is at

the Outdoor Air High Limit (OAHL). When the OAT is at OAHL, the Proportional Command is fed to

the Sequencer at the same rate as it is calculated. But if the OAT drops below the OAHL, the

Proportional Command is ramped to the Sequencer. This allows for a slower startup of stages.

OUTDOOR AIR RESET

When this option is chosen, an Outdoor Air Temperature (OAT) sensor (AI1) is required.

Four variables are used to setup the reset ramp that calculates the Actual Leaving Water Setpoint.

These are: Leaving Water Setpoint (AI4), Leaving Reset Band (AI5), Outdoor Air High Limit (OAHL),

and Outdoor Air Reset Band (OARB).

As the OAT increases above the Outdoor Air Low Limit (OALL), the Actual Leaving Water Setpoint is

decreased from its Leaving High Limit (Leaving Water Setpoint plus Leaving Reset Band) to the

Leaving Water Setpoint. When OAT reaches the OAHL, the Actual Leaving Water Setpoint equals

the Leaving Water Setpoint (AI4). If the OAT sensor is missing or unreliable, no reset occurs and the

Actual Leaving Water Setpoint equals the Leaving Water Setpoint. If the Leaving Water Sensor (AI3)

becomes unreliable, the compressor command is forced to 0%.

Outdoor Temperature Lockout: If an Outdoor Air Temperature sensor is installed and reliable, the

shutdown mode is initiated whenever it senses, for more than five minutes, an input below the

adjustable Outdoor Temperature Lockout (OTL) Setpoint (45°F).

The default value for this Setpoint is adjustable through the Zone Terminal, HVAC PRO Software, or

Johnson Controls Facility Management System.

ZONE TEMPERATURE RESET

When this option is chosen, a Zone Temperature must be made available to the controller. There are

two ways to do this. The first is through an adjustable Analog Data Float (ADF) point. With the use

of a Johnson Controls Facility Management System, a Zone Temperature or average of multiple Zone

Temperatures can be shared with the controller through the ADF point. The second is through a Zone

Temperature Sensor connected directly to the controller. Regardless of which method is used, the

control strategy is the same.

Four variables are used to setup the reset

ramp that calculates the Actual Leaving

Figure 8, Average Zone Temp. Using TE-6410S-2000

Sensors

Water Setpoint. These are: Leaving Water

Setpoint (AI4), Leaving Reset Band (AI5),

Zone Temperature High Limit (ZTHL), and

Zone Temperature Reset Band (ZTRB).

As the Zone Temperature increases above

the Zone Temperature Low Limit (ZTLL),

the controller decreases the Actual

Leaving Water Setpoint from its Leaving

High Limit (Leaving Water Setpoint plus

Leaving Reset Band) to the Leaving Water

Setpoint. When the Zone Temperature

reaches the ZTHL, the Actual Leaving

Water Setpoint equals the Leaving Water

Setpoint (AI4).

14 IOM UNT33

Page 15

Figure 9, Zone Temperature Reset

(RWLL=RWHL-RWRB

)

If the Zone Temperature sensor is

missing or unreliable, or if there is an

unreliable Zone Temperature value at

the Analog Data Float (ADF) point, no

reset occurs and the Actual Leaving

LWRB

Water Setpoint equals the Leaving

Water Setpoint. If the Leaving Water

Sensor (AI3) becomes unreliable, the

compressor command is forced to 0%.

(ZTLL=ZTHL -Z TRB)

LWSP

ZTLL ZTHL

ZTRB

RETURN WATER RESET

When this option is chosen, a Return Water Temperature (RWT) sensor (AI1) is required. Four

variables are used to setup the reset ramp that calculates the Actual Leaving Water Setpoint. These

are: Leaving Water Setpoint (AI4), Leaving Reset Band (AI5), Return Water High Limit (RWHL), and

Return Water Reset Band (RWRB).

As the RWT increases above the

Return Water Low Limit (RWLL), the

Figure 10, Return Water Reset

controller decreases the Actual Leaving

Water Setpoint from its Leaving High

Limit (Leaving Water Setpoint plus

Leaving Reset Band) to the Leaving

Water Setpoint. When RWT reaches

LWRB

the RWHL, the Actual Leaving Water

Setpoint equals the Leaving Water

Setpoint (AI4). If the RWT sensor is

missing or unreliable, no reset occurs

and the Actual Leaving Water Setpoint

equals the Leaving Water Setpoint. If

LWSP

RWLL RWHL

RWRB

the Leaving Water Sensor (AI3) becomes unreliable, the compressor command is forced to 0%.

When Return Water Reset is chosen, a Fail Smart Logic option is also available. This option works as

follows. If the Leaving Water Sensor (AI3) becomes unreliable, the controller switches from Leaving

Water control to Return Water control. Actual Return Water Setpoint equals Leaving Water Setpoint

(AI4) plus an adjustable Leaving Water Setpoint Offset. This value takes into account the

temperature differential between Leaving and Return water temperatures, which is typically about

10°F. If both the Leaving and Return water sensors are unreliable, the compressor is forced to 0%.

IOM UNT33 15

Page 16

Zone Terminal User's Guide

This user's guide contains step-bystep instructions for using the

Zone Terminal (AS-ZTU330-1) on a

McQuay Reciprocating Chiller (ASUNT33n-1).

This guide assumes you are familiar

with the McQuay Reciprocating

Chiller. This guide contains

examples of the Zone Terminal (ZT)

screen that is standard with the ZT

accessory to the McQuay

Reciprocating Chiller.

USER'S GUIDE

ORGANIZATION

Three major sections describe how

to use the Zone Terminal.

Introduction and Overview:

Explains in general terms the

features and operating modes of

the Zone Terminal.

Getting Started: Includes an explanation of the Keys, Displays, and Symbols on the Zone Terminal.

Also includes an explanation of the Zone Terminal labels and how to install them. In addition, this

section instructs the user about handling Alarm Status and connecting the Zone Terminal.

Making ZT Adjustments: Includes specific instructions for making set point adjustments with the

Zone Terminal.

OVERVIEW OF THE ZONE TERMINAL

The Zone Terminal (ZT) is a hand-held or wall-mounted device that monitors and adjusts your

McQuay Reciprocating Chiller information.

A standard telephone-style jack connects the ZT to the McQuay Reciprocating Chiller controller

directly or through the TE-6410S-2000 Zone Temperature Sensor.

Features

The ZT provides:

• Portability

• Simultaneous monitoring of three different settings or values

• Easy operation with only seven buttons

• Flashing numbers to show which items are ZT adjustable

• Flashing symbols to notify you of alarm conditions

Capabilities

With the ZT, you can:

• Quickly identify a chiller alarm and its location

• Monitor and adjust up to 18 different settings

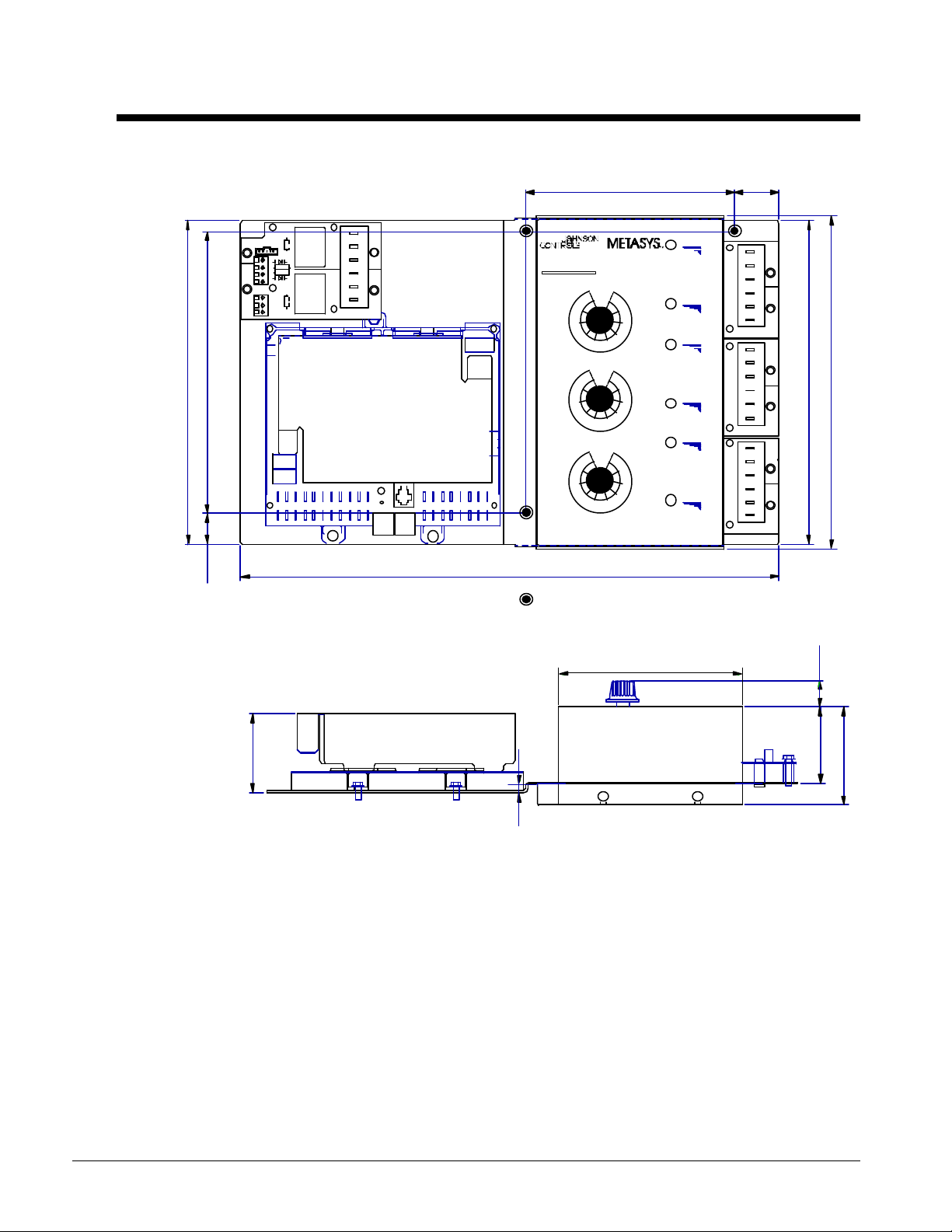

To familiarize yourself with the ZT, refer to Figure 12.

16 IOM UNT33

Page 17

Figure 11, Zone Terminal Template (See Glossary for Definitions)

Disp lay Item List Warning Signal

Displa y

Button

1

2

3

Mode

Selector

Button

M ode

Selector

Panel

Displa y Indicator Do t

Lvg Water Temp

Demand L imit

Lvg Reset Band

Lvg Cntrl Band

Lvg Dead Band

Lvg Prop Band

Lv g Setp oint

Lvg Low L imit

Low Limit Di ff

Fa ilsoft Set pt

Comp Com mand

Ice Mode S etpt

Cool Diag Time

Cool Diag Temp

Oper at ing Mode Indicat or

MONITOR

ADJUST

TIME SCHEDULE

PASSWORD

ENTER

McQuay Chiller with Demand Limit ON OFF

INSERT 12

R amp Ou tput

Ramp Time

Up/Down Arrow Keys

Door

Disp lay A rea 1 1

Disp lay Ar ea 2 1

Disp lay Ar ea 3 1

On/Off Status

Chiller Off

Cht 2 Lead

Stage 1

Fail Stage 1

Stage 2

Fail Stage 2

Stage 3

Fail Stage 3

Stage 4

Fail Stage 4

Stage 5

Fail Stage 5

Stage 6

Fail Stage 6

Stage 7

Fail Stage 7

Stage 8

Fail Stage 8

ALARM

Alarm Light

OPERATING MODES

Two operating modes are included: Monitor and Adjust.

Monitor Mode

As soon as the ZT is connected, it completes a self-check, and starts up in the Monitor Mode. Monitor Mode lets

you view up to three of chiller settings/sensed values at a time.

To allow you to monitor your system, a clear plastic Insert (factory made and installed) relates the ZT’s output to

your McQuay Reciprocating Chiller system.

You can simultaneously monitor the chiller in three ways:

• Monitor up to three settings/sensed values. A maximum of six items are accessible in each of the three

displays.

• Read the symbols to the right of the display numbers to learn the on/off status of various inputs, outputs,

or modes (| = On status; m = Off status). This provides continuous monitoring of 18 different statuses

(on/off).

• Monitor alarm status–a flashing red alarm light and any flashing symbol ( |, m, s) visually notifies you

when your chiller has an alarm condition.

Adjust Mode

In Adjust Mode, the ZT displays information in each of the three numerical displays. Typically, the displays are set

up so that the relationship between the values can be viewed simultaneously. For example:

IOM UNT33 17

Page 18

Table 10, Displays, Symbols, Keys, and Buttons

DISPLAYS,

SYMBOLS, KEYS,

DESCRIPTION

BUTTONS

Display Button

1, 2, 3

Enter Key

Flashing Numbers

Flashing

ss , mm , ( | )

Mode Selector

Button

On/Off Status

Symbols( | ) for

On/a circle ( mm ) for

Off

Red Alarm Light

Up ( ↑↑) or Down

(↓↓) Arrow Keys

ll

Select the value you want to monitor or

adjust.

Use to commit your changes.

Adjustments are not processed unless

you press Enter.

Appear in Display 1, 2, or 3 to indicate

numbers you can adjust. Numbers that

do not flash are monitor only numbers.

Shows an item is in alarm.

Press this button to select Operating

Modes: Monitor, Adjust, Password,

Time Scheduling. A green Mode

Indicator light moves through the modes.

Observe On/Off conditions of a point in

the HVAC controller with these

symbols. A bar (| ) for On, a circle (m)

for Off. These are always monitor only

items. If the symbol flashes, item is in

alarm.

Flashes anytime a problem exists

regardless of which Operating Mode

you have entered.

Use these keys to adjust a flashing

number.

Appears in the displays, and

corresponds to the item you are

monitoring or adjusting.

Display 1 = Lvg Water Temp

Display 2 = Lvg Setpoint

Display 3 = Comp Command

This operating mode allows you to adjust

any flashing setpoints. Setpoints adjusted

by the ZT remain in effect until you

change them

GETTING STARTED

DISPLAYS, SYMBOLS, KEYS, AND

BUTTONS

The Zone Terminal simultaneously

displays three set points or sensed values.

In addition, flashing symbols indicate

when items are in a state of alarm. The

keys, buttons, displays, and symbols are

explained below.

Figure 12, Installing the Insert

Note: The insert is normally factoryinstalled. These steps are required only if the

insert is not already installed.

To use the ZT, you'll need the plastic label

which is included with your ZT.

Insert

The clear plastic Insert is a custom-made label

unique to your chiller. Use this Insert when

monitoring or adjusting specific items of your

system:

1. With the ZT on a flat surface, press the

white tab with your index finger (Fig. 12).

2. Pull the front cover of the ZT away from

the back and slide the Insert into position.

3. Press the ZT together. With the Insert in

place and the ZT connected, the l in the

top position of each display lines up with

the first word.

18 IOM UNT33

Page 19

CONNECTING THE ZONE TERMINAL

You can wall-mount the ZT, or use it as a portable tool for convenient access to any chiller

information.

Figure 13, Connecting ZT to a Reciprocating

Chiller Controller Using 6 to 8 Pin Cable

6 Pin

Connection

ALARM STATUS

The ZT indicates an alarm as follows

(see Figure 12):

McQuay Reciprocating Controller

Connection

A standard telephone-style jack

connects the ZT to a McQuay Chiller

Controller directly or through a TE6410S-2000 sensor.

AS-UNT3 30-1

+15VD C

CO M MO N

B I N A R Y I NA N A L OG I NP U TS

BI N A R Y COM

BIN ARY INA NALOG INPUTS

1 2 3 4 5 6 1 2 3 4

A N A LOG I N P UT S

Connection

8 Pin

BINARY OUTPUT

CO M

1 2 3 4 5 6 7 8

TO

ZONE

P W R

STAT

I N

24 V

24 V A C TO L OA D S

A C

BIN ARY OUTPUTS

Connect ZT

here.

1 2 3 4 5 6 7 8

OFF

Figure 14, Connecting ZT to a TE-6410S-2000

(METASTAT) Sensor Using Coiled 6 to 6 Pin Cable

• The warning signal (s) flashes to the

right of the Display Indicator dot

( l ) if the system operating values

are in alarm.

• The On/Off Status bar ( | ) or circle

(m) flashes when an On/Off status is

in alarm.

• The red alarm light to the right of the

Mode Selector Panel flashes when

any of the above items are in alarm.

Alarms cannot be cleared with the ZT.

The problem must be corrected by

maintenance or repair of the affected item.

Connect ZT

here.

Open cover.

IOM UNT33 19

Page 20

MAKING ZONE TERMINAL ADJUSTMENTS

Adjusting Control Settings

You can adjust only a flashing number with the ZT. If the number does not flash, that item is a monitor only

item. Adjust Control Settings in Display 1, 2, or 3 as follows:

1. Press the Mode Selector Button until the green Mode Indicator Light moves next to the word Adjust.

2. Press either Display Button 1, 2, or 3 to locate adjustable items, which are indicated by flashing numbers.

If you continue pressing the display buttons, the dot ( l ) in each display changes positions and the

corresponding number appears.

3. Press the Up ( - ) or Down ( ¯ ) Arrow key until you reach the number you want to enter. If you hold down the

Up ( - ) or Down ( ¯ ) Arrow keys, you can speed through the numbers more quickly.

Press Enter. After you press Enter, the numbers stop flashing for a few seconds. This pause tells you the ZT

has processed your adjustment.

4. Press any of the Display Buttons to make other adjustments, and repeat Steps 2 and 3.

Note: Some adjustable set points have high and low limits beyond which you cannot adjust them.

Adjustable Points

The following McQuay Reciprocating Chiller points are adjustable by the Zone Terminal.

Table 11, Adjustable points

FULL POINT NAME TEMPLATE NAME

Leaving Low Limit Lvg Low Limit

Low Limit Differential Low Limit Diff

Ice Mode Setpoint Ice Mode Setpt

Failsoft Setpoint Failsoft Setpt

Cool Diagnostic Time Cool Diag Time

Cool Diagnostic Temperature Cool Diag Temp

Note: Refer to the Glossary (next section) for definitions

20 IOM UNT33

Page 21

Zone Terminal Glossary

Chiller Off

A "|" indicates the chiller is in Shutdown Mode.

Ckt 2 Lead

A "|" indicates circuit 2 is lead circuit.

Comp Command

The Compressor Command is the percent of Chiller capacity that is required.

Cool Diag Time/Temp

When a compressor stage is started, the controller must sense the Leaving Water Temperature change (Cool Diag

Temp) within a time span (Cool Diag Time) or a Full Stage Alarm will occur.

Demand Limit

The percentage by which the maximum Compressor Command of 100% is reduced.

Failsoft Setpt

If the adjustable Leaving Water Setpoint setting ion the face of the controller fails, the failsoft setpoint is the value

the Leaving Water Setpoint defaults to.

Fail Stage n

A "|" indicates a possible fault condition exists.

Ice Mode Setpt

The Leaving Water Temperature at which Ice Mode operation is concluded.

Low Limit Diff

The amount the Leaving Water Temperature has to increase above the Leaving Water Low Limit to allow

compressors to restart.

Lvg Cntrl Band

The Leaving Water Control Band is centered around the Leaving Water Setpoint. When the Leaving Water

Temperature is within the Leaving Water Control Band, stages will not be energized or de-energized.

Lvg Dead Band

The Leaving Water Dead Band is one half of the Leaving Water Control Band.

Lvg Low Limit

When Leaving Water reaches the Leaving Water Low Limit, the Compressor Command will be forced to 0%.

Lvg Prop Band

The Leaving Water Proportional Band is the Leaving Water Dead Band multiplied by the number of stages.

Lvg Reset Band

When reset functions are used, the Leaving Water Reset Band is the amount the Leaving Water Setpoint is

automatically increased. The Leaving Water Reset Band adjustment can be found on the face of the controller.

Lvg Setpoint

The Leaving Water Temperature setting by which the controller will control to. The Leaving Water Setpoint

adjustment can be found on the face of the controller.

Lvg Water Temp

The temperature of the leaving water from a McQuay Reciprocating Chiller.

Ramp Output/Time

Ramp Output and Time are used to determine softstart. They define the percentage rate of increase for the

Compressor Command.

Stage n

A "|" indicates stage is energized.

IOM UNT33 21

Page 22

22 IOM UNT33

Page 23

Page 24

P.O. Box 2510, Staunton, Virginia 24402 USA • (800) 432-1342 • www.mcquay.com

Loading...

Loading...