Page 1

Product Manual

Air-Cooled Reciprocating Water Chillers

ALR 110F through 150F

110 to 150 Tons, 380 to 525 kW

R-22

60 Hertz

PM ALR2-3

Group: Chiller

Date: August 2000

Supersedes: PM ALR2-2

© 2000 McQuay International

Page 2

Table of Contents

Introduction...................................................................................................................3

Design Advantages.........................................................................................................4

Selection Procedure.......................................................................................................9

Performance Adjustment Factors..................................................................................10

Performance Data........................................................................................................12

Part Load Data............................................................................................................14

Pressure Drops............................................................................................................15

Sound Data..................................................................................................................16

Electrical Data..............................................................................................................20

Physical Data...............................................................................................................27

Dimensional Data.........................................................................................................29

Installation and Application...........................................................................................30

Remote Evaporator......................................................................................................40

Dimensions, Remote Evaporator...................................................................................42

Optional Features.........................................................................................................43

Specifications...............................................................................................................45

Remote evaporator arrangement

is not in ARI certification

Our facility is ISO Certified

"McQuay" is a registered trademark of McQuay International

"Information covers McQuay International products at the time of publication and we reserve the right to make changes in

design and construction at anytime without notice"

2 ALR 110F – 150F Product Manual ALR2-3

1997 McQuay International

Page 3

Introduction

McQuay International offers a complete line of air-cooled chillers from 10 to 425 tons (35 to

1500 kW) utilizing scroll, reciprocating, and rotary screw compressors.

The McQuay ALR reciprocating compressor, air-cooled chiller is a product of the McQuay

commitment to offer reliable, energy efficient equipment design. A design approach

incorporating high quality compressors and uncompromised operating efficiency. McQuay

International will provide its customers with products and services that meet or exceed their

expectations in terms of quality, availability and competitiveness.

Efficiency

• Cross-circuit compressor unloading

• Copeland DISCUS compressors

• High efficiency lanced fin condenser coils

ARI 550/590-98 Certified

FEATURES-BENEFITS

Reliability

• Rugged compressor design

• Factory installed operating and safety controls

• Factory run tested with water hookup

• Code and agency approval

Flexibility

• Complete factory assembly

• Large size availability in small capacity increments

• A wide variety of field and factory installed options

• Available with remote evaporator (R-22 only)

Serviceability

• Semi-hermetic compressors

• Suction and discharge service valves

• Dual refrigerant circuits

Product Manual ALR2-3 ALR 110F – 150F 3

Page 4

Design Advantages

Construction

The ALR 110F through 150F are factory assembled and mounted on a rugged steel channel base. The

channel base distributes the unit weight for low roof loading. Lifting holes in the base simplify

rigging. Optional wire mesh base guards are available to prevent intrusion to the area under the coils.

The units pass the ASTM B117 500 hour salt spray test.

Compressors

ALR 110F through 150F chillers use Copeland DISCUS semi-hermetic compressors. These

compressors are designed for Refrigerant 22 and the high loading associated with air-cooled

applications.

Semi-hermetic, 1750 rpm induction type motors are used. The motors are refrigerant-gas cooled.

Solid-state modules in the motor terminal box respond to temperature sensors imbedded in all three

motor windings, providing inherent thermal overload protection for all run and start conditions.

The compressor housing is constructed from closed grained, high nickel content, alloy cast-iron with

no bolted joint between the motor and compressor. The housing includes a cast-iron cylinder head

and stator cover, and a crankcase oil sightglass. A suction strainer built into the compressor in the gas

stream between the suction service valve and the motor, filters out foreign and abrasive particles. An

internal relief valve relieves discharge pressure to the suction side for safety protection at high

compression ratios as required by ANSI/ASHRAE 15 Safety Code.

Main bearings are solid cast bronze insert type with oversized bearing area that result in ultra-low

bearing loading.

The crankshaft is die-forged, high strength iron alloy with integral counterweights, statically and

dynamically balanced for smooth operation.

Connecting rods are lightweight aluminum with integral bearing surfaces on the crankshaft and piston

ends. Pistons are close grain cast iron with oil and compression rings. Piston pins are full floating

type for long life.

Compressors have a forced-feed lubrication system with positive oil displacement, a reversible oil

pump, and an operating oil charge. The pump feeds oil through rifle drilled passages in the crankshaft

to all bearing surfaces. Magnetic plugs trap magnetic particles that enter the crankcase. The oil

supply filters through a large area oil strainer. A crankcase heater minimizes oil dilution by refrigerant

at start-up.

Condenser Coils

Condenser coils have internally enhanced seamless copper tubes arranged in a staggered row pattern.

The tubes are mechanically expanded into McQuay lanced and rippled aluminum fins with full fin

collars. See the Application Section of this manual for optional corrosive resistant fin material and

coatings. An integral subcooler circuit provides subcooling to effectively eliminate the possibility of

liquid flashing. Vinyl coated wire mesh coil guards for fin protection are supplied as standard.

Condenser Fans and Motors

Multiple direct drive propeller fans operate in formed bell shaped orifices at low tip speeds for

maximum efficiency and minimum noise and vibration. A heavy-gauge close mesh fan guard protects

each fan.

Each condenser fan motor is heavy-duty, 3-phase with permanently lubricated ball bearings and

inherent overload protection.

4 ALR 110F – 150F Product Manual ALR2-3

Page 5

Hot Gas Mufflers

Hot gas discharge line mufflers are installed in each refrigerant circuit to reduce the overall sound

levels.

Evaporator

The evaporator is direct expansion, shell-and-tube type with water flowing in the baffled shell side and

refrigerant flowing through the tubes. Two independent refrigerant circuits within the evaporator

serve the unit's dual refrigerant circuits.

The evaporator has a carbon steel shell and seamless high efficiency copper tubes roller expanded

into a carbon steel tube sheet.

Refrigerant heads are carbon steel with multi-pass baffles to ensure oil return and are removable to

permit access to the tubes from either end. For water removal and venting, 1/2" (12.7mm) vent and

drain plugs are provided on the top and bottom of the shell.

The evaporator is wrapped with an electric resistance heater cable and insulated with 3/4" (19mm)

thick vinyl nitrate polymer sheet insulation, protecting against water freeze-up at ambient air

temperatures to -20°F (-29°C). An ambient thermostat controls the heater cable.

The insulation has a K factor of 0.28 at 75°F (23°C). The fitted and cemented in place insulation is

painted with a resilient vinyl base paint to resist cracking.

The tube side maximum working pressure is 315 psig (2170 kPa). The water side working pressure is

152 psig (1047 kPa). Each evaporator is designed, constructed, inspected, and stamped according to

the requirements of the ASME Boiler and Pressure Vessel Code.

NOTE : A chilled water pump starter interlock, water flow switch or both, must be field installed to

protect against evaporator freeze-up under low water flow conditions.

Electrical Control Center

Operating controls, safety controls, control transformer, and motor starting equipment is factory wired,

operationally tested, and ready for service. All centrally located controls are in a weatherproof,

hinged control center with key-locked doors. Panel access doors include steel rod door retainers to

secure the doors when open.

A fixed 5-minute, solid-state lockout timer delays compressor restart after a safety cutout, power

interruption, or thermostat cycling.

Power connection to the unit can be single-point or multiple-point. Single point is usually more

economical. Multiple point provides separate power for each of two compressor circuits plus a third

circuit for the fans and control power.

Part winding start is standard on 208 and 230 volt compressor motors. Across-the-line start is

standard on 380, 460 and 575 volts.

Circuit Breakers

Circuit breakers are factory installed, providing unit compressor short circuit protection.

Standard UNT Controller

This microprocessor based control accomplishes unit capacity control by staging compressors and by

cylinder unloading based on leaving chilled water temperature. Setpoint and control band are easily

field adjusted. Anti-cycling and stage delay timers are included. Safety controls include low

refrigerant pressure, low evaporator flow (field installed flow switch), low oil pressure, and sensor

failures. Outside air temperature sensor is standard. Reset options are; outside air, return water,

remote reset, demand limit, zone temperature reset. The optional Zone Terminal and Display control is

required to adjust the reset setpoints.

Product Manual ALR2-3 ALR 110F – 150F 5

Page 6

Thirty feet of sensor cable is included, rolled up in the control panel, on remote evaporator models.

The cable can be field spliced for a total run not to exceed 75 feet.

Figure 1, Standard UNT Controller

UNT with Optional Zone Terminal and Display

The optional Zone Terminal and Display can be mounted in the chiller control panel or remotely

located providing monitoring and adjusting of certain functions.

• Monitoring

• Monitor up to three setting or sensed values

• Monitor 18 different on/off inputs

• Monitor alarm status via a flashing alarm light and flashing symbol

• Adjusting allows adjustment of any flashing set points, three at a time, typically set up so that the

relationship between values can be viewed simultaneously. For example:

• Display 1 = Lvg Water temp, Display 2 = Lvg Water SP, Display 3 = % Unit Load

6 ALR 110F – 150F Product Manual ALR2-3

Page 7

Figure 2, Zone Terminal Configuration

Display Item List

Display Indicator Dot

Warning Signal

On/Off Status

Display

Button 1

Mode

Selector

Button

Mode

Selector

Panel

Door

2

3

Mc Quay AGZ/AG R Global Chiller

Lvg Water Temp

Evap Pres #1

Evap Pres #2

OA/AI3 Input

OA/AI3 HiLimSP

OA/AI3 ResetSP

Lvg Water SP

LvgWtr RBnd SP

Contrl Band SP

Actual Lvg SP

Unoccpd Lvg SP

OA Lockout SP

% Unit Load

Lvg Low Lim SP

SoftSta Capcty

SoftStart Time

Cir #1 Starts

Cir #2 Starts

Operating Mode Indicator

MONI TOR

ADJU ST

TIME SCH EDU LE

PASS WORD

ENTER

INSERT 10

Display Area 11

Display Area 21

Display Area 31

Up/Down Arrow Keys

ON OFF

Occupied

Flow Failure

OA Lockout

Cir#2Lead=On

Pmp/Stp #1=0

Pmp/Stp #2=0

Solenoid #1

Solenoid #2

Frzstat#1Alm

Frzstat#2Alm

MinLowPres#1

MinLowPres#2

Compressor 1

Compressor 2

Stage 3

Stage 4

Stage 5 Opt.

Stage 6 Opt.

ALARM

Alarm Light

AGZ-AGR

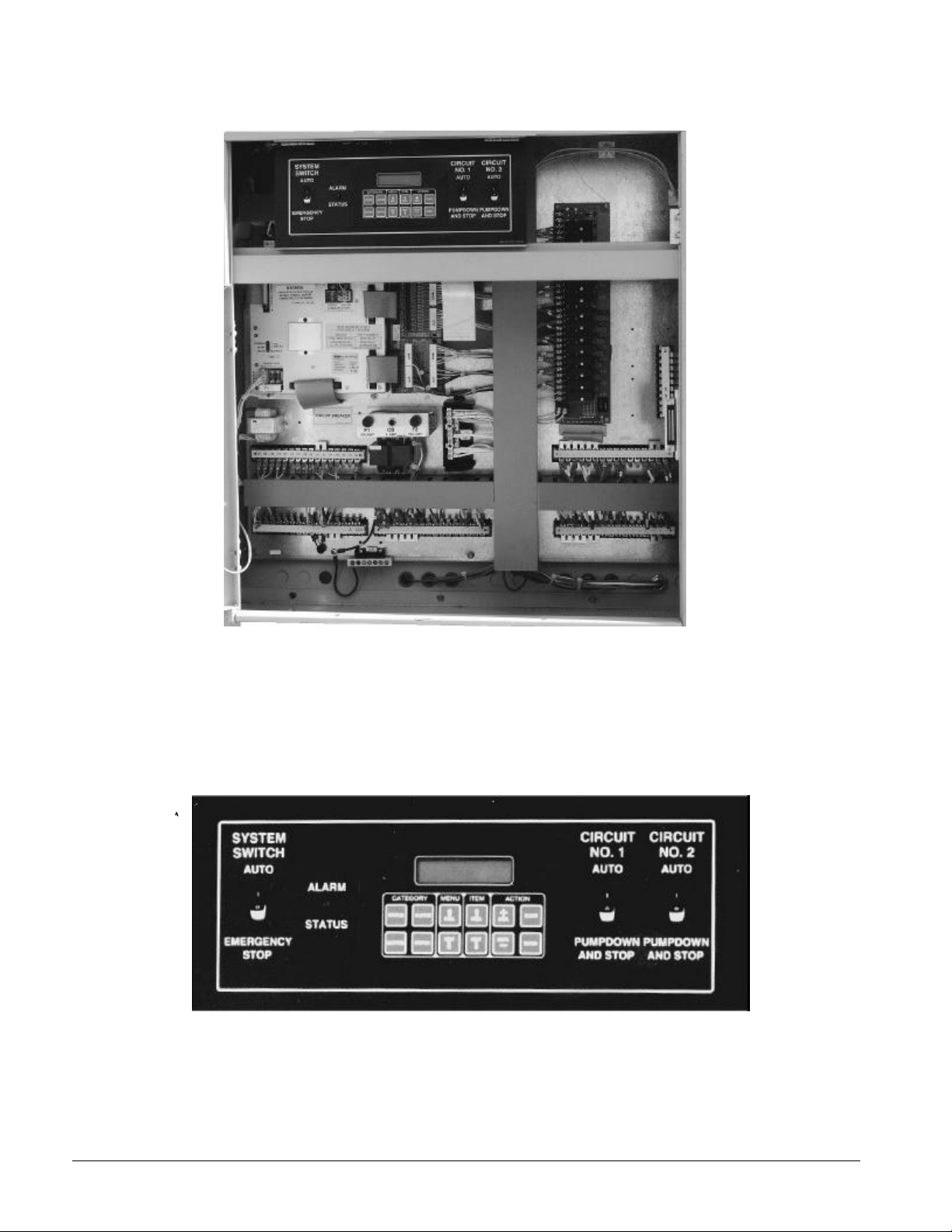

Optional MicroTech Control

The exclusive MicroTech microprocessor control is common throughout McQuay equipment. The

interface is a 12 key keypad and 2-line, 32 character backlit liquid crystal display. The MicroTech

continuously performs self-diagnostic checks on all system temperatures, pressures, and safeties, and

will automatically shut down a circuit or the entire unit if a fault condition occurs. The cause, time,

and date of the occurrence is recorded and can be displayed. The seven previous incidents are kept

in memory for service reference.

If a fault occurs, the controller takes preventive measures in an effort to keep the unit operating;

staging down capacity, activating a pre-alarm signal, and automatically switching to the alarm menu on

the display. Pre-alarms are self-clearing when the fault condition is no longer present.

Critical shutdown alarms such as high condenser pressure (with mechanical back up), freeze

protection, oil pressure (with mechanical back up), and low evaporator pressure are manual reset and

must be cleared at the keypad to resume operation.

Choose the MicroTech control and Open Protocol options to interface with virtually any building

management system and perform remote monitoring and control by hard wiring or modem. A nominal

site license fee is required for a Building Automation System (BAS) interface.

A single chiller can connect directly to the BAS. Two or more units will require an Open Protocol

Panel (OPM) for connection.

Thirty feet of sensor cable is included, rolled up in the control panel, on remote evaporator models.

The cable can be field spliced for a total run not to exceed 75 feet.

Product Manual ALR2-3 ALR 110F – 150F 7

Page 8

Figure 3, Optional MicroTech Control Panel

Figure 4, MicroTech Control

8 ALR 110F – 150F Product Manual ALR2-3

Page 9

Selection Procedure

Selection Procedure

Table 4 (R-22) covers the range of leaving evaporator water temperatures and ambient air temperatures

encompassed under ARI 550/590-98. Table 5 covers SI units. The tables are based on a 10 degree F

temperature drop through the evaporator (2.4 gpm/ton). Adjustment factors for applications having

other than a 10 degree F drop can be found in Table 3. The minimum leaving chilled water temperature

setpoint without glycol is 40°F. For brine selections, see Table 1 for ethylene glycol or Table 2 for

propylene glycol adjustment factors. Ratings are based on a 0.0001 fouling factor in the evaporator at

sea level operation. See Table 3 for other fouling factors, derates for different delta-Ts, or altitude

correction factors. For applications outside the catalog ratings contact your local McQuay sales

representative.

Selection example

Given:

R-22, 110 tons minimum.

95°F ambient temperature

264 gpm, 54°F - 44°F chilled water

0.0001 evaporator fouling factor

1. From Performance Table 4, an ALR 110F at the given conditions will produce 110.9 tons with a

compressor kW input of 120.6 and a unit EER of 9.8

2. Use the following formula (for water) to calculate missing elements:

tons°∆×

= gpm

24

FT

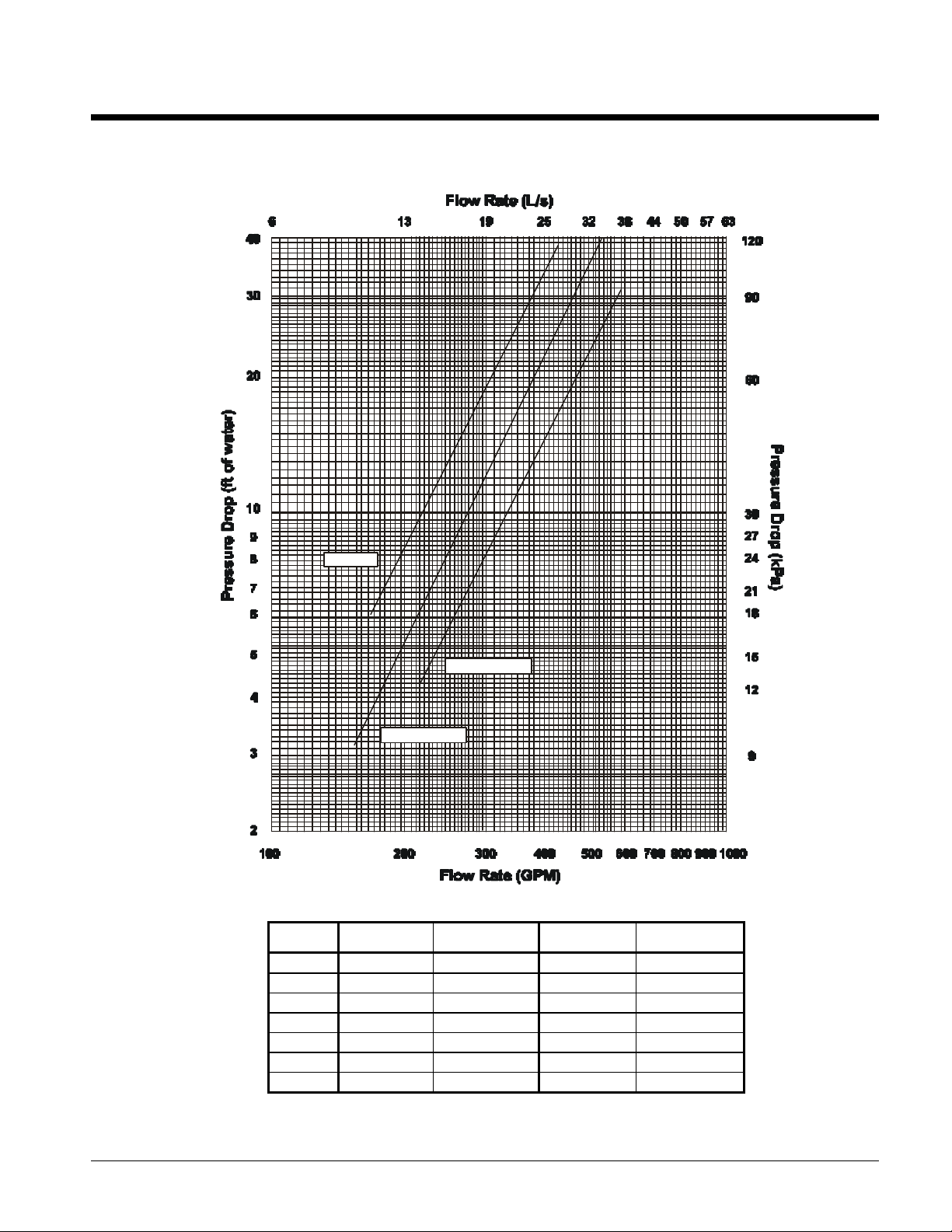

3. Determine the evaporator pressure drop. Using Figure 5, enter at 264 gpm and follow up to the

ALR 110 line intersect. Read horizontally to obtain an evaporator pressure drop of 14.3 feet of

water.

Selection example using ethylene glycol

Given:

R-22, 105 tons minimum

95°F ambient air temperature

54°F - 44°F chilled water temperature

0.0001 evaporator fouling factor

Protect from freezing down to 0°F

1. From Table 1, select an ethylene glycol concentration of 40% to protect against freezing at 0°F.

2. At 40% glycol: Capacity = 0.961, kW = 0.976,

flow = 1.121, pressure drop = 1.263

3. Consider the ALR 110F and correct with 40% ethylene glycol factors.

4. Correct capacity = 0.961 x 110.9 tons = 106.6 tons

5. Correct compressor kW = 0.976 x 120.6 kW = 119.5 kW

6. Correct chilled water flow for flow required for the glycol solution:

246.106

tons°∆×

= capacity) corrected(at flowWater

10

FT

Glycol flow (at 40% solution) = 1.121 x 256 gpm = 286.8 gpm

gpm 256 =

Determine the evaporator pressure drop. Using Figure 5, enter at 256 gpm (water flow rate) and follow

up to the ALR 110F line intersect. Read horizontally to obtain an evaporator pressure drop of 13.6

feet. The pressure drop for 40% solution = 1.263 x 13.6 feet = 17.2 feet of water

Product Manual ALR2-3 ALR 110F – 150F 9

Page 10

Performance Adjustment Factors

Ethylene and Propylene Glycol Factors

ALR units can operate with a leaving chilled fluid temperature range of 20°F (-6°C) to 60°F (10°C). A

glycol solution is required when leaving chilled fluid temperature is below 40°F (4.6°C). The use of

glycol will reduce the performance of the unit depending on concentration. Manufacturers do not

recommend the use of solutions of less than 25 percent due to the possibility of insufficient corrosion

protection.

Altitude Correction Factors

Performance tables are based at sea level. Elevations other than sea level affect the performance of the

unit. The decreased air density will reduce condenser capacity, consequently reducing the unit's

performance. For performance at elevations other than sea level refer to Table 3.

Evaporator Temperature Drop Factors

Performance tables are based on a 10 degree F (5.5 degree C) temperature drop through the evaporator.

Adjustment factors for applications having temperature drops from 6 degree F to 16 degree F (3.3

degree C to 8.9 degree C) are in Table 3. Temperature drops outside this range may affect the control

system's capability to maintain acceptable control and are not recommended.

The maximum water temperature that can be circulated through the evaporator in a non-operating

mode is 100°F (37.8°C).

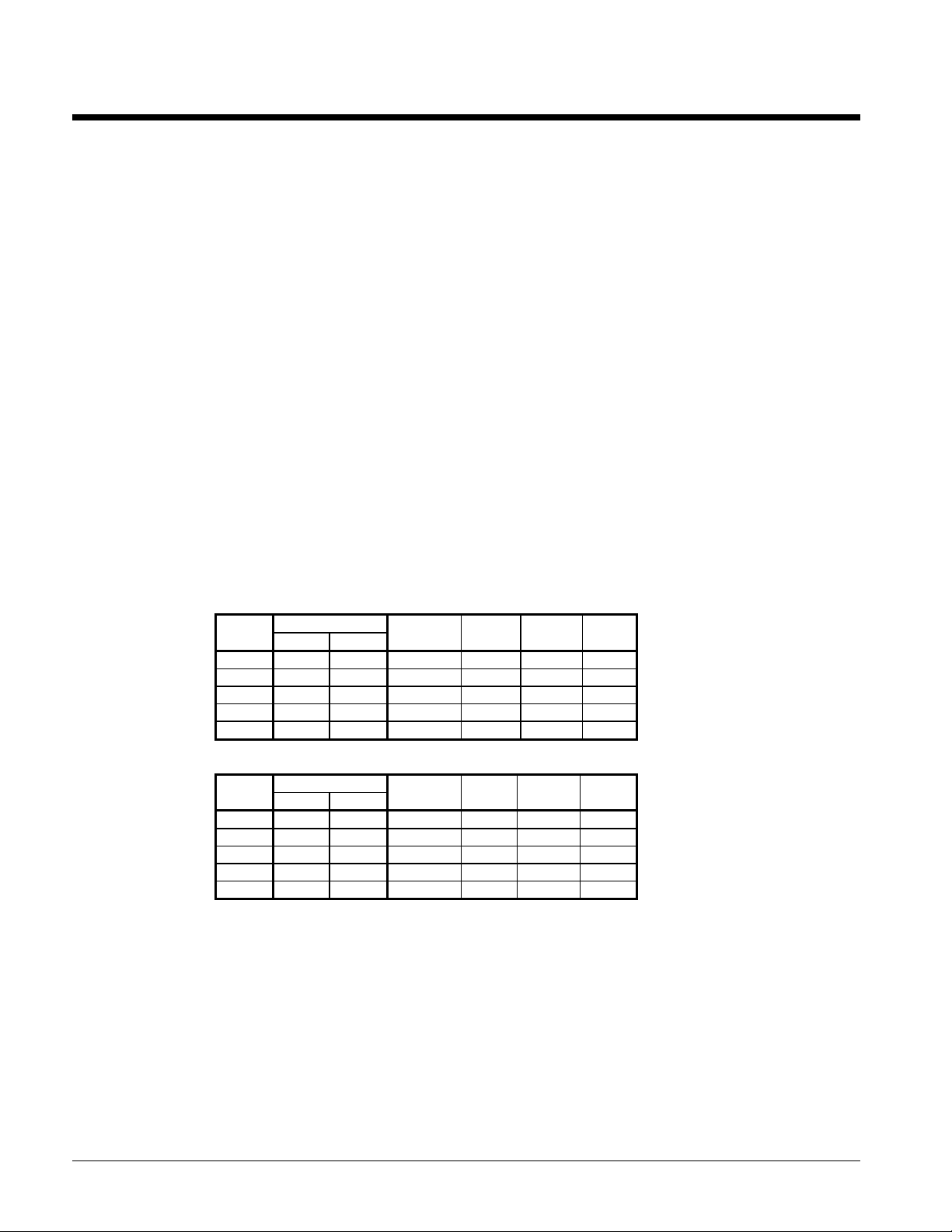

Table 1, Ethylene Glycol

Freeze Point%

E.G.

10 26 -3 0.991 0.996 1.013 1.070

20 18 -8 0.982 0.992 1.040 1.129

30 7 -14 0.972 0.986 1.074 1.181

40 -7 -22 0.961 0.976 1.121 1.263

50 -28 -33 0.946 0.966 1.178 1.308

Table 2, Propylene Glycol

P.G.

10 26 -3 0.987 0.992 1.010 1.068

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

40 -5 -21 0.946 0.971 1.078 1.366

50 -27 -33 0.929 0.965 1.116 1.481

Units operating with glycol solutions are not included in the ARI

Certification Program.

°F °C

Freeze Point%

°F °C

Capacity Power Flow PD

Capacity Power Flow PD

Fouling factor

Performance tables are based on a fouling factor of 0.0001 ft2 x hr x °F/Btu (0.0176 m2 x °C/kW) per

ARI Standard 550/590-98. As fouling is increased, performance decreases. Refer to Table 3 for

performance at other than 0.0001 (.0176) fouling factor.

Foreign matter in the chilled water system will adversely affect the heat transfer capability of the

evaporator, and could increase the pressure drop and reduce the water flow. To ensure optimum unit

operation, proper water treatment must be maintained.

10 ALR 110F – 150F Product Manual ALR2-3

Page 11

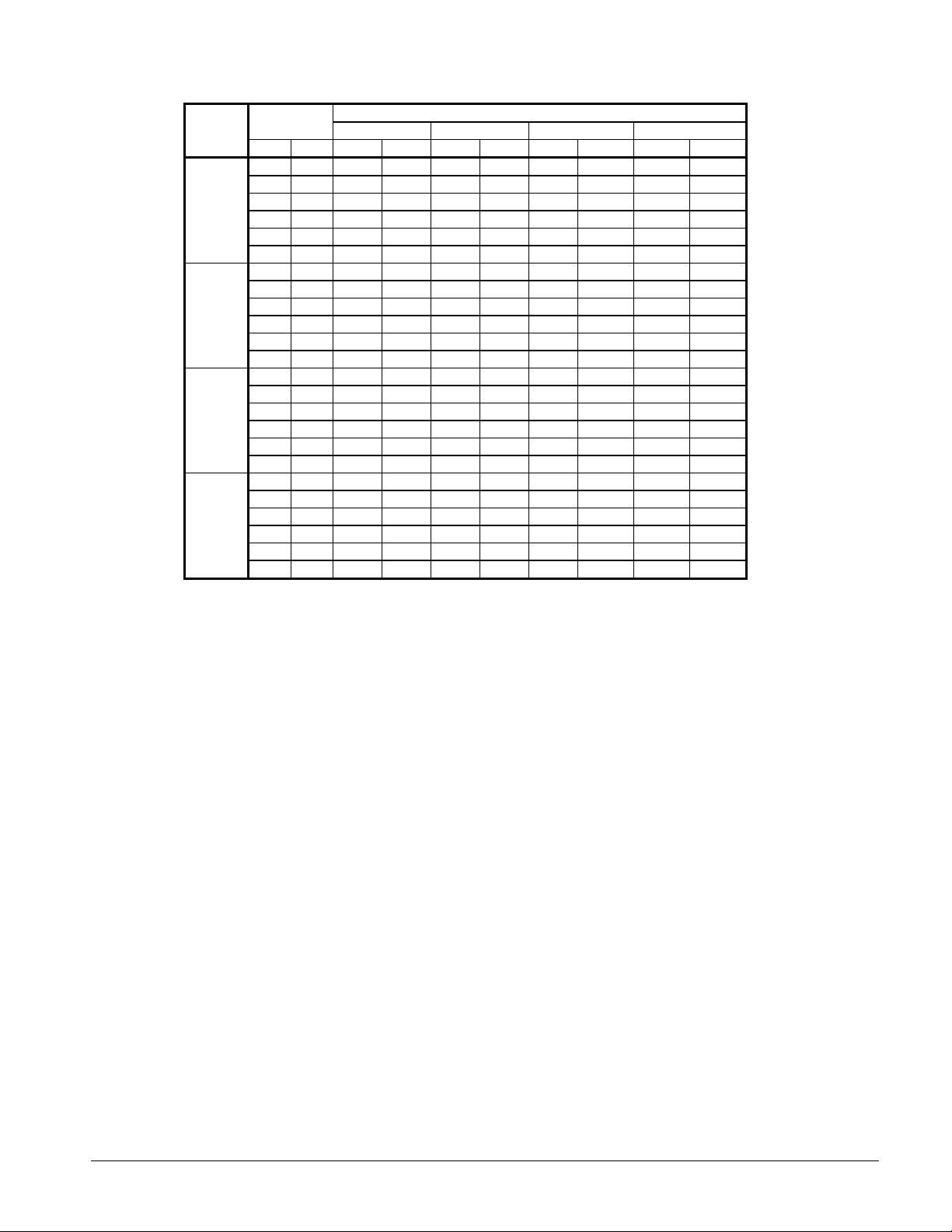

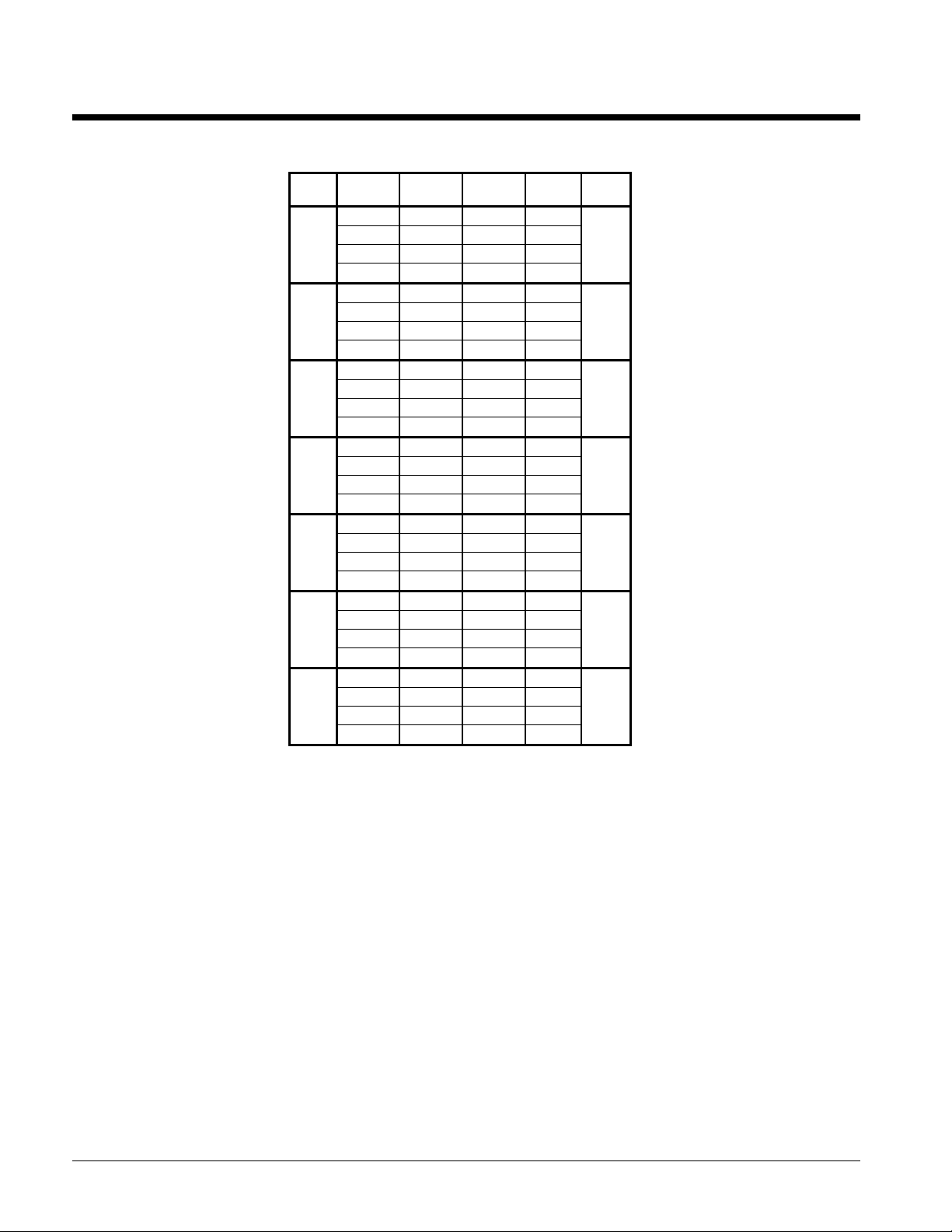

Table 3, Capacity and Power Derates

Chilled Water

SEA

LEVEL

2000 feet

(610 m)

4000 feet

(1220 m)

6000 feet

(1830 m)

Delta-T

°F °C Cap. Power Cap. Power Cap. Power Cap. Power

6 3.3 0.992 0.995 0.985 0.993 0.962 0.986 0.919 0.972

8 4.4 0.995 0.997 0.988 0.995 0.965 0.988 0.922 0.974

10 5.6 1.000 1.000 0.993 0.998 0.970 0.991 0.927 0.977

12 6.7 1.005 1.002 0.998 1.000 0.975 0.993 0.932 0.979

14 6.8 1.010 1.005 1.003 1.003 0.980 0.996 0.936 0.982

16 8.9 1.014 1.007 1.007 1.005 0.984 0.998 0.940 0.984

6 3.3 0.978 1.005 0.971 1.003 0.949 0.996 0.906 0.982

8 4.4 0.982 1.007 0.975 1.005 0.953 0.998 0.910 0.984

10 5.6 0.986 1.009 0.979 1.007 0.956 1.000 0.914 0.986

12 6.7 0.992 1.011 0.985 1.009 0.962 1.002 0.919 0.988

14 6.8 0.997 1.014 0.990 1.012 0.967 1.005 0.924 0.991

16 8.9 1.000 1.016 0.993 1.014 0.970 1.007 0.927 0.993

6 3.3 0.966 1.016 0.959 1.014 0.937 1.007 0.895 0.993

8 4.4 0.969 1.018 0.962 1.016 0.940 1.009 0.898 0.995

10 5.6 0.973 1.021 0.966 1.019 0.944 1.012 0.902 0.998

12 6.7 0.978 1.025 0.971 1.023 0.949 1.016 0.906 1.002

14 6.8 0.982 1.027 0.975 1.025 0.953 1.018 0.910 1.004

16 8.9 0.986 1.028 0.979 1.026 0.956 1.019 0.914 1.005

6 3.3 0.953 1.025 0.946 1.023 0.924 1.016 0.883 1.002

8 4.4 0.955 1.028 0.948 1.026 0.926 1.019 0.885 1.005

10 5.6 0.959 1.031 0.952 1.029 0.930 1.022 0.889 1.008

12 6.7 0.963 1.034 0.956 1.032 0.934 1.024 0.893 1.011

14 6.8 0.968 1.036 0.961 1.034 0.939 1.026 0.897 1.013

16 8.9 0.972 1.037 0.965 1.035 0.943 1.027 0.901 1.014

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)ALTITUDE

NOTE: Contact McQuay sales office for applications above 6,000 feet.

Fouling Factor

Product Manual ALR2-3 ALR 110F – 150F 11

Page 12

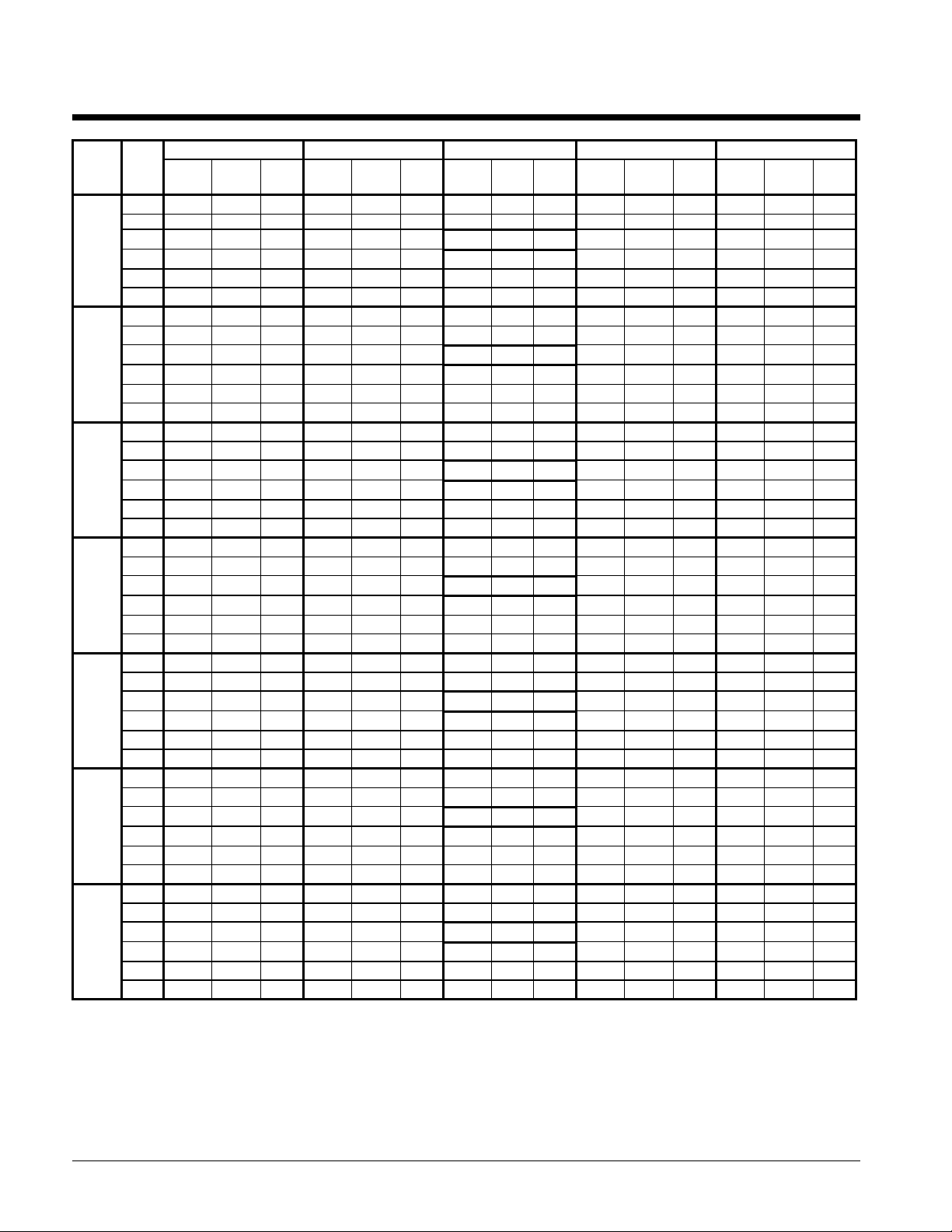

Performance Data

Table 4, ALR 110F - 150F, R-22, I-P Units

ALR

LWT

SIZE

110F

120F

130F

135F

140F

145F

150F

NOTES:

1. Bold box areas certified in accordance with ARI Standard 550/590-98.

2. Ratings based on HCFC-22, evaporator fouling of 0.0001, evaporator temperature drop of 10°F and sea level altitude.

3. For 208V units multiply capacity and EER by 0.98. For units with SpeedTrol option multiply capacity and EER by 0.99.

4. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the cataloged ratings.

5. kWi input is for compressors only. EER is for the entire unit, including compressors, fan motors and control power.

6. For LWT of 40°F and below please refer to application considerations for reciprocating chillers located in this manual.

(°F)

40.0 115.8 99.7 12.1 109.6 108.3 10.8 103.4 116.7 9.4 96.8 125.1 8.4 90.9 133.5 7.3

42.0 118.9 101.0 12.4 113.3 110.0 10.9 106.9 118.6 9.6 100.3 127.4 8.5 94.0 136.1 7.5

44.0 123.4 102.4 12.6 116.9 111.6 11.1

46.0 127.5 103.7 12.9 120.8 113.2 11.3 114.5 122.5 10.0 107.2 131.8 8.8 100.3 141.2 7.7

48.0 130.8 104.9 13.2 123.9 114.8 11.6 117.5 124.4 10.1 110.0 133.9 8.9 103.0 143.8 7.9

50.0 136.0 106.2 13.5 129.1 116.5 11.8 122.0 126.2 10.4 114.7 136.2 9.1 107.5 146.4 8.0

40.0 127.7 106.9 11.8 120.9 116.1 10.5 114.1 125.1 9.2 106.7 134.1 8.2 100.2 143.1 7.2

42.0 131.2 108.3 12.1 124.9 117.9 10.7 117.8 127.2 9.4 110.6 136.6 8.3 103.7 145.9 7.3

44.0 136.1 109.7 12.3 129.0 119.7 10.9

46.0 140.6 111.1 12.6 133.2 121.3 11.1 126.3 131.3 9.8 118.2 141.3 8.6 110.6 151.3 7.6

48.0 144.2 112.4 12.9 136.7 123.0 11.3 129.6 133.4 9.9 121.3 143.6 8.7 113.6 154.2 7.7

50.0 150.0 113.9 13.2 142.4 124.8 11.6 134.6 135.3 10.1 126.5 146.0 8.9 118.6 156.9 7.8

40.0 135.4 117.1 12.2 128.2 127.2 10.8 120.9 137.1 9.5 113.1 147.0 8.4 106.3 156.8 7.4

42.0 139.1 118.7 12.4 132.5 129.1 11.0 124.9 139.3 9.6 117.3 149.7 8.5 109.9 159.9 7.5

44.0 144.2 120.2 12.5 136.7 131.1 11.0

46.0 149.0 121.8 12.8 141.3 133.0 11.2 133.9 143.9 9.9 125.3 154.8 8.7 117.3 165.8 7.6

48.0 152.9 123.2 13.0 144.9 134.8 11.4 137.4 146.1 10.0 128.6 157.3 8.8 120.4 168.9 7.8

50.0 159.0 124.7 13.3 151.0 136.8 11.7 142.7 148.3 10.2 134.1 160.0 9.0 125.7 171.9 7.9

40.0 139.7 123.8 11.8 132.2 134.4 10.5 124.7 144.9 9.2 116.7 155.4 8.2 109.6 165.7 7.2

42.0 143.5 125.4 12.1 136.6 136.5 10.7 128.9 147.3 9.4 121.0 158.2 8.3 113.4 169.0 7.3

44.0 148.8 127.1 12.3 141.1 138.6 10.8

46.0 153.8 128.7 12.6 145.7 140.6 11.1 138.1 152.1 9.8 129.3 163.6 8.6 121.0 175.3 7.6

48.0 157.8 130.2 12.9 149.5 142.5 11.3 141.7 154.5 9.9 132.6 166.3 8.7 124.2 178.6 7.7

50.0 164.0 131.9 13.2 155.8 144.6 11.5 147.2 156.7 10.1 138.4 169.2 8.9 129.7 181.7 7.8

40.0 145.9 129.9 11.6 138.1 141.1 10.3 130.3 152.1 9.0 121.9 163.1 8.0 114.5 173.9 7.0

42.0 149.9 131.7 11.8 142.7 143.3 10.5 134.6 154.6 9.2 126.4 166.1 8.1 118.4 177.4 7.1

44.0 155.4 133.4 12.3 147.3 145.5 10.8

46.0 160.6 135.1 12.6 152.2 147.5 11.1 144.3 159.6 9.8 135.1 171.7 8.6 126.4 184.0 7.6

48.0 164.8 136.7 12.9 156.1 149.6 11.3 148.0 162.1 9.9 138.5 174.5 8.7 129.7 187.4 7.7

50.0 171.4 138.4 13.2 162.7 151.8 11.5 153.8 164.5 10.1 144.6 177.5 8.9 135.5 190.7 7.8

40.0 149.7 132.5 11.9 141.6 143.9 10.6 133.6 155.1 9.3 125.0 166.3 8.2 117.4 177.3 7.2

42.0 153.7 134.2 12.2 146.4 146.1 10.7 138.1 157.6 9.4 129.6 169.3 8.4 121.4 180.9 7.3

44.0 159.4 136.0 12.4 151.1 148.3 10.9

46.0 164.7 137.8 12.7 156.1 150.4 11.1 147.9 162.8 9.8 138.5 175.1 8.6 129.6 187.6 7.6

48.0 169.0 139.4 13.0 160.1 152.5 11.4 151.8 165.3 9.9 142.1 178.0 8.8 133.0 191.1 7.7

50.0 175.7 141.1 13.2 166.8 154.7 11.6 157.7 167.7 10.2 148.2 181.0 8.9 138.9 194.5 7.9

40.0 156.2 138.7 11.9 147.8 150.6 10.6 139.5 162.3 9.3 130.5 174.0 8.2 122.6 185.6 7.2

42.0 160.4 140.5 12.2 152.8 152.9 10.7 144.1 165.0 9.4 135.3 177.2 8.4 126.8 189.3 7.3

44.0 166.4 142.3 12.4 157.7 155.3 10.9

46.0 171.9 144.2 12.7 162.9 157.4 11.1 154.4 170.3 9.8 144.5 183.2 8.6 135.3 196.3 7.6

48.0 176.4 145.9 13.0 167.1 159.6 11.4 158.4 173.0 9.9 148.3 186.3 8.8 138.9 200.0 7.7

50.0 183.4 147.7 13.2 174.1 162.0 11.6 164.6 175.5 10.2 154.7 189.5 8.9 145.0 203.5 7.9

Capac.

Tons

75.0°F 85.0°F 95.0°F 105.0°F 115.0°F

PWR

kWi

EER

Capac.

Tons

PWR

kWi

Capac.

EER

Tons

110.9 120.6 9.8

122.2 129.2 9.6

129.6 141.6 9.7

133.7 149.7 9.6

139.7 157.1 9.6

143.2 160.2 9.6

149.5 167.7 9.6

PWR

kWi

Capac.

EER

Tons

103.8 129.6 8.5 97.1 138.6 7.6

114.4 138.9 8.3 107.1 148.6 7.4

121.3 152.2 8.4 113.5 162.8 7.5

125.1 160.9 8.3 117.1 172.2 7.4

130.7 168.9 8.3 122.3 180.7 7.4

134.1 172.2 8.4 125.5 184.2 7.5

139.9 180.2 8.4 130.9 192.8 7.5

PWR

kWi

EER

Capac.

Tons

PWR

kWi

EER

12 ALR 110F – 150F Product Manual ALR2-3

Page 13

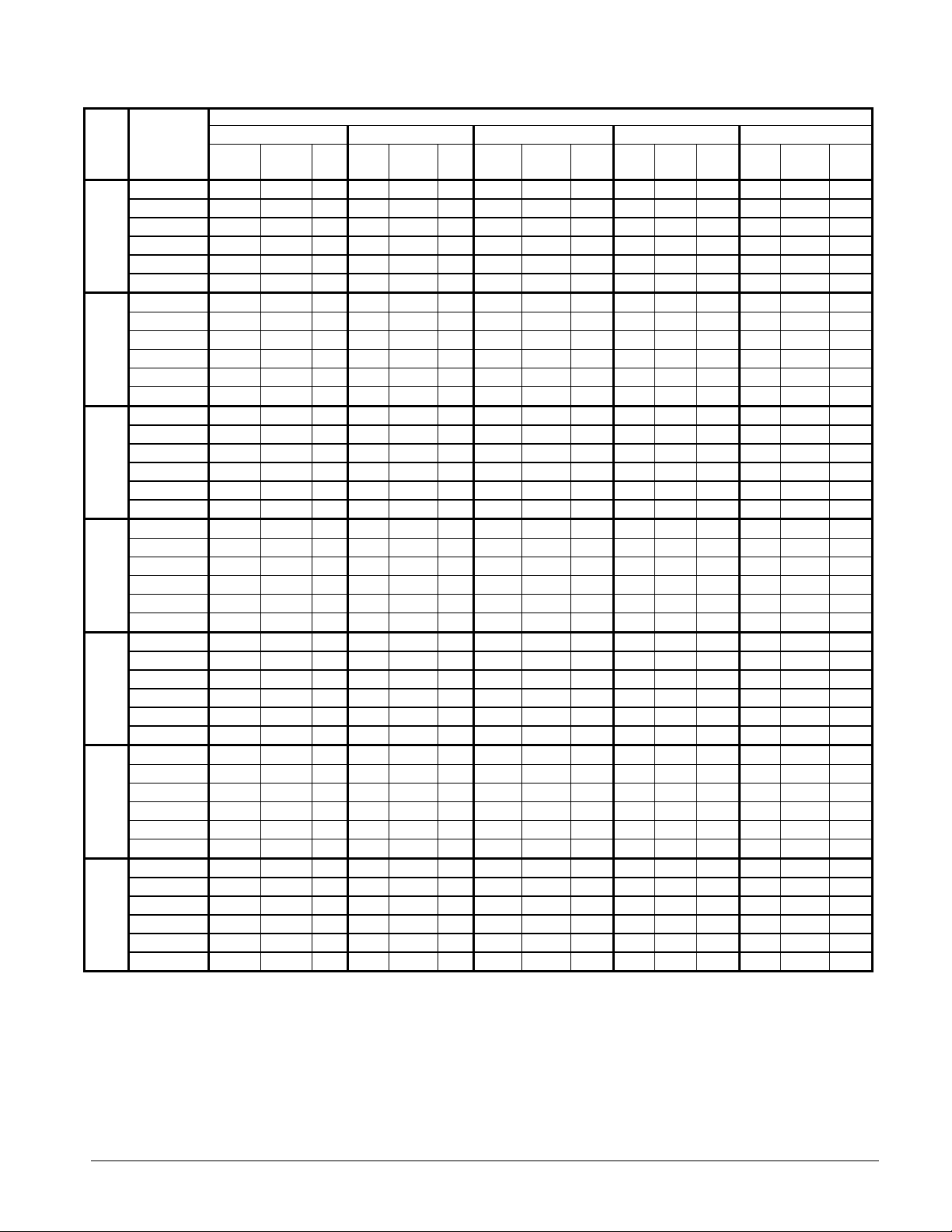

Table 5, ALR 110F - 150F, R-22, SI Units

AMBIENT AIR TEMPERATURE

ALR

SIZE

110F

120F

130F

135F

140F

145F

150F

NOTES:

1. Ratings based on HCFC-22, evaporator fouling of 0.0176, evaporator temperature drop of 5.6°C and sea level altitude.

2. For 208V units multiply capacity and COP by 0.98.

3. For units with SpeedTrol option multiply capacity and COP by 0.99.

4. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the cataloged ratings.

5. kWi input is for compressors only. COP is for the entire unit, including compressors, fan motors and control power.

6. For LWT of 5°C and below please refer to application considerations for reciprocating chillers.

LWT

(°C)

5.0 (41.0°F) 412.8 100.4 3.6 392.0 109.1 3.2 369.8 117.7 2.8 346.6 126.3 2.5 325.1 134.8 2.2

6.0 (42.8°F) 424.5 101.6 3.7 403.6 110.6 3.2 381.4 119.4 2.8 357.6 128.3 2.5 335.0 137.1 2.2

7.0 (44.6°F) 438.2 102.8 3.7 415.4 112.1 3.3 393.7 121.1 2.9 368.5 130.3 2.5 344.9 139.4 2.2

8.0 (46.4°F) 450.7 103.9 3.8 427.1 113.5 3.3 404.8 122.9 2.9 378.9 132.2 2.6 354.7 141.7 2.3

9.0 (48.2°F) 461.9 105.0 3.9 437.7 114.9 3.4 414.8 124.6 3.0 388.4 134.2 2.6 363.8 144.1 2.3

10.0 (50.0°F) 478.3 106.2 3.9 454.2 116.5 3.5 429.2 126.2 3.0 403.5 136.2 2.7 378.2 146.4 2.3

5.0 (41.0°F) 455.3 107.6 3.5 432.3 117.0 3.1 407.8 126.1 2.7 382.2 135.4 2.4 358.5 144.5 2.1

6.0 (42.8°F) 468.2 108.9 3.6 445.0 118.6 3.2 420.6 128.0 2.8 394.4 137.5 2.4 369.4 147.0 2.2

7.0 (44.6°F) 483.3 110.1 3.6 458.1 120.2 3.2 434.2 129.9 2.8 406.4 139.6 2.5 380.3 149.4 2.2

8.0 (46.4°F) 497.0 111.4 3.7 471.0 121.7 3.3 446.4 131.7 2.9 417.9 141.7 2.5 391.1 151.9 2.2

9.0 (48.2°F) 509.3 112.6 3.8 482.7 123.2 3.3 457.5 133.6 2.9 428.3 143.8 2.6 401.1 154.4 2.3

10.0 (50.0°F) 527.5 113.9 3.9 500.8 124.8 3.4 473.3 135.3 3.0 445.0 146.0 2.6 417.0 156.9 2.3

5.0 (41.0°F) 482.7 117.9 3.6 458.3 128.1 3.2 432.3 138.2 2.8 405.2 148.3 2.5 380.1 158.3 2.2

6.0 (42.8°F) 496.3 119.3 3.6 471.8 129.9 3.2 445.9 140.2 2.8 418.1 150.7 2.5 391.6 161.1 2.2

7.0 (44.6°F) 512.3 120.7 3.7 485.6 131.7 3.2 460.3 142.3 2.9 430.8 153.0 2.5 403.2 163.7 2.2

8.0 (46.4°F) 526.9 122.1 3.8 499.3 133.3 3.3 473.3 144.3 2.9 443.0 155.3 2.6 414.7 166.4 2.2

9.0 (48.2°F) 540.0 123.3 3.8 511.7 135.0 3.4 485.0 146.3 2.9 454.1 157.6 2.6 425.3 169.2 2.3

10.0 (50.0°F) 559.2 124.7 3.9 531.0 136.8 3.4 501.8 148.3 3.0 471.7 160.0 2.6 442.1 171.9 2.3

5.0 (41.0°F) 497.9 124.6 3.5 472.8 135.5 3.1 446.0 146.1 2.7 418.0 156.8 2.4 392.1 167.4 2.1

6.0 (42.8°F) 512.0 126.1 3.6 486.7 137.4 3.2 460.0 148.3 2.8 431.4 159.3 2.4 404.0 170.3 2.2

7.0 (44.6°F) 528.5 127.6 3.6 501.0 139.2 3.2 474.9 150.4 2.8 444.5 161.7 2.5 416.0 173.1 2.2

8.0 (46.4°F) 543.5 129.0 3.7 515.1 141.0 3.3 488.3 152.6 2.9 457.0 164.2 2.5 427.8 176.0 2.2

9.0 (48.2°F) 557.0 130.4 3.8 527.9 142.7 3.3 500.3 154.7 2.9 468.5 166.6 2.6 438.7 178.9 2.3

10.0 (50.0°F) 576.9 131.9 3.9 547.8 144.6 3.4 517.7 156.7 3.0 486.7 169.2 2.6 456.1 181.7 2.3

5.0 (41.0°F) 520.1 130.8 3.4 493.9 142.2 3.0 465.9 153.3 2.7 436.7 164.6 2.4 409.6 175.6 2.1

6.0 (42.8°F) 534.9 132.3 3.5 508.5 144.2 3.1 480.6 155.6 2.7 450.6 167.2 2.4 422.0 178.7 2.1

7.0 (44.6°F) 552.1 133.9 3.6 523.3 146.1 3.2 496.0 157.9 2.8 464.3 169.7 2.5 434.5 181.7 2.2

8.0 (46.4°F) 567.8 135.4 3.7 538.1 147.9 3.3 510.0 160.1 2.9 477.4 172.3 2.5 446.9 184.7 2.2

9.0 (48.2°F) 581.9 136.9 3.8 551.4 149.8 3.3 522.7 162.4 2.9 489.4 174.8 2.6 458.3 187.8 2.3

10.0 (50.0°F) 602.7 138.4 3.9 572.2 151.8 3.4 540.8 164.5 3.0 508.4 177.5 2.6 476.4 190.7 2.3

5.0 (41.0°F) 533.4 133.4 3.5 506.4 145.0 3.1 477.7 156.4 2.7 447.8 167.8 2.4 420.1 179.1 2.1

6.0 (42.8°F) 548.5 134.9 3.6 521.4 147.0 3.2 492.8 158.7 2.8 462.1 170.5 2.4 432.8 182.2 2.2

7.0 (44.6°F) 566.2 136.5 3.7 536.7 149.0 3.2 508.7 161.0 2.8 476.1 173.1 2.5 445.6 185.2 2.2

8.0 (46.4°F) 582.2 138.1 3.7 551.8 150.8 3.3 523.0 163.3 2.9 489.6 175.7 2.5 458.2 188.3 2.2

9.0 (48.2°F) 596.7 139.5 3.8 565.5 152.7 3.3 536.0 165.6 2.9 501.8 178.3 2.6 470.0 191.4 2.3

10.0 (50.0°F) 618.0 141.1 3.9 586.8 154.7 3.4 554.5 167.7 3.0 521.3 181.0 2.6 488.6 194.5 2.3

5.0 (41.0°F) 556.7 139.6 3.5 528.6 151.7 3.1 498.6 163.6 2.7 467.3 175.6 2.4 438.4 187.4 2.1

6.0 (42.8°F) 572.5 141.2 3.6 544.2 153.8 3.2 514.3 166.0 2.8 482.3 178.4 2.4 451.7 190.7 2.2

7.0 (44.6°F) 590.9 142.9 3.7 560.1 155.9 3.2 530.9 168.5 2.8 496.9 181.1 2.5 465.1 193.9 2.2

8.0 (46.4°F) 607.7 144.5 3.7 575.9 157.9 3.3 545.9 170.9 2.9 511.0 183.9 2.5 478.3 197.1 2.2

9.0 (48.2°F) 622.8 146.0 3.8 590.2 159.8 3.3 559.4 173.3 2.9 523.7 186.6 2.6 490.5 200.4 2.3

10.0 (50.0°F) 645.0 147.7 3.9 612.4 162.0 3.4 578.8 175.5 3.0 544.1 189.5 2.6 509.9 203.5 2.3

25°C (77°F) 30°C (86°F) 35°C (95°F) 40°C (104°F) 45°C (113°F)

Capac.kWPWR

kWi

COP

Capac.kWPWR

kWi

COP

Capac.kWPWR

kWi

COP

Capac.kWPWR

kWi

COP

Capac.kWPWR

kWi

COP

Product Manual ALR2-3 ALR 110F – 150F 13

Page 14

Part Load Data

Table 6, Part Load Data R-22,

Unit

% Load

Size

100.00 110.9 135.6 9.8

110F 75.00 83.5 79.9 12.5 14.0

50.00 55.6 44.9 14.9

25.00 27.9 21.1 15.9

100.00 122.2 152.8 9.6

120F 75.00 92.4 89.9 12.3 14.0

50.00 61.6 48.7 15.2

25.00 30.8 24.1 15.3

100.00 129.6 161.0 9.7

130F 75.00 97.2 95.9 12.2 13.6

50.00 64.8 54.0 14.4

25.00 32.4 24.8 15.7

100.00 133.7 168.0 9.6

135F 75.00 100.3 100.3 12.0 13.4

50.00 66.8 55.3 14.5

25.00 33.4 28.2 14.2

100.00 139.7 174.8 9.6

140F 75.00 104.7 102.5 12.3 13.7

50.00 69.8 56.9 14.7

25.00 34.9 27.0 15.5

100.00 143.2 178.2 9.6

145F 75.00 107.5 104.4 12.4 13.5

50.00 71.6 61.3 14.0

25.00 35.9 27.7 15.5

100.00 149.5 186.0 9.6

150F 75.00 112.1 109.4 12.3 13.4

50.00 74.7 64.4 13.9

25.00 37.4 29.4 15.3

Capacity

Tons

Unit Power

kW

EER IPLV

14 ALR 110F – 150F Product Manual ALR2-3

Page 15

Pressure Drops

Figure 5, 110F through 150F Evaporator Pressure Drop Curve

ALR 110

ALR 145 - 150

ALR 120 - 140

Minimum/Maximum Flow Rates

ALR Unit

Size

110

120

130

135

140

145

150

Minimum Flow

gpm (l/s)

165 (10.4) 6.0 (17.9) 435 (27.4) 39.0 (116.0)

180 (11.4) 4.3 (12.8) 480 (30.3) 30.5 (90.0)

195 (12.3) 5.1 (15.2) 520 (32.8) 37.5 (111.8)

200 (12.6) 5.3 (15.8) 535 (33.8) 40.0 (119.2)

205 (13.0) 5.8 (17.3) 550 (34.7) 42.0 (125.2)

215 (13.6) 4.3 (12.8) 570 (36.0) 29.5 (87.9)

220 (13.9) 4.5 (13.4) 590 (37.2) 31.0 (92.4)

Pressure Drop

ft. (kPa)

Maximum Flow

gpm (l/s)

Pressure Drop

ft. (kPa)

Product Manual ALR2-3 ALR 110F – 150F 15

Page 16

Sound Data

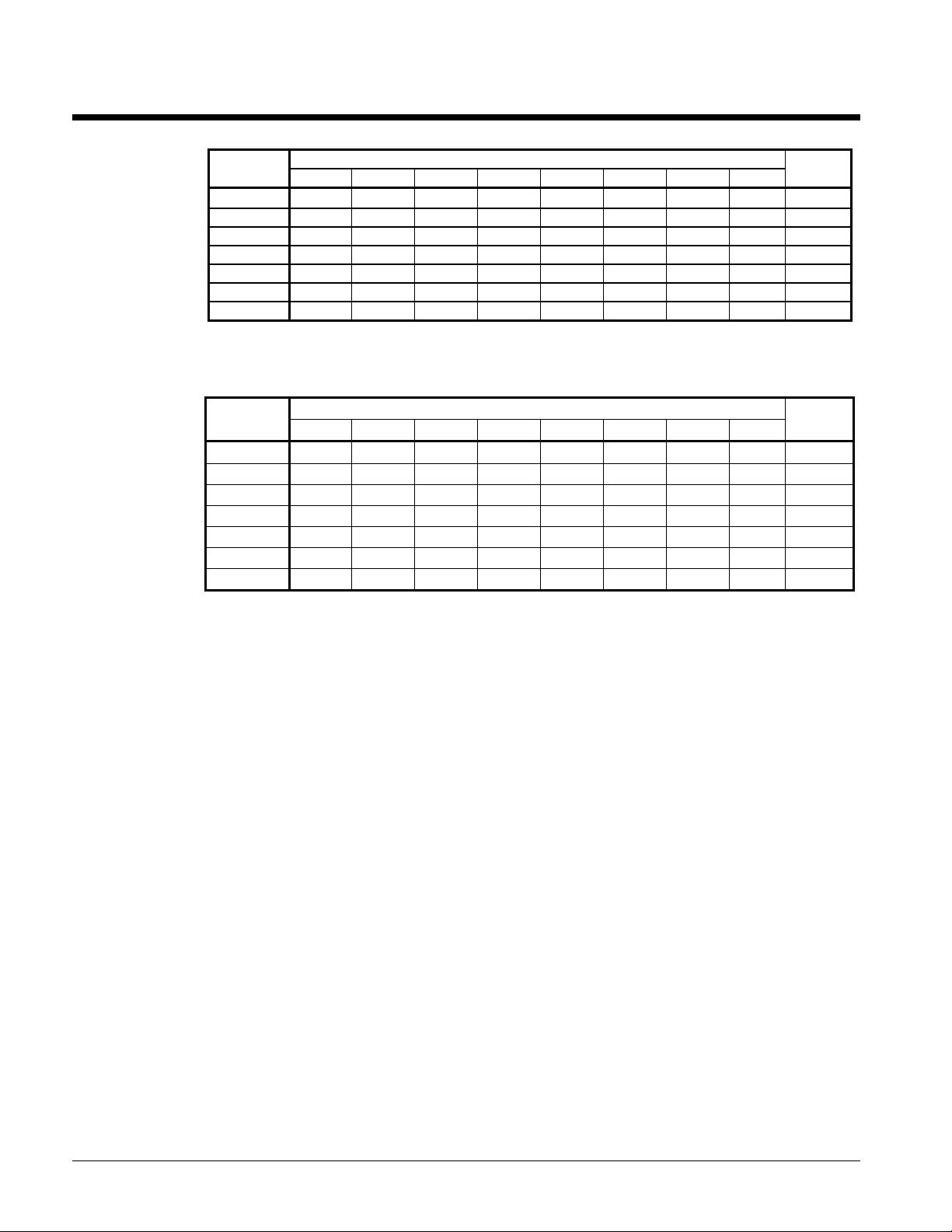

Table 7, ALR 110F - 150F, Sound Pressure

ALR

Unit Size

110 65 68 69 66 62 60 57 53 68.5

120

130

135

140

145

150

NOTES

1. Based on Uniform Spherical Radiation, Q=1

2. Sound pressure at 30 feet from unit.

63 hz 125 hz 250 hz 500 hz 1000 hz 2000 hz 4000 hz 8000 hz

65 68 69 66 62 60 57 53 68.5

66 69 70 67 63 61 58 54 69.5

66 69 70 67 63 61 58 54 69.5

67 70 71 68 63 61 59 54 70.0

67 70 71 68 63 61 59 54 70.0

68 71 72 69 64 62 59 55 71.0

Octave Band Sound Pressure Levels Per ARI Standard 370 (dB)

Table 8, ALR 110F - 150F, Sound Power

ALR

Unit Size

110 95 98 99 96 92 90 87 83 98.5

120

130

135

140

145

150

Per ARI 370 - Sound Rating of Large Outdoor Refrigerating and Air-Conditioning Equipment

63 hz 125 hz 250 hz 500 hz 1000 hz 2000 hz 4000 hz 8000 hz

95 98 99 96 92 90 87 83 98.5

96 99 100 97 93 91 89 84 99.5

96 99 100 97 93 91 89 84 99.5

97 100 101 98 93 91 89 84 100.0

97 100 101 98 93 91 89 84 100.0

98 101 102 99 94 92 89 85 101.0

Octave Band Sound Power Levels Per ARI Standard 370 (dB)

Overall "A"

Weighted

Overall "A"

Weighted

Sound levels can be as important as unit cost and efficiency, and must be addressed before the start

of any development program. Efforts by McQuay Design Engineers to design chillers that are

sensitive to the sound requirements of the market have paid off.

Background Information

Sound is a vibration in an elastic medium and is essentially a pressure and particle displacement

phenomena. A vibrating body produces compression waves and as the waves are emitted from the

vibrating body, molecules are ultimately compressed. These waves are transmitted through gases,

liquids, or solids-anything that is elastic or viscous.

The sound data provided in this section is presented with both sound pressure (Q=1 and 30 feet from

unit) and sound power levels. Sound power is the total sound energy radiated by a source per unit of

time integrated over the surface through which the sound is radiated. Sound power is a calculated

quantity and cannot be measured directly like sound pressure. Sound power is not dependent on the

surrounding environment or distance from the source, as is sound pressure.

Sound pressure varies with the distance from the source and is dependent on its surroundings. For

example, a brick wall located 10 feet from a unit will affect the sound pressure measurements differently

than a brick wall at 20 feet. Sound pressure is measured in decibels (dB), which is a dimensionless

ratio (on a logarithmic scale) between measured sound pressure and a reference sound pressure level.

Sound Pressure Levels - Full Load

Sound pressure tables give the overall "A" weighted sound pressure levels which are considered

typical of what may be measured in a free field with a hand held sound meter, in the absence of any

nearby reflective surfaces. The sound pressure levels (Table 7) are measured at 30 feet from the side

of the unit at 100% unit load, no reflecting walls Q=1, and ARI conditions, 95°F (35°C) ambient air

temperature and 54/44°F (12/7°C) evaporator water temperatures for air-cooled units.

16 ALR 110F – 150F Product Manual ALR2-3

Page 17

Sound Power Levels

Acoustical consultants may require sound power octave band data to perform a detailed acoustical

analysis. The previous tables present sound power levels per ARI Standard 370 “Sound Rating of

Large Outdoor Refrigerating and Air Conditioning Equipment”. These standards were developed to

establish uniform methods of determining the sound power radiated by large outdoor and indoor

equipment. The aforementioned methods are based on providing sound power levels by octave band

and the overall ‘A’ weighted value. Sound pressure measurements are taken over a prescribed area

around the unit and the data is mathematically calculated to give the sound power, dB.

Sound Reduction due to Distance from the Unit

The distance between a source of sound and the location of the sound measurement plays an

important role in minimizing sound problems. The equation below can be used to calculate the sound

pressure level at any distance if the sound power is known.

Lp=Lw-(20 log r) + (10 log Q) - .5

Lp = sound pressure

Lw = sound power

r = distance from unit in feet

Q = directionality factor

The directionality factor, "Q", is a dimensionless number that compensates for the type of sound

reflection from the source. For example, a unit sitting on a flat roof or ground with no other reflective

surfaces or attenuation due to grass, snow, etc., between source and receiver: Q=1.

Figure 6, "Q" Definition, Plan View, Unit Located in Center

Uniform Spherical Radiation

Q=1 no reflecting surface

Uniform Hemispherical Radiation

Q=2 single reflecting surface

Uniform Radiation over ¼ of sphere

Q=4 two reflecting surfaces

With Q=1, no reflecting walls, the equation simplifies to: Lp = Lw - (20)(log r) –0.5

With Q=2, for a unit sitting on a flat roof or ground with one wall as a reflective surface the equation

simplifies to: Lp = Lw - (20)(log r) + 2.5

The equations are reduced to table form in Table 9 for various distances and the three most usual

cases of "Q" type of location.

Table 9, dB Conversion of Sound Power to Pressure for Distance

Distance From Sound Source

ft (m)

30 (9) 30.0 27.1 24.0

50 (15) 34.5 31.6 28.5

75 (23) 38.0 35.1 32.0

100 (30) 40.5 37.6 34.5

150 (46) 44.0 41.1 38.0

200 (61) 46.5 43.6 40.5

300 (91) 50.0 47.6 44.0

dB Reduction from Sound Power at the Source

to Sound Pressure at Referenced Distance

Q=1 Q=2 Q=4

Product Manual ALR2-3 ALR 110F – 150F 17

Page 18

Figure 7, Sound Pressure Attenuation Due to Distance from Unit

(Plus or Minus from Table 7)

Air-Cooled Unit Orientation to Minimize Sound

The ALR chiller’s sound is directional in nature allowing the contractor/engineer to position the unit

to minimize potential noise problems. Because the sound pressure levels are lower at both ends of the

unit than at the sides, the chiller should be oriented such that the control box end or end opposite the

control box faces the direction where the lowest sound level is required.

The control box end provides an excellent acoustic barrier to the compressor sound as it covers one

full end of the unit. The sound pressure levels at the control box end will be 5 dBA less than on the

sides. On the end opposite the control box, the compressor sound is blocked by the coil structure,

evaporator and naturally attenuated by distance as the compressors are located approximately ¾ the

length of the unit away from this end. The sound pressure levels at the end opposite the control box

will be 4 dBA less than on the sides.

Figure 8, Sound Directionality

Sound pressure levels per Table 7

C

Compressor

Sound pressure levels

here 5 dBA lower

than Table 7

o

n

t

r

o

l

Evaporator

Compressor

Sound pressure levels per Table 7

Sound pressure levels

here 4 dBA lower

than Table 7

Sound Pressure Levels, Low Ambient Operation

Air-cooled unit operation below 95°F (35°C) will also result in lower sound pressure levels. The sound

pressure level will decrease 3 dB proportionally from 95°F to 65°F. For example, at 95°F the sound

pressure is per Error! Reference source not found., at 85°F one dB can be subtracted, at 75°F two dB

can be subtracted, and so on for any temperature between 65°F and 95°F.

18 ALR 110F – 150F Product Manual ALR2-3

Page 19

Sound Pressure Levels, Multiple Units

Multiple air-cooled unit installations will have a higher sound level than a single unit on a

doubling basis. Two units will have approximately 3 dB higher sound level of one unit, 4 units

will be approximately 6 dB louder, and 8 units approximately 9 dB louder than one unit.

Sound Control

Walls adjacent to a unit

(20 feet {6.1 meters} or

less) will reflect sound

outwards, increasing the

sound pressure on the

side away from the wall.

This sound increase could

be as high as 3 dB for one

wall and as high as 6 dB

for a corner location. Unit

orientation and/or

distance as noted above

will decrease sound levels.

Sound levels can also be controlled by the installation of barrier walls. To be effective as sound

blockers, walls must be solid with no open penetrations. Sound tends to leak out of openings.

Block walls with filler material and slots on the side facing the unit are especially effective. The

wall should be about 10 feet high (two feet higher than the unit) and located at least 10 feet away

so as not to affect unit performance. A three-sided enclosure will be the most effective solution

and will reduce sound levels by about 10 dB. Remember that the wall will increase the sound

level on the side opposite it by 3 to 6 dB (one or three sided wall). Note: The effect of adjacent

walls on air recirculation and restriction must always be considered when employing sound

barrier walls.

Product Manual ALR2-3 ALR 110F – 150F 19

Page 20

Electrical Data

Table 10, ALR 110F - 150F, Electrical Data, Single Point

ALR

Unit

Size

110F

120F

130F

135F

140F

145F

150F

NOTES

1. A "HACR" breaker is a circuit breaker designed for use on equipment with multiple motors. It stands for Heating, Air Conditioning, Refrigeration.

2. See page 25 for other Electrical Data notes.

Volts Hz

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

60

60

60

60

60

60

60

Min. Circuit

Ampacity

(MCA)

503

492

248

188

555

526

274

200

592

554

293

210

626

590

302

224

656

622

310

236

656

622

310

236

690

666

334

261

Field Wire

Quantity Wire Gauge Quantity Size

6

6

3

3

6

6

3

3

6

6

3

3

6

6

3

3

6

6

3

3

6

6

3

3

6

6

3

3

400

350

250

3/0

500

400

300

4/0

500

500

350

4/0

400

350

350

4/0

400

400

400

250

400

400

400

250

500

500

400

300

(Conduit Connection)

Hub

1 4.00 (102) 600

1 4.00 (102) 600

1 2.50 (64) 300

1 2.00 (51) 200

1 4.00 (102) 600

1 4.00 (102) 600

1 2.50 (64) 300

1 2.00 (51) 225

1 4.00 (102) 700

1 4.00 (102) 600

1 2.50 (64) 300

1 2.00 (51) 225

2 2.50 (64) 700

2 2.50 (64) 700

1 2.50 (64) 350

1 2.00 (51) 250

2 3.00 (76) 700

2 3.00 (76) 700

1 2.50 (64) 350

1 2.50 (64) 250

2 3.00 (76) 700

2 3.00 (76) 700

1 2.50 (64) 350

1 2.50 (64) 250

2 3.00 (76) 800

2 3.00 (76) 800

1 3.00 (76) 350

1 2.50 (64) 300

Fuse or HACR Breaker Size

Recommended Maximum

600

600

300

225

600

500

300

225

700

600

350

250

700

700

350

250

700

700

350

250

700

700

350

250

800

800

400

300

20 ALR 110F – 150F Product Manual ALR2-3

Page 21

Table 11, ALR 110F - 150F, Electrical Data, Multiple Point

ALR

Unit

Size

110F

120F

130F

135F

140F

145F

150F

Notes:

1. Separate disconnects are required for each circuit.

2. See page 25 for other Electrical Data notes.

Min.

Ckt.

Volts

Amps

MCA

208 60 3 6 1 1.50 (38) 60 60

230 60 3 6 1 1.50 (38) 60 60

460 29 3 10 1 1.00 (25) 30 30

575 24 3 10 1 1.00 (25) 25 25

208 60 3 6 1 1.50 (38) 60 60

230 60 3 6 1 1.50 (38) 60 60

460 29 3 10 1 1.00 (25) 30 30

575 24 3 10 1 1.00 (25) 25 25

208 71 3 4 1 2.00 (51) 80 80

230 71 3 4 1 2.00 (51) 80 80

460 35 3 8 1 1.25 (32) 35 35

575 28 3 10 1 1.00 (25) 30 30

208 71 3 4 1 2.00 (51) 80 80

230 71 3 4 1 2.00 (51) 80 80

460 35 3 8 1 1.25 (32) 35 35

575 28 3 10 1 1.00 (25) 30 30

208 71 3 4 1 2.00 (51) 80 80

230 71 3 4 1 2.00 (51) 80 80

460 35 3 8 1 1.25 (32) 35 35

575 28 3 10 1 1.00 (25) 30 30

208 71 3 4 1 2.00 (51) 80 80

230 71 3 4 1 2.00 (51) 80 80

460 35 3 8 1 1.25 (32) 35 35

575 28 3 10 1 1.00 (25) 30 30

208 71 3 4 1 2.00 (51) 80 80

230 71 3 4 1 2.00 (51) 80 80

460 35 3 8 1 1.25 (32) 35 35

575 28 3 10 1 1.00 (25) 30 30

Power Supply

Fans and Controls

Field Wire Hub Field Wire Hub Field Wire Hub

Qty.

Wire

Size

Qty.

Hub

Size

Field

Fusing(1)

Rec.

Fuse

Size

Max.

Fuse

Size

Min.

Ckt

Amps

MCA

218

218

108

83

251

240

124

91

277

257

137

97

296

277

142

104

311

293

146

110

311

293

146

110

311

293

146

110

Power Supply

Wire

Qty.

Size

3

3

3

3

3

250

3

250

3

3

3

300

3

300

3

3

3

350

3

300

3

3

3

400

3

350

3

3

3

400

3

350

3

3

3

400

3

350

3

3

Circuit #1

Qty

4/0

4/0

2

4

1

3

1/0

3

1/0

2

1/0

2

1/0

2

1/0

2

Field

Fusing (1)

Rec.

Fuse

Hub

Size

Size

2.00

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

(51)

2.00

(51)

1.25

(32)

1.00

(25)

2.50

(64)

2.50

(64)

1.25

(32)

1.25

(32)

2.50

(64)

2.50

(64)

1.50

(38)

1.25

(32)

2.50

(64)

2.50

(64)

1.50

(38)

1.25

(32)

2.50

(64)

2.50

(64)

1.50

(38)

1.25

(32)

2.50

(64)

2.50

(64)

1.50

(38)

1.25

(32)

2.50

(64)

2.50

(64)

1.50

(38)

1.25

(32)

250 300 251

250 300 240

125 150 124

100 110 91

300 300 277

300 300 257

150 150 137

110 125 97

350 400 277

300 350 257

175 175 137

110 125 97

350 400 296

350 350 277

175 200 142

125 125 104

350 400 311

350 400 293

175 200 146

125 150 110

350 400 311

350 400 293

175 200 146

125 150 110

350 400 344

350 400 336

175 200 170

125 150 135

Max.

Fuse

Size

Min.

Ckt

Amps

MCA)

Power Supply

Circuit #2

Wire

Qty.

Size

3

250

3

250

3

1

3

3

3

300

3

300

3

1/0

3

3

3

300

3

300

3

1/0

3

3

3

350

3

300

3

1/0

3

2

3

400

3

350

3

1/0

3

2

3

400

3

350

3

1/0

3

2

3

500

3

500

3

2/0

3

1/0

Qty.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Hub

Size

2.50

(64)

2.50

(64)

1.25

(32)

1.25

(32)

2.50

(64)

2.50

(64)

1.50

(38)

1.25

(32)

2.50

(64)

2.50

(64)

1.50

(38)

1.25

(32)

2.50

(64)

2.50

(64)

1.50

(38)

1.25

(32)

3.00

(76)

2.50

(64)

1.50

(38)

1.25

(32)

3.00

(76)

2.50

(64)

1.50

(38)

1.25

(32)

3.00

(76)

3.00

(76)

2.00

(51)

1.50

(38)

Field

Fusing (1)

Rec.

Max.

Fuse

Fuse

Size

Size

300 350

225 350

150 175

110 125

300 400

250 350

175 175

110 125

300 400

250 350

175 175

110 125

350 400

300 400

175 200

125 150

350 400

300 400

175 200

125 150

350 400

300 400

175 200

125 150

400 500

350 500

200 250

175 200

Product Manual ALR2-3 ALR 110F – 150F 21

Page 22

Table 12, ALR 110F -150F, Compressor and Condenser Fan Motor Amp Draw

ALR

Unit

Volts

Size

208

110F

120F

130F

135F

140F

145F

150F

See page 25 for other Electrical Data notes.

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

208

230

460

575

Rated Load Amps Locked Rotor Amps

Compressors Compressors

No.1No.2No.3No.

97 97 97 123

97 97 97 114

48 48 48 61

37 37 37 43

97 123 123 123

97 114 114 114

48 61 61 61

37 43 43 43

123 123 123 123

114 114 114 114

61 61 61 61

43 43 43 43

123 123 138 138

114 114 130 130

61 61 65 65

43 43 49 49

138 138 138 138

130 130 130 130

65 65 65 65

49 49 49 49

138 138 138 138

130 130 130 130

65 65 65 65

49 49 49 49

138 138 138 165

130 130 130 165

65 65 65 84

49 49 49 69

Motors

4

(Each)

No.

Fan

Of

Fan

Fan

Motors

Motor

(Each)

5.8 10 23.7 565 565 565 650 340 340 340 400

5.8 10 21.4 565 565 565 594 340 340 340 340

2.8 10 10.7 283 283 283 297 156 156 156 195

2.3 10 11.5 230 230 230 245 138 138 138 152

5.8 10 23.7 565 650 650 650 340 400 400 400

5.8 10 21.4 565 594 594 594 340 340 340 340

2.8 10 10.7 283 297 297 297 156 195 195 195

2.3 10 11.5 230 245 245 245 138 152 152 152

5.8 12 23.7 650 650 650 650 400 400 400 400

5.8 12 21.4 594 594 594 594 340 340 340 340

2.8 12 10.7 297 297 297 297 195 195 195 195

2.3 12 11.5 245 245 245 245 152 152 152 152

5.8 12 23.7 650 650 754 754 400 400 463 463

5.8 12 21.4 594 594 594 594 340 340 340 340

2.8 12 10.7 297 297 297 297 195 195 195 195

2.3 12 11.5 245 245 245 245 152 152 152 152

5.8 12 23.7 754 754 754 754 463 463 463 463

5.8 12 21.4 594 594 594 594 340 340 340 340

2.8 12 10.7 297 297 297 297 195 195 195 195

2.3 12 11.5 245 245 245 245 152 152 152 152

5.8 12 23.7 754 754 754 754 463 463 463 463

5.8 12 21.4 594 594 594 594 340 340 340 340

2.8 12 10.7 297 297 297 297 195 195 195 195

2.3 12 11.5 245 245 245 245 152 152 152 152

5.8 12 23.7 754 754 754 1070 463 463 463 654

5.8 12 21.4 594 594 594 1070 340 340 340 654

2.8 12 10.7 297 297 297 510 195 195 195 330

2.3 12 11.5 245 245 245 405 152 152 152 262

Across-The-Line Reduced Inrush

No. 1 No. 2 No. 3 No. 4 No. 1 No. 2 No. 3 No. 4

22 ALR 110F – 150F Product Manual ALR2-3

Page 23

Table 13, ALR 110F - 150F, Field Wiring Data, Single Point Power

ALR

Unit

Size

110F

120F

130F

135F

140F

145F

150F

See page 25 for other Electrical Data notes.

Volts

208 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

230 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

460 335 (1 qty.) #4 - 400 MCM 400 (1 qty.) 250 - 500 MCM

575 335 (1 qty.) #4 - 400 MCM 250 (1qty.) #4 - 350 MCM

208 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

230 840 (2 qty.) 1/0 - 600 MCM 600 (2 qty.) 250 - 500 MCM

460 335 (1 qty.) #4 - 400 MCM 400 (1 qty.) 250 - 500 MCM

575 335 (1 qty.) #4 - 400 MCM 250 (1qty.) #4 - 350 MCM

208 840 (2 qty.) 1/0 - 600 MCM N/A

230 840 (2 qty.) 1/0 - 600 MCM N/A

460 335 (1 qty.) #4 - 400 MCM 400 (1 qty.) 250 - 500 MCM

575 335 (1 qty.) #4 - 400 MCM 250 (1qty.) #4 - 350 MCM

208 840 (2 qty.) 1/0 - 600 MCM N/A

230 840 (2 qty.) 1/0 - 600 MCM N/A

460 335 (1 qty.) #4 - 400 MCM 400 (1 qty.) 250 - 500 MCM

575 335 (1 qty.) #4 - 400 MCM 250 (1qty.) #4 - 350 MCM

208 840 (2 qty.) 1/0 - 600 MCM N/A

230 840 (2 qty.) 1/0 - 600 MCM N/A

460 335 (1 qty.) #4 - 400 MCM 400 (1 qty.) 250 - 500 MCM

575 335 (1 qty.) #4 - 400 MCM 400 (1 qty.) 250 - 500 MCM

208 840 (2 qty.) 1/0 - 600 MCM N/A

230 840 (2 qty.) 1/0 - 600 MCM N/A

460 335 (1 qty.) #4 - 400 MCM 400 (1 qty.) 250 - 500 MCM

575 335 (1 qty.) #4 - 400 MCM 400 (1 qty.) 250 - 500 MCM

208 840 (4 qty.) 1/0 - 600 MCM N/A

230 840 (4 qty.) 1/0 - 600 MCM N/A

460 840 (2 qty.) 1/0 - 600 MCM 400 (1 qty.) 250 - 500 MCM

575 840 (2 qty.) 1/0 - 600 MCM 400 (1 qty.) 250 - 500 MCM

Terminal

Amps

Wiring to

Standard Power Block

Connector Wire Range/Phase

(Copper Wire Only)

Terminal

Amps

Wiring to Optional Factory Mounted

Disconnect Switch

Connector Wire Range/Phase

(Copper Wire Only)

Product Manual ALR2-3 ALR 110F – 150F 23

Page 24

Table 14, ALR 110F through 150F, Field Wiring Data, Multiple Point Power

ALR

Unit

Size

110F

120F

130F

135F

140F

145F

150F

See page 25 for all Electrical Data notes.

Volts

208 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

230 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

460 175 175 175 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0

575 175 175 175 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0

208 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

230 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

460 175 175 175 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0

575 175 175 175 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0

208 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

230 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

460 175 175 175 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0

575 175 175 175 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0

208 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

230 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

460 175 175 175 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0

575 175 175 175 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0 (1 qty.) #12 - 2/0

208 175 840 840 (1 qty.) #12 - 2/0 (2 qty.) 1/0 - 600 MCM (2 qty.) 1/0 - 600 MCM

230 175 840 840 (1 qty.) #12 - 2/0 (2 qty.) 1/0 - 600 MCM (2 qty.) 1/0 - 600 MCM

460 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

575 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

208 175 840 840 (1 qty.) #12 - 2/0 (2 qty.) 1/0 - 600 MCM (2 qty.) 1/0 - 600 MCM

230 175 840 840 (1 qty.) #12 - 2/0 (2 qty.) 1/0 - 600 MCM (2 qty.) 1/0 - 600 MCM

460 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

575 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

208 175 840 840 (1 qty.) #12 - 2/0 (2 qty.) 1/0 - 600 MCM (2 qty.) 1/0 - 600 MCM

230 175 840 840 (1 qty.) #12 - 2/0 (2 qty.) 1/0 - 600 MCM (2 qty.) 1/0 - 600 MCM

460 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

575 175 335 335 (1 qty.) #12 - 2/0 (1 qty.) #4 - 400 MCM (1 qty.) #4 - 400 MCM

Terminal Amps Connector Wire Range Per Phase (Copper Wire Only)

Circuit 1 Circuit 2 Circuit 3 Circuit 1 (Fans) Circuit 2 Circuit 3

Wiring to Standard Power Block

24 ALR 110F – 150F Product Manual ALR2-3

Page 25

Notes for “Electrical Data Single Point” and “Electrical Data Multiple Point” Power:

1. Table 10 through Table 11, Field Fuse Size for recommended and maximum is based on use of time-delay

fuses.

2. Unit wire size ampacity (MCA) is equal to 125% of the largest compressor-motor RLA plus 100% of RLA

of all other loads in the circuit including the control transformer.

3. The control transformer is furnished as standard.

4. If a separate 115V power supply is used for the control circuit, then size wire for 12 amps.

5. Recommended power lead wire sizes for 3 conductors per conduit are based on 100% conductor ampacity

in accordance with NEC. Wire sizes for 6 conductors per conduit are based on 80% conductor ampacity in

accordance with NEC. Voltage drop has not been included. Therefore, it is recommended that power leads

be kept short. All terminal block connections must be made with copper (type THW) wire.

6. The unit power terminal block may have 2 lugs per phase. Single or parallel conductors should be used for

power connections as listed under “Recommended Power Lead Wire Size.”

7. “Recommended Fuse Sizes” are selected at approximately 150% of the largest compressor RLA, plus 100%

of all other loads in the circuit.

8. “Maximum Fuse Sizes” are selected at approximately 225% of the largest compressor RLA, plus 100% of

all other loads in the circuit.

9. The recommended power lead wire sizes are based on an ambient temperature of 86°F. Ampacity

correction factors must be applied for other ambient temperatures. Refer to the National Electrical Code

Handbook.

10. The MCA may vary depending on options selected (SpeedTrol, totally enclosed fan motors).

Voltage Limitations:

Within 10% of nameplate rating.

Notes for “Compressor and Condenser Fan Amp Draw”:

1. Compressor RLA values are for wiring sizing purposes only but do not reflect normal operating current

draw at rated capacity. If unit is equipped with SpeedTrol condenser fan motors, the first motor on each

refrigerant circuit is a single phase, 1hp motor, with a FLA of 2.8 amps at 460 volts, 5.6 amps at 208, 230,

and 575 volts.

2. Compressor LRA for reduced inrush start is for the first winding only. If the unit is equipped with

SpeedTrol motors, the first motor is a single phase, 1 hp motor, with a LRA of 7.3 amps at 460 volts, 14.5

amps at 208, 230 and 575 volts.

Notes for “Field Wiring Data” - Both Single and Multiple Point Power:

1. Optional disconnect switch is only available on single power source units.

2. Single point power supply requires a single disconnect to supply electrical power to the unit. This power

must be fused.

3. Multiple point power supply requires three independent power circuits, each with separate disconnect.

4. All field wiring to unit power block or optional non-fused disconnect switch must be copper.

5. All field wire size values given in table apply to 75°C rated wire per NEC.

Product Manual ALR2-3 ALR 110F – 150F 25

Page 26

Figure 9, ALR 110F through 150F, Typical Field Wiring Diagram

2

8

AMBIENT

24VACOF

F

CHILLERFLOW

LEGENDFIELDCONNECTIONTERMINAL

CHILLERCONTROL(CIRCUIT1

)

(CIRCUIT2

)

3 PHASE

1

2

4

P OW ER

SUP PLY

OPTIONAL

DISCONNECT

B K

540

F 1

S 1

1 7

1 8

13 F2

UNI T MAIN

TERM I NALBLOCK

SEPARTE 115V

POW ERFORCOOLER

HEATER (SEE NOTEA)

C OOLER HEATER

THEMOSTAT TC2.

1 20 V

24 V

T2

STANDARD FUSED

CONTROL CIRCUIT

TRANSFORMER

COOLER HEATER

C HILLE R C O NTROL

TOC OMP RESSOR(S)

AND FAN MOTORS.

WH

1 6

54 5

NB

2 7

WH

SEE NOTE A

SWI TCHCONTACT

AUT O

5

ON

TI MECLOCK

CO NTACT

TH ERMOSTAT

B I4

B I1

CHI LLERCONTROL

N OTE A :

IT MA Y B E DE S IRAB L E TO HA V E T HE UN IT

C O OLER HE AT ER ON A S EPA RA TE DISC ON NE CT

S WITC H FROM T HE M A IN UN IT P OWE R S UP P LY

S O TH AT T HE U NIT M A Y B E S HUT DOWN WITH

O UT DE FE AT ING TH E FRE EZ E P ROTE C TIO N

FAC T ORY WIRING

F I ELD WIRING

P ROV IDED B Y THE CO OLE R H EA TE R. T O A C C O MP L ISH T HIS, REM OV E WIRE S 5 40 A N D 5 4 5

A N D F IELD WIRE TE RM INA LS 13 A ND 16 T O A

S E PA RAT E 11 5V P OWE R SO URC E.

26 ALR 110F – 150F Product Manual ALR2-3

Page 27

Physical Data

Table 15, Physical Data ALR 110F through 135F

PHYSICAL DATA

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Unit Capacity @ ARI Conditions, Tons (kW) (1) 110.9 (388.1) 122.2 (427.7) 129.6 (453.6) 133.7 (468.0)

Number Of Refrigerant Circuits 2 2 2 2

Unit Operating Charge, R-22, Lbs. 115 115 120 120 120 120 120 120

Unit Operating Charge, R-22, (kg) (52.1) (52.1) (54.4) (54.4) (54.4) (54.4) (54.4) (54.4)

Cabinet Dimensions, LxWxH, In. 229 x 83 x 89 229 x 83 x 89 229 x 83 x 89 229 x 83 x 89

Cabinet Dimensions, LxWxH, (mm) (5809 x 2118 x 2210) (5809 x 2118 x 2210) (5809 x 2118 x 2210) (5817 x 2118 x 2210)

Unit Operating Weight, Lbs. (kg) 9700 (4394) 9880 (4476) 9880 (4476) 9880 (4476)

Unit Shipping Weight, Lbs. (kg) 9420 (4267) 9550 (4326) 9550 (4326) 9550 (4326)

Add'l Weight If Copper Finned Coils, Lbs. (kg) 1370 (620) 1370 (620) 1370 (620) 1370 (620)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 30-30 30-35 30-35 35-35 35-35 35-35 35-40 35-40

Number Of Cylinders Per Compressor 6 - 6 6 - 6 6 - 6 6 - 6 6 - 6 6 - 6 6 - 6 6 - 6

Oil Charge Per Compressor, oz. 140 - 140 140 - 140 140 - 140 140 - 140 140 - 140 140 - 140 140 - 255 140 - 255

Oil Charge Per Compressor, (l) (4.1 – 4.1) (4.1 – 4.1) (4.1 – 4.1) (4.1 – 4.1) (4.1 – 4.1) (4.1 – 4.1) (4.1 – 6.5) (4.1 – 6.5)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Staging - Circuit #1 in Lead 0-16-32-40-48 0-15-32-39-48 0-17-33-42-50 0-16-32-40-48

Staging - Circuit #2 in Lead 0-16-32-40-48 0-17-32-41-48 0-17-33-42-50 0-16-32-40-48

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area,Sq. Ft. 115 115 115 115 115 115 115 115

Coil Face Area, (M2) (10.3) (10.3) (10.3) (10.3) (10.3) (10.3) (10.3) (10.3)

Finned Height x Finned Length, In. 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208

Finned Height x Finned Length, (mm)

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

Maximum Relief Valve Pressure Setting, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 10 - 28 (711) 10 - 28 (711) 12 - 28 (711) 12 - 28 (711)

Number Of Motors - HP (kW) 10 - 1.5 (1.1) 10 - 1.5 (1.1) 12 - 1.5 (1.1) 12 - 1.5 (1.1)

Fan And Motor RPM, 60 Hz 1140 1140 1140 1140

60 Hz Fan Tip Speed, FPM 8357 8357 8357 8357

60 Hz Total Unit Airflow, CFM 90200 90200 108240 108240

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Diameter, in. - Length, in. 12.8 x 94.6 14.0 x 95.5 14.0 x 95.5 14.0 x 95.5

Diameter, (mm) - Length, (mm) 325 x 2403 356 x 2426 356 x 2426 356 x 2426

Water Volume, Gallons, (L) 34 (127) 40 (150) 40 (150) 40 (150)

Maximum Water Pressure, psig (kPa) 152 (1047) 152 (1047) 152 (1047) 152 (1047)

Maximum Refrigerant Working Pressure, psig (kPa) 300 (2066) 300 (2066) 300 (2066) 300 (2066)

Water Inlet / Outlet Victaulic Connections, In. (mm) 5 (127) 8 (203) 8 (203) 8 (203)

Drain - NPT int, In. (mm) .5 (12.7) .5 (12.7) .5 (12.7) .5 (12.7)

Vent - NPT int, In. (mm) .5 (12.7) .5 (12.7) .5 (12.7) .5 (12.7)

NOTE:

1. Nominal capacity based on R-22, 95°F ambient air and 54°F/44°F water range.

110F 120F 130F 135F

-64-84-92-100 -67-84-91-100 -67-83-92-100 -66-84-92-100

-68-84-92-100 -65-84-91-100 -67-83-92-100 -66-84-92-100

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

ALR MODEL NUMBER

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

Product Manual ALR2-3 ALR 110F – 150F 27

Page 28

Table 16, Physical Data ALR 140F through 150F

PHYSICAL DATA

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Unit Capacity @ ARI Conditions (1), Tons (kW) 139.7 (489.0) 143.2 (501.2) 149.5 (523.3)

Number Of Refrigerant Circuits 2 2 2

Unit Operating Charge, R-22, Lbs. 125 125 130 130 130 130

Unit Operating Charge, R-22, (kg) (56.6) (56.6) (58.9) (58.9) (58.9) (58.9)

Cabinet Dimensions, LxWxH, In. 229 x 83 x 89 229 x 83 x 89 229 x 83 x 89

Cabinet Dimensions, LxWxH, (mm) (5817 x 2118 x 2210) (5817 x 2118 x 2210) (5817 x 2118 x 2210)

Unit Operating Weight, Lbs. (kg) 9885 (4478) 9890 (4480) 10090 (4571)

Unit Shipping Weight, Lbs. (kg) 9555 (4328) 9560 (4330) 9760 (4421)

Add'l Weight If Copper Finned Coils, Lbs. (kg) 1370 (620) 1370 (621) 1370 (621)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 40-40 40-40 40-40 40-40 40-40 40-50

Number Of Cylinders Per Compressor 6 - 6 6 - 6 6 - 6 6 - 6 6 - 6 6 - 8

Oil Charge Per Compressor, oz. 255 - 255 255 - 255 255 - 255 255 - 255 255 - 255 255 - 255

Oil Charge Per Compressor, (l) (6.5 – 6.5) (6.5 – 6.5) (6.5 – 6.5) (6.5 – 6.5) (6.5 – 6.5) (6.5 – 6.5)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Staging - Circuit #1 in Lead 0-17-33-42-50 0-17-33-42-50 0-15-32-40-64

Staging - Circuit #2 in Lead 0-17-33-42-50 0-17-33-42-50 0-15-32-40-48

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area,Sq. Ft. 115 115 115 115 115 115

Coil Face Area, (M2) (10.3) (10.3) (10.3) (10.3) (10.3) (10.3)

Finned Height x Finned Length, In. 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208

Finned Height x Finned Length, (mm)

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

Maximum Relief Valve Pressure Setting, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 12 - 28 (711) 12 - 28 (711) 12 - 28 (711)

Number Of Motors - HP (kW) 12 - 1.5 (1.1) 12 - 1.5 (1.1) 12 - 1.5 (1.1)

Fan And Motor RPM, 60 HZ 1140 1140 1140

60 Hz Fan Tip Speed, FPM 8357 8357 8357

60 Hz Total Unit Airflow, CFM 108240 108240 108240

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Diameter, in. - Length, in. 14.0 x 95.5 16.0 x 96.8 16.0 x 96.8

Diameter, (mm) - Length, (mm) 356 x 2426 406 x 2459 406 x 2459

Water Volume, Gallons, (L) 40 (150) 55 (208) 55 (208)

Maximum Water Pressure, psig (kPa) 152 (1047) 152 (1047) 152 (1047)

Maximum Refrigerant Working Pressure, psig (kPa) 300 (2066) 300 (2066) 300 (2066)

Water Inlet / Outlet Victaulic Connections, In. (mm) 8 (203) 8 (203) 8 (203)

Drain - NPT int, In. (mm) .5 (12.7) .5 (12.7) .5 (12.7)

Vent - NPT int, In. (mm) .5 (12.7) .5 (12.7) .5 (12.7)

NOTES:

1. Nominal capacity based on R-22, 95°F ambient air and 54°F/44°F water range.

140F 145F 150F

-67-83-92-100 -67-83-92-100 -64-84-92-100

-67-83-92-100 -67-83-92-100 -68-84-92-100

(2032 x

5283)

(2032 x

5283)

ALR MODEL

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

28 ALR 110F – 150F Product Manual ALR2-3

Page 29

Dimensional Data

Figure 10, 110F through 150F Dimensions

ALR

SIZE

110F

120F

130F

135F

140F

145F

150F

"A"

LENGTH

229 (5809) 5 (127.0) 95.8 (2433) 17.1 (434) 16.3 (414) 31.4 (798) 95.5 (2426) 41.7 (1059) 36.0 (914) 102 (2591) 192 (4877) 10

229 (5809) 8 (203.2) 94.7 (2405) 17.5 (445) 16.3 (414) 30.7 (780) 97.0 (2464) 41.7 (1059) 36.0 (914) 102 (2591) 192 (4877) 10

229 (5809) 8 (203.2) 94.7 (2405) 17.5 (445) 16.3 (414) 30.7 (780) 97.0 (2464) 41.7 (1059) 36.0 (914) 102 (2591) 192 (4877) 12

229 (5809) 8 (203.2) 94.7 (2405) 17.5 (445) 16.3 (414) 30.7 (780) 97.0 (2464) 41.7 (1059) 36.0 (914) 102 (2591) 192 (4877) 12

229 (5809) 8 (203.2) 94.7 (2405) 17.5 (445) 16.3 (414) 30.7 (780) 97.0 (2464) 41.7 (1059) 36.0 (914) 102 (2591) 192 (4877) 12

229 (5809) 8 (203.2) 94.8 (2408) 17.2 (437) 18.3 (465) 29.8 (757) 99.0 (2515) 41.7 (1059) 36.0 (914) 102 (2591) 192 (4877) 12

229 (5809) 8 (203.2) 94.8 (2408) 17.2 (437) 18.3 (465) 29.8 (757) 99.0 (2515) 41.7 (1059) 36.0 (914) 102 (2591) 192 (4877) 12

CONN.

SIZE (1)

WATER CONNECTIONS CENTER OF GRAVITY ISOLATOR LOCATION

B C E F X Y R S T

NOTE: Only left hand evaporator connections (as shown) are available.

NOTE: Add 22 in. (559 mm)

to each side for hail guards.

NO.

OF

FANS

Air

Discharge

Product Manual ALR2-3 ALR 110F – 150F 29

Page 30

Installation and Application

Unit Placement

ALR units are for outdoor applications and can be mounted either on a roof or at ground level. Set

units on a solid and level foundation. For roof mounted applications, install the unit on a steel channel

or I-beam frame to support the unit above the roof. For ground level applications, install the unit on a

substantial base that will not settle. A one-piece concrete slab with footings extended below the frost

line is recommended. Be sure the foundation is level (within 1/2"(13mm) over its length and width).

The foundation must be strong enough to support the operating weights listed in Table 15 and Table

16.

On ground level applications protect the unit against vandalism using the optional lower guard

screens or by erecting a screen fence. The fence must allow free flow of air to the condenser coil for

proper unit operation.

Clearances

The flow of air to and from the condenser coil must not be impeded. Restricting airflow or allowing air

recirculation will result in a decrease in unit performance and efficiency because discharge pressures

are increased. There must be no obstruction above the unit that would deflect discharge air

downward where it could be recirculated back to the inlet of the condenser coil. The condenser fans

are propeller type and will not operate with

ductwork on the fan outlet.

Figure 11, Clearances

Install the unit with enough side clearance for air

entrance to the coil and for servicing. Provide

service access to the evaporator, compressors,

electrical control panel and piping components as

shown in Figure 10 and Figure 11. The 10 foot

clearance opposite the control panel is for

evaporator tube pulling. This space can be reduced

to 4 feet by removing the evaporator or providing

some other means (i.e. door) for tube pulling.

Do not allow debris to accumulate near the unit. Air

movement may draw debris into the condenser coil

causing coil starvation. Give special consideration

to low ambient operation where snow can

accumulate. Keep condenser coils and fan

discharge free of snow or other obstructions to

permit adequate airflow for proper unit operation.

30 ALR 110F – 150F Product Manual ALR2-3

Page 31

Restricted Air Flow

General

The clearances required for penalty-free operation of ALR air-cooled condensers are described in the

previous section. Inevitably there are situations where these clearances cannot be maintained due to

site restrictions such as units being too close together or a fence or wall restricting airflow, or both.

Fortunately the McQuay ALR chillers have several features that mitigate the penalties attributed to

restricted airflow.

• The condenser section is “U” shaped, as shown below. This allows inlet air for these coils to

come in from either side. A vertical coil and its adjacent horizontal coil are manifolded together to

serve one circuit.

• The optional MicroTech control is proactive in response to “off-design conditions”. In the case