Page 1

Installation Manual

SeasonPak

Packaged Air-Cooled Water Chiller

Models ALR 032E Through 185E

IM 676

Group: Chiller

Part Number: 594920Y

Date: July 1996

Supersedes: None

© 1996 McQuay International

Page 2

Table of Contents

Introduction........................................................................................................... 3

General Description .........................................................................................................................3

Inspection........................................................................................................................................3

Installation ......................................................................................................................................3

Handling .........................................................................................................................................3

Location ..........................................................................................................................................4

Service Access.................................................................................................................................5

Vibration Isolators ........................................................................................................................... 6

Water Piping....................................................................................................................................7

Flow Switch.....................................................................................................................................8

Water Connections...........................................................................................................................8

Refrigerant Charge .......................................................................................................................... 9

Glycol Solutions ..............................................................................................................................9

Evaporator Water Flow and Pressure Drop.....................................................................................10

Physical Data........................................................................................................12

Electrical Data......................................................................................................18

Field Wiring.................................................................................................................................. 18

Dimensional Data.................................................................................................36

Unit Layout and Principles of Operation............................................................38

Control Center ...............................................................................................................................38

Start-up and Shutdown.......................................................................................40

Pre Start-up ...................................................................................................................................40

Start-up .........................................................................................................................................40

Sequence of Operation...................................................................................................................41

2 IM 676

Page 3

Introduction

General Description

McQuay SeasonPak air-cooled water chillers are complete, self-contained automatic refrigerating

units. Every unit is completely assembled, factory wired, charged, and tested. Each unit consists of

twin air-cooled condensers with integral subcooler sections, multiple accessible hermetic

compressors, replaceable tube dual circuit shell-and-tube evaporator, and complete refrigerant

piping. Liquid line components include manual liquid line shutoff valves, sight-glass/moisture

indicators, solenoid valves, and double diaphragm hydraulic element thermal expansion valves.

Other features include compressor crankcase heaters, an evaporator heater for chilled water freeze

protection, limited pumpdown during “on” or “off” periods, compressor lead-lag switch to alternate

the compressor starting sequence, and sequenced starting of compressors.

automatic operation. Condenser fan motors are fused in all three phases and started by their own

three-pole contactors. Compressors are not fused but may be protected by optional circuit breakers,

or by a field installed fused disconnect.

Inspection

Check all items carefully against the bill of lading. Inspect all units for damage upon arrival.

Report shipping damage and file a claim with the carrier. Check the unit name plate before

unloading, making certain it agrees with the power supply available. McQuay is not responsible for

physical damage after unit leaves the factory.

The electrical control center includes all safety and operating controls necessary for dependable

Note: Unit shipping and operating weights are available in the Physical Data tables

beginning on page 12.

Installation

Note: Installation is to be performed by qualified personnel who are familiar with local

codes and regulations.

WARNING

Sharp edges and coil surfaces are a potential hazard. Avoid contact with them.

Handling

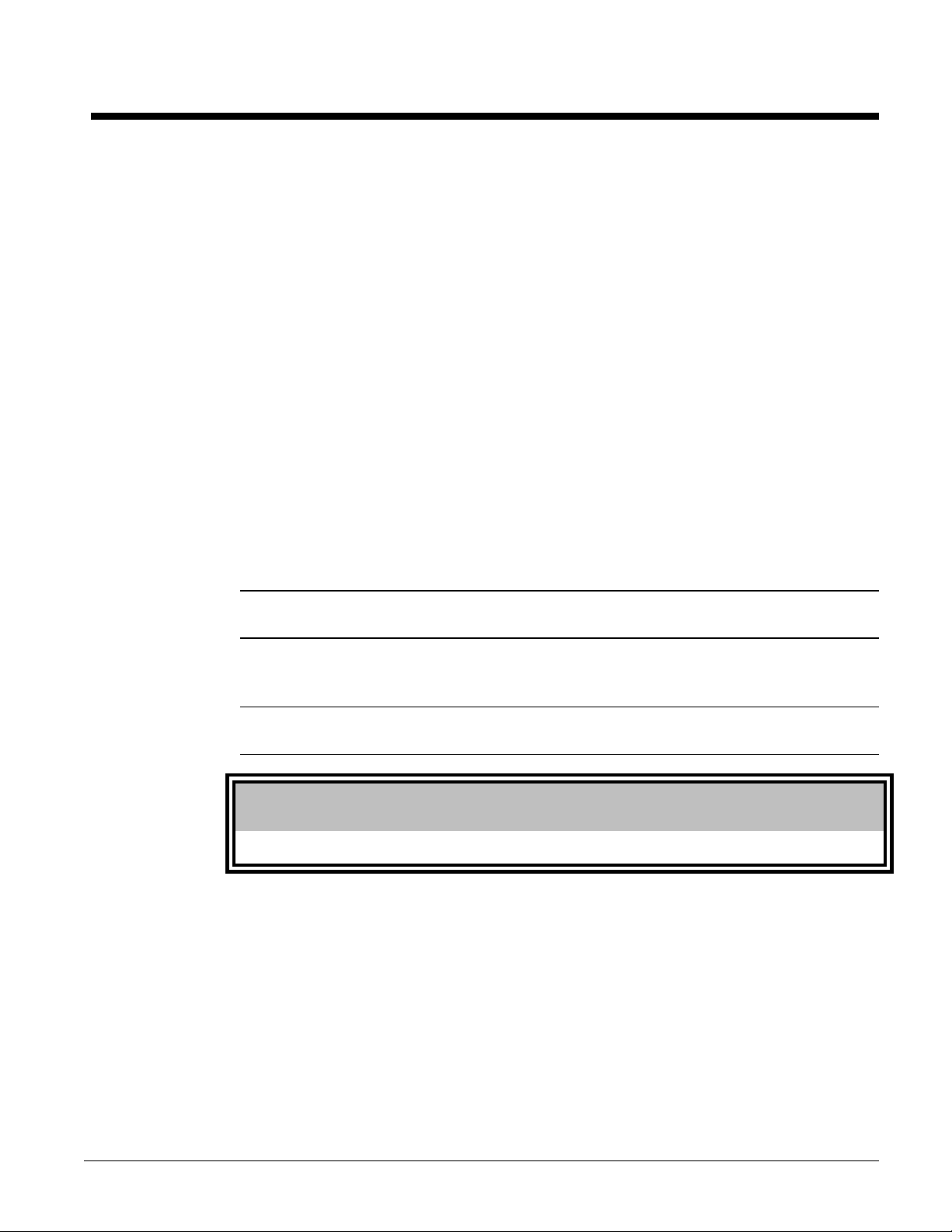

Be careful to avoid rough handling of the unit. Do not push or pull the unit from anything other

than the base. Block the pushing vehicle away from the unit to prevent damage to the sheet metal

cabinet and end frame (see Figure 1).

To lift the unit, 2 1/2" (64mm) diameter lifting holes are provided in the base of the unit.

Arrange spreader bars and cables to prevent damage to the condenser coils or cabinet (see Figure 2).

IM 676 3

Page 4

Figure 1, Suggested pushing arrangement

control box location)

Figure 2, Suggested lifting arrangement

Spreader bars

recommended (Use

Caution)

Blocking required

across full width

NOTE: Number of fans can vary

from this diagram. Lifting method

remains the same.

Must use these rigging

holes. (Be aware of

Location

Unit Placement

ALR units are for outdoor applications and can be mounted on a roof or ground level. Set units on a

solid and level foundation. For roof mounted applications, install the unit on a steel channel or Ibeam frame to support the unit above the roof. For ground level applications, install the unit on a

substantial base that will not settle. A one piece concrete slab with footings extended below the frost

line is recommended. Be sure the foundation is level (within 1/2” [13 mm] over its length and

width). The foundation must support the operating weights listed in the Physical Data tables

beginning on page 12.

On ground level applications protect fins against vandalism using the optional coil guards or by

erecting a screen fence. The fence must allow free flow of air to the condenser coil for proper unit

operation.

4 IM 676

Page 5

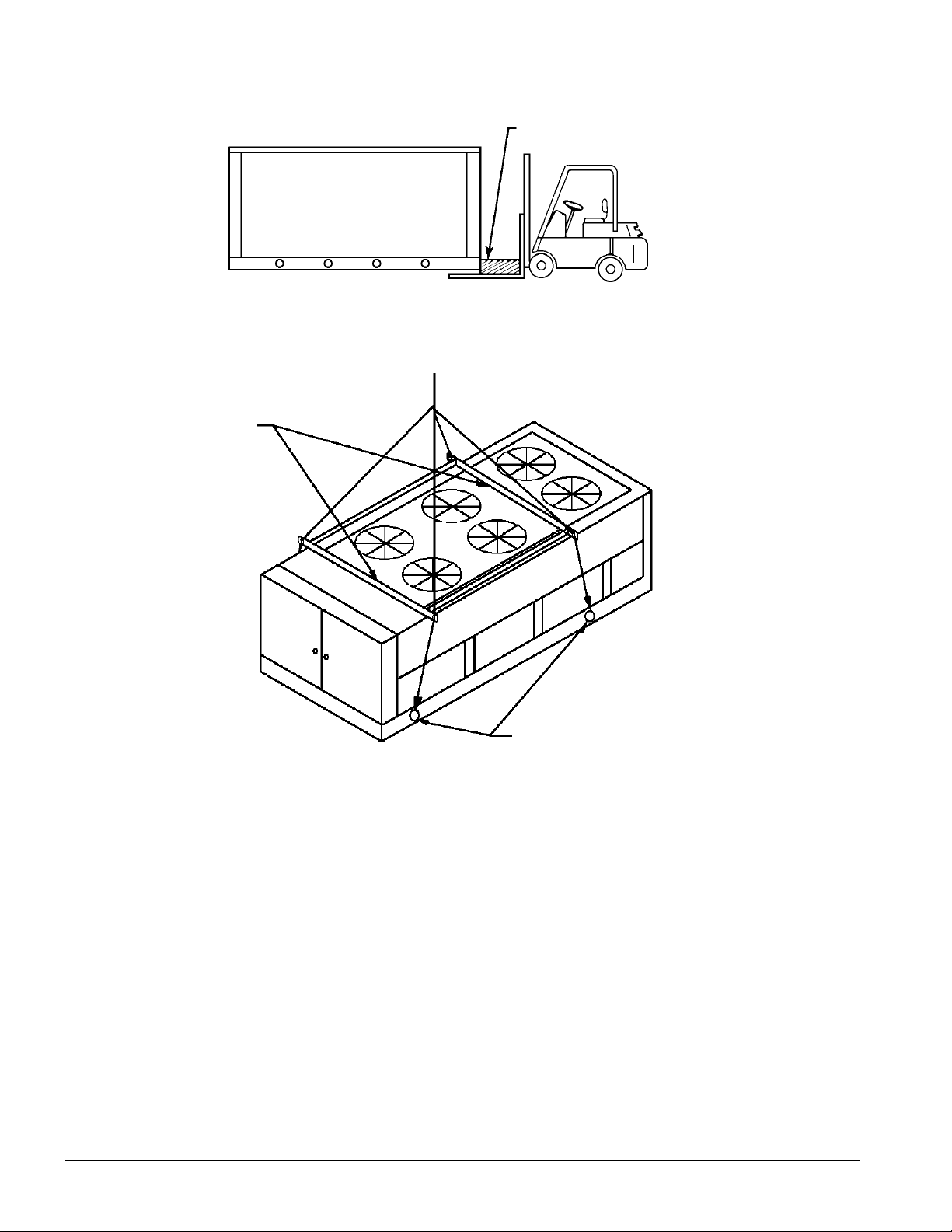

Clearances

air inlet

The flow of air to and from the condenser coil must not be limited. Restricting air flow or allowing

air recirculation will result in a decrease in unit performance and efficiency. There must be no

obstruction above the unit that would deflect discharge air downward where it could be recirculated

back to the inlet of the condenser coil. The condenser fans are propeller type and will not operate

with ductwork on the fan outlet.

Install the unit with enough side clearance for air entrance to the coil and for servicing.

Provide service access to the evaporator, compressors, electrical control panel and piping

components as shown in Figure 3.

Do not allow debris to accumulate near the unit. Air movement may draw debris into the

condenser coil causing air starvation. Give special consideration to low ambient operation where

snow can accumulate. Keep condenser coils and fan discharge free of snow or other obstructions to

permit adequate airflow.

Figure 3, Clearance requirements

5 ft. (1524mm) Clearance for

air inlet

4 Ft.

(1220mm)

clearance for

5 Ft. (1524mm) clearance for

ALR Unit Size Minimum "X" Dimension

032E -075E 8 ft (2438 mm)

080E - 185E 10 ft (3048 mm)

"X" clearance

for evaporator

tube removal

Sound Isolation

The ultra-low sound levels of the ALR reciprocating

chiller is suitable for most applications. When

additional sound reduction is necessary, locate the

unit away from sound sensitive areas. Avoid

locations beneath windows or between structures

where normal operating sounds may be

objectionable. Reduce structurally transmitted sound

by isolating water lines, electrical conduit and the

unit itself. Use wall sleeves and rubber isolated

piping hangers to reduce transmission of water or

pump noise into occupied spaces. Use flexible

electrical conduit to isolate sound through electrical

conduit. Spring isolators are effective in reducing the low amplitude sound generated by

reciprocating compressors and for unit isolation in sound sensitive areas.

Service Access

Each end of the unit must be accessible after installation for periodic service. Compressors, filterdriers, and manual liquid line shutoff valves are accessible on each side of the unit adjacent to the

control box. High pressure, low pressure, and motor protector controls are on the compressor.

Freezestats and cooler barrel thermostats are near the cooler. Most other operational, safety and

starting controls are located in the unit control box.

The condenser fan and motors can be removed from the top of the unit.

IM 676 5

Page 6

Vibration Isolators

Vibration isolators are recommended for all roof mounted installations or wherever vibration

transmission is a consideration.

Table 1 lists isolator loads and type. Table 2 lists spring isolator part numbers for all unit sizes. See

Dimensional Data beginning on page 36 for dimensions required to secure each isolator to the

mounting surface.

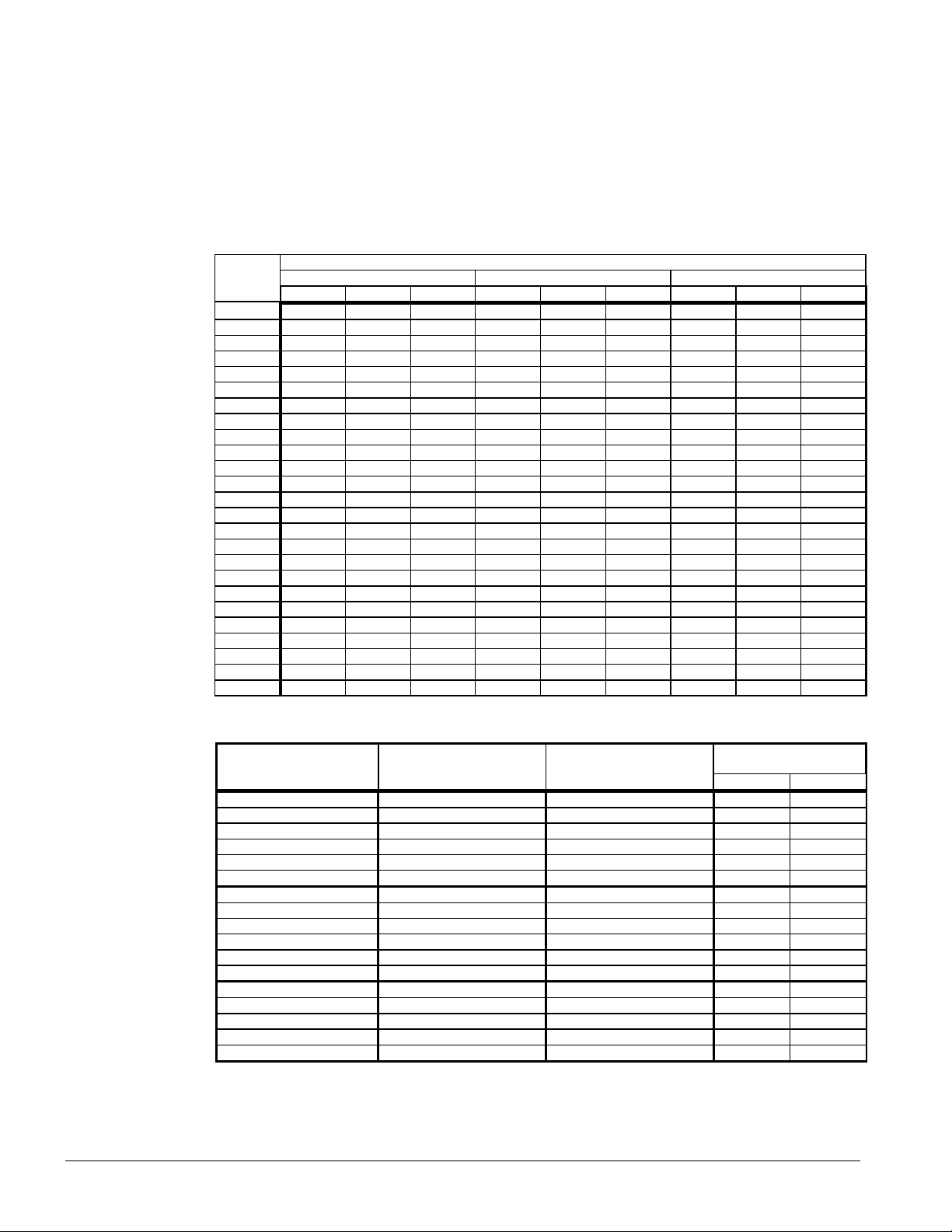

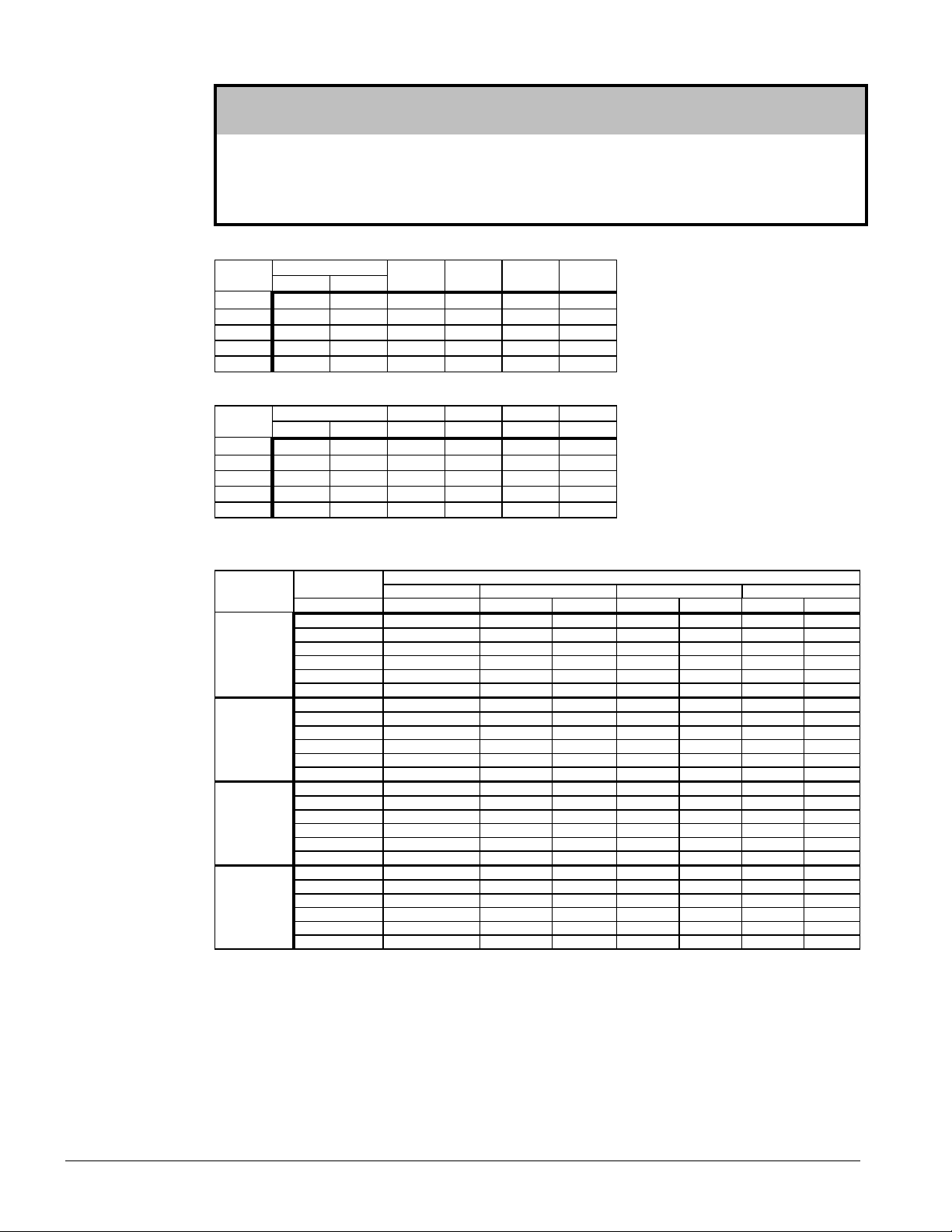

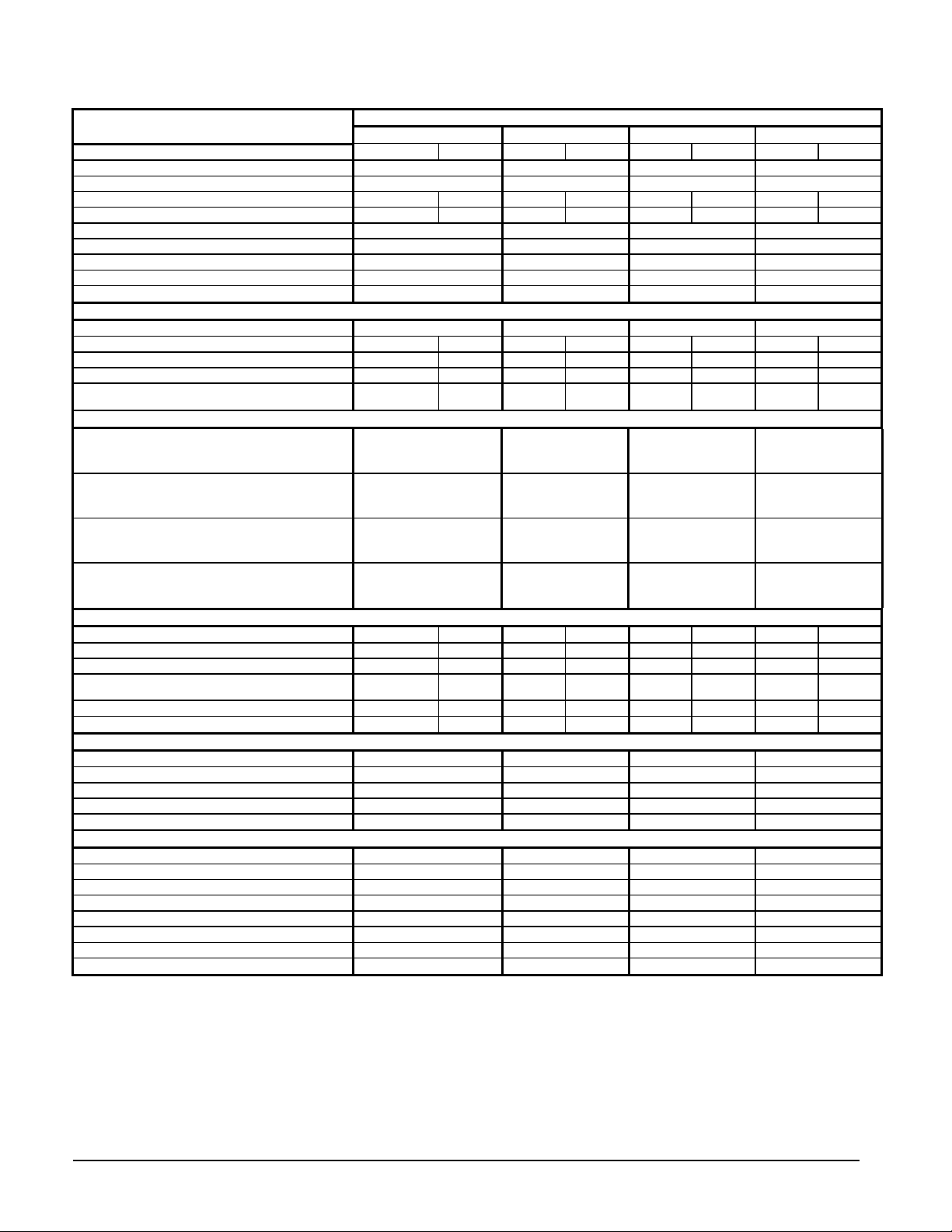

Table 1, Isolator loads and type

ALR ISOLATOR LOADS AND TYPE FOR EACH MOUNTING LOCATION

UNIT R S T

SIZE TYPE LB. KG TYPE LB. KG TYPE LB. KG

032E CP-1-28 669 303 CP-1-28 677 307 CP-1-28 677 307

035E CP-1-28 673 305 CP-1-28 680 308 CP-1-28 680 308

040E CP-1-28 692 314 CP-1-28 699 317 CP-1-28 699 317

045E CP-1-31 804 365 CP-1-31 794 360 CP-1-31 785 356

050E CP-1-31 822 373 CP-1-31 798 362 CP-1-31 800 363

055E CP-1-31 827 375 CP-1-31 819 371 CP-1-31 809 367

060E CP-1-32 850 386 CP-1-32 841 381 CP-1-32 835 379

065E CP-1-32 868 394 CP-1-32 858 389 CP-1-32 848 385

070E CP-1-32 1040 472 CP-1-32 998 453 CP-1-32 912 414

075E CP-1-32 1042 473 CP-1-32 1019 462 CP-1-32 914 415

080E CP-2-28 1110 503 CP-2-28 1122 509 CP-2-31 1296 588

085E CP-2-28 1180 535 CP-2-28 1186 538 CP-2-31 1474 669

090E CP-2-28 1182 536 CP-2-28 1186 538 CP-2-31 1475 669

100E CP-2-28 1193 541 CP-2-28 1214 551 CP-2-31 1508 684

110E CP-2-28 1339 607 CP-2-28 1364 619 CP-2-31 1697 770

120E CP-2-31 1362 618 CP-2-31 1490 676 CP-2-32 1748 793

130E CP-2-31 1492 677 CP-2-32 1570 712 CP-2-32 1838 834

135E CP-2-31 1506 683 CP-2-32 1670 758 CP-2-32 1904 864

140E CP-2-31 1556 706 CP-2-32 1752 795 CP-2-32 1912 867

145E CP-2-31 1572 713 CP-2-32 1680 762 CP-4-27 2093 949

150E CP-2-32 1601 726 CP-2-32 1704 773 CP-4-27 2120 962

160E CP-4-27 1948 884 CP-2-32 1962 890 CP-2-32 1848 838

170E CP-4-27 2052 931 CP-2-32 2002 908 CP-2-32 1849 839

180E CP-4-27 2052 931 CP-2-32 2002 908 CP-2-32 1849 839

185E CP-4-27 2052 931 CP-2-32 2002 908 CP-2-32 1849 839

NOTE: Two of each isolator type is required for a total of six per unit.

Table 2, Spring flex isolator part numbers

TYPE COLOR McQuay Each

Part No. Lb. KG

CP1-25 Red 477927A-25 450 204

CP1-26 Purple 477927A-26 600 272

CP1-27 Orange 477927A-27 750 340

CP1-28 Green 477927A-28 900 408

CP1-31 Gray 477927A-31 1100 499

CP1-32 White 477927A-32 1300 590

CP2-25 Red 477929A-25 900 408

CP2-26 Purple 477929A-26 1200 544

CP2-27 Orange 477929A-27 1500 681

CP2-28 Green 477929A-28 1800 817

CP2-31 Gray 477929A-31 2200 998

CP2-32 White 477929A-32 2600 1180

CP4-26 Purple 580513A-26 2400 1089

CP4-27 Orange 580513A-27 3000 1361

CP4-28 Green 580513A-28 3600 1633

CP4-31 Gray 580513A-31 4400 1996

CP4-32 White 580513A-32 5200 2359

6 IM 676

Max. Load

Page 7

Water Piping

Local authorities can supply the installer with the proper building and safety codes required for safe

and proper installation.

Install piping with minimum bends and changes in elevation to minimize pressure drop.

Consider the following when installing water piping:

1. Vibration eliminators to reduce vibration and noise transmission to the building.

2. Shutoff valves to isolate the unit from the piping system during unit servicing.

3. Manual or automatic air vent valves at the high points of the system. Install drains at the

lowest points in the system.

4. A means of maintaining adequate system water pressure (expansion tank or regulating valve).

5. Temperature and pressure indicators located at the unit to aid in unit servicing.

6. A strainer or other means of removing foreign matter from the water before it enters the pump.

Place the strainer far enough upstream to prevent cavitation at the pump inlet (consult pump

manufacturer for recommendations). The use of a strainer will prolong pump life and keep

system performance up.

7. Place a strainer in the water line just before the inlet of the evaporator. This will help prevent

foreign material from entering and decreasing the performance of the evaporator.

CAUTION

If separate disconnect is used for the 110V supply to the evaporator heating cable, mark

the disconnect clearly to ensure disconnect is not accidentally shut off during cold seasons.

8. The shell-and-tube evaporator has a thermostat and heating cable to prevent freeze-up down to -

20°F (-29°C). It is suggested that the heating cable be wired to a separate 110V supply circuit.

As shipped from the factory, the heating cable is wired to the control circuit. All water piping

to the unit must also be protected to prevent freezing.

9. If the unit is used as a replacement chiller on a previously existing piping system, flush the

system thoroughly before unit installation. Regular water analysis and chemical water

treatment on the evaporator is recommended immediately at equipment start-up.

10. The total water volume in the system should be sufficient to prevent frequent “on-off” cycling.

Turnover rate should not be less than 15 minutes for normal variable cooling loads. Turnover

rate for process cooling or a constant load,should not be less than 6 minutes.

11. When glycol is added to the water system for freeze protection, the refrigerant suction pressure

will be lower, cooling performance less, and water side pressure drop greater. If the percentage

of glycol is high, or if propylene is used instead of ethylene glycol, the added pressure drop and

loss of performance could be substantial. Reset the freezestat and low leaving water alarm

temperatures. The freezestat is factory set to default at 36°F (2.2°C). Reset the freezestat

setting to approximately 4 to 5 degress F (2.3 to 2.8 degress C) below the leaving chilled water

setpoint temperature. See the section titled “Glycol Solutions” for additional information

concerning glycol.

12. Perform a preliminary leak check before insulating the piping and filling the system.

13. Piping insulation should include a vapor barrier to prevent condensation and possible damage

to the building structure.

IM 676 7

Page 8

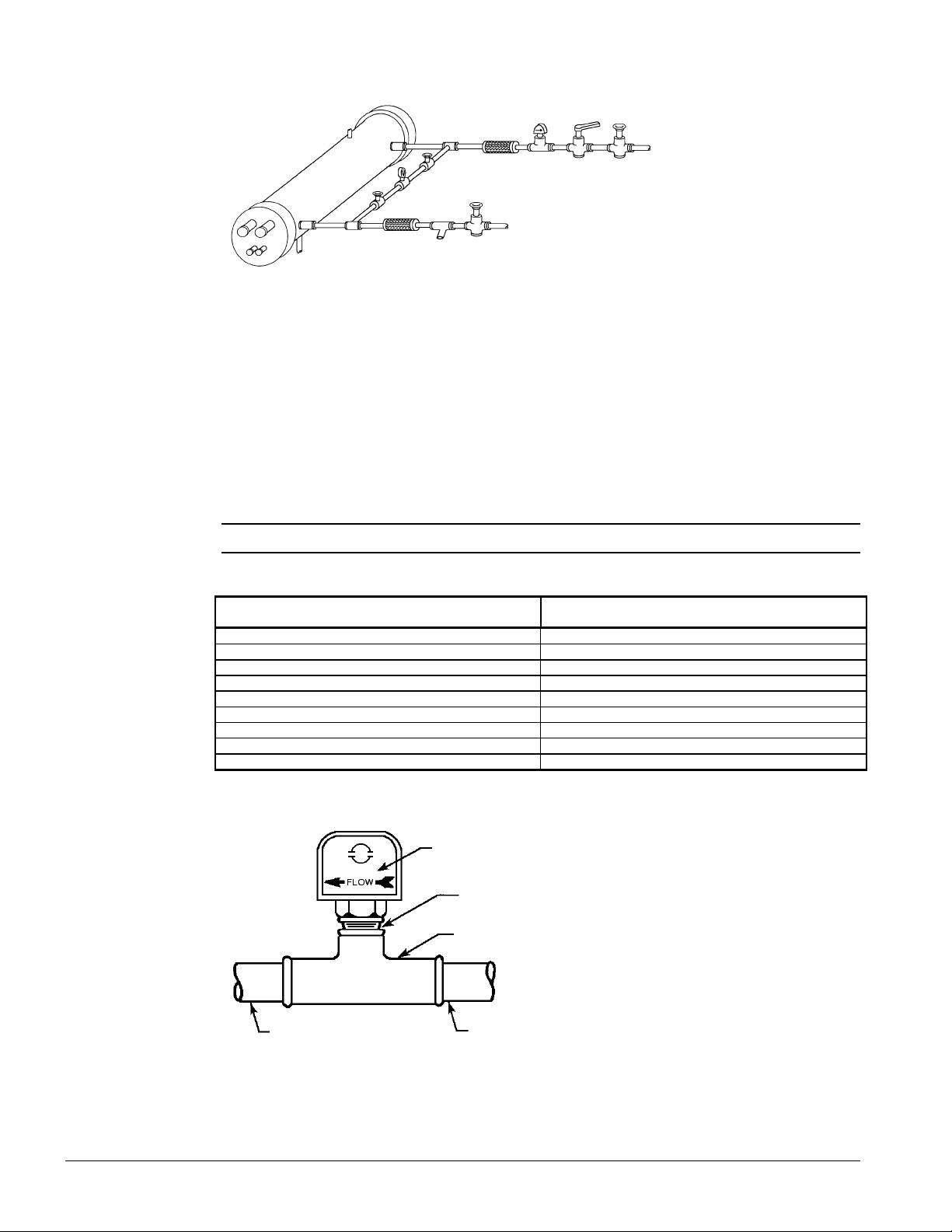

Figure 4, Typical field evaporator water piping

Vent

Outlet

Valved

pressure

gauge

Vibration

Eliminator

Flow

Switch

Balancing

valve

Gate valve

Protect all field piping

against freezing

Drain

Vibration

Eliminator

Water

strainer

Gate valve

Flow Switch

Mount a water flow switch in either the entering or leaving water line to shut down the unit when

water flow is interrupted.

A flow switch is available from McQuay (part number 00175033-00). It is a “paddle” type

switch and adaptable to any pipe size from 3” (76mm) to 8” (203mm) nominal. Certain minimum

flow rates are required to close the switch and are listed in Table 3. Installation should be as shown

in Figure 5. Connect the normally open contacts of the flow switch in the unit control center at

terminals 5 and 6. There is also a set of normally closed contacts on the switch that can be used for

an indicator light or an alarm to indicate when a “no flow” condition exists. Freeze protect any flow

switch that is installed outdoors.

NOTE: Differential pressure switches are not recommended for outdoor installation.

Table 3, Flow switch minimum flow rates

NOMINAL PIPE SIZE MINIMUM REQUIRED FLOW TO

INCHES (MM) ACTIVATE SWITCH - GPM (L/S)

1 (25.4) 6.00 (0.38)

11/4 (31.8) 9.80 (0.62)

11/2 (38.1) 12.70 (0.80)

2 (50.8) 18.80 (1.20)

21/2 (63.50 24.30 (1.50)

3 (76.20 30.00 (1.90)

4 (101.6) 39.70 (2.50)

5 (127.0) 58.70 (3.70)

6 (152.4) 79.20 (5.00)

Figure 5, Flow switch installation

Flow direction

marked on switch

1" (25mm) NPT flow

switch connection

Tee

5" (127mm) pipe dia.

Min. after switch

5" (127mm) pipe dia.

Min. before switch

Water Connections

Bring water piping to the cooler from the bottom of the unit or through the side between the vertical

supports.

8 IM 676

Page 9

Note: The procedure

does not specify the

type of glycol. Use

the derate factors

found in Table 4 for

corrections when

using ethylene glycol

and those in Table 5

for propylene glycol.

Note: On units sizes 160E through 185E there is a diagonal bracket off of a vertical support

which will interfere with the water connection if brought in from the side. This brace can be

removed, but only after the unit is in place.

Refrigerant Charge

All units are designed for use with HCFC-22 and other refrigerants. See nameplate for specific

refrigerant used. Units are shipped with an operating charge. The operating charge

(using HCFC-22) for each unit is shown in the Physical Data tables beginning on page 12.

Glycol Solutions

The system glycol capacity, glycol solution flow rate in GPM, and pressure drop through the cooler

may be calculated using the following formulas and table.

1. Capacity -- Find the reduced capacity by multiplying the chiller’s capacity with water by the

capacity correction factor C.

2. Flow -- To determine evaporator gpm (or Delta-T) knowing Delta-T (or gpm) and capacity:

×

Glycol GPM (from table)=

24 capacity glycol

Delta T

For Metric Applications -- To determine evaporator L/s (or Delta-T) knowing Delta-T (or L/s)

and kW:

Glycol L / s (from table)=

4. 18

kW

× −

Delta T

3. Pressure drop -- To determine pressure drop through the evaporator, when using glycol, enter

the water pressure drop curve on page 11 at the actual glycol GPM. Multiply the water pressure

drop by PD correction factor from Table 4 or Table 5 to obtain corrected glycol pressure drop.

4. To determine the unit's power consumption when using glycol, multiply the water system kW by

factor kW.

Test coolant with a clean, accurate glycol solution hydrometer (similar to that found in service

stations) to determine the freezing point. Obtain percent glycol from the freezing point table below.

On glycol applications it is normally recommended by the supplier that a minimum of 25% solution

by weight be used for protection against corrosion.

( )

−

×

Flow

×

G

IM 676 9

Page 10

CAUTION

Do not use an automotive grade antifreeze. Industrial grade glycols must be used.

Automotive antifreeze contains inhibitors which will cause plating on the copper tubes

within the chiller evaporator. The type and handling of glycol used must be consistent with

local codes.

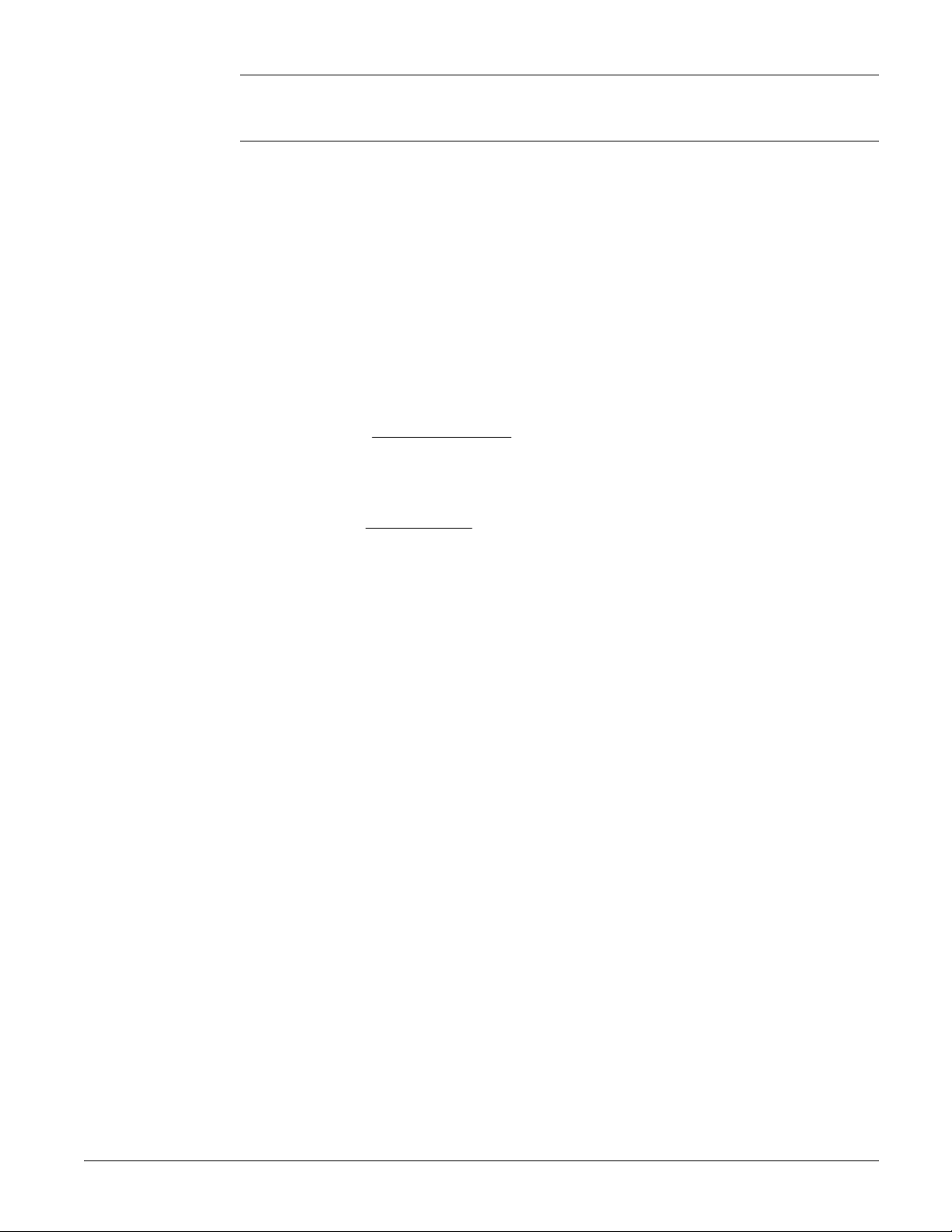

Table 4, Ethylene glycol

% Freeze Point

E.G. °F °C Cap. kW GPM PD

10 26 -3 0.991 0.996 1.013 1.070

20 18 -8 0.982 0.992 1.040 1.129

30 7 -14 0.972 0.986 1.074 1.181

40 -7 -22 0.961 0.976 1.121 1.263

50 -28 -33 0.946 0.966 1.178 1.308

Table 5, Propylene glycol

% Freeze Point

P.G. °F °C Cap. kW GPM PD

10 26 -3 0.987 0.992 1.010 1.068

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

40 -5 -21 0.946 0.971 1.078 1.366

50 -27 -33 0.929 0.965 1.116 1.481

Table 6, Capacity and power derates

Chilled Water Fouling Factor

ALTITUDE °F °C Cap. kW Cap. kW Cap. kW

SEA 10 5.6 1.000 1.000 0.975 0.986 0.919 0.939

LEVEL 12 6.7 1.005 1.002 0.980 0.989 0.923 0.941

2000 feet 12 6.7 0.992 1.011 0.970 0.998 0.914 0.949

4000 feet 12 6.7 0.978 1.025 0.956 1.008 0.904 0.958

6000 feet 12 6.7 0.963 1.034 0.942 1.017 0.895 0.966

Delta-T 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

6 3.3 0.992 0.995 0.996 0.982 0.911 0.935

8 4.4 0.995 0.997 0.969 0.984 0.914 0.937

14 6.8 1.010 1.005 0.985 0.991 0.928 0.943

16 8.9 1.014 1.007 0.989 0.993 0.930 0.944

6 3.3 0.978 1.005 0.957 0.990 0.903 0.943

8 4.4 0.982 1.007 0.961 0.993 0.905 0.945

10 5.6 0.986 1.009 0.965 0.995 0.909 0.947

14 6.8 0.997 1.014 0.973 1.001 0.919 0.952

16 8.9 1.000 1.016 0.975 1.002 0.921 0.953

6 3.3 0.966 1.016 0.944 0.999 0.894 0.951

8 4.4 0.969 1.018 0.947 1.001 0.896 0.953

10 5.6 0.973 1.021 0.952 1.005 0.900 0.956

14 6.8 0.982 1.027 0.959 1.011 0.909 0.960

16 8.9 0.986 1.028 0.961 1.015 0.911 0.961

6 3.3 0.953 1.025 0.930 1.009 0.884 0.961

8 4.4 0.955 1.028 0.934 1.011 0.887 0.962

10 5.6 0.959 1.031 0.939 1.013 0.890 0.964

14 6.8 0.968 1.036 0.946 1.020 0.899 0.968

16 8.9 0.972 1.037 0.949 1.024 0.902 0.969

10 IM 676

Page 11

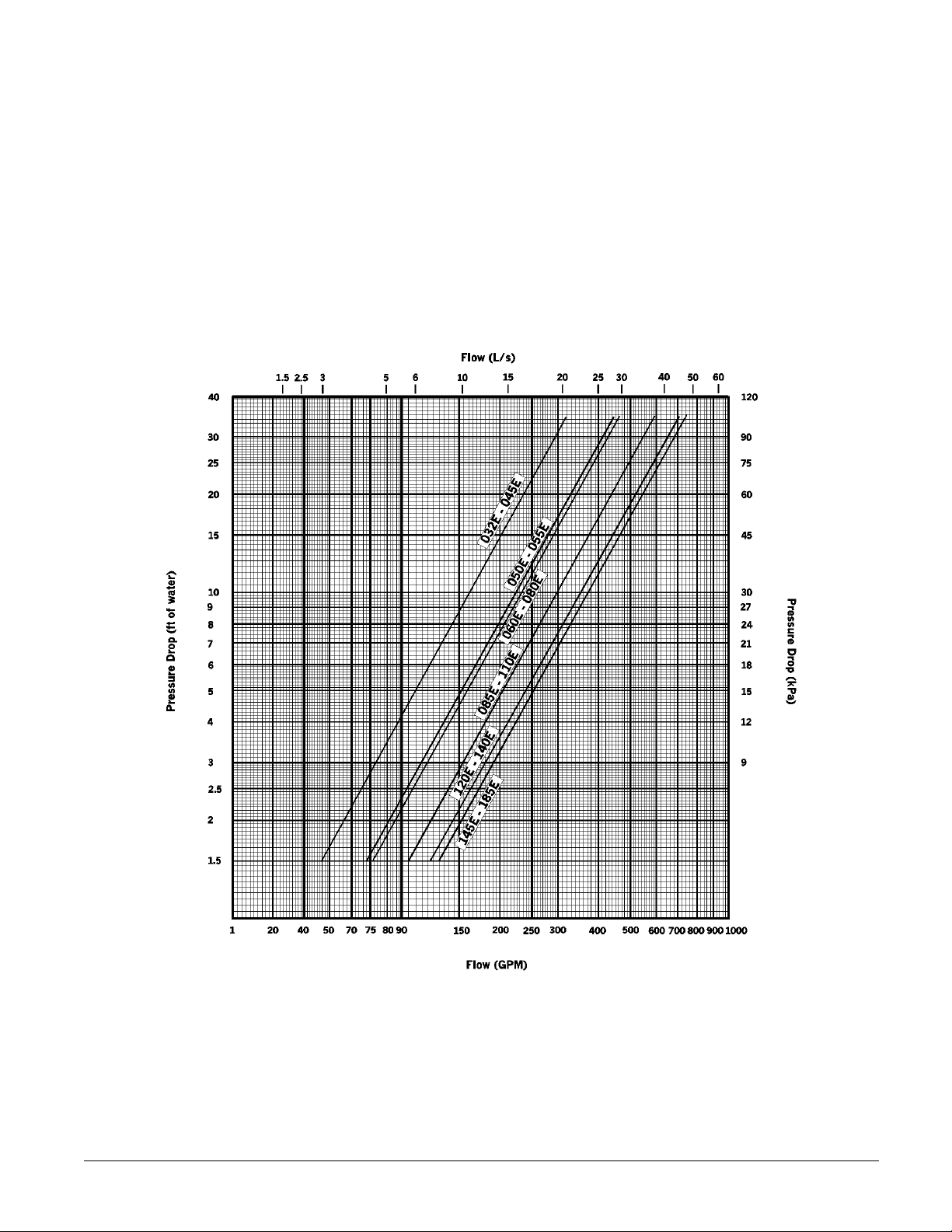

Evaporator Water Flow and Pressure Drop

Evaporator flow rate must fall between the minimum and maximum values shown in the evaporator

pressure drop curve. Flow rates below the minimum values will result in laminar flow which will

reduce efficiency, cause erratic operation of the expansion valve and could cause low temperature

cutouts. Flow rates exceeding the maximum values can cause erosion on the evaporator water

connections and tubes.

Measure the chilled water pressure drop through the evaporator at field installed pressure taps.

It is important not to include the effect of valves or strainers in these readings.

Varying chilled water flow through the evaporator while the compressor(s) are operating is not

recommended.

Figure 6, Evaporator water pressure drop curve

IM 676 11

Page 12

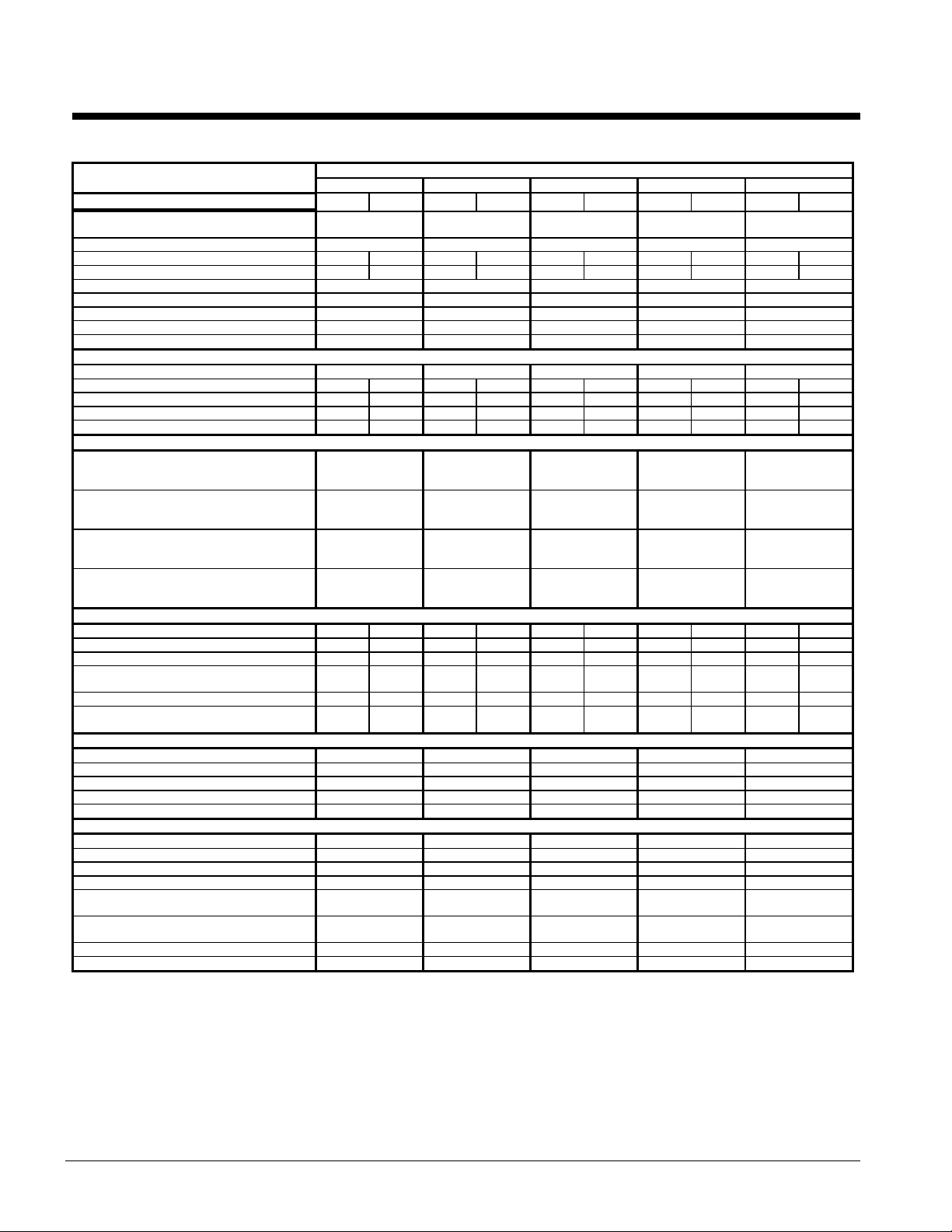

Physical Data

Table 7 , Physical data ALR032E Through 050E

PHYSICAL DATA ALR MODEL NUMBER

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Unit Capacity @ ARI Conditions (1),

Tons (kW)

Number Of Refrigerant Circuits 2 2 2 2 2

Unit Operating Charge, R-22, lb. 20 20 23 23 30 30 32 32 32 32

Unit Operating Charge, R-22, (kg) (9.1) (9.1) (11.3) (11.3) (13.6) (13.6) (13.6) (13.6) (13.6) (13.6)

Cabinet Dimensions, LxWxH, In. 123 x 83 x 59 123 x 83 x 59 123 x 83 x 59 176 x 83 x 59 176 x 83 x 59

Cabinet Dimensions, LxWxH, (mm) (3124 x 2108 x 1499) (3124 x 2108 x 1499) (3124 x 2108 x 1499) (4470 x 2108 x 1499) (4470 x 2108 x 1499)

Unit Operating Weight, Lb. (kg) 4045 (1835) 4065(1853) 4180 (1896) 4765 (2162) 4840 (2196)

Unit Shipping Weight, Lb. (kg) 3895 (1767) 3915 (1785) 4030 (1828) 4615 (2094) 4690 (2127)

Add'l Weight If Copper Finned Coils, Lb. (kg) 270 (122) 270 (122) 370 (168) 410 (186) 410 (186)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 20 20 20 22 25 25 25 30 30 30

Number Of Cylinders Per Compressor 4 4 4 4 4 4 4 6 4 6

Oil Charge Per Compressor, Oz. 130 130 130 130 130 130 130 140 140 140

Oil Charge Per Compressor, (g) (3686) (3686) (3686) (3686) (3686) (3686) (3686) (3969) (3969) (3969)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead

Standard 4 Stages 0-25-50-75-100 0-22-50-72-100 0-25-50-75-100 0-21-60-81-100 0-23-59-82-100

Standard Staging - Circuit #2 in Lead

Standard 4 Stages 0-25-50-75-100 0-28-50-78-100 0-25-50-75-100 0-39-60-79-100 0-36-59-77-100

Optional Staging - Circuit #1 in Lead

Optional 6 Stages N/A N/A N/A N/A N/A

032E 035E 040E 045E 050E

32.5 (114.3) 34.6 (121.7) 40.4 (142.0) 45.9 (161.4) 50.8 (178.6)

Optional Staging - Circuit #2 in Lead

Optional 6 Stages N/A N/A N/A N/A N/A

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Maximum Relief Valve Pressure Setting, psig

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 4 - 26 (660) 4 - 26 (660) 4 - 26 (660) 6 - 26 (660) 6 - 26 (660)

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Maximum Refrigerant Working Pressure, psig

Water Inlet / Outlet Victaulic Connections,

NOTE:

1. Nominal capacity based on 95F ambient air and 54F/44F water range.

Coil Face Area,Sq. Ft. 28.3 28.3 28.3 28.3 28.3 28.3 43.1 43.1 43.1 43.1

Coil Face Area, (M2) (2.6) (2.6) (2.6) (2.6) (2.6) (2.6) (4) (4) (4) (4)

Finned Height x Finned Length, In. 40 x 102 40 x 102 40 x 102 40 x 102 40 x 102 40 x 102 40 x 155 40 x 155 40 x 155 40 x 155

Finned Height x Finned Length, (mm) (1016 x

Fins Per Inch x Rows Deep 16 x 2 16 x 2 16 x 2 16 x 2 16 x 3 16 x 3 16 x 2 16 x 2 16 x 2 16 x 2

(kPa)

Number Of Motors - HP (kW) 4 - 1.0 (.7) 4 - 1.0 (.7) 4 - 1.0 (.7) 6 - 1.0 (.7) 6 - 1.0 (.7)

Fan And Motor RPM, 60/50Hz 1100/915 1100/915 1100/915 1100/915 1100/915

60 Hz Fan Tip Speed, FPM 7760 7760 7760 7760 7760

60 Hz Total Unit Airflow, CFM 28400 29840 26980 42000 42000

Diameter, in. - Length, Ft. 10 - 08 10 - 08 10 - 08 10 - 08 12 - 08

Diameter, (mm) - Length, (mm) (254 - 2439) (254 - 2439) (254 - 2439) (254 - 2439) (305 - 2439)

Water Volume, Gallons, (L) 17.90 (67.8) 17.90 (67.8) 17.90 (67.8) 17.90 (67.8) 24.30 (92)

Maximum Water Pressure, psig (kPa) 175 (1207) 175 (1207) 175 (1207) 175 (1207) 175 (1207)

(kPa)

In. (mm)

Drain - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

Vent - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

2591)

(3103)

(1016 x

2591)

450

(3103)

225 (1552) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

4 (101.6) 4 (101.6) 4 (101.6) 4 (101.6) 5 (127)

450

(1016 x

2591)

450

(3103)

(1016 x

2591)

450

(3103)

(1016 x

2591)

450

(3103)

(1016 x

2591)

450

(3103)

(1016 x

3937)

450

(3103)

(1016 x

3937)

450

(3103)

(1016 x

3937)

450

(3103)

(1016 x

3937)

450

(3103)

12 IM 676

Page 13

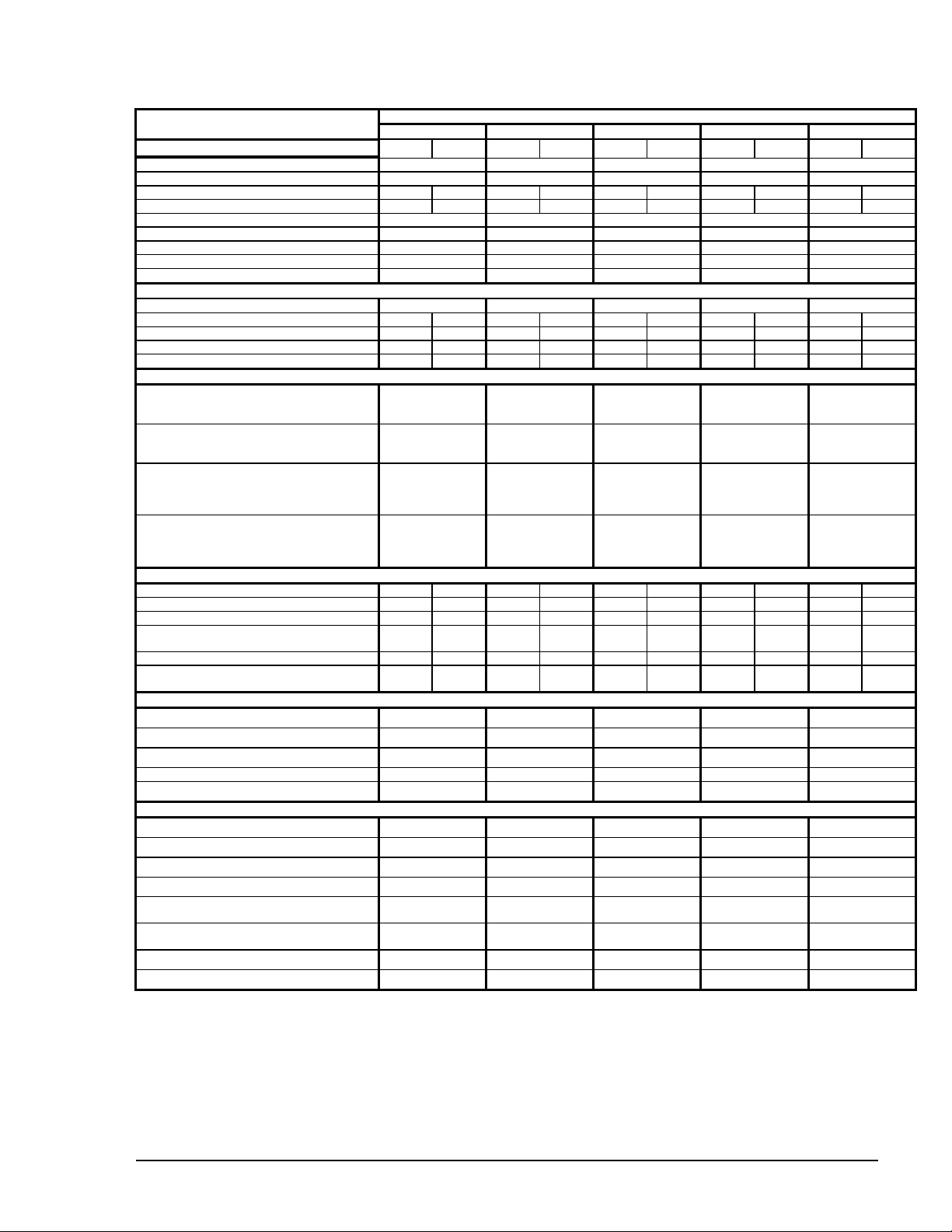

Table 8, Physical data ALR055E Through 075E

PHYSICAL DATA ALR MODEL NUMBER

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Unit Capacity @ ARI Conditions (1), Tons (kW) 54.6 (192.0) 59.6 (209.6) 64.0 (225.0) 69.0 (242.6) 72.2 (253.9)

Number Of Refrigerant Circuits 2 2 2 2 2

Unit Operating Charge, R-22, Lb. 45 45 45 45 45 45 58 58 60 60

Unit Operating Charge, R-22, (kg) (15.9) (15.9) (15.9) (15.9) (18.1) (18.1) (18.1) (18.1) (20.4) (20.4)

Cabinet Dimensions, LxWxH, In. 176 x 83 x 59 176 x 83 x 59 176 x 83 x 59 229 x 83 x 59 229 x 83 x 59

Cabinet Dimensions, LxWxH, (mm) (4470 x 2108 x 1499) (4470 x 2108 x 1499) (4470 x 2108 x 1499) (5817 x 2108 x 1499) (5817 x 2108 x 1499)

Unit Operating Weight, Lb. (kg) 4910 (2228) 5052 (2292) 5148 (2335) 5900 (2677) 5950 (2700)

Unit Shipping Weight, Lb. (kg) 4760 (2160) 4850 (2200) 4946 (2244) 5635 (2556) 5685 (2579)

Add'l Weight If Copper Finned Coils, Lb. (kg) 410 (186) 615 (279) 615 (279) 825 (374) 825 (374)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 30 30 30 35 35 35 35 40 40 40

Number Of Cylinders Per Compressor 6 6 6 6 6 6 6 6 6 6

Oil Charge Per Compressor, Oz. 140 140 140 140 140 140 140 255 255 255

Oil Charge Per Compressor, (g) (3969) (3969) (3969) (3969) (3969) (3969) (3969) (7229) (7229) (7229)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead

Standard 4 Stages 0-33-50-83-100 0-30-67-82-100 0-33-50-83-100 0-32-67-83-100 0-33-50-83-100

Standard Staging - Circuit #2 in Lead

Standard 4 Stages 0-33-50-83-100 0-36-67-85-100 0-33-50-83-100 0-35-67-84-100 0-33-50-83-100

Optional Staging - Circuit #1 in Lead

Optional 6 Stages 0-17-33-50-67-83-

Optional Staging - Circuit #2 in Lead

Optional 6 Stages 0-17-33-50-67-83-

055E 060E 065E 070E 075E

100

100

0-15-33-48-67-82-

100

0-18-33-51-67-85-

100

0-17-33-50-67-83-

100

0-17-33-50-67-83-

100

0-16-33-49-67-83-

100

0-17-33-51-67-84-

100

0-17-33-50-67-83-

100

0-17-33-50-67-83-

100

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Maximum Relief Valve Pressure Setting, psig

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 6 - 26 (660) 6 - 26 (660) 6 - 26 (660) 8 - 26 (660) 10 - 26 (660)

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Maximum Refrigerant Working Pressure, psig

Water Inlet / Outlet Victaulic Connections,

NOTE:

1. Nominal capacity based on 95F ambient air and 54F/44F water range.

Coil Face Area,Sq. Ft. 43.1 43.1 43.1 43.1 43.1 43.1 57.8 57.8 57.8 57.8

Coil Face Area, (M2) (4) (4) (4) (4) (4) (4) (5.4) (5.4) (5.4) (5.4)

Finned Height x Finned Length, In. 40 x 155 40 x 155 40 x 155 40 x 155 40 x 155 40 x 155 40 x 208 40 x 208 40 x 208 40 x 208

Finned Height x Finned Length, (mm) (1016 x

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

(kPa)

Number Of Motors - HP (kW) 6 - 1.0 (.7) 6 - 1.0 (.7) 6 - 1.0 (.7) 8 - 1.0 (.7) 10 - 1.0 (.7)

Fan And Motor RPM, 60/50Hz 1100/915 1100/915 1100/915 1100/915 1100/915

60 Hz Fan Tip Speed, FPM 7760 7760 7760 7760 7760

60 Hz Total Unit Airflow, CFM 38250 38250 38250 51000

Diameter, in. - Length, Ft. 12 - 08 12 - 08 12 - 08 12 - 08 12 - 08

Diameter, (mm) - Length, (mm) (305 - 2439) (305 - 2439) (305 - 2439) (305 - 2439) (305 - 2439)

Water Volume, Gallons, (L) 24.30 (92) 24.30 (92) 24.30 (92) 24.30 (92) 24.30 (92)

Maximum Water Pressure, psig (kPa) 175 (1207) 175 (1207) 175 (1207) 175 (1207) 175 (1207)

(kPa)

In. (mm)

Drain - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

Vent - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

3937)

(3103)

(1016 x

3937)

450

(3103)

225 (1552) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

5 (127) 5 (127) 5 (127) 5 (127) 5 (127)

450

(1016 x

3937)

450

(3103)

(1016 x

3937)

450

(3103)

(1016 x

3937)

450

(3103)

(1016 x

3937)

450

(3103)

(1016 x

5283)

450

(3103)

(1016 x

5283)

450

(3103)

(1016 x

5283)

450

(3103)

(1016 x

5283)

450

(3103)

58000

IM 676 13

Page 14

Table 9, Physical data ALR080E Through 100E

PHYSICAL DATA ALR MODEL NUMBER

080E 085E 090E 100E

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Unit Capacity @ ARI Conditions (1), Tons (kW) 81.3 (285.9) 85.3 (300.0) 92.7 (326.0) 99.2 (348.8)

Number Of Refrigerant Circuits 2 2 2 2

Unit Operating Charge, R-22, Lb. 62 62 65 65 65 65 68 68

Unit Operating Charge, R-22, (kg) (22.7) (22.7) (22.7) (22.7) (24.9) (24.9) (24.9) (24.9)

Cabinet Dimensions, LxWxH, In. 229 x 83 x 59 229 x 83 x 59 229 x 83 x 59 229 x 83 x 59

Cabinet Dimensions, LxWxH, (mm) (5817 x 2108 x 1499) (5817 x 2108 x 1499) (5817 x 2108 x 1499) (5817 x 2108 x 1499)

Unit Operating Weight, Lbs. (kg) 7055 (3200) 7680 (3484) 7685 (3486) 7830 (3552)

Unit Shipping Weight, Lbs. (kg) 6685 (3032) 7310 (3316) 7315 (3318) 7535 (3418)

Add'l Weight If Copper Finned Coils, Lb. (kg) 826 (375) 826 (375) 826 (375) 826 (375)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 25-25 25-25 25-25 30-25 30-25 30-25 30-30 30-30

Number Of Cylinders Per Compressor 4 - 4 4 - 4 4 - 4 4 - 4 6 - 4 6 - 4 6 - 4 6 - 4

Oil Charge Per Compressor, Oz. 130 - 130 130 - 130 130 - 130 140 - 130 140 - 130 140 - 130 140 - 140 140 - 140

Oil Charge Per Compressor, (g) (3686 - 3686) (3686 -

3686)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead

Standard 6 Stages 0-13-25-38-50-75-100 0-12-24-36-48-72-100 0-19-39-48-58-79-100 0-18-36-45-54-76-100

Standard Staging - Circuit #2 in Lead

Standard 6 Stages 0-13-25-38-50-75-100 0-12-24-36-48-76-100 0-19-39-48-58-79-100 0-18-36-45-54-76-100

Optional Staging - Circuit #1 in Lead

Optional 8 Stages 0-13-25-38-50 0-12-24-36-48 0-19-39-48-58 0-18-36-45-76

-63-75-88-100 -60-76-88-100 -69-81-90-100 -68-82-91-100

Optional Staging - Circuit #2 in Lead

Optional 8 Stages 0-13-25-38-50 0-12-24-36-48 0-19-39-48-58 0-18-36-45-76

-63-75-88-100 -64-76-88-100 -69-81-90-100 -68-82-91-100

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area,Sq. Ft. 57.8 57.8 57.8 57.8 57.8 57.8 57.8 57.8

Coil Face Area, (M2) (5.4) (5.4) (5.4) (5.4) (5.4) (5.4) (5.4) (5.4)

Finned Height x Finned Length, In. 40 x 208 40 x 208 40 x 208 40 x 208 40 x 208 40 x 208 40 x 208 40 x 208

Finned Height x Finned Length, (mm) (1016 x 5283) (1016 x

5283)

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

Maximum Relief Valve Pressure Setting, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 10 - 26 (660) 10 - 26 (660) 10 - 26 (660) 10 - 26 (660)

Number Of Motors - HP (kW) 10 - 1.0 (.7) 10 - 1.0 (.7) 10 - 1.0 (.7) 10 - 1.0 (.7)

Fan And Motor RPM, 60/50Hz 1100/915 1100/915 1100/915 1100/915

60 Hz Fan Tip Speed, FPM 7760 7760 7760 7760

60 Hz Total Unit Airflow, CFM 58000 58000 58000 58000

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Diameter, in. - Length, Ft. 12 - 08 14 - 10 14 - 10 14 - 10

Diameter, (mm) - Length, (mm) (305 - 2439) (356 - 3048) (356 - 3048) (356 - 3048)

Water Volume, Gallons, (L) 24.30 (92) 36.10 (136.6) 36.10 (136.6) 36.10 (136.6)

Maximum Water Pressure, psig (kPa) 175 (1207) 175 (1207) 175 (1207) 175 (1207)

Maximum Refrigerant Working Pressure, psig (kPa) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

Water Inlet / Outlet Victaulic Connections, In. (mm) 5 (127) 6 (152.4) 6 (152.4) 6 (152.4)

Drain - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

Vent - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

NOTE:

1. Nominal capacity based on 95F ambient air and 54F/44F water range.

(3686 -

3686)

(1016 x

5283)

(3969 -

3686)

(1016 x

5283)

(3969 -

3686)

(1016 x

5283)

(3969 -

3686)

(1016 x

5283)

(3969 -

3969)

(1016 x

5283)

(3969 -

3969)

(1016 x

5283)

14 IM 676

Page 15

Table 10, Physical data ALR100E Through 135E

PHYSICAL DATA ALR MODEL NUMBER

110E 120E 130E 135E

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Unit Capacity @ ARI Conditions (1), Tons (kW) 107.8 (379.0) 120.7 (424.4) 130.6 (459.2) 135.5 (476.4)

Number Of Refrigerant Circuits 2 2 2 2

Unit Operating Charge, R-22, Lb. 87 87 90 90 120 120 120 120

Unit Operating Charge, R-22, (kg) (36.3) (36.3) (36.3) (36.3) (38.6) (38.6) (38.6) (38.6)

Cabinet Dimensions, LxWxH, In. 229 x 83 x 89 229 x 83 x 89 229 x 83 x 93 229 x 83 x 93

Cabinet Dimensions, LxWxH, (mm) (5809 x 2118 x 2369) (5809 x 2118 x 2369) (5809 x 2118 x 2369) (5809 x 2118 x 2369)

Unit Operating Weight, Lbs. (kg) 8800 (3992) 9200 (4173) 9800 (4445) 10160 (4609)

Unit Shipping Weight, Lbs. (kg) 8505 (3858) 8760 (3974) 9350 (4241) 9735 (4416)

Add'l Weight If Copper Finned Coils, Lbs. (kg) 1105 (501) 1105 (501) 1652 (750) 1652 (750)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 30-30 30-35 30-35 35-35 35-35 35-35 35-40 35-40

Number Of Cylinders Per Compressor 6 - 6 6 - 6 6 - 6 6 - 6 6 - 6 6 - 6 6 - 6 6 - 6

Oil Charge Per Compressor, Oz. 140 - 140 140 - 140 140 - 140 140 - 140 140 - 140 140 - 140 140 - 255 140 - 255

Oil Charge Per Compressor, (g) (3969 -

3969)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead

Standard 6 Stages 0-16-32-40-48-71-100 0-15-32-39-48-74-100 0-17-33-42-50-75-100 0-16-32-40-48-74-100

Standard Staging - Circuit #2 in Lead

Standard 6 Stages 0-16-32-40-48-76-100 0-17-32-41-48-76-100 0-17-33-42-50-75-100 0-16-32-40-48-74-100

(3969 -

3969)

(3969 -

3969)

(3969 -

3969)

(3969 -

3969)

(3969 -

3969)

(3969 -

7229)

(3969 -

7229)

Optional Staging - Circuit #1 in Lead

Optional 8 Stages 0-16-32-40-48 0-15-32-39-48 0-17-33-42-50 0-16-32-40-48

-64-84-92-100 -67-84-91-100 -67-83-92-100 -66-84-92-100

Optional Staging - Circuit #2 in Lead

Optional 8 Stages 0-16-32-40-48 0-17-32-41-48 0-17-33-42-50 0-16-32-40-48

-68-84-92-100 -65-84-91-100 -67-83-92-100 -66-84-92-100

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area,Sq. Ft. 115.6 115.6 115.6 115.6 115.6 115.6 115.6 115.6

Coil Face Area, (M2) (10.3) (10.3) (10.3) (10.3) (10.3) (10.3) (10.3) (10.3)

Finned Height x Finned Length, In. 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208

Finned Height x Finned Length, (mm) (2032 x

5283)

Fins Per Inch x Rows Deep 16 x 2 16 x 2 16 x 2 16 x 2 16 x 3 16 x 3 16 x 3 16 x 3

Maximum Relief Valve Pressure Setting, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 10 - 28 (711) 10 - 28 (711) 12 - 28 (711) 12 - 28 (711)

Number Of Motors - HP (kW) 10 - 1.5 (1.1) 10 - 1.5 (1.1) 12 - 1.5 (1.1) 12 - 1.5 (1.1)

Fan And Motor RPM, 60/50Hz 1100/915 1100/915 1100/915 1100/915

60 Hz Fan Tip Speed, FPM 8063 8063 8063 8063

60 Hz Total Unit Airflow, CFM 94710 94710 108240 108240

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Diameter, in. - Length, Ft. 14 - 10 16 - 10 16 - 10 16 - 10

Diameter, (mm) - Length, (mm) (356 - 3048) (406 - 3048) (406 - 3048) (406 - 3048)

Water Volume, Gallons, (L) 36.10 (136.6) 43.6 (165) 43.6 (165) 43.6 (165)

Maximum Water Pressure, psig (kPa) 175 (1207) 175 (1207) 175 (1207) 175 (1207)

Maximum Refrigerant Working Pressure, psig (kPa) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

Water Inlet / Outlet Victaulic Connections, In. (mm) 6 (152.4) 6 (152.4) 6 (152.4) 6 (152.4)

Drain - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

Vent - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

NOTE:

1. Nominal capacity based on 95F ambient air and 54F/44F water range.

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

IM 676 15

Page 16

Table 11, Physical data ALR140E Through 160E

PHYSICAL DATA ALR MODEL NUMBER

140E 145E 150E 160E

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Unit Capacity @ ARI Conditions (1), Tons (kW) 139.7 (491.2) 144.7 (508.8) 149.9 (527.0) 157.8 (554.8)

Number Of Refrigerant Circuits 2 2 2 2

Unit Operating Charge, R-22, Lbs 125 125 130 130 130 130 140 140

Unit Operating Charge, R-22, (kg) (45.4) (45.4) (45.4) (45.4) (45.4) (45.4) (49.9) (49.9)

Cabinet Dimensions, LxWxH, In. 229 x 83 x 93 229 x 83 x 93 229 x 83 x 93 263 x 83 x 93

Cabinet Dimensions, LxWxH, (mm) (5809 x 2118 x 2369) (5809 x 2118 x 2369) (5809 x 2118 x 2369) (6690 x 2118 x 2369)

Unit Operating Weight, Lbs. (kg) 10440 (4736) 10690 (4849) 10850 (4922) 11515 (5223)

Unit Shipping Weight, Lbs. (kg) 10040 (4554) 10290 (4668) 10450 (4740) 11115 (5042)

Add'l Weight If Copper Finned Coils, Lb. (kg) 1652 (750) 1652 (750) 1652 (750) 1930 (876)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 40-40 40-40 40-40 40-40 40-40 40-50 40-50 40-50

Number Of Cylinders Per Compressor 6 - 6 6 - 6 6 - 6 6 - 6 6 - 6 6 - 8 6 - 8 6 - 8

Oil Charge Per Compressor, Oz. 255 - 255 255 - 255 255 - 255 255 - 255 255 - 255 255 - 255 255 - 255 255 - 255

Oil Charge Per Compressor, (g) (7229 -

7229)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead

Standard 6 Stages (N/A on MicroTech Units) 0-17-33-42-50-75-100 0-17-33-42-50-75-100 0-15-32-40-48-72-100 0-17-33-42-50-77-100

Standard Staging - Circuit #2 in Lead

Standard 6 Stages (N/A on MicroTech Units) 0-17-33-42-50-75-100 0-17-33-42-50-75-100 0-15-32-40-48-76-100 0-17-33-42-50-77-100

(7229 -

7229)

(7229 -

7229)

(7229 -

7229)

(7229 -

7229)

(7229 -

7229)

(7229 -

7229)

(7229 -

7229)

Optional Staging - Circuit #1 in Lead

Optional 8 Stages (Std. on MicroTech Units) 0-17-33-42-50 0-17-33-42-50 0-15-32-40-64 0-17-33-42-50

-67-83-92-100 -67-83-92-100 -64-84-92-100 -63-71-86-100

Optional Staging - Circuit #2 in Lead

Optional 8 Stages (Std. on MicroTech Units) 0-17-33-42-50 0-17-33-42-50 0-15-32-40-48 0-17-33-42-50

-67-83-92-100 -67-83-92-100 -68-84-92-100 -63-71-86-100

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area,Sq. Ft. 115.6 115.6 115.6 115.6 115.6 115.6 135 135

Coil Face Area, (M2) (10.3) (10.3) (10.3) (10.3) (10.3) (10.3) (12.5) (12.5)

Finned Height x Finned Length, In. 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 208 80 x 243 80 x 243

Finned Height x Finned Length, (mm) (2032 x

5283)

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

Maximum Relief Valve Pressure Setting, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 12 - 28 (711) 12 - 28 (711) 12 - 28 (711) 14 - 28 (711)

Number Of Motors - HP (kW) 12 - 1.5 (1.1) 12 - 1.5 (1.1) 12 - 1.5 (1.1) 14 - 1.5 (1.1)

Fan And Motor RPM, 60/50Hz 1100/915 1100/915 1100/915 1100/915

60 Hz Fan Tip Speed, FPM 8063 8063 8063 8063

60 Hz Total Unit Airflow, CFM 108240 108240 108240 126280

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Diameter, in. - Length, Ft. 16 - 10 18 - 10 18 - 10 18 - 10

Diameter, (mm) - Length, (mm) (406 - 3048) (457 - 3048) (457 - 3048) (457 - 3048)

Water Volume, Gallons, (L) 43.6 (165) 57.30 (216.9) 57.30 (216.9) 57.30 (216.9)

Maximum Water Pressure, psig (kPa) 175 (1207) 175 (1207) 175 (1207) 175 (1207)

Maximum Refrigerant Working Pressure, psig (kPa) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

Water Inlet / Outlet Victaulic Connections, In. (mm) 6 (152.4) 6 (152.4) 6 (152.4) 6 (152.4)

Drain - NPT int, In. (mm) 0.375 (9.5) 0.375 (9.5) 0.375 (9.5) 0.375 (9.5)

Vent - NPT int, In. (mm) 0.375 (9.5) 0.375 (9.5) 0.375 (9.5) 0.375 (9.5)

NOTE:

1. Nominal capacity based on 95F ambient air and 54F/44F water range.

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

(2032 x

5283)

(2032 x

6172)

(2032 x

6172)

16 IM 676

Page 17

Table 12, Physical data ALR170E Through 185E

PHYSICAL DATA ALR MODEL NUMBER

170E 180E 185E

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Unit Capacity @ ARI Conditions (1), Tons (kW) 167.2 (587.9) 177.3 (623.4) 185.8 (653.3)

Number Of Refrigerant Circuits 2 2 2

Unit Operating Charge, R-22, Lb. 140 140 145 145 145 145

Unit Operating Charge, R-22, (kg) (52.2) (52.2) (54.4) (54.4) (54.4) (54.4)

Cabinet Dimensions, LxWxH, In. 263 x 83 x 93 263 x 83 x 93 263 x 83 x 93

Cabinet Dimensions, LxWxH, (mm) (6690 x 2118 x 2369) (6690 x 2118 x 2369) (6690 x 2118 x 2369)

Unit Operating Weight, Lbs. (kg) 11805 (5355) 11805 (5355) 11805 (5355)

Unit Shipping Weight, Lbs. (kg) 11405 (5174) 11405 (5174) 11405 (5174)

Add'l Weight If Copper Finned Coils, Lb. (kg) 1930 (876) 1930 (876) 1930 (876)

COMPRESSORS

Type Semi-Hermetic Semi-Hermetic Semi-Hermetic

Nominal Horsepower 50-50 50-50 50-60 50-60 60-60 60-60

Number Of Cylinders Per Compressor 8 - 8 8 - 8 8 - 8 8 - 8 8 - 8 8 - 8

Oil Charge Per Compressor, Oz. 255 - 255 255 - 255 255 - 255 255 - 255 255 - 255 255 - 255

Oil Charge Per Compressor, (g) (7229 -

7229)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead

Standard 6 Stages (N/A on MicroTech Units) 0-19-37-44-50-75-100 0-17-34-40-46-73-100 0-19-37-44-50-75-100

Standard Staging - Circuit #2 in Lead

Standard 6 Stages (N/A on MicroTech Units) 0-19-37-44-50-75-100 0-17-34-40-46-73-100 0-19-37-44-50-75-100

(7229 -

7229)

(7229 -

7229)

(7229 -

7229)

(7229 -

7229)

(7229 -

7229)

Optional Staging - Circuit #1 in Lead

Optional 8 Stages (Std. on MicroTech Units) 0-19-37-44-50 0-17-34-40-46 0-19-37-44-50

-62-75-87-100 -67-89-94-100 -62-75-87-100

Optional Staging - Circuit #2 in Lead

Optional 8 Stages (Std. on MicroTech Units) 0-19-37-44-50 0-17-34-40-46 0-19-37-44-50

-62-75-87-100 -67-89-94-100 -62-75-87-100

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area,Sq. Ft. 135 135 135 135 135 135

Coil Face Area, (M2) (12.5) (12.5) (12.5) (12.5) (12.5) (12.5)

Finned Height x Finned Length, In. 80 x 243 80 x 243 80 x 243 80 x 243 80 x 243 80 x 243

Finned Height x Finned Length, (mm) (2032 x

6172)

Fins Per Inch x Rows Deep 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

Maximum Relief Valve Pressure Setting, psig (kPa) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103) 450 (3103)

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 14 - 28 (711) 14 - 28 (711) 14 - 28 (711)

Number Of Motors - HP (kW) 14 - 1.5 (1.1) 14 - 1.5 (1.1) 14 - 1.5 (1.1)

Fan And Motor RPM, 60/50Hz 1100/915 1100/915 1100/915

60 Hz Fan Tip Speed, FPM 8063 8063 8063

60 Hz Total Unit Airflow, CFM 126280 126280 126280

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Diameter, in. - Length, Ft. 18 - 10 18 - 10 18 - 10

Diameter, (mm) - Length, (mm) (457 - 3048) (457 - 3048) (457 - 3048)

Water Volume, Gallons, (L) 57.30 (216.9) 57.30 (216.9) 57.30 (216.9)

Maximum Water Pressure, psig (kPa) 175 (1207) 175 (1207) 175 (1207)

Maximum Refrigerant Working Pressure, psig (kPa) 225 (1552) 225 (1552) 225 (1552)

Water Inlet / Outlet Victaulic Connections, In. (mm) 6 (152.4) 6 (152.4) 6 (152.4)

Drain - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5)

Vent - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5)

NOTE:

1. Nominal capacity based on 95F ambient air and 54F/44F water range.

(2032 x

6172)

(2032 x

6172)

(2032 x

6172)

(2032 x

6172)

(2032 x

6172)

IM 676 17

Page 18

Electrical Data

Field Wiring

CAUTION

Internal power wiring to the compressors for single and multiple point option are different. Field wiring must be

installed according to unit wiring diagram.

Wiring must comply with all applicable codes and ordinances. Warranty is void if wiring is not in accordance with

specifications. Copper wire is required for all power lead terminations at the unit. Aluminum or copper can be used for all

other wiring.

ALR units may be ordered with internal power wiring for either single or multiple point power connection. If single

point power connection is ordered, a single large power terminal block is provided and wiring within the unit is sized in

accordance with the National Electrical Code. A single field supplied fused disconnect is required. An optional factory

mounted transformer may be installed.

If multiple point power wiring is ordered, three power connections, one per compressor circuit, one for condenser fans,

and control circuit, are required. Separate field supplied fused disconnects are required for each of the three circuits. A

single power block is provided for all of the condenser fans and the optional 115V control transformer.

If the evaporator heater is on a separate disconnect switch from the main unit power supply, the unit may be shut down

without defeating the freeze protection provided by the cooler heater.

18 IM 676

Page 19

Table 13, 032E - 070E Electrical Data Single Point

Minimum POWER SUPPLY FIELD FUSE SIZE

ALR Circuit Field Wire Hub

Unit Volts HZ. Ampacity Wire Nominal Recommended Maximum

Size (MCA) Quantity Gauge Quantity Size

208 151 3 2/0 1 1.50 (38) 175 200

032E 460 60 76 3 4 1 1.00 (25) 90 100

035E 460 60 76 3 4 1 1.00 (25) 90 100

040E 460 60 92 3 3 1 1.25 (32) 110 125

045E 460 60 108 3 2 1 1.25 (32) 125 150

050E 460 60 113 3 2 1 1.25 (32) 150 150

055E 460 60 118 3 1 1 1.25 (32) 150 150

060E 460 60 134 3 1/0 1 1.50 (51) 175 175

065E 460 60 147 3 1/0 1 1.50 (38) 175 200

070E 460 60 156 3 2/0 1 1.50 (38) 200 200

075E 460 60 164 3 2/0 1 1.50 (38) 200 225

See page 33 for all Electrical Data notes.

230 151 3 2/0 1 1.50 (38) 175 200

575 58 3 6 1 1.00 (25) 70 80

208 151 3 2/0 1 1.50 (38) 175 200

230 151 3 2/0 1 1.50 (38) 175 200

575 61 3 6 1 1.00 (25) 70 80

208 183 3 3/0 1 2.00 (51) 225 250

230 183 3 3/0 1 2.00 (51) 225 250

575 79 3 4 1 1.00 (25) 90 100

208 217 3 4/0 1 2.00 (51) 250 300

230 217 3 4/0 1 2.00 (51) 250 300

575 89 3 3 1 1.25 (32) 110 125

208 228 3 4/0 1 2.00 (51) 300 300

230 228 3 4/0 1 2.00 (51) 300 300

575 94 3 3 1 1.25 (32) 110 125

208 238 3 250 1 2.50 (64) 300 300

230 238 3 250 1 2.50 (64) 300 300

575 94 3 3 1 1.25 (32) 110 125

208 270 3 300 1 2.50 (64) 350 350

230 259 3 300 1 2.50 (64) 300 350

575 102 3 2 1 1.25 (32) 125 125

208 296 3 350 1 2.50 (64) 350 400

230 276 3 300 1 2.50 (64) 350 350

575 108 3 2 1 1.25 (32) 125 150

208 322 3 400 1 3.00 (76) 400 450

230 303 3 350 1 2.50 (64) 350 400

575 120 3 1 1 1.25 (32) 150 150

208 344 3 500 1 3.00 (76) 400 450

230 326 3 400 1 3.00 (76) 400 450

575 130 3 1 1 1.25 (32) 150 175

IM 676 19

Page 20

Table 14, 080E - 135E Electrical Data Single Point

Minimum POWER SUPPLY FIELD FUSE SIZE

ALR Circuit Field Wire Hub

Unit Volts HZ. Ampacity Wire Nominal Recommended Maximum

Size (MCA) Quantity Gauge Quantity Size

208 355 3 500 1 3.00 (76) 400 400

230 355 3 500 1 3.00 (76) 400 400

080E 460 60 177 3 3/0 1 2.00 (51) 200 200

575 154 3 2/0 1 1.50 (51) 175 175

208 368 3 500 1 3.00 (76) 400 450

230 368 3 500 1 3.00 (76) 400 450

085E 460 60 184 3 3/0 1 2.00 (51) 200 225

575 160 3 2/0 1 1.50 (51) 175 175

208 402 6 250 1 3.00 (76) 450 450

230 402 6 250 1 3.00 (76) 450 450

090E 460 60 200 3 3/0 1 2.00 (51) 225 225

575 165 3 2/0 1 1.50 (51) 200 200

208 424 6 300 1 4.00 (102) 450 500

230 424 6 300 1 4.00 (102) 450 500

100E 460 60 210 3 4/0 1 2.00 (51) 225 250

575 175 3 2/0 1 1.50 (51) 200 200

208 494 6 350 1 4.00 (102) 600 600

230 483 6 350 1 4.00 (102) 600 500

110E 460 60 244 3 250 1 2.50 (64) 300 300

575 184 3 3/0 1 2.00 (51) 200 225

208 547 6 500 1 4.00 (102) 600 600

230 517 6 400 1 4.00 (102) 600 600

120E 460 60 270 3 300 1 2.50 (64) 300 300

575 196 3 3/0 1 2.00 (51) 225 225

208 584 6 500 1 4.00 (102) 700 700

230 546 6 500 1 4.00 (102) 600 600

130E 460 60 289 3 350 1 2.50 (64) 300 300

575 206 3 4/0 1 2.00 (51) 225 225

208 615 6 350 2 2.50 (64) 700 700

230 579 6 350 2 2.50 (64) 700 700

135E 460 60 298 3 350 1 2.50 (64) 350 350

575 220 3 300 1 2.00 (51) 250 250

See page 33 for all Electrical Data notes.

20 IM 676

Page 21

Table 15, 140E - 185E Electrical Data Single Point

Minimum POWER SUPPLY FIELD FUSE SIZE

ALR Circuit Field Wire Hub

Unit Volts HZ. Ampacity Wire Nominal Recommended Maximum

Size (MCA) Quantity Gauge Quantity Size

208 643 6 500 2 3.00 (76) 700 700

230 609 6 500 2 3.00 (76) 700 700

140E 460 60 306 3 350 1 2.50 (64) 350 350

575 232 3 250 1 2.50 (64) 250 250

208 643 6 500 2 3.00 (76) 700 700

230 609 6 500 2 3.00 (76) 700 700

145E 460 60 306 3 350 1 2.50 (64) 350 350

575 232 3 250 1 2.50 (64) 250 250

208 677 6 500 2 3.00 (76) 800 800

230 653 6 500 2 3.00 (76) 800 800

150E 460 60 328 3 400 1 3.00 (76) 350 450

575 257 3 300 1 2.50 (64) 300 300

208 716 6 500 2 3.00 (76) 800 800

230 700 6 500 2 3.00 (76) 800 800

160E 460 60 352 3 500 1 3.00 (76) 400 400

575 281 3 300 1 2.50 (64) 300 300

208 770 6 600 2 3.00 (76) 800 800

230 770 6 600 2 3.00 (76) 800 800

170E 460 60 388 3 600 1 3.00 (76) 450 450

575 321 3 400 1 3.00 (76) 350 350

208 860 12 300 2 4.0 (102) 1000 1000

230 860 12 300 2 4.0 (102) 1000 1000

180E 460 60 413 3 600 1 3.00 (76) 500 500

575 337 3 500 1 3.00 (76) 400 400

208 940 12 350 2 4.0 (102) 1000 1000

230 940 12 350 2 4.0 (102) 1000 1000

185E 460 60 435 6 300 1 3.00 (76) 500 500

575 351 3 500 1 3.00 (76) 400 400

See page 33 for all Electrical Data notes.

IM 676 21

Page 22

Table 16, 032E - 075E Electrical Data Multiple Point

Electrical Circuit #1 - Fans and Transformer Electrical Circuit #2 - Compressor Circuit #1 Electrical Circuit #3 - Compressor Circuit #2

ALR Min. Power Supply Field Fusing Min. Power Supply Field

Fusing

Unit Volts HZ. Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max.

Size Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse FuseAmps Wire Hub Fuse Fuse

(MCA) Qty. Gauge Qty. Size Size Size (MCA) Qty. Gauge Qty. Size Size Size (MCA) Qty. GaugeQty. Size Size Size

Min. Power Supply Field Fusing

208 17 3 12 1 1.00

(25)

230 17 3 12 1 1.00

(25)

032E 460 60 8.5 3 14 1 .75

(19)

575 9.4 3 14 1 .75

(19)

208 17 3 12 1 1.00

(25)

230 17 3 12 1 1.00

(25)

035E 460 60 8.5 3 14 1 .75

(19)

575 9.4 3 14 1 .75

(19)

208 17 3 12 1 1.00

(25)

230 17 3 12 1 1.00

(25)

040E 460 60 8.5 3 14 1 .75

(19)

575 9.4 3 14 1 .75

(19)

208 25 3 12 1 1.00

(25)

230 25 3 12 1 1.00

(25)

045E 460 60 12.5 3 14 1 .75

(19)

575 13.8 3 14 1 .75

(19)

208 25 3 12 1 1.00

(25)

230 25 3 12 1 1.00

(25)

050E 460 60 12.5 3 14 1 .75

(19)

575 13.8 3 14 1 .75

(19)

208 25 3 12 1 1.00

(25)

230 25 3 12 1 1.00

(25)

055E 460 60 12.5 3 14 1 .75

(19)

575 13.8 3 14 1 .75

(19)

208 25 3 12 1 1.00

(25)

230 25 3 12 1 1.00

(25)

060E 460 60 12.5 3 14 1 .75

(19)

575 13.8 3 14 1 .75

(19)

See page 33 for all Electrical Data notes.

20 20 75 3 4 1 2.00

(51)

20 20 75 3 4 1 2.00

(51)

15 15 38 3 8 1 1.25

(32)

15 15 28 3 10 1 1.00

(25)

20 20 75 3 4 1 2.00

(51)

20 20 75 3 4 1 2.00

(51)

15 15 38 3 8 1 1.25

(32)

15 15 28 3 10 1 1.00

(25)

20 20 93 3 3 1 2.00

(51)

20 20 93 3 3 1 2.00

(51)

15 15 47 3 8 1 1.25

(32)

15 15 39 3 8 1 1.25

(32)

25 25 93 3 3 1 2.00

(51)

25 25 93 3 3 1 2.00

(51)

15 15 47 3 8 1 1.25

(32)

15 15 39 3 8 1 1.25

(32)

25 25 107 3 2 1 2.00

(51)

25 25 107 3 2 1 2.00

(51)

15 15 53 3 6 1 1.50

(38)

15 15 45 3 8 1 1.25

(32)

25 25 119 3 1 1 2.00

(51)

25 25 119 3 1 1 2.00

(51)

15 15 59 3 6 1 1.50

(38)

15 15 45 3 8 1 1.25

(32)

25 25 119 3 1 1 2.00

(51)

25 25 119 3 1 1 2.00

(51)

15 15 59 3 6 1 1.50

(38)

15 15 45 3 8 1 1.25

(32)

100 125 75 3 4 1 2.00

(51)

100 125 75 3 4 1 2.00

(51)

50 60 38 3 8 1 1.25

(32)

35 45 28 3 10 1 1.00

(25)

100 125 75 3 4 1 2.00

(51)

100 125 75 3 4 1 2.00

(51)

50 60 38 3 8 1 1.25

(32)

35 45 30 3 10 1 1.00

(25)

125 150 93 3 3 1 2.00

(51)

125 150 93 3 3 1 2.00

(51)

60 80 47 3 8 1 1.25

(32)

50 60 39 3 8 1 1.25

(32)

125 150 119 3 1 1 2.00

(51)

125 150 119 3 1 1 2.00

(51)

60 80 59 3 6 1 1.50

(38)

50 60 45 3 8 1 1.25

(32)

150 175 119 3 1 1 2.00

(51)

150 175 119 3 1 1 2.00

(51)

70 90 59 3 6 1 1.50

(38)

60 80 45 3 8 1 1.25

(32)

150 200 119 3 1 1 2.00

(51)

150 200 119 3 1 1 2.00

(51)

80 100 59 3 6 1 1.50

(38)

60 80 45 3 8 1 1.25

(32)

150 200 152 3 2/0 1 1.50

(38)

150 200 140 3 1/0 1 1.50

(38)

80 100 75 3 4 1 2.00

(51)

60 80 53 3 6 1 1.50

(38)

100 125

100 125

50 60

35 45

100 125

100 125

50 60

40 50

125 150

125 150

60 80

50 60

150 200

150 200

80 100

60 80

150 200

150 200

80 100

60 80

150 200

150 200

80 100

60 80

200 250

200 250

100 125

70 90

22 IM 676

Page 23

Table 17, 032E - 075E Electrical Data Multiple Point (continued)

Electrical Circuit #1 - Fans and Transformer Electrical Circuit #2 - Compressor Circuit #1 Electrical Circuit #3 - Compressor Circuit #2

ALR Min. Power Supply Field

Unit Volts HZ. Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max.

Size Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse Fuse

(MCA) Qty. Gauge Qty. Size Size Size (MCA) Qty. Gauge Qty. Size Size Size (MCA) Qty. Gauge Qty. Size Size Size

208 25 3 12 1 1.00

230 25 3 12 1 1.00

065E 460 60 12.5 3 14 1 .75

575 13.8 3 14 1 .75

208 33 3 10 1 1.00

230 33 3 10 1 1.00

070E 460 60 16.5 3 12 1 1.00

575 18.1 3 12 1 1.00

208 41 3 8 1 1.25

230 41 3 8 1 1.25

075E 460 60 21 3 12 1 1.00

575 23 3 12 1 1.00

Fusing

25 25 152 3 2/0 1 1.50

(25)

25 25 140 3 1/0 1 1.50

(25)

15 15 75 3 4 1 2.00

(19)

15 15 53 3 6 1 1.50

(19)

35 35 152 3 2/0 1 1.50

(25)

35 35 140 3 1/0 1 1.50

(25)

20 20 75 3 4 1 2.00

(25)

20 20 53 3 6 1 1.50

(25)

45 45 169 3 2/0 1 1.50

(32)

45 45 159 3 2/0 1 1.50

(32)

25 25 80 3 4 1 2.00

(25)

25 25 60 3 6 1 1.50

(25)

Min. Power Supply Field

Fusing

200 250 152 3 2/0 1 1.50

(38)

200 250 140 3 1/0 1 1.50

(38)

100 125 75 3 4 1 2.00

(51)

70 90 53 3 6 1 1.50

(38)

200 250 169 3 2/0 1 1.50

(38)

200 250 159 3 2/0 1 1.50

(38)

100 125 80 3 4 1 2.00

(51)

70 90 60 3 6 1 1.50

(38)

225 300 169 3 2/0 1 1.50

(38)

225 250 159 3 2/0 1 1.50

(38)

110 125 80 3 4 1 2.00

(51)

80 100 60 3 6 1 1.50

(38)

Min. Power Supply Field

Fusing

200 250

(38)

200 250

(38)

100 125

(51)

70 90

(38)

225 300

(38)

225 250

(38)

110 125

(51)

80 100

(38)

225 300

(38)

225 250

(38)

110 125

(51)

80 100

(38)

Table 18, 080E - 135E Electrical Data Multiple Point

Electrical Circuit #1 - Fans and Transformer Electrical Circuit #2 - Compressor Circuit #1 Electrical Circuit #3 - Compressor Circuit #2

ALR Min. Power Supply Field

Unit Volts HZ. Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max.

Size Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse Fuse

(MCA) Qty. Gauge Qty. Size Size Size (MCA) Qty. Gauge Qty. Size Size Size (MCA) Qty. Gauge Qty. Size Size Size

208 41 3 8 1 1.25

(32)

230 41 3 8 1 1.25

(32)

080E 460 60 21 3 12 1 1.00

(25)

575 23 3 12 1 1.00

(25)

208 41 3 8 1 1.25

(32)

230 41 3 8 1 1.25

(32)

085E 460 60 21 3 12 1 1.00

(25)

575 23 3 12 1 1.00

(25)

208 41 3 8 1 1.25

(32)

230 41 3 8 1 1.25

(32)

090E 460 60 21 3 12 1 1.00

(25)

575 23 3 12 1 1.00

(25)

208 41 3 8 1 1.25

(32)

230 41 3 8 1 1.25

(32)

100E 460 60 21 3 12 1 1.00

(25)

575 23 3 12 1 1.00

(25)

Fusing

45 45 167 3 2/0 1 2.00

45 45 167 3 2/0 1 2.00

25 25 84 3 4 1 1.00

25 25 70 3 4 1 1.00

45 45 167 3 2/0 1 2.00

45 45 167 3 2/0 1 2.00

25 25 84 3 4 1 1.00

25 25 70 3 4 1 1.00

45 45 193 3 3/0 1 2.00

45 45 193 3 3/0 1 2.00

25 25 96 3 3 1 1.25

25 25 76 3 4 1 1.00

45 45 204 3 4/0 1 2.00

45 45 204 3 4/0 1 2.00

25 25 101 3 2 1 1.25

25 25 81 3 4 1 1.00

See page 33 for all Electrical Data notes.

Min. Power Supply Field

Fusing

200 225 167 3 2/0 1 2.00

(51)

200 225 167 3 2/0 1 2.00

(51)

100 110 84 3 4 1 1.00

(25)

80 100 70 3 4 1 1.00

(25)

200 225 181 3 3/0 1 2.00

(51)

200 225 181 3 3/0 1 2.00

(51)

100 110 90 3 3 1 1.25

(25)

80 100 76 3 4 1 1.00

(25)

225 250 193 3 3/0 1 2.00

(51)

225 250 193 3 3/0 1 2.00

(51)

110 125 96 3 3 1 1.25

(32)

90 110 76 3 4 1 1.00

(25)

250 250 204 3 4/0 1 2.00

(51)

250 250 204 3 4/0 1 2.00

(51)

125 125 101 3 2 1 1.25

(32)

100 110 81 3 4 1 1.00

(25)

Min. Power Supply Field

Fusing

200 225

(51)

200 225

(51)

100 110

(25)

80 100

(25)

225 250

(51)

225 250

(51)

110 125

(32)

90 110

(25)

225 250

(51)

225 250

(51)

110 125

(32)

90 110

(25)

250 250

(51)

250 250

(51)

125 125

(32)

100 110

(25)

IM 676 23

Page 24

Table 19, 080E - 135E Electrical Data Multiple Point (continued)

Electrical Circuit #1 - Fans and Transformer Electrical Circuit #2 - Compressor Circuit #1 Electrical Circuit #3 - Compressor Circuit #2

ALR Min. Power Supply Field

Unit Volts HZ. Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max.

Size Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse Fuse

(MCA) Qty. Gauge Qty. Size Size Size (MCA) Qty. Gauge Qty. Size Size Size (MCA) Qty. Gauge Qty. Size Size Size

208 60 3 6 1 1.50

(38)

230 60 3 6 1 1.50

(38)

110E 460 60 29 3 10 1 1.00

(25)

575 24 3 10 1 1.00

(25)

208 60 3 6 1 1.50

(38)

230 60 3 6 1 1.50

(38)

120E 460 60 29 3 10 1 1.00

(25)

575 24 3 10 1 1.00

(25)

208 71 3 4 1 2.00

(51)

230 71 3 4 1 2.00

(51)

130E 460 60 35 3 8 1 1.25

(32)

575 28 3 10 1 1.00

(25)

208 71 3 4 1 2.00

(51)

230 71 3 4 1 2.00

(51)

135E 460 60 35 3 8 1 1.25

(32)

575 28 3 10 1 1.00

(25)

Fusing

60 60 214 3 4/0 1 2.00

60 60 214 3 4/0 1 2.00

30 30 106 3 2 1 1.25

25 25 81 3 4 1 1.00

60 60 247 3 250 1 2.50

60 60 235 3 250 1 2.50

30 30 122 3 1 1 1.25

25 25 89 3 3 1 1.25

80 80 273 3 300 1 2.50

80 80 252 3 250 1 2.50

35 35 135 3 1/0 1 1.50

30 30 95 3 3 1 1.25

80 80 290 3 350 1 2.50

80 80 271 3 300 1 2.50

35 35 140 3 1/0 1 1.50

30 30 102 3 2 1 1.25

See page 33 for all Electrical Data notes.

Min. Power Supply Field

Fusing

250 300 247 3 250 1 2.50

(51)

250 300 235 3 250 1 2.50

(51)

125 150 122 3 1 1 1.25

(32)

100 110 89 3 3 1 1.25

(25)

300 350 273 3 300 1 2.50

(64)

300 300 252 3 250 1 2.50

(64)

150 150 135 3 1/0 1 1.50

(32)

110 125 95 3 3 1 1.25

(32)

350 350 273 3 300 1 2.50

(64)

300 350 252 3 250 1 2.50

(64)

175 175 135 3 1/0 1 1.50

(38)

110 125 95 3 3 1 1.25

(32)

350 400 290 3 350 1 2.50

(64)

350 350 271 3 300 1 2.50

(64)

175 200 140 3 1/0 1 1.50

(38)

125 150 102 3 2 1 1.25

(32)

Min. Power Supply Field

Fusing

300 350

(64)

300 300

(64)

150 150

(32)

110 125

(32)

350 350

(64)

300 350

(64)

175 175

(38)

110 125

(32)

350 350

(64)

300 350

(64)

175 175

(38)

110 125

(32)

350 400

(64)

350 350

(64)

175 200

(38)

125 150

(32)

Table 20, 140E - 185E Electrical Data Multiple Point

Electrical Circuit #1 - Fans and Transformer Electrical Circuit #2 - Compressor Circuit #1 Electrical Circuit #3 - Compressor Circuit #2

ALR Min. Power Supply Field Fusing Min. Power Supply Field Fusing Min. Power Supply Field

Unit Volts HZ.Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max.

Size Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse Fuse

208 71 3 4 1 2.00

230 71 3 4 1 2.00

140E 460 60 35 3 8 1 1.25

575 28 3 10 1 1.00

208 71 3 4 1 2.00

230 71 3 4 1 2.00

145E 460 60 35 3 8 1 1.25

575 28 3 10 1 1.00

(MCA) Qty Gauge Qty Size Size Size (MCA) Qty Gauge Qty Size Size Size (MCA) Qty Gauge Qty Size Size Size

80 80 304 3 350 1 2.50

(51)

80 80 286 3 350 1 2.50

(51)

35 35 144 3 1/0 1 1.50

(32)

30 30 108 3 2 1 1.25

(25)

80 80 304 3 350 1 2.50

(51)

80 80 286 3 350 1 2.50

(51)

35 35 144 3 1/0 1 1.50

(32)

30 30 108 3 2 1 1.25

(25)

350 400 304 3 350 1 2.50

(64)

350 400 286 3 350 1 2.50

(64)

175 200 144 3 1/0 1 1.50

(38)

125 150 108 3 2 1 1.25

(32)

350 400 304 3 350 1 2.50

(64)

350 400 286 3 350 1 2.50

(64)

175 200 144 3 1/0 1 1.50

(38)

125 150 108 3 2 1 1.25

(32)

See page 33 for all Electrical Data notes.

Fusing

350 400

(64)

350 400

(64)

175 200

(38)

125 150

(32)

350 400

(64)

350 400

(64)

175 200

(38)

125 150

(32)

24 IM 676

Page 25

Table 26, 140E - 185E Electrical Data Multiple Point (continued)

Electrical Circuit #1 - Fans and Transformer Electrical Circuit #2 - Compressor Circuit #1 Electrical Circuit #3 - Compressor Circuit #2

ALR Min. Power Supply Field Fusing Min. Power Supply Field Fusing Min. Power Supply Field Fusing

Unit Volts HZ.Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max. Circuit Field Wire Hub Rec. Max.

Size Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse Fuse Amps Wire Hub Fuse Fuse

208 71 3 4 1 2.00

230 71 3 4 1 2.00

150E 460 60 35 3 8 1 1.25

575 28 3 10 1 1.00

208 83 3 4 1 2.00

230 83 3 4 1 2.00

160E 460 60 40 3 8 1 1.25

575 33 3 10 1 1.00

208 83 3 4 1 2.00

230 83 3 4 1 2.00

170E 460 60 40 3 8 1 1.25

575 33 3 10 1 1.00

208 83 3 4 1 2.00

230 83 3 4 1 2.00

180E 460 60 40 3 8 1 1.25

575 33 3 10 1 1.00

208 83 3 4 1 2.00

230 83 3 4 1 2.00

185E 460 60 40 3 8 1 1.25

575 33 3 10 1 1.00

(MCA) Qty Gauge Qty Size Size Size (MCA) Qty Gauge Qty Size Size Size (MCA) Qty Gauge Qty Size Size Size

80 80 304 3 350 1 2.50

(51)

80 80 286 3 350 1 2.50

(51)

35 35 144 3 1/0 1 1.50

(32)

30 30 108 3 2 1 1.25

(25)

90 90 338 3 500 1 3.00

(51)

90 90 330 3 400 1 3.00

(51)

40 40 167 3 2/0 1 2.00

(32)

35 35 133 3 1/0 1 1.50

(25)

90 90 365 3 500 1 3.00

(51)

90 90 365 3 500 1 3.00

(51)

40 40 185 3 3/0 1 2.00

(32)

35 35 153 3 2/0 1 2.00

(25)

90 90 415 6 300 1 3.00

(51)

90 90 415 6 300 1 3.00

(51)

40 40 199 3 3/0 1 2.00

(32)

35 35 162 3 2/0 1 2.00

(25)

90 90 455 6 350 1 4.00

(51)

90 90 455 6 350 1 4.00

(51)

40 40 210 3 4/0 1 2.00

(32)

35 35 169 3 2/0 1 2.00

(25)

350 400 338 3 500 1 3.00

(64)

350 400 330 3 400 1 3.00

(64)

175 200 167 3 2/0 1 2.00

(38)

125 150 133 3 1/0 1 1.50

(32)

400 400 338 3 500 1 3.00

(76)

400 400 330 3 400 1 3.00

(76)

200 225 167 3 2/0 1 2.00

(51)

175 200 133 3 1/0 1 1.50

(38)

450 500 365 3 500 1 3.00

(76)

450 500 365 3 500 1 3.00

(76)

225 250 185 3 3/0 1 2.00

(51)

175 200 153 3 2/0 1 2.00

(51)

500 600 415 6 300 1 3.00

(76)

500 600 415 6 300 1 3.00

(76)

225 250 199 3 3/0 1 2.00

(51)

200 225 162 3 2/0 1 2.00

(51)

600 600 455 6 350 1 4.00

(102)

600 600 455 6 350 1 4.00

(102)

250 300 210 3 4/0 1 2.00

(51)

200 225 169 3 2/0 1 2.00

(51)

400 400

(76)

400 400

(76)

200 225

(51)

175 200

(38)

400 400

(76)

400 400

(76)

200 225

(51)

175 200

(38)

450 500

(76)

450 500

(76)

225 250

(51)

175 200

(51)

500 600

(76)

500 600

(76)

225 250

(51)

200 225

(51)

600 600

(102)

600 600

(102)

250 300

(51)

200 225

(51)

See page 33 for all Electrical Data notes.

IM 676 25

Page 26

Table 21, 032E - 075E Compressor And Condenser Fan Motor Amp Draw

Rated Load Amps Locked Rotor Amps

ALR Compressors Fan No. Of Fan Compressors

Unit Volts HZ. No. No. No. No. Motors Fan Motors Across-The-Line Reduced Inrush

Size 1 2 3 4 (Each) Motors (Each) No. 1 No. 2 No. 3 No. 4 No. 1 No. 2 No. 3 No. 4

208 60 60 ---- ---- 4.0 4 17.0 308 308 ---- ---- 188 188 ---- ---230 60 60 ---- ---- 4.0 4 17.0 308 308 ---- ---- 188 188 ---- ----

032E 460 60 30 30 ---- ---- 2.0 4 8.5 154 154 ---- ---- 104 104 ---- ----

575 22 22 ---- ---- 2.2 4 10.3 135 135 ---- ---- 81 81 ---- ---208 60 60 ---- ---- 4.0 4 17.0 308 374 ---- ---- 188 222 ---- ---230 60 60 ---- ---- 4.0 4 17.0 308 374 ---- ---- 188 222 ---- ----

035E 460 60 30 30 ---- ---- 2.0 4 8.5 154 187 ---- ---- 104 108 ---- ----

575 22 24 ---- ---- 2.2 4 10.3 135 135 ---- ---- 81 81 ---- ---208 74 74 ---- ---- 4.0 4 17.0 428 428 ---- ---- 250 250 ---- ----

230 74 74 ---- ---- 4.0 4 17.0 428 428 ---- ---- 250 250 ---- ----

040E 460 60 37 37 ---- ---- 2.0 4 8.5 214 214 ---- ---- 132 132 ---- ----

575 31 31 ---- ---- 2.2 4 10.3 172 172 ---- ---- 103 103 ---- ---208 74 95 ---- ---- 4.0 6 17.0 428 565 ---- ---- 250 340 ---- ----

230 74 95 ---- ---- 4.0 6 17.0 428 565 ---- ---- 250 340 ---- ----

045E 460 60 37 47 ---- ---- 2.0 6 8.5 214 283 ---- ---- 132 156 ---- ----

575 31 36 ---- ---- 2.2 6 10.3 172 230 ---- ---- 103 138 ---- ---208 85 95 ---- ---- 4.0 6 17.0 470 565 ---- ---- 292 340 ---- ----

230 85 95 ---- ---- 4.0 6 17.0 470 565 ---- ---- 292 340 ---- ----

050E 460 60 42 47 ---- ---- 2.0 6 8.5 235 283 ---- ---- 141 156 ---- ----

575 36 36 ---- ---- 2.2 6 10.3 200 230 ---- ---- 130 138 ---- ---208 95 95 ---- ---- 4.0 6 17.0 565 565 ---- ---- 340 340 ---- ----

230 95 95 ---- ---- 4.0 6 17.0 565 565 ---- ---- 340 340 ---- ----

055E 460 60 47 47 ---- ---- 2.0 6 8.5 283 283 ---- ---- 156 156 ---- ----

575 36 36 ---- ---- 2.2 6 10.3 230 230 ---- ---- 138 138 ---- ---208 95 121 ---- ---- 4.0 6 17.0 565 650 ---- ---- 340 400 ---- ----

230 95 112 ---- ---- 4.0 6 17.0 565 594 ---- ---- 340 340 ---- ----

060E 460 60 47 60 ---- ---- 2.0 6 8.5 283 297 ---- ---- 156 195 ---- ----

575 36 42 ---- ---- 2.2 6 10.3 230 245 ---- ---- 138 152 ---- ---208 121 121 ---- ---- 4.0 6 17.0 650 650 ---- ---- 400 400 ---- ----

230 112 112 ---- ---- 4.0 6 17.0 594 594 ---- ---- 340 340 ---- ----

065E 460 60 60 60 ---- ---- 2.0 6 8.5 297 297 ---- ---- 195 195 ---- ----

575 42 42 ---- ---- 2.2 6 10.3 245 245 ---- ---- 152 152 ---- ---208 121 135 ---- ---- 4.0 8 17.0 650 754 ---- ---- 400 463 ---- ---230 112 127 ---- ---- 4.0 8 17.0 594 594 ---- ---- 340 340 ---- ----

070E 460 60 60 64 ---- ---- 2.0 8 8.5 297 297 ---- ---- 195 195 ---- ----

575 42 48 ---- ---- 2.2 8 10.3 245 245 ---- ---- 152 152 ---- ---208 135 135 ---- ---- 4.0 10 17.0 754 754 ---- ---- 463 463 ---- ----

230 127 127 ---- ---- 4.0 10 17.0 594 594 ---- ---- 340 340 ---- ----

075E 460 60 64 64 ---- ---- 2.0 10 8.5 297 297 ---- ---- 195 195 ---- ----

575 48 48 ---- ---- 2.2 10 10.3 245 245 ---- ---- 152 152 ---- ----

See page 33 for all Electrical Data notes.

26 IM 676

Page 27

Table 22, 080E -135E Compressor And Condenser Fan Motor Amp Draw

Rated Load Amps Locked Rotor Amps

ALR Compressors Fan No. Of Fan Compressors

Unit Volts HZ. No. No. No. No. Motors Fan Motors Across-The-Line Reduced Inrush

Size 1 2 3 4 (Each) Motors (Each) No. 1 No. 2 No. 3 No. 4 No. 1 No. 2 No. 3 No. 4

208 74 74 74 74 4.0 10 17.0 428 428 428 428 250 250 250 250

230 74 74 74 74 4.0 10 17.0 428 428 428 428 250 250 250 250

080E 460 60 37 37 37 37 2.0 10 8.5 214 214 214 214 132 132 132 132

575 31 31 31 31 2.2 10 10.3 172 172 172 172 103 103 103 103

208 74 74 74 85 4.0 10 17.0 428 428 428 470 250 250 250 292