Page 1

Page 2

TABLE OF CONTENTS

INTRODUCTION

General Description . . . . . . . . . . . . . . . . . . . . . . . . . ...3

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3

INSTALLATION

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4

Service Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . ...4

Vibration Isolators . . . . . . . . . . . . . . . . . . . . . . . . . ...4.5

REFRIGERANT PIPING

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6

Recommended piping arrangements . . . . . . . . . . . . ...7

Refrigerant piping connections . . . . . . . . . . . . . . . . ...7

Recommended line sizes . . . . . . . . . . . . . . . . . . . . . ...8

Holding charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8

Pressure testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8

Leak testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8

Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9

Charging the system . . . . . . . . . . . . . . . . . . . . . . . . . ...9

Hot gas bypass components.. . . . . . . . . . . . . . . . . ...9

Refrigerant charge . . . . . . . . . . . . . . . . . . . . . . . . . . ...9

Weight of refrigerant in copper lines.... . . . . . . . . ...9

Pressure-vacuum equivalents . . . . . . . . . . . . . . . . ...10

PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . ...10.11

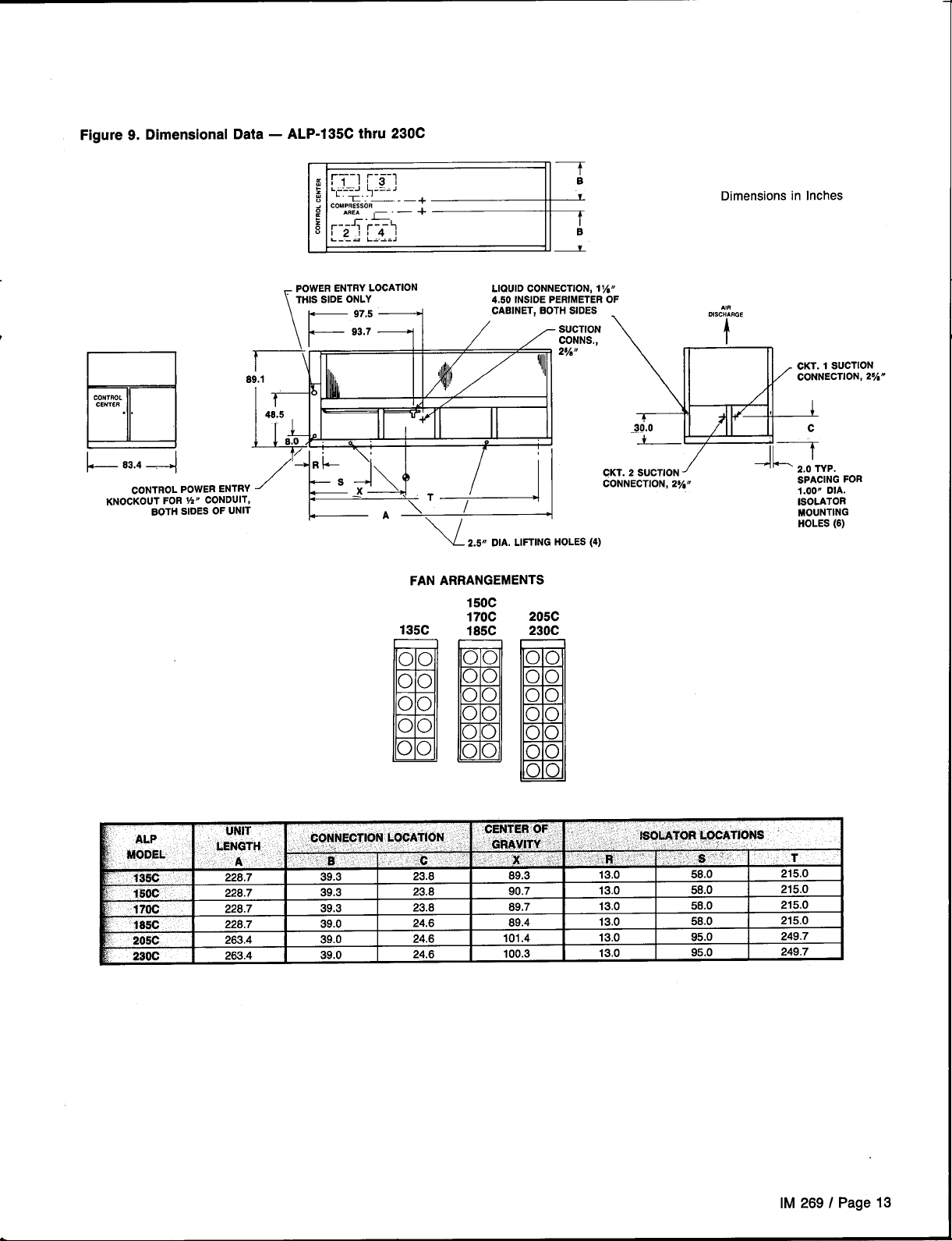

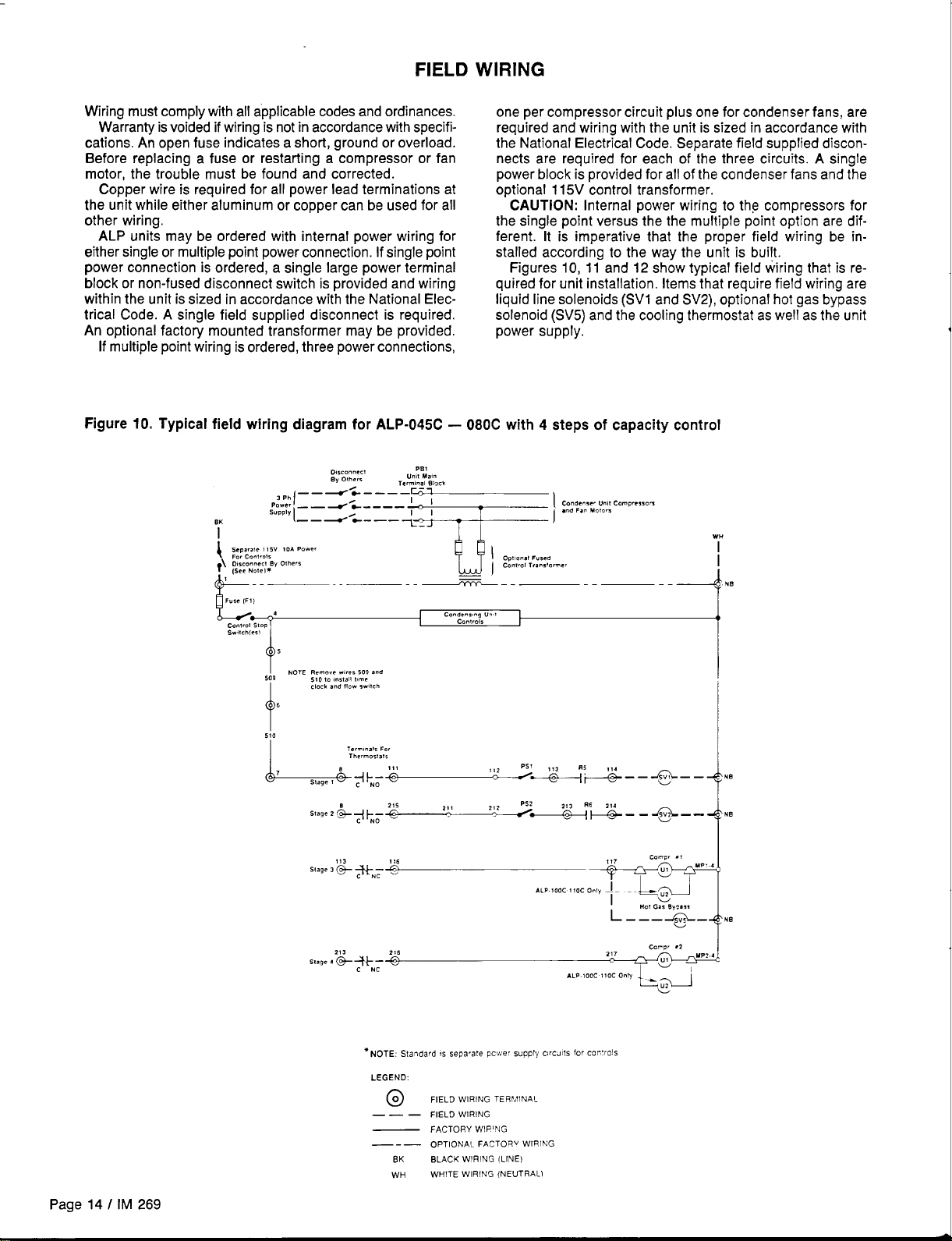

DIMENSIONAL DATA . . . . . . . . . . . . . . . . . . . . . ...12.13

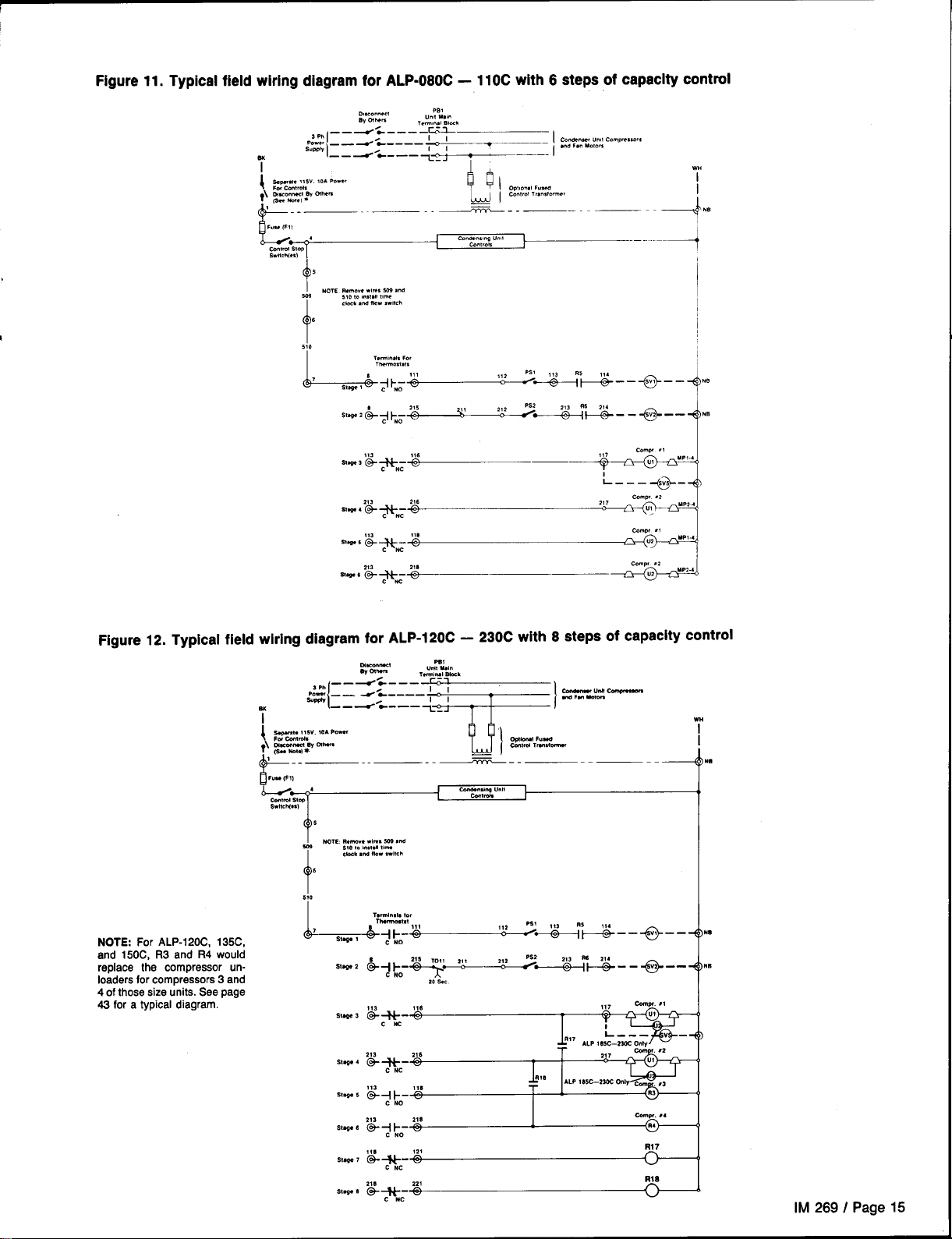

FIELD WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . ...14.15

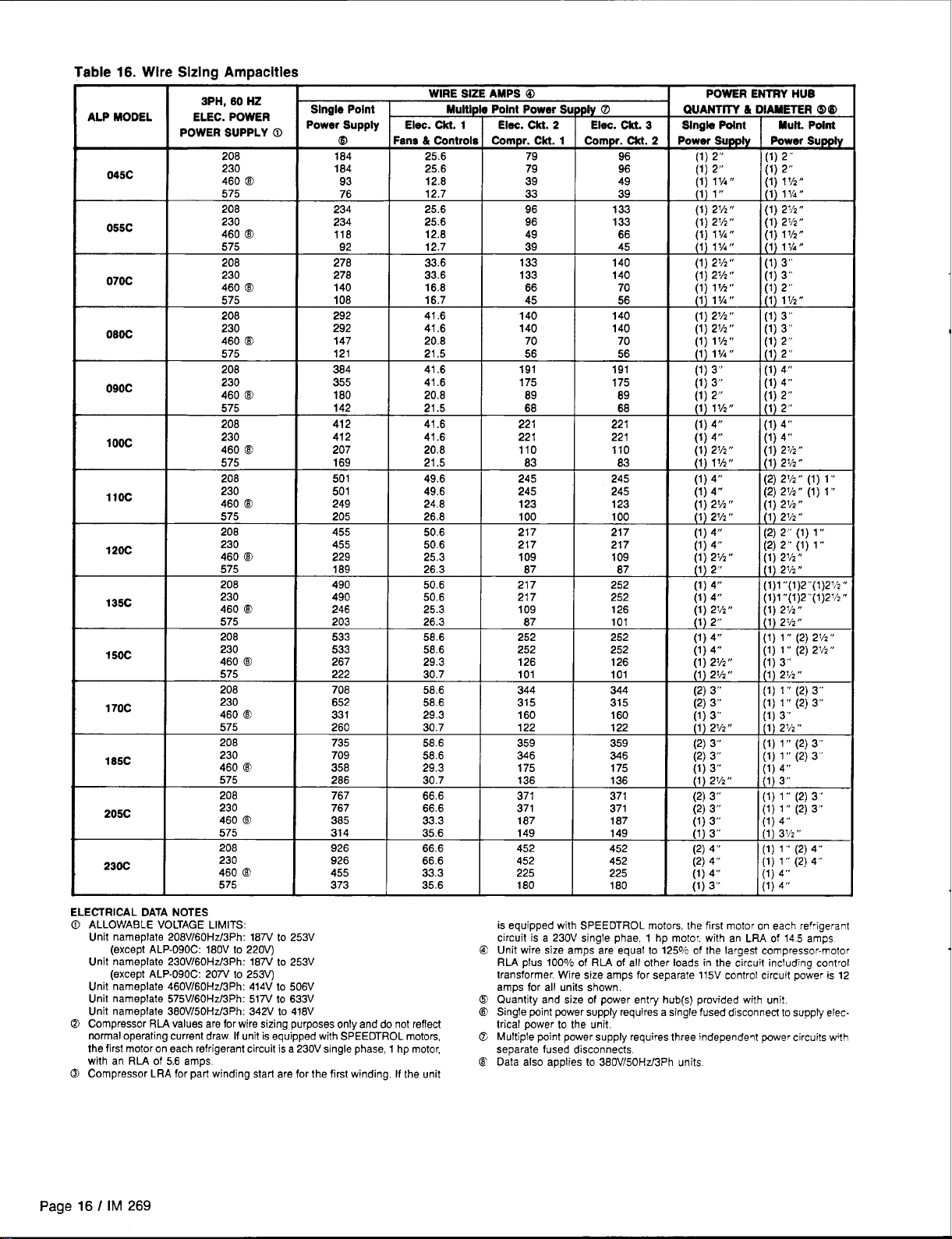

Wire sizing ampacities . . . . . . . . . . . . . . . . . . . . . . ...16

Compressor and condenser fan motors . . . . . . . . ...17

Thermostat wiring and capacity reduction . . . ...17.18

Water piping for chilled water applications , . . . . . ...18

Flow switch for chilled water applications . . . . . . . ...18

Evaporator fan interlock

for air handler coil installations . . . . . . . . . . . . . ...19

UNIT LAYOUT&PRINCIPLES OFOPERATION

Major component locations . . . . . . . . . . . . . . . . . . ...19

Control center . . . . . . . . . . . . . . . . . . . . . . . . . . ...19.20

Electrical legend . . . . . . . . . . . . . . . . . . . . . . . . . . . ...21

Unit disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...21

Sequence of operation . . . . . . . . . . . . . . . . . . . . . . ...22

TYPICAL WIRING SCHEMATICS

Power schematics . . . . . . . . . . . . . . . . . . . . . . . ...23-39

Control and safety schematics . . . . . . . . . . . . . ...40-42

Thermostat schematics, . . . . . . . . . . . . . . . . . . ...43-45

Wiring schematic decision tables.. . . . . . . . . . ...46.47

STARTUP&SHUTDOWN

Pre-startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...48

Initial startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...48

Temporary shutdown . . . . . . . . . . . . . . . . . . . . . . . . ...48

Startup after temporary shutdown . . . . . . . . . . . . . ...48

Extended shutdown . . . . . . . . . . . . . . . . . . . . . . . . . ...48

SYSTEM MAINTENANCE

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...49

Fan shaft bearings . . . . . . . . . . . . . . . . . . . . . . . . . ...49

Electrical terminals . . . . . . . . . . . . . . . . . . . . . . . . . ...49

Compressor oil level . . . . . . . . . . . . . . . . . . . . . . . . ...49

Oil Equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...49

Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...49

Refrigerant sightglass . . . . . . . . . . . . . . . . . . . . . . . ...49

SERVICE

Filter-driers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...50

Liquid line solenoid valve . . . . . . . . . . . . . . . . . . . . ...50

Thermostatic expansion valve . . . . . . . . . . . . . . . . ...50

IN-WARRANTY RETURN MATERIAL PROCEDURE

Copeland compressor . . . . . . . . . . . . . . . . . . . . . . . ...51

Components other than compressors . . . . . . . . . . ...51

APPENDIX

Standard Contr61s:

Oil pressure safety control . . . . . . . . . . . . . . . . . . . ...51

High pressure control . . . . . . . . . . . . . . . . . . . . . . . ...52

Low pressure control . . . . . . . . . . . . . . . . . . . . . . . . ...52

FANTROL head pressure control . . . . . . . . . . . ...52.53

Compressor lockout . . . . . . . . . . . . . . . . . . . . . . . . ...53

Compressor motor protector . . . . . . . . . . . . . . . . . . ...53

Optional Controls:

SPEEDTROL head pressure control . . . . . . . . . . . ...54

Compressor unloaders . . . . . . . . . . . . . . . . . . . . . . ...54

Low ambient start . . . . . . . . . . . . . . . . . . . . . . . . . . ...54

High ambient unloader . . . . . . . . . . . . . . . . . . . . . . ...54

Part winding start . . . . . . . . . . . . . . . . . . . . . . . . . . ...54

Phase/voltagemonitor . . . . . . . . . . . . . . . . . . . . . . ...55

Hot gas bypass (field installed) . . . . . . . . . . . . . . . ...55

ALP controls, settings&functions . . . . . . . . . . ...56. 57

Troubleshooting chart . . . . . . . . . . . . . . . . . . . . ...58.59

Page2/lM269

“FanTrol”, “McC!uay”, “

of McQuay Air Conditioning, McOuay International, Minneapolis MN

G 1995 McOuay Air Conditioning. McQuaylnternational. Minneapolis. MN

“Bulletin illustrations cover the general appearance of Mc@ay International products al the time of publica! ior,

and we reserve the right to make changes in design and construction at any time without notice”

SeasonCon” and “SpeedTrol” are registered trademarks

Page 3

INTRODUCTION

GENERAL DESCRIPTION

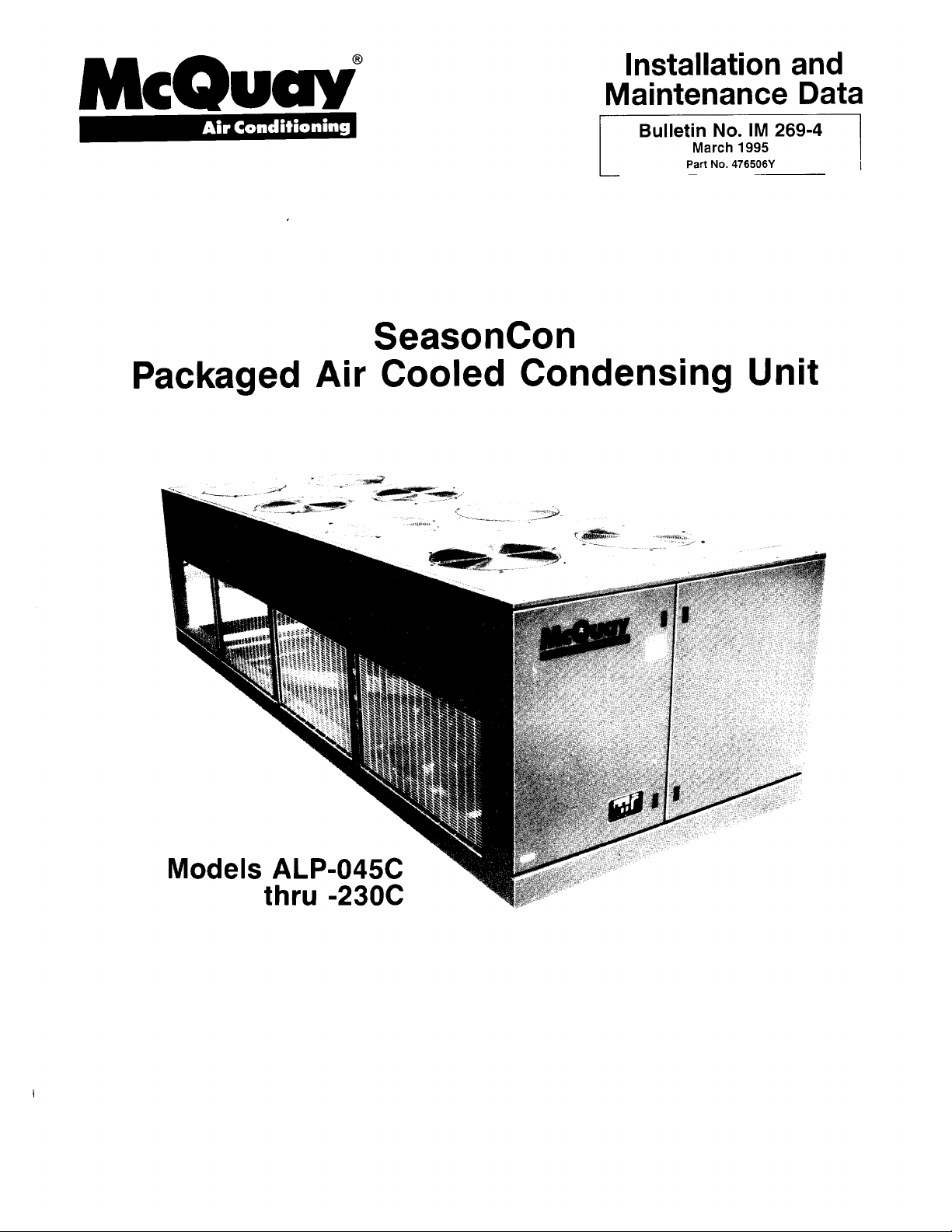

McQuay type SeasonCon air cooled water condensing units

are designed for outdoor installations and are compatible with

either air handling or chilled water systems. Each unit is completely assembled and factory wired before evacuation, charging and testing, and comes complete and ready for installation. Each unit “consists of twin air cooled condensers with

integral subcooler sections, multiple accessible hermetic compressors, complete discharge piping and suction connections

for connection to any air or water cooling evaporator.

NOMENCLATURE

INSPECTION

When the equipment is received, all items should be careful-

Iy checked against the bill of lading to insure a complete shipment. All units should be carefully inspected for damage upon

arrival. All shipping damage should be reported to the car-

rier and a claim should

be filed. The unit serial plate should

The electrical control center includes all safety and operating controls necessary for dependable automatic operation

except for the cooling thermostat since this is somewhat

dependent on the unit application. Condenser fan motors are

fused in all three conductor legs and started by their own

three-pole contractors. Compressors are not fused but may

be protected by optional circuit breakers, or by field installed

fused disconnect.

be checked before unloading the unit to be sure that it agrees

with the power supply available. Physical damage to unit after

acceptance is not the responsibility of McQuay.

NOTE: Unit shipping and operating weights are available

in the physical data tables on pages 10 and 11.

INSTALLATION

NOTE: Installation and maintenance are to be performed only by qualified personnel who are familiar with local codes

and regulations, and experienced with this type of equipment.

CAUTION: Sharp edges and coil surfaces are a potential injury hazard. Avoid contact with them.

HANDLING

Care should be taken to avoid rough handling or shock due

to dropping the unit. Do not push or pull the unit from anything

other than the base, and block the pushing vehicle away from

the unit to prevent damage to the sheetmetal cabinet and end

frame (see Figure 1).

Never allow any part of the unit to fall during unloading or

Figure 1. Suggested Pushing Arrangement

BLOCKING REQ’D.

ACROSS FULL WIDTH

moving as this may result in serious damage.

To lift the unit, 21/2” diameter lifting holes are provided in

the base of the unit. Spreader bars and cables should be arranged to prevent damage to the condenser coils or unit

cabinet (see Figure 2).

Figure 2. Suggested Lifting Arrangement

,,,,,.,, 8,,

FIECOMMENWO

(uSE CAUTION)

MO,,

NUMBER 0, F..%

FROM, H,SO,A. R

U,,(NC METHOD R, MA, NS

THE SAME

LIFT UNIT OWL Y AS SHOWN

(NOTE .0.,,0, 80., ’0,.,,0.,

IM 269 I Page 3

HOLES

Page 4

LOCATION

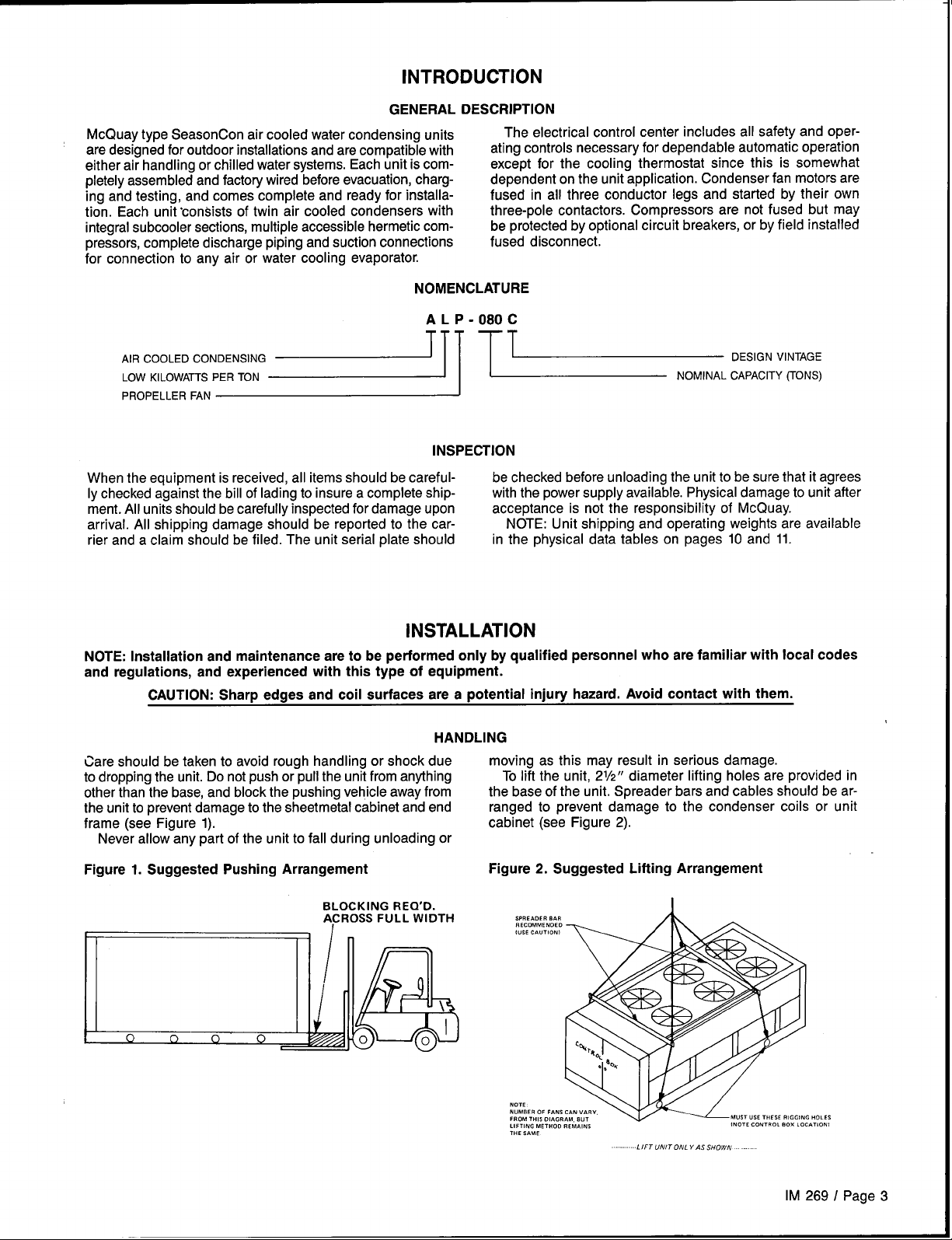

Care should be taken in the location of the unit to provide

proper airflow to the condenser, minimizing effects on condensing pressure.

Due to the vertical condenser design of the ALP-120 thru

230 chillers, it is recommended that the unit is oriented so

that prevailing winds blow parallel to the unit length, thus

minimizing the effects on condensing pressure, If it is not practical to orient the unit in this manner, a wind deflector should

be constructed.

Minimum clearances as shown in Figure 3 will prevent most

discharge air recirculation to the condenser which will have

a significant effect on unit performance,

SERVICE

Each end of the unit must be accessible after installation for

periodic service work. Compressors, filter-driers, and manual

liquid line shutoff valves are accessible on each side of the

unit adjacent to the control box. High pressure, low pressure,

and motor protector controls are on compressor. Most other

operational, safety and starting controls are located in the unit

control box.

Figure 3. Clearance Requirements ALP-045C thru 230C

6 !7. MIN. CLEARANCE

4 FT. MIN.

CLEARANCE au

FOR SERVICE

ACCESS

I

1

FOR AIR INLET

da

i-~

~ti

I

6 FT. MIN. CLEARANCE

FOR AIR INLET

I

6 FT. MIN.

CLEARANCE

1

FOR AIR

INLET

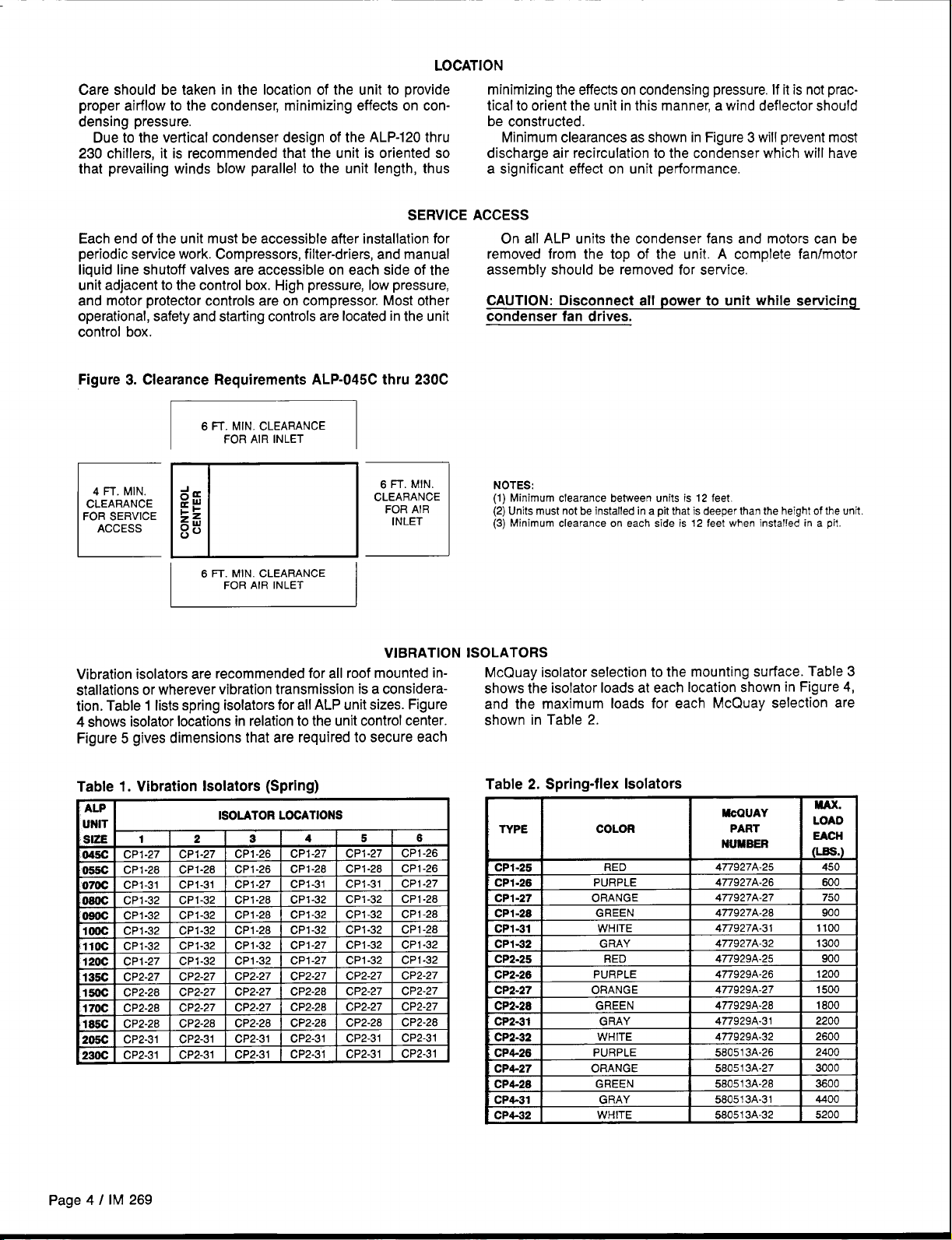

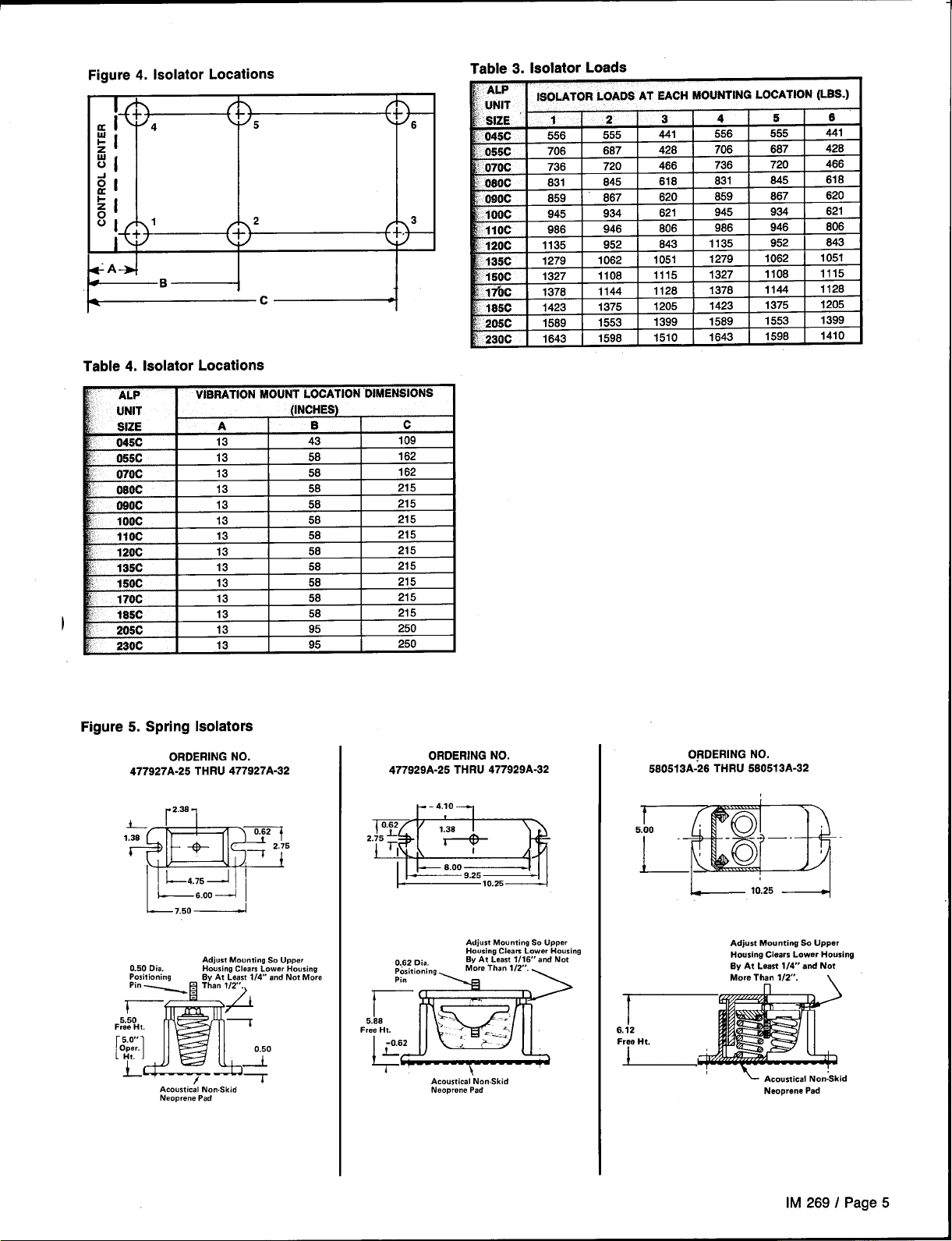

VIBRATION

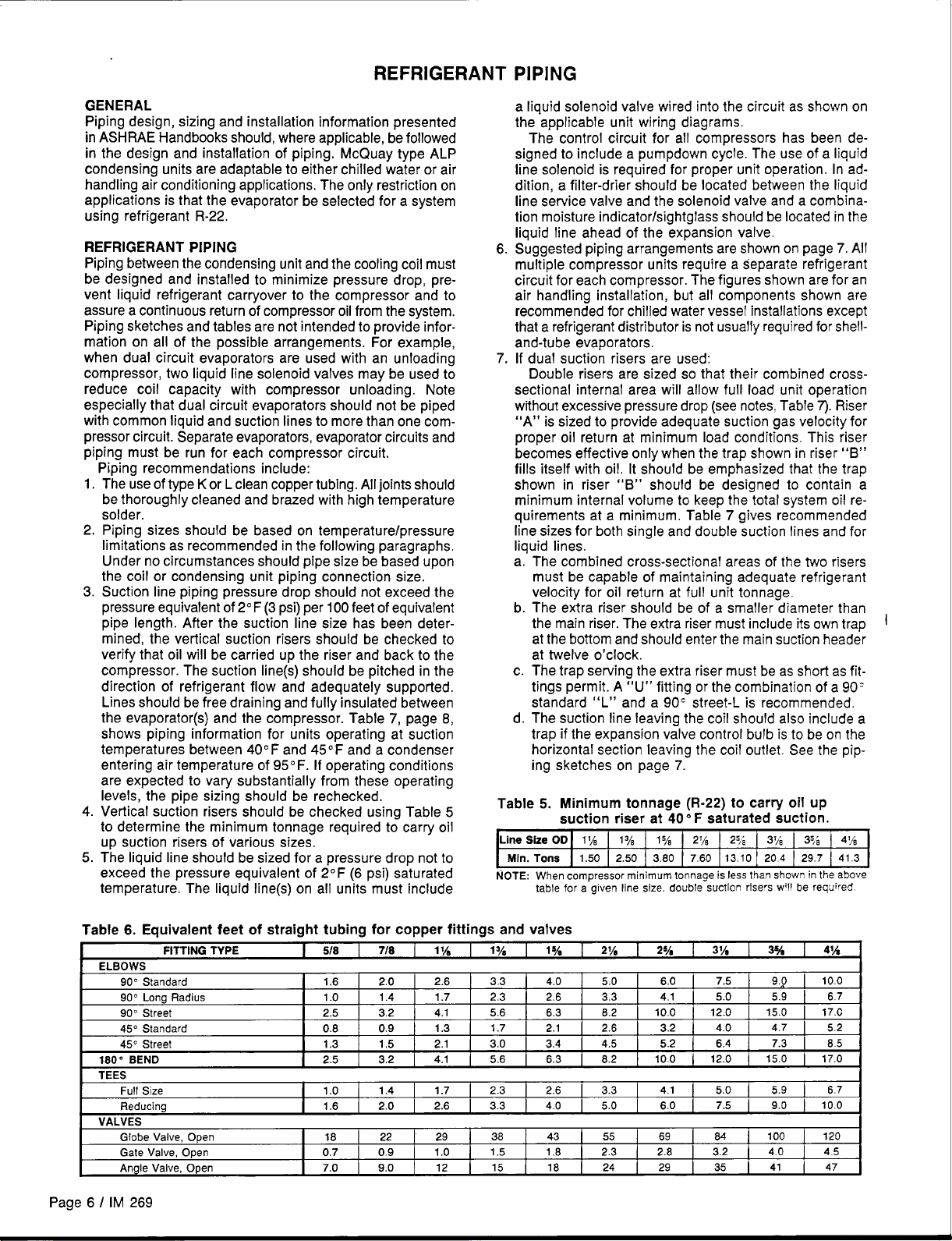

Vibration isolators are recommended for all roof mounted installations or wherever vibration transmission is a consideration. Table 1 lists spring isolators for all ALP unit sizes. Figure

4 shows isolator locations in relation to the unit control center.

Figure 5 gives dimensions that are required to secure each

ACCESS

On all ALP units the condenser fans and motors can be

removed from the top of the unit. A complete fan/motor

assembly should be removed for service.

CAUTION: Disconnect all power to unit while servicing

condenser fan drives.

NOTES:

(1)Minimum clearance between units is 12 feet,

(2) Units must not be installed in a pit that is deeper than the height of the unit

(3) Minimum clearance on

each side is 12 feet when installed in a pit.

ISOLATORS

McQuay isolator selection to the mounting surface. Table 3

shows the isolator loads at each location shown in Figure 4,

and the maximum loads for each McQuay selection are

shown in Table 2.

Table 1. Vibration Isolators (Spring)

ISOLATOR LOCATIONS

SUE

045C CP

055c CP

t=!=

------ ..-— — ——, .

Cl CPI.!17 I CP1.W I CP1-28 I CP1-32 I CP1-32 I CF

Iooc,-..-.,- .. --,-..--, ----, - -11OCICP1-32

120C I CP1-27

~ CP2-27

Page 4 I IM 269

CP1-32 CPI-32

CP1-32

CP2-27

CP1-32

CP2-27 CP2-27

CP1-27

CP1-27 CPI-32 CPI-32

CPI-32

CP2-27 CP2-27

‘1-28

CP1-32

Table 2. Spring-flex Isolators

TYPE COLOR

P+.25 RED 4n927A-25

----

tiP1-26

1

CP1-27 ORANGE

CP1-28

I

CP1-31

CPI-32

CP2-25

I

CP2-28

CP2-27

CP2-28

-.

--

CP4-27

I

CP4-28

CP4-31

I

CP4-32 WHITE 580513A-32

i=

I

I

I

I

I

1

MAX.

LOAD

EACN

0-=.)

2200

2400

3000

4400

5200

McOUAY

PART

NUMBER

PURPLE

GREEN

WHITE

GRAY

RED

PURPLE

ORANGE

GREEN

ORANGE

GREEN 58051 3A-26 3600

GRAY

477927A-26

I

477927A-27

477927A-26

I

4n927A-31 1100

4n927A-32

4n929A-25 900

477929A-26

4n929A-27

477929A-26

4n929A-31

4n929A-32 2600

580513A-26

58051 3A-27

I

58051 3A-31

I

450

600

750

900

1300

1200

1500

1800

Page 5

Figure 4. Isolator Locations

Table 4. Isolator Locations

—c—

1-

6

3

>

Table 3. Isolator 1m=~=

ALP

? UNIT

SIZE 1

: 045C

055C

~ 070C

Osoc

‘ 090C

100C

‘ 11OC

120C

, 135C

, 150C

wbc

185C

: 205C

230C

ISOLATOR LOADS AT SACH FAOUNTING LOCATION (l-SS.)

.“”””

556

706

736

831

859 867

945

986

1135

1279

1327

1376

1423

1569

1643

2

555

687

720

845

934

946

952

1062

1108

1144

1375

1553

1596

3

441

428

466

618

~]

621

806

643

1051

1115

1128

1205

1399

1510

4

556

706

736

631

659

945

986

1135

1279

1327

1378

1423

1569

1643

5

555

687

720

845

867

934

I

946

952

1062

1108

1144

1375

1553

1598

6

441

426

466

618

620

621

806

643

1051

1115

1128

1205

1399

1410

I

I

VIBRATION MOUNT LOCATION DIMENSIONS

Figure5. Spring Isolators

ORDERING NO.

477927A-26 THRU 477927A-32

(INCHES)

ORDERING NO.

477929A-25 THRU 477929A-32

ORDERING NO.

580513A-26 THRU 580513A-32

Ls.oo --- I

1-

7,,0 ~

0,50 Dia.

Positioning

Acoustical No..Skid

Neoprene Pad

Adjust Mounting So Upper

Housing Clears Lower HousinQ

By At Least IW and Not More

2“%Ezili

6

F

Acoustical No..Skid

Neoprene Pad

_ 10.25 .—~

Adjust Mounting so Upper

Housing Clears Lower Housing

By At Least 114” and Not

More Than 1/2”.

~ Acoustical Non:Skid

Neoprene Pad

\

IM 269/ Page 5

Page 6

REFRIGERANT

PIPING

GENERAL

Piping design, sizing and installation information presented

in ASHRAE Handbooks should, where applicable, be followed

in the design and installation of piping. McQuay type ALP

condensing units are adaptable to either chilled water or air

handling air conditioning applications, The only restriction on

applications is that the evaporator be selected for a system

using refrigerant R-22.

REFRIGERANT PIPING

Piping between the condensing unit and the cooling coil must

be designed and installed to minimize pressure drop, prevent liquid refrigerant carryover to the compressor and to

assure a continuous return of compressor oil from the system.

Piping sketches and tables are not intended to provide information on all of the possible arrangements. For example,

when dual circuit evaporators are used with an unloading

compressor, two liquid line solenoid valves may be used to

reduce coil capacity with compressor unloading. Note

especially that dual circuit evaporators should not be piped

with common liquid and suction lines to more than one compressor circuit. Separate evaporators, evaporator circuits and

piping must be run for each compressor circuit.

Piping recommendations include:

The use of type K or L clean copper tubing. All joints should

1.

be thoroughly cleaned and brazed with high temperature

solder.

2.

Piping sizes should be based on temperature/pressure

limitations as recommended in the following paragraphs,

Under no circumstances should pipe size be based upon

the coil or condensing unit piping connection size.

Suction line piping pressure drop should not exceed the

3.

pressure equivalent of 2° F (3 psi) per 100 feet of equivalent

pipe length. After the suction line size has been determined, the vertical suction risers should be checked to

verify that oil will be carried up the riser and back to the

compressor. The suction line(s) should be pitched in the

direction of refrigerant flow and adequately supported.

Lines should be free draining and fully insulated between

the evaporator(s) and the compressor. Table 7, page 8,

shows piping information for units operating at suction

temperatures between 40F and 45 F and a condenser

entering air temperature of 95F. If operating conditions

are expected to vary substantially from these operating

levels, the pipe sizing should be rechecked.

Vertical suction risers should be checked using Table 5

4.

to determine the minimum tonnage required to carry oil

up suction risers of various sizes:

5. The liquid line should be sized for a pressure drop not to

exceed the pressure equivalent of 2° F (6 psi) saturated

temperature. The liquid line(s) on all units must include

a liquid solenoid valve wired into the circuit as shown on

the applicable unit wiring diagrams.

The control circuit for all compressors has been designed to include a pumpdown cycle. The use of a liquid

line solenoid is required for proper unit operation. In addition, a filter-drier should be located between the liquid

line service valve and the solenoid valve and a combination moisture indicator/sightglass should be located in the

liquid line ahead of the expansion valve.

6.

Suggested piping arrangements are shown on page 7. All

multiple compressor units require a separate refrigerant

circuit for each compressor. The figures shown are for an

air handling installation, but all components shown are

recommended for chilled water vessel installations except

that a refrigerant distributor is not usually required for shell

and-tube evaporators.

7.

If dual suction risers are used:

Double risers are sized so that their combined crosssectional internal area will allow full load unit operation

without excessive pressure drop (see notes, Table 7). Riser

“A” is sized to provide adequate suction gas velocity for

proper oil return at minimum load conditions, This riser

becomes effective only when the trap shown in riser “B”

fills itself with oil. It should be emphasized that the trap

shown in riser “B” should be designed to contain a

minimum internal volume to keep the total system oil requirements at a minimum. Table 7 gives recommended

line sizes for both single and double suction lines and for

liquid lines.

The combined cross-sectional areas of the two risers

a.

must be capable of maintaining adequate refrigerant

velocity for oil return at full unit tonnage,

The extra riser should be of a smaller diameter than

b.

the main riser. The extra riser must include its own trap

at the bottom and should enter the main suction header

at twelve o’clock.

The trap serving the extra riser must be as short as fit-

c.

tings permit. A “U” fitting or the combination of a 90’

standard “L” and a 90C street-L is recommended,

The suction line leaving the coil should also include a

d.

trap if the expansion valve control bulb is to be on the

horizontal section leaving the coil outlet, See the piping sketches on page 7.

Table 5. Minimum tonnage (R-22) to carry oil up

suction riser at 400 F saturated suction.

Min. Tons

NOTE: When compressor minimum tonnage is less than shown in the above

1.50 2.50 3.80 7.60 13.10 204 29.7 41.3

table for a given line size. double suction risers will be required

I

Table 6. Equivalent feet of straight tubing for copper fittings and valves

I

I

I 90” Lono Radius I 1.0 I

.“-

TEES

VALVES

FITTING TYPE

90” Standard

90” Street

45” Standard

A6. .Wrss! 13 15 91 30

-h, .-

Full Size

Reducing

Globe Valve, Open

Gate Valve, Open 0.7

Angle Valve, Open 7.0 9.0

518

I

1.6 2.0

!

2.5 3.2 4.1

0.8 0.9

-.”

1

1.0

I

1.6 2.0

18 22 29

718 1%

2.6 3.3 4.0 5.0 6.0

1.4 I 1.7

“.-

1

1

1.4 1.7 2.3 2.6 3.3

0.9

I 2.3 I 2.6 I 3.

1,3

.,.

1

2.6 3.3 4.0 5.0 6.0

1.0

12

Page 6 I IM 269

1yf 1V*

5.6

1.7

---

38 43 55 69 84

1.5

15 18 24 29 35

6.3

2.1 2.6 3.2

34 45 57 64 7.3 I 85

---

1

1.8 2.3 2.8 3.2

2y* 2%

I

3

8.2

---

1

4.1 5.0 5.9 6.7

10.0 12.0 15.0 17.C

..- ----

,

4.1 5.0 5.9 6.7

31/s 3%

7.5 9.9

4.0

.-. .

!

7.5 9.0

100 120

4.0 4.5

41~

10.0

4.7

10.0

41 47

[

52

..-

Page 7

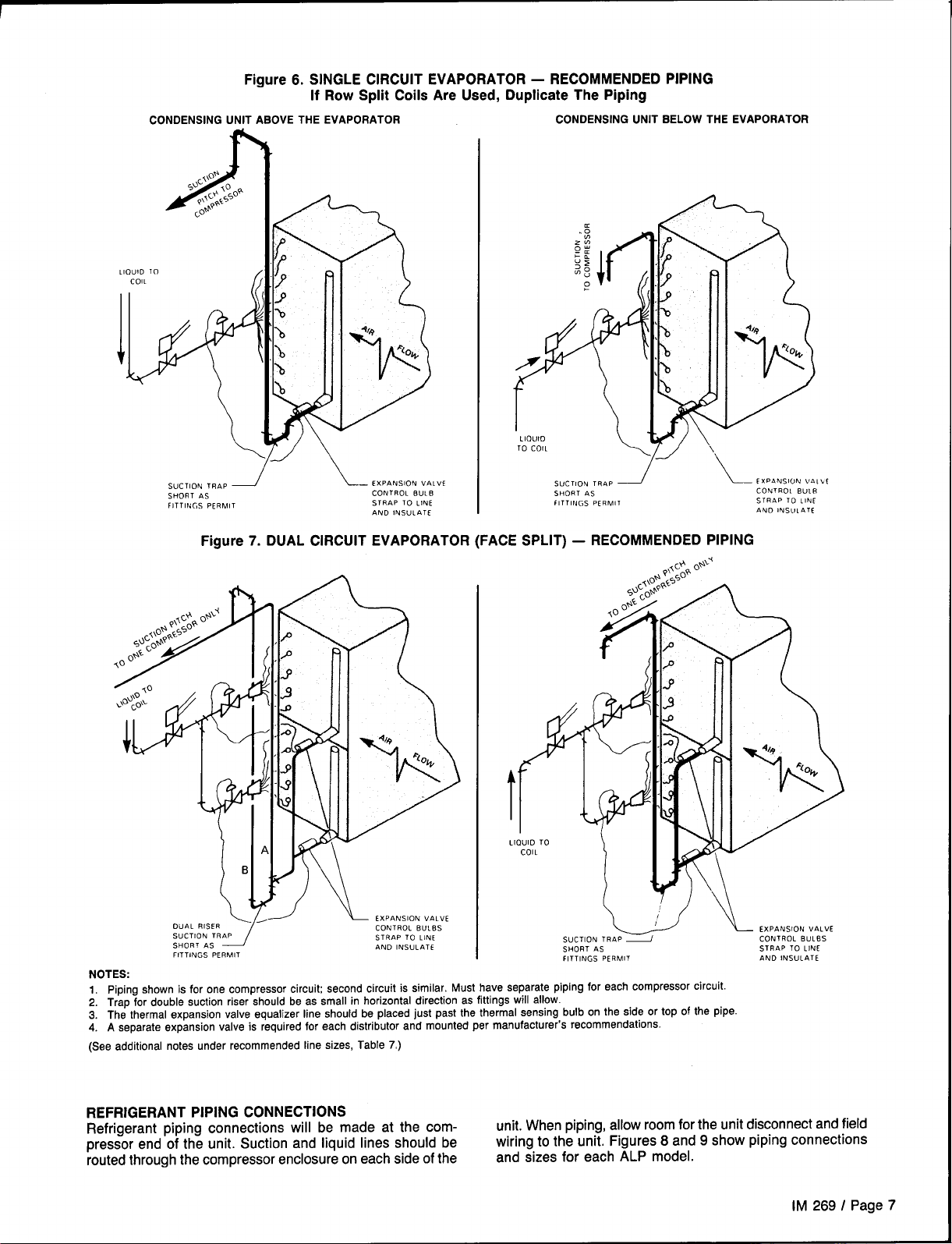

Figure 6. SINGLE CIRCUIT EVAPORATOR – RECOMMENDED PIPING

If Row Split Coils Are Used, Duplicate The Piping

CONDENSING UNIT AaOVE THE EVAPORATOR

CONDENSING UNIT BELOW THE EVAPORATOR

LlOU10

TO COIL

“L___

SUCTION TRAP

SHORT AS

FITTINGS PERMIT

1

EXPANSION VALVE

CONTROL BULB

STRAP TO LINE

AND lNSUIATf

SUCTION TRAP ~

SHORT AS

FITTINGS PERMIT

Figure 7. DUAL CIRCUIT EVAPORATOR (FACE SPLIT) – RECOMMENDED PIPING

t

L(

SUCTION TRAP ~

SHORT AS

FITTINGS PERMIT

NOTES:

1. Piping shown is for one compressor circuit; second circuit is similar. Must have separate piping for each compressor circuit.

2. Trap for double suction riser should be as small in horizontal direction as fittings will allow.

3. The thermal expansion valve equalizer line should be placed just past the thermal sensing bulb on the side or top of the pipe.

4. A separate expansion valve is required for each distributor and mounted per manufacturer’s recommendations.

(See additional notes under recommended line sizes, Table 7)

L CXP4NSION VA1bl

CONTROL BULR

5TRAP To LINE

AND INSULATE

ION vALVE

CONTROL BuLBS

STRAP TO LINE

AND INSULATE

REFRIGERANT PIPING CONNECTIONS

Refrigerant piping connections will be made at the com-

pressor end of the unit. Suction and liquid lines should be

routed through the compressor enclosure on each side of the

unit. When piping, allow room for the unit disconnect and field

wiring to the unit. Figures 8 and 9 show piping connections

and sizes for each ALP model.

IM 269 I Page 7

Page 8

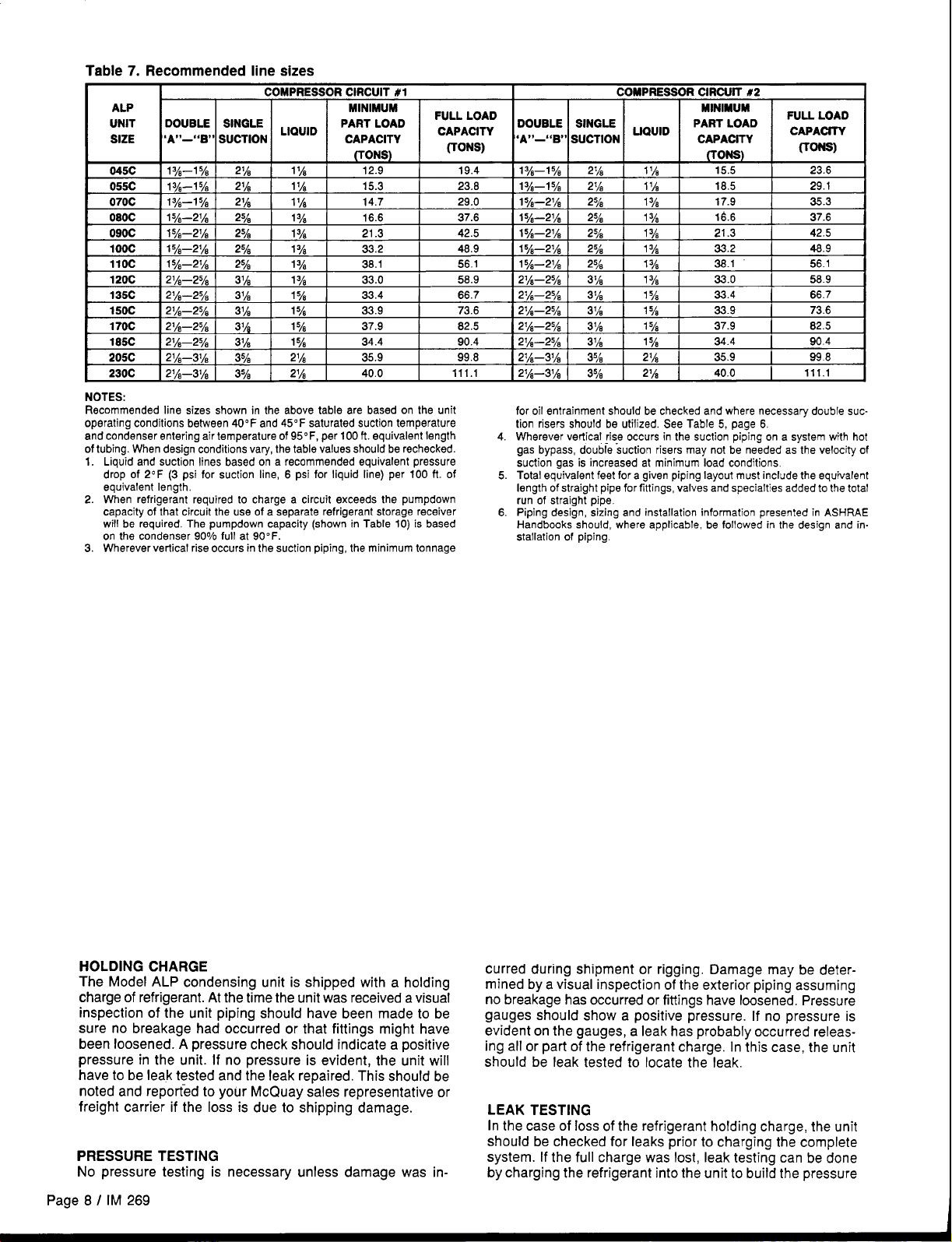

Table 7. Recommended line sizes

COMPRESSOR CIRCUIT #1

ALP

UNIT

SIZE

055C 13&15h

070C

080C

090C

100C 15/&2~h

11OC

120C 2%J—25/8

135C 27+2Y8 3X?

150C

DOUBLE

.A9*_,4

1%-1 ye

1%-15h

15h—21A

I

5~—2y8

15y&2y3

214—25A

170C 21h—25h

1MC 27’s-2y8 31~

205C 21&31~ 3%

230C

NOTES:

Recommended line sizes shown in the above table are based on the unit

operating conditions between 40F and 45 F saturated suction temperature

and condenser entering air temperature of 95F, per 100 ft. equivalent length 4.

of tubing. When design conditions vary, the table values should be rechecked.

1. Liquid and suction lines based on a recommended equivalent pressure

drop of 2F (3 psi for suction line, 6 psi for liquid line) per 100 ft. of

equivalent length,

2. When refrigerant required to charge a circuit exceeds the pumpdown

capacity of that circuit the use of a separate refrigerant storage receiver

will be required. The pumpdown capacity (shown in Table 10) is based

on the condenser 90% full at 90” F.

3. Wherever vertical rise occurs in the suction piping, the minimum tonnage

2%-31~

SINGLE

slJ~*,oN LIQulD

~,,

21h

z~~ 1% 15.3

21A

278

278

25~ 13~

2% 13~

37h 1ye 33.0 58.9

31~

31~

3%

11A

1% 14.7

1ah 16.6 37.6

1ye 21.3

1ye 33.4 66.7

1ye 33.9 73.6 2%-2Y8

1ya 37.9 82.5

1ye 34.4 90.4

21A 35.9

21A 40.0

MINIMUM

PART LOAD

CAPACITY

(TONS)

12.9 19.4

33.2

38.1

FULL LOAD

CAPACITY

(TONS)

23.8

29.0 15/’-21h

42.5 15/+2~h

48.9

56.1

99.8 21/&31~

111.1

COMPRESSOR CIRCUIT #2

DOUBLE SINGLE

,A,9_”

B“ SUCTION

1y&l

5/4

1y&l ya

15/*-21h

1y~—zl~

1y*—21h

2J&278

2J/4-25/a 3%

21&2y~ 37h

21A—25A 3Ys

21&31/s

fer oil entrainment should be checked and where necessary double suction rlsers should be utilized. See Table 5, page 6,

Wherever vertical rise occurs in the suction piping on a system with hot

gas bypass, double suction risers may not be needed as the velocity of

suction gas is increased at minimum load condtions.

Total equivalent feet for a given piping layout must include the equivalent

5

length of straight pipe for fittings, valves and specialties added to the total

run of straight pipe.

Piping design, sizing and installation information presented in ASHRAE

6

Handbooks should, where applicable, be followed in the design and

stallation of piping.

‘QU’D

214 11A 15.5 23.6

21A 11A 18.5 29.1

2% 1ya 17.9 35.3

2% 1Y* 16.6 37.6

2% 1ye 21.3

278 13h X3.2 48.9

278 1ye 38.7 56.1

31A 1ya 33.0 58.9

3%

35h 21A

35h

1ya 33.4 66.7

15~ 339 73.6

1y’ 37.9 82.5

15h 34.4 904

21A

.... .... . ... I I

mlnlmum

PART LOAD

-. -.-—..

GAPAUI I Y

m-)

35.9 998

40.0 111.1

FULL LOAD

CAPACITY

I

(TONS)

42.5

I

in-

HOLDING CHARGE

The Model ALP condensing unit is shipped with a holding

charge of refrigerant. At the time the unit was received a visual

inspection of the unit piping should have been made to be

sure no breakage had occurred or that fittings might have

been loosened. A pressure check should indicate a positive

pressure in the unit. If no pressure is evident, the unit will

have to be leak tested and the leak repaired. This should be

noted and reported to your McQuay sales representative or

freight carrier if the loss is due to shipping damage.

PRESSURE TESTING

No pressure testing is necessary unless damage was in-

Page 8 / IM 269

curred during shipment or rigging, Damage may be determined by a visual inspection of the exterior piping assuming

no breakage has occurred or fittings have loosened, Pressure

gauges should show a positive pressure. If no pressure is

evident on the gauges, a leak has probably occurred releas-

ing all or part of the refrigerant charge, In this case, the unit

should be leak tested to locate the leak.

LEAK TESTING

In the case of loss of the refrigerant holding charge, the unit

should be checked for leaks prior to charging the complete

system. If the full charge was lost, leak testing can be done

by charging the refrigerant into the unit to build the pressure

Page 9

to approximately 10 psig and adding sufficient dry nitrogen

to bring the pressure to a maximum of 125 psig. The unit

should then be leak tested with a Halide or electronic leak

detector. After making any necessary repair, the system should

be evacuated as described in the following paragraphs.

CAUTION: Do not use oxygen to build up pressure. A

serious explosion could be the result.

EVACUATION

After it has been determined that the unit is tight and there

are no refrigerant leaks, the system should be evacuated. The

use of a vacuum pump with a pumping capacity of approximately 3 cu. ft./min, and the ability to reduce the vacuum

in the unit to at least 1 millimeter (1000 microns) is recommended.

A mercury manometer, electronic or other type of micron

1.

gauge should be connected to the unit at a point remote

from the vacuum pump, For readings below 1 millimeter,

an electronic or other micron gauge should be used.

The triple evacuation method is recommended and is par-

2.

ticularly helpful if the vacuum pump is unable to obtain

the desired 1 millimeter of vacuum. The system is first

evacuated to approximately 29 inches of mercury. Enough

refrigerant vapor is then added to the system to bring the

pressure up to O pounds.

Then the system is once again evacuated to 29 inches of

3.

vacuum. This procedure is repeated three times. This

method can be most effective by holding system pressure

at Opounds for a minimum of 1 hour between evacuations.

The first pull down will remove about 90% of the noncondensibles, the second about 90%0 of that remaining

from the first pull down and after the third only 1/10 of 10%

non-condensibles will remain.

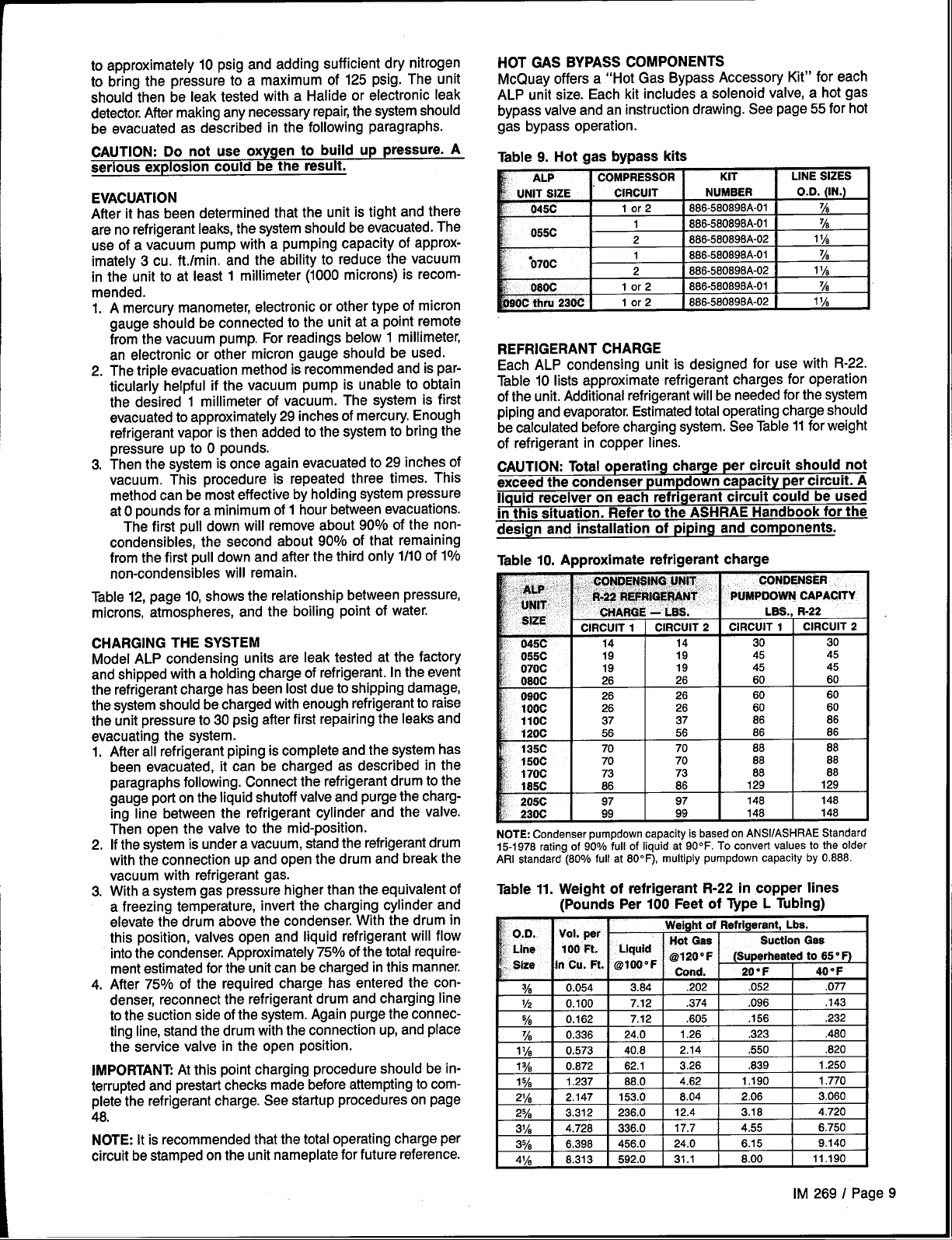

Table 12, page 10, shows the relationship between pressure,

microns, atmospheres, and the boiling point of water.

HOT GAS BYPASS COMPONENTS

McQuay offers a “Hot Gas Bypass Accessory Kit” for each

ALP unit size. Each kit includes a solenoid valve, a hot gas

bypass valve and an instruction drawing. See page 55 for hot

gas bypass operation.

Table 9. Hot gas bypass kits

COMPRESSOR

KIT

S86-580698A-01

866-580898A-01

886-580698A-02

886-5S0898A-01

886-5S0698A-02

886-580898A-01

886-580896A-02

LINE SIZES

%

~8

1IA

%

1*A

%

11A

REFRIGERANT CHARGE

Each ALP condensing unit is designed for use with R-22.

Table 10 lists approximate refrigerant charges for operation

of the unit. Additional refrigerant will be needed for the system

piping and evaporator. Estimated total operating charge should

be calculated before charging system. See Table 11 for weight

of refrigerant in copper lines.

CAUTION: Total operating charge per circuit should not

exceed the condenser pumpdown capacity

per circuit. A

liquid receiver on each refrigerant circuit could be used

in this situation. Refer to the ASHRAE Handbook for the

design and installation of piping and components.

Table 10. Approximate refrigerant charge

CHARGING THE SYSTEM

Model ALP condensing units are leak tested at the factory

and shipped with a holding charge of refrigerant. In the event

the refrigerant charge has been lost due to shipping damage,

the system should be charged with enough refrigerant to raise

the unit pressure to 30 psig after first repairing the leaks and

evacuating the system.

After all refrigerant piping is complete and the system has

1.

been evacuated, it can be charged as described in the

paragraphs following. Connect the refrigerant drum to the

gauge port on the liquid shutoff valve and purge the charging line between the refrigerant cylinder and the valve.

Then open the valve to the mid-position.

2,

If the system is under a vacuum, stand the refrigerant drum

with the connection up and open the drum and break the

vacuum with refrigerant gas.

With a system gas pressure higher than the equivalent of

3.

a freezing temperature, invert the charging cylinder and

elevate the drum above the condenser, With the drum in

this position, valves open and liquid refrigerant will flow

into the condenser. Approximately 75% of the total requirement estimated for the unit can be charged in this manner.

After 75% of the required charge has entered the con-

4.

denser, reconnect the refrigerant drum and charging line

to the suction side of the system. Again purge the connecting line, stand the drum with the connection up, and place

the service valve in the open position.

IMPORTANT At this point charging procedure should be interrupted and prestart checks made before attempting to complete the refrigerant charge. See startup procedures on page

48.

NOTE: It is recommended that the total operating charge per

circuit be stamped on the unit nameplate for future reference.

146

45

45

60

60

60

.-JC

070C

080C

090C

1Ooc

230C

NOTE: Condenser pumpdown capacity is based on ANS1/ASHRAE Standard

15-1976 rating of 90°/0 full of liquid at 900F. To convert values to the older

ARI standard (80% full at 800 F), multiply pumpdown capacity by 0,888.

19 19 45

19 19 45

26 26

26 26 60

26 28

99 99

I

60

60

148

I

Table 11. Weight of refrigerant R-22 in copper lines

(Pounds Per 100 Feet of Type L Tubing)

Weight of Refrigerant, Lba.

0.054 3.84

%

0.100

112

0.162 7.12 .605 .156

%

0.336 24,0 1.26 .323

%

11A 0.573 40.8

1% 0.872

1% 1.237 88.0

2~~ 2.147

25/8 3.312

31~

3% 6.398

4% 8.313 592.0 31.1 8.00

4.728 336.0 17.7 4.55 6.750

7.12 .374 .096

62.1

153,0

236.0 12.4 3.18 4.720

456.0 24.0 6.15 9.140

.202

2.14

3.26 .839

4.62 1.190 1.770

8.04

. . —.

Suction Gee

(Superheated to 65” F)

.052

.550

2,06 3.060

.077

.143

.232

.480

.620

1.250

11.190

I

IM 269 I Page 9

Page 10

Table 12. Pressure-vacuum equivalents

o

50

100

150

200

300

500

1,000 0.019 759.00

2,000 0.039

4,000 0.078

6,000

8,000 0.156

10,000 0.193

15,000 0.290 745.00 29.330

20,000 0.387

30,000

50,000 0.967

100,000

200,000 3.670 560.00 22.050

600,000

760,000 14.697 0

0 760,00 29.921

0.001 759.95 29.920

0.002

0.003

0.004

0.006 759.70 29.910

0.009

0.117 754.00 29.690

0.580

1.930 860.00 25.980

9.670 260.00 10.240

759.90

759.85

759.80

759.50 29.900

758.00 29.840

756.00 29.760

752.00 29,600

750.00

740.00 29.130

730,00

710.00 27.950

29.920

29.920 1/5,100 —33

29.910

29.880

29.530

28.740

0

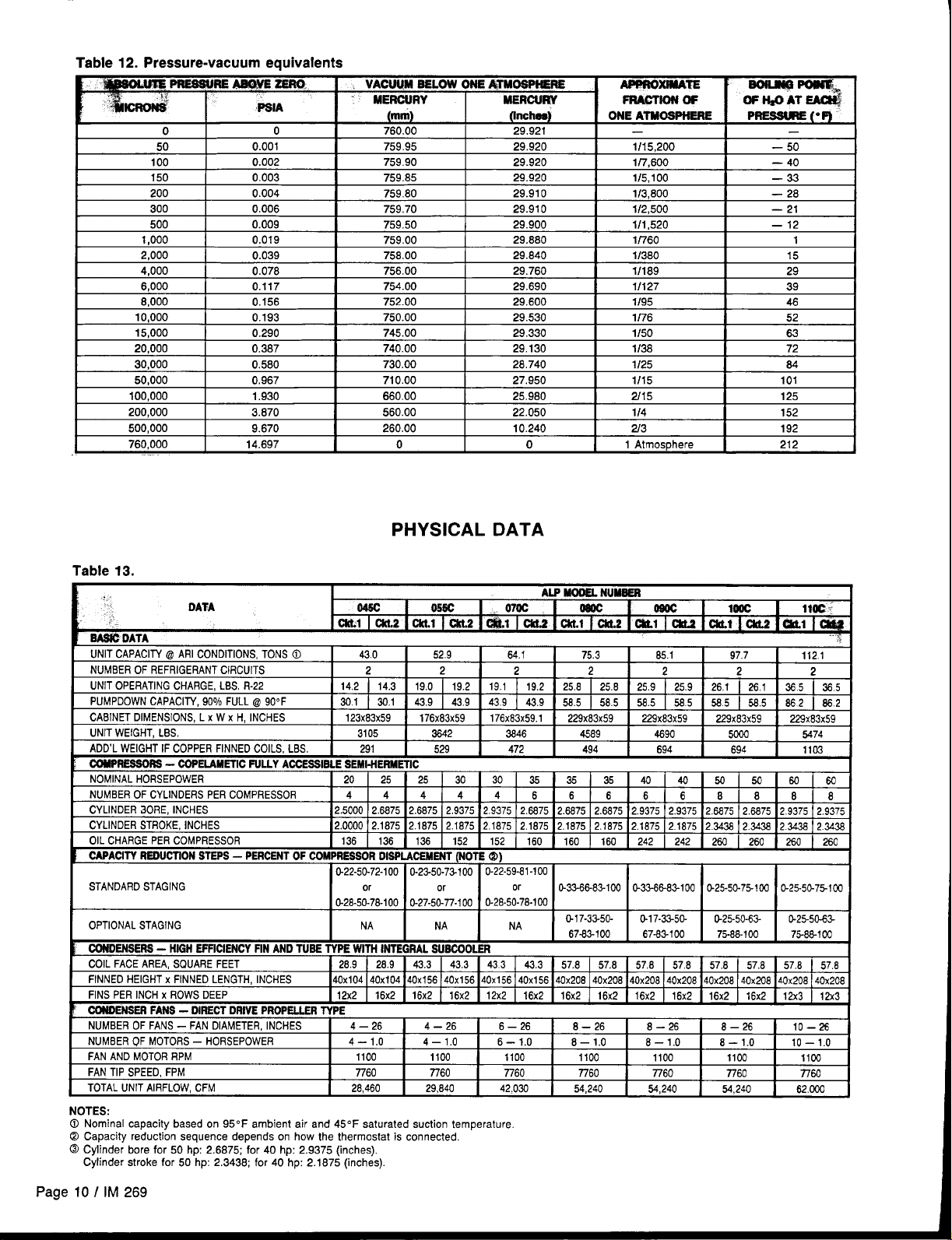

PHYSICAL DATA

— —

1/15,200

1/7,600 — 40

1/3,600

1/2,500 — 21

1/1 ,520 — 12

1/760 1

1/380 15

1/189

1/127

1/95

1/76

1/50

1138 72

1125 84

1/15 101

2/1 5 125

114

213 192

1 Atmosphere 212

— 50

— 28

152

29

39

46

52

83

NDITIONS,TONS 0

T CIRCUITS

ER COMPRESSOR

t

C)DTlntd Al CTAC!KIC

“, ,, W! .-L “In”,, .”

CONDENSERS- HIGH EFFICIENCYFIN AND TUSL . ,, - ....,, ....-”..,.- ““””””— .

I

COIL FACE AREA, SQUARE FEET I 28.9 28.9 1 43.3 43.3I433

FINNED HEIGHT

FINS PER INCH

~

CO&NSEiFANS-lili.. . ..... . ... . . .. . .._

NUMBEROF FANS – FAN DIAMETER,INCHES 4–26

NUMBEROF MOTORS– HORSEPOWER 4– 1.0 4– 1.0

FAN AND MOTORRPM 1100

FAN TIP SPEED, FPM 7760

TOTAL UNIT AIRFLOW, CFM 28,460 29,640 42.030

NOTES:

@ Nominal capacity based on 950F ambient air and 450F saturated suction temperature

@ Capacity reduction sequence depends on how the thermostat is connected.

@ Cylinder bore for 50 hp: 2,6875; for 40 hp: 2.9375 (inches).

Cylinder stroke for 50 hp: 2.3438; for 40 hp: 2.1875 (inches).

X FINNED LENGTH, INCHES I4OX1O414OX1O4140x156140x156140x156140x156140x208140x208140x208140x206]40x206 140x208l~x208 140x208

X ROWS D)EEP

IECTDRIVE PROPELLERTYPE

43.0

I

2 2

4 4

I

12.500012.667512.6875 2,9375 2.9375 2.6875 2.6875

0-28-50-78-100 O-27-5C-77-I00

NA NA NA

IF TVDC WITU lhlTC130Al Cl lRf!!l Cm

I 12X2 16x2

52.9

I

25 30 30 35 34

4 4 4

I

.ziwu-r+luu U-z< -sY-u 1- ! w

1 16x2

4–26

1100 1100 1100 1100 1100

7760 7760

I

or

0-28-50-78-100

16x2 j 12X2 16x2I16x2

64.1

2

43.9 [ 58.5

6 6 6 6 6 8 8

or

43.3 I 57.8

6–26 8–26 8–26 8–26 10–.2%

6– 1,0

75.3

I

2

58.5 j58.5 I 585

35 40 40 54 547

2.6875 2,9375 2.9375 2.6675 2..5875

O-3366-83-1OQ

G17-33-50- o-17-32-5c- &25-50-6?- 0-25-50.6S

67-83-100

57.6

16x2I16x2

8– 1.0

7760

54,240 54,240 54,240

65.1

1

2 2 2

K13-8&83-l 00 0.25-50-75-103 O-25-5C-75-1OO

67-83-100 75-88-1oo 75-88-1OC

I 57.6 57.8 I 57.8 57.8 1 57.8

16x2 1 16x2 16x2 [ 12X3

8–1.0

7760 7760

97.7

I

I 585 5&5 1862 I 862

8– 1.0

112.1

I

608C

88

2.9375 2.9375

EM

10– 1.0

llCO

n60

62.CCO

1

57.8

12x3

I

Page

10 / IM 269

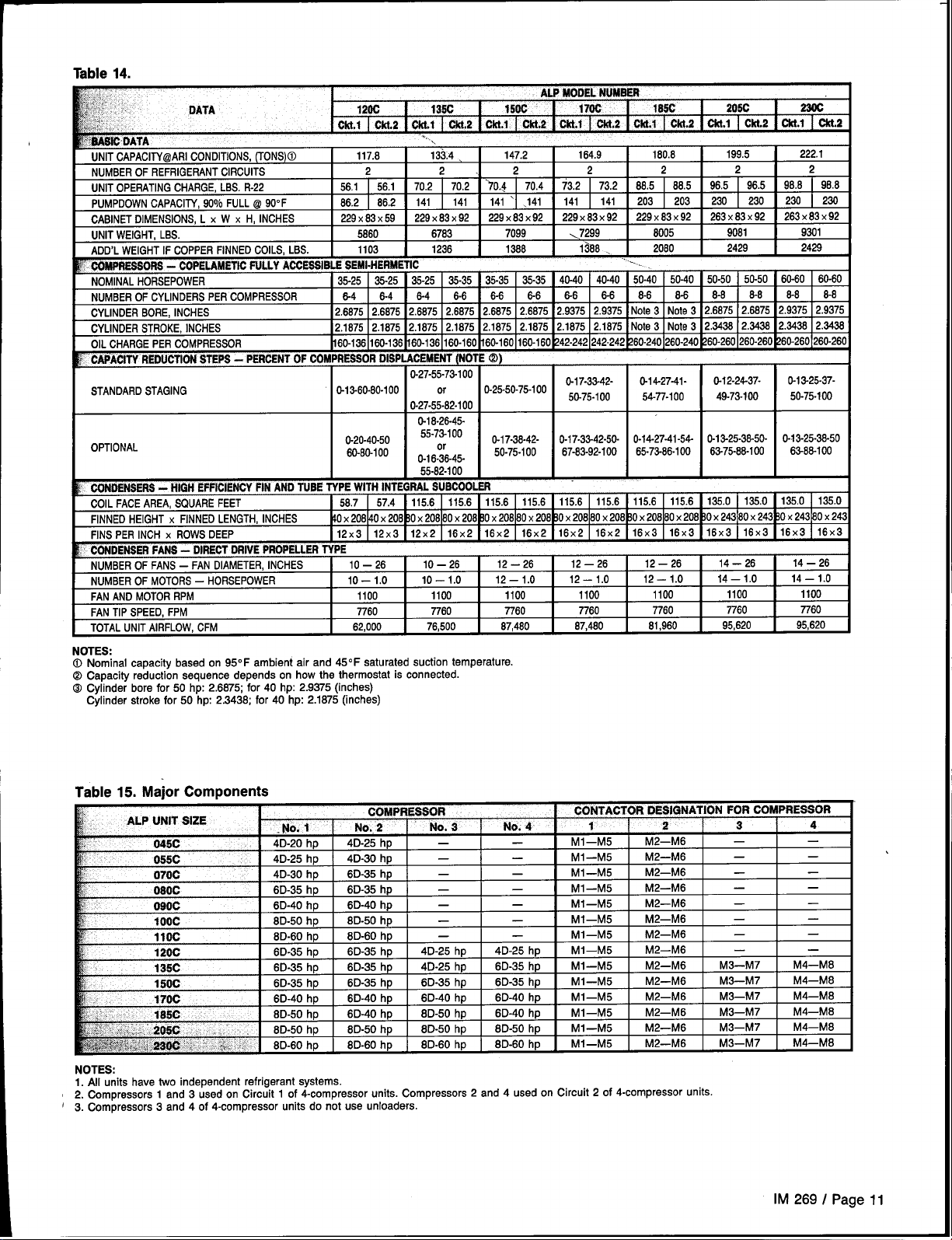

Page 11

Table 14.

1200

Of&l I ckt.2 I CkLl I ckt.2

UNIT CAPACllY@ARlCONDITIONS,(TONS)@

NUMBEROF REFRIGERANTCIRCUITS

UNIT OPERATING[

PUMPDOWNCAPACITY, 900/0FULL @ 90”F

CABINET DIMENSIONS,L X W X H, INCHES

UNIT WEIGHT, LBS.

ADD’L WEIGHT IF COPPERFINNED COILS, LBS.

: COfdPfE880f?8 - COPELAMETICFULLY AGGRiWI%t

NOMINALHORSEPOWER

NUMBEROF CYLINDERS PER COMPRESSOR

CYLINDERBORE, INCHES

CYLINDERSTROKE, INCHES

OIL CHARGE PER COMPRESSOR

~ CAPACITY REDUCTIONSTEPS - PERCENTOF COMPRESSORDISPLACEMF”’

STANDARDSTAGING

I

) HEIGHT X FINNED LENGTH, INCHES ~0 X206~0 X206~0 X208180 X208~0 X208160X206~0 X208180X2C

CHARGE,LBS. R-22

. ... . .. . ... . .. --------- - --. ., ..--. .—. -

117.8 1334> 147.2

56.1 ] 56.1 70.2

86.2 86.2 141

229X83X 59 229X83X 92

5860 6783 7099

stmi.ntnsmIw

35-25

8-4

2.6875 2.6875

=1211375 ]2187512167521875121675121875 12~875lNote3INote312~ 12~

~60-1361160-136 ~6Ll136~

0-13-60-80-100 or

I

.,,\

2

1103 1236

35-25 35-25

6-4 6-4

2.6875

.“7.

U-L(-55-73-1OO

0-27-55-82-100

I1400CAC

ALP MODELNUMBEN

135C 150C

EI+T(NOTE Q

Cftt.1 I CW2 1 Cfrt.1 I CM.2

—

2. 2

70.2 )0.4 70,4 73.2 73.2

141 141 ‘1 .141 141

229X83X 92 229X83X 92 229X83X 92 263X83X 92 263X83X 92

1388

35-35 35-35

6-6

6-6

2.6675 2.6875

0-25-50-75-100

40-40 40-40

35-35

6-6 6-6 8-8 8-6 6-6 8-8

2.9375 2.9375

2.6675

170C

164.9

2 2

141

\7299

1388, 2060

0-17-33-42- 0-14-27-41-

50-75-100 54-77-100

105C

Cfd.1 ckt.2

~

180.8

88.5 98.5 96.5 98.8

68.5

203 203

6005

50-40 50-50

50-40

Note 3 2.6875 2.6675

Note 3

2060 220C’

Cld.1 ckr.2 Ckt.1 citt.2

~

199.5 222.1

230

9081 9301

2429 2429

0-12-24-37- 0-13-25-37-

49-73-100

~

2 2

I 98.8

230 I 230

230

50-50

60-60

8-6 8-8 M

2.9375

2.3436 2.3438

50-75-100

60-80

2.9375

TOTAL UNIT AIRFLOW, CFM

I

NOTES:

0 Nominal capacity based on 95°F ambient air and 45°F saturated auction temperature.

@ Capacity reduction sequence depends on how the thermostat is connected.

COCylinder bore for 50 hp: 2.6875; for 40 hp: 2.9375 (inches)

Cylinder stroke for 50 hp: 2.3438; for 40 hp: 2.1875 (inches)

62,000

I

76,500

I

87,480

I

67,480

I

81,960

I

Table 15. Major Components

COMPRESSOR CONTACTOR DESIGNATION FOR COMPRESSOR

4D-20 hp

4D-25 hp

4D-30 hp 6D-35 hp

Eli

..

090C

1Ooc

I1OC

Osoc

6D-35 hp

I

6D-40 hp

8D-50 hp

I

BD-60 hp

120C 6D-35 hp

135C

150C 6D-35 hp

w$:$~k.i,

...

NOTES:

1. All units have two independent refrigerant systems.

2. Compressors 1 and 3 used on Circuit 1 of 4-compressor units. Compressors 2 and 4 used on Circuit 2 of 4-compressor units.

3. Compressors 3 and 4 of 4-compressor units do not use unloaders.

G:. ,.

-$’”*W “t ..’5:.$% “ $

6D-35 hp

6D-40 hp

I

8D-50 hp

6D-50 hp

1

6D-60 hp

4D-25 hp

4D-30 hp

6L-W” ,IV

I

6D-40 hp ] —

8D-50 hp

6D-60 hp ] —

6D-35 hp

6D-35 hp

6D-35 hp 6D-35 hp ] 6D

8D-40 hp 6D-40 hp

6D-40 hp 8D-50 hp

6D-50 hp 8D-50 hp

8D-60 hp 8D-60 hp

—

—

—

1 1 1

— —

4D-25 hp

—

—

—

—

—

4D-25 hp

)-35 hp

6D-40 hp

6D-40 hp MI–M5 M2—M6

8D-50 hp

8D-60 hp

M1—M5 M2—M6 —

MI—M5

M1—M5 M2—M6 —

Mi—MK

,.! . . , ...- ..M1—M5 M2

MI—M5 M2—M6 —

I

MI–M5 M2—M6 —

MI—M5 M2—M6 I —

I

MI—M5 M2—M6 M3—M7

M1—M5 M2—M6

MI–M5 M2–M6

M1—M5 M2—M6

1

MI—M5 M2—M6

M2—M6 —

M7—M6

&flJ6 — —

95,820

I

M3—M7 M4—M6

M3—M7 M4—M8

M3–M7 M4—M6

M3–M7 M4—M6

M3–M7 M4—M8

I

— —

,

95,620

—

—

—

—

—

—

M4—M8

1

!

1

1

IM 269 / Page 11

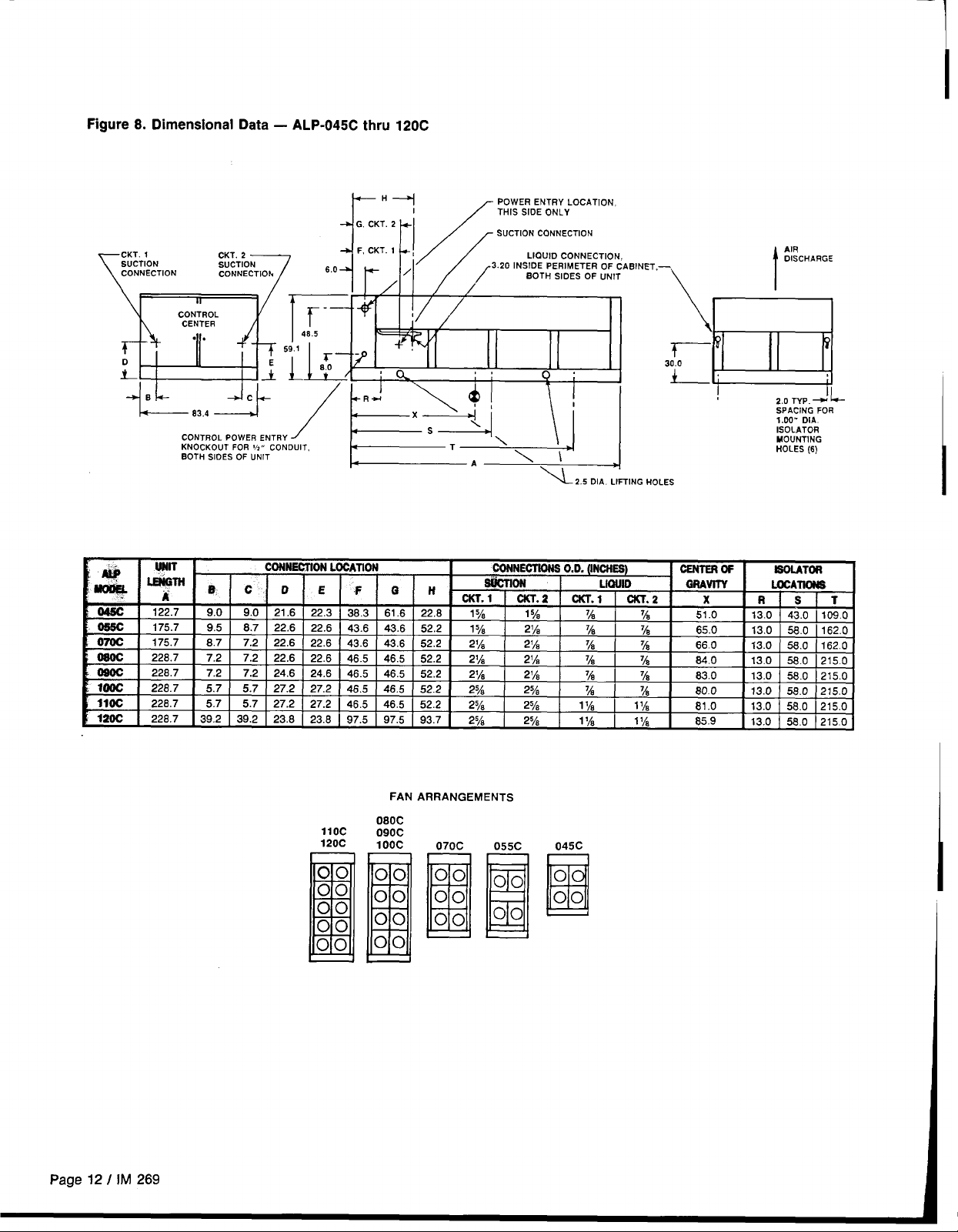

Page 12

1

Figure 8. Dimensional Data — ALP-045C thru 120C

~ 2.5

,—

ABINET

DIA. LIFTING HOLES

AIR

DISCHARGE

\

t

\

,o~

Eli/

Lli J

2.0 TYP. -’~

SPACING FOR

1.00. DIA

ISOLATOR

MOUNTING

HOLES (6)

II

Mac

Ossc

070c

Oaoc

Osoc

100C 226.7

11OC 226.7 5.7

120C

122.7

175.7

175.7

228.7 7.2 7.2 22.6

228.7 7.2

226.7

39.2

9.0

9.5

8.7

5.7

9.0 21.6

8.7 22.6

7.2 22.6

7.2 24.6

5.7 27.2

5.7 27.2

39.2 23.6

22,3 38.3

22.6 43.6

22,6 43.6

22.6 46.5

24,6 46.5

27.2 46,5

27.2 46.5

23.8 97.5

11OC

120C

00

00

00

00

00

El

61,6 22,8

43,6 52,2

43.6 52,2

46.5 52,2

46.5 52,2

46,5 52.2

46,5 52.2

97,5 93.7

FAN ARRANGEMENTS

080C

090C

1Ooc

070C

00

00

00

El

1ye

15h 2%

21A 2%

21A 21/i

21A 21A

25A

2%

25h

1ye

278

278

2%

055C

00

00

1

045C

o

00

El

%

%

7%

%

% %

7%

11A

11A

CENTEROF lSOIATOR

7/8

%

%

7/8

‘h

1~~

11A

51.0

65.0

66.0

64.0

63.0

80.0

81.0

85.9

13.0 43.0

13.0 58.0

13.0 58.0

13.0 58.0

13.0 58.0

13.0 56.0

13.0 58.0

13.0 58.0

109.0

162.0

162.0

215.0

215.0

215.0

215.0

215.0

Page 12/ IM 269

Page 13

Figure 9. Dimensional

CONTROL

CENTER

..

lid

1-8-’4

cONTROL POWERENTRY

KNOCKOUTFOR !4If CONDUIT,

BOTHSIDES OF UNIT

— ALP-135C thru 230C

Data

1

r

8

+

v

2.5,1 DIA. LIFTING HOLES

FAN ARRANGEMENTS

150C

135C

———

170C

185C

00

00

00

00

00

B

205C

230C

00

::

00

00

00

00

%

II 4

CKT. 2 SUCTION

CONNECTION,2%11

(4)

Dimensions in Inches

AK!

DISCHARGE

t

/

+~ 2.O’TYP.

SPACINGFOR

1.00~ DIA.

iSOiATOR

MOUNTING

HOLES(6)

LENGTH ‘ “.

:

23SC

B

263.4

263.4

B ‘. ~ 6 ‘ ;.3 :’ “

39.0

39.0

24.6

24.6

101.4

100.3

ISOLA’TO,RLOCATIONS

ii ‘ ‘

13.0

13.0

“,.:”’.s-’’ ,”:

95.0

95.0

.T

249.7

249.7

IM 269 / Page 13

Page 14

FIELD WIRING

Wring must comply with all applicable codes and ordinances.

Warranty is voided if wiring is not in accordance with specifications. An open fuse indicates a short, ground or overload.

Before replacing a fuse or restarting a compressor or fan

motor, the trouble must be found and corrected.

Copper wire is required for all power lead terminations at

the unit while either aluminum or copper can be used for all

other wiring.

ALP units may be ordered with internal power wiring for

either single or multiple point power connection. If single point

power connection is ordered, a single

block or non-fused disconnect switch is provided and wiring

within the unit is sized

in accordance with the National Elec-

large power terminal

trical Code. A single field supplied disconnect is required,

An optional factory mounted transformer may be provided,

If multiple point wiring is ordered, three power connections,

Figure 10. Typical field wiring diagram for ALP-045C

L),,mnn,d

,Ph,––-r,l--r,l

BK

~“w::z:::---~;j;j

By O!her.

Termna-

PB 1

U“,!Ma!”

Bl,ck

one per compressor circuit plus one for condenser fans, are

required and wiring with the unit is sized in accordance with

the National Electrical Code. Separate field supplied discon-

nects are required for each of the three circuits. A single

power block is provided for all of the condenser fans and the

optional 115V control transformer.

CAUTION: Internal power wiring to the compressors for

the single point versus the the multiple point option are different. It is imperative that the proper field wiring be installed according to the way the unit is built.

Figures 10, 11 and 12 show typical field wiring that is required for unit installation, Items that require field wiring are

liquid line solenoids (SVI and SV2), optional hot gas bypass

solenoid (SV5) and the cooling thermostat as well as the unit

power supply.

— 080C with 4 steps of capacity control

Condense,U.(I Comrx-m”

1

●nd Fan

T

T

M.!ors

F.,,(F,]

L..i—,

cont..! stop

SW!ch,,,,

,

6

t

510

L

T,rm<na!, For

T1’,mmsta!s

8 yl+

2!3

slag, 4 G+ >N;

Co”d,n,>ngU“ 1

control,

236

.

I

PSI ,,,

,,2

~—@+w&”-–@Y ---

‘Lp’Occ’’OcO”” la”””’

camp, .1

217

0

c

Page 14 / IM 269

●NOTE: Standard M separate Pcwr supply c,rcaI1s for ccc:rols

LEGEND:

@ FIELD WIRING TERFIINAL

———

— FACTORY WIPING

‘-— OPTIONAL FACTORv WIRING

FIELD WIRING

BK BLACK WIRING (LINE)

WHITE WIRING (NEUTRAL)

WH

Page 15

Figure11.Typicalfield wiring diagram for ALP-080C –

10C with 6 steps of

capacitycontrol

D!mmcec!

B, Olht.

—

.--” . . ...%

ml

Si’+-:-::--?: ! :

CO.,*

stop

S.”ch,e%)

~

Nom mm.”.w!m. m .?4

5?0 m 0“.,.11 t,-.

dock .“d !!0. ,.,,,.

6

t

570

L-#J;.i ~ 2aii.-e-.jNn

m 1

U“ll u.,.

TWm..( B-k

—--—

..-’3,”.!!

_ ,

~

T

h

OPI’.”.,~“-

Ca.tr.i Tr..,tc.me!

1

C.tatncec “.<1 C.m,re’t.m

I

. . . F.. ..,.-

I

---—--i”

----4

Figure 12. Typical field wiring diagram for ALP-120C –

ym;:w. ,OA m-

i

—*W m

NOTE: For ALP-120C, 135C,

and 150C, R3 and R4 would

replace the compressor un-

loaders for compressors 3 and

4 of those size units. See page

43 for a typical diagram.

?’(9a No,.)

,.” p,,

L.i —, —,

4

‘aMld Stw

S“llchl”)

s

?

~ NOTE R.Mv. .1”. - .“d

—.-—--

s, 0,.,.,,.11 ,he

dock sw lb. ,wl,ch

Stm

2

Stw.e 3

w+- ‘z

CW2

213

Stls+ 4

(+ ~c- ‘~

,13

S,qw 5

@:I-o- Y

230C with 8 steps of capacity control

~+TF&y_

w

ml

C4nds.sing U“(I

Cantmh

R78

R17

ALP , 8SC–2W Only

117

Y

I

L

..—

c-w .,

,8

IB

Sting. 6

SW.9 7

SW+ a

IM 269 / Page 15

Page 16

Table 16. Wire Sizing Ampacities

3PH, 60 HZ

ALP MODEL

045C

055C

070C

090C

1Ooc

Iloc

120C

135C

150C

170C

185C

205C

230C

ELEC. POWER

POWER SUPPLY O

208

230 184

460 @

208 1 278

208

230

5ktt

T

208 412

230 412

460 @ 207

460 (B

575 203

208

230

460 ~

575 222

206 708

230

4600

575 266

208 767

230 767

460 @

575

206

230

460 @

575

Single Point

Power Supply

r

m

184

I

I 93

292

292

I

246

533

533

267

652

331

385

314

926

926

455

373

I

WIRE SIZE AMPS @

Muitlple Point Power Supply O

Elec. Ckt. 1 Elec. Ckt. 2 Elec. CM. 3

Fene & tintrols Cornpr.Cti. 1 hmpf. m. 2

25.6 79

25.6

12.8

12.7

25.6 96 133

25.6

12.6 49 66

12.7 39

33.6 I 133 140

33.6

16,8

16,7 45

41.6

41.6 140

20.8 70

21,5

41.6

41.6 175 175 (1) 3“

20.6

21.5

41.6

41.6 221

20.8 110 110 (1) 2V2°

50.6 217

25.3

26.3

50.6 217

50.6

25.3

26.3

58.6 252 252 (1) 4“

58.6 252

29.3 126 126 (1) 21/2“

30.7 101 101

58.6

58.6 315 315 (2) 3“

29.3 160 160 (1) 3“

30.7

56.6 359 359 (2) 3“

58.6 346

29.3 175 175 (1) 3“

66.6 452 452 (2j 4“

33.3 225 225 (1) 4“

35.6 180

79

39 49 (1) 11/’4”

I

33 39

96

133

66 70

140

I

56 56

191

I

69 69

66

221 221

109 109 (1) 2v2 “

87 87

217

109

I

87

344

I

122 122

96

96

I

133 (1) 23/2”

45

140

56

140

140

I

70

191

I

68

221

217

252

252

126 (1) ZV2°

I

101

252

344

I

346

180 (1) 3“

POWER ENTRY HUB

I

QUANTIYY & i

I

Slngb Point

Power Supply

I

(1) 2“

ilj 2

I

‘l’ ,,,

(1) 23/2”

(1) 11A”

(Ij IIA,I

I

[1)2M”

{lj 2Th”

(1) lvz”

(1) l!~,,

(1)2V2“

(1) 2V2“

I

~1j 1VZ”

(1) 11/4,,

(1) 3“

I

~lj 2

1) 11/2”

1(

(1) 4“

(1) 4“

I

~lj 4!s

(1) 2“

(1) 49’

ilj 4’

I

‘1’ 2<,

(1) 4“

(1) 21/2,,

(2) 3“

I

21/2,,

~1j

(2) 3“

mm. Point

Power supply

(1) 2“

(1) 2“

(1)

l%”

~lj lIA.

(1) 272”

(1) 27/2“

(1)lYz”

11) 11~”

(1) 3“

(1) 3“

(1) 2’”

Jl) 1

1/2,,

(1) 3“

(1) 3“

(;) :“

(1) 4“

(1) 4“

(1) 2“

, 2.,

(1) 4“

(1) 4“

(1) 21/2“

(lj 2v2 r’

(2) 21A” (1) 1“

(2) 2Y2“ (1) 1 “

(1) 2V2“

jl j 21/2,,

(2) 2“ (1) 1’”

(2) 2“ (1) 1“

(1) 21/2“

(1) 21/2“

(1)1’’(1)2’’(1)2 ?>”

(1)1’’(1)2’’(1)2Y”

(1) 2Vz”

~lj z~hn

(1)1“(2) 2V2“

(1) 1“ (2)

(1)

(1) 21,2,,

(1) 1“ (2) 3“

(1) 1“ (2)3”

[1) 3“

[1) 21/2”

[1) 1“ (2) 3“

(1) 1“ (2) 3“

ilj 3

[1) 1“ (2) 3“

[1) 1“ (2) 3“’

[1) 4’”

[1) 3~/’2“

:1) 1“ (2) 4“

:1) 1“ (2) 4“

‘1) 4“

;1) 4“

2Y, “

3“

I

ELECTRICAL DATA NOTES

0 ALLOWABLE VOLTAGE LIMITS:

Unit nameplate 208V/60Hz/3Ph: 187V to 253V

(except ALP-090C: 180V to 220V)

Unit nameplate 230V/60Hz/3Ph: 187V to 253V

(except ALP-090C: 207U to 253V)

Unit nameplate 460V/60Hz/3Ph: 414V to 506V

Unit nameplate 575V/60Hz/3Ph: 517V to 633V

Unit nemerYate 360V/50Hz/3Ph: 342V to 418V

@ Compressor RLA values are for wire sizing purposes only and do not reflect

normal operating current draw If unit is equipped with SPEEDTROL motors,

the first motor on each refrigerant circuit is a 230V single phase, 1 hp

RLA of 5.6 amps

with an

@ Compressor LRA for part winding start are for the first winding. If the unit

Page 16 / IM 269

motor,

is equipped with SPEEDTROL motors, the first motor on each refrigerant

circuit is a 230V single phae, 1 hp motor, with an LRA of 145 amps

Unit wire size amps are equal to 125% of the largest compressor-motor

(!3

RLA plus 100o1oof RL4 of

transformer Wre size amps for separate 115V control circuit po;er is 12

amps for all units shown.

o

Quantity and size of power entry hub(s) provided with unit

E’

Single fxJint ~wer supply requires a single fused disconnect to supply electrical power to the unit.

Multiple point power supply requires three independent power circuits with

CL

separate fused disconnects

Data also applies to 380V/50Hz/3Ph units

@

all other loads in the circuit includnq control

Page 17

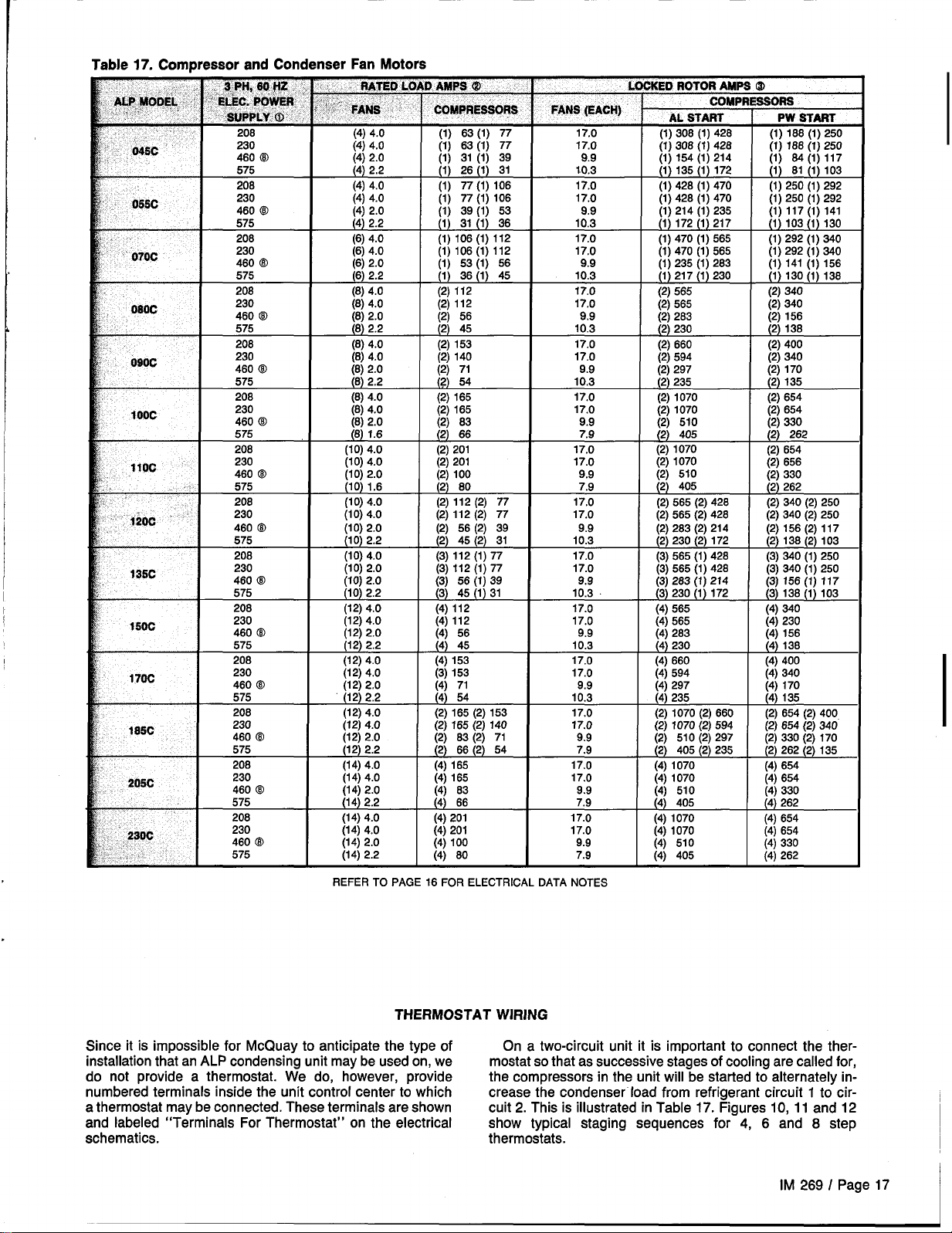

Table 17. Compressor and Condenser Fan Motors

XEO ROTOR AMPS @

COMPRESSORS

056C

“ 070C

080c

beoc

100C

11OC

.1200 ““”

f35c

160C

170C

185C

206C

Z30C

,.,’

(1) 31 (1) 39

208 (4) 4.0

230 (4) 4.0

4600

575

208 (6) 4.0

230 (6) 4.0

46063 (6) 2.0

575 (6) 2.2

208 (8) 4.0

230 (8) 4.0

460 @ (6) 2.0

575 (6) 2.2

206

230 (6) 4.0

460 @ (6) 2.0

575 (8) 2.2

208 (8) 4.0

230

460 @ (8) 2.0

575

I

208 (lo) 4.0

230

. .

460 @ (lo) 2.0

575

208

230 (lo) 4.0

460 @ (lo) 2.0

575

208 (lo) 4.0

230

460 @

575

208

230 (12) 4.0

460 @ (12) 2.0

575

208 (12) 4.0

230 (12) 4.0

460 @ (12) 2.0

575

206

230 (12) 4.0

460 @ (12) 2.0

575

208 (14) 4.0

230

460 @ (14) 2.0

575

208 (14) 4.0

230 (14) 4.0

460 @ (14) 2.0

575 (14) 2.2

(4) 2.0

(4) 2.2

(8) 4.0

(8) 4.0

(8) 1.6

I

(lo) 4.0

(10) 1.6

(lo) 4.0

(1o) 2.2

(lo) 2.0

(lo) 2.0

(lo) 2.2

(12) 4.0

(12) 2.2

(12) 2.2

(12) 4.0

(12) 2.2

(14) 4.0

(14) 2.2

REFER TO PAGE 16 FOR ELECTRICAL DATA NOTES

(1) 26 (1) 31

(1) 77 (1) 106

(1)77 (1) 106

(1) 39 (1) 53

(1) 31 (1) 36 10.3

(1) 106 (1) 112

(1) 106(1) 112

(1) 53 (1) 56 9.9

(1) 36 (1) 45 10.3

(2) 112

(2j 112

(2) 56

%--t-ik

i2i 71

m

{2j 66

(2) 201

(2) 201 17.0

%--HE

(2j 56 (2j 39

(2) 45 (2) 31 10.3

w--l--+

i4i 56

(4j 45

(4)

153

h--l-+

m

I

I

I

I

I

I

10.3

17.0

17.0

17.0

17.0

17.0

17.0

17.0

9.9

9.9

10.3

17.0

9.9

9.9

9.9

9.9

7.9

-

(2j 565

(2) 283 (2) 156

{2j 405

(2) 1070

(2) 1070 (2) 656

(2j 565 (2j 428 @j 340 @j 250

(2) 283 (2) 214

(2) 230 (2) 172

(3) 565 (1) 426

(3) 565 (1) 428 (3) 340 (1) 250

(3) 283 (1) 214 (3) 156 (1) 117

(3) 230 (1) 172 (3) 138 (1) 103

(4) 565

(4) 565 (4) 230

i4i 283

i4j 230 i4j 138

(4) 660 (4) 400

(zj340

I

(2j 262

(2) 654

(2) 156(2) 117

(2) 138 (2) 103

(3) 340 (1) 250

(4) 340

I i4i 156

km--l-L

i4j 510 I i~ 330

m

THERMOSTAT WIRING

Since it is impossible for McQuay to anticipate the type of

installation that an ALP condensing unit maybe used on, we mostat so that as successive stages of cooling are called for,

do not provide a thermostat. We do, however, provide the compressors in the unit will be started to alternately innumbered terminals inside the unit control center to which

a thermostat maybe connected. These terminals are shown

and labeled “Terminals For Thermostat” on the electrical show typical staging sequences for 4, 6 and 8 step

schematics. thermostats.

On a two-circuit unit it is important to connect the ther-

crease the condenser load from refrigerant circuit 1 to circuit 2. This is illustrated in Table 17. Figures 10, 11 and 12

IM 269 / Page 17

Page 18

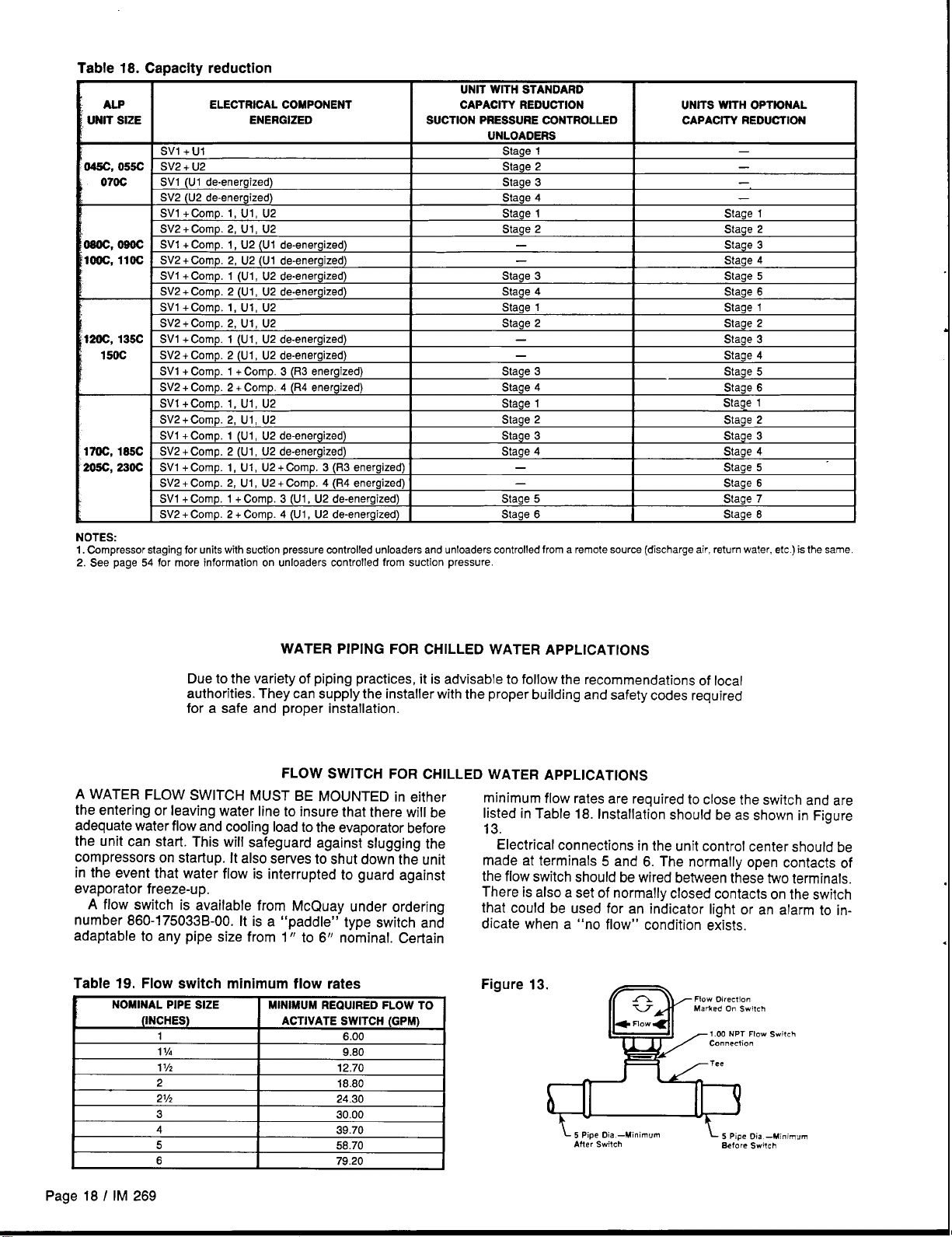

Table 18. Capacity reduction

UNIT WrTH STANDARD

ELECTRICAL COMPONENT

ENERGIZED SUCTION PRESSURE CONTROLLED

I

UNIT

ALP

SIZE

Svl +Ul

45C, 055C

070C

Sot, Oeoc SVl+Comp. l, U2(Ul da-energized)

Ooc,

20C, 135C SVI + Comp. 1 (UI, U2 de-energized)

150C SV2 + Comp. 2 (U1, U2 de-energized)

70C,

05C, 230C

NOTES:

1. Compressor staging for units with suction pressure controlled unloaders and unloaders controlled from a remote source (discharge air, return water, efc ) is the same

2. See page 54 for more information on unloaders controlled from suction pressure.

SV2 + U2

SV1 (Ul de-energized)

SV2 (U2 de-energized)

SV1 +Comp. 1, Ul, U2

SV2 +Comp. 2, Ul, U2

11OC SV2+Comp.2, U2(Ul da-energized)

SVl+Comp, 1 (Ul, U2 de-energized)

SV2 + Comp, 2 (Ul, U2 de-energized)

SVI +Comp, 1, Ul, U2

SV2 +Comp. 2, Ul, U2

SVI + Comp. 1 + Comp. 3 (R3 energized)

SV2 + Comp. 2 + Comp. 4 (R4 energized)

SV1 +Comp. 1, I-H, U2

SV2+Comn. 2. U1. U2

SV1 + Comp, 1 (U1, U2 de-energized)

SV2 + Comp. 2 (Ul, U2 de-energized)

1S5C

SV1 + Comp. 1, U1, U2 + Comp. 3 (R3 energized)

SV2 + Comp. 2, UI, U2 + Comp. 4 (R4 energized)

SV1 + Comp. 1 + Comp. 3 (Ul, U2 de-energized)

SV2 + Comp. 2 + Comp. 4 (Ul, U2 de-energized)

I

1

CAPACITY REDUCTION

I

UNLOADERS

Stage 1

Stage 2

Stage 3

Stage 4

Stage 1

Stage 2

—

—

Stage 3 Stage 5

Stage 4 Stage 6

Staga 1 Stage 1

Stage 2

—

—

Stage 3

Stage 4 Stage 6

Stage 1

Staoe 2

Stage 3 Stage 3

Stage 4

—

—

Stage 5

Stage 6

1

I

UNtTS WITH OPTiONAL

CAPACITV REDUCTION

—

—

—

—

Stage 1

Stage 2

Stage 3

Stage 4

Stage 2

Stage 3

Stage 4

Stage 5

Stage 1

Staae 2

Stage 4

Stage 5

Stage 6

Stage 7

Stage 6

WATER PIPiNG FOR CHILLED WATER APPLICATIONS

Due to the variety of piping practices, it is advisable to follow the recommendations of local

authorities. They can supply the installer with the proper building and safety codes required

for a safe and proper installation.

FLOW SWITCH FOR CHILLED WATER APPLICATIONS

A WATER FLOW SWITCH MUST BE MOUNTED in either

the entering or leaving water line to insure that there will be

adequate water flow and cooling load to the evaporator before

the unit can start. This will safeguard against slugging the

compressors on startup. it also serves to shut down the unit

in the event that water flow is interrupted to guard against

evaporator freeze-up.

A flow switch is available from McQuay under ordering

number 860-175033B-O0. it is a “paddle” type switch and

adaptable to any pipe size from 1” to 6“ nominal. Certain

Table 19. Flow switch minimum flow rates

NOMINAL PIPE SIZE

I

i

I

(INCHES) ACTIVATE SWITCH (GPh3)

1

11A

11/2

2

21/2

3 30.00

4 39.70

5 58.70

6 79.20

MINIMUM REQUIRED FLOW TO

I

6.00

9.80

12,70

I

18.80

24.30

minimum flow rates are required to close the switch and are

listed in Table 18. installation should be as shown in Figure

13.

Electrical connections in the unit control center should be

made at terminals 5 and 6. The normally open contacts of

the flow switch should be wired between these two terminals.

There is also a set of normally closed contacts on the switch

that could be used

dicate when a “no

Figure 13.

I

for an indicator light or an alarm to inflow” condition exists.

Flow Oireclion

1.00 NPT FIOW Switch

L,,,,, 0,. -M”,rn”nl

Switch

Aiter

~ 5 Pipe Oia -Minimum

eefore %ftch

Page 18 I iM 269

Page 19

EVAPORATOR FAN INTERLOCK FOR AIR HANDLER COIL INSTALLATIONS

It is important to interlock the air handler evaporator fan with

the condensing unit control to insure that there will be a cool-

ing load on the evaporator before the unit can start to pre-

vent compressor slugging. A pair of terminals for each

refrigerant circuit is available in the unit control center for this

UNIT LAYOUT & PRINCIPLES OF OPERATION

purpose. Remove the jumpers between terminals 111 and

112 for circuit 1 and211 and 212 for circuit 2. Use these ter-

minals for the evaporator fan interlock contacts. Be sure to

keep circuits separate by using two contacts on dual circuit

machines.

-J

Figure14.

Major Component Locations

The figures below illustrate component locations within the unit for each unit size.

COMPRESSOR No. 1

M

~ E? I@@@@

COMPRESSOR No. 2

L- -1

TOP VIEW OF UNIT

205C, 230C

*

COMPRESSOR No. 1

COMPRESSOR

No. 2

CONTROL CENTER

All electrical controls are enclosed in a weatherproof control

center with keylocked, hinged access doors. The control

center is composed of two separate compartments, line

voltage and control voltage, All of the line voltage components, except for the input terminals of the PVM, are

‘\

— COMPRESSOR No. 4

located in the compartment on the right side of the unit. The

control voltage components are located on the left side with

the live terminals located behind a deadfront panel. This protects service personnel from live terminals when accessing

the adjustable and resettable controls.

IM 269 / Page 19

Page 20

CONTROL CENTER LAYOUTS – ALP-045C thru 11OC

————_

Figure 15. Left Side, 115V Control Section

Figure 16. Right Side, High Voltage Power Section

7 FHmmI

ODDOU

P

m

PB2

El

o

PB3

n

————

CBS

CB1

.—— ——— —

m

II EII

CONTROL CENTER LAYOUTS — ALP-120C thru 230C

Figure 17. Left Side, 115V Control Section

TB5 (40–63)

Raceway

=

El

[ TB4(II0-124)(210-224) I I I ~[~

I

I II

TB6 (70–93)

Raceway

GRD 9

IT

T2

n

NOTE: PB1, PB2, PB3 are used with multiple point power wiring.

Figure 18. Right Side, High Voltage Power Section

I

PVM

o

PB2

El

n

PB3

El

~mmjm

——————

.——————

—. —

————

——

EIEI

Page 20 / IM 269

EIEI

TC

1

11

mIimEIE

NOTE: PB1, PB2, PB3 are used with multiple point power wiring.

Page 21

ELECTRICAL LEGEND

DESIGNATION

AB

Cll, C21

CBI-S

COMPFI.1-4

CP1

CP2

DAC1

DAS1

DW

FI

F2

FB1–4

FS5

FB6–10

FBI ,2

GFI

GRD

HPI, 2

—4

HTRI

HTR5

JB5

JS6

LP1 , 2

Ml–lo

MI1-27

MJ

MPI-4

MTR1 1-27

NB

NSS

OP1–4

PBI–3

PC1–4

PC5, 6

PC8–10

PC12-22

Psi, 2

PVM

DESCRIPTION STD. LOCATION

ALARM SELL

CAPACITORS FOR SPEEDTROL MOTORS

CIRCUIT BREAKERS, COMPRESSOR

MOTORS

COMPRESSORS 1 THRU 4

CENTRAL PROCESSOR

CENTRAL PROCESSOR SATELLITE

DISCHARGE AIR CONTROL

DISCHARGE AIR SATELLITE

DISCONNECT SWITCH, MAIN

FUSE, CONTROL CIRCUIT

FUSE COOLER HEATER

FUSEBLOCKS, COMPRESSOR MOTORS

FUSE SLOCK, CONTROL POWER

FUSESLOCKS, FAN MOTORS

FREEZESTATS, CONTROL

GROUND FAULT INTERRUPTOR

GROUND

HIGH PRESSURE CONTROLS

HEATERS, COMPRESSOR CRANKCASE

HEATER, COOLER BARREL

JUNCTION SOX FOR COOLER HEATER

JUNCTION SOX FOR HEAT RECOVERY

LOW PRESSURE CONTROLS

CONTRACTORS, COMRPESSOR

CONTRACTORS, FAN MOTORS

MECHANICAL JUMPERS

MOTOR PROTECTORS, COMPRESSOR

MOTORS, CONDENSER FANS

NEUTRAL SLOCK

NIGHT SETBACK

OIL PRESSURE CONTROLS

POWER SLOCK, MAIN

PRESSURE CONTROLS, SPECIALS

PRESSURE CONTROLS, HI AMSIENT

UNLOAOER

PRESSURE CONTROLS, SUCTION UNLOAOER

PRESSURE CONTROLS, FANTROL

PUMPDOWN SWITCHES

PHASE VOLTAGE MONITOR

FIELD MOUNTEO

BACK OF CONTROL SOX OR

ON BULKHEAD

CONTROL SOX

BASE OF UNIT

CONTROL SOX

CONTROL SOX

CONTROL SOX

CONTROL SOX

CONTROL SOX

CONTROL SOX

CONTROL BOX

CONTROL SOX

CONTROL BOX

CONTROL BOX

SUCTION LINE NEAR COOLER

CONTROLSOX

CONTROLSOX

ON COMPRESSOR

ON COMPRESSOR

WRAPPEO AROUNO COOLER

SARREL

NEAR COOLER ON SASE RAIL

UNOERSIOE OF COIL ON lNTERMEOIATE TUSE SHEET

ON COMPRESSOR

CONTROL BOX

CONTROL SOX

CONTROL BOX

COMPRESSOR JUNCTION BOX

CONOENSER SECTION

CONTROL BOX

CONTROL SOX

CONTROL SOX

CONTROL SOX

CONTROL SOX OR ON UNIT

ON COIL HEADER

CONTROL SOX

ON COIL HEADER

CONTROL SOX

CONTROL SOX

DESIGNATION

Rl, 2

R5–8

R9–12

R13, 14

R3, 4, 17, IS

R19

R21 ,22

R23-30

RS14

51

S2-4

S5

SC1l, 12

SL1

Svl , 2

SV5, 6

SV1O, 20

Svll, 21

T1

T2

T3

TS2

TS3

TB4-6

TCI

TC2

TCIO

TC11

TC12

TC12-25

TOI-4

T05–S

T09, 10

TO1l, 12, 13

TO14

T015, IS

T017; 18, 19

T020–24

U1, 2

OESCFNPTION

RELAYS, RESET OR ALARM

RELAYS, SAFETY

RELAYS, STARTING

RELAYS, LOW AMBIENT START

RELAYS, CAPACITY CONTROL

RELAY, HEAT RECOVERY

RELAYS, HI AMBIENT, HI RETURN

SUCTION UNLOAOERS

RELAYS, SPECIALS

RESET SWITCHES

SWITCH, CONTROL STOP

SWITCHES, LEAO-LAG

SWITCH, HEAT RECOVERY

SPEEO CONTROLS

SOLENOIO 000R LOCK

SOLENOIO VALVES, LIc2UI0 LINES

SOLENOIO VALVES, HOT GAB BYPASS

SOLENOIO VALVES, WATER CONOENSER

(NORMALLY OPEN)

SOLENOIO VALVES, AIR CONOENSER

TRANSFORMER, MAIN CONTROL

TRANSFORMER, 24V CONTROL

TRANSFORMER, FAN SPEEOTROL

TERMINAL BLOCK, 120V, FIELO

TERMINAL BLOCK, 24V. FIELO

TERMINAL BLOCKS, CONTROL

THERMOSTAT, UNIT

THERMOSTAT, COOLER SARREL

THERMOSTAT, SPECIAL

THERMOSTAT, HIRETURN WATER UNLOAOER CONTROLSOX

THERMOSTAT, SPECIAL

THERMOSTATS, FANTROL

TIME OELAYS, COMPRESSOR LOCKOUT

TIME OELAYS, COMPRESSOR PART WINOING CONTROL BOX

TIME OELAYS, LOW AMSIENT

TIME OELAYS, COMPRESSOR SEQUENCING

TIME OELAY, ALARM BELL

TIME OELAYS, FREEZESTAT

TIME OELAYS, HEAT RECOVERY

TIME OELAYS, SPECIAL

UNLOADERS

WATER &

S70. LOCATION

CONTROL BOX

CONTROL BOX

CONTROL BOX

CONTROL SOX

CONTROL SOX

CONTROL BOX

CONTROL SOX

CONTROL BOX

CONTROL BOX

CONTROL SOX

CONTROL SOX

CONTROL BOX

SACK OF CONTROL SOX OR

ON BULKHEAD

CONTROL SOX

CONOENSER SECTION

CONOENSER SECTION

CONOENSER SECTION

CONDENSER SECTION

CONTROL SOX

CONTROL SOX

ON BULKHEAD

CONTROL BOX

CONTROL BOX

CONTROL BOX

CONTROL SOX

ON COOLER

cONTROL sox OR ON UNIT

CONTROL SOX OR ON UNIT

CONTROL BOX

CONTROL BOX

CONTROL BOX

CONTROL SOX

CONTROL SOX

CONTROL SOX

CONTROL SOX

CONTROL SOX

ON COMPRESSORS

Figure 19. Recommended Unit Disconnect Location

HINGEO 000RS

ON CONTROL

CENTER

\

NOTE:

MOUNT DISCONNECT ON STATIONARY

PANEL SO THAT IT 00ES NOT INTER.

FERE WITH HINGED 000RS OR WITH

AIR INTAKE INTO COIL.

\

S.00 MIN.

4’

IM 269 I Page 21

Page 22

NORMAL SEQUENCE OF OPERATION

The following sequence of operation is typical for ALP

SEASONCON air cooled condensing unit, models ALP-045C

through ALP-230C (items in italics apply only to Mode/s

ALP-720C thru ALP-230C). The sequence varies somewhat

depending upon options.

Startup

stop switch S1 closed, 115V power is applied through the control circuit fuse F1to the compressor crankcase heaters HTR1,

HTR2 (HTR3, HTR4), the compressor motor protectors MP1,

MP2 (MP3, MP4) and the primary of the 24V control circuit

transformer. The 24V transformer provides power to the contacts of the low pressure controls LPI and LP2 and the com-

pressor lockout time delays TDI and TD2.

When the remote time clock or manual shutdown switch

turns on the chilled water pump, the flow switch closes and

115V power is applied to the relay contacts on the unit ther-

mostat. The unit will automatically operate in response to the

unit thermostat provided the manual pumpdown switches PS1

and PS2 are closed (in the ‘(auto” position); the compressor

lockout time delays TD1 and TD2 have closed, energizing the

safety relays R5, R6 (Rz R8); and the freezestats FS1 and

FS2, high pressure controls HP1 and HP2, and compressor

motor protectors MP1, MP2 (MP3, MP4) do not sense failure

conditions.

On a call for cooling, the unit thermostat energizes the liquid line solenoid valve SV1 for refrigerant circuit #1. This

opens the valve and allows refrigerant to flow through the expansion valve and into the evaporator. As the evaporator

refrigerant pressure increases, the low pressure control LPI

closes. This energizes the compressor starting relay R9, starting the compressor via the compressor contractors Ml and

With the control circuit power on and the control

—

M5. Closing the R9 contacts also energizes the condenser

fan motor contacts Mll, M12, M13 and M14, starting the fan

motors.

As additional stages of cooling capacity are required, the

unit thermostat energizes the liquid line solenoid valve SV2

of the refrigerant circuit #2. After the compressor sequenc-

ing time de/ay TD77 has closed, the same starting sequence

is initiated in refrigerant circuit #2.

If still more cooling is required, the unit thermostat will start

the remaining compressors and then de-energize unloader

solenoids until the capacity requirement is met.

Pumpdown

energize unloaders and unload the compressors, and then

de-energize the liquid line solenoid valves SV1 and SV2, causing the valves to close, When the compressor has pumped

most of the refrigerant out of the evaporator and into the condenser, the low pressure controls LPI and LP2 WiIIopen, shutting down the compressors and the condenser fan motors,

If refrigerant leaks into the evaporator, the increse in pressure

will cause the low pressure control LPI or LP2 to close, This

will energize the compressor starting relays R9 or R1O and

start the compressor, which will quickly pump the refrigerant

out of the evaporator and into the condenser (recycling

pumpdown).

A compressor which repeats recycling pumpdown every 5

minutes indicates a malfunction due to the temperature con-

trol or a system cause. A build up of heat in the compressor

without proper cooling of suction gas could cause a

mechanical failure in the compressor. McQuay recommends

corrective measures be taken if the compressor recycles

repeatedly within 15-minute intervals. “

— As the unit thermostat is satisfied, it will

CANADIAN

Canadian units which are CSA listed and are equipped for

multiple point power connections have a sticker (see figure

at right) next to the wiring diagram in the control box, This

notifies the installer that local authorities may require the unit

to be connected to a single electrical power source. Check

with local authorities for requirements.

CSA LISTING

Although this unit may

be provided with

options requiring more

than one source of

electrical supply, some

electrical inspection

authorities may require

this unit to be

connected to a single

external electrical

supply.

Page 22 / IM 269

Page 23

TYPICAL POWER WIRING DIAGRAMS

SINGLE POINT, WITHOUT SPEEDTROL

I

ALP-045C

ALP-045CI055C —

— 2081230V, AL, PW

380/41 514601575V, AL, PW

Ill

P%l

F“=E

L_L_T*’”

,,..,

+&t-t-.+’ ,

.!, 0“ ““ITS WITH

s.0/.13/4.0 /57,“-AL.

F

!.”.

...

I

L

I*

J

=%l=’=z

FB6

Ml!

.--,,,—

—,!, —

—,, ,—

FB7

..

I

M!2

m=’== =

ila---”

—,, s—

1“

I

<

f’”’%+y:[

7+”k @~; - –

1,

COMPR

*2