Page 1

SEASONCON”

Packaged air cooled condensing unit

McQuay

GROUP

McQuay-PERFEX

Models

Inc. 13600 Industrial Park Blvd., P.O. Box 1551, Minneapolis, Mn.

ALP-O16A

thru -033A

55440 @

Page 2

Page 3

.

McQUAY

type ALP SEASONCON air cooled condensing

units are designed for outdoor installations and are

compatible with either air handling or chilled water

systems. Each unit is completely assembled and factory

INTRODUCTION

consists of an air cooled condenser with integral subcooler

section,

piping and suction and liquid connections for connection to

any air or water cooling evaporator.

an unloading compressor, complete discharge

wired before evacuation, charging and testing. Each unit

NOMENCLATURE

A L P-033 A-S

Nomtnal

Capacity

(Tons)

INSPECTION

When the equipment is received, all items should be

carefully checked against the bill of lading to insure a

complete shipment. All units should be carefully inspected

for damage upon arrival. All shipping damage should be

INSTALLATION

NOTE: Installation and maintenance are to be performed only by qualified personnel who are familiar

with local codes and regulations, and experienced with this type of equipment. CAUTION: Sharp edges

and coil surfaces are a potential injury hazard. Avoid contact with them.

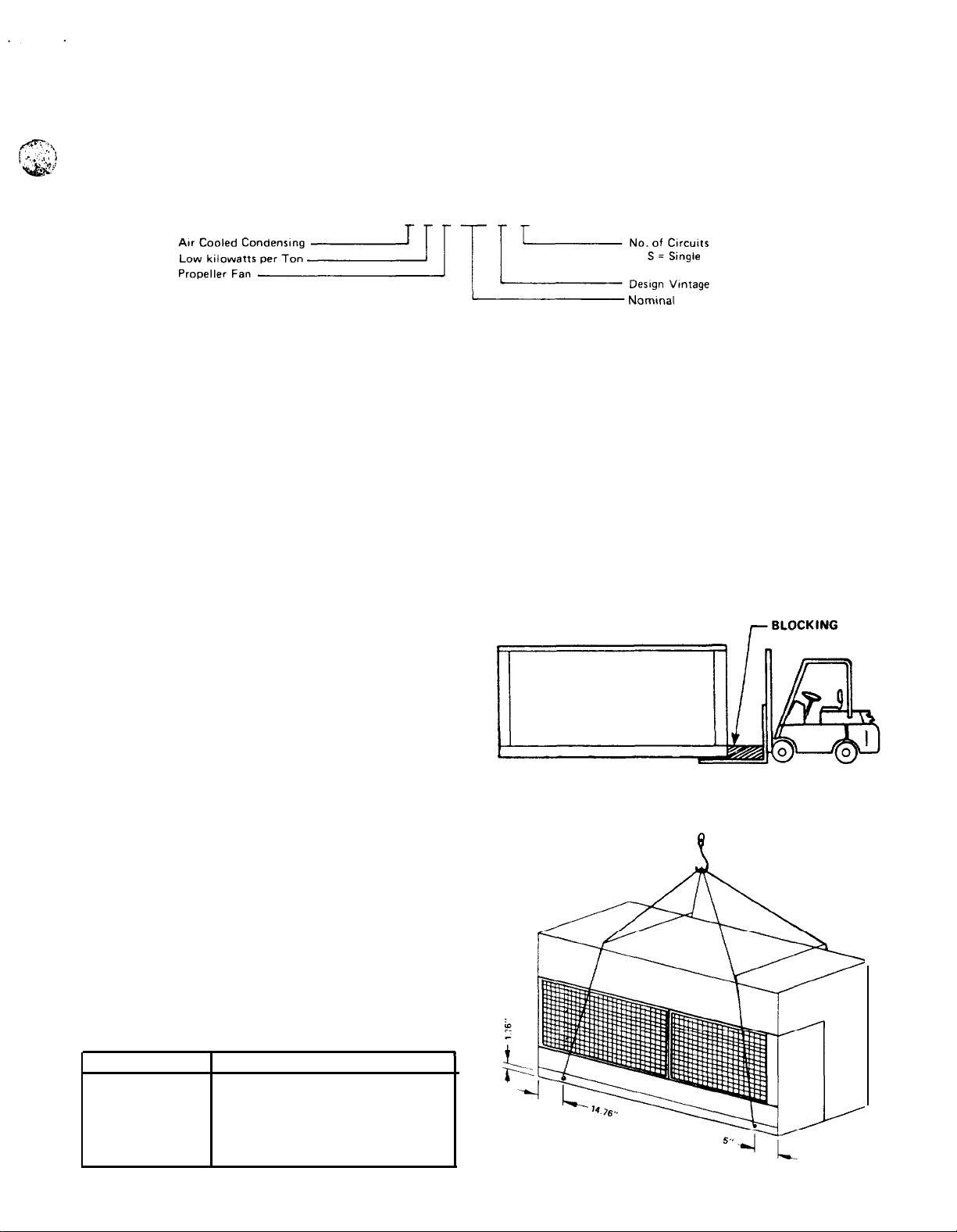

HANDLING

Care should be taken to avoid rough handling or shock due

to dropping the unit. Do not push or pull the unit from

anything other than the base, and block the pushing vehicle

away from the unit to prevent damage to the sheet metal

cabinet. (See Figure 1.)

To lift the unit,

provided in the base of the unit. Spreader bars and cables

should be arranged to prevent damage to the condenser

coils or unit cabinet. (See Figure 2.)

LOCATION

Due to vertical condenser design, it is recommended that

the unit is oriented so that prevailing winds blow parallel to

the unit length, thus minimizing effects on condensing

pressure. If it is not practical to orient the unit in this

manner, a wind deflector should be constructed.

Units are designed for outdoor application and may be

mounted on a roof or concrete slab (ground level

installation). Roof-mounted units should be installed level

on steel channels or an l-beam frame to support the unit

above the roof. Use of vibration pads or isolators is

recommended. The roof must be strong enough to support

the weight of the unit. See Table 1 for unit weights.

Concrete slabs used for unit mounting should be installed

level and be properly supported to prevent settling. A

one-piece concrete slab with footings extended below the

frost line is recommended.

TABLE 1. UNIT WEIGHTS

ALP MODEL

016A

019A

023A

027A

033A

2-1/2-inch

diameter lifting holes are

OPERATING WEIGHT (LBS.)

1122

1383

1471

1600

1866

reported to the carrier and a claim should be filed. The unit

serial plate should be checked before unloading the unit to

be sure that it agrees with the power supply available.

FIGURE 1.

GOOD PUSHING ARRANGEMENT -CABINET DAMAGE UNLIKELY

SUGGESTED PUSHING ARRANGEMENT

FIGURE 2.

-?

PAGE 3

Page 4

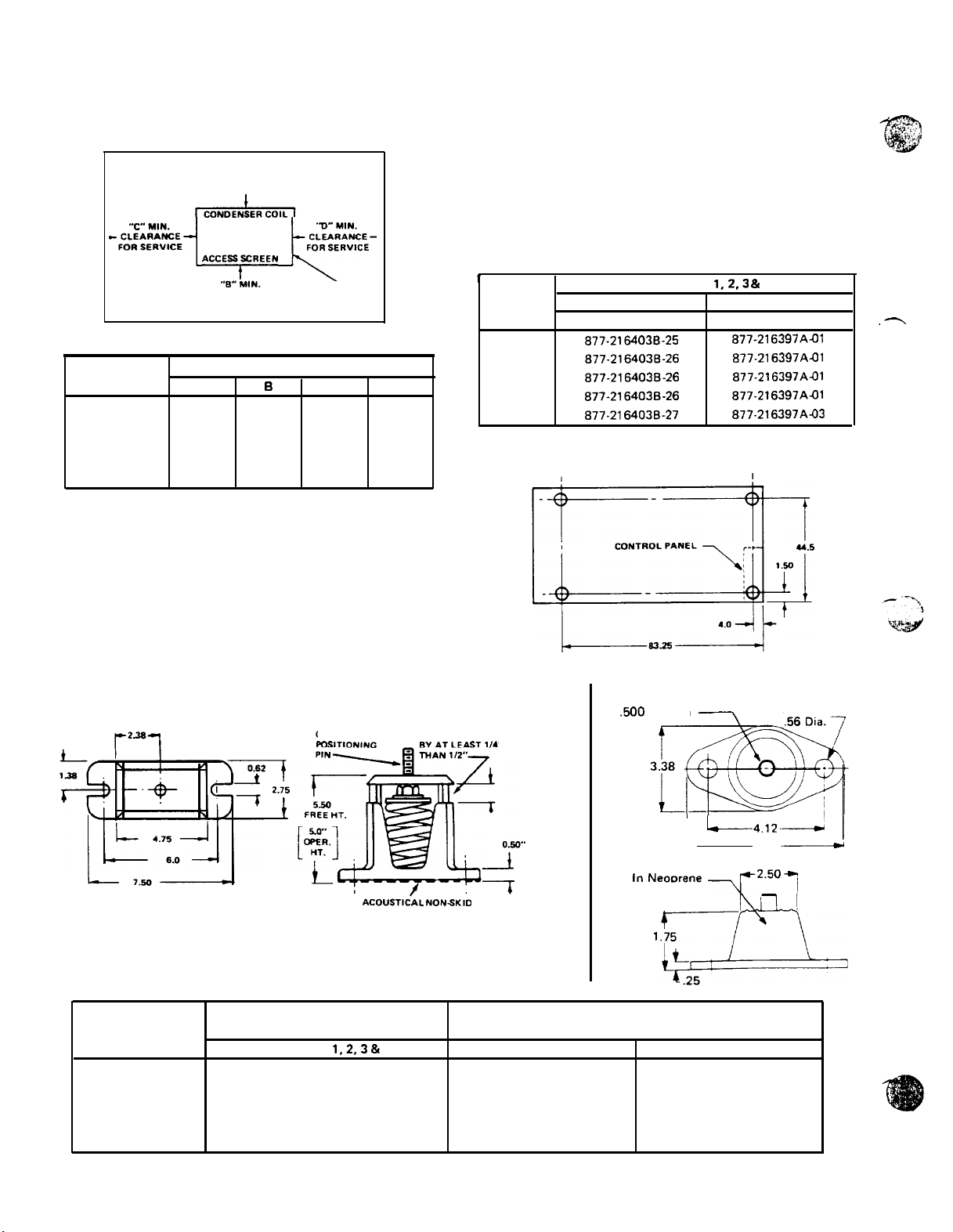

ACCESS

It is necessary to provide adequate clearance on all sides of

the

unit for service access and satisfactory performance.

Necessary clearances are shown in Figure 3.

VIBRATION ISOLATORS

Vibration isolators are recommended for all roof-mounted

installations or wherever vibration transmission is a

potential problem. Table 2 lists spring and rubber-in-shear

isolators for all ALP unit sizes. Table 3 shows isolator loads

FIGURE 3.

CLEARANCE AROUND UNIT

and the maximum allowable load for each isolator. Figure 4

shows isolator locations in relation to the unit control

“A-‘MIN.

CLEARANCE

FOR AIR INLET

panel. Figure 5 gives dimensions that are required to secure

each

Each unit base frame is provided with the necessary holes

to accept the

isolator.

-i%q

Acc~~~~~N

pQ%z-

TABLE 2.

’

ALP LOCATIONS

UNIT

SIZE ORDERING NUMBER

016A

019A

023A

027A

033A

FIGURE 4.

ALP

MODEL

016A

019A

023A

027A

033A

CLEARANCE

FOR DISCHARGE

DIMENSIONS (IN FEET)

A

3

3

3 5

3

3 6

CONTROL PANEL

0

4

4

5

C

3

3

3

3

3

D

4

4

4

4

4

McQUAY

isolator selection to the mounting surface.

0.50-inch

diameter positioning pin of each

ISOLATOR SELECTIONS

1,2.3

& 4

SPRING-FLEX

877-2164036-25

877-2164030-26

877-2164030-26

877-2164030-26

877-2164030-27

RUBBER-IN-SHEAR

ORDERING NUMBER

a77-216397Aal

877-216397A-01

877.216397AJJl

877-216397Aal

a77-216397A-03

ISOLATOR LOCATIONS

By removing the access screens, access can be gained to

the compressor, refrigerant lines, refrigerant components,

condenser fans and SPEEDTROL components. All other

controls are located in the unit control panel. They are

protected by a keylocked, weatherproof enclosure which

contains an internal “dead front” door for protection of

service personnel from high voltage starting controls while

servicing low voltage operational controls.

FIGURE 5.

ISOLATOR DIMENSIONS

(IN.)

Spring-Flex Isolators

ADJUST MOUNTING SO UPPER

HOUSING CLEARS LOWER

TABLE 3.

LATO R LOADS

IS0

0.50 DIA.

ACOUSTkAL NONSKlD

NEOPRENE PAD

HOUSING

AND NOT MORE

”

Rubber-In-Shear Isolators

,600

Dia. Pin

Mounting Molded

in

Neoorene

L4.12---

-\1’2.5”7

5.50

2 Holes

A

1

PAGE

ALP

UNIT

SIZE LOCATION

016A

019A

023A

027A

033A

4

ISOLATOR LOADS AT

EACH MOUNTING LOCATION

1.2,3

&

4 SPRING-FLEX

281

346

368

400

467

MAXIMUM LOADS ALLOWABLE

FOR EACH ISOLATOR SELECTION

RUBBER-IN-SHEAR

450

600

600

600

750

525

525

525

525

750

Page 5

REFRIGERANT PIPING

McQUAY

adaptable to either chilled water or air handling air

conditioning applications using refrigerant 22. Refrigerant

piping to and from the unit should be sized and installed

according to the latest

type ALP SEASONCON condensing units are

ASHRAE

Guide. The following

discussion is for use as a general guide to sound, economical

and trouble-free piping. The correct application of the

principles discussed here is the responsibility of the

installer.

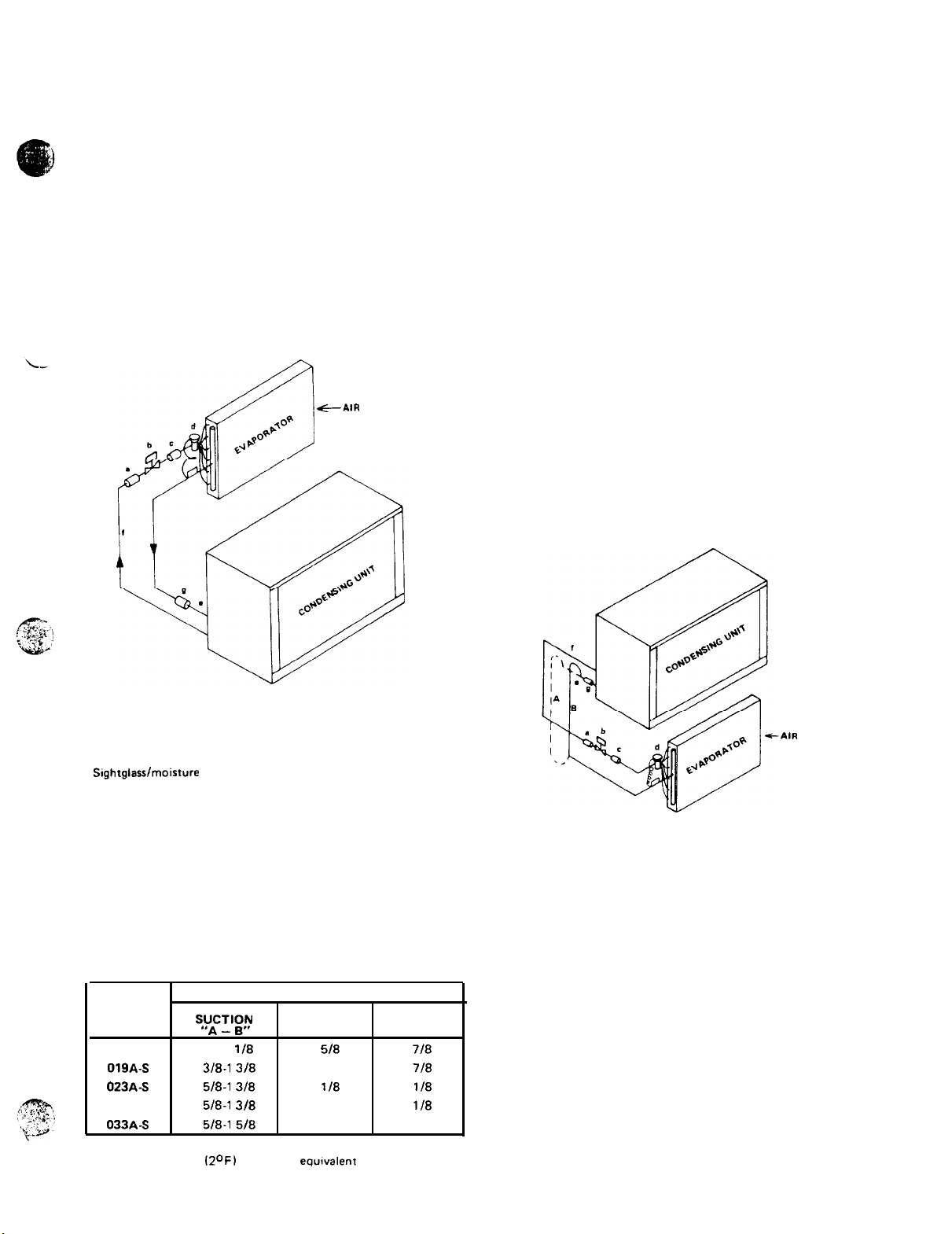

EVAPORATOR ABOVE CONDENSING UNIT

Figure 6 shows an installation where the evaporator is

installed above the condensing unit. It is shown for an air

handling installation, but all components shown are

recommended for chilled water installations except that a

refrigerant distributor is not usually required for

shell-and-tube evaporators.

FIGURE 6.

Evaporator Above Condensing Unit

-G-AIR

FLOW

EVAPORATOR BELOW CONDENSING

UNIT

Figure 7 shows an installation where the evaporator is

installed below the condensing unit. It is shown for an air

handling installation, but all components shown are

recommended for chilled water installations except that a

refrigerant

distributor is not usually required for

shell-and-tube evaporators. Note that a double suction riser

is shown for this arrangement.

Risers

“A + B”

are sized so that their combined

cross-sectional internal area will allow full load unit

operation without excessive pressure drop (see notes, Table

4). Riser

“B” is sized to provide adequate suction gas

velocity for proper oil return at minimum load conditions.

This riser becomes effective only when the trap shown in

riser “A” fills itself with oil. It should be emphasized that

the trap shown in riser “A” should be designed to contain a

minimum internal volume to keep the total system oil

requirements at a minimum. Table 4 gives recommended

line sizes for both single and double suction lines and for

liquid lines.

FIGURE 7.

Evaporator Below Condensing Unit

LEGEND

a Filterdrier

b Solenoid valve

c

Sightglasslmoisture indicator

d Thermal expansion valve

e

Suction line, pitched toward compressor

f Liquid line

g Vibration absorber

NOTES: All piping and piping components are by others.

TABLE 4.

ALP

UNIT

SIZE

016A-S

019A-S 1318-l 318 2118

023A-S 1518-l

027A-S 1518-l 318 2118 1l/8

033A-S 1518-l 518 2118 1 118

Note: Liquid and suction lines based on a recommended pressure

drop of 3 PSIG

RECOMMENDED LINE

DOUBLE

+y;.?l

1

118-l

l/8 1518

318 2 118 1l/8

12OF)

per 100 ft.

SINGLE

SUCTION

equrvalent

SIZE

LIQUID

718

718

length.

e-AIR

FLOW

LEGEND

a Filterdrier

b Solenoid valve

c

Sightglass/moisture

d Thermal expansion valve

e

Suction line, pitched toward compressor

f Liquid line

g

Vibration absorber

A+8 - Double suction riser (see note 2)

NOTES:

1. All piping and piping components are by others.

2. Trap for double suction riser should be as small in the

horizontal direction as fittings will allow.

indicator

REFRIGERANT PIPING CONNECTIONS

Refrigerant piping connections should be made through the

holes provided in the base frame on access screen side of

the unit.

PAGE 5

Page 6

LIQUID LINE COMPONENTS

McQUAY

each ALP unit size. Table 5 shows the ordering number to

be used for each ALP unit size. The components included

in these kits are:

has available a “Liquid Line Accessory Kit” for

TABLE 5. LIQUID LINE ACCESSORY KITS

ALP LIQUID LINE

UNIT ACCESSORY KIT

SIZE ORDERING NUMBER

016A-S

019A-S

023A-S

027A-S

033A-S

,

886-368903641

886366903641

8863689039-01

886-368903841

aa6-36890384x2

FILTER-

DRIER VALVE GLASS

718 718

718

718 718 718

7/a 7/a 7/a

7ta

Replaceable core type filter-drier.

1.

Filter-drier core element.

2.

3

Refrigerant

Refrigerant

4:

Expansion valve.

5.

CONNECTION SIZES O.D.

SOLENOID SIGHT-

7/a

718 718

solenoid valve.

sightglass/moisture

(IN.1

7ta

7/a

indicator.

EXPANSION VALVE

IN

718

7/a

718

718

718

OUT

I

318

i

3/a

I

3/a

i

318

i

3/a

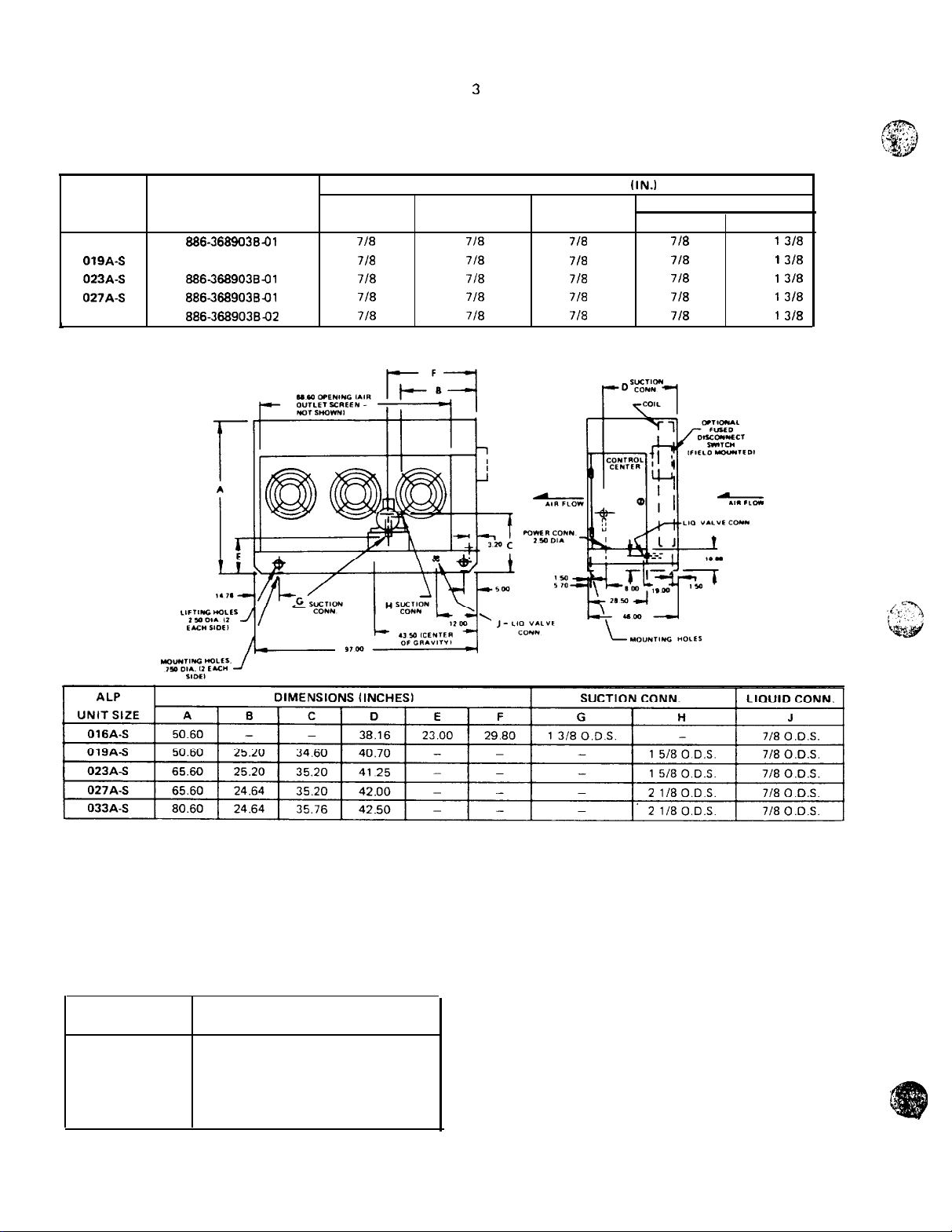

FIGURE 8.

DIMENSIONAL DRAWING

REFRIGERANT CHARGE

Each ALP condensing unit is designed for operation using

refrigerant 22. Table 6 lists refrigerant charge required for a

condensing unit/cooler combination.

TABLE 6. APPROXIMATE REFRIGERANT CHARGE

PAGE 6

ALP

MODEL

016A-S

019A-S

023A-S

027AS

033A-S

l

Refrigerant

will require

charge is for a

an additional charge.

‘R-22 REFRIGERANT

CHARGE (LBS.)

17

23

32

37

53

close-coupled

system. A remote cooler

ADDING REFRIGERANT CHARGE

On systems that have been

refrigerant, an

insufficient

previously

charge is indicated by bubbling

in the sightglass. On uncharged systems, the system should

be leak tested and evacuated before charging. Upon

charging

a system, the discharge and suction shut-off valves

on the compressor should be open and there should be

normal water flow through the cooler.

CAUTION: Do not make any safety controls inoperative

during the charging operation: cooler damage from freezing

may result.

1. Back seat the liquid line shut-off valve and connect the

charging hose to the

1/4-inch

flare connectron.

2. Install pressure gauges and review start-up instructions.

3. Purge the charging hose and open the

to allow refrigerant

into

the system.

charged with

charging

cylinder

Page 7

Turn the liquid line shut-off valve in three turns to

‘4.

permit a back flow of refrigerant into the subcooler.

After refrigerant stops flowing into the system, close the

5.

liquid line shut-off valve. Start the compressor to charge

the system.

If the amount of refrigerant has been predetermined,

6.

add this amount and check the sightglass afterward.

If the amount of charge is unknown, close the charging

cylinder valve every five minutes, open the liquid line

shut-off valve and check for proper charge by examining

the sightglass. Continue charging and checking the

sightglass until it is clear.

NOTE: Fluorocarbon refrigerants should not be released to

the atmosphere. For a means of recovery, refer to the

following section.

REMOVING REFRIGERANT CHARGE

To prevent freeze-up when removing the refrigerant for

ALP installations on water chiller systems, either drain the

water or circulate the water. If water cannot

make sure the cooler heater is energized. Do not remove

refrigerant rapidly since this can cause freeze-ups. Have a

sufficient number of refrigerant containers and a scale for

weighing them. The containers should be clean, dry and

empty.

gauge manifold from the compressor discharge valve service

port to the container and purge the iines. Note the capacity

of the container. Place the container in ice to cool the

container so the fusible plug does not melt as the

refrigerant condenses. Operate the compressor normally.

Turn the discharge service valve in three turns to open the

gauge manifold. Do not close off the discharge valve to the

condenser. Discharge gas can enter the container and

condense.

overfill. When the container is filled use additional ones.

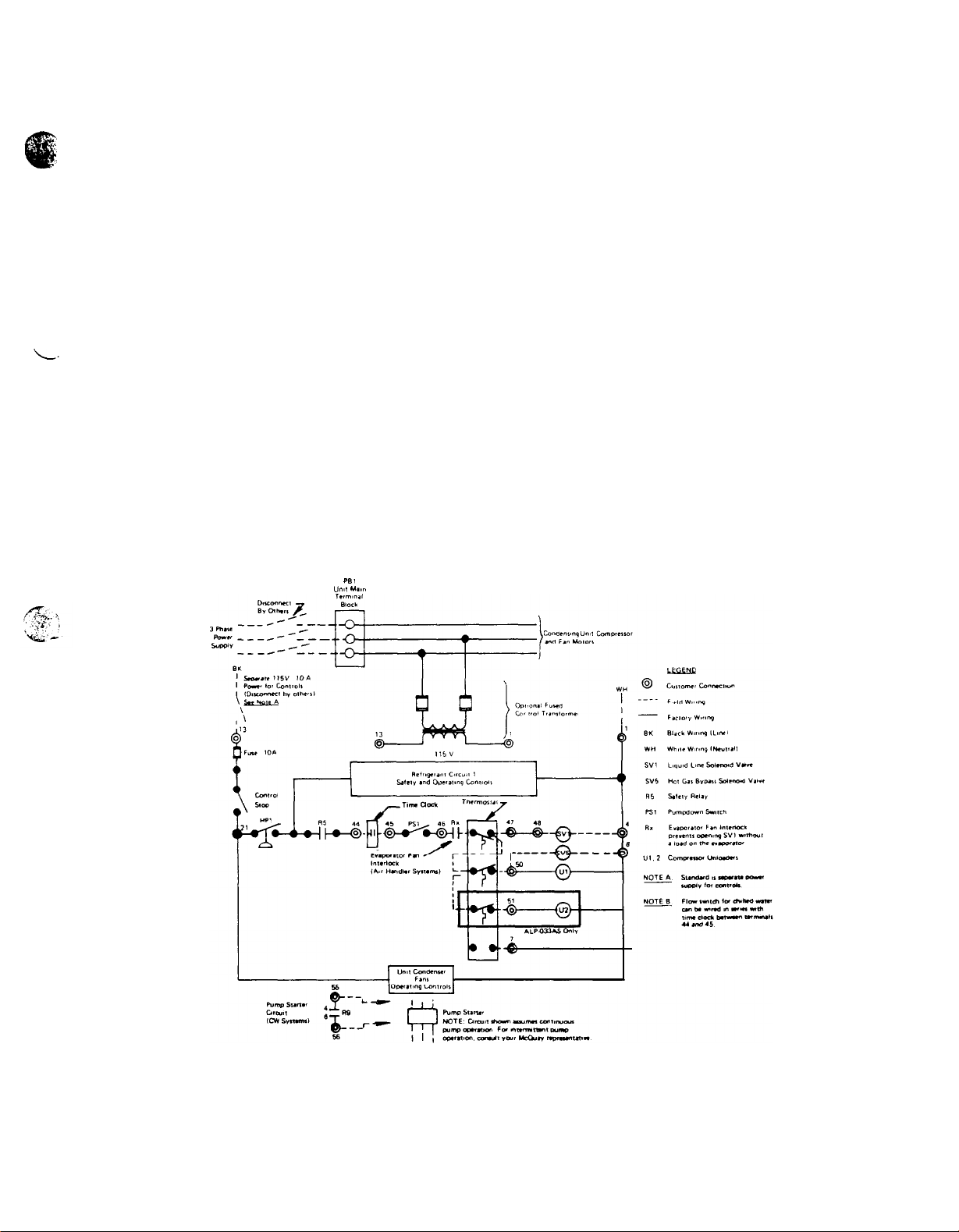

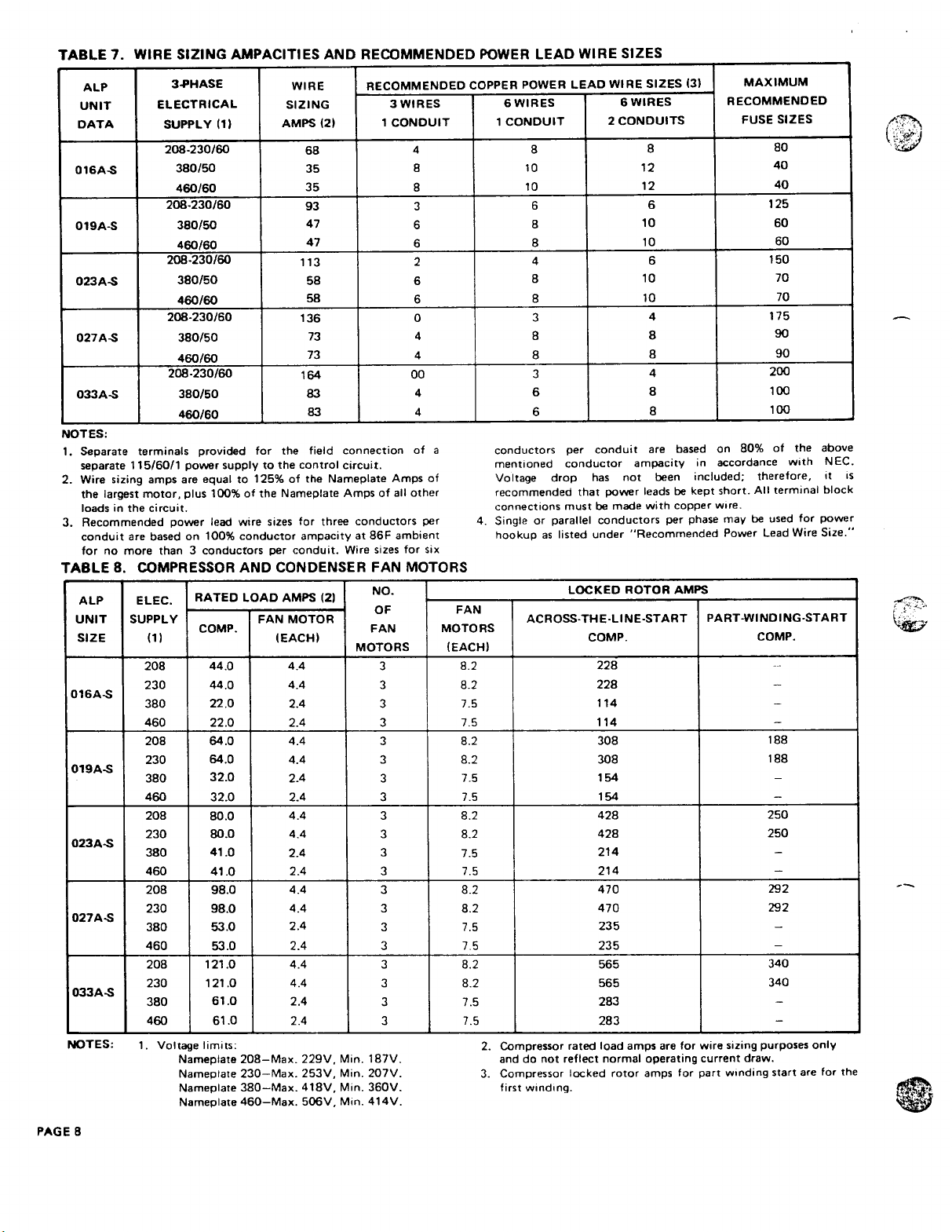

FIELD WIRING

WARNING: USE ONLY COPPER CONDUCTORS IN MAIN TERMINAL BLOCK.

Wiring should be done in accordance with all applicable

codes and ordinances. Warranty is voided if wiring is not in

accordance with specifications. An open fuse indicates a

short, ground or overload. Before replacing a fuse or

restarting a compressor or fan motor, the trouble must be

found and corrected.

All standard units require a 115 volt power supply for

the control circuit. If the optional control circuit

transformer is ordered, the control circuit is powered off

the main power supply.

unit installation. Items that require field wiring are liquid

line solenoid

and the cooling thermostat, as well as the unit power

supplies.

be

drained,

To transfer the refrigerant to a container, connect the

Frequently weigh the container so as not to

Figure 9 shows typical field wiring that is required for

SV1,

optional hot gas bypass solenoid

SV5

FIGURE 9.

TYPICAL FIELD WIRING

““ll Ml,”

PB1

,

Since it is impossible for

installation that an ALP condensing unit may be used on,

we do not factory install a thermostat. We do, however,

provide numbered terminals inside the unit control center

McQUAY

to anticipate the type of

THERMOSTAT WIRING

to which a thermostat may be connected. These terminals

are shown and labeled “Terminals For Thermostat” on the

electrical schematics. Figure 9 shows typical field wiring for

a thermostat with temperature controlled unloading.

PAGE 7

Page 8

Page 9

FLOW SWITCH FOR CHILLED WATER APPLICATIONS

A water flow switch or pump starter interlock is required

on chilled water applications to insure that there will be

adequate water flow and cooling load to the evaporator

before the unit can start.

slugging the compressors on start-up. It also serves to shut

down the unit in the event that water flow is interrupted to

guard against evaporator freeze-up.

A flow switch is available from

ordering number 860-175033X-00. It is a “paddle” type

This will safeguard against as shown in Figure 10.

McQUAY

under

switch and adaptable to any pipe size from l-inch to

6-inch

nominal. Certain minimum flow rates are required to close

the switch and are listed in Table 9. Installation should be

FIGURE 10.

,/ -

FLOW DIRECTION

HARKED ON SWITCH

TABLE 9. FLOW SWITCH MINIMUM FLOW RATES

SWITCH UPRIGHT

IN A HORIZONTAL

RUN OF PIPE

NO RESTRICTIONS

5 PIPE DIAMETERS MIN.

AFTER SWITCH

/

rJ

NO RESTRICTIONS

5 PIPE DIAMETERS MIN

BEFORE SWITCH

Electrical connections in the unit control center should

be made at terminals 12 and 21. The normally open

contacts of the flow switch should be wired between these

two terminals. There is also a set of normally closed

contacts on the switch that could be used for an indicator

light or an alarm to indicate when a “no flow” condition

exists.

EVAPORATOR FAN INTERLOCK FOR AIR HANDLER COIL INSTALLATIONS

It is important to interlock the air handler evaporator fan

with the condensing unit control center to insure that there

will be a cooling load on the evaporator before the unit can

start to prevent compressor slugging. A pair of terminals is

available in the unit control center for this purpose. These

terminal numbers are shown in Figure 9.

ELECTRICAL

CONTROL CENTER

All electrical controls are enclosed in a weatherproof

control center with a keylocked, hinged access door (see

Figure

11).

The left section is the largest and contains all of the 208,

230, 380 or 460 volt compressor and fan motor starting

controls. Also included in this section, but partitioned

separately, are the exposed terminal type, 115 volt

operational controls. A “dead front” cover over the left

section protects service personnel from high voltage starting

controls and exposed terminal operational controls.

panel, contains 115 volt adjustable or resettable controls.

bottom of the control center. Figure 11 shows a

recommendation for unit mounting arrangements if the

disconnect is to be unit mounted.

The control center is composed of two sections.

The right section, not covered by the “dead front”

Power supply conduits are intended to come into the

FIGURE 11.

IT DISCONNECT

CONTROL CENTER’

Page 10

Page 11

SkUENCE

The following sequence of operation is for an ALP

SEASONCON air cooled

circuit power on, control stop switch S1 closed and manual

pumpdown switch PS1 closed (“auto” position), 115 volt

power is applied through control circuit fuse

compressor crankcase heater

of low pressure switch LPI.

When the remote time clock, ambient thermostat,

manual shutdown switch and/or evaporator fan interlocks

energize the thermostatic circuit and, provided that high

pressure control

ALP-016A)

sense an alarm condition, safety relay R5 is energized

closed, applying power to temperature control thermostat.

At this point the unit will operate automatically in response

to the thermostat.

control thermostat

SV1,

the evaporator. As refrigerant pressure builds up, low

pressure control

R9

which closes to energize time delay TD14. The closing

of TD14 energizes fan motor relay Ml 1, closing its contacts

and providing power to condenser fan motor contactors

Mll,

thermostat

and normally open contact R21 is closed. Relay Ml is

energized and normally closed Ml AUX. contacts are open.

Compressor contactor Ml is closed and the compressor is

running at slow speed.

open, relay R21 is de-energized and normally closed

contact R21 is closed. On 208 volt and 230 volt units, relay

M9 is energized and normally open contacts M9 are closed.

Compressor contactors M9 (on 208 volt and 230 volt only)

and M5 are closed and the compressor is running at fast

speed.

cooling, temperature control thermostat

liquid line solenoid valve

allowing refrigerant to flow into the evaporator. As

refrigerant pressure builds up, low pressure control

closes, energizing low pressure relay R9 which closes to

energize compressor contactor Ml, starting the compressor.

Closing relay R9 contacts also energizes condenser fan relay

Ml 1, closing its contacts and providing power to condenser

fan motor contactors Ml 1, Ml2 and M13. At reduced load

conditions, thermostat

is energized and the compressor is unloaded. At full load

conditions, thermostat

de-energized and the compressor is loaded.

OF OPERATION

condensing unit. With control

HTR1

and also to the contacts

HP1,

and compressor motor protector

For ALP416

opening the valve and allowing refrigerant to flow into

Ml 2 and M13. At reduced load conditions,

TC1,

At full load conditions, thermostat

For

ALP-019,

oil pressure control

-

On a call for cooling, temperature

TC1

energizes liquid line solenoid valve

LP1

closes, energizing low pressure relay

stage 2, is closed, relay R21 is energized

023, 027 and 033 - On a call for

SV1,

opening the valve and

TC1,

stage 2, is closed, unloader

TC1,

stage 2, is open, unloader U1 is

OP1

MP1

TC1,

stage 2, is

TC1

energizes

F1

to the

(not on

do not

LP1

U1

PUMPDOWN

As the temperature control thermostat is satisfied, it opens

its contacts, de-energizing liquid line solenoid valve

causing the valve to close. When the compressor has

pumped most of the refrigerant from the evaporator to the

condenser, the low pressure control

down the compressor and condenser fan motors.

Should a closed

to the low

time, the buildup in pressure will cause the low pressure

control to close, energizing the low pressure relay and

starting

TABLE 10.

MODEL

NUMBER SIZE

I

NOTE: Condenser

SPEEDTROL motor.

CYCLE

LP1

solenoid

side

of the refrigerant circuit during unit “off”

the compressor for pumpdown.

MAJOR COMPONENT LOCATIONS

REAR VIEW OF UNIT

COIL ON OPPOSITE SIDE

COh4PRESSOR

valve allow refrigerant to leak

I

Fan

11

is location of optional

SV1,

opens, shutting

PAGE 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

START-UP & SHUT-DOWN

PRE START-UP

1.

With electrical disconnects open, check all screw or lug

type electrical connections to be sure they are tight for

good electrical contact. Check all compressor valve connections for tightness to avoid refrigerant loss at startup. Although all factory connections are tight before

shipment, some loosening may have resulted from shipping vibration.

A. On chilled water installations, check to see that all

2.

4.

water piping is properly connected.

B. Open all water flow valves and start the chilled

water pump. Check all piping for leaks and vent the

air from the evaporator and system piping. Flush

the evaporator and system piping to obtain clean,

non-corrosive water in the evaporator circuit.

Check the compressor oil level. Prior to start-up, the oil

3.

level should cover at least

Check the voltage of the unit power supply and see that

it is within the

voltage unbalance must be within &2%.

Check the unit power supply wiring for adequate

5.

ampacity and a minimum insulation temperature rating

of 75c.

Verify that all mechanical and electrical inspections

6.

have been completed per local codes.

See that all auxiliary control equipment is operative and

7.

that an adequate cooling load is available for initial

start-up.

INITIAL START-UP

1. Open the compressor suction and discharge shut-off

valves until back seated. Always replace valve seal caps.

2. Open the manual liquid line shut-off valve at the outlet

of the subcooler.

3. Allow the crankcase heater to operate for at least eight

hours prior to start-up.

4. Check to see that

“manual pumpdown” position and the control switch

S1 is in the “on” position.

5. Adjust the dial on the temperature controller to the

desired chilled water or leaving air temperature.

CAUTION: Most relays and terminals in the unit control

canter are hot with

on.

Throw the main power and control circuit disconnects

6.

to the “on” position.

7.

Start the auxiliary equipment for the installation.

Start the system by moving pumpdown switch PS1 to

8.

the “auto. pumpdown” position.

After system performance has stabilized, it is necessary

9.

that the “Compressorized Equipment Warranty Form”

(Form No.

warranty benefits. This form is shipped with the unit

and after completion should be returned to

Service Department through your sales representative.

TEMPORARY SHUT-DOWN

Move

pumpdown

position. After the compressors have pumped down, turn

RIO%

S1

206036A)

switch

1/2

of the oil sightglass.

tolerance that is allowed. Phase

pumpdown

and the control circuit disconnect

be completed to obtain full

PS1

switch PS1 is in the

to the “manual pumpdown”

McQUAY’s

off the chilled water pump or evaporator fan.

NOTE: With the unit left in this condition, it is capable

of recycling pumpdown operation. To defeat this mode of

operation, move the control stop switch

position.

It is especially important on chilled water installations

that the compressors pump down before the water flow to

the evaporator is interrupted to avoid freeze-up.

START-UP AFTER TEMPORARY SHUT-DOWN

Start the chilled water pump or evaporator fan.

With control stop switch

pumpdown switch PS1 to the “auto. pumpdown”

position.

Observe the unit operation for a short time to be sure

that the compressors do not cut out on low oil pressure.

EXTENDED SHUT-DOWN

Close the manual liquid line shut-off valve.

1.

After the compressor has pumped down, turn off the

2.

chilled water pump or evaporator fan.

3.

Turn off all power to the unit and to the auxiliary

equipment.

Move the control stop switch

4.

5.

Close the compressor suction and discharge valves.

6.

Tag all opened disconnect switches to warn against

start-up before opening the compressor suction and

discharge valves.

START-UP AFTER EXTENDED SHUT-DOWN

1.

inspect all auxiliary equipment (pumps, fans, etc.) to

see that each device is in satisfactory operating

condition.

2.

Remove all debris that has collected on the surface of

the condenser coils.

3.

Open the compressor suction and discharge valves.

4.

Open the manual liquid line shut-off valve.

5.

Check to see that

“manual pumpdown” position.

Turn on the electric power to the unit and other parts

6.

of the system.

Allow the crankcase heaters to operate for at least eight

hours prior to start-up.

On chilled water installations, start the chilled water

pump and purge the water piping as well as the

evaporator.

Check to see that the control stop switch

“on” position.

CAUTION: Most relays and terminals in the unit control

center are hot with

on.

Start the unit by moving

10.

“auto. pumpdown” position.

After running the unit tor a short time, check the oil

11.

level in the compressor crankcase and check for

flashing in the refrigerant sightglass.

S1

S1

in the “on” position, move

S1

pumpdown

and the control circuit

pumpdown

S1

to the “off”

to the “off” position.

switch PS1 is in the

S1

is in the

disconnect

switch PS1 to the

PAGE 17

Page 18

CONTROLS

OIL PRESSURE SAFETY CONTROL

ALP-OlSA, 023A, 027A,

The oil pressure safety control is a manually resettable

device which senses the differential between oil pressure at

the discharge of the compressor oil pump and suction

pressure inside the compressor crankcase. When the oil

pressure reaches approximately 15 PSI above the crankcase

suction pressure, the pressure actuated contact of the

control opens from its normally closed position. If this

pressure differential cannot be developed, the contact will

remain closed and energize a heater element within the

control. The heater element warms a normally closed

bimetallic contact and causes the contact to open,

de-energizing a safety relay and breaking power to the

compressor.

It takes about 120 seconds to warm the heater element

enough to open the bimetallic contact, thus allowing time

for the pressure differential to develop.

If during operation the differential drops below 10 PSI,

the heater element will be energized and the compressor

will stop. The control can be reset by pushing the reset

button on the control. If the compressor does not restart,

033A (NOT ON

ALP-OlGAI

allow a few minutes for the heater element and bimetallic

contacts to cool and reset the control again.

To check the control, pump down and shut off all

power to the unit. Remove the compressor relay wiring at

terminals 2 and 8, and install a voltmeter between terminals

L and M of the oil pressure control. Turn on power to the

unit control circuit (separate disconnect or main

disconnect, depending on the type of installation). Check

to see that the control stop switch

S1

is in the “on”

position. The control circuit should now be energized, but

with the absence of the compressor running, no oil pressure

differential can develop and thus the pressure actuated

contacts of the control will energize the heater element and

open the bimetallic contacts of the control within 120

seconds. When this happens the safety relay is de-energized,

the voltmeter reading will rise to

115V

and the compressor

contactor should open. Repeated operations of the control

will cause a slight heat build-up in the bimetallic contacts

resulting in a slightly longer time for reset with each

successive operation.

unit

LINE (SEE NOTE

LINE (SEE NOTE 2)

NOTES: 1. Hot only

1)

CONTACT

when

the

to run.

2. Hot only when other safety control contacts are closed.

L

M

41

I

unit

thermostat calls for compressor

NOTE: PERFORM AN OPERATIONAL CHECK ON ALL UNIT SAFETY CONTROLS ONCE PER YEAR.

SOLID STATE COMPRESSOR MOTOR PROTECTION

All air cooled condensing units have compressors with solid

state motor protection. Both Robertshaw and Texas

Instruments systems are used and their components are not

interchangeable.

There are two major components in a protection

system. First, the protector sensors are mounted internally

in the motor windings. The sensors monitor winding

temperature. A change in temperature causes a change in

sensor resistance. Sensor resistance is monitored by the

second component of the system

-

the control module

which is a sealed enclosure containing a relay, transformer

and other electronic components. Leads from the sensors

are connected to the module. Sensor resistance triggers the

control module relay at definite opening and closing

settings.

The module voltage will always be 120V and will be so

marked. When the control module needs repair no attempt

should be made to repair it. It should be returned intact for

replacement . If the module is opened or physically

damaged the warranty is void.

The control module and solid state sensor can be

damaged by high voltage. A high potential test should never

be made to the module or sensors.

If the compressor motor is not operating properly, the

following procedure may be used to check the solid state

motor control circuit.

I

1

y

BIMETALLIC CONTACTS

If the compressor has been operating and has been

1.

120

I

m

t

HEATER ELEMENT

stopped by the motor protector, allow one hour for the

compressor to cool and the motor protector to reset.

2.

If reset does not occur, connect a jumper wire across

the motor protector from terminal 30 to 36. If the

compressor does not operate with the jumper installed,

the problem is not within the solid state protector

system. If the compressor operates with the jumper

-

installed and does not operate without the jumper, the

control circuit relay in the module is open for some

reason.

CAUTION: Only check compressor operation with jumper

installed. Do not continue operation.

A possible cause of the open relay is the motor sensors.

They may be checked by first removing the connections to

the terminal board. Use an ohmmeter of 3 volt maximum

voltage to check resistance from each sensor terminal to the

common terminal. No voltage or current should be applied

to the sensors to check continuity. The resistance across

each motor sensor should be approximately 500 to 2400

ohms with a motor temperature below 1400F. If the

resistance is zero, there is a short. If the resistance is

infinity, there is an open connection.

NEUTRAL

NEUTRAL

SAFETY RELAY

PAGE 18

Page 19

On

reset the resistance of the sensors must be below the

reset point before the relay contacts will close. The reset

resistance is 2700 to 4500 ohms.

If the sensor resistance has been checked and found to be

satisfactory and the compressor will run with the control

bypassed but will not run with the control wired properly,

the control module is defective and must be replaced.

In case the resistance across a sensor is infinity, the

module will prevent compressor operation. As an

emergency means of obtaining compressor operation until

the compressor can be replaced, a resistor may be added

between the terminal of the open sensor and the common

terminal in the terminal box. The control module then

“sees” an acceptable resistance and compressor operation

will be restored. The emergency resistor should be 1 watt,

2200 ohms

provide the same degree of

reasonable measure of safety.

L

10% resistor. The emergency resistor will not

protection, but it provides a

RESIS

OPEN

L--L-

L-J

SENSORS

HIGH PRESSURE CONTROL

The high pressure control is a single pole pressure activated

switch that opens on a pressure rise to de-energize the

entire control circuit except for compressor crankcase

heater. It senses condenser pressure and is factory set to

open at 380 PSIG and can be manually reset closed at 315

PSIG. To check the control, block off condenser surface

and observe the cut-out point of the control by watching

. .

LOW PRESSURE CONTROL

The low pressure control is a single pole pressure switch

that closes on a pressure rise. It senses evaporator pressure

and is factory set to close at 60 PSIG and automatically

open at 25 PSIG. The control has an adjustable range of 20

rn. of Hg. to 100 PSIG and an adjustable differential of 6 to

40 PSIG. To check the control (unit must be running),

move the

pumpdown” position.

pumpdown

switch PS1 to the “manual

As the compressor pumps down,

SOLID STATE MODULE

1

l

condenser pressure rise. The highest point reached before

cut-out is the cut-out setting of the control.

CAUTION: Although there is an additional pressure

relief device in the system set at 425 PSIG, it is highly

recommended that the control stop switch S1 be close at

hand in case the high pressure control should malfunction.

condenser pressure will rise and evaporator pressure will

drop. The lowest evaporator pressure reached before

cut-out is the cut-out setting of the control. By moving the

pumpdown switch PS1 to the “auto. pumpdown” position,

evaporator pressure will rise. The highest evaporator

pressure reached before compressor restart is the cut-in

setting of the control.

FANTROL

FANTROL is a system for progressively turning on or off

condenser fans when they are no longer required.

done to reduce condenser capacity (typically in low

outdoor ambient temperatures) and is accomplished by a

combination of pressure and temperature actuated controls.

The first fan (No. 11) is started by its contactor when the

compressor in the unit starts. The second fan (No. 12) is

controlled by a pressure switch which senses condenser

pressure. The third fan (No. 13) is controlled by a

temperature switch which senses condenser air inlet

temperature. Pressure and temperature control setpoints are

indicated below.

To check the cut-in points of the controls, the unit

-

HEAD

This

is

PRESSURE CONTROL

must initially be off. With the unit prepared for start-up

according to the procedures outlined in this bulletin, move

pumpdown switch PS1 to the “auto. pumpdown” position.

Evaporator pressure will begin to rise and the compressor

should start with Fan 11 starting immediately. After the

compressor starts, observe condenser pressure as it rises.

When the condenser pressure reaches approximately 270

PSIG, contactor Ml2 should pull in to start Fan 12. On

three-fan units Fan 13 should start via contactor Ml3

whenever the ambient air at the condenser inlet reaches

8OF.

It may be difficult to check the cut-out point of Fan 13

(on three-fan units) at the instant it happens, but it should

be off whenever the ambient air at the condenser inlet is

below 70F. To check the cut-out point of Fan 12, some

means of reducing the load on the unit must be available or

the fan operation and condenser pressure must be observed

as the load drops off naturally. When the condenser

pressure drops to approximately 170 PSIG, contactor Ml2

should drop out to turn off Fan 12.

PAGE

19

Page 20

OPTIONAL CONTROLS

SPEEDTROL (OPTIONAL)

McQUAY’s

side of the control center, continuously varies No. 11 condenser fan motor speed on air cooled condensers by sensing

changes in refrigerant head pressure. SPEEDTROL makes

possible unit operation in lower ambient temperatures.

With an increase in refrigerant head pressure

TROL increases fan motor speed. With a decrease in pressure fan motor speed is decreased.

The pressure connection of the transducer is made to the

high pressure side of the refrigeration system at the purge

valve connection on the condenser coil header. This transducer coupled with a solid stage unit modulates the phase

Part winding start consists of a solid state time delay wired is energized instantly, while that for the second motor

in series with the contactor that energizes the second winding is delayed for one second.

winding of each compressor motor. Its purpose is to limit Control checkout is best accomplished by observation

current in-rush to the compressors upon start-up. As each

compressor starts, the contactor for the first motor winding

solid state SPEEDTROL, located on the back-

SPEED-

PART WINDING START (OPTIONAL)

conduction angle of the AC sine wave supplied to the fan

motor. The fan motor is a special

208/230V

SPEEDTAOL

motor. For 460 volt units a transformer is supplied to

decrease line voltage to 230 volt motor voltage. The

SPEEDTROL controller is calibrated to deliver 90% of line

voltage at the setpoint pressure of 230 PSIG. It has an

effective throttling range of 60 PSIG which is the decrease

in pressure below the calibration setpoint where 45% of

supply voltage is transmitted to the motor. When 45% of

supply voltage is transmitted to the motor, minimum motor

speed is reached; below this point there is no change in

speed.

as each contactor is pulled in to see that the one-second

delay occurs before the second contactor pulls in.

LINE

PART WINDING

TIME DELAY

LINE

+

1

LOW AMBIENT START (OPTIONAL)

Low ambient start is available on all units as an option with

F ANTROL and included automatically with optional

SPEEDTROL. It consists of a solid state normally closed

time delay wired in series with a relay. These are both wired

in parallel to the liquid line solenoid valve so that when the

solenoid valve is energized by the unit thermostat, the low

ambient start relay is

The relay has contacts that essentially short circuit the low

pressure control and allow the compressor to start with the

low pressure control open.

After about

de-energize the relay. If the system has not built up enough

evaporator pressure to close the low pressure control, the

compressor will stop. The time delay can be reset to its

original normally closed position by moving the

also energized through the time delay.

2-3/4

minutes, the time delay will open and

pumpdown

NEUTRAL

COMPRESSOR CONTACTOR

(1st

MOTOR WINDING)

NEUTRAL

COMPRESSOR CONTACTOR

(2nd MOTOR WINDING)

switch

the

PS1

to the “manual pumpdown” position. Moving

pumpdown

switch PS1 back to the “auto. pumpdown”

position will again energize the relay for another attempt at

start-up. If the system has built up enough evaporator

pressure, the compressor will continue to run.

To check the control, turn off all power to the unit and

remove the wire leading to the low pressure control

LP1

from terminal 11 in the unit control center. Remove the

wires leading from the contactors to the compressor and

jumper across terminals L and M of the oil pressure safety

control. Energize the control circuit by turning on the

control circuit disconnect or main power disconnect

(depending on the installation) and the control stop switch

S1.

The compressor contactors should pull in instantly.

PAGE

20

NOTE :

Line

is

only hot when the unit thermostat

calls

for compressor to run

Page 21

COMPRESSOR LOCKOUT (OPTIONAL)

Compressor lockout consists of a solid state time delay

wired in series with the compressor

contactor(

Its

purpose is to prevent rapid compressor cycling when

cooling

demands are erratic.

When the unit thermostat no longer calls for cooling

and the compressor

contactor(s)

have opened, the lockout

time delay breaks open the circuit preventing compressor

restart.

The circuit remains open for a period of five minutes so

that if the unit thermostat should call for cooling before

the delay period has expired, the compressor will not

restart. After five minutes, the time delay will close its

contacts to complete the circuit and be ready for start-up.

The time delay opens its contacts whenever there is power

to the terminals of the compressor relay and resets closed

automatically after the time delay period.

To check the control, the compressor must be running

initially.

pumpdown”

Move the pumpdown switch PS1 to the “manual

position. immediately after the compressor

has stopped running, move the

the “auto. pumpdown” position.

not restart for five minutes.

LINE

(SEE NOTE)

NOTE: Hot whenever freeze

cc,n,r~,

and hqh

pumpdown

switch back to

The compressor should

,xessure contrd permt

safe

~,xtatcr

It is expected

that the customer will want to locate the

ALARM BELL (OPTIONAL)

alarm bell where it will be heard in the event of a safety

failure. After mounting, the bell should be wired to

transformer T4. When the bell is wired into the control

HOT GAS BYPASS (OPTIONAL)

Hot gas bypass is a system for maintaining evaporator

pressure at or above a minimum value. The purpose for

doing this is to keep the velocity of the refrigerant as it

passes through the evaporator high enough for proper oil

return to the compressor when cooling load conditions are

light.

The system usually consists of a solenoid valve piped in

series with a pressure regulating valve as shown. Provisions

are provided for installing the hot gas bypass kit.

The solenoid valve should be wired to operate as close to

the unit’s maximum unloaded state as possible. The

pressure regulating valve that McQuay offers is factory set

to

being opening at 58 PSIG

(32F

for R-22) when the air

charged bulb is in an 80F ambient temperature. The bulb

can be mounted anywhere as long as it senses a fairly

constant temperature at various load conditions. The

compressor suction line is one such mounting location. It is

generally in the 50F to 60F range. The chart below

indicates that when the bulb is sensing 50F to 60F

temperatures, the valve will begin opening at 54 to 56

PSIG. This setting can be changed, as indicated above, by

changing the pressure of the air charge in the adjustable

bulb. To raise the pressure setting, remove the cap on the

bulb and turn the adjustment screw clockwise. To lower the

setting, turn the screw counter-clockwise. Do not force the

adjustment beyond the range it is designed for as this will

damage the adjustment assembly.

The regulating valve opening point can be determined

by slowly reducing the system load while observing the

suction pressure. When the bypass valve starts to open, the

refrigerant line on the evaporator side of the valve will

begin to feel warm to the touch.

CAUTION: The

hot gas line may become hot enough to

cause injury in a very short time, so care should be taken

during valve checkout.

On installations where the condensing unit is remote

from the evaporator, it is recommended that the hot gas

bypass valve be mounted near the condensing unit to

minimize the amounts of refrigerant that will condense in

the hot gas line during periods when hot gas bypass is not

required.

circuit it will sound whenever there is a failure due to

oil pressure (not on

ALP-OlGAI,

motor overload, or

excessive condenser pressure.

HOT GAS BYPASS PIPING DIAGRAM

Hot

Gas Bypass

Solenoid Valve

r

in ALP Unit

with Factory

Capped Tee for

Connection. A

manual shut-off

valve between the

bypass tee and

solenoid valve is

recommended.

Bypass Valve

y-

Surt1on

Line

External Equalizer

Expansion Valve

(On DX Coil with

Distributor, use

Sporlan Auxiliary

Sideport Connector

or Equivalent.)

HOT GAS BYPASS ADJUSTMENT RANGE

REMOTE BULB

80

30

40

30

52 6070

TEuP

ADJUSTMENT

f0F1

AT BULB LOCATION

RANGE

80

90

100

low

1,:

PAGE 21

Page 22

MAINTENANCE PROCEDURES

NOTE: Service on

must be investigated and corrected. CAUTION: Disconnect all power before doing any service inside the unit.

this equipment is to he performed by qualified refrigeration service personnel. Causes for repeated

tripping of Safety controls

On

Initial

be necessary to perform

Among these are checking the compressor

taking condensing, suction and oil pressure readings. During

operation the oil level should be

with the compressor running. On units ordered

The refrigerant sightglass should be observed periodically.

(A

of liquid indicates that there is adequate

in the system to insure proper feed through the expansion

valve. Bubbling refrigerant in the srghtglass indicates that

the system is short of

start-up and periodically

certain

monthly observation should be adequate.) A clear glass

refrigerant

during operation

routine service checks,

visible

in the oil sightglass

refrigerant

charge. On

it will

oil

level and

with

gauges,

REFRIGERANT SIGHTGLASS

charge

sightglasses

condensing,

gauges. Oil pressure gauge is not available on

The gauges are installed with a manual shut-off valve

each gauge line. The valves should be closed at all times

except when gauge readings are being taken.

ordered from

Accessory

what moisture condition corresponds to a

color. If the sightglass does not indicate a dry

after a few hours of operation, the unit should be pumped

down and the cores in the

suction

and

oil

pressures can be read from the

McQUAY

an element Inside the sightglass indicates

Kits”,

as part of the

filter-driers

changed.

FILTER-DRIERS

To change the filter-drier core, pump the unit down by

moving

position. Turn off all power to the

from terminal 31 to 34. Turn power to the

and restart the unit by moving

the “auto. pumpdown” position. Close the manual liquid

line shut-off valve and when evaporator pressure reaches 0 recommended after the core has been changed.

PSIG. move the control stop switch

The

automatic

not normally require any maintenance. It may, however,

require replacement of the solenoid coil or of the entire

valve assembly.

without

pumpdown

position. The

pumpdown

liquid

line solenoid valve, which is responsible for

pumpdown

The solenoid

opening the refrigerant

switch PS1 to the “manual pumpdown”

switch PS1 to the “manual pumpdown”

during normal

coil

may be removed from the valve body

coil

can then be removed from the valve bodv

unit

and install a jumper

pumpdown

unit

unit

switch PS1 to After core replacement, replace the cover plate. A leak

S1 to the “off”

LIQUID LINE SOLENOID VALVE

operation, does

piping

by moving

back on shell and replace the core.

position.

isolate

filter-drier.

check around the flange of the filter-drier shell is

by simply removing a nut or snap ring located at the top of

the coil. The coil can then be slipped off

for replacement. Be sure to replace the

stud before

pumpdown” position.

pumped down by use of the manual

valve.

This will

the short section of refrigerant

To replace the

close the

Remove the cover plate from the

returning pumpdown

entire

liquid

line solenoid valve and

piping

its mounting

coil

on its mounting

switch PS1 to the “auto.

solenoid valve, the unit must be

liquid

ALP-OIGA.

on

"Liquid

Line

given

element

condition

containing the

filter-drier

stud

line shut-off

CONDENSERS

Condensers are air cooled and constructed

copper tubes bonded in a staggered pattern

aluminum fins. No maintenance IS

except the occasional removal of dirt and debris from the

with 3/8

ordinarily

O.D.

into

rippled

required

outside surface of the fins. Care should be taken not to

damage the fins during cleaning. Periodic use of the Purge

valve on

non-condensables.

COMPRESSOR OIL LEVEL

Because of the large refrigerant charge required in an air At the present

cooled condensing unit it IS usually necessary to put approved by

additional

watched carefully upon

thereafter.

oil

into the system. The oil level should be

initial

start-up and for

sometime

compressors. The oil level should be

the

midpoint

use of a light may be required for proper

ADDING OIL TO COMPRESSOR

Oil may be added to the

011 1111

hole in the crankcase

compressor through the

of the compressor. To add

pour or pump the necessary

no

rcfrrgerant.

than keeping the

If the system contains a refrigerant charge, close the

suction valve and reduce crankcase pressure to 1 to 2 PSIG.

PAGE 22

no special

oil

Copeland

3/8-Inch

precautrons

clean and

compressor through the Stop the compressor and close the discharge valve.

and

to the Sundstrand

process tube on the side compressor IS exposed to the atmosphere the refrigerant

011,

Isolate the crankcase and

011

in. If the system

are necessary other

dry.

contains

Add the

will

qeneratc a vapor pressure,

contamrnants.

crdnkcasr! by

seconds. Close the

restore the system to operation.

the condenser will prevent the build-up of

time,

Copeland

of the sightglass on the compressor body. The

requrred

Before resealing the compressor purge the

openrnq

Suniso 3GS

and Sundstrand for use in these

amount of

retarding

the suctrorr valve slightly for 1 or

oil

port, open

the

oil

is the only oil

maintained

oil

011. Durirrg

the entrance Of

compressor valves and

at about

level reading.

the

perrod the

2

.I.

Page 23

I

ELECTRICAL TERMINALS

CAUTION: ELECTRIC

SHOCK HAZARD -TURN OFF ALL POWER BEFORE CONTINUING WITH

FOLLOWING SERVICE.

All

power electrical terminals should be retightened every six months, as they tend to loosen in service

due to normal heating and cooling of the wire.

FAN MOTOR BEARINGS

All

fan motors are pre-lubricated and do not require the addition of grease.

THERMOSTATIC EXPANSION VALVE

The expansion valve is responsible for allowing the proper

amount of refrigerant to enter the evaporator, regardless of

cooling load. It does this by maintaining a constant

superheat. (Superheat is the difference between refrigerant

temperature as it leaves the evaporator and the saturation

temperature corresponding to the evaporator pressure.)

Typically, superheat should run in the range of

On valves purchased through McQUAY, the superheat

setting can be adjusted by removing a cap at the bottom of

the valve to expose the adjustment screw. Turn the screw

clockwise (when viewed from the adjustment screw end) to

increase the superheat setting and counter-clockwise to

reduce superheat. Allow time for system rebalance after

each superheat adjustment.

The expansion valve, like the solenoid valve, should not

normally require replacement, but if it does, the unit must

be pumped down by using the manual liquid line shut-off

valve. If the problem can be traced to the power element

only, it can be unscrewed from the valve body without

removing the valve, but only after pumping the unit down

with the manual liquid line shut-off valve.

10F

to 15F.

‘POWER ELEMENT

(CONTAINS DIAPHRAGM)

IN1.ET

OUTLET

SPRING

ADJUSTMENT SCREW

IN-WARRANTY RETURN MATERIAL PROCEDURE

COMPRESSOR

Bristol Corporation [compressor used in the ALP-0161, and

Copeland Corporation [all other units], have stocking

wholesalers who maintain a stock of replacement compressors and service parts to service refrigeration contractors

and servicemen.

When a compressor fails in warranty, contact your local

sales representative or McQuay Warranty Claims Department at the address on the cover of this bulletin. You will

be authorized to exchange the defective compressor locally

(an advance replacement can be obtained), or we will ship

you a replacement from our stock. A salvage credit is issued

to you by the wholesaler on the returned compressor after

COMPONENTS OTHER THAN COMPRESSORS

Material may not be returned except by permission of

authorized factory service personnel of McQUAY Inc. at

Minneapolis, Minnesota. A “Return Goods” tag will be sent

to be included with the returned material. Enter the

information as called for on the tag in order to expedite

handling at our factories and prompt issuance of credits.

The return of the part does not constitute an order for

replacement. Therefore, a purchase order must be entered

through your nearest McQUAY Representative. The order

Bristol or Copeland factory inspection of the inoperative

compressor. Provide McQuay with full details and invoices

and we will reimburse the difference. In this transaction, be

certain that the compressor is definitely defective. If a

compressor is received from the field that tests satisfactor-

ily, a service charge plus a transportation charge will be

charged against its original credit value.

Copeland offer the same field facilities for service and/or

replacement as described above. The credit issued by Bristol

or Copeland on the returned compressor will be determined

by the repair charge established for that particular unit.

should include part name, part number, model number and

serial number of the unit involved.

and if it is determined that the failure is due to faulty

material or workmanship and in warranty, credit will be

Issued

McQUAY factory, transportation charges prepaid.

CAP

On all out-of-warranty compressor failures, Bristol and

Following our personal inspection of the returned part,

on customer’s purchase order.

All parts shall be returned to the pre-designated

PAGE 23

Page 24

Loading...

Loading...