Page 1

Installation and Operation Manual

Packaged Air-Cooled Condensing Units

Models ALP-012D - ALP-019D

50 and 60 Hertz

IM 687

Group: Chiller

Part Number: 629950

Date: January 1997

Supersedes: None

© 1997 McQuay International

Page 2

Table of Contents

INTRODUCTION.............................3

INSPECTION ...................................3

INSTALLATION..............................3

Handling....................................................3

Location.....................................................4

Service Access...........................................5

Refrigerant Piping ............................5

General......................................................5

Refrigerant Piping .....................................5

Application Considerations..............6

Water Piping .............................................. 8

Flow Switch ............................................. 10

Initial Start-up................................11

Holding Charge ....................................... 11

Leak Testing............................................ 11

Evacuation............................................... 11

Charging The System............................... 11

Refrigerant Charge ..................................12

Pre-Startup ..............................................12

Startup ..................................................... 13

Dimensional Data............................14

Physical Data................................... 16

Field Wiring....................................19

Electrical Legend.....................................21

Normal Sequence Of Operation.....22

Startup.....................................................22

Pumpdown...............................................22

System Maintenance .......................23

General....................................................23

Fan Motor Bearings .................................23

Electrical Terminals.................................23

Condensers ..............................................23

Refrigerant Sightglass..............................23

Service.............................................24

Thermostat Expansion Valve....................24

Filter-Driers.............................................24

Liquid Line Solenoid................................24

Standard Controls ..........................25

High Pressure Control..............................25

Low Pressure Control ...............................25

Compressor Lockout ................................25

Compressor Motor Protector ....................26

Fantrol Head Pressure Control .................26

Optional Controls...........................27

Speedtrol Head Pressure Control..............27

Low Ambient Start...................................27

Hot Gas Bypass........................................27

Electrical Data................................. 17

“McQuay” is a registered trademarks of McQuay International.

©1997 McQuay International

“Illustrations cover the general appearance of McQuay International products at the time of publication and

we reserve the right to make changes in design and construction at anytime without notice.”

2 ALP 012D through 019D IM 687

Troubleshooting Chart....................29

Page 3

INTRODUCTION

ALP air-cooled condensing units are designed for outdoor installations and are compatible with

either air handling units or chilled water evaporators. Each unit is completely assembled and

factory wired before evacuation, charging and testing. Each unit consists of an air-cooled condenser

with integral subcooler section, tandem scroll compressors, complete discharge piping and suction

and liquid connections for connect to any air or water cooling evaporator.

INSPECTION

When the equipment is received, check all items against the bill of lading and inspect for damage

upon arrival. Report all shipping damage to the carrier and file a claim. In most cases, equipment

is shipped fob factory and claims for freight damage should be filed by the consignee. Check the

unit serial plate before unloading the unit to be sure that it agrees with the power supply available.

INSTALLATION

Note: Installation and maintenance are to be performed only by qualified personnel who

are familiar with local codes and regulations, and experienced with this type of equipment.

CAUTION

Sharp edges and coil surfaces are a potential injury hazard. Avoid contact with them.

Handling

Be careful to avoid rough handling of the unit. Do not push or pull the unit from anything other

than the base. Block the pushing vehicle away from the unit to prevent damage to the sheet metal

cabinet and end frame See Figure 1.

Figure 1, Suggested pushing arrangement

Blocking required

across full width

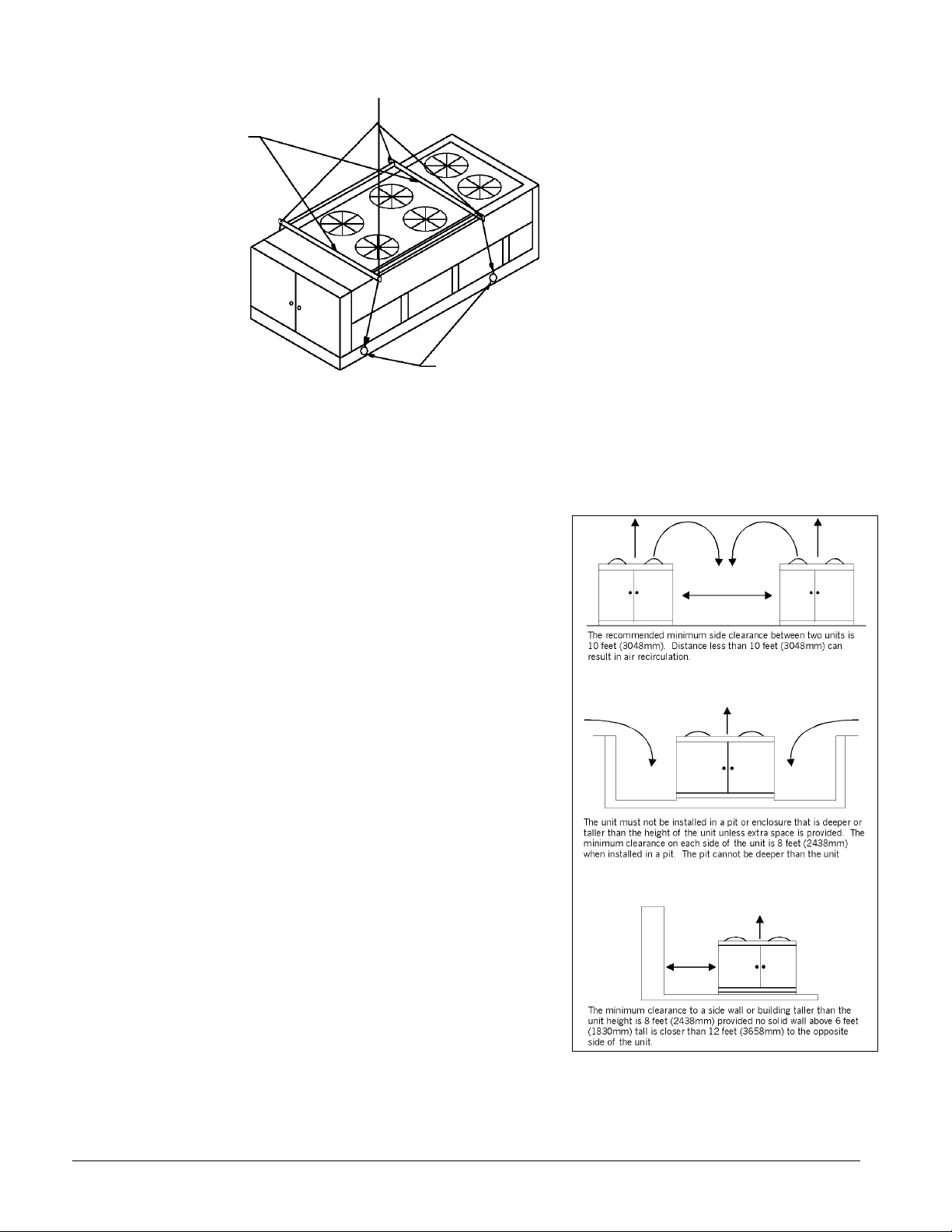

Lifting slots are provided in the base of the unit. Arrange spreader bars and cables to prevent

damage to the condenser coils or cabinet). See Figure 2.

IM 687 ALP 012D through 019D 3

Page 4

Figure 2, Suggested lifting arrangement

Spreader bars

recommended

(Use Caution)

Location

Unit Placement

ALP units are for outdoor applications and can be mounted on a roof or ground level. Set units on a

solid and level foundation. For roof mounted

applications, install the unit on a steel channel or Ibeam frame to support the unit above the roof. For

ground level applications, install the unit on a

substantial base that will not settle. A one piece

concrete slab with footings extended below the frost

line is recommended. Be sure the foundation is

level (within 1/2” [13 mm] over its length and

width). The foundation must support the operating

weights listed in the Physical Data tables beginning

on

page 16.

NOTE: Number of fans can vary

from this diagram. Lifting method

remains the same.

Must use these rigging holes.

(Be aware of contol box location.)

On ground level applications protect fins

against vandalism using the optional coil guards or

by erecting a screen fence. The fence must allow

free flow of air to the condenser coil for proper unit

operation.

Unit operation is affected by wind. Located the

unit so length is parrallel with the prevailing wind.

If this is not practical, use wind deflectors.

Clearances

The flow of air to and from the condenser coil must

not be limited. Restricting air flow or allowing air

recirculation will result in a decrease in unit

performance and efficiency. There must be no

obstruction above the unit that would deflect

discharge air downward where it could be

recirculated back to the inlet of the condenser coil. The condenser fans are propeller type and will

not operate with ductwork on the fan outlet.

4 ALP 012D through 019D IM 687

Page 5

Install the unit with three feet of side clearance for air entrance to the coil and for servicing.

Provide four feet of service access at each end to access the evaporator, compressors, electrical

control panel and piping components.

Do not allow debris to accumulate near the unit. Air movement may draw debris into the

condenser coil causing air starvation. Give special consideration to low ambient operation where

snow can accumulate. Keep condenser coils and fan discharge free of snow or other obstructions to

permit adequate airflow.

Service Access

Each end of the unit must be accessible after installation for periodic service. Compressors, filterdriers, and manual liquid line shutoff valves are accessible from the end of the unit. High pressure,

low pressure, and motor protector controls are on the compressor. Most operational, safety and

starting controls are located in the unit control box.

The condenser fan and motors can be removed from the top of the unit.

Refrigerant Piping

General

Piping design, sizing and installation information presented in ASHRAE Handbooks should, where

applicable, be followed in the design and installation of piping. ALP condensing units are adaptable

to either chilled water or air handling air conditioning applications. The only restriction on

applications is that the evaporator be selected for a system using refrigerant R-22.

Refrigerant Piping

Design and install piping between the condensing unit and the cooling coil to minimize pressure

drop, prevent liquid refrigerant carryover to the compressor and to assure a continuous return of

compressor oil from the system. Piping sketches and tables are not intended to provide information

on all of the possible arrangements.

Piping recommendations include:

1. The use of type K or L clean copper tubing. Thoroughly clean and braze all joints with high

temperature solder.

2. Piping sizes should be based on temperature/pressure limitations as recommended in the

following paragraphs. Under no circumstances should pipe size be based upon the coil or

condensing unit piping connection size.

3. Suction line pressure drop should not exceed the pressure equivalent of 2° (3 psi) per 100 feet of

equivalent pipe length. After the suction line size has been determined, the vertical suction

risers should be checked to verify that oil will be carried up the riser and back to the

compressor. The suction line should be pitched in the direction of refrigerant flow and

adequately supported. Lines should be free draining and fully insulated between the evaporator

and the compressor. Table 3, shows piping information for units operating at suction

temperatures between 40°F and 45°F and a condenser entering air temperature of 95°F. If

operating conditions are expected to vary substantially from these operating levels, the pipe

sizing should be rechecked.

4. Vertical suction risers should be checked using Table 1 to determine the minimum tonnage

required to carry oil up suction risers of various sizes.

5. The liquid line should be sized for a pressure drop not to exceed the pressure equivalent of 2°F

(6 psi) saturated temperature.

IM 687 ALP 012D through 019D 5

Page 6

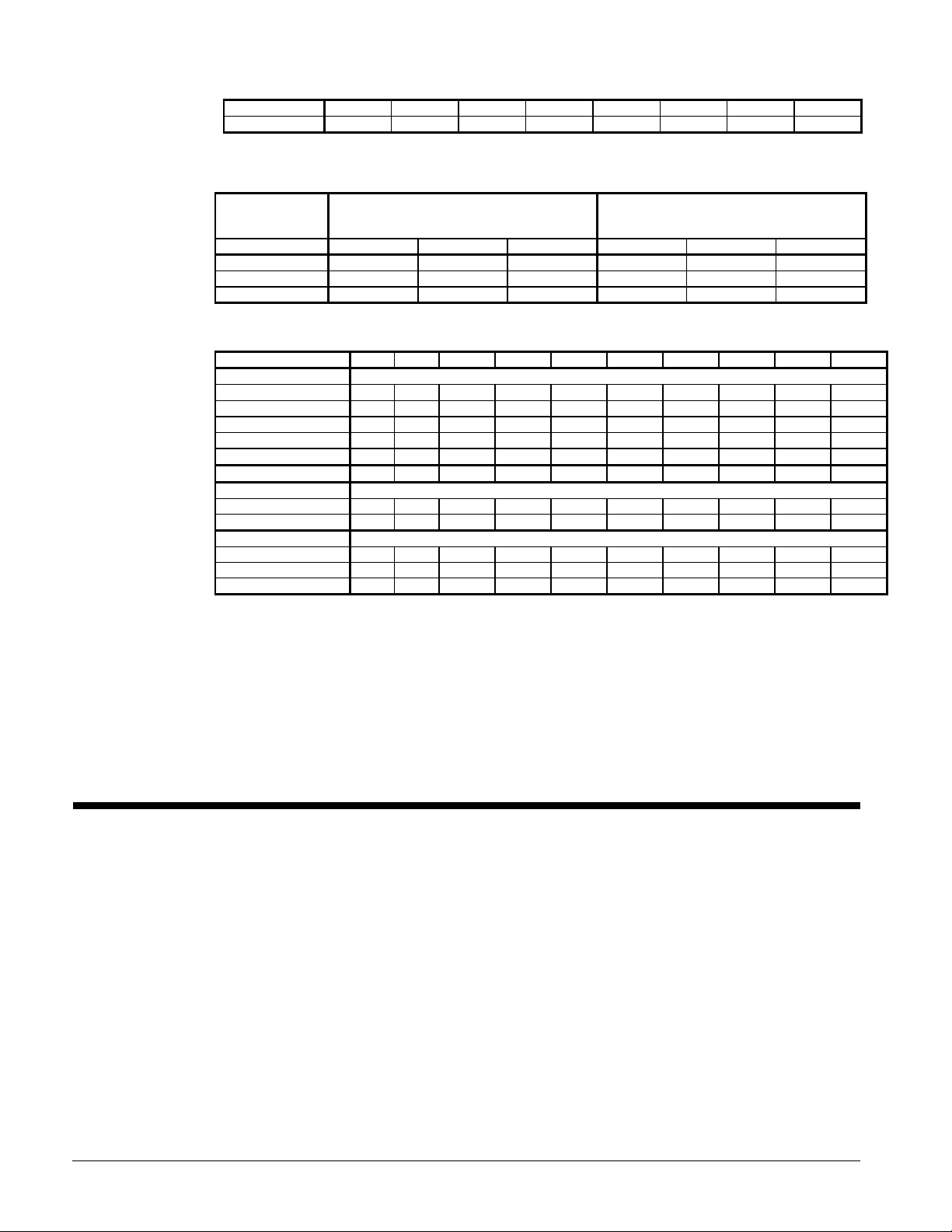

Table 1. Minimum tonnage to carry oil up suction riser at 40°°F saturated suction.

Line Size 1 1/8 1 3/8 1 5/8 2 1/8 2 5/8 3 1/8 3 5/8 4 1/8

Min. Tons 1.50 2.50 3.80 7.60 13.10 20.40 29.70 41.30

NOTE: When compressor minimum tonnage is less than shown in the above table for a given line size, reselection of risers will be

required or hot gas bypass at the coil will be required.

Table 2, Recommended line sizes (Max. equivalent feet of copper tubing*)

MODEL

NUMBER

1 3/8” 1 5/8” 2 1/8” 5/8” 7/8” 1 1/8’

012D 70 160 -- 35 200 -015D 35 80 300 16 100 365

019D -- 50 180 -- 60 220

*Equivalent line lengths in the above table are suitable for a unit operating at 40°F sat. suction, 50°F return gas and 95°F ambient.

SUCTION

LINE SIZE

O.D. COPPER

LIQUID

LINE SIZE

O.D. COPPER

Table 3. Equivalent feet of straight tubing for copper fittings and valves

FITTING TYPE 5/8” 7/8” 1 1/8” 1 3/8” 1 5/8” 2 1/8” 2 5/8” 3 1/8” 3 5/8” 4 1/8”

ELBOWS

90° Standard

90° Long Radius

90° Street

45° Standard

45° Street

180° BEND

TEES

Full Size 1.0 1.4 11.7 2.3 2.6 3.3 4.1 5.0 5.9 6.7

Reducing 1.6 2.0 2.6 3.3 4.0 5.0 6.0 7.5 9.0 10

VALVES

Globe Valve, Open 18 22 29 38 43 55 69 84 100 120

Gate Valve, Open 0.7 0.9 1.0 1.5 1.8 2.3 2.8 3.2 4.0 4.5

Angle Valve, Open 7. 9. 12 15 18 24 29 35 41 47

Notes:

1. Liquid and suction lines based on a recommended equivalent pressure drop of 2°F (3 psi for suction line, 6 psi for liquid line)

per 100 ft. of equivalent length.

2. When the refrigerant required to charge a system exceeds the pumpdown capacity of the unit plus the capacity of the liquid

line (see Table 4), the use of separate refrigerant storage receiver will be required. The pumpdown capacity of each unit is

based on the condenser 90% full at 90°F (see physical data).

3. Total equivalent feet for a given piping layout must include the equivalent length of straight pipe for fittings, valves and

specialties added to the total run of straight pipe.

4. Piping design, sizing an installation information presented in ASHRAE Handbooks should, where applicable, be followed in the

design and installation piping.

5. Units running at 50% load do not require double suction risers.

1.6 2.0 2.6 3.3 4.0 5.0 6.0 7.5 9.0 10

1.0 1.4 1.7 2.3 2.6 3.3 4.1 5.0 5.9 6.7

2.5 3.2 4.1 5.6 6.3 8.2 10. 12 15 17

0.8 0.9 1.3 1.7 2.1 2.6 3.2 4.0 4.7 5.2

11.3 1.5 2.1 3.0 3.4 4.5 5.2 6.4 7.3 8.5

2.5 3.2 4.1 5.6 6.3 8.2 10 12 15 17

Application Considerations

Suction Accumulators

Field experience indicates that as the refrigerant charge in a small tonnage system increases, the

potential stress level from liquid floodback during system startup and stabilization also increases.

Since there is no factory control of condensing unit applications, piping and design, a suction

accumulator is recommended. The accumulator’s function is to intercept liquid refrigerant before it

reaches the compressor crankcase causing mechanical damage. It should be located in the suction

line between the evaporator and compressor, have a refrigerant capacity large enough to hold the

maximum amount of refrigerant that could flood through, and must have provisions for a positive

return of oil to the crankcase.

VAV Direct Expansion Systems

Variable air volume (VAV) application to direct expansion cooling coil systems is increasingly

attractive because of the potential energy savings in fan motor power. Extra care must be exercised

in the design of VAV direct expansion systems because of the potential for coil icing, oil trapping,

loss of stable expansion valve control, excessive compressor cycling, and nuisance operation of

protective controls.

6 ALP 012D through 019D IM 687

Page 7

Equipment damage and nuisance tripping can be avoided by proper total system design. Special

consideration must be given to reduced load operating conditions as well as peak design, and coil

selection, capacity unloading, and system control modified as required to provide a trouble-free

system.

Head Pressure Control

Condenser coils on these ALP condensing units are vertical in position and are subject to wind. The

standard head pressure control offered controls the operation or speed of condenser fans. This type

of control has no effect if condenser coils are subjected to wind.

The design engineer or contractor has the responsibility of locating the equipment or protecting

the condenser coil so that prevailing winds have minimum effect on unit performance.

Oil Charge

Excessive piping or refrigerant charge or both may require the addition of some oil to the

compressor. If additional oil is required, use Suniso brand for the Copeland compressors. Add only

enough oil to maintain an oil level at the indicated point in the compressor sightglass.

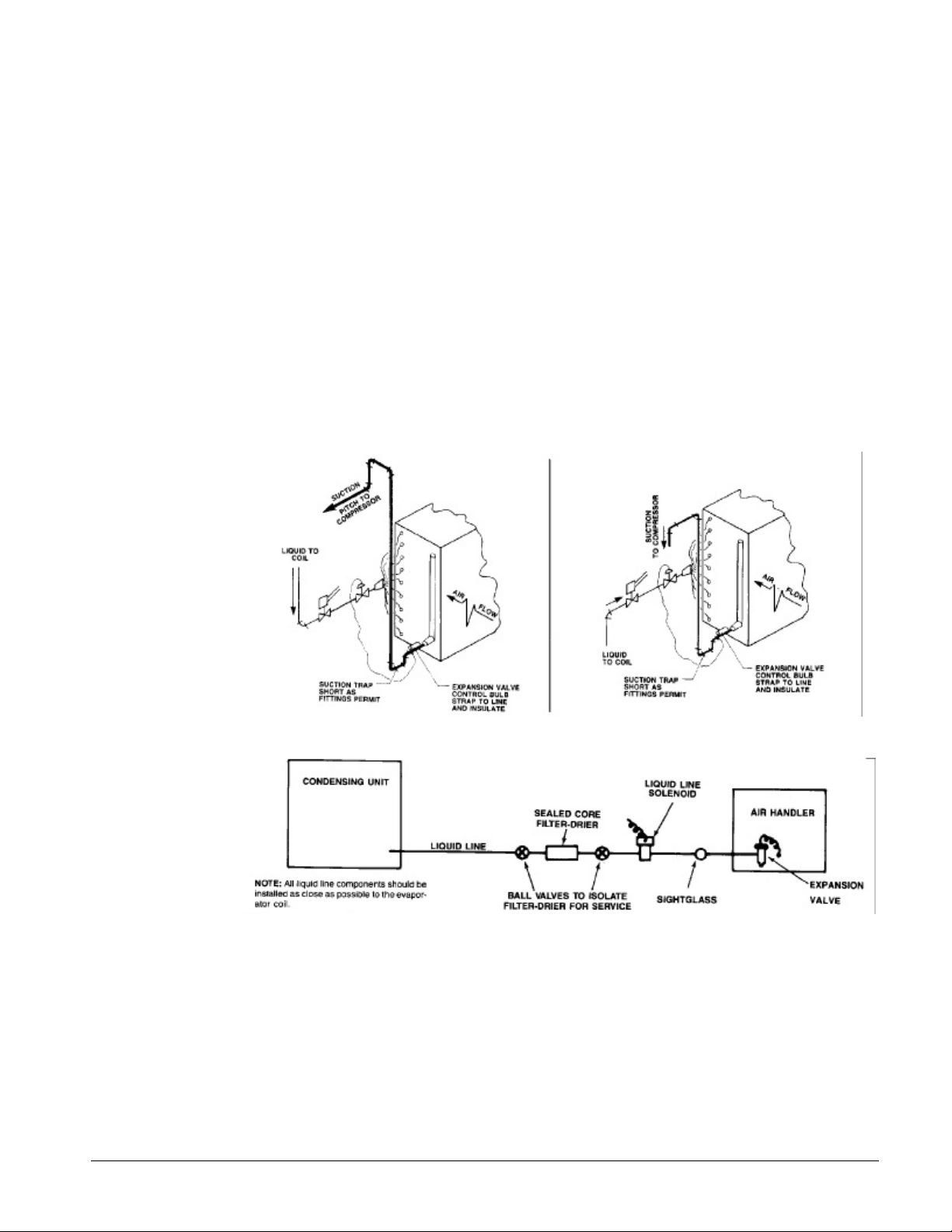

Figure 3, Single Circuit Evaporator—Recommended Piping

Figure 4, Recommended Liquid Line Piping

IM 687 ALP 012D through 019D 7

Page 8

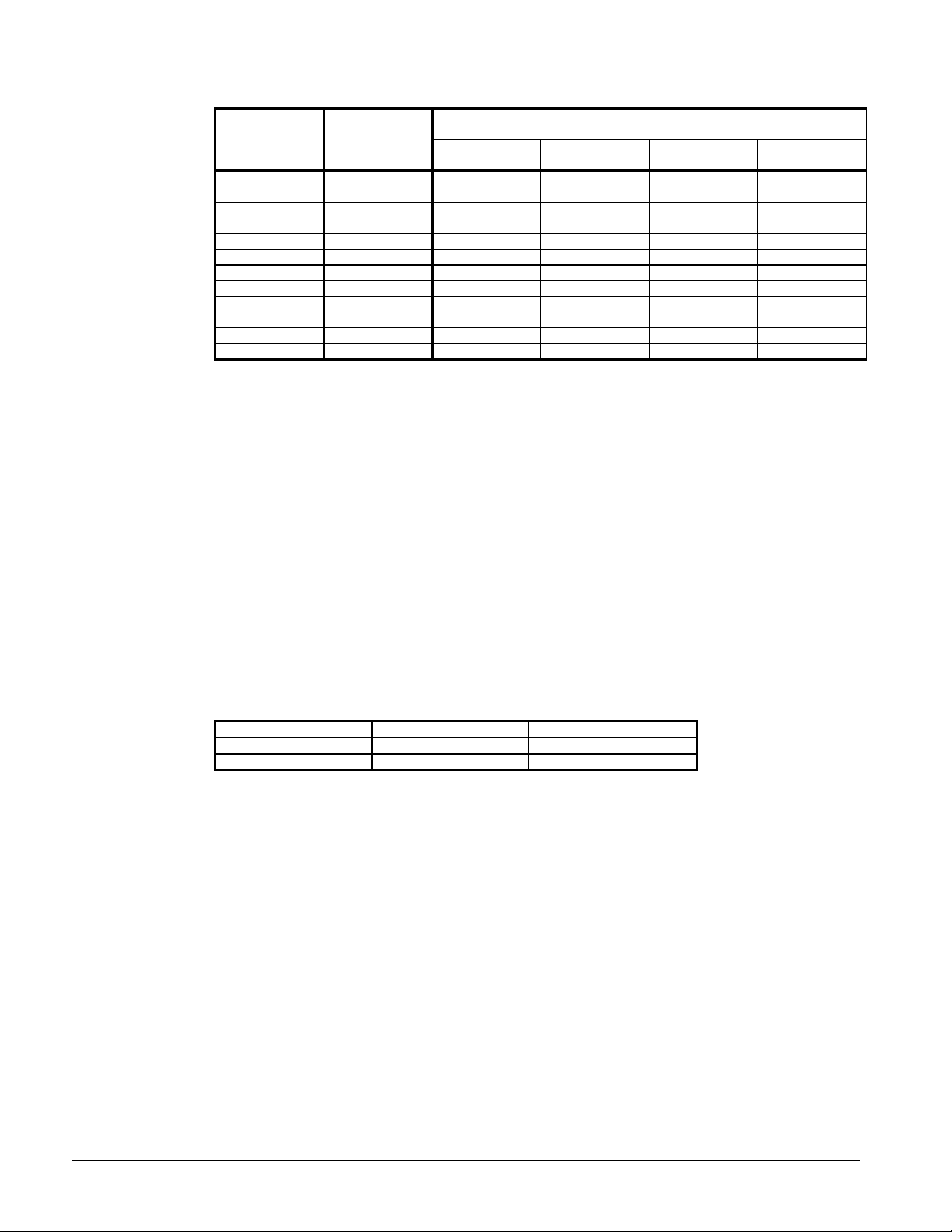

Table 4, Weight of R-22 in copper lines (Pounds Per 100 feet of type L tubing)

LINE SIZE

O.D.(in.)

3/8 0.054 3.84 0.202 0.052 0.077

1/2 0.100 7.12 0.374 0.096 0.143

5/8 0.162 11.5 0.605 0.156 0.232

7/8 0.336 24.0 1.26 0.323 0.480

1 1/8 0.573 40.8 2.14 0.550 0.820

1 3/8 0.872 62.1 3.26 0.839 1.25

1 5/8 1.237 88.0 4.62 1.19 1.77

2 1/8 2.147 153.0 8.04 2.06 3.06

2 5/8 3.312 236.0 12.4 3.18 4.72

3 1/8 4.728 336.0 17.7 4.55 6.75

3 5/8 6.398 456.0 24.0 6.15 9.14

4 1/8 8.313 592.0 31.1 8.00 11.19

VOL PER 100

FT (CU, FT)

LIQUID @

100°F

WEIGHT OF REFRIGERANT (LBS)

HOT GAS @

120°F

SUCTION GAS

@20°F

SUCTION GAS

@ 40°F

Liquid Line Components

Liquid line components should include:

1. Filter-drier

2. Refrigerant solenoid valve/115 volt coil

3. Refrigerant sightglass/moisture indicator

4. Expansion valve/R-22

5. Manual shutoff valve

All liquid line components are field supplied and should be selected and installed according to good

field piping practices, ASHRAE Guide, and individual component manufacturer recommendations.

Hot Gas Bypass Components

Hot gas bypass kits are available for each ALP unit size. Each kit includes a solenoid valve, a hot

gas bypass valve and instruction drawing. See page 8 for hot gas bypass operation.

Table 5, Hot Gas Bypass Kits

ALP UNIT SIZE KIT NUMBER LINE SIZE O.D. (IN.)

012D 550443A-03 5/8

015D & 019D 550443A-04 7/8

Refrigerant Piping Connections

Refrigerant piping connections will be made at the compressor end of the unit. Suction and liquid

lines should be routed through the compressor enclosure on the side of the unit.

Water Piping

The following section applies to remote mounted DX water chillers.

Local authorities can supply the installer with the proper building and safety codes required for safe

and proper installation.

Install piping with minimum bends and changes in elevation to minimize pressure drop.

Consider the following when installing water piping:

1. Vibration eliminators to reduce vibration and noise transmission to the building.

2. Shutoff valves to isolate the unit from the piping system during unit servicing.

3. Manual or automatic air vent valves at the high points of the system. Install drains at the

lowest points in the system.

4. A means of maintaining adequate system water pressure (expansion tank or regulating valve).

8 ALP 012D through 019D IM 687

Page 9

5. Temperature and pressure indicators located at the unit to aid in unit servicing.

6. A strainer or other means of removing foreign matter from the water before it enters the pump.

Place the strainer far enough upstream to prevent cavitation at the pump inlet (consult pump

manufacturer for recommendations). The use of a strainer will prolong pump life and keep

system performance up.

7. Place a strainer in the water line just before the inlet of the evaporator. This will help prevent

foreign material from entering and decreasing the performance of the evaporator.

CAUTION

If separate disconnect is used for the 110V supply to the evaporator heating cable, mark

the disconnect clearly to ensure disconnect is not accidentally shut off during cold seasons.

8. The brazed plate evaporator has a thermostat and heating cable to prevent freeze-up down to 20°F (-29°C). It is suggested that the heating cable be wired to a separate 110V supply circuit.

As shipped from the factory, the heating cable is wired to the control circuit. All water piping

to the unit must also be protected to prevent freezing.

9. If the unit is used as a replacement chiller on a previously existing piping system, flush the

system thoroughly before unit installation. Regular water analysis and chemical water

treatment on the evaporator is recommended immediately at equipment start-up.

10. The total water volume in the system should be sufficient to prevent frequent “on-off” cycling.

Turnover rate should not be less than 15 minutes for normal variable cooling loads. Turnover

rate for process cooling or a constant load,should not be less than 6 minutes.

11. When glycol is added to the water system for freeze protection, the refrigerant suction pressure

will be lower, cooling performance less, and water side pressure drop greater. If the percentage

of glycol is high, or if propylene is used instead of ethylene glycol, the added pressure drop and

loss of performance could be substantial. Reset the freezestat and low leaving water alarm

temperatures. The freezestat is factory set to default at 36°F (2.2°C). Reset the freezestat

setting to approximately 4 to 5 degress F (2.3 to 2.8 degress C) below the leaving chilled water

setpoint temperature. See the section titled “Glycol Solutions” for additional information

concerning glycol.

12. Perform a preliminary leak check before insulating the piping and filling the system.

13. Piping insulation should include a vapor barrier to prevent condensation and possible damage

to the building structure.

Figure 5, Typical field evaporator water piping

Vent

Outlet

Vibration

Drain

Vibration

Eliminator

Valved

pressure

gauge

Water

strainer

Eliminator

Gate valve

IM 687 ALP 012D through 019D 9

Flow

Balancing

Switch

Protect all field piping

against freezing

valve

Gate valve

Page 10

Flow Switch

Mount a water flow switch in either the entering or leaving water line to shut down the unit when

water flow is interrupted.

A flow switch is available from McQuay (part number 0701804-04). It is a “paddle” type

switch and adaptable to pipe sizes down to 1 1/4 ” (32mm) nominal. Certain minimum flow rates

are required to close the switch and are listed in Table 6. Installation should be as shown in

Figure 6. Connect the normally open contacts of the flow switch in the unit control center at

terminals 4 and 5. There is also a set of normally closed contacts on the switch that can be used for

an indicator light or an alarm to indicate when a “no flow” condition exists. Freeze protect any flow

switch that is installed outdoors.

Table 6, Flow switch minimum flow rates

NOMINAL PIPE SIZE MINIMUM REQUIRED FLOW TO

INCHES (MM) ACTIVATE SWITCH - GPM (L/S)

1 (25.4) 6.00 (0.38)

11/4 (31.8) 9.80 (0.62)

11/2 (38.1) 12.70 (0.80)

2 (50.8) 18.80 (1.20)

21/2 (63.50 24.30 (1.50)

3 (76.20 30.00 (1.90)

Figure 6, Flow switch installation

Flow direction

marked on switch

5" (127mm) pipe

dia. Min. after

1" (25mm) NPT

flow switch

Tee

5" (127mm) pipe

dia. Min. before

10 ALP 012D through 019D IM 687

Page 11

Initial Start-up

Holding Charge

The condensing unit is shipped with a holding charge of refrigerant. Perform a pressure check of

the unit. If no pressure is evident, leak test the unit and repair leak. This should be noted and

reported to your sales representative or freight carrier if the loss is due to shipping damage.

Leak Testing

When the refrigerant holding charge is lost, check for leaks before charging the complete system.

Leak testing can be done by charging the refrigerant into the unit to build the pressure to

approximately 10 psig and adding sufficient dry nitrogen to bring the pressure to a maximum of 125

psig. Leak test with a Halide or electronic leak detector. After making any necessary repair,

evacuate the system.

Do not use oxygen to build up pressure. A serious explosion could be the result.

WARNING

Evacuation

Use a vacuum pump with a pumping capacity of approximately 3 cu. ft./min. and the ability to

reduce the vacuum in the unit to at least 1 millimeter (1000 microns).

1. Connect a mercury manometer, electronic or other type of micron gauge to the unit at a point

remote from the vacuum pump. For readings below 1 millimeter, an electronic or other micron

gauge should be used.

2. If the vacuum pump is unable to obtain the desired 1 millimeter of vacuum, evacuate the system

to about 29 inches of mercury. Add enough refrigerant vapor to the system to bring the pressure

up to 0 pounds.

3. Evacuate the system to 29 inches of vacuum. Repeat three times. This method can be most

effective by holding system pressure at 0 pounds for a minimum of 1 hour between evacuations.

The first pull down will remove about 90% of the noncondensables, the second about 90% of

that remaining from the first pull down and after the third only 1/10 of 1% noncondensables

will remain.

Charging The System

After all refrigerant piping is complete and the system has been evacuated, charge the unit as

follows:

1. Connect refrigerant drum to gauge port on liquid line and purge the charging line between the

refrigerant cylinder and the valve. Open the valve to mid-position.

2. If the system is under a vacuum, stand refrigerant drum with connection up and open drum and

break the vacuum with refrigerant gas.

3. With a system gas pressure higher than the equivalent of a freezing temperature, invert the

charging cylinder and elevate the drum above the condenser. With the drum in this position,

valves open and liquid refrigerant will flow into the condenser. Approximately 75% of the total

requirement estimated for the unit can be charged in this manner.

4. After 75% of the required charge has entered the condenser, reconnect the refrigerant drum and

charging line to the suction side of the system. Purge the connecting line, stand the drum with

the connection up, and place service valve in open position.

IM 687 ALP 012D through 019D 11

Page 12

Important: At this point charging procedure should be interrupted and prestart checks

made before attempting to complete the refrigerant charge, (see startup procedures).

Note: It is recommended that the total operating charge per circuit be stamped on the unit

nameplate for future reference.

Refrigerant Charge

Each ALP condensing unit is designed for use with R-22. See Physical Data for approximate

refrigeration charges for operation of the unit. Additional refrigerant will be needed for the system

piping and evaporator. Estimated total operating charge should be calculated before charging

system.

CAUTION

Total operating charge per circuit should not exceed the condenser pumpdown capacity per

circuit plus the capacity of the liquid line. A liquid receiver on each refrigerant circuit

should be used if the unit operating charge exceeds the pumpdown capacity. Refer to the

ASHRAE Handbook for the design and installation of piping and components.

Pre-Startup

1. With electric disconnects open, check all screw or lug type electrical connections to be sure they

are tight. Check all compressor valve connections for tightness to avoid refrigerant loss at

startup. Although all factory connections are tight before shipment, some loosening may have

resulted from shipping vibration.

2. Check the voltage of the unit power supply and verify it is within 10% of the nameplate rating.

Phase voltage unbalance must be within 2%.

3. Check the unit power supply wiring for adequate ampacity and a minimum insulation

temperature rating of 75°C.

4. Verify all mechanical and electrical inspections have been completed according to local codes.

5. Verify all auxiliary control equipment is operative and that an adequate cooling load is available

for initial startup.

6. Adjust the dial on the temperature controller to well below desired set point to prevent unit

operation. Leave the unit disconnect on and allow the crankcase heater to operate at least 8

hours before start-up.

WARNING

Most relays and terminals in the unit control center are energized with the unit

disconnect on.

12 ALP 012D through 019D IM 687

Page 13

Startup

1. Start the auxiliary equipment for the installation.

2. Adjust the dial on the temperature controller to the desired leaving air temperature.

3. After running the unit for a short period of time, check for proper rotation of the condenser fans

and check for refrigerant flashing in the sightglass.

4. Adjust superheat to maintain between 10°F and 12°F at the evaporator.

5. Adjust subcooling to maintain between 8°F to 12°F.

6. After system performance has been stabilized, Complete the “Compressorized Equipment

Warranty Registration Form” (Form No. 550488A-01) to obtain full warranty benefits. Consult

the Product Warranty Certificate for details. Both forms are supplied with the units where

required.

IM 687 ALP 012D through 019D 13

Page 14

Dimensional Data

Figure 7. ALP-012D

14 ALP 012D through 019D IM 687

Page 15

Figure 8, ALP 015 and 019

IM 687 ALP 012D through 019D 15

Page 16

Physical Data

Table 7, ALP Physical Data

DATA ALP MODEL NUMBER

012D 015D 019D

BASIC DATA

Unit Capacity @ ARI Conditions, Mbh (kW)(1) 155 (39) 183 (54) 236 (69)

Number Of Refrigerant Circuits 1 1 1

Unit Holding Charge, R-22, Lbs. (kg) 11.0 (5.0) 11.0 (5.0) 12.0 (5.4)

Cabinet Dimensions, LxWxH, In. 78x36x36 78x40x36 78x40x36

Cabinet Dimensions, LxWxH, mm (1981x914x914) (1981x1016x914) (1981x1016x914)

Unit Shipping Weight, Lbs. (kg) 625 (284) 858 (389) 873 (396)

Add'l Weight If Ccopper Finned Coils, Lbs. (kg) 210 (95) 210 (95) 220 (100)

COMPRESSORS

Type Scroll Scroll Scroll

Nominal Horsepower 6.0 / 6.0 7.5 / 7.5 9.0 / 9.0

Oil Charge Per Compressor, Oz. (g) 60 (1866) 140 (4354) 140 (4354)

CAPACITY REDUCTION STEPS - % OF COMPRESSOR DISPLACEMENT

Standard taging 0-50-100 0-50-100 0-50-100

Optional SStaging N/A N/A N/A

CONDENSERS - HIGH EFF. FIN & TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area,Sq. Ft. (M2) 30.3 (2.8) 30.3 (2.8) 30.3 (2.8)

Finned Height x Finned Length, In. 66 x 66 66 x 66 66 x 66

Finned Height x Finned Length, mm (1676x1676) (1676x1676) (1676x1676)

Fins Per Inch x Rows Deep 16 x 2 16 x 2 16 x 3

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 2 - 24 (610) 2 - 24 (610) 2 - 24 (610)

Number Of Motors - HP (kW) 2 - .5 (.4) 2 - .5 (.4) 2 - .5 (.4)

Fan And Motor RPM, 60/50Hz 1075/896 1075/896 1075/896

60 Hz Fan Tip Speed, FPM 6750 6750 6750

50 Hz Fan Tip Speed, M/sec 28.6 28.6 28.6

60 Hz Total Unit Airflow, CFM 10150 10150 9800

50 Hz Total Unit Airflow, M3/sec 4.0 4.0 3.9

Notes:

1. Nominal capacity based on 95°F ambient air and 45°F suction.

2. Total pumpdown capacity will be unit pumpdown capacity plus liquid line capacity.

3. “Unit operating charge” does NOT include any estimate of the refrigerant quantity required for the evaporator and interconnecting piping.

4. Some oil may need to be added to satisfy the requirements of the finished refrigerant system due to the miscibility of the refrigerant and oil. If oil must

be added, it should be of the same type and grade recommended by the compressor manufacturer. Care must be taken to prevent adding excessive

oil since equipment damage including compressor failure may result. Contact the McQuay Service technical group in Staunton for additional

information if necessary.

16 ALP 012D through 019D IM 687

Page 17

Electrical Data

Table 8, Electrical data single point

012D 460 60 25 3 10 1 0.50 (13) 30 30

015D 460 60 33 3 8 1 0.75 (19) 40 40

019D 460 60 39 3 8 1 0.75 (19) 45 50

Minimum POWER SUPPLY FIELD FUSE SIZE

ALP Circuit Field Wire Hub

Unit Volts HZ. Ampacity Wire Nominal Recommended Maximum

Size (MCA) Quantity Gauge Quantity Size

208 51 3 6 1 1.00 (25) 60 60

230 51 3 6 1 1.00 (25) 60 60

575 20 3 10 1 0.50 (13) 25 25

415 50 25 3 10 1 0.50 (13) 30 30

380 25 3 10 1 0.50 (13) 30 30

208 60 3 6 1 1.00 (25) 70 80

230 60 3 6 1 1.00 (25) 70 80

575 24 3 10 1 0.50 (13) 30 30

415 50 30 3 8 1 0.75 (19) 40 40

380 30 3 8 1 0.75 (19) 40 40

208 76 3 4 1 1.00 (25) 90 100

230 76 3 4 1 1.00 (25) 90 100

575 30 3 10 1 0.50 (13) 35 40

415 50 37 3 8 1 0.75 (19) 45 50

380 37 3 8 1 0.75 (19) 45 50

Table 9, Compressor and condenser fan motor amp draw

Rated Load Amps Locked Rotor Amps

Compressors Fan No. Of Fan Compressors

Volts HZ. No. No. No. No. Motors Fan Motors Across-The-Line Reduced Inrush

1 2 3 4 (Each) Motors (Each) No. 1 No. 2 No. 3 No. 4 No. 1 No. 2 No. 3 No. 4

ALP 208 18.6 18.6 ---- ---- 4.2 2 8.8 156 156 ---- ---- N/A N/A ---- ----

Unit 230 18.6 18.6 ---- ---- 4.2 2 8.8 156 156 ---- ---- N/A N/A ---- ----

012D 460 60 9 9 ---- ---- 2.1 2 4.8 70 70 ---- ---- N/A N/A ---- ----

575 7.4 7.4 ---- ---- 1.6 2 3.7 54 54 ---- ---- N/A N/A ---- ---415 50 9 9 ---- ---- 2.1 2 4.8 74 74 ---- ---- N/A N/A ---- ---380 9 9 ---- ---- 2.1 2 4.8 67 67 ---- ---- N/A N/A ---- ---208 22.9 22.9 ---- ---- 4.2 2 8.8 189 189 ---- ---- N/A N/A ---- ---230 22.9 22.9 ---- ---- 4.2 2 8.8 189 189 ---- ---- N/A N/A ---- ----

015D 460 60 12.5 12.5 ---- ---- 2.1 2 4.8 94 94 ---- ---- N/A N/A ---- ----

575 9.1 9.1 ---- ---- 1.6 2 3.7 74 74 ---- ---- N/A N/A ---- ---415 50 11.3 11.3 ---- ---- 2.1 2 4.8 99 99 ---- ---- N/A N/A ---- ---380 11.3 11.3 ---- ---- 2.1 2 4.8 89 89 ---- ---- N/A N/A ---- ---208 29.9 29.9 ---- ---- 4.2 2 8.8 232 232 ---- ---- N/A N/A ---- ---230 29.9 29.9 ---- ---- 4.2 2 8.8 232 232 ---- ---- N/A N/A ---- ----

019D 460 60 15.3 15.3 ---- ---- 2.1 2 4.8 116 116 ---- ---- N/A N/A ---- ----

575 11.5 11.5 ---- ---- 1.6 2 3.7 97 97 ---- ---- N/A N/A ---- ---415 50 14.4 14.4 ---- ---- 2.1 2 4.8 123 123 ---- ---- N/A N/A ---- ---380 14.4 14.4 ---- ---- 2.1 2 4.8 110 110 ---- ---- N/A N/A ---- ----

IM 687 ALP 012D through 019D 17

Page 18

Table 10, Field wiring data

Wiring to

ALP Standard Power Block

Unit Volts HZ. Terminal Connector Wire Range

Size Amps (Copper Wire Only)

208 175 (1 qty.) #12 - 2/0

230 175 (1 qty.) #12 - 2/0

012D 460 60 175 (1 qty.) #12 - 2/0

575 175 (1 qty.) #12 - 2/0

415 50 175 (1 qty.) #12 - 2/0

380 175 (1 qty.) #12 - 2/0

208 175 (1 qty.) #12 - 2/0

230 175 (1 qty.) #12 - 2/0

015D 460 60 175 (1 qty.) #12 - 2/0

575 175 (1 qty.) #12 - 2/0

415 50 175 (1 qty.) #12 - 2/0

380 175 (1 qty.) #12 - 2/0

208 175 (1 qty.) #12 - 2/0

230 175 (1 qty.) #12 - 2/0

019D 460 60 175 (1 qty.) #12 - 2/0

575 175 (1 qty.) #12 - 2/0

415 50 175 (1 qty.) #12 - 2/0

380 175 (1 qty.) #12 - 2/0

Notes:

1. Voltage must be within 10% of nameplate rating

2. Unit wire size amps are equal to 125% of the compressor branch circuit selection current plus 100% of RLA of all other

loads in the circuit including control transformer.

3. RLA of 2 speed compressors running on low speed will be 50% of Table 11 RLA value.

4. Each ALP unit is provided with 7/8” dia. knockouts to be used as a pilot for making larger power entry hubs.

18 ALP 012D through 019D IM 687

Page 19

Field Wiring

CAUTION

Use only copper conductors in main terminal block

Wiring must be in accordance with all applicable codes and ordinances. Warranty is void if wiring

is not in accordance with specifications. An open fuse indicates a short, ground or overload. Before

replacing a fuse or restarting a compressor or fan motor, find and correct the trouble.

Figure 7 shows typical field wiring required for unit installation. Items that require field wiring are

liquid line solenoid SV1, cooling thermostat, and unit power supplies.

Note: See dimensional data for knockout locations.

IM 687 ALP 012D through 019D 19

Page 20

Figure 9, Typical Field Wiring

20 ALP 012D through 019D IM 687

Page 21

Electrical Legend

DESIGNATION DESCRIPTION STD. LOCATION

AB ALARM BELL FIELD MOUNTED

C11, C12 CAPACITORS FOR FAN MOTORS BACK OF CONTROL BOX

COMPR.1 COMPRESSOR BASE OF UNIT

F1 FUSE, CONTROL CIRCUIT CONTROL BOX

FB5 FUSE BLOCK, CONTROL POWER CONTROL BOX

FB6 FUSE BLOCK, FAN MOTORS CONTROL BOX

GRD GROUND CONTROL BOX

HP1,2 HIGH PRESSURE CONTROL ON COMPRESSOR

HTR HEATER, COMPRESSOR CRANKCASE ON COMPRESSOR

LP1 LOW PRESSURE CONTROL ON COMPRESSOR

M1-9 CONTRACTORS, COMPRESSOR CONTROL BOX

M11-12 CONTRACTORS, FAN MOTORS CONTROL BOX

MJ MECHANICAL JUMPERS CONTROL BOX

MP1-4 MOTOR PROTECTOR COMPRESSOR COMPRESSOR JUNCTION BOX

MTR11 MOTORS, CONDENSER FANS CONDENSER SECTION

NB NEUTRAL BLOCK CONTROL BOX

PB1 POWER BLOCK, MAIN CONTROL BOX

PC12 PRESSURE CONTROL, (FANTROL) CONTROL BOX

DESIGNATION DESCRIPTION STD. LOCATION

R13 RELAYS, LOW AMBIENT START CONTROL BOX

R3,4 RELAYS CAPACITY CONTROL CONTROL BOX

SC11 SPEED CONTROLS ON BULKHEAD

T1 TRANSFORMER, MAIN CONTROL CONTROL BOX

T2 TRANSFORMER, 24V CONTROL CONTROL BOX

TB2 TERMINAL BLOCK, 120V, FIELD CONTROL BOX

TB3 TERMINAL BLOCK, 24V, FIELD CONTROL BOX

TB4-6 TERMINAL BLOCKS, CONTROL CONTROL BOX

TD4-6 TERMINAL BLOCKS, CONTROL CONTROL BOX

TD1-2 TIME DELAYS, COMPRESSOR LOCKOUT CONTROL BOX

TD9 TIME DELAYS, LOW AMBIENT CONTROL BOX

IM 687 ALP 012D through 019D 21

Page 22

Normal Sequence Of Operation

The following sequence of operation is typical. The sequence varies somewhat depending upon

options.

Startup

With power to the unit and the control stop switch S1 closed, 115V power is applied to the control

circuit. If there is no call for cooling the crankcase heaters HTR1 and HTR2 will be energized and

operating. Power will also be supplied to the 24V transformer providing power for the thermostat,

the compressor motor protector, and compressor lockout time delay TD1. The unit will

automatically operate in response to the thermostat provided the compressor lockout time delay TD1

has closed, energizing safety relay R5, and the high pressure control HP1 and motor protector MP1

do not sense failure conditions.

On call for the first stage of cooling relay R3 is energized which will energize the liquid line

solenoid valve SV1. This allows refrigerant to flow through the thermostatic expansion valve and

into the evaporator. As the refrigerant pressure in the evaporator increases, the low pressure control

LP1 closes. Power will now be fed to the compressor contactor M1, starting the first compressor.

Power will also be fed to the condenser fan motor contactors M11 and M12.

On a call for the second stage of cooling TD2 will energize relay R4. R4 will energize M2,

starting the second compressor.. TD2 will time out for 5 minutes with initial power applied.

Pumpdown

As the unit’s thermostat is satisfied, it will de-energize the liquid line solenoid valve SV1 causing

the valve to close. When the compressor has pumped most of the refrigerant out of the evaporator

and into the condenser, the low pressure control LP1 will open, shutting down the compressor and

condenser fan motors. The compressor will now be unable to start for 5 minutes via the compressor

lockout time delay TD1.

If refrigerant leaks into the evaporator, the increase in pressure will cause the low pressure

switch LP1 to close. This will energize the compressor contactor M1 starting the compressor which

will quickly pump the refrigerant out of the evaporator and into the condenser (recycling

pumpdown).

A compressor which recycles pumpdown every 5 minutes indicates a malfunction. Corrective

measures must be taken if the compressor recycles repeatedly within 15-minute intervals.

22 ALP 012D through 019D IM 687

Page 23

System Maintenance

General

On initial startup and periodically during operation, it will be necessary to perform certain routine

service checks. Among these are taking condensing and suction pressures. On units ordered with

gauges, condensing and suction pressures can be read from the vertical support on the side of the

unit adjacent to the compressors.

The gauges are factory installed with a manual shutoff valve on each gauge line. The valves

should be closed at all times except when gauge readings are being taken.

Fan Motor Bearings

The fan motor bearings are of the permanently lubricated type. No lubrication is required.

Electrical Terminals

Electric shock hazard. Turn off all power before continuing with following service.

WARNING

Retighten all power electrical terminals every six months.

Condensers

WARNING

Cleaners may contain potentially harmful chemicals.

Condensers are air-cooled and constructed with 3/8” O.D. internally finned copper tubes bonded in

a staggered pattern into slit aluminum fins. No maintenance is ordinarily required except the

occasional removal of dirt and debris from the outside surface of the fins. Use locally purchased

foaming condenser coil cleaners for periodic cleaning of the coil. Do not damage the fins during

cleaning.

Refrigerant Sightglass

Visually check refrigerant sightglass at least once a month A clear glass of liquid indicates there is

adequate refrigerant charge in the system to ensure proper feed through the expansion valve.

Bubbling refrigerant in the sightglass indicates the system is short of refrigerant charge. Refrigerant

gas flashing in the sightglass could also indicate an excessive pressure drop in the line, possible due

to a clogged filter-drier or a restriction elsewhere in the system.. If the sightglass does not indicate a

dry condition after about 12 hours of operation, the unit should be pumped down and the filterdriers changed.

IM 687 ALP 012D through 019D 23

Page 24

Service

Note: Service on this equipment is to be performed by qualified service personnel. Causes

for repeated tripping of safety controls must be investigated and corrected.

WARNING

Disconnect all power before doing any service inside the unit.

Thermostat Expansion Valve

The expansion valve allows the proper amount of refrigerant to enter the evaporator (regardless of

cooling load) by maintaining a constant superheat. (Superheat is the difference between refrigerant

temperature as it leaves the evaporator and the saturation temperature corresponding to the

evaporator pressure.) Typically, superheat should run in the range of 10°F to 15°F.

Adjust the superheat setting as follows:

1. Remove cap at the bottom of valve to expose adjustment screw.

2. Turn screw clockwise (when viewed from the adjustment screw end) to increase the superheat

setting and counterclockwise to reduce superheat. Allow time for system rebalance after each

superheat adjustment.

The expansion valve, like the solenoid valve, should not normally require replacement, but if it does

the unit must be pumped down by following the steps involved when changing a filter-drier.

If the problem can be traced to the power element only, it can be unscrewed from the valve body

without removing the valve, but only after pumping the unit down.

Filter-Driers

To change the liquid line filter-drier,

1. Close the field supplied manual liquid line shutoff valve.

2. Jump out the low pressure control and allow the unit to pump down to 0-5 PSIG.

3. When the evaporator pressure reaches 0-5 PSIG, shut the unit off at the disconnect.

After the filter-drier has been changed, purge some refrigerant through the line to remove

noncondensables that may have entered during filter replacement. A leak check is recommended

before returning unit to operation.

Liquid Line Solenoid

The liquid line solenoid valve does not normally require any maintenance. The solenoid coil may

require replacement. To remove solenoid coil from valve body (without opening the system):

1. Disconnect power to the unit.

2. Remove the nut or snap ring located at the top of coil.

3. Remove coil from valve body.

24 ALP 012D through 019D IM 687

Page 25

Standard Controls

Note: Perform an operational check on all unit safety controls once per year.

High Pressure Control

The high pressure control is a single pole pressure activated switch that closes on a rise in pressure.

When the switch closes, it de-energizes the compressor circuit preventing unit operation until the

high pressure control is reset. The control is factory set to close at 400 PSIG and reset at 300 PSIG.

The control is attached to a Shrader fitting on the discharge line located in the compressor

compartment.

Although there is an additional pressure relief device in the system set at 450 PSIG , it is

highly recommended that the control stop switch S1 be near at hand in case the high

pressure control should malfunction.

To check the control:

1. Block off the condenser surface --OR-- start the unit with condenser fan motors off.

2. Observe the cutout point of the control on the high side of the system.

3. Reset by opening and closing control stop switch S1.

4. Check pressure relief device for leaks.

CAUTION

Low Pressure Control

The low pressure control is a single pole pressure switch that closes on a pressure rise. It senses

evaporator pressure and is factory set to close at 60 PSI and automatically opens at 35 PSIG. To

check the low pressure control:

1. Make certain unit is running.

2. Remove wire #215 from terminal #28 (De-energizes R-3 relay which in turn will de-energize

the liquid line solenoid.)

3. As the compressor pumps down, condenser pressure will rise and evaporator pressure will drop.

The lowest evaporator pressure reached before cut-out is the cut-out setting of the control.

4. Wait five minutes.

5. Reconnect wire #215 to terminal #28. (Energizes the liquid line solenoid allowing evaporator

pressure to rise.) The highest evaporator pressure reached before compressor restart is the cutin setting of the control.

Compressor Lockout

Compressor lockout consists of a 5-minute time delay TD1. It is wired in series with the R5 safety

relay that energizes after 5 minutes, enabling the compressor to start. Its purpose is to prevent rapid

compressor cycling when cooling demands are erratic.

When the unit thermostat no longer calls for cooling and the compressor contactors have

opened, the lockout time delay breaks open the circuit, preventing compressor restart.

The circuit remains open for a period of 5 minutes. If unit thermostat should call for cooling

before the delay period has expired, the compressor will not restart. After 5 minutes the time delay

will close its contacts to complete the circuit to R5, enabling the compressor to start. When R9 is

IM 687 ALP 012D through 019D 25

Page 26

energized with the compressor, another set of contacts will shunt around TD1, allowing TD1 to reset

open for timing out the next compressor cycle.

To check the time delay,

1. Make certain the compressor is running.

2. Adjust the temperature control to simulate no call for cooling. (Allows the unit to pump down)

3. Immediately after the compressor has stopped running adjust the temperature control to call for

cooling. The compressor should not restart for 5 minutes.

Compressor Motor Protector

The solid-state compressor motor protector module incorporates a 2-minute “time off” relay

utilizing the bleed down capacitor principle. Any time the protection system opens or power to the

module is interrupted, the 2-minute “time off” delay is triggered and the module will not reset for

two minutes. Once the 2-minute period has passed the motor protector contacts M1 and M2 reset,

provided the protection system is satisfied and power is applied to the module.

Note: If the power circuit is broken once the 2-minute period is passed the pilot circuit will

reset without delay when power is reapplied.

Fantrol Head Pressure Control

FanTrol is a method of head pressure control which automatically cycles condenser fan motor M12

in response to condenser pressure. This maintains head pressure and allows the unit to run at low

ambient air temperatures.

All ALP units have FanTrol which is a nonadjustable control set to open at 150 PSIG and close

at 225 PSIG. The control is attached to a Shrader fitting on the discharge line inside the compressor

compartment.

CAUTION

SpeedTrol and FanTrol will provide reasonable operating refrigerant discharge pressures to

the ambient temperatures listed for them PROVIDED THE COIL IS NOT AFFECTED BY

THE EXISTENCE OF WIND. If wind may occur and the unit includes vertical condenser

coils, it is the responsibility of the system designer or installer to make other provisions for

low ambient control. Consideration should be given to deflecting awnings, dampers, or a

floodback receiver system as required to satisfy specific job conditions.

Table 11, Fan Control Minimum Ambient Operation

ALP UNIT SIZE FANTROL (STANDARD FANTROL WITH LOW

012D

015D

019D

60°F 45°F 0°F

55°F 30°F 0°F

45°F 10°F 0°F

AMBIENT

SPEEDTROL

26 ALP 012D through 019D IM 687

Page 27

Optional Controls

Speedtrol Head Pressure Control

The SpeedTrol method of head pressure control operates in conjunction with FanTrol by modulating

the motor speed on fan M11 in response to condenser pressure. By reducing the speed of the last fan

as the condensing pressure falls, the unit can operate at lower ambient temperatures.

The SpeedTrol fan motor is a single phase, 230/460 volt, thermally protected motor specially

designed for variable speed operation. The solid-state speed control SC11 is mounted in the unit

control panel and is connected to a Schrader fitting on the liquid line. The control is factory set to

start modulating fan speed at 230 PSIG, and will maintain a minimum condensing pressure of 170

to 180 PSIG. Minimum starting voltage for SpeedTrol motors is 120 volts.

Low Ambient Start

Low ambient start is available on all units as an option with FanTrol and included automatically

with optional SpeedTrol. It consists of a solid-state, normally closed time delay wired in series with

a relay. These are both wired in parallel to the liquid line solenoid valve. When the solenoid valve

is energized by the unit thermostat the low ambient start relay is also energized through the time

delay. The relay has contacts that essentially short-circuit the low pressure control and allow the

compressor to start with the low pressure control open.

After about 2-3/4 minutes, the time delay will open and de-energize the relay. If the system has

not built up enough evaporator pressure to close the low pressure control, the compressor will stop.

The time delay can be reset to its original normally closed position by de-energizing relay R3 in the

thermostat circuit.

Due to the vertical condenser design, it is recommended that the unit be oriented so prevailing

winds blow parallel to the unit length, minimizing effects on minimum ambient operation. If it is

not practical to orient the unit in this manner, a wind deflector should be constructed.

Figure 10, Low ambient start time delay/relay R13

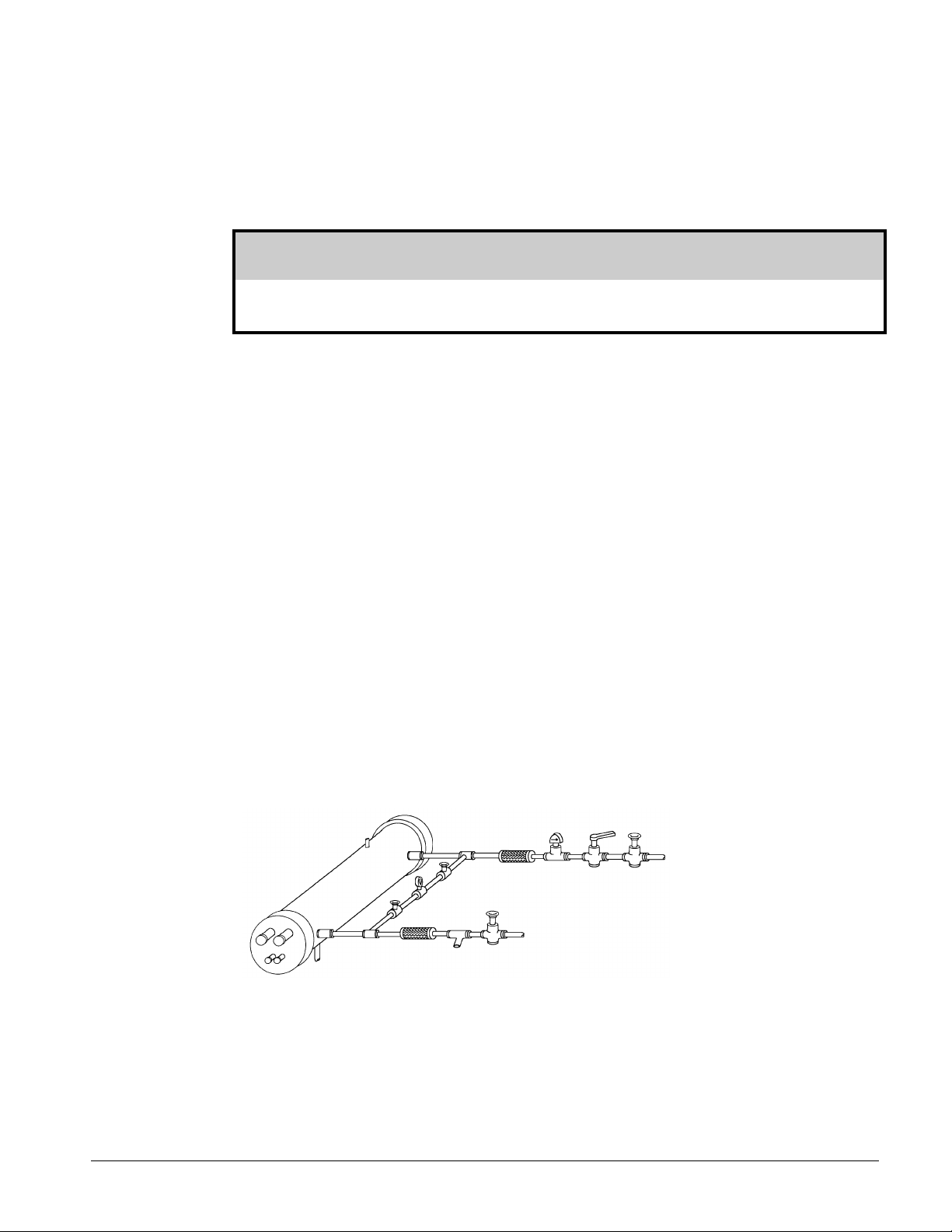

Hot Gas Bypass

Hot gas bypass is a system for maintaining evaporator pressure at or above a minimum value. This

keeps the velocity of the refrigerant as it passes through the evaporator high enough for proper oil

return to the compressor when cooling load conditions are light. It also maintains continuous

operation of the chiller at light load conditions.

Wire the hot gas solenoid (SV5) in parallel with the liquid line solenoid at terminals 14 and 15.

(Solenoid valve will open whenever the liquid line solenoid valve is energized.) The pressure

regulating valve is factory set to begin opening at 58 PSIG (32°F for R-22) when the air charged

bulb is in an 80°F ambient temperature. The bulb can be mounted anywhere as long as it senses a

fairly constant temperature at various load conditions. The compressor suction line is a good

mounting location. It is generally in the 50°F to 60°F range.

IM 687 ALP 012D through 019D 27

Page 28

The chart below indicates that when the bulb is sensing 50°F to 60°F temperatures, the valve will

begin opening around 54 PSIG. This setting can be changed. To raise the pressure setting, remove

the cap on the bulb and turn the adjustment screw clockwise. To lower the setting, turn the screw

counterclockwise. Do not force the adjustment beyond the range it is designed for, as this will

damage the adjustment assembly.

WARNING

The hot gas line may become hot enough to cause injury in a very short time.

Be careful during valve checkout.

The regulating valve opening point can be determined by slowly reducing the system load (or

increasing the required chiller water temperature setting indicated on the unit thermostat), while

observing the suction pressure. When the bypass valve starts to open, the refrigerant line on the

evaporator side of the valve will begin to feel warm to the touch.

When the condensing unit is remote from the evaporator, mount the hot gas bypass valve near

the condensing unit to minimize the amount of refrigerant that will condense in the hot gas line

during periods when hot gas bypass is not required.

Figure 11, Hot Gas Bypass Piping Figure 12, Hot Gas Bypass Adjustment

Table 12, ALP CONTROLS, SETTINGS AND FUNCTIONS

DESCRIPTION FUNCTION SYMBOL SETTING RESET LCATION DIFFERENTIAL

HIGH PRESSURE

CONTROL

LOW PRESSURE

CONTROL

MOTOR

PROTECTOR

FANTROL

CONTROL

SPEEDTROL

CONTROL

LIQUID LINE

SOLENOID

HGBP SOLENOID

VALVE

LOCKOUT TIME

DELAY

LOW AMBIENT

START DELAY

HIGH PRESSURE

SPEED CONTROL

28 ALP 012D through 019D IM 687

Stops compressor at

high discharge

Stops compressor at

low suction

High motor

temperature

Cycles fans by

condensing pressure

Modulates fan speed

by condensing press.

Close liquid line for

pumpdown

Close HGBP for

pumpdown

Prevents

compressor short

cycling

Bypass LP control

for cold starts

HP1 Closes at 400 PSIG

Opens at 300 PSIG

LP1 Closes at 60 PSIG

Opens at 35 PSIG

MP1 500 ohms cold to

20,000 ohms hot

PC12 See Fantrol

description

SC11 Maintains min. of

170 to 180 PSIG

SV1 N/A N/A Field

SV5 N/A N/A Condenser

TD1 Fixed 5 minutes Auto Control box N/A

TD9 2 3/4 minutes Auto Control box N/A

Manual thruS1Discharge

Auto Suction line 25 PSIG fixed

Auto 2700 to

4500 ohms

Auto Discharge

Auto Liquid line N/A

line

Compressor

junction box

line

installed

section

100 PSIG fixed

15,000 ohms

120 PSIG fixed

N/A

N/A

Page 29

Troubleshooting Chart

PROBLEM POSSIBLE CAUSES POSSIBLE CORRECTIVE STEPS

COMPRESSOR

WILL NOT RUN

1. Main switch open

2. Fuse blown, breakers open

3. Thermal overloads tripped

4. Defective contactor or coil

5. System of by safety device

6. No cooling required

7. Liquid line solenoid will not open

8. Motor electrical problem

9. Loose wiring

1. Close switch

2. Check electrical circuits and motor windings for

shorts. Check for overloads and loose connections.

Replace fuse or reset breaker.

3. Check unit when back on line, auto reset

4. Repair or replace

5. Determine cause and correct

6. None, should start on call for cooling

7. Repair or replace coil

8. Check motor for open or short circiut, or burnout

9. Check all wire junction. Tighten all terminals.

COMPRESSOR

NOISY OR

VIBRATING

HIGH DISCHARGE

PRESSURE

LOW DISCHARGE

PRESSURE

HIGH SUCTION

PRESSURE

LOW SUCTION

PRESSURE

MOTOR

OVERLOAD

RELAYS OPEN OR

BLOWN FUSES

COMPRESSOR

THERMAL SWITCH

OPEN

1. Refrigerant flooding compressor

2. Improper line support

3. Worn compressor

1. Noncondensables in system

2. Refrigerant overcharge

3. Discharge valve partially closed

4. Fan not running

5. Dirty condenser coils

6. FanTrol out of adjustment

1. Faulty condenser control

2. Low refrigerant charge

3. Low suction pressure

1. Excessive load

2. Expansion valve overfeeding

1. Lack of refrigerant

2. Evaporator dirty

3. Clogged filter-drier

4. Clogged suction strainer

5. Expansion valve malfunctioning

6. Low condensing temperature

7. Compressor will not load

8. Low evaporator air flow

1. Low voltage during high loads

2. Defective or grounded motor wiring

3. Loose power wiring

4. High condensing temperature

5. Unbalanced voltage

6. High ambient at overload relay

1. Operating beyond design conditions 1. Add facilities so conditions are within allowable

1. Chect expansion valve setting

2. Relocate or add supports

3. Replace

1. Remove with authoriized procedures

2. Remove excess

3. Open valve

4. Check electrical circuit

5. Clean coil

6. Adjust FanTrol settingd

1. Check condenser control operation

2. Check for leaks. Add refrigerant

3. See low suction pressure steps below

1. Reduce load or add capacity

2. Check remote bulb. Regulate superheat

1. Check for leaks. Repair and replace refrigerant.

2. Clean chemically

3. Replace

4. Clean strainers

5. Check and adjust for proper superheat

6. Check discharge pressure control devices

7. See steps below for correcting failure to unload

8. Adjust airflow

1. Check supply voltage

2. Replace compressor

3. Check all connections and tighten

4. See steps for high discharge presure

5. Check voltage. Contact power company

6. Provide ventilation to reduce heat

limits

IM 687 ALP 012D through 019D 29

Page 30

13600 Industrial Park Boulevard, P.O. Box 1551, Minneapolis, MN 55440 USA (612) 553-5330

Loading...

Loading...