Page 1

BULLETIN NO. IM 121

JULY 1968

INSTALLATION AND

MAINTENANCE DATA

MODEL AHP

AIR COOLED CONDENSING UNIT

2, 3, 5,

7% &

10 H.P.

INC.*

13600 INDUSTRIAL PARK BLVD., P.O. BOX 1551, MINNEAPOLIS, MINNESOTA 55440

PHONE: 545-2892 l AREA CODE: 612

Page 2

Page 3

Page 4

INSTALLATION

GENERAL - Commercial equipment of this type is intended for installation by qualified refrigeration mechanics. As a condition of the warranty, the check,

test, and startup procedure must be performed by such

personnel and properly reported on the form provided.

Failure to do so voids the warranty. Arrangement for

service should be made prior to installation,

not included in the warranty or the catalog price. See

warranty terms on Page 11.

INSPECTION

items should be carefully checked against the bill of

lading, to be sure all crates and cartons have been

received. All units should be carefully inspected for

damage when received. Visible or

should be reported immediately to the carrier, and a

claim filed for damage.

should be checked, to be sure it agrees with the power

supply available.

LOCATION

channels for rigging the unit. Be sure to use spreaders to avoid any possible damage to the unit cabinet.

The condensing unit should be located so that all

four sides of the unit have free area for air flow and

access room. Be sure to orient the unit so the air discharge is not

SEASONCON condensing units draw air in through

the coi I and discharge through the expanded metal

grille.

Mounting holes have been provided for securing the

unit. Vibration pads or isolators are recommended for

rooftop installation. The units must be mounted level.

-

When the equipment is received, all

concealed

The electrical nameplate

-

Holes have been provided in the unit

facing

the prevailing winds. All AHP

as it is

damage

SERVICEABILITY

doors are provided on either side of the unit for quick

access to the compressor, fan motor(s), unit piping

and control box. In addition, all other exterior unit

panels are removable, to provide complete access to

all areas.

REFRIGERANT PIPING

should be installed according to standard practice

and should follow latest

tions.

prevent wear and vibration. Suction and liquid line

sizing tables on Page 5 show recommended line sizing

for R-12 and R-502.

vent foreign material from entering the compressor. A

Schroeder tap on the filter inlet allows a check on

filter pressure drop.In addition, a liquid line

drier, moisture indicating sight glass, and solenoid

valve must be installed, by others, for safe operation.

SOLENOID VALVE MUST BE INSTALLED. AHP

SEASONCON air cooled condensing units are designed

to operate with a liquid pumpdown cycle.

necting refrigerant lines during the brazing operation,

to prevent oxidation of the piping interior. Soft soldered joints are not acceptable.

FILTER-DRIERS, LIQUID LINE SOLENOID VALVE,

All lines should be checked and secured, to

A suction line filter is provided as standard, to pre-

It is especially important to note that A LIQUID

It is urged that dry nitrogen be run through the con-

-

Large, easily removed access

-

The refrigerant piping

ASHRAE

Guide recommenda-

filter-

AND MOISTURE INDICATING SIGHT GLASSES - No

fi Iter-drier,

dicating sight glass is furnished with the condensing

unit; however, they must be installed in the liquid

line of every unit.

liquid line solenoid valve, or moisture in-

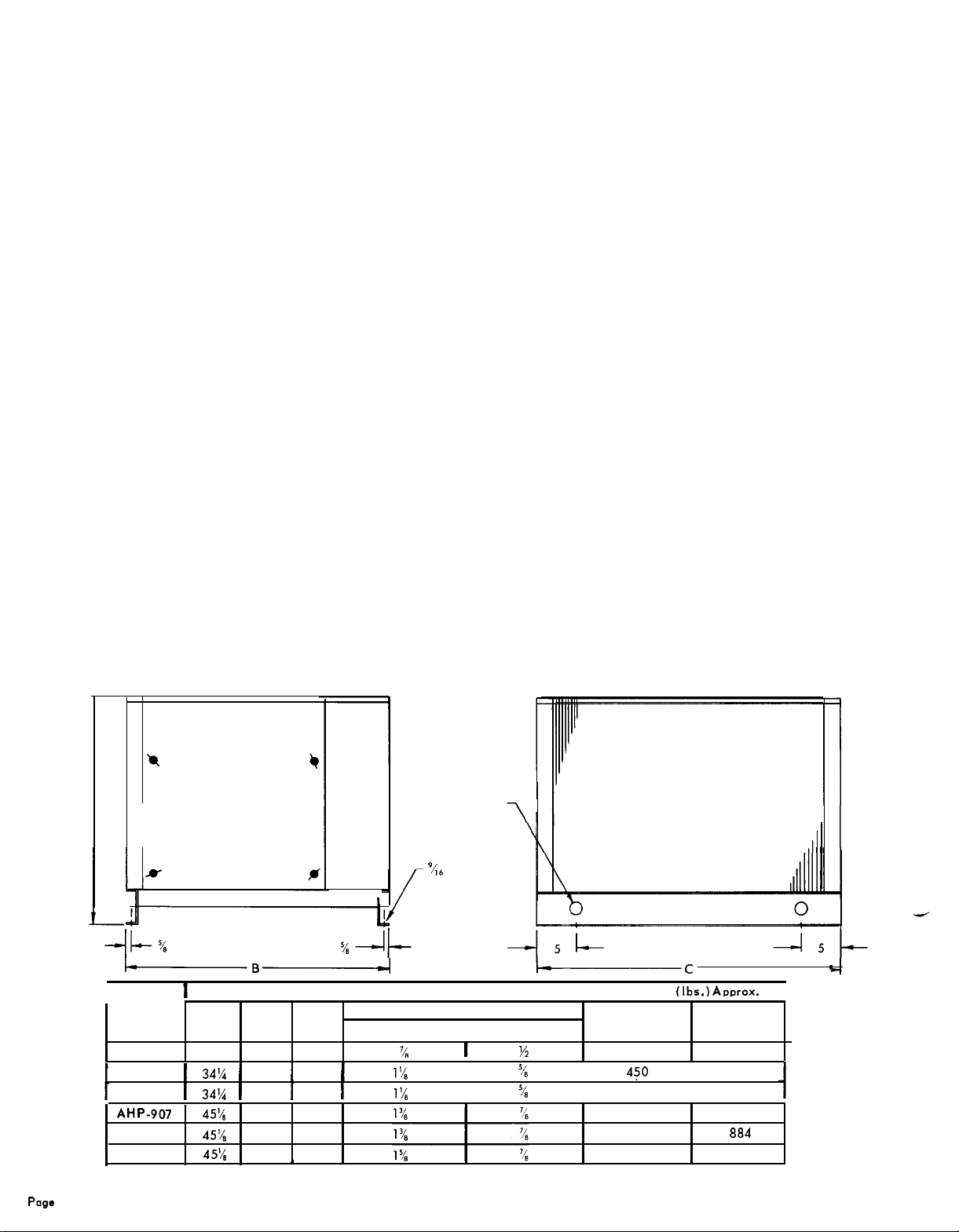

FIGURE 1

*

CONTROL AND

PIPING ACCESS

+

r

-B-

I I

MODEL

NUMBER

AHP-902

AHP-903

AHP-905

AHP-907

AH P-908

AHP-910

28%

1

34%

1

34%

45’4

45’4

45%

A

B C

32% 38

1 391

1

39

45

46% 63

46%, 63

DIMENSIONS (Inches)

SUCTION (ODM)

1

40

40

41

1

1

DIMENSION DIAGRAM

LIFTING

HOLES (4)

‘46

DIA. MTG.

HOLES (4)

CONNECTIONS

LIQUID (ODF)

‘/,

1’4

1%

I

I ‘4 I

‘/2

‘/8

I

iC

WEIGHTS

OPERATING

310

4$0

568

673

a33

940

(Ibs.) Ammx.

SHIPPING

350

494

I

612

720

884

991

I

Page

4

Page 5

Page 6

ELECTRICAL

CONTROL PANEL

The AHP SEASONCON air

cooled condensing unit control panel is fabricated of

heavy gauge steel for ruggedness and is located behind a unit access panel for safety and weather protection. Controls are reached easily by opening the

hinged control box door.

FIELD WIRING

Wiring of the systems should be

done in accordance with all applicable codes and

ordinances.

Main power leads must be connected to the condensing unit circuit breaker. Table 3 gives the recommended lead wire sizes for not more than three conductors

in a rocewoy.

Maximum supply voltage variation is

+

10% of the

nameplate value. Phase voltage unbalance must not

exceed 2%.

The condensing unit must be wired to operate on a

pumpdown cycle. Consequently, it is necessary to

install a liquid line solenoid valve in the system to

operote on signal from a room thermostot. In addition,

interlocking of the evaporator fan motor is essential

so the condensing unit wi II not run unless the evapo-

rator fan motor is running.

This can be accomplished

by wiring evaporator fan motor relay auxiliary con-

TABLE 3

ELECTRICAL DATA

tacts in series with the compressor contactor holding

coi I. A typical AHP condensing unit schematic wiring

diagram is shown in Diagram 1.

CIRCUIT BREAKER

The circuit breaker for the

compressor and condenser fan motor is located in the

control box. Some electrical

codes

also require a

fused disconnect switch (furnished by others) in the

unit supply circuit, located within easy reach or within sight of the unit.

CRANKCASE HEATERS

-

The compressors are

equipped with crankcase heaters installed under the

crankcase to retard refrigerant from migrating to the

crankcase and condensing in the oil.

When a system is started up initially in cold weather, the power to the heaters should be turned on for

at least 8 hours before the compressor is started, to

minimize liquid slugging. When shutting down the

system for on extended period, care should be taken

that ower to the heater is left on. This may be

camp rshed

P.

by opening the unit circuit breaker since

ac-

the heater is connected to the line side of the circuit

breaker.

907A-H1208-240/60/3

907A.M

._.

907A-L

908A.L

910A-H

910A-L

NOTES:

1

20%240/60/3

--

208.240/60/3

208.240/60/3

208-240/60/3

208.240/60/3

(A)

Allowable Voltage Tolerances

Nomeplote

(B) Wire sizing

See Notional Electric Code.

(C) Recommended power lead wires

ing to the National Electric Code. Voltage drop has not been included; therefore, it is recommended that leads be as

short as possible. For applications above

208-240:

amps

equal 125% of the FLA for the largest motor plus 100% of the FLA for

1

27.0 135.0 4.0

1Rl

7

1

_ ..-

14S.O

._._

31.2 145.0 10.0 43

1

(24.i.O

31.2 145.0

46.4

46.4 215.0

Min. 187V; Max. 264V.

215.0

(2) 4.0

(2) 4.0

based

on not more than 3 conductors in a rocewoy at 86F ambient air. Wire accord-

86F,

consult N.E.C.

4.0

.._

1

10.0 38

1

10.0

(2) 10.0

(2) 10.0

(2) 10.0

I

43

47

66

66

RECOMMENDED POWER

LEAD WIRE SIZE

8

I

6

I

6

6 6

4

4 4

all

other motors in the unit.

8

8

8

4

-

Page 6

Page 7

DIAGRAM 1

Hl

TYPICAL SCHEMATIC WIRING DIAGRAM

CBl

COMPRESSOR

y-1

COMPONENT LEGEND

Hl

-CRANKCASE HEATER

CBl

-CIRCUIT BREAKER

Ml - CONTACTOR

-

FAN MOTOR

:: -

CAPACITOR

OPl -OIL

PC1 - PRESSURE SWITCH

FAILURE SWITCH

PC1

PREPARATION AND START UP

EVACUATING AND CHARGING

unit as shipped from the factory has been checked

under normal operating conditions and given a holding

charge of the refrigerant indicated on the unit serial

plate.

Care should be taken to prevent dirt and moisture

from entering the system during installation. To this

end, always cap or seal open refrigerant lines,use

clean, dry tubing or pipe, and use good refrigeration

practices.

To assure a dry, clean system, a triple evacuation

procedure should follow the system leak check. Break

the initial and second vacuum with dry refrigerant and

then evacuate to at least 500 microns before charging

the system. Table 4 on Page 8 shows the condensing

unit charge required for various minimum design ambient temperatures. This table shows the condensing

unit charge only. The liquid and suction line charge

and the evaporator charge must be added to determine

the total charge.

LOW PRESSURE CONTROL SETTING

-

The

condensing

-

Because the

CONDENSER

FAN MOTOR

system is designed to operate with a pumpdown cycle,

the operation of the compressor is dependent on the

low pressure switch. It is important, therefore, that

the low pressure switch be set properly for the lowest

ambient in which the condensing unit is to be operated.

Table 5 on Page 8 shows the correct cut-in settings

for various ambient temperatures. The cut-out setting

should be set low enough to avoid short cycling. Compressor operation should be observed to be sure the

settings are correct for the particular applications.

OIL CHARGE

erant charge required in an air cooled condensing unit

system, it is usually necessary to put additional oil

into the system. The oi I level should be watched care-

fully upon initial startup and for some time thereafter.

At the present time, Suniso #3G oil is the only oil

approved by

The oil level should be maintained at a level about

midpoint of the glass bullseye on the compressor body

during operation.

-

Because of the rather large refrig-

Copeland

for use in these compressors,

Page 7

Page 8

Page 9

START UP AFTER EXTENDED SHUTDOWN

A. Inspect all eqwipment.

B. Check face of condenser coil for paper or other

obstruction that might be lodged on the surface.

C. Open the suction and discharge service valves.

D. Turn on the electrical power to the system.

E. Open the liquid line shut-off valve or valves.

-

SEASONTROL head pressure control

F. Start the evaporator fan motors.

G. Check crankcase heater & crankcase warmth.

H. Start the unit by closing the circuit breaker.

ten for unusual sounds indicating liquid slugging.

I. After the unit has run for several minutes, check

the oil level in the crankcase, and observe flow

through the refrigerant sight glass for sufficient

refrigerant charge.

Lis-

SEASONTROL head pressure control is a factory in-

stalled system based on liquid refrigerant flooding

back into the condenser coil, thereby reducing the

effective condenser surface available for condensing.

The SEASONTROL head pressure control system is

an improved method of head pressure control incorporating two modulating valves.

The main, or liquid line, valve 239 series is normally closed, and opens on pressure rise in the condenser. This valve is located in the liquid line between the condenser and receiver. The gas, or bypass,

valve (237 series) is normally

pressure rise in the receiver. This valve is located

between the compressor discharge line and the receiver. See Figure 2.

The head pressure control system operates as fol-

lows: On system startup, the bypass valve is normally

open and the main or liquid line is closed. Hot gas

moves from the compressor, with part going into the

condenser, and part going through the bypass circuit

FIGURE 2

open and

closes on

SEASONTROL III head pressure control

SYSTEM PIPING DIAGRAM

through the open valve and into the receiver. The by-

pass gas goes directly into the receiver to maintain

or build up pressure in the receiver. As the compressor continues to run, hot gas condenses in the con-

denser and raises the liquid level since the liquid

valve on the leaving side of the condenser is still

closed. As the liquid level in the condenser rises, the

condensing capacity of the condenser decreases and,

as a result, the head pressure rises. As the pressure

in the condenser rises to the control point of the

valve, the liquid valve starts modulating towards the

open position, permitting liquid to leave the condenser and flow into the receiver. At the same time, the

bypass valve starts modulating towards the closed

position, limiting the hot gas flow into the receiver.

The modulation of the two valves maintains the proper

liquid level in the condenser, to maintain proper head

pressure.

liquid from the condenser to near saturation tempera-

ture.

The bypass gas also warms up the cold

COMPRESSOR

DISCHARGE

TYPE 237

HOT GAS VALVE

CHECK VALVE-

I

r.

I

/

RECEIVER

,Y

TYPE 239

LIQUID VALVE

/

L

;

TO SUBCOOLER

LIQUID SHUTOFF

LIQUID TOEXPANSIONVALVE

Page 9

Page 10

VALVE CHECKING AND SETTING

TROL head pressure control valves are factory set

and checked to maintain a minimum head pressure

equivalent to 95 F condensing for R-12 ond 85 F

condensing for R-502. The valves have a nominal 15

PSIG

modulating range between fully open and fully

closed positions. Factory settings ore 110

R-12 valves and 175

Referring to Figure 3, it is to be noted that on pressure increase on the system,

compress the bellows and the valve stroke will be up

or toward the adjustment end of the valve. This applies to both the liquid and gas valves. The valve

travel is nominal 1/10" for all models.

As indicated in the diagrams, the adjustment of the

nut in a clockwise direction will increase the modu-

lating pressure point. A wide bladed screwdriver or

similar instrument inserted into the nut slot moy be

used for making the adiustment.

The modulating pressure point and range may be

checked as follows:

A. Make up a “depth gouge” for inserting through

the adjusting nut opening and long enough to hit

the bottom of the bellows section, as indicated in

Figure 3. A piece of insuloted wire, 8 to 12 gouge,

PSIG

for R-502 valves. the top of the valve.

the

-

The

SEASON-

PSIG

for

pressure wi II tend to

is a simple and convenient material from which to

make a gauge.

valve,

OS shown in the diagram. Trim off the

lotion, for about one inch off the end to be inserted, and at a point just above the top of the valve

at the other end. When in use, hold the gauge

down lightly against the bellows and sight olong

B.

A high side gauge should be connected to a line

so it can be brought to the valve area, unless a

second person is available to call out head pres-

sure readings while valve observations ore made.

Start up the unit and note pressures at which the

C.

valve bellows rise. We assume that the pressure

was low enough at startup so that the bellows is

in the down position. The test may also be done

in reverse by running the system up to o high

ressure,

head p

servations at what pressure the valve changes

position.

The valves should be set so that the movement of

D.

both

valves

Be sure system hos sufficient refrigeront before

E.

making any change in valve adiustment.

FIGURE 3 SEASONTROL head pressure control

TYPE 239 LIQUID VALVE

8A. SECTIONAL VIEW

Insert a piece of the wire into the

insu-

stopping the unit, and making ob-

is through the some pressure range.

8B.

CONTROL SETTING

COVER

ADJUSTING NUT

CONTROL SPRING

VALVE SEAT

r l/10”

TRAVEL

FEELER GAUGE INSERTE

Page 10

LIQUID

OUTLET

Page 11

SERVICE AND WARRANTY PROCEDURE

MOTOR-COMPRESSOR

poration has stocking

stock of replacement motor-compressors and service

parts to serve refrigeration contractors and servicemen

as required.

When a motor-compressor fails in warranty, the in-

operative motor-compressor can be taken to any author-

ized

Copeland

exchange, or an advance replacement can be obtained.

Credit is issued on the returned motor-compressor

upon receipt and factory inspection of the inoperative

motor-eompressor. In this transaction, be certain that

the motor-compressor is received from the field that

tests satisfactory, a service charge plus a transportation charge will be charged against its original credit

value.

On all out-of-warranty motor-compressor failures,

Copeland

and/or replacement as described above. The credit

issued on the returned motor-compressor will be deter-

mined by the repair charge established far that partic-

ular unit.

Wholesaler for an

offers the same field facilities for service

-

Copeland

wholesalers

Refrigeration Cor-

who maintain a

over-the-counter

IN-WARRANTY RETURN MATERIAL PROCEDURE

(Other Than Compressors) Material may not be re-

turned except by permission of authorized factory

service personnel of McQUAY, Inc. at Minneapolis,

Minnesota. A “Return Goods” tag will be sent to be

included with the returned material. Enter the information as called for on the tag, in order to expedite

handling at our factories and prompt issuance of

credits.

The return of the part does not constitute an order

for replacement. Therefore, a purchase order must be

entered through your nearest McQUAY representative

or directly with McQUAY, Inc. at Minneapolis, Minne-

sota. The order should include part name, part number,

model number and serial number of the unit involved.

Following our personal inspection of the returned

part, and if it is determined that the failure is due to

faulty material or workmanship, and is in warranty,

credit will be issued on customer’s purchase order.

All parts shall be returned to the pre-designated

McQUAY factory, transportation charges prepaid.

REPLACEMENT PARTS

Replacement service parts can be ordered through your unit involved. Replacement parts for the motornearest

QUAY, Inc. at Minneapolis, Minnesota. Always pro-

vide complete description of service part, part number

(if known), plus complete serial and model number of

McQuay

representative or directly with Mc- compressor assembly can be procured direct from your

nearest franchised

Wholesaler.

Copeland

Refrigeration Corporation

-

Page 11

Loading...

Loading...