Page 1

Installation Manual IM 747

MicroTech II™ Unit Ventilator Controls

for AAF®-HermanNelson® Classroom Unit Ventilators

Group: Unit Ventilator

Part Number: 106506201

Date: July 2002

Supercedes: New

Used with AAF-HermanNelson Models: Vertical Floor - AVS, AVV, AVB, and AVR

Self-Contained Vertical Floor - AZS, AZQ, AZU, AZV, AZR, AED, AEQ, ARQ, ERQ

This manual is to be used by the installer as a guide. Each installation is unique, only general topics are covered.

©2002 McQuay Incorporated

Horizontal Ceiling - AHF, AHV, AHB, and AHR

IMPORTANT

Before beginning installation, please read this publication in its entirety.

Develop a thorough understanding before starting the installation procedure.

The order in which topics are covered may not be those required for the actual installation.

Page 2

Table of Contents

Safety Information........................................................ 3

Warnings and Cautions ................................................ 3

Introduction .................................................................. 4

General Description................................................... 4-5

Component Data ........................................................... 5

Unit Ventilator Controller (UVC)............................. 5

Expansion Board (EXP) ............................................ 6

Local User Interface (LUI) ....................................... 6

Plug-in LonMark Space Comfort Controller (SCC)

Communication Module (optional)........................... 6

Plug-in BACnet MS/TP

Communication Module (optional)........................ 6-7

Plug-in Metasys N2 Open Communication Module ..

Face & Bypass Damper Actuator (optional)............. 9

Modulating Valve Actuator (optional) ................... 10

2-position End-of-Cycle (EOC) Valves (optional) . 10

2-position Motorized Water Valves (optional) ....... 10

Time Clock (option) ........................................... 11-13

Make Electrical Wiring Connections ......................... 14

Field Wiring Harness Locations................................. 14

Field Wiring Remote Mounted Temperature Sensor . 15

Remote Wall Mounted Temperature Sensors ............ 15

Locating Wall Sensors ............................................... 16

Installing Wall Sensors.......................................... 17-19

External Input Option Wiring .................................... 19

External Output Option Wiring ............................. 19-20

(optional) ................................................................... 7

Temperature Sensor .................................................. 7

Humidity Sensor (optional)....................................... 8

Carbon Dioxide (CO2) Sensor (optional) ................. 8

Outdoor Air Damper (OAD) Actuator...................... 9

Split-System Condensing Unit Signal Wiring ........... 21

Communication Module Wiring ................................ 21

UVC Input and Output Tables ..............................22-27

UVC Configuration Parameters ............................ 28-30

Page 2 of 32 IM 747

Page 3

Safety Information

NOTICE

WARNING

!

CAUTION

!

WARNING

!

Follow all safety codes. Wear safety glasses and work

gloves. Have a fire extinguisher available. Follow all

warnings and cautions in these instructions and attached

to the unit. Consult applicable local building codes and

National Electrical Codes (NEC) for special requirements.

Electric shock hazard. Can cause personal injury, or death, or

equipment damage. This equipment must be properly grounded.

Connections and service to the MicroTech II control panel must be

performed only by personnel that are knowledgeable in the

operation of the equipment being controlled.

Recognize safety information. When you see a safety

symbol on the unit or in these instructions, be alert to the

potential for personal injury or death. Understand the

meanings of the words DANGER, WARNING, and

CAUTION. DANGER identifies the most serious hazards

that will result in death or severe personal injury; WARNING

means the hazards can result in death or severe personal

injury; CAUTION identifies unsafe practices that can

result in personal injury or product and property damage.

Improper installation, adjustment, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may result in personal injury or property

damage. This product must be installed only by personnel

with the training, experience, skills, and applicable licensing

that makes him/her “a qualified professional HVACR

installer.”

! DANGER

DISCONNECT ALL ELECTRICAL

POWER BEFORE SERVICING UNIT

TO PREVENT INJURY OR DEATH

DUE TO ELECTRICAL SHOCK.

If the unit ventilator is to be used for temporary heating or cooling,

the unit must first be properly commissioned. Failure to comply

with this requirement will void the warranty.

Static sensitive components. A static discharge while handling

electronic circuit boards can cause damage to the components.

Discharge any static electrical charge by touching the bare metal

inside the main control panel before performing any service work.

Never unplug any cables, circuit board terminal blocks, relay

modules, or power plugs while power is applied to the panel.

CAUTION

!

For proper space control, and a more trouble free unit operation,

it is important that End-of-Cycle (EOC) valves be used in all face

& bypass damper equipped unit ventilators. An EOC valve is

required for the wet heat coil in any unit ventilator that

combines both a refrigerant coil and a wet heat coil. Use an

EOC valve on all wet heat coils to minimize the potential for

overheating.

CAUTION

!

For proper space control, and a more trouble free unit operation,

it is important that an occupancy control means be used such that

the unit is placed into unoccupied mode during regular low load

conditions such as nighttime, weekends and holidays.

CAUTION

!

HAZARDOUS VOLTAGE!

DISCONNECT ALL ELECTRIC POWER INCLUDING REMOTE DISCONNECTS BEFORE

SERVICING. FAILURE TO DISCONNECT

POWER BEFORE SERVICING CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

USE COPPER CONDUCTORS ONLY.

UNIT TERMINALS ARE NOT DESIGNED TO

ACCEPT OTHER TYPES OF CONDUCTORS.

FAILURE TO DO SO MAY CAUSE DAMAGE

TO THE EQUIPMENT.

IM 747 Page 3 of 32

WARNING

!

CAUTION

CUS

Extreme temperature hazard. Can cause damage to system

components.

This MicroTech II controller is designed to operate in ambient

temperatures from -40°F to 158°F. It can be stored in ambient

temperatures from -65°F to 176°F. The controller is designed to

operate in a 10% to 90% RH (non-condensing) and be stored in a

5% to 95% RH (non-condensing) environment.

This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with this

instruction manual, may cause interference to radio

communications. It has been tested and found to comply with the

limits for a Class A digital device, pursuant to part 15 of the FCC

rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is

operated in a normal commercial environment. Operation of this

equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference

at his own expense.

McQuay International disclaims any liability resulting from

any interference or for the correction thereof.

!

Page 4

Introduction

This manual contains information regarding

the MicroTech II™ Direct Digital Control

(DDC) system used in the

®

-HermanNelson® Unit Ventilator

AAF

product line. It describes the MicroTech II

Table 1. Model-Specific Unit Ventilator Installation Literature

Unit Ventilator

Model Designations

AED, AEQ Air Source Heat Pump IM 502

ARQ, ERQ Water Source Heat Pump IM UV-3-202

AZS, AZQ, AZV, AZU, AZR Self-contained Air Conditioner IM 503

AVS, AVV, AVR, AVB Vertical Floor Buildup and Split-system

AHF, AHV, AHR, AHB Horizontal Ceiling Buildup and Split-system

components, input/output configurations, field

wiring options and requirements.

For installation and commissioning

instructions and general information on a

particular unit ventilator model, refer to the

Description Data Bulletin

appropriate model-specific installation and

maintenance bulletin, see Table 1.

Installation & Maintenance

Number

IM 725

For a description of unit operation and information on using the Local User Interface (LUI) to view data and set control parameters, refer to the

appropriate software model-specific operation manual, see Table 2.

Table 2. Software Model-Specific Operation and Maintenance Literature

Type UV Description Software Model UV Model OM Bulletin

2 Pipe Damper Control, Chilled Water/Hot Water 12 AVS, AHF OM 755

2 PIPE

4 PIPE

2CLG

DX Direct Expansion Only 5 AVV, AHV, AZV, AZU OM 751

DX/WET

ASHP Air Source Heat Pump 0 AEQ, AED OM 748

WSHP

2 Pipe Damper Control w/Wet Heat Only 10 AVS, AHF OM 754

2 Pipe Valve Control, Chilled Water/Hot Water 11 AVV, AHV OM 755

2 Pipe Valve Control w/Wet Heat Only 9 AVV, AHV OM 754

4 Pipe Damper Control, Chilled Water & Wet Heat 14 AVS, AHF

4 Pipe Valve Control, Chilled Water & Wet Heat 13 AVV, AHV, AVR, AHR

2 Pipe Damper Control, Chilled Water Only 16 AVS, AHF OM 757

2 Pipe Damper Control, Chilled Water & Electric Heat 18 AVS, AHF OM 758

2 Pipe Valve Control, Chilled Water Only 15 AVV, AHV OM 757

2 Pipe Valve Control, Chilled Water & Electric Heat 17 AVV, AHV OM 758

Direct Expansion & Electric Heat 4 AZV, AZU, AZR, AVV, AHV, AVR, AHR OM 750

Electric Heat Only 6 AVV, AHV OM 752

Damper Control, Direct Expansion and Wet Heat 8 AZS, AZQ, AVS, AHF

Valve Control, Direct Expansion and Wet Heat 7 AZV, AZU, AZR, AVV, AHV.

Water Source Heat Pump 2 ARQ, ERQ

Water Source Heat Pump with Electric Heat 3 ARQ, ERQ

OM 756

OM 753

OM 749

For installation and maintenance instructions on a particular plug-in communications module, refer to the appropriate protocol-specific installation

and maintenance bulletin, see Table 3. For network wiring or master/slave units, follow the network wiring instructions provided in IM 729.

Table 3. Protocol-Specific Communication Card Installation Literature

Unit Ventilator Available Protocols Operation Manual Bulletin Number

Unit Ventilator Unit Controller LonWorks® Communications Module IM 729

Unit Ventilator Unit Controller BACnet® Communications Module IM 731

Unit Ventilator Unit Controller JCI N2Open® Communications Module IM 730

Protocol Data Packet ED 15065

General Description

The AAF-HermanNelson unit ventilator

comes equipped with a Direct Digital Control

(DDC) system that controls the unit in response

to various inputs e.g. temperatures, etc., in

either a stand-alone or network controlled by

a compatible Building Automation System

(BAS) with communications capability in

one of several industry standardized protocols.

The unit can operate in several modes;

occupied, unoccuped, stand-by, and bypass

Page 4 of 32 IM 747

(tenant override). The MicroTech II controls

are made up of the following standard

components.

The MicroTech II Unit Ventilator Controller

(UVC) is a DDC microprocessor-based

controller designed to provide sophisticated

comfort control of an economizer-equipped

AAF-HermanNelson unit ventilator. In

addition to providing normal operating

control, the MicroTech II UVC provides alarm

monitoring and alarm-specific component

shutdown if critical system conditions occur.

Each UVC is factory wired, factory

programmed and factory run tested for the

specific unit ventilator model and

configuration ordered by the customer.

The operator can view actual temperatures,

set the most common operating parameters,

view alarms, etc., through use of the Local

User Interface (LUI). The LUI provides a

Page 5

user adjustable security feature to protect

against unauthorized or accidental control

parameter changes. When networked with a

BAS, additional parameters can be remotely

read / set in addition to all those available on

the LUI.

This MicroTech II™ UVC is capable of

complete, stand-alone unit control or it can be

incorporated into a building-wide network

using an optional plug-in communication

module. Available communication modules

include BACnet

®

MS/TP, LonMark Space

Comfort Controller (SCC), and Metasys® N2

Open.

Optional MicroTech II UV ServiceTool

software can be used along with a PC to adjust

operating parameters within the UVC. The

UV ServiceTool software, while optional, is

very useful for trouble-shooting and

commissioning by allowing access to all user

adjustable parameters within the UVC

controller including many parameters not

available through the LUI. The UV

ServiceTool requires one of the optional plugin communication modules as well as

additional hardware components dependent

upon which communications module is being

used.

Basic Component Data

The main components of the unit ventilator

MicroTech II DDC system include the Unit

Ventilator Controller (UVC), an expansion

board (EXP), the local user interface (LUI),

and optional plug-in communication modules.

Following are brief descriptions of these

components.

Unit Ventilator Controller

(UVC)

The UVC contains a 16-bit microprocessor

that is preprogrammed with the application

code required to operate the unit (see figure

1). The UVC supports up to 6 analog inputs,

12 binary inputs, and 9 binary outputs, (see

table 4). Optional network communications

is provided via plug in communication cards

that connect directly to the UVC. The UVC

supports additional I/O points via an I

communications bus used to add the EXP

board. The LUI connects directly to the UVC

and is limited to unit mounted applications.

2

Figure 1. MicroTech II Unit Ventilator Confroller (UVC)

Table 4. MicroTech II Unit Ventilator Confroller (UVC) Specifications

Power Supply 24 VAC +/-20% 50/60 Hz

Transformer Sizing 16 VA (Class 2)

Operating Temperature -4OF(-20OC) to 158OF(70OC)

Storage Temperature -40OF(-40OC) to 185OF(85OC)

Humidity 10%RH to 90%RH (non-condensing)

- CSA C22.2 NO. 205 – Signal Equipment

- CFR47 Part 15, Class A

- UL 873

- CE Directive 89/336/EEC

Agency Compliance Emissions: EN50081-1, EN61000-3-2, EN61000-3-3

Immunity: EN50082-1 and EN50082-2 (the most stringent

requirements of either, as applicable)

- C-Tick Directive

- Low Voltage Directive 73/23/EEC EN 60730

- AI-1,2,3,4,5,6

Analog Inputs

Binary Inputs - BI-3,4,5,6

C

Binary Outputs - BO-3,4,5,6,9

Positive Temperature Coefficient (PTC) Thermistor,

Reference Resistance = 1035 ohms @ 77OF(25OC)

- A/D Resolution: 10-bit (software enhanced to 12-bit)

- BI-1,2

Supports dry contact closure using on board 9 VDC. On board

jumpers are used to disable the BO-1 and BO-2 interlocks with BI-1

and BI-2.

Supports dry contact closure using on board 9 VDC

- BI-7,8,9,10,11,12

Supports dry contact closure using 24 VAC

(Note: all binary inputs can be daisy-chained from controller to controller

providing that polarity is respected)

- BO-1,2

120 VAC, 1 HP, 16 FLA, 96 LRA, 750 VA Pilot Duty

240 VAC, 2 HP, 12 FLA, 72 LRA, 1150 VA Pilot Duty

277 VAC, 3 HP, 14.1 FLA, 84.7 LRA, 1550 VA Pilot Duty

BO-1: 277 VAC, 16 A Resistive

BO-2: 277 VAC, 25 A Resistive

120 VAC, 1/10 HP, 3 FLA, 18 LRA, 100 VA Pilot Duty

240 VAC, 1/4 HP, 2.9 FLA, 17.4 LRA, 250 VA Pilot Duty

277 VAC, 1/3 HP, 2.98 FLA, 17.88 LRA, 300 VA Pilot Duty

277 VAC, 16 A Resistive

- BO-7,8

Triac, 24 VAC, Class 2, 5 VA Maximum

IM 747 Page 5 of 32

Page 6

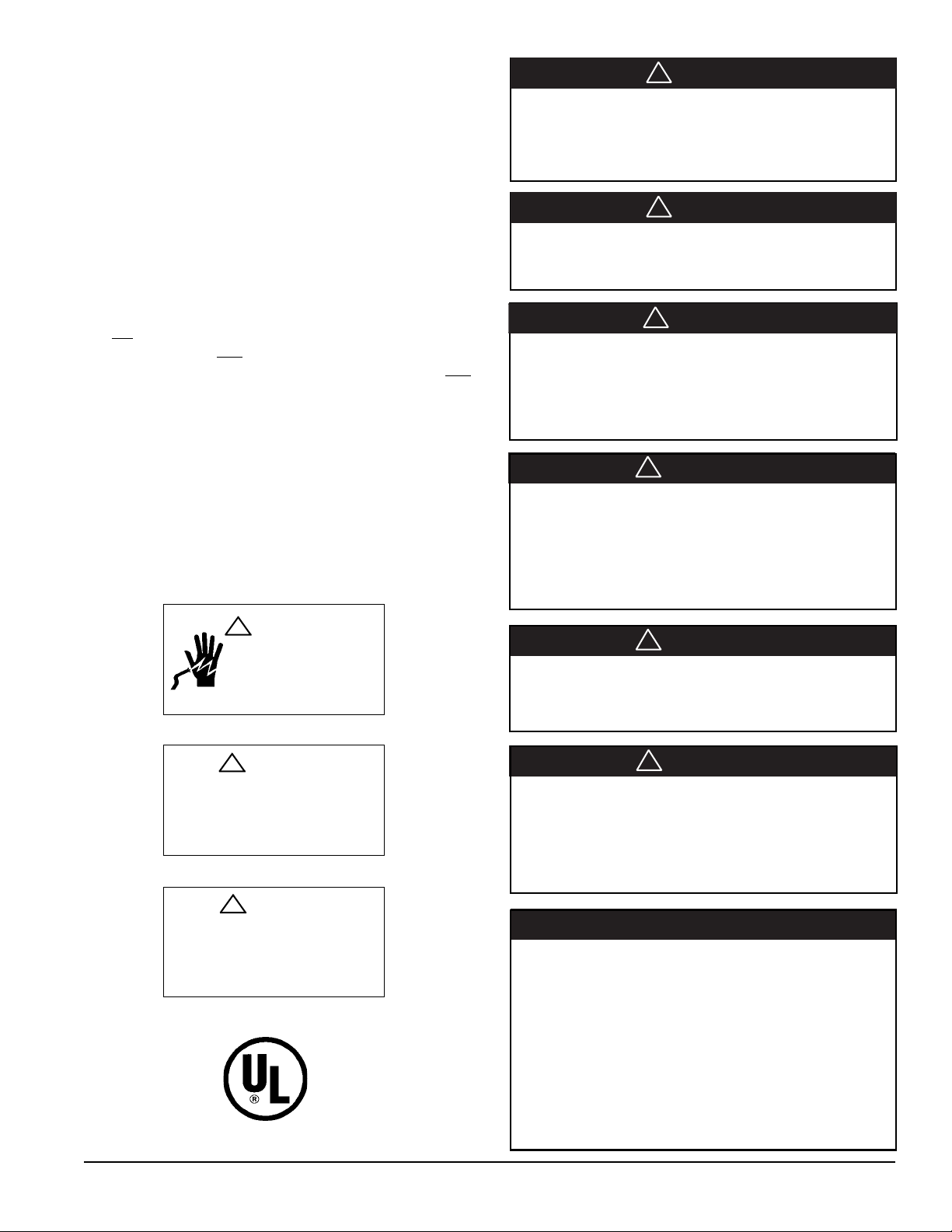

Expansion Board (EXP)

The EXP board provides additional I/O points required by the UVC for unit ventilator operation

(see figure 2). The EXP is operated and monitored by the UVC through the use of an I2C bus.

The EXP I/O board supports up to 4 analog inputs and 8 binary outputs

(see table 5).

Figure 2. Expansion Board (EXP)

Plug-in LonMark Space

Comfort Controller (SCC)

Communication Module

(optional)

The LonMark SCC communication module

is designed to be an add-on module to the

UVC for networking to Building Automation

Systems using LonWorks

communications. It supports the LonMark

Space Comfort Controller (SCC) profile

number 8500. It is an optional plug-in module

that can be attached to the UVC via a 12-pin

header and 4 locking standoffs to securely

attach it to the UVC.

®

network

Table 5. Expansion Board (EXP) Specifications

Operating Temperature

Storage Temperature

Humidity

Agency Compliance

Analog Inputs 0 to 10 VDC

Binary Outputs Triac, 24 VAC, Class 2, 5 VA Maximum

Same as UVC

- xAI-1,2

Ratiometric 0.5 to 4.5 VDC

- xAI-3

- xAI-4

Positive Temperature Coefficient (PTC) Thermistor,

Reference Resistance = 1035 ohms @ 77OF(25OC)

- A/D Resolution: 10-bit (software enhanced to 12-bit)

- xBO-1,2

120 VAC, 1/10 HP, 3 FLA, 18 LRA, 100 VA Pilot Duty

240 VAC, 1/4 HP, 2.9 FLA, 17.4 LRA, 250 VA Pilot Duty

277 VAC, 1/3 HP, 2.98 FLA, 17.88 LRA, 300 VA Pilot Duty

277 VAC, 16 A Resistive

- xBO-3,4,5,6

- xBO-7,8

120 VAC, 1 HP, 16 FLA, 96 LRA, 750 VA Pilot Duty

240 VAC, 2 HP, 12 FLA, 72 LRA, 1150 VA Pilot Duty

277 VAC, 3 HP, 14.1 FLA, 84.7 LRA, 1550 VA Pilot Duty

xBO-1: 277 VAC, 16 A Resistive

xBO-2: 277 VAC, 25 A Resistive

Figure 4. Lonworks SCC Communication

Module - (4" x 2") PN-107293127

Figure 5. Communication Module Location Behind Right Front Access Panel on AH Unit

Types, or Below the Top Right Access Door

on AV, AZ, AE, and AR Unit Types

®

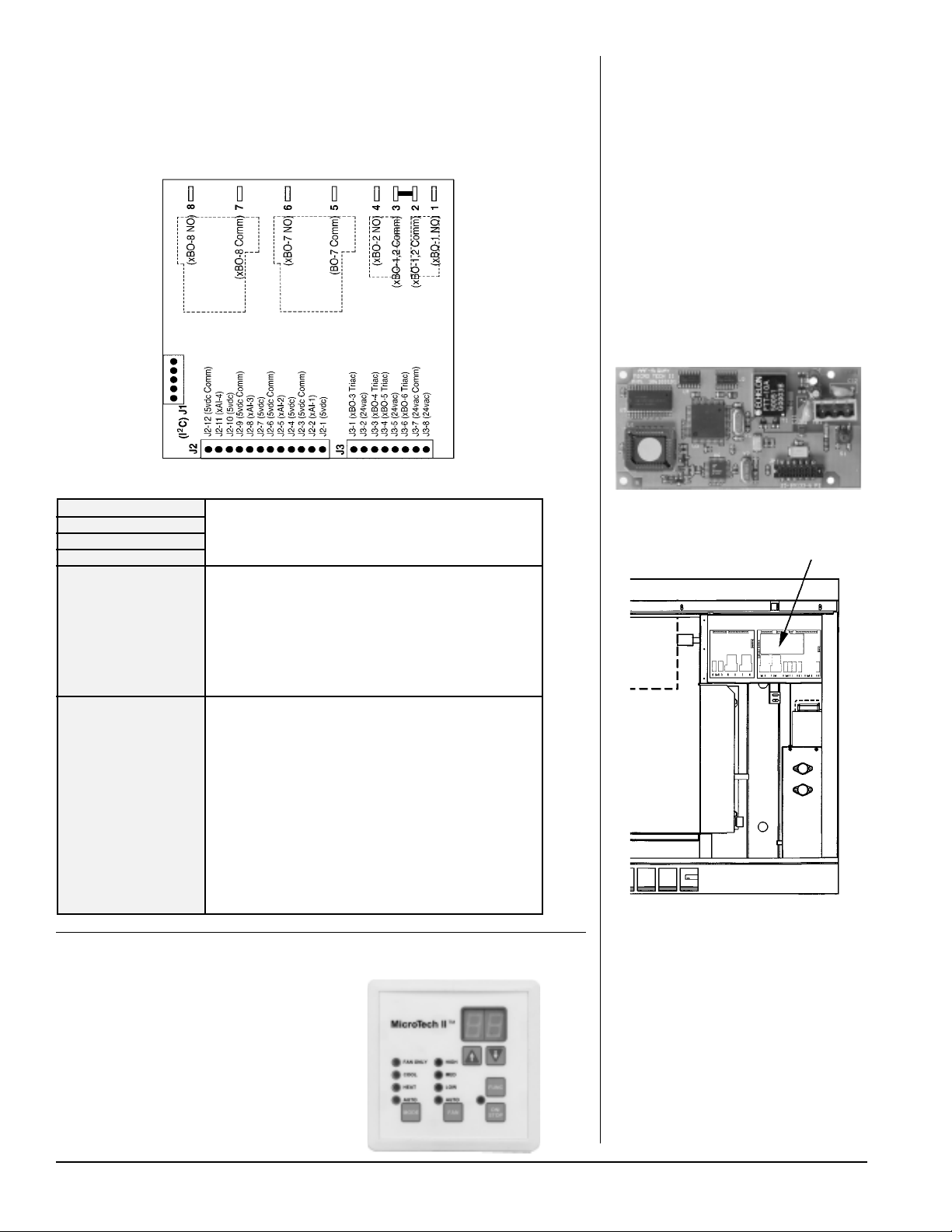

Local User Interface (LUI)

The LUI provides the user a local unit mounted

interface which indicates the current unit

operating state and can be used to adjust many

unit ventilator operating parameters. The LUI

features a 2-digit display, 7 keys (1 key is

hidden), and 9 individual LED indicators.

Figure 3. Local User Interface (LUI)

Plug-in BACnet

MS/TP Communication

Module (optional)

The BACnet MS/TP communication module

is designed to be an add-on module to the

UVC for networking to Building Automation

and Control Network (BACnet) systems. It is

an optional plug-in module that can be attached

to the UVC via a 12-pin header and 4 locking

standoffs to securely attach it to the UVC (see

figure 6). It allows the UVC to inter-operate

Page 6 of 32 IM 747

Page 7

with systems that use the BACnet Master

Slave / Token Passing (MS/TP) protocol with

a conformance level of 3. It meets the

requirements of ANSI/AHSRAE 135-1995

standard for BACnet systems.

Figure 6. BACnet MS/TP Communication

Module - (4" x 2") PN-107293126

Plug-in Metasys® N2 Open

Communication Module

(optional)

The Metasys N2 Open communication module

is designed to be an add-on module to the

UVC for networking to a Building Automation

System of the Metasys N2 type. It provides

N2 Open network communication capability

to the UVC. It is an optional plug-in module

that can be attached to the UVC via a 12-pin

header and 4 locking standoffs to securely

attach it to the UVC (see figure 7).

Figure 7. Metasys N2 Open Communication

Module - (4" x 2") PN-107293125

Master-Slave Communication

Modules (optional)

On master-slave unit ventilators a

communication module is designed to be an

add-on module to the UVC for peer-to-peer

communications. It is an optional plug-in

module that can be attached to the UVC via a

12-pin header and 4 locking standoffs to

securely attach it to the UVC. It allows the

UVC to inter-operate with another unit setup

for master slave communication capability.

NOTICE

Do not use master/slave units when a

BAS will be connected to the UVC.

NOTICE

Master/slave units will not be able to be

connected with other LonWorks devices

without re-performing the network

variable binding process in the field.

When using master/slave control, you

cannot use the Cycle Fan feature. Refer

to the appropriate software model-specific

operation manual for more information on

the Fan Cycle feature.

NOTICE

Master / Slave Control

(optional)

When it is desirable to have multiple units

within one space (i.e. conference rooms,

library, stairwells, cafeteria, etc.), and there is

no BAS present, it may be necessary to use

one master unit connected to one or more

slave units to ensure each unit within the

space operates in a like manner.

Each unit provided as a master or slave unit

will be factory provided with one master or

slave module. The factory will pre-bind

network variables from the master and slave

unit to provide the master / slave relationship.

This binding process will in effect “marry”

the master unit with its corresponding slave

units for the life of the communication

modules.

The UVC has been provided with a

configuration variable to select if slave units

will operate as Independent (default) or

Dependent slaves (see table 6).

Refer to Unit Ventilator Unit Controller

LonWorks Communications Module IM729

for wiring master/slave units.

NOTICE

For proper master/slave operation, it is

very important that the factory correctly

understand which units will be master,

which units will be slaves, and which

slaves will be connected to which master

units at the job site. It is the responsibility

of the purchaser when placing orders to

ensure that the factory understands these

things. It is strongly recommended that

each group of master/slave units be

purchased separately from stand-alone

units, or other master/slave unit groups,

to help ensure proper configuration.

Table 6. Master / Slave Network Variable Binding List

Master Variables Slave Variables Used With...

Space Temp Space Temp Independent Slave

Setpoint Output Setpoint Input

Effective Occupancy Occupancy Sensor

Fan Speed Output

Space Humidity Output Space Humidity Input Independent Slave

Outdoor Air Humidity Output Outdoor Air Humidity Input Independent Slave

Space CO2 Output Space CO2 Input Independent Slave

Primary Heat Output Primary Heat Input Dependent Slave

Secondary Heat Output Secondary Heat Input Dependent Slave

Primary Cool Output Primary Cool Input Dependent Slave

Secondary Cool Output Secondary Cool Input Dependent Slave

Fan Speed Independent Slave

Command Input and Dependent Slave

Independent Slave Control

Independent slave control allows a slave

unit(s) to use its own sensors in determining

if conditioning is required local to the slave

unit while forcing the slave to use the master

unit setpoints and unit mode. For example, if

the master is in heat mode, then the slave units

will be in heat mode, however, because this is

independent slave control some units may

actually be heating while other units remain

idle (no heating). If heating is not required in

the area local to a slave unit, cooling will not

be allowed in this case. This type of slave

control is ideal for spaces with varying loads

across the space such as stairwells, cafeterias,

etc.

When the master unit is provided with CO2

(optional) and or humidity (optional) sensors,

independent slave units will automatically

share the value of these sensors from the

master unit.

Dependent Slave Control

Dependent slave control forces the slave

unit(s) to follow the master unit operation.

This type of slave control is ideal for spaces

with consistent loads across the space such as

libraries, conference rooms, etc. With this

type of control, if the master is in heat mode

providing 20% of its heating capability, then

all slave units will be in heat mode providing

20% of their heating capability.

Independent Slave

IM 747 Page 7 of 32

Page 8

Temperature Sensor

The UVC is configured to use passive Positive

Temperature Coefficient (PTC) unit-mounted

and wall-mounted sensors (see figure 8and

figure 31, 32, 33). These sensors vary their

input resistance to the UVC as the sensed

temperature changes (see table 7), see figure

9 for sensor locations.

Figure 8. Unit Mounted Sensor, for Outdoor

Air, Discharge Air, and Room Air

Table 7. Temperature Sensor Specifications

Type Passive Positive

Temperature Coefficient

(PTC) - Silicon Sensing

Element

Range -40OF(-40OC) to

212OF(100OC)

Reference Resistance 1035 ohms at 77OC(25OC)

Accuracy 0.9OF(0.5OC) between

5OF(-15OC) to 167OF(75OC)

Leads 22 AWG, 2-wire (white)

Figure 9. Sensor Locations

Discharge Air Sensor

Room Air Sensor

Holes in Front

Access Panel

Indoor Humidity Sensor

Outdoor

Air Sensor

Outdoor

Humidity Sensor

Outdoor Air Opening

Carbon Dioxide (CO2)

Sensor (optional) for

Demand

Controlled

Ventilation (DCV)

On units equipped for Demand Controlled

Ventilation (CO

is configured to use a 0-2000 PPM, 0-10

VDC, single beam absorption infrared gas

sensor (see figure 11 and table 9). The CO

sensor is used by the UVC’s CO2 Demand

Controlled Ventilation feature. CO

are available as unit mounted only. An air

collection probe (pitot tube and filter) is

installed in the return air of the unit (see figure

12).

Figure 11. Carbon Dioxide (CO2) Sensor

Figure 12. Air Collecting Probe

sensor installed), the UVC

2

sensors

2

2

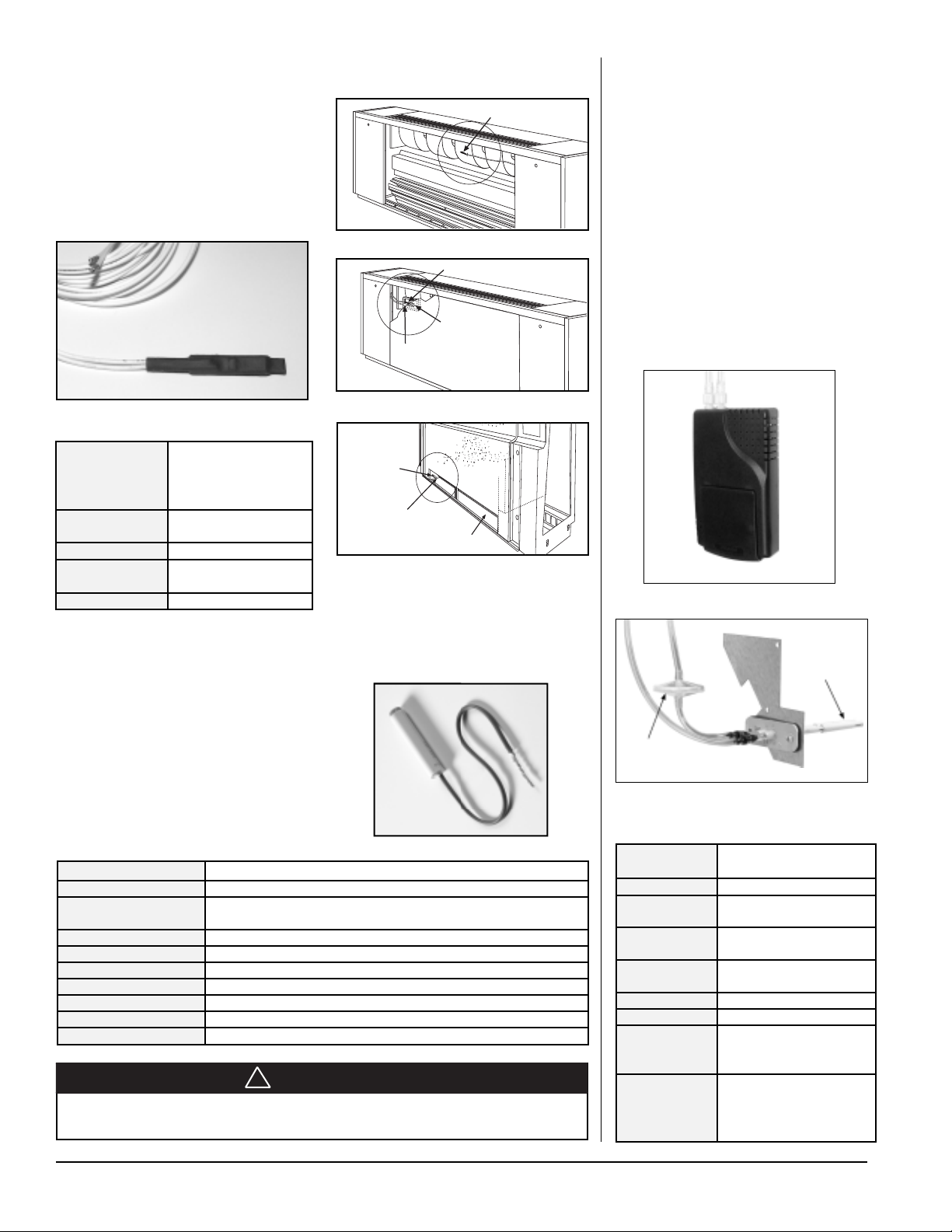

Humidity Sensor (optional)

On units equipped with humidity sensors, the

Figure 10. Humidity Sensor

UVC is configured to use a 0-100% RH, 0-5

VDC, capacitive humidity sensor(s) (see

figure 10 and table 8). Humidity sensors are

available as unit mounted only. The humidity

sensors are used with units capable of passive

or active dehumidification, or with units using

outdoor enthalpy economizer or indoor/

outdoor enthalpy economizer.

Table 8. Humidity Sensor Specifications

Type Capacitive Humidity Sensor

Voltage Supply 5 VDC Nominal (4.75 VDC to 5.25 VDC)

Voltage Output

Operating Temp -22OF(-30OC) to 140OF(60OC)

Storage Temp -40OF(-30OC) to 158OF(70OC)

Humidity 0%RH to 100%RH (not affected by water immersion)

Sensing Range 1 to 99 %RH

Accuracy +/- 3 %RH Typical, +/- 5 %RH Maximum

Calibration Calibrated to within +/- 2 %RH at 55 %RH

Leads 24 AWG, 3-wire (blue-supply, yellow-output, white-ground)

The humidity sensor is not protected against reversed polarity. Check carefully when

servicing the device or equipment damage will result.

1 to 4 VDC output for 0 to 100 %RH at 5 VDC supply (ratiometric to

voltage supply) (70 ohm output impedence)

CAUTION

!

Pitot Tube

Filter

Table 9. Carbon Dioxide (CO2)

Type Single Beam Absorption

Operating Temp 60OF(15OC) to 90OF(32OC)

Storage Temp -40OF(-40OC) to

Humidity 0%RH to 95%RH

Power Supply 18 to 30 VAC 50/60 Hz

Transformer Sizing 1.75 VA (Class 2)

Sensing Range 0 to 2000 PPM

Voltage Output 0 to 10 VDC

Accuracy +/- 100 PPM or 7% of

Calibration

Sensor Specifications

Infrared Gas Sensor

158OF(70OC)

(non-condensing)

(100 ohm output impedance)

range whichever is greater

Self-calibration system

eliminates the need for

manual calibration in most

applications

Page 8 of 32 IM 747

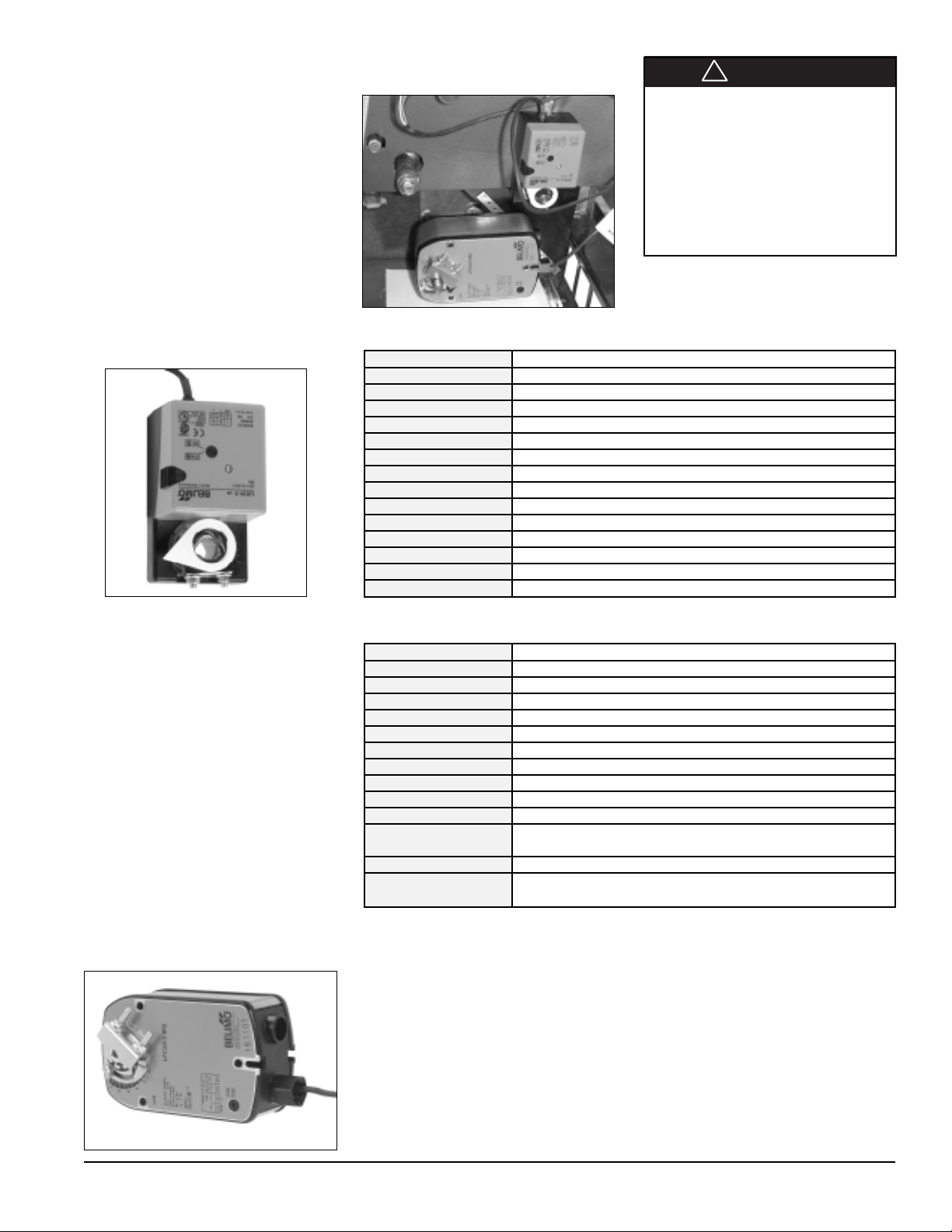

Page 9

Face & Bypass Damper

Actuator (optional)

On units equipped with a face & bypass

damper, the UVC is configured to operate a

floating-point (tri-state) face & bypass

damper, direct coupled actuator (see figure

13 and table 18).

To determine the modulating damper position

the UVC uses a separate factory preset,

configurable setting for each actuator's stroke

time. To ensure the accuracy of actuator

positioning the UVC is provided with an

overdrive feature for the 0% and 100%

positions and also periodic (12-hour) autozero algorithm for each modulating actuator.

Figure 13. Face & Bypass Damper Actuator

Figure 15. Damper Actuators Located in Left

End Compartment

For correct space control, and proper unit

operation, use End-of-Cycle (EOC) valves

in all face & bypass damper equipped

unit ventilators.

for the wet heat coil in any unit

ventilator that combines both a

refrigerant coil and a wet heat coil.

Use an EOC valve on all wet heat coils

to minimize the potential for

overheating.

Table 10. Face & Bypass Damper Actuator Specifications

Type Floating Point (tri-state), Direct Coupled Actuator

Power Supply 24 VAC +/- 20% 50/60 Hz

Power Consumption 2 W Running

Transformer Sizing 3 VA (Class 2)

Operating Temp -22OF(-30OC) to 122OF(50OC)

Storage Temp -40OF(-40OC) to 176OF(80OC)

Humidity 5%RH to 95%RH (non-condensing)

Torque 35 in-lb (4 Nm)

Run Time 80 to 110-second for 0 to 35 in-lb

Overload Protection Electronic throughout rotation

Manual Override External push button

Noise Level Less than 35 dB(A) Running

Direction of Rotation Reversible with built-in switch

Position Indication Clip-on Indicator

Leads 18 AWG, 3-wire (black-24 VAC common, red-ccw, white-cw)

CAUTION

!

An EOC valve is required

Outdoor Air/Return Air

Damper (OAD) Actuator

The UVC is configured to operate a floatingpoint (tri-state) Outdoor Air Damper direct

coupled, spring returned shut actuator (see

figure 14 and table 11). The OAD actuator

provides spring return operation upon loss of

power positive close-off of the outdoor air

damper.

To determine damper position the UVC uses

a separate factory preset, configurable setting

for each actuator's stroke time. To ensure the

accuracy of actuator positioning the UVC is

provided with an overdrive feature for the 0%

and 100% positions and also a periodic (12hour) auto-zero algorithm for each modulating

actuator.

Figure 14. Outdoor Air/Return Air Damper

Actuator

Table 11. Outdoor Air/Return Air Damper (OAD) Actuator Specifications

Type Floating Point (tri-state), Spring Return, Direct Coupled Actuator

Power Supply 24 VAC +/- 20% 50/60 Hz

Power Consumption 2.5 W Running, 1 W Holding

Transformer Sizing 5 VA (Class 2)

Operating Temp -22OF(-30OC) to 122OF(50OC)

Storage Temp -40OF(-40OC) to 176OF(80OC)

Humidity 5%RH to 95%RH (non-condensing)

Torque 35 in-lb (4 Nm)

Run Time 90-second constant, independent of load

Overload Protection Electronic throughout rotation

Noise Level Less than 30 dB(A) Running, less than 62 dB(A) Spring Return

Direction of Rotation Spring: Reversible with cw/ccw mounting

Motor: Reversible with built-in switch

Position Indication Visual Indicator, 0O to 90O (0O is the spring return position)

Leads

18 AWG, 4-wire (red-24 VAC supply, black-24 VAC common, white-ccw,

green-cw)

IM 747 Page 9 of 32

Page 10

2-position End-of-Cycle

Figure 16. 2-Position End of Cycle Valve

Actuator (EOC)

(EOC) Valves (option)

On units equipped with 2-way or 3-way endof-cycle (EOC) valves, the UVC is configured

to operate 2-position End-Of-Cycle (EOC)

valve actuators (see figure 16 and table 12).

Spring return actuators are used for all End of

Cycle (EOC) valves. All wet heat and heat/

cool EOC valves are normally open, and all

cooling EOC valves are normally closed.

Table 12. 2-Position End of Cycle (EOC) Valve Actuator Specifications

Type 2-position, Spring Return, Electric Valve Actuator

Power Supply 24 VAC 50/60 Hz

Power Consumption 6.5 W Running

Transformer Sizing 7 VA (class 2)

Dependent upon valve ordered:

Fluid Limits at Ambient General: 32OF(0OC) to 200OF(93OC) at 104OF(40OC)

Temp Limit Steam: 32OF(0OC) to 250OF(121OC) at 169OF(76OC),

15 psig (103 kPa)

Run Time 9 to 11-seconds

Spring Return 4 to 5-seconds

Table 13. WSHP 2-Position Motorized Valve Actuator Specifications

Type 2-position, Spring Return, Electric Valve Actuator

Power Supply 24 VAC 50/60 Hz

Power Consumption 6.5 W Running

Transformer Sizing 7 VA (class 2)

Fluid Limits at Ambient

Temp Limit

Run Time 9 to 11-seconds

Spring Return 4 to 5-seconds

O

F(0OC) to 200OF(93OC) at 104OF(40OC)

32

WSHP 2-position Motorized

Water Valves (option)

On water source heat pump unit ventilators

equipped with a motorized water valve, the

UVC is configured to operate a 2-position

motorized water valve actuator (see figure 17

and table 13).

Spring return actuators are used for all

motorized water valves. All motorized water

valves are normally closed.

Figure 17. WSHP 2-Position Motorized

Water Valve

Modulating Valve Actuator

(option)

On units equipped with modulating valves,

the UVC is configured to operate floatingpoint (tri-state) actuators for modulating 2way and 3-way valves (see figure 18 and 19,

and table 14).

Spring return actuators are used for all

Modulating valves. All wet heat and heat/

Table 14. Modulating Valve Actuator Specifications

Type Floating Point (tri-state), Spring Return, Electric Valve Actuator

Power Supply 20 to 30 VAC 50/60 Hz

Transformer Sizing 12 VA (class 2)

Operating Temp 32OF(0OC) to 122OF(50OC)

Storage Temp -85OF(-65OC) to 185OF(85OC)

Humidity

Fluid Temp Limits 35OF(2OC) to 250OF(121OC); 15 psig (103 kPa) saturated steam

Force Output Minimum 61 lb (271 N)

Maximum Stroke 29/32 in. (23 mm)

Run Time 76-seconds (proportionally less for shorter stroke)

Spring Direction Stem-up, 3 to 15-seconds spring return

Noise Level 35 dB(A)

Leads

90 %RH non-condensing at 70OF(21OC) ambient temperature and

40OF(4OC) fluid temperature

20 AWG, 4-wire (yellow-24 VAC supply, white-24 VAC common, white/

brown-stem up, brown-stem down)

cool valves are normally open, all cooling

valves are normally closed.

To determine modulating valve position the

UVC uses a separate factory preset,

configurable setting for each actuator's stroke

time. To ensure the accuracy of actuator

positioning the UVC is provided with an

overdrive feature for the 0% and 100%

positions and also periodic (12-hour) autozero algorithm for each modulating actuator.

Figure 18. 2-Way Modulating Valve Actuator

Figure 19. 3-Way Modulating Valve Actuator

Page 10 of 32 IM 747

Page 11

Time Clock (optional) with

Stand-Alone Unit Ventilators

As an option, stand-alone non-slave unit

ventilators can be factory equipped with a

unit mounted digital electronic 24-hour/7day time clock with 20 programs (see figure

20 and table 15). In stand-alone unit ventilators

with this option, the time clock is factory

wired to the UVC unoccupied input such that

it can be used to automatically place the unit

into occupied and or unoccupied modes based

upon its schedule. The time clock features

large keys with unique “circular

programming” for easy schedule setup, a LCD

display, manual 3-way override On/Auto/Off

and capacitor backup to retain program

memory during power outages. (See OM 761

for operating and setting the time clock.)

Figure 20. Time Clock

Figure 21. Time Clock Located Under Top

Right Access Door on Models AVS, AVV,

AVB, and AVR

Time Clock

Figure 22. Time Clock Located Behind Right

Front Access Door on Horizontal/Ceiling

Models AHF, AHV, AHB, and AHR

Time Clock

Figure 24. Time Clock Located Under Top

Right Access Door on Models AZS, AZQ,

AZU, AZV, AZR, AED, AEQ, ARQ, and ERQ

Time Clock

Figure 25. Time Clock Terminal Connections

Table 15. Time Clock Specifications

Type

Power Supply 24 VAC 50/60 Hz

Transformer Sizing 4 VA (class 2)

Operating Temp

Humidity

Programs 20

Override

Switching Time 1-minute (shortest)

Daylight Changeover Manual

Switch 16 A Resistive at

Full Charge

Capacity Backup

Electronic 24-hour/7-day

time switch

-20OF(29OC) to 140OF

(60OC)

5%RH to 95%RH

(non-condensing)

Manual 3-way override:

On/Auto/Off

Type: SPDT, Rating:

277 VAC

100 Hours

Figure 23. Time Clock Dimensions

2.36" (60mm)

2.12" (54mm)

0.06"

(2mm)

Power

2

1

345

Timer Internal Wiring

Unit Wiring

1.26" (32mm)

0.83" (21mm)

Switch

M

COM NO

Time

NC

UVC

∅ 2.44"

(62mm)

∅ 0.134" (3.4mm)

IM 747 Page 11 of 32

Page 12

Time Clock - Operating

Instructions

■

Keypad Description

Setting the Time/Automatic Run

Mode

Prog. Program Mode

Res.* Reset: Clears all programs and time

Select ON or OFF in Prog. Mode,

Manual Override in Run Mode

±1h* Manual Daylight Change Key

h Setting the Hour (12:– – AM)

m Setting the Minute (12:01 AM)

Day Set Day(s) for time and programs

*Recessed keys; use a pen point to press

■

LCD Display Elements

The LCD incorporates a number of

different elements to display various data and

information (see figure 26).

Figure 26. LCD Display Elements

Days of Week >

Daylight Time Symbol >

AM and PM Symbol >

Run Mode Symbol

OFF Symbol Continuous OFF Symbol

ON Symbol Continuous ON Symbol

1234567

+1h

AM

▼

ON/OFF Symbol

■

Programs

The Digi 20 will accept up to 20 programs

A program consists of:

1. An ON or OFF command

2. Time of day (Hour and Minute)

3. Single day or multiple days

A program is required for each ON event, and

a program is required for each OFF event.

NOTE: MULTIPLE ON OR OFF EVENTS

MAY BE PROGRAMMED.

For example, Program 1 may turn the unit air

conditioning ON at 8AM Mon.-Fri. Program

2 may turn the air conditioning OFF at 5PM

Mon.-Fri.

If someone is working late, they may press the

override key to turn on the air conditioning. If

they forget to press the override key again

when they leave, the air conditioning will stay

on all night (or all weekend).

To prevent this from occurring, additional

OFF times may be programmed.

• Program 3 can turn the air conditioning

OFF at 6PM.

• Program 4 can turn the air conditioning

OFF at 7PM.

• Program 5 can turn the air conditioning

OFF at 8PM., etc.

IMPORTANT!

Before proceeding with setting the time

and programming the unit, press the reset

key to clear all data from the memory

<Time of Day or

Switching Time

▼

▼

Manual Override ON

■

Selecting AM/PM or

Military Time

After pressing reset, the display may show

AM (right). The numbered day symbols will

be flashing on and off.

If the display does not show AM, it is in

military time mode (24:00 hr.) To change to

AM/PM mode, press and hold the h key and

press the

AM will appear in display.

If display is in AM mode and military mode is

desired, press and hold the h key, press the

±1h key once.

±1h key once.

Figure 27. AM/PM Time Display

1234567

AM

■

Setting The Time

NOTE: If the h and m keys are held down

longer than 2 seconds, the numbers will

advance rapidly.Press and hold the key

during the following:

(If Daylight Savings Time is in effect, press

±1h first)

1. Press h to advance to the current hour

(while holding down the

2. Press m to advance to the current minute

(while holding down the

3. Press Day repeatedly to advance to

current day (while holding down the

key)

NOTE: If the days are flashing, it indicates

the day of the week was not set when setting

the time. The timer cannot be programmed

unless the day of the week is entered.

■

Manual Daylight Time

key)

key)

Changeover

Each year, in the Spring, press ±1h to advance

the time an hour. In the Fall, press ±1h to set

back an hour.

■

Programming 24 Hour or

7 Day Schedules

It is helpful to write out the program schedules

before beginning.

IMPORTANT!

The current time of day and day of week

must be set prior to programming. See

“Setting The Time”

Page 12 of 32 IM 747

Page 13

Example

Program 1: ON at 7:00AM Monday thru Saturday

Program 2: OFF at 5:00PM Monday thru Friday

Program 3: OFF at 7:00PM Saturday

Three programs need to be entered.

Press Prog. key only once. Display shows:

1234567

AM

Program 1: (ON at 7:00AM Monday thru Saturday)

Press

Press h key ........................................ to 07AM

Press m key once ................................. to 00

Press Day key once .............................. 1 2 3 4 5 6 is displayed

Press Prog. key to enter

Program 2: (OFF at 5:00PM Monday thru Friday)

Press

Press h key ........................................... to 05PM

Press m key once ................................. to 00

Press Day key two times ...................... 1 2 3 4 5 is displayed

Press Prog. key to enter

Program 3: (OFF at 7:00PM Saturday)

Press key twice ............................ OFF symbol appears

Press h key ........................................... to 07PM

Press m key once ................................. to 00

Press Day key 9 times .......................... until only 6 is displayed

Press Prog. key to enter

Press

If an “ON” time was programmed that is earlier in the day than the current time, press

once to turn the timer “ON”. (It does not “Look Back” to determine if it should be on or off after

programming).

NOTE: If 24 hour time control (same schedule every day of the week) is desired, ignore

Day key. If a ON or OFF symbol is not entered, the ON symbol will flash, and program will

not be accepted.

■

Press Day Key Display Shows Days

0 times 1234567 Every Day

1 time 123456 Mon.–Sat.

2 times 12345 Mon.–Fri.

3 times 6 7 Sat. & Sun.

4 times 1 Monday

5 times 2 Tuesday

6 times 3 Wednesday

7 times 4 Thursday

8 times 5 Friday

9 times 6 Saturday

10 times 7 Sunday

key once ............................. ON symbol appears

key twice ............................ OFF symbol appears

key to enter Run Mode

IMPORTANT!

Day Key Selections

■

Reviewing Programs

To review the programs at any time, press

Prog. key. Programs will appear in the order

they were entered with repeated presses of the

Prog. key. After all programs have been

reviewed, the blank display will appear to

allow entering another program. Another press

of the Prog. key will display the number of

free programs available, such as Fr 16 if four

programs have been entered.

■

Manual Override

TEMPORARY: While in the Run Mode,

pressing the key once will reverse the

output; ON to OFF or OFF to ON. The

symbol appears in the display to indicate a

temporary override. At the next scheduled

switching time, automatic control resumes,

eliminating the override.

CONTINUOUS: While in the Run Mode...

• Pressing the

output to ON permanently. symbol

appears in display.

• Pressing the

turn the output OFF permanently.

appears in display.

• To terminate a continuous override, press

the

■

Select the program to be changed with the

Prog. key. A new set of days may be selected

with the Day key just as in initial

programming. Hour and minute can be

changed with the h and m keys.

Press Prog. or

program.

■

To delete only one or a few programs: Press

Prog. key until the desired program is

displayed.

Press m key to :59 and press once more to

blank out.

Press h key to 11PM and press once more to

blank out.

Press

seconds and then enter the Run Mode.

Using the reset key will delete ALL programs,

the time of day, and day of the week.

key until appears in the display.

Changing A Program

Deleting A Program

key, display will flash for several

key twice will turn the

key three times will

symbol

key to store the new

IM 747 Page 13 of 32

Page 14

Make Electrical Wiring

Connections

WARNING

!

To avoid electrical shock, personal

injury or death, be sure that field wiring

complies with local and national fire,

safety, and electrical codes, and

voltage to the system is within the

limits shown in the job-specific

drawings and unit electrical data

plate(s).

WARNING

!

DANGER

Power supply to unit must be

disconnected when making field

connections. To avoid electrical shock,

personal injury or death, be sure to

rigorously adhere to field wiring

procedures regarding proper lockout

and tagout of components.

CAUTION

!

Use copper conductors only. Use of

aluminum conductors may result in

equipment failure and overheating

hazards. All wiring in right hand

compartment must be class 1.

Figure 28. Model AV - Field Wiring Whips with Caps Viewed from Right End Compartment

Field Wiring at back of Local

User Interface (LUI) Panel

Two pin plug for unit

mounted sensor

Figure 29. Wiring Location Using Wall Sleeve with Models ASZ, AZQ, AZV, AZU, AZR, AED

and AEQ

2.5/1.75" Dia. Knockout

3.0/2.0" Dia. Knockout

Wall Sleeve

▲

Wire Wips for Field Wiring with

Caps (see the wiring diagram

provided on the unit ventilator

right front access panel)

.875" Dia. Knockouts (3)

SW1-Main Power Nonfused “On-Off” Switch (AAFHermanNelson)

NOTICE

Reverse this cover when unit is removed from wall sleeve

to cover opening in the end of switch box.

Field Wiring Harness

Locations

The low voltage field wiring connections

have all been centrally located within the unit

ventilator and are easily accessible.

To simplify field connections, multi-pin plugs

are factory provided and pre-wired with short

wire whips. Each of the wires in these wire

whips is capped and should remain capped if

not used. To make a field connection simply

locate the correct wire, cut the wire cap from

the wire and then connect the wire with your

field wiring as shown in the field wiring

diagrams.

All low voltage field wiring connections must

be run in shielded cable with the shield drain

wires connected as shown in the field wiring

diagrams.

The following are descriptions of the various

options and features that may require field

wiring.

See the wiring diagram provided on the unit

ventilator right front access panel.

In addition, those unit ventilators equipped

with optional electric heating coil have electric

heating coil power connections at right end

only.

Wall Sleeve Junction Box

5

/8" x 35/8" opening (for main power wiring from wall

Rear edge

of wall sleeve

Figure 30. Wall Mounted Temperature Sensor Wiring for Basic Wall Sensor

Unit Ventilator

Connector

GND

AI-2

Comm

AI-1

LED

P1

896

GRN

BLK

WHT

RED

Wire

Caps

sleeve to chassis). Field connection by others.

Control receptacle with plug-in disconnect (AAF

HermanNelson

to all remote controls.

®

). Leads are provided for wire nut connection

Wall Sensor

1

Shield

5

6

4

3

2

Factory Wiring

Field Wiring (by Others)

External Device (by Others)

(option)

Setpt. Adj.

Comm

Sensor

LED

®

-

Page 14 of 32 IM 747

Page 15

Field Wiring Remote

NOTICE

NOTICE

CAUTION

!

Mounted Temperature

Sensor

The low voltage field wiring connections

have all been centrally located within the unit

ventilator and are easily accessible.

To simplify field connections, multi-pin plugs

are factory provided and pre-wired with short

wire whips (see figure 28). Each of the wires

in these wire whips is capped and should

remain capped if not used. To make a field

connection simply locate the correct wire, cut

the wire cap from the wire and then connect

the wire with your field wiring as shown in the

two black wires coming out. This disables the

unit mounted sensor (see figure 28).

Remote Wall Mounted

Sensors (Optional)

All MicroTech II™ units come with unit

mounted room air temperature sensors as

standard. Units can also accept Remote Wall

Mounted Room Temperature Sensors for

remotely sensing room temperatures.

The UVC is configured for Basic and

Expanded remote sensors. To use the

Deluxe remote sensor, you must

reconfigure the UVC through the LUI.

See the LUI menu reference in the

appropriate OM for the correct settings.

The setpoint will operate incorrectly

otherwise when using a Deluxe remote

sensor.

All low voltage field wiring connections must

be run in shielded cable with the shield drain

wires connected as shown in the field wiring

diagrams.

The following are descriptions of the various

options and features that may require field

wiring.

Table 16. Remote Wall-Mounted

Sensor Types (optional)

Remote Tenant

Setpoint Override

Adjustment Button

None x x

+/- 3OFxx

55OF to 85OFx x

Status

LED

Static sensitive components. A static

discharge while handling electronic circuit

boards can cause damage to the

components.

Discharge any static electrical charge by

touching the bare metal inside the main

control panel before performing any

service work. Never unplug any cables,

circuit board terminal blocks, relay

modules, or power plugs while power is

applied to the panel.

When using remote wall sensors on wall

applications, where the wall may influence

the sensor reading, ensure that the remote

wall sensor is thermally isolated from the

wall.

Figure 31. Basic, Remote Wall-Mounted

Sensor with no adjustment

Figure 32. Expanded Remote Wall-Mounted

Sensor with +/- 3OF adjustment

Figure 33. Deluxe Remote Wall-Mounted

Sensor with 55OF to 85OF

adjustment

Table 17. Basic Remote Wall-Mounted Sensor with no adjustment Specifications

PN-111048101

Type Passive Positive Temperature Coefficient (PTC) - Silicon Sensing Element

Sensing Range -40OF(-40OC) to 212OF(100OC)

Reference Resistance 1035 ohms at 77OC(25OC)

Accuracy 0.9OF(0.5OC) between 5OF(-15OC) to 167OF(75OC)

Adjustment Range None

Table 18. Expanded Remote Wall-Mounted Sensor with +/– 3°F adjustment Specifications

PN-111048103

Type Passive Positive Temperature Coefficient (PTC) - Silicon Sensing Element

Sensing Range -40OF(-40OC) to 212OF(100OC)

Reference Resistance 1035 ohms at 77OC(25OC)

Accuracy 0.9OF(0.5OC) between 5OF(-15OC) to 167OF(75OC)

Adjustment Range +/- 3OF(1.5OC)

Table 19. Deluxe Remote Wall-Mounted Sensor with 55OF to 85OF adjustment Specifications

PN-111048102

Type Passive Positive Temperature Coefficient (PTC) - Silicon Sensing Element

Sensing Range -40OF(-40OC) to 212OF(100OC)

Reference Resistance 1035 ohms at 77OC(25OC)

Accuracy 0.9OF(0.5OC) between 5OF(-15OC) to 167OF(75OC)

Adjustment Range 55OF(12.8OC) to 85OF(29.4OC)

When Using A Remote Wall

Mounted Temperature

Sensor

If a decision is made to use a Remote Wall

Mounted Temperature Sensor instead of the

unit mounted room air sensor then placement

of the Remote Wall Mounted Temperature

Sensor is critical for proper room temperature

sensing (see figures 35 and 36). The UVC is

capable of using one of three remote wall

mounted temperature sensors. Figure 34

shows a 4-wire connection (plus shield drain

wire) (see table 20). It is recommended that

additional wires be pulled to compensate for

potential wire breakage or future options. The

Basic Wall Mounted Temperature Sensor

requires only 3-wires (plus shield drain wire)

since the Basic Wall Mounted Temperature

Sensor has no setpoint adjustment

(see figure 30).

IM 747 Page 15 of 32

Page 16

Figure 34. Wall Mounted Temperature Sensor Wiring for Expanded and Deluxe Wall Sensor

Wall Sensor

(option)

1

5

6

Setpt. Adj.

4

Comm

3

Sensor

2

LED

Connector

GND

AI-2

Comm

AI-1

LED

Unit Ventilator

P1

896

GRN

BLK

WHT

RED

Wire

Caps

Shield

Factory Wiring

Field Wiring (by Others)

External Device (by Others)

Note:

Unit mounted room air sensors are recommended for most situations to provide

optimal unit performance. Unit mounted sensors are factory installed (see figure 9).

Remote mounted can be used (see figure 35).

Table 20. Max Sensor Wire Length and

Guage

Maximum sensor wire length for less than 1°F error

Gauge Length

14 AWG 800 ft. (244 m)

16 AWG 500 ft. (152 m)

18 AWG 310 ft. (94 m)

20 AWG 200 ft. (61 m)

22 AWG 125 ft. (38 m)

NOTICE

All MicroTech II equipped unit ventilators

are provided as standard with a unit

mounted space temperature sensor. The

unit mounted temperature sensor is

provided with a quick disconnect plug

which can be located using the unit

electrical schematic. When using a remote

wall mounted temperature sensor the unit

mounted temperature sensor quick

disconnect plug must be separated so

that the unit mounted sensor is

disconnected from the UVC.

Figure 35-

Interior Wall

Interior Wall

Correct

Wall Sensor Locations

Window Exposure

Window Exposure

Unit

Interior Wall

Window Exposure

Unit

= Correct Sensor Location

Interior Wall

Window Exposure

Figure 36Locations

Interior Wall

Interior Wall

Incorrect

Window Exposure

Unit and Wall Sensor

Unit

Cubicle Wall

Interior Wall

Interior Wall

Shelving

Window Exposure

= Incorrect Sensor Location

Shelving

File Cabinet

Unit

Window Exposure

Window Exposure

Unit

Window Exposure

Unit

Note:

Avoid placing wall sensor near drafty areas such as doors or windows. Avoid external walls, or dead spots near exposed

columns. Avoid direct sunlight on wall sensor.

Page 16 of 32 IM 747

Page 17

WARNING

DANGER

!

To avoid electrical shock, personal injury or death, be sure that field wiring complies with local and national fire, safety, and electrical codes,

and voltage to the system is within the limits shown in the job-specific drawings and unit electrical data plate(s).

Power supply to unit must be disconnected when making field connections. To avoid electrical shock, personal injury or death, be sure to

rigorously adhere to field wiring procedures regarding proper lockout and tagout of components.

Installation

This document describes the installation of the following

three wall mounted sensor models:

• P/N 111048101

• P/N 111048102

• P/N 111048103

Parts Included - All Models

• pre-assembled sensor that includes:

- large (50.8 x 101.6 mm [2 x 4 in.]) mounting base (1)

- terminal block (1)

- 1.5 mm (1/16 in.) cover screw (1)

- endcaps (2)

• alternate small (80 x 80 mm [3.15 x 3.15 in.]) mounting

base (1) with attached terminal block (1)

• cover slider insert with printed logos for McQuay® (1)

and AAF® (1)

• No. 6-32 x 1 in. flat-head screw (2)

• No. 8 x 1.25 in. panhead tapping screw (2)

• hollow plastic wall anchor (2)

Parts Included - 111048102 and 111048103 Only

• alternate serrated setpoint dial (attached)

• smooth setpoint dial (separate)

Special Tools Needed

• .5 mm (1/16 in.) Allen wrench

•7 mm (1/4 in.) flat-blade screwdriver

• hole saw with 35 mm (1-3/8 in.) blade (for surface

mounting only)

• drill with 8 mm (5/16 in.) drill bit (for surface mounting

only)

Mounting

The MicroTech II™ Wall Mount Sensor allows for two mounting methods: wallbox mounting and surface mounting.

Note: Wallbox mounting requires the large mounting base.

Use either the large or small mounting base for surface

mounting.

6. Fasten the base to the wallbox with the No. 6-32 x 1 in.

screws provided.

7. Remove terminal block and wire to the appropriate terminals as shown in ”Wiring”.

IMPORTANT

8. Install terminal block onto sensor with terminal 6 next to the

edge of sensor.

9. Replace the sensor and tighten the cover screw.

10. Replace the two endcaps on the mounting base.

Figure 37 - Wallbox Mounting

Performing Surface Mounting Using Large Base

To perform surface mounting using the large base.

(Figure 38):

1. Slide the desired cover slider insert onto the sensor until it

snaps into place.

2. Remove the two endcaps from the mounting base.

3. Loosen the cover screw using a 1.5 mm (1/16 in.) Allen

wrench and remove the sensor.

4. Drill a 35 mm (1-3/8 in.) hole in the surface where the sensor will be mounted.

5. Pull the cable or wiring through the hole.

Figure 38 - Surface Mounting Using Large Base

Performing Wallbox Mounting

To perform wallbox mounting (Figure 37):

1. Slide the desired cover slider insert onto the cover until it

snaps into place.

2. Remove the two endcaps from the mounting base.

3. Loosen the cover screw using a 1.5 mm (1/16 in.) Allen

wrench and remove the sensor.

4. Pull the cable or wiring through the wallbox and mounting base.

5. Rotate the mounting base until one of the arrows on the

base points up and the screw openings in the base align

with the threaded holes in the wallbox. If necessary, reposition the cover screw above the arrow.

IM 747 Page 17 of 32

Page 18

6. Rotate the mounting base until one of the arrows on the

base points up. If necessary, reposition the cover screw

above the arrow. Place the base against the wall, and mark

the screw holes using the base as a template.

7. Drill two 8 mm (5/16 in.) holes at the markings.

8. Insert the hollow plastic wall anchors (Figure 39), position

the base, and then drive the two pan-head tapping screws.

9. Pull the wiring through the mounting base.

10. Remove terminal block and wire to the appropriate terminals as shown in “Wiring”.

IMPORTANT

11. Install terminal block onto sensor with terminal 6 next to the

edge of sensor.

Figure 40 - Surface Mounting Using Small Base

12. Replace the sensor and tighten the cover screw.

13. Replace the two endcaps on the mounting base.

Figure 39 - Insert Wall Anchors

Performing Surface Mounting Using Small Base

To perform surface mounting using the small base (Figure 40):

1. Slide the desired cover slider insert onto the sensor until it

snaps into place.

2. Remove the two endcaps from the mounting base.

3. Remove the cover screw using a 1.5 mm (1/16 in.) Allen

wrench and discard it. Remove the sensor.

4. Remove and discard the terminal block from inside the

sensor.

5. Drill a 35 mm (1-3/8 in.) hole in the surface where the sensor will be mounted.

6. Pull the cable or wiring through the hole.

7. Place the small base against the wall, (with the arrow on

the base pointing up) and mark the screw holes using the

base as a template.

8. Drill two 8 mm (5/16 in.) holes at the markings.

9. Insert the hollow plastic wall anchors (Figure 39), position

the base, and then drive the two pan-head tapping screws.

10. Pull the wiring through the mounting base.

11.Wire to the appropriate terminals to the small mounting

base as shown in “Wiring”.

12. Snap the sensor into the small mounting base (cover screw

is not required).

Wiring

NOTICE

It is suggested that shielded cable always be used, however,

shielded cable is generally not required, except in electrically

noisy environments, such as near gas ignition systems, radar

or magnetic resonance imaging equipment, etc. It is the

responsibility of others to determine what constitutes an

“electrically noisy” environment for each installation. Refer to

table 21 or 20 for maximum wire length.

Figure 41 - 111048101 Sensor Wiring

Figure 42 - 111048102 and 111048103 Sensor Wiring

Table 21 - Maximum Wire Length

Maximum Wire Length for Less Than 1°F Error

Wire Gauge Wire Length

14 AWG 800 Ft. (244mm)

16 AWG 500 Ft. (152mm)

18 AWG 310 Ft. (94mm)

20 AWG 200 Ft. (61mm)

22 AWG 125 Ft. (38mm)

Page 18 of 32 IM 747

Page 19

Setup and Adjustments

Figure 43 - Removing the Standard Setpoint Dial

Switching Setpoint Dials

To switch setpoint dials:

1. Remove the sensor from the mounting base.

2. Rotate the smooth setpoint dial so that it points

straight up.

3. As shown in Figure 43, insert the Allen wrench

through the hole in the back of the printed wiring

board (A) and push gently until the smooth setpoint

dial is free.4. Press the serrated setpoint dial into

place on the sensor, making sure that the dial points

straight up.

A

5. Replace the sensor on the mounting base.

Repairs and Replacement

No repair options available. Call your local AAF-McQuay

representative for sensor replacement.

External Input Option Wiring

The external input options can be one of the

following, dependent upon the unit ventilator

software model: Unoccupied Signal, Remote

Shutdown Signal, Ventilation Lockout Signal,

Dewpoint/Humidity Signal, Boiler-less

System Kit Signal, or Exhaust Interlock

Static sensitive components. A static discharge while handling electronic circuit boards can

cause damage to the components.

Discharge any static electrical charge by touching the bare metal inside the main control

panel before performing any service work. Never unplug any cables, circuit board terminal

blocks, relay modules, or power plugs while power is applied to the panel.

Figure 44. External Input Wiring Examples with or without Daisy Chaining of Units

Unit Ventilator #1

P1

Connector

GND

Comm

BI-6

BI-5

BI-4

BI-3

Unit Ventilator #2

P1

Connector

GND

Comm

BI-6

BI-5

BI-4

BI-3

Unit Ventilator #3

P1

Connector

GND

Comm

BI-6

BI-5

BI-4

BI-3

896

908A

907A

906A

905A

904A

896

908A

907A

906A

905A

904A

896

908A

907A

906A

905A

904A

Wire

Caps

Wire

Caps

Wire

Caps

Shield

Shield

Shield

Additional Units

Signal.

CAUTION

!

External Input

Option 4 Device

(by Others)

WSHP

Boilerless System

(low temp switch)

Each of these inputs has been designed such

that units can be daisy-chained to one set of

dry contacts as shown in figure 44. Size

wiring for minimal voltage drop in accordance

with local codes.

External Input

Option 3 Device

(by Others)

Ventilation Lockout

(default) or

Exhaust Interlock

Factory Wiring

Field Wiring (by Others)

External Device (by Others)

External Input

Option 2 Device

(by Others)

Remote Shutdown

External Input

Option 1 Device

(by Others)

Unoccupied

(default) or

Dewpoint Humidity

Setpoint Dial

External Output Option

Wiring

The external output options can be configured

as one of the following, dependent upon the

unit ventilator software model: Lights On/

Off Signal, Motorized Water Valve Open/

Close, Fault Indication Signal, Pump Restart

Signal, Exhaust Fan On/Off Signal, and

Auxiliary Heat Signal (see figure 45).

Each of these external outputs is connected to

the dry contacts of UVC board mounted relays

and can be used as a “signal” to operate the 24

VAC coil of a field-installed pilot duty relay

as shown. Size wire for minimum voltage

drop in accordance with local codes. In the

case of the motorized water valve on water

source heat pumps, the appropriate output

can be used to operate the valve actuator.

The second wiring example (see figure 46),

shows how multiple units could be connected

to a single relay by others.

NOTICE

Not all of the external output options can

be used simultaneously. Not all of the

external output options can be used on all

software models. See the “UVC Input and

Output Tables” in order to verify which

external output option can be used on

which external outputs for each specific

software model.

IM 747 Page 19 of 32

Page 20

NOTICE NOTICE

For correct space control, and proper unit

operation, it is important that an occupancy

control means be used such that the unit

is placed into unoccupied mode during

regular low load conditions such as

nighttime, weekends and holidays.

NOTICE

Using any of the external input options

that are not designated as the “default”

option in the

“UVC Input and Output Tables” will require

field configuration to the UVC using the

Local User Interface (LUI) in order to

select the non-default external input option

be used by the UVC. See the appropriate

Software Model-Specific Operation

Literature for external input configuration

instructions. Do not make final

connections of any external devices

to the external inputs when using a

non-default external option until you

insure that the required configuration

is complete. Damage to the equipment

and or improper equipment operation

can result.

NOTICE

Not all of the external input options can be used simultaneously. Not all of the external input

options can be used on all software models. See the “UVC Input and Output Tables” in order

to verify which external input option can be used on which external inputs for each specific

software model.

Figure 45. External Output Wiring – Single Unit

Unit Ventilator

P6

Connector

UVC

xBO-2

Comm

xBO-1

BO-6

BO-6

Comm

24vac Supply

24vac Comm

The total VA of all field-mounted devices powered by the unit ventilator’s 24 VAC power

supply cannot exceed 15 VA. All field connected relays must use 24 VAC Class 2 coils.

Wire

Caps

601A

602A

603A

604A

605A

606A

608A

610A

Shield

Factory Wiring

Field Wiring (by Others)

External Device (byOthers)

!

External Output

Option 1 Device

(by Others)

Lights On/Off

MotorizedWater

Valve Open/Close

CAUTION

Signal

or

External Output

Option2Device

(by Others)

Fault Indictaion

or

Pump Restart

Signal

External Output

Option 3 Device

(by Others)

Auxiliary Heat

Signal

or

ExhaustFan

On/Off Signal

Figure 46. External Output Wiring – Multiple Units Shown

Unit Ventilator #1

UVC

XBO-2

Comm

XBO-1

BO-6

BO-6

Comm

24vac Supply

24vac Comm

P6

Connector

Wire

Caps

601A

602A

603A

604A

605A

606A

608A

610A

Unit Ventilator #2

UVC

XBO-2

Comm

XBO-1

BO-6

BO-6

Comm

24vac Supply

24vac Comm

P6

Connector

Wire

Caps

601A

602A

603A

604A

605A

606A

608A

610A

Unit Ventilator #...X (last unit)

UVC

XBO-2

Comm

XBO-1

BO-6

BO-6

Comm

24vac Supply

24vac Comm

P6

Connector

Wire

Caps

601A

602A

603A

604A

605A

606A

608A

610A

Shield

Shield

Additional Units

External Output

Option 2 Device

(by Others)

Fault Indication

or

Pump Restart

Signal

Factory Wiring

Field Wiring (by Others)

External Device (by Others)

Page 20 of 32 IM 747

Page 21

Split-System Condensing Unit Signal Wiring (Model AVS, AVV, AVR, AHF, AHV, AHR)

The UVC and split-system unit ventilator are

Figure 47. Split-System Condensing Unit Signal Wiring

pre-wired to provide a condensing unit On/

Off signal as shown in figure 47.

CAUTION

!

Condensing unit capacity must be

properly sized for proper unit ventilator

operation. Unit ventilator damage and or

poor space control will result from

improperly sized, or oversized condensing

units.

CAUTION

!

The total VA of all field-mounted devices

powered by the unit ventilator’s 24 VAC

power supply cannot exceed 15 VA. All

field connected relays must use 24 VAC

Class 2 coils.

UVC

BO-9

Comm

24vac Supply

24vac Comm

Communication Module Wiring (see table 3)

Figure 48. BACnet® Communication Module Wiring Diagram

Split System Unit Ventilator

P6

Connector

607A

608A

610A

Factory Wiring

Field Wiring (by Others)

External Device (by Others)

Dip Switches

Wire

Caps

Shield

Condensing Unit

On/Off Signal

(24vac)

RT+ (Non-Inverting)

RT- (Inverting)

RTcom (Reference)

Shield

Figure 49. LonWorks® Communication Module Wiring Diagram

ECHELON

SHLD (Shield)

A (LON A)

B (LON B)

Figure 50. Metasys® N2 Open Communication Module Wiring Diagram

REF (Reference)

N2- (Inverting)

N2+ (Non-Inverting)

Dip Switches

IM 747 Page 21 of 32

Page 22

UVC Input and Output Data

All UVC input and output connections and their corresponding unit ventilator usage are shown in the following tables.

Table 23. Inputs and Outputs for Software

Model 0 – Air Source Heat Pump

w/Electric Heat

Model 0

Air Source Heat Pump w/ Electric Heat

Description

BO-1 Inside Fan High

BO-2 Inside Fan Medium

BO-3 Electric Heat 1

BO-4 Electric Heat 2

BO-5 Electric Heat 3

External Output Option 3:

BO-6

Fault Indication 2

BO-7 Outside Drain Pan Heater

BO-8 Drain-less Condensate Heater 1

BO-9 Compressor

BI-1 Condensate Overflow

BI-2

BI-3

External Input Option 1:

BI-4 Ventilation Lockout (default) or

Exhaust Interlock 3

External Input Option 2:

BI-5

Remote Shutdown 3

External Input Option 3:

BI-6 Unoccupied (default) or Dewpoint/

Humidity 3

BI-7

BI-8

BI-9

BI-10

BI-11

BI-12 DX Press Switch (NC)

AI-1 IA Temp. Sensor + T.O.

AI-2 Remote Setpt. Adjust. Pot.

AI-3 DA Temp Sensor

AI-4 OA Temp Sensor

AI-5 IA Coil DX Temp Sensor

AI-6 OA Coil DX Temp Sensor

Expansion Board

External Output Option 2:

xBO-1

Lights On/Off 2

External Output Option 1:

xBO-2

Exhaust Fan On/Off 2

xBO-3 OA Damper Open

xBO-4 OA Damper Close

xBO-5

xBO-6 Reversing Valve

xBO-7 Outdoor Fan

xBO-8 Inside Fan Low

xAI-1 IA Humidity Sensor 1

xAI-2 OA Humidity Sensor 1

xAI-3 Indoor CO2 Sensor 1

xAI-4

1Optional

2Field selectable external output options

(all possible options are shown)

3Field selectable external input options

(all possible options are shown)

Table 24. Inputs and Outputs for Software Models 2 and 3 – Water Source Heat Pump

w/ or w/o Electric Heat

Model 2 Model 3

Water Source Heat Pump w/ Electric Heat Water Source Heat Pump

Description Description

BO-1 Inside Fan High Inside Fan High

Inside Fan Medium Inside Fan Medium

BO-2

BO-3 Electric Heat 1

BO-4 Electric Heat 2

BO-5 Electric Heat 3

External Output Option 3:

BO-6 Fault Indication (default) or Pump Restart 2 External Output Option 3:

Fault Indication (default) or Pump Restart 2

BO-7

BO-8

BO-9 Compressor Compressor

BI-1 Condensate Overflow Condensate Overflow

BI-2

BI-3 External Input Option 4: Boiler-less System 3 External Input Option 4: Boiler-less System 3

External Input Option 1: External Input Option 1:

BI-4 Ventilation Lockout (default) Ventilation Lockout (default) or Exhaust

or Exhaust Interlock 3 Interlock 3

External Input Option 2: External Input Option 2:

BI-5

Remote Shutdown 3 Remote Shutdown 3

External Input Option 3: External Input Option 3:

BI-6

Unoccupied (default) or Dewpoint/Humidity 3 Unoccupied 3

BI-7

BI-8

BI-9

BI-10

BI-11