Page 1

Installation and Maintenance Manual

IM 967-1

Group: Controls

Part Number: IM 967-1

Date: March 2012

Supercedes: IM 967

MicroTech® III Chiller Unit Controller

BACnet® Communication Module (MS/TP)

Pathfinder™ Chiller, Model AWS

Air-Cooled Scroll Compressor Chiller, Model AGZ-D

Use this manual to physically install the BACnet MS/TP Communication Module into the MicroTech III chiller

unit controller and connect the chiller unit controller to your network. Use the appropriate Engineering Data

(ED), known as the Protocol Information document, to integrate the unit into your network. The Protocol

Information document contains addressing details, BACnet® protocol information, and a list of the data points

available to the network. See the Reference Documents section of this manual for Protocol Information

document numbers. MicroTech III control integration literature is available from your local Daikin McQuay

sales representative and www.daikinmcquay.com.

© 2012 McQuay International

NOTICE

Page 2

Contents

Figures................................................................................................................................................... 2

Revision History.................................................................................................................................... 3

Reference Documents ........................................................................................................................... 3

Limited Warranty.................................................................................................................................. 3

General Information.............................................................................................................. 4

Hazard Identification Messages ............................................................................................................ 4

Description............................................................................................................................................ 5

Application............................................................................................................................................ 5

Component Data.................................................................................................................................... 5

Light Emitting Diodes (LEDs).......................................................................................................... 6

BACnet Network Connector............................................................................................................. 7

Board-To-Board Connector .............................................................................................................. 7

Installation .............................................................................................................................9

Contents of the BACnet Communication Module Kit........................................................................... 9

Installing a new BACnet Communication Module................................................................................ 9

To install a BACnet Communication Module................................................................................... 9

Replacing an Existing BACnet Communication Module.................................................................... 10

To Replace a BACnet Communication Module.............................................................................. 10

Integration............................................................................................................................11

Configuring the BACnet Communication Module.............................................................................. 11

BACnet MS/TP Configuration using the Keypad/Display.............................................................. 11

Changing the BACnet MS/TP Data Transmission Rate.................................................................. 12

Service Information.............................................................................................................15

Test Procedures................................................................................................................................... 15

Parts List ............................................................................................................................................. 15

Installation Kit................................................................................................................................. 15

Figures

Figure 1. BACnet MS/TP Communication Module Attached to MicroTech III Chiller Unit Controller5

Figure 2. BACnet MS/TP Communication Module Components......................................................... 6

Figure 3. BACnet MS/TP Communication Module and Knockout ...................................................... 7

Figure 4. Diagram of Board-to-Board Connector ................................................................................. 8

Figure 5. BACnet MSTP Communication Module with Board-to-Board Connector Inserted.............. 8

Figure 6. MicroTech III Chiller Unit Controller Password Menu and Main Features ........................ 12

Figure 7. MicroTech III Chiller Unit Controller MSTP Setup Menu – Change Baud Rate................ 13

Figure 8. MicroTech III Chiller Unit Controller MSTP Setup Menu – Apply Change....................... 13

2 IM 967-1

Page 3

Revision History

IM 967 October 2009 Initial release

IM 967-1 October 2010 Updated OMM 998 to OM 1051. Added AGD Model.

IM 967-1 March 2012 Updated with Daikin McQuay logo and associated references

Reference Documents

Number Company Title Source

ANSI/ASHRAE 1352004

IM 1002 (50Hz )

IM 997 (60Hz)

OM 1051

ED 15120 McQuay International MicroTech III Chiller Unit Controller Protocol

OMM 1087 McQuay International Air-cooled Scroll Chiller, Model AGZ Operation Manual www.daikinmcquay.com

American Society of

Heating, Refrigerating and

Air-Conditioning Engineers

McQuay International

McQuay International

BACnet® A Data Communication Protocol for Building

Automation and Control Networks

Pathfinder™ Air Cooled Chiller Installation Manual www.daikinmcquay.com

Pathfinder Air Cooled Chiller Operation Manual

Information, BACnet and LONW

ORKS

Networks

www.ashrae.org

www.daikinmcquay.com

www.daikinmcquay.com

Limited Warranty

Consult your local Daikin McQuay Representative for warranty details. Refer to Form 933-43285Y.

To find your local Daikin McQuay Representative, go to www.daikinmcquay.com.

Notice

Copyright © 2012 McQuay International, Minneapolis MN. All rights reserved throughout the world.

McQuay reserves the right to change any information contained herein without prior notice. The user is

responsible for determining whether this software is appropriate for his or her application.

® ™ The following are tradenames or registered trademarks of their respective companies: BACnet

from the American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.; Windows

from Microsoft Corporation; D-Net, Pathfinder, Daikin McQuay and MicroTech III from McQuay

International.

IM 967-1 3

Page 4

General Information

This manual contains the information you need to install the BACnet® Communication Module on a

MicroTech III Chiller Unit Controller, incorporate it into the BACnet network, and maintain it.

Hazard Identification Messages

Dangers indicate a hazardous situation that will result in death or serious injury if not

avoided.

Warnings indicate potentially hazardous situations, which can result in property damage,

severe personal injury, or death if not avoided.

Cautions indicate potentially hazardous situations, which can result in personal injury or

equipment damage if not avoided.

DANGER

!

WARNING

!

CAUTION

!

WARNING

!

Electric shock hazard. Can cause personal injury or equipment damage.

This equipment must be properly grounded. Connections and service to the MicroTech III

Chiller Unit Controller must be performed only by personnel knowledgeable in the

operation of the equipment being controlled.

CAUTION

!

Static sensitive components. Can cause equipment damage.

Discharge any static electrical charge by touching the bare metal inside the control panel

before performing any service work. Never unplug cables, circuit board terminal blocks, or

power plugs while power is applied to the panel.

NOTICE

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with this instruction manual, may cause interference to

radio communications. It has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be required to correct the

interference at his or her own expense. Daikin McQuay disclaims any liability

resulting from any interference or for the correction thereof.

4 IM 967-1

Page 5

Description

Application

The MicroTech III® BACnet Communication Module incorporates a MicroTech III Chiller Unit

Controller into a BACnet local area network (LAN). It supports the BACnet MS/TP (EIA 485) data

link layer (physical layer.)

The BACnet Communication Module is a printed circuit board with a plastic enclosure that connects

to the left side of the D-Net™ Module as shown in Figure 1 or directly to the MicroTech III Chiller

Unit Controller. The BACnet Communication Module provides access to the MicroTech III Chiller

Unit Controller variables and parameters via BACnet.

Note: The D-Net module is an optional feature that provides remote monitoring and diagnostic

capability for certain models of Daikin McQuay chillers. Please refer to supporting

literature, available on www.daikinmcquay.com, for additional details about D-Net.

The BACnet Communication Module connects the MicroTech III Chiller Unit Controller to a

building automation system (BAS) on a BACnet local area network. It is the interface for the

exchange of BACnet objects between the network and the unit controller. Refer to the MicroTech III

Chiller Operation Manual, available on www.daikinmcquay.com, for keypad details.

Component Data

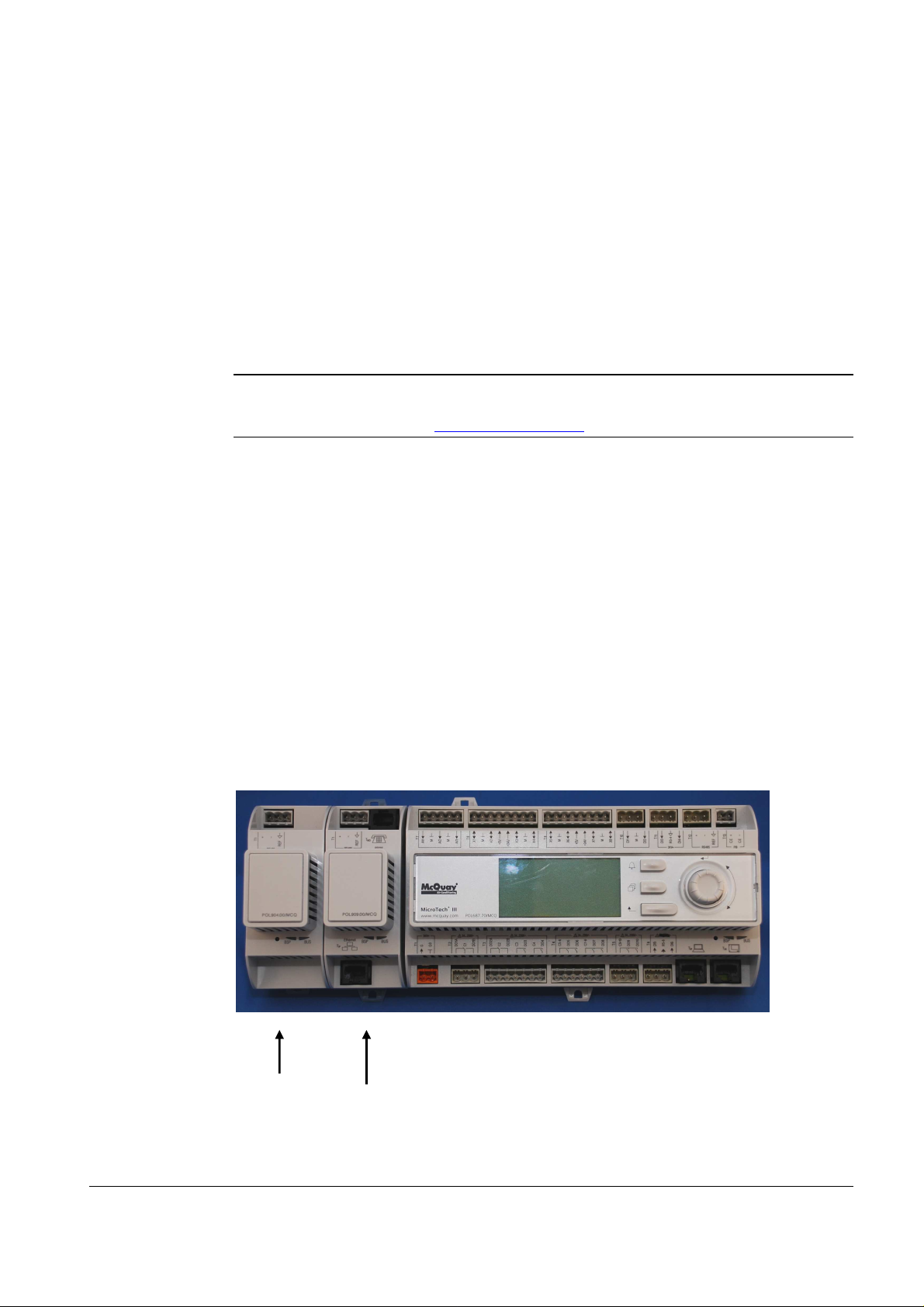

Figure 1 shows the BACnet Communication Module, located on the far left-hand side of the image

below. It is connected to the D-Net Module, which is mounted directly to the unit controller. Figure

2 shows the important features of the BACnet Communication Module.

Figure 1. BACnet MS/TP Communication Module Attached to MicroTech III Chiller Unit

Controller

BACnet MS/TP

Communication

Module

IM 967-1 5

D-Net Module attached to unit

controller

Page 6

Figure 2 shows the location of the major components of the BACnet MS/TP Communication Module.

Figure 2. BACnet MS/TP Communication Module Components

Network Connector

+ - Ref

BUS LED

BSP LED

Light Emitting Diodes (LEDs)

The BACnet Communication Module has a BSP LED and a BUS LED to indicate communication

activity and status of the BACnet Communication Module. These indicators are visible when the

communication module is connected to the MicroTech III Chiller Unit Controller and the unit is

powered on (see Figure 2).

BSP LED

The BSP LED indicates the communication state between the BACnet Communication Module and

the MicroTech III Chiller Unit Controller. The table below describes the status of the BSP LED.

BSP LED Color Meaning

Flashing between Red & Green Board Support Package (BSP) upgrade in progress

Green Communication is established with the unit controller

Communication is established between the communication

module and the unit controller.

Yellow The communication module is capable of communicating to

the unit controller. However, communication is not

established.

Red flashing with 2Hz Red flashing with 2Hz = Software error.1

Red Hardware error. 1

1

In the event that this should occur, cycle power to the unit controller to attempt to clear the problem. Contact

the Controls Customer Support Group at 866-462-7829 for additional assistance if necessary.

6 IM 967-1

Page 7

connector

BUS LEDs

The BUS LED indicates the communication status between the BACnet Communication Module and

the BACnet MS/TP network. The table below describes the status of the BUS LED.

BUS LED Color Meaning

Green The unit controller is capable of communicating to the network.

Red The unit controller is not capable of communicating to the network.

Orange / Yellow Communication module is initializing.

BACnet Network Connector

An RS485 connector connects the BACnet Communication Module to the MS/TP Network and has

three pins: + , -, and ref (see Figure 2).

Board-To-Board Connector

The board-to-board connector connects the MicroTech III Chiller Unit Controller to the BACnet

Communication Module (see Figures 3, 4 and 5).

Figure 3. BACnet MS/TP Communication Module and Knockout

Knockout

permanently

Board-to-board

removed

Slot in module must line

up with baffle in boardto-board connector

IM 967-1 7

Page 8

Figure 4. Diagram of Board-to-Board Connector

Figure 5. BACnet MSTP Communication Module with Board-to-Board Connector Inserted

8 IM 967-1

Page 9

!

Installation

The following section describes how to field install a new BACnet Communication Module or replace

an existing BACnet Communication Module on the MicroTech III Chiller Unit Controller so that it

can be incorporated into the BACnet network.

CAUTION

Electrostatic discharge hazard. Can cause equipment damage.

This equipment contains sensitive electronic components that may be damaged by

electrostatic discharge from your hands. Before you handle a communications module, you

need to touch a grounded object, such as the metal enclosure, in order to discharge the

electrostatic potential in your body.

Contents of the BACnet Communication Module Kit

The following is the list of items included in the field-installed kit:

• The BACnet Communication Module

• Board-to-board connector

• Network connector (attached to module)

• Installation Manual (IM 967)

Installing a new BACnet Communication Module

Follow these steps to install a BACnet Communication Module on the unit controller. The BACnet

Communication Module can be connected directly to the unit controller itself or to an existing

module, if one is attached.

To install a BACnet Communication Module

WARNING

!

Electric shock hazard. Can cause personal injury or equipment damage.

This equipment must be properly grounded. Only personnel knowledgeable in the operation of the

equipment being controlled must perform connections and service to the MicroTech III Chiller Unit

Controller.

1. Set the Unit On/Off Switch to “Off” from inside the control panel of the unit. This must be done

prior to installing a new communication module. Refer to Figure 3, IM 1122 (Pathfinder chiller)

or OMM 1087 (AGZ-D chiller), available on www.daikinmcquay.com.

2. Remove power from the unit controller.

3. Remove the knockout on the far left end of the unit controller itself (or additional module, if

present). See Figure 3.

Note: To prevent damage to the unit controller, insert a small screwdriver or other tool to the tab on

the bottom of the unit controller and pull the screwdriver away from the controller.

IM 967-1 9

Page 10

4. Remove the knockout on the right side of the BACnet Communication Module.

5. Insert the board-to-board connector into the BACnet Communication Module (see Figures 3 and

4). Note that it only fits one way and that the baffles must line up with corresponding slots in

BACnet Communication Module and the unit controller (see Figures 4 and 5).

6. Insert the other end of the board-to-board connector to the far-left side of the unit controller or

other device (i.e. module), if attached (see Figure 1).

7. Connect the BACnet Communication Module to the network by inserting a network cable into the

communication module’s network connector (see Figure 2).

8. Power up the unit controller.

9. The unit controller automatically resets itself approximately 30 seconds after it is powered up.

This reset is necessary so that the BACnet Communication Module is synchronized with the unit

controller.

Note: There is a limit of three devices that can be attached to the left side of the unit controller.

Replacing an Existing BACnet Communication Module

Follow these steps to remove an existing BACnet Communication Module from unit controller and

replace it with a new BACnet Communication Module.

To Replace a BACnet Communication Module

WARNING

!

Electric shock hazard. Can cause personal injury or equipment damage.

This equipment must be properly grounded. Only personnel knowledgeable in the operation of the

equipment being controlled must perform connections and service to the MicroTech III Chiller Unit

Controller.

1. Set the Unit On/Off Switch to “Off” from inside the control panel of the unit. This must be done

prior to replacing a communication module. Refer to Figure 3, IM 1122 (Pathfinder chiller) or

OMM 1087 (AGZ-D chiller), available on www.daikinmcquay.com.

2. Remove power from the unit controller.

3. Locate the BACnet Communication Module to the left of the unit controller (see Figure 1).

4. Pull the network cable connector from the BACnet Communication Module.

5. Grasp the BACnet Communication Module and carefully pull it from the unit controller (or from

an adjacent module, if it is attached to one.)

6. Install the new BACnet Communication Module (see steps 2-5 from previous section).

7. Insert the network cable connector into the BACnet Communication Module (see Figure 2 for

location of network connector).

8. Power up the unit controller.

10. The unit controller automatically resets itself approximately 30 seconds after it is powered up.

This reset is necessary so that the BACnet Communication Module is synchronized with the unit

controller.

10 IM 967-1

Page 11

Integration

Once the BACnet Communication Module has been properly installed on the MicroTech III Chiller

Unit Controller, it is then necessary to configure the unit controller for integration into a Building

Automation System (BAS) via the BACnet MS/TP network. The configuration process is described

in the following section.

Configuring the BACnet Communication Module

The BACnet Communication Module is configured using the keypad/display on unit controller.

Table 1 describes all of the available BACnet MS/TP network parameters used to establish

communication between the unit controller and the BAS. The items shown in boldface are required

for minimum network configuration. Table 1 also defines the factory defaults (as indicated by the

Initial Value/Note column) for each network parameter.

See your system integrator for additional information regarding proper BACnet MS/TP addressing.

Refer to the MicroTech III Chiller Unit Controller Operation Manual for additional information on

using keypad/display to set unit parameters and factory defaults for unit setpoints. Refer to Protocol

Document ED 15120, available on www.daikinmcquay.com, for descriptions of the available BACnet

objects.

BACnet MS/TP Configuration using the Keypad/Display

1. If you have not already entered a password, select Enter Password from the Main Menu screen

(i.e. turn the circular knob on the unit controller until the cursor is in the proper location) and

press Enter (i.e. press down on the knob). See Figure 6.

a. If you are not at the Main Menu and need to enter a password, press the Back button from

any other menu screen until you reach the Main Menu and follow step 1. See Figure 6 for the

location of the Back button.

b. If you have already entered a password, skip to step 3. See Figure 6 if you are not certain

whether or not a password has been entered.

2. Enter Password: 5321 and then press Enter.

3. Scroll down to View/Set Unit (i.e. turn the knob clockwise) and press Enter.

4. Scroll down to BACnet MSTP Setup and press Enter.

Note: The BACnet MSTP Setup menu only appears if a BACnet Communication Module

installed correctly (see Installation section of this document for details.) If the BACnet

Communication Module is installed correctly and this menu still does not appear, cycle

power to the unit controller and repeat the procedure above.

5. Scroll down to MSTP Address (MAC Address) and press Enter. Change this parameter to the

value specified by the network administrator. Press Enter again to confirm selection.

Note: The BACnet MS/TP Media Access Control (MAC) address is a one-octet address that must

be set during the BACnet Communication Module configuration. The MAC address must

be unique to the MS/TP network and have a valid range of 0-127.

6. Change additional parameters as required for your network (see Table 1).

7. Set Apply Changes to Yes. This will save the changes and cycle power to unit controller.

IM 967-1 11

Page 12

8. Navigate back to the BACnet MSTP Setup menu (see steps 1-4) to verify the settings of all

parameters. This procedure may take a minute while the BACnet Communication Module

powers up.

Figure 6. MicroTech III Chiller Unit Controller Password Menu and Main Features

Back button Circular knob (press

down to Enter value)

Changing the BACnet MS/TP Data Transmission Rate

The BACnet Communication Module is set with a factory default baud rate of 38400 bps. Additional

baud rate options (in bps) include: 9600, 19200, 38400, and 76800. The following section describes

how to change the BACnet MS/TP data transmission rate via the keypad display.

WARNING

!

Electric shock hazard. Can cause personal injury or equipment damage.

This equipment has exposed electrical connections inside BACnet Communication Module.

Only personnel that are knowledgeable in the operation of this equipment must perform

connections and service to the BACnet Communication Module.

1. If you have not already entered a password, select Enter Password from the Main Menu screen

(i.e. turn the circular knob on the unit controller until the cursor is in the proper location) and

press Enter (i.e. press down on the knob). See Figure 6.

a. If you are not at the Main Menu and need to enter a password, press the Back button from

any other menu screen until you reach the Main Menu and follow step 1. See Figure 6 for the

location of the Back button.

b. If you have already entered a password, skip to step 3. See Figure 6 if you are not certain

whether or not a password has been entered.

2. Enter Password: 5321 and then press Enter.

3. Scroll down to View/Set Unit (i.e. turn the knob clockwise) and press Enter.

4. Scroll down to BACnet MSTP Setup and press Enter.

5. Change the Baud Rate by scrolling to Baud Rate and press Enter to selected desired baud rate

(see Figure 7 to view a baud rate that has been changed to 76800 bps).

6. Scroll to ApplyMSTPChgs and set to Yes. This will save the changes and cycle power to the

unit controller (see Figure 8).

12 IM 967-1

Page 13

Figure 7. MicroTech III Chiller Unit Controller MSTP Setup Menu – Change Baud Rate

Figure 8. MicroTech III Chiller Unit Controller MSTP Setup Menu – Apply Change

IM 967-1 13

Page 14

acter Device Object Name.

No/Selecting Yes enables an internal resistor.

Table 1. BACnet MS/TP Network Configuration Parameters

Parameter Value (Range)/Definition Initial Value/Note

Apply Changes1

No-Yes/Setting this to yes will cycle

No

power to the controller to allow the

network setup changes to take place.

Name Up to a 17-char

Change this value as needed to match

installation parameters.

POL904_FF2BEE/This name must be unique

throughout the entire BACnet network. The

last 6 characters of the default are the last 6

digits of the MAC Address, which is printed on

a label located on the left end of the module.

Dev Instance

MSTP Address1

Baud Rate1

0-4194302/Device Instance of the BACnet

Communication Module.

0-127/ This is the MS/TP address of the

BACnet Communication Module.

9600-19200-38400-76800/ Data transfer

368136/This must be unique throughout the

entire BACnet network.

18/ Each device on the BACnet network must

have a unique MS/TP address.

38400

speed (bps).

Max Master

0-127/ This variable specifies the highest

127

possible address for master. Nodes and

shall be less than or equal to 127.

Max Info Frm 0-255/ This variable specifies the

10

maximum number of information frames

the BACnet Communication Module may

send before it must pass the token.

Unit Support Metric-English/Controls the type of units

English

that are passed through BACnet (English

or Metric).

Term Resistor1 No-Yes

Select No, if there is an external resistor or if

this unit is not the first or last unit on the

segment.

NC Dev 11 0-4194303/Alarm Recipient Device 1 0 (no device)/This is the device instance of the

BACnet workstation or device that will receive

the alarm notification. Use this in place of the

Recipient List in the Notification Class.

NC Dev21 0-4194303/Alarm Recipient Device 2 0 (no device)/This is the device instance of the

BACnet workstation or device that will receive

the alarm notification. Use this in place of the

Recipient List in the Notification Class.

BACnetBSP1 Basic Support Package Version 1.1.30s

1

Parameter only available via the keypad/display.

2

Items in boldface are required for minimum network configuration.

Note: If unit controller application software requires downloading in the field, the network

14 IM 967-1

configuration parameters revert to their default values. Please contact the Technical

Response Center at 877-349-7782 for assistance with upgrading unit controller application

software.

Page 15

Service Information

Test Procedures

If you can control the unit from its keypad, but you are not able to communicate with the unit via the

network, follows these steps:

• Check the network wiring

• Check the network parameters and verify that they are correct and that there are no duplicate devices

on the network

• Check communications

If the BACnet Communication Module still does not respond, contact the Controls Customer Support

Group at 866-462-7829.

Parts List

Installation Kit

Description Part Number

MicroTech III Chiller Communication Module, BACnet MS/TP kit

(kit includes communication module, board-to-board connector, and

Installation Manual)

350147414

IM 967-1 15

Page 16

This document contains the most current product information as of this printing. For the most current product

information, please go to www.daikinmcquay.com. All McQuay equipment is sold pursuant to Daikin McQuay

Standard Terms and Conditions of Sale and Limited Warranty.

Loading...

Loading...