Page 1

Installation and Operation Manual

Air-Cooled Global Chiller

Type AGZ 030A through 065A

60 Hertz, English and Metric

Scroll Compressors using Refrigerant R-22

IOM 686

Group: Chiller

Part Number: 062994901

Effective: March 1997

Supersedes: None

© 1997 McQuay International

Page 2

Table of Contents

Introduction.........................................3

General Description.......................................3

Inspection ....................................................... 3

Installation...........................................4

Handling......................................................... 4

Location.......................................................... 5

Service Access................................................ 5

Vibration Isolators......................................... 6

Water Piping...................................................7

Flow Switch................................................... 9

Water Connections.........................................9

Refrigerant Charge......................................... 9

Superheat and Subcooling............................. 9

Glycol Solutions..........................................10

Evaporator Water Flow and Pressure Drop 11

Physical Data.....................................13

Electrical Data...................................16

Field Wiring ................................................. 16

Dimensional Data..............................28

Optional Sensors..........................................31

Pre Start-up .................................................. 31

Start-Up........................................................31

Shutdown......................................................32

Sequence of Operation.................................33

Standard Controller Setpoints (optional Zone

Terminal required to change values)...........33

Software Description (Global UNT Interface

Kit required to read or change variables)....34

Hot Gas Bypass (Optional)..........................34

Combination Filter Drier.............................35

System Adjustment ...................................... 35

Liquid Sightglass and Moisture Indicator... 35

Refrigerant Charging ................................... 35

Thermostatic Expansion Valve.................... 35

Crankcase Heaters........................................ 36

Water Cooler................................................36

Controller Inputs /Outputs..........................38

Additional Global UNT Controller Features41

Alarms .......................................................... 43

ZONE TERMINAL (optional)....................44

Zone Terminal Glossary...............................48

Global UNT Controller Troubleshooting

Chart.............................................................50

MicroTech Controller Installation

and Operation....................................51

AGZ Unit Check-out.........................29

Water piping checkout ................................. 29

Refrigerant piping checkout........................29

Electrical Check Out....................................29

AGZ Troubleshooting Chart........................30

Global UNT Controller Installation

and Operation....................................31

General Description.....................................31

"McQuay" is a registered trademark of McQuay International

"Illustrations cover the general appearance of McQuay International products at the time of publication and we

reserve the right to make changes in design and construction at anytime without notice"

1997 McQuay International

General Description.....................................51

Optional Sensor Packages ........................... 51

Installation.................................................... 51

Sequence of Operation.................................60

Start-Up and Shutdown................................62

Keypad / Display..........................................63

Menu Descriptions....................................... 66

Trouble Analysis for the AGZ MicroTech

Controller.....................................................77

Test Procedures............................................79

2 AGZ 030A through 065A IOM 686

Page 3

Introduction

General Description

McQuay Air-Cooled Global water chillers are complete, self-contained automatic refrigerating units.

Every unit is completely assembled, factory wired, charged, and tested. Each unit consists of twin AirCooled condensers with integral subcooler sections, multiple tandem scroll compressors, replaceable

tube dual circuit shell-and-tube evaporator, and complete refrigerant piping. Liquid line components

include manual liquid line shutoff valves, sight-glass/moisture indicators, solenoid valves, and double

diaphragm hydraulic element thermal expansion valves. Other features include compressor crankcase

heaters, an evaporator heater for chilled water freeze protection, limited pumpdown during “on” or

“off” periods, compressor lead-lag switch to alternate the compressor starting sequence, and sequenced

starting of compressors.

automatic operation. Condenser fan motors are fused in all three phases and started by their own

three-pole contactors. Compressors are not fused but may be protected by optional circuit breakers.

Inspection

Check all items carefully against the bill of lading. Inspect all units for damage upon arrival. Report

shipping damage and file a claim with the carrier. Check the unit name plate before unloading, making

certain it agrees with the power supply available. McQuay is not responsible for physical damage after

unit leaves the factory.

The electrical control center includes all safety and operating controls necessary for dependable

Note: Unit shipping and operating weights are available in the Physical Data tables

beginning on page 13.

IOM 686 AGZ 030A through 065A 3

Page 4

Installation

Note: Installation is to be performed by qualified personnel who are familiar with local

codes and regulations.

WARNING

Sharp edges and coil surfaces are a potential hazard. Avoid contact with them.

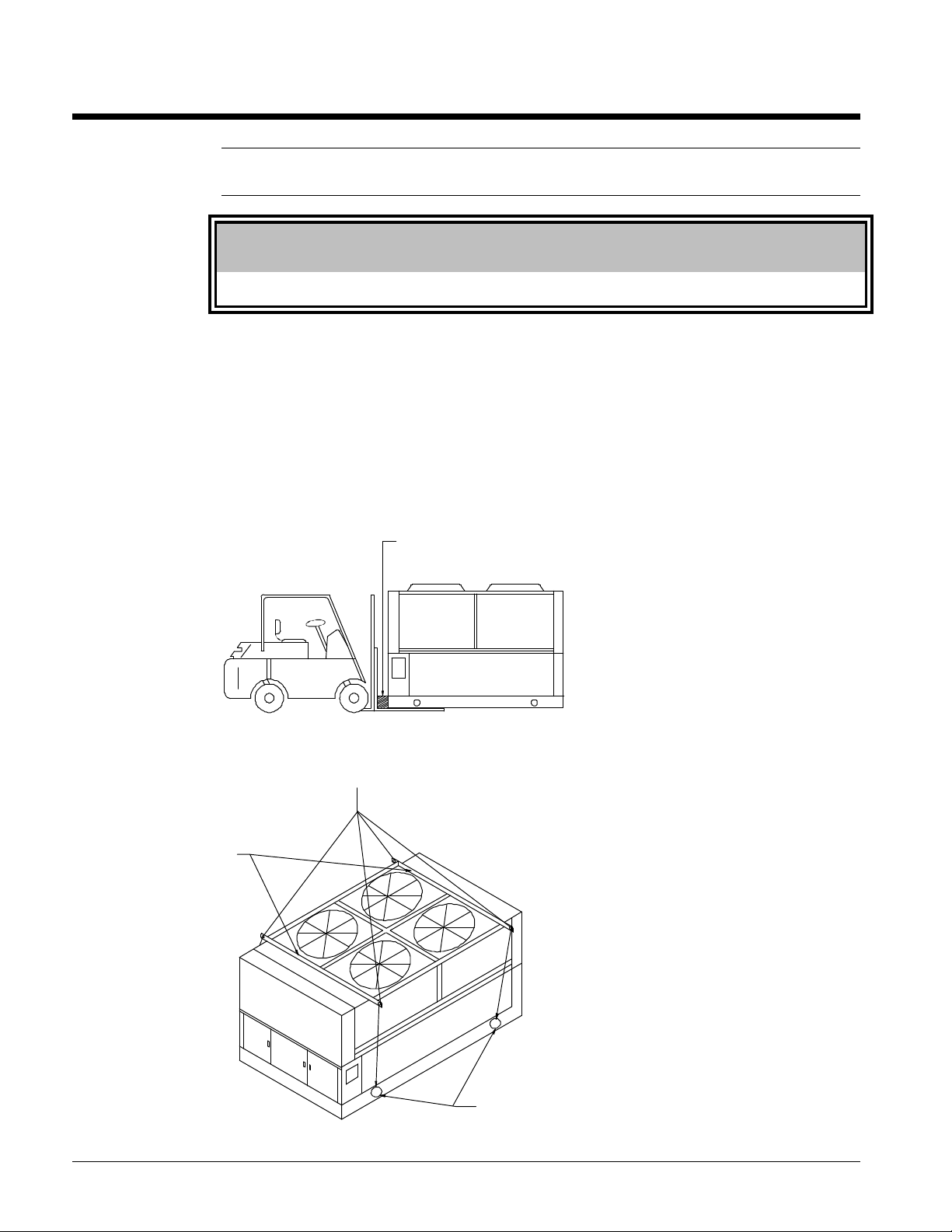

Handling

Be careful to avoid rough handling of the unit. Do not push or pull the unit from anything other than

the base. Block the pushing vehicle away from the unit to prevent damage to the sheet metal cabinet

and end frame (see Figure 1).

To lift the unit, 2 1/2" (64mm) diameter lifting holes are provided in the base of the unit. Arrange

spreader bars and cables to prevent damage to the condenser coils or cabinet (see Figure 2).

Figure 1, Suggested pushing arrangement

Blocking is required

across full width

Figure 2, Suggested lifting arrangement

Number of fans may vary

Spreader Bars

recommended

(use caution)

4 AGZ 030A through 065A IOM 686

from this diagram. The

lifting method will remain

the same

These rigging holes

must be used.

Page 5

Location

Unit Placement

AGZ units are for outdoor applications and can be mounted on a roof or ground level. Set units on a

solid and level foundation. For roof mounted applications, install the unit on a steel channel or I-beam

frame to support the unit above the roof. For ground level applications, install the unit on a

substantial base that will not settle. A one piece concrete slab with footings extended below the frost

line is recommended. Be sure the foundation is level (within 1/2” [13 mm] over its length and width).

The foundation must support the operating weights listed in the Physical Data tables beginning on page

13.

On ground level applications protect fins against vandalism using the optional coil guards or by

erecting a screen fence. The fence must allow free flow of air to the condenser coil for proper unit

operation.

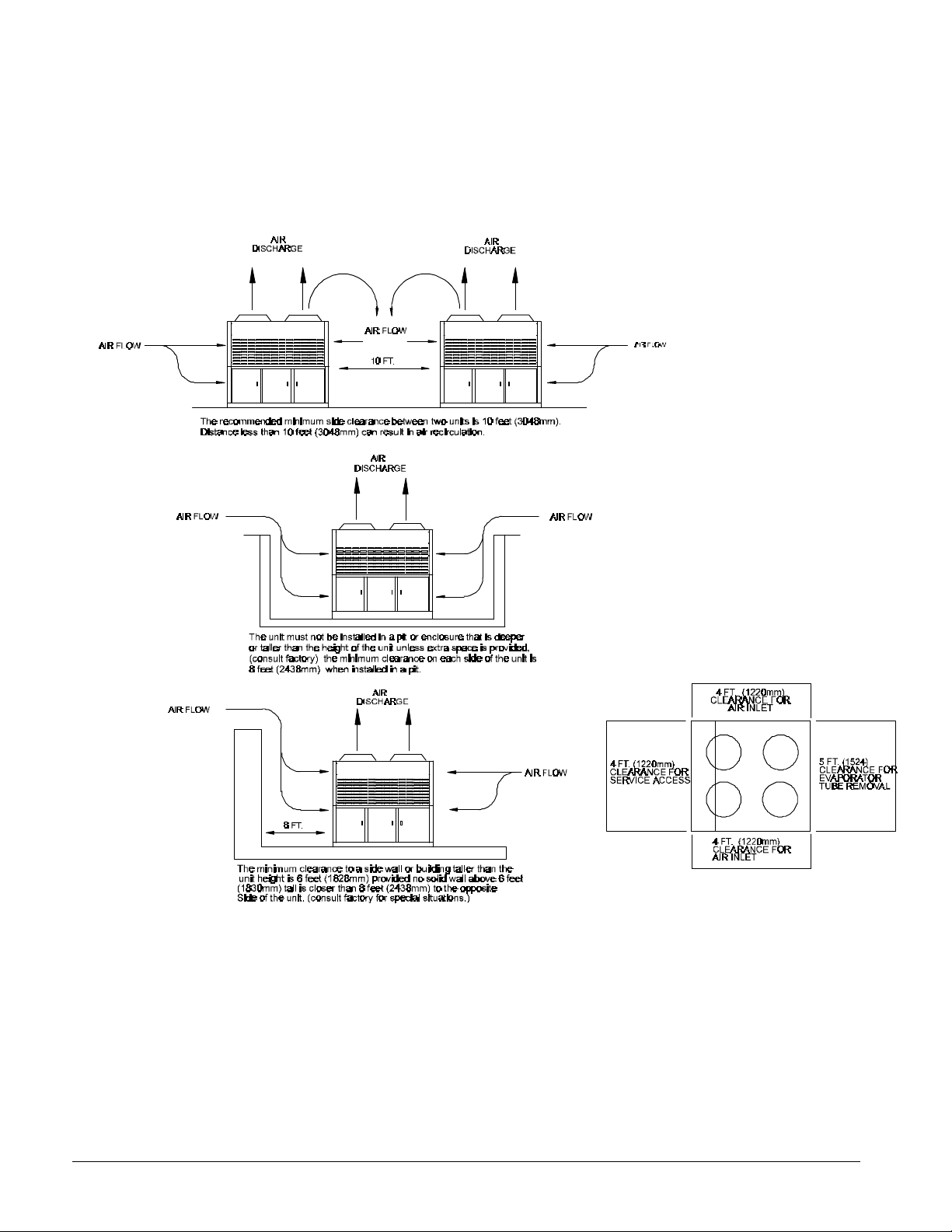

Clearances

The flow of air to and from the condenser coil must not be limited. Restricting air flow or allowing

air recirculation will result in a decrease in unit performance and efficiency. There must be no

obstruction above the unit that would deflect discharge air downward where it could be recirculated

back to the inlet of the condenser coil. The condenser fans are propeller type and will not operate with

ductwork on the fan outlet.

Install the unit with enough side clearance for air entrance to the coil and for servicing. Provide

service access to the evaporator, compressors, electrical control panel and piping components as

shown in Figure 3.

Do not allow debris to accumulate near the unit. Air movement may draw debris into the

condenser coil causing air starvation. Give special consideration to low ambient operation where

snow can accumulate. Keep condenser coils and fan discharge free of snow or other obstructions to

permit adequate airflow.

Sound Isolation

The ultra-low sound levels of the AGZ chiller is suitable for most applications. When additional

sound reduction is necessary, locate the unit away from sound sensitive areas. Avoid locations beneath

windows or between structures where normal operating sounds may be objectionable. Reduce

structurally transmitted sound by isolating water lines, electrical conduit and the unit itself. Use wall

sleeves and rubber isolated piping hangers to reduce transmission of water or pump noise into

occupied spaces. Use flexible electrical conduit to isolate sound through electrical conduit. Spring

isolators are effective in reducing the low amplitude sound generated by reciprocating compressors

and for unit isolation in sound sensitive areas.

Service Access

Each end of the unit must be accessible after installation for periodic service. Compressors, filterdriers, and manual liquid line shutoff valves are accessible. High pressure control is located in the

control panel when using the Global UNT controller, and on the compressor when using the

MicroTech controller. Low pressure, and motor protector controls are on the compressor. Most other

operational, safety and starting controls are located in the unit control box.

The condenser fan and motors can be removed from the top of the unit.

IOM 686 AGZ 030A through 065A 5

Page 6

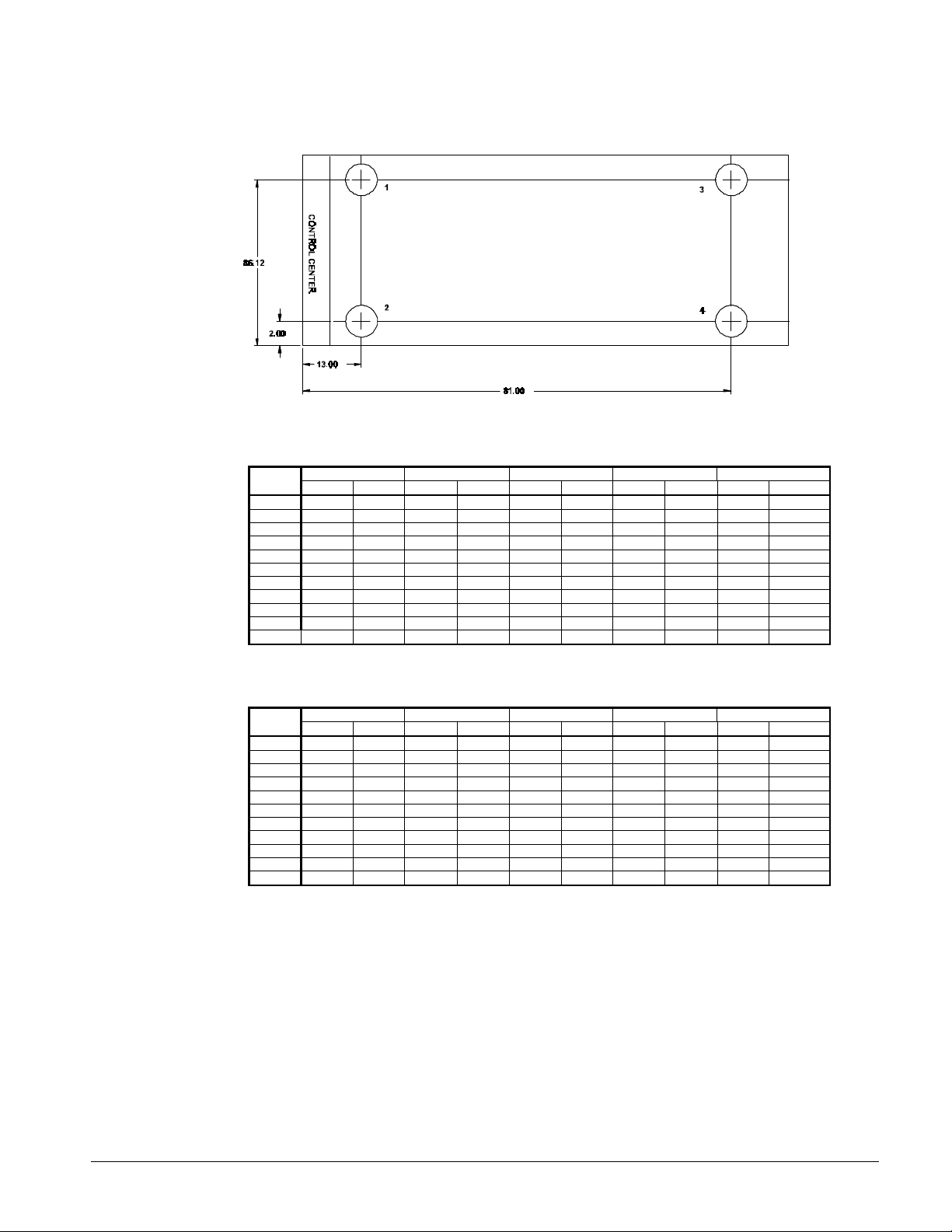

Vibration Isolators

Vibration isolators are recommended for all roof mounted installations or wherever vibration

transmission is a consideration.

lists isolator loads and type. Table 2 lists spring isolator part numbers for all unit sizes. See

Dimensional Data for dimensions required to secure each isolator to the mounting surface.

Figure 3, Clearance requirements

6 AGZ 030A through 065A IOM 686

Page 7

The spring flex isolators are white type CP2-32, McQuay part number 047792932. A total of four per

unit is required.

Figure 4, Isolator Locations

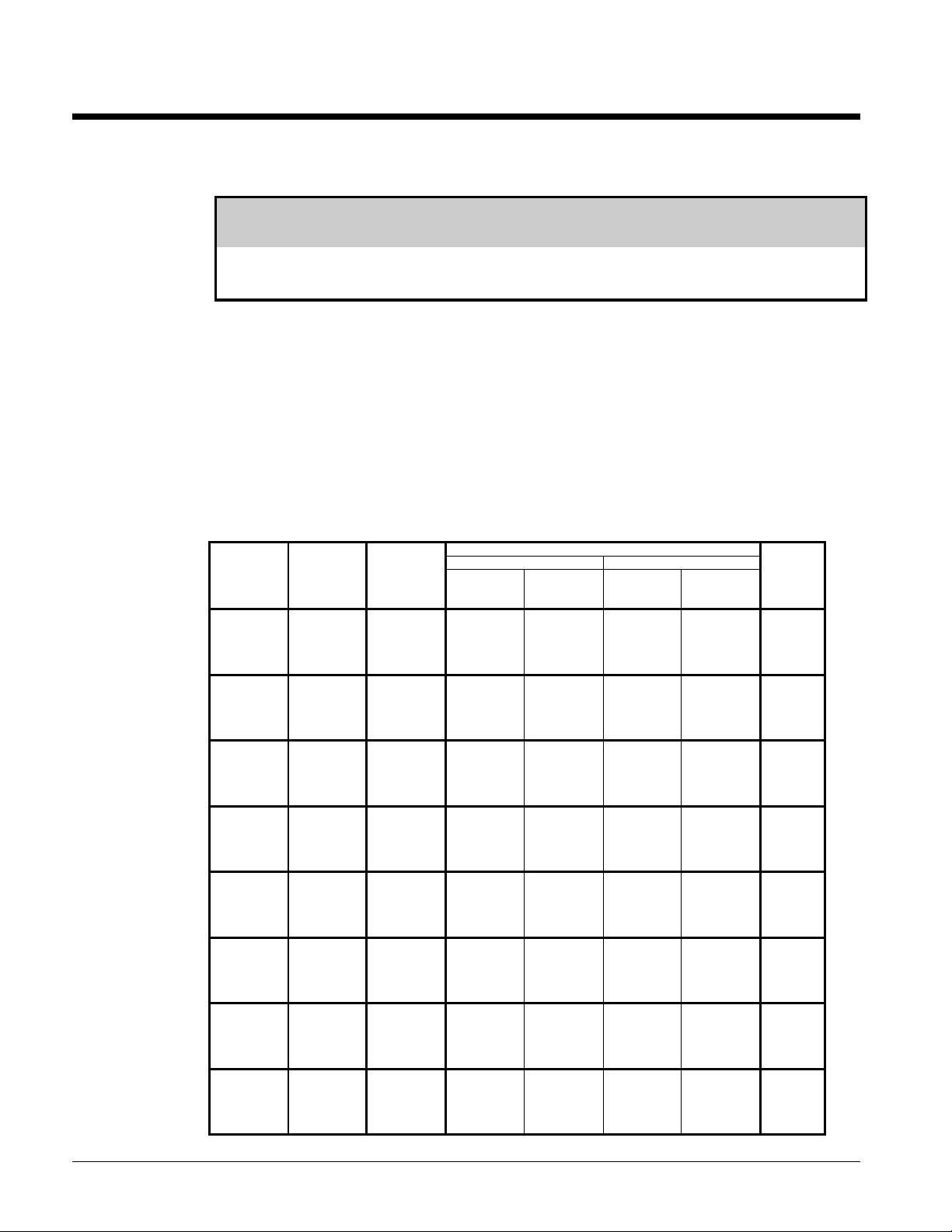

Table 1 , Isolator Loads at each Mounting Location with Aluminum Fins

Unit 1 2 3 4 Total Unit

Size Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg

030AS 838 380 944 428 773 351 870 395 3425 1554

035AS 850 386 960 435 785 356 885 401 3480 1579

040AS 864 392 974 442 797 362 900 408 3535 1603

045AS 928 421 1048 475 858 389 966 438 3800 1724

050AS 940 426 1062 482 868 394 980 445 3850 1746

055AS 990 449 1118 507 915 415 1032 468 4055 1839

060AS 1006 456 1134 514 928 421 1047 475 4115 1867

065AS 1050 476 1184 537 970 440 1091 495 4295 1948

030AE 852 386 960 435 786 357 887 402 3485 1581

040AE 904 410 1017 461 834 378 940 426 3695 1676

050AE 980 445 1105 501 905 411 1020 463 4010 1819

Table 2, Isolator Loads at each Mounting Location with Copper Fins

Unit 1 2 3 4 Total Unit

Size Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg

030AS 946 429 1066 484 873 396 985 447 3870 1755

035AS 960 435 1082 491 886 402 997 452 3925 1780

040AS 973 441 1096 497 899 408 1012 459 3980 1805

045AS 1038 471 1170 531 958 435 1079 489 4245 1926

050AS 1050 476 1184 537 970 440 1091 495 4295 1948

055AS 1154 523 1300 590 1066 484 1200 544 4720 2141

060AS 1166 529 1320 599 1078 489 1216 552 4780 2168

065AS 1252 568 1412 640 1156 524 1305 592 5125 2325

030AE 960 435 1083 491 887 402 1000 454 3930 1783

040AE 1066 484 1202 545 984 446 1108 503 4360 1978

050AE 1142 518 1288 584 1055 479 1190 540 4675 2121

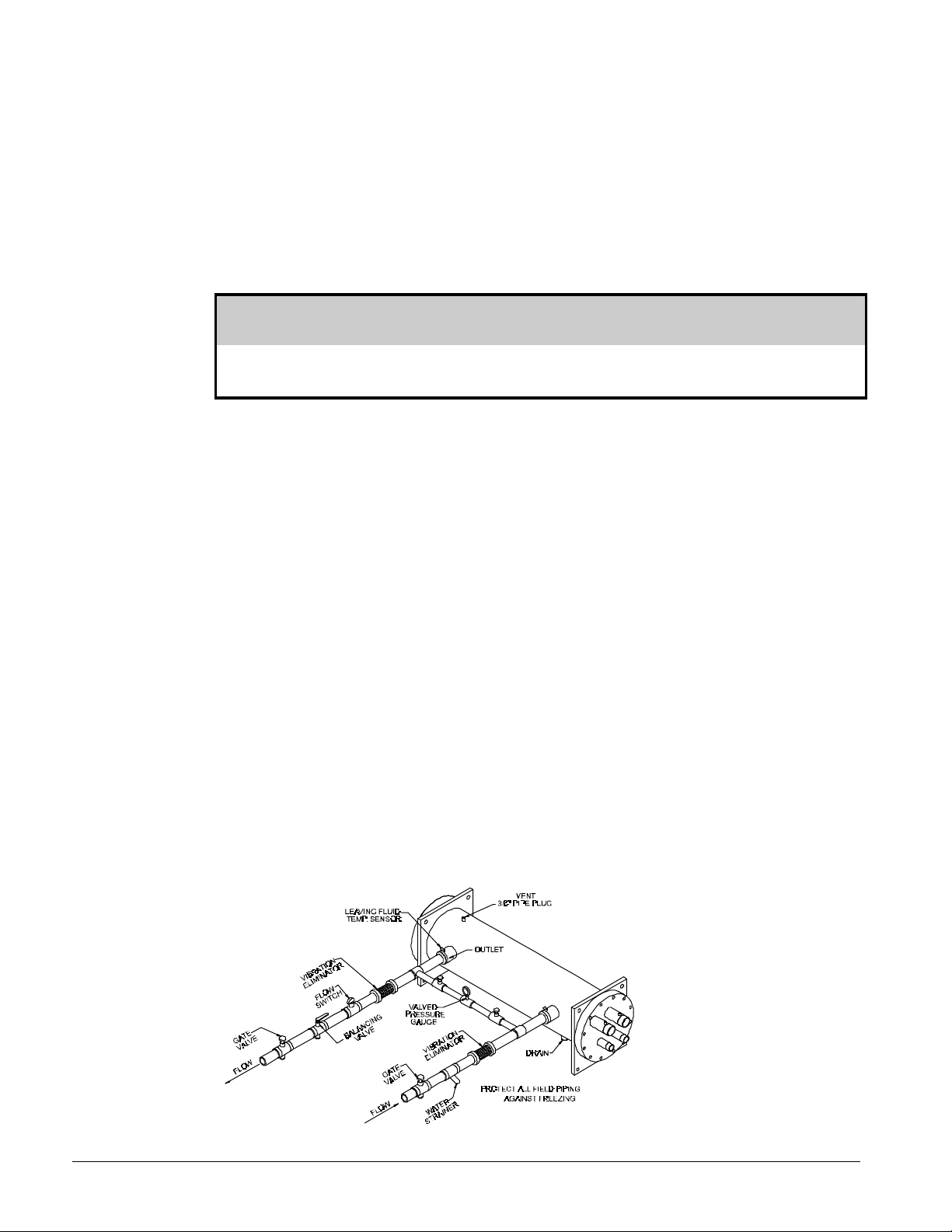

Water Piping

Local authorities can supply the installer with the proper building and safety codes required for safe

and proper installation.

Install piping with minimum bends and changes in elevation to minimize pressure drop. Consider

the following when installing water piping:

1. Vibration eliminators to reduce vibration and noise transmission to the building.

2. Shutoff valves to isolate the unit from the piping system during unit servicing.

IOM 686 AGZ 030A through 065A 7

Page 8

3. Manual or automatic air vent valves at the high points of the system. Install drains at the lowest

points in the system.

4. A means of maintaining adequate system water pressure (expansion tank or regulating valve).

5. Temperature and pressure indicators located at the unit to aid in unit servicing.

6. A strainer or other means of removing foreign matter from the water before it enters the pump.

Place the strainer far enough upstream to prevent cavitation at the pump inlet (consult pump

manufacturer for recommendations). The use of a strainer will prolong pump life and keep

system performance up.

7. Place a strainer in the water line just before the inlet of the evaporator. This will help prevent

foreign material from entering and decreasing the performance of the evaporator.

CAUTION

If separate disconnect is used for the 115V supply to the evaporator heating cable, mark

the disconnect clearly to ensure disconnect is not accidentally shut off during cold seasons.

8. The shell-and-tube evaporator has a thermostat and heating cable to prevent freeze-up down to 20°F (-29°C). It is suggested that the heating cable be wired to a separate 110V supply circuit.

As shipped from the factory, the heating cable is wired to the control circuit. All water piping to

the unit must also be protected to prevent freezing.

9. If the unit is used as a replacement chiller on a previously existing piping system, flush the system

thoroughly before unit installation. Regular water analysis and chemical water treatment for the

evaporator loop is recommended immediately at equipment start-up.

10. The total water volume in the system should be sufficient to prevent frequent “on-off” cycling.

Turnover rate should not be less than 15 minutes for normal variable cooling loads. Turnover rate

for process cooling or a constant load, should not be less than 6 minutes.

11. When glycol is added to the water system for freeze protection, the refrigerant suction pressure

will be lower, cooling performance less, and water side pressure drop greater. If the percentage of

glycol is high, or if propylene is used instead of ethylene glycol, the added pressure drop and loss

of performance could be substantial. Reset the freezestat and low leaving water alarm

temperatures. The freezestat is factory set to default at 36°F (2.2°C). Reset the freezestat setting

to approximately 4 to 5 degrees F (2.3 to 2.8 degrees C) below the leaving chilled water setpoint

temperature. See the section titled “Glycol Solutions” for additional information concerning

glycol.

12. Perform a preliminary leak check before insulating the piping and filling the system.

13. Piping insulation should include a vapor barrier to prevent condensation and possible damage to

the building structure.

Figure 5, Typical field evaporator water piping

8 AGZ 030A through 065A IOM 686

Page 9

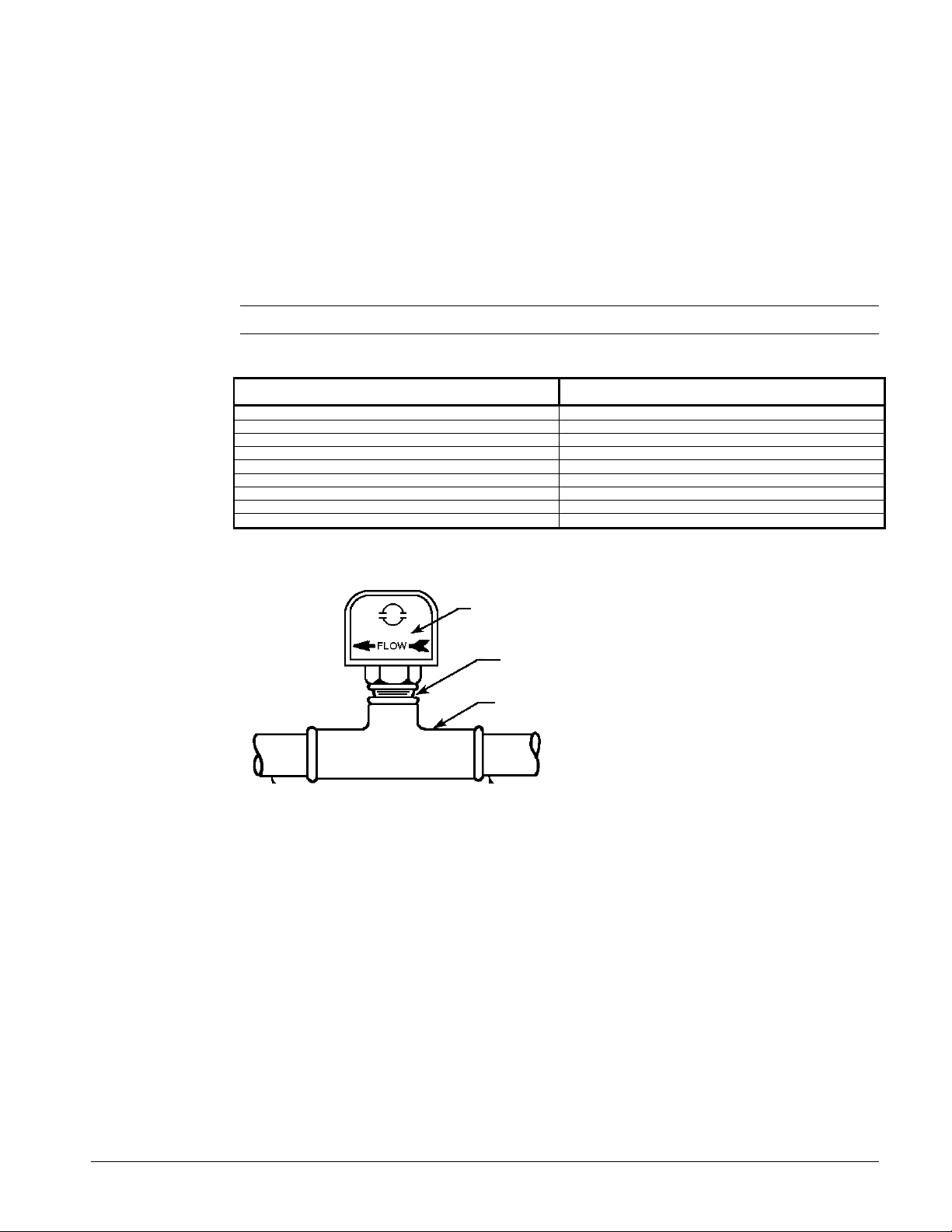

Flow Switch

Mount a water flow switch in either the entering or leaving water line to shut down the unit when

water flow is interrupted.

A flow switch is available from McQuay (part number 0017503300). It is a “paddle” type switch

and adaptable to any pipe size from 3” (76mm) to 8” (203mm) nominal. Certain minimum flow rates

are required to close the switch and are listed in Table 3. Installation should be as shown in Figure 6.

Connect the normally open contacts of the flow switch in the unit control center at terminals 5 and 6.

There is also a set of normally closed contacts on the switch that can be used for an indicator light or

an alarm to indicate when a “no flow” condition exists. Freeze protect any flow switch that is installed

outdoors.

NOTE: Differential pressure switches are not recommended for outdoor installation.

Table 3, Flow switch minimum flow rates

NOMINAL PIPE SIZE MINIMUM REQUIRED FLOW TO

INCHES (MM) ACTIVATE SWITCH - GPM (L/S)

1 (25.4) 6.00 (0.38)

11/4 (31.8) 9.80 (0.62)

11/2 (38.1) 12.70 (0.80)

2 (50.8) 18.80 (1.20)

21/2 (63.50 24.30 (1.50)

3 (76.20 30.00 (1.90)

4 (101.6) 39.70 (2.50)

5 (127.0) 58.70 (3.70)

6 (152.4) 79.20 (5.00)

Figure 6, Flow switch installation

Flow direction

marked on switch

1" (25mm) NPT flow

switch connection

Tee

Water Connections

Bring water piping to the evaporator through the side between the vertical supports.

Refrigerant Charge

All units are designed for use with R-22 and other refrigerants. See nameplate for specific refrigerant

used. Units are shipped with an operating charge. The operating charge

(using R-22) for each unit is shown in the Physical Data tables beginning on page 13.

Superheat and Subcooling

For optimum operation, set the evaporator superheat for 8 - 12°F (4.4 - 6.6°C) and condenser

subcooling (at the liquid shutoff valves) to 15°F (8.3°C).

IOM 686 AGZ 030A through 065A 9

Page 10

Note: The procedure

does not specify the

type of glycol. Use

the derate factors

found in Table 4 for

corrections when

using ethylene glycol

and those in Table 5

for propylene glycol.

Glycol Solutions

The system glycol capacity, glycol solution flow rate in GPM, and pressure drop through the cooler

may be calculated using the following formulas and table.

1. Capacity -- Find the reduced capacity by multiplying the chiller’s capacity with water by the

capacity correction factor C.

2. Flow -- To determine evaporator gpm (or Delta-T) knowing Delta-T (or gpm) and capacity:

×

Glycol GPM (from table)=

24 capacity glycol

Delta T

For Metric Applications -- To determine evaporator L/s (or Delta-T) knowing Delta-T (or L/s)

and kW:

Glycol L / s (from table)=

4.18

kW

× −

Delta T

3. Pressure drop -- To determine pressure drop through the evaporator, when using glycol, enter the

water pressure drop curve on page 12 at the actual glycol GPM. Multiply the water pressure drop

by PD correction factor from Table 4 or Table 5 to obtain corrected glycol pressure drop.

4. To determine the unit's power consumption when using glycol, multiply the water system kW by

factor kW.

Test coolant with a clean, accurate glycol solution hydrometer (similar to that found in service

stations) to determine the freezing point. Obtain percent glycol from the freezing point table below.

On glycol applications it is normally recommended by the supplier that a minimum of 25% solution by

weight be used for protection against corrosion.

( )

−

×

Flow

×

G

CAUTION

Do not use an automotive grade antifreeze. Industrial grade glycols must be used.

Automotive antifreeze contains inhibitors which will cause plating on the copper tubes within

the chiller evaporator. The type and handling of glycol used must be consistent with local

codes.

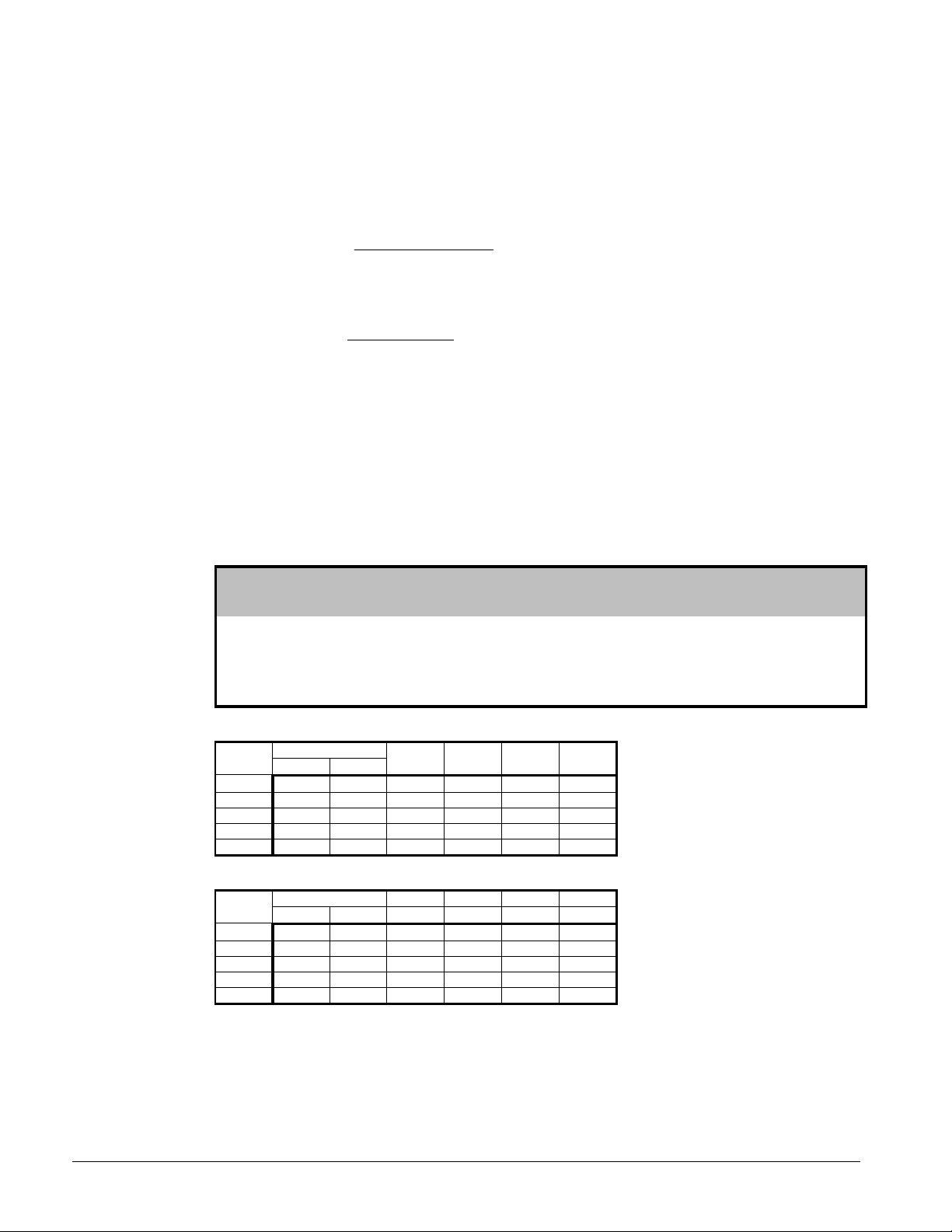

Table 4, Ethylene glycol

% Freeze Point

E.G. °F °C Cap. kW GPM PD

10 26 -3 0.991 0.996 1.013 1.070

20 18 -8 0.982 0.992 1.040 1.129

30 7 -14 0.972 0.986 1.074 1.181

40 -7 -22 0.961 0.976 1.121 1.263

50 -28 -33 0.946 0.966 1.178 1.308

Table 5, Propylene glycol

% Freeze Point

P.G. °F °C Cap. kW GPM PD

10 26 -3 0.987 0.992 1.010 1.068

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

40 -5 -21 0.946 0.971 1.078 1.366

50 -27 -33 0.929 0.965 1.116 1.481

10 AGZ 030A through 065A IOM 686

Page 11

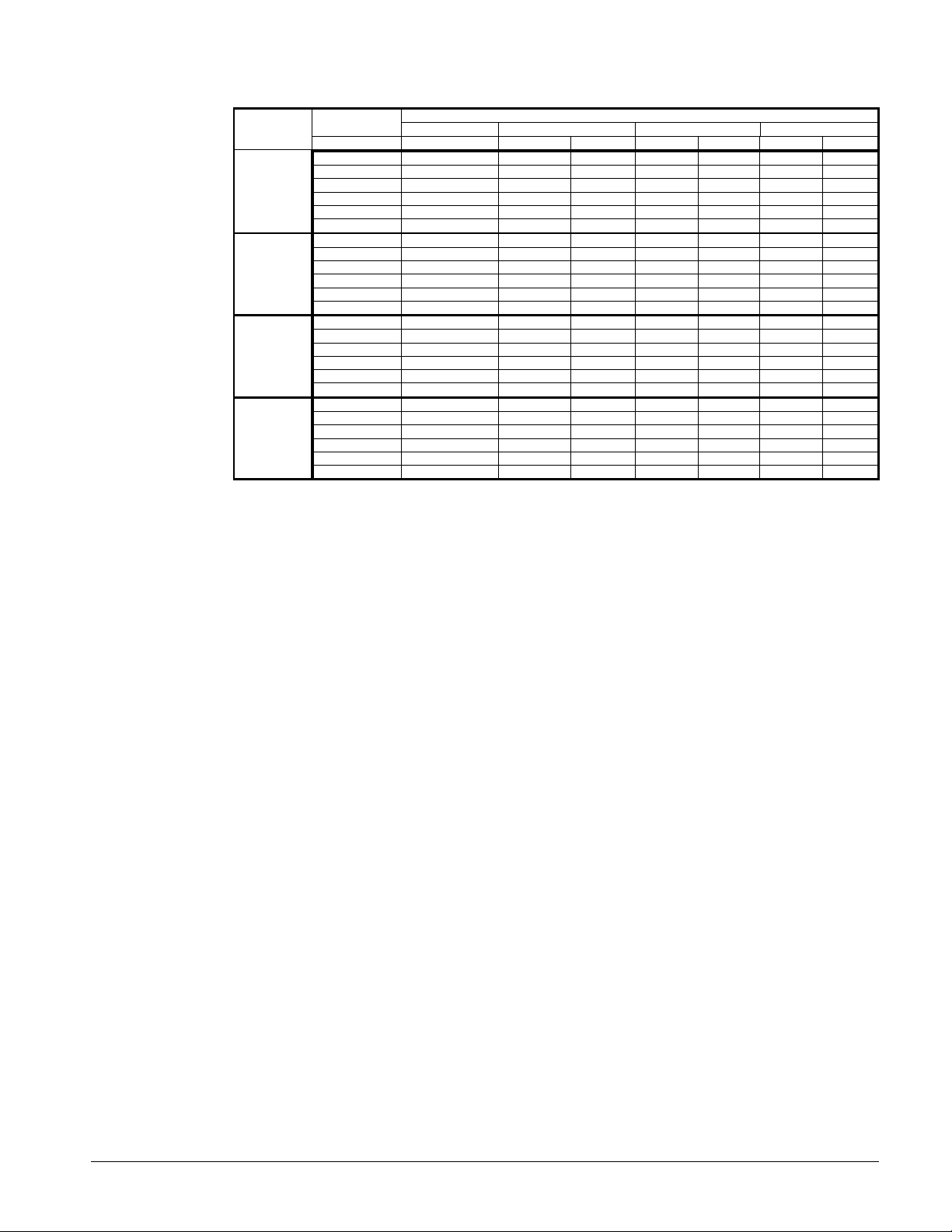

Table 6, Capacity and power derates

Chilled Water Fouling Factor

ALTITUDE °F °C Cap. kW Cap. kW Cap. kW

SEA 10 5.6 1.000 1.000 0.975 0.986 0.919 0.939

LEVEL 12 6.7 1.005 1.002 0.980 0.989 0.923 0.941

2000 feet 12 6.7 0.992 1.011 0.970 0.998 0.914 0.949

4000 feet 12 6.7 0.978 1.025 0.956 1.008 0.904 0.958

6000 feet 12 6.7 0.963 1.034 0.942 1.017 0.895 0.966

Delta-T 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

6 3.3 0.992 0.995 0.996 0.982 0.911 0.935

8 4.4 0.995 0.997 0.969 0.984 0.914 0.937

14 6.8 1.010 1.005 0.985 0.991 0.928 0.943

16 8.9 1.014 1.007 0.989 0.993 0.930 0.944

6 3.3 0.978 1.005 0.957 0.990 0.903 0.943

8 4.4 0.982 1.007 0.961 0.993 0.905 0.945

10 5.6 0.986 1.009 0.965 0.995 0.909 0.947

14 6.8 0.997 1.014 0.973 1.001 0.919 0.952

16 8.9 1.000 1.016 0.975 1.002 0.921 0.953

6 3.3 0.966 1.016 0.944 0.999 0.894 0.951

8 4.4 0.969 1.018 0.947 1.001 0.896 0.953

10 5.6 0.973 1.021 0.952 1.005 0.900 0.956

14 6.8 0.982 1.027 0.959 1.011 0.909 0.960

16 8.9 0.986 1.028 0.961 1.015 0.911 0.961

6 3.3 0.953 1.025 0.930 1.009 0.884 0.961

8 4.4 0.955 1.028 0.934 1.011 0.887 0.962

10 5.6 0.959 1.031 0.939 1.013 0.890 0.964

14 6.8 0.968 1.036 0.946 1.020 0.899 0.968

16 8.9 0.972 1.037 0.949 1.024 0.902 0.969

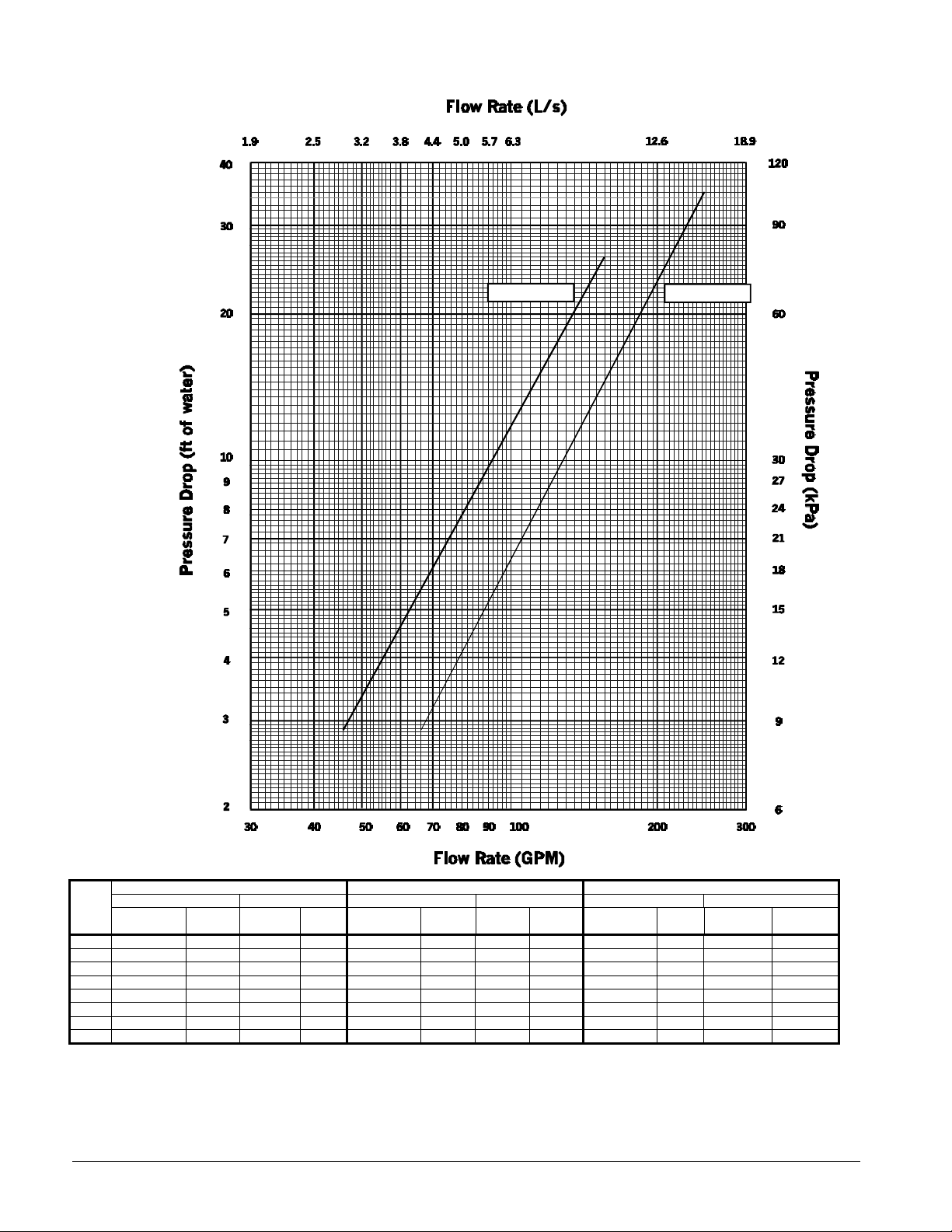

Evaporator Water Flow and Pressure Drop

Evaporator flow rate must fall between the minimum and maximum values shown in the evaporator

pressure drop table on page 12.

Measure the chilled water pressure drop through the evaporator at factory installed pressure taps.

It is important not to include the effect of valves or strainers in these readings.

Varying chilled water flow through the evaporator while the compressor(s) are operating is not

recommended.

IOM 686 AGZ 030A through 065A 11

Page 12

Figure 7, Pressure Drop Curve

030A - 040A

045A - 065A

Unit (ft) of water KPa (GPM) (L / s) (ft) of

Pressure Drop Flow Pressure Drop Flow Pressure Drop Flow

030A 6.6 12.9 73.00 4.61 16.6 49.7 122.00 7.70 2.9 8.6 46.00 2.90

035A 8.3 24.8 82.00 5.17 20.6 61.7 136.00 8.58 3.5 10.6 51.00 3.22

040A 10.4 31.1 93.00 5.87 26.1 78.0 155.00 9.78 4.4 13.3 58.00 3.66

045A 6.8 20.3 106.00 6.69 16.9 50.6 176.00 11.10 2.9 8.7 66.00 4.16

050A 8.0 23.9 117.00 7.38 20.1 60.0 195.00 12.30 3.4 10.2 73.00 4.61

055A 10.2 30.5 130.00 8.20 25.4 76.0 216.00 13.63 4.3 12.7 80.00 5.05

060A 12.2 36.5 141.00 8.90 30.6 91.5 235.00 14.83 5.2 15.6 88.00 5.55

065A 14.0 41.8 148.00 9.34 35.2 105.2 247.00 15.58 5.9 17.8 92.00 5.80

Minimum and maximum flows are established to ensure the Delta-T for each unit size falls within the 6 - 16°F range for proper unit control.

NOMINAL MAXIMUM MINIMUM

KPa (GPM) (L / s) (ft) of water KPa (GPM) KPa

Water

12 AGZ 030A through 065A IOM 686

Page 13

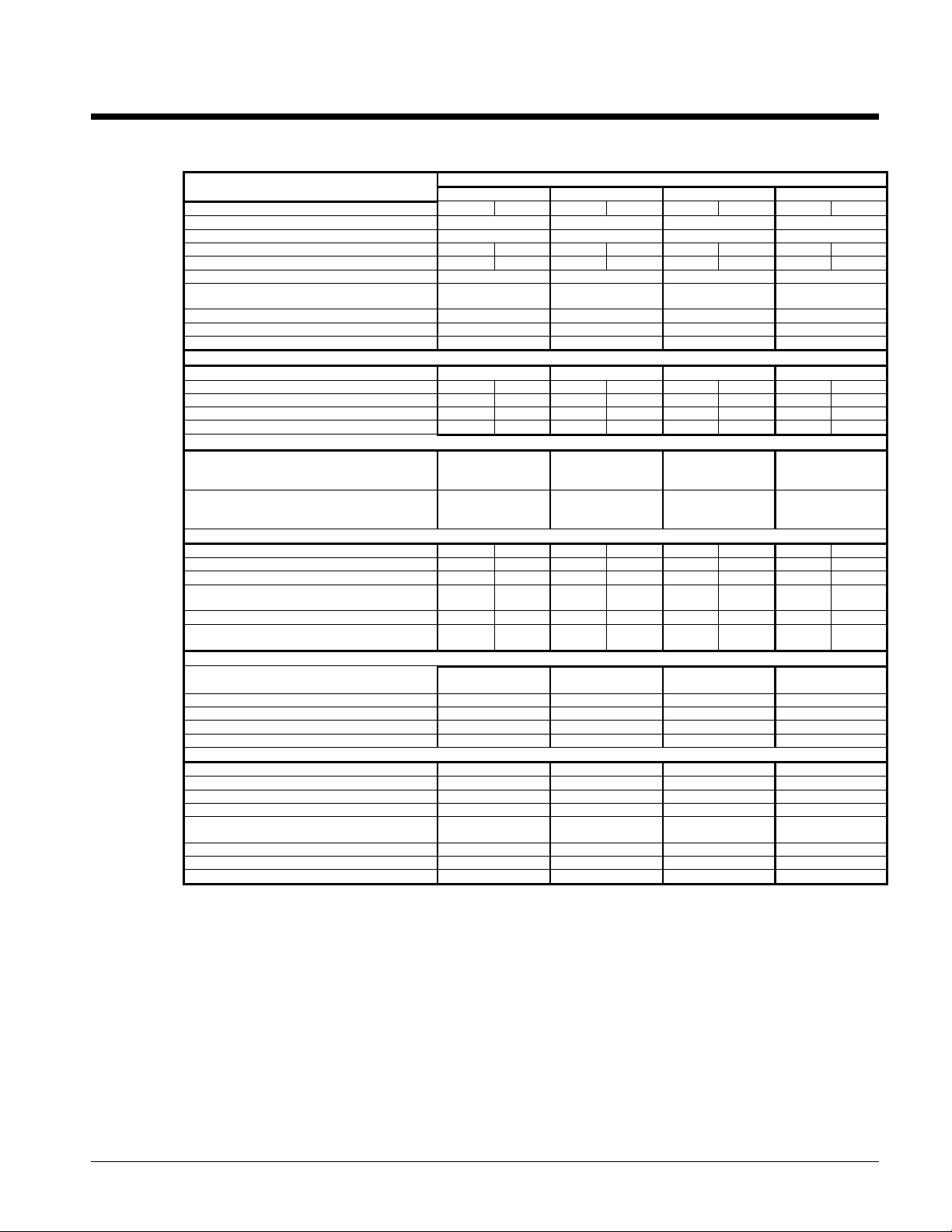

Physical Data

Table 7, AGZ030AS Through 045AS

PHYSICAL DATA AGZ MODEL NUMBER

STANDARD EFFICIENCY 030AS 035AS 040AS 045AS

Unit Capacity @ ARI Conditions (1), Tons (kW) 30.5 (107.2) 34.3 (120.5) 38.9 (136.7) 44.3 (156.0)

Number Of Refrigerant Circuits 2 2 2 2

Unit Operating Charge, R-22, Lbs. 34 34 36 36 40 40 42 42

Unit Operating Charge, R-22, (kg) (15.4) (15.4) (16.3) (16.3) (18.1) (18.1) (19.0) (19.0)

Cabinet Dimensions, LxWxH, In. 94.0 x 88.2 x 86.2 94.0 x 88.2 x 86.2 94.0 x 88.2 x 86.2 94.0 x 88.2 x 86.2

Cabinet Dimensions, LxWxH, (mm) 2388 x 2241 x 2190 2388 x 2241 x 2190 2388 x 2241 x 2190 2388 x 2241 x 2190

Unit Operating Weight, Lb (kg) 3425 (1555) 3480 (1580) 3535 (1605) 3800 (1725)

Unit Shipping Weight, Lb (kg) 3350 (1520) 3405 (1545) 3460 (1570) 3695 (1675)

Add'l Weight If Copper Finned Coils, Lb (kg) 445 (200) 445 (200) 445 (200) 445 (200)

COMPRESSORS

Nominal tonnage of each Compressor 7.5 9.0 9.0 9.0 10.0 10.0 10.0 13.0

Number Of Compressors per Circuit 2 2 2 2 2 2 2 2

Oil Charge Per Compressor, Oz. 140 140 140 140 140 140 140 140

Oil Charge Per Compressor, (g) (496) (496) (496) (496) (496) (496) (496) (496)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead

Standard 4 Stages 0-23-50-73-100 0-25-50-75-100 0-25-50-75-100 0-22-50-72-100

Standard Staging - Circuit #2 in Lead

Standard 4 Stages 0-27-50-77-100 0-25-50-75-100 0-25-50-75-100 0-28-50-78-100

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Coil Face Area,Sq. Ft. 46.4 46.4 46.4 46.4 46.4 46.4 46.4 46.4

Coil Face Area, (M2) (4.3) (4.3) (4.3) (4.3) (4.3) (4.3) (4.3) (4.3)

Finned Height x Finned Length, In. 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5

Finned Height x Finned Length, (mm) (2032 x

Fins Per Inch x Rows Deep 16 x 2 16 x 2 16 x 2 16 x 2 16 x 2 16 x 2 16 x 2 16 x 2

Maximum Relief Valve Pressure Setting, psig (kPa) 450

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 4 - 28 (712) 4 - 28 (712) 4 - 28 (712) 4 - 28 (712)

Number Of Motors - HP (kW) (2) 4 - 1.0 (0.7) 4 - 1.0 (0.7) 4 - 1.0 (0.7) 4 - 1.5 (1.1)

Fan And Motor RPM, 60Hz 1140 1140 1140 1140

60 Hz Fan Tip Speed, FPM (M/Sec) 8357 (35.4) 8357 (35.4) 8357 (35.4) 8357 (35.4)

60 Hz Total Unit Airflow, CFM (M3/sec) 34400 (16.2) 34400 (16.2) 34400 (16.2) 38000 (17.9)

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Diameter, in. - Length, Ft. 10 - 04 10 - 04 10 - 04 12 - 04

Diameter, (mm) - Length, (mm) (254) - (1220) (254) - (1220) (254) - (1220) (305) - (1220)

Water Volume, Gallons, (L) 9.1 (34.5) 9.1 (34.5) 9.1 (34.5) 12.8 (48.5)

Maximum Water Pressure, psig (kPa) 175 (1207) 175 (1207) 175 (1207) 175 (1207)

Maximum Refrigerant Working Pressure, psig

Water Inlet / Outlet Victaulic Connections, In. (mm) 4 (101.6) 4 (101.6) 4 (101.6) 4 (101.6)

Drain - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

Vent - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

NOTES:

1. Nominal capacity based on 95F ambient air and 54F/44F water range.

2. Units with 1.0 Hp Fan Motors, Uses 1.5 Hp Fan Motors when unit is 380V / 60 Hz and 575V / 60Hz.

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Type Tandem Scrolls Tandem Scrolls Tandem Scrolls Tandem Scrolls

(kPa)

2121)

(3103)

(2032 x

2121)

(3103)

225 (1552) 225 (1552) 225 (1552) 225 (1552)

450

(2032 x

2121)

450

(3103)

(2032 x

2121)

450

(3103)

(2032 x

2121)

450

(3103)

(2032 x

2121)

450

(3103)

(2032 x

2121)

450

(3103)

(2032 x

2121)

450

(3103)

IOM 686 AGZ 030A through 065A 13

Page 14

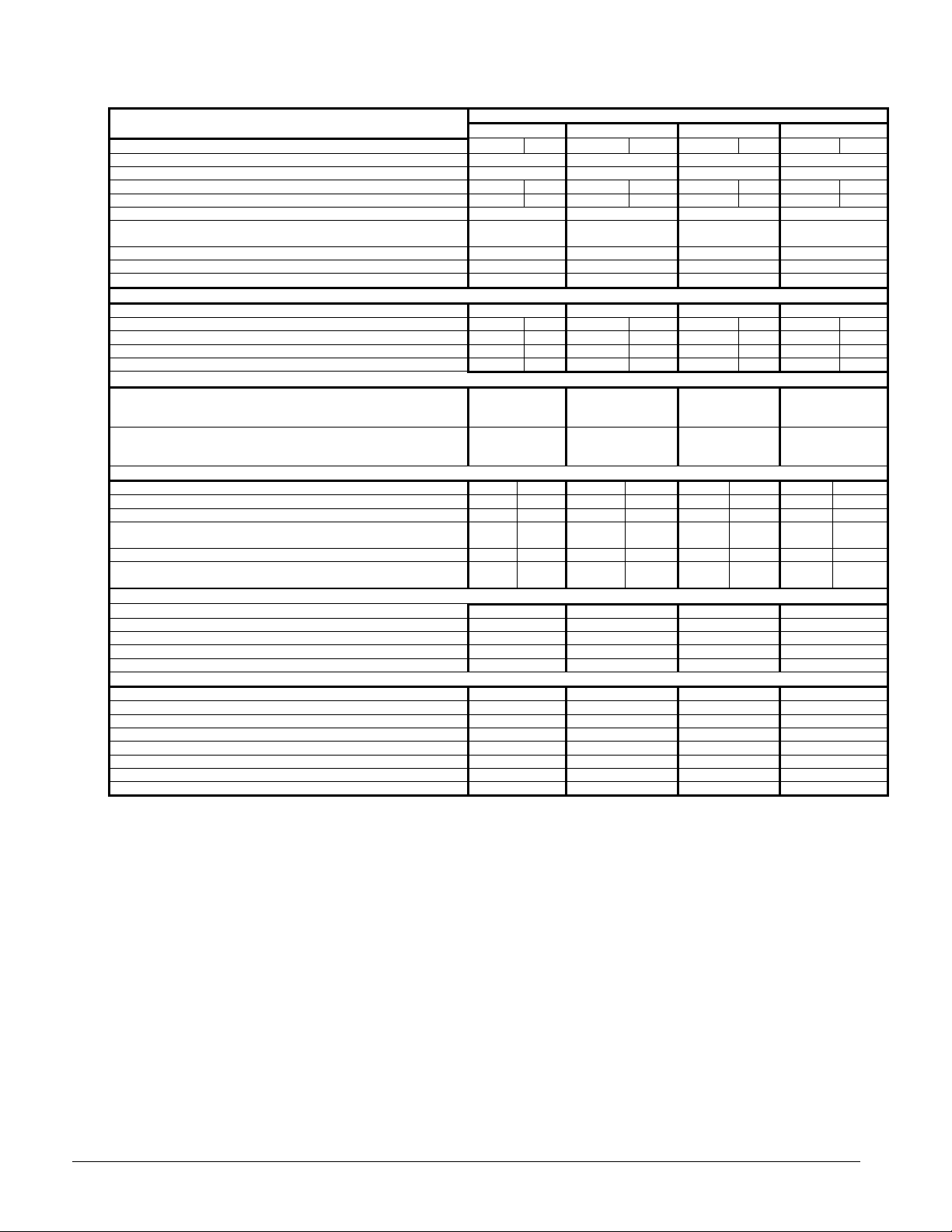

Table 8, AGZ050AS Through 065AS

PHYSICAL DATA AGZ MODEL NUMBER

STANDARD EFFICIENCY 050AS 055AS 060AS 065AS

Unit Capacity @ ARI Conditions (1), Tons (kW) 48.9 (172.2) 54.1 (190.1) 58.9 (207.4) 61.6 (216.5)

Unit Operating Charge, R-22, (kg) (18.1) (18.1) (22.6) (22.6) (23.5) (23.5) (28.1) (28.1)

Cabinet Dimensions, LxWxH, (mm) 2388 x 2241 x

Add'l Weight If Copper Finned Coils, Lb. (kg) 445 (200) 665 (300) 665 (300) 830 (375)

Nominal Horsepower of each Compressor 13.0 13.0 13.0 15.0 15.0 15.0 15.0 15.0

Number of Compressors per Circuit 2 2 2 2 2 2 2 2

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead

Standard Staging - Circuit #2 in Lead

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Finned Height x Finned Length, In. 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5 100x 83.5 100x 83.5

Finned Height x Finned Length, (mm) (2032 x

Maximum Relief Valve Pressure Setting, psig (kPa) 450

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number of Fans - Fan Diameter, In. (mm) 4 - 28 (712) 4 - 28 (712) 4 - 28 (712) 4 - 28(712)

60 Hz Fan Tip Speed, FPM (M/Sec) 8357 (35.4) 8357 (35.4) 8357 (35.4) 8357 (35.4)

60 Hz Total Unit Airflow, CFM (M3/sec) 38000 (17.9) 36800 (17.4) 36800 (17.4) 38400 (18.1)

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Maximum Water Pressure, psig (kPa) 175 (1207) 175 (1207) 175 (1207) 175 (1207)

Maximum Refrigerant Working Pressure, psig (kPa) 225 (1552) 225 (1552) 225 (1552) 225 (1552)

Water Inlet / Outlet Victaulic Connections, In. (mm) 4 (101.6) 4 (101.6) 4 (101.6) 4 (101.6)

NOTE:

1. Nominal capacity based on 95F ambient air and 54F/44F water range.

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Number of Refrigerant Circuits 2 2 2 2

Unit Operating Charge, R-22, Lb. 44 44 54 54 56 56 62 62

Cabinet Dimensions, LxWxH, In. 94.0 x 88.2 x 86.2 94.0 x 88.2 x 86.2 94.0 x 88.2 x 86.2 94.0 x 88.2 x 96.2

2121)

(3103)

2190

(2032 x

2121)

450

(3103)

Unit Operating Weight, Lb. (kg) 3850 (1745) 4055 (1840) 4115 (1865) 4295 (1950)

Unit Shipping Weight, Lb. (kg) 3745 (1700) 3950 (1790) 4010 (1820) 4190 (1900)

COMPRESSORS

Type Tandem Scrolls Tandem Scrolls Tandem Scrolls Tandem Scrolls

Oil Charge Per Compressor, Oz. 140 140 140 140 140 140 140 140

Oil Charge Per Compressor, (g) (496) (496) (496) (496) (496) (496) (496) (496)

Standard 4 Stages 0-25-50-75-100 0-23-50-73-100 0-25-50-75-100 0-25-50-75-100

Standard 4 Stages 0-25-50-75-100 0-27-50-77-100 0-25-50-75-100 0-25-50-75-100

Coil Face Area,Sq. Ft. 46.4 46.4 46.4 46.4 46.4 46.4 58.0 58.0

Coil Face Area, (M2) (4.3) (4.3) (4.3) (4.3) (4.3) (4.3) (5.4) (5.4)

Fins Per Inch x Rows Deep 16 x 2 16 x 2 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3 16 x 3

Number of Motors - HP (kW) 4 - 1.5 (1.1) 4 - 1.5 (1.1) 4 - 1.5 (1.1) 4 - 1.5 (1.1)

Fan And Motor RPM, 60Hz 1140 1140 1140 1140

Diameter, in. - Length, Ft. 12 - 04 12 - 04 12 - 04 12 - 04

Diameter, (mm) - Length, (mm) (305) - (1220) (305) - (1220) (305) - (1220) (305) - (1220)

Water Volume, Gallons, (L) 12.8 (48.5) 12.8 (48.5) 2.8 (48.5) 12.8 (48.5)

Drain - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

Vent - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5) .375 (9.5)

2388 x 2241 x 2190 2388 x 2241 x 2190 2388 x 2241 x 2444

(2032 x

2121)

450 (3103) 450

(2032 x

2121)

(3103)

(2032 x

2121)

450

(3103)

(2032 x

2121)

450

(3103)

(2540 x

2121)

450

(3103)

(2540 x

2121)

450

(3103)

14 AGZ 030A through 065A IOM 686

Page 15

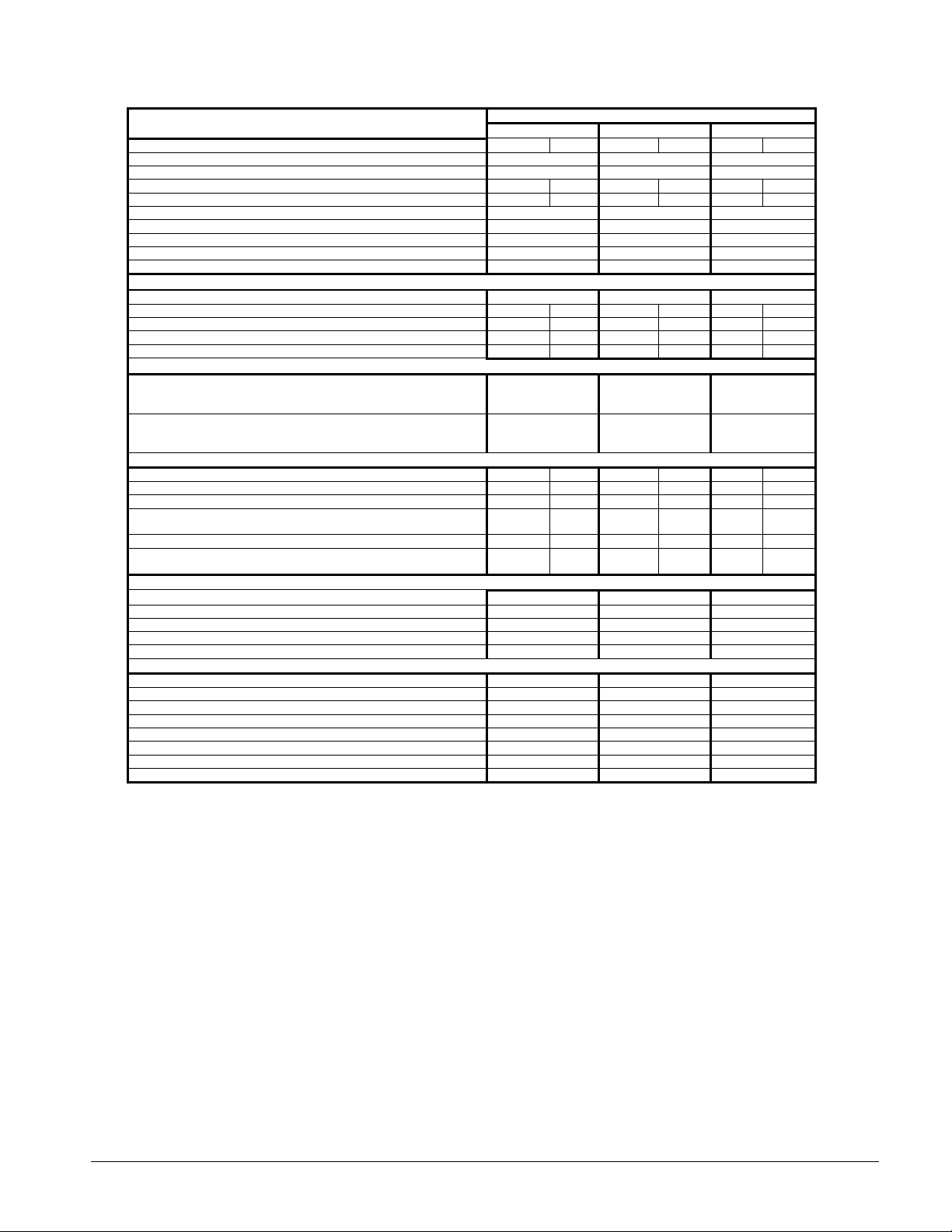

Table 9, AGZ030AE Through 050AE

PHYSICAL DATA AGZ MODEL NUMBER

HIGH EFFICIENCY 030AE 040AE 050AE

Unit Capacity @ ARI Conditions (1), Tons (kW) 31.5 (110.7) 39.2 (137.7) 49.2 (172.8)

Unit Operating Charge, R-22, Lbs. 40 40 50 50 52 52

Unit Operating Charge, R-22, (kg) (16.3) (16.3) (22.6) (22.6) (23.5) (23.5)

Cabinet Dimensions, LxWxH, In. 94.0 x 88.2 x 86.2 94.0 x 88.2 x 86.2 94.0 x 88.2 x 86.2

Cabinet Dimensions, LxWxH, (mm) 2388 x 2241 x 2190 2388 x 2241 x 2190 2388 x 2241 x 2190

Unit Operating Weight, Lbs. (kg) 3485 (1580) 3695 (1675) 4010 (1820)

Add'l Weight If Copper Finned Coils, Lbs. (kg) 445 (200) 665 (300) 830 (375)

COMPRESSORS

Nominal Horsepower of each Compressor 7.5 9.0 9.0 9.0 10.0 10.0

Number Of Compressors per Circuit 2 2 2 2 2 2

Oil Charge Per Compressor, Oz. 140 140 140 140 140 140

Oil Charge Per Compressor, (g) (496) (496) (496) (496) (496) (496)

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Standard Staging - Circuit #1 in Lead

Standard Staging - Circuit #2 in Lead

CONDENSERS - HIGH EFFICIENCY FIN AND TUBE TYPE WITH INTEGRAL SUBCOOLING

Finned Height x Finned Length, In. 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5 80 x 83.5

Finned Height x Finned Length, (mm) (2032 x

Maximum Relief Valve Pressure Setting, psig (kPa) 450 (3103) 450

CONDENSER FANS - DIRECT DRIVE PROPELLER TYPE

Number Of Fans - Fan Diameter, In. (mm) 4 - 28 (712) 4 - 28 (712) 4 - 28 (712)

60 Hz Fan Tip Speed, FPM (M/Sec) 8357 (35.4) 8357 (35.4) 8357 (35.4)

60 Hz Total Unit Airflow, CFM (M3/sec) 34400 (16.2) 33600 (15.9) 36800 (17.4)

DIRECT EXPANSION EVAPORATOR - BAFFLED SHELL AND THRU-TUBE

Maximum Water Pressure, psig (kPa) 175 (1207) 175 (1207) 175 (1207)

Maximum Refrigerant Working Pressure, psig (kPa) 225 (1552) 225 (1552) 225 (1552)

Water Inlet / Outlet Victaulic Connections, In. (mm) 4 (101.6) 4 (101.6) 4 (101.6)

NOTE:

Nominal capacity based on 95F ambient air and 54F/44F water range.

BASIC DATA Ckt.1 Ckt.2 Ckt.1 Ckt.2 Ckt.1 Ckt.2

Number Of Refrigerant Circuits 2 2 2

Unit Shipping Weight, Lbs. (kg) 3410 (1545) 3620 (1640) 3905 (1770)

Type Tandem Scrolls Tandem Scrolls Tandem Scrolls

Standard 4 Stages 0-23-50-73-100 0-25-50-75-100 0-25-50-75-100

Standard 4 Stages 0-27-50-77-100 0-25-50-75-100 0-25-50-75-100

Coil Face Area,Sq. Ft. 46.4 46.4 46.4 46.4 46.4 46.4

Coil Face Area, (M2) (4.3) (4.3) (4.3) (4.3) (4.3) (4.3)

Fins Per Inch x Rows Deep 16 x 2 16 x 2 16 x 3 16 x 3 16 x 3 16 x 3

2121)

Number Of Motors - HP (kW) 4 - 1.0 (0.7) 4 - 1.0 (0.7) 4 - 1.5 (1.1)

Fan And Motor RPM, 60Hz 1140 / 950 1140 / 950 1140 / 950

Diameter, in. - Length, Ft. 10 - 04 10 - 04 12 - 04

Diameter, (mm) - Length, (mm) (254) - (1220) (254) - (1220) (305) - (1220)

Water Volume, Gallons, (L) 9.1 (34.5) 9.1 (34.5) 12.8 (48.5)

Drain - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5)

Vent - NPT int, In. (mm) .375 (9.5) .375 (9.5) .375 (9.5)

(2032 x

2121)

(3103)

(2032 x

2121)

450 (3103) 450

(2032 x

2121)

(3103)

(2032 x

2121)

450

(3103)

(2032 x

2121)

450

(3103)

IOM 686 AGZ 030A through 065A 15

Page 16

Electrical Data

Field Wiring

Internal power wiring to the compressors for single and multiple point option are different.

Field wiring must be installed according to unit wiring diagram.

Wiring must comply with all applicable codes and ordinances. Warranty is void if wiring is not in

accordance with specifications. Copper wire is required for all power lead terminations at the unit.

Aluminum or copper can be used for all other wiring.

AGZ units have internal power wiring for single point power connection. A single large power

terminal block is provided and wiring within the unit is sized in accordance with the National

Electrical Code. A single field supplied fused disconnect is required. An optional factory mounted

transformer may be installed.

If the evaporator heater is on a separate disconnect switch from the main unit power supply, the

unit may be shut down without defeating the freeze protection provided by the cooler heater.

Table 10, AGZ030A - 065A, 60 Hz, Single Point Power Electrical Data

AGZ Circuit Field Wire Hub or

Unit Volts Ampacity Wire Nominal HACR

Size (MCA) Quantity Gauge Quantity Size Size

030AS 380 86 3 3 1 1.25 (32) 100

030AE 460 68 3 4 1 1.00 (25) 80

035AS 380 93 3 3 1 1.25 (32) 110

040AS 380 111 3 2 1 1.25 (32) 125

040AE 460 78 3 3 1 1.25 (32) 90

045AS 380 123 3 1 1 1.25 (32) 150

050AS 380 134 3 1/0 1 1.50 (38) 150

050AE 460 94 3 2 1 1.25 (32) 110

055AS 380 148 3 1/0 1 1.50 (38) 175

060AS 380 161 3 2/0 1 1.50 (38) 175

065AS 380 161 3 2/0 1 1.50 (38) 175

CAUTION

Minimum POWER SUPPLY Max. Fuse

Breaker

208 129 3 1 1 1.25 (32) 150

230 129 3 1 1 1.25 (32) 150

575 53 3 6 1 1.00 (25) 60

208 143 3 1/0 1 1.50 (38) 150

230 143 3 1/0 1 1.50 (38) 150

460 73 3 4 1 1.00 (25) 80

575 58 3 4 1 1.00 (25) 70

208 159 3 2/0 1 1.50 (38) 175

230 159 3 2/0 1 1.50 (38) 175

575 67 3 4 1 1.00 (25) 80

208 180 3 3/0 1 2.00 (51) 175

230 180 3 3/0 1 2.00 (51) 175

460 88 3 2 1 1.25 (32) 90

575 76 3 3 1 1.25 (32) 80

208 191 3 3/0 1 2.00 (51) 225

230 191 3 3/0 1 2.00 (51) 225

575 83 3 3 1 1.25 (32) 100

208 221 3 4/0 1 2.00 (51) 250

230 221 3 4/0 1 2.00 (51) 250

460 103 3 2 1 1.25 (32) 125

575 87 3 2 1 1.25 (32) 100

208 247 3 250 1 2.50 (64) 250

230 247 3 250 1 2.50 (64) 250

460 112 3 2 1 1.25 (32) 125

575 90 3 2 1 1.25 (32) 100

208 247 3 250 1 2.50 (64) 250

230 247 3 250 1 2.50 (64) 250

460 112 3 2 1 1.25 (32) 125

575 90 3 2 1 1.25 (32) 100

16 AGZ 030A through 065A IOM 686

Page 17

Table 11, AGZ030A - 065A, 60 Hz, Compressor and Condenser Fan Motor Amp Draw

AGZ Compressors No. Of Compressors

Unit Volts No. No. Fan Fan Fan Across-The-Line

Size 1 & 3 2 & 4 Motors Motors Motors No.1 & 3 No.2 & 4

208 22.9 29.9 4.0 4 17.0 169 232

230 22.9 29.9 4.0 4 17.0 189 232

030AS 380 14.9 18.6 3.4 4 14.4 112 144

030AE 460 12.5 15.3 2.0 4 8.5 94 116

575 9.1 11.6 2.2 4 10.3 74 97

208 29.9 29.9 4.0 4 17.0 232 232

230 29.9 29.9 4.0 4 17.0 232 232

035AS 380 18.6 18.6 3.4 4 14.4 144 144

460 15.3 15.3 2.0 4 8.5 116 116

575 11.6 11.6 2.2 4 10.3 97 97

208 33.6 33.6 4.0 4 17.0 255 255

230 33.6 33.6 4.0 4 17.0 255 255

040AS 380 22.8 22.8 3.4 4 14.4 151 151

040AE 460 16.4 16.4 2.0 4 8.5 127 127

575 13.7 13.7 2.2 4 10.3 100 100

208 33.6 39.5 5.8 4 23.7 255 318

230 33.6 39.5 5.8 4 23.7 255 318

045AS 380 22.8 28.2 3.4 4 14.4 151 188

460 16.4 19.3 2.8 4 10.7 127 158

575 13.7 17.3 2.3 4 11.5 100 125

208 39.5 39.5 5.8 4 23.7 318 318

230 39.5 39.5 5.8 4 23.7 318 318

050AS 380 28.2 28.2 3.4 4 14.4 188 188

050AE 460 19.3 19.3 2.8 4 10.7 158 158

575 17.3 17.3 2.3 4 11.5 125 125

208 39.5 52.6 5.8 4 23.7 318 411

230 39.5 52.6 5.8 4 23.7 318 411

055AS 380 28.2 34.6 3.4 4 14.4 188 249

460 19.3 23.7 2.8 4 10.7 158 187

575 17.3 19.0 2.3 4 11.5 125 150

208 52.6 52.6 5.8 4 23.7 411 411

230 52.6 52.6 5.8 4 23.7 411 411

060AS 380 34.6 34.6 3.4 4 14.4 249 249

460 23.7 23.7 2.8 4 10.7 187 187

575 19.0 19.0 2.3 4 11.5 150 150

208 52.6 52.6 5.8 4 23.7 411 411

230 52.6 52.6 5.8 4 23.7 411 411

065AS 380 34.6 34.6 3.4 4 14.4 249 249

460 23.7 23.7 2.8 4 10.7 187 187

575 19.0 19.0 2.3 4 11.5 150 150

Rated Load Amps Locked Rotor Amps

(Each) (Each) (Each) (Each) (Each) (Each)

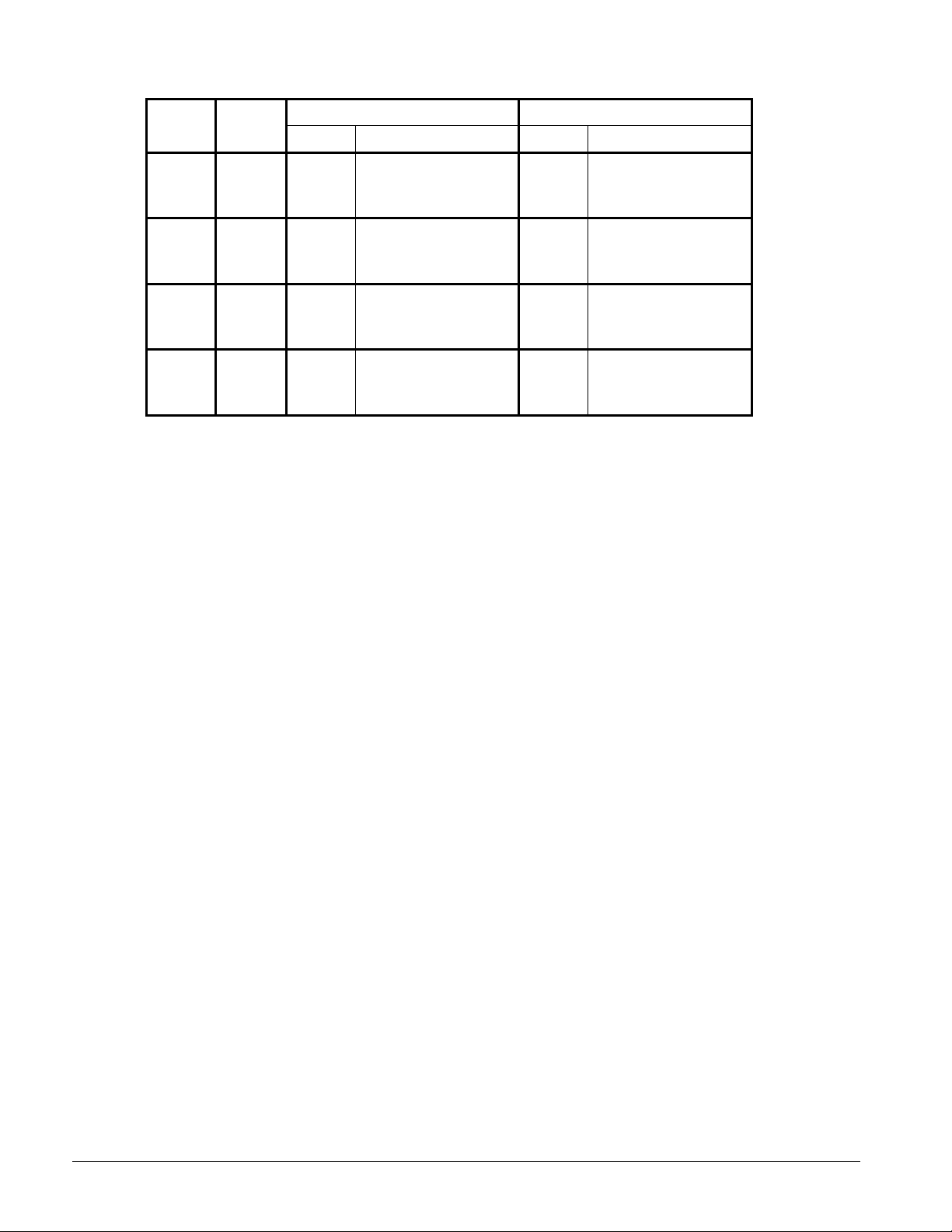

Table 12, AGZ030A - 065A, 60 Hz Single Point Power, Field Wiring Data

AGZ Power Block Non-Fused Disconnect Switch

Unit Volts Terminal Connector Wire Range Terminal Connector Wire Range

Size Amps (Copper Wire Only) Amps (Copper Wire Only)

208 175 #12 - 2/0 225 # 3 - 300 MCM

230 175 #12 - 2/0 225 # 3 - 300 MCM

030AS 380 175 #12 - 2/0 100 #14 - 1/0

030AE 460 175 #12 - 2/0 100 #14 - 1/0

575 175 #12 - 2/0 100 #14 - 1/0

208 175 #12 - 2/0 225 # 3 - 300 MCM

230 175 #12 - 2/0 225 # 3 - 300 MCM

035AS 380 175 #12 - 2/0 100 #14 - 1/0

460 175 #12 - 2/0 100 #14 - 1/0

575 175 #12 - 2/0 100 #14 - 1/0

208 175 #12 - 2/0 225 # 3 - 300 MCM

230 175 #12 - 2/0 225 # 3 - 300 MCM

040AS 380 175 #12 - 2/0 150 #4 - 4/0

040AE 460 175 #12 - 2/0 100 #14 - 1/0

575 175 #12 - 2/0 100 #14 - 1/0

208 335 # 4 - 400 MCM 225 # 3 - 300 MCM

230 335 # 4 - 400 MCM 225 # 3 - 300 MCM

045AS 380 175 #12 - 2/0 150 #4 - 4/0

460 175 #12 - 2/0 100 #14 - 1/0

575 175 #12 - 2/0 100 #14 - 1/0

Table continued on next page

IOM 686 AGZ 030A through 065A 17

Wiring to Standard Wiring to Optional

Page 18

Table 12, AGZ030A - 065A, 60 Hz Single Point Power, Field Wiring Data (continued)

AGZ Power Block Non-Fused Disconnect Switch

Unit Volts Terminal Connector Wire Range Terminal Connector Wire Range

Size Amps (Copper Wire Only) Amps (Copper Wire Only)

208 335 # 4 - 400 MCM 225 # 3 - 300 MCM

230 335 # 4 - 400 MCM 225 # 3 - 300 MCM

050AS 380 335 # 4 - 400 MCM 150 #4 - 4/0

050AE 460 175 #12 - 2/0 150 #4 - 4/0

575 175 #12 - 2/0 150 #4 - 4/0

208 335 # 4 - 400 MCM 400 250 - 500 MCM

230 335 # 4 - 400 MCM 400 250 - 500 MCM

055AS 380 335 # 4 - 400 MCM 250 #4 - 350 MCM

460 175 #12 - 2/0 150 #4 - 4/0

575 175 #12 - 2/0 150 #4 - 4/0

208 335 # 4 - 400 MCM 400 250 - 500 MCM

230 335 # 4 - 400 MCM 400 250 - 500 MCM

060AS 380 335 # 4 - 400 MCM 250 #4 - 350 MCM

460 175 #12 - 2/0 150 #4 - 4/0

575 175 #12 - 2/0 150 #4 - 4/0

208 335 # 4 - 400 MCM 400 250 - 500 MCM

230 335 # 4 - 400 MCM 400 250 - 500 MCM

065AS 380 335 # 4 - 400 MCM 250 #4 - 350 MCM

460 175 #12 - 2/0 150 #4 - 4/0

575 175 #12 - 2/0 150 #4 - 4/0

Wiring to Standard Wiring to Optional

Notes for “Electrical Data Single Point” Power:

1. Unit wire size ampacity (MCA) is equal to 125% of the largest compressor-motor RLA plus

100% of RLA of all other loads in the circuit including the control transformer.

2. If the control transformer option is furnished, no separate 115v power is required.

3. If a separate 115V power supply is used for the control circuit, then the wire sizing amps is 10

amps for all unit sizes.

4. Recommended power lead wire sizes for 3 conductors per conduit are based on 100% conductor

ampacity in accordance with NEC. Voltage drop has not been included. Therefore, it is

recommended that power leads be kept short. All terminal block connections must be made with

copper (type THW) wire.

5. “Recommended Fuse Sizes” are selected at approximately 150% to 175% of the largest

compressor RLA, plus 100% of all other loads in the circuit.

6. “Maximum Fuse Sizes” are selected at approximately 225% of the largest compressor RLA, plus

100% of all other loads in the circuit.

7. The recommended power lead wire sizes are based on an ambient temperature of 86° F.

Ampacity correction factors must be applied for other ambient temperatures. Refer to the

National Electrical Code Handbook.

Voltage Limitations:

Within ± 10 percent of nameplate rating

Notes for “Compressor and Condenser Fan Amp Draw”:

1. Compressor RLA values are for wiring sizing purposes only but do not reflect normal operating

current draw at rated capacity. If unit is equipped with SpeedTrol condenser fan motors, the first

motor on each refrigerant circuit is a single phase, 1hp motor, with a FLA of 2.8 amps at 460

volts, 5.6 amps at 208, 230, 380, and 575 volts.

2. Compressor LRA for reduced inrush start are for the first winding only. If the unit is equipped

with SpeedTrol motors, the first motor is a single phase, 1 hp motor, with a LRA of 7.3 amps at

460 volts, 14.5 amps at 208, 230, 380, and 575 volts.

Notes for “Field Wiring Data”

1. Requires a single disconnect to supply electrical power to the unit. This power must be fused.

2. All field wiring to unit power block or optional non-fused disconnect switch must be copper.

3. All field wire size values given in table apply to 75° C rated wire per NEC.

18 AGZ 030A through 065A IOM 686

Page 19

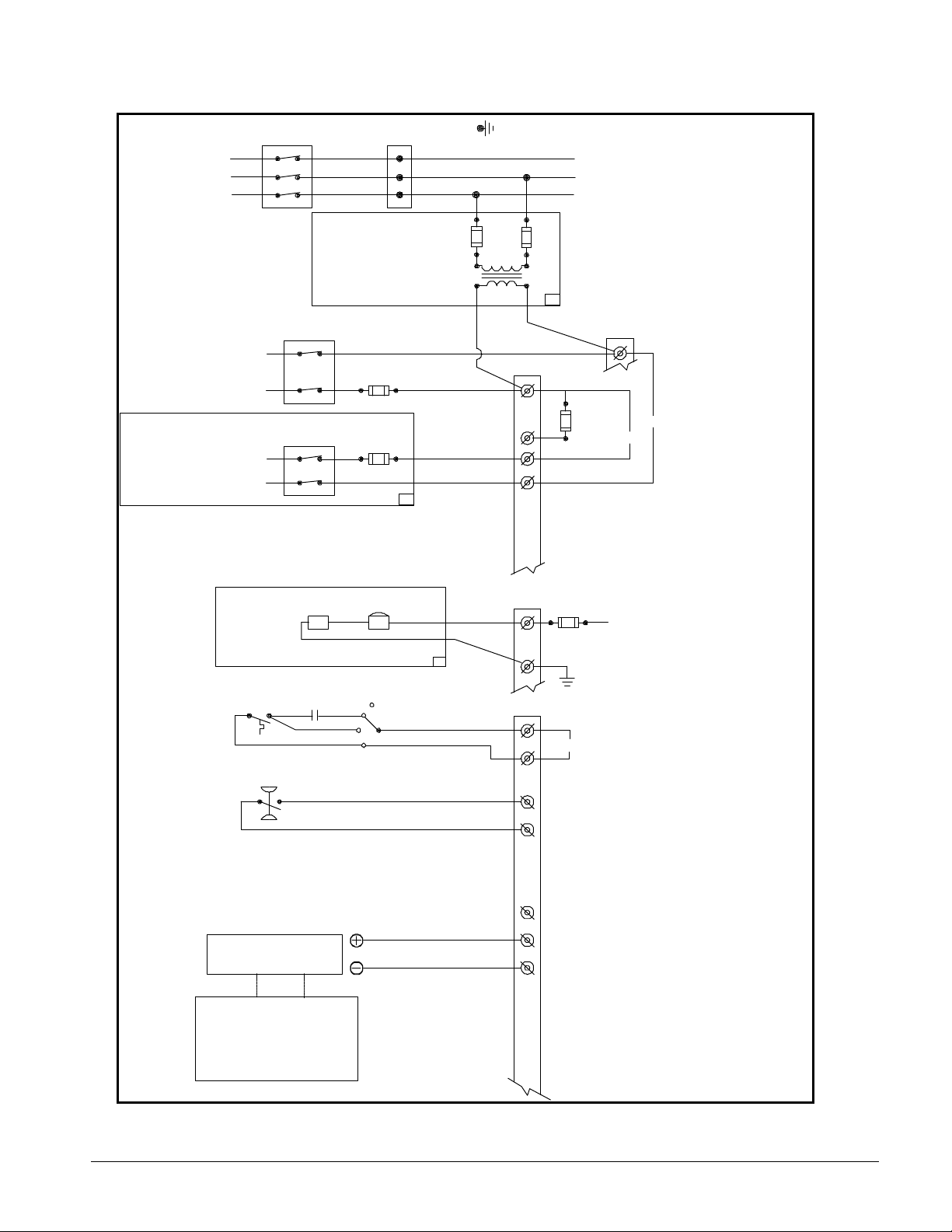

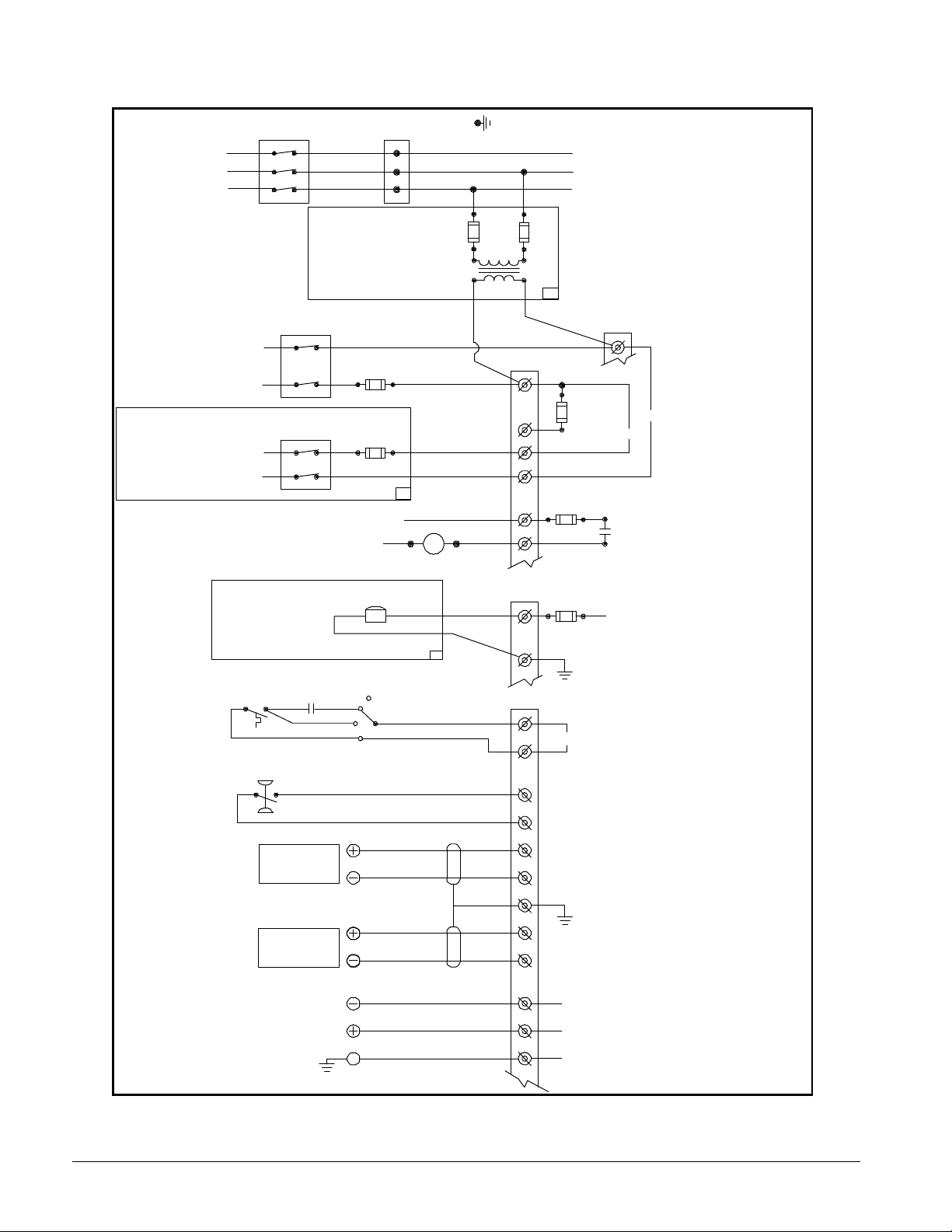

Figure 8, Typical Field Wiring with Global UNT Controller

UNITMAI

N

GNDLU

3PHAS

POWER

SUPPL

E

Y

DISCONNEC

(BYOTHE

R

T

TERMINALBLOCK

S

)

G

TOCOMPRESSOR(S)

ANDFANMOTOR

S

120

V

CONTR

SEPARATEEVAPORA

HEATERP

OPTIO

A

OLPOWER

O

WER

N

120VA

(BYOTHERS

ALARMBELL

CIRCUIT

DISCONNEC

(BYOTHERS

N

C

TOR

D

ISCONNECT

(BYOTHERS

C

)

N

FACTORYSUPPLIEDALAR

TIMEDELAY

OPTIO

N

(BYOTHERS

FUSEDCONTRO

TRANSFORMER

OPTIO

N

T

)

10A

FUS

E

(BYOTHERS

10A

)

FUS

FIELDWIRE

ALARMBELL

)

E

)

M

L

120VA

C

N

B

TB2

1

C

ONTRO

FUS

E

540

24VAC

L

545

IFSEPARATEEVAPORATO

HEATERPOWEROPTION

ISUSED-REMOVE

WIRES540AND545.

R

CIRCUIT

2

1

3

1

6

D

TB3

1

9

THERMOSTA

REMOTESTO

(BYOTHERS

SEEOPTIONSBELOW

(ONLYONESELECTION

0-1

TEMP.-ZONETEMP.

2-10V-R

TEMP.-RETURNEVAP.WATE

TEMP.-*

*STAN

AMBIENT

P

)

CHWFLOWSWITCH

(BYOTHERS

AVAIL.ATA

0

V-DEMANDLIMIT

E

MOTERESET

O

UTSIDEAIR

D

ARDSELECTIO

CLO

T

TIME.

TIM

2

TB7

1

1

143

133

134

135

4

141

4

8

GND

IFREMOTESTOPCONTROL

0

M

J

2

ORTIMECLOCK

ISUSE

D,REMOVEJUMPE

FROMTERM140TO

R

1

41.

E

OFF

C

K

AUT

O

O

N

MANUA

L

)

)

R

N

IOM 686 AGZ 030A through 065A 19

Page 20

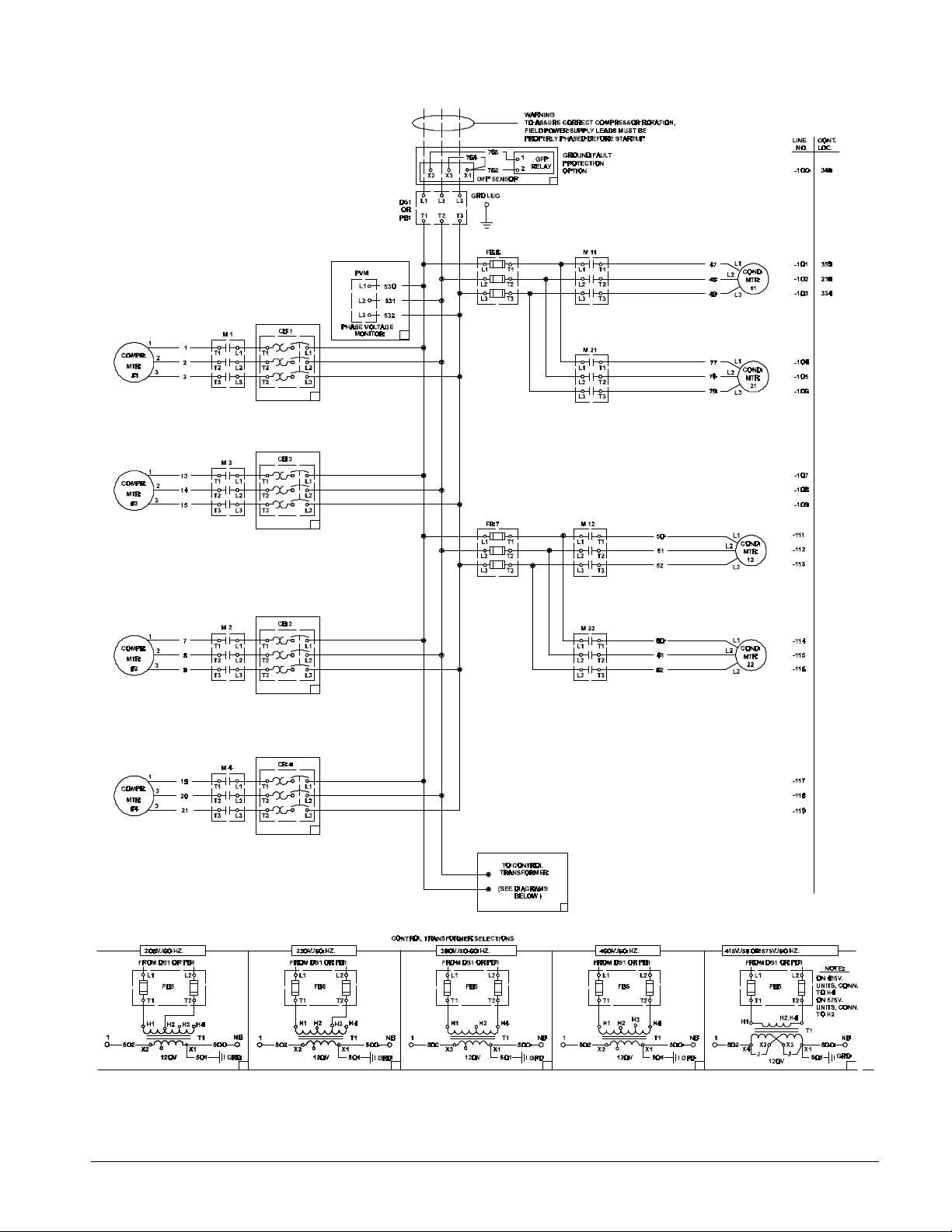

Figure 9, Typical Field Wiring Diagram with MicroTech Controller

UNITMAI

N

GNDLU

G

TOCOMPRESSOR(S)

ANDFANMOTOR

3PHAS

POWER

SUPPL

E

Y

DISCONNEC

(BYOTHE

R

T

S

)

TERMINALBLOCK

S

120VA

CONTR

SEPARATEEVAPORA

HEATERP

OPTIO

REMOTESTO

(BYOTHERS

C

OLPOWER

O

WER

N

120VA

(BYOTHERS

ALA

AMBIENT

THERMOSTA

P

)

CHWFLOWSWITCH

DISCONNEC

(BYOTHERS

N

TOR

DISCONNEC

(BYOTHERS

C

)

N

RMBEL

OPTIO

N

(BYOTHERS

FUSEDCONTRO

CIRCUITTRANSFORME

OPTIO

T

)

10A

FUS

E

(BYOTHERS

T

10A

)

FUS

E

(BYOTHERS

2

4

VOR120VAC

(BYOTHERS

N

FACTORYSUPPLIEDAL

L

T

CLOCK

T

IME

)

FIELDWIRE

ALARMBELL

OFF

AUT

O

O

N

MANUA

L

L

N

)

)

)

CHWPU

(BYOTHERS

A

R

M

D

R

M

PRELA

1

2

0VA

C

N

B

T

B

2

1

CON

TRO

CIRCUIT

2

1

3

1

6

9

5

A

1

0

Y

)

TB3

1

9

2

8

GND

TB7

1

4

0

M

J

141

L

FUS

I

F

ISUSED,RE

545

E

REMOTESTOPCONTROL

FROMTERM1

IFSEPARATEEVAPORATO

540

HEATERPOWEROPTION

ISUSED-REMOVE

WIRES540AND545.

SOLIDSTATERELAY

24VOR12

1.5AMPSMA

24VAC

0

MOVEJUMPE

40TO141

VAC

R

X

.

R

.

142

143

4-20MAFOR

CHWRESE

(BYOTHERS

4-20MAFOR

DEMANDLIMIT

(BYOTHERS

*(CONNECTIONTORMS

(REMOTEMONITORINGSEQUENCE

ORTONMP

(NETWORKMASTERPANEL

*MICROTECHONL

Y

)

T

)

)

GND

)

135

134

133

132

131

137

138

139

GND

3

4

5

*

COMMU

PORT"B"

N

ICATION

20 AGZ 030A through 065A IOM 686

Page 21

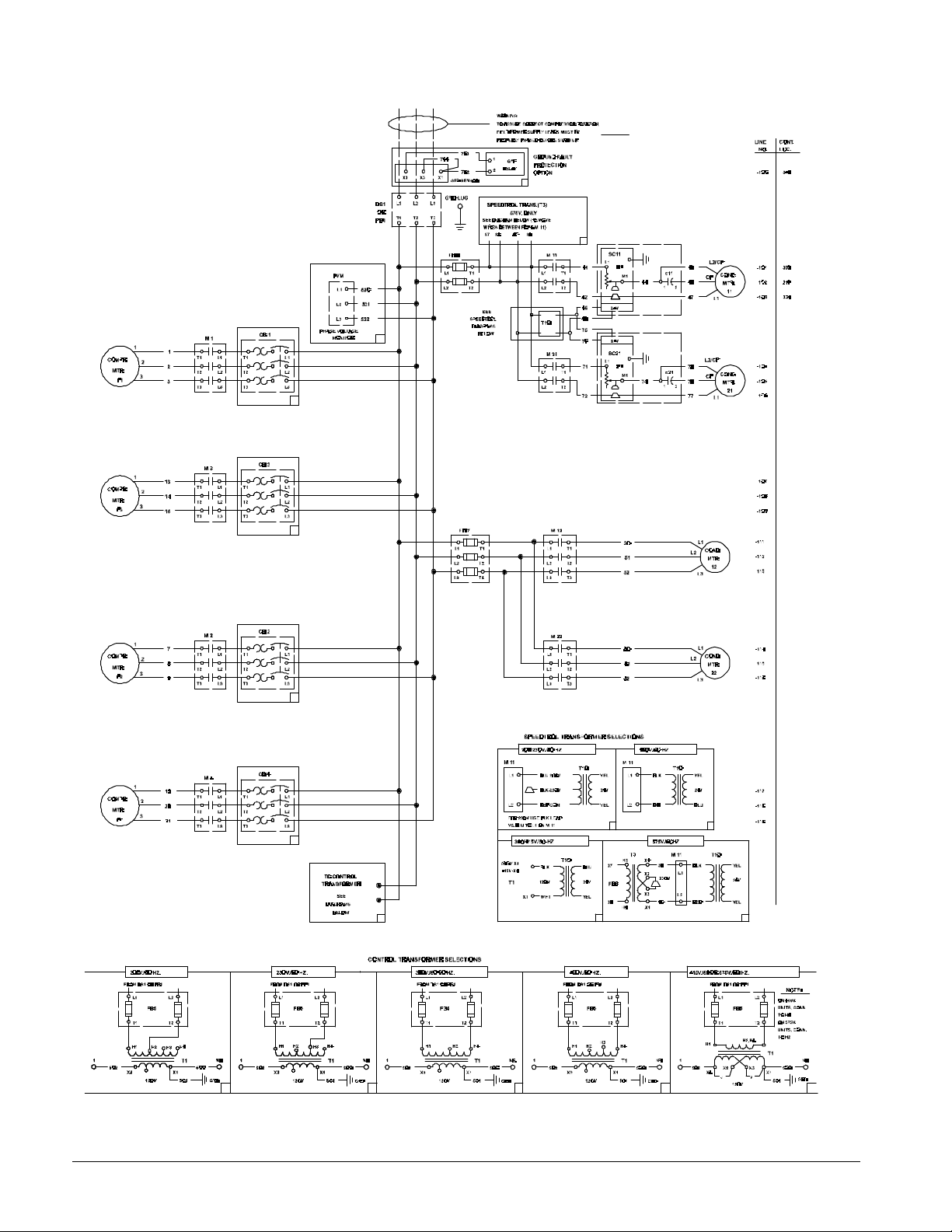

Figure 10, Single-point Connection with FanTrol

IOM 686 AGZ 030A through 065A 21

Page 22

Figure 11, Single-point Connection with SpeedTrol

22 AGZ 030A through 065A IOM 686

Page 23

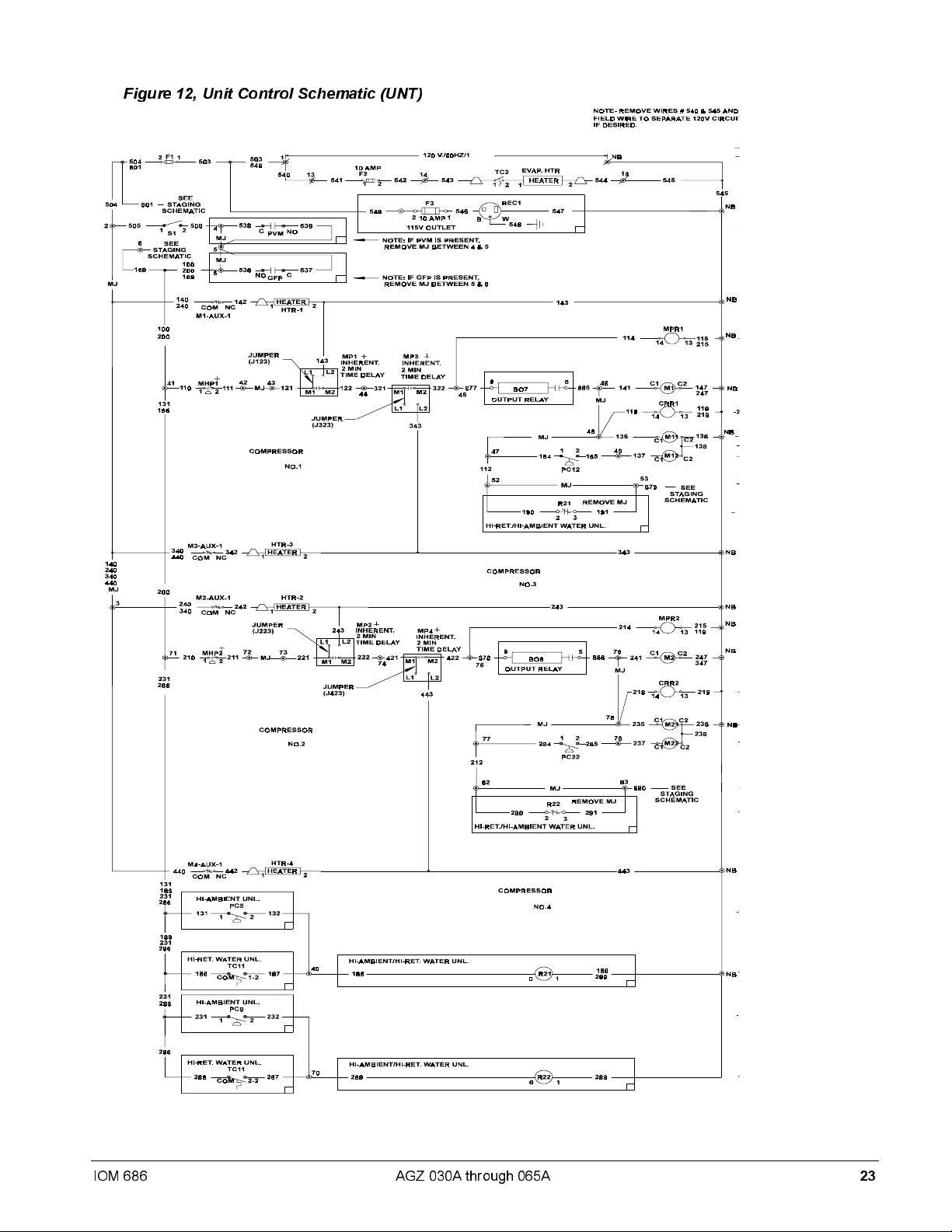

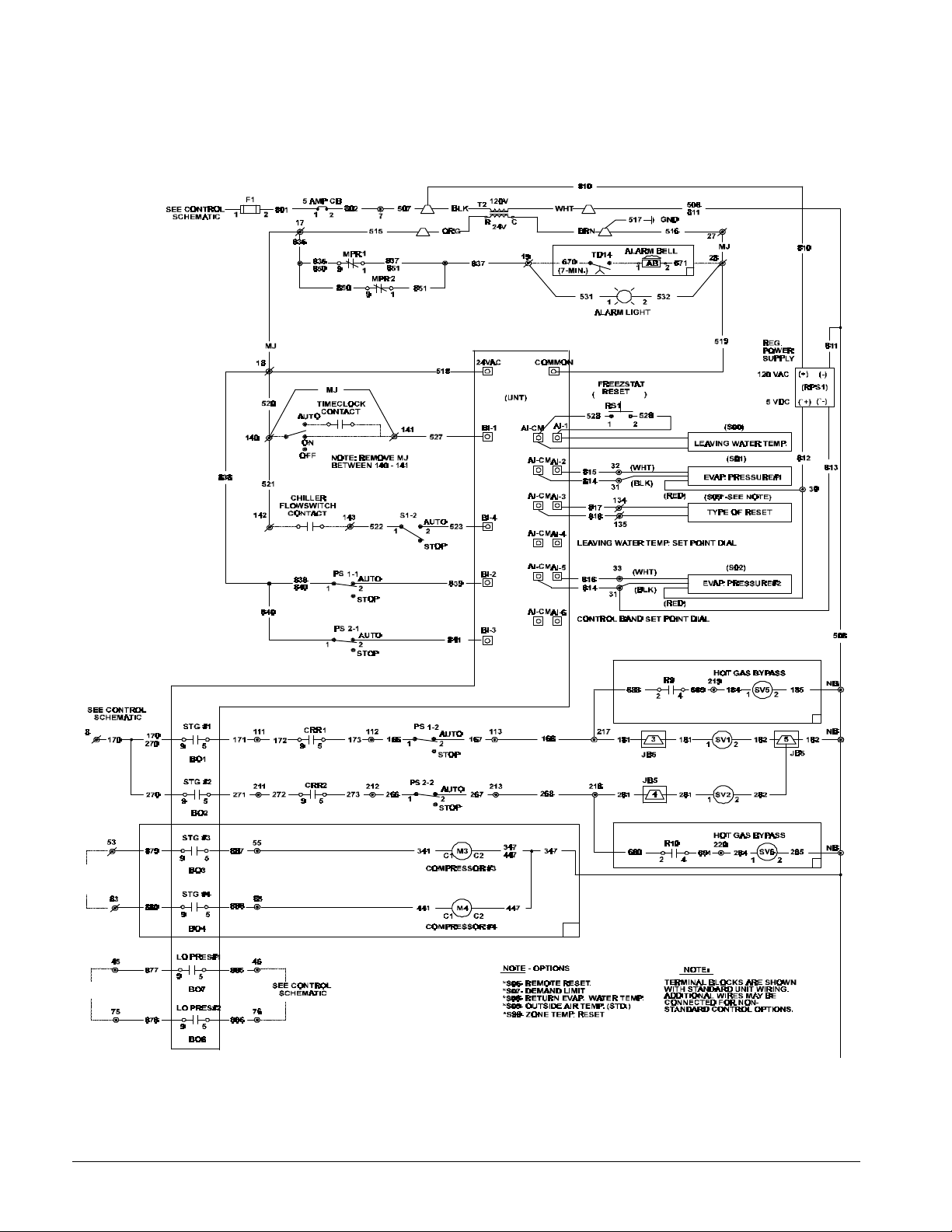

)LJXUH

8QLW &RQWURO 6FKHPDWLF 817

,20 $*= $ WKURXJK $

Page 24

Figure 13, Staging Schematic (UNT)

24 AGZ 030A through 065A IOM 686

Page 25

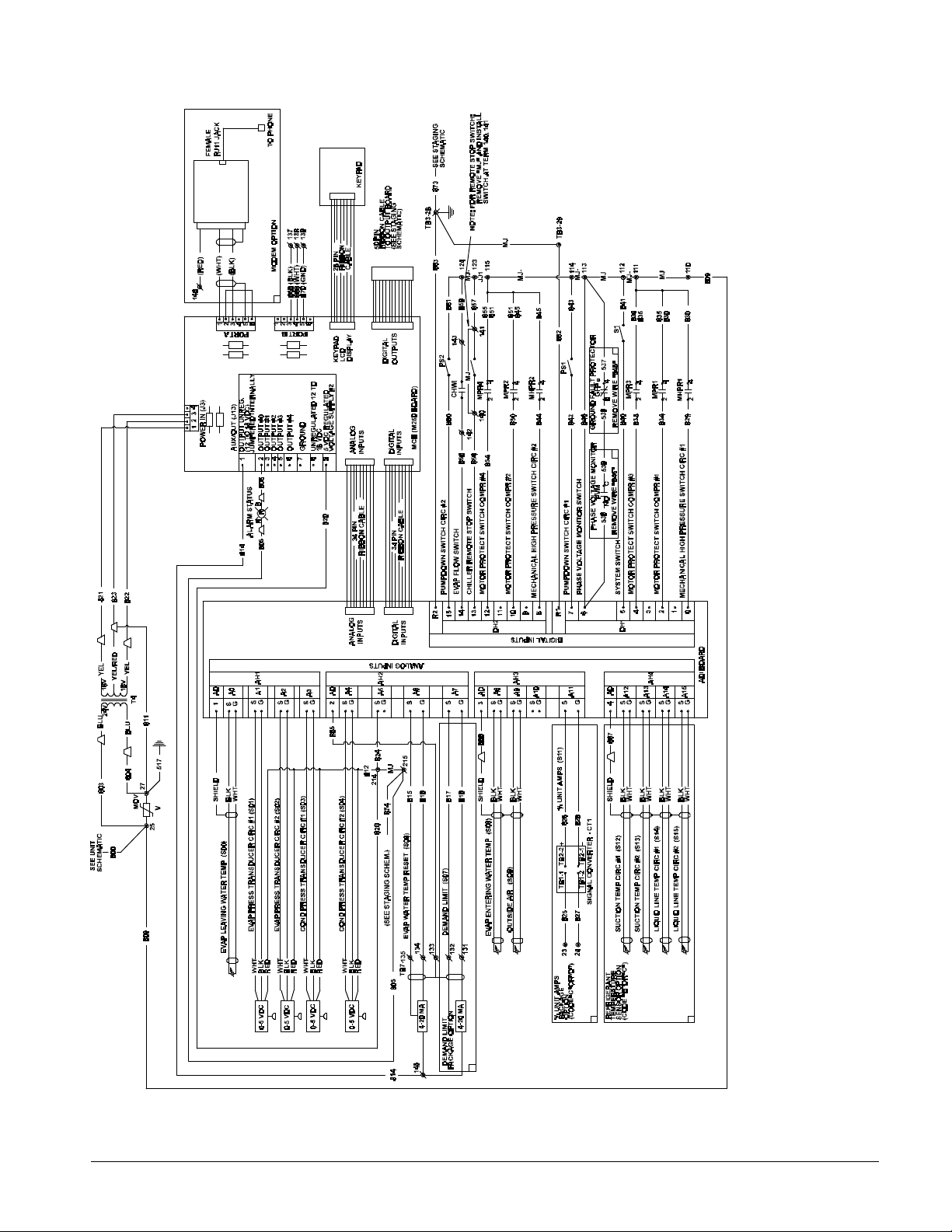

Figure 14, MicroTech Controller Schematic

IOM 686 AGZ 030A through 065A 25

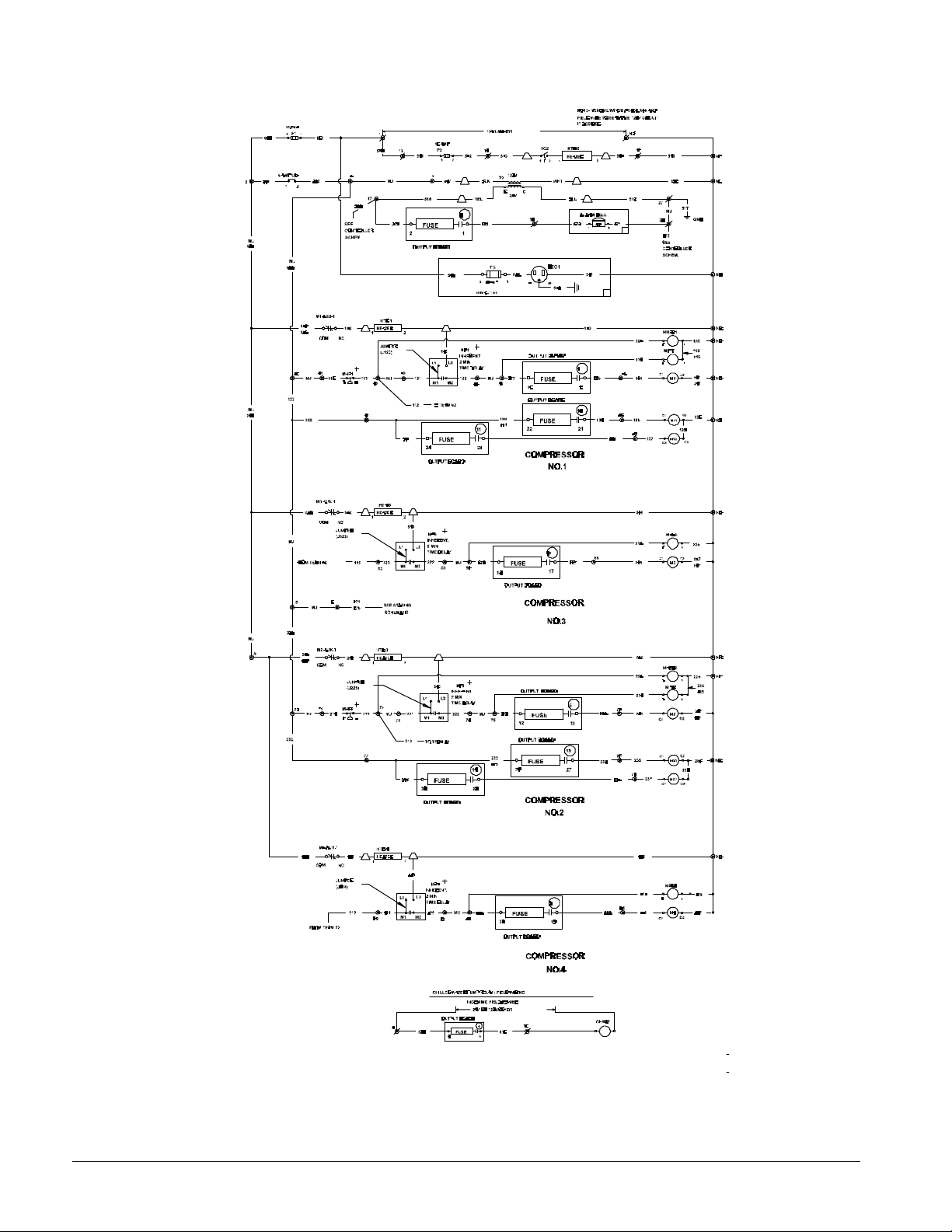

Page 26

Figure 15, Unit Control Schematic (MicroTech)

26 AGZ 030A through 065A IOM 686

Page 27

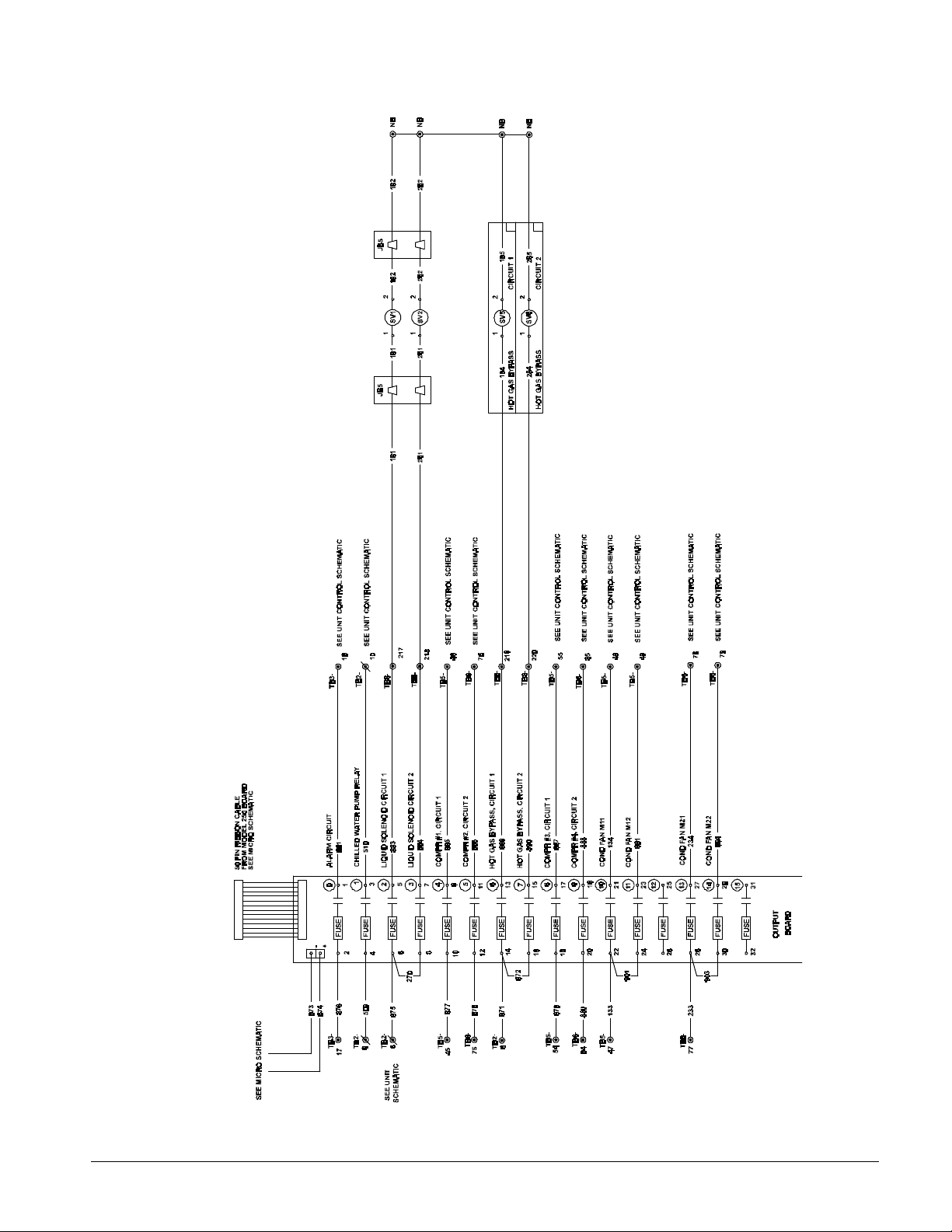

Figure 16, Staging Schematic (MicroTech)

IOM 686 AGZ 030A through 065A 27

Page 28

Dimensional Data

Figure 17, Dimensions AGZ 030A through 065A

AGZ Center of Gravity Additional Weight

MODEL inch / mm for Units with Copper

Number A B C D E F X Y Z Operating Shipping Fin Coils lb / kg

030AS 86.2

030AE 86.2

040AS 86.2

040AE 86.2

045AS 86.2

050AS 86.2

050AE 86.2

055AS 86.2

060AS 86.2

065AE 96.2

(2189.5)

(2189.5)

(2189.5)

(2189.5)

(2189.5)

(2189.5)

(2189.5)

(2189.5)

(2189.5)

(2443.5)

81.7

(2075.2)

81.7

(2075.2)

81.7

(2075.2)

81.7

(2075.2)

81.7

(2075.2)

81.7

(2075.2)

81.7

(2075.2)

81.7

(2075.2)

81.7

(2075.2)

91.7

(2329.2)

61.6

(1565.3)

61.6

(1565.3)

61.6

(1565.3)

61.6

(1565.3)

61.6

(1565.3)

60.0

(1524.0)

60.0

(1524.0)

60.0

(1524.0)

60.0

(1524.0)

60.0

(1524.0)

22.3

(566.4)

22.3

(566.4)

22.3

(566.4)

22.3

(566.4)

22.3

(566.4)

24.0

(609.6)

24.0

(609.6)

24.0

(609.6)

24.0

(609.6)

24.0

(609.6)

5.3

(133.8)

5.3

(133.8)

5.3

(133.8)

5.3

(133.8)

5.3

(133.8)

4.3

(108.4)

4.3

(108.4)

4.3

(108.4)

4.3

(108.4)

4.3

(108.4)

15.0

(381.0)

15.0

(381.0)

15.0

(381.0)

15.0

(381.0)

15.0

(381.0)

16.0

(406.4)

16.0

(406.4)

16.0

(406.4)

16.0

(406.4)

16.0

(406.4)

43.9

(1115)

43.9

(1115)

43.9

(1115)

43.9

(1115)

43.9

(1115)

44.2

(1123)

44.6

(1133)

44.6

(1133)

44.6

(1133)

44.6

(1133)

40.2

(1021)

44.6

(1133)

44.6

(1133)

44.6

(1133)

44.6

(1133)

40.8

(1036)

41.2

(1046)

41.2

(1046)

41.2

(1046)

41.8

(1062)

35.9

(912)

35.9

(912)

36.2

(920)

36.2

(920)

37.4

(950)

35.6

(904)

37.4

(950)

36.4

(925)

36.4

(925)

38.8

(986)

3425

(1555)

3485

(1580)

3480

(1580)

3535

(1605)

3695

(1675)

3850

(1745)

4010

(1820)

4055

(1840)

4115

(1865)

4295

(1950)

3350

(1520)

3410

(1545)

3405

(1545)

3460

(1570)

3620

(1640)

3745

(1700)

3905

(1770)

3950

(1790)

4010

(1820)

4190

(1900)

445

(200)

445

(200)

445

(200)

445

(200)

665

(300)

445

(200)

665

(300)

665

(300)

665

(300)

830

(375)

28 AGZ 030A through 065A IOM 686

Page 29

AGZ Unit Check-out

Water piping checkout

1. Check the pump operation and vent all air from the system.

2. Circulate evaporator water checking for proper system pressure and pressure drop across the

chiller barrel. Compare the pressure drop to the Evaporator water pressure drop curve.

3. Clean all water strainers before placing the chiller into service.

Refrigerant piping checkout

1. Check all exposed brazed joints for evidence of leaks. Joints may have been damaged during

shipping or when the unit was installed.

2. Check that all refrigerant valves are either opened or closed as required for proper operation of the

chiller.

3. Check all valve stem packing for leaks. Replace all refrigerant valve caps and tighten.

4. Check all refrigerant lines to insure that they will not vibrate against each other or against other

chiller components.

5. Check all flare connections and all refrigerant threaded connectors.

6. Look for any signs of refrigerant leaks around the condenser coils and for damage during shipping

or installation.

7. Leak detector is applied externally to refrigerant joints at the factory. Do not confuse this residue

with an oil leak.

8. Connect refrigerant service gauges to each refrigerant circuit before starting unit.

Electrical Check Out

CAUTION

Electrical power must be applied to the compressor crankcase heaters 24 hours before

starting unit.

1. Open all electrical disconnects and check all power wiring connections. Start at the power block

and check all connections through all components to and including the compressor terminals.

These should be checked again after 3 months of operations and at least yearly thereafter.

2. Check all control wiring by pulling on the wire at the spade connections and tighten all screw

connections. Check plug-in relays for proper seating and to insure retaining clips are installed.

3. Put System Switch (S1) to the Emergency Stop position.

4. Put both circuit #1 & #2 switches to the Pumpdown and Stop position.

5. Apply power to the unit. The panel Alarm Light will stay on until S1 is closed. Ignore the Alarm

Light for the check out period. If you have the optional Alarm Bell, you may wish to disconnect

it.

6. Check at the power block or disconnect for the proper voltage and proper voltage between phases.

7. Check for 120VAC at the optional control transformer and at TB-2 terminal #1 and the neutral

block (NB).

8. Check between TB-2 terminal #7 and NB for 120VAC supply for transformer #2.

9. Check between TB-2 terminal #2 and NB for 120VAC control voltage. This supplies the

compressor crank case heaters.

10. Check between TB-3 terminal #17 and #27 for 24Vac control voltage.

11. Check on the Global UNT controller between terminals marked 24Vac and common for 24 Vac

control voltage. Green light on Global UNT controller should be flashing.

IOM 686 AGZ 030A through 065A 29

Page 30

AGZ Troubleshooting Chart

PROBLEM POSSIBLE CAUSES POSSIBLE CORRECTIVE STEPS

Compressor will not 1. Main Switch. 1. Close Switch.

Run 2. Fuse Blown. Circuit breakers open 2. Check electrical circuits and motor windings for shorts or

3. Thermal overloads tripped 3. Overloads are auto-reset Check unit closely when unit comes

4. Defective contactor or coil. 4. Repair or replace

5. System Shutdown by safety devices 5. Determine type and cause of shutdown and correct it before

6. No cooling required 6. None. Wait until unit calss for cooling

7. Liquid line solenoid will not open 7. Repair or replace solenoid coil. Check wiring

8. Motor electrical trouble 8. Check motor for opens, shorts, or burnout

9. Loose wiring 9. Check all wire junctions. Tighten all terminal screws

Compressor noisy 1. Compressor running in reverse 1. Check unit and compressor for correct phasing

or vibrating 2. Improper piping support on suction or discharge 2. Relocate, add, or remove hangers

High Discharge 1. Noncondensables in system 1. Purge the noncondensables

Pressure 2. System overcharged with refrigerant 2. Remove excess, check liquid subcooling

Low Discharge 1. Wind blowing into coil at low ambient 1. Shield coil from direct wind

Pressure 2. Faulty condenser temperature regulation 2. Check condenser control operation

High Suction 1. Excessive water temperature 1. Check control settings

Pressure 2. Excessive load 2. Reduce load or add additional equipment

Low Suction

Pressure

Compressor will not 1. Defective capacity control 1. Replace

stage up 2. Faulty thermostat stage or broken wire 2. Replace

Compressor Staging 1. Thermostat control band not set properly 1. Set control band wider

Intervals to Short 2. Erratic water thermostat 2. Replace

Compressor Oil 1. Low oil level 1. Check and add oil

Level Too high or 2. Loose fitting on oil line 2. Check and tighten system

Too Low 3. Level too high 3. Adjust thermal expansion valve

Compressor loses 1. Lack of refrigerant 1. Check for leaks and repair. Add refrigerant

Oil 2. Excessive compression ring blow-by 2. Replace compressor

Motor Overload 1. Low voltage during high load conditions 1. Check supply voltage for excessive line drop

Relays or Circuit 2. Defective or grounded wiring in motor 2. Replace compressor motor

Breakers Open 3. Loose power wiring 3. Check all connections and tighten

Compressor 1. Operating beyond design conditions 1. Add facilities so conditions are within allowable limits

Thermal Protection 2. Discharge valve partially shut 2. Open valve

Switch Open 3. Blown compressor internal gasket 3. Replace gasket

3. Worn compressor isolator bushing 3. Replace

4. Worn Compressor 4. Replace

3. Discharge shutoff valve partially closed 3. Open valve

4. FanTrol wiring not correct 4. Check FanTrol wiring

5. Fan not running 5. Check electrical circuit, Check fan motor

6. Dirty condenser coil 6. Clean coil

3. Insufficient refrigerant in system 3. Check for leaks. Repair and add charge

4. Low suction pressure 4. See corrective steps for Low Suction Pressure

5. Only one compressor operating 5. See corrective steps for Compressor Will Not Stage Up

3. Expansion valve overfeeding 3. Check remote bulb. Regulate superheat

4. Compressors running in reverse 4. Check for proper phasing

1. Lack of refrigerant 1. Check for leaks, Repair and add charge. Ckeck liquid

2. Clogged liquid line filter drier 2. Check pressure drop across filter drier. Replace

3. Expansion valve malfunctioning 3. Check and reset for proper superheat

4. Condensing temperature to low 4. Check means for regulating condenser temperature

5. Compressor will not unload 5. See corrective steps for Compressor Staging Intervals Too

6. Insufficient water flow 6. Adjust flow

7. Evaporator head ring gasket slippage 7. Take pressure drop across vessel and contact factory to

8. Evaporator dirty 8. Clean chemically

3. Stages not set for application 3. Reset thermostat setting for application

3. Insufficient water flow 3. Adjust flow

4. Insufficient water flow - Level too high 4. Adjust flow

5. Excessive liquid in crankcase - Level too high 5. Check crankcase heater. Reset expansion valve for higher

3. Suction superheat too high 3. Adjust superheat

4. Crankcase heater burnout 4. Replace crankcase heater

4. High condenser temperature 4. See corrective steps for High Discharge Pressure

5. Power line fault causing unbalanced voltage 5. Check supply voltage. Notify power company. Do not start

grounds. Investigate for possible overloading. Replace fuse

or reset breakers after fault is corrected. Check for loose or

corroded connections.

back on line. Allow time for auto-reset.

resetting safety switch

sightglass

Low

obtain design pressure drop for that vessel

superheat. Check liquid line solenoid valve operation.

until fault is corrected.

30 AGZ 030A through 065A IOM 686

Page 31

Global UNT Controller Installation and Operation

This section provides installation, setup and troubleshooting information for the Global UNT

controller.

All operational descriptions are based on the Global UNT software SUZE4-2A. Operational

characteristics may vary with other versions of software.

General Description

The Global UNT is a microprocessor based leaving water controller designed for multiple stage

operation.

The Global UNT’s operation is based on an adjustable setpoint and control band. Controller software

is available for different reset options, refrigerants and metric units. Optional equipment includes a

Zone Terminal that can be installed in the unit or remotely. The Zone Terminal provides a user

interface to all reset options and adjusts specific setpoints. Downloading of software or changing

selected operating parameters requires the Global UNT Interface Kit.

Optional Sensors

• Return water temperature sensor

• Zone temperature sensor

Pre Start-up

The chiller must be inspected to ensure no components became loose or damaged during shipping or

installation.

Start-Up

Refer to the Global UNT Controller section to become familiar with its operation before starting

chiller.

There should be adequate building load (25% of unit capacity minimum) to properly check the

operation of the chiller refrigerant circuits.

Be prepared to record all operating parameters required by the “Compressorized Equipment Warranty

Form”. Return this information within 10 working days to McQuay International as instructed on the

form to obtain full warranty benefits.

1. Verify chilled water flow.

2. Verify remote start / stop or time clock has requested the chiller to start.

3. Set the chilled water setpoint to required temperature. (The system water temperature must be

greater than the total of the leaving water temperature setpoint plus 1/2 the control band before

the Global UNT controller will stage on cooling.)

4. Set the control band to 4° F as a starting point.

5. Put both circuit switches to the AUTO position.

6. Put switch S1 to AUTO position.

IOM 686 AGZ 030A through 065A 31

Page 32

7. There will be a delay of 2 minutes after closing S1. The time delay is due to the compressor

inherent motor protection. This may allow more than one compressor to start after this time

period. This should only occur on initial start-up or when power to the chiller has been turned off

and back on. The panel Alarm Light will turn off.

8. After the chiller has been operating for a period of time and has become stable, check the

following:

§ Compressor oil level. (Some Scroll compressors do not have oil sight glasses)

§ Refrigerant sight glass for flashing.

§ Rotation of condenser fans.

9. Complete the “Compressorized Equipment Warranty Form”.

Shutdown

Temporary

1. Put both circuit switches to Pumpdown and Stop.

2. After compressors have stopped, put System Switch (S1) to Emergency Stop.

3. Turn off chilled water pump. Chilled water pump to operate while compressors are pumping

down.

To start the chiller after a temporary shutdown follow the start up instructions.

Extended

1. Front seat both condenser liquid line service valves.

2. Put both circuit switches in Pumpdown and Stop position.

3. After the compressors have stopped, put System Switch (S1) in Emergency Stop position.

4. Front seat both refrigerant circuit discharge valves.

5. If chilled water system is not drained, maintain power to the evaporator heater to prevent freezing.

Maintain heat tracing on the chilled water lines.

6. Drain evaporator and water piping to prevent freezing.

7. If electrical power is on to unit, the compressor crankcase heaters will keep the liquid refrigerant

out of the compressor oil. This will minimize start up time when putting the unit back into

service. The evaporator heater will be able to function.

8. If electrical power is off, make provisions to power the evaporator heater (if chilled water system

is not drained). Tag all opened electrical disconnect switches to warm against startup before the

refrigerant valves are in the correct operating position. When starting the unit, electrical power

must be on for 24 hours before starting the chiller.

To start the chiller after an extended shutdown, follow the pre startup and startup instructions.

32 AGZ 030A through 065A IOM 686

Page 33

Sequence of Operation

Starting

With control power on, 115VAC power is applied through F1 to the compressor crankcase heaters and

control transformer T2. T2 supplies 24Vac to the Global UNT controller. The green light on the

Global UNT controller will begin to flash. The panel Alarm Light will illuminate. Put the System

Switch S1 into the AUTO position. This applies power to the control circuit and a digital input to the

Global UNT controller. Control power is applied through the MHP’s to the compressor inherent

motor protectors. After approximately a two (2) minute time delay, the MP’s are energized and the

panel Alarm Light will turn off. If this is a first start, depress the Freezestat Reset Button for 1

seconds. There is a default time delay of 5 minutes on the Freezestat reset.

Start the chiller water pump and put the chiller into the run mode by closing the remote start / stop

input or time clock input. After the flow switch has made, the Global UNT controller will begin to

ramp up if the chilled water temperature is above the leaving water setpoint dial plus 1/2 the control

band dial. Internal timing functions will vary the stage up time.

The refrigerant circuit starting is switched between circuits every ten (10) starts. This maintains equal

starts on the first compressor of each refrigerant circuit. Refrigerant circuit #1 is assumed as the

starting circuit for the following.

When the first stage of cooling is required, relay BO1 will be energized and if the evaporator pressure

is above the LPSS (low pressure starting setpoint), relay BO7 will be energized starting Compressor

#1 and energizing the liquid line solenoid valve (SV1) through control relay CCR1.

As additional cooling is required, relay BO2 will be energized and if the evaporator pressure is above

the LPSS (low pressure starting setpoint), relay BO8 will be energized starting Compressor #2 and

energizing the liquid line solenoid valve (SV2) through control relay CCR2.

As additional cooling is required, relays BO3 and BO4 will start compressor #3 and #4 respectively.

The reverse will occur as the cooling requirements are reduced. Relays BO4 and BO3 will open

stopping compressors #4 and #3. Relay BO2 will open closing the #2 refrigerant liquid line solenoid

valve. Compressor #2 will continue to operate until the LPLL (low pressure low limit) is reached or

the PDTD (pumpdown delay time period) timer times out. Relay BO8 will open stopping compressor

#2. Relay BO1 will open closing the #1 refrigerant liquid line solenoid valve. Compressor #1 will

continue to operate until the LPLL is reached or the PDTD timer times out. Relay BO7 will open

stopping compressor #1. The compressors will not cycle on if the evaporator pressure exceeds the

LPSS setpoint. The Global Scroll Chiller has a one time pumpdown.

Standard Controller Setpoints (optional Zone Terminal required to change values)

TEMPLATE VALUES

NAME FACTORY SETPOINT RANGE

OA/AI3 Lim SP 80oF 0 to 100oF

OA/AI3 Reset SP -40oF -100 to 100oF

LvgWtr Rband SP 0oF 0 to 15oF

Unoccpd Lvg SP 70oF 40 to 90oF

OA Lockout SP -10oF -20 to 65oF

Lvg Low Lim SP 20oF 20 to 40oF

SoftSta Capcty 50% 0 to 100%

SoftStart Time 2 min 0 to 20 minutes

IOM 686 AGZ 030A through 065A 33

Page 34

Software Description (Global UNT Interface Kit required to read or change variables)

Variable

Name

LPSS Low Pressure Starting Setpoint 10 psi 5 to 15 psi

SLPT Starting Low Pressure Time 260 sec 90 to 300 seconds

MLPS Minimum Low Pressure Setpoint 5 psi Calculated (LPSS-LPSD)

LPSD Low Pressure Starting Differential 5 psi 3 to 10 psi

LPFS Low Pressure Freezestat setpoint 54 psi 30 to 55 psi

LPHL Low Pressure High Limit 57 psi 40 to 60 psi

LPLL Low Pressure Low Limit 55 psi 40 to 55 psi

FSTP Freezestat Time Period 60 sec 60 seconds fixed

PDTD Pumpdown Delay Time Period 60 sec 60 seconds fixed

Description Default Value Range

5 psi

Hot Gas Bypass (Optional)

This option allows the system to operate at low loads without the ON-OFF cycling of the compressor.

When the hot gas bypass option is used it is required to be on both refrigerant circuits because of the

lead / lag feature of the Global UNT controller.

This option allows passage of discharge gas into the evaporator inlet (between the TX valve and the

evaporator) which generates a false load to supplement the actual chilled water load.

Note: The hot gas bypass valve cannot generate a 100% false load.

The valve that is supplied can provide a load of approximately 10 tons. The system load added to the

ten tons of the hot gas bypass valve has to exceed the compressor capacity for stage 1 compressors for

stable system operation. This requires 3-6 tons of system load.

A solenoid valve in the hot gas bypass lines is wired in parallel with both circuit’s liquid line solenoid

valves SV1 and SV2. The hot gas bypass is available whenever a refrigerant circuit is operating. The

hot gas valve is regulating by the evaporator pressure and the remote adjustable bulb. The pressure

regulating valve is factory set to begin opening at 58 psig (32° F for R-22). This setting can be

changed by adjusting the remote adjustable bulb. Remove the cap on the remote bulb and raise the

pressure by turning the adjustment screw clockwise. Lower the pressure by turning the adjusting

screw counterclockwise. This changes the pressure that the hot gas bypass valve will start to open. Do

not force the adjusting screw as this can damage the adjusting assembly.

WARNING

The hot gas line may become hot enough to cause injury. Be careful during valve checkout.

Note: The remote adjusting bulb must be installed on the outside of the suction line

insulation. The bulb has to have a stable ambient air temperature for proper operation.

Placing the bulb in contact with the evaporator refrigerant line will limit the operation of the

hot gas bypass valve.

34 AGZ 030A through 065A IOM 686

Page 35

Combination Filter Drier

Each refrigerant circuit is furnished with a full flow filter drier or an optional replaceable core type

filter-drier. The core assembly of the replaceable core drier consists of a filter core held tightly in the

shell in a manner that allows full flow without bypass.

Pressure drop across the filter drier at full load conditions must not exceed 10 psig. If pressure

drop is more than 10 psig, then replace the filter drier.

CAUTION

Pump out refrigerant before removing end flange for replacement of core(s).

A condenser liquid line service valve is provided for isolating the charge in the condenser, but also

serves as the point from which the liquid line can be pumped out. With the line free of liquid, the

filter-drier core(s) can be easily replaced.

System Adjustment

To maintain peak performance at full load operation, the system superheat and liquid subcooling may

require adjustment. Read the following subsections closely to determine if adjustment is required.

Liquid Sightglass and Moisture Indicator

The color of the moisture indicator is an indication of the dryness of the system and is extremely

important when the system has been serviced. Immediately after the system has been opened for

service, the element may indicate a wet condition. It is recommended that the equipment operate for

about 12 hours to allow the system to reach equilibrium before deciding if the system requires a

change of drier cores.

Bubbles in the sightglass to expansion valve at constant full load conditions indicates a shortage of

refrigerant, a plugged filter-drier, or a restriction in the liquid line. However, it is not unusual to see

bubbles in the sightglass during changing load conditions.

Refrigerant Charging

Liquid line subcooling at the liquid shut-off valve should be between 15° and 20°F at full load. If the

unit is at steady full load operation and bubbles are visible in the sightglass, then check liquid

subcooling.

Thermostatic Expansion Valve

The expansion valve performs one specific function. It keeps the evaporator supplied with the proper

amount of refrigerant to satisfy the load conditions.

The sensing bulb of the expansion valve is installed in the closest straight run of suction line from the

evaporator. The bulb is held on by clamps around the suction line and is insulated to reduce the effect

of surrounding ambient temperatures. In case the bulb must be removed, simply slit the insulation on

each side of the bulb, remove the clamps and then remove the capillary tubing that runs along the

suction line from the valve.

The power element is removable from the valve body without removing the valve from the line.

IOM 686 AGZ 030A through 065A 35

Page 36

Note: The superheat is factory set and adjustment is not needed unless unless operation is

outside the 8° to 12°F range.

CAUTION

Before adjusting superheat, check unit charge is correct and liquid line sightglass is full with

no bubbles.

The suction superheat for the suction leaving the evaporator is set at the factory for 8° to 12°F at full

load. To have full rated unit performance the superheat must be about 8°F at 95°F outdoor ambient.

Crankcase Heaters

The scroll compressors are equipped with externally mounted band heaters located at the oil sump

level. The function of the heater is to keep the temperature in the crankcase high enough to prevent

refrigerant from migrating to the crankcase and condensing in the oil during off-cycle.

Power must be supplied to the heaters 24 hours before starting the compressors.

Water Cooler

The water cooler is of the direct expansion type with removable internally finned tubes. The copper

tubes are individually rolled into heavy duty steel tube sheets and sealed by a steel refrigerant head.

The water connection nozzles which enter and leave the shell are on the same side of the unit. No

special attention is required for the cooler except that clean, filtered water should be supplied.

Sensors and Transducers

Sensors and transducers are mounted and connected to the Global UNT controller with sensor cable.

The evaporator pressure transducers depress the schrader fittings and can be replaced without pumping

the unit down. The pressure transducers are connected to the Global UNT controller analog inputs

with IDC connectors (Insulation Displacement Connectors). The low pressure transducers have a blue

dot. The leaving water sensor is in a thermal well for easy replacement without draining the water

system. As standard, an outside air sensor is provided on the back of the control box. When other

reset options are selected, the outside air sensor is not provided as only one (1) type of reset is

available.

Control Wiring

Low voltage control wiring is installed, labeled and tested by the factory before shipment.

External Voltage Inputs

The signal for remote reset option (2 to 10 VDC) or demand limit (0 to 10VDC) is provided by the

installing contractor. Connect to TB -7 terminals #134 (+) and #135 (-) as indicated by the unit wiring

diagram. A 4 to 20mA signal conditioned by a 500 ohm resistor can provide the 2 to 10 VDC input