Page 1

Engineered for flexibility and performance™

®

Air-Cooled Scroll-Compressor Chillers Catalog 611

Model AGZ-D • 25 to 190 Tons • R-410A • 60Hz/50Hz

Page 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Modbus

*AHRI Certification and ETL Listing apply to 60Hz models only

©2010 McQuay International. Illustrations and data cover the McQuay International product at the time of publication and we reserve the right to

make changes in design and construction at anytime without notice. ™® The following are trademarks or registered trademarks of their

respective companies: LEED is a registered trademark of the U.S. Green Building Council; BACnet from ASHRAE; LONMARK, LonTalk,

LONWORKS, and the LONMARK logo are managed, granted and used by LONMARK International under a license granted by Echelon

Corporation; ElectroFin from AST ElectroFin Inc.; Modbus from Schneider Electric; FanTrol, MicroTech III, Open Choice from McQuay

International

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . 4

Optional Remote Interface Panel . . . . . . . . . . . 6

Application Considerations. . . . . . . . . . . . . . . . . . . 7

Unit Placement. . . . . . . . . . . . . . . . . . . . . . . . . 7

Chilled Water Piping. . . . . . . . . . . . . . . . . . . . 11

Typical Piping. . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating and Standby Limits . . . . . . . . . . . . 13

Selction Procedure. . . . . . . . . . . . . . . . . . . . . . . . . 14

Performance Data. . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ethylene & Propylene Glycol Factors. . . . . . . 15

Altitude Correction Factors. . . . . . . . . . . . . . . 15

Part Load Performance Data (60 Hz) . . . . . . . . . . 28

Part Load Performance Data (50 Hz) . . . . . . . . . . 30

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Physical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Pressure Drop Data. . . . . . . . . . . . . . . . . . . . . . . . 45

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Electrical Data Notes . . . . . . . . . . . . . . . . . . 46

Field Wiring Diagram . . . . . . . . . . . . . . . . . . 47

Sound Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Lifting and Mounting Weights . . . . . . . . . . . . . . . 70

Options and Accessories . . . . . . . . . . . . . . . . . . . 73

Engineering Guide Specification . . . . . . . . . . . . . 75

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Hazard Identification

DANGER

Dangers indicate a hazardous situation which will result in death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can result in property damage, severe personal injury, or death if not avoided.

CAUTION

Cautions indicate potentially hazardous situations, which can result in personal injury or equipment damage if not avoided.

Note: Cover photograph is an AGZ190D with standard protective coil grilles.

This catalog covers AGZ-D vintage air cooled scroll chillers. For AGZ-C vintage models, see CAT AGZC, available at www.mcquay.com.

Document: CAT 611

Issue Date: October 18, 2010

Revision Date: -Replaces: NEW

Software Version: MST Pathfinder v 2.01

2 CAT 611

Page 3

Introduction

Introduction

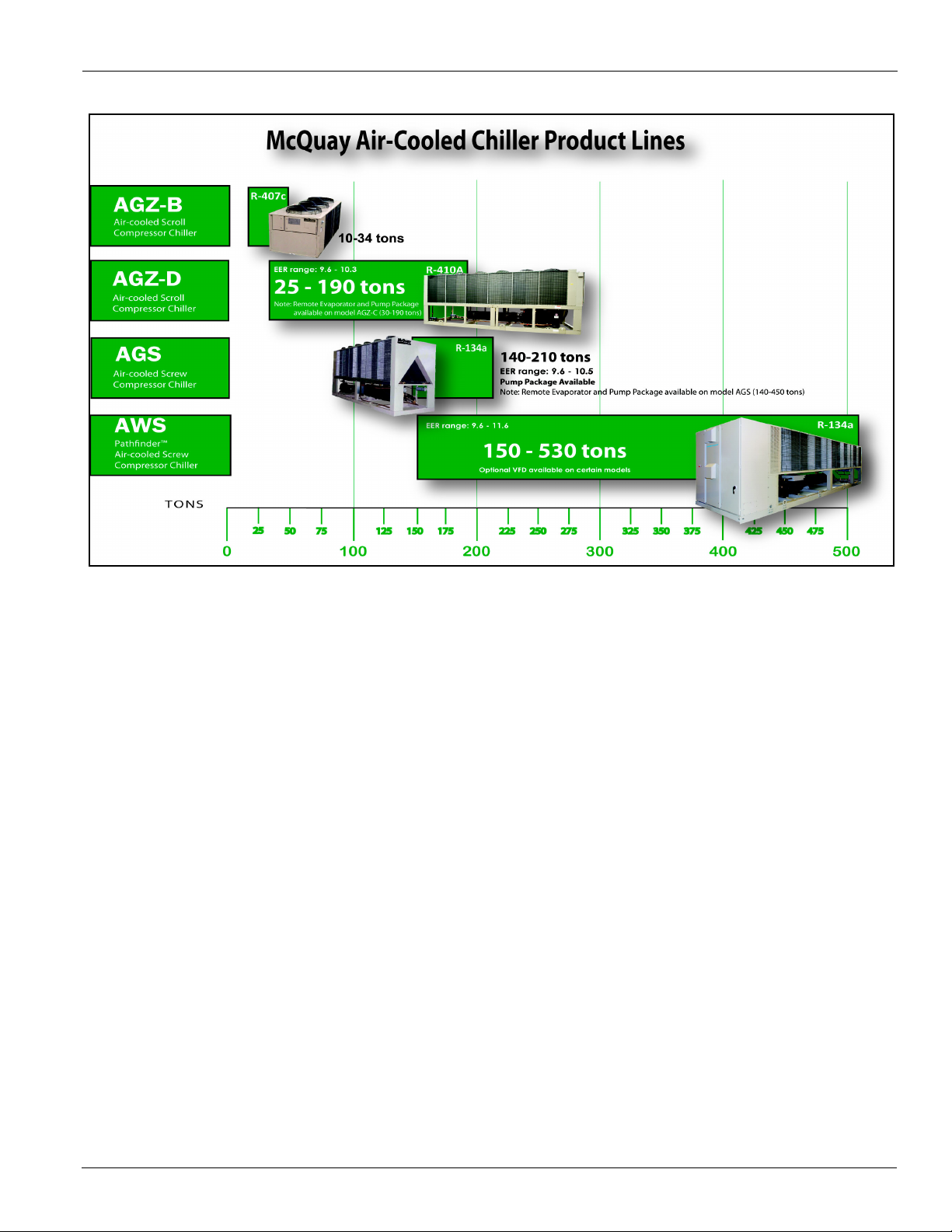

The AGZ-D family of air-cooled scroll chillers offers a wide

selection of units from 25 to 190 tons with dual refrigerant

circuits and either two or three scroll compressors per circuit.

The AGZ series of air-cooled scroll chillers continues

McQuay's legacy of high quality, high efficiency, latest

technology and quiet operation. These features make the AGZ

family the best overall value in air-cooled packaged chillers

available today.

Efficient Operation

The AGZ units utilize environmentally acceptable R-410A

refrigerant and meet the performance requirements of

ASHRAE Standard 90.1 for efficiency. Excellent part-load

performance is achieved with four or six scroll compressors.

High overall efficiency = lower annual energy costs

Latest Control Technology

These units have the latest control technology through

utilization of McQuay's MicroTech III® microprocessor.

Integrating with your building automation system is easy with

the Open Choice™ feature using LonTalk®, BACnet® or

Modbus® network communication, via field mounting of a

small communication module to the unit controller.

Compact Size

Our reputation for compact designs with small footprints to

minimize space requirements continues to be a primary

feature. The coil design and canted fan deck allow close

spacing to walls and other units. These attributes can lower

installation cost and are excellent for replacement/retrofit jobs.

Quiet Operation

The AGZ units further enhance McQuay's reputation for low

operating sound levels to make these chillers "neighborhood

friendly".

LEED® Points

Developed by the U.S. Green Building Council (USGBC) in

1998, Leadership in Energy and Environmental Design

(LEED®) is an internationally recognized certification

program and intends to provide building owners and operators

a consistent structure for identifying and implementing

practical and measurable green building design, construction,

operations and maintenance solutions.

For building owners who want to pursue LEED Green

Building Certification, the AGZ-D series of air-cooled chillers

can qualify for the Energy and Atmosphere Credit 4, Enhanced

Refrigerant Management worth 2 points.

CAT 611 3

Page 4

Features and Benefits

A

G Z XXX D H

Air-Cooled

Global Design

Scroll Compressor

Nominal Tons

Application

Design Vintage

H = Standard Packaged

Chiller Nomenclature

Features and Benefits

Unit Design Features

McQuay AGZ air-cooled Chillers are a product of the McQuay

commitment to offer quiet, reliable, energy efficient

equipment, incorporating high quality compressors, state-ofthe-art coil design, and innovative packaging.

Construction

AGZ chillers are factory-assembled and mounted on a heavygauge steel base. The base rails, supports and cabinetry are

powder-coat painted for long life. The base distributes the unit

weight for roof loading. Their small footprint allows smaller

mounting pads or support structures and is a plus for retrofit or

replacement applications.

Compressors

Reliable hermetic scroll compressors with cast iron scrolls and

three Teflon® impregnated bearings are used on the AGZ-D

chillers to promote longevity.

Each model has four to six steps of capacity modulation

depending on model size. One to six compressors can run,

depending on the load of the system, resulting in excellent

part-load efficiency and reduced annual operating costs.

Evaporator

Models AGZ-025 through AGZ-130

The evaporator is a compact, high efficiency, dual circuit,

brazed plate-to-plate type heat exchanger consisting of parallel

stainless steel plates. These heat exchangers provide excellent

heat exchange efficiency in a compact footprint and are

especially attractive for smaller capacity units.

Condenser Coils

Condenser coils have internally enhanced seamless copper

tubes arranged in a staggered row pattern. The coils are

mechanically expanded into McQuay lanced and rippled

aluminum fins with full fin collars. A variety of optional coil

material and coatings are available so that the unit can be

constructed to meet almost any environment. Options include

copper fins, black fin and ElectroFin® coating; see page 73 for

description of options.

Condenser Fans and Motors

Multiple direct-drive, dynamically balanced propeller fans

operate in formed venturi openings at low tip speeds for

maximum efficiency and minimum noise and vibration. A

heavy-gauge vinyl-coated fan guard protects each fan.

Each condenser fan motor (including the optional VFD fan

motor) is Totally Enclosed Air Over (TEAO), heavy-duty, 3phase with permanently lubricated ball bearings and inherent

overload protection. These motors are designed specifically for

outdoor use.

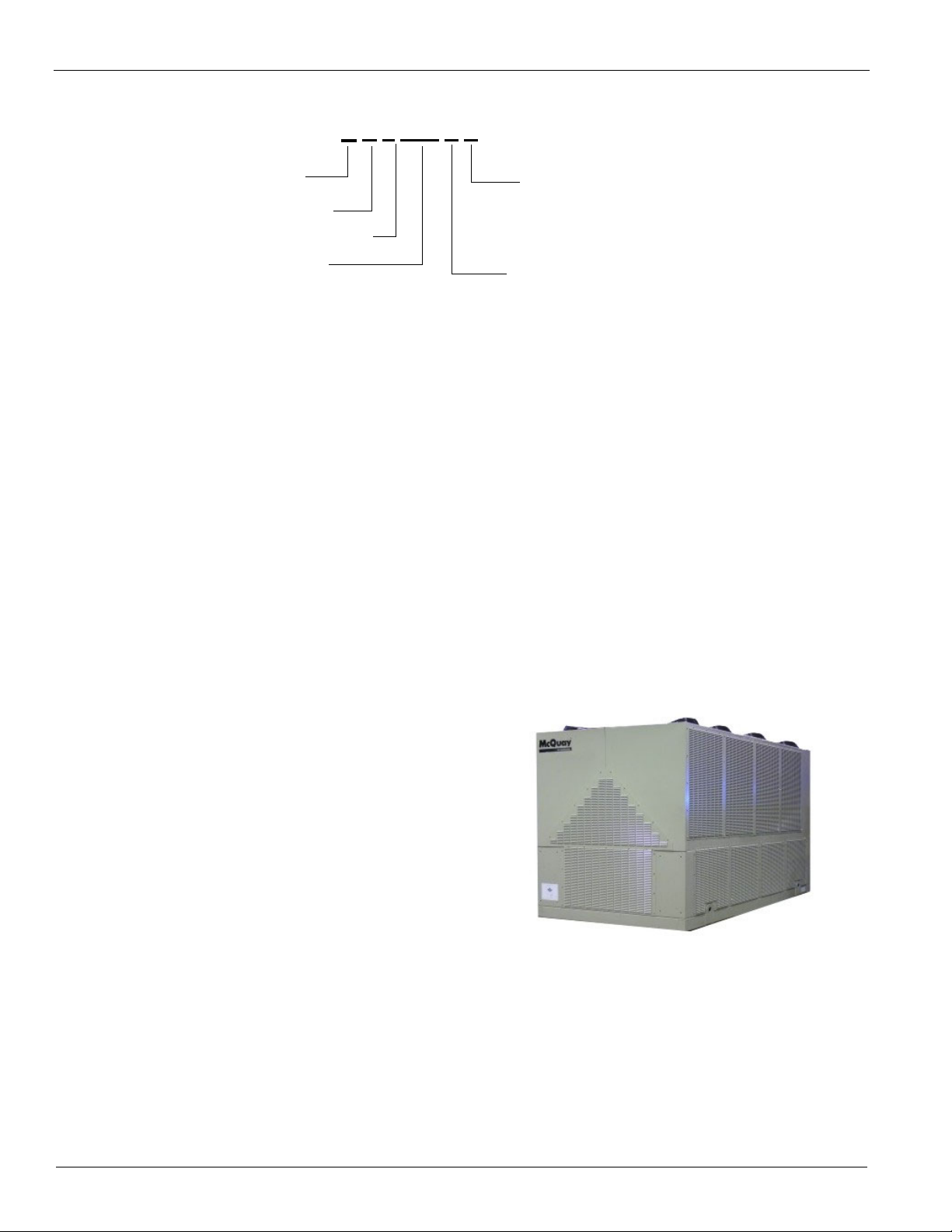

Figure 1: AGZ130D with Optional Full Louver Package

The water side working pressure is 653 psig (4502 kPa).

Evaporators are designed and constructed according to, and

listed by, Underwriters Laboratories (UL).

Models AGZ-140 through AGZ-190

The evaporator is direct-expansion, U-tube type with water

flowing in the baffled shell side and refrigerant flowing

through the tubes. Two independent refrigerant circuits within

the evaporator serve the unit's dual refrigerant circuits. The

water side working pressure is 152 psig (1048 kPa). Each

evaporator is designed, constructed, inspected, and stamped

according to the requirements of the ASME Boiler and

Pressure Vessel Code. Double thickness insulation is available

as an option.

4 CAT 611

Fan Deck

The fan deck is canted inward and directs discharge air toward

the center of the unit, reducing the tendency to spill over the

sides and into the coil, reducing capacity. This feature, combined with the coil design allows closer unit spacing than most

competitors. The result is a smaller installation footprint and

reduced first cost. The external condenser coils are fitted with

a standard wire mesh guards to protect the coil from damage.

Optional louvers create an attractive appearance that can

eliminate the need for screening walls

Page 5

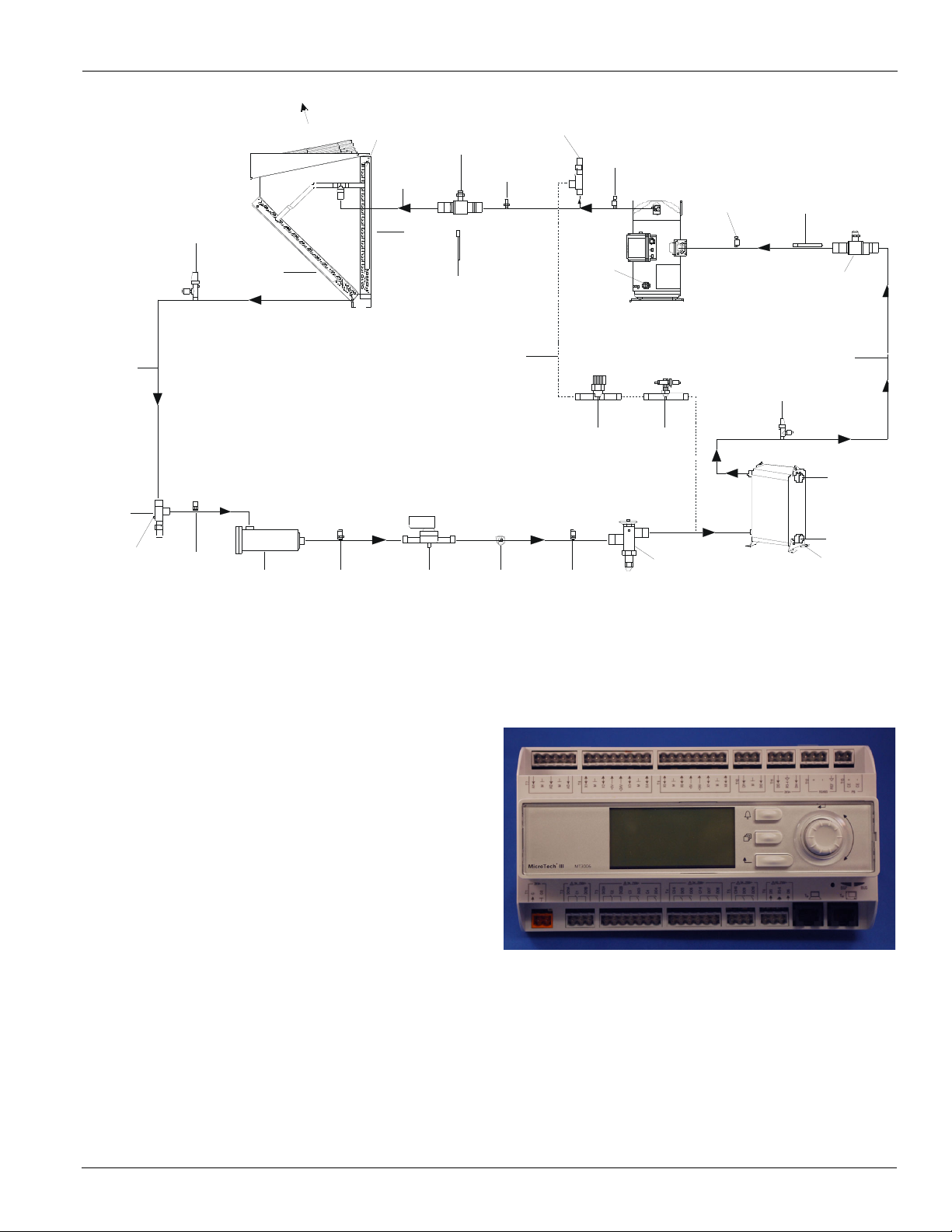

Figure 2: AGZ-D Piping Schematic (One circuit shown)

CHARGING

VA LVE

LIQUID

TUBI NG

LIQUI D

SHU T-OFF

SC H R A D ER

VALVE

FI LTER

R

SO LENOI D

VALVE

SIG H T

GLASS

THERMAL

EX PA N S I O N

VA LVE

WA TER

IN

WATER

OUT

PL A TE TYPE

EV AP O R A TOR

SUC TIO N

SHU T-OFF

BALL VALVE

(OPTIO NA L)

SUC TIO N

TUBIN G

SCHRAD ER

VALVE

DISCHA RGE

TUBIN G

AIR

FLO W

AI R

FLOW

AIR

FLOW

CONDENSER

A SSE M B LY

SC ROLL

C O M PR ESSO R

(TANDEM O R TRIO)

CHARGING

VA L VE

SC H RADER

VALVE

(HEADER)

(ST1, ST2)

SUC TION

TRANSDUCER

(WL1, WL2)

TRANSD UCER

(WH1, WH2)

OUTSIDE AIR

TEM PERATURE

(WAA)

SCHRA DER

VA LVE

SC H RAD ER

VALVE

BYPA SS

TUBING

(OPTIO NA L)

VALVE

TEMP. SENSOR

A C C ESS

FITTIN G

HGBP

VALVE

DISCHA RGE

SHU T-OFF

VA L VE

NOTES:

1. Evaporator is brazed-plate on AGZ 025-130 and shell-and-tube on AGZ 140-190.

2. Hot gas bypass (shown in dotted lines) is an option. The controls are factory installed.

3. Models 025 to 045 have TXV valves only, Models 140 to 190 have EXV valves only, Models 050 to 130 have TXV as

standard with EXV available as an option.

Features and Benefits

VALVE

DRIE

HOT G AS

SH UT-OFF

DI SCHA RGE

OIL

SIG H T

GLASS

SO LENOI D

HGBP

VALVE

SUC TIO N

TEMP. SENSOR

LEAVIN G WATER

(ON O PPOSITE SIDE)

Control System

The MicroTech III advanced DDC chiller controller surpasses

all other microprocessor-based chiller control systems

available today. This powerful, user-friendly control system

provides the flexibility and performance needed for either

stand-alone unit operation or the controller can be easily tied

into your building automation system of choice using

McQuay's Open Choices feature. Open Choices allows you to

choose from open standard protocols such as BACnet®,

Modbus and LonWorks® to communicate easily with the

building automation system that best meets your facility

requirements. These optional communications modules are

available factory installed or can be easily field installed.

The MicroTech III controller's state-of-the-art design will not

only permit the chiller to run more efficiently, but will also

simplify troubleshooting if a system failure occurs. Every

MicroTech III controller is programmed and tested prior to

shipment to help provide a trouble-free start-up.

Operator-friendly

The MicroTech III control menu structure is separated into

four distinct categories that provide the operator or service

technician with a full description of current unit status, control

parameters, and alarms. Security protection helps prevent

unauthorized changing of the setpoints and unit control

parameters.

CAT 611 5

Page 6

Features and Benefits

MicroTech III control continuously performs important selfdiagnostic checks while monitoring system temperatures,

pressures and protection devices. It will automatically

shutdown a compressor, a refrigerant circuit or the entire unit

if a fault occurs. The cause of the shutdown will be retained in

memory and can be easily displayed in plain English or metric

units for operator review. In addition to displaying alarm

diagnostics, the MicroTech III chiller controller also provides

the operator with a warning of pre-alarm conditions. Alarm

notification data can also be passed to a BAS through an

optional communication module.

Staging

The scroll compressors are staged on and off as a function of

leaving chilled water temperature. Lead/lag is automatic and

switched based on starts and operating hours.

Equipment Protection

The unit is protected in three ways:

1 alarms that shut the unit down and require manual reset

to restore unit operation,

2 alarms that shut the unit down and then restart

automatically (do notrequire manual restart), and

3 limit alarms that reduce unit capacity in response to

some out-of-limit condition. Shut down alarms activate

an alarm signal that can be exported to a remote location.

Limit alarms activate a light on the controller and do not

trigger a remote alarm.

Building Automation System (BAS) Interface

The following BAS protocols are supported:

•BACnet/IP

• BACnet MS/TP

• LonWorks (FTT-10A)

• Modbus

• All operating conditions, system alarms, control parameters and schedules are monitored.

Features

• Can be wired up to 1,000 feet (308 meters) from the unit

for flexibility in placing each remote user interface

within your building.

Benefits

• Allows you to access the user interface for each unit

from one location, inside the building.

• Users need to learn one format because the remote user

interface is identical to the unit-mounted version.

• No additional field commissioning is required for the

remote user interface.

• Can be retrofit after unit installation.

• Is fully compatible with the optional BAS communication modules.

Cable and Wiring Recommendations

Communications: Belden 9841 or equal AWG 22 twisted pair.

See McQuay manual IM1005 for wiring and installation

information.

Figure 3: Remote Interface Panel

Optional Remote Interface Panel

In addition to the unit-mounted user interface provided with

MicroTech III controls, the AGZ chillers can be individually

equipped with a remote user interface. It provides convenient

access to unit diagnostics and control adjustments, without

having to access a rooftop or outdoor location. One remote

panel can be connected to up to eight chillers.

Each remote user interface is similar to its unit-mounted

counterpart and offers the same functionality and display,

including:

• Three buttons and a navigating wheel with a 8 line by

30-character display format.

• Digital display of messages in English language.

6 CAT 611

Page 7

Application Considerations

Full Load Capacity Reduction (AGZ110-130)

0.0

1.0

2.0

0 8 12 16 20 24

Wall He ight (ft)

Distance = 4ft Distance = 5f t

Power Increase (AGZ110-130)

0.0

1.0

2.0

0 8 12 16 20 24

Wall Height (ft)

% Power Increase

Distance = 4ft Distance = 5ft

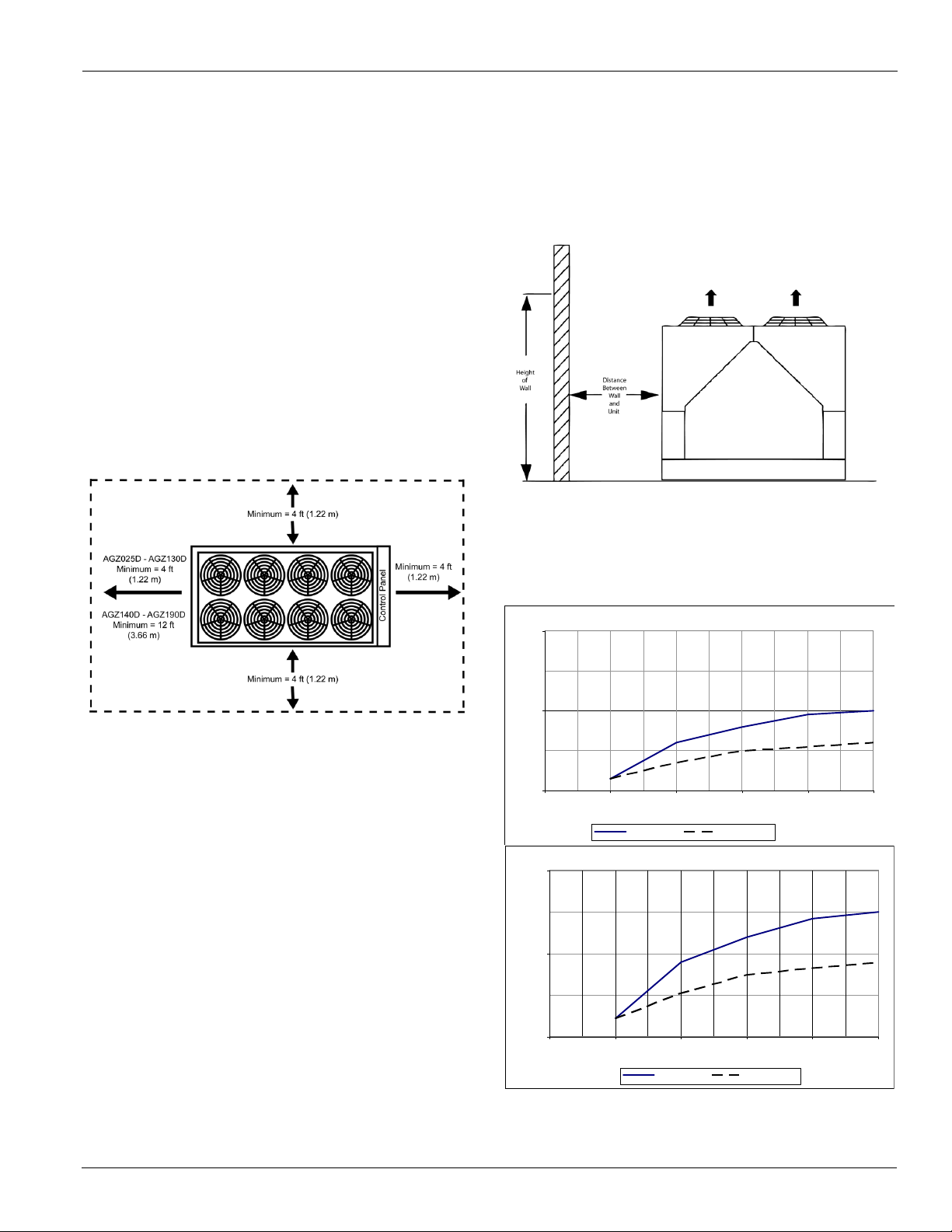

Unit Placement

AGZ units are for outdoor applications and can be mounted

either on a roof or at ground level. For roof mounted

applications, install the unit on a steel channel or I-beam frame

to support the unit above the roof. For ground level

applications, install the unit on a substantial base that will not

settle. Use a one-piece concrete slab with footings extended

below the frost line. Be sure the foundation is level within 0.5”

(13mm) over its length and width. The foundation must be

strong enough to support the weights listed in the Physical

Data Tables beginning on page 39.

Service Clearance

Sides: Minimum of 4 feet (1.22 m)

Control panel end: Minimum of 4 feet

Opposite control panel:

• Minimum 4 feet on models 025 to 130;

• 12 feet on models 140-190 (allows clearance to remove

the evaporator ).

Application Considerations

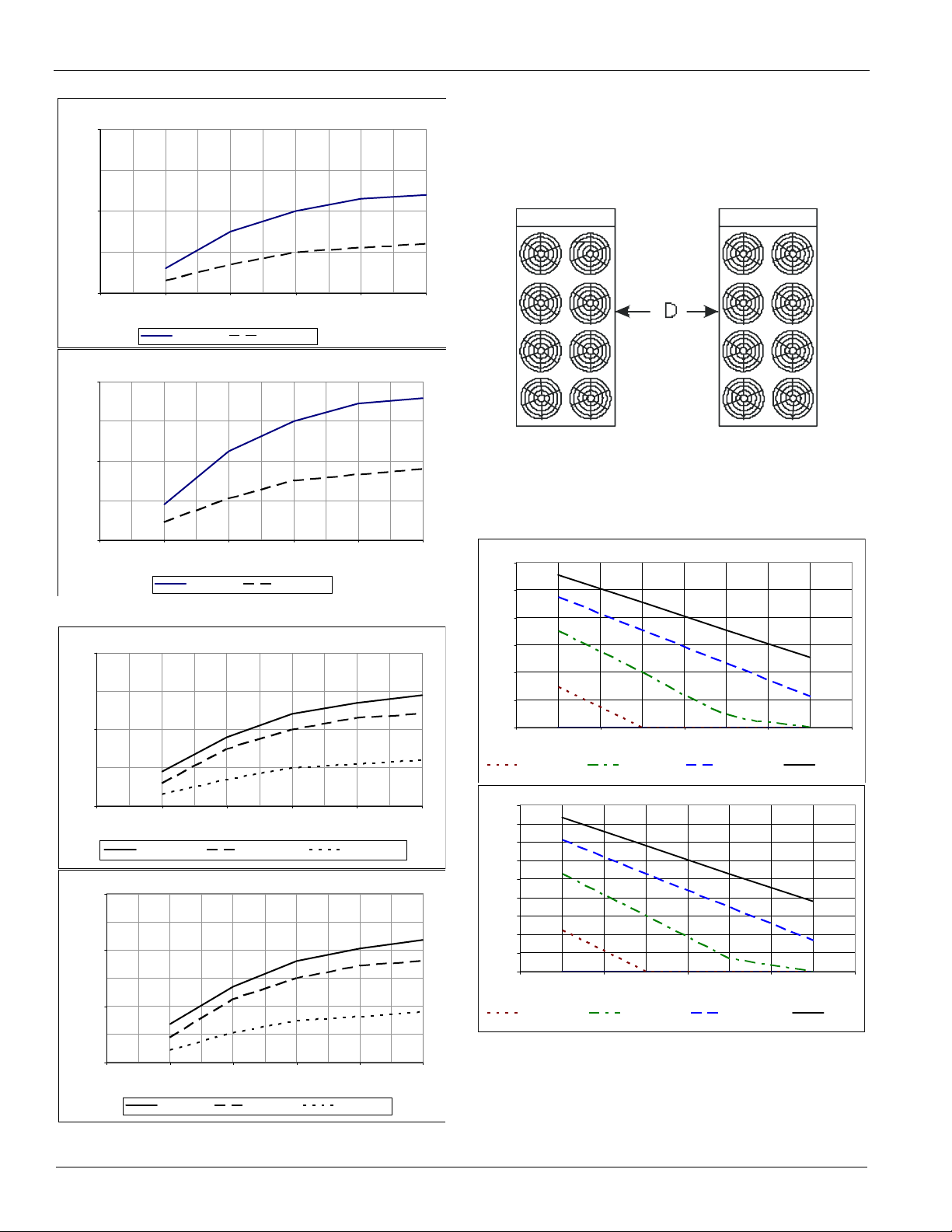

Case 1: Wall on One Side

In this case a solid wall up to 24-feet is considered. (For walls

higher than 24 ft., use the 24-foot values.) Also use these

charts for an adjacent building. For perforated screening walls,

use Case 4. Spacing is differentiated by unit size families.

Figure 4: Wall on One Side of Unit

Note: Maintain a minimum of 4-feet on all sides; except models

140-190, which require 12-feet opposite the control

panel to remove the evaporator.

For models AGZ 025-100: use 4 feet from any height wall. For

models 110-190, use Performance Adjustment curves below.

Figure 5: Case 1 Adjustment Factors (AGZ110D-130D)

Air Clearance

McQuay's advanced “W” coil design and open air-passage

ends allow very close unit spacing and a small installation

footprint. The AGZ-D fans are canted inward and reduce

recirculation by directing discharge air to the center of the unit,

reducing the tendency to flow outward and spill over into the

coil inlet.

Sufficient clearance must be maintained between the unit and

adjacent walls or other units to allow the required unit air flow

to reach the coils. Failure to do so will result in a capacity

reduction and an increase in power consumption. No

obstructions are allowed above the unit at any height.

Spacing Requirements

In general, with a small performance penalty in some cases,

AGZ-D units can be spaced at four feet from other units or a

wall. Curves on the following pages give the minimum

clearance for different types of installations and also capacity

reduction and power increase if closer spacing is used.

CAT 611 7

% Ca pacity Reduction

Page 8

Application Considerations

Full Loa d Ca pa city Re ducti on (AGZ140-180)

0.0

1.0

2.0

0 8 12 16 20 24

Wall Height (ft)

Distance = 4ft Distance = 6f t

Power Increase (AGZ140-180)

0.0

1.0

2.0

0 8 12 16 20 24

Wall Height (ft)

% Power Increase

Distance = 4ft Distance = 6ft

Full Load Capacity Reduction (AGZ190)

0.0

1.0

2.0

0 8 12 16 20 24

Wall Height (ft)

Dist ance = 4ft Distance = 5ft Distance = 7ft

Power Increase (AGZ190)

0.0

1.0

2.0

3.0

0 8 12 16 20 24

Wall Height (ft)

% Power Increase

Distance = 4ft Dis tan ce = 5 ft Distance = 7f t

Full Load Capacity Reduction

0.0

0.5

1.0

1.5

2.0

2.5

3.0

4568

Distance Be tw een Units (ft)

% Capacity Reducti on

AGZ075-100D AGZ110-130D AGZ140-180D AGZ190D

Power Increase

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

4568

Distance Between Units (ft)

% Power Increase

AGZ075-100D AGZ110-130D AGZ140-180D

D

Figure 6: Case 1 Adjustment Factors (AGZ140D-180D)

% Capacity Reduction

Case 2: Two Units, Side-by-Side

Maintain a minimum of 6-feet on all sides; except models 140190, which require 12-feet opposite the control panel to

remove the evaporator.

Figure 8: Case 2 - Two units side by side

For models AGZ 025-100: use 4 feet between units. For

models 110-190, use Performance Adjustment chart in

Figure 9.

Figure 9: Case 2 Adjustment Factors

Figure 7: Case 1 Adjustment Factors (AGZ190D)

% Capacity Reduction

8 CAT 611

AGZ190

Page 9

Application Considerations

Full Load Capacity Reduction

0

1

2

3

4

5

6

4568

Distance Betwe en Units

% Capacity Reduction

AGZ075-100D AGZ110-130D AGZ 14 0-1 8 0D AGZ190D

Power Incre ase

0

1

2

3

4

5

6

7

8

9

4568

Distance Between Units (ft)

% Power Increase

AGZ075-100D AGZ110-130D AGZ140-180D AGZ190D

Wall Free Area vs. Distance

0

1

2

3

4

5

6

7

8

0 1020304050

% Open Wall Area

Distance from Wall to Unit (ft)

AGZ025-070 AGZ075-130 AGZ140-190

Case 3: Three or More Units, Side-by-Side

Maintain a minimum of 6-feet on all sides; except models 140190, which require 12-feet opposite the control panel to

remove the evaporator. For more than three units, allow an

additional 2-feet clearance between units.

Figure 10: Case 3 - 3 units side by side

Data is for the middle unit - with a unit on each side. See Case

2, page 8 for Adjustment Factors for the two outside units.

Figure 11: Case 3 Adjustment Factors

Case 4: Open Screening Walls

Decorative screening walls are often used to help conceal a

unit either on grade or on a rooftop. Design these walls such

that the combination of their open area and distance from the

unit do not require performance adjustment. It is assumed that

the wall height is equal to or less than the unit height when

mounted on its base support. If the wall height is greater than

the unit height, see Case 5, Pit Installation, page 10. The

distance from the sides of the unit to the side walls must be

sufficient for service, such as opening control panel doors. For

uneven wall spacing, the distance from the unit to each wall

can be averaged providing no distance is less than 4 feet.

Values are based on walls on all four-sides.

Figure 12: Case 4 Adjustment Factor

CAT 611 9

Page 10

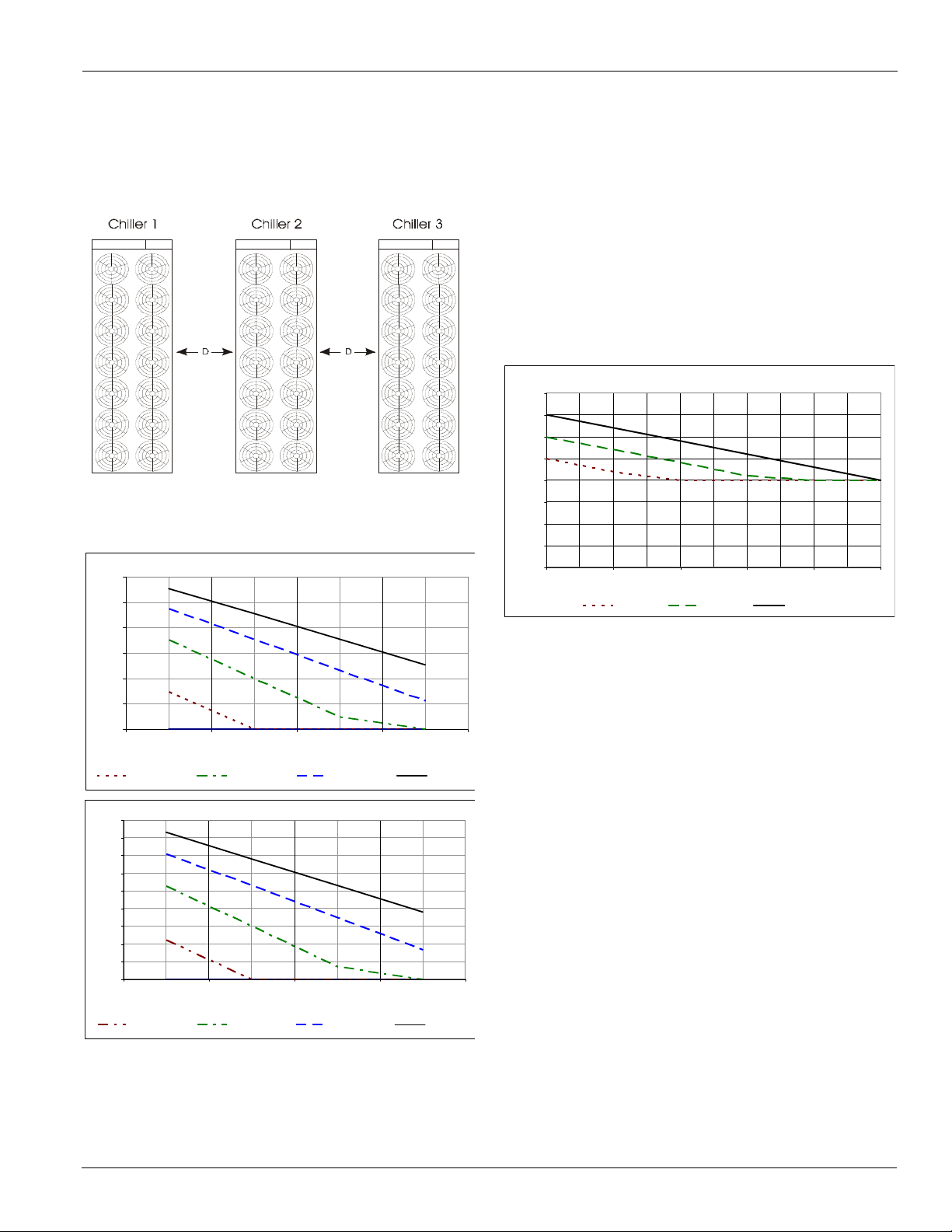

Application Considerations

Full Load Capacity Reduction (AGZ025-07 0)

0.0

1.0

2.0

3.0

4.0

5.0

6.0

0 8 10 12 13 14

Depth of Pit (ft)

% Capacity Red uction

Distance = 4 ft Distance = 5 ft Distance = 6 ft

Power Increase (AGZ025-070)

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

0 8 10 12 13 14

Depth of Pit (ft)

% Power Increase

Distance = 4 ft Distance = 5 ft Distance = 6 ft

Full Load Capacity Reduction (AGZ075-130)

0

1

2

3

4

5

6

0 8 10 12 13 14

Depth of Pit (ft)

% Capacity Reduction

Distance = 5 ft Distance = 6 ft Distance = 8 ft

Power Increase (AGZ075-130)

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

0 8 10 12 13 14

Depth of Pit / Wall Height (ft)

% Power In crease

Distance = 5 ft Distance = 6 f t Dis tance = 8 ft

Full Load Capacity Reduction (AGZ140-190)

0.0

1.0

2.0

3.0

4.0

5.0

6.0

0 8 10 12 13 14

Depth of Pit (ft)

% Capacity Reduction

Distance = 6 ft Di sta nc e = 8 f t Dis tan ce = 10 f t

Power Increase (AGZ140-190)

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

0 8 10 12 13 14

Depth of Pit / Wall He ight (ft)

% Power Increase

Distance = 6 ft Distance = 8 ft Distance = 10 ft

Case 5: Pit Installation

Pit installations can cause operating problems resulting from

recirculation and restriction, and require care that sufficient air

clearance is provided, safety requirements are met and service

access is provided. Pit covers must have abundant open area at

least equal to the chiller footprint.A solid wall surrounding a

unit is substantially a pit and this data should be used.

Steel grating is sometimes used to cover a pit to prevent

accidental falls or trips into the pit. The grating material and

installation design must be strong enough to prevent such

accidents, yet provide abundant open area to avoid

recirculation problems. Have any pit installation reviewed by

the McQuay sales representative prior to installation to ensure

it has sufficient air-flow characteristics, and approved by the

installation design engineer avoid risk of accident.

Figure 13: Case 5 - Pit Installation

Figure 15: Case 5 Adjustment Factors (AGZ075D-130D)

Figure 14: Case 5 Adjustment Factors (AGZ025D-070D)

10 CAT 611

Figure 16: Case 5 Adjustment Factors (AGZ140D-190D)

Page 11

Application Considerations

Chilled Water Piping

Follow all instructions and recommendations for Chilled Water

Piping in IM 1100, available on www.mcquay.com. Design the

water piping so the chilled water circulating pump discharges

into the evaporator inlet. A 40-mesh strainer must be installed

in the inlet pipe to the chiller to avoid debris entering the

evaporator. The strainer may be field-supplied, or is available

as field-installed kit. See Optional Inlet Strainer below for

more information.

A water flow switch must be installed in the horizontal piping

of the supply (evaporator outlet) water line to avoid evaporator

freeze-up under low or no flow conditions. The flow switch

may be ordered as a factory-installed option, a field-installed

kit, or may be supplied and installed in the field (See Options

and Accessories, page 73for more information).

Vibration eliminators are recommended in both the supply and

return water lines. Pressure gauges must be installed in the

inlet and outlet water lines to the evaporator.

Insulate chilled water piping to reduce heat loss and prevent

condensation. Chillers not running in the winter should have

their water systems thoroughly drained to protect against

freezing. If the chiller operates year-round, or if the system is

not drained for the winter, protect the chilled water piping

exposed to outdoor temperature against freezing. Wrap the

lines with a heater cable and add proper amount of glycol to

the system to further protect the system.

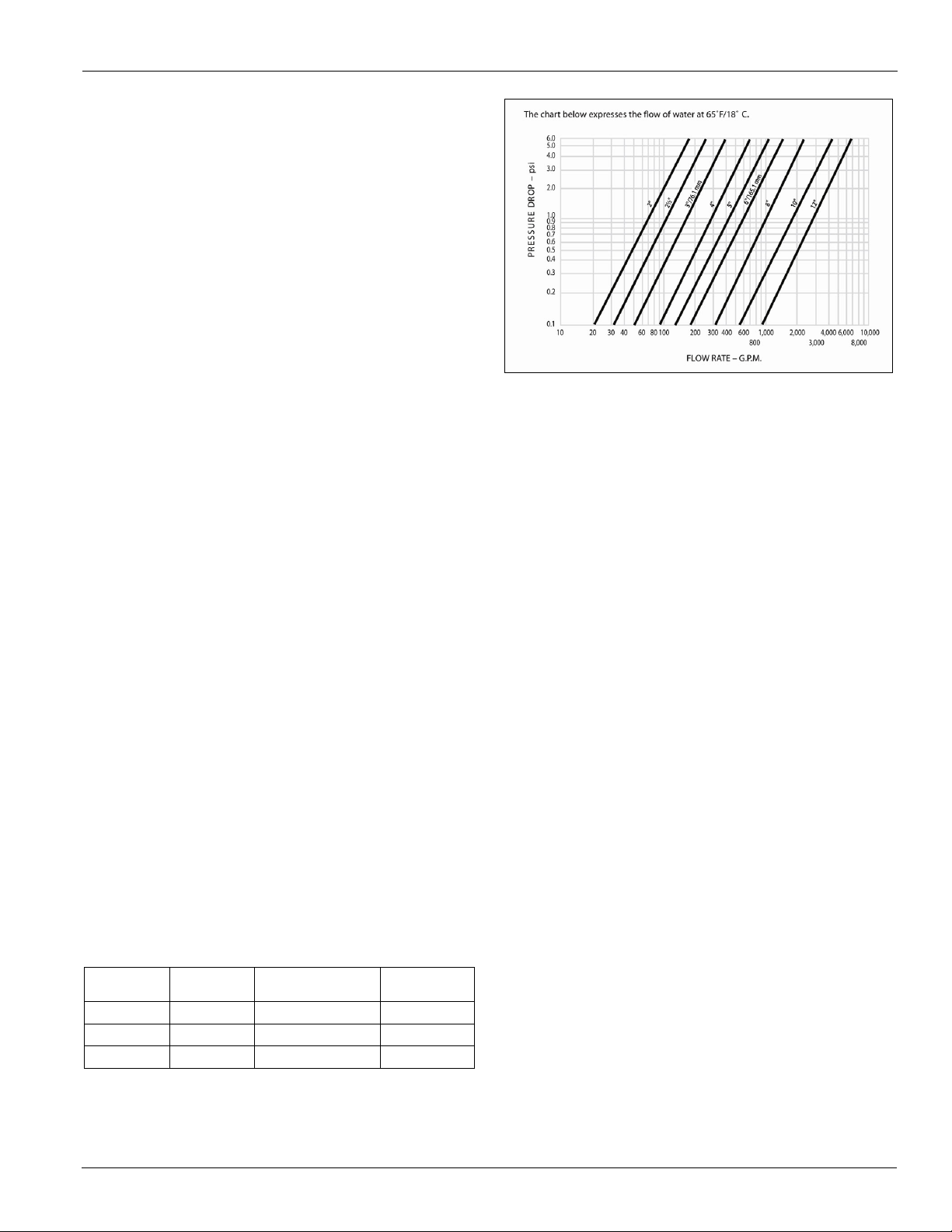

Optional Inlet Strainer

An inlet water strainer kit is available to be field-installed,

sized per Table 1 and with the pressure drop show in

Figure 17. This pressure drop must be accounted for in the

total system pressure drop. The kit consists of:

• (1) Y-type 40% open area strainer with 304 stainless

steel perforated basket, Victaulic pipe connections and

strainer cap

• (1) Extension pipe with (2) Schrader fittings that can be

used for a pressure gauge and thermal dispersion flow

switch. The pipe provides sufficient clearance from the

evaporator for strainer basket removal.

• (1) ½-inch blowdown valve

• (2) Victaulic clamps

Table 1: Strainer Data

AGZ Model

025-055 2.5 16.75 14

060-130 3.0 17.75 20

140-190 8.0 36.00 125

Strainer

Size (in.)

Strainer Plus Pipe

Length (in.)

Strainer

Weight (lbs)

Figure 17: Strainer Pressure Drop

Water Flow Limitations

Constant Flow

The evaporator flow rates and pressure drops shown on page

page 45 are for full load design purposes. The maximum flow

rate and pressure drop are based on a 6°F temperature drop.

Avoid higher flow rates with resulting lower temperature drops

to prevent potential control problems resulting from very small

control bands and limited start up/shut off temperature

changes.

The minimum flow and pressure drop is based on a full load

evaporator temperature drop of 16°F. Evaporator flow rates

below the minimum values can result in laminar flow causing

freeze-up problems, scaling and poor control. Flow rates above

the maximum values will result in unacceptable pressure drops

and can cause excessive erosion, potentially leading to failure.

Evaporator Variable Flow

Reducing evaporator flow in proportion to load can reduce

system power consumption. The rate of flow change should be

a maximum of 10 percent of the flow per minute. For example,

if the maximum design flow is 200 gpm and it will be reduced

to a flow of 140 gpm, the change in flow is 60 gpm. Ten

percent of 200 gpm equals 20 gpm change per minute, or a

minimum of three minutes to go from maximum to minimum.

Do not reduce flow lower than the minimum flows listed in the

evaporator pressure drop section, page 45. The water flow

through the vessel must remain between the minimum and

maximum values listed on page 45. If flow drops below the

minimum allowable, large reductions in heat transfer can

occur. If the flow exceeds the maximum rate, excessive

pressure drop and tube erosion can occur.

CAT 611 11

Page 12

Application Considerations

Figure 18: Typical Piping, Brazed-Plate Evaporator (models AGZ025D-130D)

Figure 19: Typical Piping, Shell and Tube Evaporator (models AGZ140D-190D)

Typical Piping

Piping for units with brazed-plate evaporators must have a

drain and vent connection provided in the bottom of the lower

connection pipe and to the top of the upper connection pipe

respectively. These evaporators do not have drain or vent

connections due to their construction.

System Water Volume Considerations

All chilled water systems need adequate time to recognize a

load change, respond to the change and stabilize to avoid

undesirable short cycling of the compressors or loss of

temperature control. In air conditioning systems, the potential

for short cycling usually exists when the building load falls

below the minimum chiller plant capacity or on close-coupled

systems with very small water volumes. Some of the things the

designer should consider when looking at water volume are the

minimum cooling load, the minimum chiller plant capacity

12 CAT 611

during the low load period and the desired cycle time for the

compressors. Assuming that there are no sudden load changes

and that the chiller plant has reasonable turndown, a rule of

thumb of “gallons of water volume equal to two to three times

the chilled water gpm flow rate” is often used. A storage tank

may have to be added to the system to reach the recommended

system volume.

Evaporator Freeze Protection

Evaporator freeze-up can be a concern in the application of aircooled water chillers. To protect against freeze-up, insulation

and electric heaters are furnished with the unit. Models 140

through 190 have immersion heaters with a thermostat; models

025 through 130 have an external plate heater and thermostat.

They protect the evaporator down to -20°F (-29°C) ambient air

temperature. Although the evaporator is equipped with freeze

protection, it does not protect water piping external to the unit

or the evaporator itself if there is a power failure or heater

Page 13

Application Considerations

cable burnout. Consider the following recommendations for

additional protection.

1 If the unit will not be operated during the winter, drain

evaporator and chilled water piping and flush with

glycol. Drain and vent connections are provided on the

evaporator to ease draining.

2 Add a glycol solution to the chilled water system to

provide freeze protection. Freeze point should be

approximately 10°F below minimum design ambient

temperature.

3 The addition of thermostatically controlled heat and

insulation to exposed piping.

The evaporator heater cable is factory wired to the 115 volt

circuit in the control box. This power should be supplied from

a separate source to maximize unit protection, but it can be

supplied from the control circuit. Operation of the heaters is

automatic through the ambient sensing thermostat that

energizes the evaporator heaters for protection against freezeup. Unless the evaporator is drained in the winter or contains

an adequate concentration of anti-freeze, the disconnect switch

to the evaporator heater must not be open.

Temperature and Water Flow Limitations

Low Ambient Operation

Compressor staging is adaptively determined by system load,

ambient air temperature, and other inputs to the MicroTech III

control. A low ambient option with fan VFD allows operation

down to -10° F (-23° C). The minimum ambient temperature is

based on still conditions where the wind is not greater than

five mph. Greater wind velocities will result in reduced

discharge pressure, increasing the minimum operating ambient

temperature. Field installed hail/wind guards are available to

allow the chiller to operate effectively down to the ambient

temperature for which it was designed.

High Ambient Operation

AGZ-D units for high ambient operation (105ºF to 125 F, 40.1

C to 51.7 C) require the addition of the optional high ambient

package that includes a small fan with a filter in the air intake

to cool the control panel.

All units with the optional VFD low ambient fan control

automatically include the high ambient option.

Evaporator flow rates below the minimum values can result in

laminar flow causing freeze-up problems, scaling and poor

control. Flow rates above the maximum values will result in

unacceptable pressure drops and can cause excessive erosion,

potentially leading to failure.

Operating and Standby Limits

Table 2: Operating Limits

Maximum standby ambient temperature 130°F (55°C)

Maximum operating ambient temperature 105°F (40°C)

-with optional high ambient package (see information under High Ambient Operation 125°F (52°C)

Minimum operating ambient temperature (standard control) 35°F (2°C)

Minimum operating ambient temperature (with optional low-ambient control) -10°F (-23°C)

Leaving chilled water temperature 40°F to 60°F (2°C to 16°C)

Leaving chilled fluid temperatures (with anti-freeze) - Unloading is not permitted with fluid leaving

temperatures below 25°F (-4°C). When ambient air temperature is above 100º F, minimum leaving

chilled fluid temperature (with antifreeze) is 25°F (4°C)

Operating chilled water delta-T range 6 to 16°F (-14 to -9°C)

Maximum evaporator operating inlet fluid temperature 76°F (24°C)

Maximum evaporator non-operating inlet fluid temperature 100°F (38°C)

15°F to 60°F (-9°C to 16°C)

CAT 611 13

Page 14

Selction Procedure

tons 24

T F

-----------------------

gpm=

kW

4.18

T C

-------------------------------------

ls=

Selction Procedure

AGZ-D chillers are ideal for a wide range of applications and

operating conditions.

Selection with Inch-Pound (I-P) units

The performance tables beginning on page 16 cover the range

of leaving evaporator water temperatures and outside ambient

temperatures included under AHRI Standard 550/590-2003.

The tables are based on a 10°F (5.5°C) temperature drop

through the evaporator.

Adjustment factors for applications having other than a 10°F

(5.5°C) drop can be found in Table 5, page 15. The minimum

leaving chilled water temperature setpoint without glycol is

40°F (4ºC). For brine selections, see Tab le 3 and Table 4 on

page 15 for glycol adjustment factors. Ratings are based on a

0.0001 ft

level operation. For other fouling factors, different Delta-Ts, or

altitude correction factors see Table 5, page 15. For

applications outside the catalog ratings, please contact your

local McQuay sales representative.

Selection example

Given:

2

x hr x ºF/Btu fouling factor in the evaporator at sea

• 50 tons minimum

• 95°F ambient temperature

• 120 gpm, 54ºF to 44°F chilled water

• 0.0001 evaporator fouling factor

1 From Table 6, page 16, an AGZ 055D at the given

conditions will produce 52 tons with a unit kW input of

61.9 and a unit EER of 10.0.

2 Use the following formula to calculate any unknown

elements (water only):

Selection example using ethylene glycol

Given:

• 44 tons minimum

• 95°F ambient air temperature

• 54°F - 44°F chilled water temperature

• 0.0001 evaporator fouling factor

• Protect from freezing down to 0°F

1 From Table 3, page 15, select an ethylene glycol

concentration of 40% to protect against freezing at 0°F.

2 At 40% ethylene glycol, the adjustment factors are:

• Capacity = 0.980

• kW = 0.992

• GPM = 1.132

• Pressure Drop = 1.557

3 Select the AGZ 050D from Table 6, page 16 and correct

with 40% ethylene glycol factors.

4 Correct capacity = 0.980 X 48.1 tons = 47.1 tons

5 Correct kW = 0.992 X 57.1 kW = 56.6 kW

6 Calculate chilled water flow:

Water flow @ corrected capacity=

440. tons x 24 / 10 F = 105.6 gpm

Glycol flow (at 40% solution) =

1.132 x 105.6 gpm = 119.5 gpm

Determine the evaporator pressure drop. Using Figure 27,

page 45, enter at 106 gpm (water) and follow up to the

AGZ050 line intersect. Read horizontally to obtain an

evaporator pressure drop of 11 feet. Correct the pressure drop

for 40% solution = 1.557 x 11.3 feet = 17.6 feet for ethylene

glycol using Table 3, page 15.

3 Determine the evaporator pressure drop. Using

Figure 27, page 45, enter at about 124 gpm and follow

up to the AGZ 055 line intersect. Read horizontally to

obtain an evaporator pressure drop of 13 feet of water.

14 CAT 611

Selection with SI units

Use the SI tables and the same procedures as with I-P units.

Use the following formula to calculate any missing elements

(water only):

Page 15

Performance Data

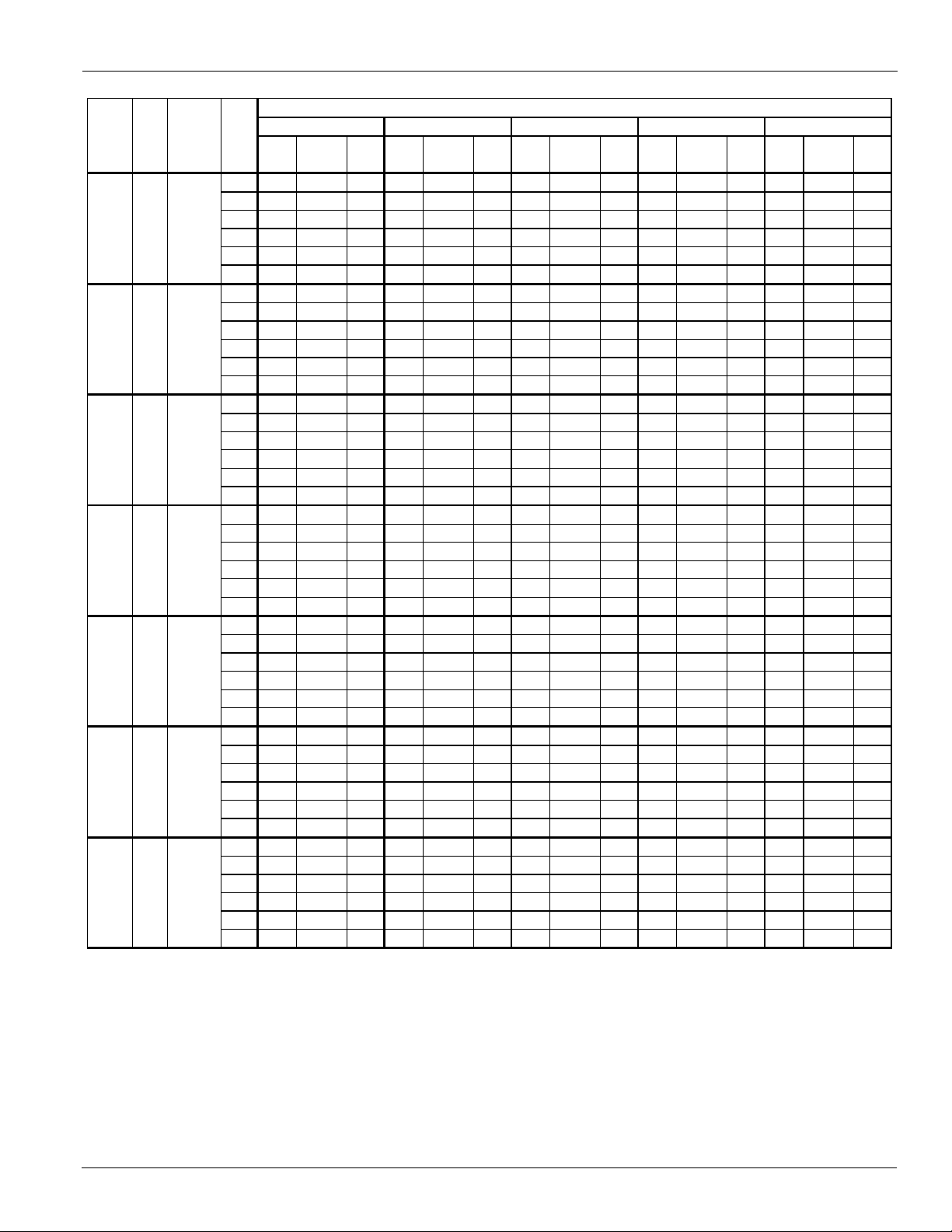

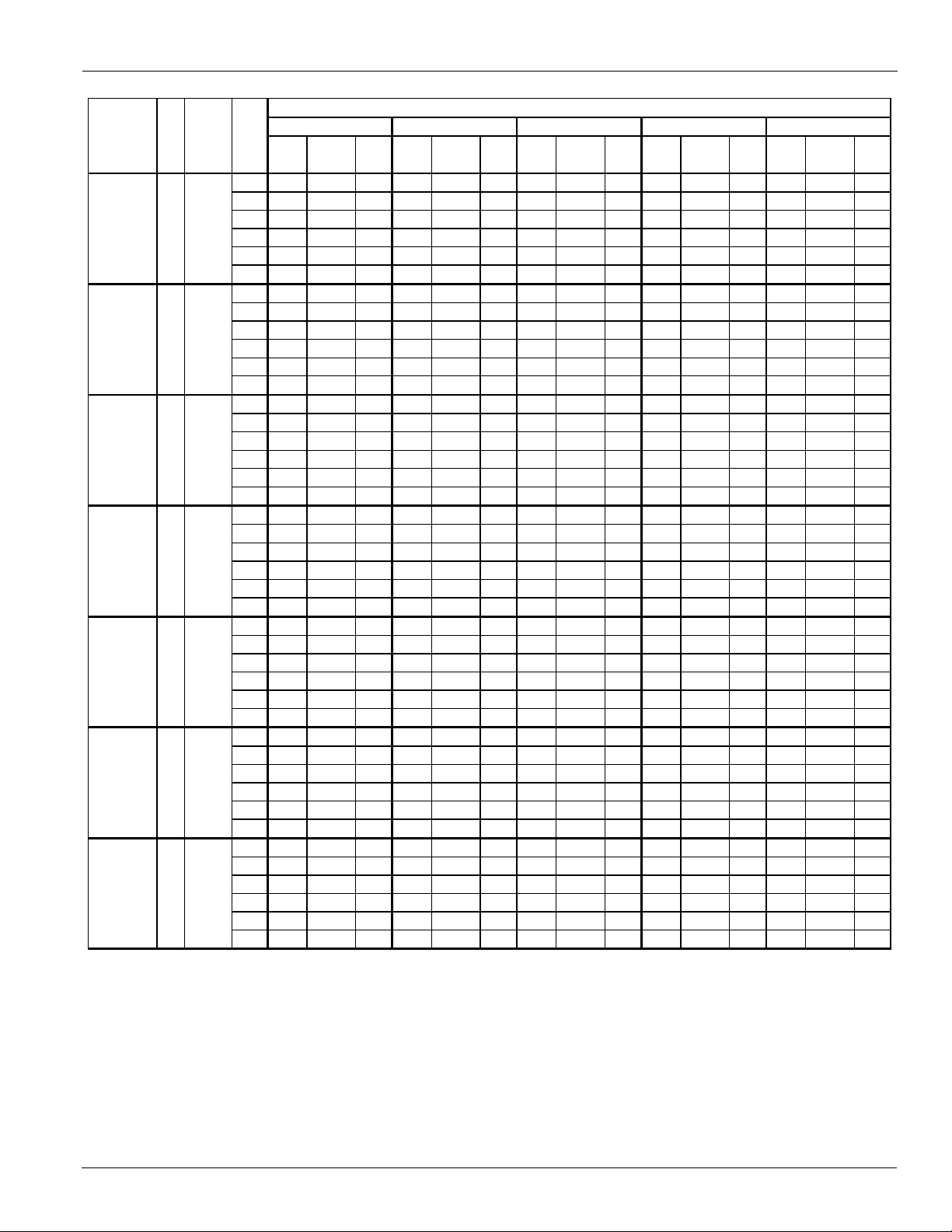

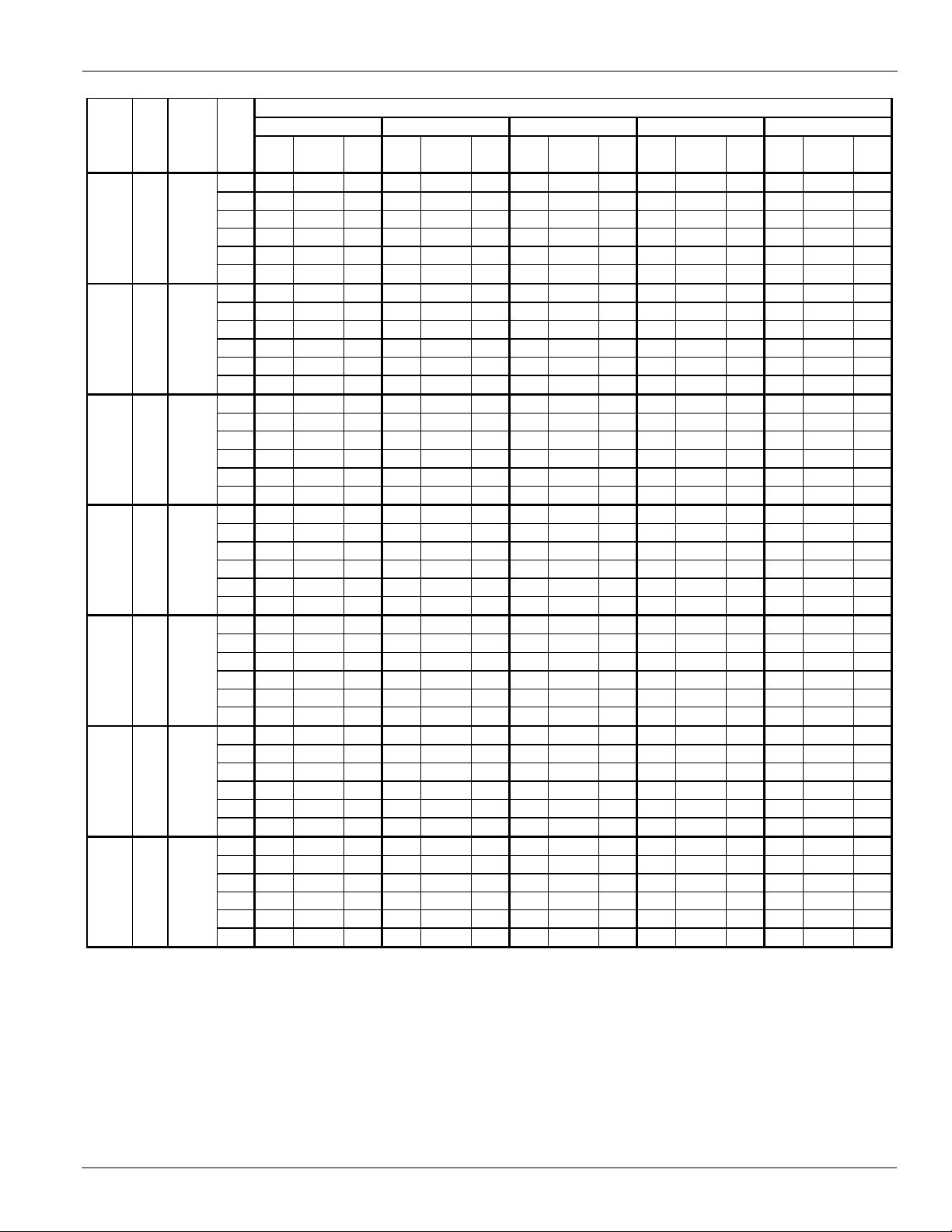

Ethylene Glycol Factors for Models AGZ 025D to 130D

° F ° C

10

26 -3.3 0.998 0.998 1.036 1.097

20

18 -7.8 0.993 0.997 1.06 1.226

30

7 -14 0.987 0.995 1.092 1.369

40

-7 -22 0.98 0.992 1.132 1.557

50

-28 -33 0.973 0.991 1.182 1.791

Ethylene Glycol Factors for Models AGZ 140D to 190D

° F ° C

10

26 -3.3 0.994 0.998 1.038 1.101

20

18 -7.8 0.982 0.995 1.063 1.224

30

7 -14 0.97 0.992 1.095 1.358

40

-7 -22 0.955 0.987 1.134 1.536

50

-28 -33 0.939 0.983 1.184 1.755

% E.G.

Point

Flow PDCapacity Pow e r

Flow PD% E.G.

Point

Capacity Pow e r

Propylene Glycol Factors for Models AGZ 025D to 130D

° F ° C

10

26 -3.3 0.995 0.997 1.016 1.1

20

19 -7.2 0.987 0.995 1.032 1.211

30

9 -13 0.978 0.992 1.057 1.38

40

-5 -21 0.964 0.987 1.092 1.703

50

-27 -33 0.952 0.983 1.14 2.251

Propylene Glycol Factors for Models AGZ 140D to 190D

° F ° C

10

26 -3.3 0.988 0.996 1.019 1.097

20

19 -7.2 0.972 0.992 1.035 1.201

30

9 -13 0.951 0.987 1.059 1.351

40

-5 -21 0.926 0.979 1.095 1.598

50

-27 -33 0.906 0.974 1.142 2.039

Flo w PD% P.G.

Point

Capacity Pow e r

Flo w PD% P.G.

Point

Capacity Pow e r

Capacity and Power Derates, Models AGZ 025 to 130

°F °C Cap. P ower C ap. Po wer Cap. P ower Cap. Power

6 3.3 0.978 0.993 0.975 0.991 0.963 0.987 0.940 0.980

8 4.4 0.989 0.996 0.986 0.994 0.973 0.990 0.950 0.983

10 5.6 1.000 1.000 0.996 0.999 0.984 0.994 0.961 0.987

12 6.7 1.009 1.003 1.005 1.001 0.993 0.997 0.969 0.990

14 7.7 1.018 1.004 1.014 1.003 1.002 0.999 0.978 0.991

16 8.9 1.025 1.007 1.021 1.006 1.009 1.001 0.985 0.994

6 3.3 0.977 1.001 0.973 1.000 0.961 0.996 0.938 0.989

8 4.4 0.987 1.006 0.984 1.004 0.971 1.000 0.948 0.993

10 5.6 0.998 1.009 0.995 1.007 0.982 1.003 0.959 0.996

12 6.7 1.007 1.011 1.004 1.010 0.991 1.006 0.967 0.998

14 7.7 1.014 1.014 1.011 1.013 0.998 1.009 0.974 1.001

16 8.9 1.022 1.016 1.018 1.014 1.005 1.010 0.981 1.003

6 3.3 0.973 1.011 0.970 1.010 0.957 1.006 0.935 0.998

8 4.4 0.984 1.014 0.980 1.013 0.968 1.009 0.945 1.001

10 5.6 0.995 1.019 0.991 1.017 0.979 1.013 0.955 1.005

12 6.7 1.004 1.021 1.000 1.020 0.987 1.016 0.964 1.008

14 7.7 1.011 1.024 1.007 1.023 0.994 1.018 0.971 1.011

16 8.9 1.018 1.027 1.014 1.026 1.002 1.021 0.978 1.014

6 3.3 0.969 1.021 0.966 1.020 0.954 1.016 0.931 1.008

8 4.4 0.980 1.026 0.977 1.024 0.964 1.020 0.942 1.013

10 5.6 0.989 1.029 0.986 1.027 0.973 1.023 0.950 1.015

12 6.7 0.998 1.033 0.995 1.031 0.982 1.027 0.959 1.020

14 7.7 1.007 1.036 1.004 1.034 0.991 1.030 0.967 1.022

16 8.9 1.014 1.037 1.011 1.036 0.998 1.031 0.974 1.024

Sea

Level

2000

feet

4000

feet

6000

feet

Altitude

Water

Delta T

Fouling Factor

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

Capac ity and Power Derates, Models AGZ 140 to 190

°F °C C a p . P o we r C a p. P o w er C a p. P o w e r C a p. P o we r

6 3.3 0.990 0.997 0.976 0.994 0.937 0.983 0.868 0.964

8 4.4 0.994 0.998 0.981 0.995 0.942 0.984 0.872 0.965

10 5.6 1.000 1.000 0.987 0.996 0.947 0.986 0.877 0.967

12 6.7 1.005 1.001 0.991 0.997 0.951 0.986 0.881 0.968

14 7.7 1.009 1.002 0.995 0.998 0.955 0.987 0.884 0.968

16 8.9 1.013 1.004 1.000 1.000 0.960 0.989 0.889 0.970

6 3.3 0.987 1.005 0.974 1.002 0.934 0.991 0.865 0.972

8 4.4 0.992 1.006 0.979 1.003 0.940 0.992 0.870 0.973

10 5.6 0.997 1.008 0.984 1.004 0.944 0.994 0.875 0.975

12 6.7 1.002 1.009 0.989 1.005 0.949 0.994 0.879 0.975

14 7.7 1.007 1.011 0.993 1.007 0.953 0.996 0.883 0.977

16 8.9 1.011 1.012 0.998 1.008 0.958 0.997 0.887 0.978

6 3.3 0.985 1.014 0.972 1.010 0.933 0.999 0.864 0.980

8 4.4 0.991 1.015 0.977 1.012 0.938 1.001 0.869 0.981

10 5.6 0.995 1.016 0.982 1.013 0.943 1.002 0.873 0.982

12 6.7 1.000 1.018 0.987 1.014 0.947 1.003 0.877 0.984

14 6.8 1.005 1.019 0.991 1.015 0.951 1.004 0.881 0.985

16 8.9 1.009 1.021 0.995 1.017 0.955 1.006 0.884 0.987

6 3.3 0.982 1.023 0.969 1.020 0.930 1.009 0.861 0.989

8 4.4 0.988 1.025 0.975 1.022 0.935 1.010 0.866 0.991

10 5.6 0.992 1.026 0.979 1.022 0.940 1.011 0.870 0.992

12 6.7 0.997 1.028 0.984 1.024 0.944 1.013 0.875 0.994

14 7.7 1.002 1.029 0.989 1.025 0.949 1.014 0.879 0.995

16 8.9 1.006 1.031 0.992 1.027 0.952 1.016 0.882 0.996

2000

feet

4000

feet

6000

feet

Altitude

Sea

Level

Wate r

De lta T

Fouling Factor

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

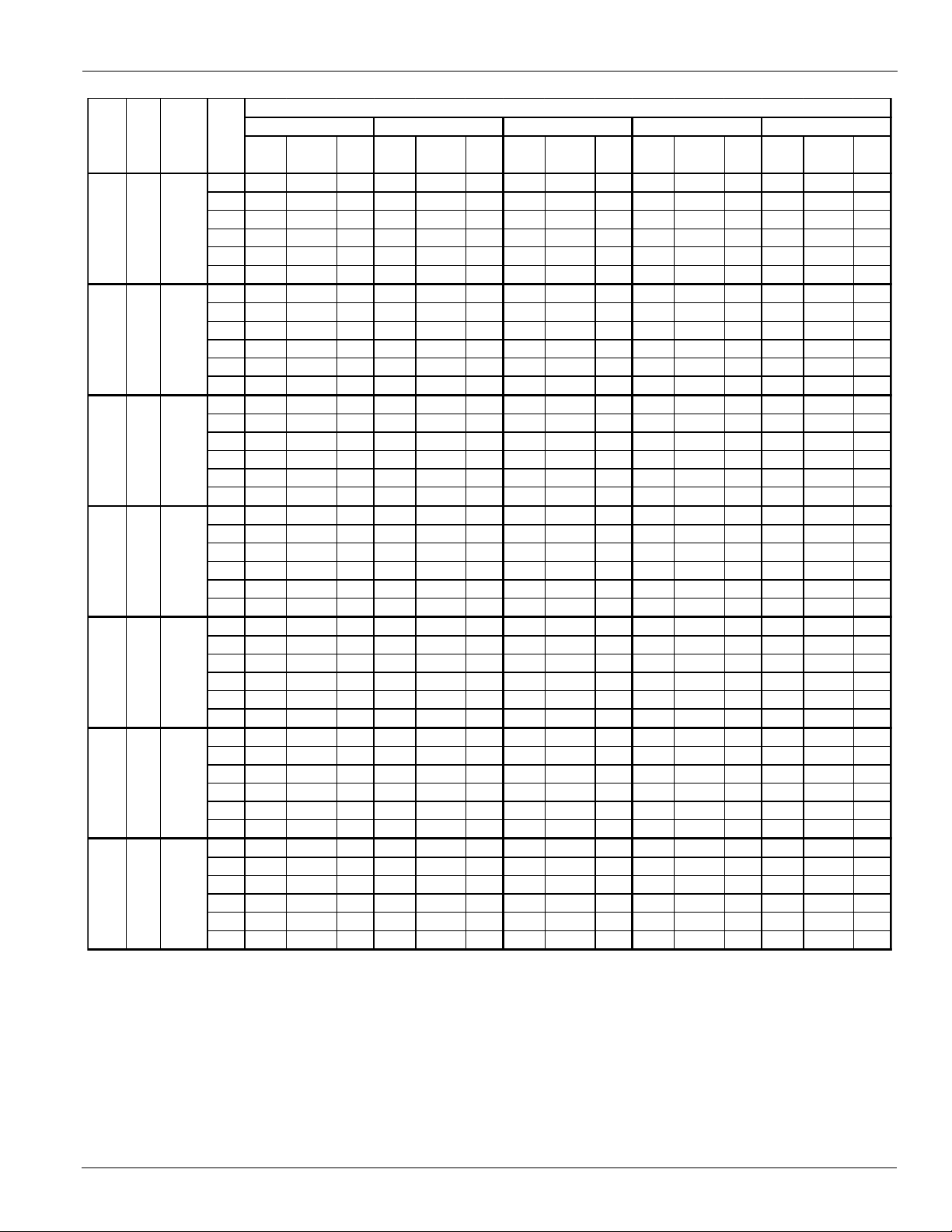

Note: Due to different performance characteristics, the factors

shown in the following tables are separated into brazedplate evaporators (AGZ025D - 130D) and shell-and-tube

evaporators (AGZ140D - 190D).

Ethylene & Propylene Glycol Factors

AGZ units can operate with a leaving chilled fluid temperature

range of 20°F (-6°C) to 60°F (10°C). A glycol solution is

required when leaving chilled fluid temperature is below 40°F

(4.6°C). The use of glycol will reduce the performance of the

unit depending on concentration.

Note: Ethylene and propylene glycol ratings are outside the

scope of AHRI Standard 550/590-2003 certification

program.

Table 3: Ethylene Glycol Correction Factors

Performance Data

Altitude Correction Factors

Performance tables are based at sea level. Elevations other

than sea level affect the performance of the unit. The decreased

air density will reduce condenser capacity consequently

reducing the unit's performance. For performance at elevations

other than sea level refer to Table 5.

Table 5: Capacity and Power Derates

Table 4: Propylene Glycol Correction Factors

CAT 611 15

Page 16

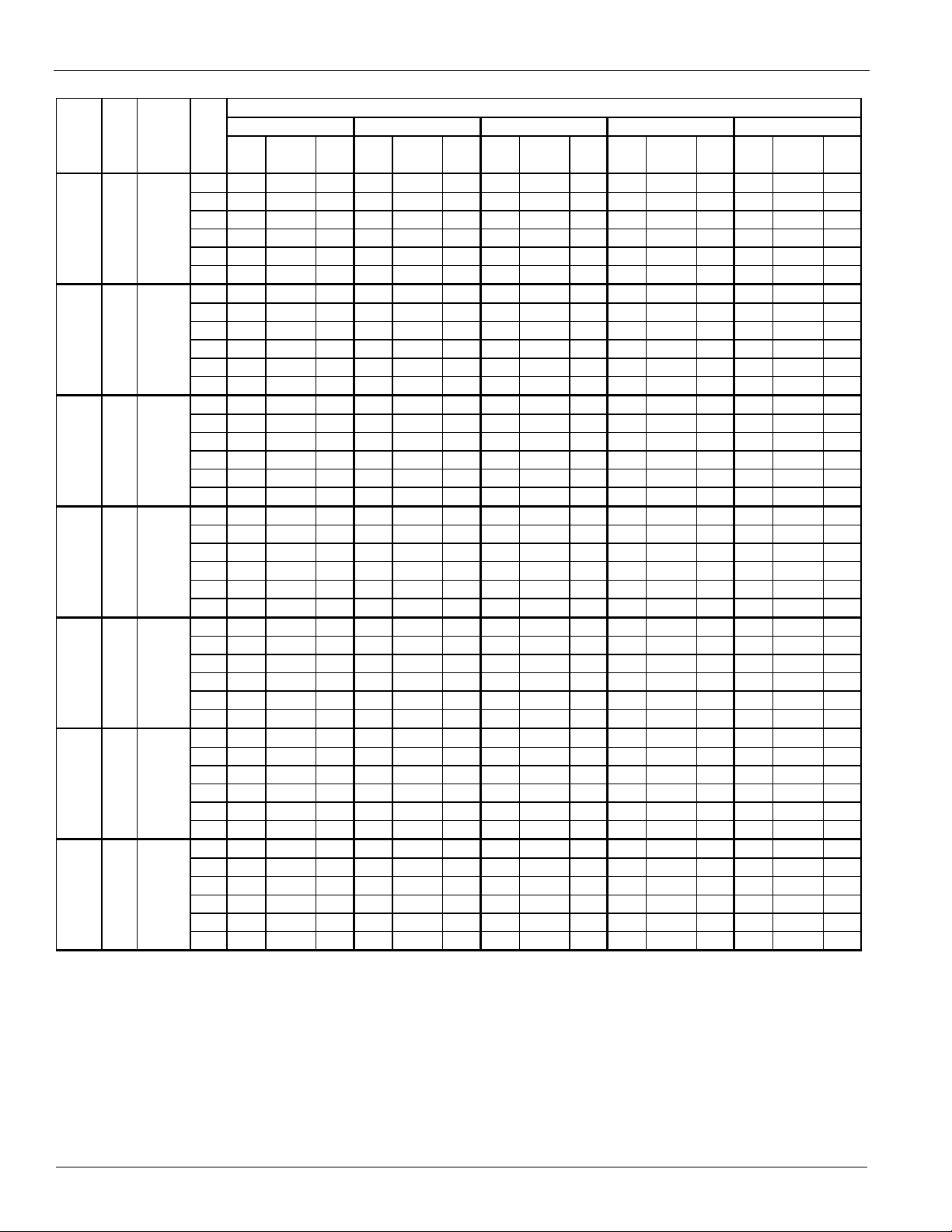

Performance Data

Unit Power Unit Unit Power Unit Unit Power Unit Unit Power Unit Unit Power Unit

T o n s k Wi EER T o n s k W i EER T o n s k Wi EER T o n s k W i EER T o n s k Wi EER

40

29 27.4 12.6 27 30.2 10.8 26 33.6 9.2 24 37.3 7.7 22 41.4 6.4

42

30 27.6 12.9 28 30.5 11.1 26 33.8 9.4 25 37.6 7.9 23 41.8 6.6

44

31 27.9 13.1 29 30.8 11.3

27 34.1 9.6

26 37.9 8.1 24 42.1 6.7

46

32 28.2 13.4 30 31.1 11.5 28 34.4 9.8 26 38.2 8.3 24 42.5 6.9

48

32 28.5 13.7 31 31.3 11.8 29 34.7 10.0 27 38.5 8.4 25 42.9 7.0

50

33 28.8 13.9 32 31.6 12.0 30 35.1 10.2 28 38.8 8.6 26 43.3 7.2

40

33 31.7 12.6 32 35.0 10.8 30 38.9 9.2 28 43.2 7.7 26 48.0 6.4

42

34 32.0 12.9 33 35.3 11.0 31 39.2 9.4 29 43.5 7.9 27 48.4 6.6

44

35 32.3 13.1 34 35.6 11.3

32 39.5 9.6

30 43.9 8.1 27 48.8 6.7

46

36 32.6 13.4 35 36.0 11.5 33 39.8 9.8 30 44.3 8.2 28 49.2 6.9

48

38 33.0 13.7 36 36.3 11.8 34 40.2 10.0 31 44.6 8.4 29 49.7 7.0

50

39 33.4 13.9 37 36.7 12.0 35 40.6 10.2 32 45.0 8.6 30 50.1 7.1

40

37 33.6 13.1 35 37.2 11.2 33 41.2 9.5 31 45.8 8.0 28 50.9 6.7

42

38 33.9 13.4 36 37.5 11.5 34 41.6 9.8 32 46.2 8.2 29 51.4 6.8

44

39 34.3 13.7 37 37.8 11.8

35 41.9 10.0

33 46.6 8.4 30 51.8 7.0

46

40 34.6 14.0 38 38.2 12.0 36 42.2 10.2 34 47.0 8.6 31 52.2 7.2

48

41 35.0 14.2 39 38.5 12.3 37 42.7 10.4 35 47.3 8.8 32 52.7 7.3

50

43 35.4 14.5 40 38.9 12.5 38 43.1 10.6 36 47.7 9.0 33 53.2 7.4

40

40 36.1 13.2 38 39.9 11.4 36 44.3 9.7 33 49.2 8.1 31 54.7 6.8

42

41 36.5 13.5 39 40.2 11.6 37 44.6 9.9 34 49.6 8.3 32 55.2 6.9

44

42 36.8 13.8 40 40.6 11.9

38 45.0 10.1

35 50.0 8.5 33 55.6 7.1

46

44 37.2 14.1 41 41.0 12.1 39 45.4 10.3 36 50.4 8.7 34 56.1 7.2

48

45 37.6 14.4 43 41.4 12.4 40 45.8 10.5 38 50.9 8.9 35 56.6 7.4

50

46 38.0 14.6 44 41.8 12.6 41 46.3 10.7 39 51.3 9.1 36 57.1 7.5

40

45 39.8 13.5 43 44.0 11.6 40 48.8 9.8 37 54.2 8.3 35 60.3 6.9

42

46 40.2 13.8 44 44.3 11.9 41 49.2 10.1 39 54.7 8.5 36 60.8 7.1

44

48 40.6 14.1 45 44.7 12.1

43 49.6 10.3

40 55.1 8.7 37 61.3 7.2

46

49 41.0 14.4 47 45.2 12.4 44 50.0 10.5 41 55.6 8.9 38 61.8 7.4

48

51 41.4 14.7 48 45.6 12.6 45 50.5 10.8 42 56.0 9.1 39 62.3 7.5

50

52 41.9 14.9 49 46.0 12.9 47 51.0 11.0 44 56.5 9.2 40 62.9 7.7

40

51 45.9 13.2 48 50.6 11.4 45 56.2 9.7 42 62.4 8.1 39 69.4 6.8

42

52 46.3 13.5 49 51.0 11.6 47 56.6 9.9 44 62.9 8.3 40 70.0 6.9

44

54 46.7 13.8 51 51.5 11.9

48 57.1 10.1

45 63.4 8.5 42 70.6 7.1

46

56 47.2 14.1 53 52.0 12.1 50 57.6 10.3 46 64.0 8.7 43 71.1 7.2

48

57 47.7 14.4 54 52.5 12.4 51 58.1 10.5 48 64.5 8.9 44 71.8 7.4

50

59 48.2 14.6 56 53.0 12.6 53 58.7 10.7 49 65.0 9.1 45 72.5 7.5

40

54 49.7 13.1 51 54.9 11.3 49 60.9 9.6 45 67.7 8.0 42 75.2 6.7

42

56 50.1 13.4 53 55.3 11.5 50 61.4 9.8 47 68.2 8.2 43 75.9 6.8

44

58 50.6 13.7 55 55.8 11.8

52 61.9 10.0

48 68.8 8.4 45 76.5 7.0

46

60 51.1 14.0 56 56.4 12.0 53 62.4 10.2 50 69.4 8.6 46 77.1 7.2

48

61 51.7 14.2 58 56.9 12.3 55 63.0 10.4 51 69.9 8.8 47 77.8 7.3

50

63 52.3 14.5 60 57.4 12.5 56 63.6 10.6 53 70.5 9.0 49 78.6 7.4

Unit

Siz e

Hz

Fan

Pow e r

(kW)

LWT

(°F)

Ambient Air Temperature

75

°

F

85

°

F

95

°

F

105

°

F

115

°

F

030D

050D 60 5.7

055D 60 5.7

025D 5.660

5.660

035D 5.660

5.6040D 60

5.7045D 60

Evaporator Temperature Drop Factors

Performance tables are based on a 10°F (5°C) temperature

drop through the evaporator. Adjustment factors for

applications with temperature ranges from 6°F to 16°F (3.3°C

to 8.9°C) are in Table 5. Temperature drops outside this 6°F to

16°F (3.3°C to 8.9°C) range can affect the control system's

capability to maintain acceptable control and are not

recommended.

Table 6: 60 Hz Full Load Performance Data (IP)

16 CAT 611

AHRI Certification

60Hz performance is certified per AHRI standard 550/590.

Ratings in bold are at AHRI standard conditions.

Page 17

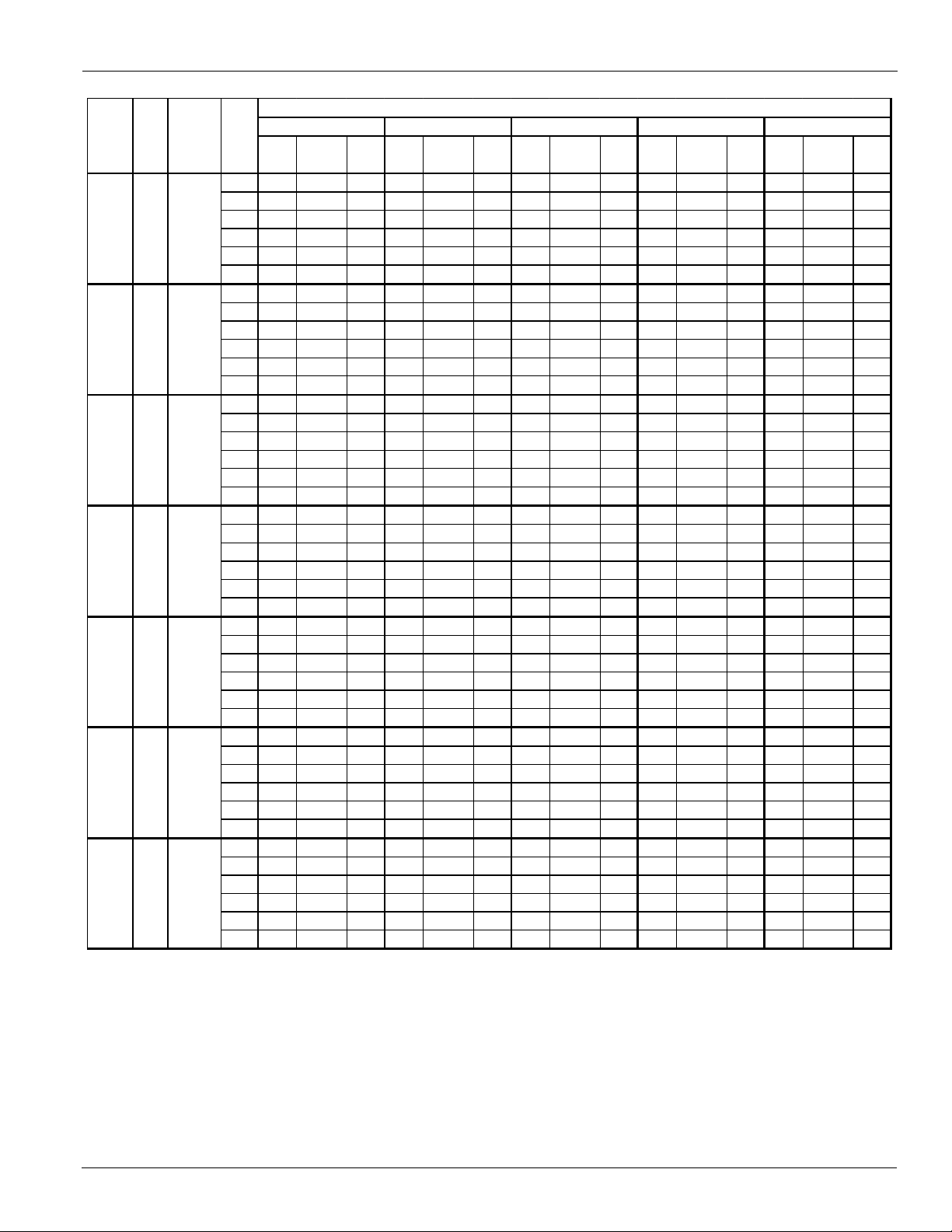

Table 7: 60 Hz Full Load Performance Data (IP) (continued)

Unit Power Unit Unit Power Unit Unit Power Unit Unit Power Unit Unit Power Unit

T o n s k W i EER T o n s k Wi EER T o n s k W i EER T o n s k W i EER T o n s k Wi EER

40

59 55.2 12.8 56 60.9 11.0 53 67.6 9.4 49 75.1 7.9 46 83.5 6.6

42

61 55.6 13.1 58 61.4 11.3 54 68.1 9.6 51 75.7 8.1 47 84.2 6.7

44

63 56.2 13.4 60 62.0 11.5

56 68.7 9.8

52 76.3 8.2 49 84.9 6.9

46

65 56.7 13.7 61 62.6 11.8 58 69.2 10.0 54 77.0 8.4 50 85.6 7.0

48

67 57.4 13.9 63 63.1 12.0 60 69.9 10.2 56 77.6 8.6 51 86.3 7.2

50

69 58.0 14.2 65 63.7 12.3 61 70.6 10.4 57 78.2 8.8 53 87.2 7.3

40

61 54.4 13.5 58 60.0 11.6 55 66.6 9.8 51 74.0 8.3 47 82.2 6.9

42

63 54.8 13.8 60 60.5 11.9 56 67.1 10.1 53 74.6 8.5 49 83.0 7.0

44

65 55.4 14.1 62 61.1 12.1

58 67.7 10.3

54 75.2 8.7 50 83.7 7.2

46

67 55.9 14.4 64 61.7 12.4 60 68.2 10.5 56 75.9 8.8 52 84.3 7.4

48

69 56.5 14.7 65 62.2 12.6 62 68.9 10.7 58 76.5 9.1 53 85.1 7.5

50

71 57.2 14.9 67 62.8 12.9 64 69.6 11.0 59 77.1 9.2 55 85.9 7.7

40

67 63.7 12.7 64 70.3 10.9 60 78.0 9.3 56 86.7 7.8 52 96.3 6.5

42

70 64.2 13.0 66 70.9 11.2 62 78.7 9.5 58 87.4 8.0 54 97.2 6.6

44

72 64.9 13.3 68 71.5 11.4

64 79.3 9.7

60 88.1 8.2 55 98.0 6.8

46

74 65.5 13.6 70 72.2 11.6 66 79.9 9.9 62 88.9 8.3 57 98.8 6.9

48

76 66.2 13.8 72 72.9 11.9 68 80.7 10.1 64 89.6 8.5 59 99.7 7.1

50

78 67.0 14.0 74 73.6 12.1 70 81.5 10.3 66 90.3 8.7 61 100.6 7.2

40

77 72.2 12.8 73 78.7 11.1 69 86.3 9.6 64 94.8 8.1 59 104.3 6.8

42

79 72.8 13.1 75 79.5 11.4 71 86.9 9.8 66 95.5 8.3 61 105.1 7.0

44

82 73.5 13.3 78 80.2 11.6

73 87.7 10.0

68 96.3 8.5 63 105.9 7.2

46

84 74.1 13.6 80 80.9 11.9 75 88.5 10.2 70 97.1 8.7 65 106.8 7.3

48

87 74.7 14.0 82 81.6 12.1 78 89.2 10.4 73 97.8 8.9 67 107.7 7.5

50

90 75.4 14.2 85 82.1 12.4 80 90.0 10.7 75 98.8 9.1 69 108.6 7.6

40

85 81.7 12.5 81 89.1 10.9 76 97.7 9.4 71 107.3 8.0 66 118.1 6.7

42

88 82.4 12.8 83 90.0 11.1 79 98.4 9.6 73 108.1 8.2 68 119.0 6.9

44

91 83.2 13.1 86 90.8 11.4

81 99.3 9.8

76 109.0 8.3 70 119.9 7.0

46

94 83.9 13.4 89 91.6 11.6 84 100.2 10.0 78 109.9 8.5 72 121.0 7.2

48

96 84.6 13.7 91 92.4 11.9 86 101.0 10.2 81 110.7 8.7 74 121.9 7.3

50

99 85.4 14.0 94 93.0 12.2 89 101.9 10.4 83 111.8 8.9 77 122.9 7.5

40

94 89.9 12.5 89 98.0 10.9 84 107.5 9.4 78 118.0 8.0 73 129.8 6.7

42

97 90.6 12.8 92 98.9 11.1 87 108.2 9.6 81 118.9 8.2 75 130.8 6.9

44

100 91.5 13.1 95 99.8 11.4

89 109.2 9.8

83 119.9 8.3 77 131.8 7.0

46

103 92.3 13.4 98 100.7 11.6 92 110.2 10.0 86 120.9 8.5 79 133.0 7.2

48

106 93.0 13.7 101 101.6 11.9 95 111.1 10.2 89 121.8 8.7 82 134.1 7.3

50

109 93.9 14.0 104 102.2 12.2 98 112.0 10.5 91 123.0 8.9 84 135.2 7.5

40

105 102.7 12.2 100 111.9 10.7 94 122.8 9.2 88 134.9 7.8 81 148.4 6.6

42

108 103.6 12.5 103 113.1 10.9 97 123.7 9.4 90 135.9 8.0 84 149.5 6.7

44

112 104.6 12.8 106 114.1 11.1

100 124.8 9.6

93 137.0 8.2 86 150.6 6.9

46

115 105.5 13.1 109 115.1 11.4 103 125.9 9.8 96 138.2 8.3 89 152.0 7.0

48

119 106.3 13.4 112 116.1 11.6 106 126.9 10.0 99 139.2 8.5 92 153.3 7.2

50

122 107.3 13.7 116 116.8 11.9 109 128.0 10.2 102 140.5 8.7 94 154.5 7.3

070D

065D

Unit

Siz e

100D

090D

080D

075D

Hz

Fan

Pow e r

(kW)

LWT

(°F)

Ambient Air Temperature

75

°

F

85

°

F

95

°

F

105

°

F

115

°

F

10.9

10.9

10.9

10.9

060D 5.7

7.3

7.3

60

60

60

60

60

60

60

Performance Data

CAT 611 17

Page 18

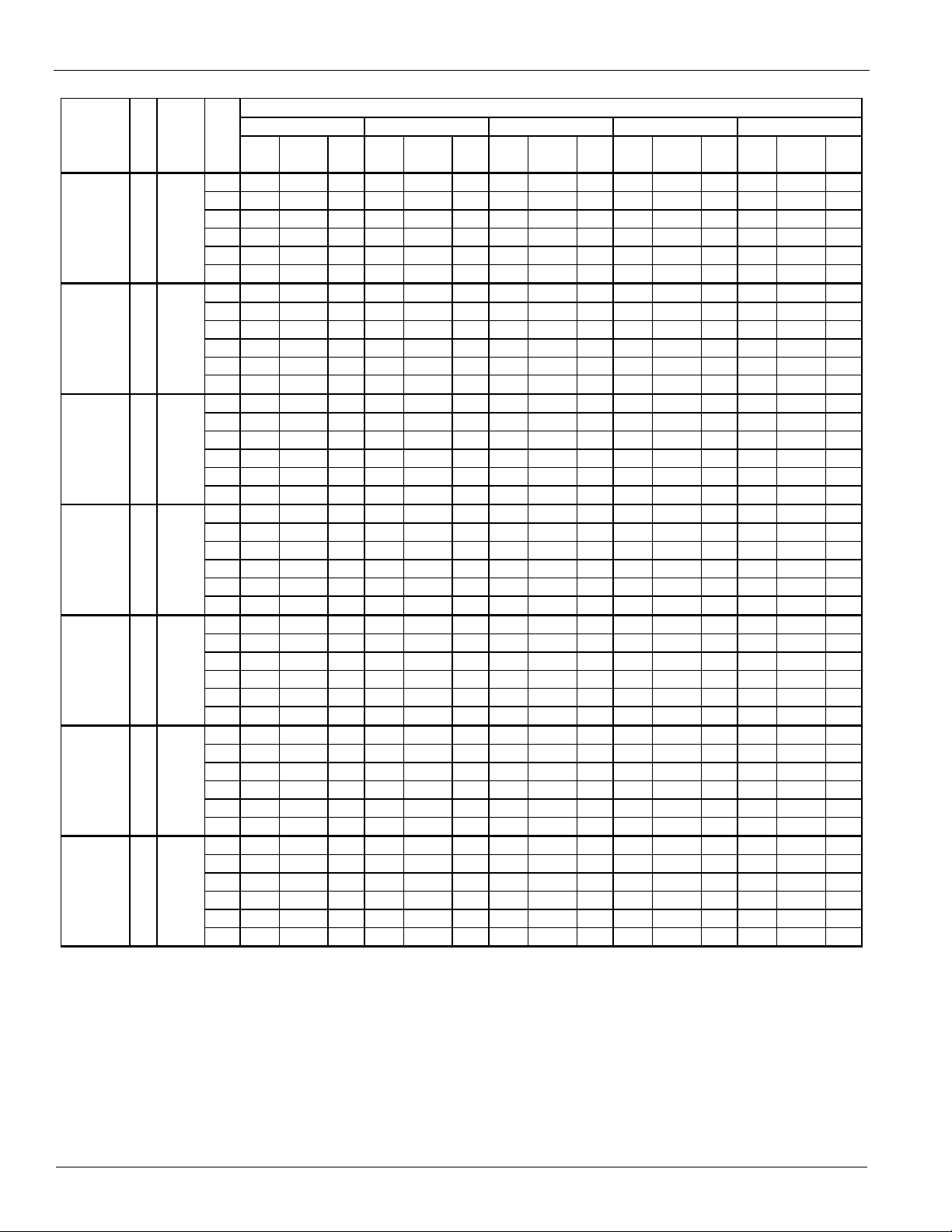

Performance Data

Unit Power Unit Unit Power Unit Unit Power Unit Unit Power Unit Unit Power Unit

T o n s k Wi EER T o n s k Wi EER T o n s k W i EER T o n s k Wi EER T o n s k Wi EER

40

111 106.9 12.5 106 116.5 10.9 100 127.8 9.4 93 140.4 8.0 86 154.5 6.7

42

115 107.8 12.8 109 117.7 11.1 103 128.7 9.6 96 141.5 8.2 89 155.6 6.9

44

119 108.9 13.1 113 118.7 11.4

106 129.9 9.8

99 142.6 8.3 92 156.8 7.0

46

122 109.8 13.4 116 119.8 11.6 109 131.1 10.0 102 143.8 8.5 95 158.2 7.2

48

126 110.7 13.7 120 120.8 11.9 113 132.1 10.2 105 144.8 8.7 97 159.5 7.3

50

130 111.7 14.0 123 121.6 12.2 116 133.3 10.5 108 146.3 8.9 100 160.8 7.5

40

123 118.0 12.5 117 128.6 10.9 110 141.1 9.4 103 155.0 8.0 95 170.5 6.7

42

127 119.0 12.8 120 129.9 11.1 114 142.1 9.6 106 156.2 8.2 98 171.8 6.9

44

131 120.2 13.1 124 131.1 11.4

117 143.4 9.8

109 157.5 8.3 101 173.1 7.0

46

135 121.2 13.4 128 132.2 11.6 121 144.7 10.0 113 158.7 8.5 104 174.7 7.2

48

139 122.2 13.7 132 133.4 11.9 124 145.8 10.2 116 159.9 8.7 107 176.1 7.3

50

143 123.3 14.0 136 134.2 12.2 128 147.1 10.4 120 161.5 8.9 111 177.5 7.5

40

136 133.3 12.2 129 145.3 10.7 122 159.4 9.2 114 175.1 7.8 105 192.6 6.6

42

140 134.5 12.5 133 146.8 10.9 126 160.5 9.4 117 176.4 8.0 109 194.1 6.7

44

145 135.8 12.8 138 148.1 11.1

130 162.0 9.6

121 177.9 8.2 112 195.5 6.9

46

149 136.9 13.1 142 149.4 11.4 134 163.5 9.8 125 179.3 8.4 115 197.3 7.0

48

154 138.0 13.4 146 150.7 11.6 138 164.8 10.0 129 180.6 8.5 119 198.9 7.2

50

159 139.3 13.7 151 151.6 11.9 142 166.2 10.2 132 182.4 8.7 122 200.6 7.3

40

143 131.8 13.0 136 143.7 11.4 128 157.6 9.7 120 173.2 8.3 111 190.5 7.0

42

148 133.0 13.3 140 145.1 11.6 132 158.8 10.0 123 174.5 8.5 114 191.9 7.1

44

152 134.2 13.6 145 146.4 11.8

136 160.2 10.2

127 175.9 8.7 118 193.4 7.3

46

157 135.4 13.9 149 147.7 12.1 140 161.6 10.4 131 177.3 8.9 121 195.1 7.5

48

162 136.5 14.2 153 149.0 12.4 145 162.9 10.7 135 178.6 9.1 125 196.7 7.6

50

167 137.8 14.5 158 149.9 12.7 149 164.4 10.9 139 180.4 9.3 129 198.3 7.8

40

161 151.4 12.8 153 165.0 11.1 144 181.0 9.6 135 198.9 8.1 125 218.7 6.8

42

166 152.7 13.1 158 166.7 11.4 149 182.3 9.8 139 200.3 8.3 129 220.4 7.0

44

171 154.2 13.3 163 168.1 11.6

153 184.0 10.0

143 202.0 8.5 133 222.0 7.2

46

177 155.4 13.6 168 169.6 11.9 158 185.6 10.2 148 203.6 8.7 137 224.1 7.3

48

182 156.7 14.0 173 171.1 12.1 163 187.1 10.4 152 205.1 8.9 141 225.9 7.5

50

188 158.2 14.2 178 172.2 12.4 168 188.7 10.7 157 207.1 9.1 145 227.7 7.6

40

181 177.2 12.2 172 193.1 10.7 162 211.9 9.2 151 232.7 7.8 140 256.0 6.6

42

187 178.7 12.5 177 195.1 10.9 167 213.4 9.4 156 234.5 8.0 144 257.9 6.7

44

193 180.4 12.8 183 196.8 11.1

172 215.3 9.6

161 236.4 8.2 149 259.9 6.9

46

199 181.9 13.1 188 198.5 11.4 178 217.2 9.8 166 238.3 8.3 153 262.2 7.0

48

205 183.4 13.4 194 200.2 11.6 183 219.0 10.0 171 240.1 8.5 158 264.4 7.2

50

211 185.2 13.7 200 201.5 11.9 188 220.9 10.2 176 242.4 8.7 163 266.5 7.3

40

189 176.1 12.9 180 192.0 11.2 169 210.6 9.6 158 231.3 8.2 146 254.4 6.9

42

195 177.6 13.2 185 193.9 11.5 175 212.1 9.9 163 233.0 8.4 151 256.4 7.1

44

201 179.3 13.5 191 195.6 11.7

180 214.0 10.1

168 235.0 8.6 156 258.3 7.2

46

208 180.8 13.8 197 197.3 12.0 186 215.9 10.3 173 236.9 8.8 160 260.7 7.4

48

214 182.3 14.1 203 199.0 12.2 191 217.6 10.5 179 238.6 9.0 165 262.8 7.5

50

221 184.0 14.4 209 200.3 12.5 197 219.6 10.8 184 241.0 9.2 170 264.9 7.7

Ambient Air Temperature

75

°

F

110D

125D

130D

140D

160D

180D

60

60

85

°

F

95

°

F

105

°

F

115

°

F

18.2

14.5

14.5

14.5

LWT

(°F)

60

60

60

Unit

Siz e

Hz

Fan

Pow er

(kW)

190D 21.8

18.2

18.2

60

60

Table 8: 60 Hz Full Load Performance Data (IP) (continued)

18 CAT 611

Page 19

Table 9: 60 Hz Full Load Performance Data (SI)

Unit Power Unit Unit Power Unit Unit Powe r Unit Unit Power Unit Unit Power Unit

kW kWi COP kW kWi COP kW kWi COP kW kWi COP kW kWi COP

5

102 28.1 3.6 97 30.7 3.2 92 33.7 2.7 86 37.0 2.3 81 40.8 2.0

6

104 28.3 3.7 99 30.9 3.2 94 33.9 2.8 89 37.3 2.4 83 41.1 2.0

7

107 28.6 3.8 102 31.2 3.3 97 34.2 2.8 91 37.6 2.4 85 41.4 2.1

8

110 28.8 3.8 105 31.5 3.3 100 34.4 2.9 94 37.9 2.5 88 41.7 2.1

9

113 29.1 3.9 108 31.7 3.4 102 34.7 2.9 96 38.1 2.5 90 42.0 2.1

10

116 29.4 4.0 111 32.0 3.5 105 35.1 3.0 99 38.4 2.6 92 42.4 2.2

5

118 32.5 3.6 112 35.6 3.1 106 39.0 2.7 100 42.9 2.3 93 47.2 2.0

6

121 32.8 3.7 115 35.8 3.2 109 39.3 2.8 103 43.2 2.4 96 47.6 2.0

7

124 33.1 3.8 118 36.1 3.3 112 39.6 2.8 106 43.5 2.4 99 48.0 2.1

8

128 33.4 3.8 122 36.4 3.3 115 39.9 2.9 108 43.9 2.5 101 48.3 2.1

9

131 33.7 3.9 125 36.7 3.4 118 40.3 2.9 112 44.2 2.5 104 48.7 2.1

10

135 34.0 4.0 128 37.1 3.5 121 40.6 3.0 114 44.5 2.6 107 49.1 2.2

5

130 34.6 3.8 124 37.8 3.3 117 41.4 2.8 110 45.5 2.4 101 50.2 2.0

6

133 34.9 3.8 127 38.1 3.3 120 41.7 2.9 113 45.9 2.5 104 50.6 2.1

7

137 35.1 3.9 131 38.3 3.4 124 42.0 2.9 116 46.2 2.5 107 50.9 2.1

8

141 35.4 4.0 134 38.6 3.5 127 42.3 3.0 119 46.6 2.6 110 51.3 2.1

9

145 35.7 4.1 138 38.9 3.5 131 42.7 3.1 122 47.0 2.6 113 51.8 2.2

10

149 36.0 4.1 142 39.3 3.6 134 43.1 3.1 125 47.4 2.6 116 52.2 2.2

5

141 37.2 3.8 134 40.6 3.3 127 44.5 2.9 119 48.9 2.4 110 53.9 2.0

6

145 37.5 3.9 138 40.9 3.4 131 44.8 2.9 122 49.3 2.5 113 54.3 2.1

7

149 37.7 4.0 142 41.1 3.5 135 45.1 3.0 126 49.6 2.5 116 54.7 2.1

8

153 38.0 4.0 146 41.5 3.5 138 45.5 3.0 129 50.0 2.6 120 55.1 2.2

9

157 38.3 4.1 150 41.8 3.6 142 45.9 3.1 133 50.4 2.6 123 55.6 2.2

10

161 38.7 4.2 154 42.2 3.6 146 46.2 3.1 136 50.9 2.7 126 56.1 2.2

5

158 41.0 3.9 151 44.7 3.4 143 49.0 2.9 134 53.9 2.5 124 59.4 2.1

6

163 41.3 3.9 155 45.0 3.4 147 49.4 3.0 137 54.3 2.5 127 59.9 2.1

7

167 41.6 4.0 160 45.3 3.5 151 49.7 3.0 141 54.7 2.6 131 60.3 2.2

8

172 41.9 4.1 164 45.7 3.6 155 50.1 3.1 145 55.1 2.6 134 60.8 2.2

9

177 42.3 4.2 168 46.1 3.7 159 50.5 3.2 149 55.6 2.7 138 61.3 2.3

10

181 42.6 4.3 173 46.5 3.7 164 51.0 3.2 153 56.1 2.7 142 61.8 2.3

5

179 47.2 3.8 170 51.5 3.3 162 56.4 2.9 151 62.1 2.4 140 68.4 2.0

6

184 47.5 3.9 175 51.9 3.4 166 56.9 2.9 155 62.5 2.5 144 69.0 2.1

7

189 47.8 4.0 180 52.2 3.5 171 57.2 3.0 160 62.9 2.5 148 69.4 2.1

8

194 48.2 4.0 185 52.6 3.5 175 57.7 3.0 164 63.5 2.6 152 70.0 2.2

9

199 48.6 4.1 190 53.1 3.6 180 58.2 3.1 168 64.0 2.6 156 70.6 2.2

10

205 49.1 4.2 195 53.5 3.6 185 58.7 3.1 173 64.5 2.7 160 71.2 2.2

5

192 51.1 3.8 183 55.8 3.3 173 61.2 2.8 162 67.3 2.4 150 74.2 2.0

6

197 51.5 3.8 188 56.2 3.3 178 61.7 2.9 166 67.8 2.5 154 74.8 2.1

7

203 51.9 3.9 193 56.6 3.4 183 62.0 3.0 171 68.2 2.5 159 75.2 2.1

8

208 52.3 4.0 199 57.0 3.5 188 62.5 3.0 176 68.8 2.6 163 75.8 2.1

9

214 52.7 4.1 204 57.5 3.5 193 63.1 3.1 181 69.4 2.6 167 76.5 2.2

10

220 53.2 4.1 209 58.0 3.6 198 63.6 3.1 185 70.0 2.6 172 77.1 2.2

Unit

Size

Hz

Fan

Pow er

(kW)

LWT

(°C)

Ambient Air Te mperature

25°C 30°C 35°C 40°C 45°C

025D 60 5.6

030D 60 5.6

035D 60 5.6

040D 60 5.6

045D 60 5.7

050D 60 5.7

055D 60 5.7

Performance Data

CAT 611 19

Page 20

Performance Data

Unit Power Unit Unit Powe r Unit Unit Power Unit Unit Power Unit Unit Power Unit

kW kWi COP kW kWi COP kW kWi COP kW kWi COP kW kWi COP

5

209 56.6 3.7 199 61.8 3.2 188 67.9 2.8 178 74.5 2.4 166 82.1 2.0

6

215 57.0 3.8 204 62.3 3.3 194 68.4 2.8 183 75.1 2.4 170 82.8 2.1

7

221 57.5 3.8 210 62.8 3.3 199 68.9 2.9 188 75.7 2.5 175 83.4 2.1

8

227 58.0 3.9 216 63.4 3.4 205 69.4 2.9 193 76.3 2.5 180 84.0 2.1

9

233 58.6 4.0 222 63.9 3.5 210 70.0 3.0 198 76.8 2.6 185 84.7 2.2

10

239 59.2 4.0 228 64.4 3.5 216 70.6 3.1 203 77.3 2.6 189 85.4 2.2

5

216 55.7 3.9 206 60.9 3.4 195 66.9 2.9 184 73.5 2.5 172 81.0 2.1

6

222 56.2 4.0 212 61.4 3.4 201 67.4 3.0 189 74.0 2.6 176 81.6 2.2

7

228 56.7 4.0 218 61.9 3.5 206 67.9 3.0 194 74.6 2.6 181 82.2 2.2

8

235 57.2 4.1 224 62.4 3.6 212 68.4 3.1 199 75.2 2.7 186 82.8 2.2

9

241 57.7 4.2 230 62.9 3.6 218 69.0 3.2 205 75.7 2.7 191 83.4 2.3

10

247 58.3 4.2 236 63.5 3.7 223 69.6 3.2 210 76.2 2.8 196 84.1 2.3

5

238 65.3 3.7 227 71.4 3.2 215 78.3 2.7 203 86.1 2.4 189 94.8 2.0

6

245 65.8 3.7 234 71.9 3.2 221 78.9 2.8 209 86.7 2.4 195 95.6 2.0

7

252 66.4 3.8 240 72.5 3.3 228 79.5 2.9 214 87.3 2.5 200 96.3 2.1

8

259 67.0 3.9 247 73.1 3.4 234 80.1 2.9 220 88.0 2.5 206 97.0 2.1

9

266 67.6 3.9 253 73.7 3.4 240 80.8 3.0 226 88.7 2.6 211 97.8 2.2

10

273 68.3 4.0 260 74.4 3.5 246 81.5 3.0 232 89.3 2.6 217 98.6 2.2

5

272 73.8 3.7 259 79.8 3.2 246 86.6 2.8 231 94.2 2.5 216 102.8 2.1

6

279 74.4 3.8 266 80.5 3.3 252 87.2 2.9 238 94.9 2.5 222 103.5 2.1

7

287 75.0 3.8 274 81.1 3.4 259 88.0 3.0 244 95.6 2.6 228 104.2 2.2

8

295 75.6 3.9 281 81.8 3.4 267 88.6 3.0 251 96.3 2.6 234 105.1 2.2

9

303 76.2 4.0 289 82.4 3.5 274 89.3 3.1 258 96.9 2.7 240 105.8 2.3

10

312 76.8 4.1 297 82.9 3.6 281 90.0 3.1 264 97.8 2.7 247 106.6 2.3

5

301 83.6 3.6 287 90.4 3.2 272 98.1 2.8 256 106.7 2.4 239 116.4 2.1

6

310 84.3 3.7 295 91.1 3.2 280 98.8 2.8 264 107.4 2.5 246 117.2 2.1

7

319 84.9 3.8 304 91.9 3.3 288 99.6 2.9 271 108.2 2.5 253 118.0 2.1

8

328 85.6 3.8 312 92.6 3.4 296 100.4 2.9 278 109.0 2.6 260 118.9 2.2

9

337 86.2 3.9 321 93.3 3.4 304 101.1 3.0 286 109.7 2.6 267 119.8 2.2

10

346 86.9 4.0 330 93.8 3.5 312 101.9 3.1 293 110.7 2.7 274 120.7 2.3

5

331 91.9 3.6 316 99.4 3.2 300 107.8 2.8 282 117.3 2.4 263 128.0 2.1

6

341 92.6 3.7 325 100.2 3.2 308 108.6 2.8 290 118.1 2.5 271 128.8 2.1

7

350 93.4 3.8 334 101.0 3.3 317 109.5 2.9 298 119.0 2.5 278 129.8 2.1

8

360 94.1 3.8 343 101.8 3.4 325 110.4 2.9 306 119.8 2.6 286 130.8 2.2

9

370 94.8 3.9 353 102.6 3.4 334 111.2 3.0 315 120.6 2.6 293 131.7 2.2

10

380 95.6 4.0 363 103.2 3.5 343 112.0 3.1 323 121.7 2.7 301 132.7 2.3

5

371 105.0 3.5 354 113.6 3.1 335 123.2 2.7 315 134.1 2.4 295 146.2 2.0

6

381 105.9 3.6 364 114.5 3.2 345 124.1 2.8 324 135.0 2.4 303 147.2 2.1

7

392 106.7 3.7 374 115.4 3.2 354 125.1 2.8 334 136.0 2.5 311 148.3 2.1

8

403 107.6 3.7 384 116.4 3.3 364 126.1 2.9 343 137.0 2.5 320 149.5 2.1

9

414 108.4 3.8 395 117.2 3.4 374 127.0 2.9 352 137.9 2.6 328 150.6 2.2

10

426 109.2 3.9 406 117.9 3.4 384 128.0 3.0 361 139.1 2.6 337 151.7 2.2

Unit

Siz e

Hz

Fan

Pow er

(kW)

LWT

(°C)

Ambient Air Temperature

25°C 30°C 35°C 40°C 45°C

060D 60 5.7

065D 60 7.3

070D 60 7.3

075D 60 10.9

080D 60 10.9

090D 60 10.9

100D 60 10.9

Table 10: 60 Hz Full Load Performance Data (SI) continued

20 CAT 611

Page 21

Table 11: 60 Hz Full Load Performance Data (SI) continued

Unit Power Unit Unit Power Unit Unit Power Unit Unit Powe r Unit Unit Pow er Unit

kW kWi COP kW kWi COP kW kWi COP kW kWi COP kW kWi COP

5

394 109.3 3.6 376 118.2 3.2 356 128.3 2.8 335 139.5 2.4 313 152.2 2.1

6

405 110.2 3.7 387 119.2 3.2 366 129.2 2.8 345 140.5 2.5 322 153.3 2.1

7

417 111.1 3.8 397 120.2 3.3 377 130.3 2.9 355 141.6 2.5 331 154.4 2.1

8

428 112.0 3.8 408 121.1 3.4 387 131.3 2.9 364 142.6 2.6 340 155.6 2.2

9

440 112.8 3.9 419 122.0 3.4 397 132.2 3.0 374 143.5 2.6 349 156.7 2.2

10

452 113.7 4.0 431 122.8 3.5 408 133.3 3.1 384 144.8 2.7 358 157.9 2.3

5

435 120.7 3.6 415 130.5 3.2 393 141.6 2.8 370 154.0 2.4 346 168.0 2.1

6

447 121.7 3.7 427 131.6 3.2 404 142.6 2.8 381 155.1 2.5 355 169.2 2.1

7

460 122.7 3.8 439 132.6 3.3 416 143.8 2.9 391 156.3 2.5 365 170.4 2.1

8

473 123.6 3.8 451 133.7 3.4 427 144.9 2.9 402 157.4 2.6 375 171.8 2.2

9

486 124.5 3.9 463 134.7 3.4 439 146.0 3.0 413 158.4 2.6 385 173.0 2.2

10

499 125.5 4.0 476 135.5 3.5 451 147.1 3.1 424 159.9 2.6 395 174.3 2.3

5

481 136.3 3.5 459 147.4 3.1 435 160.0 2.7 410 174.0 2.4 383 189.8 2.0

6

495 137.4 3.6 472 148.7 3.2 448 161.1 2.8 421 175.2 2.4 393 191.1 2.1

7

509 138.6 3.7 485 149.9 3.2 460 162.4 2.8 433 176.5 2.5 404 192.5 2.1

8

523 139.6 3.7 499 151.0 3.3 473 163.7 2.9 445 177.8 2.5 415 194.0 2.1

9

538 140.7 3.8 512 152.2 3.4 486 164.9 2.9 457 179.0 2.6 426 195.4 2.2

10

553 141.8 3.9 527 153.1 3.4 499 166.2 3.0 469 180.6 2.6 438 196.9 2.2

5

506 134.8 3.8 483 145.8 3.3 457 158.2 2.9 430 172.1 2.5 402 187.7 2.1

6

520 135.9 3.8 496 147.0 3.4 470 159.3 3.0 443 173.3 2.6 413 189.0 2.2

7

535 137.0 3.9 510 148.2 3.4 483 160.6 3.0 455 174.6 2.6 425 190.4 2.2

8

550 138.1 4.0 524 149.4 3.5 497 161.9 3.1 468 175.8 2.7 436 191.9 2.3

9

565 139.1 4.1 538 150.5 3.6 510 163.1 3.1 481 177.0 2.7 448 193.3 2.3

10

581 140.2 4.1 554 151.4 3.7 524 164.4 3.2 493 178.6 2.8 460 194.7 2.4

5

570 154.8 3.7 543 167.4 3.2 515 181.7 2.8 484 197.6 2.5 452 215.6 2.1

6

586 156.1 3.8 558 168.8 3.3 529 183.0 2.9 498 199.0 2.5 465 217.0 2.1

7

602 157.4 3.8 574 170.2 3.4 544 184.5 3.0 512 200.5 2.6 478 218.6 2.2

8

619 158.5 3.9 590 171.5 3.4 559 185.9 3.0 526 201.9 2.6 491 220.3 2.2

9

636 159.7 4.0 606 172.8 3.5 574 187.3 3.1 541 203.2 2.7 504 221.9 2.3

10

654 161.0 4.1 623 173.8 3.6 590 188.7 3.1 555 205.1 2.7 518 223.6 2.3

5

640 181.2 3.5 610 195.9 3.1 578 212.6 2.7 544 231.3 2.4 508 252.3 2.0

6

658 182.7 3.6 627 197.6 3.2 595 214.1 2.8 560 232.9 2.4 523 254.0 2.1

7

676 184.2 3.7 645 199.2 3.2 611 215.9 2.8 576 234.6 2.5 537 255.9 2.1

8

695 185.6 3.7 663 200.7 3.3 628 217.6 2.9 591 236.3 2.5 552 257.9 2.1

9

715 187.0 3.8 681 202.2 3.4 645 219.2 2.9 608 237.9 2.6 566 259.7 2.2

10

734 188.4 3.9 700 203.5 3.4 663 220.9 3.0 623 240.0 2.6 582 261.7 2.2

5

669 180.1 3.7 638 194.8 3.3 605 211.3 2.9 569 229.9 2.5 532 250.8 2.1

6

688 181.6 3.8 656 196.4 3.3 622 212.8 2.9 586 231.5 2.5 547 252.5 2.2

7

708 183.0 3.9 674 198.0 3.4 639 214.6 3.0 602 233.2 2.6 562 254.3 2.2

8

727 184.4 3.9 693 199.5 3.5 657 216.3 3.0 618 234.9 2.6 577 256.3 2.3

9

748 185.8 4.0 712 201.0 3.5 675 217.8 3.1 636 236.4 2.7 592 258.2 2.3

10

768 187.3 4.1 732 202.2 3.6 693 219.6 3.2 652 238.6 2.7 608 260.1 2.3

Unit

Siz e

Hz

Fan

Pow er

(kW)

LWT

(°C)

Ambient Air Temperature

25°C 30°C 35°C 40°C 45°C

110D 60 14.5

125D 60 14.5

130D 60 14.5

140D 60 18.2

160D 60 18.2

180D 60 18.2

190D 60 21.8

Performance Data

CAT 611 21

Page 22

Performance Data

Unit Power Unit Unit Power Unit Unit Power Unit Unit Power Unit Unit Power Unit

Tons kWi EER Tons kWi EER Tons kWi EER Tons kWi EER Tons kWi EER

40

24 21.9 13.1 23 24.2 11.2 21 26.8 9.5 20 29.8 8.0 18 33.1 6.7

42

25 22.1 13.4 23 24.4 11.5 22 27.1 9.7 21 30.1 8.2 19 33.4 6.8

44

25 22.3 13.6 24 24.6 11.7

23 27.3 10.0

21 30.3 8.4 20 33.7 7.0

46

26 22.5 13.9 25 24.9 12.0 23 27.5 10.2 22 30.6 8.6 20 34.0 7.1

48

27 22.8 14.2 26 25.1 12.2 24 27.8 10.4 23 30.8 8.8 21 34.3 7.3

50

28 23.1 14.4 26 25.3 12.5 25 28.0 10.6 23 31.1 8.9 21 34.6 7.4

40

28 25.4 13.0 26 28.0 11.2 25 31.1 9.5 23 34.5 8.0 21 38.4 6.7

42

28 25.6 13.3 27 28.3 11.5 25 31.3 9.7 24 34.8 8.2 22 38.7 6.8

44

29 25.8 13.6 28 28.5 11.7

26 31.6 10.0

25 35.1 8.4 23 39.1 7.0

46

30 26.1 13.9 29 28.8 12.0 27 31.9 10.2 25 35.4 8.6 23 39.4 7.1

48

31 26.4 14.2 30 29.0 12.2 28 32.2 10.4 26 35.7 8.8 24 39.7 7.3

50

32 26.7 14.4 30 29.3 12.5 29 32.5 10.6 27 36.0 8.9 25 40.1 7.4

40

30 26.9 13.6 29 29.7 11.7 27 33.0 9.9 25 36.6 8.3 24 40.7 6.9

42

31 27.2 13.9 30 30.0 11.9 28 33.3 10.1 26 36.9 8.5 24 41.1 7.1

44

32 27.4 14.2 31 30.2 12.2

29 33.5 10.4

27 37.2 8.7 25 41.4 7.3

46

33 27.7 14.5 32 30.5 12.5 30 33.8 10.6 28 37.6 8.9 26 41.8 7.4

48

34 28.0 14.8 33 30.8 12.7 31 34.1 10.8 29 37.9 9.1 27 42.1 7.6

50

35 28.3 15.0 34 31.1 13.0 32 34.5 11.0 30 38.2 9.3 27 42.5 7.7

40

33 28.9 13.7 31 31.9 11.8 30 35.4 10.0 28 39.3 8.4 26 43.7 7.0

42

34 29.2 14.0 32 32.2 12.1 31 35.7 10.3 29 39.7 8.6 26 44.1 7.2

44

35 29.4 14.3 33 32.5 12.3

31 36.0 10.5

29 40.0 8.8 27 44.5 7.3

46

36 29.7 14.6 34 32.8 12.6 32 36.3 10.7 30 40.4 9.0 28 44.9 7.5

48

37 30.1 14.9 35 33.1 12.9 33 36.6 10.9 31 40.7 9.2 29 45.3 7.7

50

38 30.4 15.2 36 33.4 13.1 34 37.0 11.1 32 41.0 9.4 30 45.7 7.8

40

37 31.9 14.0 35 35.2 12.0 33 39.0 10.2 31 43.4 8.6 29 48.2 7.2

42

38 32.1 14.3 36 35.5 12.3 34 39.4 10.5 32 43.7 8.8 30 48.6 7.3

44

40 32.5 14.6 38 35.8 12.6

35 39.7 10.7

33 44.1 9.0 31 49.0 7.5

46

41 32.8 14.9 39 36.1 12.8 36 40.0 10.9 34 44.5 9.2 32 49.4 7.7

48

42 33.1 15.2 40 36.5 13.1 38 40.4 11.2 35 44.8 9.4 32 49.9 7.8

50

43 33.5 15.5 41 36.8 13.4 39 40.8 11.4 36 45.2 9.6 33 50.4 8.0

40

42 36.7 13.7 40 40.5 11.8 38 44.9 10.0 35 49.9 8.4 32 55.5 7.0

42

43 37.0 14.0 41 40.8 12.1 39 45.3 10.3 36 50.3 8.6 33 56.0 7.2

44

45 37.4 14.3 42 41.2 12.3

40 45.7 10.5

37 50.8 8.8 35 56.5 7.3

46

46 37.7 14.7 44 41.6 12.6 41 46.0 10.7 38 51.2 9.0 36 56.9 7.5

48

47 38.1 14.9 45 42.0 12.9 42 46.5 10.9 40 51.6 9.2 37 57.4 7.7

50

49 38.6 15.2 46 42.4 13.1 44 47.0 11.2 41 52.0 9.4 38 58.0 7.8

40

45 39.8 13.6 43 43.9 11.7 40 48.7 9.9 38 54.1 8.3 35 60.2 7.0

42

46 40.1 13.9 44 44.3 11.9 42 49.1 10.1 39 54.6 8.5 36 60.7 7.1

44

48 40.5 14.2 45 44.7 12.2

43 49.5 10.4

40 55.0 8.7 37 61.2 7.3

46

49 40.9 14.5 47 45.1 12.5 44 49.9 10.6 41 55.5 8.9 38 61.7 7.4

48

51 41.3 14.8 48 45.5 12.7 45 50.4 10.8 43 56.0 9.1 39 62.2 7.6

50

52 41.8 15.0 50 46.0 13.0 47 50.9 11.0 44 56.4 9.3 40 62.8 7.7

Unit Size Hz

Fan

Pow e r

(kW)

LWT

(°F)

Ambie nt Air Te mpe rature

95

°

F

105

°

F

115

°

F

025D 50 4.6

4.6

75

°

F

85

°

F

035D 50 4.6

030D 50

040D 50 4.6

045D 50 4.7

050D 50

055D 50 4.7

4.7

Table 12: 50 Hz Full Load Performance Data (IP)

22 CAT 611

Page 23

Table 13: 50 Hz Full Load Performance Data (IP) continued

Unit Power Unit Unit Power Unit Unit Power Unit Unit Power Unit Unit Power Unit

Tons kWi EER Tons kWi EER Tons kWi EER Tons kWi EER Tons kWi EER

40

49 44.1 13.3 46 48.7 11.4 44 54.1 9.7 41 60.1 8.2 38 66.8 6.8

42

51 44.5 13.6 48 49.1 11.7 45 54.5 9.9 42 60.6 8.4 39 67.4 7.0

44

52 45.0 13.9 49 49.6 12.0

47 55.0 10.2

44 61.1 8.6 40 67.9 7.1

46

54 45.4 14.2 51 50.1 12.2 48 55.4 10.4 45 61.6 8.7 42 68.5 7.3

48

55 45.9 14.5 52 50.5 12.5 49 55.9 10.6 46 62.1 8.9 43 69.1 7.4

50

57 46.4 14.7 54 51.0 12.7 51 56.5 10.8 48 62.6 9.1 44 69.7 7.6

40

51 43.5 14.0 48 48.0 12.0 45 53.3 10.2 42 59.2 8.6 39 65.8 7.2

42

52 43.9 14.3 50 48.4 12.3 47 53.7 10.4 44 59.7 8.8 40 66.4 7.3

44

54 44.3 14.6 51 48.8 12.6

48 54.2 10.7

45 60.2 9.0 42 66.9 7.5

46

56 44.7 14.9 53 49.3 12.8 50 54.6 10.9 46 60.7 9.2 43 67.5 7.7

48

57 45.2 15.2 54 49.8 13.1 51 55.1 11.1 48 61.2 9.4 44 68.1 7.8

50

59 45.8 15.5 56 50.3 13.4 53 55.7 11.4 49 61.7 9.6 46 68.7 8.0

40

56 50.9 13.2 53 56.3 11.3 50 62.4 9.6 47 69.3 8.1 43 77.1 6.7

42

58 51.4 13.5 55 56.7 11.6 52 62.9 9.8 48 69.9 8.3 45 77.8 6.9

44

60 51.9 13.8 57 57.2 11.8

53 63.4 10.1

50 70.5 8.5 46 78.4 7.0

46

61 52.4 14.1 58 57.8 12.1 55 63.9 10.3 51 71.1 8.6 47 79.0 7.2

48

63 53.0 14.3 60 58.3 12.3 57 64.6 10.5 53 71.7 8.8 49 79.7 7.3

50

65 53.6 14.6 62 58.9 12.6 58 65.2 10.7 54 72.3 9.0 50 80.5 7.5

40

64 57.8 13.2 61 62.9 11.5 57 69.1 9.9 53 75.9 8.4 49 83.4 7.1

42

66 58.2 13.6 62 63.6 11.8 59 69.5 10.2 55 76.4 8.6 51 84.1 7.3

44

68 58.8 13.8 64 64.1 12.0

61 70.2 10.4

57 77.1 8.8 52 84.7 7.4

46

70 59.3 14.2 66 64.7 12.3 63 70.8 10.6 58 77.7 9.0 54 85.5 7.6

48

72 59.8 14.5 68 65.3 12.6 64 71.4 10.8 60 78.2 9.2 56 86.2 7.7

50

74 60.4 14.8 71 65.7 12.9 66 72.0 11.1 62 79.0 9.4 57 86.9 7.9

40

71 65.4 13.0 67 71.3 11.3 63 78.2 9.7 59 85.9 8.3 55 94.5 7.0

42

73 65.9 13.3 69 72.0 11.5 65 78.7 10.0 61 86.5 8.5 56 95.2 7.1

44

75 66.6 13.6 71 72.6 11.8

67 79.4 10.2

63 87.2 8.7 58 95.9 7.3

46

78 67.1 13.9 74 73.2 12.1 69 80.2 10.4 65 87.9 8.8 60 96.8 7.4

48

80 67.7 14.2 76 73.9 12.3 71 80.8 10.6 67 88.6 9.1 62 97.6 7.6

50

82 68.3 14.5 78 74.4 12.6 74 81.5 10.8 69 89.5 9.2 64 98.4 7.8

40

78 71.9 13.0 74 78.4 11.3 70 86.0 9.7 65 94.4 8.3 60 103.9 7.0

42

80 72.5 13.3 76 79.1 11.6 72 86.6 10.0 67 95.1 8.5 62 104.7 7.1

44

83 73.2 13.6 79 79.8 11.8

74 87.4 10.2

69 95.9 8.7 64 105.4 7.3

46