Page 1

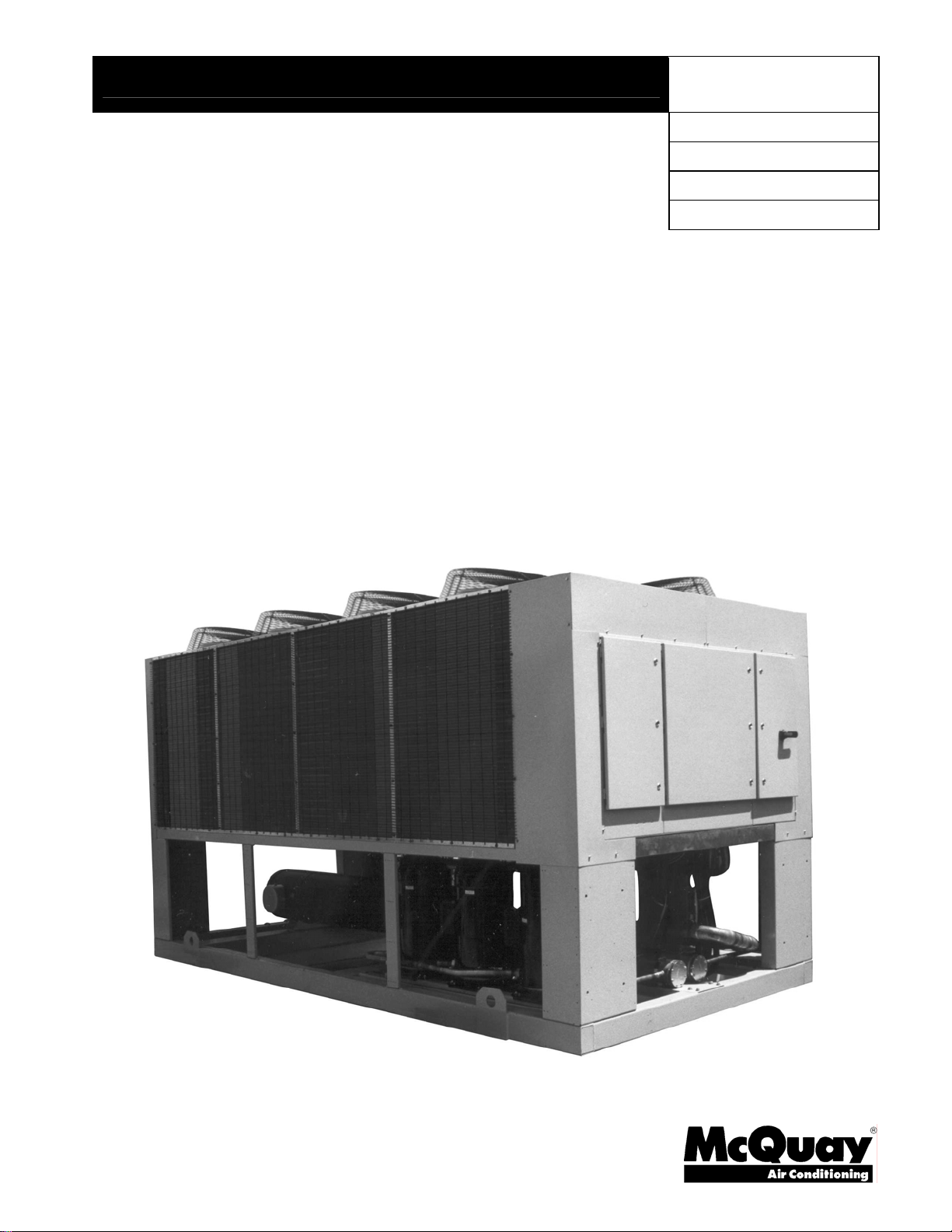

Operation Manual

Air-Cooled Scroll Compressor Chiller

Packaged and Remote Evaporator

AGZ 026BS/M through 130BS/M

60 Hertz

R-22, R407c

Software Version AGZDU0102C

OM AGZ-1

Group: Chiller

Part Number: 331374101

Effective: July 2007

Supercedes: January 2007

Page 2

Table of Contents

Introduction........................................3

General Description.....................................3

Nomenclature...............................................3

Ambient Air Temperature Limitations.........4

Water Flow Limitations ...............................5

System W ater Volume Considerations.........5 Pre Start-up.................................................54

Variable Speed Pumping..............................5 Start-Up......................................................54

Glycol Solutions ..........................................6 Shutdown ...................................................55

Operating/Standby Limits..........................10 Water Piping Checkout ..............................55

R-407C Units ....................................13

MicroTech II Controller..................15

Controller Section Table of Contents.........15

Overview....................................................16

General Description...................................16

Setpoints ....................................................18

Logging......................................................20

Control Logic............................................. 21

Chilled Water Pump Control......................22

Compressor Control...................................22

Condenser Fan Control..............................26

Low Ambient Startup.................................28

Evaporator Pressure Control......................29

Optional Low Ambient VFD......................29

Using the Controller...................................39

Building Automation System Interface (BAS)

....................................................................53

Startup..............................................54

Refrigerant Piping Checkout......................55

Electrical Check Out..................................56

Operation .........................................56

Hot Gas Bypass (Optional) ........................56

VFD Low Ambient Control (Optional)......57

Filter-Driers................................................57

System Adjustment.....................................57

Liquid Line Sight Glass .............................57

Refrigerant Charging..................................57

Thermostatic Expansion Valve...................58

Crankcase Heaters......................................58

Evaporator..................................................58

Phase Voltage Monitor (Optional)..............58

Our facility is ISO Certified

"McQuay" is a registered trademark of McQuay International

Illustrations and data cover McQuay International products at the time of publication and we reserve the right

to make changes in design and construction at anytime without notice.

©2005 McQuay International

2 AGZ 026B through 130B OM AGZ-1

Page 3

Introduction

General Description

McQuay Air-Cooled Global Water Chillers are complete, self-contained automatic

refrigerating units. Every unit is completely assembled, factory wired, charged, and

tested. Each unit consists of twin air-cooled condensers with integral subcooler

sections, two tandem or triple scroll compressors, brazed-plate or replaceable tube, dual

circuit shell-and-tube evaporator, and complete refrigerant piping. Liquid line

components include manual liquid line shutoff valves, sight-glass/moisture indicators,

solenoid valves, and thermal expansion valves. Other features include compressor

crankcase heaters, an evaporator heater for chilled water freeze protection, limited

pumpdown during “on” or “off” periods, automatic compressor lead-lag to alternate the

compressor starting sequence, and sequenced starting of compressors.

The electrical control center includes all equipment protection and operating controls

necessary for dependable automatic operation. Condenser fan motors are protected in

all three phases and started by their own three-pole contactors.

This manual covers units with software version AGZDU0102C. Installation,

maintenance and service information is in IMM AGZ-7 (or current latest dash number)

manual.

BOOT Version 3.0F

BIOS Version 3.56

Air-Cooled

Global

Scroll Compressor

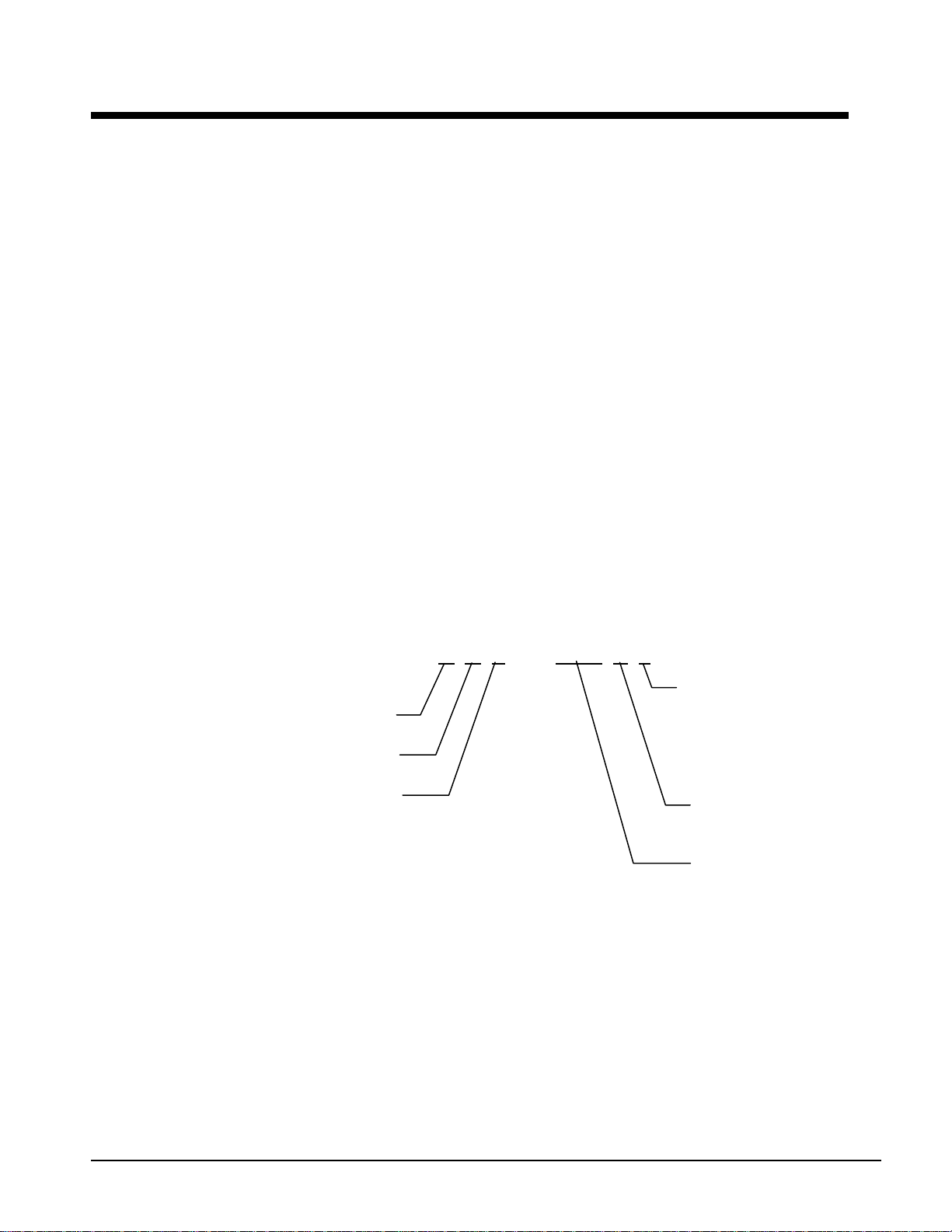

Nomenclature

A G Z - XXX B S

Application

S= Standard Ambient, Packaged

M= Standard Ambient, Remote

H= High Ambient, Packaged

B= High Ambient, Remote

Design Vi ntage

Model Size

(Nominal Tons)

OM AGZ-1 AGZ 026B through 130B 3

Page 4

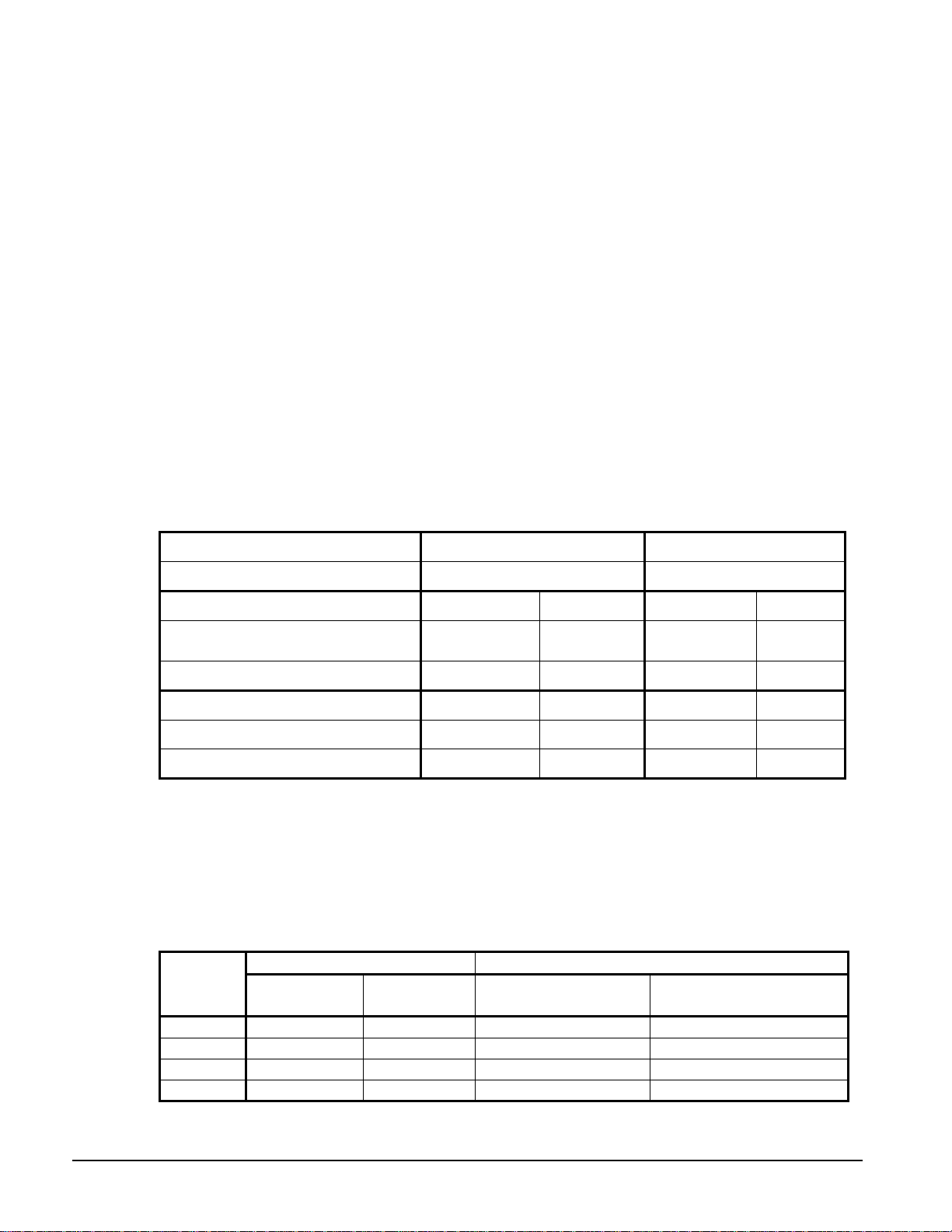

Ambient Air Temperature Limitations

Standard/High Ambient Panels

Models AGZ-B (26 to 130 tons, two circuit) have electrical data and subsequent field wiring

requirements that are tailored to individual applications.

There are many installations where the expected summer ambient air temperatures will be at

105°F (40.1°C) or less, resulting in smaller unit electrical requirements compared to operation at

106°F (41.1) and above. In these lower temperature cases, there can be considerable installation

cost savings by using smaller and more appropriate electrical service.

Therefore, the AGZ electrical data is divided into two classifications based on the design ambient

temperature where the unit will operate. Standard Ambient unit electrical data (BS and BM

models) is for operation in ambient temperatures of 105°F (40.1°C) or less. Units with the High

Ambient designation (BH and BB models) are for use above 105°F (40.1°C) to 125°F (51.7°C).

The AGZ-B units for high ambient operation require the addition of the High Ambient Control

Panel Option, which includes the addition of a small fan with a filter in the air intake to cool the

control panel, and a unit nameplate that lists the larger electrical requirements.

All units with the optional VFD low ambient fan control automatically include the High Ambient

Control Panel Option. Operation of the VFD generates a quantity of panel heat best removed by

use of a control panel fan.

Winter Operation Temperatures

0°F to 34°F 35°F and Above

Fan Control Optional High VFD (1) Standard FanTrol (2)

Design Ambient Air Temperature

Electrical Data (3)

≤105°F >106°F ≤105°F >106°F

Standard

Ambient

High

Ambient

Standard

Ambient

High

Ambient

Panel Fan Required (4) Yes Yes No Yes

Model Designator (5)

Packaged BS BH BS BH

Remote Evaporator BM BB BM BB

NOTES

1. VFD is variable speed, fan control through the MicroTech Ii controller.

2. FanTrol is fan cycling off discharge pressure.

3. Standard Ambient and High Ambient electrical data is located in the installation and

maintenance manual.

4. The VFD option automatically includes the factory-installed panel fan and filter set

5. The designator is the last two characters in the model number, i.e. AGZ 100BS.

Panel Ratings

Vo ltage

208-230

240

380-460

575

Standard

Standard Options

Panel

Optional

VFD

High Short Circuit

Panel (kA)

High Interrupt Panel w/

Disconnect Swt. (kA)

35 5 120 120

35 5 100 100

35 5 65 65

5 5 25 25

4 AGZ 026B through 130B OM AGZ-1

Page 5

Water Flow Limitations

The evaporator flow rates and pressure drops shown on page 11 are for full load design purposes in

order to maintain proper unit control. The maximum flow rate and pressure drop are based on a 6degree temperature drop. Avoid higher flow rates with resulting lower temperature drops to prevent

potential control problems resulting from very small control bands and limited start up/shut off

temperature changes.

The minimum flow and pressure drop is based on a full load evaporator temperature drop of 16-degrees.

Evaporator flow rates below the minimum values can result in laminar flow causing freeze-up problems,

scaling and poor control. Flow rates above the maximum values will result in unacceptable pressure

drops and can cause excessive erosion, potentially leading to failure.

This full load minimum flow is not to be confused with the part load minimum flow rat e that must be

maintained for chillers operating in primary variable flow pumping systems. As chiller capacity drops,

the flow rate for this pumping system will reduce proportionally. See the following table for the part

load minimum flo w rates.

These minimum flow rates assume that flow will be reduced proportionally to the cooling load.

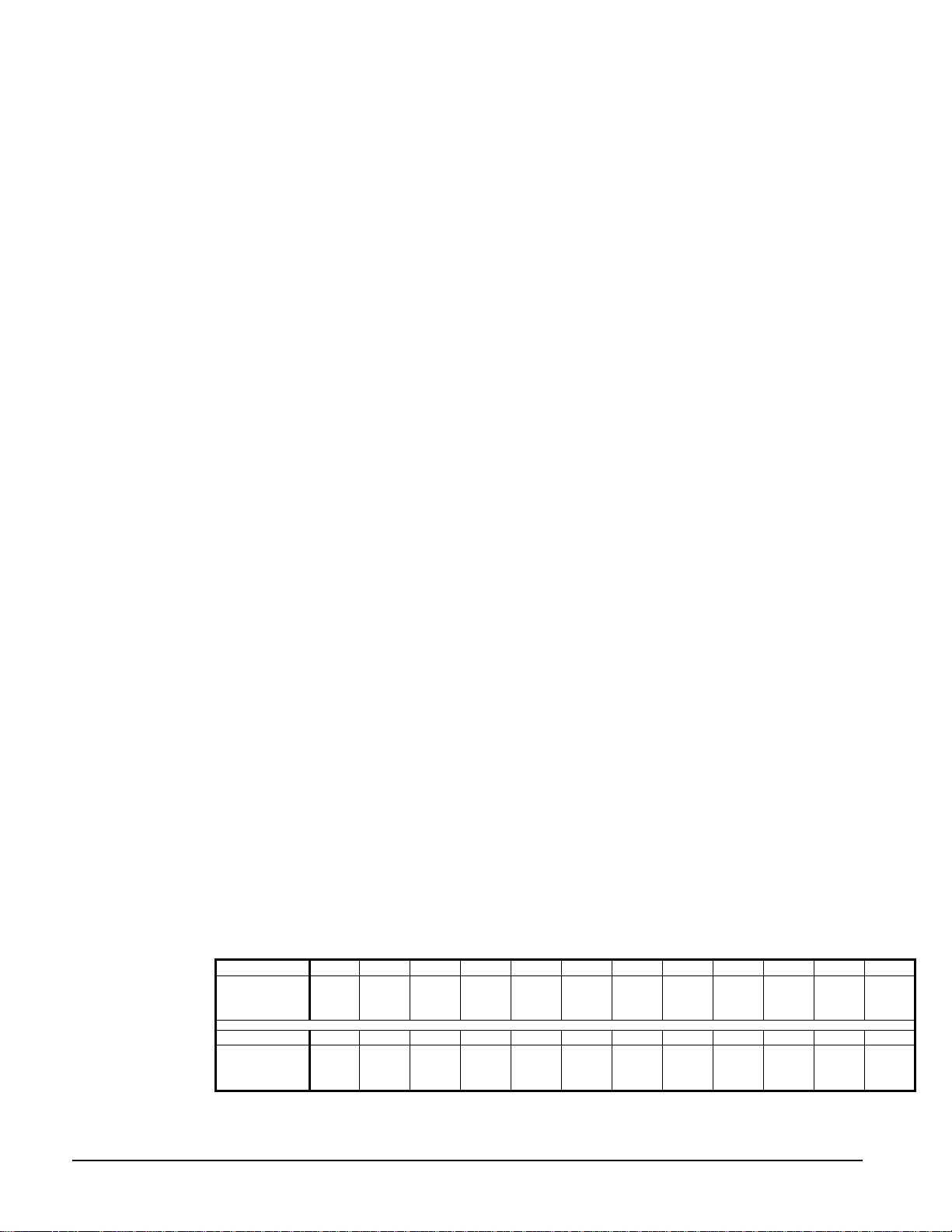

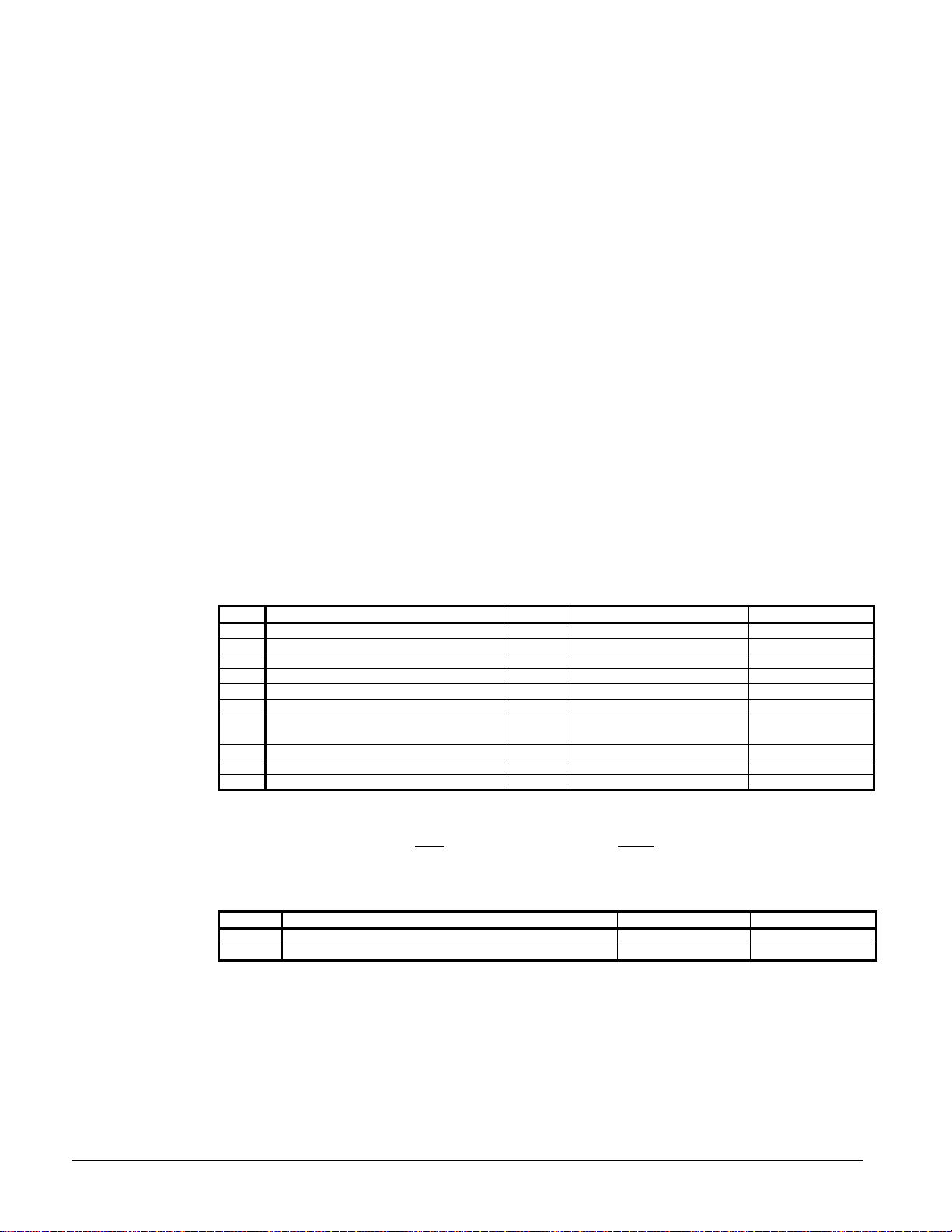

Table 1, Minimum Part Load Flow Rates

AGZ Model 026 030 035 040 045 050 055 060 065

Minimum Part

Load Flow (GPM)

AGZ Model 070 075 085 090 100 110 120 130

Minimum Part

Load Flow (GPM)

26 29 32 37 41 45 50 55 59

63 71 119 128 146 161 180 194

System Water Volume Considerations

All chilled water systems need adequate time to recognize a load change, respond to that load change

and stabilize, without undesirable short cycling of the compressors or loss of control. In air

conditioning systems, the potential for short cycling usually exists when the building load falls below

the minimum chiller plant capacity or on close-coupled systems with very small water volumes.

Some of the things the designer should consider when looking at water volume are the minimum

cooling load, the minimum chiller plant capacity during the low load period and the desired cycle time

for the compressors.

Assuming that there are no sudden load changes and that the chiller plant has reasonable turndown, a

rule of thumb of “gallons of water volume equal to two to three times the chilled water gpm flow rate”

is often used.

A properly designed storage tank should be added if the system components do not provide sufficient

water volume.

Variable Speed Pumping

Variable water flow involves reducing the water flow through the evaporator as the load decreases.

McQuay chillers are designed for this duty provided that the rate of change in water flow is not greater

than 10 percent of the change per minute.

The water flow through the vessel must remain between the minimum and maximum values listed on

11. If flow drops below the minimum allowable, large reductions in heat transfer can occur. If

page

the flow exceeds the maximum rate, excessive pressure drop and tube erosion can occur.

OM AGZ-1 AGZ 026B through 130B 5

Page 6

Glycol Solutions

T

The use of a glycol/water mixture in the evaporator to prevent freezing will reduce system capacity and

efficiency, as well as increase pressure drop. The system capacity, required glycol solution flow rate,

and pressure drop with glycol may be calculated using the following formulas and tables.

1. Capacity – Multiply the capacity based on water by the Capacity correction factor

Table 2 through Table 5.

from

2. Flow – Multiply the water evaporator flow by the Flow correction factor from

Table 2 through Table 5 to determine the increased evaporator flow due to glycol.

If the flow is unknown, it can be calculated from the following equation:

×

=

(gpm) Flow Glycol FactorCorrectionFlow

For Metric Applications

– Use the following equation for metric applications:

(l/s) Flow Glycol

CapacitykW

Delta

−×=18.4

3. Pressure drop -- Multiply the water pressure drop from page

correction factor from

Table 2 through Table 5. High concentrations of propylene

glycol at low temperatures may cause unacceptably high pressure drops.

4. Power -- Multiply the water system power by Power correction factor from

through

Table 5.

Test coolant with a clean, accurate glycol solution hydrometer (similar to that found in

service stations) to determine the freezing point. Obtain percent glycol from the

freezing point table below. It is recommended that a minimum of 25% solution by

weight be used for protection against corrosion or that additional compatible inhibitors

be added.

Concentrations above 35 percent do not provide any additional burst protection and

should be carefully considered before using.

glycolCapacityTons

)(24

−

TDelta

×

×

FactorCorrectionFlow

)

11 by Pressure Drop

Table 2

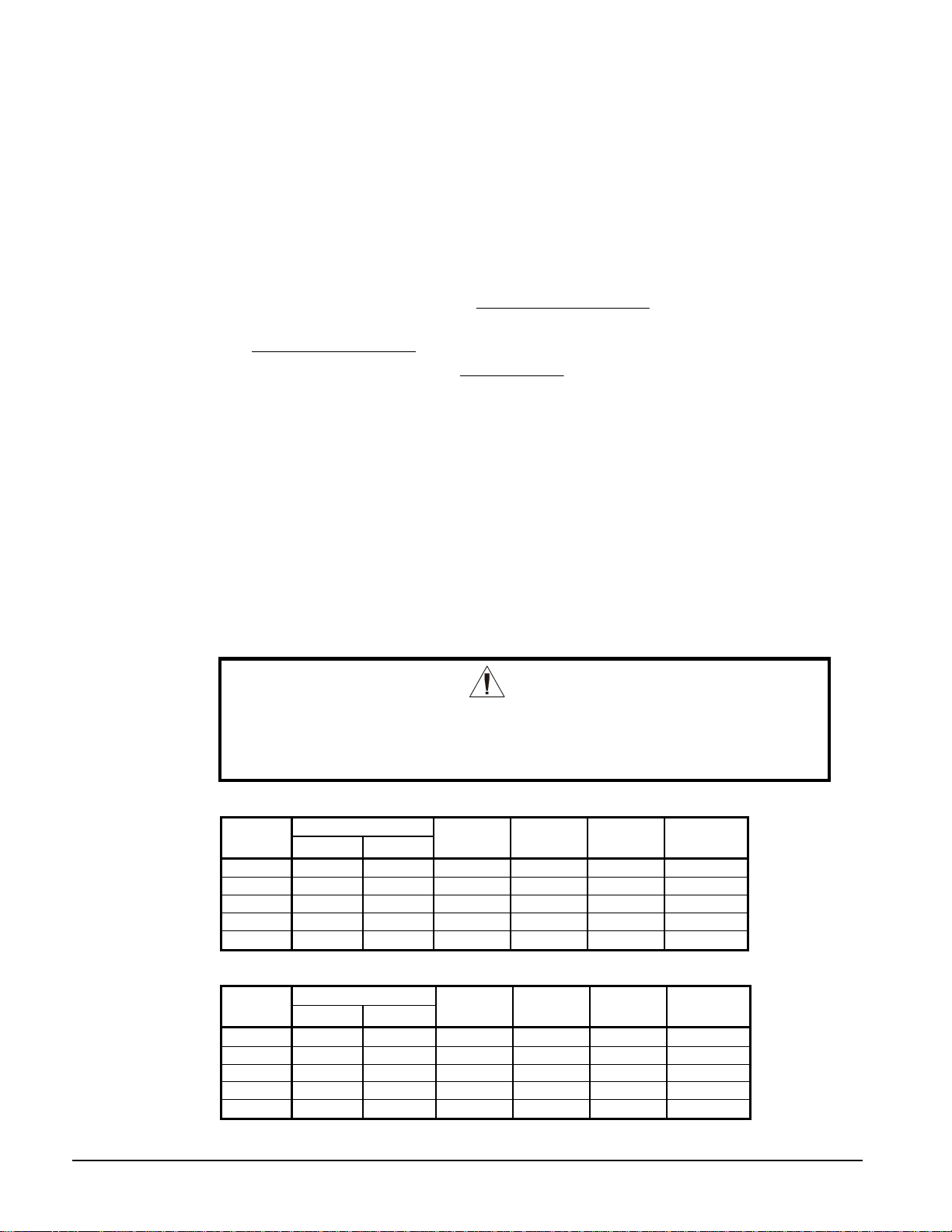

CAUTION

Do not use an automotive grade antifreeze. Industrial grade glycols must be

used. Automotive antifreeze contains inhibitors which will cause plating on the

copper tubes within the chiller evaporator. The type and handling of glycol used

must be consistent with local codes.

Table 2, Ethylene Glycol Factors for Models AGZ 026B to 070B

% E.G. Capacity Power Flow PD

10

20

30

40

50

Freeze Point

o

F

26 -3.3 0.998 0.998 1.036 1.097

18 -7.8 0.993 0.997 1.060 1.226

7 -13.9 0.987 0.995 1.092 1.369

-7 -21.7 0.980 0.992 1.132 1.557

-28 -33.3 0.973 0.991 1.182 1.791

o

C

Table 3, Propylene Glycol Factors for Models AGZ 026B to 070B

% P.G. Capacity Power Flow PD

10

20

30

40

50

Freeze Point

o

F

26 -3.3 0.995 0.997 1.016 1.100

19 -7.2 0.987 0.995 1.032 1.211

9 -12.8 0.978 0.992 1.057 1.380

-5 -20.6 0.964 0.987 1.092 1.703

-27 -32.8 0.952 0.983 1.140 2.251

o

C

6 AGZ 026B through 130B OM AGZ-1

Page 7

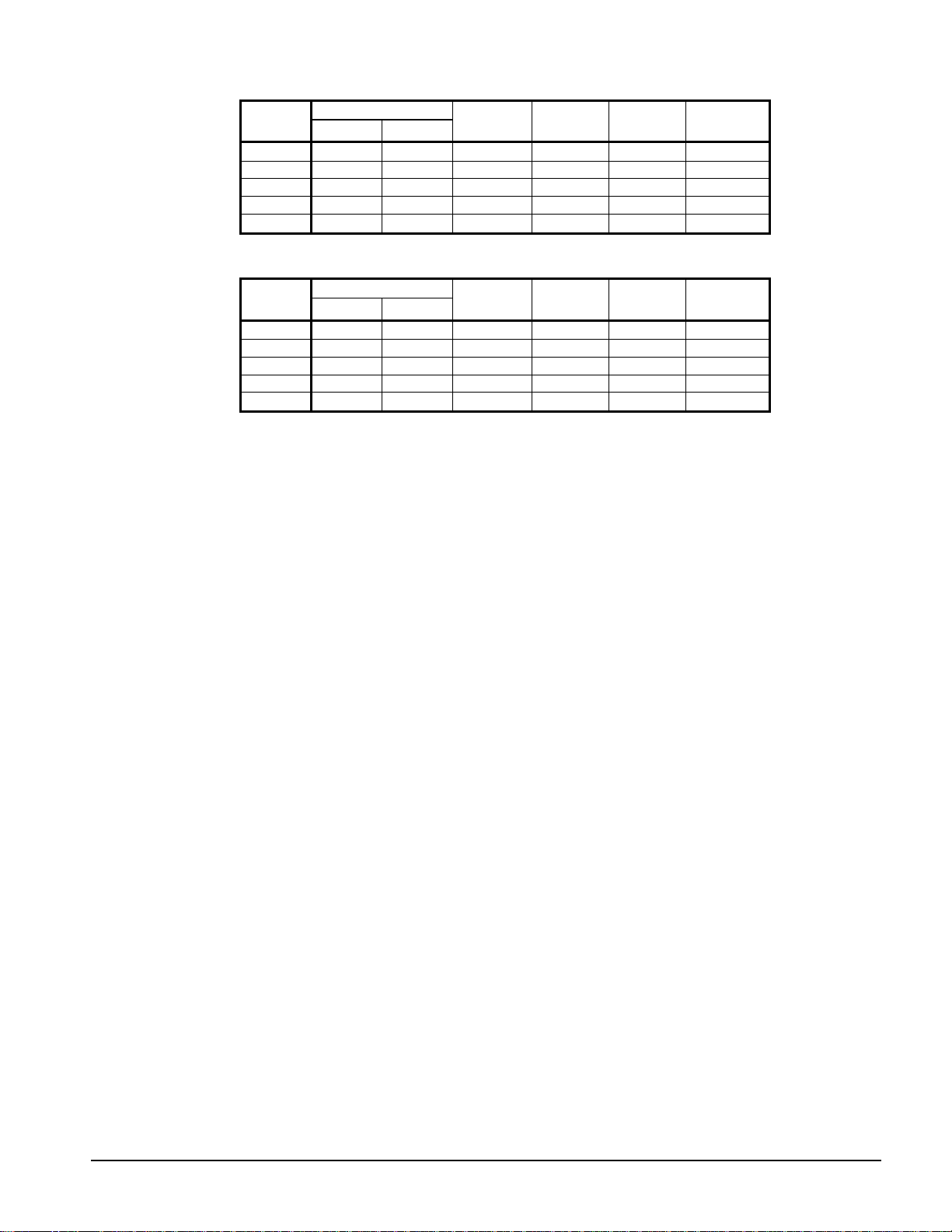

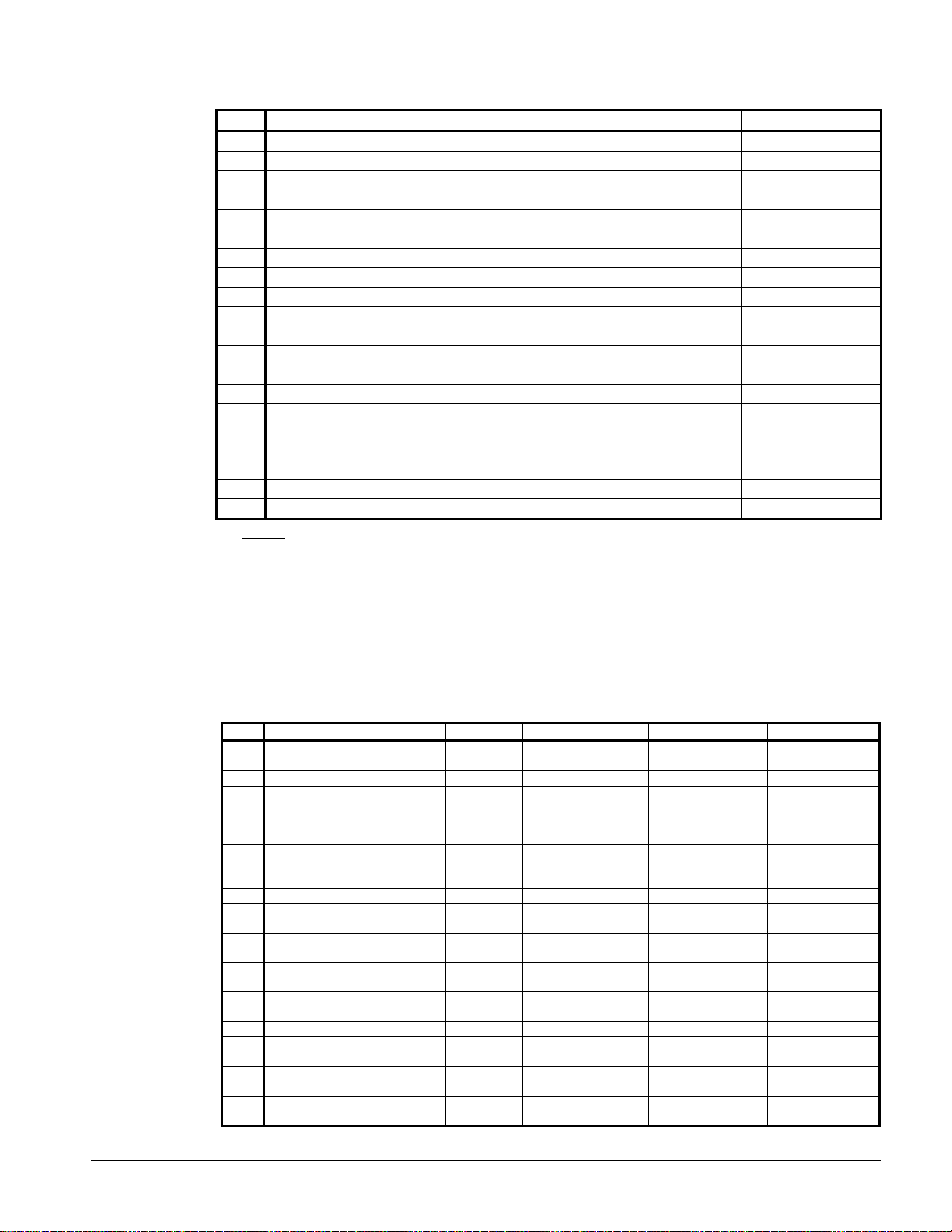

Table 4, Ethylene Glycol Factors for Models AGZ 075B to 130B

% E.G. Capacity Power Flow PD

10

20

30

40

50

Freeze Point

o

F

26 -3.3 0.994 0.998 1.038 1.101

18 -7.8 0.982 0.995 1.063 1.224

7 -13.9 0.970 0.992 1.095 1.358

-7 -21.7 0.955 0.987 1.134 1.536

-28 -33.3 0.939 0.983 1.184 1.755

o

C

Table 5, Propylene Glycol Factors for Models AGZ 075B to 130B

% P.G.

10

20

30

40

50

Freeze Point

o

F

26 -3.3 0.988 0.996 1.019 1.097

19 -7.2 0.972 0.992 1.035 1.201

9 -12.8 0.951 0.987 1.059 1.351

-5 -20.6 0.926 0.979 1.095 1.598

-27 -32.8 0.906 0.974 1.142 2.039

o

C

Capacity Power Flow PD

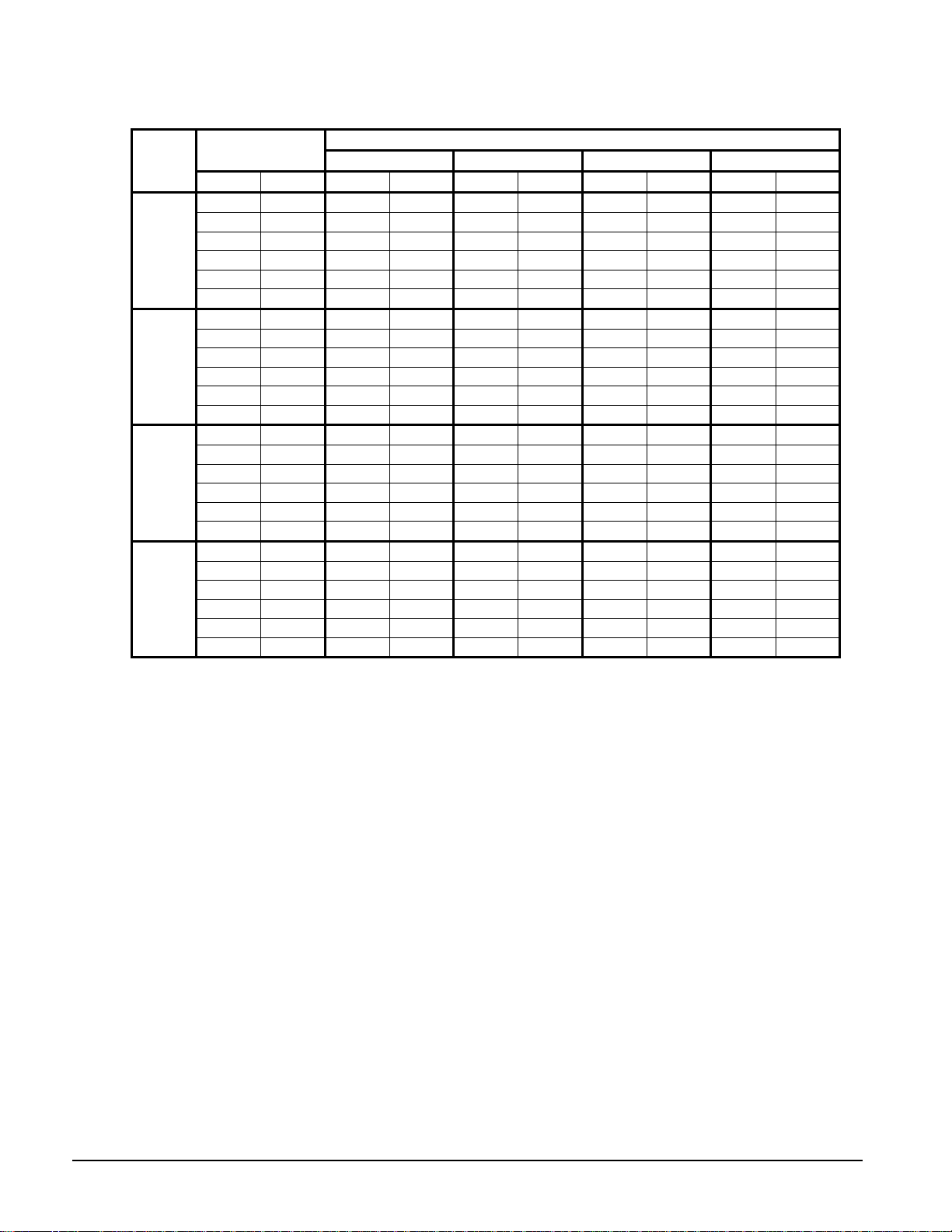

Altitude Correction Factors

Performance tables are based at sea level. Elevations other than sea level affect the performance of

the unit. The decreased air density will reduce condenser capacity consequently reducing the unit's

performance. For performance at elevations other than sea level, refer to

Table 6 and Table 7.

Evaporator Temperature Drop Factors

Performance tables are based on a 10°F (5°C) temperature drop through the evaporator. Adjustment

factors for applications with temperature ranges from 6°F to 16°F (3.3°C to 8.9°C) are in

Table 7.

Table 6 and

Temperature drops outside this 6°F to 16°F (3.3°C to 8.9°C) range can affect the control system's

capability to maintain acceptable control and are not recommended.

The maximum water temperature that can be circulated through the evaporator in a non-operating

mode is 100°F (37.8°C).

Fouling Factor

Performance tables are based on water with a fouling factor of

As fouling is increased, performance decreases. For performance at other than 0.0001 (0.0176)

fouling factor, refer to

Foreign matter in the chilled water system will adversely affect the heat transfer capability of

the evaporator and could increase the pressure drop and reduce the water flow. Maintain

proper water treatment to provide optimum unit operation.

22

per ARI 550/590-98.

)/0176.0(/0001.0

kWCmorBTUFhrft °×°××

OM AGZ-1 AGZ 026B through 130B 7

Page 8

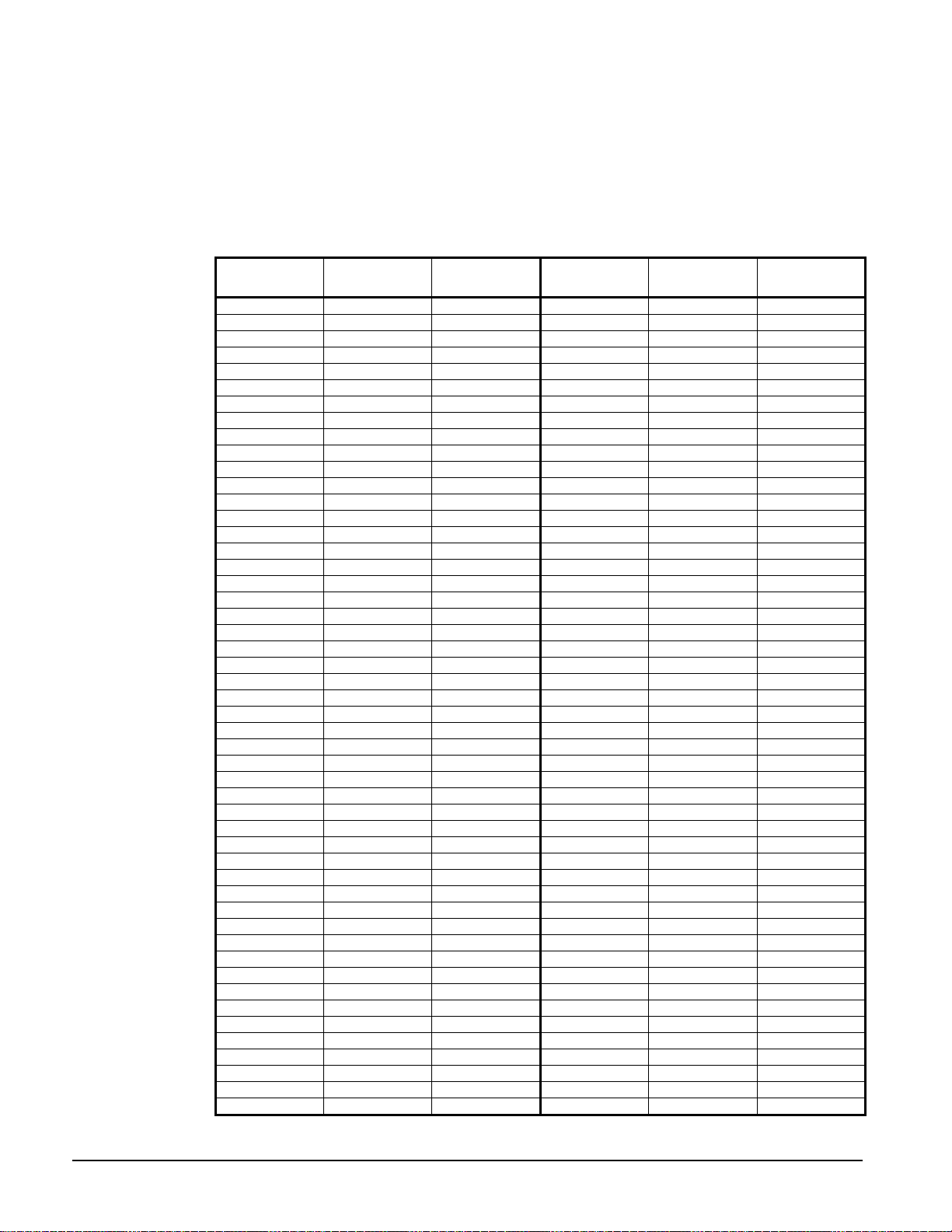

Table 6, Capacity and Power Derates, Models AGZ 026 to 070

Fouling Factor

Altitude

Sea

Level

2000 feet

4000 feet

6000 feet

Chilled Water Delta T

°F °C Cap. Power Cap. Power Cap. Power Cap. Power

6 3.3 0.978 0.993 0.975 0.991 0.963 0.987 0.940 0.980

8 4.4 0.989 0.996 0.986 0.994 0.973 0.990 0.950 0.983

10 5.6 1.000 1.000 0.996 0.999 0.984 0.994 0.961 0.987

12 6.7 1.009 1.003 1.005 1.001 0.993 0.997 0.969 0.990

14 7.7 1.018 1.004 1.014 1.003 1.002 0.999 0.978 0.991

16 8.9 1.025 1.007 1.021 1.006 1.009 1.001 0.985 0.994

6 3.3 0.977 1.001 0.973 1.000 0.961 0.996 0.938 0.989

8 4.4 0.987 1.006 0.984 1.004 0.971 1.000 0.948 0.993

10 5.6 0.998 1.009 0.995 1.007 0.982 1.003 0.959 0.996

12 6.7 1.007 1.011 1.004 1.010 0.991 1.006 0.967 0.998

14 7.7 1.014 1.014 1.011 1.013 0.998 1.009 0.974 1.001

16 8.9 1.022 1.016 1.018 1.014 1.005 1.010 0.981 1.003

6 3.3 0.973 1.011 0.970 1.010 0.957 1.006 0.935 0.998

8 4.4 0.984 1.014 0.980 1.013 0.968 1.009 0.945 1.001

10 5.6 0.995 1.019 0.991 1.017 0.979 1.013 0.955 1.005

12 6.7 1.004 1.021 1.000 1.020 0.987 1.016 0.964 1.008

14 7.7 1.011 1.024 1.007 1.023 0.994 1.018 0.971 1.011

16 8.9 1.018 1.027 1.014 1.026 1.002 1.021 0.978 1.014

6 3.3 0.969 1.021 0.966 1.020 0.954 1.016 0.931 1.008

8 4.4 0.980 1.026 0.977 1.024 0.964 1.020 0.942 1.013

10 5.6 0.989 1.029 0.986 1.027 0.973 1.023 0.950 1.015

12 6.7 0.998 1.033 0.995 1.031 0.982 1.027 0.959 1.020

14 7.7 1.007 1.036 1.004 1.034 0.991 1.030 0.967 1.022

16 8.9 1.014 1.037 1.011 1.036 0.998 1.031 0.974 1.024

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

8 AGZ 026B through 130B OM AGZ-1

Page 9

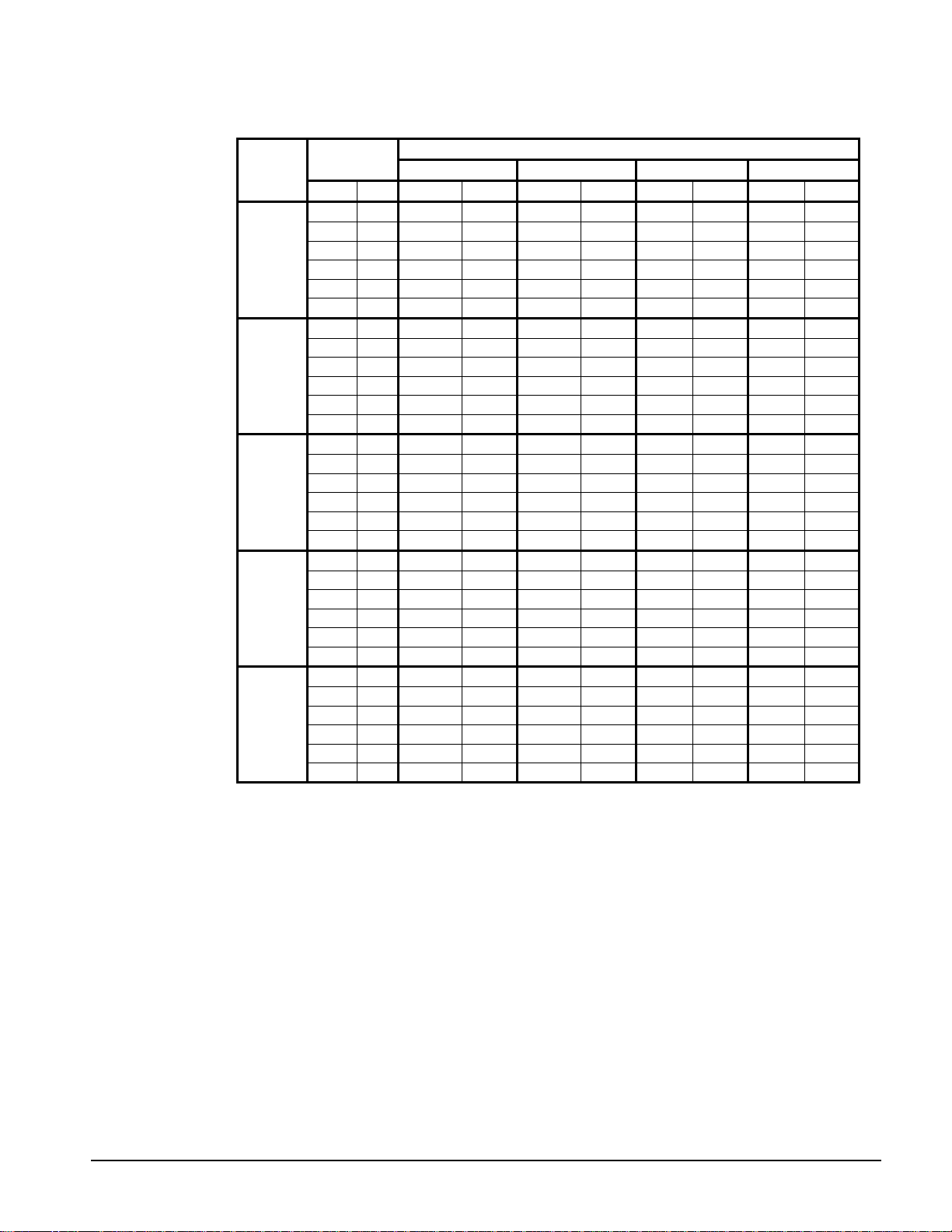

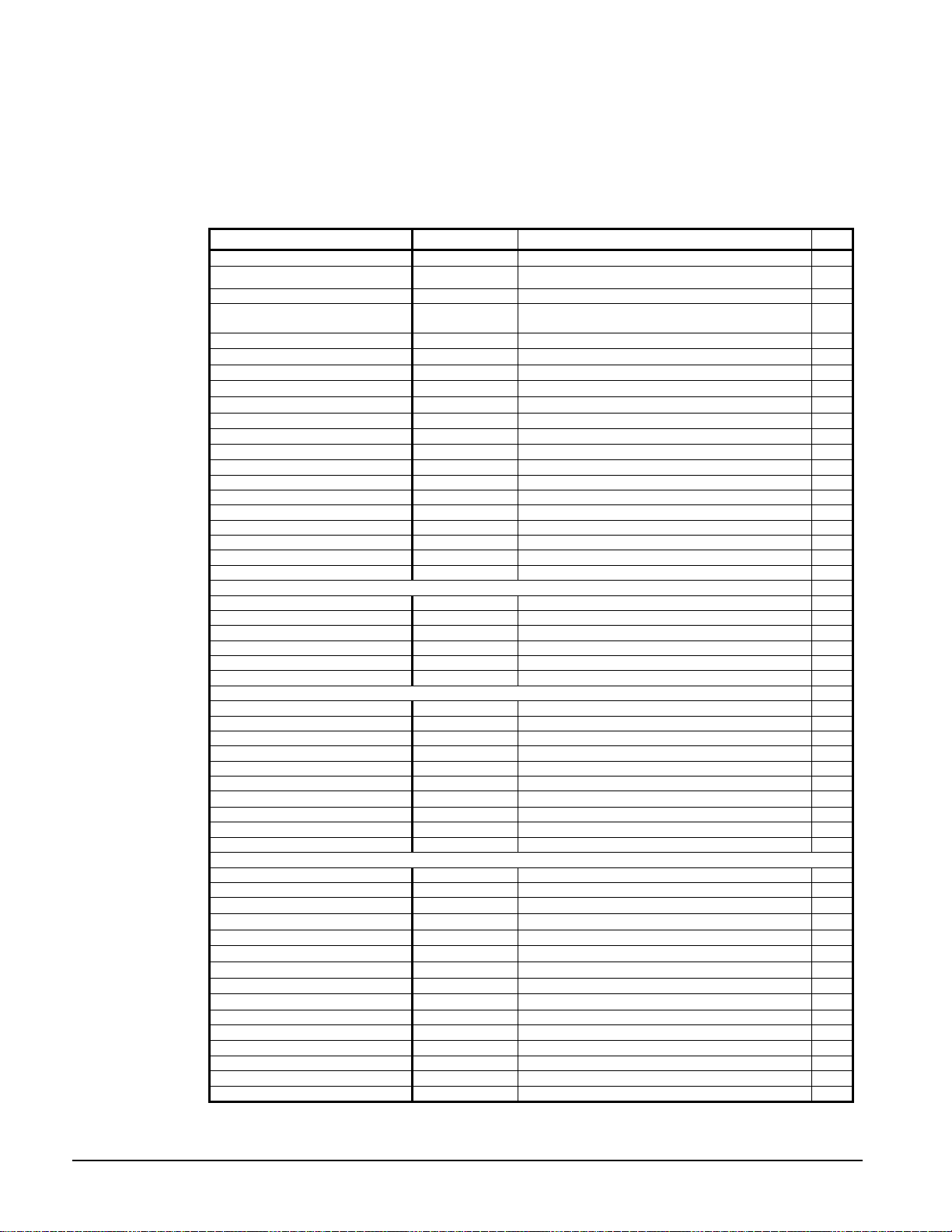

Table 7, Capacity and Power Derates, Models AGZ 075 to 130

Fouling Factor

Altitude

Sea

Level

2000 feet

4000 feet

6000 feet

8000 feet

Chilled Water

Delta T

°F °C Cap. Power Cap. Power Cap. Power Cap. Power

6 3.3 0.990 0.997 0.976 0.994 0.937 0.983 0.868 0.964

8 4.4 0.994 0.998 0.981 0.995 0.942 0.984 0.872 0.965

10 5.6 1.000 1.000 0.987 0.996 0.947 0.986 0.877 0.967

12 6.7 1.005 1.001 0.991 0.997 0.951 0.986 0.881 0.968

14 7.7 1.009 1.002 0.995 0.998 0.955 0.987 0.884 0.968

16 8.9 1.013 1.004 1.000 1.000 0.960 0.989 0.889 0.970

6 3.3 0.987 1.005 0.974 1.002 0.934 0.991 0.865 0.972

8 4.4 0.992 1.006 0.979 1.003 0.940 0.992 0.870 0.973

10 5.6 0.997 1.008 0.984 1.004 0.944 0.994 0.875 0.975

12 6.7 1.002 1.009 0.989 1.005 0.949 0.994 0.879 0.975

14 7.7 1.007 1.011 0.993 1.007 0.953 0.996 0.883 0.977

16 8.9 1.011 1.012 0.998 1.008 0.958 0.997 0.887 0.978

6 3.3 0.985 1.014 0.972 1.010 0.933 0.999 0.864 0.980

8 4.4 0.991 1.015 0.977 1.012 0.938 1.001 0.869 0.981

10 5.6 0.995 1.016 0.982 1.013 0.943 1.002 0.873 0.982

12 6.7 1.000 1.018 0.987 1.014 0.947 1.003 0.877 0.984

14 6.8 1.005 1.019 0.991 1.015 0.951 1.004 0.881 0.985

16 8.9 1.009 1.021 0.995 1.017 0.955 1.006 0.884 0.987

6 3.3 0.982 1.023 0.969 1.020 0.930 1.009 0.861 0.989

8 4.4 0.988 1.025 0.975 1.022 0.935 1.010 0.866 0.991

10 5.6 0.992 1.026 0.979 1.022 0.940 1.011 0.870 0.992

12 6.7 0.997 1.028 0.984 1.024 0.944 1.013 0.875 0.994

14 7.7 1.002 1.029 0.989 1.025 0.949 1.014 0.879 0.995

16 8.9 1.006 1.031 0.992 1.027 0.952 1.016 0.882 0.996

6 3.3 0.979 1.034 0.966 1.031 0.927 1.019 0.859 1.000

8 4.4 0.984 1.036 0.971 1.032 0.932 1.021 0.863 1.002

10 5.6 0.990 1.037 0.976 1.033 0.937 1.022 0.868 1.002

12 6.7 0.993 1.039 0.980 1.035 0.941 1.024 0.871 1.004

14 7.7 0.998 1.041 0.985 1.037 0.945 1.026 0.875 1.006

16 8.9 1.003 1.041 0.990 1.038 0.950 1.026 0.879 1.007

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

Evaporator Freeze Protection

Evaporator freeze-up can be a concern in the application of air-cooled water chillers. To

protect against freeze-up, insulation and an electric heater cable are furnished with the

unit. This protects the evaporator down to -20°F (-29°C) ambient air temperature.

Although the evaporator is equipped with freeze protection, it does not protect water

piping external to the unit or the evaporator itself if there is a power failure or heater

cable burnout. Consider the following recommendations for additional protection.

1. If the unit will not be operated during the winter, drain evaporator and chilled water

piping and flush with glycol. Drain and vent connections are provided on the

evaporator to ease draining.

2. Add a glycol solution to the chilled water system to provide freeze protection.

Freeze point should be approximately ten degrees below minimum design ambient

temperature.

3. The addition of thermostatically controlled heat and insulation to exposed piping.

4. Continuous circulation of water through the chilled water piping and evaporator.

OM AGZ-1 AGZ 026B through 130B 9

Page 10

The evaporator heater cable is factory wired to the 115-volt circuit in the control box.

This power should be supplied from a separate source, but it can be supplied from the

control circuit. Operation of the heater cable is automatic through the ambient sensing

thermostat that energizes the evaporator heater cable for protection against freeze-up.

Unless the evaporator is drained in the winter, the disconnect switch to the evaporator

heater must not be open.

Operating/Standby Limits

Maximum standby ambient air temperature, 130°F (55°C)

Maximum operating ambient air temperature

Standard Ambient Unit, 105°F (40.6°C) and below, Models BS and BM

High Ambient Unit, above 105°F (40.6°C) to 125°F 51.7°C), Models BH and BB

Minimum operating ambient temperature (standard), 35°F (2°C)

Minimum operating ambient temperature (with optional low-ambient control), 0°F (-

18°C)

Leaving chilled water temperature, R-22, 40°F to 60°F (4.4°C to 15.6°C)

Leaving chilled water temperature, R-407C, 42°F to 60°F (5.5°C to 15.6°C)

Leaving chilled fluid temperatures (with anti-freeze), 20°F to 60°F (-7°C to 16°C

Design chilled water Delta-T range, 6 degrees F to 16 degrees F (3.3 degrees C to 8.9

degrees C)

Part load minimum flow for variable flow systems, varies with unit size, see table

below.

Maximum operating inlet fluid temperature, 76°F (24°C)

Maximum non-operating inlet fluid temperature, 100°F (38°C)

Water Flow Limitations, Variable Flow

The full load, minimum flow limitation for constant flow is not to be confused with the

part load minimum flow rate that must be maintained for chillers operating in primary

variable flow pumping systems. As chiller capacity drops, the flow rate for this

pumping system will reduce proportionally. See the following table for the part load

minimum flo w rates.

Other design practices for variable flow systems requiring a range of evaporator flow

rates can be found below.

These minimum flow rates assume that flow will be reduced proportionally to the

cooling load.

Table 8, Minimum Part Load Flow Rates

AGZ Model 010 013 017 020 025 029 034 026 030 035 040 045

Minimum

Part Load

Flow (GPM)

AGZ Model 050 055 060 065 070 075 085 090 100 110 120 130

Minimum

Part Load

Flow (GPM)

10 13 15 20 22 27 33 26 29 32 37 41

45 50 55 59 63 71 119 128 146 161 180 194

10 AGZ 026B through 130B OM AGZ-1

Page 11

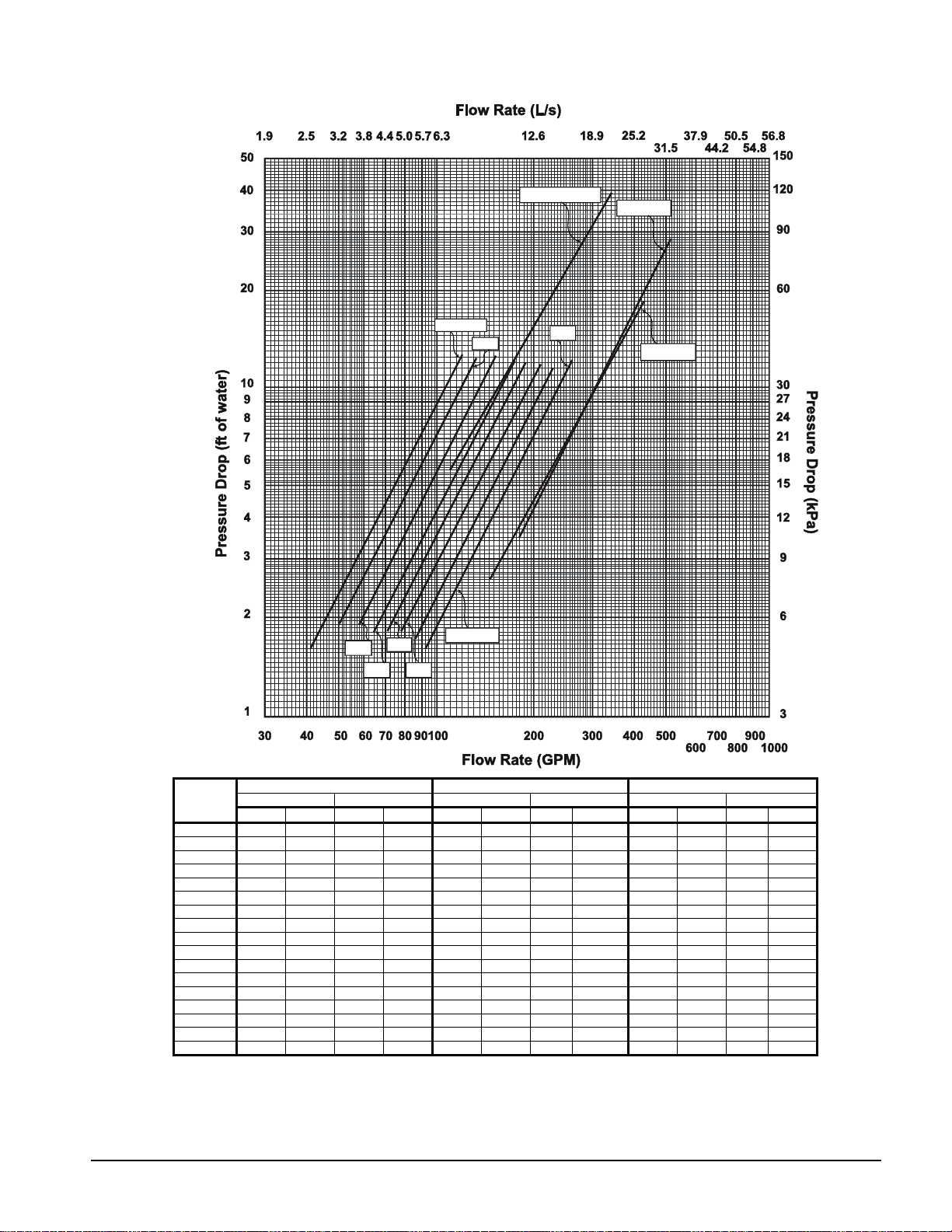

Figure 1, AGZ 026B – 130B, Evaporator Pressure Drop

040

045

050

055

026-030

065-070

035

075-085-090

120-130

060

100-110

AGZ Unit

Model

026B

030B

035B

040B

045B

050B

055B

060B

065B

070B

075B

085B

090B

100B

110B

120B

130B

NOTE: Minimum and maximum flows are established to ensure the Delta-T for each unit size falls within the 6 - 16°F range for

Inch-Pound S.I. Inch-Pound S.I. Inch-Pound S.I.

gpm DP ft. lps DP kpa gpm DP ft. lps DP kpa gpm DP ft. lps DP kpa

41 1.6 2.6 4.7 65 3.9 4.1 11.6 109 10.4 6.9 30.9

45 1.9 2.9 5.7 72 4.7 4.6 14.1 121 12.7 7.6 37.8

50 1.9 3.1 5.6 80 4.6 5.0 13.8 133 12.4 8.4 36.9

58 1.9 3.6 5.7 92 4.7 5.8 14.0 154 12.6 9.7 37.5

64 1.8 4.0 5.4 102 4.5 6.4 13.4 170 12.1 10.7 35.9

71 1.8 4.4 5.4 113 4.5 7.1 13.3 188 12.0 11.9 35.7

78 1.8 4.9 5.3 125 4.4 7.9 13.0 209 11.7 13.2 34.8

86 1.7 5.4 5.2 137 4.3 8.6 12.8 228 11.5 14.4 34.2

92 1.6 5.8 4.9 147 4.1 9.3 12.1 246 10.9 15.5 32.5

98 1.9 6.2 5.6 157 4.6 9.9 13.7 262 12.3 16.5 36.8

111 5.6 7.0 16.5 177 12.5 11.2 37.4 295 30.4 18.6 90.7

119 6.3 7.5 18.9 191 14.3 12.1 42.7 318 34.8 20.1 103.6

128 7.2 8.1 21.4 205 16.2 12.9 48.4 342 39.4 21.6 117.3

146 2.6 9.2 7.7 234 6.1 14.8 18.2 390 15.5 24.6 46.2

161 3.1 10.2 9.2 258 7.3 16.3 21.7 430 18.5 27.1 55.1

180 3.5 11.3 10.4 288 8.9 18.1 26.5 479 24.6 30.2 73.4

194 4.1 12.2 12.1 311 10.4 19.6 30.9 518 28.7 32.7 85.6

proper unit control.

OM AGZ-1 AGZ 026B through 130B 11

Minimum Nominal Maximum

Page 12

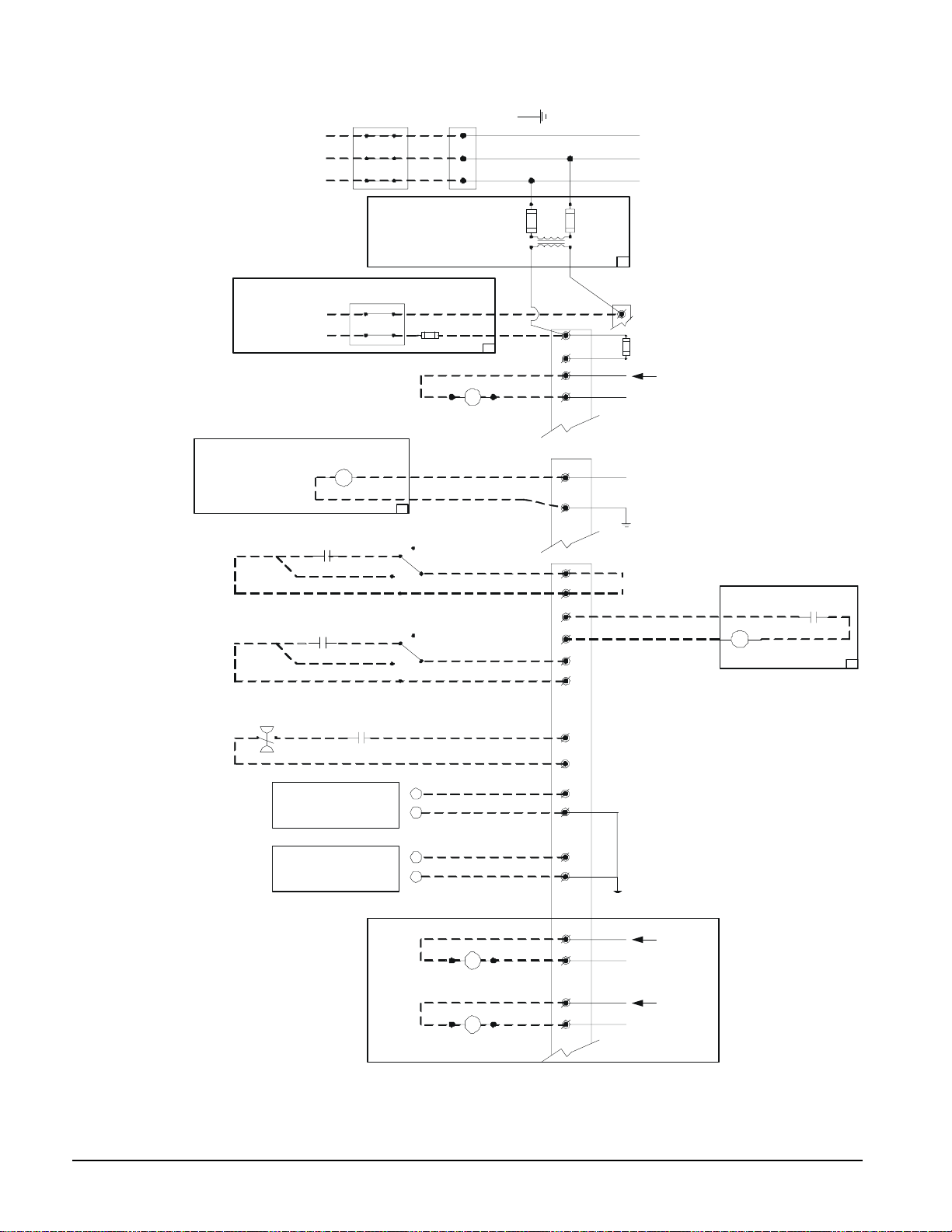

Figure 2, AGZ 026B – AGZ 130B, Typical Field Wiring

3 PHASE

POWER

DISCONNECT

(BY OTHERS)

UNIT MAIN

TERMINAL BLOCK

GND LUG

TO COMPRESSOR(S)

AND FAN MOTORS

NOTE: ALL FIELD WIRING TO BE

INSTALLED AS NEC CLASS 1

WIRING SYSTEM WITH CONDUCTOR

RATED 600 VOLTS

FIELD SUPPLIED

REMOTE STOP SWITCH

(BY OTHERS)

ICE MODE SWITCH

(BY OTHERS)

ALARM BELL

OPTION

CHW FLOW SWITCH

---MANDATORY–(BY OTHERS)

OPTION

CONTROL POWER

N

120VAC

FACTORY SUPPLIED ALARM

FIELD WIRED

ALARM BELL RELAY

TIME

CLOCK

FUSED CONTROL

CIRCUIT TRANSFORMER

DISCONNECT

(BY OTHERS)

10A

FUSE

(BY OTHERS)

CHW PUMP RELAY

120 VAC 1.0 AMP MAX

OFF

AUTO

ON

MANUAL

OFF

AUTO

ON

MANUAL

(BY OTHERS)

120 VAC

CONTROLLER

TB1

TB2

TB1-20

1

2

35

33

34

CONTROL

CIRCUIT

FUSE

120 VAC

N

120 VAC

32

GND

IF REMOTE STOP

52

72

43

83

54

CONTROL IS USED,

REMOVE LEAD 585

585

FROM TERM. 52

TO 72.

BELL

12

ALARM BELL OPTION

ALARM BELL

RELAY

COM NO

74

NOR. OPEN PUM P AUX.

CONTACTS (OPTIONAL)

44

61

4-20MA FOR

EVAP. WATER RESET

(BY OTHERS)

4-20MA FOR

DEMAND LIMIT

(BY OTHERS)

DWG. 330423101 REV.0A

+

-

+

-

LESS EVAPORATOR ONLY

LIQUID LINE #1 SOLENOID

24 VAC 1.5 AMP MAX

LIQUID LINE #2 SOLENOID

24 VAC 1.5 AMP MAX

68

69

70

71

GND

91

93

92

93

24 VAC

N

24 VAC

N

12 AGZ 026B through 130B OM AGZ-1

Page 13

R-407C Units

AGZ chillers are available with R-407C refrigerant as non-ARI certified units. R-407C is a

zeotropic blend of three compounds, and as such exhibits the characteristic of glide. It does

not behave as one substance like R-22 does. Glide is the difference (in degrees F) between the

beginning and end phase-change process in either the evaporator or condenser. During these

processes, different ratios of the refrigerant’s components change phase from the beginning to

the end of the process. The following functions, conditions and settings will differ from units

charged with R-22.

1. Polyolester lubricants are used instead of mineral oil.

2. The saturated pressure/temperature relationship

3. Control and alarm settings

4. Charging procedures

1. Lubrication. The units are factory-charged with polyoester (POE) lubricant and one of

the following lubricants must be used if lubricant is to be added to the system:

Copeland Ultra 22 CC

Mobil EAL™ Arctic 22 CC

ICI EMKARATE RL RL™ 32CF

POEs are very hydroscopic and will quickly absorb moisture if exposed to air. Pump the

lubricant into the unit through a closed transfer system. Avoid overcharging the unit.

2. Pressure/temperature relationship. See

temperature chart. Due to refrigerant glide, use the following procedures for superheat

and subcooling measurement.

To determine superheat, only vapor must be present at the point of measurement, no

liquid. Use the temperature reading, the pressure reading and the Saturated P/T Chart. If

the pressure is measured at 78 psig, the chart shows the saturated vapor

50.6°F. If the temperature is measured at 60°F, the superheat is 9.4 degrees F.

To determine subcooling, only liquid must be present, no vapor. Use the temperature

reading, the pressure reading and the Saturated P/T Chart. If the pressure is measured at

250 psig, the chart shows the saturated liquid

temperature is measured at 98°F, the subcooling is 10.2 degrees F.

The P/T relationship between R-407C and R-22 is similar enough to allow the use of R-22

expansion valves. The valves may be marked as “R-22’ or “R-22/R-407C”.

3. Control and alarm settings. The software that controls the operation of the unit is

factory-set for operation with R-407C, taking into account that the pressure/temperature

relationship differs from R-22. The software functionality is the same for either

refrigerant.

4. Charging procedure. The units are factory-charged with R-407C. Use the following

procedure if recharging in the field is necessary:

Whether topping off a charge or replacing the circuit’s entire charge, always remove the

refrigerant from the charging vessel as a liquid. Many of the cylinders for the newer

refrigerants have a dip tube so that liquid is drawn off when the cylinder is in the upright

position. Do not vapor charge out of a cylinder unless the entire contents will be charged

into the system.

Figure 3 on page 14 for the saturated pressure-

temperature to be

temperature to be 108.2°F. If the

With the system in a 250-micron or lower vacuum, liquid can be charged into the

high side. Initially charge about 80 percent of the system total charge.

OM AGZ-1 AGZ 026B through 130B 13

Page 14

Start the system and observe operation. Use standard charging procedures (liquid

only) to top off the charge.

It may be necessary to add refrigerant through the compressor suction. Because the

refrigerant leaving the cylinder must be a liquid, exercise care to avoid damage to

the compressor. A sight glass can be connected between the charging hose and the

compressor. It can be adjusted to have liquid leave the cylinder and vapor enter the

compressor.

Figure 3, R-407C Saturated Pressure/Temperature Chart

Pressure

(PSIG)

20 -10.7 1.5 150 74.8 84.9

22 -8.2 4.0 155 76.8 86.8

24 -5.7 6.4 160 78.7 88.7

26 -3.4 8.7 165 80.6 90.5

28 -1.1 11.0 170 82.5 92.3

30 1.1 13.1 175 84.3 94.0

32 3.2 15.2 180 86.1 95.8

34 5.3 17.2 185 87.8 97.5

36 7.3 19.2 190 89.6 99.1

38 9.2 21.0 195 91.3 100.7

40 11.1 22.9 200 92.9 102.3

42 12.9 24.7 205 94.6 103.9

44 14.7 26.4 210 96.2 105.4

46 16.4 28.1 215 97.7 107.0

48 18.1 29.7 220 99.3 108.4

50 19.7 31.3 225 100.8 109.9

52 21.3 32.9 230 102.3 111.4

54 22.9 34.4 235 103.8 112.8

56 24.4 35.9 240 105.3 114.2

58 25.9 37.4 245 106.7 115.6

60 27.4 38.8 250 108.2 116.9

62 28.8 40.2 255 109.6 118.2

64 30.2 41.6 260 111.0 119.6

66 31.6 43.0 265 112.3 120.9

68 33.0 44.3 270 113.7 122.1

70 34.3 45.6 275 115.0 123.4

72 35.6 46.9 280 116.3 124.7

74 36.9 48.1 285 117.6 125.9

76 38.2 49.3 290 118.9 127.1

78 39.4 50.6 295 120.2 128.3

80 40.6 51.8 300 121.4 129.5

82 41.9 52.9 305 122.7 130.7

84 43.0 54.1 310 123.9 131.8

86 44.2 55.2 315 125.1 133.0

88 45.4 56.3 320 126.3 134.1

90 46.5 57.4 325 127.5 135.2

92 47.6 58.5 330 128.7 136.3

94 48.7 59.6 335 129.8 137.4

96 49.8 60.7 340 131.0 138.5

98 50.9 61.7 345 132.1 139.6

100 51.9 62.7 350 133.2 140.6

105 54.5 65.2 355 134.3 141.7

110 57.0 67.7 360 135.4 142.7

115 59.5 70.0 365 136.5 143.7

120 61.8 72.3 370 137.6 144.7

125 64.1 74.6 375 138.7 145.7

130 66.4 76.7 380 139.8 146.7

135 68.5 78.8 385 140.8 147.7

140 70.7 80.9 390 141.8 148.7

145 72.8 82.9 395 142.9 149.6

Liquid Temp

(°F)

Vapor Temp

(°F)

Pressure

(PSIG)

Liquid Temp

(°F)

Vapor Temp

(°F)

14 AGZ 026B through 130B OM AGZ-1

Page 15

MicroTech II Controller

Software Version AGZDU0102B

Controller Section Table of Contents

Overview.............................................................................. 16

Inputs/Outputs ................................................................. 16

Setpoints ......................................................................... 18

Shutdown Alarms ............................................................ 19

Limit Alarms................................................................... 20

Control Logic.................................................................. 21

Compressor Control .......................................................22

Condenser Fan Control.................................................... 26

Using the Controller ............................................................. 30

Getting Started...................................................................... 39

Menu Screens.................................................................. 39

Menu Matrix ................................................................... 42

View Screens Defined ..................................................... 43

Alarm Screens Defined.................................................... 46

Set Screens Defined ........................................................ 46

Building Automation Systems (BAS)...............................53

OM AGZ-1 AGZ 026B through 130B 15

Page 16

Overview

MicroTech II controller’s state-of-the-art design not only permits the chiller to run more

efficiently, but also can simplify troubleshooting if a system failure occurs. Every

MicroTech II controller is programmed and tested prior to shipment to facilitate startup.

Operator-friendly

The MicroTech II controller menu structure is separated into three distinct categories

that provide the operator or service technician with a full description of 1) current unit

status, 2) control parameters, and 3) alarms. Security protection prevents unauthorized

changing of the setpoints and control parameters.

MicroTech II control continuously performs self-diagnostic checks, monitoring system

temperatures, pressures and protection devices, and will automatically shut down a

compressor or the entire unit should a fault occur. The cause of the shutdown will be

retained in memory and can be easily displayed in plain English for operator review.

The MicroTech II chiller controller will also retain and display the date/time the fault

occurred. In addition to displaying alarm diagnostics, the MicroTech II chiller

controller also provides the operator with a warning of limit (pre-alarm) conditions.

General Description

AGZ-B Inputs/Outputs

Table 9, Analog Inputs

No. Description Type Signal Source Range

1 Evaporator Refrigerant Pressure #1 C1 0 to 132 psi

2 Evaporator Refrigerant Pressure #2 C2 0 to 132 psi

3 Condenser Refrigerant Pressure #1 C1 3.6 to 410 psi

4 Leaving Evaporator Water Temperature UT NTC Thermister (10k@25°C) -58 to 212°F

5 Outside Ambient Temperature UT NTC Thermister (10k@25°C) -58 to 212°F

6 Condenser Refrigerant Pressure #2 C2 3.6 to 410 psi

7 Reset of Leaving Water Temperature UT 4-20 mA Current

8 Demand Limit UT 4-20 mA Current 0-100 % Load

9 Compressor Suction Temperature #1 C1 NTC Thermister (10k@25°C) -58 to 212°F

10 Compressor Suction Temperature #2 C2 NTC Thermister (10k@25°C) -58 to 212°F

NOTES:

1. C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, UT = Unit

2. Value at the converter board input. Value at the converter board output is 0.1 VDC – 0.9 VDC.

0.5 - 4.5 VDC (NOTE 2)

0.5 - 4.5 VDC (NOTE 2)

0.5 - 4.5 VDC (NOTE 2)

0.1 to 0.9 VDC

Table 10, Analog Outputs

No. Description Output Signal Range

1 Fan #1 VFD 0 to 10 VDC 20 to 60 Hz

2 Fan #2 VFD 0 to 10 VDC 20 to 60 Hz

0 to10 degrees

60°F max inlet

16 AGZ 026B through 130B OM AGZ-1

Page 17

Table 11, Digital Inputs

# Description Type Signal Signal

1 Unit OFF Switch UT 0 VAC (Disable) 24 VAC (Enable)

2 Pump Down Switch #1 C1 0 VAC (Disable) 24 VAC (Enable)

3 Evaporator Water Flow Switch UT 0 VAC (No Flow) 24 VAC (Flow)

4 Open

5 Open

6 Pump Down Switch #2 C2 0 VAC (Disable) 24 VAC (Enable)

7 Open

8 Open

9 Phase Voltage Fault #1 (See Note 1) C1 0 VAC (Fault) 24 VAC (No Fault)

10 Phase Voltage Fault #2 (See Note 1) C2 0 VAC (Fault) 24 VAC (No Fault)

11 Ground Fault Prot. #1 (See Note 2 Below) C1 0 VAC (Fault) 24 VAC (No Fault)

12 Ground Fault Prot. #2 (See Note 2 Below) C2 0 VAC (Fault) 24 VAC (No Fault)

13 Remote Start/Stop UT 0 VAC (Disable) 24 VAC (Enable)

14 Open

15 Mechanical High Pressure/Motor Protect

Circuit 1

16 Mechanical High Pressure/Motor Protect

Circuit 2

17 Ice Mode Switch UT 0 VAC (Cool) 24 VAC (Ice)

18 Open

NOTES:

1. See Safety Alarms Table for “Phase Voltage Protection”. Units with single point electrical connection

will have one PVM with Inputs 9 and 10 wired together. Units with multiple point connection will

have two PVM’s with Input 9 for Electrical Circuit #1 and Input 10 for Electrical Circuit #2.

C2 0 VAC (Fault) 24 VAC (No Fault)

C2 0 VAC (Fault) 24 VAC (No Fault)

2. See Safety Alarms

Table 14 for “Ground Fault Protection”. Units with single point electrical

connection will have one GFP with Inputs 11 and 12 wired together. Units with multiple point

connection will have two GFP’s with Input 11 for Electrical Circuit #1 and Input 12 for Electrical

Circuit #2.

Table 12, Digital Outputs

No. Description Type Load Output OFF Output ON

1 Alarm C1,C2,UT Alarm Indicator Alarm OFF Alarm ON

2 Evaporator Water Pump UT Pump Contactor Pump OFF Pump ON

3 Condenser Fan #1 C1 Fan Contactor Fan OFF Fan ON

Motor Control Relay #1 =

4

Compr#1

Motor Control Relay #3 =

5

Compr#3

Motor Control Relay #5 =

6

Compr#5

7 Liquid Line #1 C1 Solenoid Cooling OFF Cooling ON

8 Condenser Fan #2 C2 Fan Contactor Fan OFF Fan ON

Motor Control Relay #2 =

9

Compr#2

Motor Control Relay #4 =

10

Compr#4

Motor Control Relay #6 =

11

Compr#6

12 Liquid Line #2 C2 Solenoid Cooling OFF Cooling ON

13 Condenser Fan #3 C1 Fan Contactor Fan OFF Fan ON

14 Hot Gas Bypass #1 C1 Solenoid Cooling OFF Cooling ON

15 Hot Gas Bypass #2 C2 Solenoid Cooling OFF Cooling ON

16 Condenser Fan #4 C2 Fan Contactor Fan OFF Fan ON

Condenser Fan #5 ( on 8

17

Fans Only)

Condenser Fan #6 ( on 8

18

Fans Only)

C1 Starter Compressor OFF Compressor ON

C1 Starter Compressor OFF Compressor ON

C1 Starter Compressor OFF Compressor ON

C2 Starter Compressor OFF Compressor ON

C2 Starter Compressor OFF Compressor ON

C2 Starter Compressor OFF Compressor ON

C1 Fan Contactor Fan OFF Fan ON

C2 Fan Contactor Fan OFF Fan ON

OM AGZ-1 AGZ 026B through 130B 17

Page 18

Setpoints

The setpoints shown in Table 13 are retained by battery-back-up and remembered

during power off, are factory set to the Default value, and can be adjusted within the

values shown in Range.

The PW (password) column indicates the password. Passwords are as follows:

O = Operator =0100 M = Manager=2001

Table 13, Setpoints

Description Default Range PW

Unit Enable OFF OFF, ON O

Unit Mode COOL COOL, COOL w/Glycol, ICE w/Glycol, TEST O

Control source DIGITAL IN KEYPAD, BAS, DIGITAL INPUT O

Available Modes COOL

Cool LWT O

Ice LWT O

Evap Delta T O

Startup Delta T O

Stop Delta T O

Max Pulldown Rate M

Evap Recirculate Timer 30 15 to 300 sec M

Low Ambient Lockout M

Demand Limit No No,Yes M

* Refrigerant Select None R22, R407c -* Multipoint Power No No,Yes M

Ice Time Delay 12 1 to 23 hrs.

Clear Ice Delay No No, Yes

Protocol Modbus BACnet, LonWorks, Modbus M

Ident number (Modbus only) 001 001-999 M

Baud rate (Modbus only) 9600 1200,2400,4800,9600,19200 M

Compressor

* Number of Compressors 4 4,6 M

Stage Up Delay 240 90 to 480 sec M

Stage Down Delay 30 20 to 60 sec M

Start-Start 15 min 10 to 60 min M

Stop-Start 5 min 3 to 20 min M

Clear Cycle Timers No No,Yes M

Alarms

Low Evap Pressure-Hold, R22 59 psi Glycol =31 to 65 psi Cool=55 to 65 psi M

Low Evap Pressure-Hold,R407c 60 psi Glycol =26 to 75 psi Cool=58 to 75 psi M

Low Evap Pressure-Unload,R22 58 psi Glycol =31 to 65 psi Cool=55 to 65 psi M

Low Evap Pressure-Unload,R407 59 psi Glycol =26 to 75 psi Cool=58 to 75 psi M

High Condenser Stage Down 370 psi 365 to 380 psi M

High Condenser Pressure 385 psi 385 to 390 psi M

Evaporator Water Freeze M

* Phase Voltage Protection No No,Yes M

* Ground Fault Protection No No,Yes M

Evap Flow Proof 3 sec 1 to 10 sec A

Condenser Fans

VFD Enable No No,Yes M

* Number of Fans 4 4,6,8 M

Stage Down 2 Deadband 6 to 10 F M

VFD Max Speed 100% 90 to 110% M

VFD Min Speed 25% 25 to 60% M

Sat Condenser Temp Target 100 M

Forced Fan 1 1 1 to # Fans Per Circuit M

Forced Fan 2 2 1 to # Fans Per Circuit M

Forced Fan 3 3 1 to # Fans Per Circuit M

(*) These items are factory set prior to shipment.

44. 0°F 20.0(40.0) to 60.0 °F

40. 0°F 20.0 to 40.0 °F

10. 0°F 6.0 to 16.0 °F

10.0°F 1.0 to 15.0 °F

0.5°F 0.5 to 3.0°F

1.0°F 0.2 to 5.0 °F

35 °F –2 to 70°F

38.0 °F 18(37) to 42°F

15°F

10°F

10°F

15°F

15°F

10°F

10°F

COOL, COOL w/GLYCOL, COOL/ICE

w/GLYCOL, ICE w/GLYCOL. TEST

15 to 25oF Stage Up 2 Deadband M

10 to 15oF Stage Up 3 Deadband M

10 to 15oF Stage Up 4 Deadband M

15 to 20oF Stage Down 0 Deadband M

10 to 15oF Stage Down 1 Deadband M

6 to 10oF Stage Down 3 Deadband M

90 to 120°F

M

18 AGZ 026B through 130B OM AGZ-1

Page 19

Automatic Adjusted Ranges

The following are setpoints that will be limited based on the option selected.

Evaporator Leaving Water Temperature

Mode Range

Unit Mode = Cool

Unit Mode = Cool w/Glycol

40 to 60°F

20 to 60°F

Evaporator Freeze Temperature

Mode Range

Unit Mode = Cool

Unit Mode = Cool w/Glycol,

Ice w/Glycol

37 to 42°F

18 to 42°F

Low Evaporator Pressure Hold and Unload

Mode Range

Unit Mode = Cool 55 to 65 Psig

Unit Mode = Cool w/Glycol,

Ice w/Glycol

31 to 65 Psig

Low Ambient Lockout Temperature

VFD Range

VFD = N

VFD = Y

35 – 60°F

-2 – 60°F

Forced Fan 1,2,3

Number of Fans Range

4 1 – 2 fans

6 1 – 3 fans

8 1 – 4 fans

Shutdown Alarms

Shutdown alarms (also know as “Stop Alarms” or “Safeties”) execute rapid compressor

shutdown and require manual reset. They are also logged in the Alarm Log.

The following table identifies each equipment protection alarm, gives the condition that

causes the alarm to occur, and states the action taken because of the alarm. If the alarm

is auto-clearing, the reset condition is also shown. Otherwise, the alarm is manually

reset, requiring the operator to clear the alarm.

OM AGZ-1 AGZ 026B through 130B 19

Page 20

Table 14, Shutdown Alarms

Description Occurs When:

No Evaporator Water Flow

Low Evaporator Pressure

High Condenser Pressure Condenser Press > High Condenser Pressure SP

Mechanical High Condenser

Pressure/Motor Protect

Phase Voltage Protection (opt.)

Ground Fault Protection (opt.)

Re-Start Fault Re-Start = Third Time Manual

Evap. Freeze Protect

Leaving Evap. Water Temp.

Sensor Fault

Evaporator Pressure Sensor

Fault

Condenser Pressure Sensor

Fault

Outside Ambient Temp. Sensor

Fault

Evap Pump State = RUN AND Evap Flow Digital

Input = No Flow for time > Evap Flow Proof SP

Evaporator Press < Low Evap Pressure SP for time

> Low Evap Pressure Delay SP

Digital Input = Off Rapid Stop

On Power Up: Delay 150 Sec. before checking

If Phase Voltage Protection = Y, Then Rapid Stop

Digital Input Off= Phase/Voltage Problem

If Phase Voltage Protection = Y, Then Rapid Stop

Digital Input Off= Phase/Voltage Problem

Evap LWT < Evaporator Freeze SP AND Unit state

= enable

Sensor shorted or open

Sensor shorted or open

Sensor shorted or open

Sensor shorted or open

Action

Taken

Rapid Stop

Unit

Rapid Stop

Circuit

Rapid Stop

Circuit

Circuit

Circuit

Circuit

Rapid Stop

Circuit

Rapid Stop

Unit

Normal Stop

Unit

Rapid Stop

Circuit

Rapid Stop

Circuit

Normal Stop

Unit

Reset

Manual

Manual

Manual

Manual

Phase/Voltage

Input returns to

normal

Manual

Manual

Manual

Manual

Manual

Manual

Events (Limit Alarms)

The following events limit the operation of the chiller in some way, as described in the Action

Taken column. These events are auto-clearing based on reaching the conditions in the reset

column.

Table 15, Events, Limit Alarms

Description Occurs When: Action Taken Reset

Condenser Pressure Stage

Down

Low Ambient Lockout Any compressor is running AND Outside

Low Evaporator Pressure –

Hold

Low Evaporator Pressure –

Unload

Failed Pumpdown Circuit fails to reach the setpoint Shut off circuit Not applicable

NOTES:

1. Low and high pressure events are disabled in the ICE mode.

Pressure > High Condenser Stage Down

Setpoint

Ambient < Low Amb Lockout SP

Pressure < Low Evap Pressure–Hold

Setpoint

Pressure < Low Evap Pressure–Unload

Setpoint

Shutoff Condenser Press drops

Stage #2

Shutoff Stages #1

& #2

Hold @ Evap Press rises above

Stage 1

Shutoff Evap Press rises above

Stage 2

below (SP – 100psi)

Outside Ambient > Low

Amb Lockout, (SP + 5ºF)

(SP + 8psi)

(SP + 10 psi)

Logging

When an alarm or event occurs, the description, date, and time are stored in the active alarm

buffer and can be viewed on the Alarm Active screens or on the Alarm Log or Event Log

screens. The active alarm buffers hold a record of all current alarms. The active alarms can be

cleared by pressing the Enter key when the end of the list has been reached by scrolling.

A password is NOT required to clear active alarms at the unit controller. The cause for an alarm

must be remedied before clearing the alarm. If the user attempts to clear an alarm while the

alarm condition still exists, a new alarm will be generated immediately.

Separate alarm and event logs store the last 25 alarms and events respectively. When an alarm

or event occurs, it is put into the first slot in the log, and all others are moved down one,

dropping the last entry.

If the alarm is a circuit alarm, then the circuit state, refrigerant pressures and temperatures, and

number of fans on are also stored. The parameters may be accessed by scrolling the last line on

the alarm log screen (similar to a setpoint).

20 AGZ 026B through 130B OM AGZ-1

Page 21

Control Logic

Unit Enable

Enabling and disabling the chiller is controlled by the Unit Enable Setpoint, with

options of OFF and ON. This setpoint can be altered by the Unit Off Input, Digital

Input, keypad entry, or BAS request. The Control Source setpoint determines which

source can change the Unit Enable setpoint with options of DIGITAL INPUT,

KEYPAD, or BAS.

Changing the Unit Enable Setpoint can be accomplished according to the following

table.

Table 16, Unit Enable Conditions

Unit Off

Input

OFF x x x x OFF

x SWITCHES OFF x x OFF

ON SWITCHES ON x x ON

ON KEYPAD X OFF x OFF

ON KEYPAD X ON x ON

ON NETWORK x x OFF OFF

ON NETWORK OFF x x OFF

ON NETWORK ON x ON ON

NOTE: An “x” indicates that the value is ignored

Unit Mode Selection

The overall operating mode of the chiller is set by the Unit Mode Setpoint with options

of COOL, COOL w/Glycol, ICE w/Glycol, and TEST. This mode setting can be altered

by the keypad, BAS, and Mode input. Changes to the Unit Mode Setpoint are

controlled by two additional setpoints:

Control Source

Setpoint

Remote Input Keypad Entry BAS Request Enable

Available Modes Setpoint: Determines the operational modes available at any time

•

with options of COOL, COOL w/Glycol, COOL/ICE w/Glycol, and TEST.

•

Control Source Setpoint: Determines the source that can change the Unit Mode

Setpoint with options of KEYPAD, NETWORK, or SWITCHES.

When the Control source is set to KEYPAD, the Unit Mode stays at its previous setting

until changed by the operator. When the Control source is set to BAS, the most recent

BAS mode request goes into effect, even if it changed while the Control source was set

to KEYPAD or DIGITAL INPUTS.

Changing the Unit Mode Setpoint can be accomplished according to the following

table.

Table 17, Unit Mode Selection

Control Source

Setpoint

x x x x

x x x x COOL w/Glycol COOL w/Glycol

SWITCHES OFF x x COOL/ICE w/Glycol COOL w/Glycol

SWITCHES ON x x COOL/ICE w/Glycol ICE w/Glycol

KEYPAD x COOL w/Glycol x COOL/ICE w/Glycol COOL w/Glycol

KEYPAD x ICE w/Glycol x COOL/ICE w/Glycol ICE w/Glycol

NETWORK x x COOL COOL/ICE w/Glycol COOL w/Glycol

NETWORK x x ICE COOL/ICE w/Glycol ICE w/Glycol

x x x x ICE w/Glycol ICE w/Glycol

x x x x TEST TEST

NOTE: An “x” indicates that the value is ignored.

Mode

Input

Keypad Entry Unit Mode

BAS

Request

Available Modes

Setpoint

COOL

COOL

OM AGZ-1 AGZ 026B through 130B 21

Page 22

Unit Test Mode

N

N

The unit test mode allows manual testing of controller outputs. Entering this mode

requires the following conditions.

Unit OFF input = OFF (i.e., entire chiller is shut down).

Manager password active.

Available Unit Mode setpoint = TEST

A test menu can then be selected to allow activation of the outputs. It is possible to

switch each digital output ON or OFF and set the analog outputs to any value.

Chilled Water Pump Control

Operation of the evaporator pump is controlled by the state-transition diagram shown

below.

TEST: Unit State=OFF &

All Comp State=OFF &

O Evap water freeze condition

Power ON

RUN

OFF

TEST: Unit State = AUTO AND

At least one circuit is enabled for start

OR

Evap water freeze condition

TEST: Unit State=OFF &

All Comp State=OFF &

O Evap water freeze condition

START

TEST: Flow OK for

Evap Recirc Time

Compressor Control

Compressor Sequencing

This section defines which compressor is the next one to start or stop. The next section

defines when

Compressor sequencing is based primarily on compressor run-hours and starts.

Compressors that have less starts will start before those with more starts. Compressors

that have more run-hours will shut off before those with less run-hours. In the event of a

tie on number of starts, the lower numbered compressor starts first. In the event of a tie

on run-hours, the lower numbered compressor shuts off first.

If possible, the number of running compressors on each circuit will be balanced. If a

circuit is unavailable for any reason, the other circuit is allowed to stage on all

compressors.

22 AGZ 026B through 130B OM AGZ-1

the start, or stop, is to occur.

Page 23

Required Parameters

• Number of starts for all compressors

• Number of run-hours for all compressors

• Status of all compressors (Available/Unavailable)

• Compressor number

Compressor Start/Stop Timing-Cool Mode

This section defines when a compressor is to start, or stop, and the scenario for doing

so.

Initial Start Time Delay

There is a 150-second delay after power-up before any compressor is allowed to start.

This is required since the motor overloads and the Manual High Pressure (MHP) are

ignored during this time.

Required Parameters

1. Start Delta setpoint.

2. Max Pulldown Rate setpoint

3. Evap Delta T setpoint

4. Number of Compressors/Circuit setpoint

5. LWT error

6. LWT Slope

7. Number of compressors running

8. Interstage timer status

Stage Up

For 2 compressors/circuit:

Control band = Evap Delta T x .25

For 3 compressors/circuit:

Control band = Evap Delta T x .17

IF [LWT Error > Startup_Delta_T_SP + 0.5(Control band)

AND No Compressors Running

AND Stage Up Timer Expired]

THEN Stage_Up_Now = YES

ELSE IF

[LWT Error > 0.5(Control band) AND LWT Slope <= Max Pulldown setpoint

AND Stage Up Timer Expired]

THEN Stage_Up_Now = YES

Stage Down

IF [LWT Error < -0.5(Control band)

AND Stage Down Timer Expires]

THEN Stage_Down_Now = YES

OM AGZ-1 AGZ 026B through 130B 23

Page 24

Compressor Start/Stop Timing – Ice Mode

This section defines when a compressor is to start, or stop, and the scenario for doing

so.

Required Parameters

Start Delta setpoint

Evap Delta T setpoint

Number of Compressors/Circuit setpoint

LWT error

Number of compressors running

Interstage timer status

Ice timer status (12 hours between starts)

Stage Up

For 2 compressors/circuit:

Control band = Evap Delta T x .3

For 3 compressors/circuit:

Control band = Evap Delta T x .2

IF

[LWT Error > Startup_Delta_T_SP + 0.5(Control band)

AND Number Comps Running = 0

AND Ice Timer Expired]

THEN Stage_Up_Now = YES

ELSE IF

[LWT Error > 0

AND Number Comps Running > 0

AND Stage Up Timer Expired]

THEN Stage_Up_Now = YES

Stage Down

IF LWT Error < 0

THEN Stage_Down_Now = YES

Leaving Water Reset

The leaving water reset input uses a 4-to-20mA signal to reset the leaving water

setpoint to a higher value. The adjustment varies linearly from 0 degrees F to 10

degrees F, with a reset of 0 for a 4mA signal and a reset of 10 for a 20mA signal.

At all times, the active leaving water setpoint is limited to a maximum of 60°F. Th e

reset remains proportional within the 10 degree band, but the setpoint will simply stop

resetting when it reaches the maximum.

24 AGZ 026B through 130B OM AGZ-1

Page 25

Circuit Capacity Overrides – Limits of Operation

The following conditions override the automatic capacity control when the chiller is in

COOL mode or ICE mode. These overrides keep a circuit from entering a condition in

which it is not designed to run.

Low Evaporator Pressure

If a circuit is running, and the evaporator pressure drops below the Low Evaporator

Pressure-Hold setpoint, no more compressors will be allowed to start on that circuit.

This limit is active until the evaporator pressure reaches the hold setpoint plus 8 psi.

If a circuit is running with two or three compressors on, and the evaporator pressure

drops below the Low Evaporator Pressure-Unload setpoint, the circuit will begin

reducing capacity. If two compressors are running, one of the running compressors will

be stopped. If three compressors are running, then one compressor will be stopped

initially. Ten seconds later, if the pressure has not risen above the unload setpoint,

another compressor will be stopped. The last compressor on a circuit will not stop due

to the unload condition.

High Condenser Pressure

If the discharge pressure rises above the High Condenser Pressure Unload setpoint, and

more than one compressor on the circuit is running, the circuit will stage down. One

compressor will shutdown as soon as the pressure rises above the unload setpoint, and

if two remain running, then one more will shut down 10 seconds later, if the pressure is

still above the unload setpoint. No stage up will be allowed on the circuit until the

condenser pressure drops to the unload setpoint, less 100 psi, and the outdoor ambient

temperature drops 5 degrees F.

Low Ambient Lockout

If the OAT drops below the low ambient lockout setpoint, then all running circuits will

do a normal stop. Once the lockout has been triggered, no compressors will start until

the OAT rises to the lockout setpoint plus 5 degrees F.

If the unit is shutdown because the outside air temperature is to low (Low OAT

Lockout) then the evaporator pump will be shut down after all active circuits have been

pumped down.

The evaporator pump will remain off as long is the chiller is locked out on a low

ambient air temperature condition.

High Ambient Limit

On units not configured with multi-point power connections, the maximum load amps

could be exceeded at high ambient temperatures. If all circuit 1 compressors are

running or all but one compressor on circuit 1, power connection is single point, and the

OAT is greater than 116°F, circuit 2 is limited to running all but one compressor. The

circuit 2 status will indicate if this is the case. This action will allow the unit to operate

at higher temperatures than 116°F.

Unit Capacity Overrides

The following conditions override the automatic capacity control when the chiller is in

COOL mode only.

Demand Limit

The maximum unit capacity can be limited by a 4-to-20 mA signal on the Demand

Limit analog input. This function is only enabled if the Demand Limit setpoint is set to

ON. The maximum unit capacity stage is determined as shown in the following graphs:

OM AGZ-1 AGZ 026B through 130B 25

Page 26

Max

Stage

Limit Signal vs. Max Stage

(with 4 compressors)

4

3

2

1

Max

Stage

0.0 25.0 50.0 100.075.0

6

5

4

3

2

1

0

0 16.7 66.7 83.350.0

Limit Signal (%)

Limit Signal vs. Max Stage

(with 6 compressors)

33.3 100.0

Limit Signal (%)

BAS Limit

The maximum unit capacity can be limited by a BAS signal. This function is only

enabled if the unit control source is set to network. The maximum unit capacity stage is

based on the BAS limit value received from the BAS, and is determined as shown in the

graphs in the previous section.

Maximum LWT Rate

The maximum rate at which the leaving water temperature can drop is limited at all

times by the Maximum Rate setpoint. If the rate exceeds this setpoint, no more

compressors will be started until the pulldown rate is less than the setpoint.

Pumpdown

When a circuit reaches a condition where it needs to shut down normally, a pumpdown

cycle will be performed. All but the lowest numbered running compressor will shut off.

During pumpdown, the hot gas bypass and liquid line valves are closed, while a

compressor continues to run. The pumpdown is complete when the evaporator pressure

is less than the low evaporator pressure unload setpoint, less 15 psi, or the circuit has

been in the pumpdown state for 60 seconds.

Condenser Fan Control

Stage Up Compensation

In order to create a smoother transition when another fan is staged on, the VFD

compensates by slowing down initially. This is accomplished by adding the new fan

stage up deadband to the VFD target. The higher target causes the VFD logic to

decrease fan speed. Then, every 10 seconds, 0.5 degree F is subtracted from the VFD

target until it is equal to the saturated condenser temperature target setpoint. This will

allow the VFD to slowly bring the saturated condenser temperature back down.

26 AGZ 026B through 130B OM AGZ-1

Page 27

Fantrol

Condenser Fans Staging is based on condenser pressure as selected by Fan Stage On &

Off setpoints. Fans 1, 3, 5, and 7 are for circuit 1, and fans 2, 4, 6, and 8 are for circuit

2. Fans 1 and 2 start with the first compressor on the respective circuit when the

ambient temperature is greater than 75°F. Below 75°F, these fans start when the

condenser pressure gets up to the stage on setpoint. The compressor must be running in

order to run any fans.

Fan Stages

There are 2, 3, or 4 fans available per circuit. On 8 fan units, fans 5/7 and 6/8 are

controlled by one contactor for each pair, using virtual stages to allow a difference of

only one fan between stages. See the tables below:

4 and 6 Fan Units

Stage (3-Fan) Fans On Cir. 1 Fans On Cir. 2

1 1 2

2 1,3 2,4

3 1,3,5 2,4,6

8 Fan Units

Stage (2&4-Fan) Fans On Cir 1 Fans On Cir. 2

1 1 2

2 1,3 2,4

3 1,5,7 2,6,8

4 1,3,5,7 2,4,6,8

Normal Operation - Staging Up

At startup, the first fan will start when the saturated condenser temperature rises above

the target. After this, the stage-up deadbands apply.

When the saturated condenser temperature is above the Target + the active deadband, a

Stage Up error is accumulated.

Stage Up Error Step = Saturated Condenser Refrigerant temperature – (Target + Stage

Up dead band)

The Stage Up Error Step is added to Stage Up Accumulator once every Stage Up Error

Delay seconds. When Stage Up Error Accumulator is greater than the Stage Up Error

Setpoint another stage is started.

When a stage-up occurs or the saturated condenser temperature falls back within the

Stage Up dead band, the Stage Up Accumulator is reset to zero.

Normal Operation - Staging Down

There are four Stage Down dead bands, one for each stage.

When the saturated condenser refrigerant temperature is below the Target – the active

deadband, a Stage Down error is accumulated.

Stage Down Error Step = (Target − Stage Down dead band) − Saturated Condenser

Refrigerant temperature

The Stage Down Error Step is added to Stage Down Accumulator once every Stage

Down Error Delay seconds. When the Stage Down Error Accumulator is greater than

the Stage Down Error Setpoint, another stage of condenser fans turns off. The last

stage on will not shut off until the circuit is in an off state.

OM AGZ-1 AGZ 026B through 130B 27

Page 28

When a stage down occurs, or the saturated temperature rises back within the Stage Down dead

band, the Stage Down Error Accumulator is reset to zero.

Forced Fan Stage At Start

Fans may be started simultaneously with the compressor based on outdoor ambient temperature.

When the compressor starts, a FanTrol stage is forced based on the following table.

Table 18, Forced Fan Staging

,

> 75 oF Forced Fan 1 SP

> 90 oF Forced Fan 2 SP

> 105 oF Forced Fan 3 SP

FanTrol Stage At Start

Up to four fans may be forced on when the compressor starts. If the unit has the Optional Low

Ambient VFD option, then only three fans can start with the compressor, and the VFD will start

normally when the saturated condenser temperature is higher than the target.

After forcing fans on, the saturated condenser temperature may temporarily stay below the

target by some amount. In order to keep these fans from staging off, no stage down error can be

accumulated until either the OAT drops below 75

o

F, or the saturated condenser temperature

goes above the target.

Low Ambient Startup

A new low ambient start logic has been implemented in this version. A low ambient start takes

place if the saturated condenser temperature is less than 85.0°F when the first compressor starts.

The low ambient start is active for a time defined by the Low OAT Start Timer set point. This

set point is found on screen four in the alarm set points menus.

During the low ambient start, the freezestat logic for the low pressure stop alarm and the low

pressure events are disabled. The low pressure stop alarm can still be triggered if the evaporator

pressure drops below 5.0 psi at any time while the circuit is in the ‘Run’ state. Also, during the

low ambient start the second compressor is not allowed to start.

The evaporator pressure is checked at the end of the low ambient start timeframe. If the pressure

is less than the low pressure unload set point, then the low ambient start is not successful and

the compressor will shut off. This will not be a manual reset alarm until three consecutive

attempts have failed. The circuit alarm triggered after the third failed attempt is a Low OAT

Restart fault.

Low Ambient Stage Up

In colder ambient conditions, the evaporator pressure may take several minutes to rise and

stabilize after the first compressor starts. Starting the second compressor too soon will cause a

low-pressure situation that usually cannot be recovered from. To avoid this problem the

following occurs:

• The Interstage Up Time Delay set point range is 90 to 480 seconds.

• The default value of the Interstage Up Time Delay set point is 240 seconds.

When a second compressor stages on, there is a temporary drop in evaporator pressure until the

TXV has a chance to react. This condition is especially evident in colder conditions. In order to

avoid short cycling the second compressor just after it starts, the following logic exists:

• The low evaporator pressure events are disabled temporarily after the second stage starts up.

The delay time is 30 seconds.

• Normal protection against low evaporator pressure conditions resumes after the 30-second

delay timer expires

28 AGZ 026B through 130B OM AGZ-1

Page 29

Evaporator Pressure Control

Low Evaporator Pressure Protection

• The minimum time allowed to run in low evaporator pressure conditions with the

freezestat logic has been changed from 10 to 20 seconds.

• The absolute minimum pressure limit logic has been changed to trip the low-pressure

alarm only when the circuit state is in a Run state.

Low Evaporator Pressure Hold Events

• The Low Evaporator Pressure Hold can trigger with two compressors running. With this

logic, the Hold event can be logged and if the evaporator pressure continues to drop

enough to trip the Low Evaporator Pressure Unload event, the Unload event will be

added to the Event log.

• The Low Evaporator Pressure Hold event reset logic will clear the Hold event at 5.0 psi

above the Hold set point.

• The logic will allow the Low Evaporator Pressure Hold events to occur when the Unit is

in the Ice mode.

Low Evaporator Pressure Unload Events

• The Low Evaporator Pressure Unload events clear with the Low Evaporator Pressure

Hold events.

• The logic allows the Low Evaporator Pressure Unload events to occur when the Unit is

in the Ice mode

Optional Low Ambient VFD

Low ambient air temperature control is accomplished by using the Optional Low Ambient VFD

to control the speed of the first fan on each circuit. This VFD control uses a proportional

integral function to drive the saturated condenser temperature to a target value by changing the

fan speed. The target value is normally the same as the saturated condenser temperature target

setpoint.

The fan VFD always starts when the saturated condenser temperature rises higher than the

target.

What is an Inverter?

The term inverter and variable-frequency drive are related and somewhat interchangeable. An

electronic motor drive, for an AC motor, controls the motor’s speed by varying the frequency of

the power sent to the motor.

An inverter, in general, is a device that converts DC power to AC power. The figure below

shows how the variable-frequency drive employs an internal inverter. The drive first converts

incoming AC power to DC through a rectifier bridge, creating an internal DC bus voltage. Then

the inverter circuit converts the DC back to AC again to power the motor. The special inverter

can vary its output frequency and voltage according to the desired motor speed.

OM AGZ-1 AGZ 026B through 130B 29

Page 30

Inverter Output to the Motor

The AC motor must be connected only to the inverter’s output

terminals. The output terminals are uniquely labeled (to

differentiate them from the input terminals) with the

designations U/T1, V/T2, and W/T3. This corresponds to

typical motor lead connection designations T1, T2, and T3. The

consequence of swapping any two of the three connections is

the reversal of the motor direction. This must not be done. In

applications where reversed rotation could cause equipment

damage or personnel injury, be sure to verify direction of

rotation before attempting full-speed operation. For safety to

personnel, the motor chassis ground must be connected to the

ground connection at the bottom of the inverter housing.

Notice the three connections to the motor do not include one marked “Neutral” or “Return.” The

motor represents a balanced “Y” impedance to the inverter, so there is no need for a separate

return. In other words, each of the three “Hot” connections serves also as a return for the other

connections, because of their phase relationship.

Do not to switch off power to the inverter while the motor is running (unless it is an emergency

stop). Also, do not install or use disconnect switches in the wiring from the inverter to the motor

(except thermal disconnect).

Inverter Front Panel Keypad

The CR100 Series inverter front keypad contains all the elements for both monitoring and

programming parameters. The keypad layout is pictured below. The fan VFD is programmed in

the factory before shipment and no field programming is required.

Key and Indicator Legend

Run/Stop LED - ON when the inverter output is ON and the motor is developing torque (Run

Mode), and OFF when the inverter output is OFF (Stop Mode).

Program/Monitor LED - This LED is ON when the inverter is ready for parameter editing

(Program Mode). It is OFF when the parameter display is monitoring data (Monitor Mode).

Run Key Enable LED - is ON when the inverter is ready to respond to the Run key, OFF when

the Run key is disabled.

Run Key - Press this key to run the motor (the Run Enable LED must be ON first). Parameter

F_04, Keypad Run Key Routing, determines whether the Run key generates a Run FWD or Run

REV command.

Stop/Reset Key - Press this key to stop the motor when it is running (uses the programmed

deceleration rate). This key will also reset an alarm that has tripped.

30 AGZ 026B through 130B OM AGZ-1

Page 31

Potentiometer -Allows an operator to directly set the motor speed when the potentiometer is

enabled for output frequency control.

Potentiometer Enable LED - ON when the potentiometer is enabled for value entry.

Parameter Display - A 4-digit, 7-segment display for parameters and function codes.

Display Units, Hertz/Amperes - One of these LEDs will be ON to indicate the units associated

with the parameter display.

Power LED - This LED is ON when the power input to the inverter is ON.

Function Key - This key is used to navigate through the lists of parameters and functions for

setting and monitoring parameter values.

Up/Down (

1

,

2

) Keys - Use these keys alternately to move up or down the lists of

parameter and functions shown in the display, and increment/decrement values.

Sto re ( ) Key - When the unit is in Program Mode and you have edited a parameter value,

press the Store key to write the new value to the EEPROM.

Keypad Navigational Map

The CR100 Series inverter front keypad contains all the elements for both monitoring and

programming parameters. The diagram below shows the basic navigational map of parameters

and functions.

OM AGZ-1 AGZ 026B through 130B 31

Page 32

NOTE: The inverter 7-segment display shows lower case “b” and “d,” meaning the same as the

upper case letters “B” and “D” used in this manual (for uniformity “A to F”).

NOTE: The Store Key saves the edited parameter (shown in the display) to the EEPROM in the

inverter, regardless of the programming device. Upload and download of parameters is

accomplished through a separate command—do not confuse Store with Download or Upload.

Troubleshooting Tips

The table below lists typical symptoms and the corresponding solution(s).

Symptom

Condition

The inverter

outputs [U],

[V], [W] are not

supplying

voltage.

The

motor

will not

run.

Inverter

outputs [U],

[V], [W] are

supplying

voltage.

The optional

remote

operator is

used (SRW).

The direction of the motor

is reversed.

The motor speed will not

reach the target

frequency (desired

speed).

Continued on next page.

•

•

• •

• • Is there an error code E X X displayed? Press the Func. key and determine the error

•

•

•

•

• • Is the RS (reset) function or FRS (free-run

• • Is the motor load too heavy? Reduce load, and test the motor

• • Are the operational settings between the

•

•

•

•

• •

• •

• •

Probable Cause Solution

Is the frequency command source A_01

parameter setting correct?

Is the Run command source A-02

parameter setting correct?

Is power being supplied to terminals [L1],

[L2], and [L3/N]? If so, the POWER lamp

should be ON.

Are the signals to the intelligent input

terminals correct?

Is the Run Command active?

Is the {FW] terminal (or [RV]) connected to

[P24] (via switch, etc.)

Has the frequency setting for F_01 been

set greater than zero?

Are the control circuit terminals [H], [O],

and [L] connected to the potentiometer?

stop) function ON?

remote operator and the inverter unit

correct?

[U/T1], [V/T2], and [W/T3] correct?

Is the phase sequence of the motor

forward or reverse with respect to [U/T1],

[V/T2], and [W/T3]?

Are the control terminals [FW] and [RW]

wired correctly?

Is parameter F_04 properly set?

If using the analog input, is the current or

voltage at [O] or [OI]?

Is the load too heavy? Reduce the load

Is the inverter internally limiting the output

frequency?

•

Make sure the parameter setting A-01 is

correct.

•

Make sure the parameter setting A-02 is

correct.