Mc Leod Soft Lok User Manual

Soft Lok Clutch Instruction

Warning: DO NOT USE SOFT LOK ON ANY DYNO!!

The Soft Lok clutch assemblies consist of an adjustable Ford/Long style pressure plate, sintered iron disc

and flywheel. Steel flywheels are normally used on engines that are under 450hp but usually are not

heavier than 22 lbs. Engines over 450hp use an aluminum flywheel with a steel insert. Car weight, tire

size and gearing do play into this decision. Call the McLeod Tech Line if you need a recommendation.

The McLeod Ford/Long style pressure plate has an aluminum pressure ring inside with a steel face

riveted to it. It has nine springs, six are adjustable. Most Soft Lok clutches have 200 lbs of base pressure.

Each of the six adjusters are found on either side of the levers. It is important to have steel surfaces on

either side of the disc to keep the same coefficient of friction.

The disc is sintered iron and is very aggressive. In order to control the aggression, McLeod reduced the

pressure in the pressure plate. This disc has a special characteristic and is expressed as: “The hotter it

gets, the harder it bites”. This will be explained further in these instructions.

Soft Lok Assembly shown with aluminum flywheel

PREPARATION:

When you receive your Soft Lok assembly, bolt it up to the flywheel. Remove the lever blocks

between the three levers and the pressure plate cover. Get yourself a T-Handle Allen wrench that fits the

six adjusters. (Helpful Hint: mark one of the ‘T’ by painting, striping or taping it). Put the T-Handle in one

of the adjusters and move it back and forth ½ turn. Get used to the feel of what base pressure feels like.

You need to know how it feels because most often times you will make the adjustment to the clutch

12 turns of all (6) adjusters increases total pressure to 1760#

through a hole in the bellhousing; this will be covered in Phase 1. Once you are used to the feel we will

make the initial adjustment to the pressure. We want to have the clutch high enough so there is no

slippage in any gear. A good rule of thumb is to start at 8 – 10 turns. The adjuster turns just the opposite

of what one might think, counterclockwise adds pressure and clockwise take it out. If needed, mark the

bellhousing hole to reflect this. Start turning your T-Handle CCW until you feel tension on the Allen

screw. Check to see where the marked end is on the T-Handle and turn it 360 degrees for at least 8 – 10

turns. There will be a counterweight kit with your assembly. It has aluminum nuts, steel nuts and bolts

and steel weights. Put it in the toolbox until we get to the section on adjusting the clutch.

CONCEPT:

Most clutches are high-pressure lockup types. When you launch the car with these, the high

spring pressure will shock the car like pulling the trigger on a shotgun and feel like someone hitting the

back of the seat with a baseball bat. The trouble is it breaks parts and sometimes will cause the tires to

spin and get the car out of shape. Using the Soft Lok your ET and MPH will improve. You will have little

to no breakage because we are causing a controlled slip in the clutch that takes out all of the shock and

violence. Transmissions and rear ends last longer.

With its lower spring pressure and lighter weight, it will not hit the tires or chassis as hard and tire spin

can be controlled so traction is better and the lighter weight will let the engine rev quicker and pull

harder through mid range and top end.

Warning: Do not use the Soft Lok on any dyno!!

Do not drive the car onto the trailer or car hauler!!

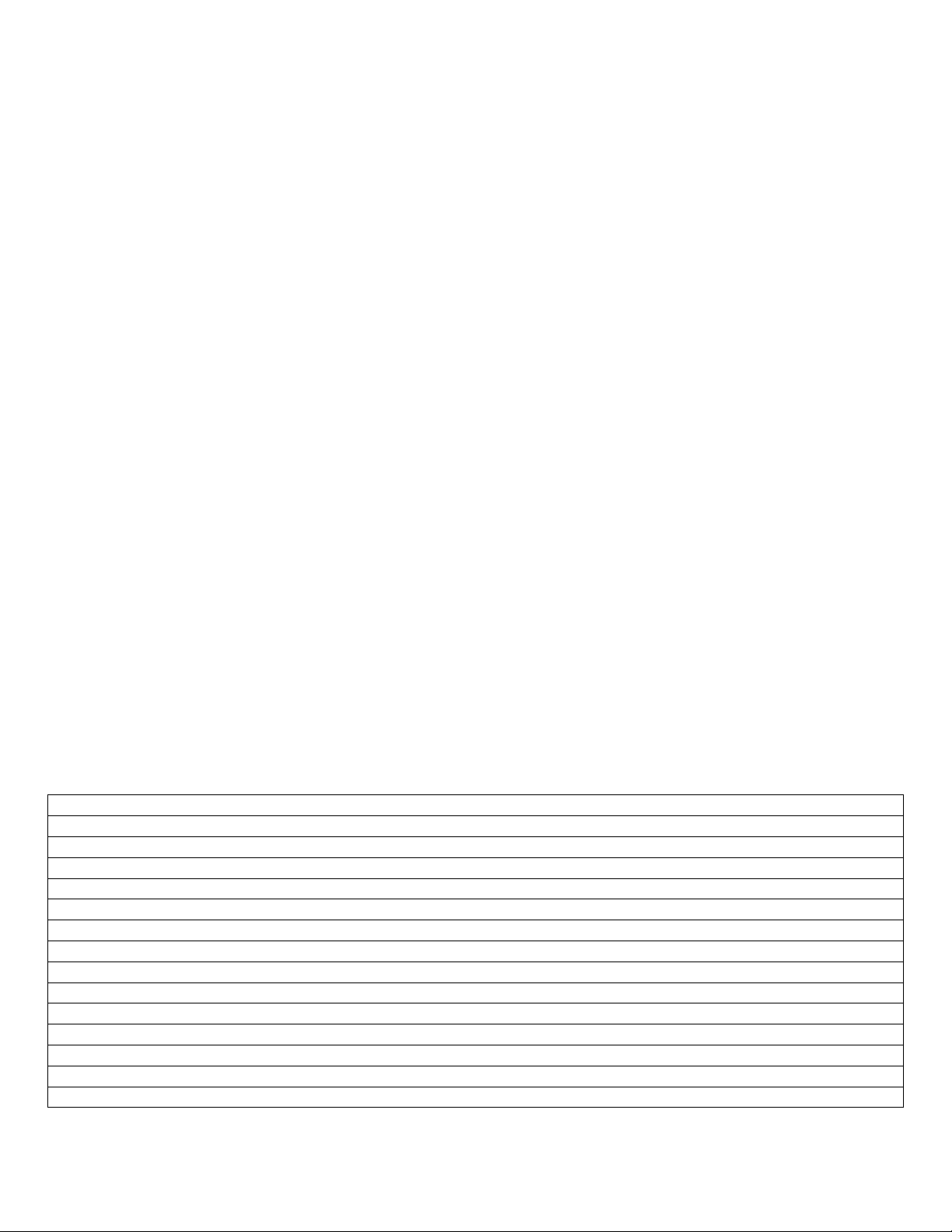

Soft Lok Assembly with six adjusters

and a .280” thick Disc Base Pressure = 200#

1 turn of all (6) adjusters increases total pressure to 330#

2 turns of all (6) adjusters increases total pressure to 460#

3 turns of all (6) adjusters increases total pressure to 590#

4 turns of all (6) adjusters increases total pressure to 720#

5 turns of all (6) adjusters increases total pressure to 850#

6 turns of all (6) adjusters increases total pressure to 980#

7 turns of all (6) adjusters increases total pressure to 1110#

8 turns of all (6) adjusters increases total pressure to 1240#

9 turns of all (6) adjusters increases total pressure to 1370#

10 turns of all (6) adjusters increases total pressure to 1500#

11 turns of all (6) adjusters increases total pressure to 1630#

13 turns of all (6) adjusters increases total pressure to 1890#

Loading...

Loading...