Mc Leod RST, RXT User Manual

RST & RXT Street Twin Clutch Installation Instructions

Congratulations! You have just purchased the finest Street Twin clutch system on the market today. The

RST and RXT Street Twin clutch systems are capable of handling extremely high horsepower engines in

street driven vehicles. The key benefits with this system are low rotating mass, lighter than stock pedal

effort and dual discs for extreme holding capacity with exceptional release qualities. Properly installed,

this clutch system will provide the strength and durability you have come to rely on in all of the McLeod

Racing family of products.

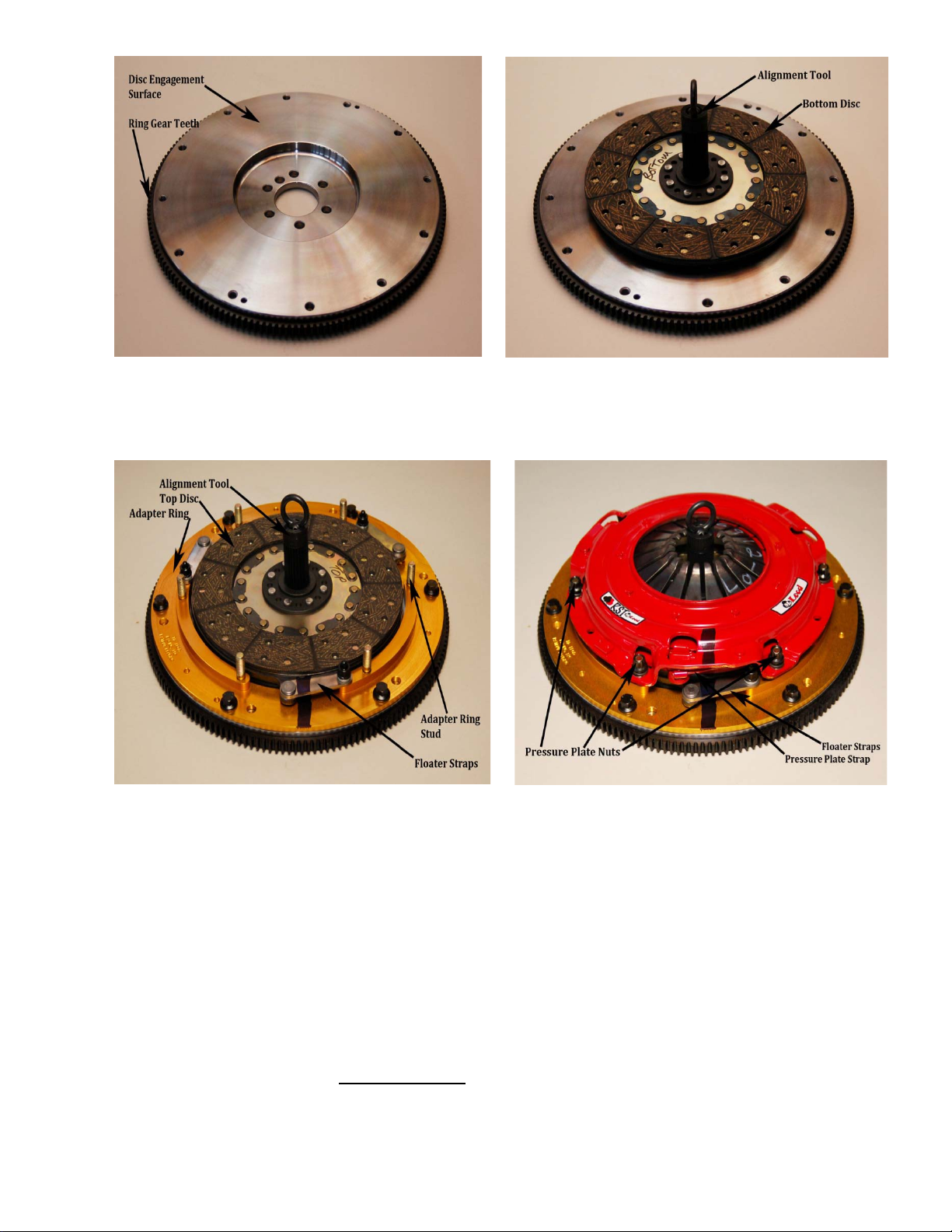

1) See Figure 1 for component parts identification and alignment mark!

Figure 1 Figure 2

2) Remove six pressure plate nuts, lock washers and flat washers and set aside.

3) Lift off pressure plate and top disc from the adapter ring and set aside. Figure 2.

4) Inspect flywheel for chipped teeth on Ring Gear and be certain the flywheel/disc engagement

surface is clean, flat and free of oil and/or grease. Be certain the pilot bearing is in place and is

clean and free of nicks and burrs. If damaged, replace the pilot bearing. Test fit the pilot tool to see

how far the tool engages the pilot bearing. See Figure 3.

I0004

Figure 3 Figure 4

5) Install disc labeled “bottom” to the flywheel using the supplied alignment tool. Be sure the disc is

installed with the label indicating ‘flywheel side’ is forward toward the flywheel. Figure 4

Figure 5 Figure 6

6) 4.6L and 5.4L Ford Modular engines require the installation of the supplied dowel pins (3) into the

factory flywheel. GM LS engines require the installation of 2 of the supplied dowel pins into the

factory flywheel. Place adapter ring on flywheel, with the floater attached, using OEM pressure

plate bolts. (Some kits are supplied with new bolts for attaching adapter ring. In these cases

use these bolts as they provide necessary clearance.) (Do not use LocTite!) Do not add any

washers to any locations if they were not present with the McLeod clutch assembly! Torque

these bolts to factory specs. Note: If the floater was removed from the adapter ring re-torque all

5/16” nuts to 25 ft/lbs.

7) At this point the “bottom” disc should rotate freely without any drag. If the disc will not rotate call

McLeod’s Tech Service Line.

8) Install the top disc using the alignment tool and be certain it fully engages the pilot bearing to

correctly center the discs. Figure 5

Do not proceed!

Loading...

Loading...