Mc Leod 4400 User Manual

Truck Pull Clutch Assembly Instructions

All assemblies should be match balanced to your Flywheel

Assemblies are not Pre-Balanced!!

This assembly’s pressure plate has an adjustable counterweight lever. This allows you to increase clutch

– holding power by adding more weight to each lever if needed. McLeod assembles the unit with a 2 inch

¼-20 Allen bolt and (6) gram weights and self-locking nut. This is a common counterweight amount.

You may need more or less. If a change is desired always use an Allen headed (socket head) bolt and selflocking style nut.

The torque on the (6) pressure plate nuts should not exceed 35 ft. lbs. A small amount of blue Loctite

may be used.

The (3) 3/8-24 self-locking nuts on the (3) floater stands should not be removed unless you are replacing

the floater stands.

Be sure the throw out bearing has sufficient free play at the clutch fork. The bearing will burn up if there

is too little free play. .1875” - .250” (3/16-1/4 inch) is sufficient at the fork, not pedal. If unit appears

glazed from excessive slippage, holding power will diminish. Sanding of all parts to break the glaze with

#36 grit paper or glass beading all parts at 40 -45 psi will restore the holding power.

Whenever the clutch assembly is out of the vehicle always measure disc thickness and check shim

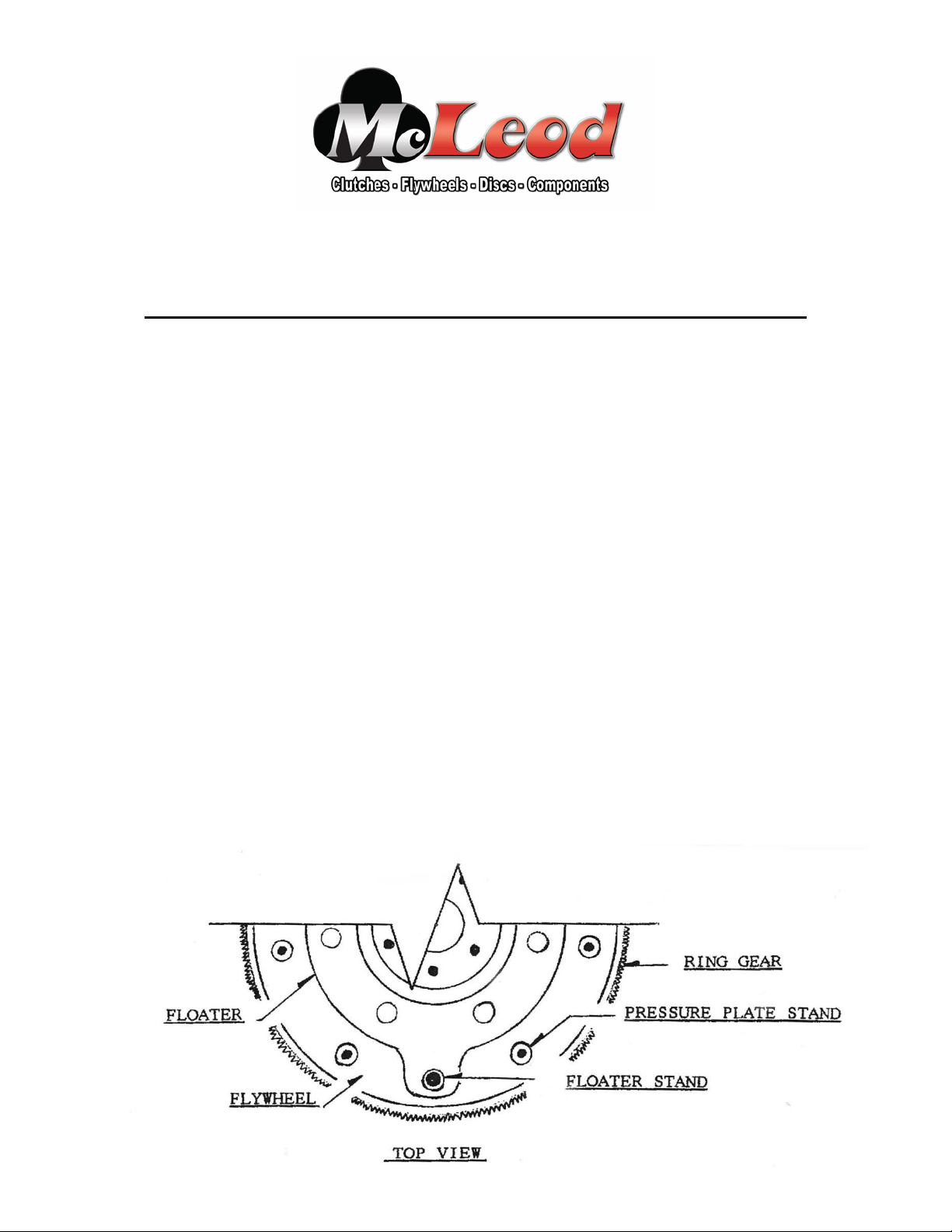

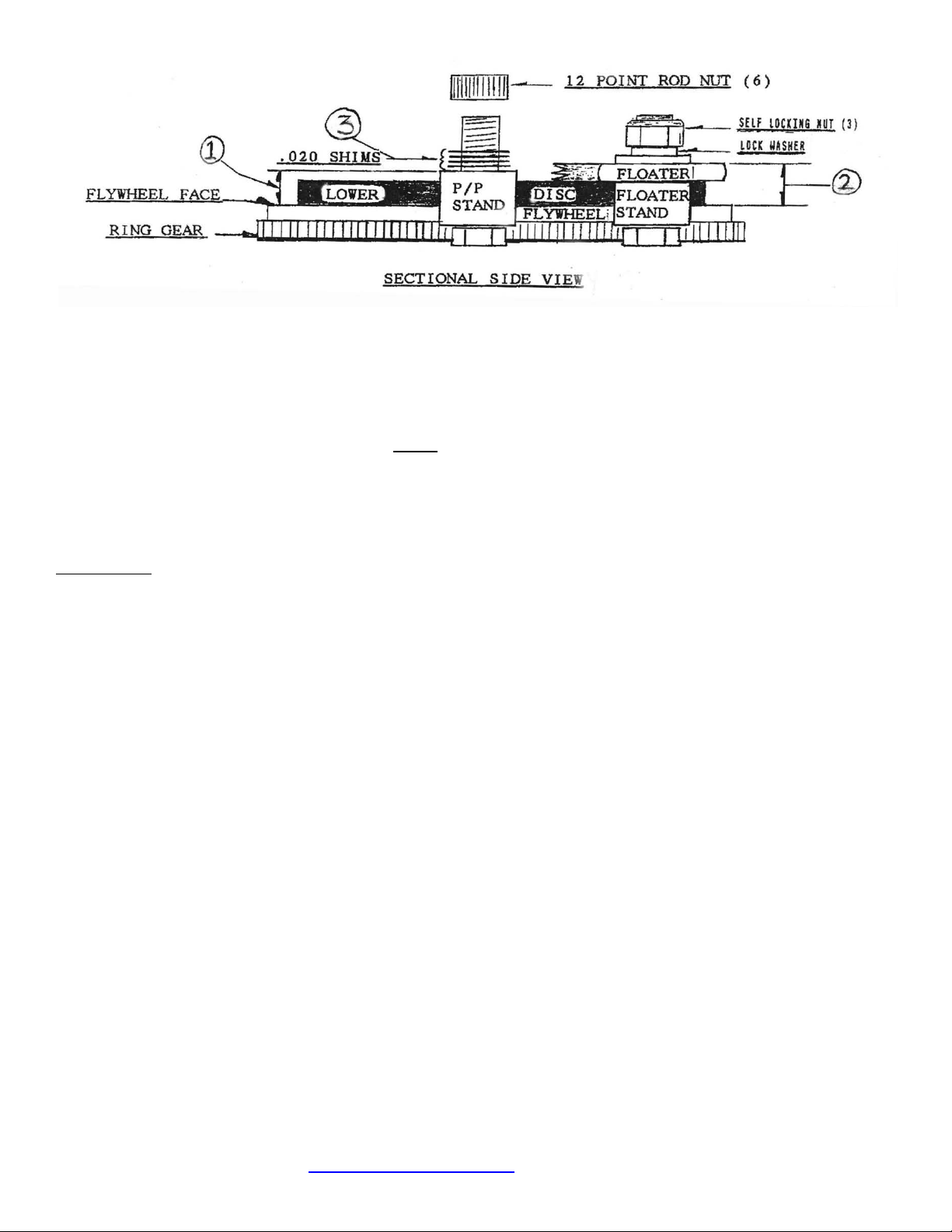

tolerances. Review the below two drawings and familiarize yourself with the key noted components.

Review the following and make notes in your log book of your ‘New’ measurements.

Notes:

Step 1 – With bottom (lower) disc in place and floater installed, measure (with depth micrometer or

caliper) from the top of the pressure plate stand

Step 2 – Measure from the top of the floater to face of the flywheel. Note this number____________________.

Step 3 – Add shims to make up the difference, so step #1 measurement equals step #2 measurement.

Wear Shims

The shims under the pressure plate (on top of the 6 pressure plate stands) are called wear shims. As the

discs wear, you remove the amount of shim equal to the total wear of the discs.

Example:

Starting disc thickness new is .330” each. If you have 2 discs you add .330” and .330” getting you a total

of .660” thickness. Now measure your used discs, let’s say one disc is .320” and the other is .317”. You

add .320 and .317 getting a combined total of .637”. Now subtract .637 from .660 (original starting

thickness) and the total wear is the amount of shim you must remove.

to face of flywheel. Note this number___________________.

.660”(New thickness) minus .637” (Used thickness) equals .023” Total wear

In this case .023” is the amount of shim thickness you need to remove. This would be (1) .020” thick shim

from each stand. Now the unit is back to its original starting pressure.

The shims are approximately .020” thick. See shim removal chart:

Disc Wear Remove Disc Wear Remove

.000” - .015” 0 Shims .016” - .039” 1 Shim

.040” - .059” 2 Shims .060” - .079” 3 Shims

And so on…

McLeod Racing, LLC 1600 Sierra Madre Circle Placentia, CA 92870 714.630.2764

www.mcleodracing.com I0022

Loading...

Loading...